Patents

Literature

405 results about "Isosorbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

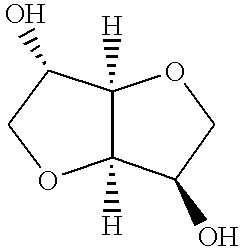

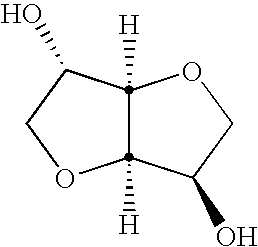

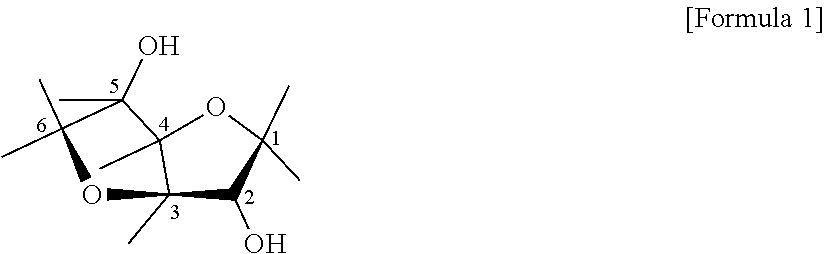

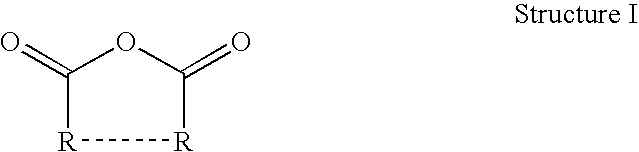

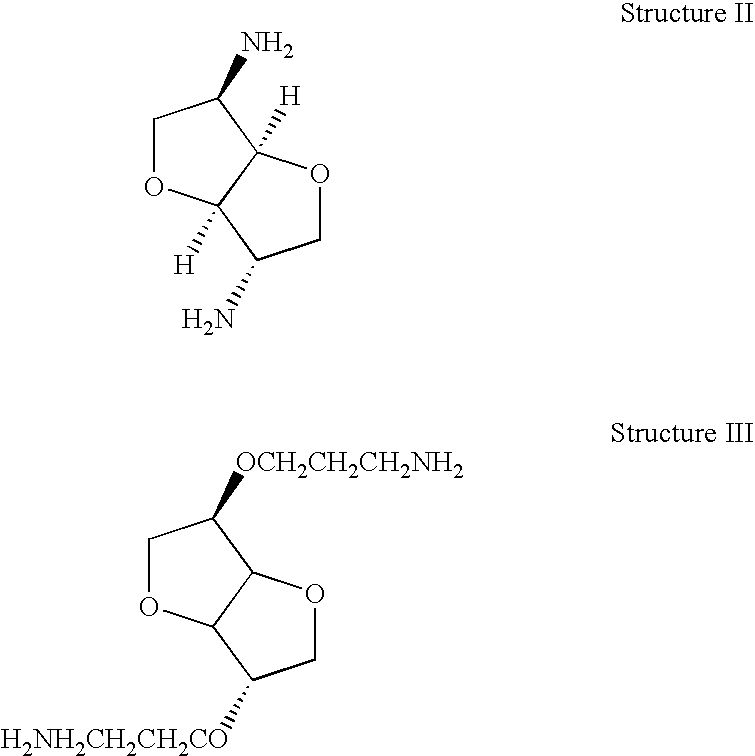

Isosorbide is a bicyclic chemical compound from the group of diols and the oxygen-containing heterocycles, containing two fused furan rings. The starting material for isosorbide is D-sorbitol, which is obtained by catalytic hydrogenation of D-glucose, which is in turn produced by hydrolysis of starch. Isosorbide is discussed as a plant-based platform chemical from which biodegradable derivatives of various functionality can be obtained.

Isosorbide containing polyesters and methods for making same

InactiveUS6063464AHigher inherent viscosityInherent viscosityBottlesSynthetic resin layered productsPolyesterDiol

A polyester polymer and method for making the polyester, wherein the polyester is prepared by (1) combining in a reactor a monomer containing a diacid moiety; a monomer comprising a diol moiety; and a monomer containing an isosorbide moiety; with a condensation catalyst suitable for condensing aromatic diacids and diols; and (2) heating the monomers and catalyst to polymerize the monomers to yield a polyester having an inherent viscosity of at least about 0.15 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

Sheets formed from polyesters including isosorbide

InactiveUS6025061AImprove low temperature impact strengthIncrease the maximum use temperatureLayered productsAnimal housingPolyesterInherent viscosity

A sheet made of a polyester which includes monomer units of terephthaloyl moieties, ethylene glycol moieties and isosorbide moieties is described. The polyester has an inherent viscosity of at least about 0.35 dL / g when measured as a 1% (weight / volume) solution of said polyester in o-chlorophenol at a temperature of 25 DEG C. The present invention also relates to a method of making the polyester sheet described above and a method of thermoforming the sheet into articles.

Owner:EI DU PONT DE NEMOURS & CO

Polyester container and method for making same

A polyester container made from a polymer having ethylene glycol moieties, isosorbide moieties and terepthaloyl moieties, and the method of making the container is described. The polyester container is suitable for holding liquids and solids, and may be hot-filled or cold-filled. In particular, wide-mouth jars and narrow-necked bottles may be formed. The polyester has an inherent viscosity of at least 0.35 dL / g when measured as a 1% (weight / volume) solution of the polyester in o-chlorophenol at a temperature of 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

Polyesters including isosorbide as a comonomer blended with other thermoplastic polymers

A polymer blend including a polyester and another thermoplastic polymer. The polyester includes terephthaloyl moieties and, optionally, other aromatic diacid moieties; and ethylene glycol moieties; optionally diethylene glycol moieties; isosorbide moieties; and, optionally one or more other diol moieties. The polyester has an inherent viscosity of at least about 0.35 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

Method for making isosorbide containing polyesters

This invention relates to a process for producing a polyester comprising the steps of:(g) obtaining an aqueous homogenous solution of isosorbide;(h) feeding the aqueous homogenous solution of step (a) into a reactor;(i) feeding one or more glycols and one or more dicarboxylic acids either into the aqueous solution of step (a) or into the reactor of step (b) either prior to, during and / or subsequent to step (b);(j) esterifying the reactor contents at sufficient temperatures and pressures, and optionally in the presence of suitable catalysts, to effect esterification;(k) forming a prepolymer; and(l) polycondensing the prepolymer at sufficient temperatures and pressures in the presence of a suitable catalyst to effect polycondensation to form a polyester.

Owner:EASTMAN CHEM CO

Polyester resin and method for preparing the same

InactiveUS20120177854A1Superior heat-resistanceHigh impact strengthBio-packagingSynthetic resin layered productsCyclohexanedimethanolDiol

A polyester resin copolymerized with isosorbide and 1,4-cyclohexane dimethanol and having an improved impact strength, and a method for preparing the same are disclosed. The copolymerized polyester resin has an alternating structure of acid moieties which are derived from acid components and diol moieties which are derived from diol components, wherein the acid components comprise terephthalic acid, and the diol components comprise (i) 5˜99 mol % of 1,4-cyclohexanedimethanol and (ii) 1˜60 mol % of isosorbide with respect to the total diol components.

Owner:SK CHEM CO LTD

Process to produce polyesters which incorporate isosorbide

The present invention provides a process to produce isosorbide-containing polyesters. The process allows for higher isosorbide incorporation than previously found while maintaining high polymeric molecular weights.

Owner:EI DU PONT DE NEMOURS & CO

Bis(2-hydroxyethyl isosorbide); preparation, polymers derived therefrom, and enduses thereby

This invention provides a new, biomass-derived glycol, bis(2-hydroxyethyl)isosorbide, which is found to be a valuable monomer for a wide variety of polymeric materials.

Owner:EI DU PONT DE NEMOURS & CO

Polymers made from bis(2-hydroxyethyl)isosorbide and enduses thereof

Owner:HAYES RICHARD +1

Thermoset epoxy polymers from renewable resources

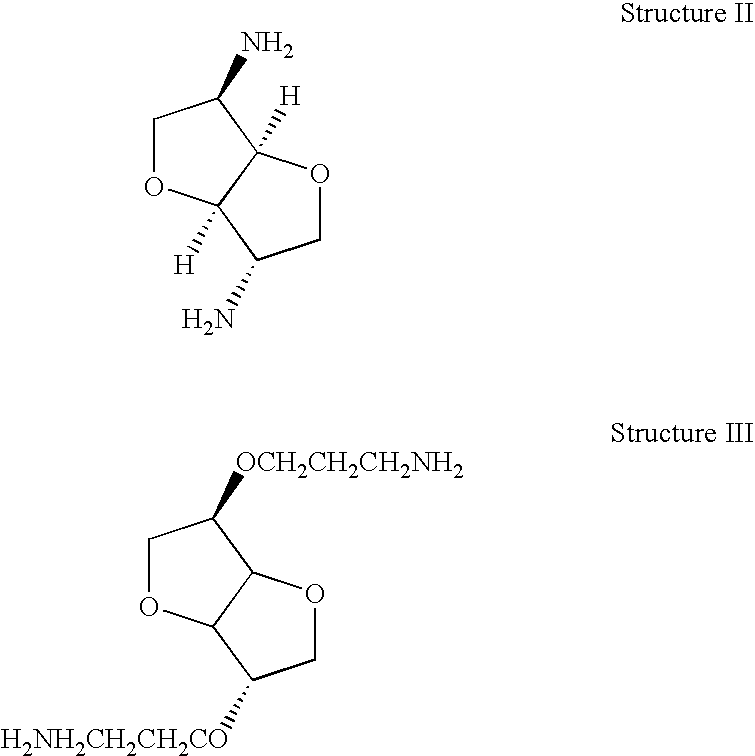

Novel thermoset epoxy polymers using the bisglycidyl ethers of anhydrosugars, such as isosorbide, isomannide, and isoidide, are disclosed. The bisglycidyl ethers are useful as substitutes for bisphenol A in the manufacture of thermoset epoxy ethers. The anhydrosugars are derived from renewable sources and the bisglycidyl ethers are not xenoestrogenic and the thermoset curing agents are likewise derived form renewable resources.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

