Patents

Literature

297results about How to "High Tg" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6627704B2Fast curingReduce sensitivitySynthetic resin layered productsPolyether coatingsHeat resistanceEther

Owner:SABIC INNOVATIVE PLASTICS IP BV

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

Polyester container and method for making same

A polyester container made from a polymer having ethylene glycol moieties, isosorbide moieties and terepthaloyl moieties, and the method of making the container is described. The polyester container is suitable for holding liquids and solids, and may be hot-filled or cold-filled. In particular, wide-mouth jars and narrow-necked bottles may be formed. The polyester has an inherent viscosity of at least 0.35 dL / g when measured as a 1% (weight / volume) solution of the polyester in o-chlorophenol at a temperature of 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6812276B2Fast curingReduce sensitivitySynthetic resin layered productsSpecial tyresEndcappingHeat resistance

Owner:SABIC GLOBAL TECH BV

Encapsulation compositions and process for preparing the same

InactiveUS20100289164A1Improve physical stabilityReduce lossesBiocidePowder deliveryPolymer sciencePlasticizer

Encapsulation compositions in which an encapsulate (A) is encapsulated in a matrix (B) may be prepared by:(i) mixing matrix (B) with a liquid plasticizer and encapsulate (A) in an extruder, to obtain a melted mixture of encapsulate (A) and matrix (B); and(ii) extruding the melted mixture, to obtain an extruded mixture.

Owner:MCCORMICK & CO INC

Thermosetting resin composition and use

InactiveCN101481490AImprove heat resistanceExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsGlass fiberTetrabromobisphenol A

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

High-thermal conductivity resin composition and application thereof

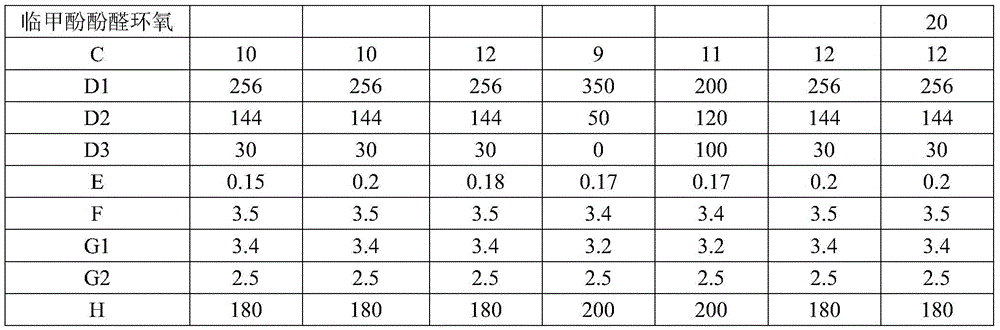

The invention discloses a high-thermal conductivity resin composition. The high-thermal conductivity resin composition is prepared from the following components in parts by weight: 40 to 75 parts of BMI (Bismaleimides) modified epoxy resin, 5 to 40 parts of flexible modified epoxy resin, 360 to 480 parts of thermal conducting fillers, 8 to 30 parts of curing agent, 2 to 6 parts of coupling agent, 0.05 to 0.85 part of curing accelerator and 1 to 5 parts of additive. According to the high-thermal conductivity resin composition disclosed by the invention, by introducing the BMI modified epoxy resin in a system, the advantages of epoxy resin and BMI are integrated; meanwhile, the flexible modified epoxy resin and the thermal conducting fillers are added, so that a new resin composition has excellent toughness, excellent thermal conductivity and higher Tg (Glass Transition Temperature). A metal-based copper-clad plate prepared by adopting the high-thermal conductivity resin composition disclosed by the invention has the excellent comprehensive properties such as high thermal conductivity coefficient, high breakdown voltage, high peel strength, higher Tg and good flexibility.

Owner:SHAANXI SHENGYI TECH

Thermosetting resin composition and application

The invention discloses a thermosetting resin composition, which comprises the following components: bifunctional or multifunctional epoxy resin, styrene-maleic anhydride copolymer SMA as a curing agent with styrene / maleic anhydride molar ratio of 5-12:1, low-bromine or high-bromine BPA type epoxy resin or tetrabromo bisphenol A as a fire retardant, an accelerator and a solvent. The resin composition after curing has quite low dielectric property, higher heat reliability and better toughness, has quite low dielectric constant and dielectric loss coefficient, high Td, better toughness and excellent PCB processability with a copper-clad plate made of glass fiber cloth and other reinforcing materials, is suitable for manufacturing a copper-clad plate and a semi-cured plate for PCB, and can also be used in common application of the epoxy resin, such as molding resin, composite materials for buildings, automobiles and aviation, and the like.

Owner:ITEQ DONGGUAN

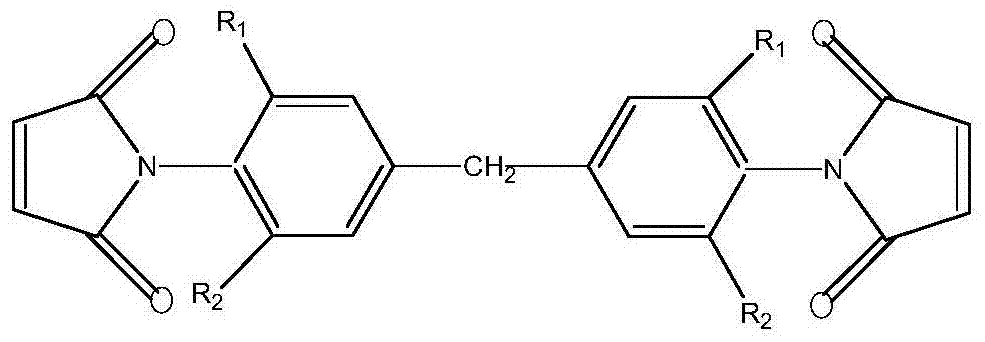

Resin composition, prepreg using resin composition and laminate

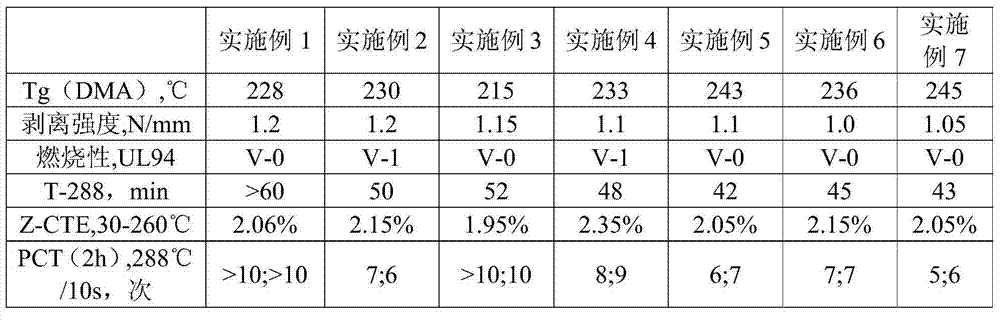

ActiveCN104725781AHigh TgLow CTESynthetic resin layered productsCircuit susbtrate materialsDielectric lossElastic modulus

The invention belongs to the technical field of copper clad laminates and particularly relates to a resin composition, prepreg using the resin composition and a laminate. The resin composition contains the ingredients in percentage by weight: 15-55% of amine modified bismaleimide (BMI), 10-45% of benzoxazine resin and 0-75% of epoxy resin. According to the resin composition, through further reaction of benzoxazine (BOZ) and amine modified bismaleimide (BMI), performance advantages of two kinds of high-performance resin, namely BMI and BOZ, are excellently exerted, so that the prepreg and the copper clad laminates, manufactured from the resin composition, have the properties of high Tg, relatively high peeling strength, relatively low CTE, relatively low water absorbing capacity, relatively low dielectric loss, relatively high elastic modulus high-temperature retention rate, relatively good resistance to hot and damp and the like, and reach a flame-retardant level UL94-V0.

Owner:GUANGDONG SHENGYI SCI TECH

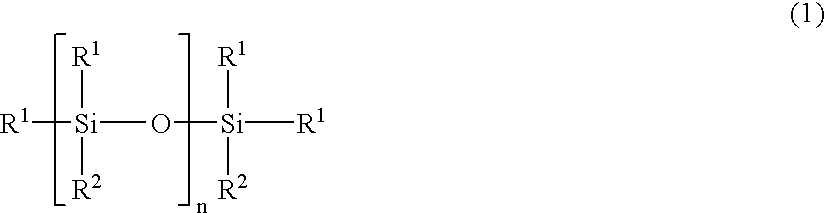

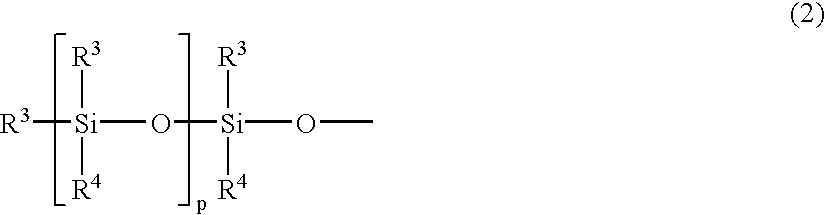

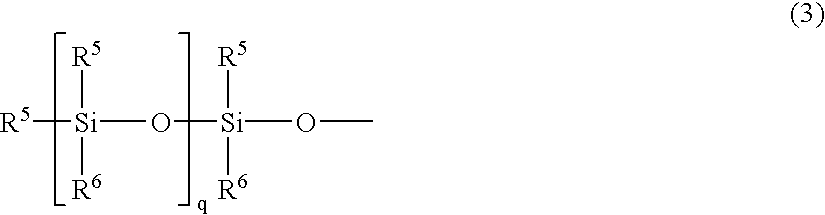

Partial condensate of glycidyl ether group-containing alkoxysilane, silane-modified resin, compositions thereof and preparation methods thereof

The present invention provides a partial condensate of glycidyl ether group-containing alkoxysilane which is obtainable by dealcoholization reaction between glycidol and a partial condensate of alkoxysilane, compositions comprising the same and preparation methods thereof. Further, the present invention provides an alkoxy-containing silane-modified polyimide resin, alkoxy-containing silane-modified polyamide-imide resin and alkoxy-containing silane-modified phenol resin which are modified with the partial condensate of glycidyl ether group-containing alkoxysilane, and preparation methods thereof.

Owner:ARAKAWA CHEM IND LTD

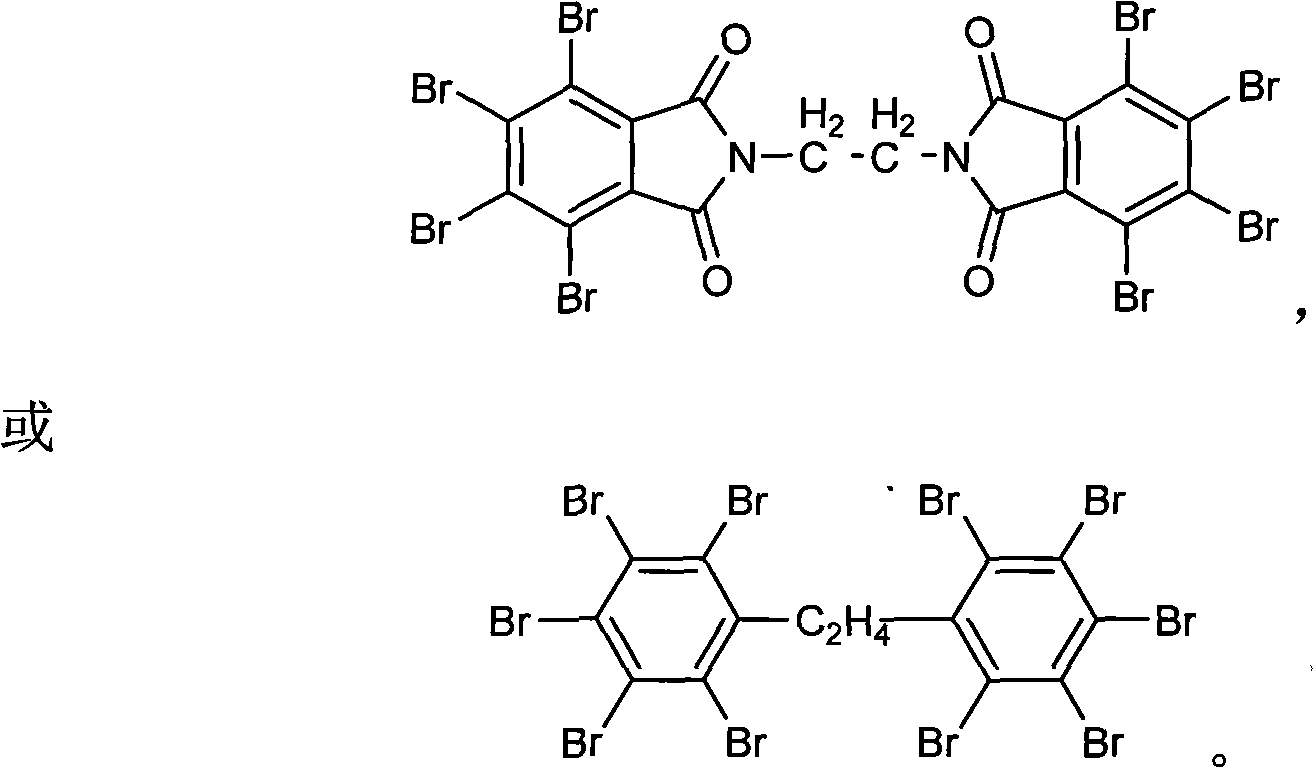

Flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and preparation method thereof

The invention discloses a flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and a preparation method thereof. The flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion comprises three components of A, B, and C, and is characterized in that the A component comprises diglycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents; the B component comprises cycloaliphatic acid anhydride, arene poly(acid anhydride), a thermoplastic phenolic resin curing agent, a maleic anhydride-grafted rubber flexibilizer, a polysiloxane toughening modifier, and an epoxy resin curing accelerator; the C component comprises an inorganic fire retardant which has an ultrafine particle size and is subjected to surface modification by a silane coupling agent and a hydrophobic modifier; the weight ratio of the A, B, and C components is that A:B:C=100:50-250:20-150.

