Patents

Literature

438 results about "Palladium on carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Palladium on carbon, often referred to as Pd/C, is a form of palladium used as a catalyst. The metal is supported on activated carbon in order to maximize its surface area and activity.

Palladium carbon catalyst as well as preparation method and application thereof

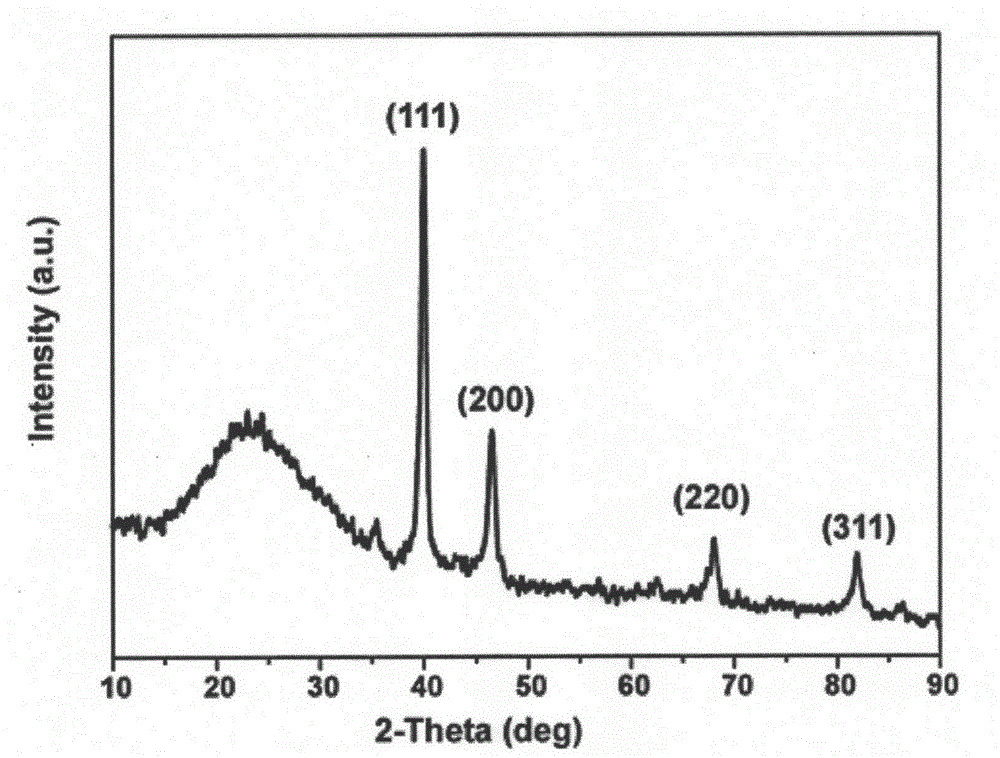

ActiveCN103691431AThe load rate is close to or even fullyFull loadOrganic compound preparationCarbonyl compound preparationActivated carbonPalladium on carbon

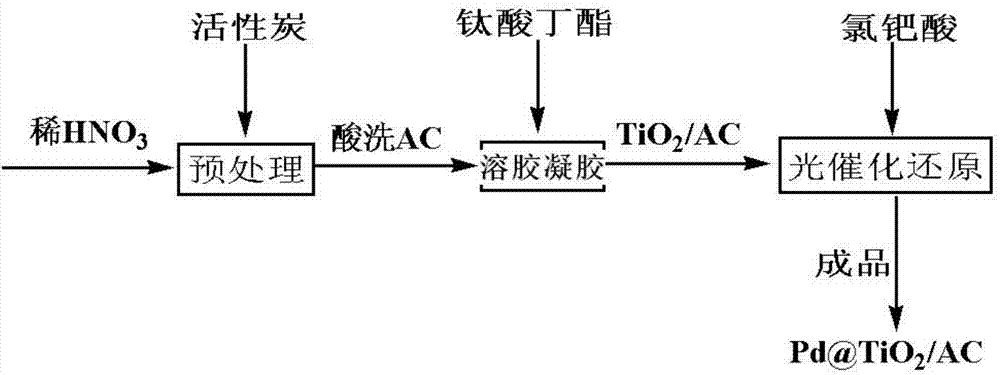

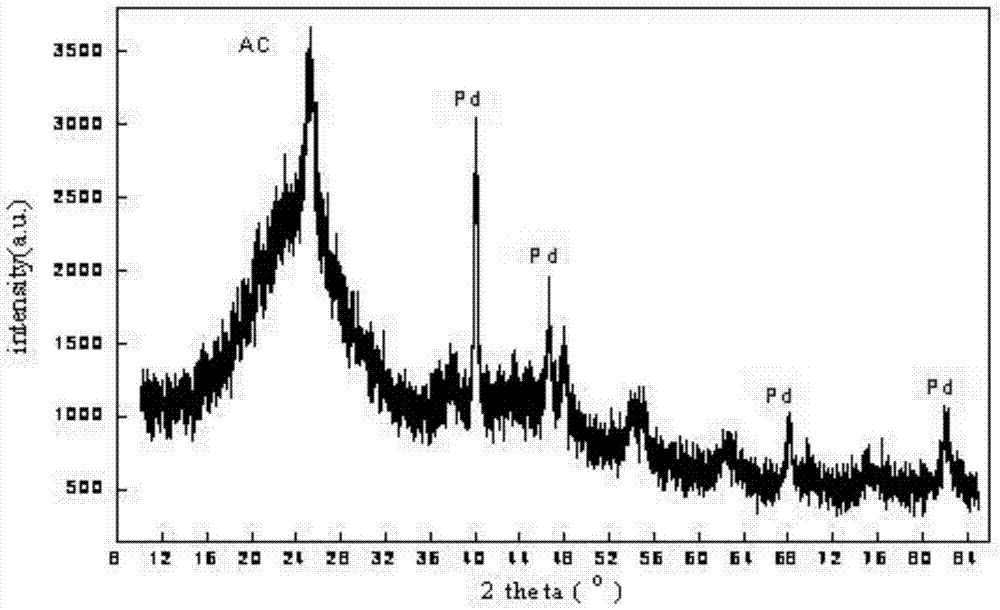

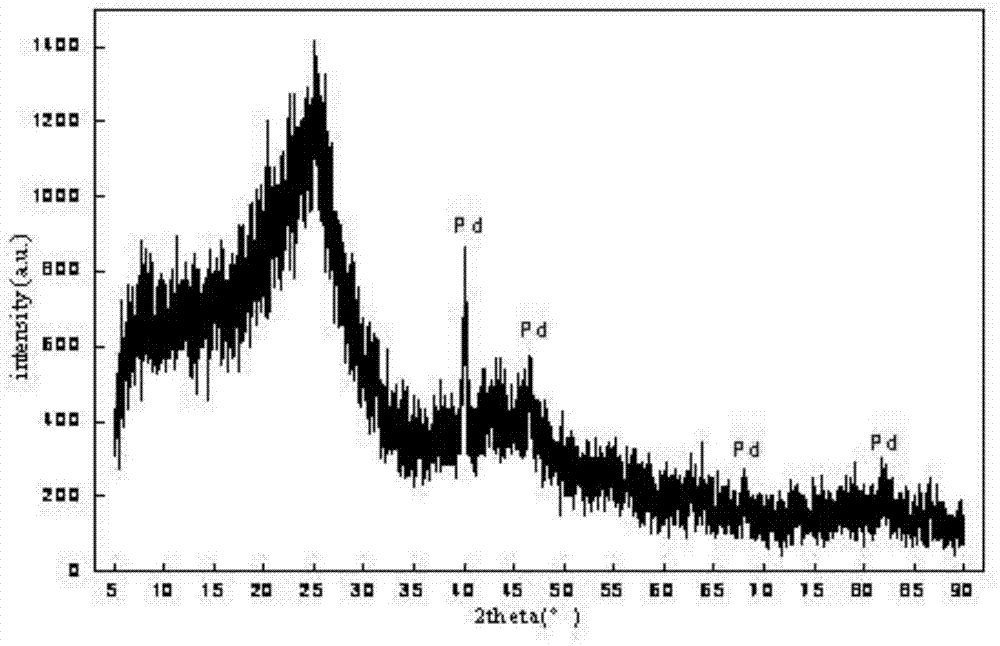

The invention relates to a palladium carbon catalyst which comprises the following components: (1) nanometer TiO2-modified active carbons are used as composite carriers; (2) Pd nanometer particles are used as active components, wherein the strong interaction between metals and the carriers exists in the active components and TiO2 on the composite carriers to form a Pd@TiO2 structure so as to form structural Pd@TiO2 / active carbons of the catalyst.

Owner:XIANGTAN UNIV

Method for reclaiming precious metal palladium from waste palladium-carbon catalyst

ActiveCN101186971AHigh recovery rateReduce pollutionProcess efficiency improvementPalladium on carbonHydrogen

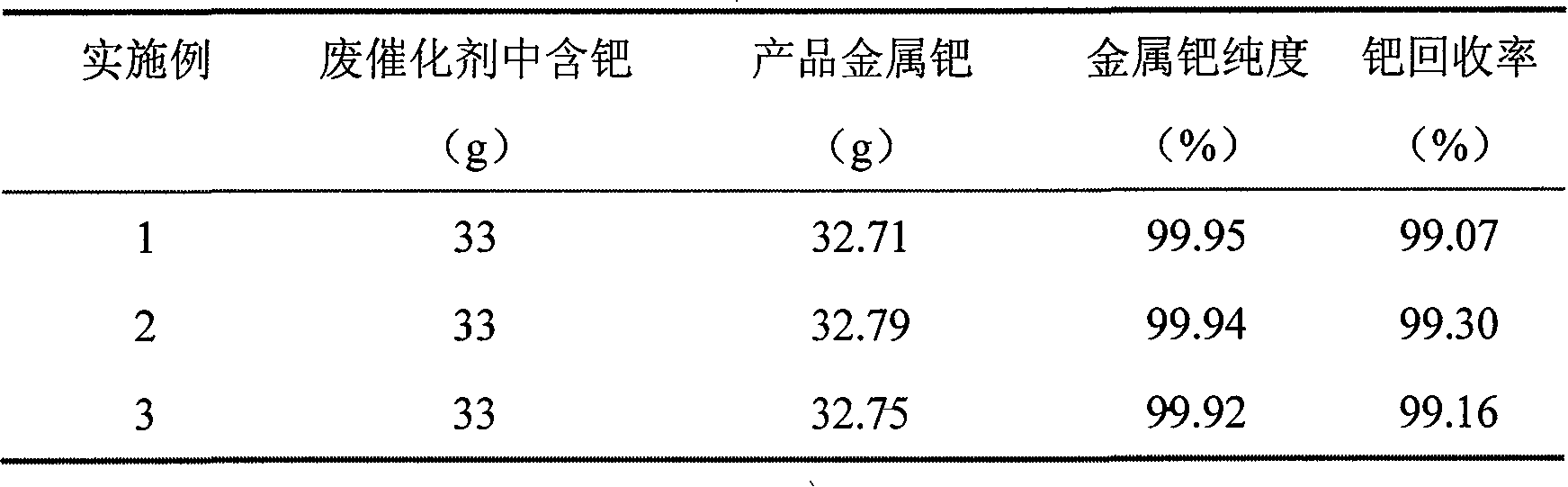

The invention belongs to the technical field of recycling solid waste, in particular relating to a process of recycling noble metal palladium from dead palladium carbon catalysts. The process includes roasting, reduction, leaching out, impurity removal of ion-exchange, ammonia complexingk, acidifying, roasting and hydrogen reduction, and then the metal palladium is obtained. The invention is simple in technique and low in costs, the palladium recovery ratio is more than 99%, and the purity of metal palladium is more than 99.9%.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Preparation technique of isosorbide

The invention relates to a preparation technique of isosorbide, belonging to the technical field of pharmacy. In the preparation technique, solid sorbitol is used as the raw material, a mixture of perfluoro-sulfonic acid resin and palladium on carbon is used as the catalyst, and hydrogen is used as an anti-carbonation agent to prepare the non-carbonized light-colored isosorbide reaction liquid; and low-temperature concentration and solvent crystallization are utilized to substitute the original high-temperature distillation. The preparation technique comprises the following steps: dehydration reaction, neutralization decolorization, electrodialysis desalination, water removal by concentration, extraction crystallization, freeze-drying, and quality inspection and packaging (after the product is qualified in inspection, packaging, and warehousing as the finished product). The invention can prevent carbonization and prevent the reaction liquid from becoming dark, thereby enhancing the utilization ratio of the raw material; most calcium salts are precipitated due to low solubility, and the electric conductivity of the reaction liquid is low, thereby being beneficial to subsequent extraction; and the invention overcomes the defect of high energy consumption in the high-temperature distillation technique, and the quality of the prepared isosorbide is more excellent.

