Low-warpage PET/PBT composite material and preparation method thereof

A composite material and low warpage technology, applied in the field of low warpage PET/PBT composite material and its preparation, can solve the problems of poor heat resistance and large warpage, and achieve improved formability, heat resistance and crystallization ability , the effect of reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

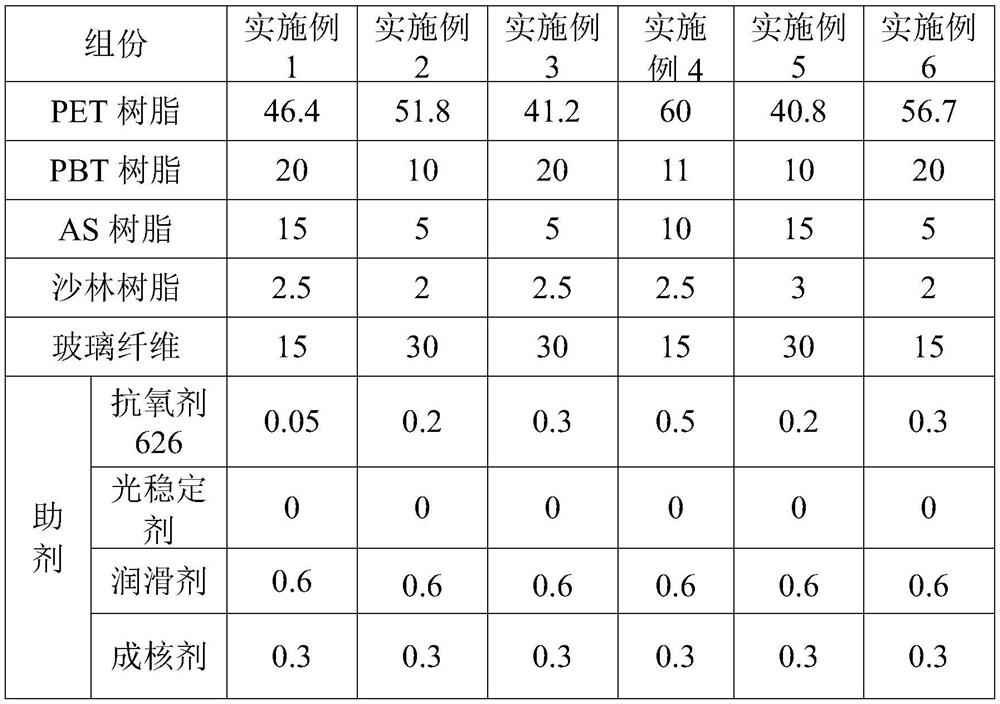

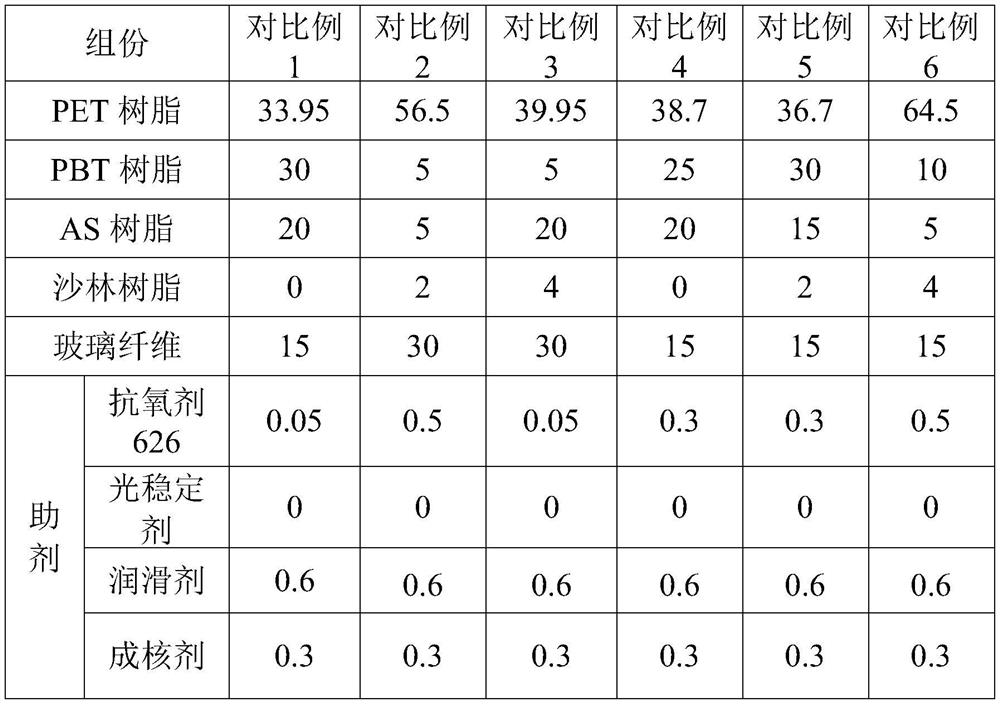

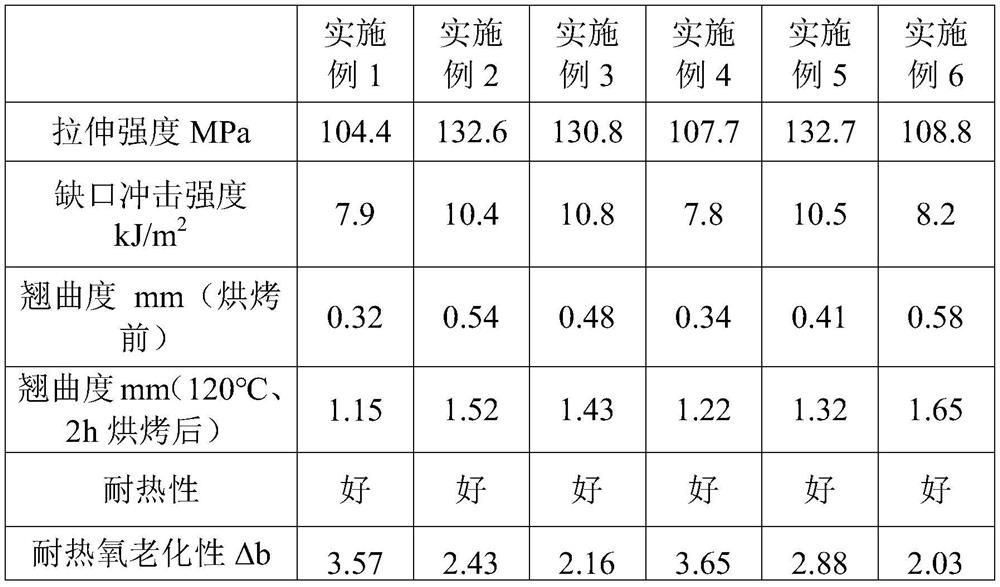

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below in conjunction with examples.

[0032] The main components used in the embodiments of the present invention are as follows, but those skilled in the art will know that the following components are just examples to illustrate the scheme of the application, and are not limited to the selection of these components:

[0033] PET resin: Kingfa Technology Co., Ltd., brand PET-1, intrinsic viscosity 0.68dl / g, density 1.33g / cm 3 ;

[0034] PBT resin: Kingfa Technology Co., Ltd., brand PBT-1, intrinsic viscosity 0.84dl / g, density 1.31g / cm 3 ;

[0035] AS resin: Taiwan Chemical Fiber Co., Ltd., brand N2200, under the test conditions of 220°C and 10kg, the melt mass flow rate is 25g / 10min, and the density is 1.07g / cm 3 ;

[0036] Sarin resin: American ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com