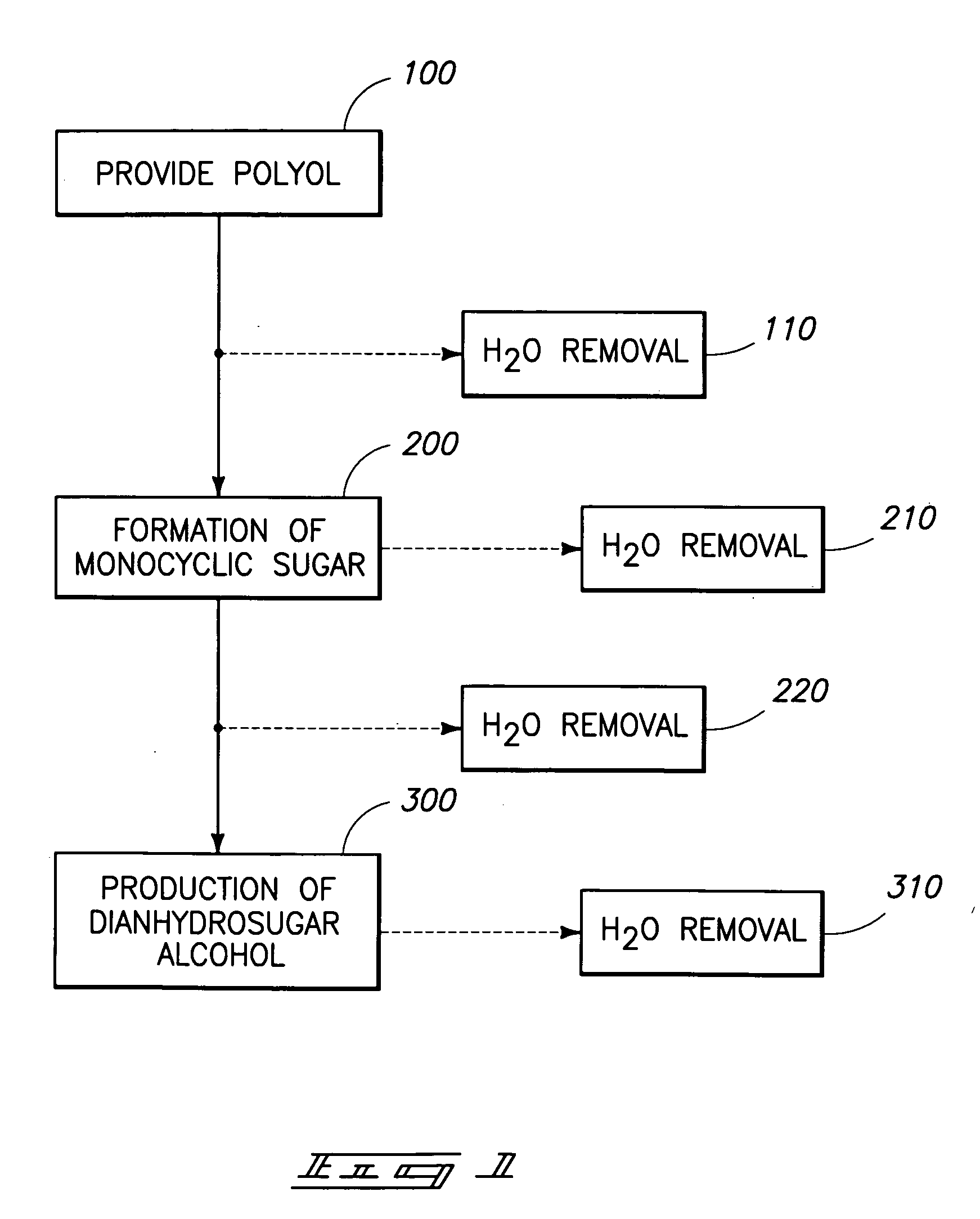

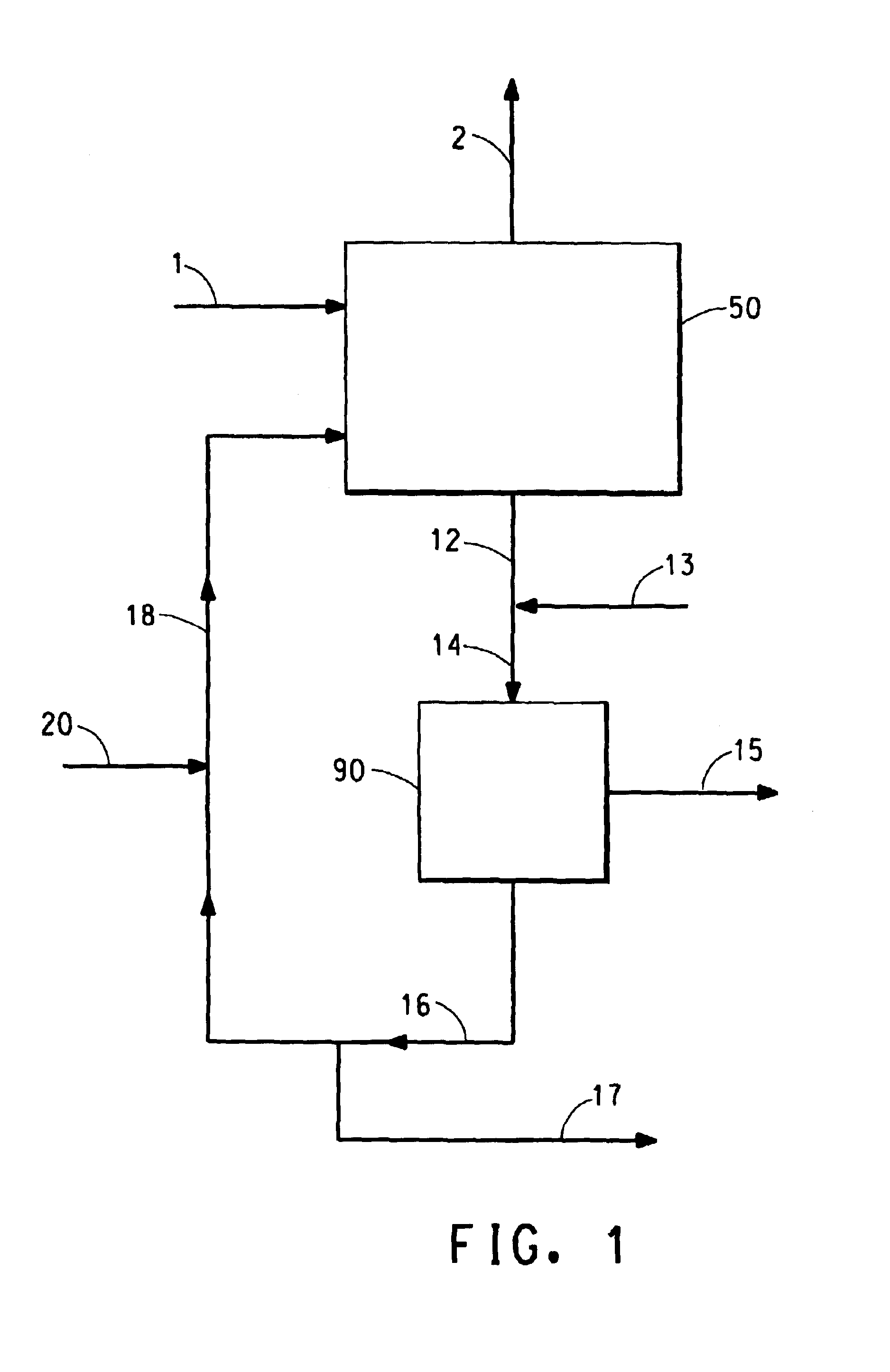

Method of forming a dianhydrosugar alcohol

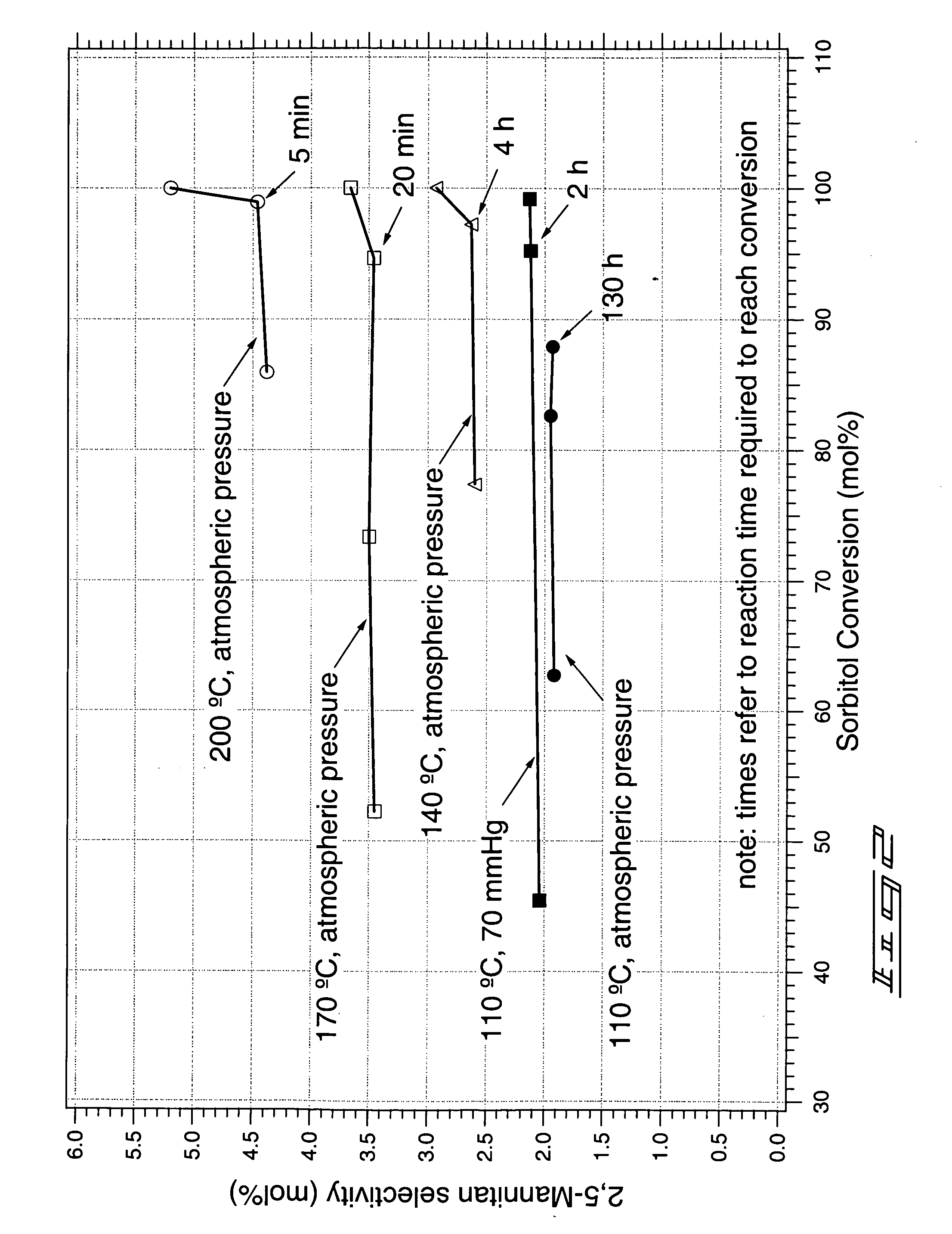

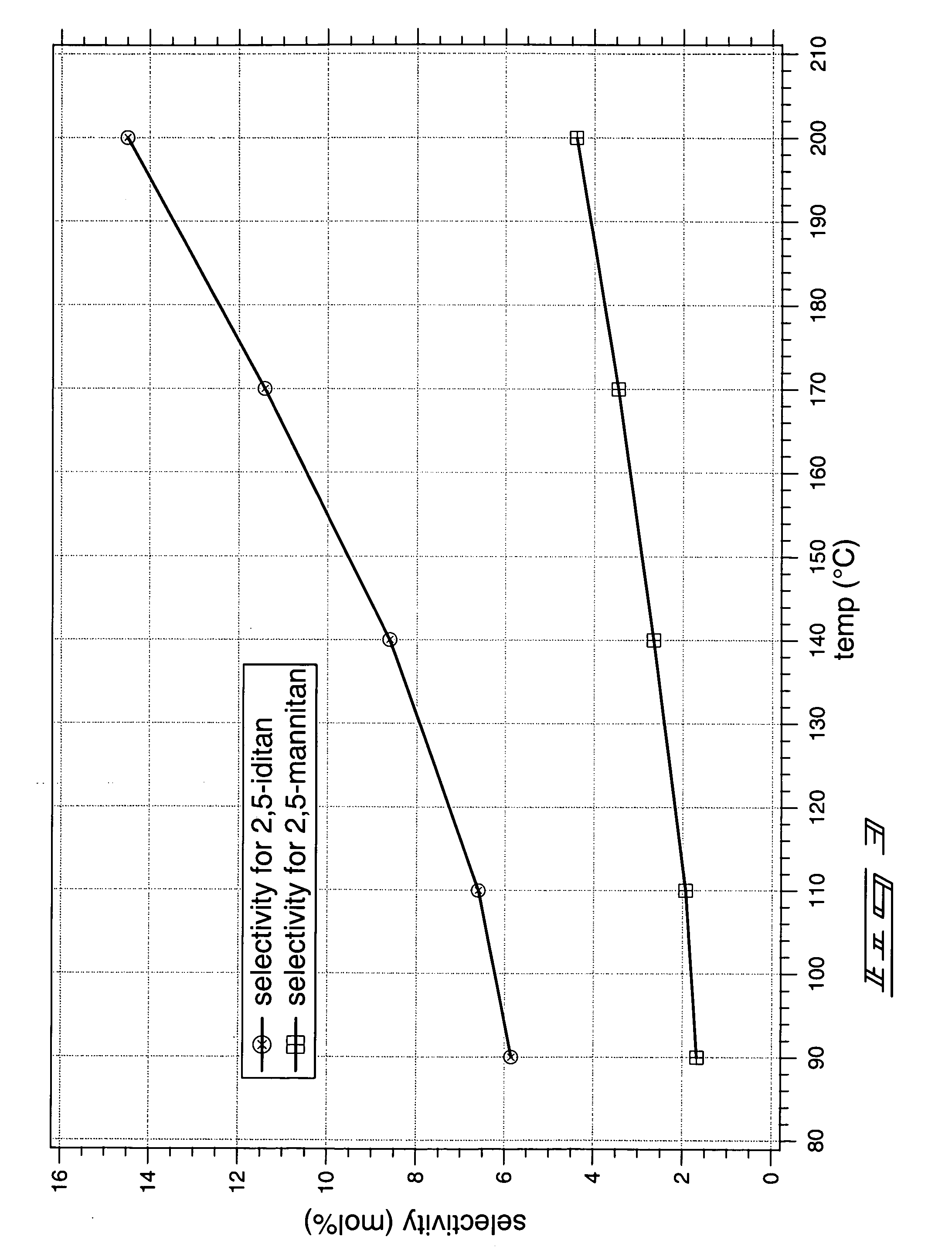

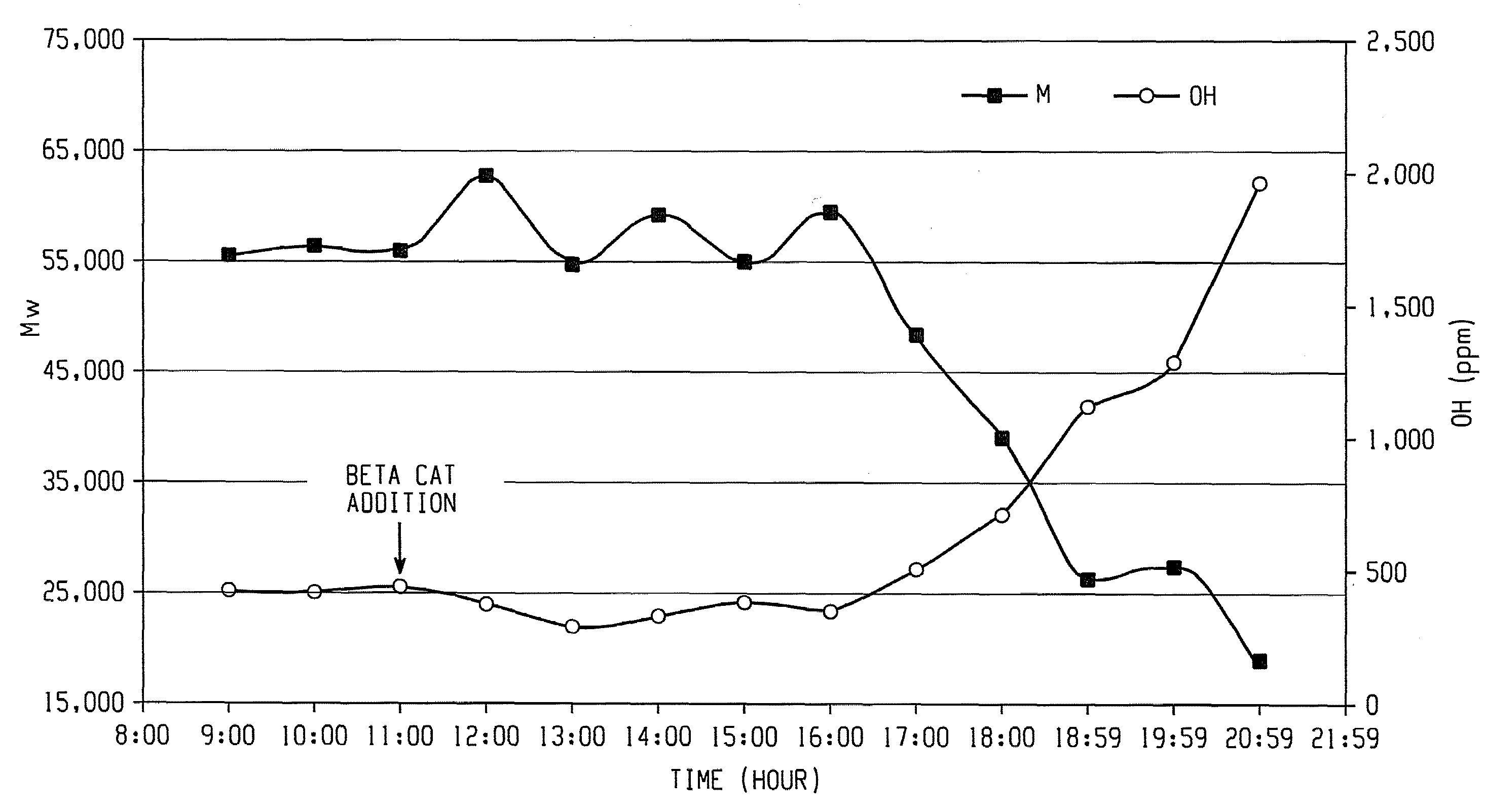

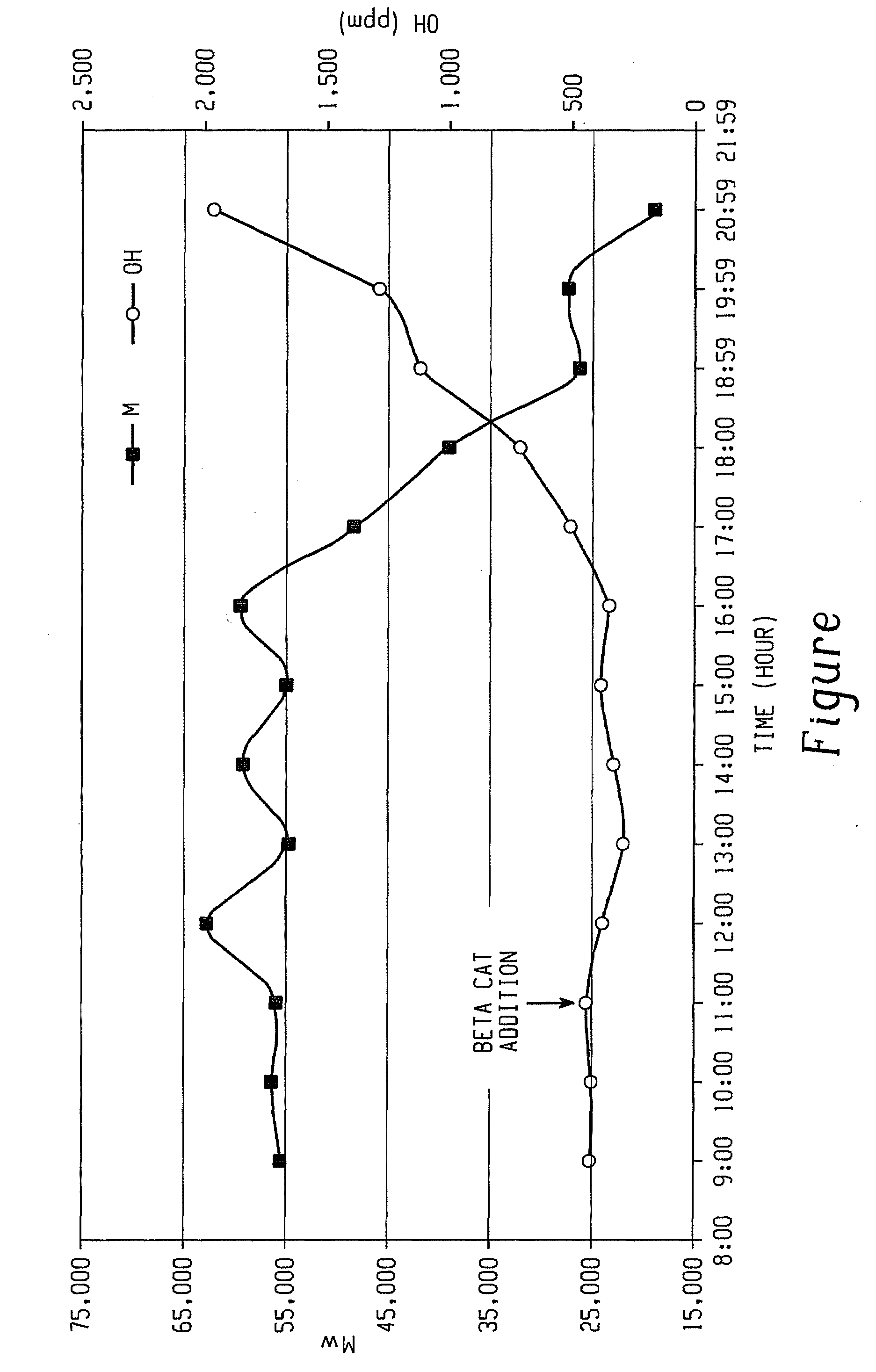

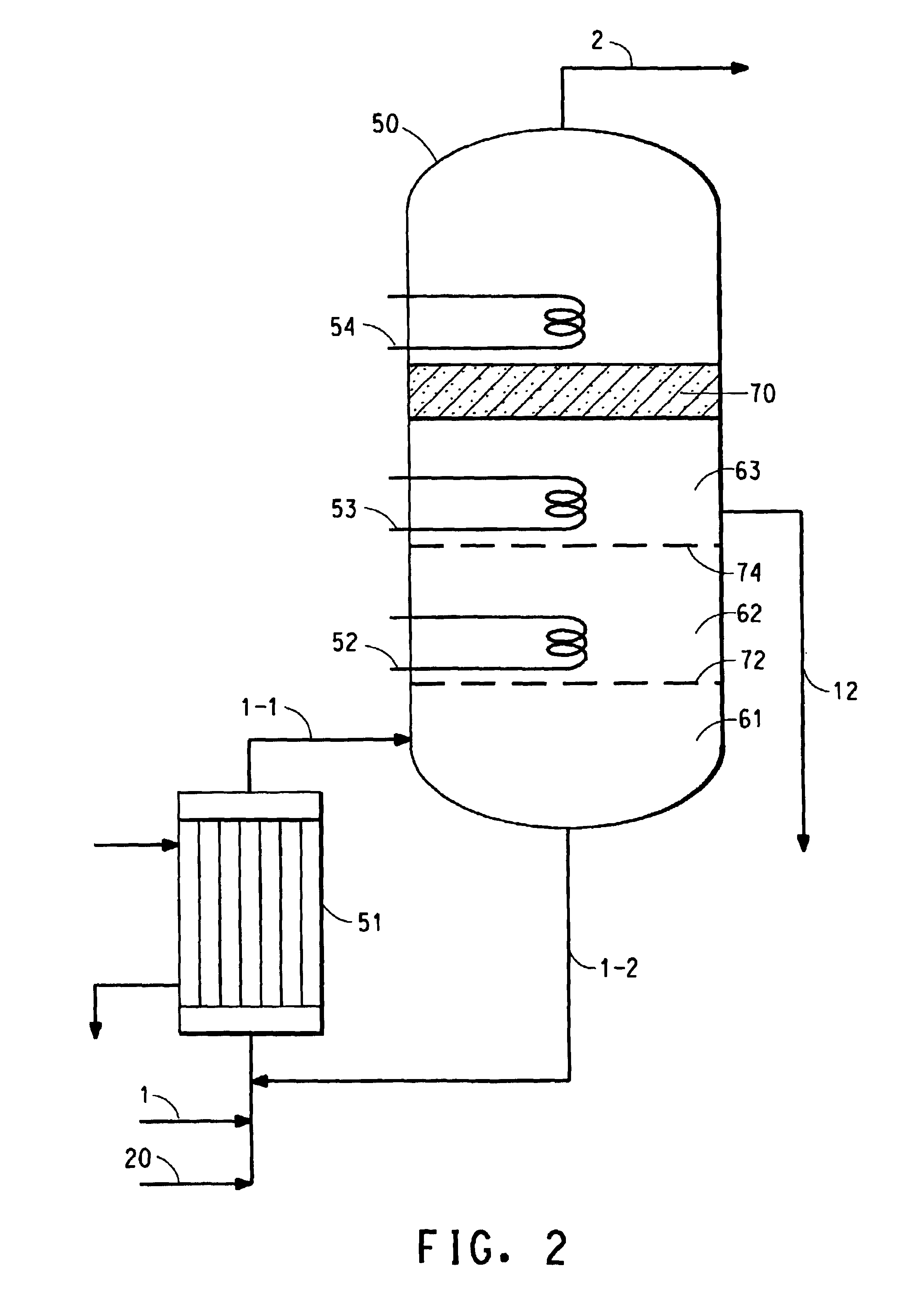

The invention includes methods of producing dianhydrosugars. A polyol is reacted in the presence of a first catalyst to form a monocyclic sugar. The monocyclic sugar is transferred to a second reactor where it is converted to a dianhydrosugar alcohol in the presence of a second catalyst. The invention includes a process of forming isosorbide. An initial reaction is conducted at a first temperature in the presence of a solid acid catalyst. The initial reaction involves reacting sorbitol to produce 1,4-sorbitan, 3,6-sorbitan, 2,5-mannitan and 2,5-iditan. Utilizing a second temperature, the 1,4-sorbitan and 3,6-sorbitan are converted to isosorbide. The invention includes a method of purifying isosorbide from a mixture containing isosorbide and at least one additional component. A first distillation removes a first portion of the isosorbide from the mixture. A second distillation is then conducted at a higher temperature to remove a second portion of isosorbide from the mixture.

Owner:BATTELLE MEMORIAL INST

Aliphatic diol-based polycarbonates, method of making, and articles formed therefrom

Owner:SABIC INNOVATIVE PLASTICS IPBV

Process to produce polyesters which incorporate isosorbide

The present invention provides a process to produce isosorbide-containing polyesters. The process allows for higher isosorbide incorporation than previously found while maintaining high polymeric molecular weights.

Owner:EI DU PONT DE NEMOURS & CO

Thermoset epoxy polymers from renewable resources