Owner:SHANDONG FUTASTE

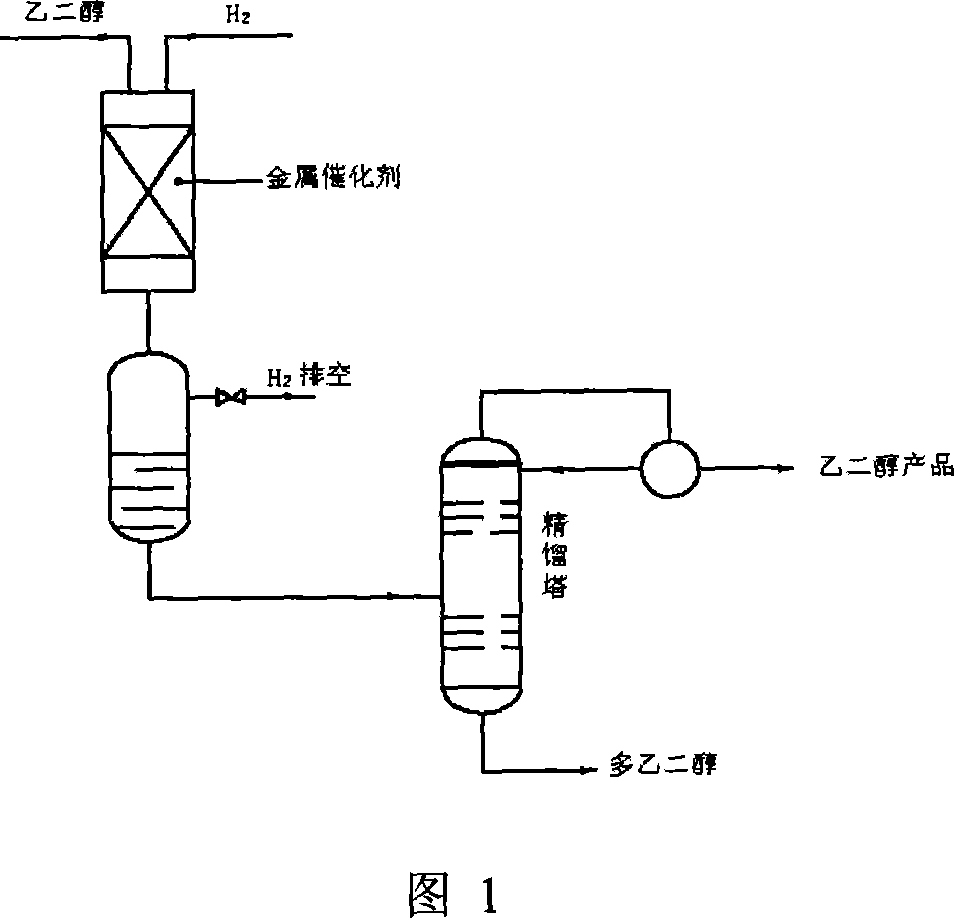

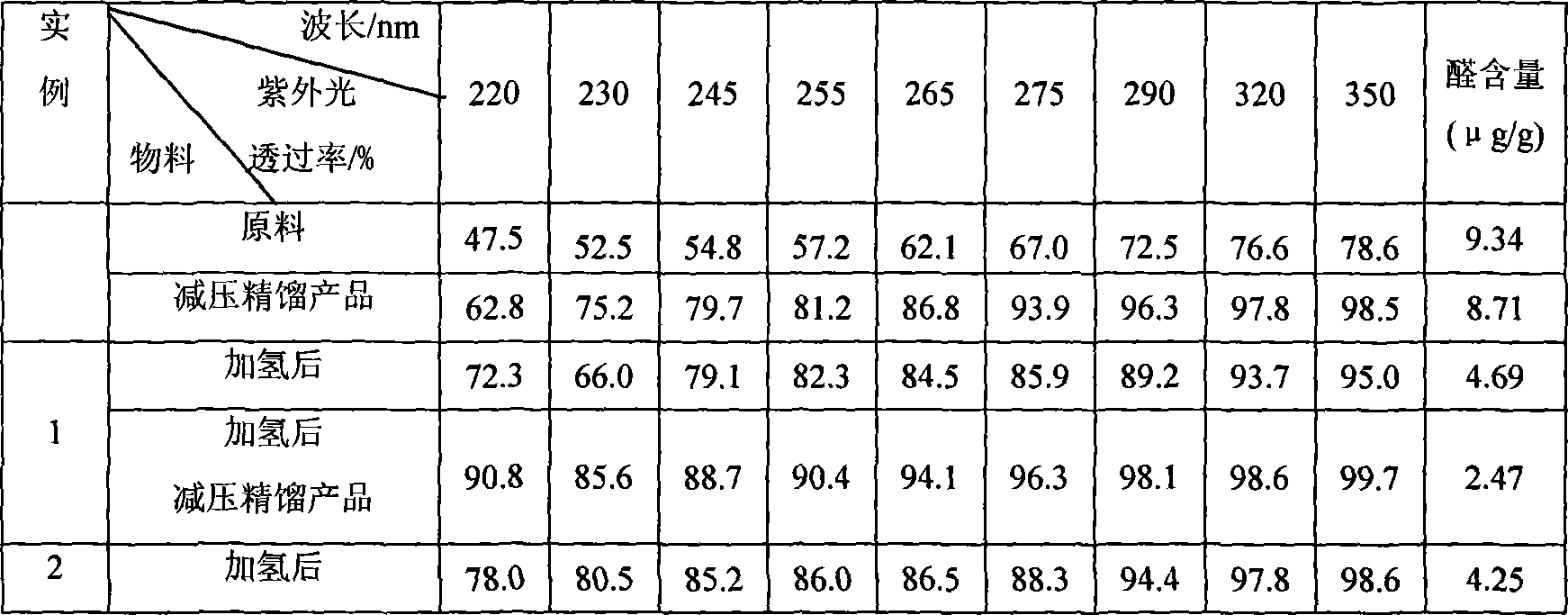

Method of increasing quality of glycol

InactiveCN101058526AQuality improvementThe implementation process is simpleOrganic compound preparationHydroxy compound preparationPalladium on carbonVolumetric Mass Density

The invention discloses an interval or continuous catalytic hydrogenating for ethandiol (weight density at 10-100%), which is characterized by the following: adopting aggregate nickel or palladium carbon as catalyst; transmitting C=C and C-O into saturated material not to adsorbed by ultraviolet in the ethandiol; reducing the content of aldehyde; improving ultraviolet transmission rate; controlling the reacting temperature between 45 deg. c and 95 deg. c; setting the reacting pressure between 0. 05 and 0. 5Mpa and air speed not less than 60h-1; obtaining the product with ultraviolet transmitting rate more than 90% at 220nm, more than 95% at 275nm, more than 99% at 350nm.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

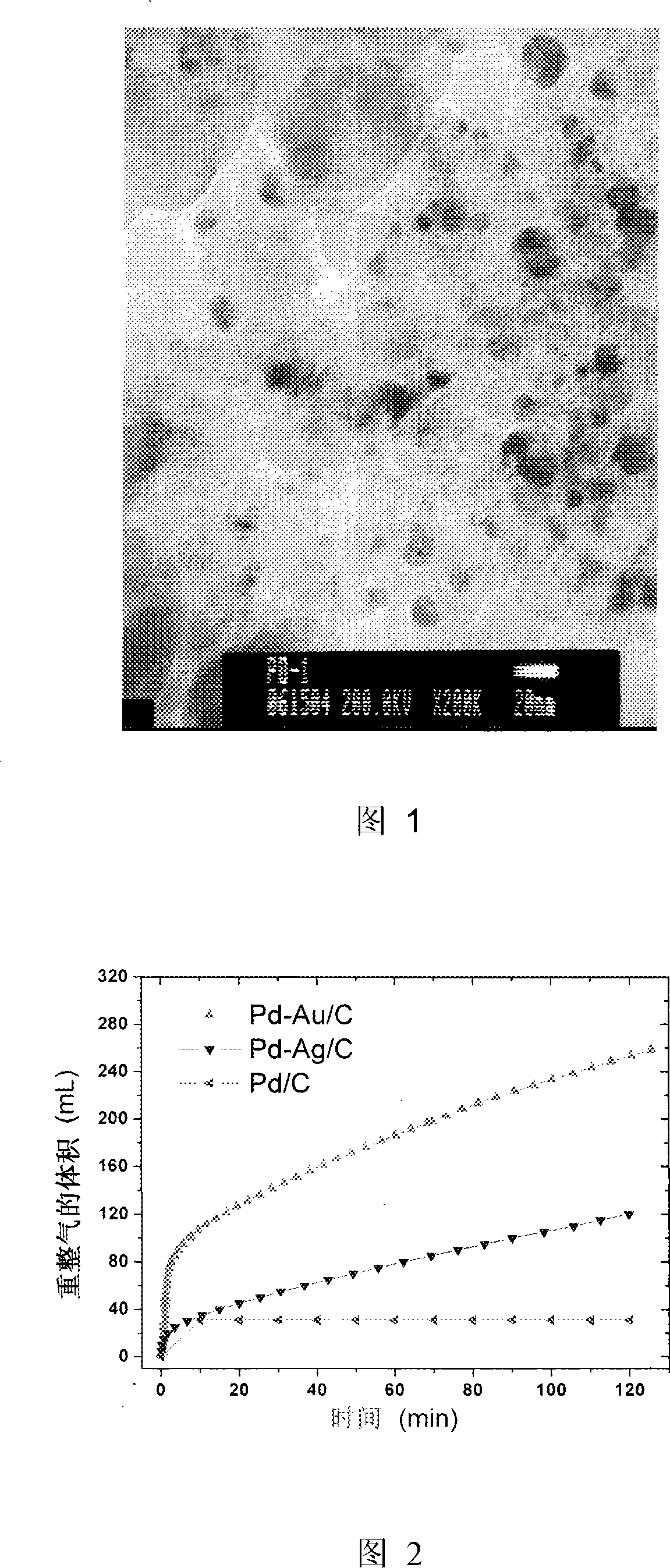

Palladium-on-carbon base nano-catalyst for producing hydrogen gas by direct decomposition of methanoic acid and method for producing the same

InactiveCN101219379AStrong resistance to CO poisoningHigh purityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNano catalystPalladium on carbon

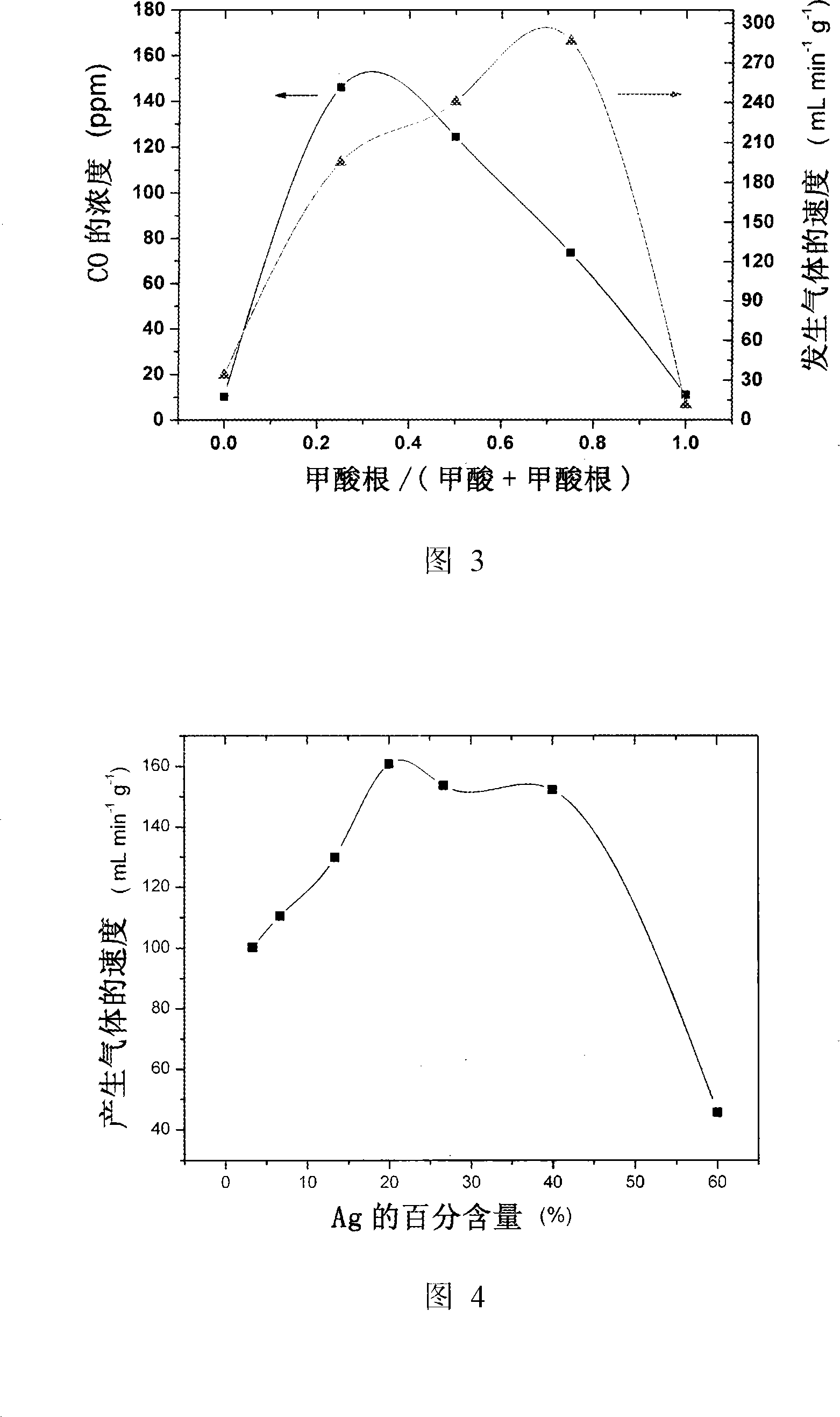

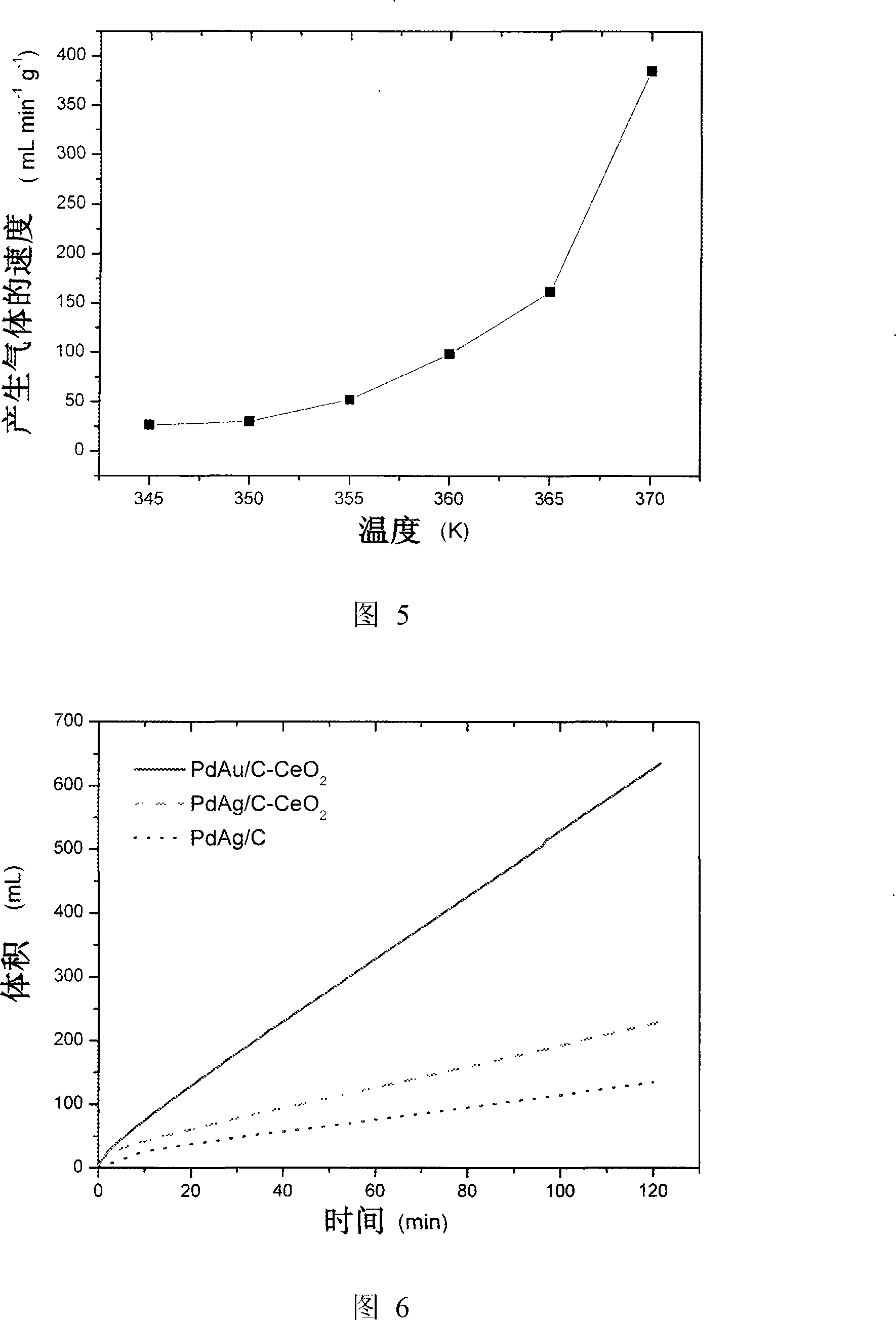

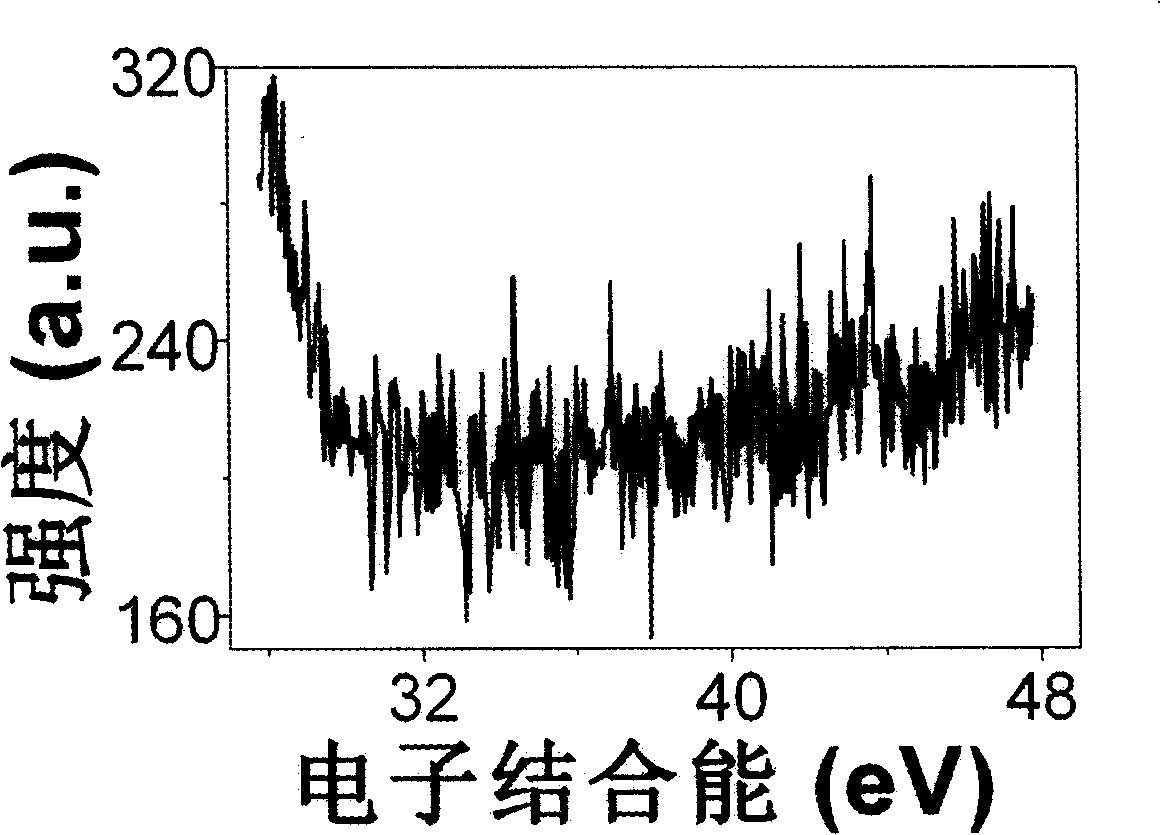

The invention relates to a preparation method of a carbon-carrier Pd-based nano catalyst that used for hydrogen preparation from the direct decomposition of formic acid. A solution of soluble palladium compound and other soluble metal compounds is added with strong reducer to obtain a Pd-based nano catalyst; these Pd-based nano catalysts can be dispersed to activated carbon to prepare the carbon-carrier Pd-based nano catalyst, and then added with rare earth oxide or rare earth hydroxide to improve the activity of the Pd-based nano catalyst. The so prepared carbon-carrier Pd-based nano catalyst has quite a high activity in catalyzing the decomposition of formic acid and high selectivity; apart from hydrogen and carbon dioxide, the content of other gases in the obtained gas is very low, the obtained gas can provide material for the field that needs hydrogen or carbon dioxide, hydrogen fuel for fueled batteries, and supports the practical applications of hydrogen fueled batteries.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method for direct methanoic acid fuel cell palladium-on-carbon nano-catalyst