Owner:江苏绿材谷新材料科技发展有限公司

Amino compound for organic light-emitting device and organic light-emitting device including the same

ActiveUS20070228941A1High TgImprove mobilityOrganic chemistryDischarge tube luminescnet screensArylHydrogen

An amino compound for an organic light-emitting device of general formula [1]:wherein X1 is bonded to the pair of fluorenyl groups at meta-positions to each other and is substituted or unsubstituted aromatic ring, fused polycyclic ring, or heterocyclic ring; Y1 and Y2 are each substituted or unsubstituted alkyl, aryl, or heterocyclic and are the same or different; Z1 to Z4 are each hydrogen, halogen, or substituted or unsubstituted alkyl, aralkyl, alkenyl, alkynyl, alkoxy, aryl, or heterocyclic and are the same or different; R1 to R4 are each hydrogen, halogen, or substituted or unsubstituted alkyl, aryl, or heterocyclic and are the same or different; a and d are each 1 to 4; and b and c are each 1 to 3.

Owner:CANON KK

Method for manufacturing copper clad laminated board adapted to leadless process

ActiveCN101456276AHigh TgImprove toughnessLamination ancillary operationsPrinted circuit detailsChemistryCopper foil

The invention discloses a lead-free copper-clad laminate manufacturing method, which comprises: (1), preparing a glue solution by mixing a brominated epoxy resin, a phenol formaldehyde curing agent, a toughening agent, dimethylimidazole and ethanediyl methoxy methyl ethyl acetate according to weight portion; (2), spreading glue by soaking glass fiber cloth in the glue solution prepared in the step (1) in a glue basin of a glue spreading machine; (3), making a prepregs by placing the glass fiber impregnated with the glue solution in the step (2) in an oven of the glue spreading machine; (4) covering copper foil layers by laminating the prepregs made in the step (3) and covering copper foil layers on the surfaces of the utmost two layers after lamination; and (5) pressing by placing the composite laminate made in the step (4) in a vacuum press for pressing. The copper-clad laminate made by the method has high Tg, toughness and heat resistant and can meet the requirement for lead-free manufacturing. In addition, due to the high toughness, the copper-clad laminate is insusceptible to delamination during punching and V cutting after the lead-free manufacturing of a PCB.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

Solid siliconized polyester resins for powder coatings

InactiveUS20050136267A1High TgUse of compositionLayered productsCoatingsParticulatesRoom temperature

The present invention pertains to a siliconized polyester resin that has a sufficiently high Tg that the siliconized polyester is a solid at room temperature. The silicone polyester preferably has a Tg of 30° C. or greater. The silicone polyester can be produced as a particulate and remain stable at room temperature. The particulate silicone polyester is suitable for use in coating compositions, including powder coating compositions. The coating can be clear or pigmented, and thus optionally can include pigment. The coating composition also includes a crosslinker. The coating composition can be ground into a powder. The powder is stable at room temperature. The powder is then capable of being coated on a suitable substrate and then baked to form a coated metal object.

Owner:WACKER CHEM CORP

Single-component under-filler with favorable repairing property and preparation method thereof

ActiveCN101880514AFirmly connectedImprove curing effectSemiconductor/solid-state device detailsSolid-state devicesChemistryTO-18

The invention discloses a single-component under-filler with the favorable repairing property, which is prepared by the following raw materials in percentage by weight: 11.8-69 percent of liquid-state epoxy resin, 2-10 percent of epoxy polybutadiene, 11.8-69 percent of polyurethane-modified epoxy resin, 0.5-14.8 percent of alicyclic epoxy resin, 1.5 to 18.5 percent of epoxy diluting agent, 0.5-14.8 percent of latency curing agent, 1.1-30.8 percent of accelerating agent, 0-39 percent of spherical silica micropowder and 0-6 percent of pigment. The invention also discloses a preparation method of the single-component under-filler with the favorable repairing property. The invention has the advantages of low viscosity, rapid curing for 40 seconds at 150 DEG C, high adhesive force, favorable heat-resistant impact-resistant performance and simple manufacture process, and can keep favorable adhesion reliability and solidifiability during heat circulation treatment, can improve the repairing performance of the single-component under-filler at the same time, and can be widely applied to the technical field of backbonded chip package.

Owner:深圳市库泰克电子材料技术有限公司

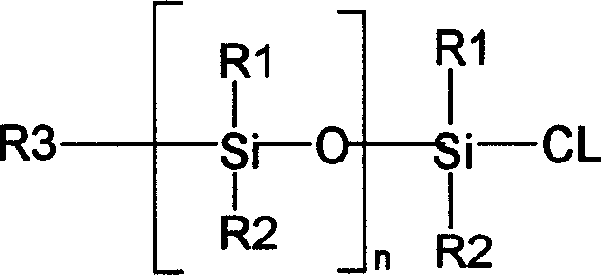

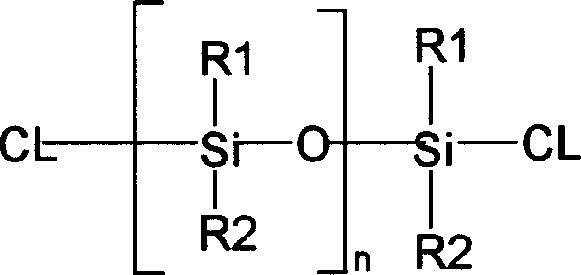

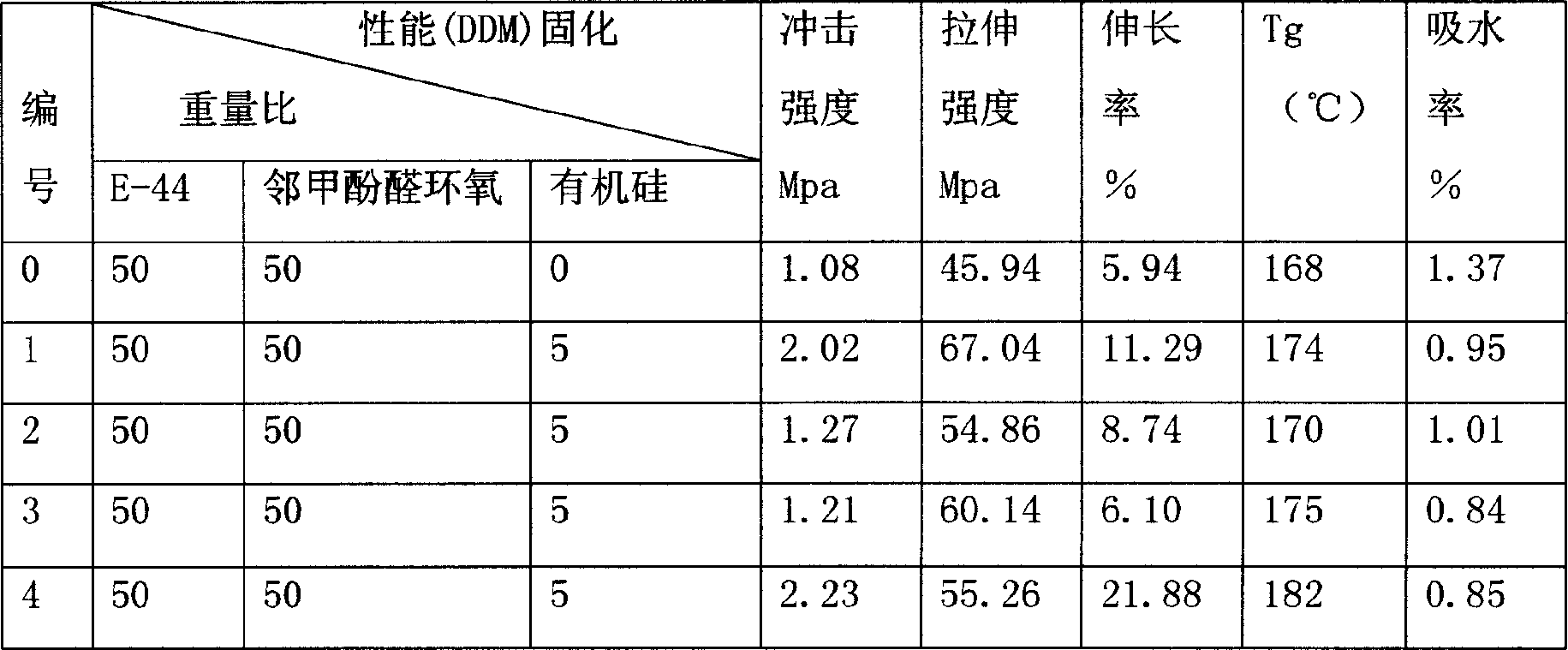

Modified epoxy resin by organic silicon and its electronic packag material and preparation process thereof

InactiveCN1560106AImprove toughnessImprove heat resistanceOther chemical processesEpoxyAbsorption ratio

The invention relates to an organic modified epoxy resin and its preparing method as well as electronic packaging material made from it and the preparing method of this packaging material. At normal temperature and normal pressure, using 100 share biphenol A epoxy resin to react with 0-20 share alkyl silicon and 0-100 share chloride terminated polysiloxane in an organic solvent in weight share, after completing reaction, washing out quaternary ammonium salts, then making vacuum distillation to eliminate the organic solvent, and obtaining the product modified resin; in weight share, mixing the obtained modified resin with 0-200 share phenol aldehyde epoxy resin, 0-100 share bromic epoxy resin and 0-100 share phosphoric epoxy resin, using 0-80 share high-temperature solidifying agent so as to obtain more excellent performance electronic packaging epoxy resin material, which has high Tg, high flexibility, low water absorption ratio, and other properties, beneficial to large-scale spread and application as well as industrialization.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

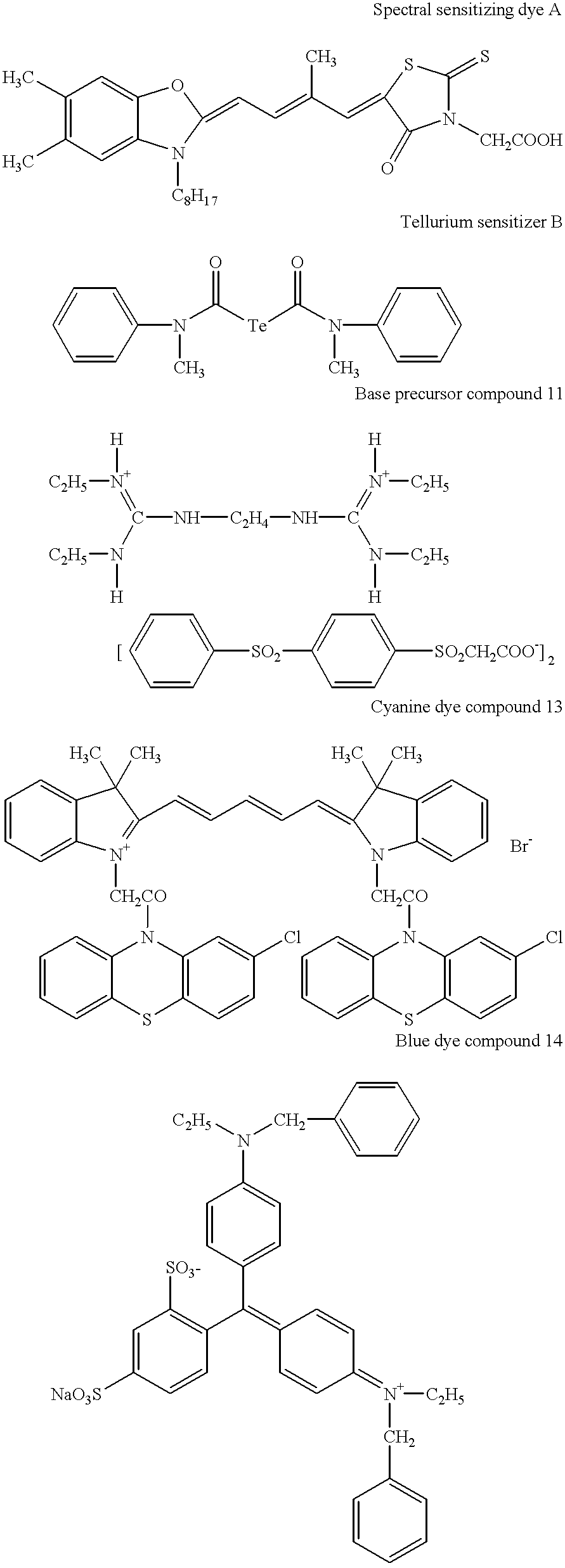

Thermally processed image recording material

InactiveUS20010023049A1Good colorImprove brittlenessPhotothermographic systemsElectrographic process apparatusVitrificationOrganic acid

Disclosed is a thermally processed image recording material having an image-forming layer that contains a non-photosensitive silver salt of an organic acid, a reducing agent for silver ions and a binder on a support, wherein the binder is coated as a dispersion of polymer microparticles having a core / shell structure, glass transition temperature of shell part of the core / shell structure is higher than glass transition temperature of core part, and the binder shows a minimum film-forming temperature of 30° C. or lower. According to the present invention, there is provided a thermally processed image recording material that provides improved image storability after heat development, i.e., improved coloration of white portions when the material is left at a high temperature, and has a transparent coated film with low haze that is also excellent in brittleness.

