High-tenacity gas shielded welding wire for welding low-temperature steel and using method thereof

A gas shielded welding wire, high toughness technology, applied in welding/welding/cutting items, welding media, welding equipment, etc., can solve the problems of low Ni content, can not meet the low temperature toughness requirements of weld metal, can not meet the requirements of low temperature Ductile-brittle transition temperature, good low temperature toughness, the effect of improving low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with experimental data and embodiment the present invention will be further described.

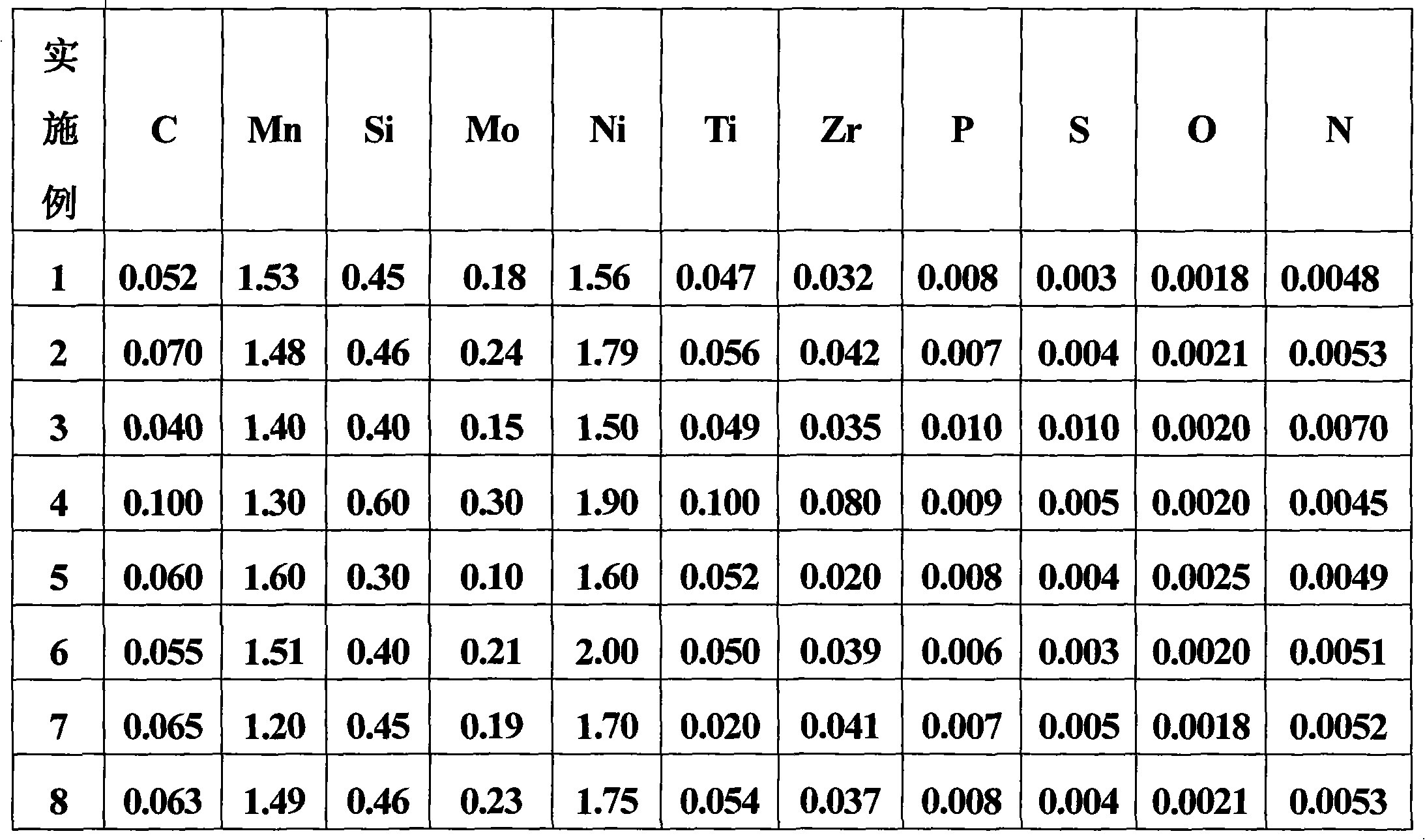

[0022] According to the chemical composition range of the welding wire of the present invention and the mass percentages used in the following examples, a vacuum induction furnace is used to smelt multi-furnace welding wire steel, and through forging, rolling, wire drawing, copper plating and shaft winding, it is processed into a wire with a diameter of 1.2mm. The chemical composition of the finished welding wire and the welding wire of each furnace is shown in Table 1.