Novel thermoset epoxy polymers using the bisglycidyl ethers of anhydrosugars, such as isosorbide, isomannide, and isoidide, are disclosed. The bisglycidyl ethers are useful as substitutes for bisphenol A in the manufacture of thermoset epoxy ethers. The anhydrosugars are derived from renewable sources and the bisglycidyl ethers are not xenoestrogenic and the thermoset curing agents are likewise derived form renewable resources.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

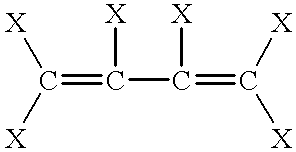

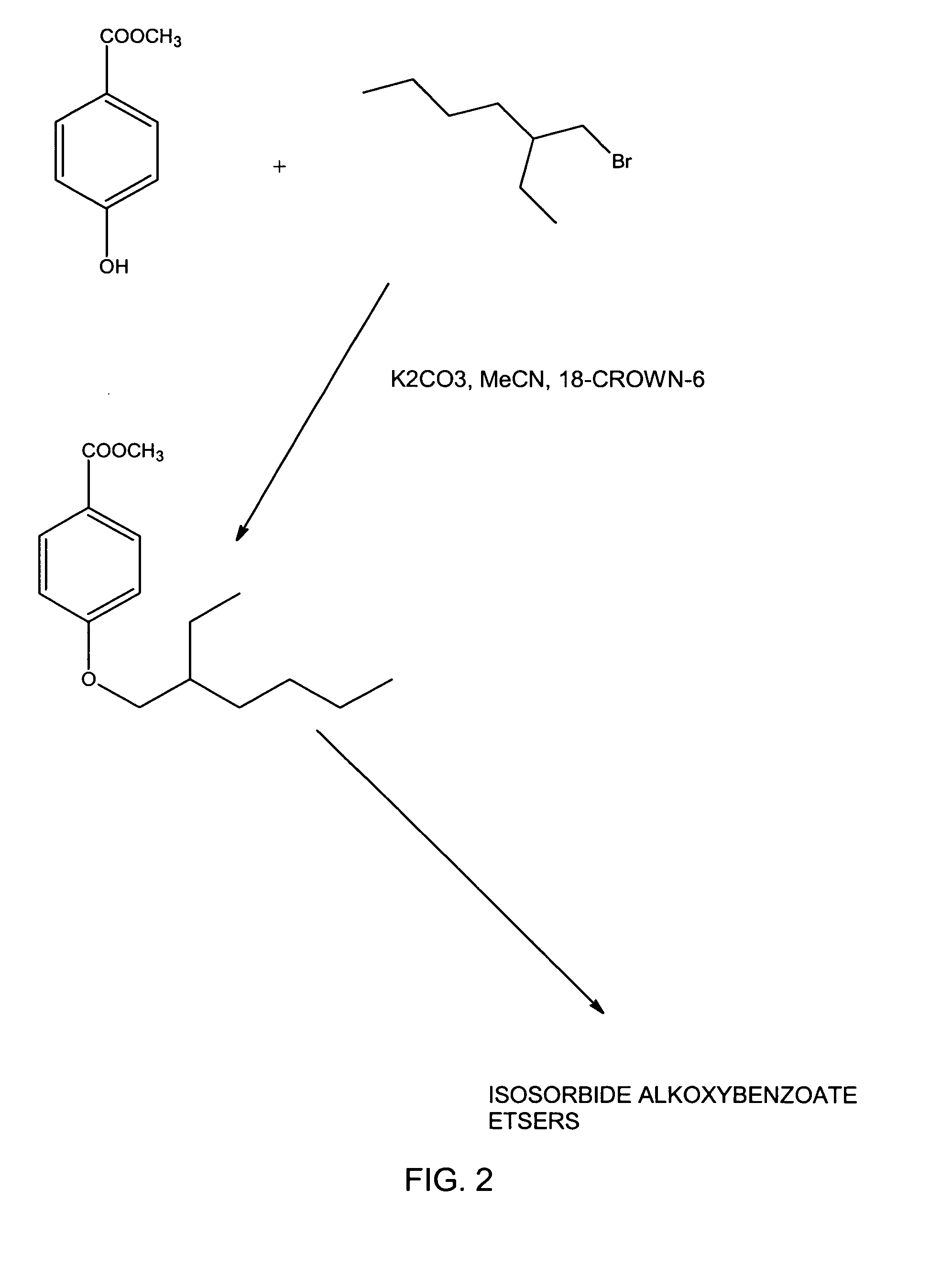

Ethers of bisanhydrohexitols

A novel method for the synthesis of ethers of anhydrosugars, such as isosorbide, isomannide, and isoidide, is disclosed. The bisglycidyl ethers are useful as substitutes for bisphenol A in the manufacture of thermoset epoxy ethers. Anhydrosugar ethers are derived from renewable sources and are not xenoestrogenic. Higher alkyl and aralkyl ethers are stable high-boiling oils that are good plasticizers for materials such as PVC.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Method for preparing isosorbide taking supported heteropoly acid as catalyst

InactiveCN101691376AHigh selectivityEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHeteropoly acidFixed bed

The invention discloses a method for preparing isosorbide by taking supported heteropoly acid as a catalyst. Sorbitol from a biological radical is used as a raw material to prepare the isosorbide directly through dehydration reaction. The method comprises the following steps: putting the catalyst into a constant temperature section of a fixed-bed reactor; introducing a reactant sorbitol solution into a reactor, and performing reaction through a catalyst bed after gasification; and separating a mixture obtained after the reaction to obtain the isosorbide. The method has simple operation process of the reaction, low production cost and light environmental pollution; the selectivity and yield of the isosorbide reaches up to 75.2 percent and 71.4 percent respectively, and the catalyst is easy to separate and recycle; and the method is a novel method which meets industrial demands and has strong practicality.