Owner:FUJIFILM CORP

Toner composition for preventing image blocking

InactiveUS20090297970A1Improving toner image sticking resistanceResisting print stickingDevelopersElectrographic process apparatusEthylene bisWax

Images produced by electrophotography are often subjected to harsh conditions, such as high temperature and high relative humidity conditions. Prints when subjected to face-to-face stacking under these conditions tend to stick and are difficult to separate without damage. Ethylene-bis-stearamide is incorporated in a protective toner formulation employing a toner binder having a higher glass transition temperature than that of the conventional CYMK colored image toners employed to provide a protective layer in fused images. Further, ethylene-bis-stearamide does not interfere with typical oil release additives used in fuser rollers. By combining ethylene-bis-stearamide with polyalkane waxes having a weight average molecular weight of equal to or greater than 2000 and a poly dispersity of less than 2.0, addition protection can be realized.

Owner:EASTMAN KODAK CO

Ink composition

ActiveUS20150105504A1Good dispersionImprovement ingredientsInksEmulsion paintsPolymer scienceOrganic chemistry

Disclosed is an aqueous ink composition including between 1 and 40 weight % of a water dispersible resin, between 0.5 and 15 weight % of a colorant, between 20 and 80 weight % of water and between 1 and 30 weight % of an acetal cosolvent, wherein all amounts are relative to the total ink composition. The ink composition may further include between 15 and 75 weight % of a dispersion stabilizing cosolvent.

Owner:OCE TECH

Thermosetting resin composition, and prepreg, laminated board for wiring board and printed wiring board using the same

InactiveUS20060008632A1Low dissipation factorHigh modulusSynthetic resin layered productsThin material handlingBenzoxazolePolymer science

The present invention discloses a thermosetting resin composition which comprises (A) 35 to 75 parts by weight of a thermosetting resin comprising a compound having a hydrobenzoxazine ring as a main component, (B) 10 to 25 parts by weight of a polycondensation product of a phenol, a compound having a triazine ring and an aldehyde, and (C) 10 to 45 parts by weight of an epoxy resin, based on 100 parts by weight of the total amount of organic solid components of Components (A), (B) and (C), and (i) a bisphenol F epoxy resin having a weight-average molecular weight of 1,000 to 3,000, or (ii) a mixed epoxy resin of bisphenol F epoxy resin and bisphenol A epoxy resin having a weight average molecular weight of 1,000 to 3,000, is contained in Component (C) in an amount of 0 to 100% by weight of Component (C); and a prepreg, a laminated board for a wiring board and a wiring board using the same.

Owner:HITACHI CHEM CO LTD

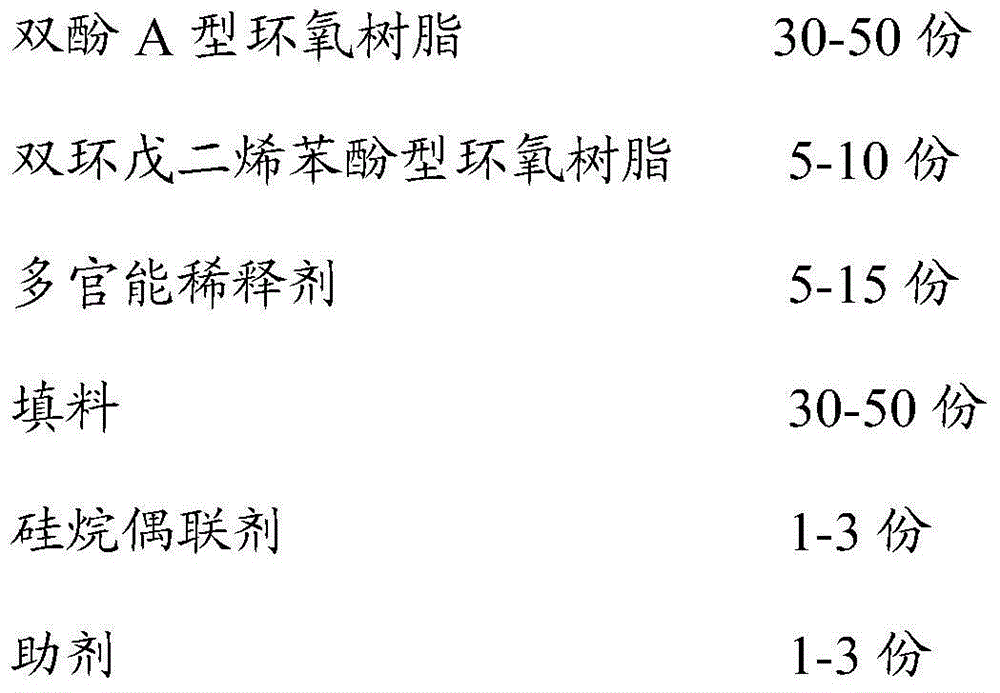

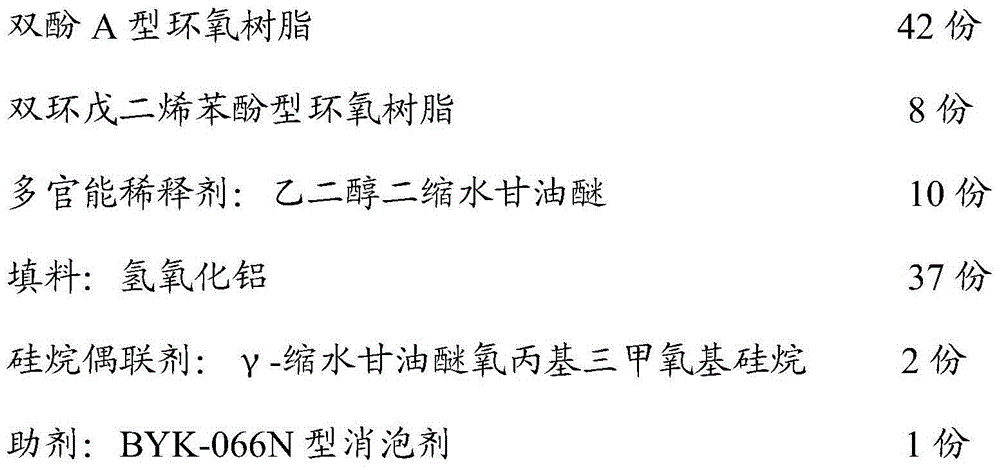

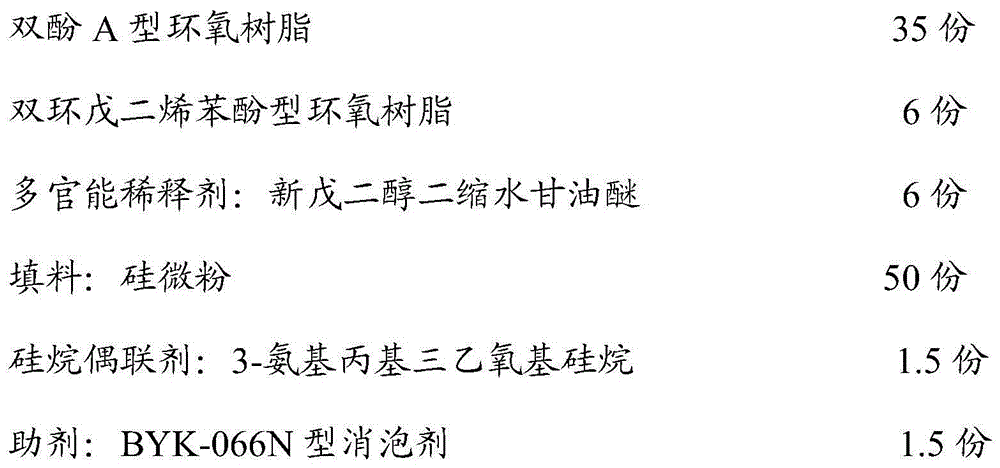

Epoxy resin encapsulating material as well as preparation method and application thereof

ActiveCN104531027AGood heat resistanceHeat resistance Very low moisture absorptionNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryElectronic materials

The invention discloses an epoxy resin encapsulating material as well as a preparation method and application thereof, and belongs to the technical field of electronic materials. The epoxy resin encapsulating material is prepared from the following raw materials: a resin part, namely a bisphenol A epoxy resin, a dicyclopentadiene phenol-type epoxy resin, a multifunctional diluent, a filler, a silane coupling agent and auxiliaries, and a curing agent part, namely methyl nadic anhydride and / or methyl tetrahydrophthalic anhydride, a cycloaliphatic epoxy resin and an accelerant; the resin part is mixed with the curing part to obtain the epoxy resin encapsulating material. According to the encapsulating material, the dicyclopentadiene phenol-type epoxy resin is added to the resin part, the silane coupling agent is applied to activating the filler in combination with the multifunctional diluent, and the cycloaliphatic epoxy resin is added to the curing part, and therefore, the finally obtained encapsulating material has the characteristics of high temperature resistance and high humidity resistance. The encapsulating material is used for preparing a capacitor, and consequently, the capacitor is enabled to be stable in capacity, small in change tolerance and longer in service life under the conditions of a high temperature, high humidity, and running with load after being powered on.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

