Patents

Literature

455 results about "Propanamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propanamide has the chemical formula CH₃CH₂C=O(NH₂). It is the amide of propanoic acid. This organic compound is a mono-substituted amide. Organic compounds of the amide group can react in many different organic processes to form other useful compounds for synthesis.

Melatonin agonist treatment

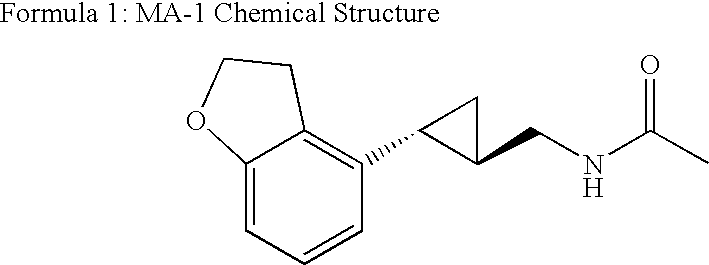

This invention provides methods of administering (1R-trans)-N-[[2-(2,3-dihydro-4-benzofuranyl)cyclo-propyl]methyl]propanamide as a melatonin receptor agonist to a human subject to treat or prevent a circadian rhythm disorder or sleep disorder.

Owner:VANDA PHARMA INC

Liquid and Semi-Solid Pharmaceutical Formulations for Oral Administration of a Substituted Amide

InactiveUS20070298099A1Improve oral bioavailabilityImprove compoundBiocideNervous disorderAntioxidantSolvent