Owner:NANJING UNIV OF TECH

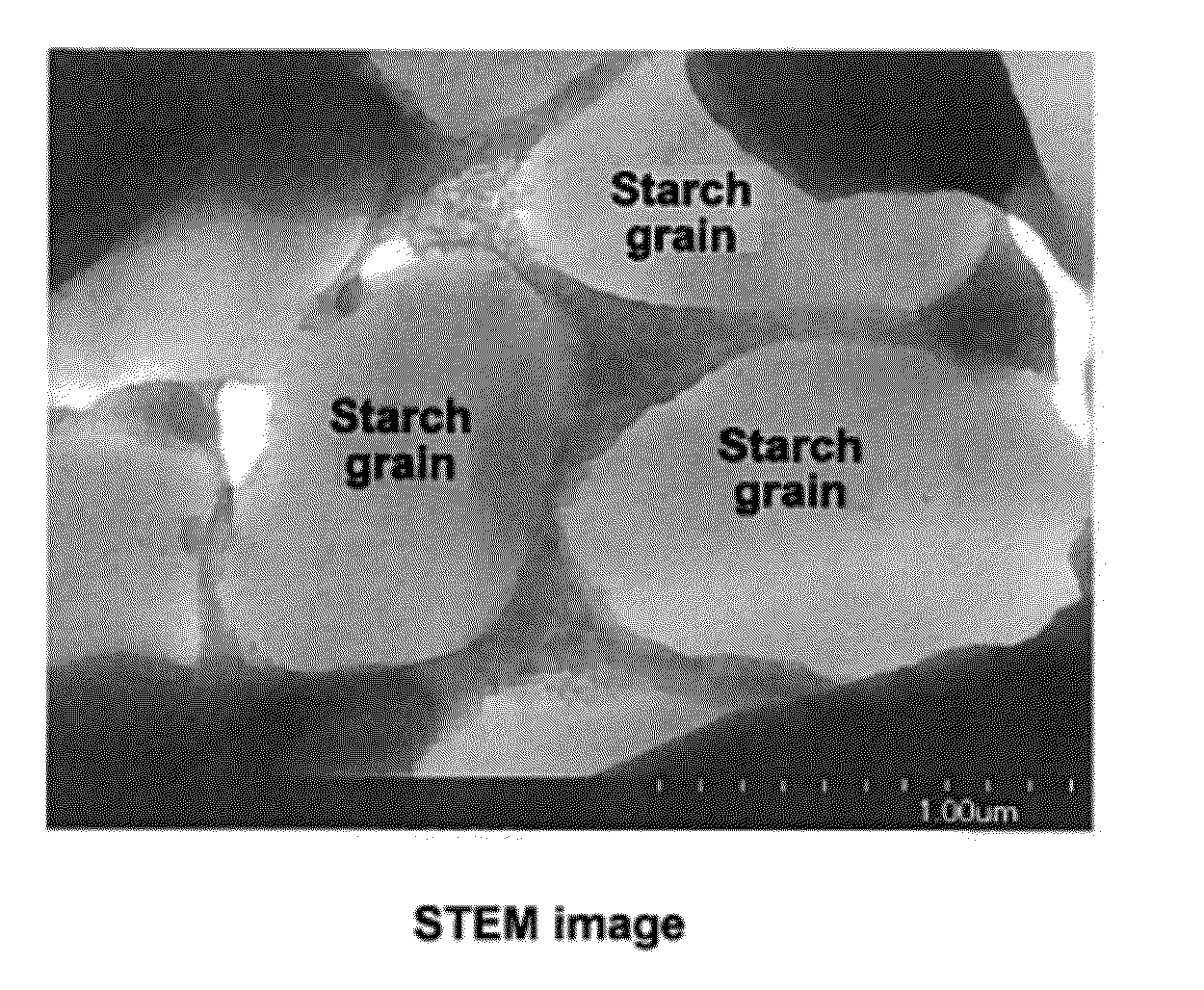

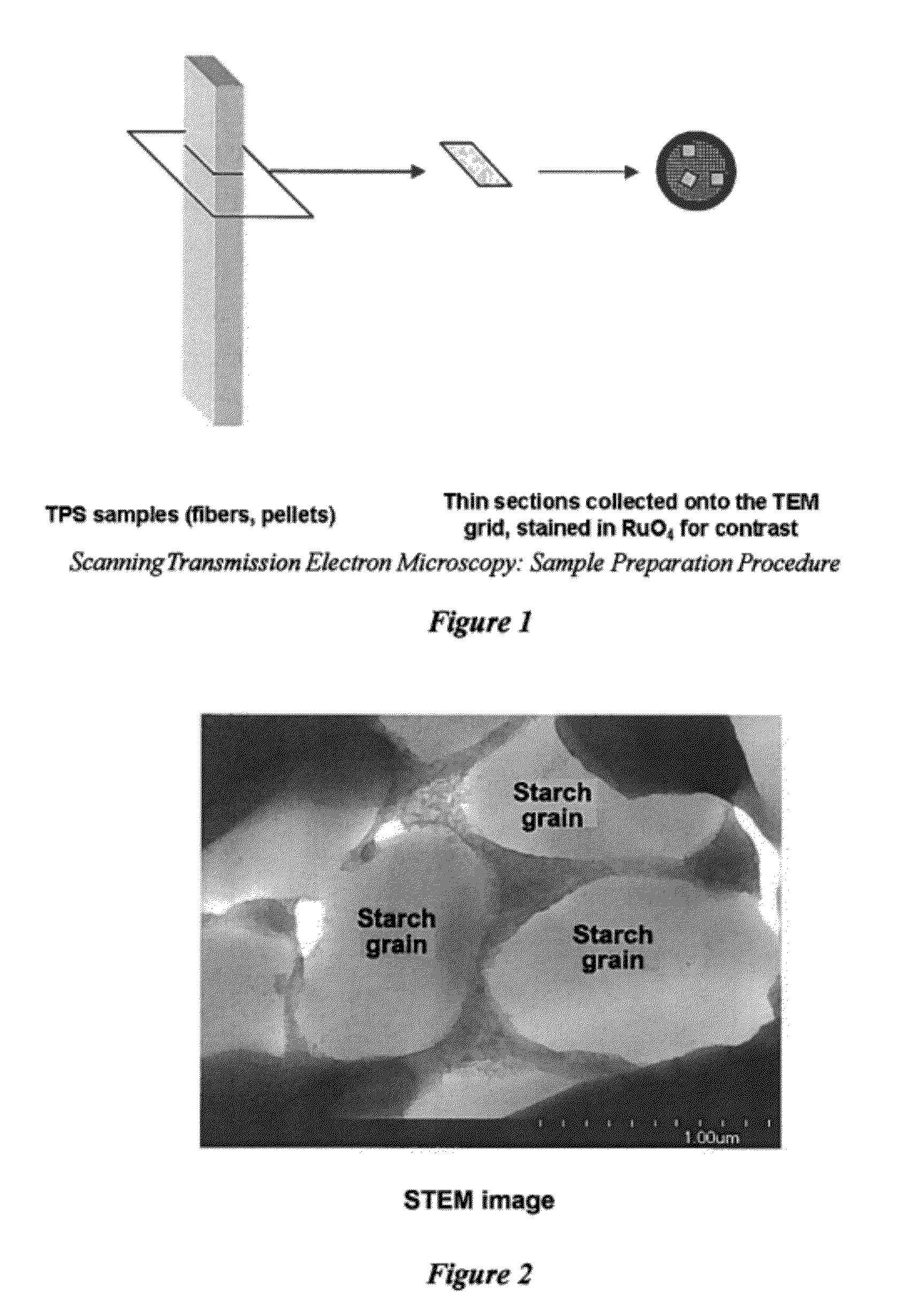

Isosorbide-Plasticized Starch And Uses Thereof

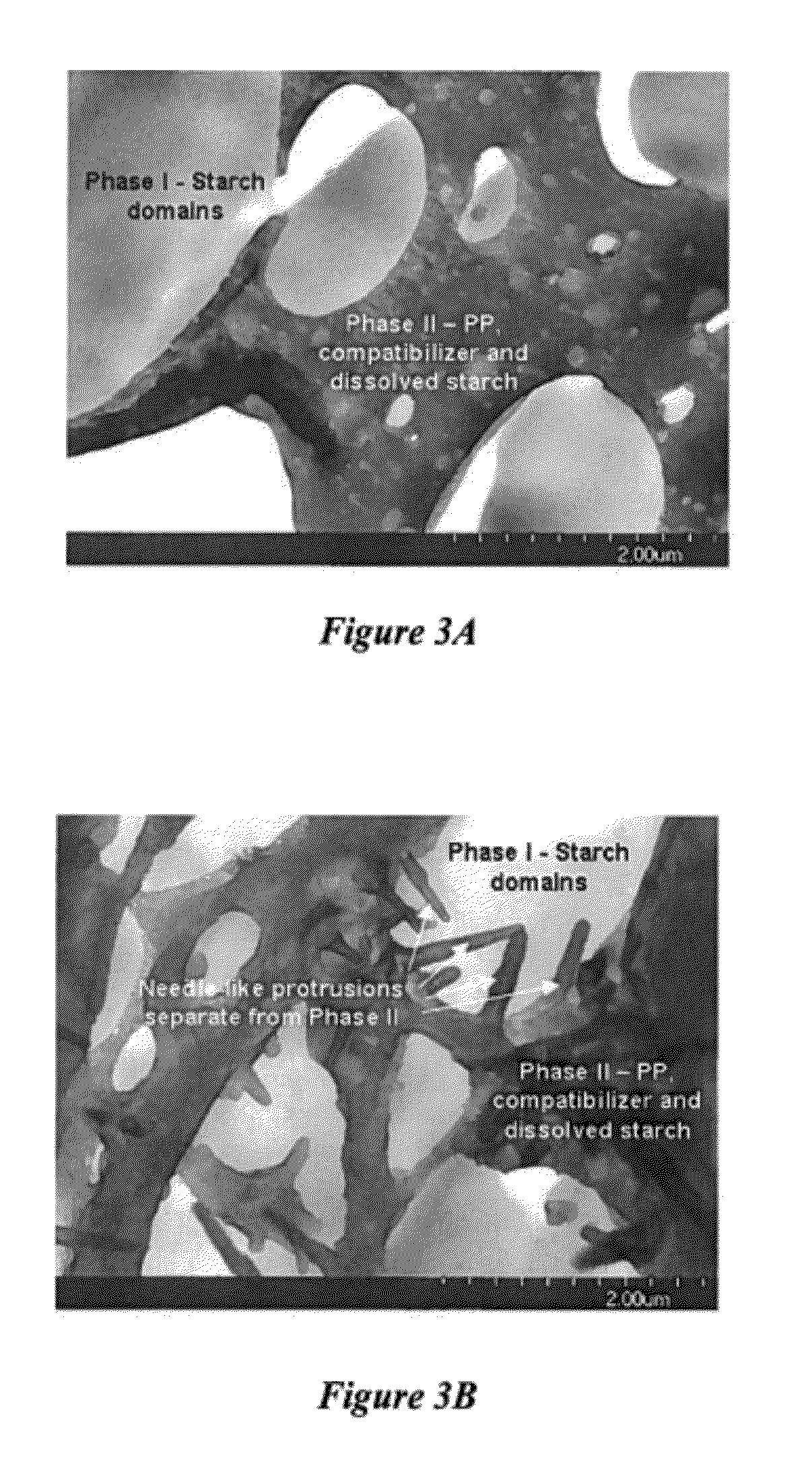

InactiveUS20120178858A1Thermal degradationImprove thermal stabilityNon-macromolecular adhesive additivesPaper coatingPolyolefinIsosorbide

Starch plasticized, wholly or in part, with isosorbide, isomannide, isoidide, or a mixture thereof is disclosed. Blends of the plasticized starch and a synthetic polymer, like a polyolefin, also are disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