InactiveCN101318131ASmall particle sizeImprove performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonNano catalyst

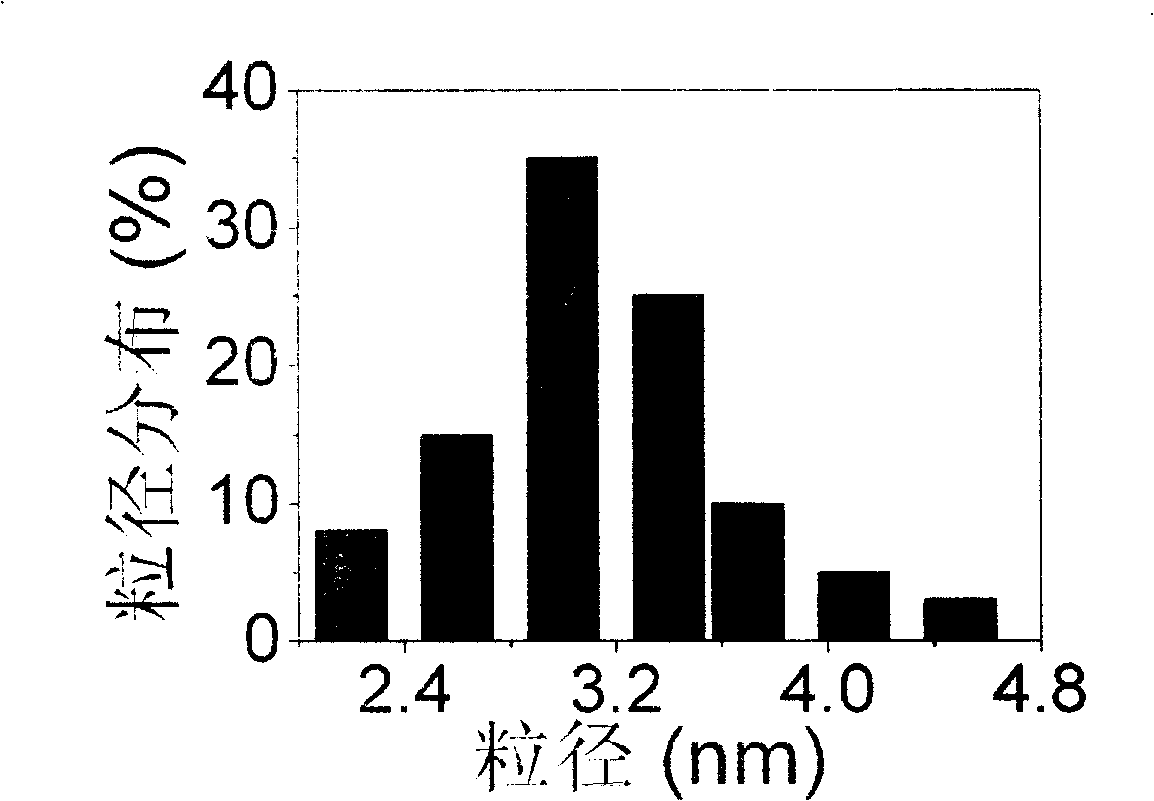

The invention belongs to a preparation method for a direct formic acid fuel cell carbon-supported palladium nanometer catalyst, which takes (WO3) n and xH2O or (MoO3) n and xH2O as colloid source to form metal colloid with PdCl2 and uses NaBH4 for reducing, thus obtaining the carbon-supported palladium catalyst. The palladium particles of the catalyst have uniform distribution and small average grain size. The catalyst prepared by the method has higher performance on the catalytic oxidation of formic acid than the carbon-supported palladium catalyst prepared by the traditional impregnation method which has the same loading capacity but no colloid source. The method with simple practice does not need protective agent and the colloid source can be removed through simple washing; therefore, the method is suitable for batch preparation of the carbon-supported palladium catalyst.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

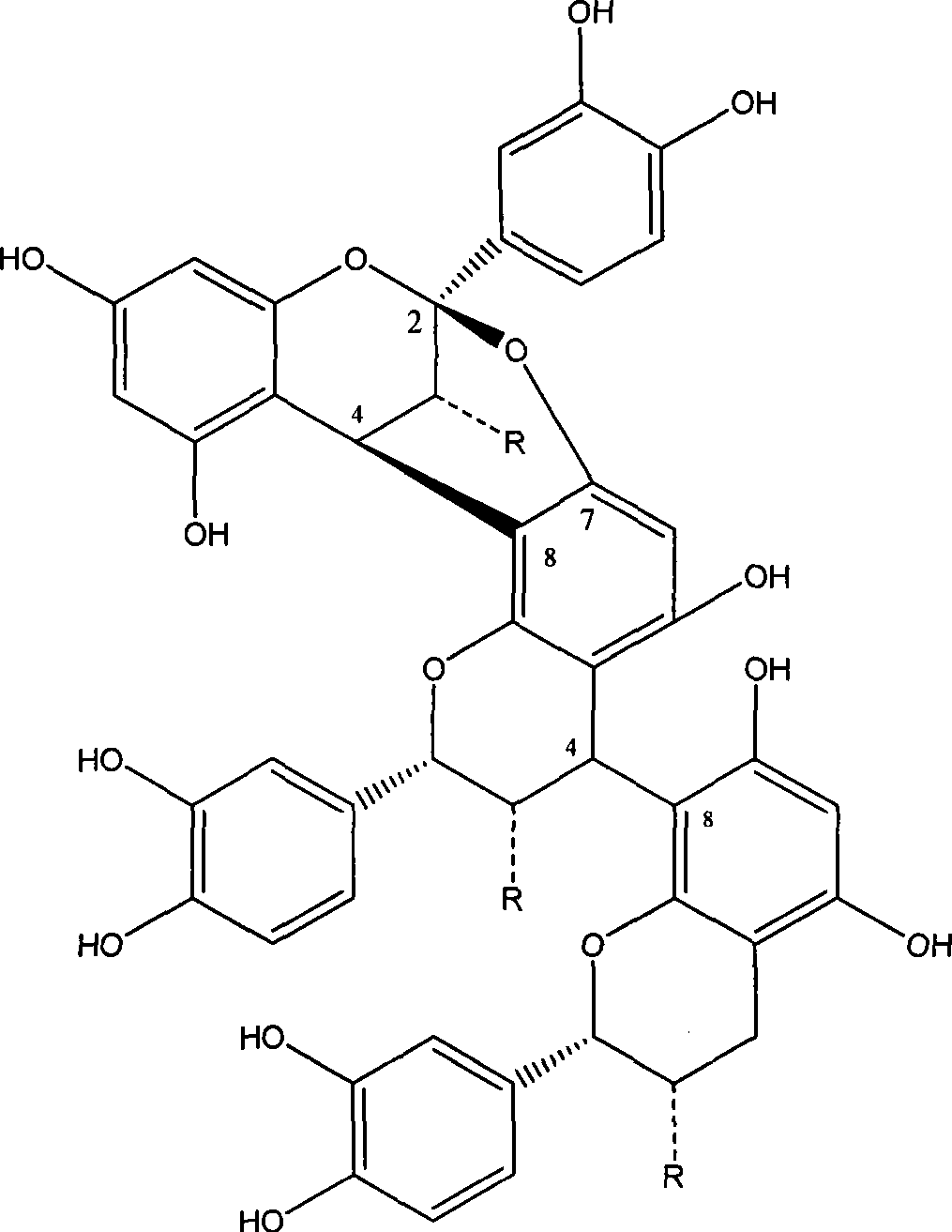

Method for catalytic hydrogenolysis of cinnamon proanthocyanidins high polymer to oligomer

InactiveCN101239963ARetain biological activityResolve liveness issuesOrganic chemistryPalladium on carbonPolymer science

The invention relates to a method for catalyzing and hydrogenolysis of cinnamon procyanidine high polymers to procyanidine low polymers. The method comprises: extracting cinnamon procyanidine high polymers; hydrogenation catalyzing and degradating cinnamon procyanidine high polymers to obtain crude products; separating crude products LSA-21 macroporous resin column to obtain procyanidine low polymers. The invention uses Pd / C catalyst and hydrogen to catalyze and hydrogenize cinnamon high poly-procyanidine to procyanidine low polymers, solves activity problems of the products, and maintains the bioactivity of procyanidine. The method of the invention can not only open C4-C8 keys, but also open C2-O-C7 keys, thereby realizing depolymerization of high polymers. In the reaction, reagents such as acid or alkali, which have pollution on environment, are avoided to be use, ethanol aqueous sollution can be recycled. The low poly-procyanidine obtained by catalyzing and hydrogenolysis, improves the rate of low poly-procyanidine in cinnamon, widens the application range in food and cosmetic fields.

Owner:SHANGHAI UNIV

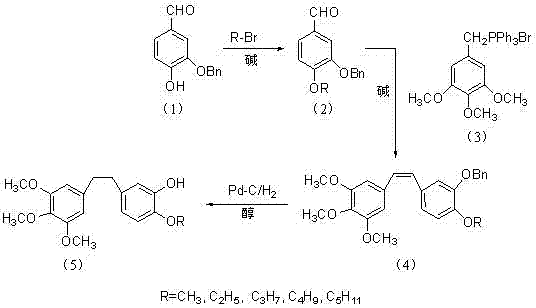

Method for preparing 3,4,5-trimethoxy-3'-hydroxy-4'-alkoxy diphenylethane

InactiveCN103539642AImprove protectionSignificant technological progressOrganic compound preparationCarbonyl compound preparationPalladium on carbonBenzaldehyde

Owner:SHANGHAI INST OF TECH

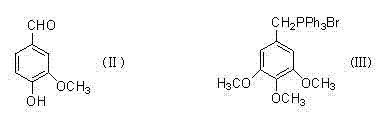

Preparation method of supported palladium-carbon catalyst

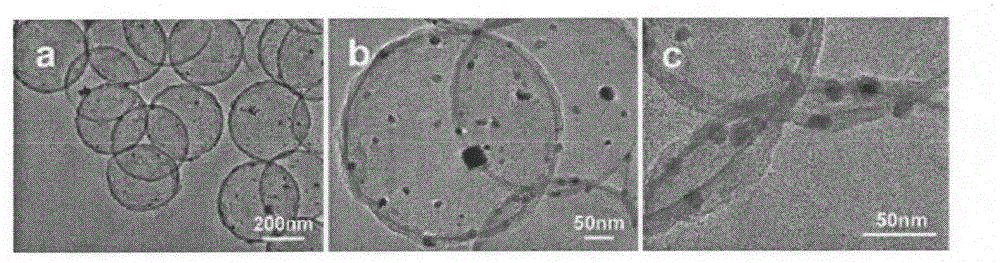

InactiveCN104971759AInhibit migrationAvoid reunionPhysical/chemical process catalystsPalladium on carbonAqueous solution

The present invention discloses a preparation method of a supported palladium-carbon catalyst. The preparation method is characterized by comprising the following steps of: firstly, dispersing silicon dioxide spheres modified by an amnio functional group into water; adding a water solution containing noble metal palladium nano particles; adsorbing the palladium nano particles on the surface of silicon dioxide under an ultrasonic condition to form a palladium / silicon dioxide compound sphere; then adding dopamine to form a poly-dopamine shell layer on the surface of the palladium / silicon dioxide compound sphere under an alkaline condition; carbonizing poly-dopamine at a high temperature under an inert atmosphere and embedding the palladium nano particles into a carbon shell layer in the process; and finally, removing the silicon dioxide spheres with an alkaline solution to prepare the palladium-carbon catalyst. The catalyst prepared by the invention has a high catalytic performance.

Owner:DONGHUA UNIV

Method for preparing ticagrelor key intermediate

InactiveCN106279095AReduce pressure on environmental protectionSuitable for large-scale industrial productionOrganic chemistryBulk chemical productionChemical synthesisPalladium on carbon

The invention relates to a chemical synthesis method of ticagrelor key intermediate 2-[[(3aR, 4S, 6R, 6aS)-6-aminotetrahydro-2,2-dimethyl-4H-cyclopenta-1,3-dioxolane-4-yl] oxy]ethanol (a key intermediate A). The method comprises the following steps: taking D-ribose as a raw material, and carrying out ten chemical reaction steps of 1-locus methylation and 2,3-loci isopropylidene protection, 4-locus derivatization, iodination, furan ring-opening, hydroxylamine reaction, palladium on carbon catalytic hydrogenation, amino Cbz protection, hydroxy protection, sodium borohydride reduction ester, Cbz removal protection and the like, thereby obtaining the key intermediate A. The raw materials are cheap and readily available, the preparation process is high in operability, steps of optical resolution, chiral induction and the like are avoided, the total yield is relatively high, and the product quality is better; particularly due to the use of sodium borohydride reduction ester, the preparation cost of ticagrelor is greatly reduced; and the method is suitable for large-scale industrial production.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +1