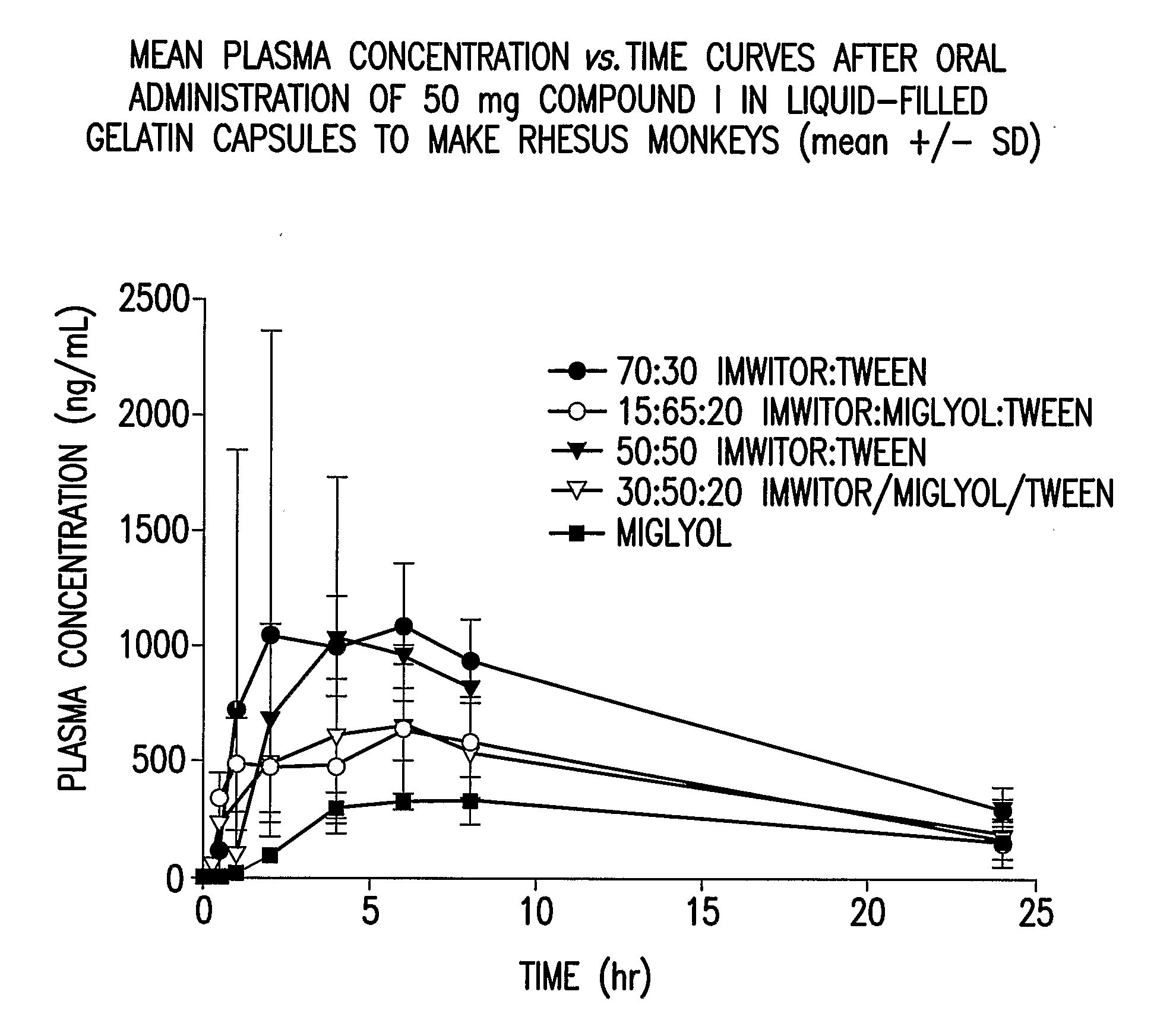

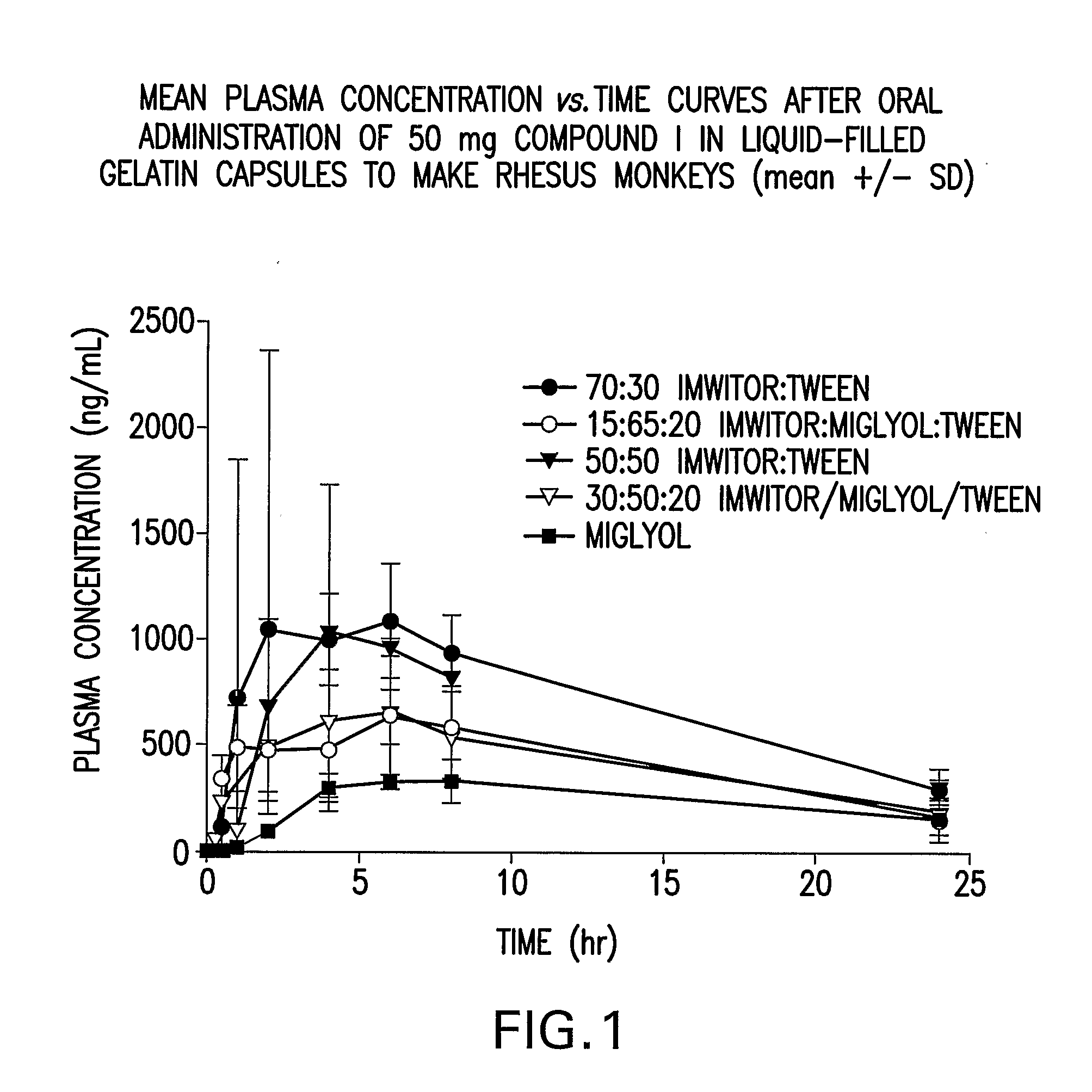

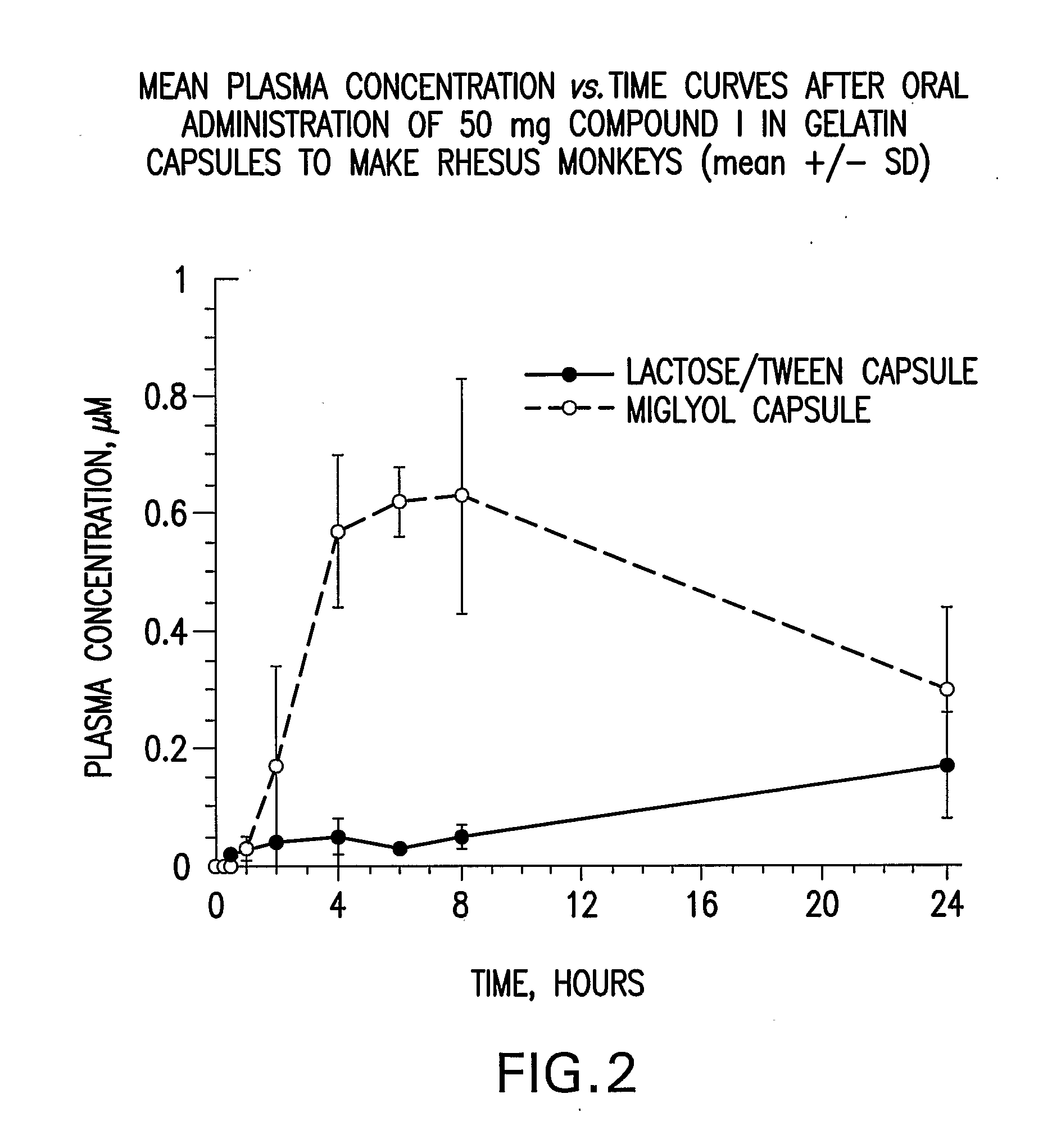

N-[1S,2S]-3-(4-chlorophenyl)-2-(3-cyanophenyl)-1-methylpropyl]-2-methyl-2-{[5-trifluoromethyl]pyridine-2-yl}oxy}propanamide (Compound I) has surprisingly improved solubility and bioavailability in a lipophilic vehicle comprising a pharmaceutically acceptable digestible oil, a surfactant, or a cosolvent, or a mixture of any two or more thereof. In one embodiment of the present invention are self-emulsifying or self-microemulsifying composition comprising 1) Compound I; 2) a surfactant having an HLB of 1 to 8; and 3) a surfactant having an HLB of over 8 to 20; and optionally, 4) a digestible oil and / or cosolvent and / or antioxidant or preservative.

Owner:MERCK SHARP & DOHME CORP

Indole-3-propionamide and derivatives thereof

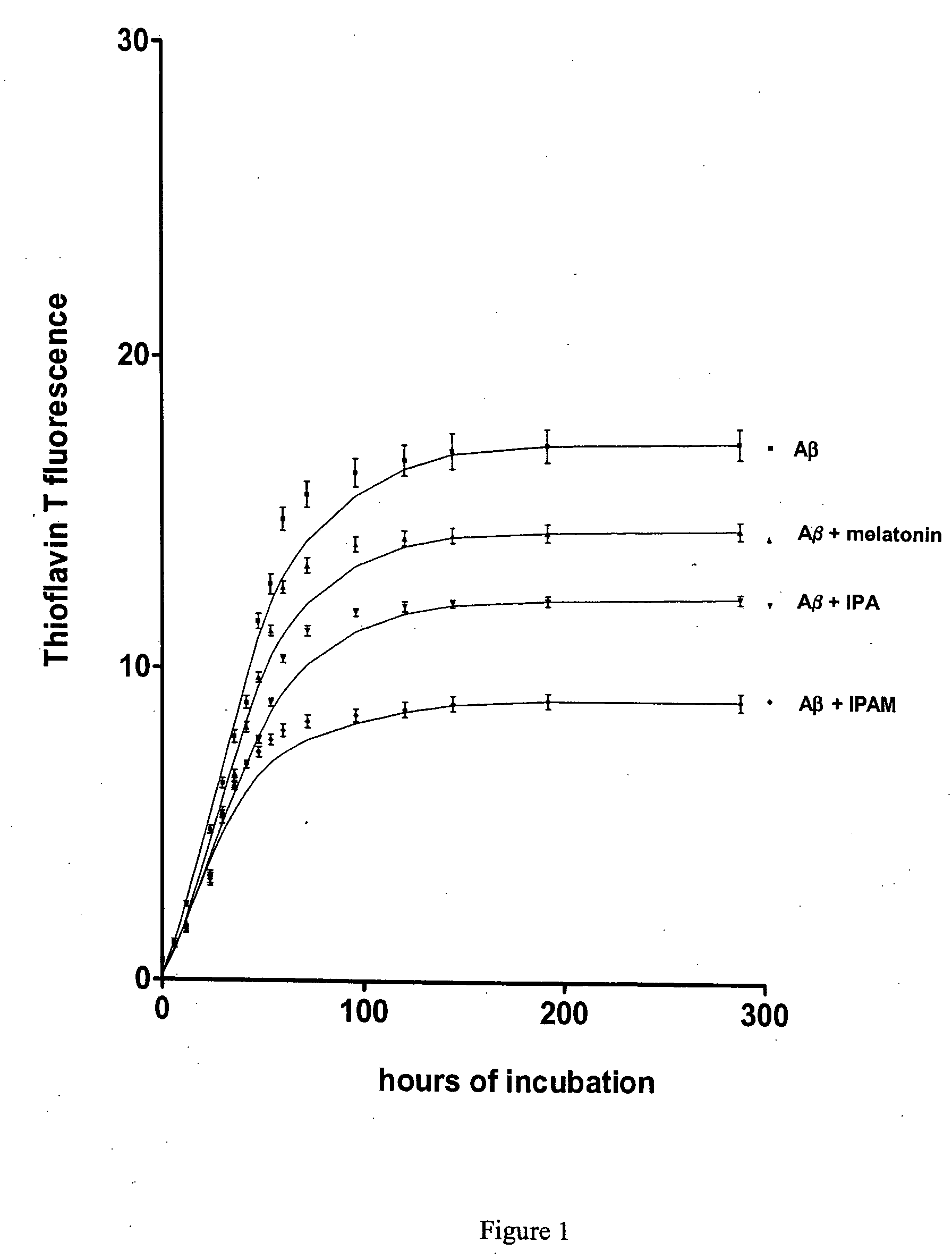

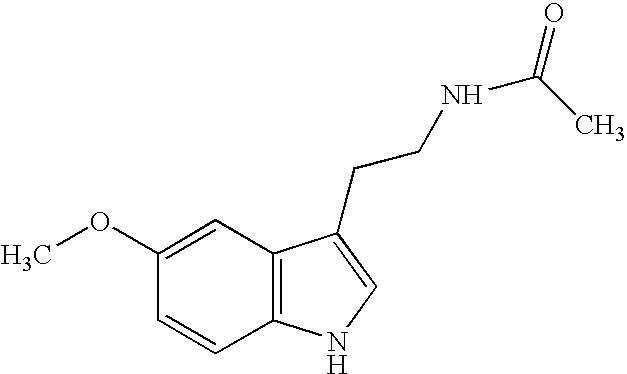

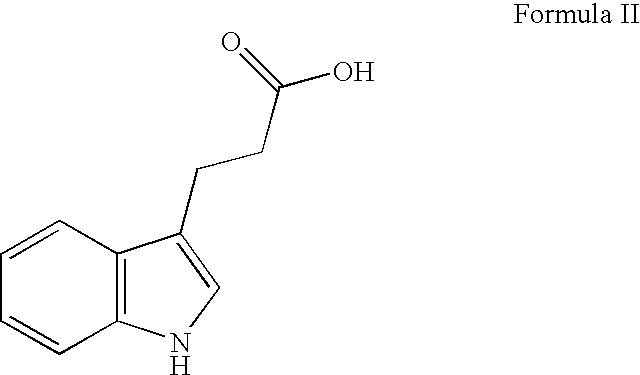

InactiveUS20070105937A1Sufficient lipophilicityImprove stabilityBiocideTetracycline active ingredientsAge related diseaseMedicine

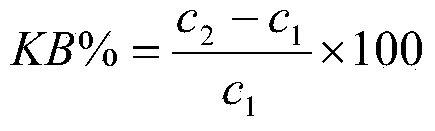

Indolepropionamide (IPAM) and related compounds, pharmaceutical or dietary compositions thereof and methods of using said compounds are disclosed for use as a preventative or therapeutic treatment for many conditions related to oxidative damage. Oxidative damage increases in aging and age related disorders and is widespread in many neurodegenerative conditions including Alzheimer's disease, Parkinson's disease and others. Indolepropionamide is a potent anti-oxidant and anti-aging molecule, with superior properties as compares to previously known compounds.