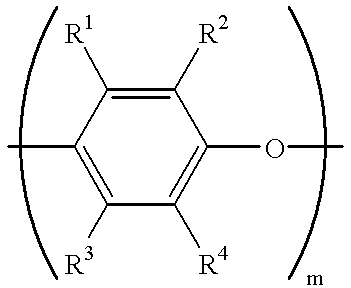

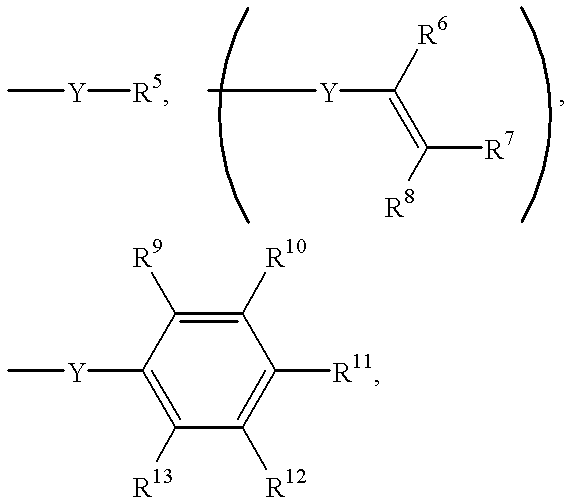

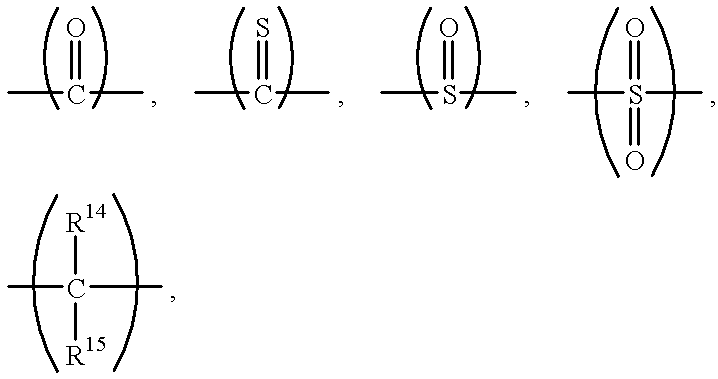

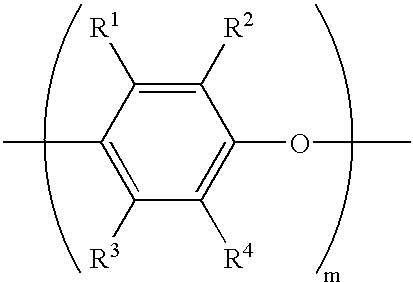

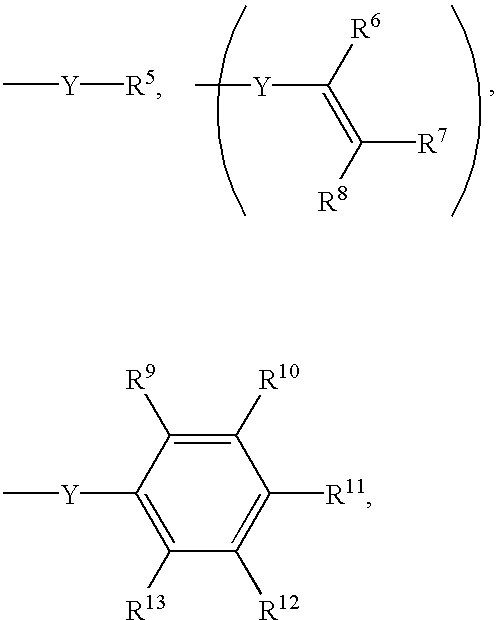

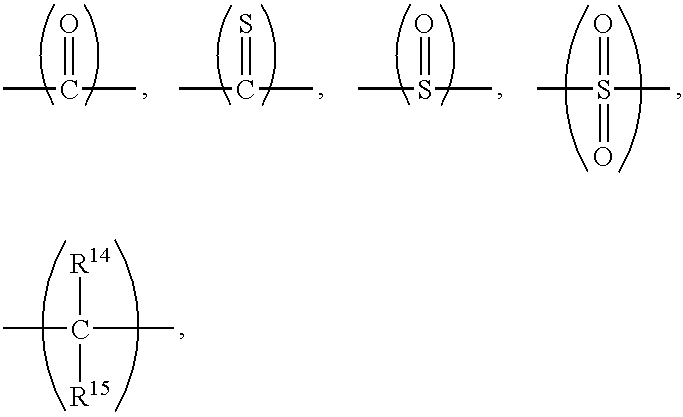

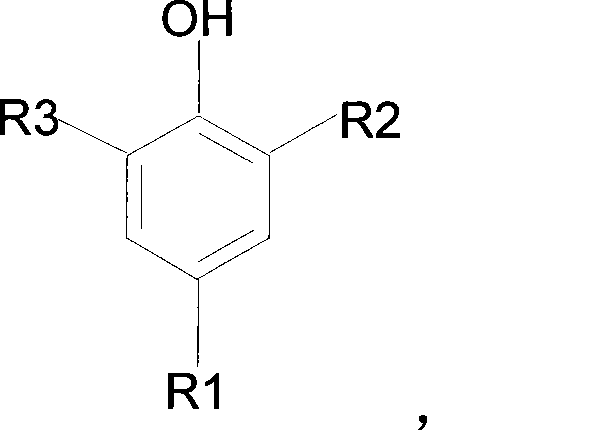

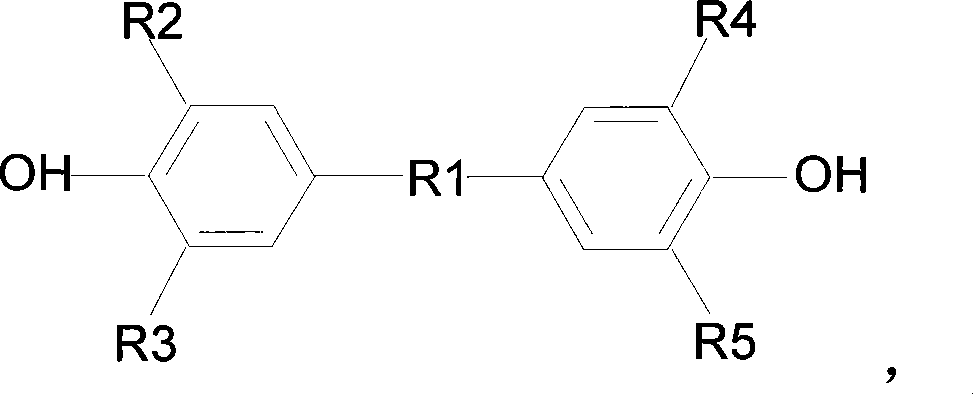

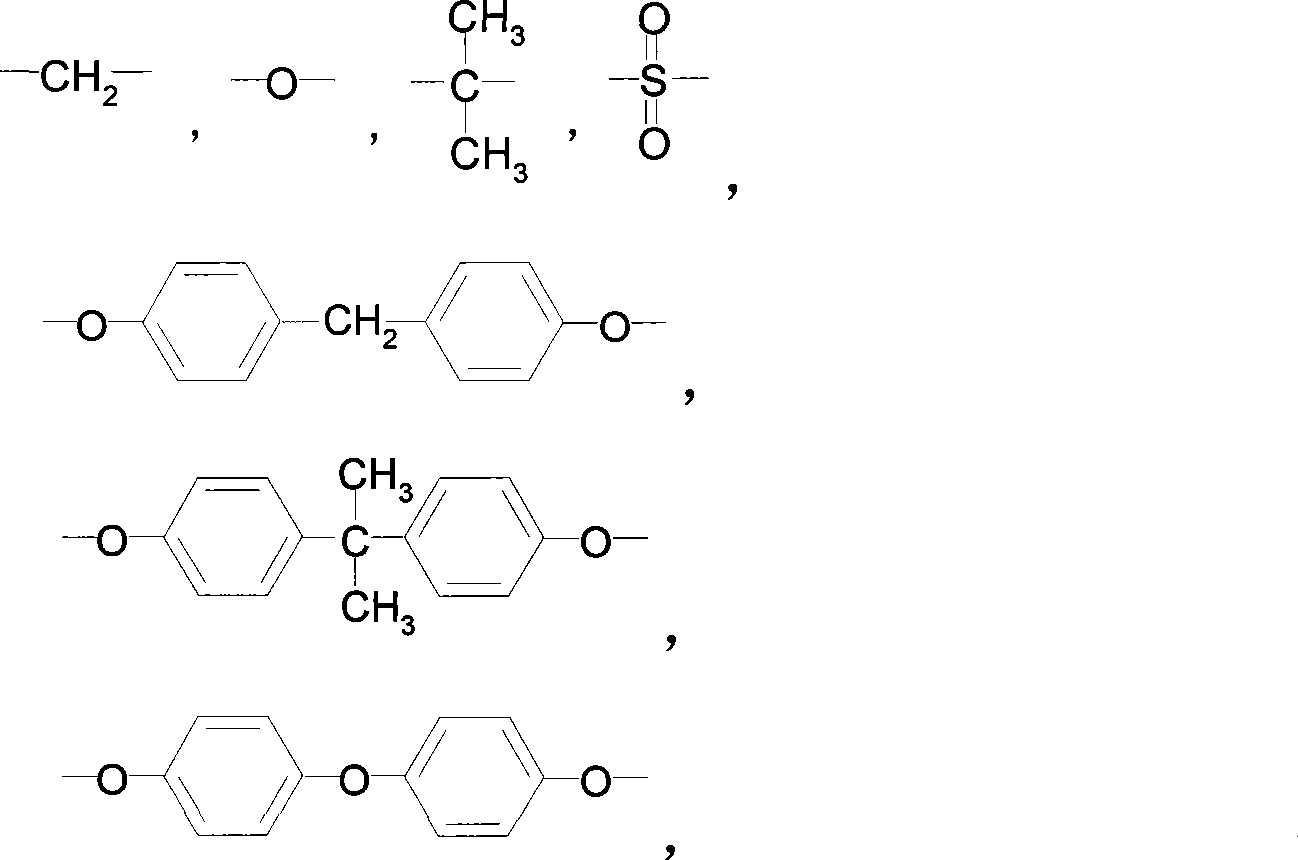

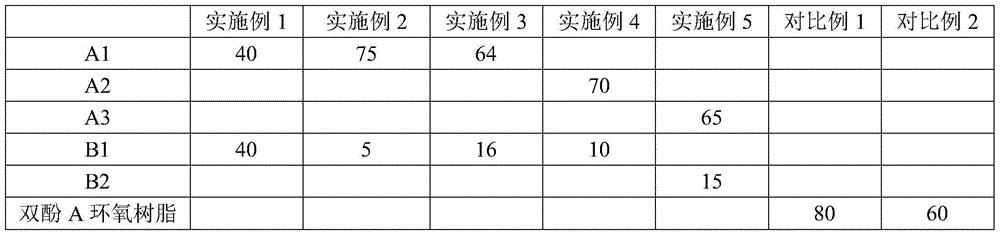

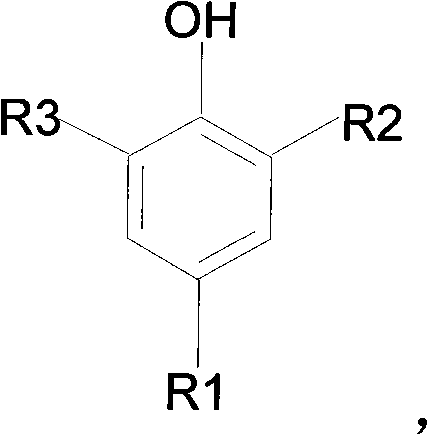

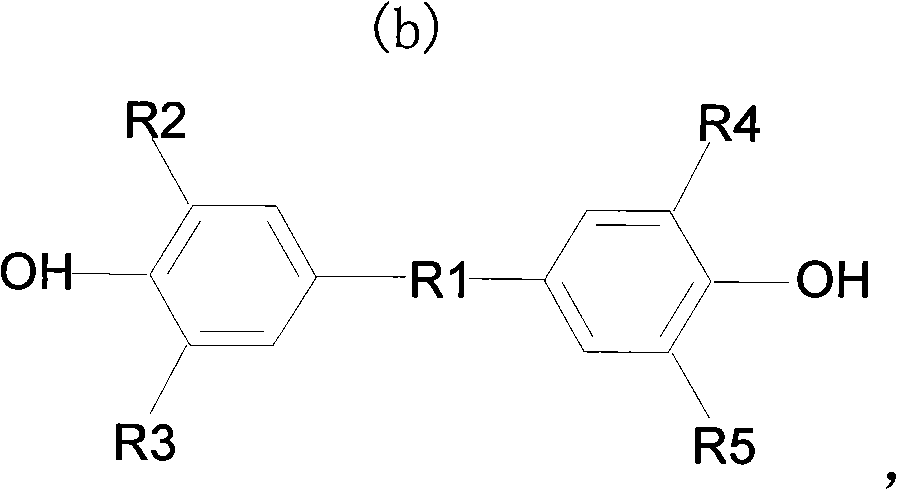

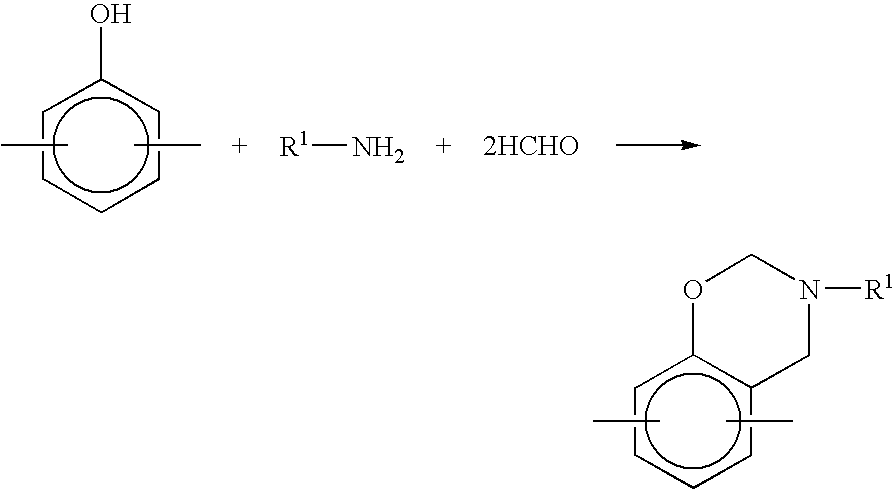

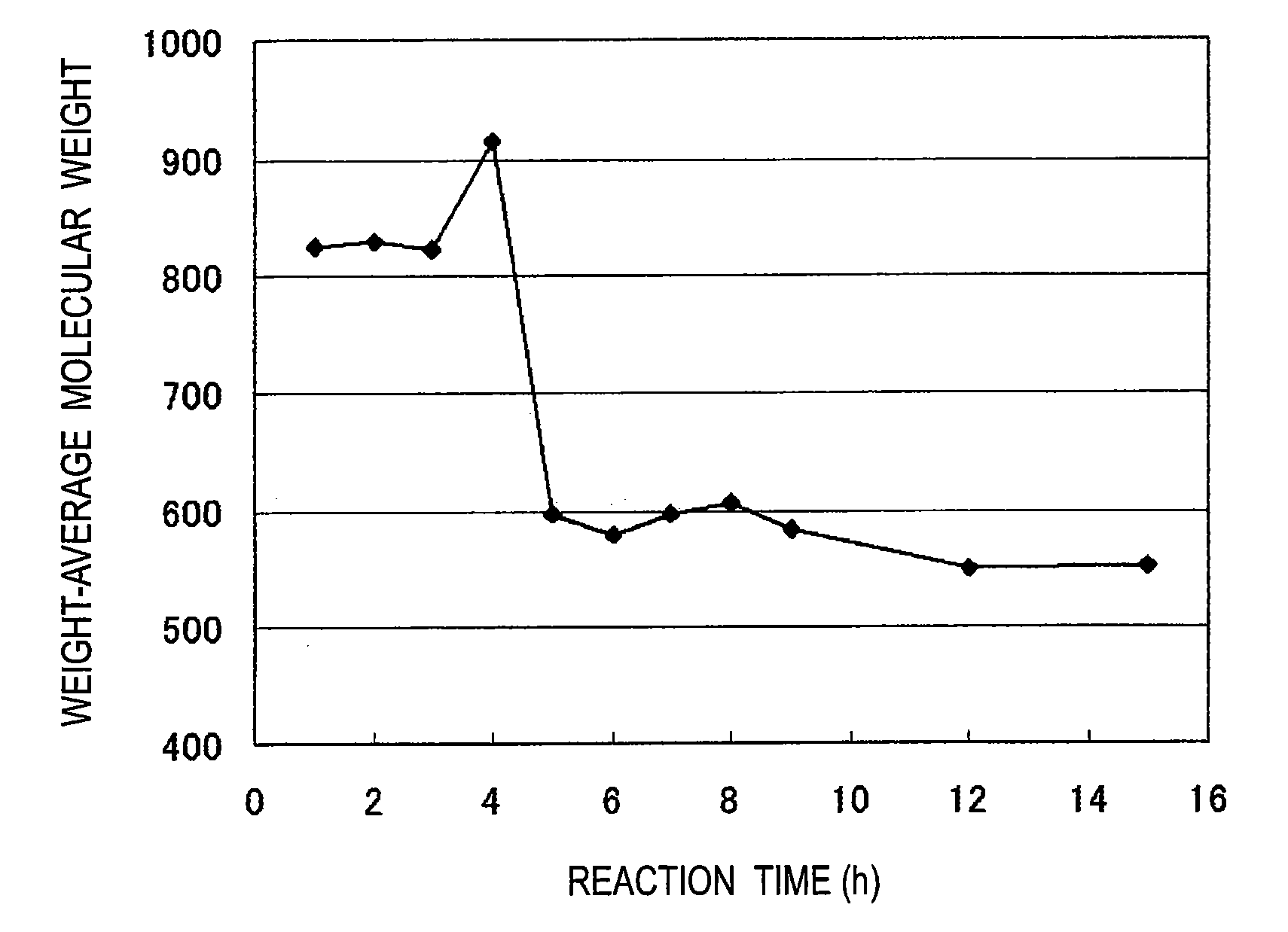

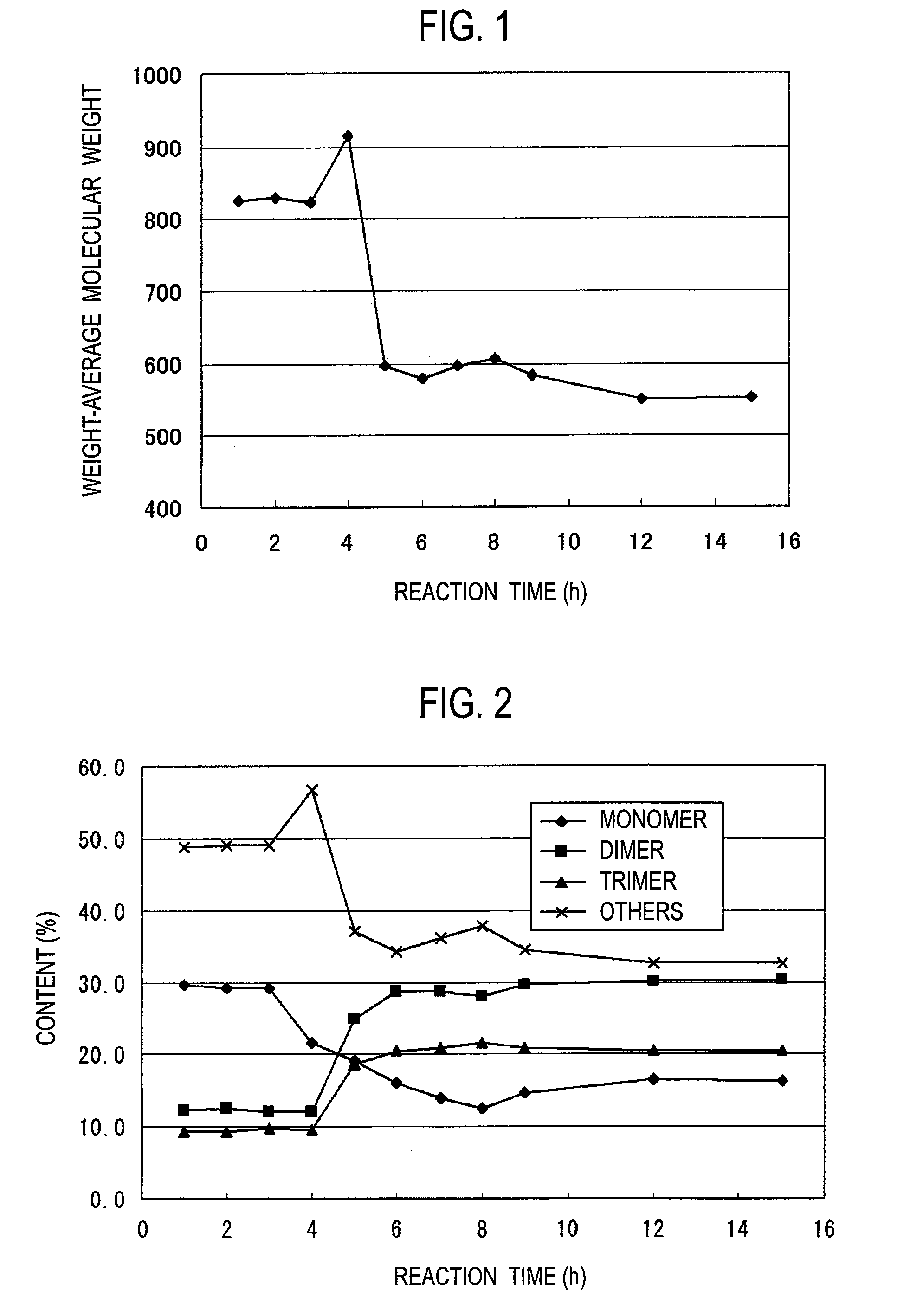

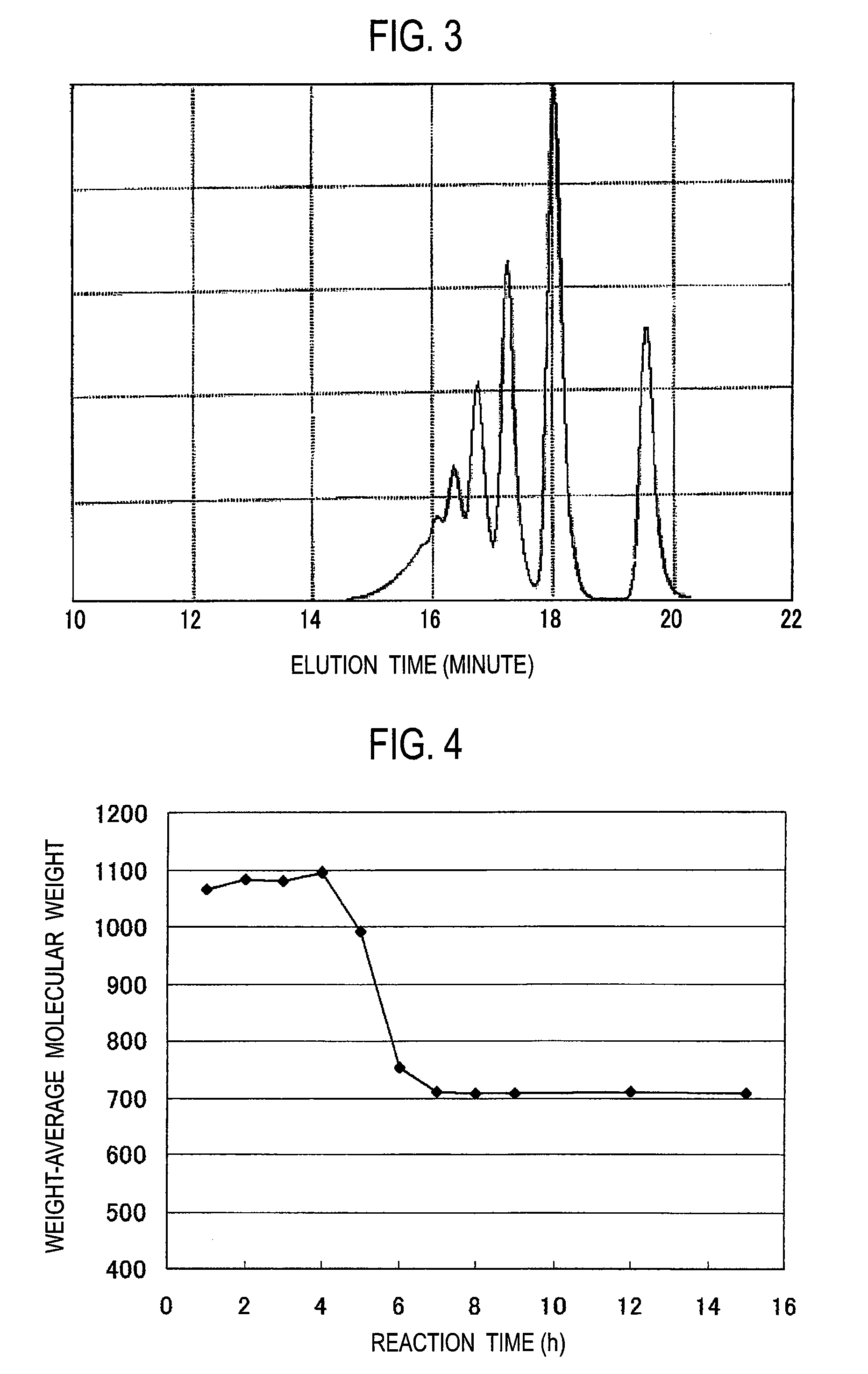

Phenol resin and resin composition

The present invention provides a phenol resin having, as a unit in its main-chain skeleton, a structure represented by the following general formula (I), as well as a resin composition using the same. According to the phenol resin of the invention, epoxylation thereof, chemical modification thereof, reaction thereof with an epoxy resin, and the like are facilitated. Phenol resins ranging from low-molecular-weight resins rich in fluidity to high-melting resins can be synthesized, and these phenol resins are industrially useful. When the phenol resin of the present invention is used as a hardening agent for epoxy resin etc., its resin composition can give a cured product of high Tg without deteriorating adhesiveness.

