Patents

Literature

81results about How to "Good impact resistance at low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

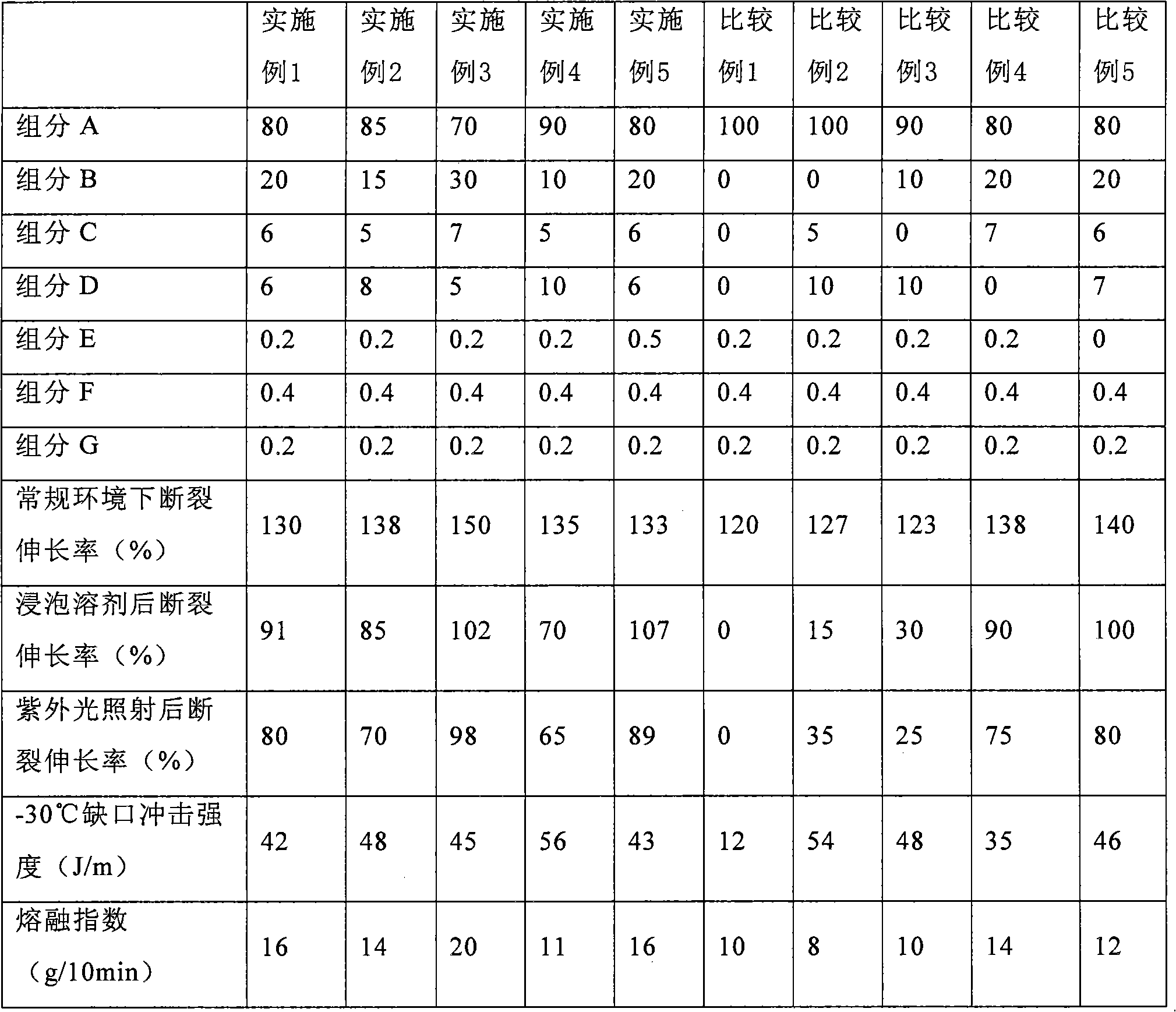

Polycarbonate composition and preparation method thereof

The invention provides a polycarbonate composition and a preparation method thereof. The polycarbonate composition comprises 30-90% of polycarbonate, 5-50% of polyester, 1-10% of compatible toughening agents, 1-10% of low-temperature impact modifiers, 0.1-1% of anti-ultraviolet assistant, 0.1-2% of antioxidants and 0.1-1% of lubricant by mass. The preparation method comprises the following steps: weighing the components in the composition according to the mass proportion; throwing the polycarbonate, the polyester, the compatible toughening agents, the low-temperature impact modifiers, the anti-ultraviolet assistant, the antioxidants and the lubricant into a mixer to be uniformly mixed; and melting, mixing, extruding and pelleting the uniformly mixed raw materials by an eight-temperature zone double-screw extruder. The polycarbonate composition has high molding processing mobility and excellent chemical reagent resistance, anti-ultraviolet property and low-temperature anti-impact property and can be widely applied to thin-wall workpieces.

Owner:SINOPLAST NEW MATERIAL

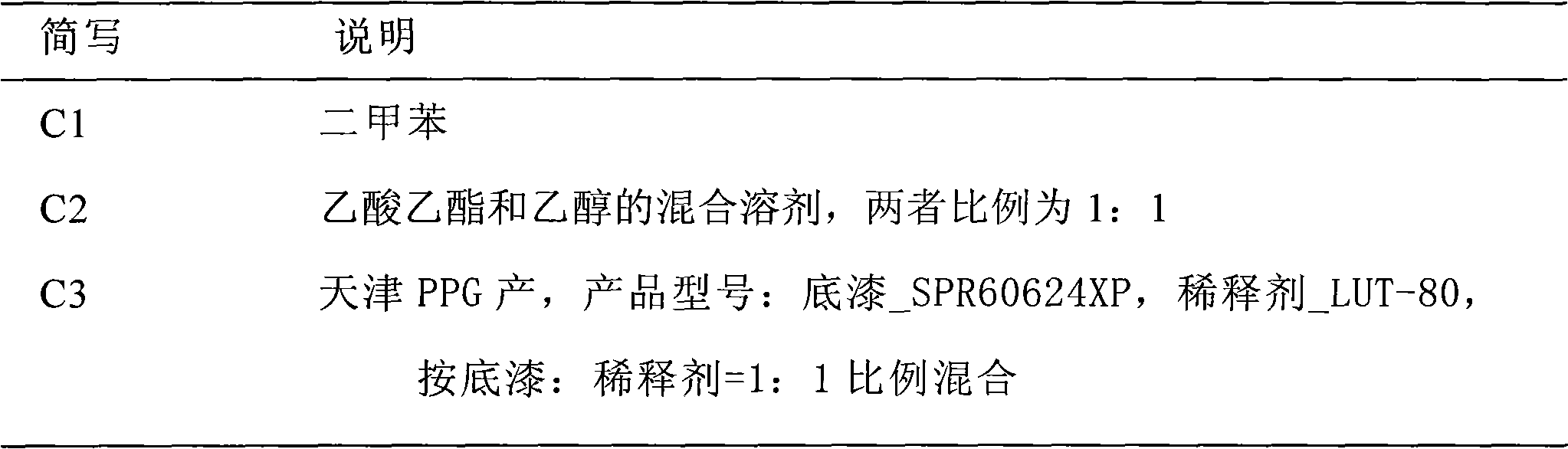

Polycarbonate/polyester composition and preparation method thereof

InactiveCN101787195AExcellent chemical resistanceGood low temperature impact resistanceChemistryCompound (substance)

The invention relates to a polycarbonate / polyester composition and a preparation method thereof. The composition comprises the following components by wt%: 50-80wt% of polycarbonate, 10-30wt% of polybutylene terephthalate (PBT), 5-15wt% of toughening agents, 1-5wt% of functional agents, 0.1-1wt% of antioxidant and 0.1-2wt% of lubricants. The method comprises the following steps: proportioning according to the components, then proportionally charging the PBT and the functional agents into a high mixing machine to be premixed and carrying out extrusion pelletization on the premixed materials in an extruder to obtain functional master batches; and then fully mixing the rest components with the master batches in the high mixing machine and then carrying out extrusion pelletization on the mixture in a double-screw extruder to obtain the product. Compared with the prior art, the composition has excellent resistance to chemicals and low temperature impact resistance and simultaneously improves the mechanical properaty of the materials.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Polyamide composition for high impact thick wall product

The invention discloses a polyamide composition of high impact thick-walled product, which comprises the following parts: a) 1-99wt% polyamide resin, b) 0. 5-40wt% thermoplastic elastomer of olefin copolymer, c) 1-95wt% phenylethene resin, d) 0. 05-60wt% modified ethylene copolymer with alpha, beta-unsaturated fatty acid anhydrides or its deritative, or e) 0. 05-60wt% modified ethylene copolymer with alpha, beta-unsaturated fatty acid. The invention can keep original superior strength, fluidity and low-temperature shock resistance of thin-walled product, which confers superior shock resistance for thick-walled product.

Owner:TORAY IND INC

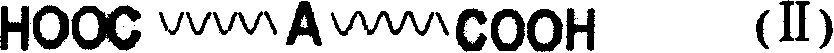

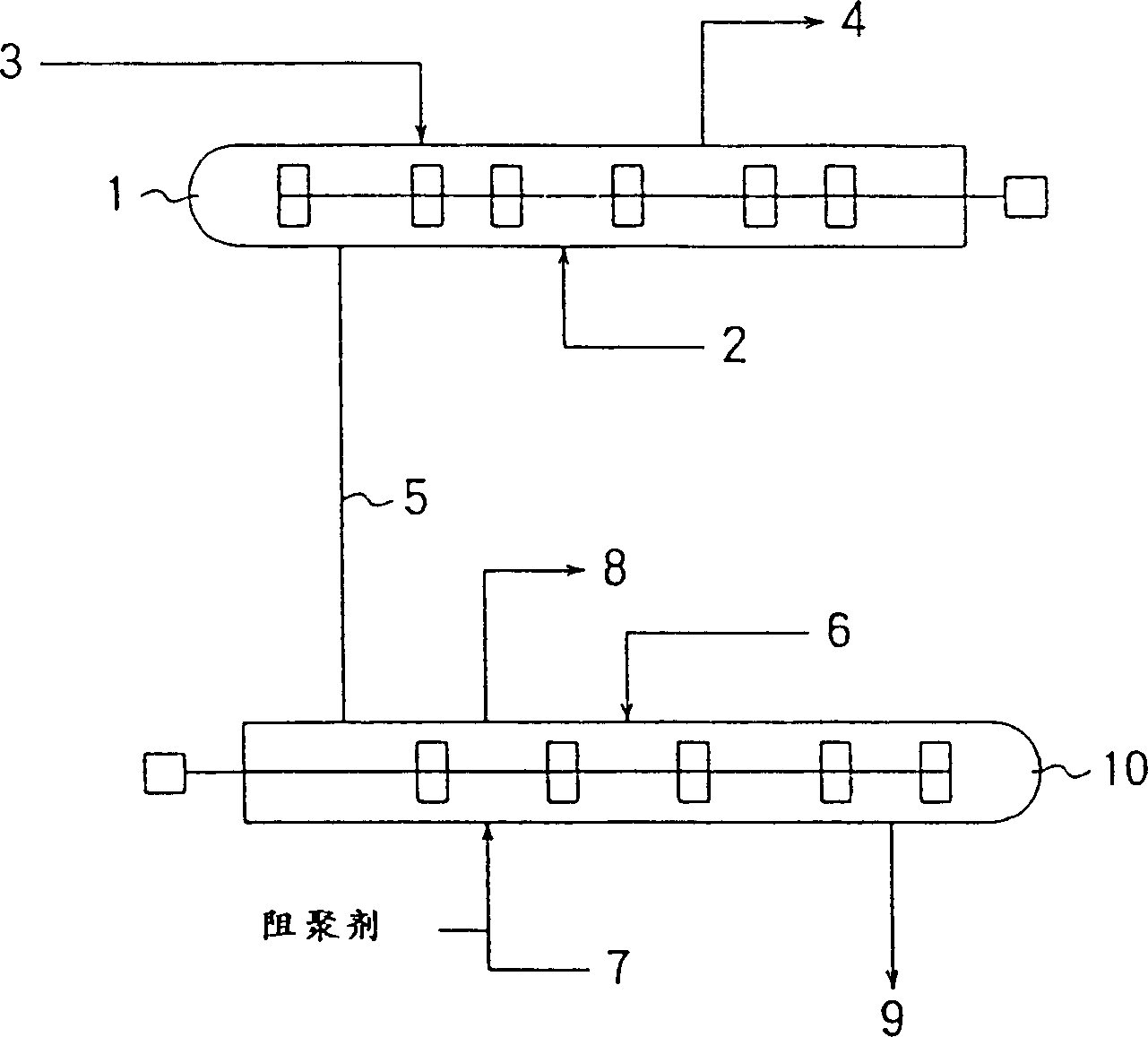

Multi-phase polypropylene copolymer having high ethylene-propylene rubber content and preparation method thereof