Owner:PAPPOLLA MIGUEL +1

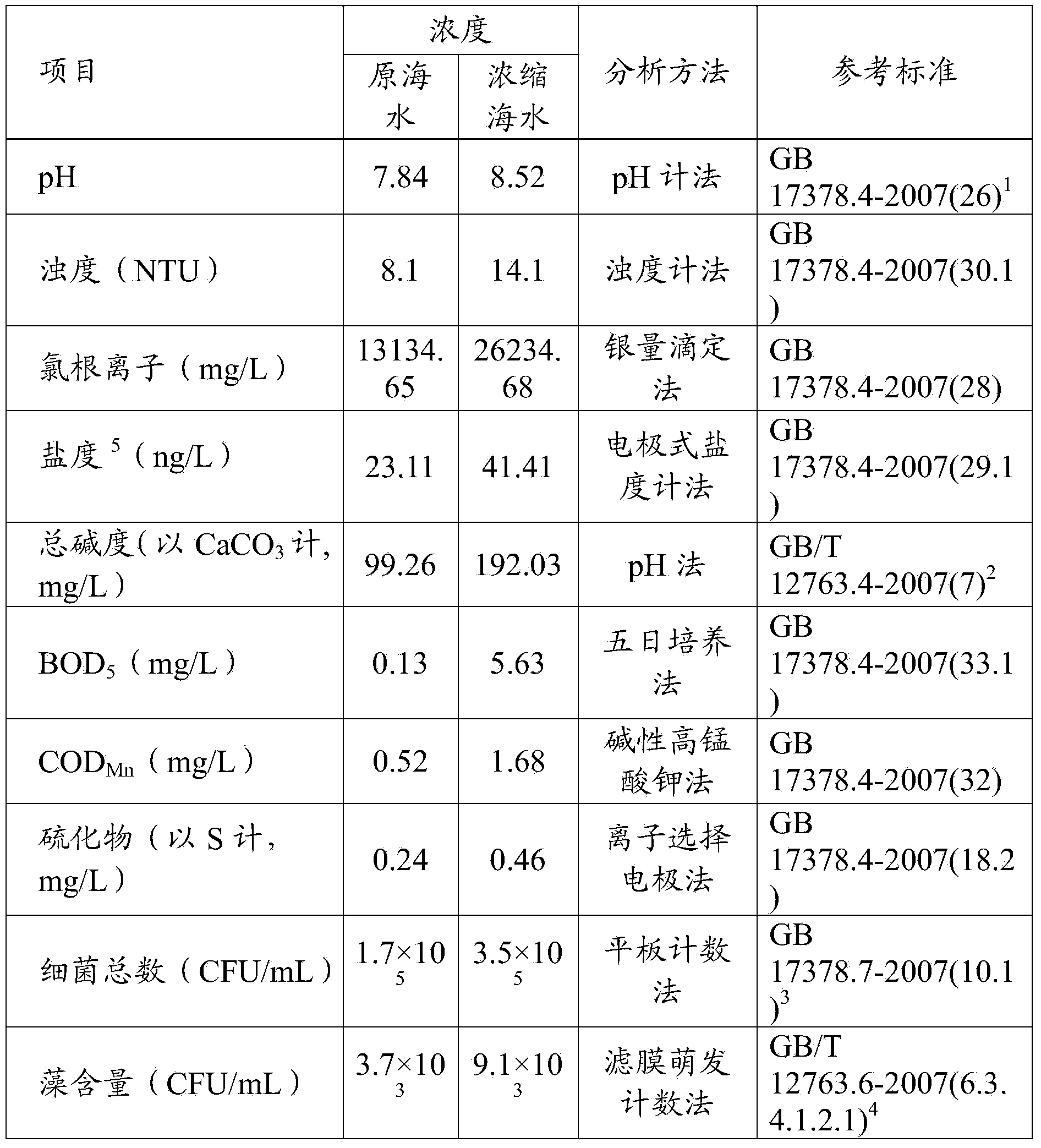

Composite bacteria and algae inhibitor and application thereof

ActiveCN104068028AHigh biodegradation rateGood use concentrationBiocideSeawater treatmentChemical industryBacterioplankton

The invention belongs to the fields of chemical industry and water treatment and in particular relates to a composite bacteria and algae inhibitor and application thereof. The composite bacteria and algae inhibitor contains the following components in percentage by mass: 1-40 percent of isothiazolinone, 5-40 percent of 2,2-dibromo-3-nitrilo-propanamide, 20-60 percent of solvent and 10-70 percent of water. The composite bacteria and algae inhibitor is a non-oxide biocide, and when the bacteria and algae inhibitor is applied to a water treatment system, an impact type intermittent dosing mode is adopted, and the addition amount of the bacteria and algae inhibitor in each liter of water is 1mg-100mg. The components in the formula have an obvious synergistic effect and are high in compatibility with a scale inhibitor and a corrosion inhibitor, and the bacteria and algae inhibitor is low in biotoxicity and high in biodegradation rate, has the effects of killing and inhibiting bacterioplankton and algae in water and has effects of stripping and inhibiting bacteria and algae attachments settling and growing on equipment surfaces. During actual application, the composite bacteria and algae inhibitor has the advantages of small addition amount, low using cost, convenience in operation, pollution-free discharge and the like.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