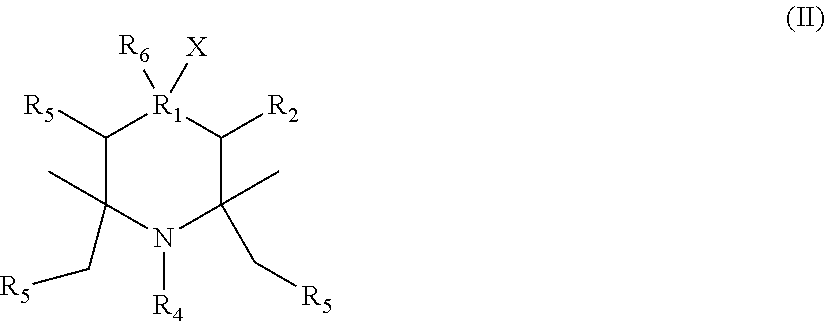

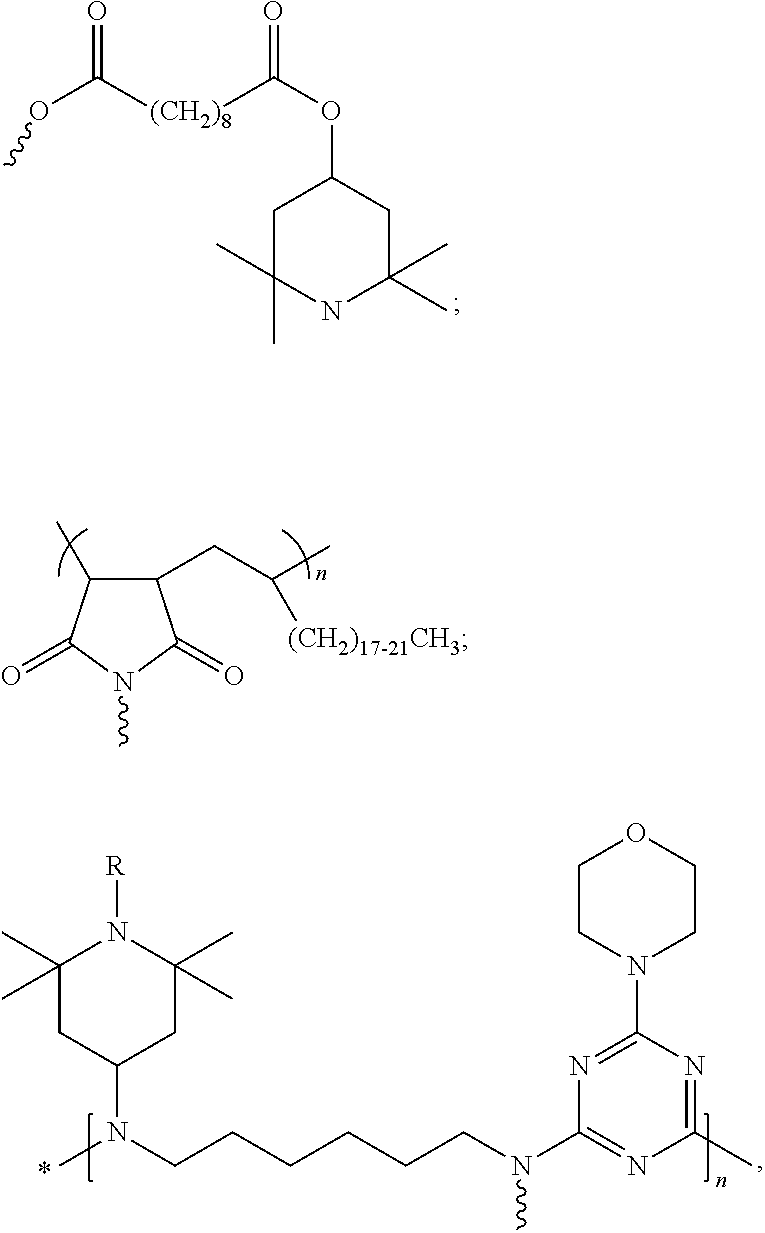

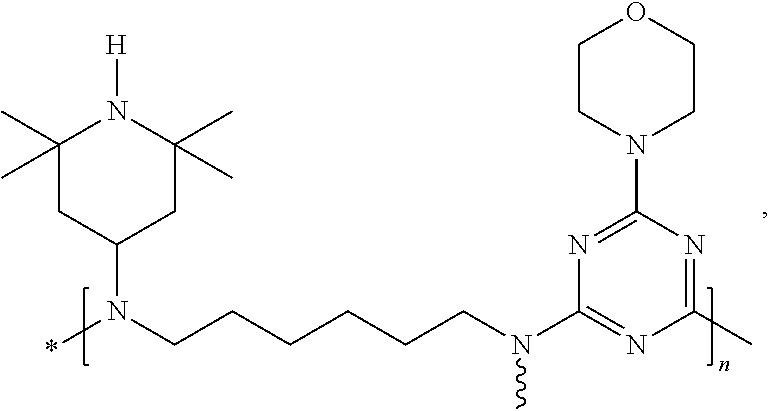

UV Stabilization of Isosorbide Polycarbonates

ActiveUS20120184651A1Ceramic shaping apparatusLiquid carbonaceous fuelsPolymer scienceHindered amine light stabilizers

Provided herein are polymeric compositions that are suitable protected from UV-induced discoloration and degradation. Such resins comprise an isosorbide polymer and one or more hindered amines. These resin compositions are useful in the manufacture of various shaped, formed and / or molded articles.

Owner:SHPP GLOBAL TECH BV

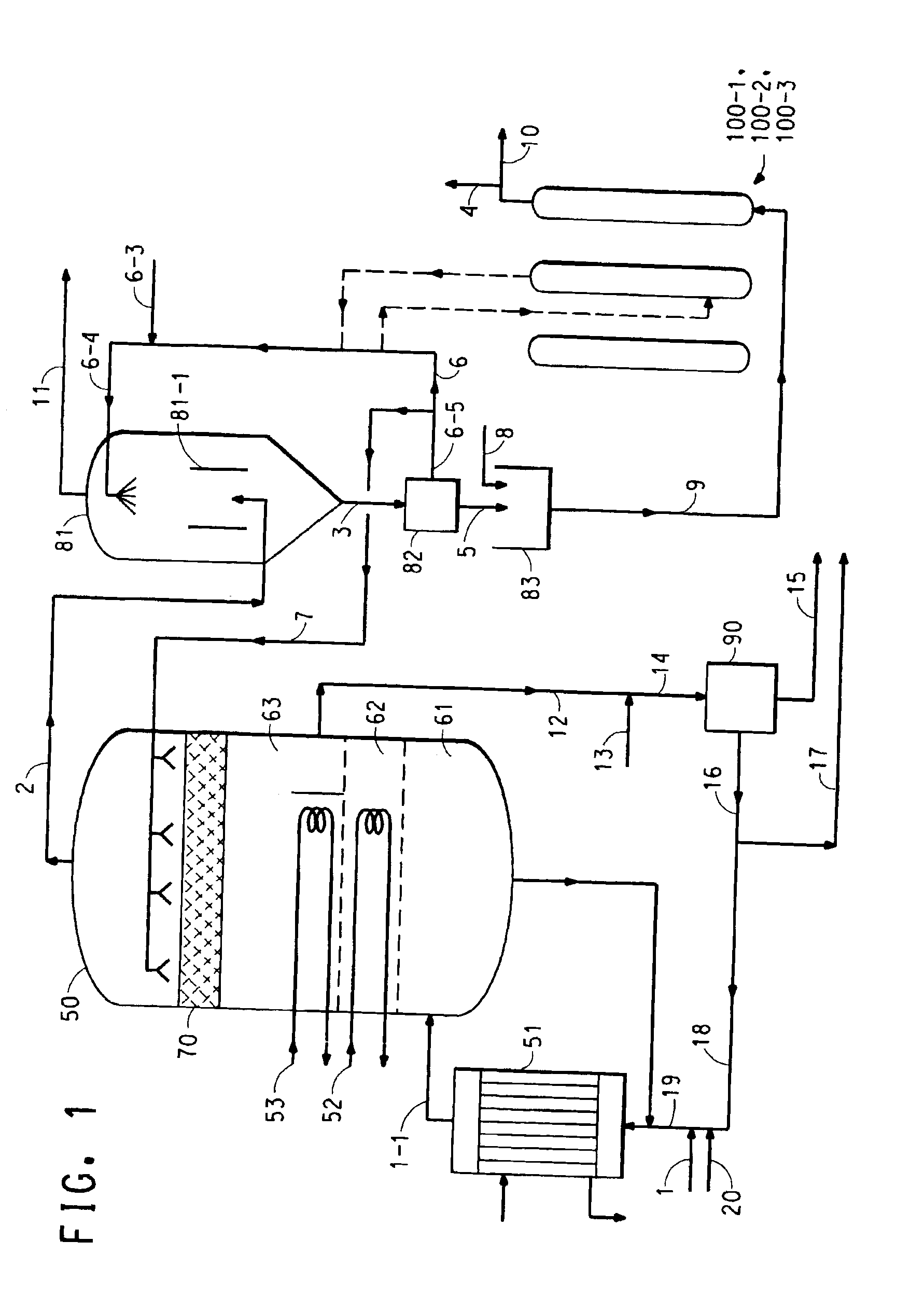

Integrated continuous process for anhydro sugar alcohol manufacture

Owner:EI DU PONT DE NEMOURS & CO

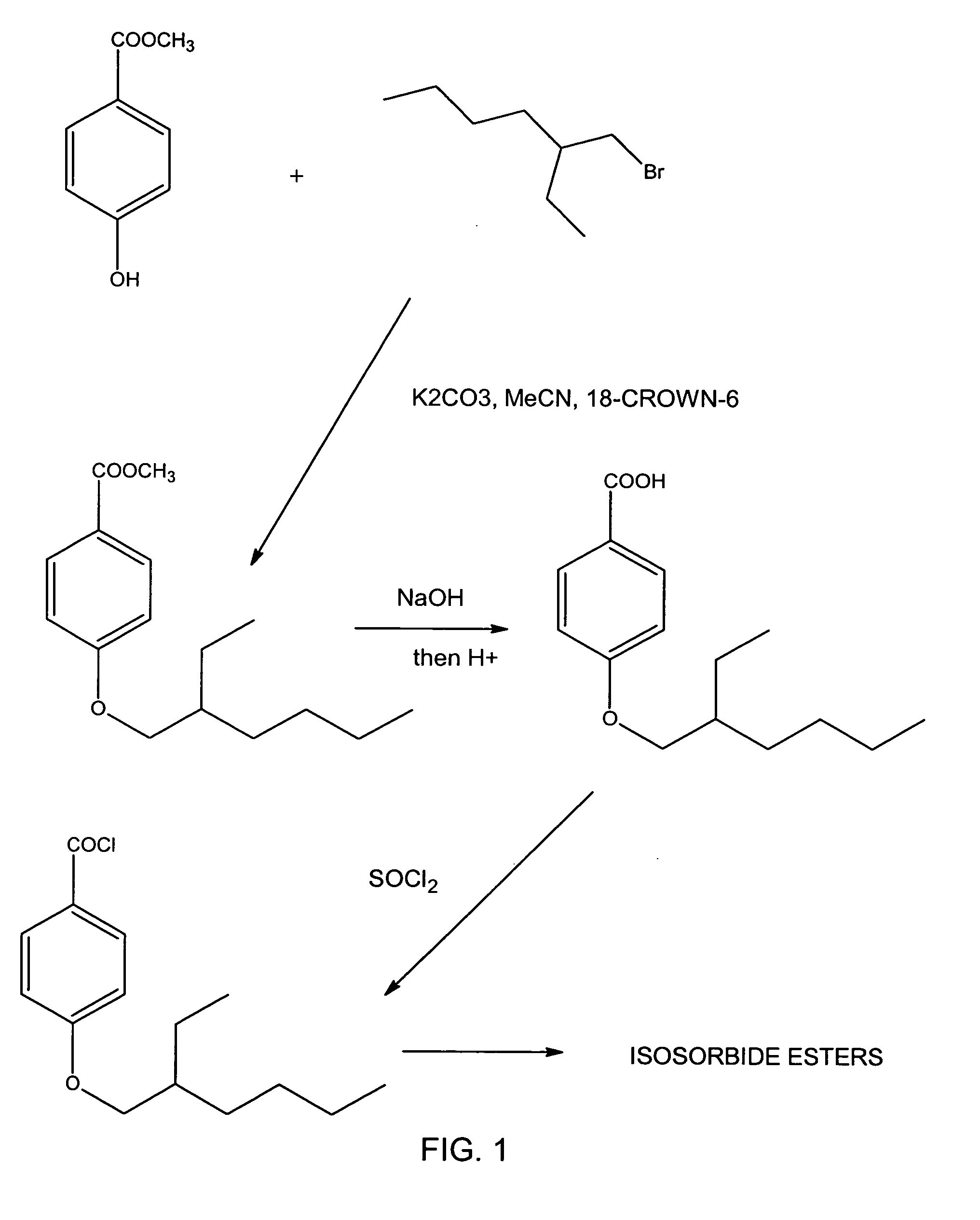

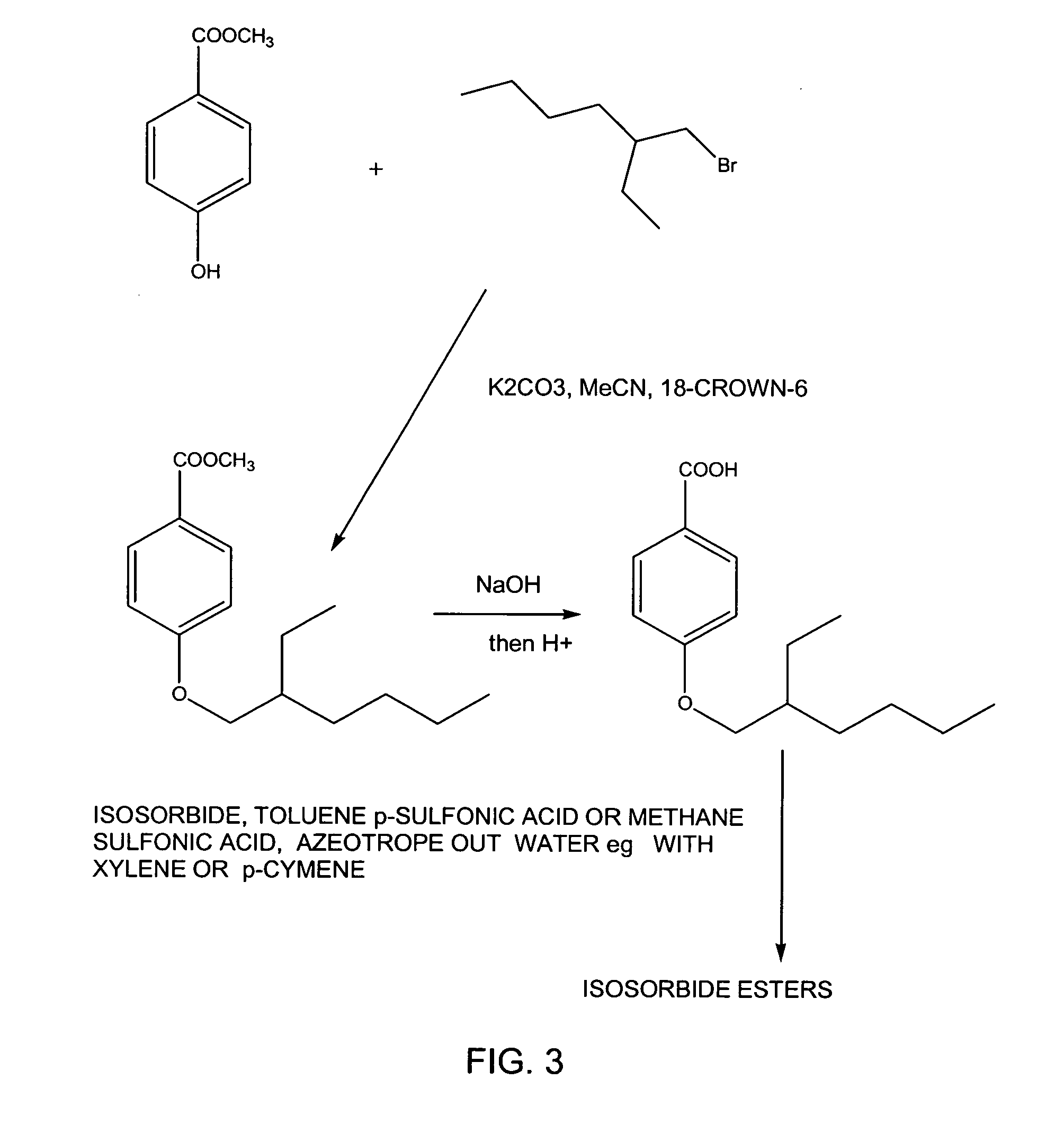

Esters of anhydrosugar alcohols as plasticizers

InactiveUS20070282042A1Organic compound preparationCarboxylic acid esters preparationAlcoholPlasticizer