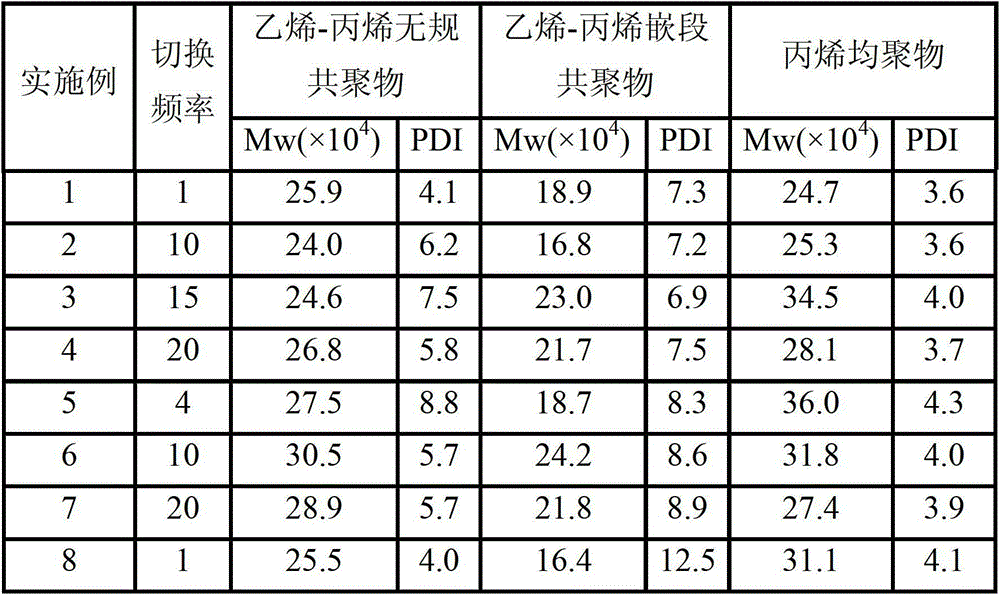

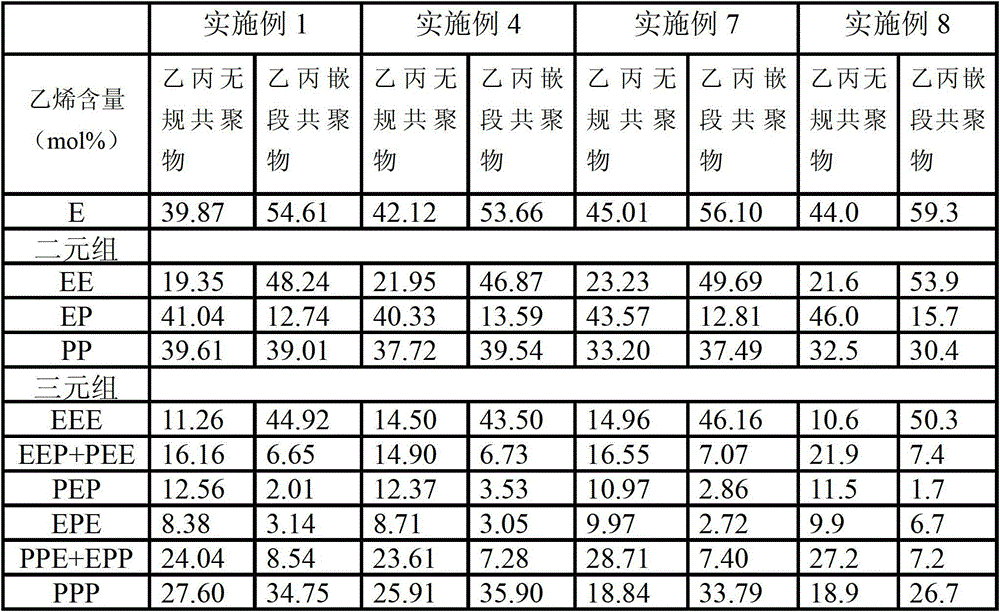

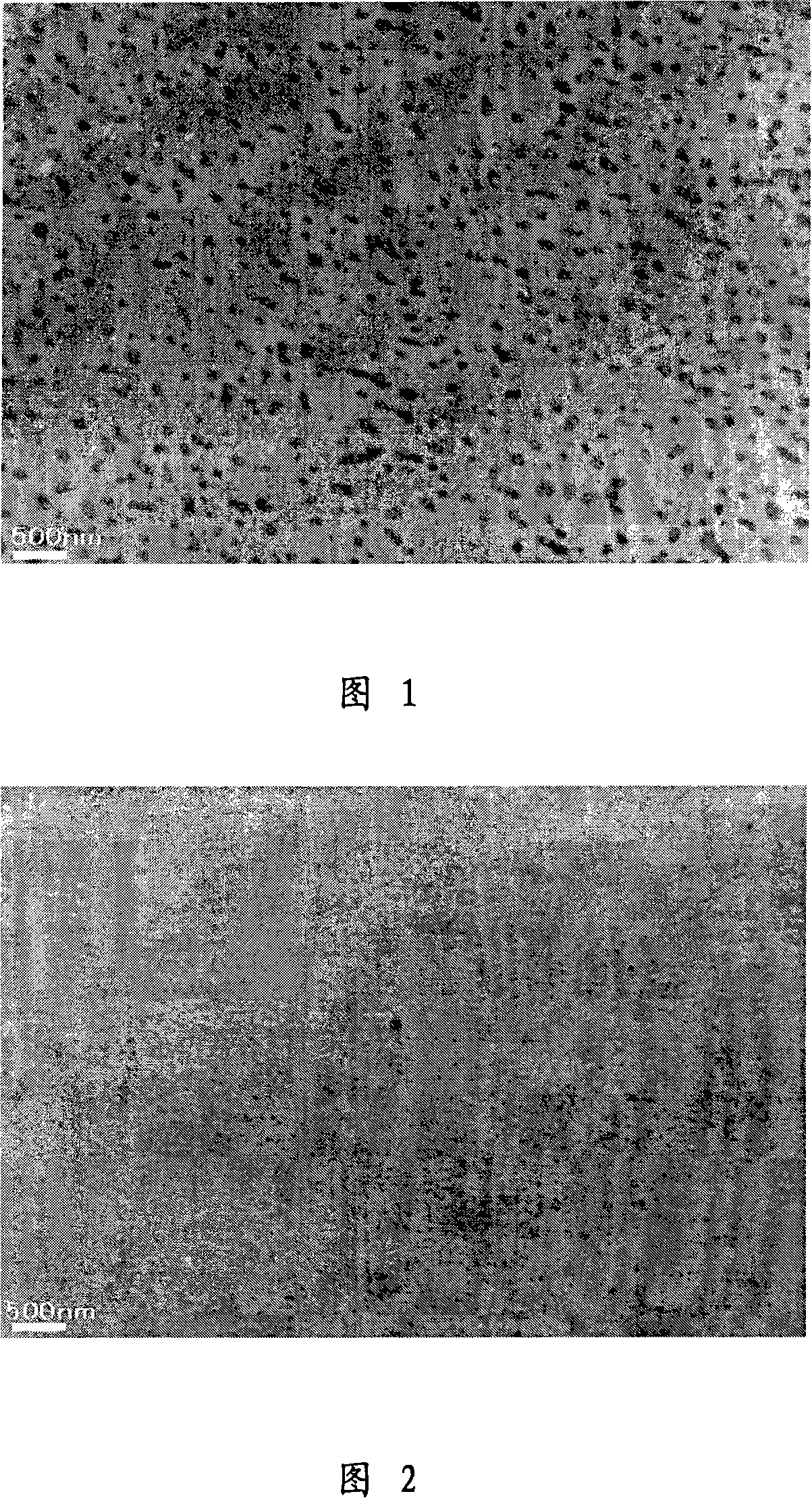

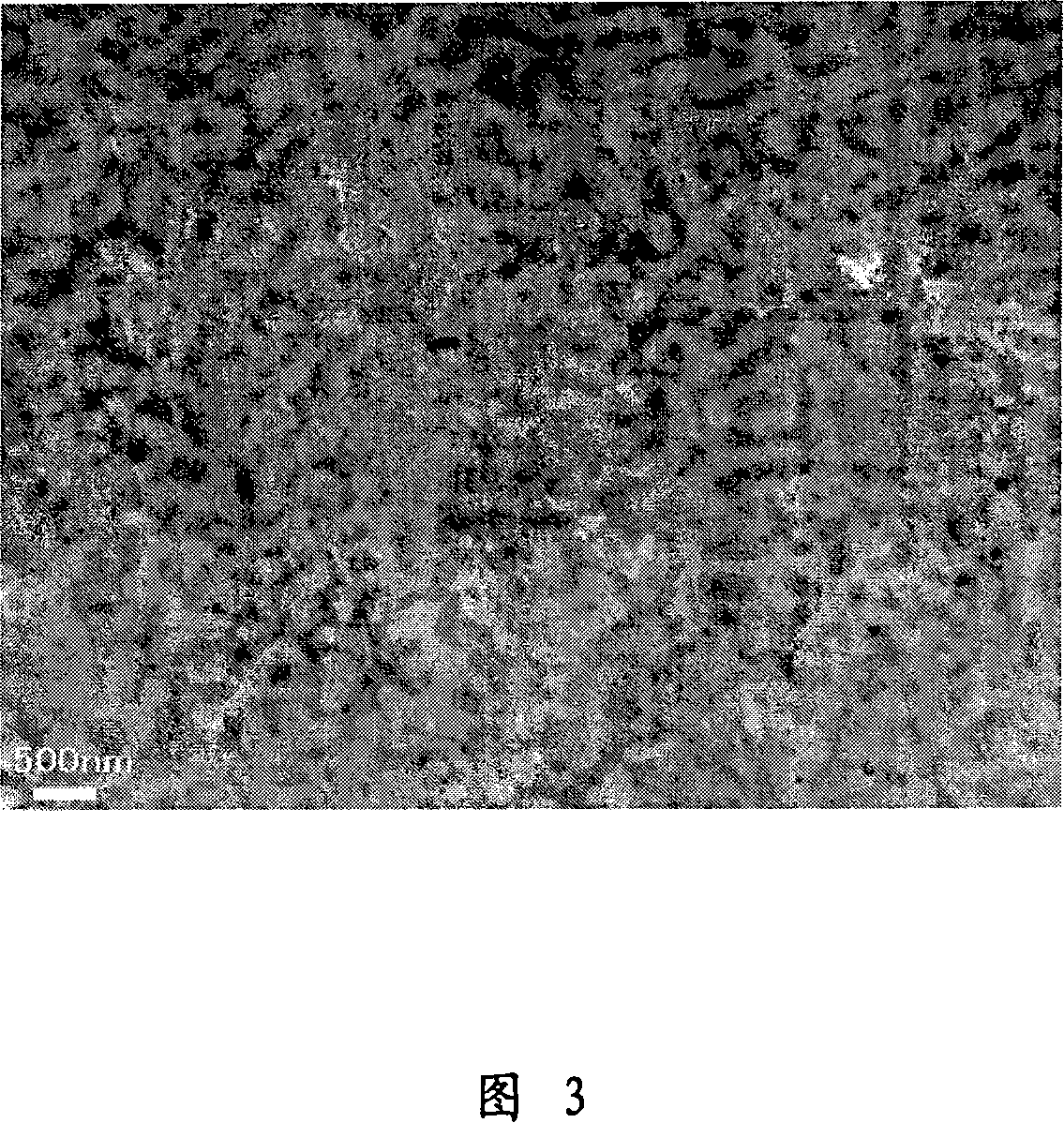

The invention discloses a multi-phase polypropylene copolymer having a high ethylene-propylene rubber content. The multi-phase polypropylene copolymer comprises the following components in percentage by weight: 10-70% of propylene polymer matrix, 25-70% of ethylene-propylene random copolymer and 5-20% of ethylene-propylene block polymer. According to the invention, the multi-phase polypropylene copolymer has an ethylene-propylene rubber content of no less than 30wt%, and has excellent toughness and high shock strength (especially low-temperature shock strength). The invention also discloses a preparation method of the multi-phase polypropylene copolymer having a high ethylene-propylene rubber content. The preparation method combines propylene polymerization and gas phase ethylene-propylene copolymerization.

Owner:ZHEJIANG UNIV

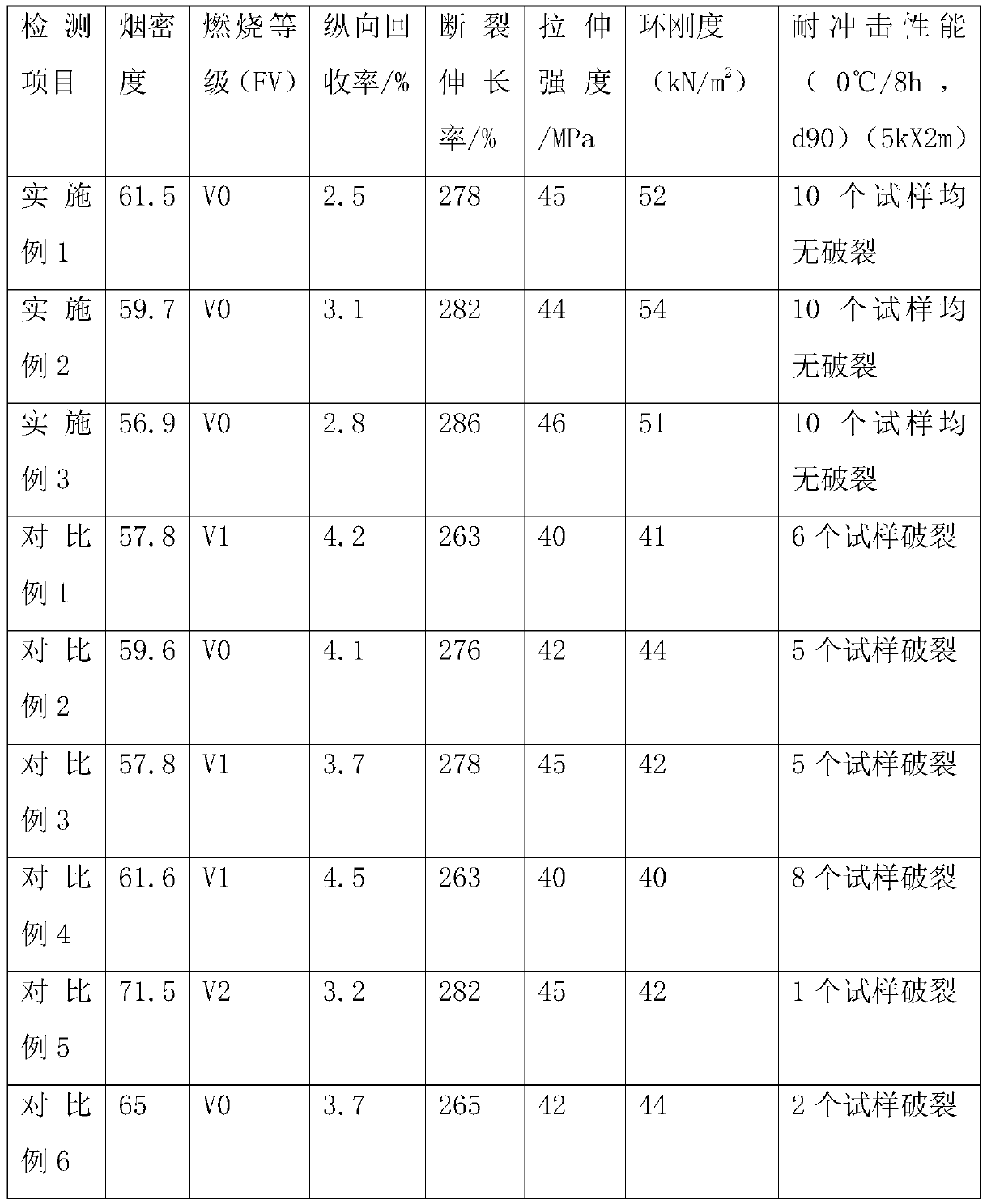

Modified polypropylene corrugated pipe and manufacturing method thereof

ActiveCN102964689AImprove flame retardant performanceImprove insulation performanceAntioxidantPolypropylene

The invention discloses a modified polypropylene corrugated pipe, relating to a conduit for paving cables. The modified polypropylene corrugated pipe is prepared from a modified polypropylene material which consists of the following components in parts by weight: 100 parts of base material, 0.1-1 part of polytetrafluoroethylene, 0.1-1 part of calcium stearate, 0.2-1 part of antioxidant and 0.01-0.1 part of pigment, wherein the base material consists of 65-80% of polypropylene, 5-10% of ethylene propylene diene monomer and 15-25% of microcapsule red phosphorus master batch. A manufacturing method of the modified polypropylene corrugated pipe comprises the following steps of: preparing the modified polypropylene material; and manufacturing the modified polypropylene corrugated pipe. The modified polypropylene corrugated pipe disclosed by the invention has the advantages of good flame retardance, excellent electrical insulation property, good impact resistance, higher heat distortion temperature, good low-temperature impact resistance, light weight, smooth surface and low friction resistance in cable threading, and can be abut-jointed through thermofussion welding, thus the modified polypropylene corrugated pipe is suitable for underground pavement of pipelines and cables and is widely applied to the projects of telecommunication, electric power and the like.

Owner:GUANGDONG SANLING PLASTIC PIPE MATERIAL

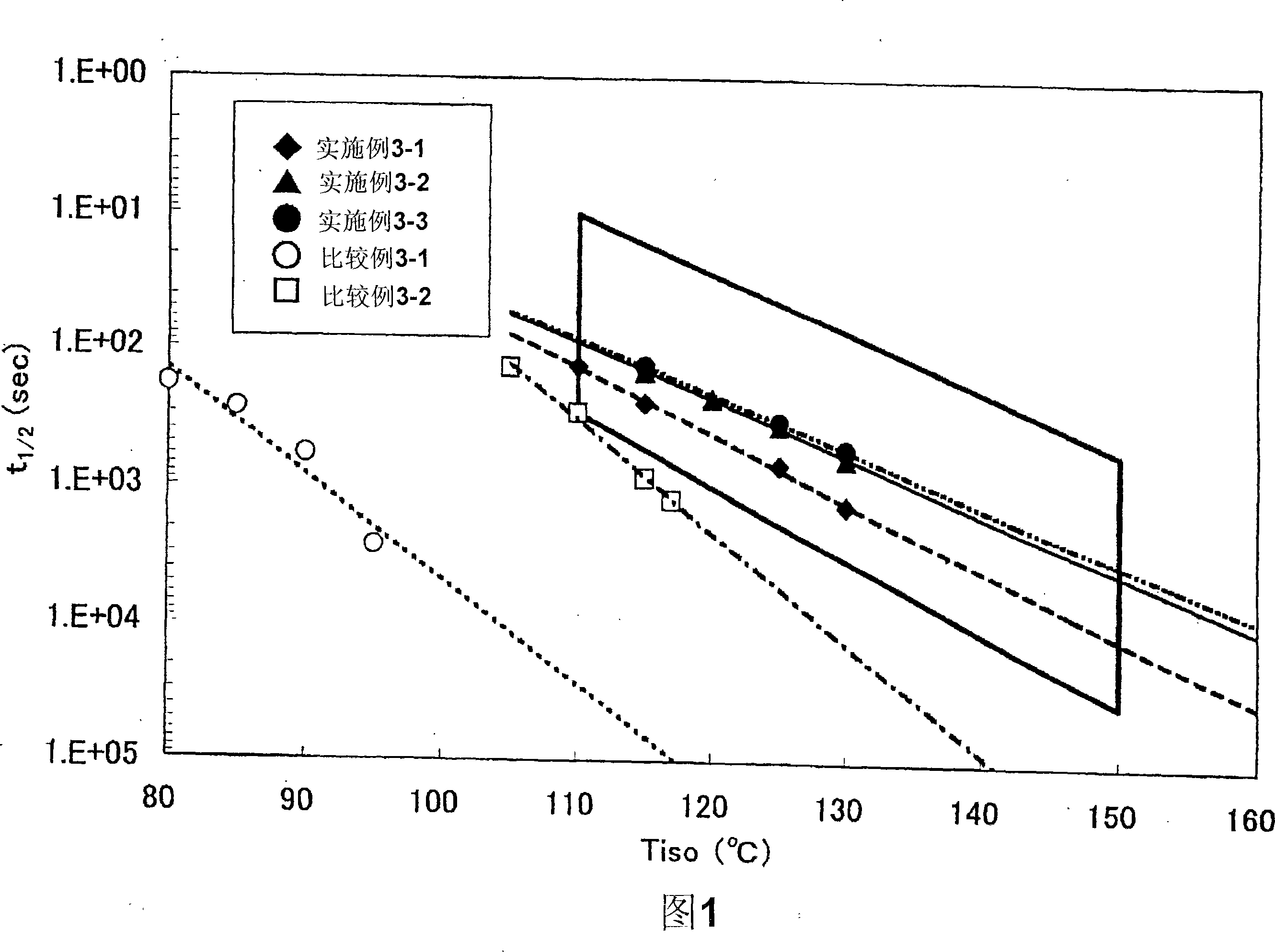

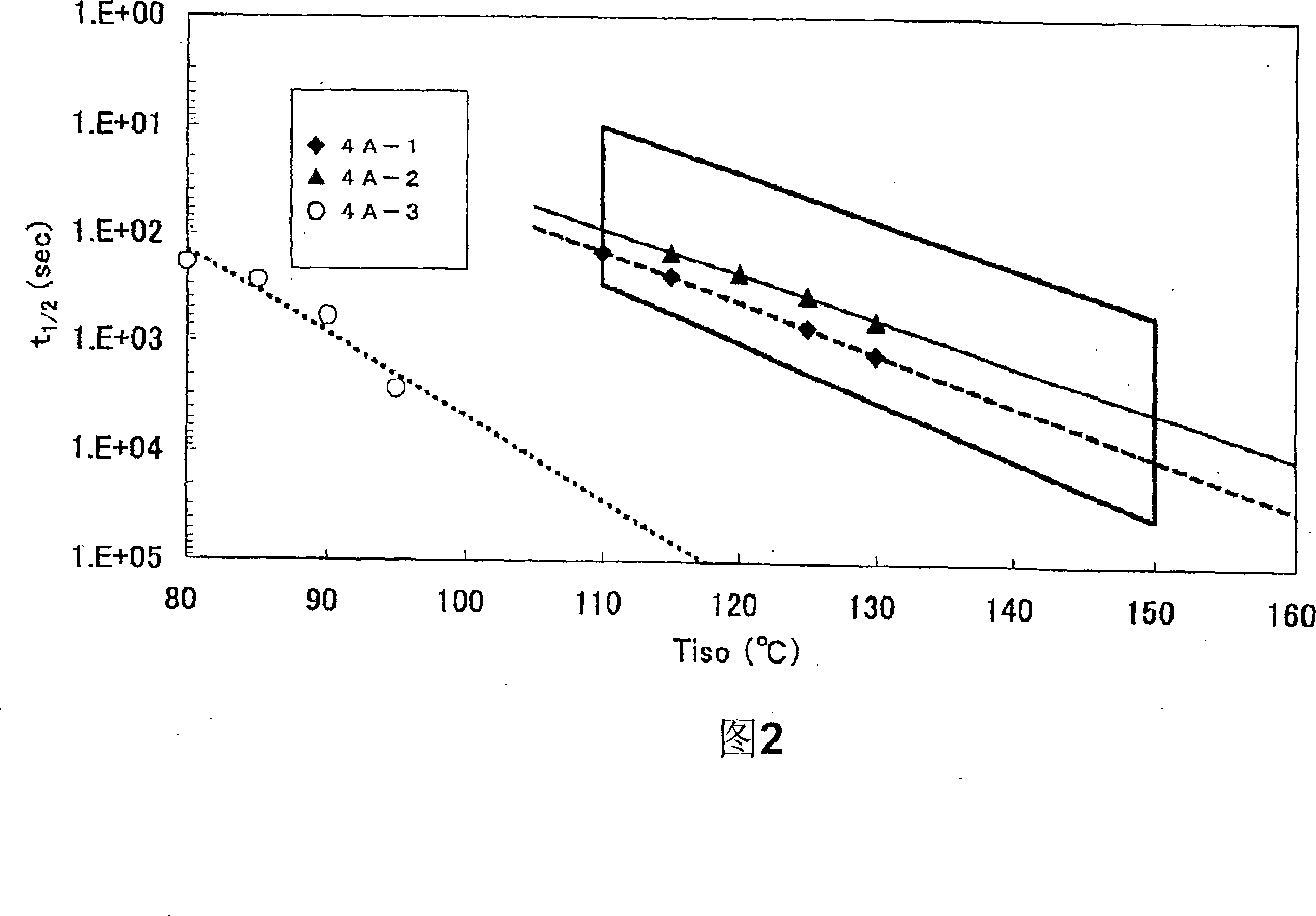

Propylene-based polymer composition, use thereof, and method for producing thermpolastic polymer composition

A propylene polymer composition comprising: (A) 41 to 95 parts by weight of a propylene polymer having Tm within the range from 120 DEG C to 170 DEG C inclusive as measured by DSC; (B) 59 to 5 parts by weight of a propylene / ethylene / a-olefin copolymer which comprises a constituent unit derived from propylene in an amount of 84.0 to 60.0 mol%, a constituent unit derived from ethylene in an amount of 15.0 to 30.0 mol% and a constituent unit derived from an a-olefin having 4 to 20 carbon atoms in an amount of 1.0 to 10.0 mol% and which has a B value within the range from 0.9 to 1.5 inclusive, based on 100 parts by weight of the total of the components (A) and (B). This polymer composition is excellent in transparency, impact resistance at low temperatures, mechanical properties (e.g., flexibility, stiffness) and heat resistance.