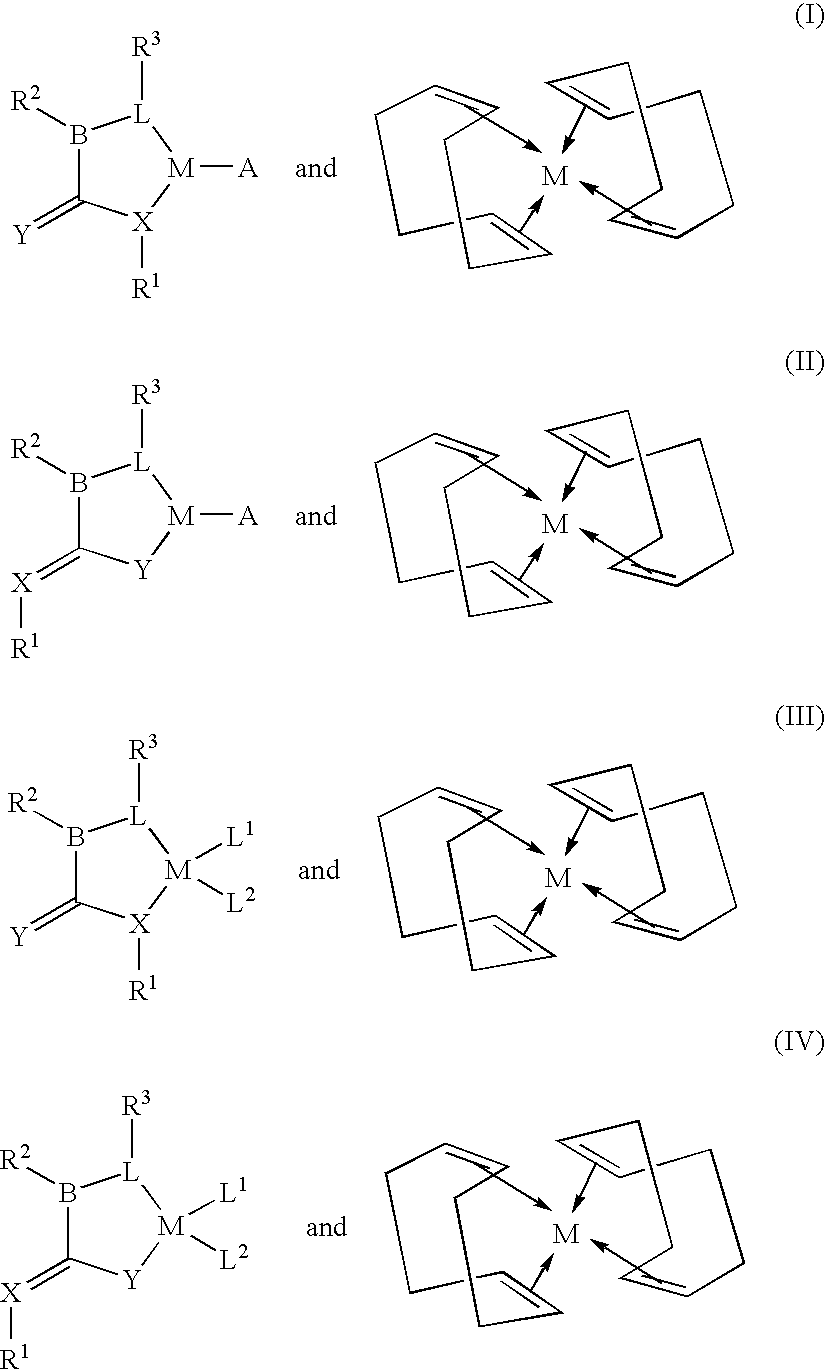

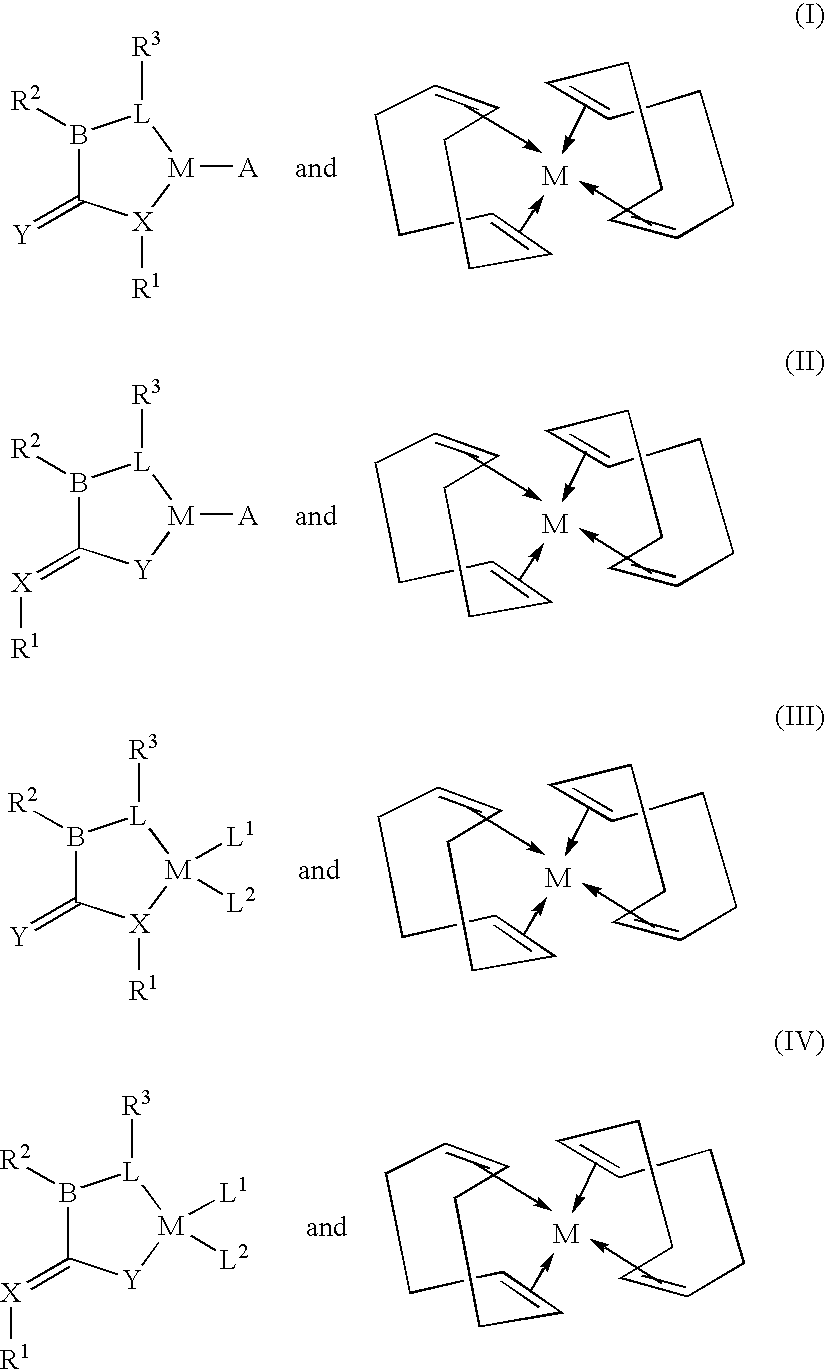

Metal catalyst for olefin polymerization and co-polymerization with functional monomers

InactiveUS20040171479A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationFunctional monomerPolyolefin

A catalyst is disclosed for the polymerization and co-polymerization of olefins with functionalized monomers. The catalyst is formed from a combination of two neutral metal complexes, L(Pr2)M(CH2Ph)(PMe3)[L=N-(2,6-diisopropylphenyl)-2-(2,6-diisopropylphenylimino)propanamide] and M(COD)2(COD=cyclooctadiene). The catalyst displays a unique mode of action and performs at ambient conditions producing high molecular weight polyolefins and co-polymers with functional groups. The polymerized olefins include ethylene, alpha-olefins and functionalized olefins.

Owner:RGT UNIV OF CALIFORNIA

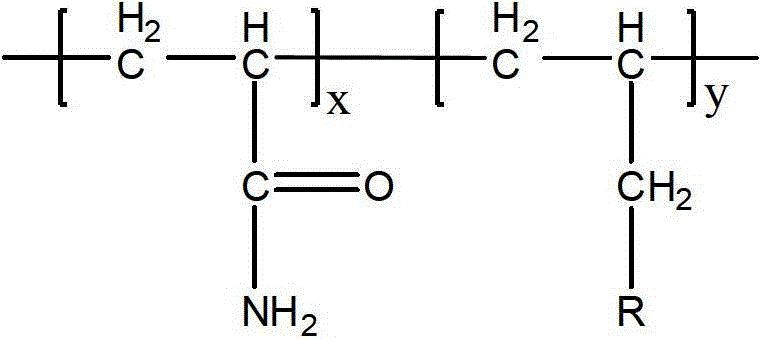

Salt-tolerant resistance-reducing agent applied for shale gas reservoir

InactiveCN103333672AImprove salt toleranceGood resistance reduction effectDrilling compositionBiopolymerDivalent metal ions

The invention relates to a salt-tolerant resistance-reducing agent applied for a shale gas reservoir. The resistance-reducing agent is a biopolymer comprising an acrylamide unit and a propenyl quaternary ammonium salt unit. The weight percent of the acrylamide in the biopolymer is 10%-80%. The propenyl quaternary ammonium salt is one of a propenyl trialkyl ammonium chloride, an alkyl acrylamido propyl trialkyl ammonium chloride or a dialkyl diallyl ammonium chloride. The weight percent of the propenyl quaternary ammonium salt in the biopolymer is 20%-90%, and the molecular weight of the propenyl quaternary ammonium salt is 1*10<6> to 2*10<6>. The resistance-reducing agent provided by the invention can be used as resistance-reducing agents for fracturing flow-back fluid, cavern water and underground produced water, wherein the fracturing flow-back fluid, the cavern water and the underground produced water contain divalent metal ions, and the weight percent resistance-reducing agent provided by the invention for using is 0.05%-0.1%. The resistance-reducing agent provided by the invention has good salt tolerance and resistance-reducing properties, and overcomes problems, of other polypropanamide resistance-reducing agents at present, comprising salt tolerance deficiency in using processes and incapability of being applied for hypersalinity water that comprises Ca<2+> and Mg<2+> at the same time.

Owner:PETROCHINA CO LTD

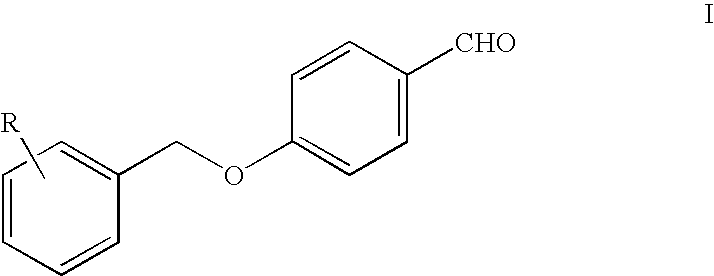

(Halobenzyloxy) Benzylamino-Propanamides as Sodium and/or Calcium Channel Selective Modulators

The invention relates to the use of selected (R)-2-[(halobenzyloxy)benzylamino]-propanamides and the pharmaceutically acceptable salts thereof for the manufacture of medicament, that are selectively active assodium and / or calcium channel modulators and therefore useful in preventing, alleviating and curing a wide range of pathologies, including, pain, migraine, periferal diseases, cardiovascular diseases, inflammatory processes affecting all body systems, disorders affecting skin and related tissues, disorders of the respiratory system, disorders of the immune and endocrinological systems, gastrointestinal, urogenital, metabolic and seizure disorders, where the above mechanisms have been described as playing a pathological role.