Owner:RESONAC CORP

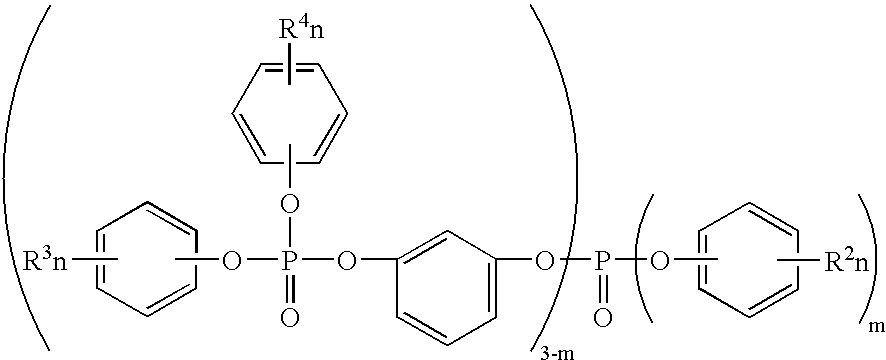

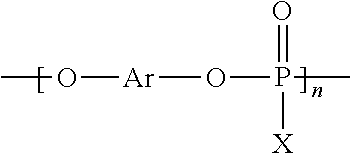

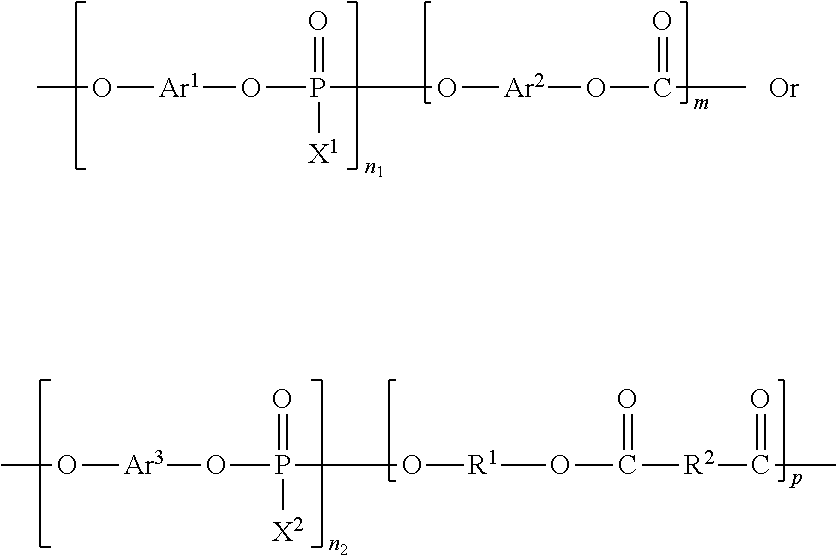

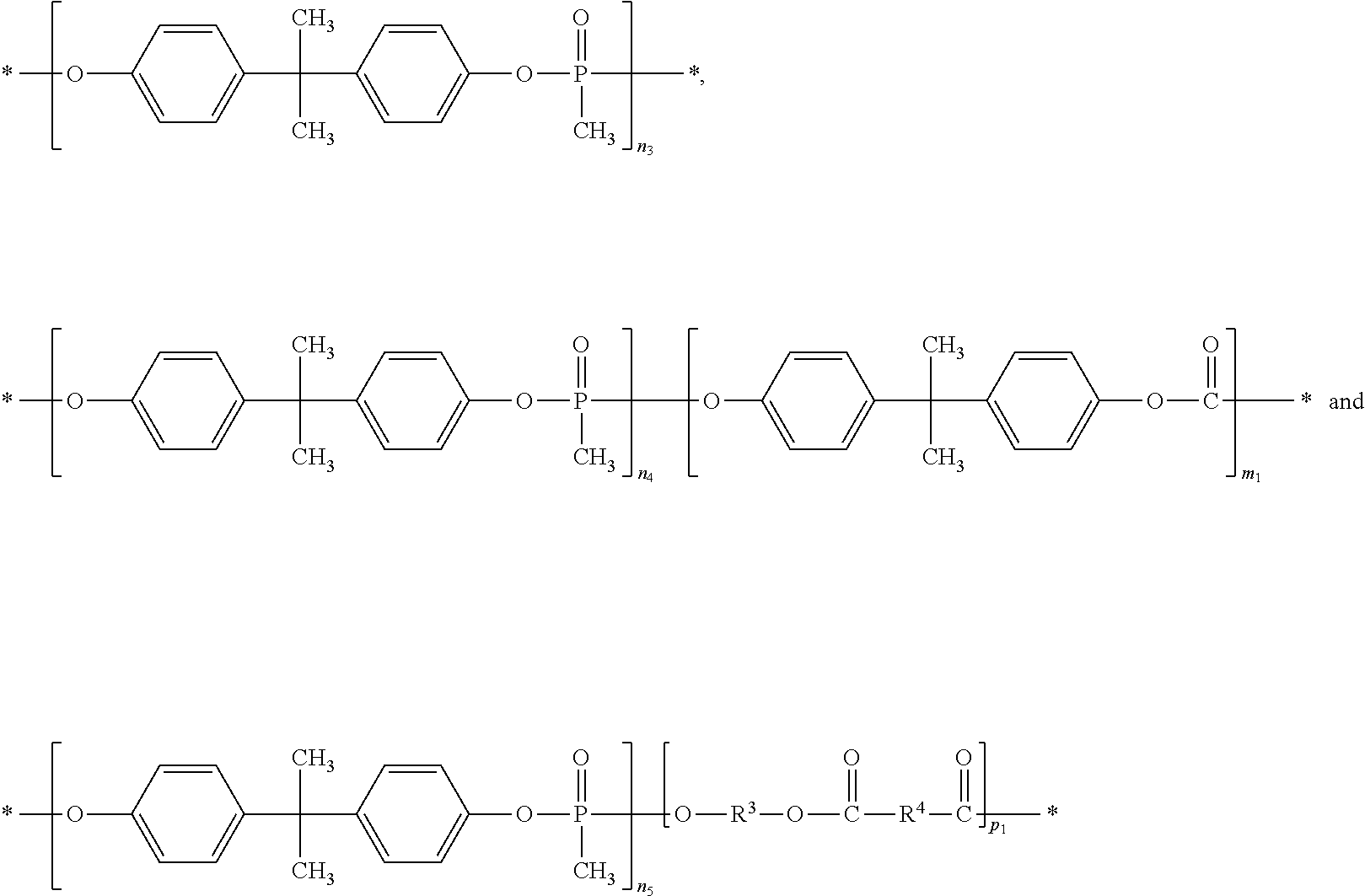

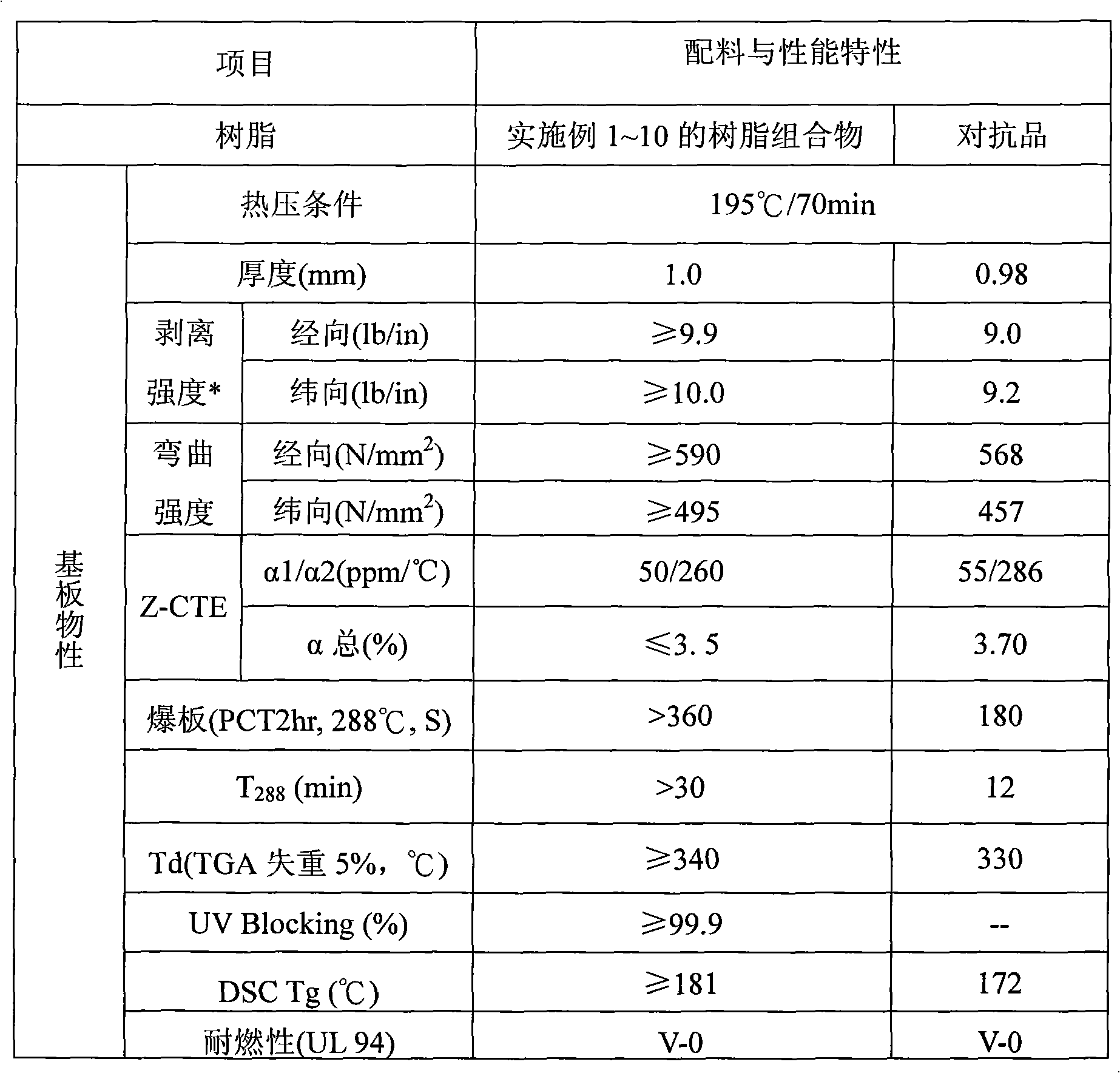

Thermosetting resin composition and use thereof

InactiveUS20150189747A1Excellent dielectric propertyGood processing characteristicDielectric materialsSemiconductor/solid-state device detailsPrepolymerDielectric loss

The present invention relates to a thermosetting resin composition, which comprises: (A) cyanate ester compound and / or cyanate ester prepolymer; and (B) polyphosphonate ester and / or phosphonate-carbonate copolymer. The thermosetting resin composition provided by the present invention has low dielectric constant and dielectric loss tangent. The prepreg and copper clad laminate made from the above-mentioned thermosetting resin composition have excellent dielectric properties and wet-heat resistance, UL94 V-0 flame resistance, and good processability.

Owner:GUANGDONG SHENGYI SCI TECH

Epoxy resin composition for printed circuit copper-clad plate

ActiveCN101864146AHigh glass transition temperatureImprove heat resistanceCircuit susbtrate materialsMetal layered productsHeat resistanceThermal expansion

The invention discloses an epoxy resin composition for a printed circuit copper-clad plate, which consists of the following components in part by weight: 130 to 140 parts of butane solution containing modified epoxy resin, 60 to 70 parts of composite phenolic aldehyde curing agent or 4.5 to 6.5 parts of dicyandiamide curing agent, 0.02 to 0.04 part of curing catalyst, 30 to 40 parts of solvent and 25 to 30 parts of filler, wherein the butane solution containing the modified epoxy resin is prepared by modifying bis-functional epoxy resin, brominated bisphenol epoxy resin, multi-functional novolac epoxy resin and linear novolac epoxy resin. The epoxy resin composition has the characteristics of low viscosity, easy impregnation, convenient operation, good reactivity and high Tg; and the printed circuit copper-clad plate made of the epoxy resin composition has good reliability and workability, excellent heat resistance and Z-axis thermal expansion coefficient and other comprehensive performance.