Owner:MITSUI CHEM INC

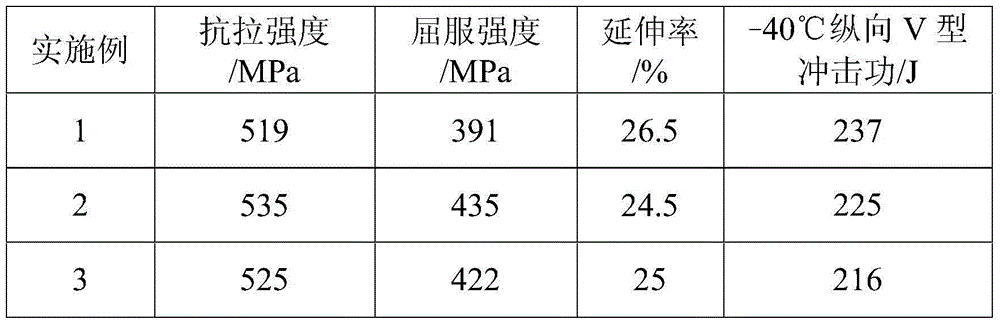

Titaniferous high-chromium weathering resistant steel and preparing method thereof

The invention belongs to the field of steel smelting, and particularly relates to titaniferous high-chromium weathering resistant steel and a rolling method thereof. The titaniferous high-chromium weathering resistant steel comprises, by weight, smaller than or equal to 0.07% of C, smaller than or equal to 0.50% of Si, smaller than or equal to 1.5% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.10% of S, 0.20%-0.55% of Cu, 3.00%-5.50% of Cr, 0.10%-0.65% of Ni, 0.04%-0.10% of Ti, and the balance Fe and inevitable impurities. The weathering resistant steel and a preparing method thereof have the beneficial effects that the production cost is low, the technology is simple, the product yield is high, and the comprehensive performance of the weathering resistant steel is superior. The requirement of the existing industry for high weathering resistance of the weathering resistant steel can be met, the requirement for stable mechanical performance of steel can also be met, and especially superior low-temperature impact resistance and good ductility are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Catalyst for olefin polymerization, method for producing olefin polymer, method for producing propylene copolymer, propylene polymer, propylene polymer composition, and use of those

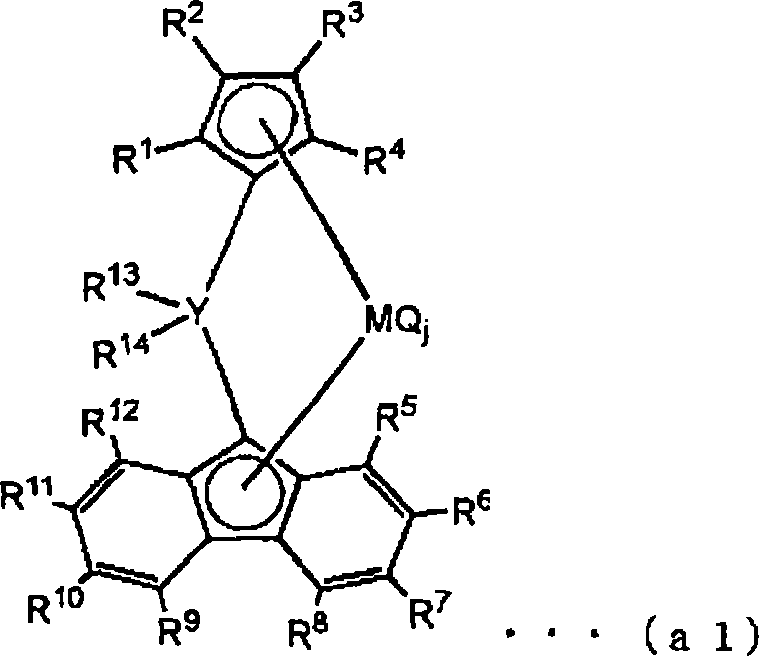

Disclosed is a catalyst for olefin polymerization composed of a crosslinked metallocene compound (A-1) represented by the general formula [1-1] below and at least one or more compounds (b) selected from organic aluminum oxy compounds (b-1), compounds (b-2) forming an ion pair, and organic aluminum compounds (b-3). [1-1] (In the general formula [1-1], R<1>, R<2>, R<3>, R<4>, R<5>, R<8>, R<9> and R<12> respectively represent one selected from a hydrogen atom, a hydrocarbon group and a silicon-containing group; R<6>, R<7>, R<10> and R<11> are not hydrogen atoms and respectively represent one selected from a hydrocarbon group and a silicon-containing group; R<13> and R<14> respectively represent a hydrogen atom, a hydrocarbon group other than a methyl group or the like; M represents Ti, Zr or the like; Y represents carbon or the like; Q represents a halogen or the like; and j represents an integer of 1-4.

Owner:MITSUI CHEM INC

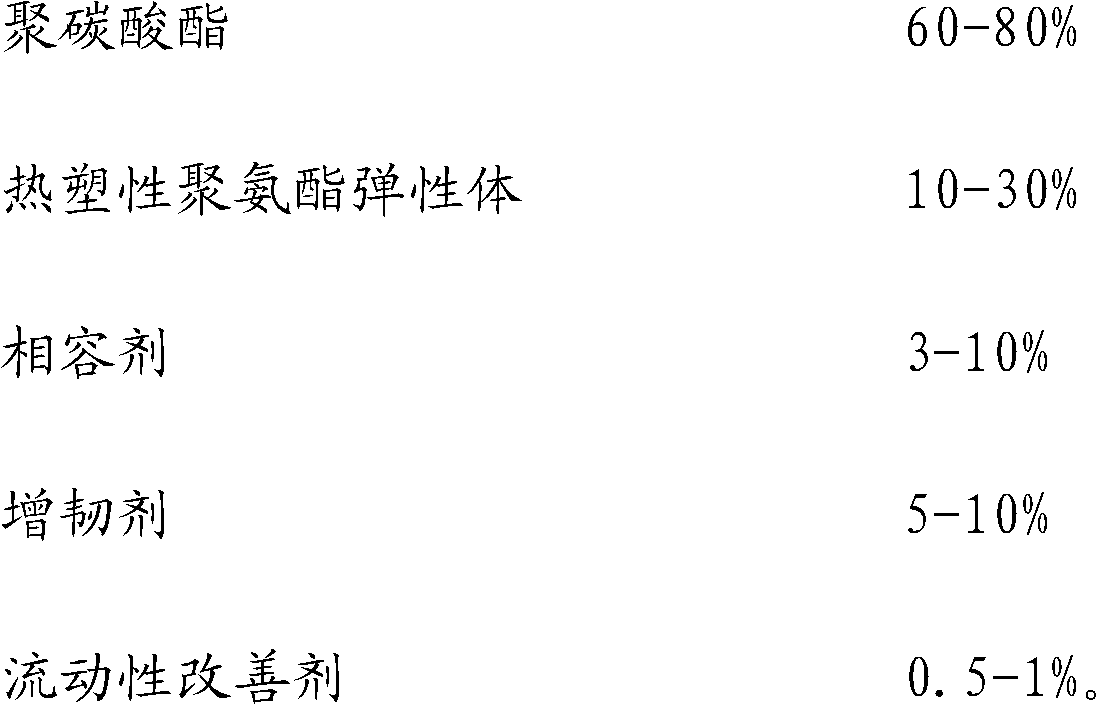

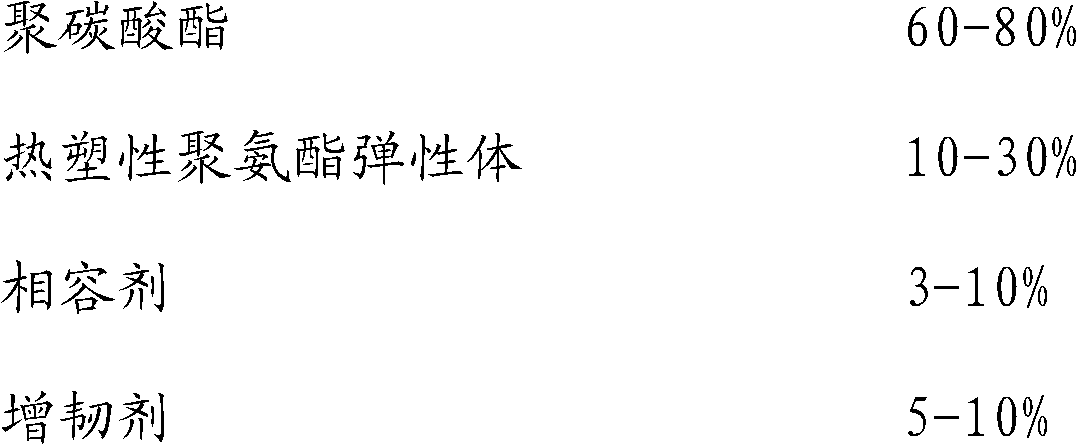

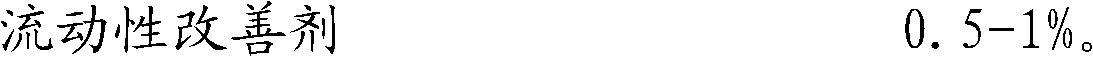

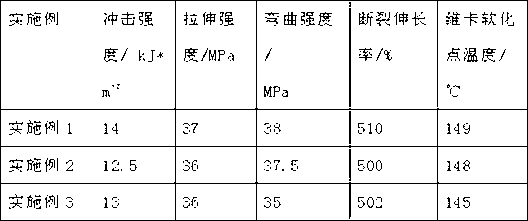

High-fluidness PC/TPU (polycarbonate/thermoplastic urethane) alloy material and preparation method thereof

The invention discloses a high-fluidness PC / TPU (polycarbonate / thermoplastic urethane) alloy material and a preparation method thereof. The high-liquidity PC / TPU alloy material comprises the following compositions in percentage by weight: 60-80% of polycarbonate, 10-30% of thermoplastic polyurethane elastomer, 3-10% of compatilizer, 5-10% of toughening agent, and 0.5-1% of fluidness improver. The high-liquidity PC / TPU alloy material prepared by using the method disclosed by the invention concurrently has the advantages of PC and TPU, and is good in low-temperature impact resistance, coating performance and solvent resistance and excellent in fluidness; and the preparation method can be implemented in one step through granulation by using a double-screw blending extrusion process, so that the preparation method is simple in process, convenient to operate, high in efficiency, low in cost, and suitable for being applied to industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

Sun-proof composite modified polypropylene pipe for power cable protection

InactiveCN103012956AImprove heat stabilityReduce dosageInsulated cablesInsulated conductorsElastomerPolyolefin

The invention relates to a sun-proof composite modified polypropylene pipe for power cable protection. The pipe comprises the following components in percentage by weight: 73 to 78 percent of PP (Propene Polymer), 10 to 15 percent of POE (Polyolefin Elastomer), 4.8 to 5.2 percent of nano calcium carbonate, 0.3 to 0.4 percent of nucleating agent, 0.2 to 0.25 percent of coupling agent and 0.5 to 1 percent of sun-proof lubricating composite functional master batch. Not only does the pipe have better low-temperature impact resistance, wherein impact energy in a falling weight impact test at a temperature of minus 5 DEG C is improved by over 2.5 times, the friction coefficient is reduced by 40 percent and the Vicat heat-resistance temperature is risen by 5 DEG C, but also sun-proof performance of the pipe is improved and the application range of the power pipe is enlarged.

Owner:ZHEJIANG HUAFENG NEW MATERIAL

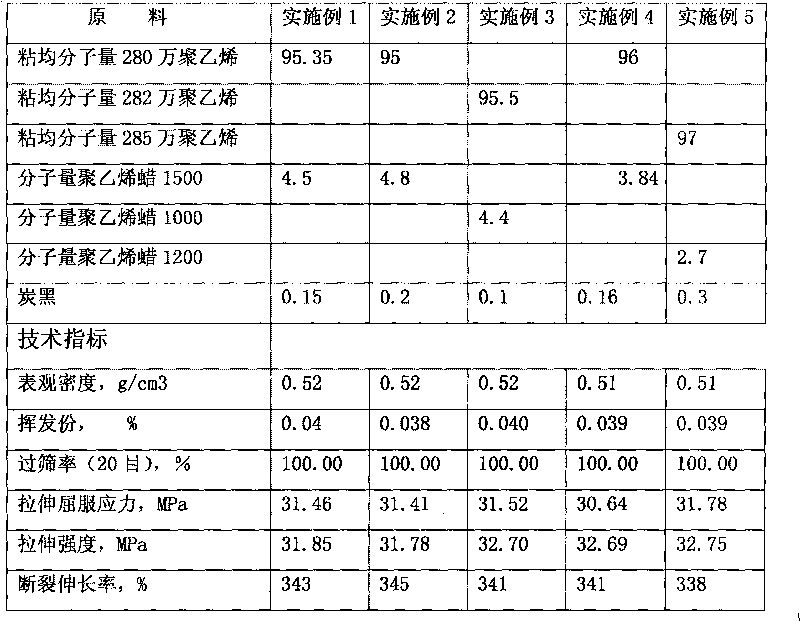

Wearable ultrahigh molecular weight polyethylene tubular product and preparation method thereof

InactiveCN101696291AImprove toughnessGood chemical stabilityRigid pipesChemical industryPolymer science

The invention discloses a wearable ultrahigh molecular weight polyethylene tubular product and a preparation method thereof, belonging to a composite of macromolecular compounds, and comprising the following raw material components in parts by weight: 95-98 parts of ultrahigh molecular weight polyethylene with viscosity-average molecular weight of 2800,000-2850,000, 1.8-4.8 parts of polyethylene wax with molecular weight of 1,000-1,500, and 0.1-0.3 part of carbon black. The invention provides the wearable ultrahigh molecular weight polyethylene tubular with performances of corrosion resistance, anti-adhesion, compression resistance, impact resistance, high surface hardness, good abrasion resistance, high mechanical strength, high heat distortion temperature, convenient process, long service life and low manufacture cost, and a preparing method thereof with simple manufacturing process and low production cost. As the substitute of steel tubes, the invention meets the market requirements, overcomes the defects of poor performances of corrosion resistance, abrasion resistance and anti-adhesion in the prior steel tubes, and is widely applied to the transportation of wastewater, waste residue and corrosive medium in the industries such as metallurgy, electric power, paper-making, chemical industry, machine, petroleum and the like.

Owner:沂源县联创工贸有限公司

Low-temperature-resistant H-shaped steel and production process thereof

ActiveCN104018074AReduce the ductile-brittle transition temperatureGood impact resistance at low temperatureChemical compositionManganese

The invention discloses low-temperature-resistant H-shaped steel comprising the following chemical components in percentage by mass: 0.08-0.13% of C, 0.15-0.35% of Si, 1.25-1.45% of Mn, less than or equal to 0.01% of P, less than or equal to 0.01% of S, 0.02-0.05% of V and the balance of Fe and impurity elements. The rolling technological parameters are as follows: the heating temperature ranges from 1220 DEG C to 1240 DEG C, the initial blooming temperature ranges from 1050 DEG C to 1150 DEG C, the initial finish rolling temperature ranges from 930 DEG C to 950 DEG C, and the final finish rolling temperature ranges from 780 DEG C to 900 DEG C; the cooling technological parameters are as follows: a rolled piece is cooled to the interval of 550-650 DEG C at the speed of 100-150 DEG C / s to generate phase change, then, the rolled piece is heated to 700-750 DEG C, and finally, the H-shaped steel is naturally cooled to room temperature. The H-shaped steel can have extremely low ductile-brittle transition temperature and favorable low temperature impact resistance in high and cold areas and low-temperature environments with the temperature of 40 DEG C below zero and even lower.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Rubbery product or rubbery substance containing product

Rubber-like articles or articles containing rubber-like substances, consisting of or made from hydrogenated natural polyisoprene products or modified products thereof. In the rubbery product or the rubbery substance-containing product, a rubbery elastic body made of a natural polyisoprene hydrogenated product or a modified product thereof is contained. As the natural polyisoprene hydrogenation product, for example, a polymer obtained by reacting natural polyisoprene with hydrogen in a solvent in the presence of a hydrogenation catalyst can be used. The hydrogenation ratio of the natural polyisoprene hydrogenated product is preferably 50% or higher. In addition, it is preferable that the natural polyisoprene hydrogenated product has a weight average molecular weight of 20×10 4 or higher and exhibits a molecular weight distribution of 2.0 or higher. The rubber-like article or article containing a rubber-like substance exhibits high thermal stability and weather resistance, and is also preferable from the viewpoint of resources and the environment since a plant-derived raw material is used.