Owner:NEWRON PHARMACEUTICALA SPA

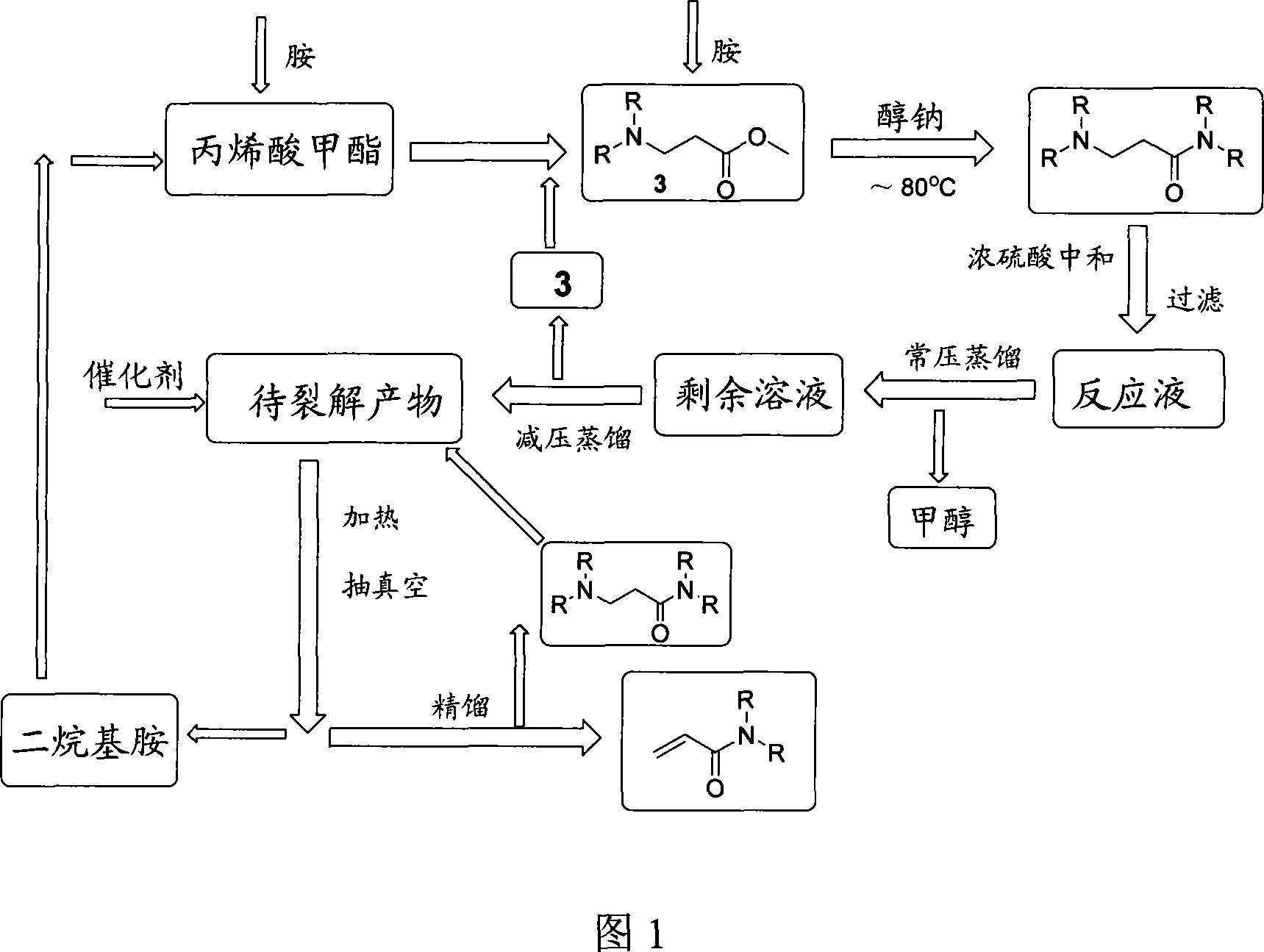

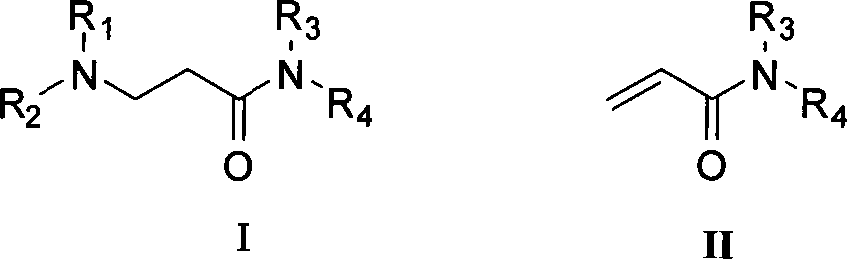

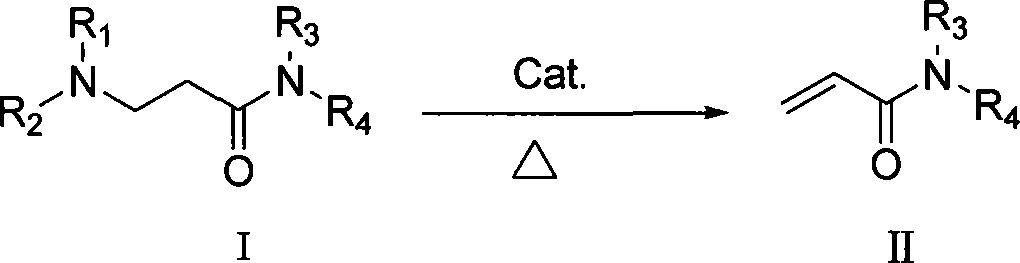

Method for preparing N,N-dialkylacrylamide

InactiveCN101143832ALower activation energyReduce energy consumptionOrganic compound preparationCarboxylic acid amides preparationPolymer scienceActivation energy

The invention discloses a preparation method of new polymer monomer N, N-dialkyl acrylamide and the improvement of a process route, that is, under the existance of polymerization inhibitor and the function of catalyst, the 3-dialkyl amidocyanogen propanamide shown in the formula (I) goes through thermal cracking reaction for two the twenty hours under the conditions of temperature between 100 DEG C and 280 DEG C and pressure between 200 mmHg and 760 mmHg, and after a cracking product is processed, the N, N-dialkyl acrylamide shown in the formula (II) is obtained. Because acid as catalyst is added into the reaction system, the activation energy of the thermal cracking reaction is lowered, the reactive selectivity and the reactive yield rate are increased, and therefore energy consumption is reduced. Compared with the original cracking technique, the temperature of cracking is lowered, the time of reaction is shortened, that is, the time of reaction is shortened to a few hours from over twenty hours, the yield rate of cracking is increased, and byproducts are reduced.