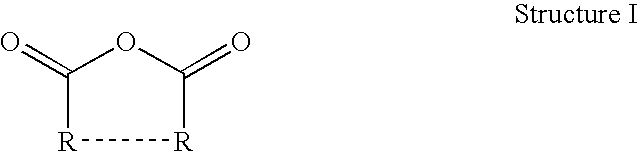

The invention consists of esters of anhydrosugar alcohols useful as plasticizers for polymeric compounds. Specifically, esters are formed of bis-anhydrohexitols, such as isosorbide, isomannide and isosiditide, and used as substitutes for the phthalate-based plasticizers in common use. The bis-anhydrohexitols are preferably produced from biological sources.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Preparation technique of isosorbide

The invention relates to a preparation technique of isosorbide, belonging to the technical field of pharmacy. In the preparation technique, solid sorbitol is used as the raw material, a mixture of perfluoro-sulfonic acid resin and palladium on carbon is used as the catalyst, and hydrogen is used as an anti-carbonation agent to prepare the non-carbonized light-colored isosorbide reaction liquid; and low-temperature concentration and solvent crystallization are utilized to substitute the original high-temperature distillation. The preparation technique comprises the following steps: dehydration reaction, neutralization decolorization, electrodialysis desalination, water removal by concentration, extraction crystallization, freeze-drying, and quality inspection and packaging (after the product is qualified in inspection, packaging, and warehousing as the finished product). The invention can prevent carbonization and prevent the reaction liquid from becoming dark, thereby enhancing the utilization ratio of the raw material; most calcium salts are precipitated due to low solubility, and the electric conductivity of the reaction liquid is low, thereby being beneficial to subsequent extraction; and the invention overcomes the defect of high energy consumption in the high-temperature distillation technique, and the quality of the prepared isosorbide is more excellent.

Owner:SHANDONG FUTASTE

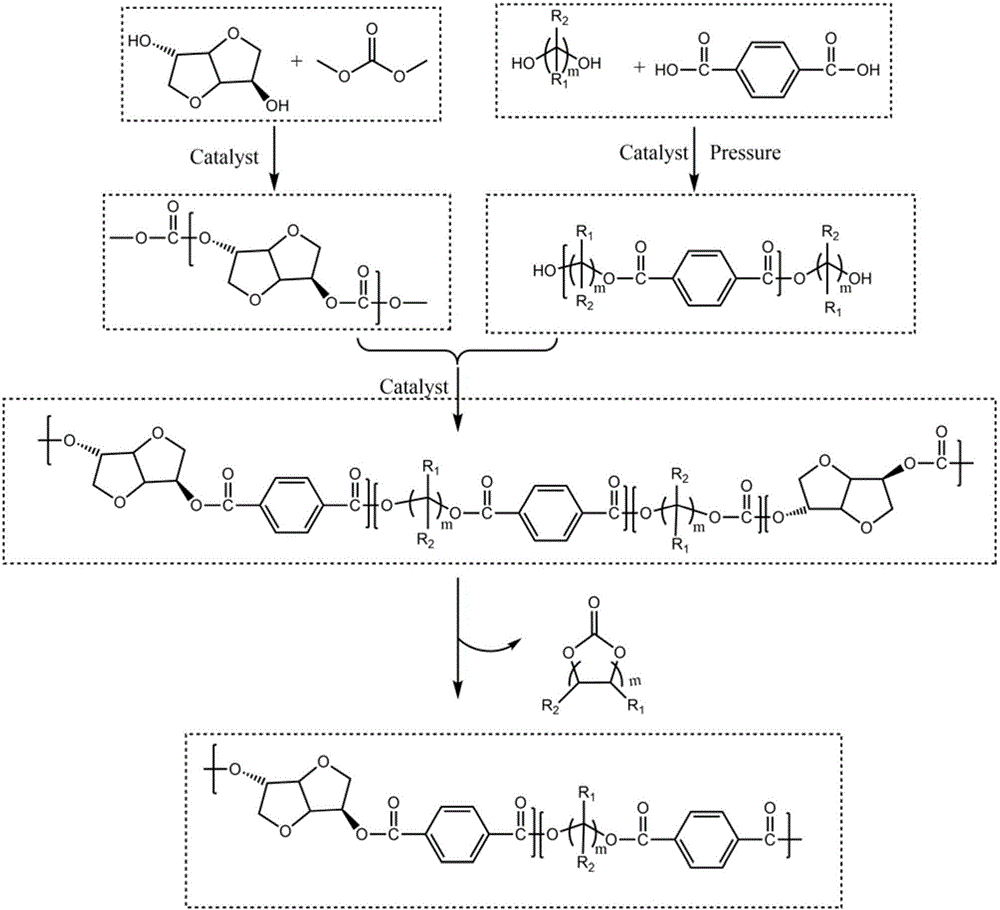

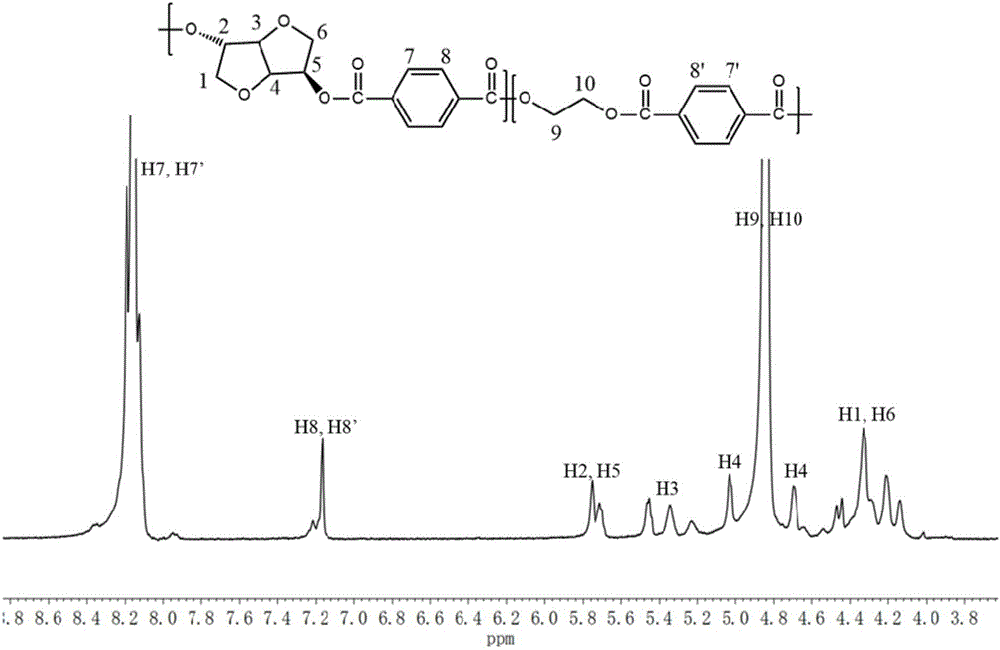

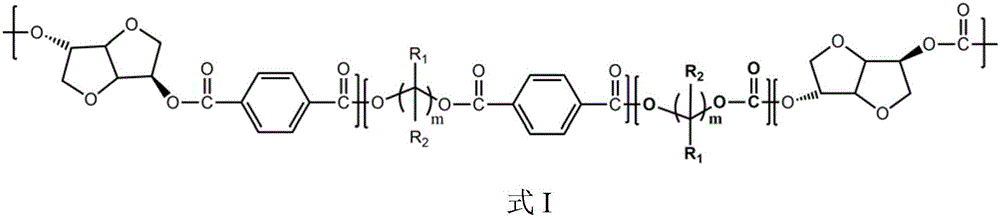

Preparation method of high heat resistance isosorbide type random copolyester

ActiveCN106800643AImprove heat resistanceOvercoming the problem of low reactivityFiberPolymer science

The invention relates to a preparation method of high heat resistance isosorbide type random copolyester. As for the high heat resistance isosorbide type random copolyester, by controlling the feed molar ratio of a monomer, a short-chain alkyl carbonate structure is constructed between aromatic dibasic acid and isosorbide, and then cyclic allyl ester carbonate is removed under a certain condition to realize linkage of the aromatic dibasic acid and an isosorbide structure unit. The prepared isosorbide type random copolyester has high glass transition temperature which decides that the high heat resistance isosorbide type random copolyester has good heat resistance and is low in preparation cost and environment-friendly in preparation process. The random copolyester has the viscosity being 0.6-1.0dL / g and the glass transition temperature being 90-190 DEG C, is excellent in comprehensive performance and can be used for preparing polymer blends, polymer alloy, heat resistant vessels, bottles, films, fibers, sheets, optical products and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High yield byproduct recycle process for anhydro sugar alcohols

A process for recycling reaction byproducts in the manufacture of dianhydro sugar alcohols, such as isosorbide, from corresponding sugar alcohols.