Owner:NITTA CORP +1

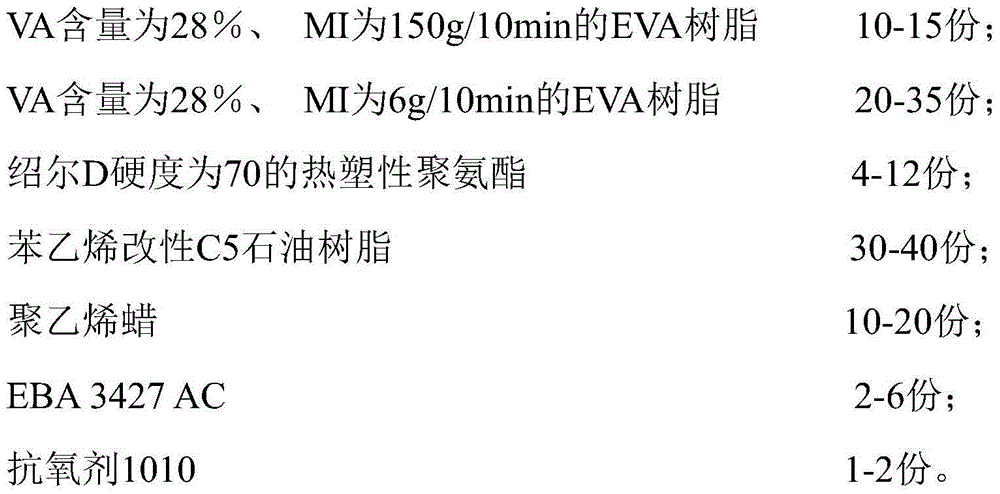

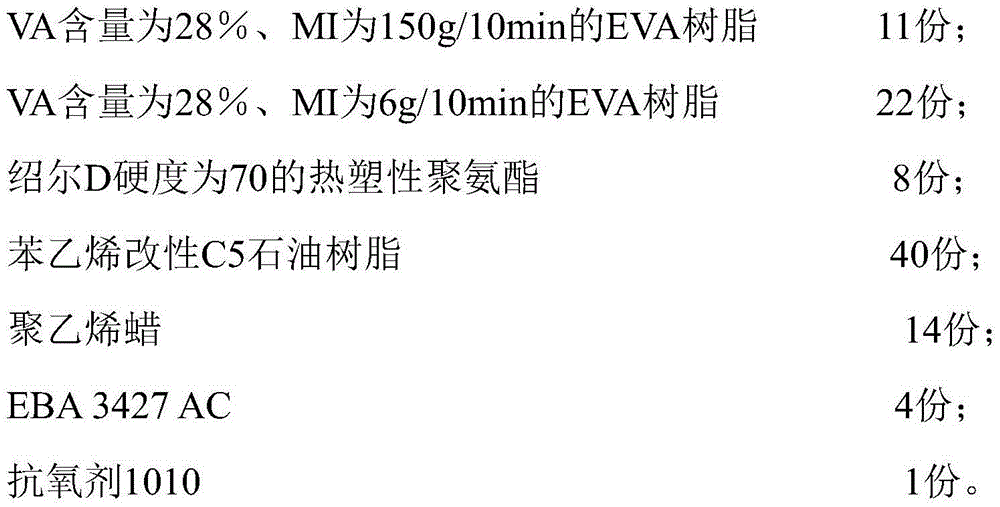

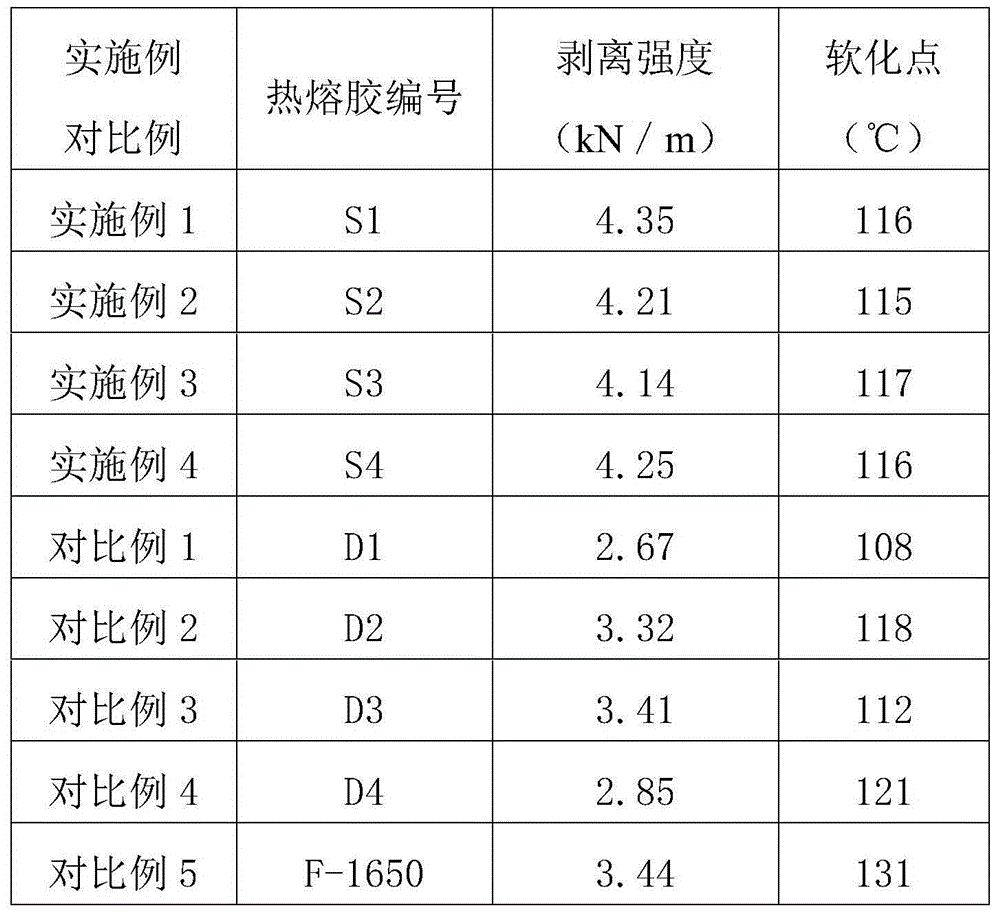

Hot melt adhesive for acrylic hot-fix rhinestone and preparation method thereof

ActiveCN105273669AAdjust melt viscosityReduce crystallinityMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesPetroleum resinThermoplastic polyurethane

The invention provides a hot melt adhesive for an acrylic hot-fix rhinestone. The hot melt adhesive comprises the following components by weight: 10 to 15 parts of EVA resin with the VA content of 28% and the MI of 150 g / 10min, 0 to 35 parts of EVA resin with the VA content of 28% and the MI of 6 g / 10min, 4 to 12 parts of thermoplastic polyurethane with Shore D hardness of 70, 30 to 40 parts of styrene modified C5 petroleum resin, 10 to 20 parts of polyethylene wax, 2 to 6 parts of EBA3427AC and 1 to 2 parts of an antioxidant 1010. The hot melt adhesive for the acrylic hot-fix rhinestone provided by the invention has a hot-press temperature of 115 to 120 DEG C, is not prone to scalding the acrylic hot-fix rhinestone and fabrics, and has peeling strength of no less than 4.0kN / m , thereby having high bonding strength at the same time; meanwhile, the hot melt adhesive has the advantage of good adhesive force with a variety of fabrics and acrylic hot-fix rhinestones, and is an ideal hot melt adhesive for the acrylic hot-fix rhinestone.

Owner:HUANGSHAN XINDECHENG GLUE IND CO LTD

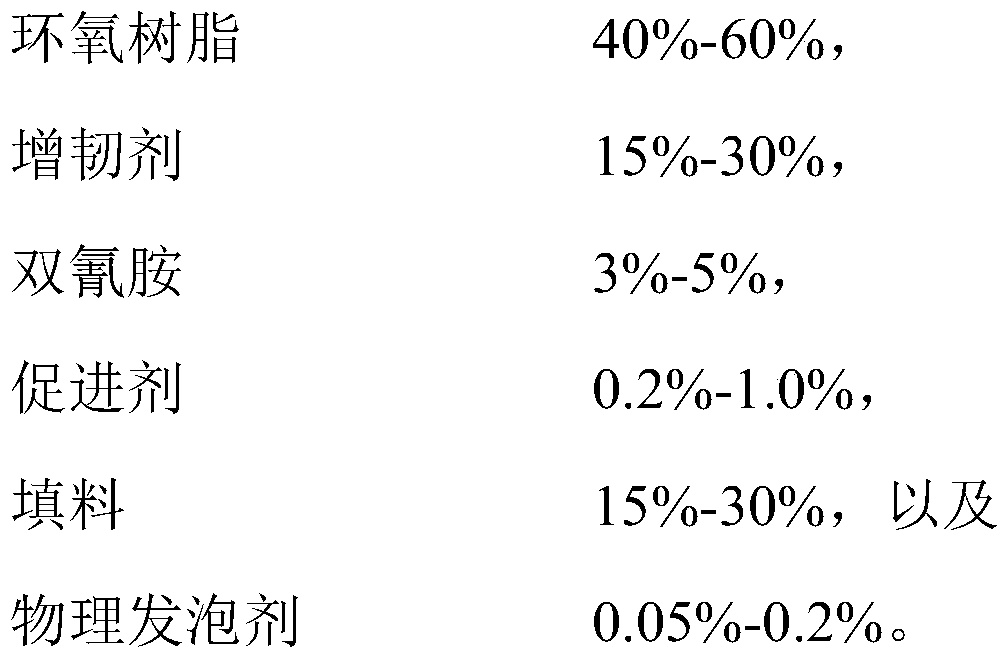

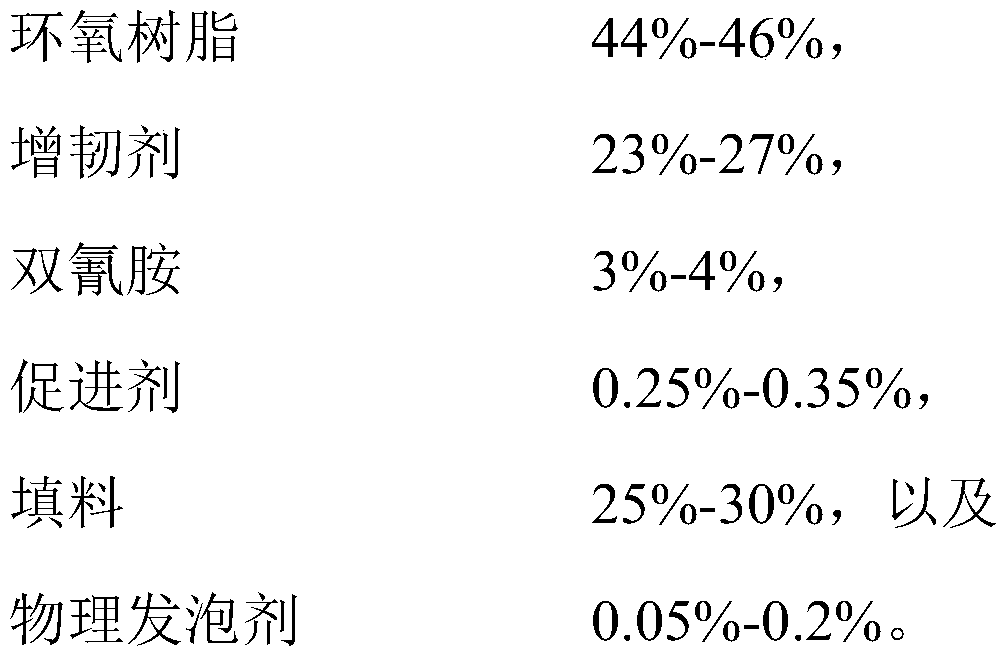

Structural adhesive with excellent low-temperature impact peel strength and preparation method thereof

ActiveCN111139010AMeet performance needsGood impact resistance at low temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention relates to a structural adhesive with excellent low-temperature impact peel strength and a preparation method thereof. The structural adhesive is prepared from specific weight percentages of epoxy resin, a toughening agent, dicyandiamide, an accelerant, a filler and a physical foaming agent, can overally achieve excellent low-temperature impact resistance, has good high-and-low-temperature shear strength, and meets the use performance requirements of automobiles in low-temperature cold weather.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +2

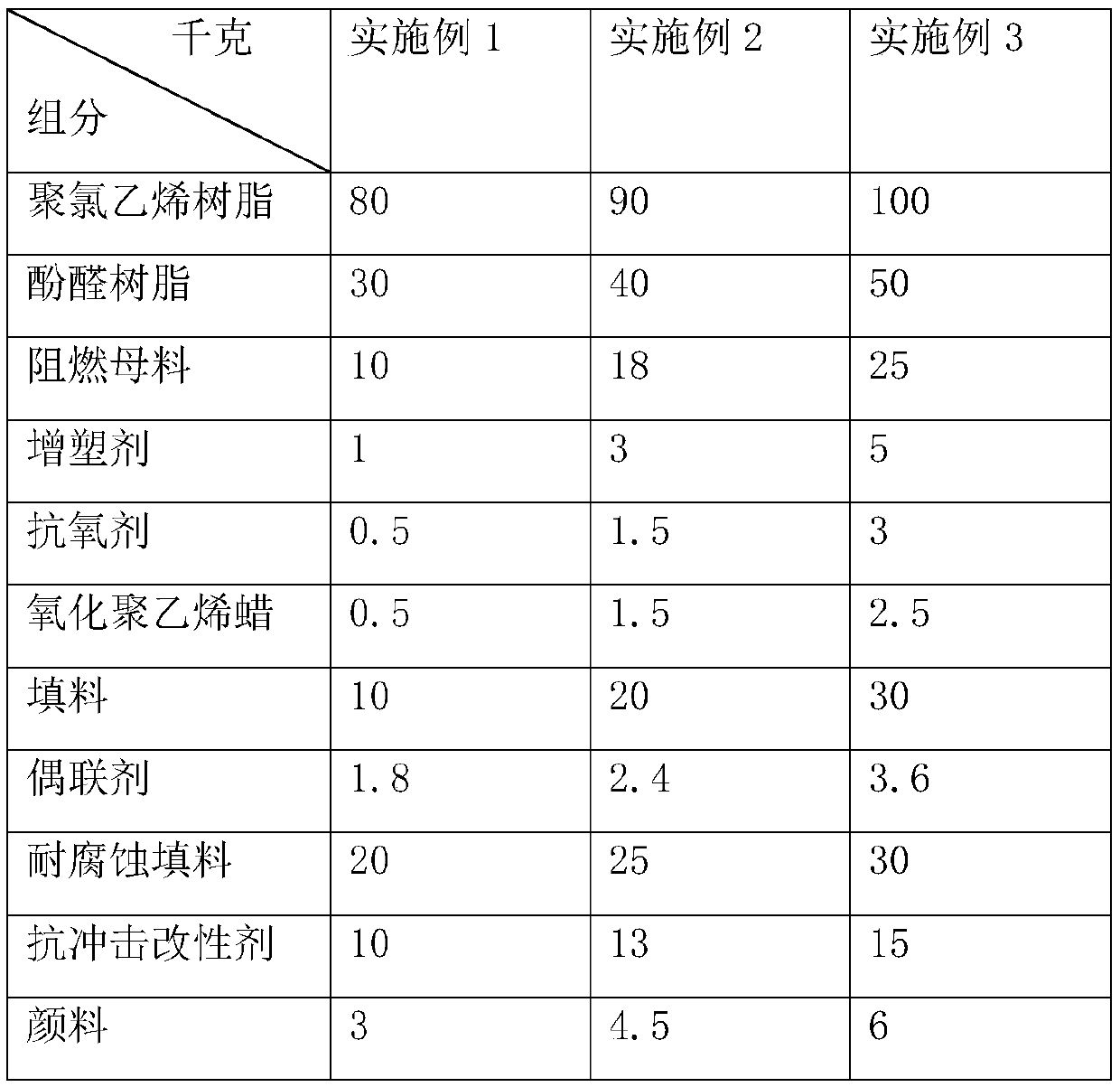

Flame-retardant PVC cable tube and preparation method thereof

The invention discloses a flame-retardant PVC cable tube and a preparation method thereof. The flame retardant PVC cable tube comprises the following components: polyvinyl chloride resin, phenolic resin, flame retardant masterbatch, a plasticizer, an antioxidant, oxidized polyethylene wax, a filler, a coupling agent, a corrosion resistant filler, a shock resistance modifier and pigment. The corrosion resistant filler includes, by weight, 5-12 parts of modified aramid fibers, 16-20 parts of ceramsite, 3-8 parts of graphene, 15-30 parts of epoxy resin emulsion, 5-10 parts bentonite and 3-6 partsof a ceramic adhesive. The shock resistance modifier includes, by weight, 11-16 parts of polylactic acid, 7-13 parts lignin fiber, 4-8 parts beet pulp, 3-7 parts of soybean meal, 8-14 parts of polyolefin elastomer, 5-10 parts of piperazine pyrophosphate and 20-30 parts of polystyrene resin. The flame-retardant PVC cable tube has the advantages of good flame retardancy, high corrosion resistance and strong impact resistance.

Owner:深圳市深捷通管业发展有限公司

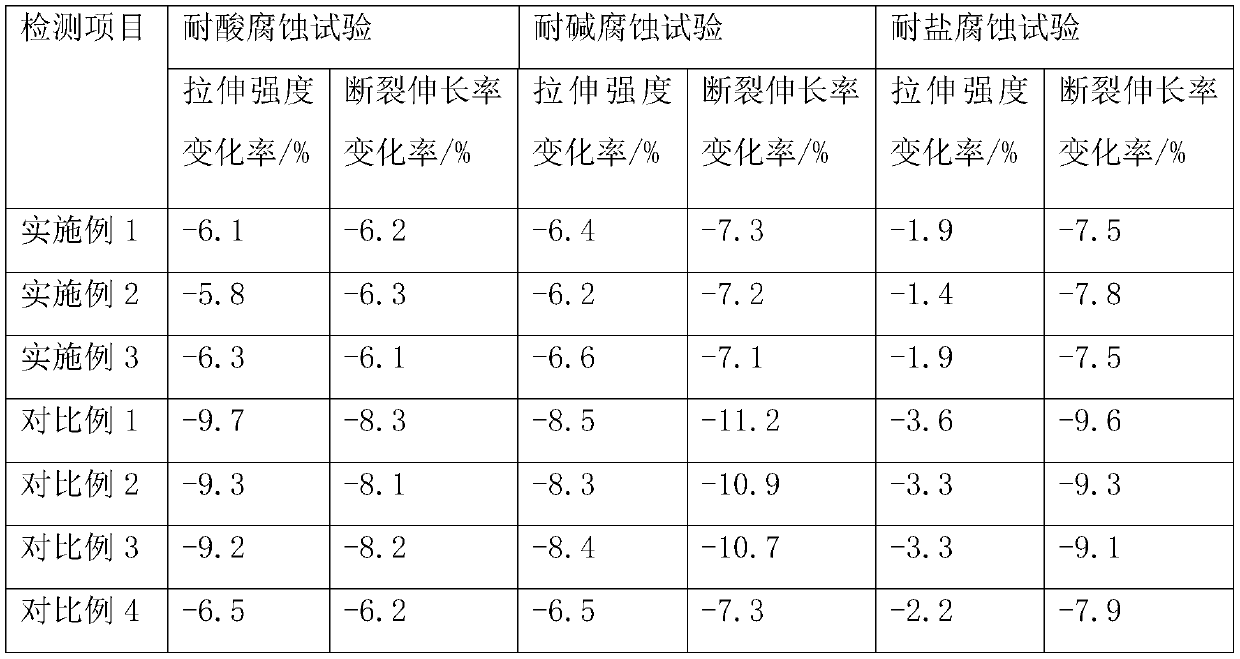

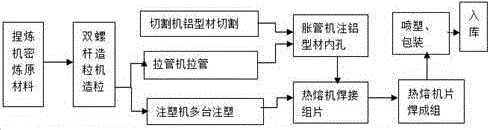

Thermal conductive plastic alloy, radiator based on alloy and preparation method

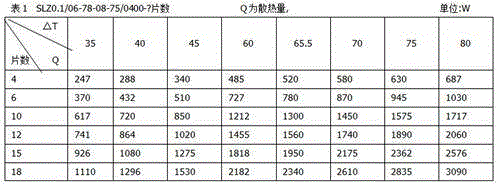

InactiveCN105175907AGood frost and heat resistanceStable molecular structureHeat exchange apparatusFiberAlloy

The invention discloses a thermal conductive plastic alloy used for a radiator, a radiator and a preparation method. The thermal conductive plastic alloy comprises polybutene or polyisobutene, polyethylene, graphite powder, carbon fiber, thermal conductive carbon black, a thermal conductive reinforcing agent, a titanate coupling agent and stearic acid. The thermal conductive plastic alloy is subjected to granulation, then pipe drawing and injection molding are carried out, an inner water channel pipe and a connecting piece of an radiator are prepared, the inner water channel pipe is expanded into an inner hole of an aluminum wing pipe of the radiator to obtain a radiator column material or sheet material, the column material or the sheet material and the connecting piece are subjected to sweat soldering to prepare a radiator single sheet, and finally the radiator single sheets are subjected to sweat soldering to compose a radiator. The thermal conductive plastic alloy and the radiator are advantaged by good environmental protection and excellent heat radiation performance, are stable and durable, and have protruding characteristics of no fouling, no rusting, no corrosion, no cracking, no pollution, no deformation, no abnormal sound and no aging.