Owner:ZHEJIANG UNIV OF TECH +1

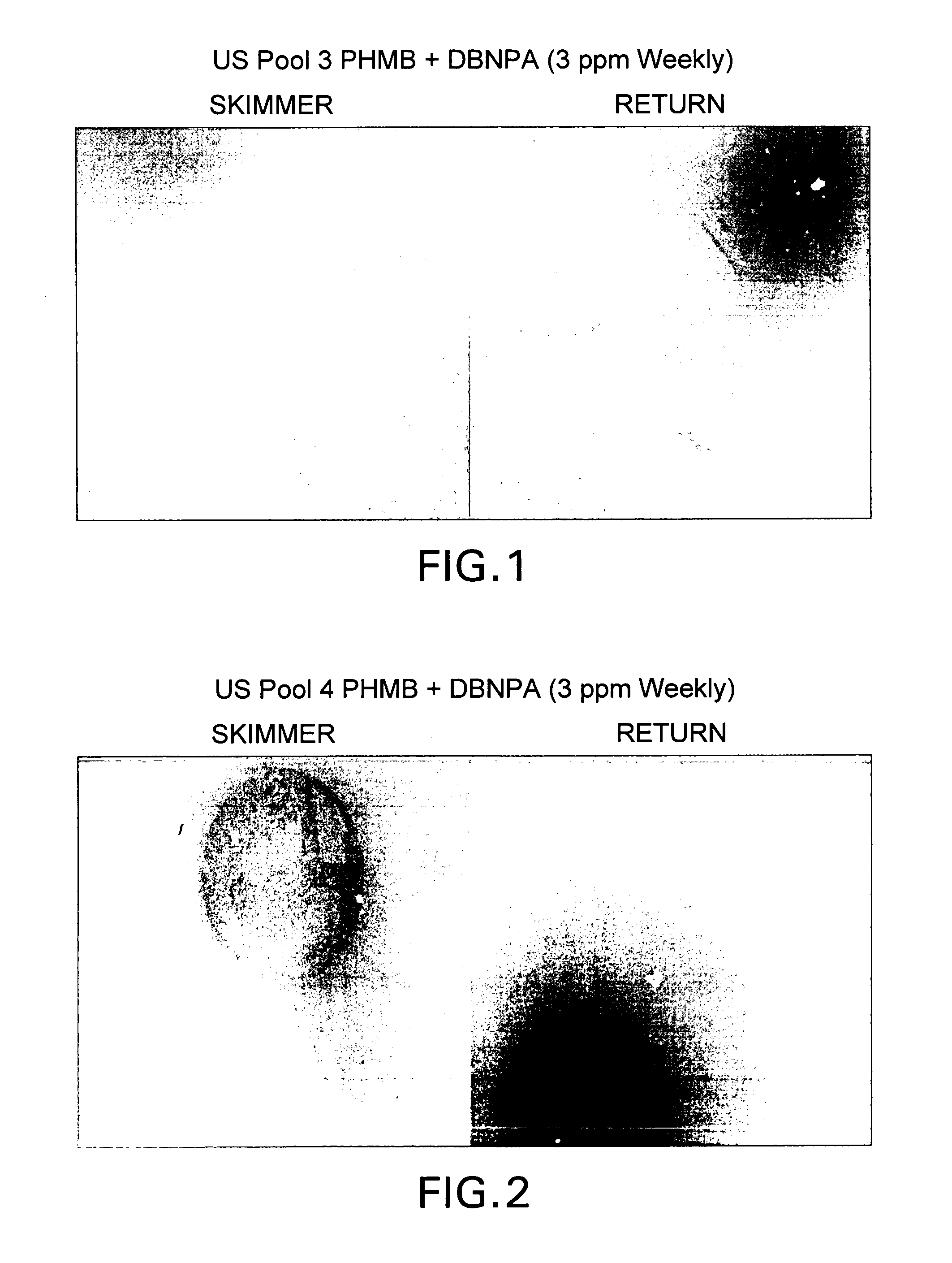

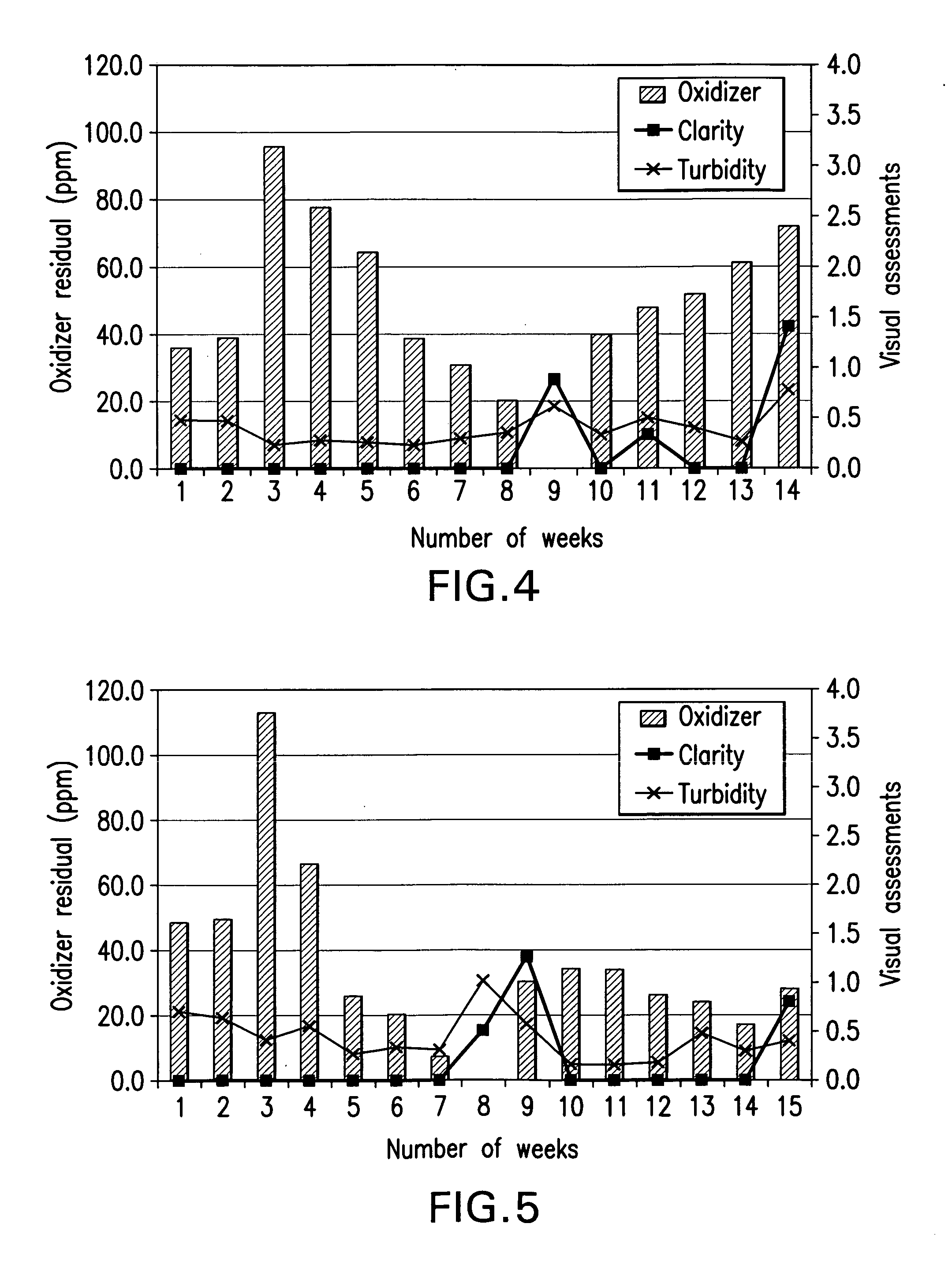

Methods and kits for stabilizing oxidizers and sanitizing water

InactiveUS20110049058A1Other chemical processesSolid sorbent liquid separationMedicineOxidizing agent

The present invention is directed to a kit and method for preventing a body of water from clouding, comprising: (a) a first container containing a first water treatment composition, the first water treatment composition comprising 2,2-dibromo-3-nitrilopropionamide (DBNPA); and (b) a second container containing a second water treatment composition, the second water treatment composition comprising an oxidizer; wherein the body of water contains polyhexamethylene biguanide (PHMB). The present invention is also directed to a kit and method for remediating a cloudy body of water, comprising: (a) a first container containing a first water treatment composition, the first water treatment composition comprising 2,2-dibromo-3-nitrilopropionamide (DBNPA); (b) a second container containing a second water treatment composition, the second water treatment composition comprising an oxidizer; and (c) a third container containing a third water treatment composition, the third water treatment composition comprising a flocculant; wherein the body of water contains polyhexamethylene biguanide (PHMB).

Owner:ARCH CHEM INC

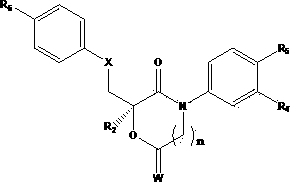

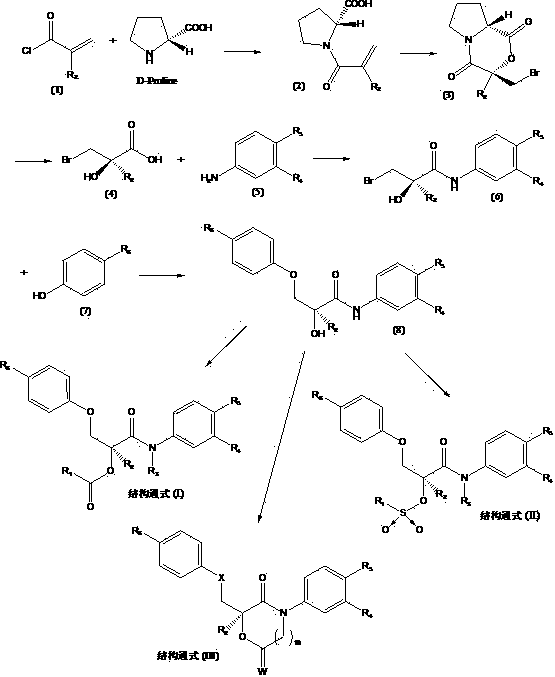

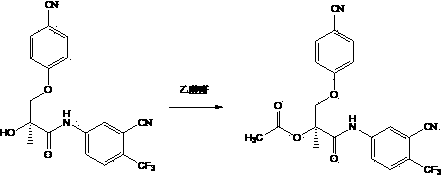

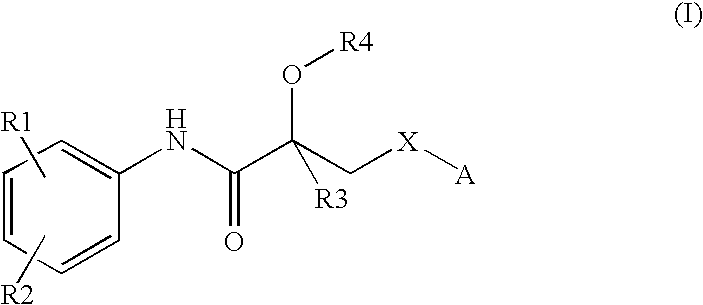

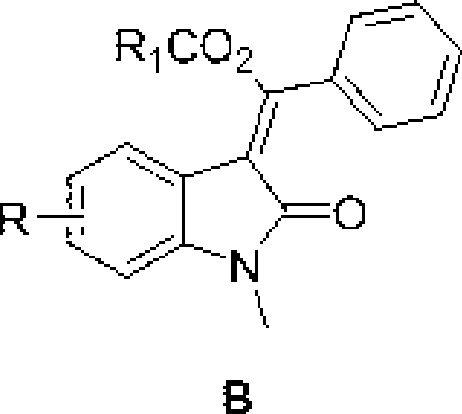

Novel ester group-containing aromatic propionamide compound as well as preparation method and application thereof

The invention discloses a novel ester group-containing aromatic propionamide compound as well as a preparation method and an application thereof, and provides a chemical structure formula of the novel ester group-containing aromatic propionamide compound. The compound is prepared by taking an acyl chloride compound and proline as starting raw materials. The compound has the effect of adjusting an androgen receptor and can be independently used or being used as a composition to be used for treating and / or preventing various diseases related to androgens, such as diseases of male androgen deficiency (ADAM), diseases of female androgen deficiency (ADIF), muscle consumption, muscle emaciation, amyotrophy, osteoporosis, sclerotin reduction, anemia, obesity, diabetes mellitus, cancers and the like; the compound can also be used for an exercise and / or body function enhancing agent or an animal feed additive.

