Polyester resin and method for preparing the same

a polymer resin and polymer technology, applied in the field of polymer resins, can solve the problems of difficult to enhance the heat resistance of bisphenol-a through stretching or crystallization process, limitations on application and enhancement of heat resistance, etc., and achieve the effect of superior heat resistance and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

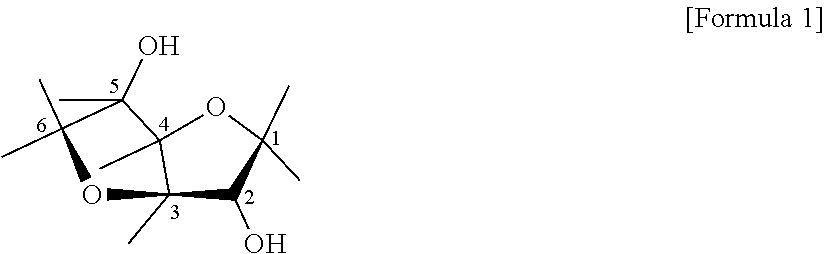

Image

Examples

examples 1-6

Preparation of Polyester Resin

[0025]Except for using the amounts of TPA, IPA, ISB, and EG according to Table 1, polyester resin was prepared by the same manner described in Comparative Example 1. Intrinsic viscosity, heat-resistance (Tg) and izod impact strength of the polyester resin were measured, and represented in Table 1.

TABLE 1ExamplesComparative Examples12345612345TPA(%)1001009010010010010010010090100IPA(%)1010ISB(%)9381920401841039200CHDM(%)912242585521000060EG(%)04039225619690618040IV(dl / g)0.660.590.630.690.550.700.740.650.580.630.75Heat-resistance92123104107130102859312410485(Tg, ° C.)Impact9068129N.B3029138373032N.Bstrength(J / m)

[0026]In Example 4 and Comparative Example 5, impact strength could not be measured because any break did not occur (No-Break: N.B) due to high mechanical strength. As shown in Table 1, to compare a conventional polyester resin, the polyester resin according to the present invention has much superior impact strength though it has same or higher hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mol % | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com