Owner:EPOXY BASE ELECTRONICS MATERIAL

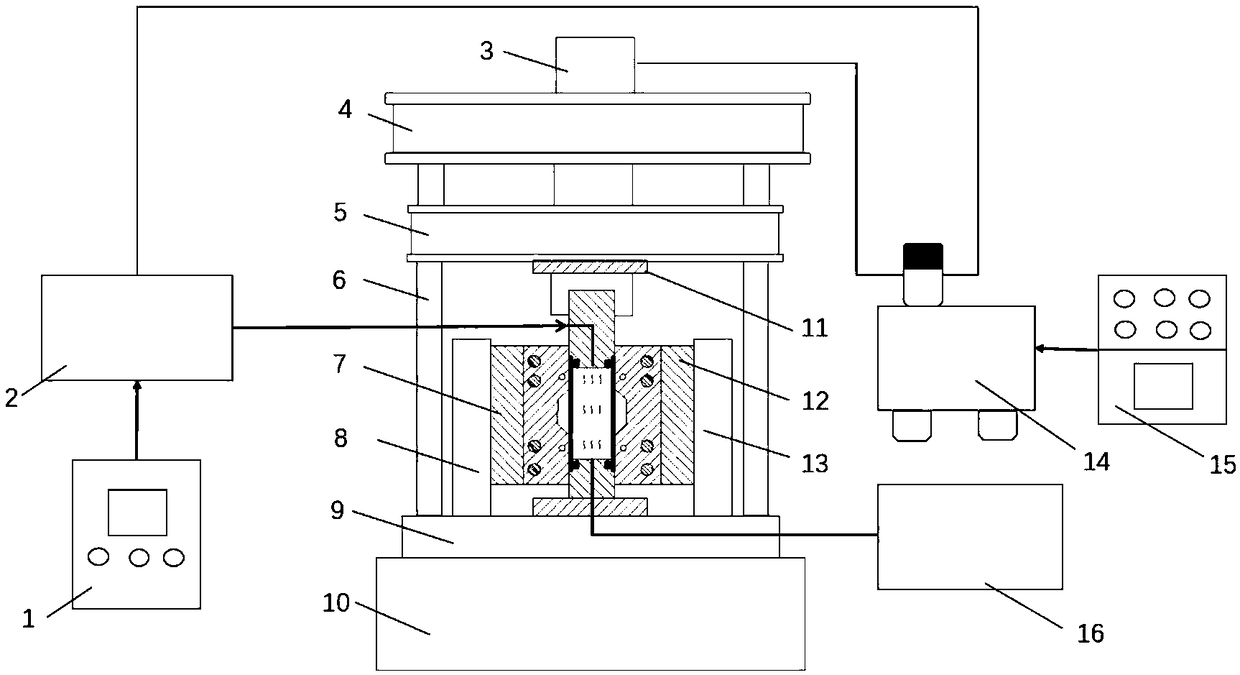

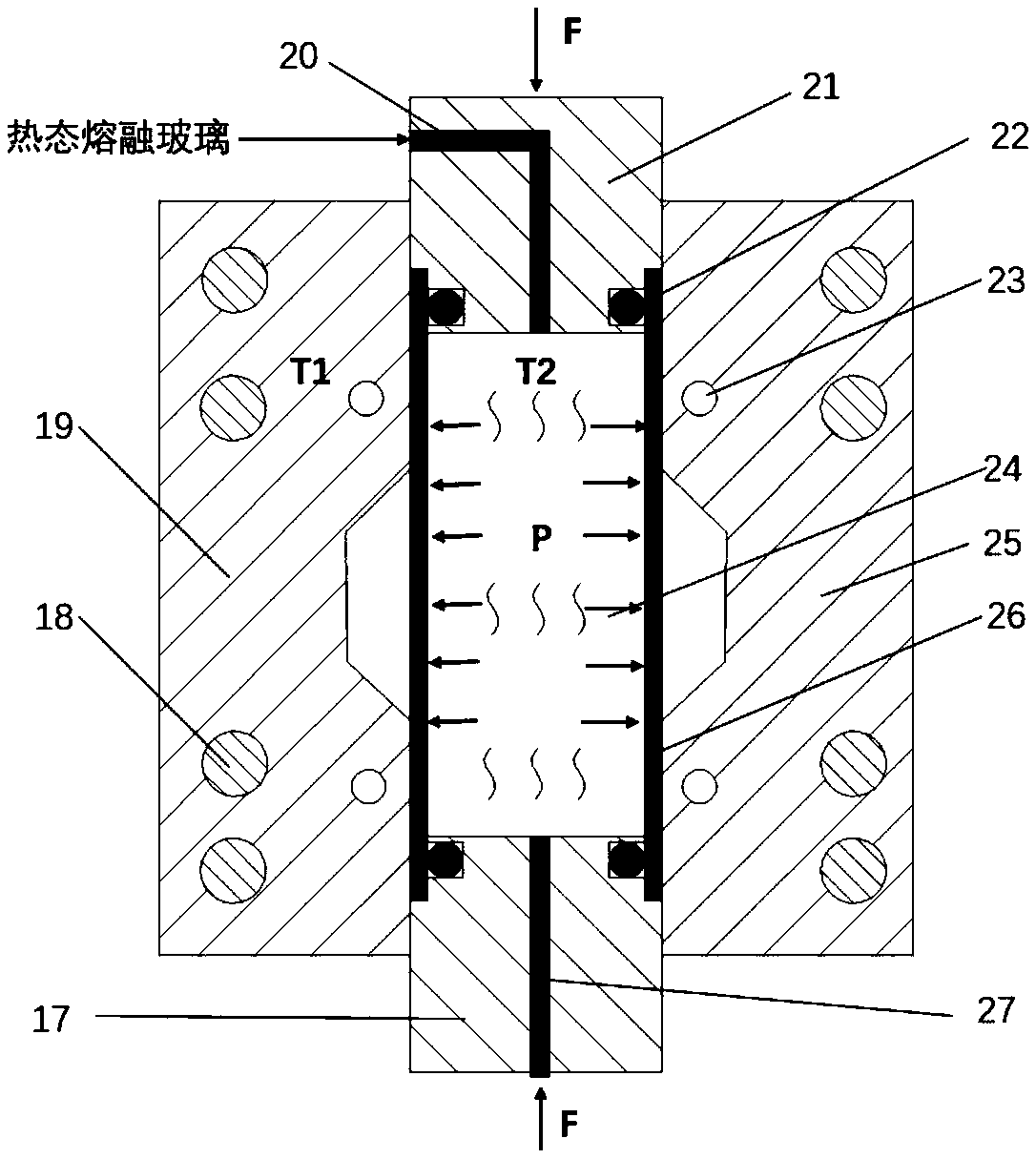

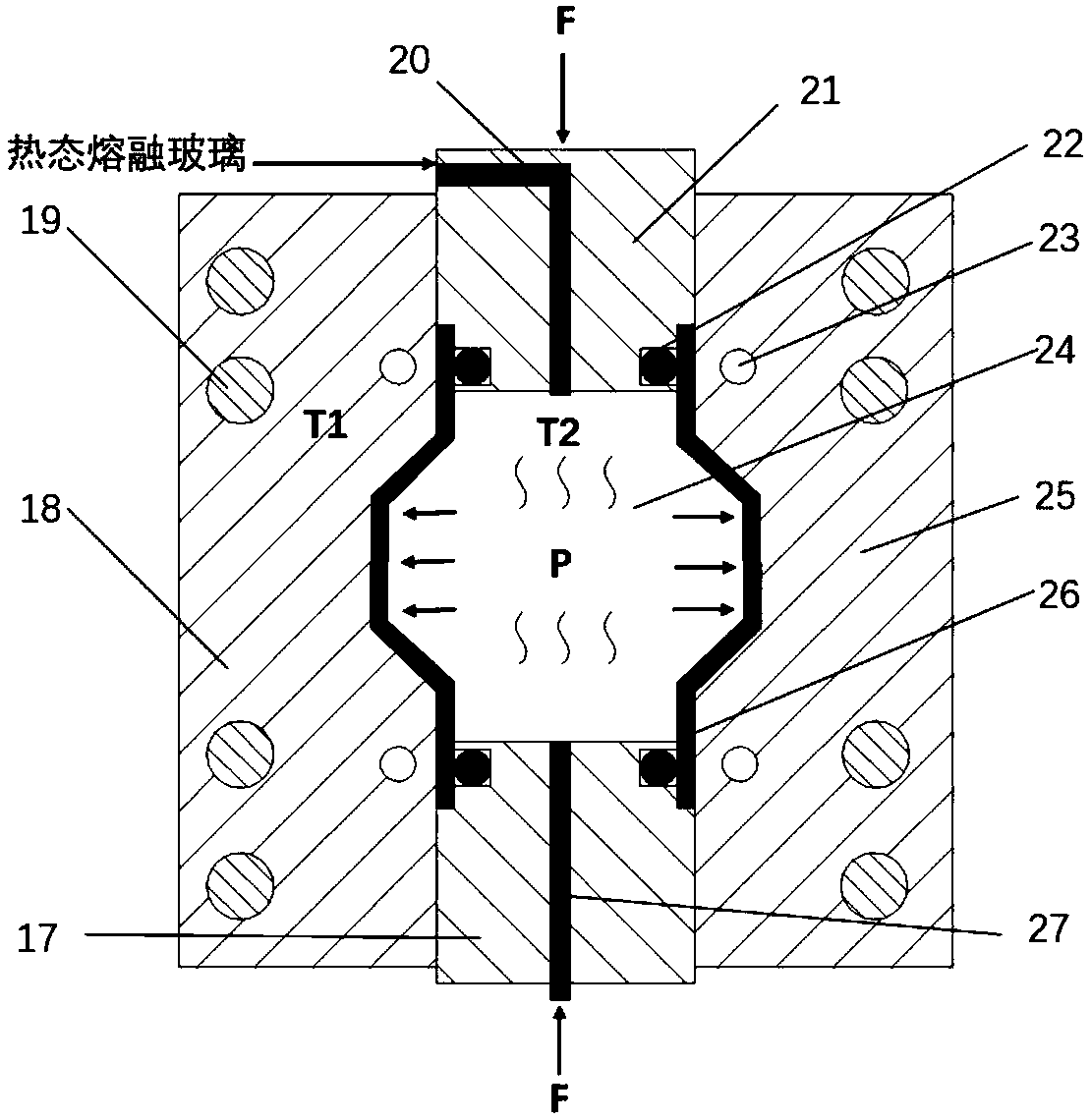

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

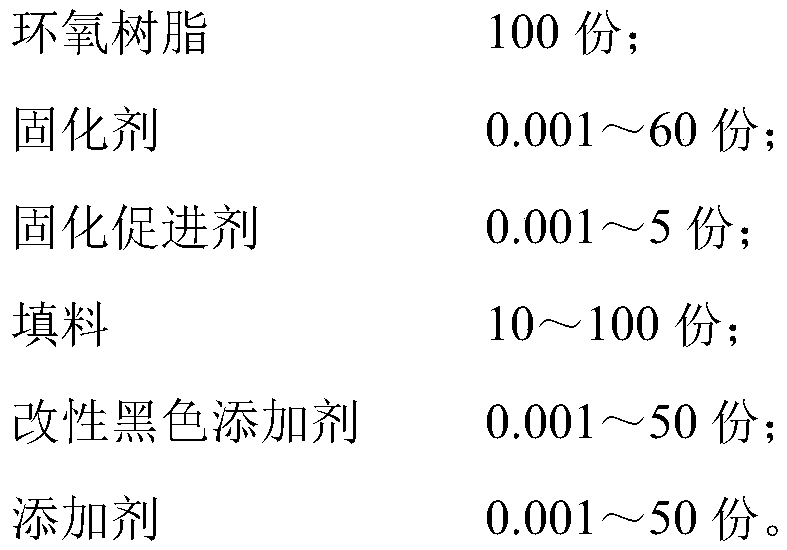

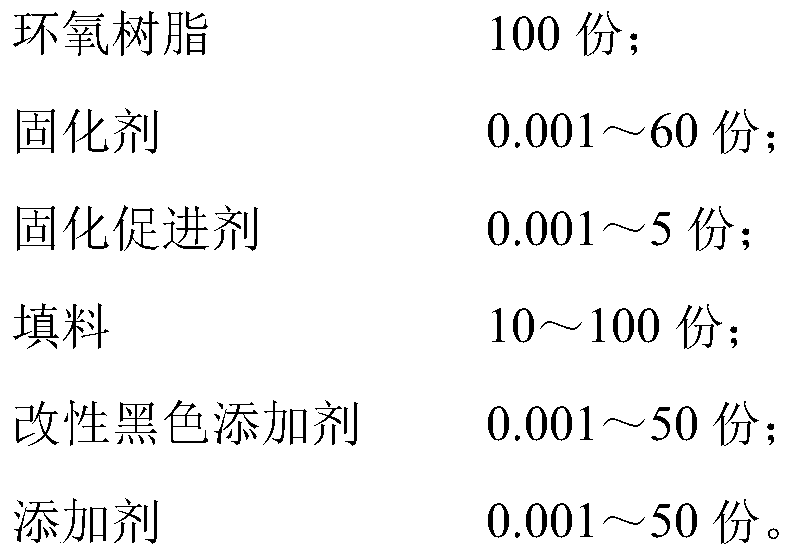

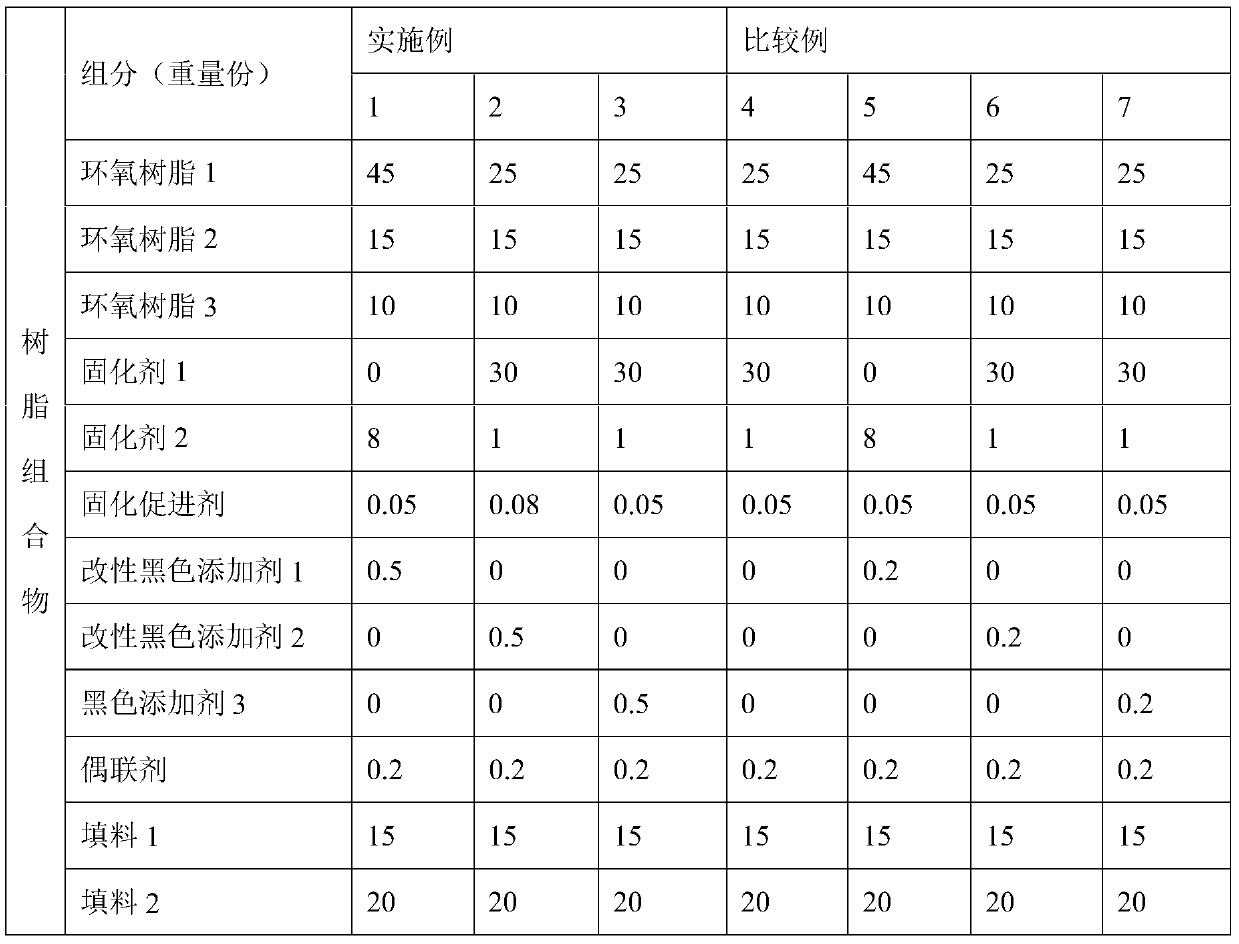

Black resin composition, prepreg and laminated plate

InactiveCN110305445AImprove Difficult DispersionHigh strengthSynthetic resin layered productsElectrical equipmentEpoxyPrinted circuit board