Owner:CHANGCHUN GENESCIENCE PHARM CO LTD

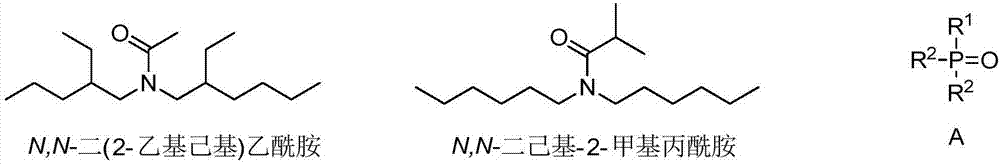

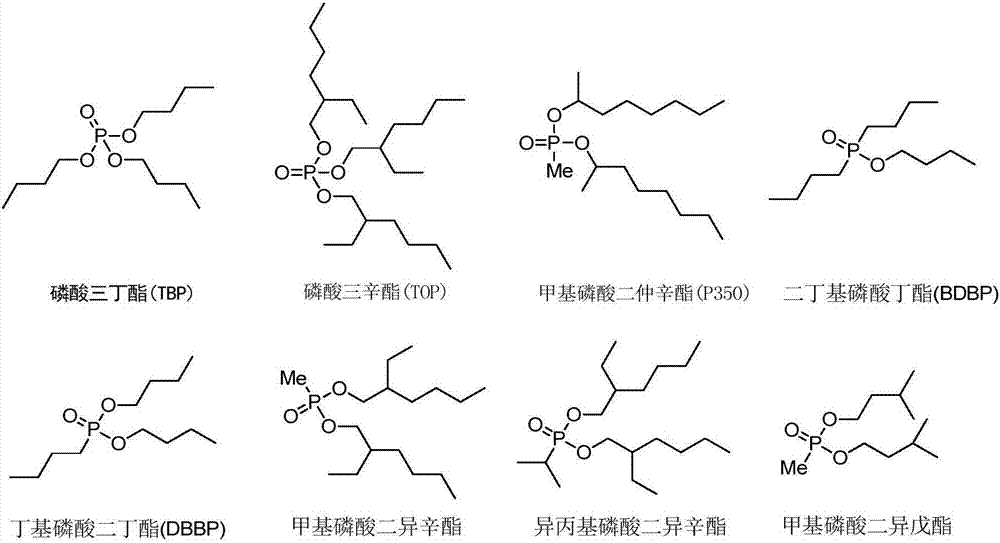

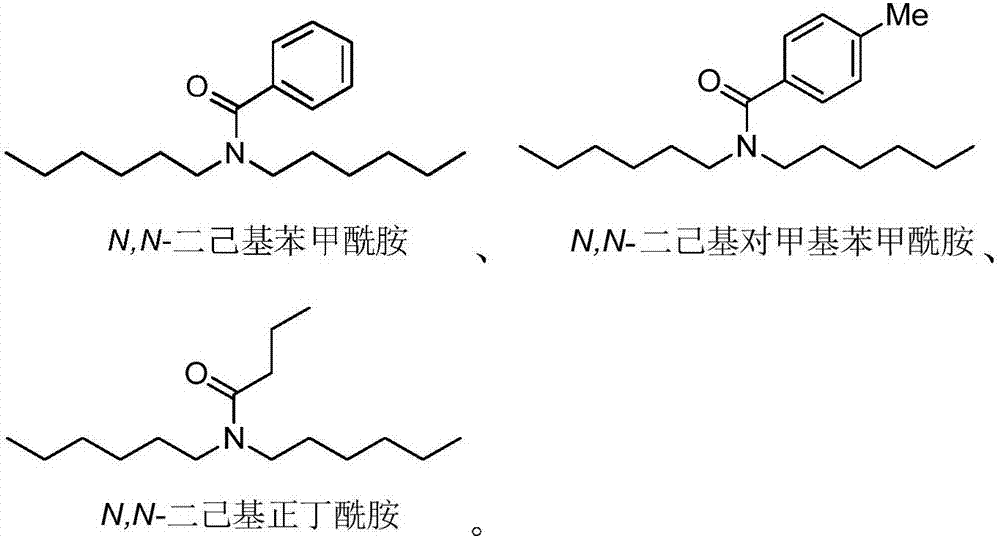

Extraction composition, extraction system and application thereof

ActiveCN107441766ASpeed up extractionLow costLithium compoundsLiquid solutions solvent extractionLithiumPartition coefficient

