PBT/PC/ASA composite material and preparation method thereof

A composite material and PBT resin technology, applied in the field of PBT/PC/ASA composite material and its preparation, can solve the problems of low low temperature impact resistance, limit the application of composite materials, warpage, etc., and achieve improved and excellent warpage resistance Warpage resistance and low mold shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

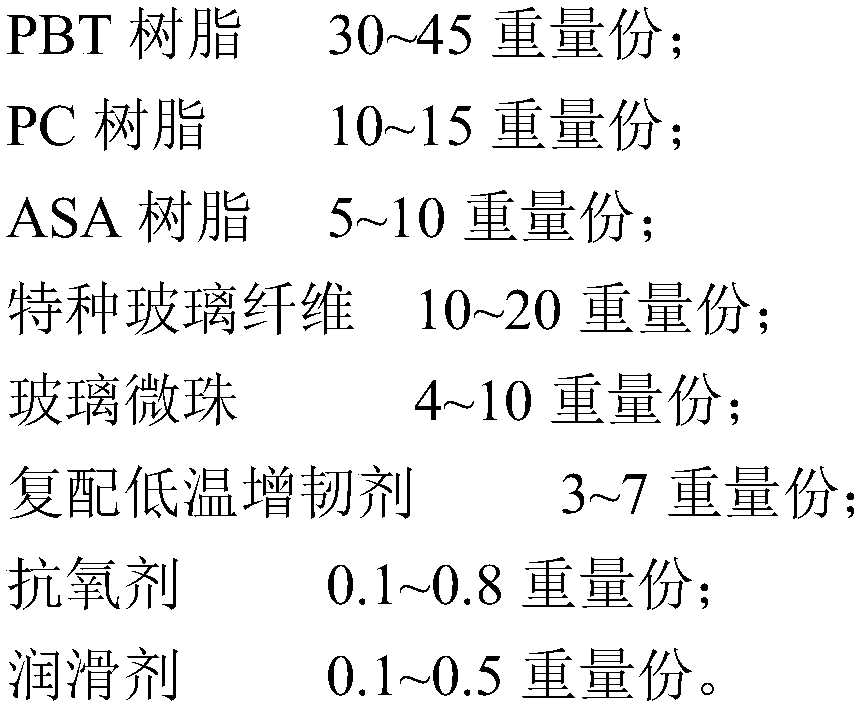

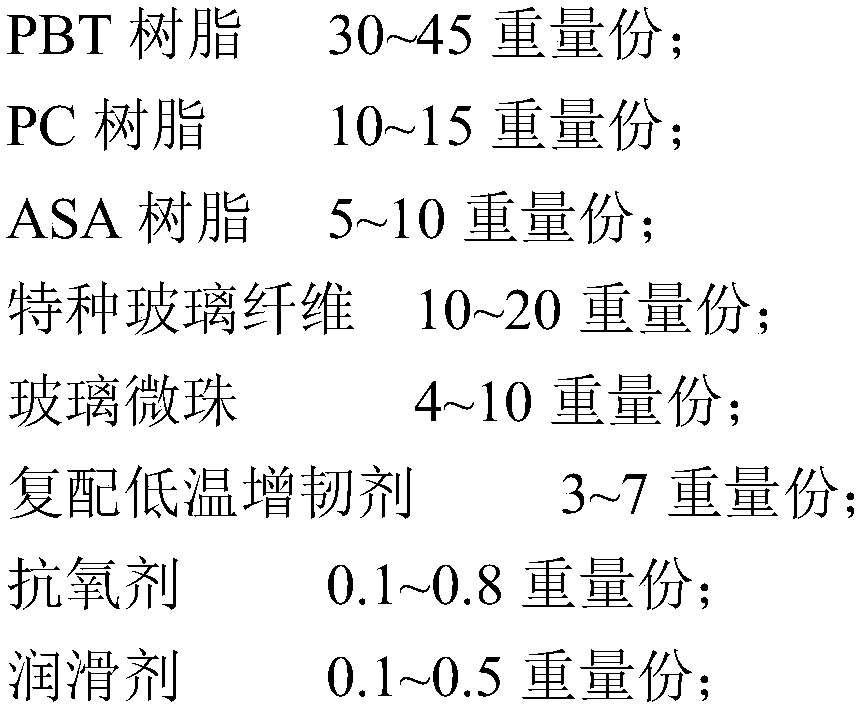

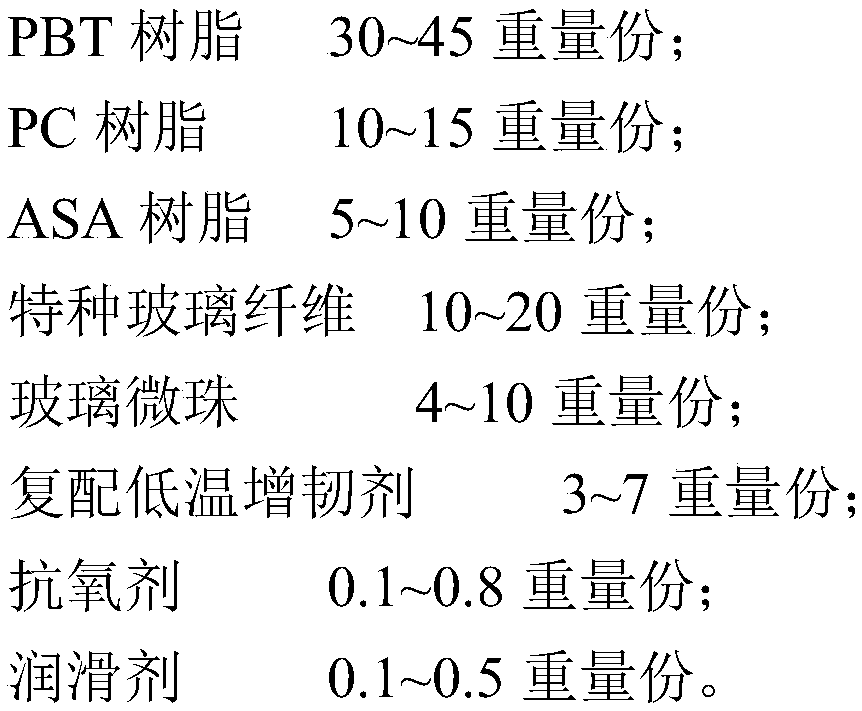

Method used

Image

Examples

Embodiment 1

[0034] Weigh 45 parts by weight of PBT resin, 10 parts by weight of PC resin, 5 parts by weight of ASA resin, 3 parts by weight of styrene-acrylonitrile-glycidyl methacrylate copolymer, 2 parts by weight of low-temperature vulcanized silicone rubber, antioxidant 0.6 parts by weight, 0.5 parts by weight of lubricant, added to the high mixer in a certain order and mixed evenly, added to the twin-screw extruder through the main feeding hopper, and 20 parts by weight of special glass fiber was added through the glass fiber port at the same time, Through twin-screw extruder melting, mixing, extrusion, and granulation, the anti-warping and low-temperature impact glass fiber reinforced PBT / PC / ASA composite material is obtained. 240°C, 240°C in the third zone, 240°C in the fourth zone, 245°C in the fifth zone, 240°C in the sixth zone, 235°C in the seventh zone, 235°C in the eighth zone, and 245°C of the machine head; the speed of the main engine is 300rpm.

Embodiment 2