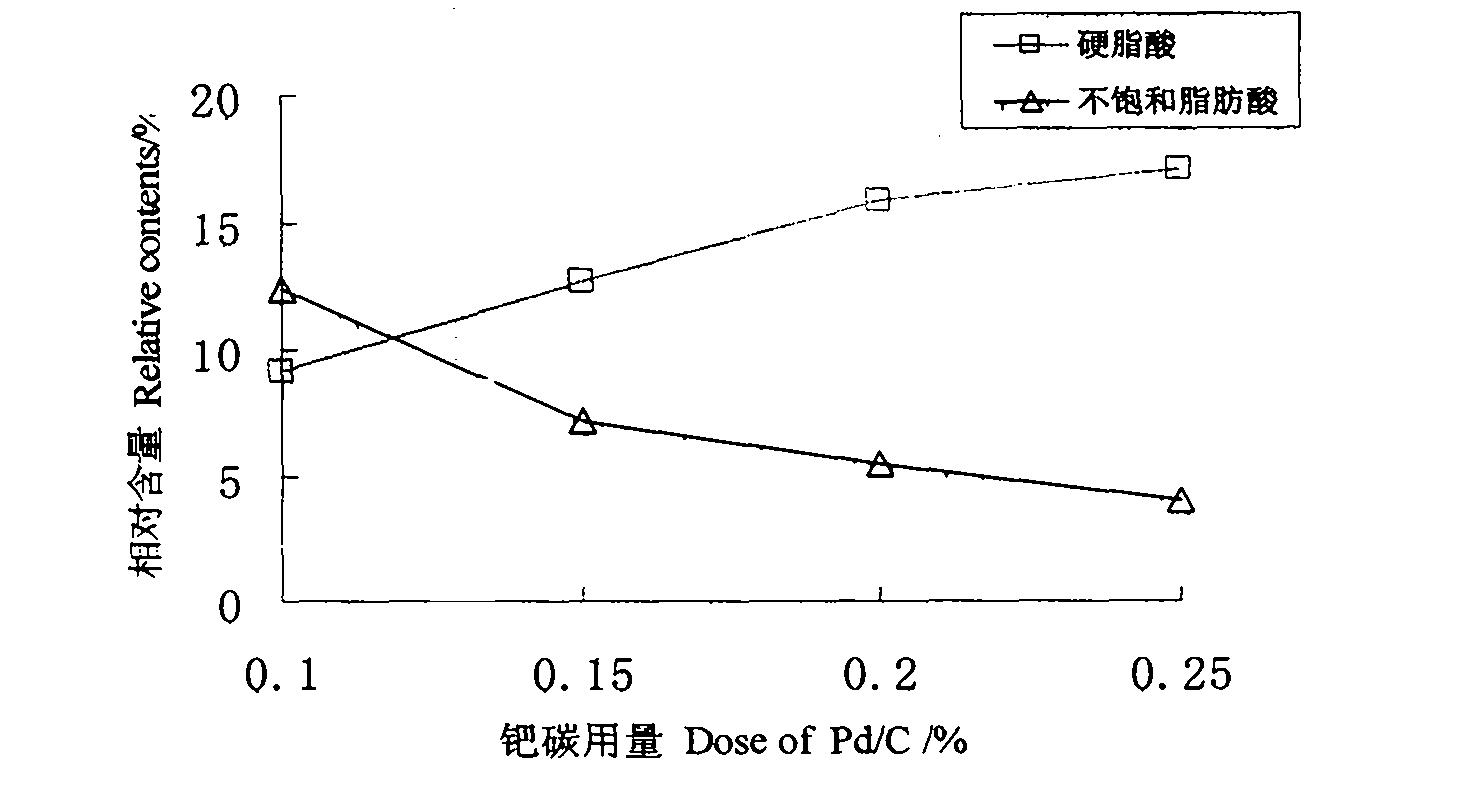

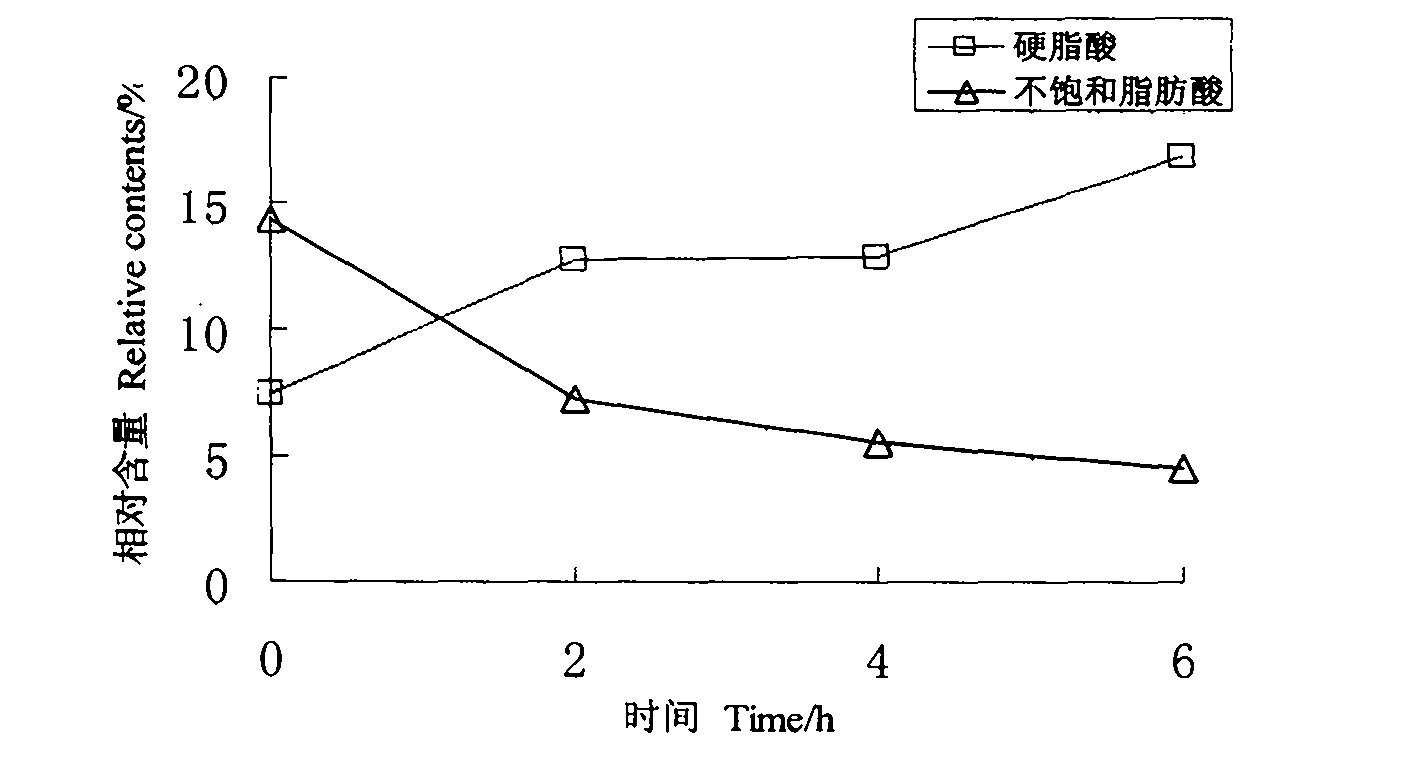

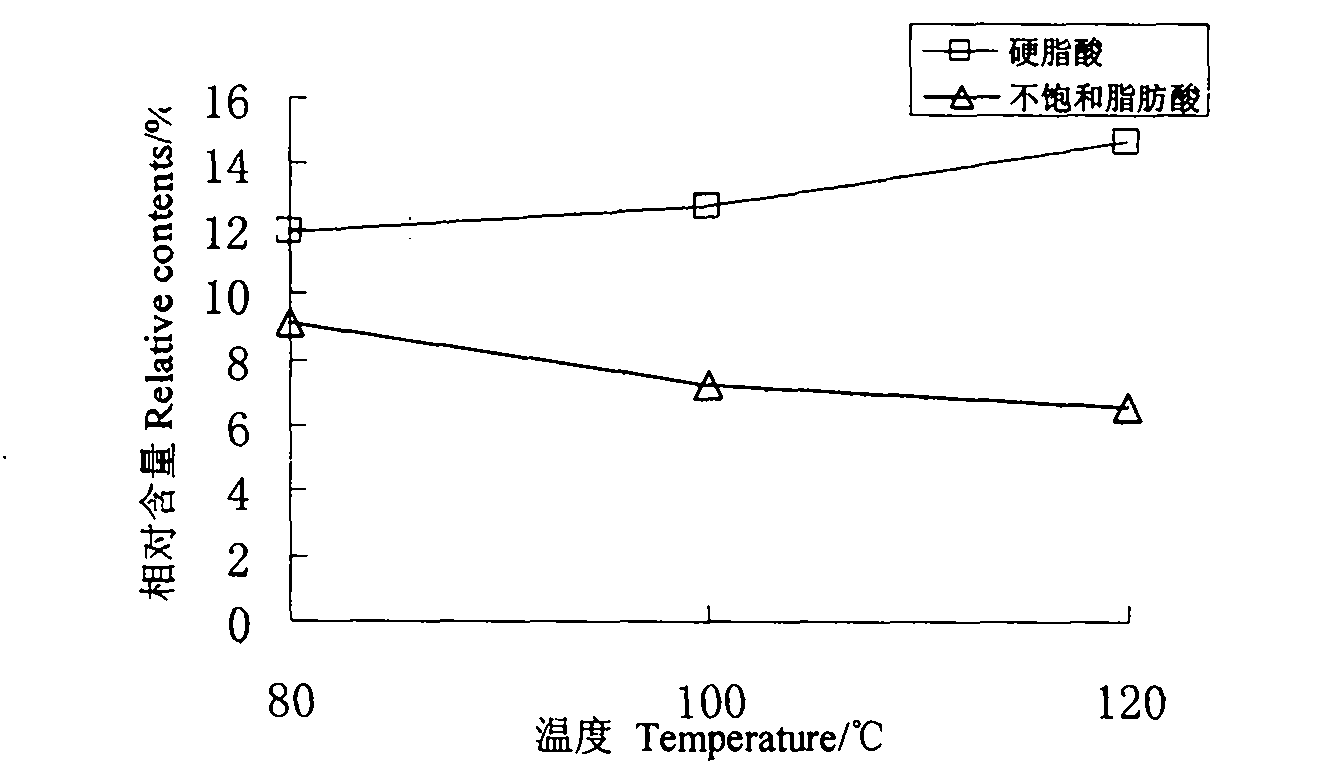

Method for preparing high-quality fine lacquer wax product

ActiveCN102329693APrevent mildewReduce moisture contentFatty substance recovery/refiningFatty substance recoveryPalladium on carbonLacquer

The invention discloses a method for preparing high-quality fine lacquer wax product, which comprises the following steps of: firstly, microwave drying lacquer seeds, separating skin and cores, and lixiviating the skin and flesh part of the lacquer seeds by using a non-polar solvent to obtain rough lacquer wax; heating and uniformly mixing the lacquer wax and a certain proportion of Pd / C catalyst in a high-temperature high-pressure reactor, charging hydrogen gas and maintaining a certain hydrogen gas pressure for reaction; after the reaction is completed, and filtering and discoloring the product while hot to obtain highly saturated lacquer wax; and detecting the variation of fatty acid content in the lacquer wax, by using gas chromatography. The method is simple and convenient, and the problems of low lacquer wax melting point, easy rancidity and the like caused by high content of unsaturated fatty acid in rough lacquer wax can be effectively solved. The obtained hydrogenated fine lacquer wax product has similar physical and chemical properties to Star Cherry-A white wax processed by Japan Araki Wax Manufacturing Company and can be widely applied to the field of daily chemicals.

Owner:NANJING ZHONGSEN BIOLOGICAL TECH CO LTD

Method for reactivating palladium carbon catalyst

ActiveCN103623843AReduce production power costsNo need for high temperature and high pressureMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonAlcohol

The invention provides a method for reactivating a palladium carbon catalyst. The method comprises the following steps: washing an inactivated palladium carbon catalyst with an alcohol solution, then, cleaning the inactivated palladium carbon catalyst on an ultrasonic cleaning machine by using water as a solvent, soaking the inactivated palladium carbon catalyst in alkali liquor, finally washing the palladium carbon catalyst to neutral by using water, and drying the palladium carbon catalyst to obtain a reactivated palladium carbon catalyst. The method provided by the invention is suitable for reactivating moderately inactivated palladium carbon catalyst and recovering the catalytic effect necessary for a hydrogenation reaction. The activity of the activated palladium carbon catalyst is equivalent to that of a new palladium carbon catalyst. The method has the advantages of reducing the production power cost, needing no high temperature or high pressure, ensuring simple operation and being environmental-friendly.

Owner:安徽泰格维生素实业有限公司

Method for reactivating palledium/carbon catalyst

The invention relates to a Pd carbon catalyst anew active method. The method did justice of inactivation catalyst to obtain anew active Pd / carbon catalyst supplied for the TA hydrorefining reaction. The method includes: use out threshold CO2 extract washing inactivation Pd / carbon catalyst; put the inactivation Pd / carbon catalyst into nitric acid solution to boil up; after drying park in the hartshorn; in addition add to PdCl2; after filtration get the catalyst prosome; catalyst prosome through NaOH and formaldehyde revert,drying get the anew active Pd / carbon catalyst.