Owner:EI DU PONT DE NEMOURS & CO

Waterborne polyurethane emulsion and preparation method thereof

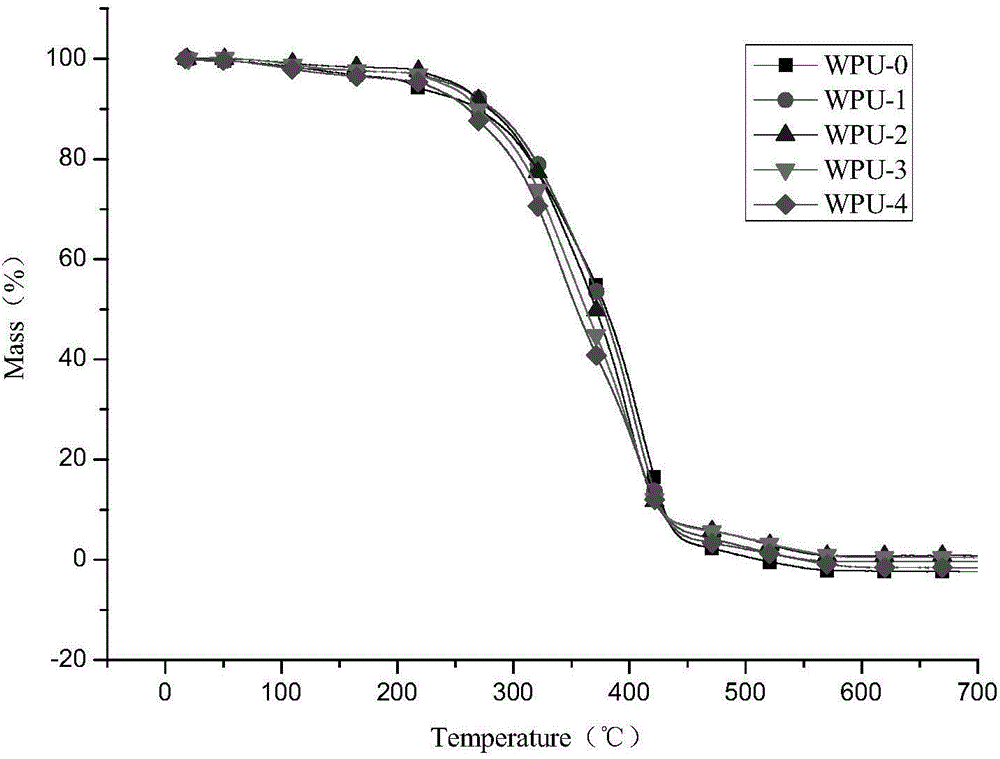

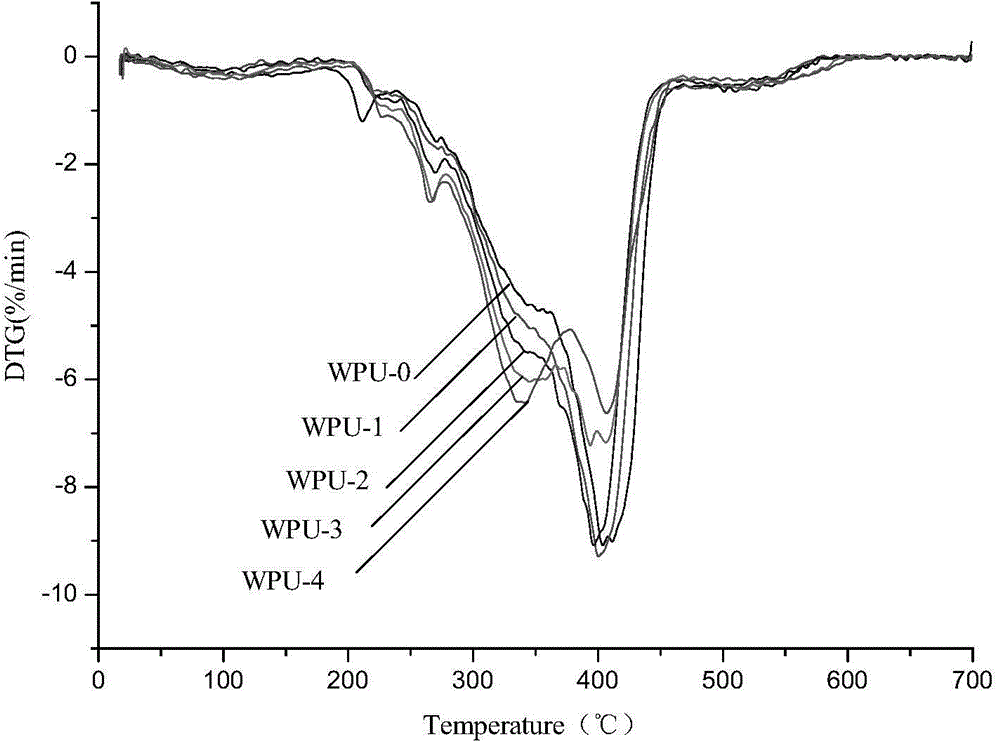

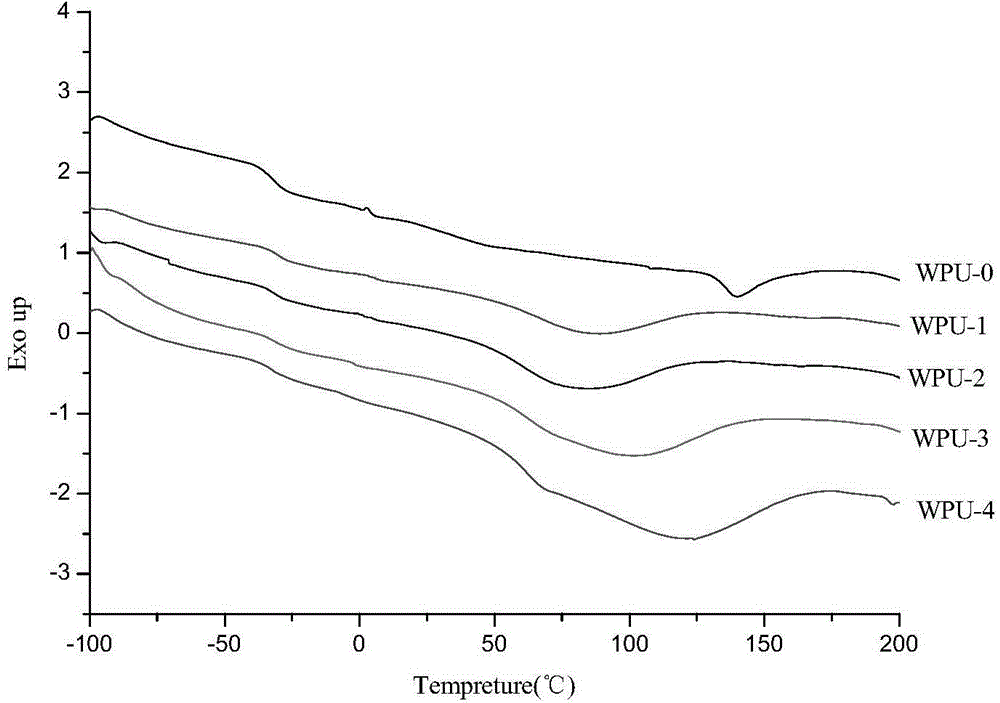

InactiveCN104974327AImprove performanceKeep hydrophilicPolyurea/polyurethane coatingsLeather surface finishingPolymer scienceEmulsion

The invention discloses a waterborne polyurethane emulsion and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out vacuum dehydration on polymer polyol, a hydrophilic chain extender, isosorbide and N-methyl pyrrolidone at 90 DEG C for 1-2 hours, reducing the temperature to 80-90 DEG C, adding diisocyanate and reacting for 2.5-3 hours until NCO% reaches the theoretical value; then reducing the temperature, adding a neutralizer to an NCO-terminated polyurethane prepolymer and reacting at 60 DEG C for 0.5 hour until the neutralization degree is 95-100%; finally dispersing the polyurethane prepolymer containing isosorbide into deionized water under the high-speed shearing action of an agitator and dropwise adding a mixture of diamine and water after dispersing for a period of time, thus obtaining the waterborne polyurethane emulsion. Isosorbide is successfully introduced into the waterborne polyurethane emulsion, thus obviously improving the glossiness of waterborne polyurethane films.