[0036] Weigh 30 parts by weight of PBT resin, 15 parts by weight of PC resin, 10 parts by weight of ASA resin, 3 parts by weight of styrene-acrylonitrile-glycidyl methacrylate copolymer, 2 parts by weight of low-temperature vulcanized silicone rubber, antioxidant 0.6 parts by weight, 0.5 parts by weight of lubricant, added to the high mixer in a certain order and mixed evenly, added to the twin-screw extruder through the main feeding hopper, and 20 parts by weight of special glass fiber was added through the glass fiber port at the same time, Through twin-screw extruder melting, mixing, extrusion, and granulation, the anti-warping and low-temperature impact glass fiber reinforced PBT / PC / ASA composite material is obtained. 240°C, 240°C in the third zone, 240°C in the fourth zone, 245°C in the fifth zone, 240°C in the sixth zone, 235°C in the seventh zone, 235°C in the eighth zone, and 245°C of the machine head; the speed of the main engine is 300rpm.

Embodiment 3

[0038] Weigh 45 parts by weight of PBT resin, 10 parts by weight of PC resin, 5 parts by weight of ASA resin, 6 parts by weight of glass beads, 3 parts by weight of styrene-acrylonitrile-glycidyl methacrylate copolymer, low-temperature vulcanized silicone rubber 2 parts by weight, 0.6 parts by weight of antioxidant, 0.5 parts by weight of lubricant, added to the high mixer in a certain order and mixed evenly, added to the twin-screw extruder through the main feeding hopper, and 16 parts by weight of special glass The fiber is added through the glass fiber port, melted, kneaded, extruded, and granulated by a twin-screw extruder to obtain a warpage-resistant and low-temperature impact-resistant glass fiber reinforced PBT / PC / ASA composite material. The temperatures of each section are: Zone 1 Temperature 210°C, zone 2 temperature 240°C, zone 3 temperature 240°C, zone 4 temperature 240°C, zone 5 temperature 245°C, zone 6 temperature 240°C, zone 7 temperature 235°C, zone 8 temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com