Owner:徐继煌

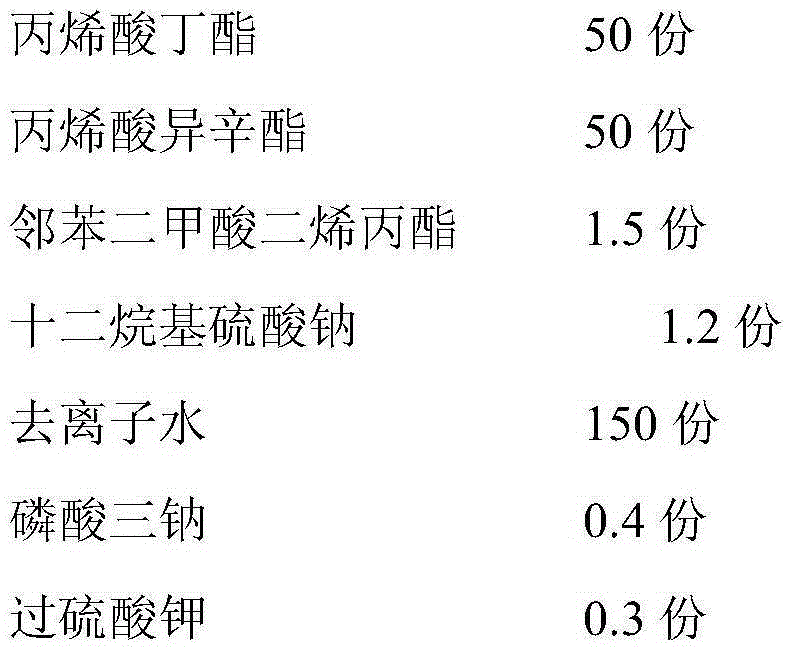

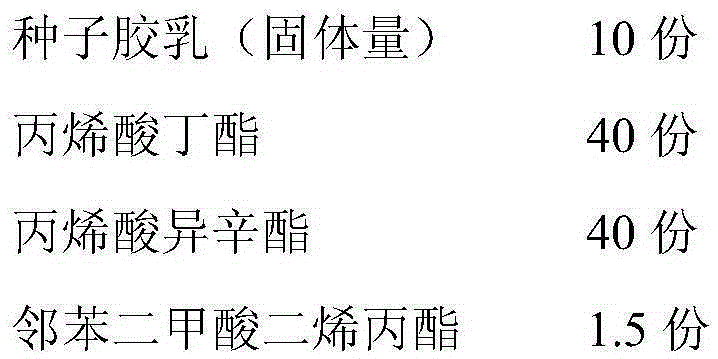

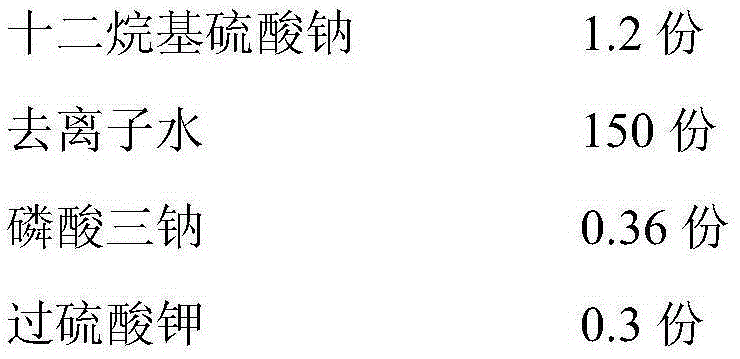

Low-temperature-resisting high-impact-resistance PVC modifying agent and preparation method thereof

The invention belongs to the field of high molecular material synthesis and particularly relates to a low-temperature-resisting high-impact-resistance PVC modifying agent. The low-temperature-resisting high-impact-resistance PVC modifying agent is of a core-shell structure, the internal of the structure is an acrylate rubber core, and the external of the structure is a methyl methacrylate shell. The modifying agent can improve the toughness of PVC products, still keep the good impact resistance strength even in a low-temperature environment, improves the fluidity, thermal deformation and weatherability of PVC melts and the surface gloss of the products. The invention further provides a preparation method of the modifying agent. The preparation method comprises the steps that deionized water, an expanding agent, an emulsifier, a soft acrylic ester monomer, a crosslinking agent and an initiator are added into a reactor, and acrylate seed latex is obtained through rection; a part of the acrylate seed latex is taken, the soft acrylic ester monomer is added, a core-layer latex is obtained through reaction, a hard acrylic ester monomer is added into the core-layer latex, high-impact-resistance modifying agent latex is obtained after reaction, and the low-temperature-resisting high-impact-resistance modifying agent is obtained after the latex coagulates and is dehydrated and dried. The raw materials of the modifying agent are easy to obtain, a process is simple and easy to operate, and the modifying agent is pollution-free to the environment and is convenient to use.

Owner:淄博华星助剂有限公司

Nylon alloy with high thermal deformation resistance and preparation method thereof

The invention which relates to a nylon alloy with high thermal deformation resistance and a preparation method thereof belongs to the technical field of nylon alloys. The nylon alloy (by nylon alloy) comprises the following components, by weight, 40-60% of polyhexamethylene adipamide, 8-15% of polypropylene, 25-35% of a glass fiber, 4-8% of a compatilizer, and 2-4% of an antistatic agent, and thenylon alloy is prepared through carrying out extrusion granulation on the components. The glass fiber which is added in the invention allows the mechanical performance of polyhexamethylene adipamide to be improved, so the shrinkage of the nylon alloy is reduced to 0.2-1% from 1-2%; and the compatilizer maleic anhydride graft copolymer which is added in above formula allows the density, the melting point, the elastic modulus and the like of the nylon alloy to be improved, so the nylon alloy of the invention which is a nylon alloy with alcohol and ether resistance and high thermal deformation resistance receives good graces of users.

Owner:徐州峰登农业开发有限公司

Propylene polymer, a propylene polymer composition, and use of those

The invention relates to a propylene polymer, a propylene polymer composition, and use of those. The propylene polymer is characterized by including more than 9mol% of constitution units derived from propylene (wherein, the total quantity of the constitution units in a polymer (A) is 100mol%), and meeting conditions [1] and [2-2], [1]: a syndiotactic five-unit component ratio (rrrr fraction) measured by 13C-NMR is more than 85%; [2-2]: a melting point (Tm) calculated by a differential scanning catorimetry (DSC) is more than 150 DEG C and the melting heat (Delta H) is more than 50mJ / mg.

Owner:MITSUI CHEM INC

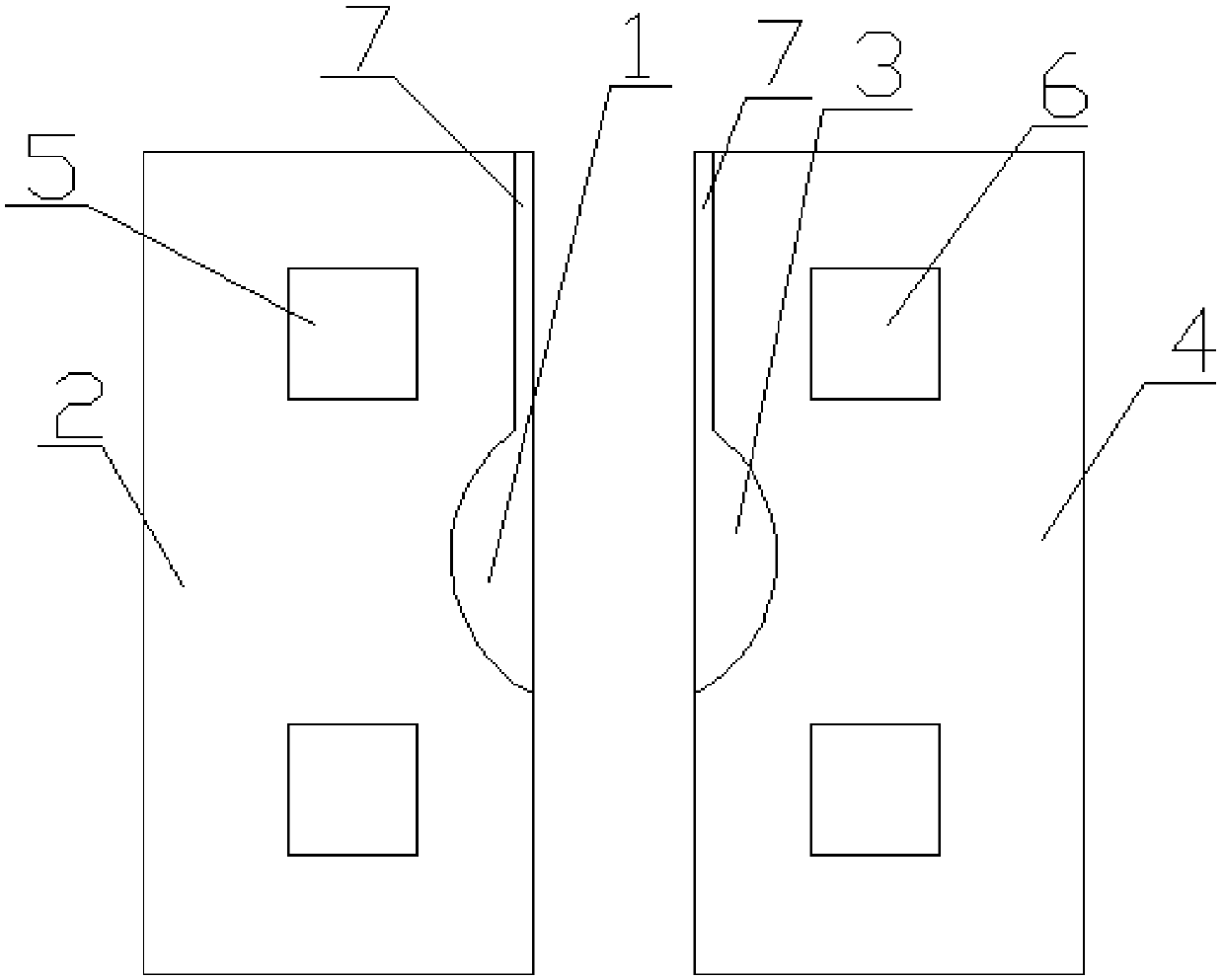

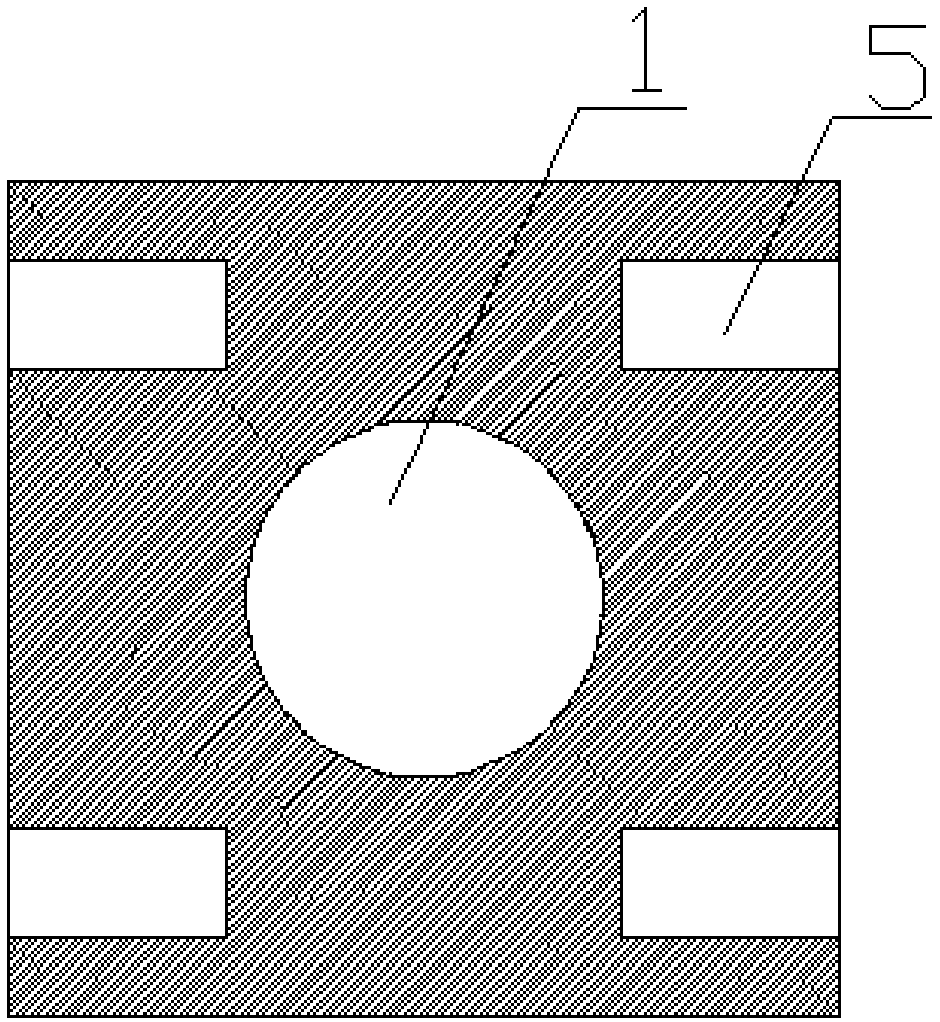

Gypsum slip casting mold

InactiveCN107650239AImprove physicsImprove mechanical propertiesSlip casting mouldsCasting moldGypsum

The invention discloses a gypsum slip casting mold. The gypsum slip casting mold comprises a first half mold body (2) forming a first cavity (1) and a second half mold body (4) forming a second cavity(3). The first cavity (1) and the second cavity (3) are matched to form a cavity for gypsum injection. At least one first containing cavity (5) is formed inside the first half mold body (2). At leastone second containing cavity (6) is formed inside the second half mold body (4). Permanent magnets are arranged in the first containing cavities (5) and the second containing cavities (6). The materials of the first half mold body (2) and the second half mold body (4) are ABS resin and nanometer zeolite powder composite materials. The effects of good use performance, convenient demolding, good water absorption performance, simple and convenient processing and great reduction of production cost are realized.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