Owner:SINOPEC YANGZI PETROCHEM

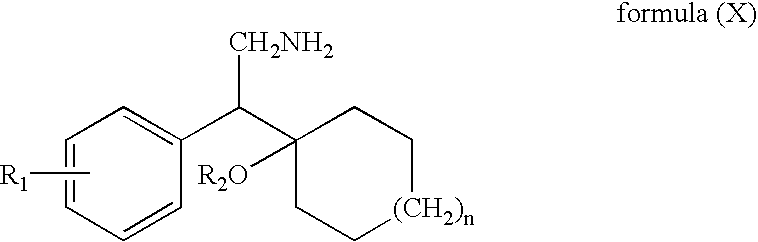

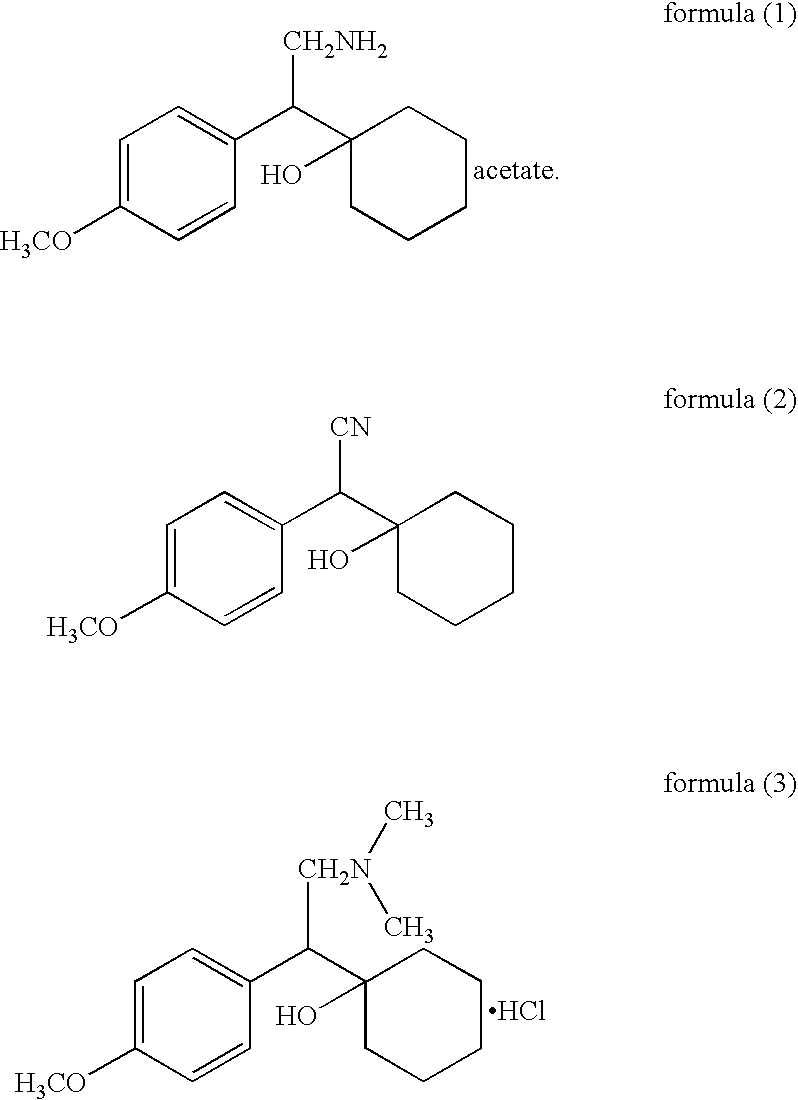

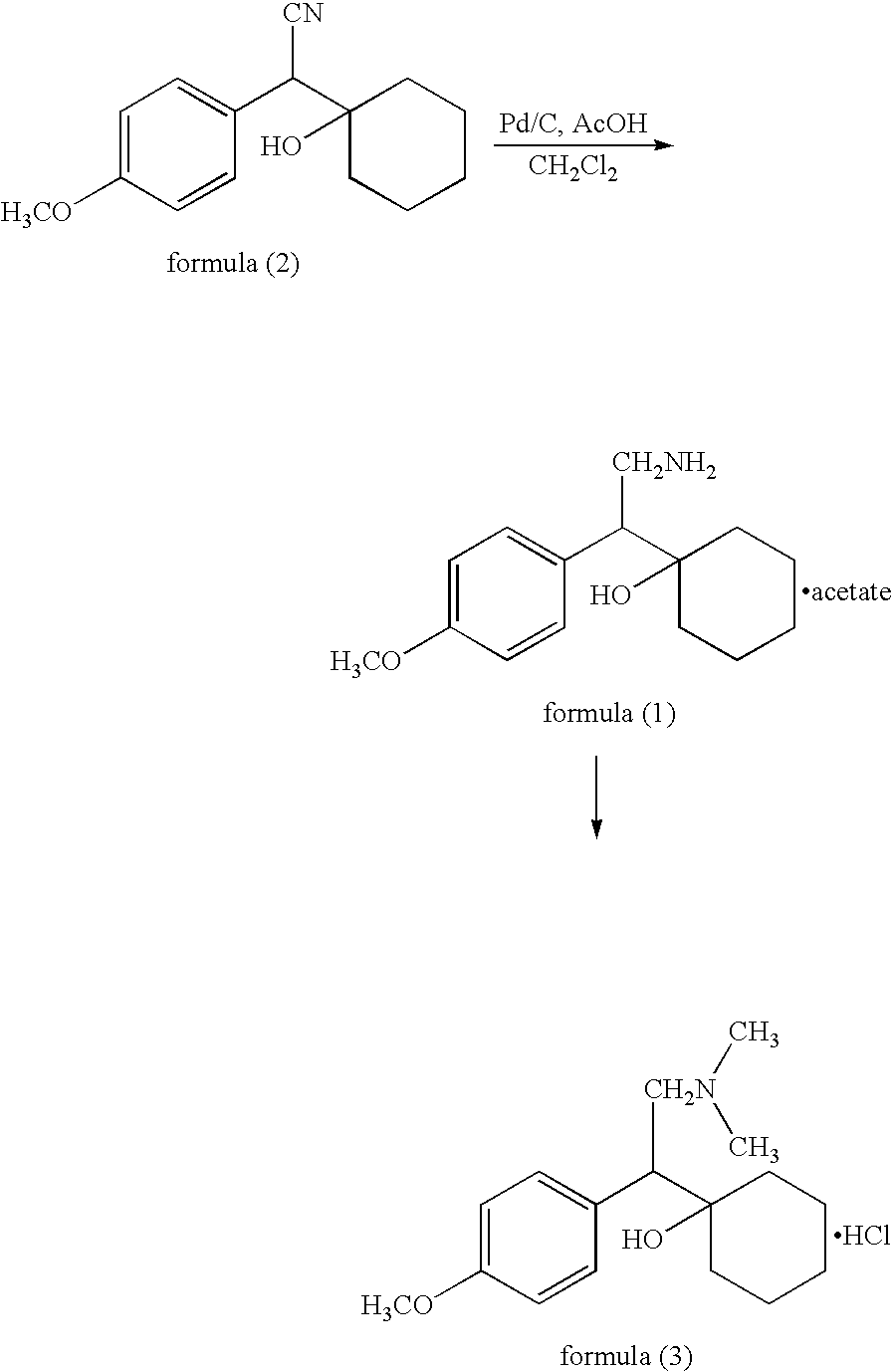

Process for the preparation of phenethylamine derivative, an intermediate of Venlafaxine hydrochloride

InactiveUS20050033088A1High yieldOrganic compound preparationCarboxylic acid amides preparationPalladium on carbonPhenethylamine derivative

The present invention relates to an improved process for the preparation of phenethylamine derivatives or salts by hydrogenation of phenylacetonitriles in the presence of heterogeneous palladium on carbon catalyst.

Owner:DR REDDYS LAB LTD +1

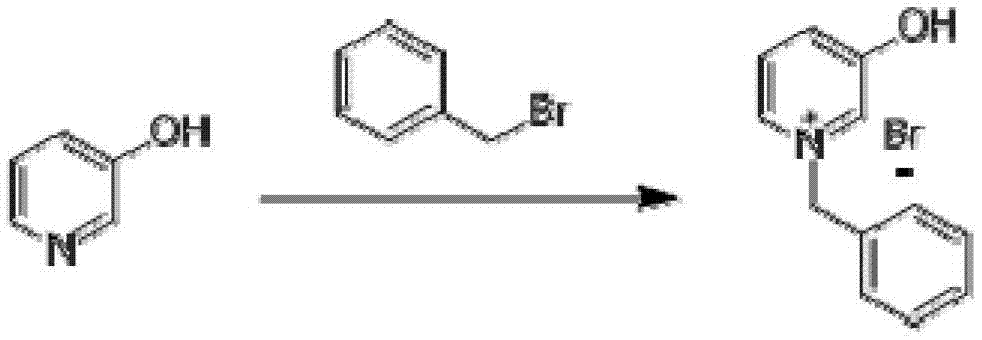

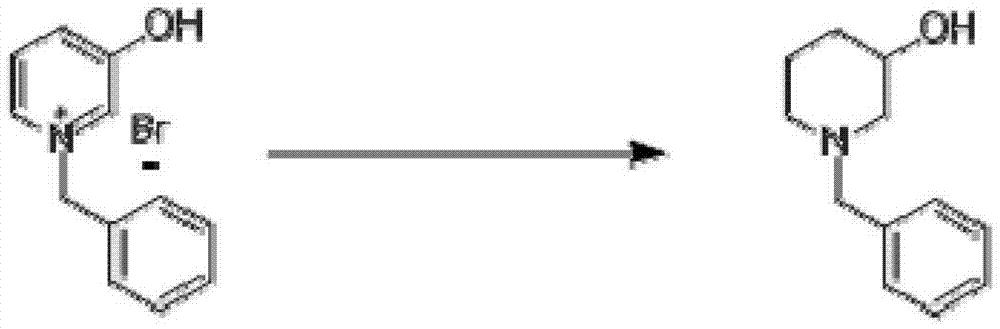

Synthesis method for N-Boc-3-piperidone

InactiveCN103204801AEasy to separate and purifyShort synthetic routeOrganic chemistryPalladium on carbonBenzoyl bromide

The invention discloses a synthesis method for N-Boc-3-piperidone. The synthesis method comprises the following steps of: reacting 3-hydroxyl pyridine with benzyl bromide in an organic solvent to obtain an N-benzyl-3-hydroxyl pyridine quaternary ammonium salt; reducing the N-benzyl-3-hydroxyl pyridine quaternary ammonium salt by sodium borohydride to obtain N-benzyl-3-hydroxyl piperidine; reacting N-benzyl-3-hydroxyl piperidine with di-tert-butyl dicarbonate ester to obtain N-Boc-3-hydroxyl piperidine under hydrogen protection and the catalysis of a palladium-carbon catalyst; and reacting N-Boc-3-hydroxyl piperidine with the mixed oxidant of dimethyl sulfoxide and oxalyl chloride to obtain N-Boc-3-piperidone under the action of an organic base. Compared with the existing synthesis method, the synthesis method disclosed by the invention is shorter in synthesis route, and easier for separation and purification of reactants, thus reducing the production cost, the energy consumption and the pollution; and the total productivity of N-Boc-3-piperidone can achieve more than 42%, and the purity thereof is greater than 98%.

Owner:甘肃天骄商贸有限公司

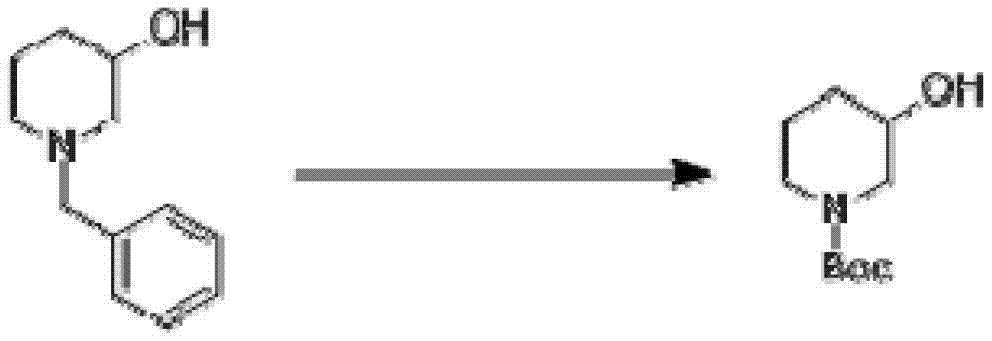

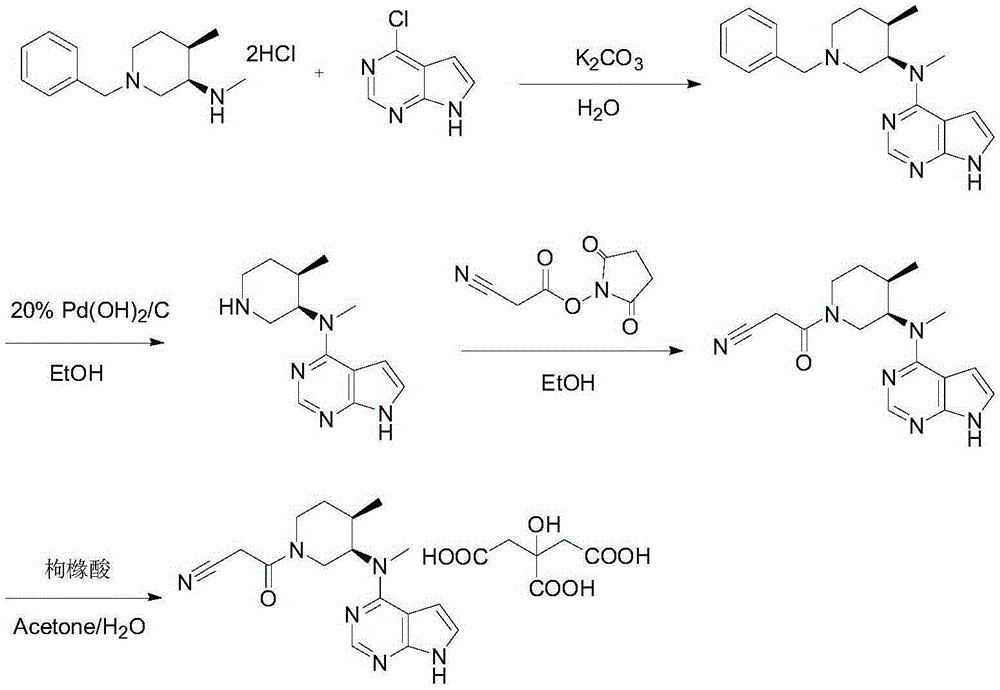

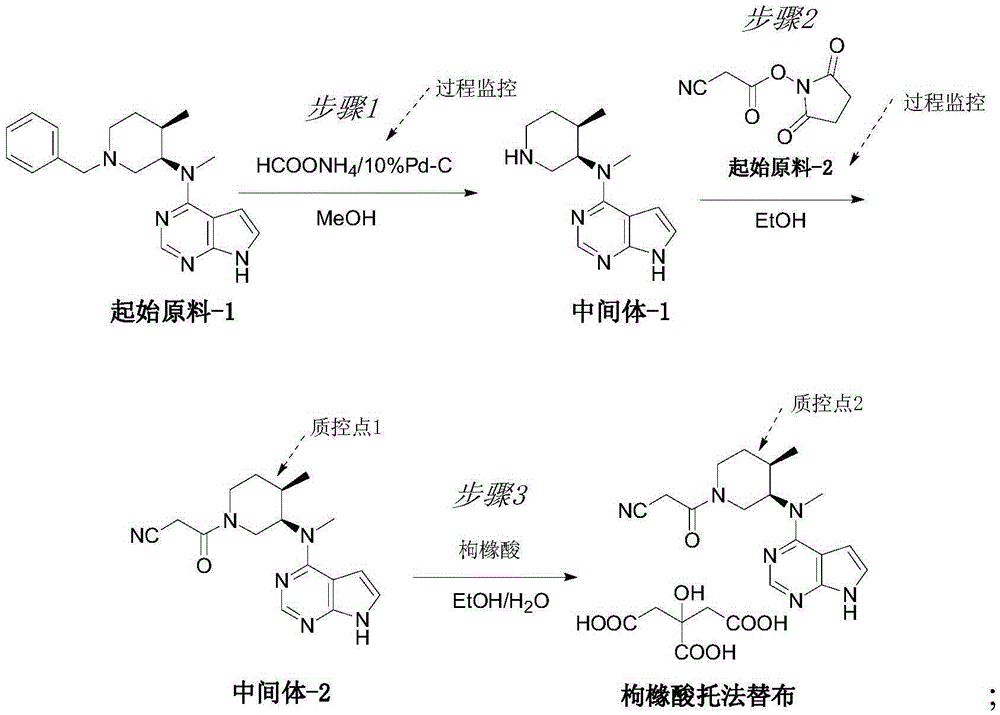

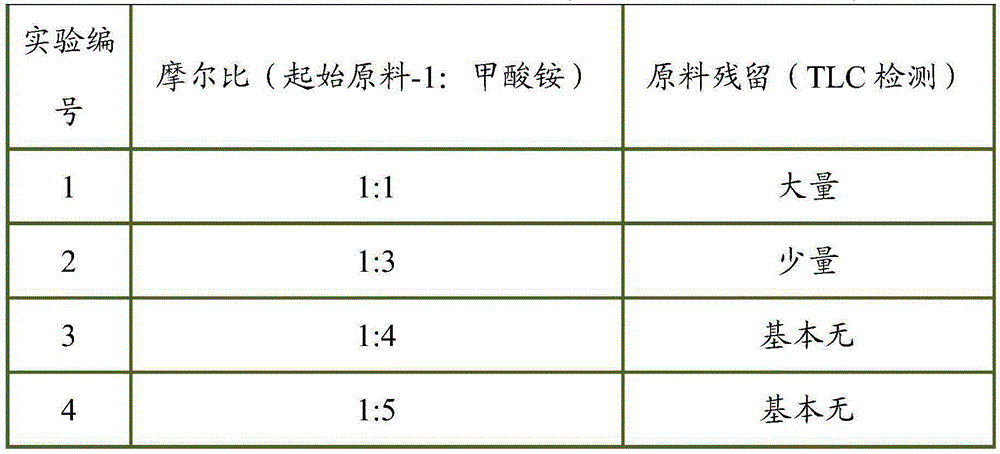

Novel synthetic process of tofacitinib citrate

InactiveCN105348287AReasonable routingMild reaction conditionsOrganic chemistryPalladium on carbonChemical synthesis

The invention discloses a novel synthetic process of tofacitinib citrate. The novel synthetic process comprises the steps that 1, an initial raw material-1, 10% of palladium on carbon, absolute methanol and ammonium formate are mixed in a reaction container, and reacting is carried out to obtain a midbody-1; 2, the midbody-1 prepared in the step 1 is dissolved into absolute ethyl alcohol, an initial raw material-2 is added, reacting is carried out at the reaction temperature of 20 DEG C to 50 DEG C, reaction liquid is purified to obtain a crude midbody-2 after reacting is finished, and the crude midbody-2 is refined to obtain a refined midbody-2; 3, the refined midbody-2 is subjected to heating reflux and dissolved clarification through absolute ethyl alcohol, a citric acid water solution is dropwise added, and reacting continues to be carried out at the temperature of 50 DEG C to 90 DEG C; then the mixture is slowly cooled to 20 DEG C to 45 DEG C, and stirring and devitrification are carried out; crystals are filtered and washed with ethyl alcohol, drying is carried out under reduced pressure at the temperature of 40 DEG C to 60 DEG C, and white crude tofacitinib citrate is obtained. The chemical synthetic process is more reasonable in route, and the reaction conditions are milder.

