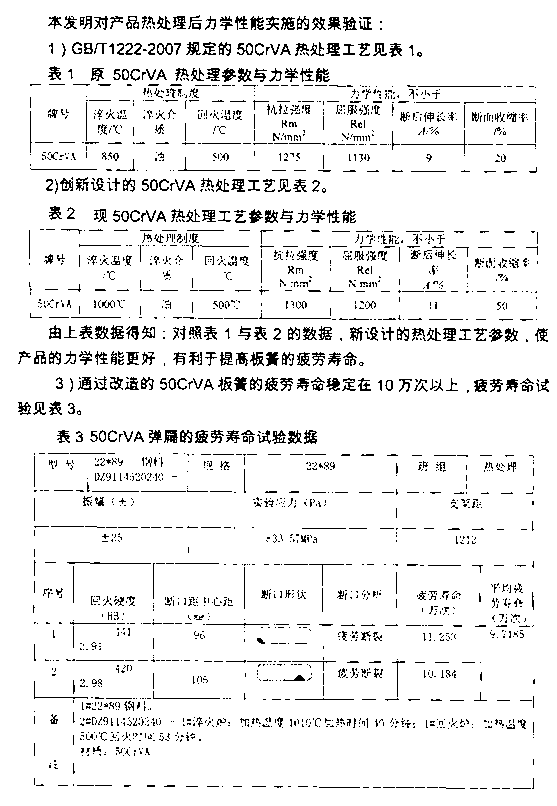

Technique for prolonging fatigue life of 50CrVA plate spring

A technology of fatigue life and process method, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problem of low fatigue life of 50CrVA leaf spring, and achieve the effect of improving heat treatment process, eliminating MnS inclusions, and improving deoxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described with reference to examples.

[0020] Operation smelting steps and technical points control of the present invention:

[0021] 1. Optimal design of the chemical composition of its smelted steel

[0022] Prepared by mass percentage, C: 0.50%; Si: 0.25%; Mn: 0.65%; Cr: 0.90%; V: 0.12%; Al: 0.007%; P: 0.018%; S: 0.018%; %; Cu: ≤0.25% composition;

[0023] 2. Control and denaturation treatment of inclusions in smelted steel

[0024] (1) At the joint between the long nozzle of the large ladle and the submerged nozzle of the tundish, an argon sealing ring is used to seal it to prevent secondary oxidation of molten steel in contact with air;

[0025] (2) Tapping with slag is strictly prohibited, and the amount of slag during tapping is controlled at ≤3kg / t;

[0026] (3) Strictly control the weight of molten steel ≥ 7t in the tundish to prevent gas, covering agent and steel slag from being involved in the crystallizer due to the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com