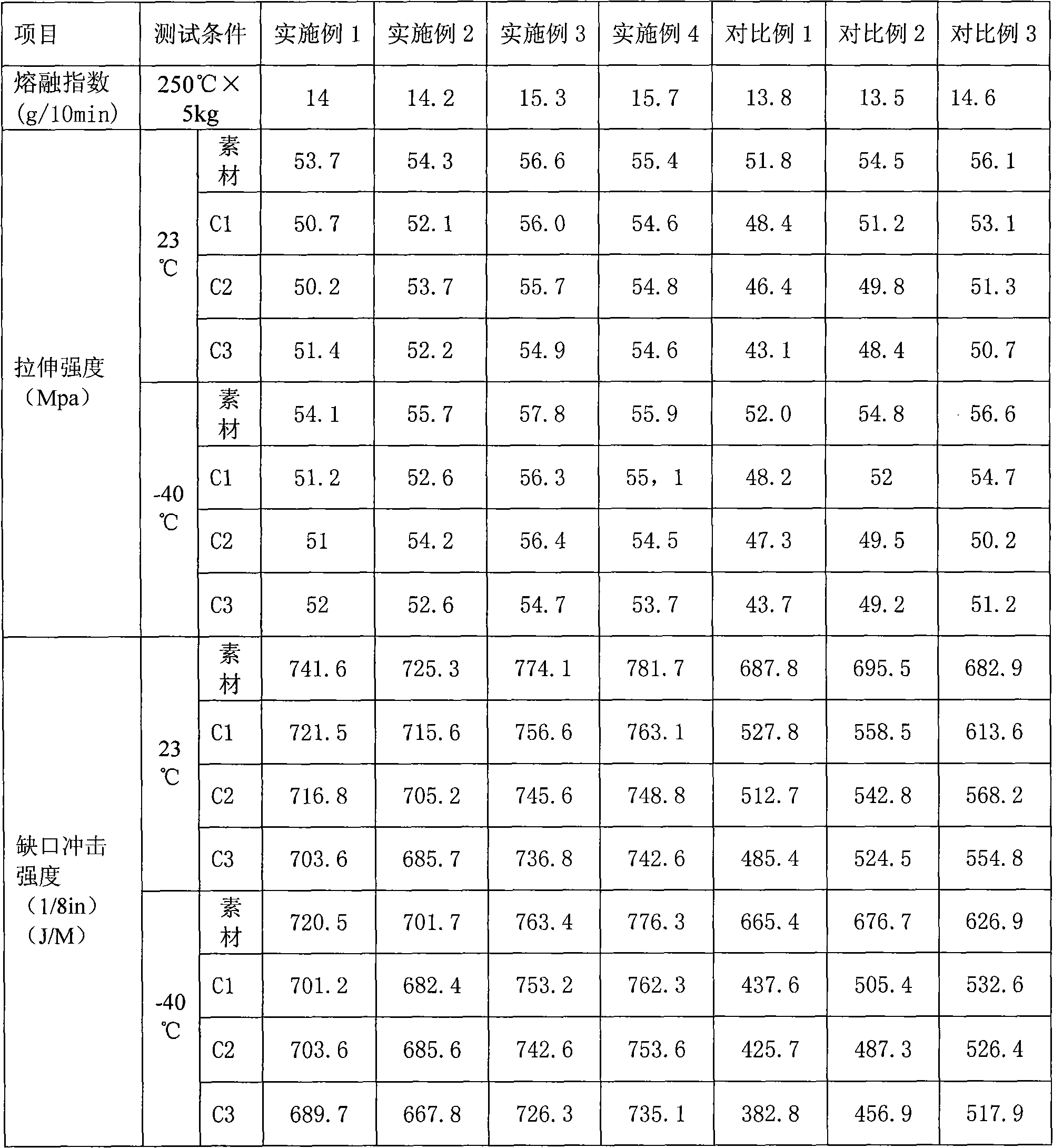

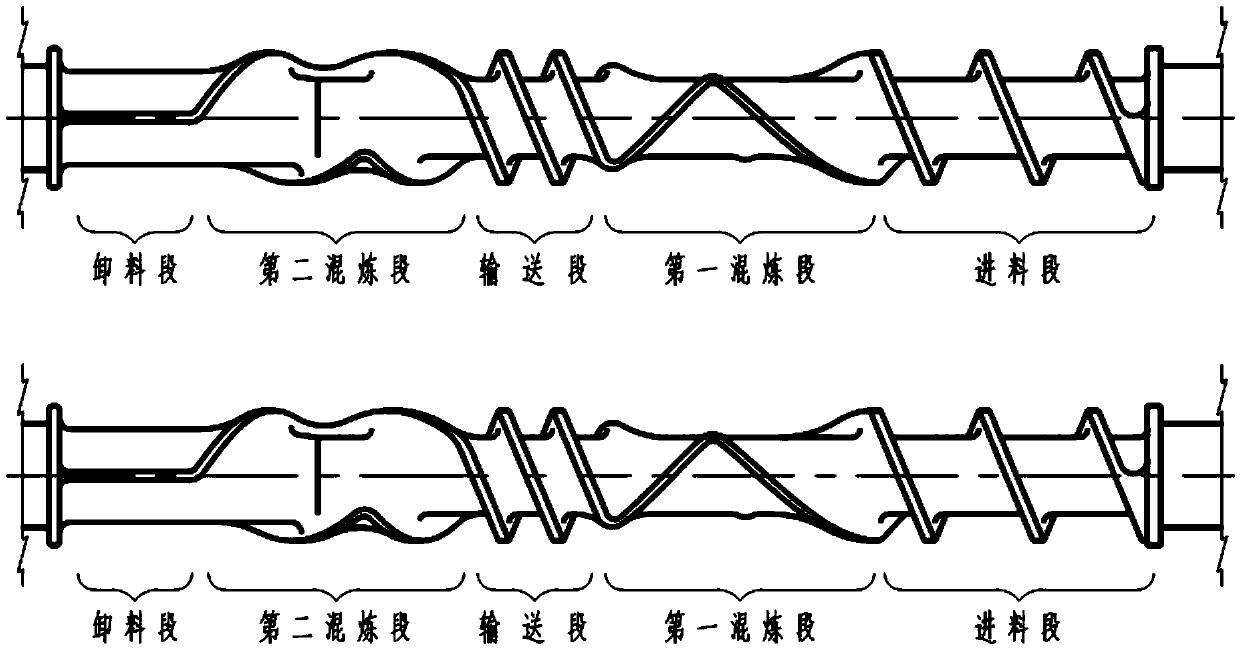

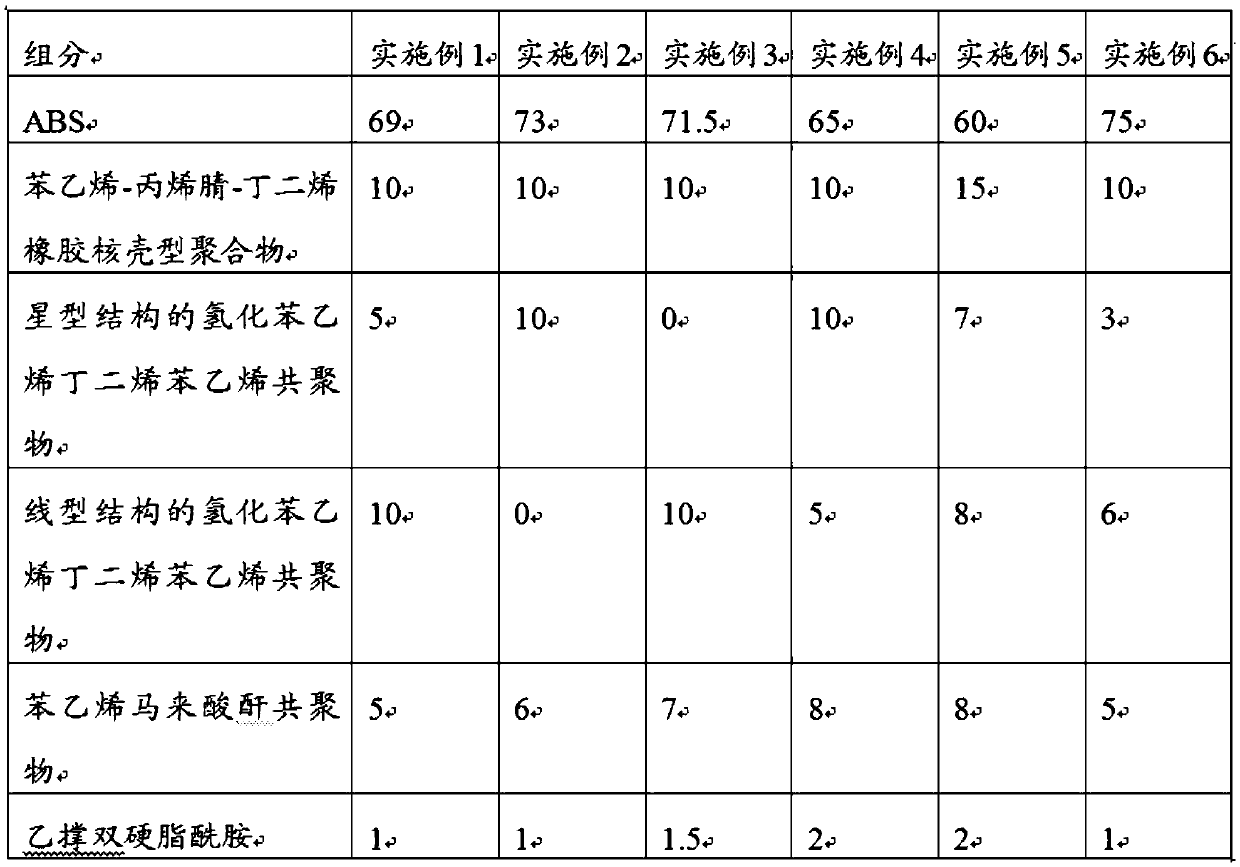

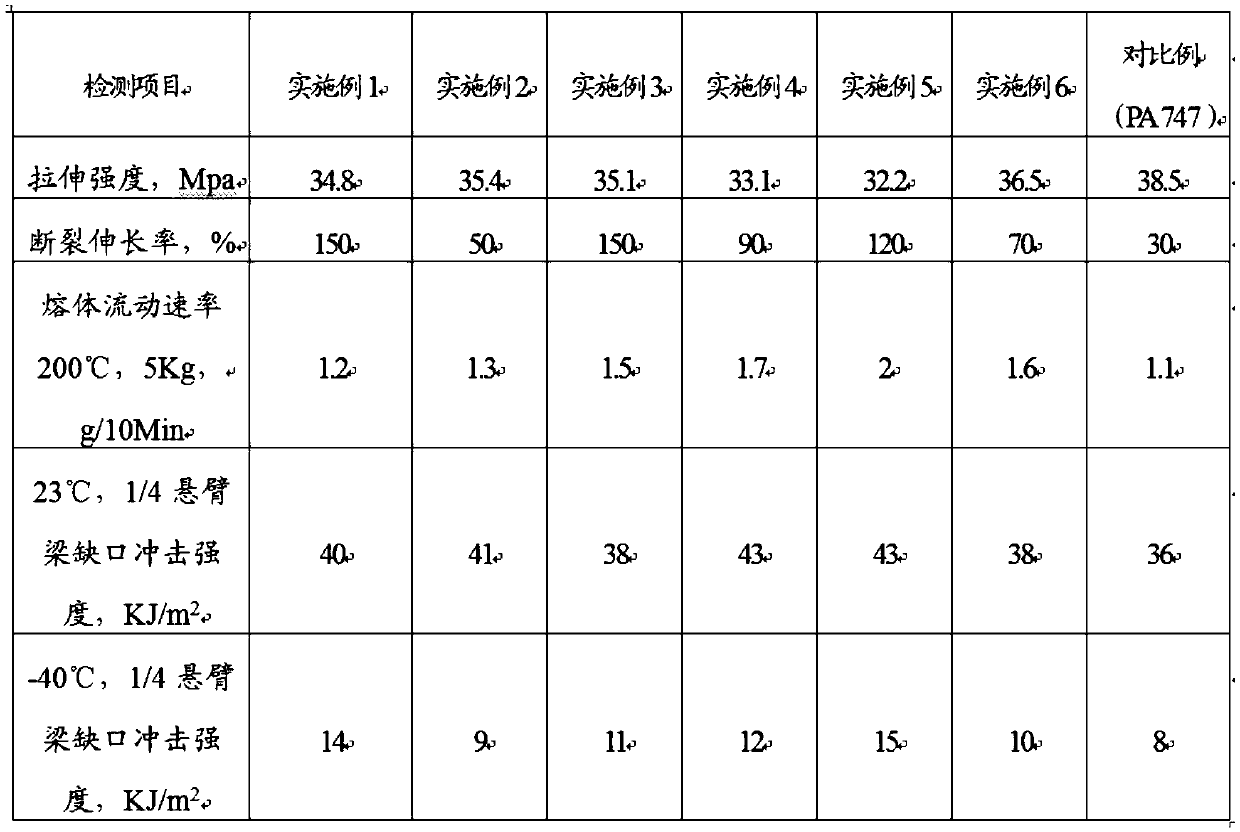

High-impact-strength ABS material used at -40 DEG C and preparation method thereof

InactiveCN105504659AHigh normal temperature elongation at breakGood impact resistance at low temperaturePolymer scienceContinuous mixing

The invention discloses a high-impact-strength ABS material used at -40 DEG C and a preparation method thereof. According to the method, by mass, 50-80 parts of ABS, 5-20 parts of a toughening agent, 5-20 parts of a cold-resistant modifying agent, 3-10 parts of compatilizer and 0.5-3 parts of a lubricating agent are added into a double-rotor continuous mixing mill to be subjected to melt mixing granulation, mixing temperature ranges from 170 DEG C to 200 DEG C, and the high-impact-strength ABS material used at -40 DEG C is obtained. The high-impact-strength ABS material used at -40 DEG C has excellent low-temperature anti-impact performance and still has excellent anti-impact performance especially at -40 DEG C, the normal-temperature elongation at break is high, and the high-impact-strength ABS material used at -40 DEG C can be used outdoors in a severe-cold environment.

Owner:JILIN DESIGNING INST OF CNPC NORTHEAST REFINING & CHEM ENG

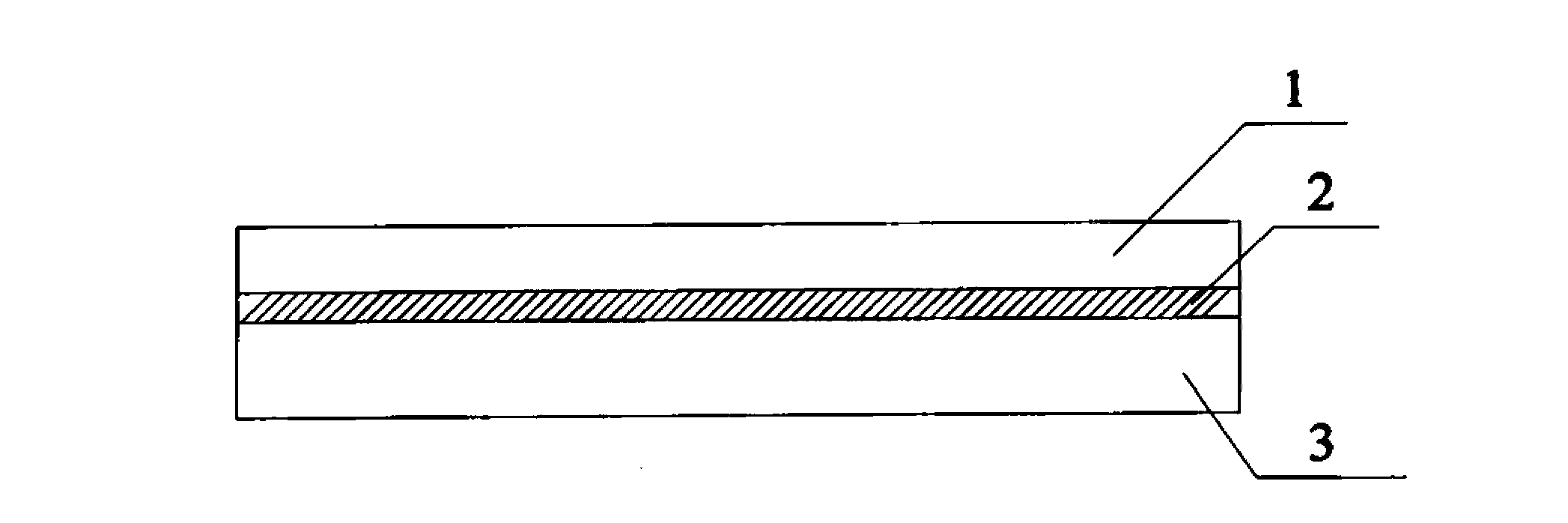

Thermal insulation thermoplastic composite material for roadbed

InactiveCN103835204AGood bond strengthGood insulation performanceRoadwaysSynthetic resin layered productsThermal insulationCold area

The invention discloses a thermal insulation thermoplastic composite material for a roadbed. The material comprises an upper layer, a middle layer and a base layer in sequence from up to bottom, wherein the upper layer and the base layer are bonded, combined and pressed through the middle layer, the upper layer is thermoplastic composite material; the middle layer is a bonding layer and the base layer is thermal insulation material. According to the invention, the thermal insulation thermoplastic composite material adopts the thermoplastic composite material as the upper layer, so that the intensity and the rigidity of the whole material are provided and more importantly the shock resistance performance which is far better than that of a common thermal insulation material is provided; the base layer is the thermal insulating layer and connected through the bonding layer, so that material of which the bonding performance is poor between the upper layer and the base layer has good bonding intensity; the thermal insulation thermoplastic composite material is mainly applied for thermal insulating of roadbeds of highways and railways in plateau areas or cold areas.

Owner:LIAONING LIAOJIE SCI & TECH

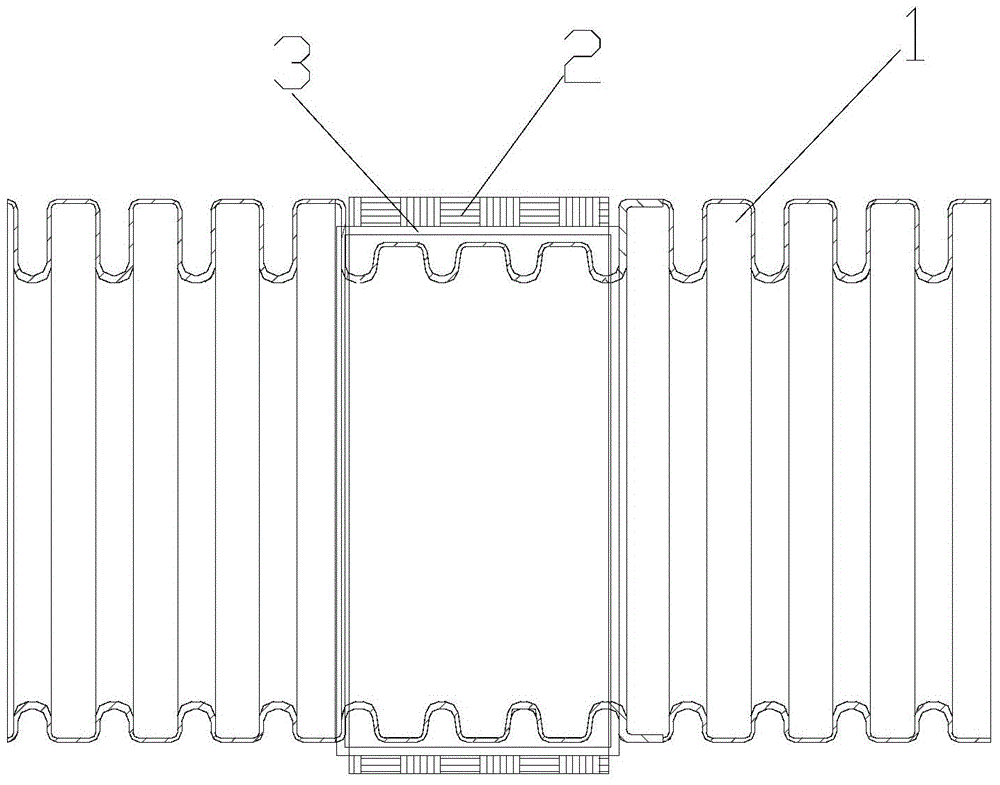

Connecting structure and manufacturing method of composite polypropylene GHFB square high-voltage cable

InactiveCN104065005AImprove insulation performanceStrong ability to resist external pressureElectrical apparatusPower cableEngineering

The invention relates to the technical field of power cable production, in particular to a connecting structure and a manufacturing method of a composite polypropylene GHFB square high-voltage cable. According to the technical scheme, pipe material bodies are included, the inner wall and the outer wall of each pipe material body are both in a corrugated shape, the two pipe material bodies are connected through a sealing ring and a clamping hoop, one end of each of the two pipe material bodies is connected into the sealing ring, the clamping hoop is arranged on the outer layer of the sealing ring in a sleeved mode, and the width of the clamping hoop is at least the width of the wave crests of three ripples of the pipe material bodies. The connecting structure has the advantages of being good in insulation performance and good in connecting sealing performance, great low-temperature shock resistance is achieved, meanwhile, materials are the lightest in all ground burying pipe materials, and conveying cost and mounting type hoisting cost can be greatly lowered.

Owner:GUIZHOU HUANRUI TECH

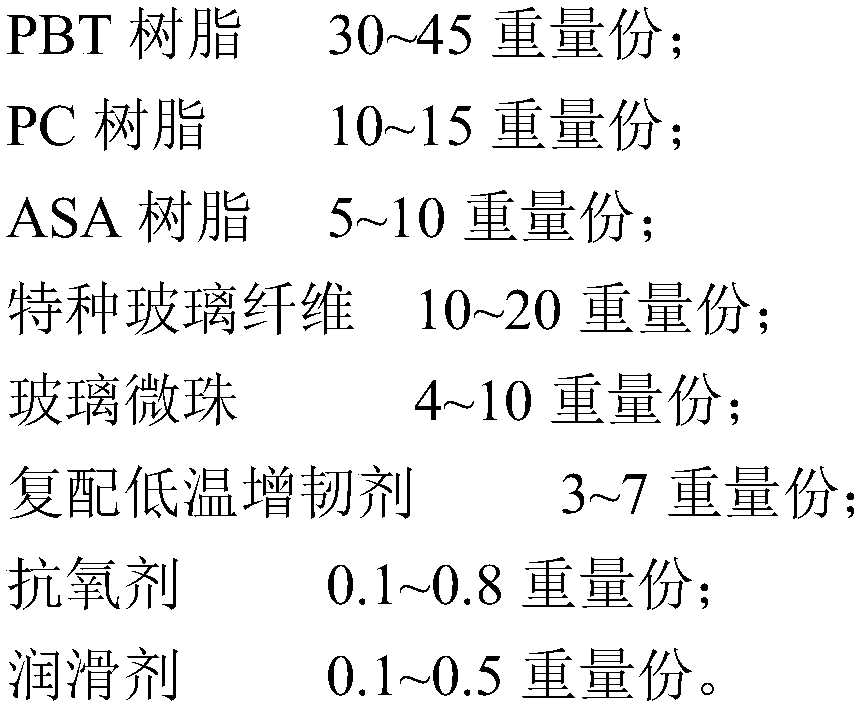

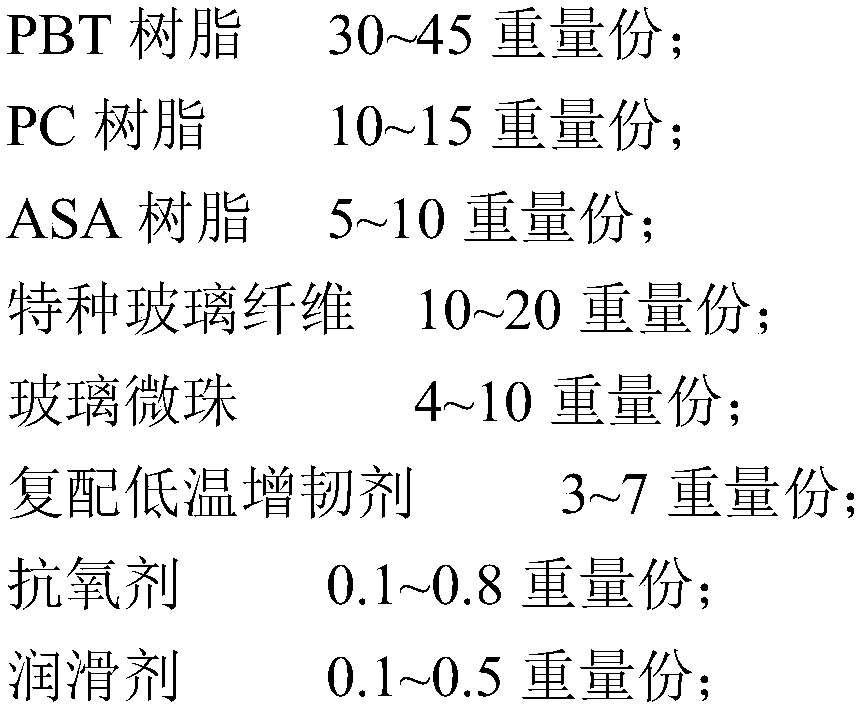

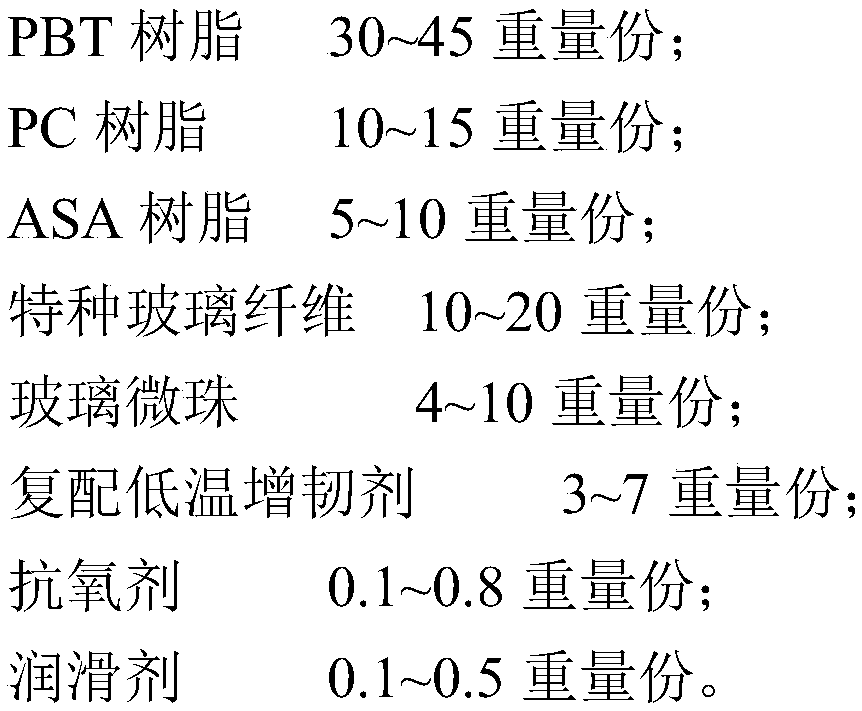

PBT/PC/ASA composite material and preparation method thereof

The invention discloses a PBT / PC / ASA composite material, which comprises the following components by weight: 30-50 parts of PBT resin; 10-15 parts of PC resin; 5-10 parts of ASA resin; 10-30 parts ofspecial glass fiber; 4-10 parts of glass bead; 3-7 parts of a compound low temperature toughening agent; 0.1-0.8 part of an antioxidant; and 0.1-0.5 part of a lubricant. The invention also discloses apreparation method of the PBT / PC / ASA composite material. The ternary composite material prepared by the method provided by the invention has the characteristics of low molding shrinkage and warpage resistance, and also can maintain good impact toughness in a low temperature environment.