Owner:NINGBO LIWAH PHARM CO LTD

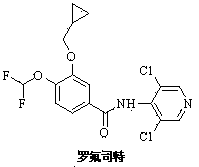

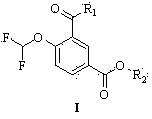

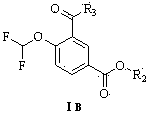

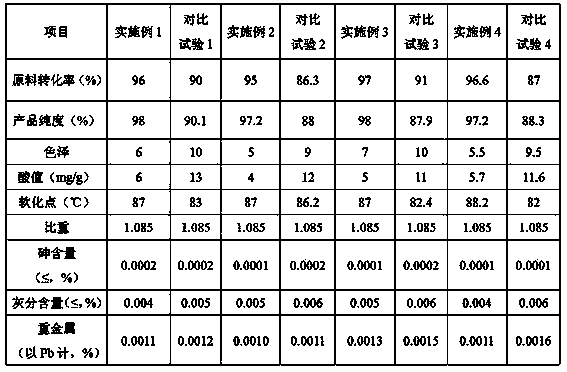

Method for preparing roflumilast intermediate

ActiveCN103539671AMild reaction conditionsHigh purityOrganic compound preparationCarboxylic acid esters preparationPalladium on carbonBiochemical engineering

The invention relates to a new roflumilast intermediate compound and a preparation method thereof, and application of the intermediate compound in preparing roflumilast. The roflumilast prepared from the intermediate has the advantages of mild reaction conditions, low requirements for reaction conditions and equipment, fewer byproducts, high product purity and yield and low production cost, does not use palladium on carbon, carbon monoxide or any other high-cost high-toxicity reagent, and is suitable for large-scale industrial production.

Owner:BEIJING WINSUNNY PHARMA CO LTD

Preparation method of palladium carbon catalyst

ActiveCN102626619AFirmly connectedEliminate Strong Restore CenterOrganic compound preparationCarboxylic compound preparationPalladium on carbonActivated carbon

The invention discloses a preparation method of a palladium carbon catalyst for hydrorefining of terephthalic acid. The method is characterized by employing the following steps of: exposing pretreated particles or molding activated carbon to light hydrocarbon solvent of titanium-containing compounds; filtering and purging with nitrogen gas; drying and impregnating the mixture into a solution of palladium-containing compound; reducing and washing the mixture to neutral, so as to obtain the palladium carbon catalyst. Compared with the prior art, the invention is characterized in that, first, grafted titanium dioxide and its cluster are firmly connected with activated carbon carrier, thereby effectively eliminating a strong reduction center on the activated carbon surface; second, the palladium carbon catalyst has high microcrystal content of metal palladium, good dispersion and high activity of catalyst. and third, the preparation method of the catalyst is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrogenated rosin glyceride

InactiveCN104194641AReduce generationImprove conversion rateNatural resin chemical modificationPalladium on carbonGlycerol

The invention discloses a preparation method of hydrogenated rosin glyceride, which comprises the following steps: adding a rosin and a palladium-carbon catalyst into a reaction kettle, introducing hydrogen gas to carry out addition reaction to obtain the hydrogenated rosin, sequentially adding glycerol and zinc oxide, and carrying out esterification reaction to obtain the hydrogenated rosin glyceride. The hydrogenated rosin glyceride has the advantages of light color, no peculiar smell, favorable mouthfeel, chewing resistance, favorable foaming property and favorable plasticity, and can be used instead of food-grade rosin glyceride as a chewing gum bodying agent in bubble gum, chewing gum, gum, sugar-free gum and other products.

Owner:WUZHOU CAYIN GUM

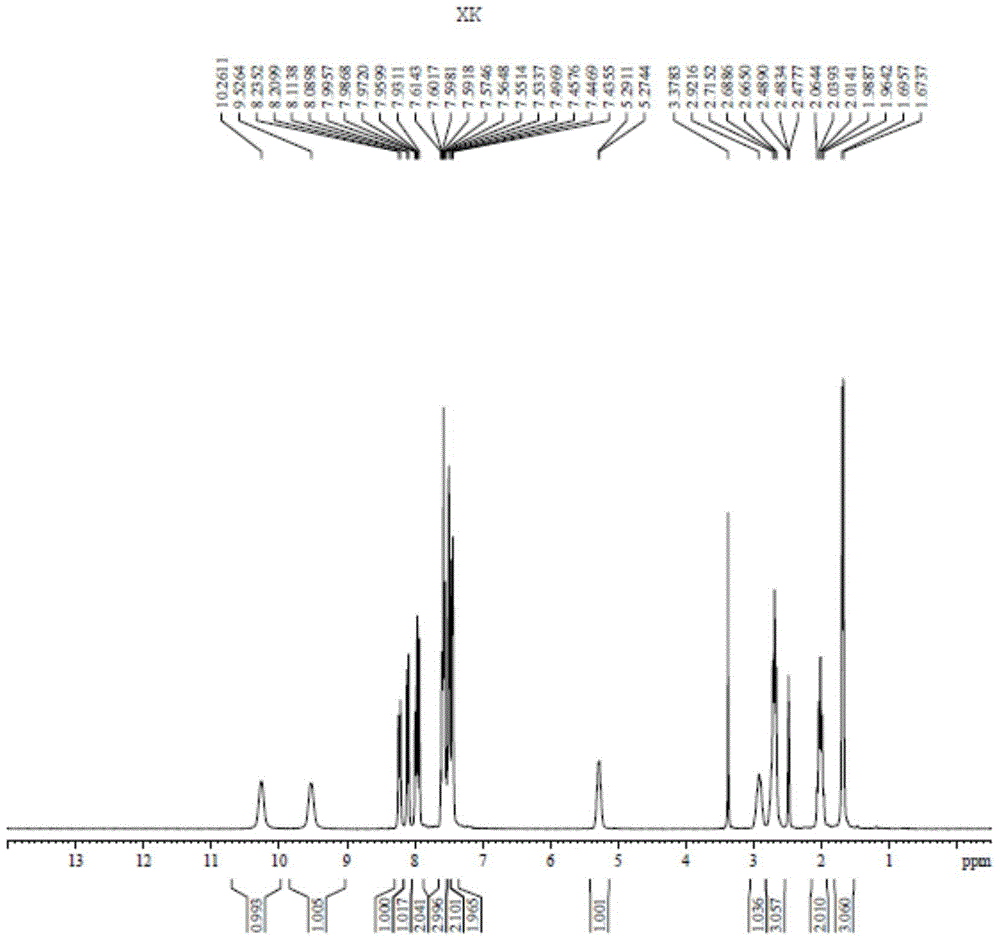

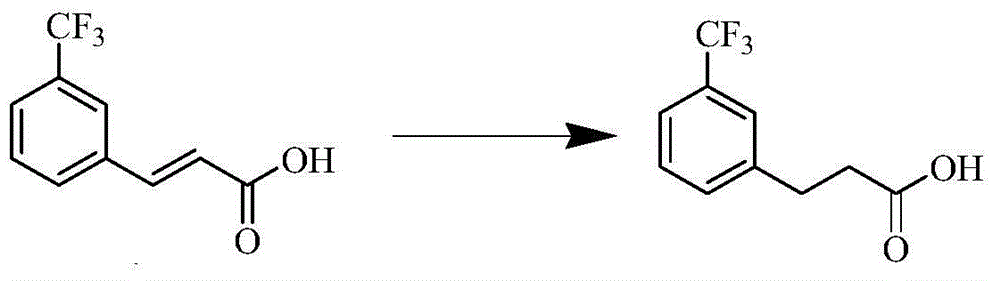

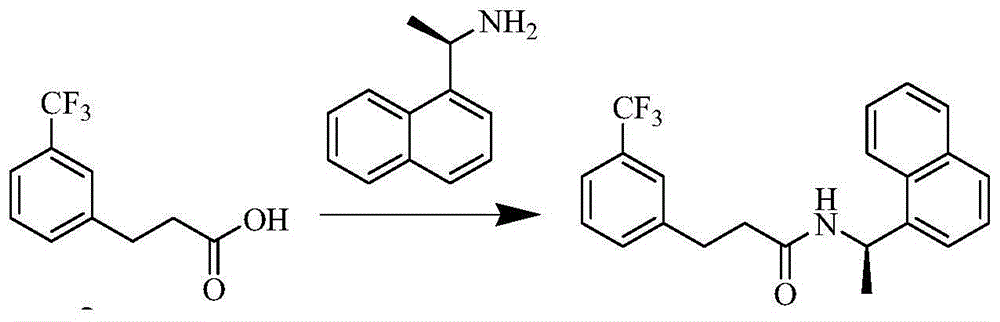

Cinacalcet hydrochloride preparation method

InactiveCN104478736ALow impurity contentNo pollution in the processOrganic compound preparationAmino compound preparationPalladium on carbonCinacalcet Hydrochloride

The invention provides a cinacalcet hydrochloride preparation method which comprises the following steps: (A) by taking trifluoromethylcinnamic acid as a raw material and palladium on carbon as a catalyst, performing hydrogenation reduction to obtain m-trifluoromethylbenzoic acid; (B) performing condensation reaction on the m-trifluoromethylbenzoic acid and R-(1) naphthylethylamine, thus obtaining (R)-N-(1-(naphthalen-1-yl)ethyl)-3-(trifluoromethyl)phenyl)propanamide; (C) performing catalytic reduction on the (R)-N-(1-(naphthalen-1-yl)ethyl)-3-(trifluoromethyl)phenyl)propanamide to obtain cinacalcet; and (D) reacting the cinacalcet and hydrochloric acid to obtain cinacalcet hydrochloride. The method has the advantages of thorough reaction, high yield, no pollution in the reaction process and the like.

Owner:CHENGDU QITAI PHARMA TECH

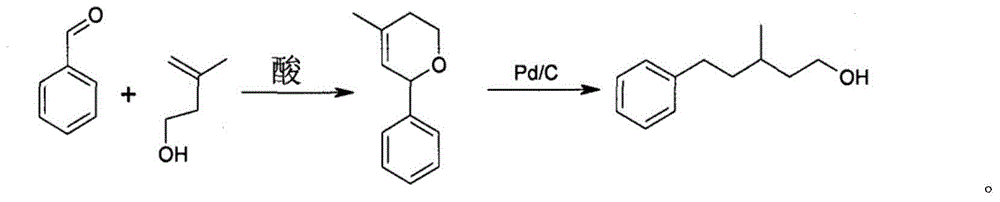

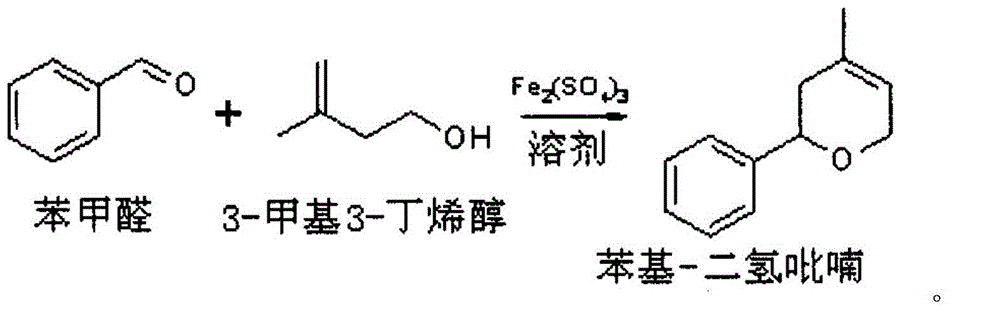

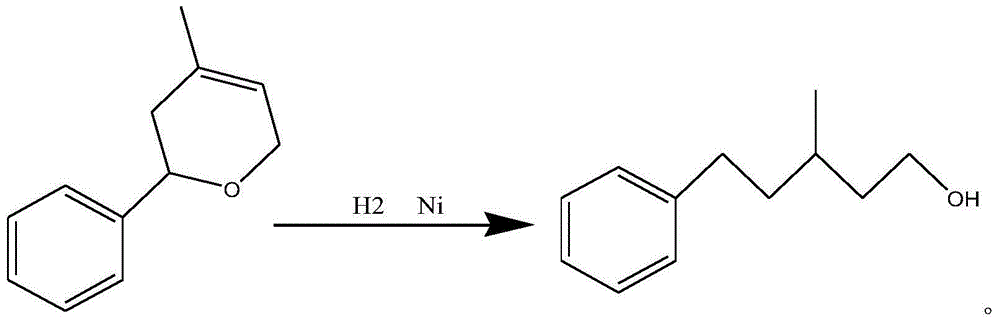

Process for preparing benorilate amyl alcohol

InactiveCN104876800AHigh yieldHigh hydrogenation yieldPreparation by hydrogenationPalladium on carbonAmyl alcohol

The invention belongs to the technical field of fine chemicals and relates to benorilate amyl alcohol, particularly a process for preparing benorilate amyl alcohol. According to the technical scheme of the invention, phenyl dihydro pyran is synthesized firstly, and then is hydrogenated preliminarily. The reaction liquid of phenyl dihydro pyran is filtered, and the filtered clear liquid is hydrogenated. After that, the filtered clear liquid is filtered and washed, and benorilate amyl alcohol can be obtained through decompressing and rectifying the obtained crude product. According to the invention, benorilate amyl alcohol is prepared by means of a Raney-Ni catalyst and a Pd / C catalyst successively through the secondary hydrogenation process, so that the hydrogenation yield is high. Meanwhile, enorilate amyl alcohol, as a final product, is large in yield. Therefore, the industrialization of the above process is high in production and promotion value.

Owner:江苏绿源精细化工有限公司

Preparation method for 2,3-dichloropyridine

The invention discloses a preparation method for 2,3-dichloropyridine. The method provided by the invention is carried out through the following steps: with 2,3,6-trichloropyridine as a raw material,a basic compound as an acid-binding agent, palladium on carbon as a catalyst and hydrogen as a hydrogen source, carrying out a hydrodechlorination reaction in a pure organic solvent system at a temperature of 20 to 100 DEG C and a pressure of 1.0 to 8.0 Mpa under stirring with a rotating speed controlled to be 100 to 1000 rmp / min, and after the reaction is performed for 2 to 10 h, subjecting a reaction liquid to post-treatment so as to obtain a 2,3-dichloropyridine product. The preparation method provided by the invention has the following advantages: the conversion rate of the raw material is95% or above; the selectivity of the product can reach 88%; meanwhile, the usage amount of the catalyst is small; operation is simple; the requirements for equipment are low; a solvent is easy to recycle; the product is easy to separate; the quality of the product is high; few three wastes are produced; and the preparation method is a green process applicable to industrial production.