Owner:JINCHUANGJING NEW MATERIAL TECH SHANGHAI

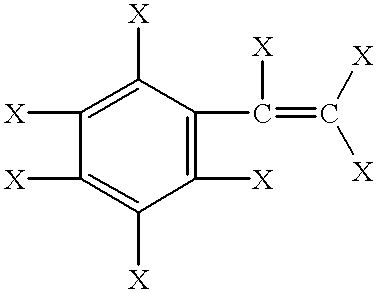

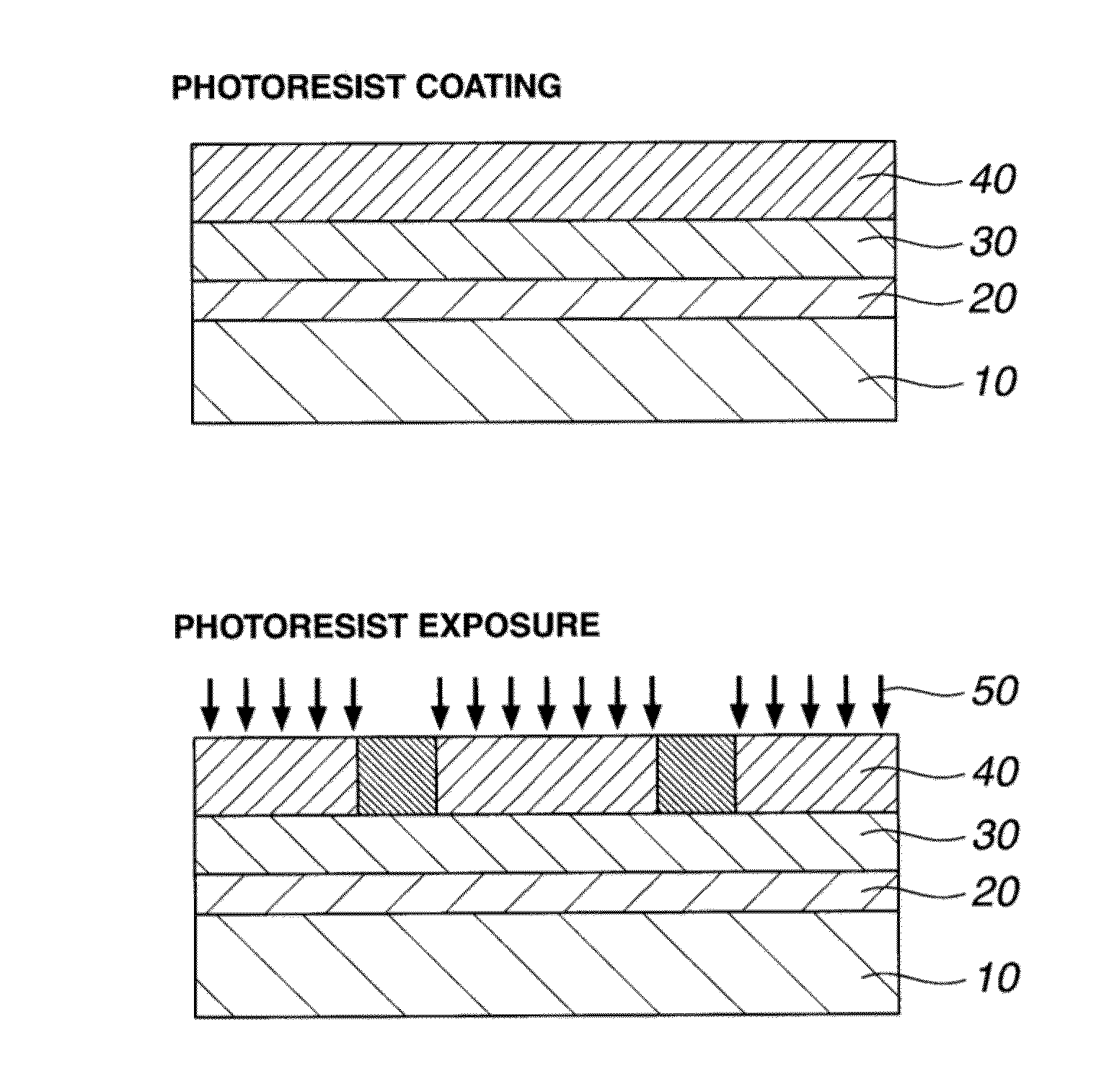

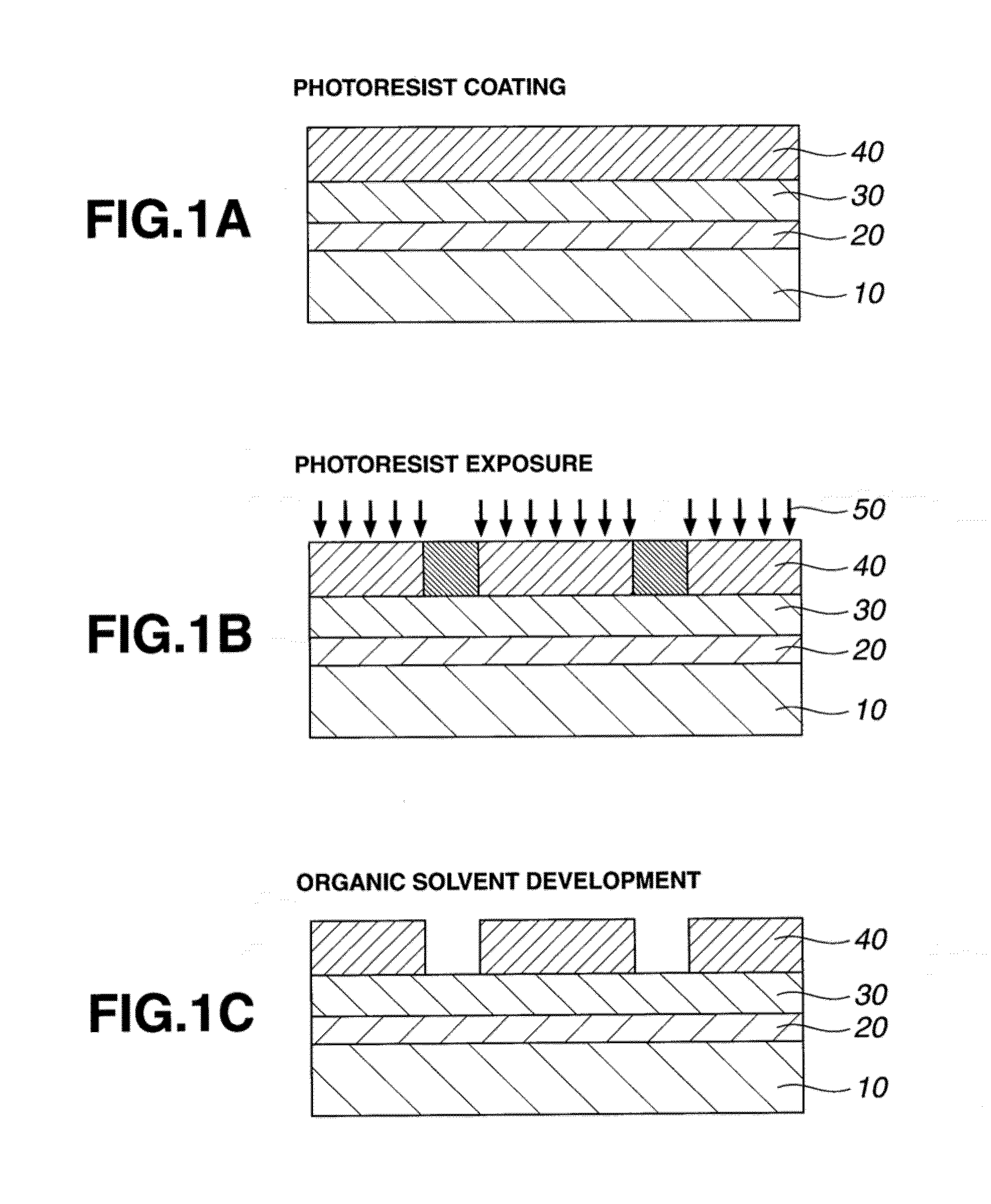

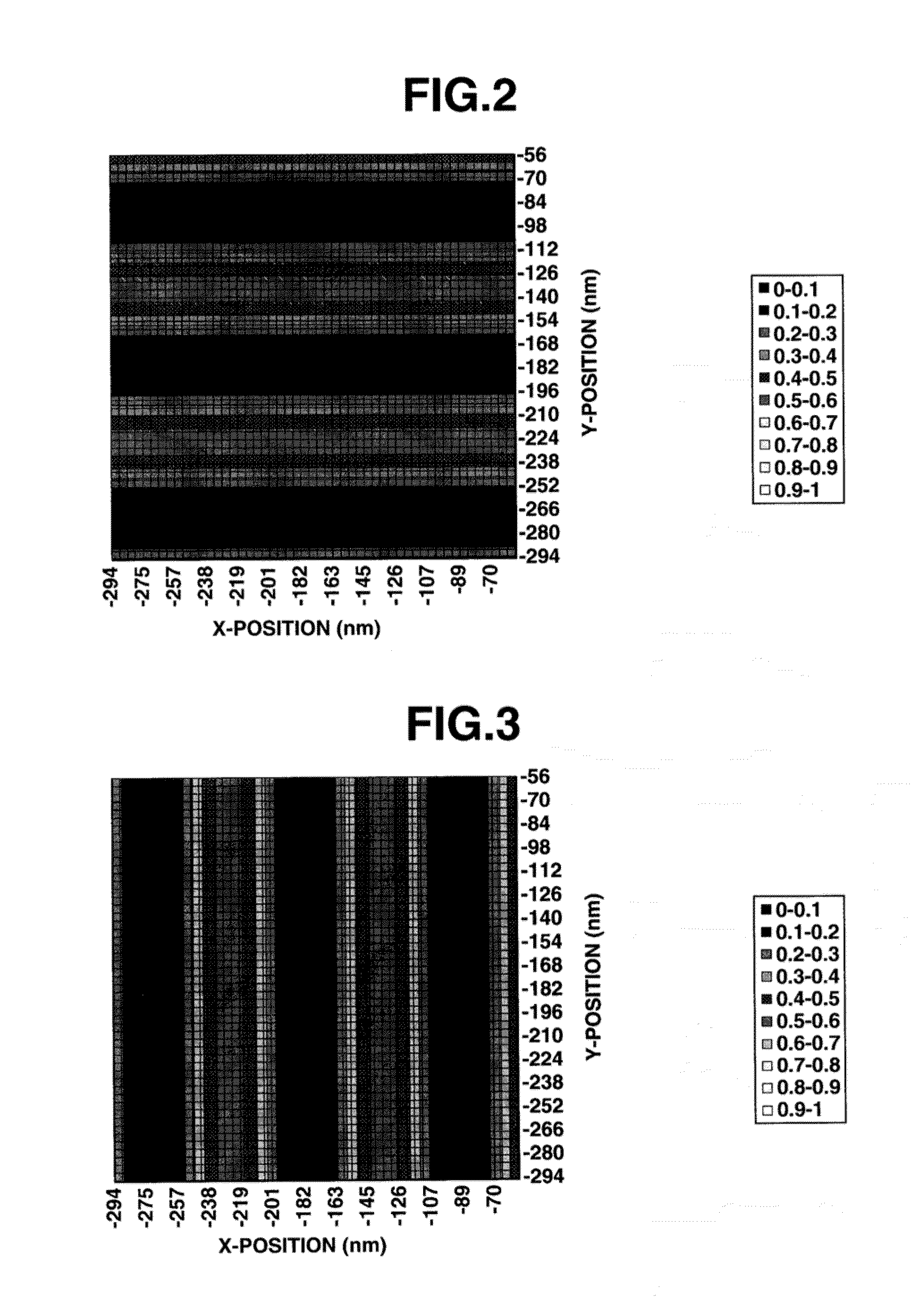

Patterning process and resist composition

ActiveUS20130017492A1High dissolution contrastGood size controlPhotosensitive materialsElectric discharge tubesResistOrganic solvent

An image is formed via positive / negative reversal on organic solvent development using a photoresist film comprising a polymer comprising recurring units of isosorbide (meth)acrylate in which one hydroxyl group of isosorbide is bonded to form (meth)acrylate and the other hydroxyl group is substituted with an acid labile group and an acid generator. The resist film is characterized by a high dissolution contrast between the unexposed and exposed regions. The photoresist film is exposed to radiation and developed in an organic solvent to form a fine hole pattern with good size control and high sensitivity.

Owner:SHIN ETSU CHEM IND CO LTD

Polyesters including isosorbide as a comonomer and methods for making same

This invention relates to an isotropic polyester polymer and method for making the polyester is prepared by (1) combining in a reactor a monomer containing a terephthaloyl moiety; optionally, one or more other monomers containing an aromatic diacid moiety; a monomer comprising an ethylene glycol moiety; a monomer containing an isosorbide moiety; optionally, one or more other monomers containing a diol moiety; and optionally, a monomer containing a diethylene glycol moiety; with a condensation catalyst suitable for condensing aromatic diacids and glycols; and (2) heating the monomers and catalyst to polymerize the monomers to yield a polyester having an inherent viscosity of at least about 0.35 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

Formulations comprising isosorbide-modified unsaturated polyester resins and low profile additives which produce low shrinkage matrices

InactiveUS20110040004A1High strengthAlkaline-earth metal silicatesFibre treatmentPolymer scienceFiber-reinforced composite

Formulations comprising an isosorbide-modified unsaturated polyester comprising maleic acid, fumaric acid, itaconic acid or maleic anhydride and isosorbide and one or more low profile additives. The formulations exhibit better shrink control in molding compound formulations with standard low profile additives than their non-isosorbide-modified analogues. These isosorbide-modified unsaturated polyester resins may be applied in molding compounds like sheet molding compounds or bulk molding compounds and may be components of fiber reinforced composites or other composite materials.

Owner:INEOS COMPOSITES IP LLC

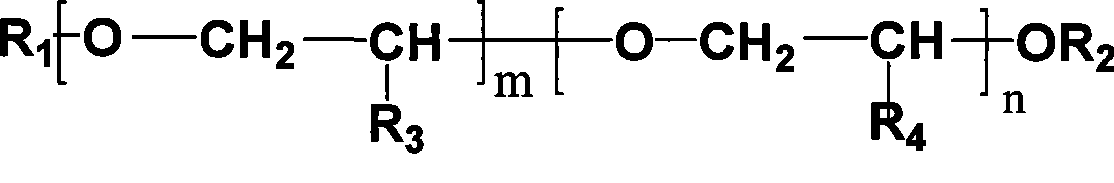

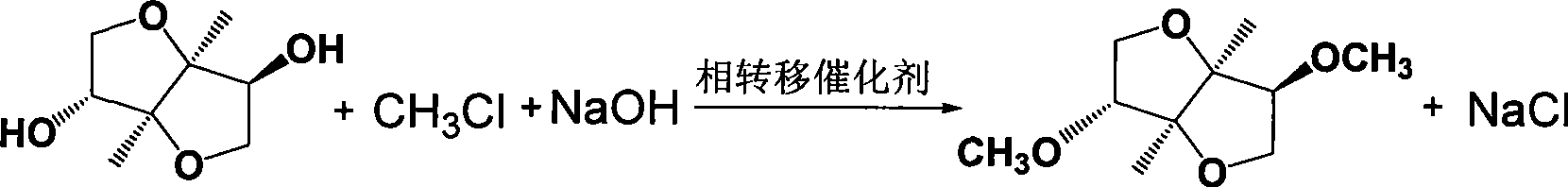

Method for synthesizing isosorbide dimethyl ether

ActiveCN101445508ANo pollution in the processAchieving zero emissionsOrganic chemistryHydrogenHydrogen atom

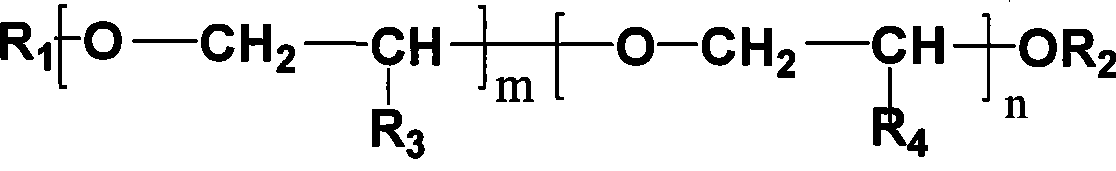

A method for synthesizing isosorbide dimethyl ether comprises the following steps: (1) adding solvent, isosorbide, alkali and phase transfer catalyst in a reaction vessel; (2) stirring and raising the temperature to 80 to 100 DEG C, reducing the pressure until the gauge pressure is minus 0.095 MPa, and dewatering; (3) leading into chloromethane under the condition of the phase transfer catalyst, and complete the etherification reaction with the pressure 0.1 to 1.0 MPa and the temperature 50 to 90 DEG C; (4) carrying out acid neutralization; (5) filtering and desalting; (6) and carrying out reduced pressure distillation, and collecting fraction with the temperature of 92 to 93 DEG C to get isosorbide dimethyl ether and recovering the solvent. The solvent adopts low molecular polyether with alkyl sealing the ends, in the formulae, R1 and R2 are hydrogen atoms or alkyl; the adopted alkyl comprises 1 to 15 carbon atoms; R3 and R4 are hydrogen atoms or methyl, or other lower alkyl; and m plus n is an integer between 4 to 15. The invention realizes zero discharge, reduces cost and increases production efficiency.

Owner:南京威尔药业科技有限公司

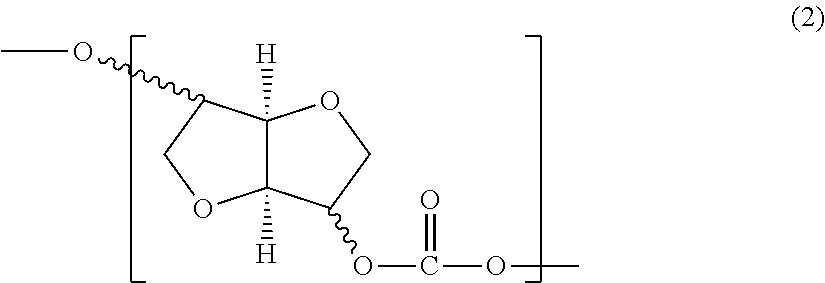

Isosorbide-based polycarbonates, method of making, and articles formed therefrom

Disclosed herein is a polycarbonate polymer comprising: an isosorbide unit, a polysiloxane unit, and an aliphatic unit different from the isosorbide unit, wherein the isosorbide unit, polysiloxane unit, and aliphatic unit are each carbonate, or a combination of carbonate and ester units, the aliphatic unit different from the isosorbide unit is derived from an aliphatic oligomeric polyester polyol having a molecular weight of 900 to 4000, and the calculated bio-content is greater than or equal to 40 weight percent, based on the total weight of the polycarbonate polymer.

Owner:SHPP GLOBAL TECH BV

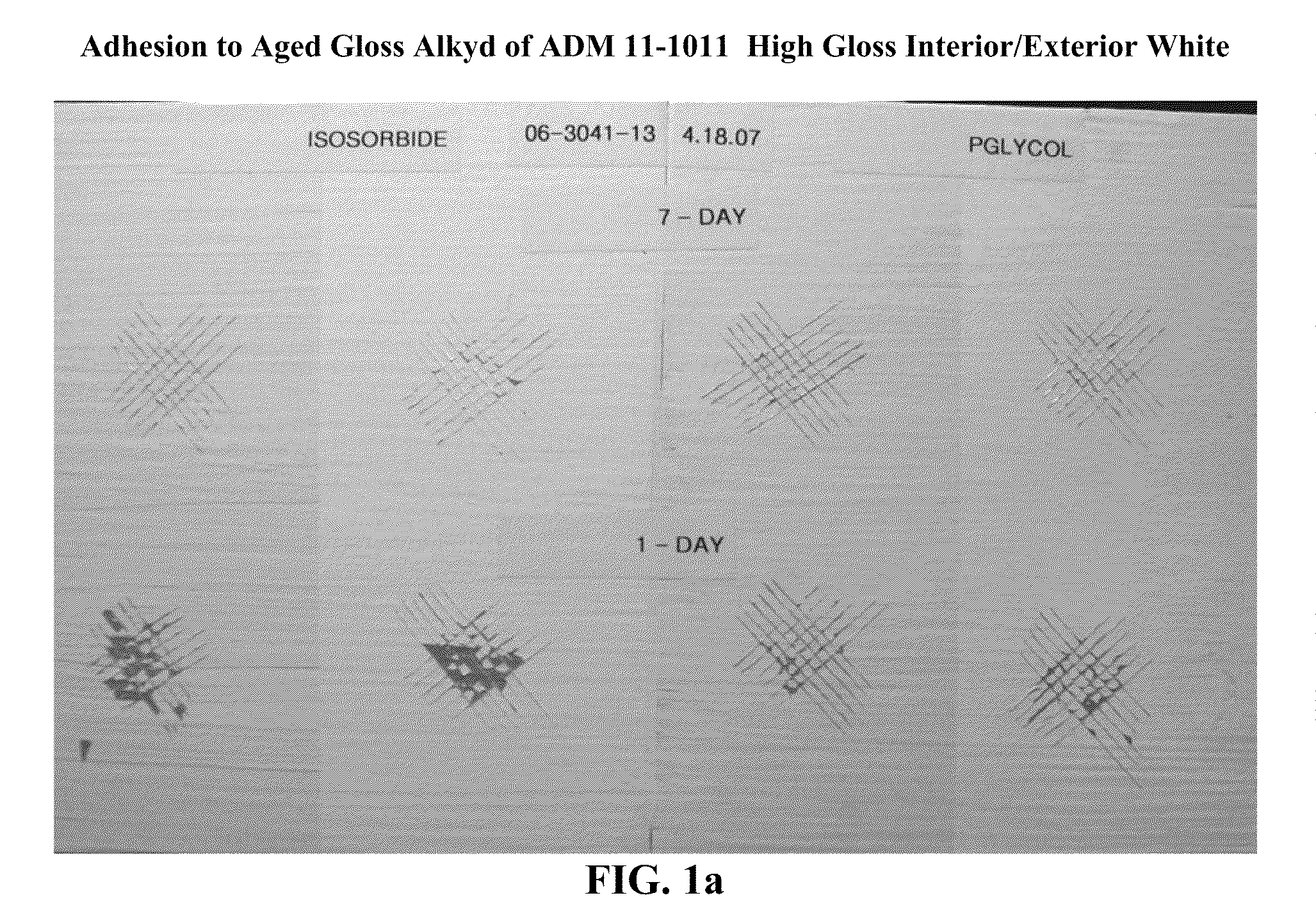

Waterborne Film-Forming Compositions Containing Reactive Surfactants and/or Humectants

ActiveUS20100104884A1Lower Level RequirementsControlled evaporationFireproof paintsUnspecified rubber coatingsCross-linkWater resistant

The present invention is directed to aqueous coating compositions, such as paints, containing a film-forming latex polymer and a reactive surfactant and / or a low VOC humectant. The reactive surfactant, a polyglycerol ester or ether of an unsaturated fatty acid, reduces or eliminates the need for traditional water-soluble additives that lower the water resistance of the dry coating. Additionally, the reactive surfactants of the invention are capable of oxidative cross-linking during the curing process, forming a dry film that is more durable and water-resistant than traditional latex paint composition. The low VOC humectant polyglycerol, isosorbide, or a derivative of isosorbide can replace at least in part traditional humectants such as propylene glycol which contribute to VOCs, while maintaining an effective open time for application of the aqueous coating compositions.

Owner:ARCHER DANIELS MIDLAND CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com