Owner:横店集团得邦工程塑料有限公司

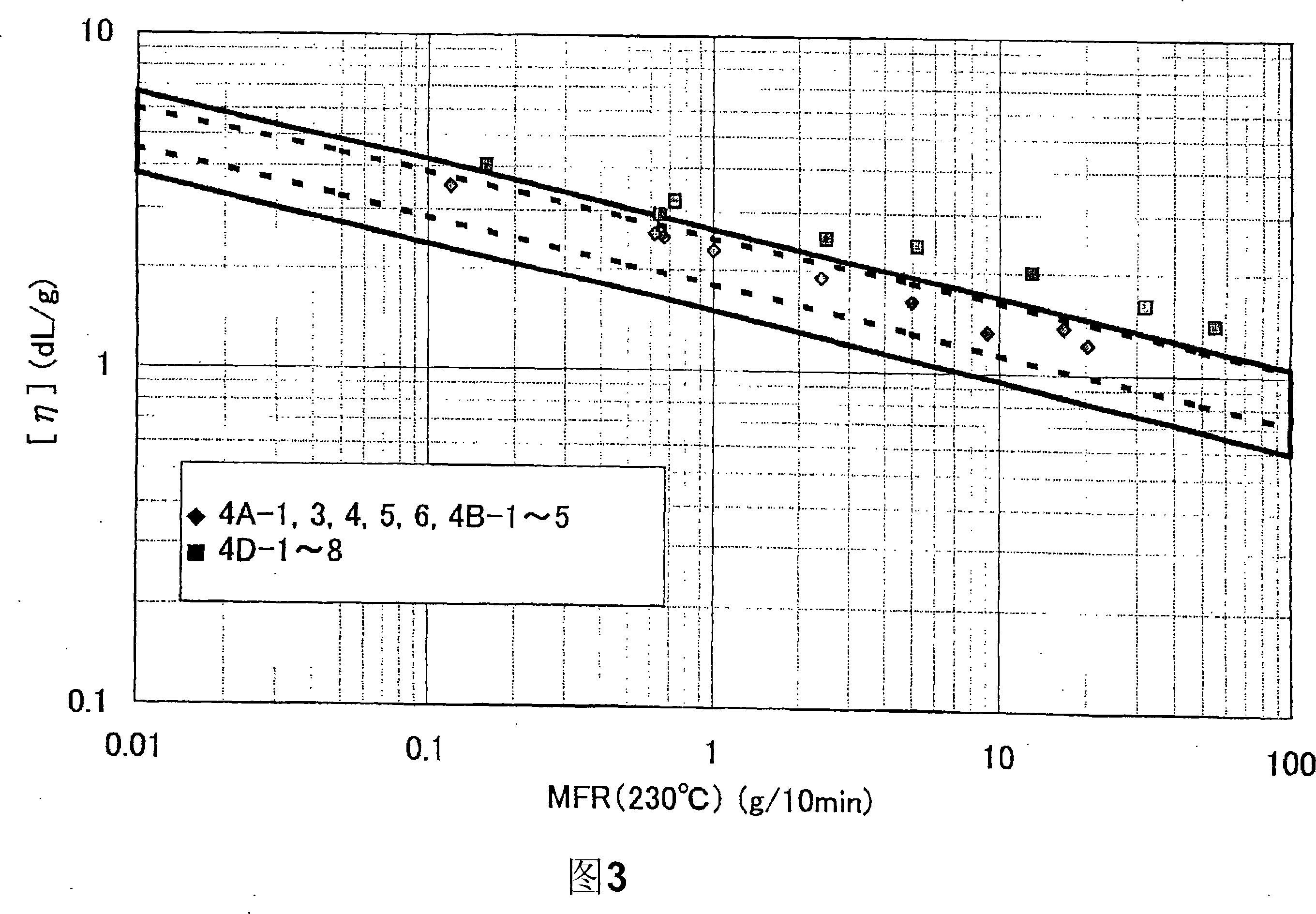

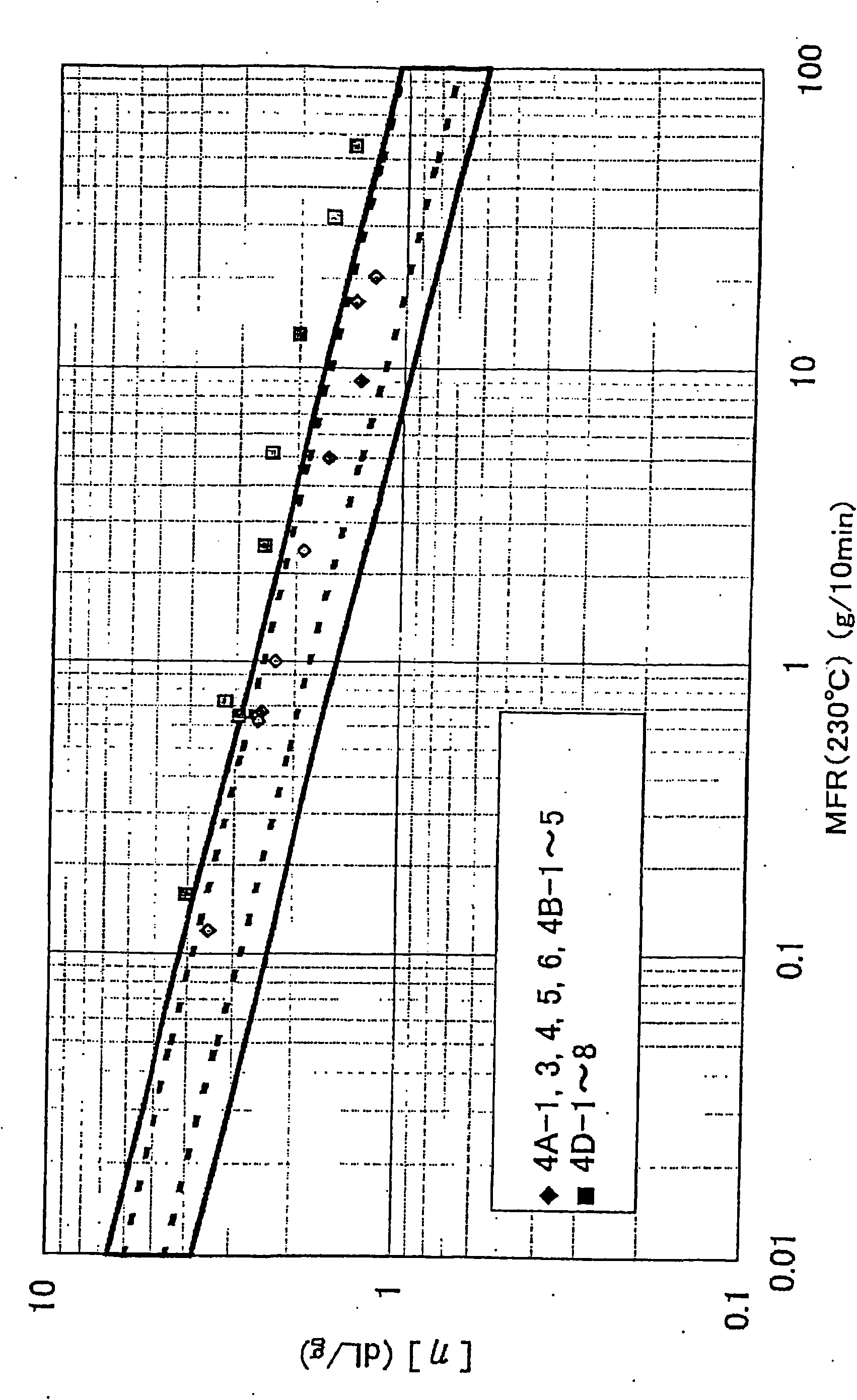

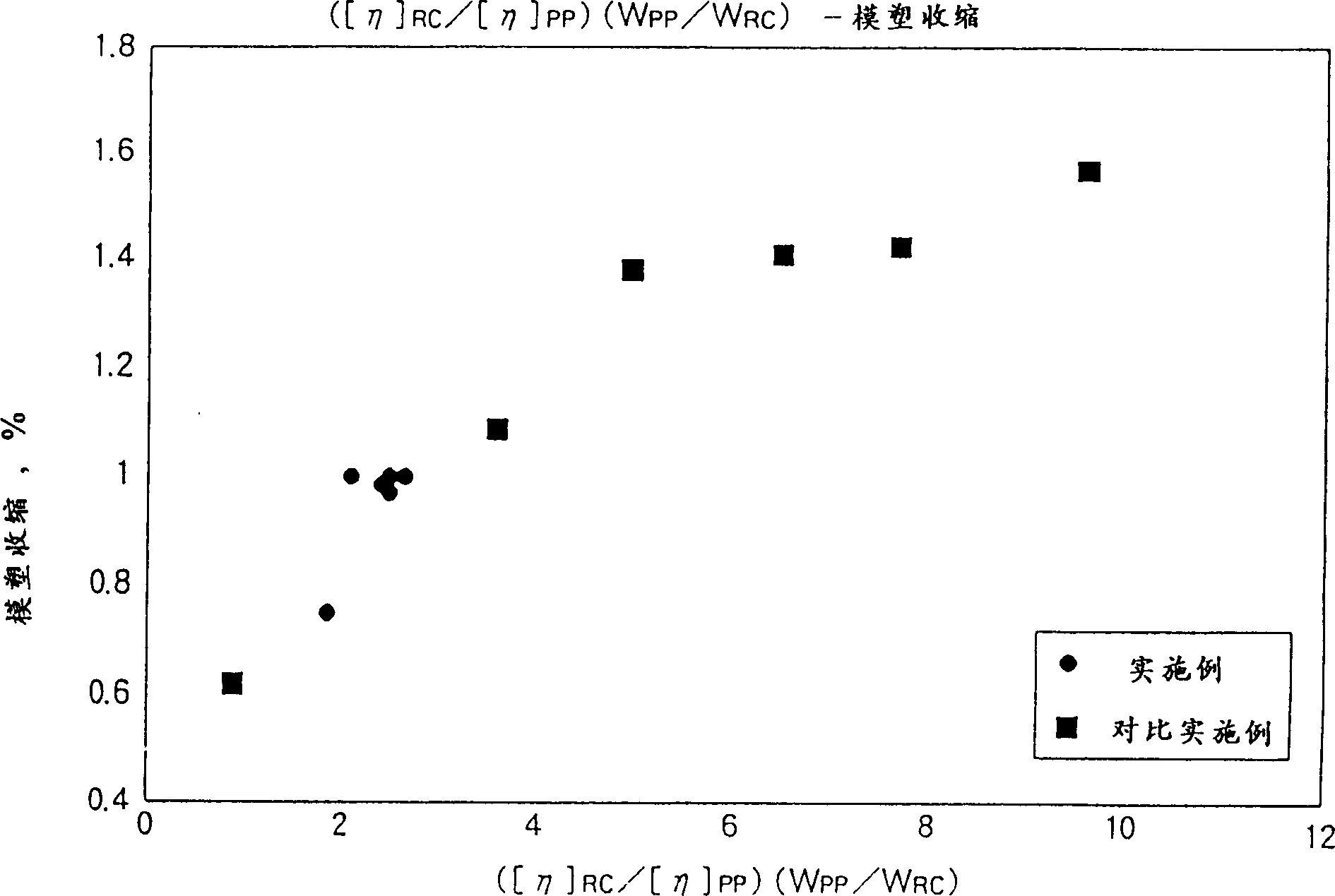

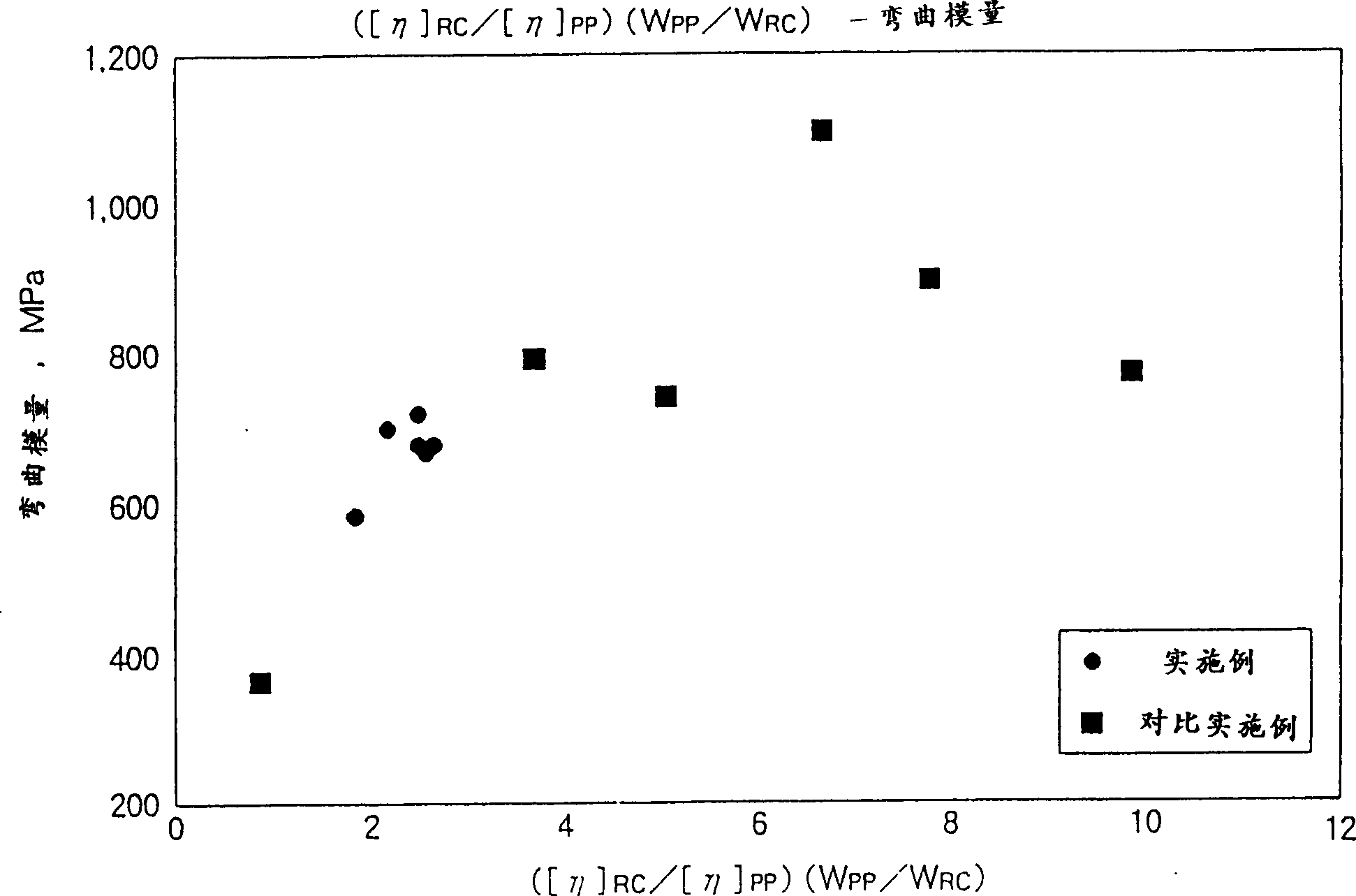

Propylene compsn, process for preparing same, polypropylene compsn., and molded articles

InactiveCN1109715CGood moldabilityExcellent mold shrinkageSynthetic resin layered productsPolymer sciencePolypropylene

A polypropylene composition for preparing various molded articles having well-balanced properties among moldability, molding shrinkage, rigidity, flexibility, impact resistance particularly at low temperatures, transparency, gloss and blushing resistance; various molded articles possessing the above properties; a propylene composition suitable as a base resin for the polypropylene composition; and a process for preparing the same. The propylene composition is characterized by comprising a homopolymer of propylene and a propylene / ethylene copolymer, the intrinsic viscosity ([ eta ]RC) of the copolymer being in the range of from 1.7 to 2.8 dl / g, the intrinsic viscosity ratio ([ eta ]RC / [ eta ]PP) of the homopolymer to the copolymer being in the range of from 0.7 to 1.2, and the product of the homopolymer to copolymer weight ratio (WPP / WRC) and the intrinsic viscosity ratio thereof, (WPP / WRC)x([ eta ]RC / [ eta ]PP), being in the range of from 1.0 to 3.0.