The invention belongs to the field of resin materials for printed circuit boards, in particular to a black resin composition, a prepreg and a laminated plate, wherein the black resin composition comprises the following components in parts by weight: 100 parts of epoxy resin; 0.001-60 parts of curing agents; 0.001-5 parts of curing accelerators; 10-100 parts of fillers; 0.001-50 parts of modified black additives; and 0.001-50 parts of additives. The resin composition improves the defects of difficult dispersion of the resin system, weak light shielding strength of the prepreg and the laminatedplate and large dust adsorption by modifying the black additive, and has good processability.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

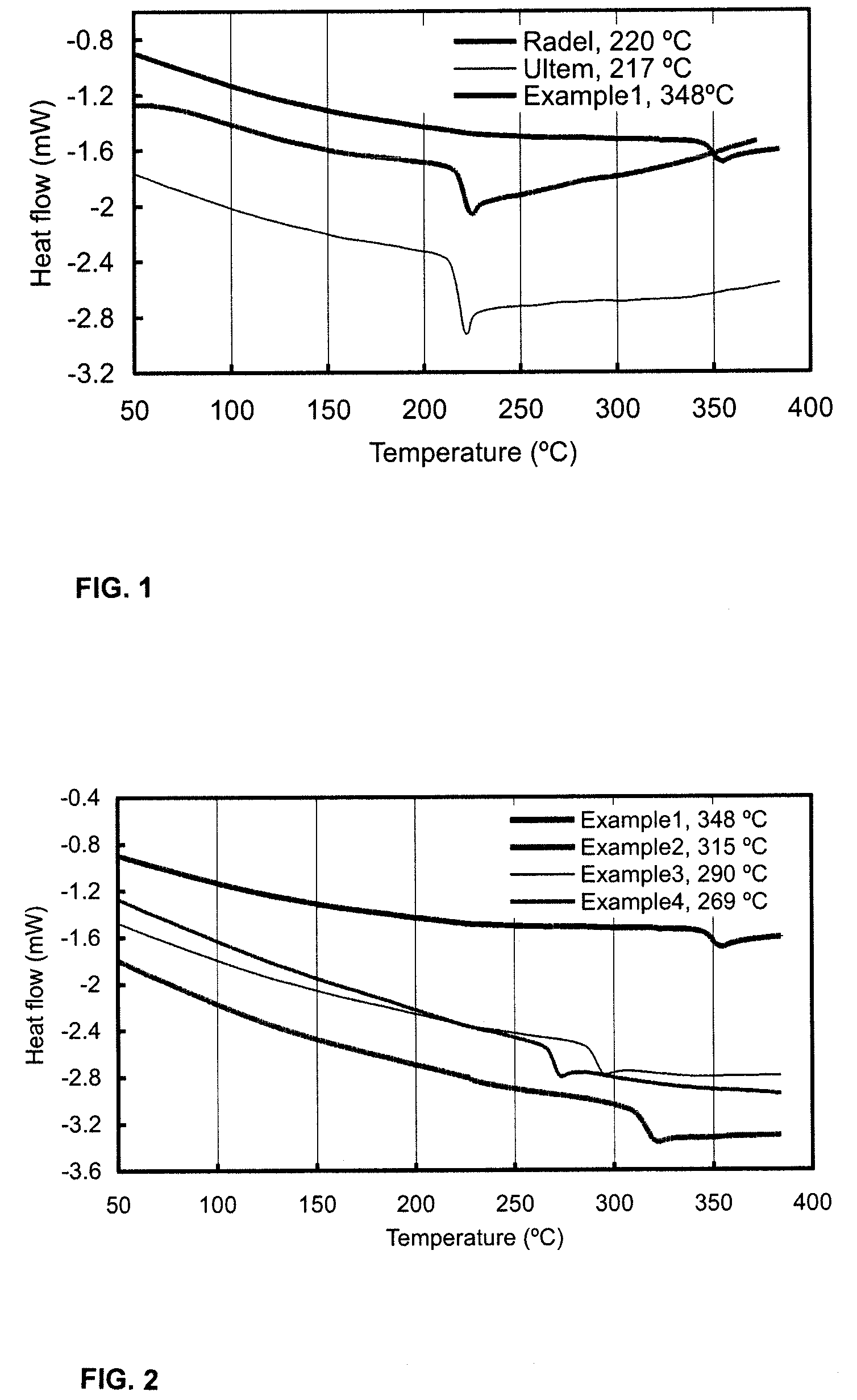

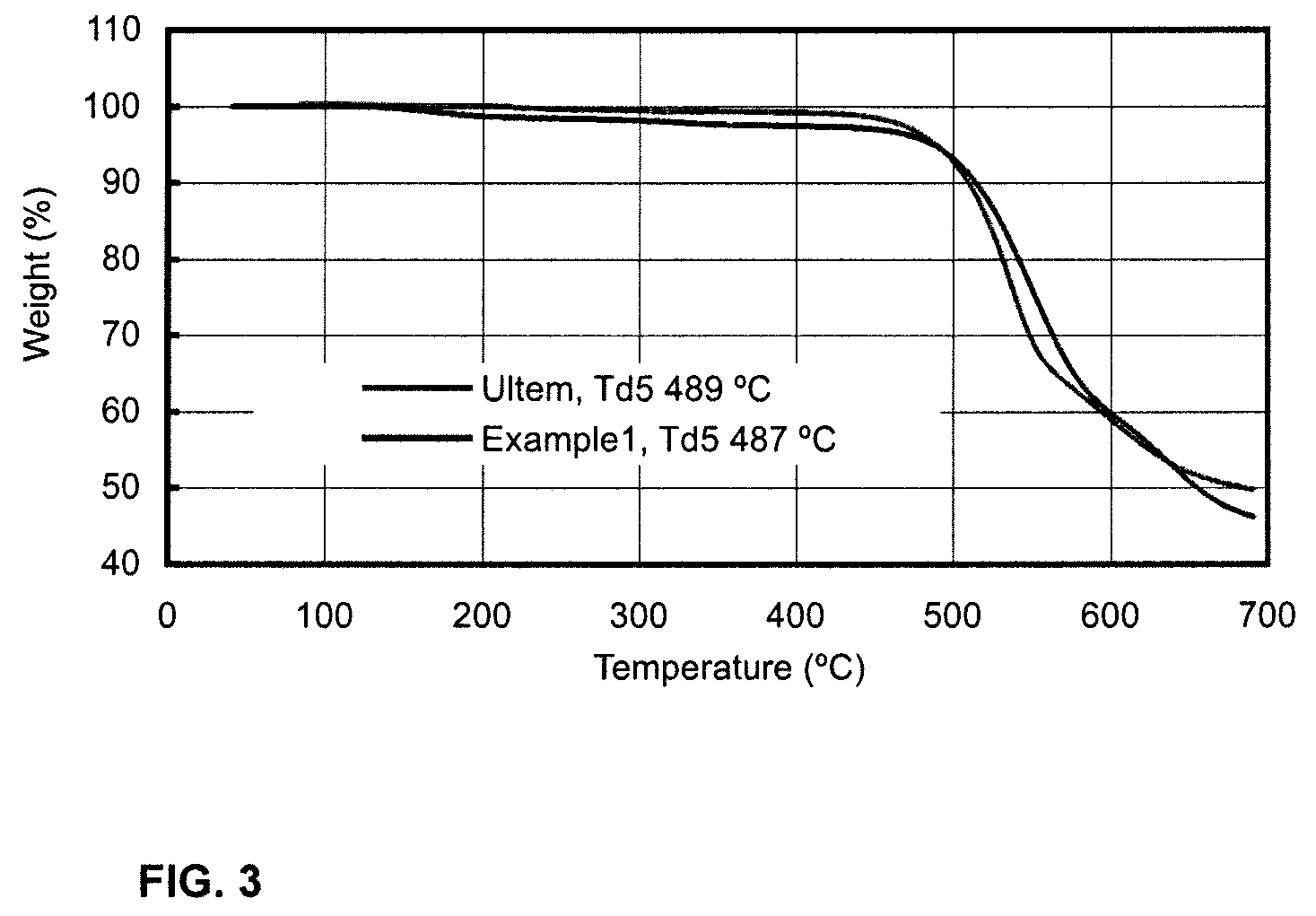

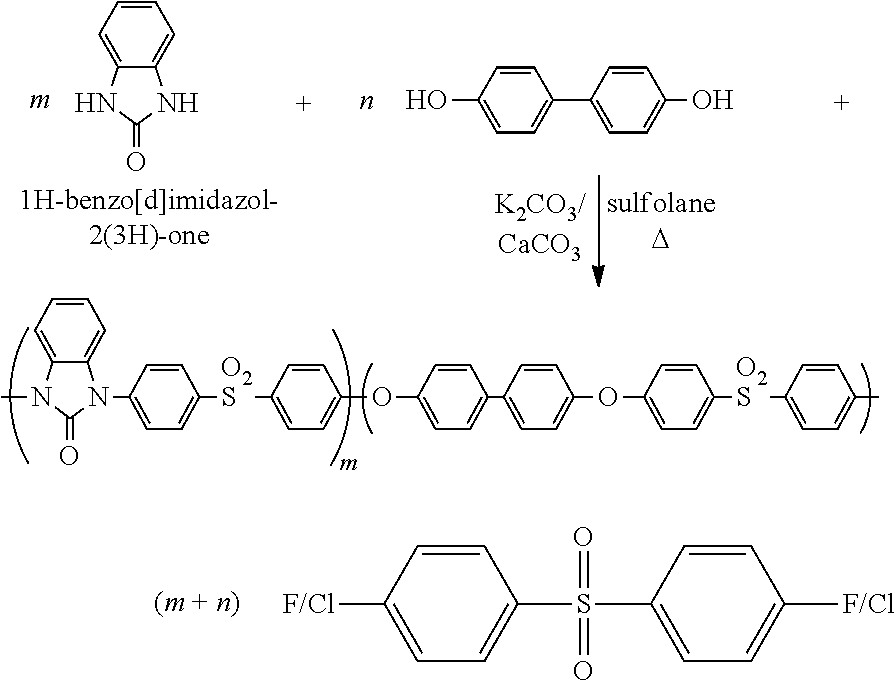

Polymers and copolymers containing 2H-benzimidazol-2-one moieties

Polymers and copolymers containing 1H-benzo[d]imidazol-2(3H)-one units have been synthesized under conditions generally used for the synthesis of poly(aryl ether)s. 1H-benzo[d]imidazol-2(3H)-one behaves like a biphenol in the polymerization reaction.The soluble homopolymer has a very high glass transition temperature (348° C.), good thermal stability, and forms flexible transparent films. Because of the low molecular weight (134.14) of the benzoimidazolone monomer in the copolymer formed with 4,4′-biphenol that contains 30 mole % of the benzimidazolone unit, only 8.9 weight % is required to raise the Tg of the poly(arlyl ether)sulfone from 220° C. to 269° C.

Owner:HT MATERIALS CORP

Encapsulation compositions comprising of spices, herbs, fruit, and vegetable powders

InactiveUS20140272011A1Reduced functionalityUnique antioxidantFood shapingFood preparationParticulatesFood flavor

A dense solid particulate encapsulation compositions comprising above 40% and up to 100% spices, herbs, fruit and vegetable powders in the encapsulating matrix are disclosed. The encapsulation of encapsulants including flavors, fragrances, medications, nutritional supplements, and vitamins, all in the range from 0.1% to 20% by weight of the encapsulation composition is described. Also disclosed is the process of making of the encapsulation compositions. The target applications of the encapsulated compositions are also described.

Owner:MCCORMICK & CO INC

Epoxy adhesive for electron component integrated molding technology and preparation method of epoxy adhesive

InactiveCN103555246AMeet the requirements of one-piece molding processAdapt to different needsNon-macromolecular adhesive additivesEpoxynovolac adhesivesSolventUltimate tensile strength

The invention discloses an epoxy adhesive for an electron component integrated molding technology and a preparation method of the epoxy adhesive. The epoxy adhesive comprises the following components in parts by weight: 30-70 parts of epoxy resin, 1-10 parts of curing agent, 1-10 parts of accelerator, 20-40 parts of solvent, and 0.1-5.0 parts of additive. Compared with the prior art, the epoxy adhesive is capable of satisfying the demand of an integrated molding process, and well adapting to different requirements of a new process in comparison with the traditional adhesive; the adhesive has high body strength, high modulus, high Tg, and high bonding strength, and is high in reliability. The epoxy adhesive is capable of satisfying the production process demand of the integrated molding process of the electron element and has higher reliability.

Owner:TONSAN ADHESIVES INC

High-reliability fast-curing filling glue

ActiveCN109401706AAchieve reworkabilityIncrease crosslink densityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention relates to filling glue and a preparation method thereof, in particular to high-reliability fast-curing filling glue. The high-reliability fast-curing filling glue is prepared from the following raw materials in percentage by weight: 10-50% of epoxy resin, 5-20% of an epoxy diluent, 5-15% of epoxy resin with capability of free radical reaction, 0-10% of an olefin monomer with capability of free radical reaction, 5-20% of a toughener, 0.5-3% of a coupling agent, 0.1-5% of a cationic initiator, 0.1-5% of a radical initiator, 0-5% of filler and 0-5% of pigment. The bottom filling glue provided by the invention can fast cure, has a high glass-transition temperature (Tg), a low expansion coefficient and good repair property, and can be mainly used for flip chip bottom filling to improve the connection reliability.

Owner:深圳广恒威科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com