Owner:CHONGQING ZHONGBANG TECH CO LTD

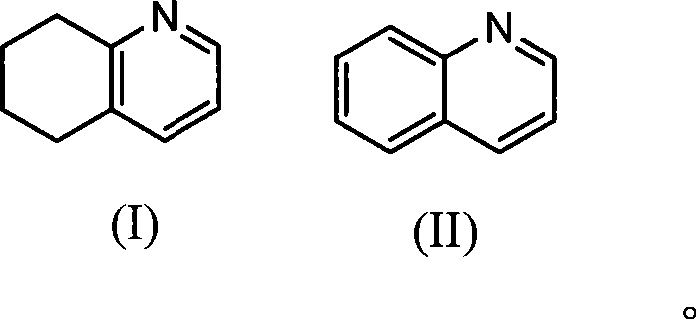

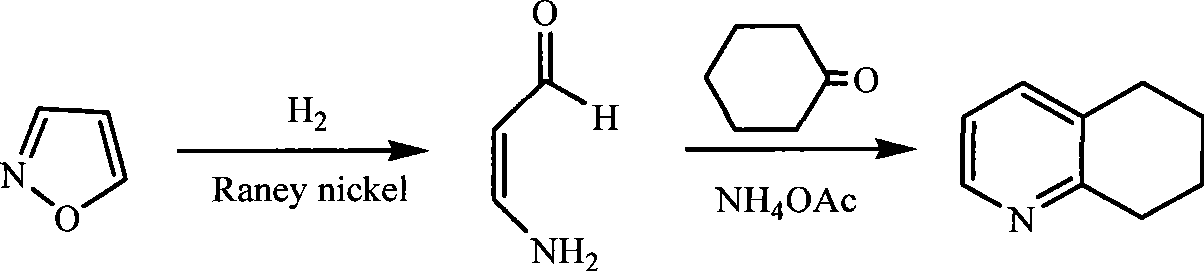

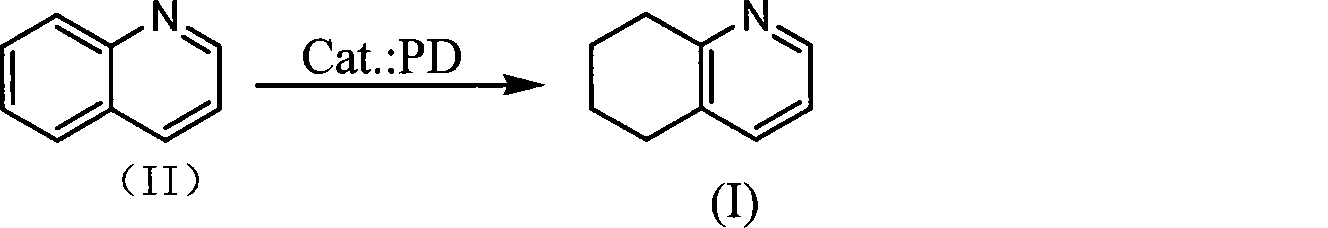

Method for synthesizing 5,6,7,8-tetrahydroquinoline

ActiveCN101544601AAvoid pollutionReduce lossesOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonIsomerization

The invention discloses a method for synthesizing 5,6,7,8-tetrahydroquinoline represented by a formula (I), which comprises the following steps: using quinoline represented by a formula (II) as a raw material and using PD as a catalyst, performing a catalytic hydrogenation reaction at a temperature of between 20 and 110 DEG C till the pressure of hydrogen is constant; emptying the hydrogen till the pressure is 2 atmospheres; stirring and raising temperature to between 140 and 300 DEG C to perform an isomerization reaction for 1 to 4 hours; and performing post treatment of reaction products after the reaction is finished to obtain the 5,6,7,8-tetrahydroquinoline. The method for preparing the PD catalyst comprises the following steps: adding a palladium-carbon catalyst with a palladium loading capacity of 5 weight percent into an aqueous of a hydrochloride, stirring the solution and heating the solution to between 10 and 50 DEG C, and adding a supercarbonate solution in the same amount into the solution; stirring the mixed solution for 1 to 4 hours; filtering the mixed solution; washing a filter cake; and drying the filter cake to obtain the PD catalyst. The method adopts the self-prepared PD catalyst with special selectivity, so the hydrogenation reaction and the isomerization reaction are continuative, the reaction temperature is reduced greatly, the material loss and energy consumption are reduced and the yield is improved greatly.

Owner:GREAT FOREST BIOMEDICAL LTD

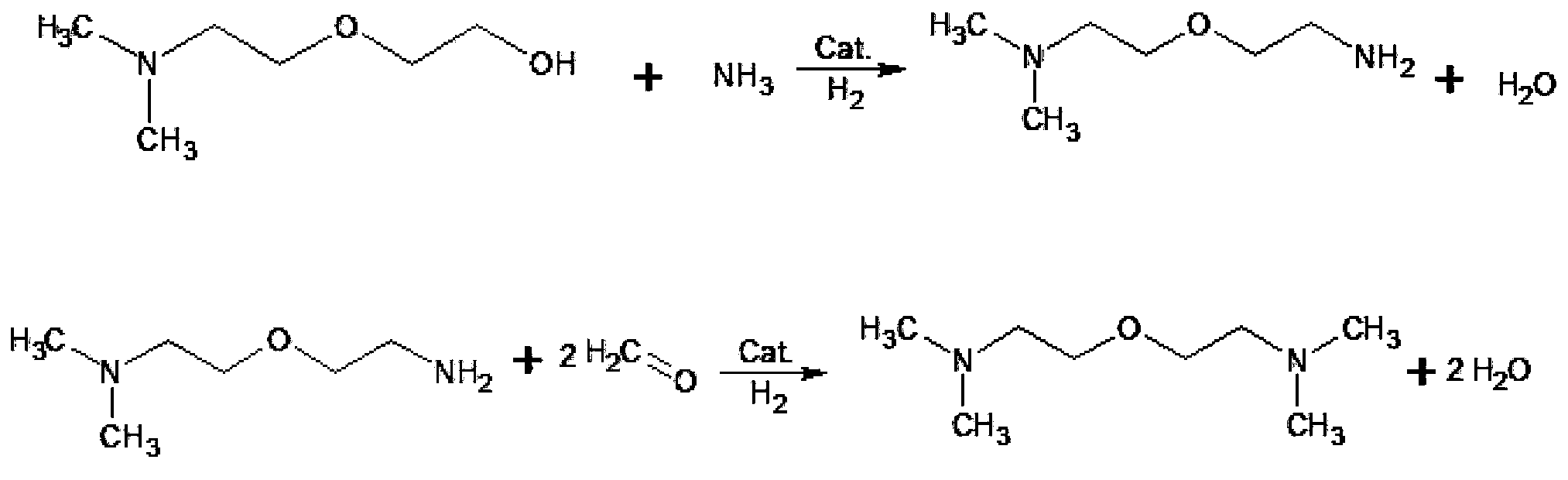

Preparation method of bis(2-dimethyl aminoethyl) ether

ActiveCN103450035ARaw materials are easy to getSimple processOrganic compound preparationAmino-hyroxy compound preparationPalladium on carbonHydrogen

The invention discloses a preparation method of bis(2-dimethyl aminoethyl) ether. The preparation method comprises the following steps: adding dimethyaminoethoxyethanol, water and a Cu-Al / diatomite catalyst into a high-pressure reaction kettle, introducing nitrogen to perform replacement, introducing anhydrous liquid ammonia and hydrogen, heating to 100-250 DEG C, reacting for 3-15 hours under the pressure of 5-15 Mpa and keeping stirring; cooling and emptying to normal pressure after the reaction is finished, discharging, filtering the catalyst and rectifying filtrate; adding rectified dimethyaminoethoxyethanol, adding a Pd / C palladium carbon catalyst, introducing nitrogen to perform replacement, then introducing hydrogen to maintain the pressure to be 0.5-5 Mpa, heating to 50-60 DEG C, adding formaldehyde, heating to 60-150 DEG C, reacting for 3-10 hours under the pressure of 0.5-5 Mpa, introducing hydrogen and keeping stirring; cooling and emptying to normal pressure after the reaction is finished, discharging, filtering the catalyst and rectifying the filtrate to obtain the bis(2-dimethylaminoethyl) ether. The preparation method has the advantages of simple process and high yield.

Owner:GOLDENKEYS HIGH TECH MATERIALS CO LTD

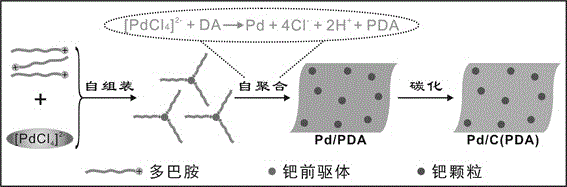

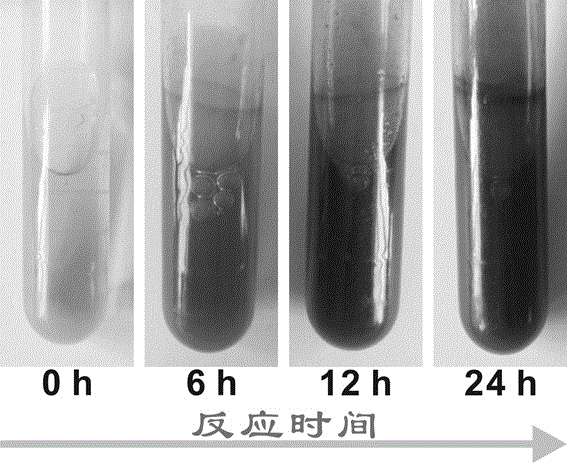

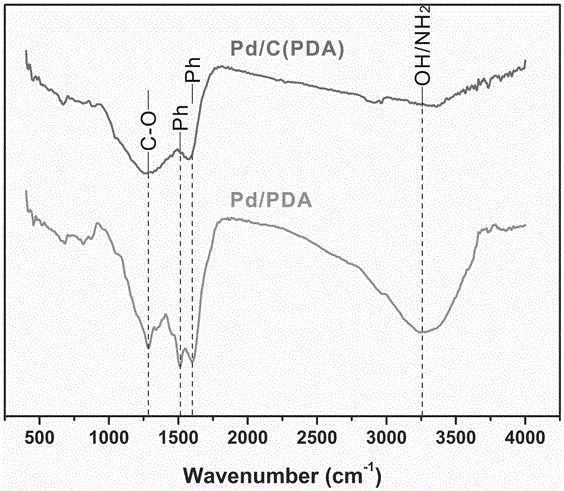

Method for preparing supported palladium/carbon catalyst through self-polymerization of dopamine, and application

The invention belongs to the technical field of preparation, relates to preparation of supported palladium / carbon catalyst and particularly relates to a method for preparing supported palladium / carbon catalyst through self-polymerization of dopamine, and application. The method for preparing the supported palladium / carbon catalyst through self-polymerization of dopamine comprises the steps of enabling metal precursor chloropalladite and DA to automatically carry out oxidation-reduction reaction in an alkalescence (pH 8.5) environment, thereby obtaining Pd / PDA compound; and carbonizing Pd / PDA compound in inert atmosphere (N2), thereby obtaining the supported Pd / C(PDA) catalyst. The preparation method disclosed by the invention is very simple, is few in step and convenient in operation. Through control of input of the metal precursor, the capacity of precious metal can be controlled. The supported palladium / carbon catalyst prepared by the method has excellent activity for electrocatalytic oxidation of methanol in the alkaline environment and has good application prospect in the field of a low-temperature methanol fuel cell.

Owner:江阴智产汇知识产权运营有限公司

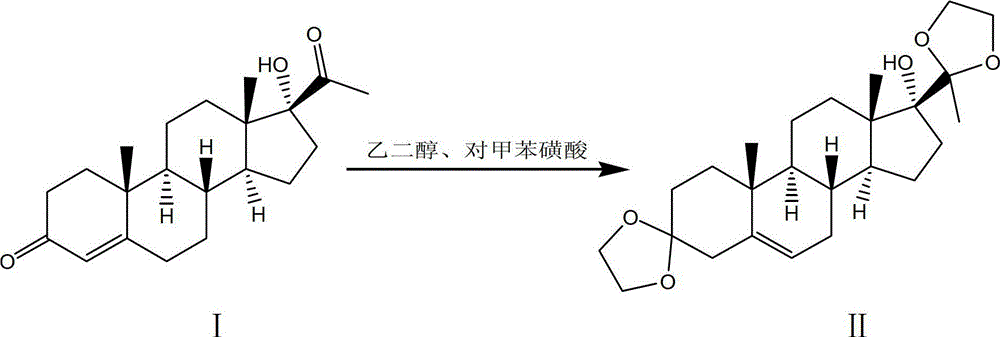

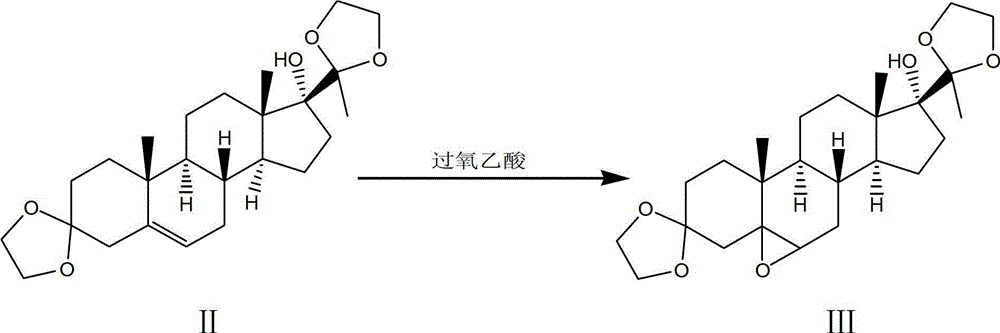

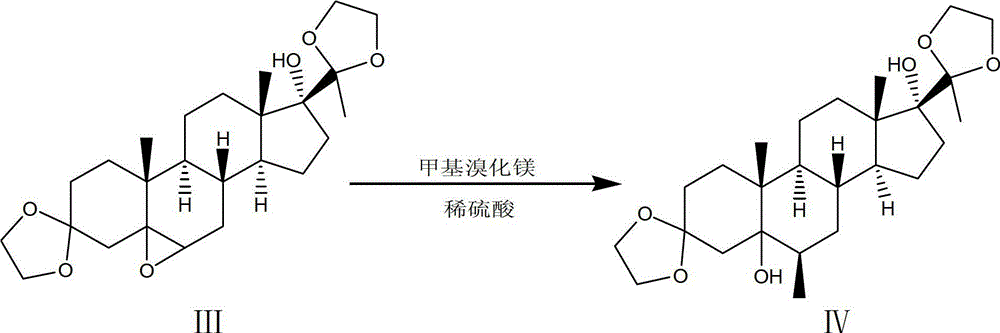

Synthesis method of medroxyprogesterone acetate

The invention discloses a synthesis method of medroxyprogesterone acetate. The method comprises the following steps of: 1) enabling 17 alpha-hydroxyprogesterone and ethylene glycol to perform ketalation under the catalysis of para-toluenesulfonic acid to obtain a ketal; 2) enabling the ketal to perform epoxidation reaction under the action of a peroxyacetic acid solution of anhydrous sodium acetate to obtain an epoxide; 3) enabling the epoxide and methylmagnesium bromide to perform Grignard reaction, and then performing hydrolysis reaction by dilute sulphuric acid to obtain a Grignard matter; 4) performing hydrolysis on the Grignard matter by glacial acetic acid to perform deprotection so as to obtain 5 alpha, 17 alpha-dihydroxy-6 beta-methyl progesterone; 5) performing hydrogenation translocation reaction under the action of hydrogen chloride to obtain 6 alpha-methyl-17 alpha-hydroxyprogesterone; and 6) enabling the 6 alpha-methyl-17 alpha-hydroxyprogesterone to perform acetylation reaction with acetic acid and acetic anhydride so as to obtain the medroxyprogesterone acetate. During the reaction process of the method disclosed by the invention, the use of a precious metal catalyst, namely palladium on carbon is avoided, the cost of auxiliary materials and the recovery cost are greatly reduced, the reaction conditions in each step are mild, the violent heat release and deflation phenomena are avoided, and the safety in production is good.

Owner:BAOJI KANGLE BIOTECH

Method for preparing coated-type palladium carbon catalyst

InactiveCN105536867AInhibit aggregationStop lossCatalyst protectionOrganic-compounds/hydrides/coordination-complexes catalystsPalladium on carbonSlurry

A method for preparing a coated-type palladium carbon catalyst comprises the following steps: a) preparing a solution of a palladium salt; b) adding a certain amount of a stabilizer and a reducer into the solution of the palladium salt to form a nano palladium suspension at a certain temperature from the palladium salt; c) after adding a certain amount of the stabilizer into the nano palladium suspension, continuing to add a solution of an embedding agent, adjusting the pH with an alkali liquid for hydrolysis of the embedding agent to produce a coated nano palladium particles; and d) Finally, adding the coated nano palladium particles into active carbon charcoal slurry to obtain the coated-type palladium carbon catalyst; technical effects are that after metal palladium is coated, on one hand, loss, coalescing or poisoning of the metal palladium in a subsequent reaction process can be effectively reduced, on the other hand the coated-type palladium carbon catalyst has certain hydrophobic or hydrophilic effect, the use range and cycle times of the coated-type palladium carbon catalyst can be improved, the plant cost can be reduced, environmental pollution can be reduced, and the coated-type palladium carbon catalyst is more in line with the concept of green chemistry. The preparation method is simple and easy, raw materials are cheap and easily obtained, and the method is more suitable for industrial production.