Owner:JNC CORP

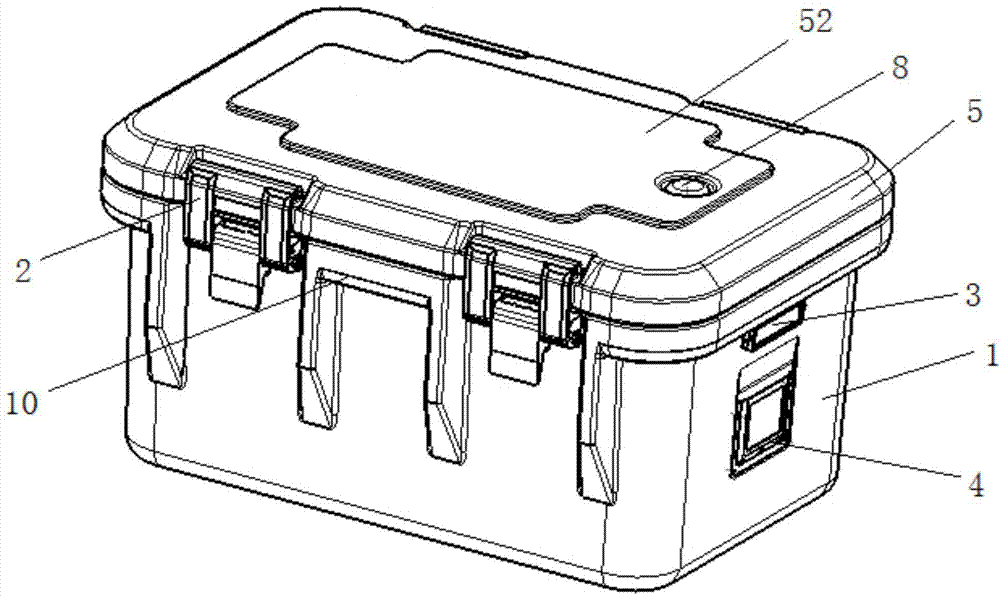

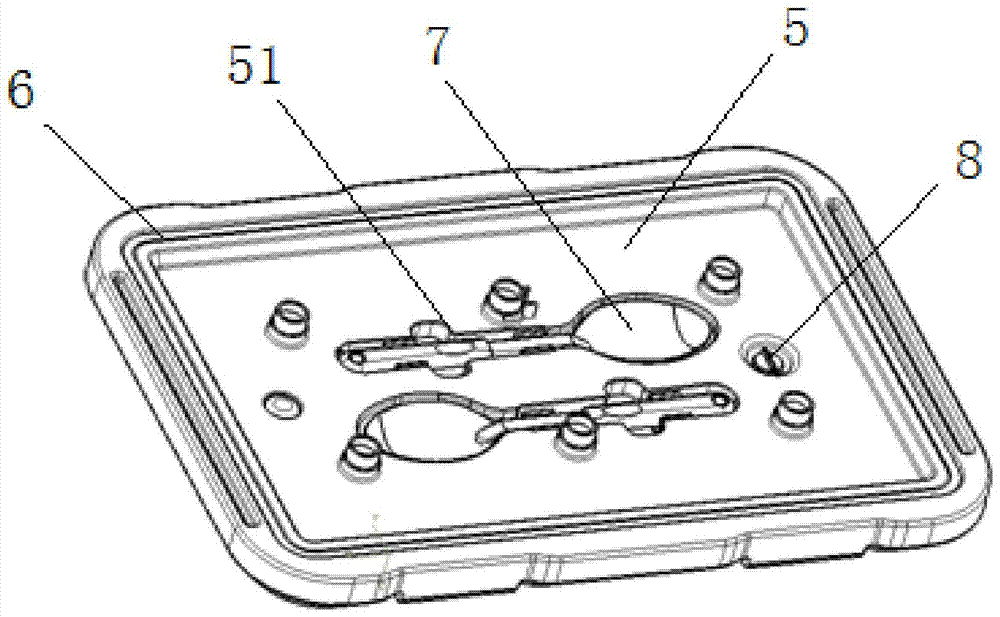

Food heat-preservation and delivering box

InactiveCN104495083AExcellent comprehensive physical and mechanical propertiesGood low temperature impact resistanceDomestic cooling apparatusLighting and heating apparatusPressure balanceElectronic identification

The invention relates to a food heat-preservation and delivering box which comprises a box body, wherein a pair of hasps is arranged on each of the two long sides of the box body; a cross slot for allowing an electronic identification card to be inserted is formed in each of the two sides of the box body; a slot for allowing a menu holder to be inserted is formed below each cross slot; the hasps are buckled to connect a top opening of the box body with an upper box body cover; a sealing ring is arranged at the bottom of the upper box body cover, and a plurality of clamping grooves for placing soup ladles are formed in the middle of the upper box body cover; a pressure balancing valve for balancing the inner and outer pressure difference of the heat-preservation box body is arranged on the upper box body cover; a plurality of dishes are arranged in the box body. The food heat-preservation and delivering box can be widely used for field catering.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

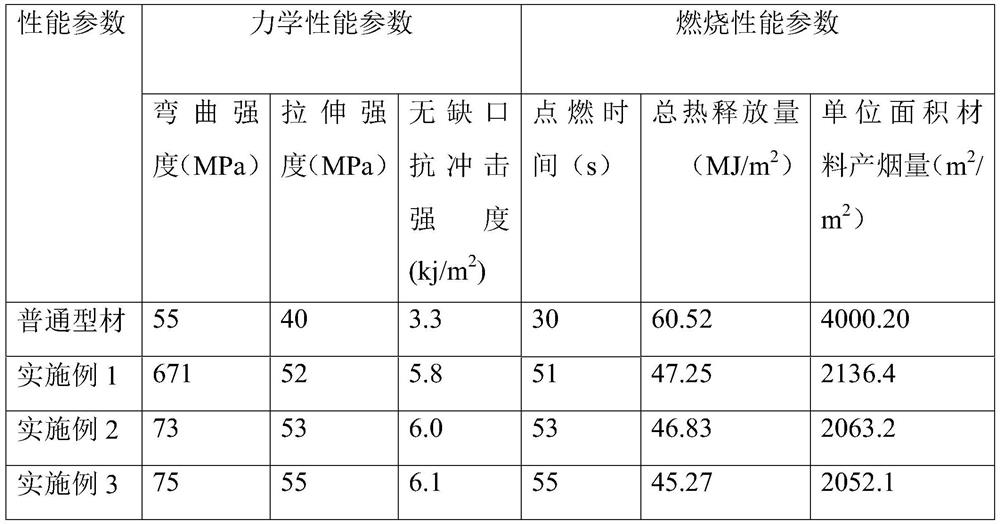

Preparation method of halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile

InactiveCN111806024AImprove flame retardant performanceHigh smoke suppression effectSynthetic resin layered productsPolymer sciencePhosphoric acid

The invention provides a preparation method of a halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile, which comprises the following steps of: (1) mixing high-density polyethylene, wood flour, a coupling agent, a lubricant, a plasticizer, expanded graphite and a composite halogen-free flame-retardant smoke suppressant, and granulating the mixture to obtain core layer material particles; (2) mixing sodium-zinc ionized resin, high-density polyethylene, expanded graphite, the composite halogen-free flame-retardant smoke suppressant and a coloring agent, and then granulating the mixture to obtain coating layer material particles; and (3) adding the core layer material particles into a charging barrel of a conical double-screw main extruder, adding the coating layer material particles into a charging barrel of a single-screw auxiliary extruder, simultaneously starting up the extruders for extrusion molding, and carrying out shaping and cooling after extrusion. Thecomposite halogen-free flame-retardant smoke suppressant is prepared from ammonium polyphosphate APP, a triazine charring agent CFA and silicon dioxide. The wood-plastic profile prepared by the preparation method provided by the invention has good flame-retardant and smoke-suppressing effects, does not release toxic and harmful substances at high temperature, and avoids secondary harm to human bodies.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

Modified polyethylene corrugated pipe and preparing method thereof

InactiveCN106317567AHigh heat distortion temperatureGood impact resistance at low temperatureFlexible pipesMaleic anhydrideHeat deflection temperature

The invention discloses a modified polyethylene corrugated pipe and preparing method thereof. The modified polyethylene corrugated pipe is made of modified polyethylene material which comprises, by weight, the following raw material: 300-320 parts of polyethylene, 40-50 parts of polypropylene, 15-25 parts of polytetrafluoroethylene, 10-12 parts of calcium stearate, 16-22 parts of carbon black, 30-40 parts of EVA resin, 24-28 parts of sodium silicate powder, 36-42 parts of maleic anhydride. The modified polyethylene corrugated pipe has relatively high heat distortion temperature, comparatively good low-temperature impact resistance performance, and can be used in the environment of -20-80oC for a long time. The modified polyethylene corrugated pipe also has excellent flame retardance and electrical insulation.

Owner:JIANGSU CHANGFENG BELLOWS CO LTD

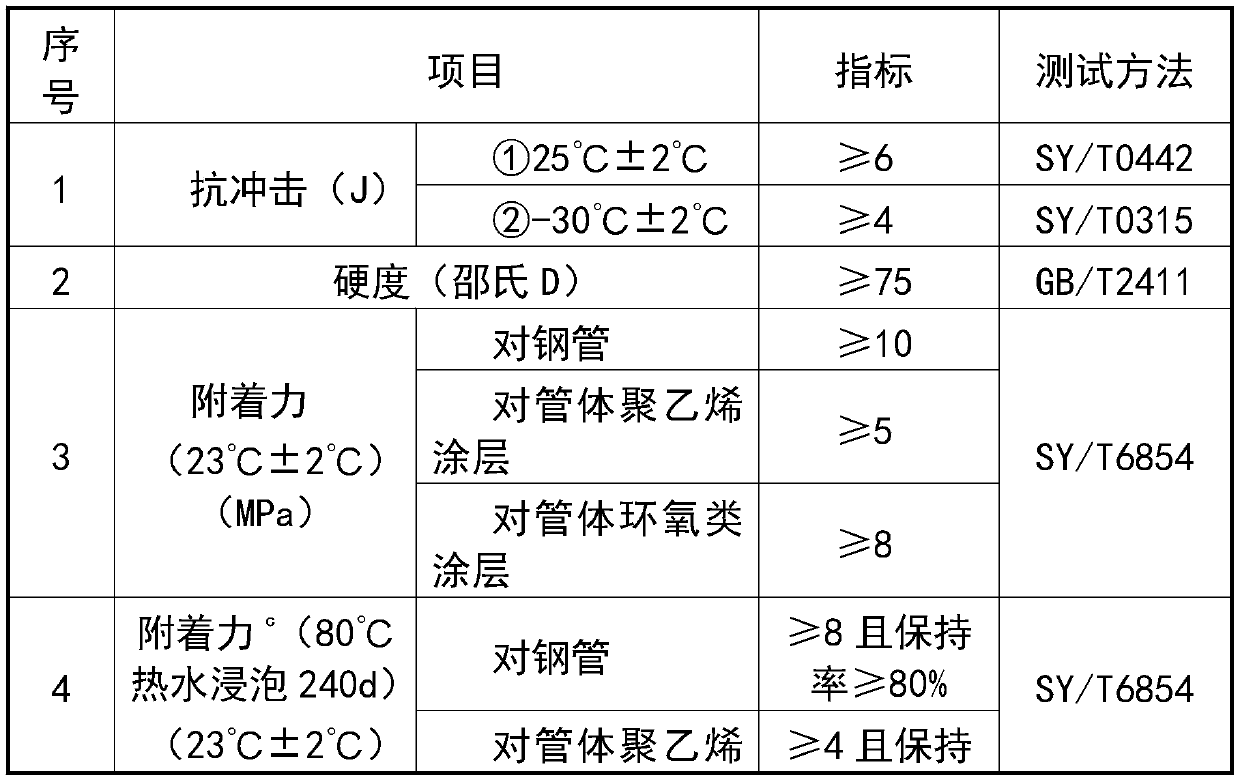

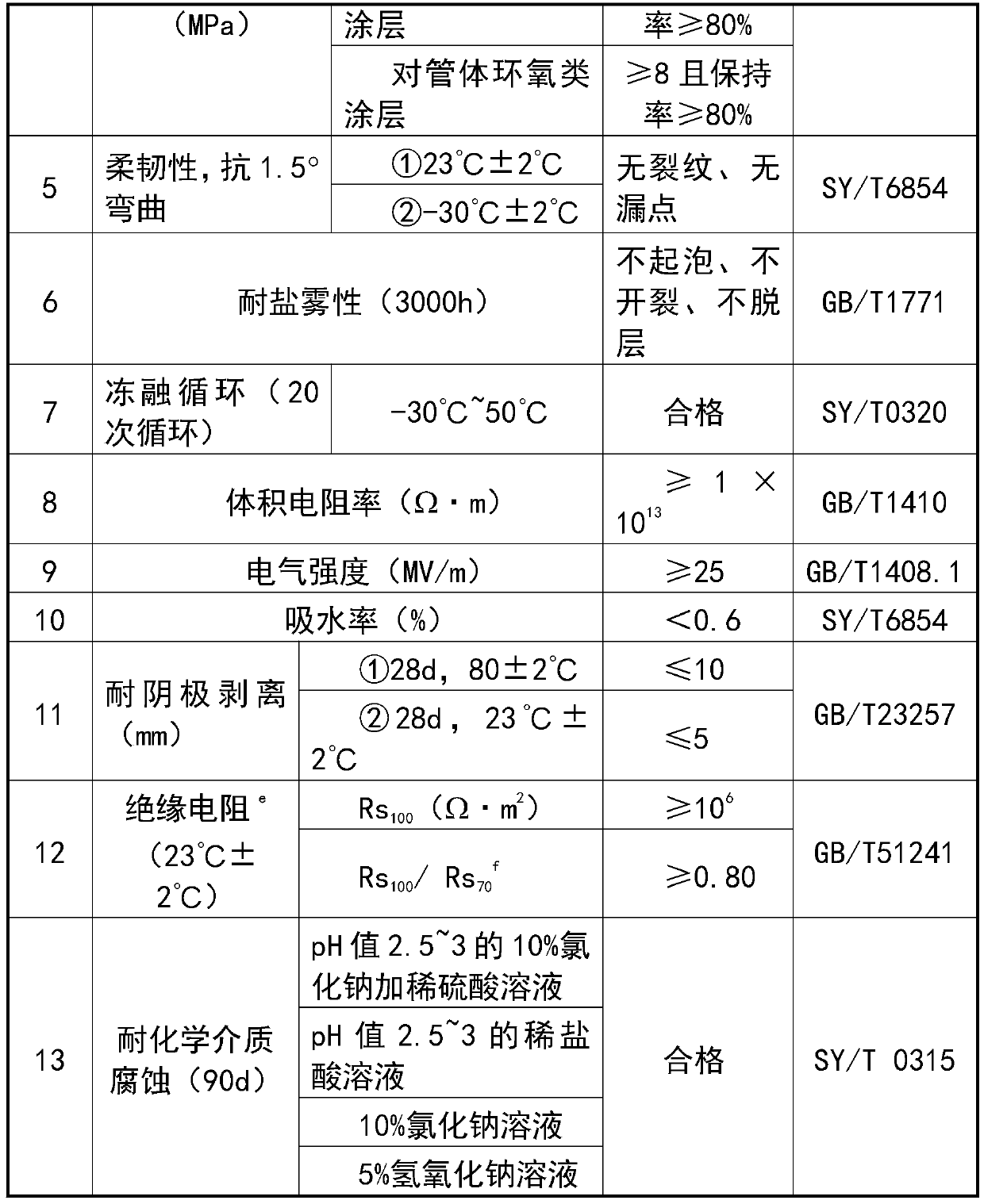

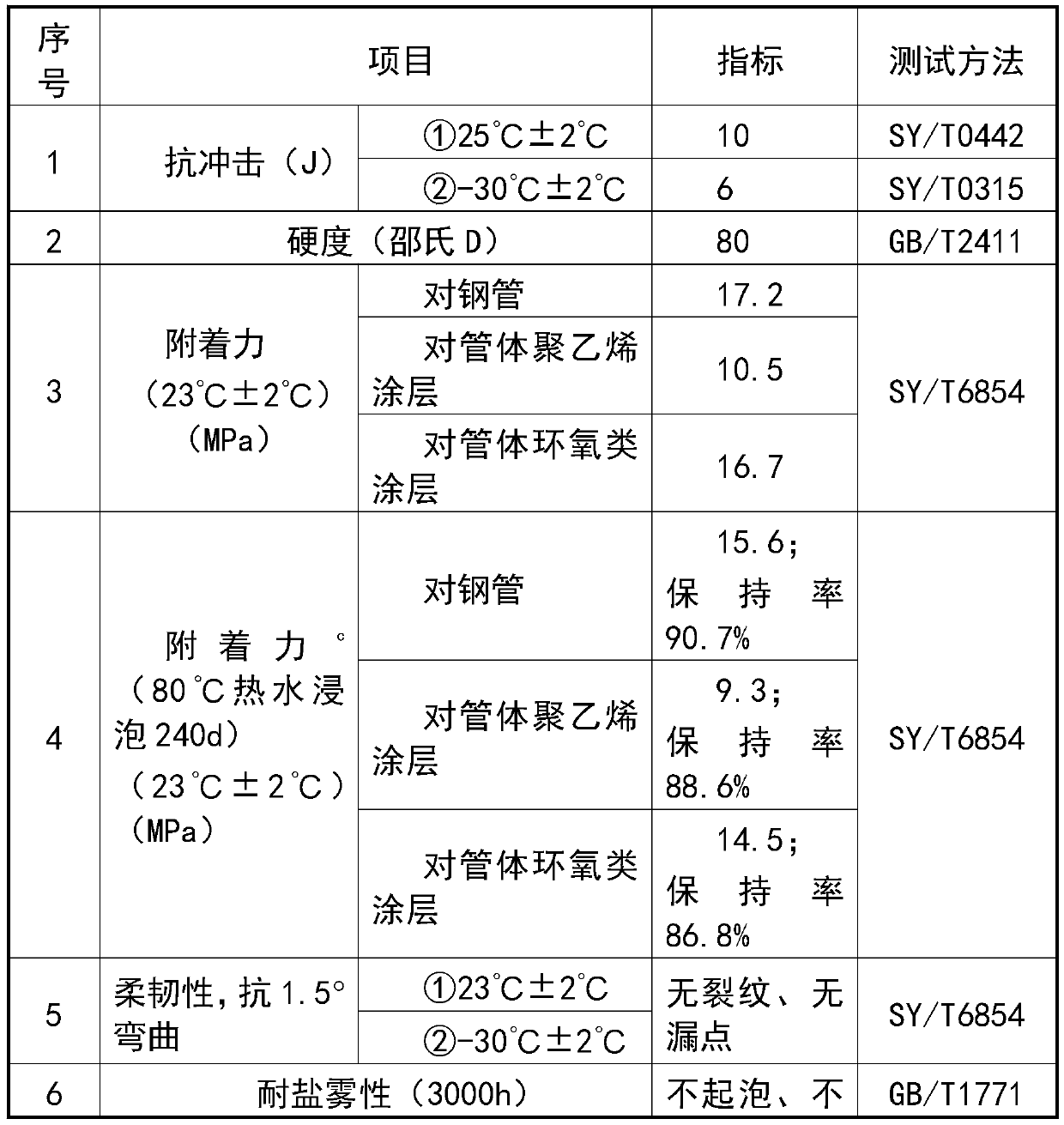

Low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating

ActiveCN110724440AFast curing at low temperatureNo crackRubber derivative coatingsAnti-corrosive paintsPolymer scienceThiourea

The invention discloses a low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating. The low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating is composed of a component A and a component B; wherein the component A comprises, by weight, 30 to 45% of bisphenol F epoxy resin; 5-10% of bisphenol A epoxy resin; 5 to 10% of epoxy butyronitrile prepolymer; 3-7% of a glycidyl ether reactive diluent, 15-25% of modified silica powder, 8-15% of titanium dioxide, 3-10% of aluminum dihydrogen tripolyphosphate, 4-10% of mica powder, 0.6-1.4% of a thixotropic agent, 0.2-0.5% of a dispersing agent, 0.2-0.5% of a leveling agent, 0.3-0.7% of an antifoaming agent and 0.1-0.7% of carbon black; the component B is prepared from 50 to 75% of Mannich base and 25 to 50% of a thiourea-polyamine condensate. Compared with a common epoxy coating, the low-temperature-resistant two-component solvent-free epoxy coating for pipeline joint coating has the characteristics of being high in low-temperature curing speed, free of crystallization and precipitation, excellent in low-temperature bending resistance, excellent in low-temperature impact resistance, excellent in hot water soaking resistance, excellent in cold and hot impact resistance and the like.

Owner:CYG CHANGTONG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com