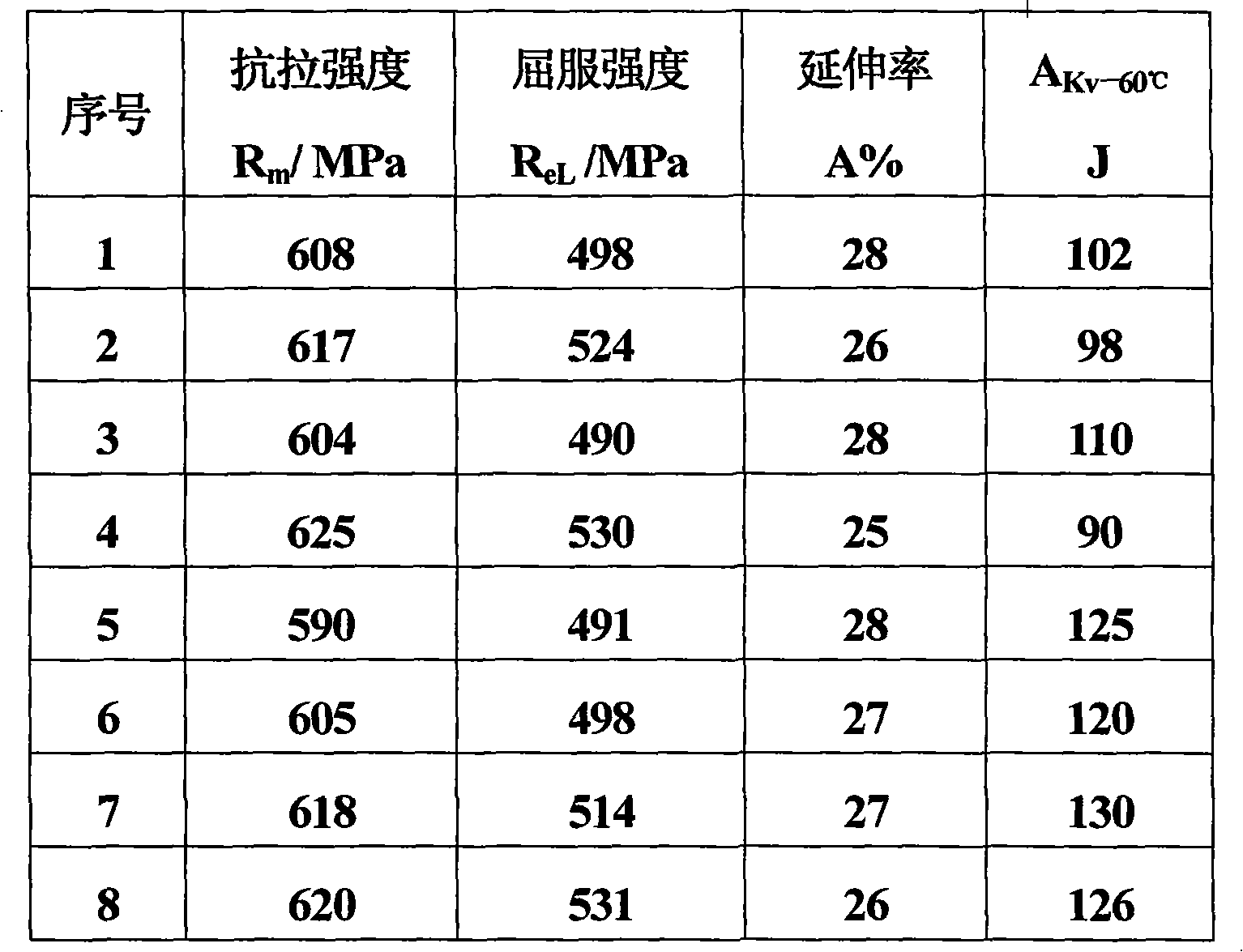

[0023] The welding wire of each furnace adopts volume 80% Ar+20% CO 2 Under argon-enriched gas protection, the same part was welded by the same person by the same person, and the same mechanical properties were tested with the same equipment and conditions at the same time after welding. The mechanical properties of the deposited metal are shown in Table 2.

[0024] The chemical composition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com