Owner:ZHEJIANG METALLURGICAL RES INST

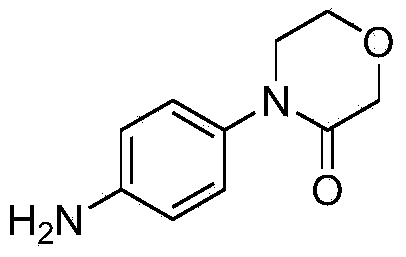

Preparation method of 4-(4-amino phenyl)-3-morpholone and intermediate of 4-(4-amino phenyl)-3-morpholone

ActiveCN103804221AEasy to synthesizeLow costOrganic compound preparationSulfonic acid esters preparationPalladium on carbonNitration

The invention belongs to the technical field of preparing 4-(4-amino phenyl)-3-morpholone, especially relates to a preparation method of 4-(4-amino phenyl)-3-morpholone and intermediate of the 4-(4-amino phenyl)-3-morpholone. The method comprises the following steps: amide intermediate cyclization, nitration, and reduction. The raw material aniline is a low-cost chemical, and the acylation raw material is easy to synthetize and low in cost. Compared with documents in which acylation is directly carried out after nitration, in the method disclosed by the invention, nitration is carried out after acylation, so that the method disclosed by the invention has the advantages no substituted group protection, high selectivity, less steps, high yield and the like. The preparation process does not need harsh reaction conditions such as high pressure, high temperature and deep cooling and also does not need an expensive palladium-carbon catalyst, and meets the requirements of industrial production.

Owner:HUBEI XUNDA PHARMA

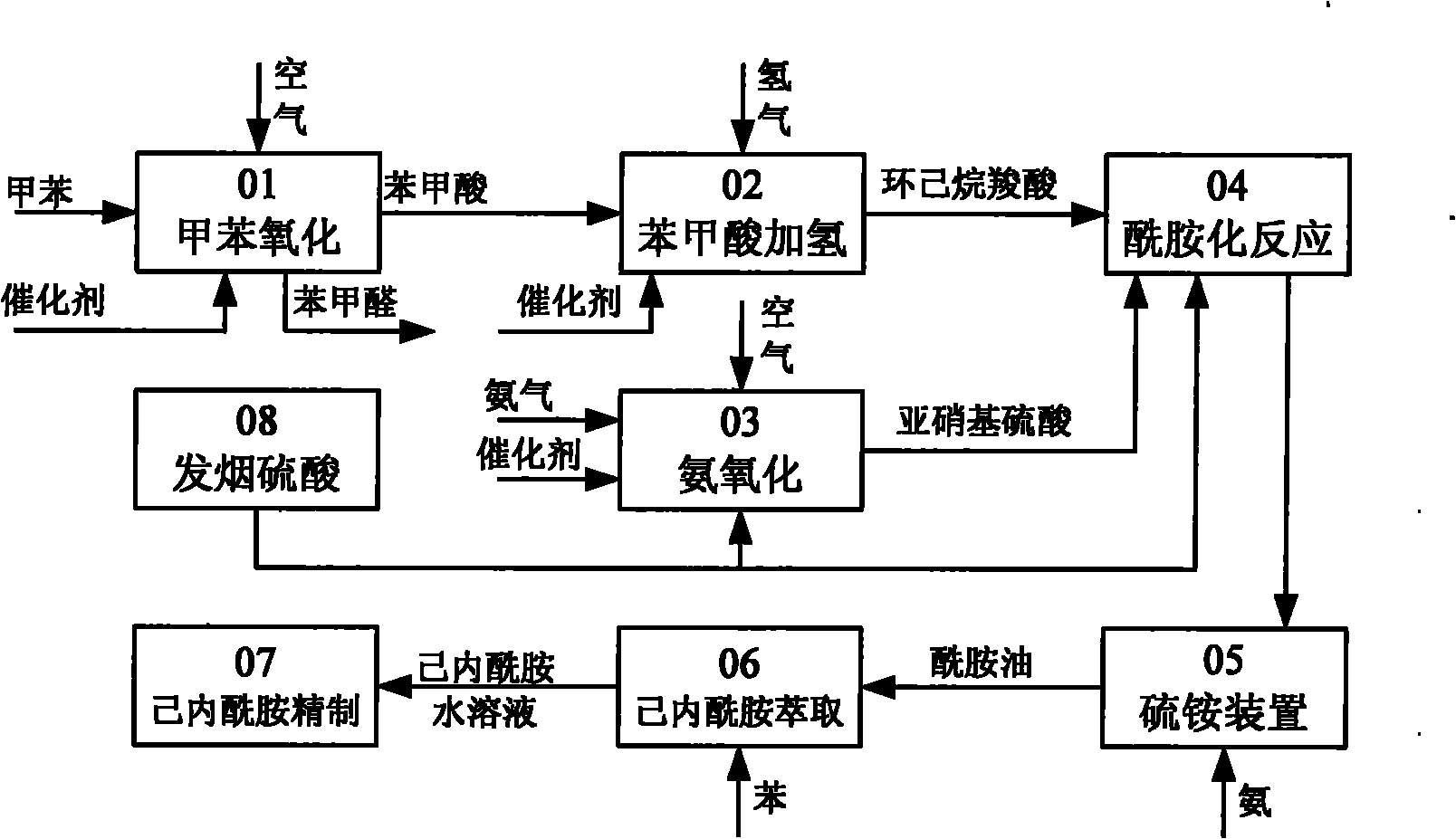

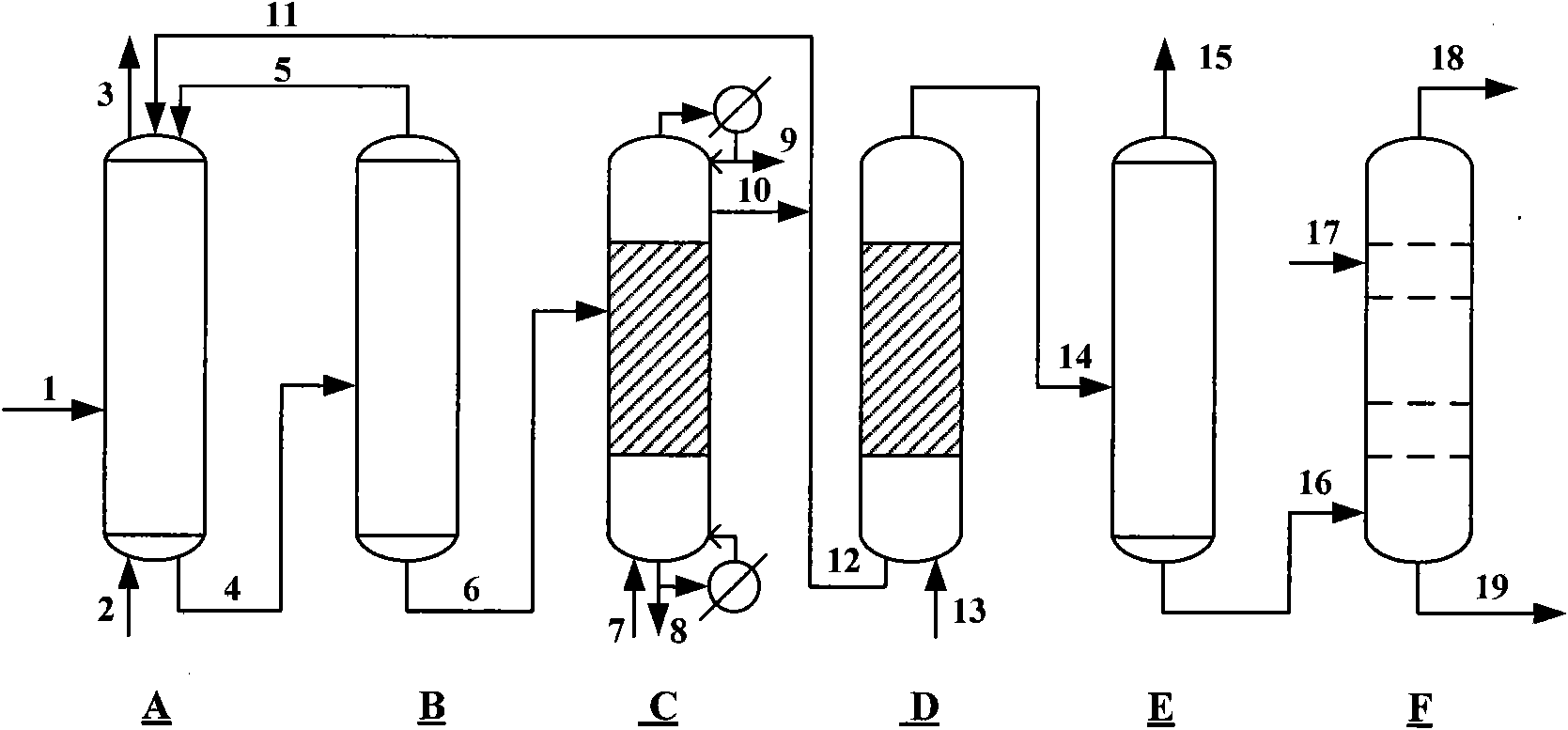

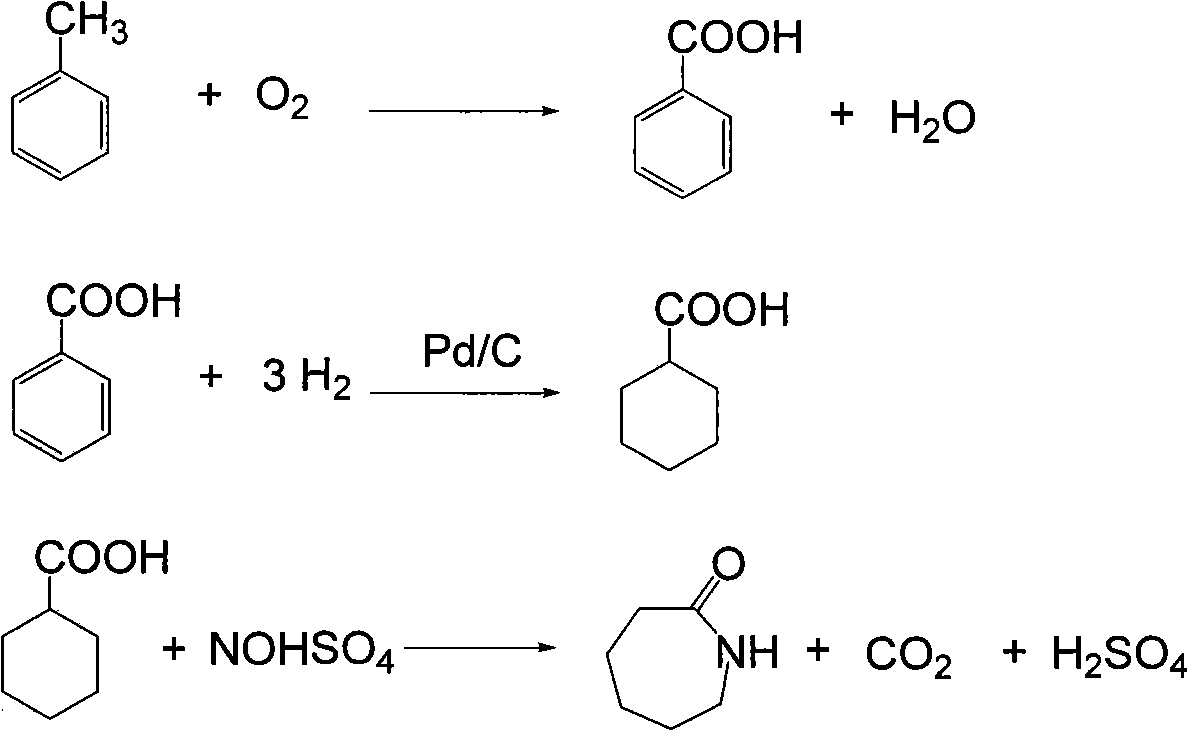

Method for producing caprolactam by methylbenzene

ActiveCN102060767AEasy to separateReduce corrosionLactams preparationPalladium on carbonBenzoic acid

Owner:中科化物(大连)科技实业有限公司

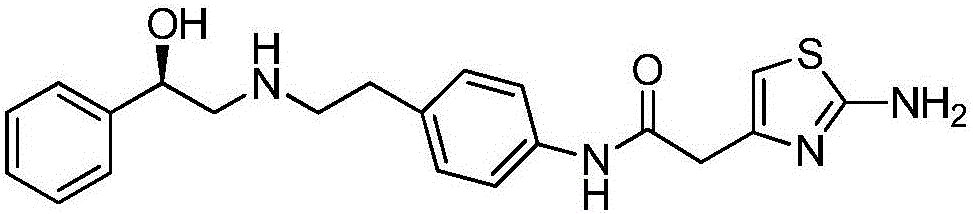

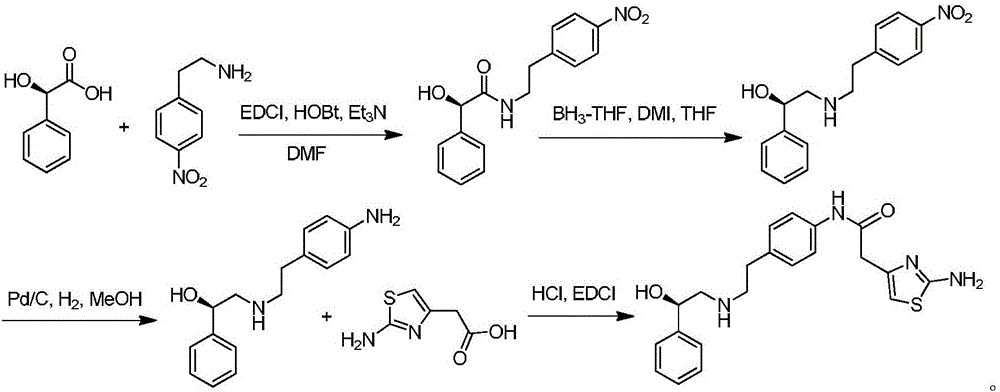

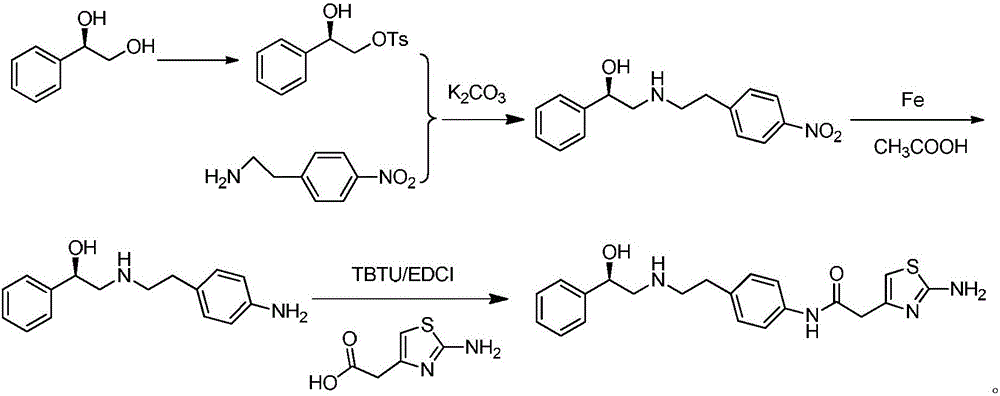

Efficient synthesis method of mirabegron

InactiveCN106083758AThe reaction route is simpleLower reaction costOrganic chemistryPalladium on carbonHydrazine compound

The invention discloses an efficient synthesis method of mirabergron. The method comprises the specific steps that nitrophenylacetonitrile is subjected to a nitroreduction and nitrile group reduction reaction in hydrazine hydrate under the catalysis effect of a catalyst of palladium on carbon hydrogenation to obtain ethylamine; (R)-1-phenyl-1,2-ethanediol and methylsulfonyl chloride react under the catalysis effect of a basic catalyst of piperidine or triethylamine to obtain (R)-1-phenyl-1-hydroxy-2-mesyl-ethane; the (R)-1-phenyl-1-hydroxy-2-mesyl-ethane and the ethylamine react under the catalysis effect of a basic catalyst of potassium carbonate or triethylamine to obtain (R)-2-((4-amino phenyl ethyl amine)-1-phenethyl alcohol; the (R)-2-((4-amino phenyl ethyl amine)-1-phenethyl alcohol and 2-aminothiazole-4-ethyl acetate are subjected to a condensation reaction under the effect of potassium methoxide to obtain mirabergron. The method is simple and easy to implement, the raw materials are cheap and easy to obtain, the reaction efficiency is high, and the repeatability is good.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com