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

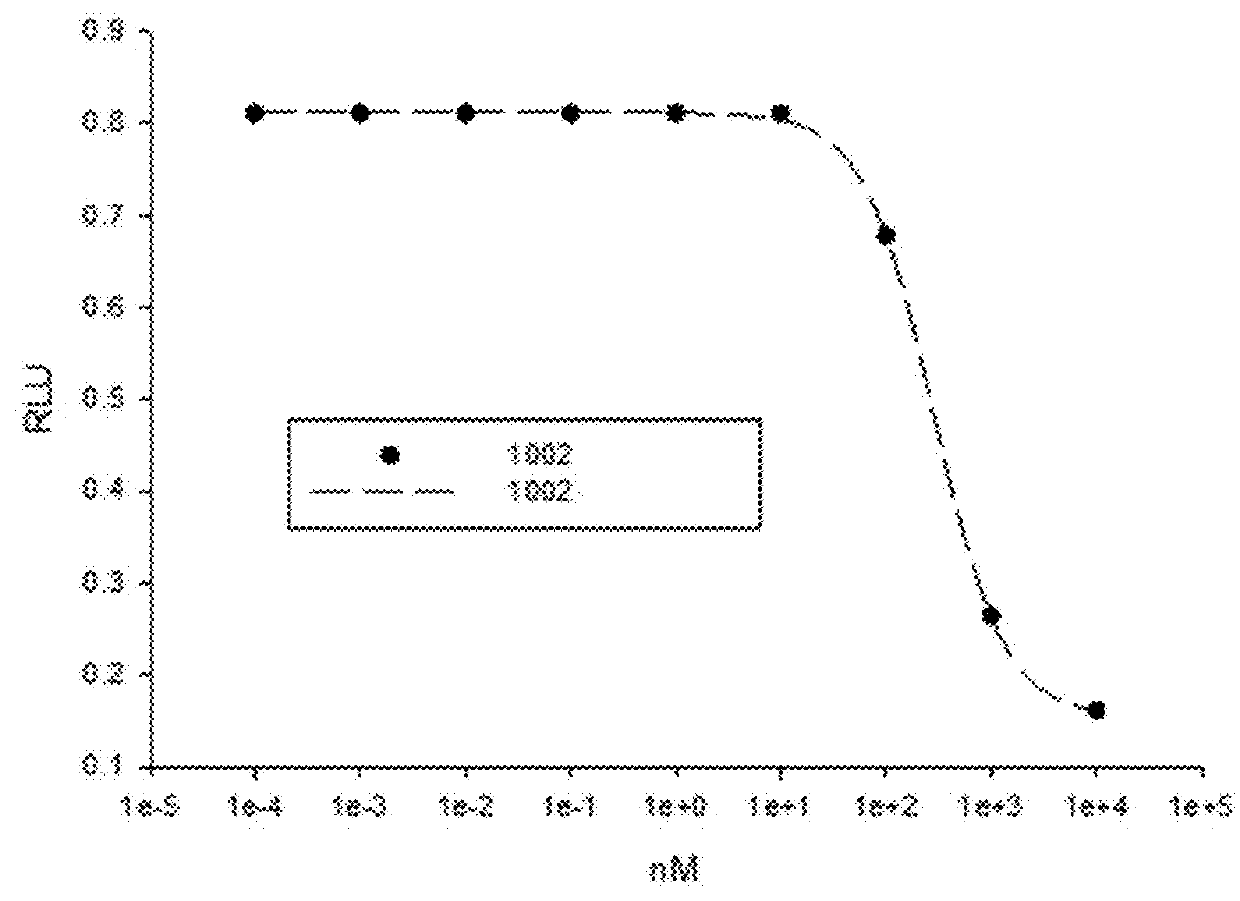

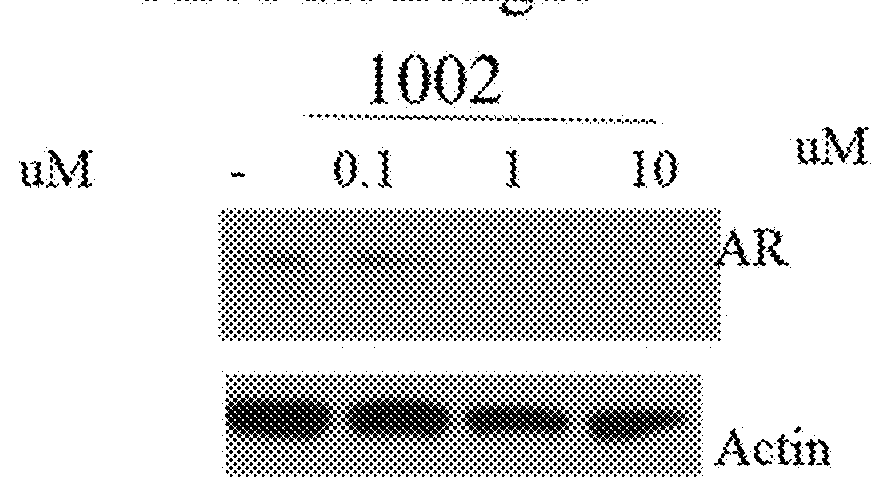

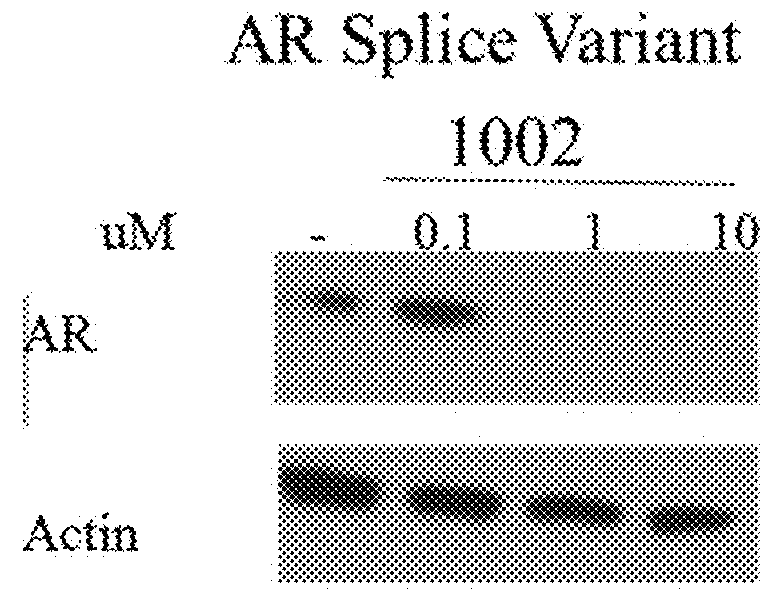

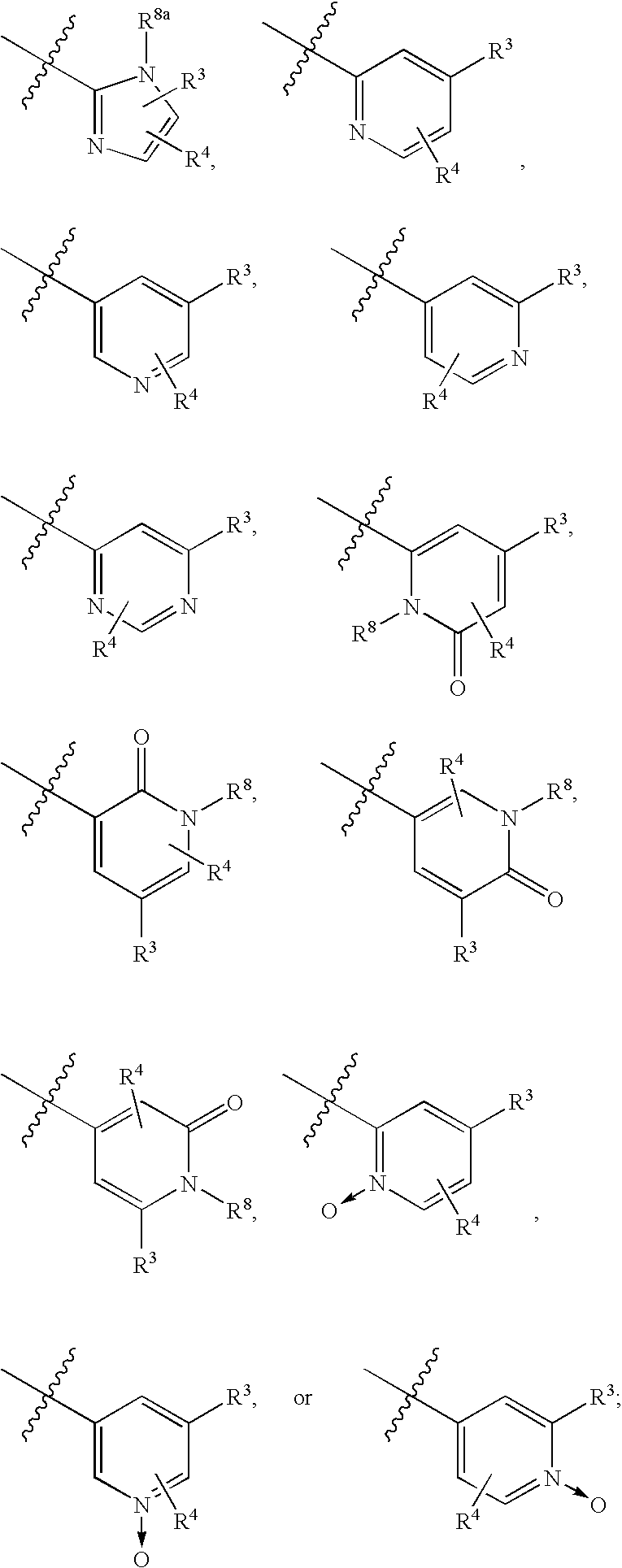

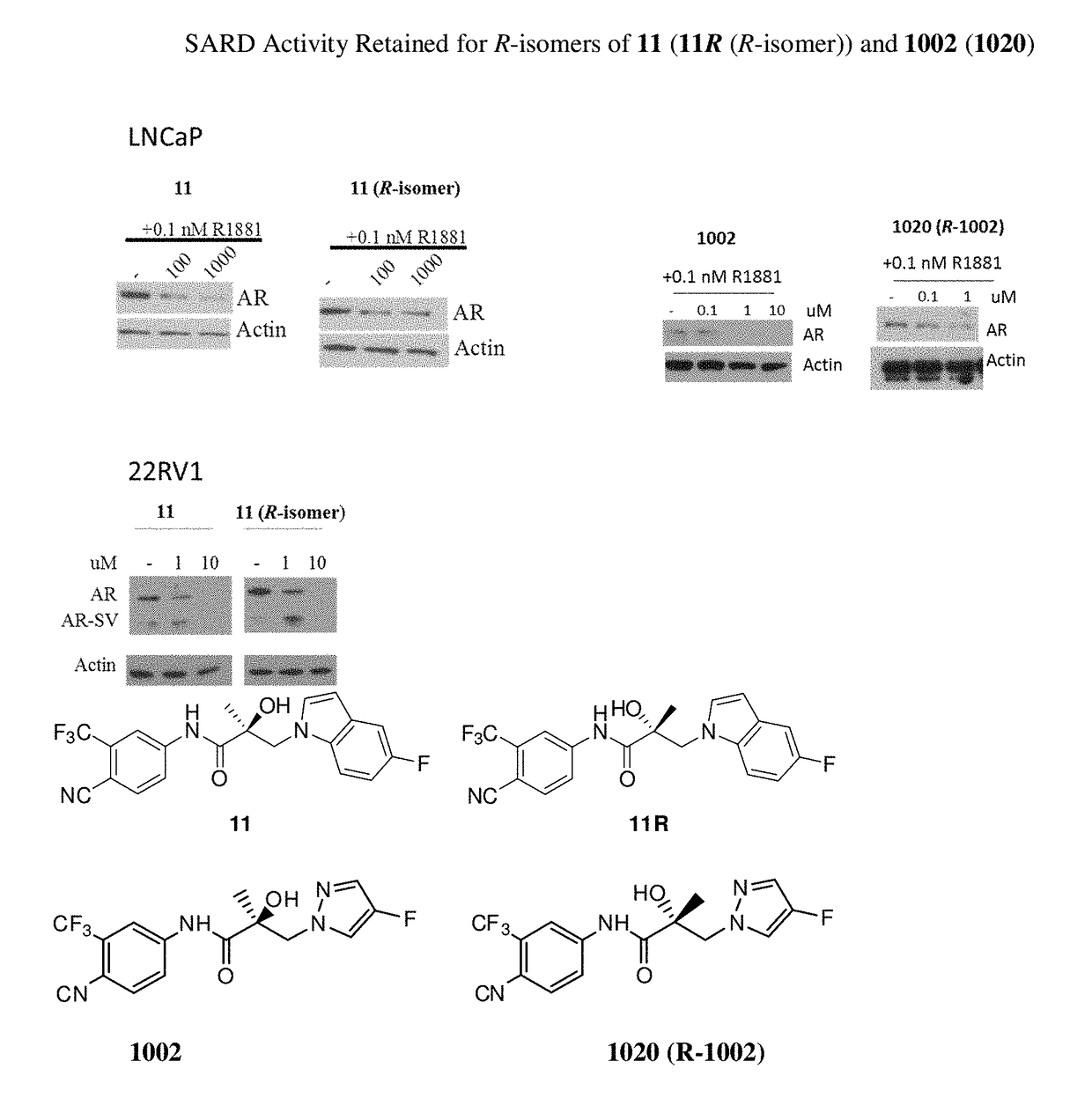

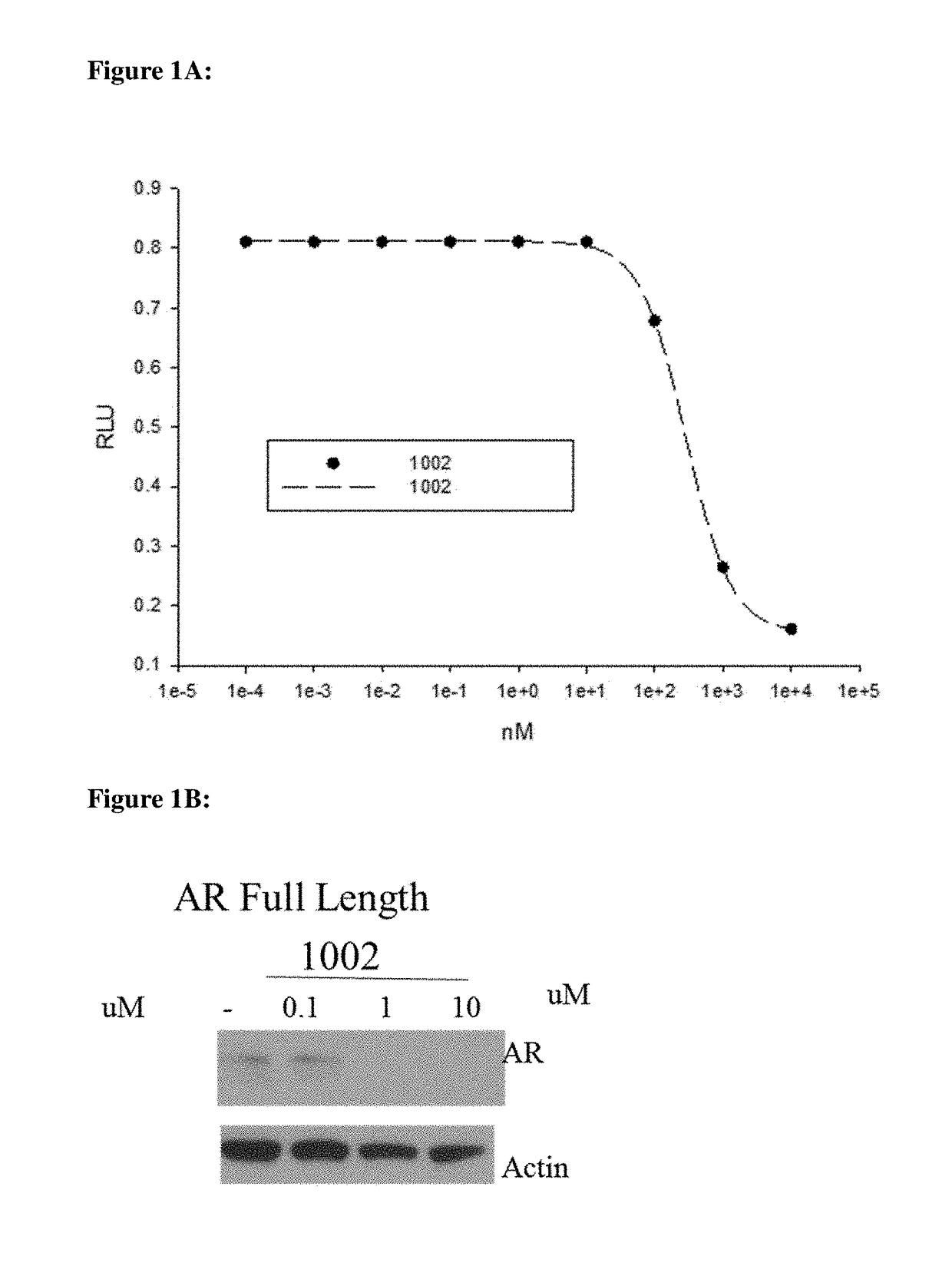

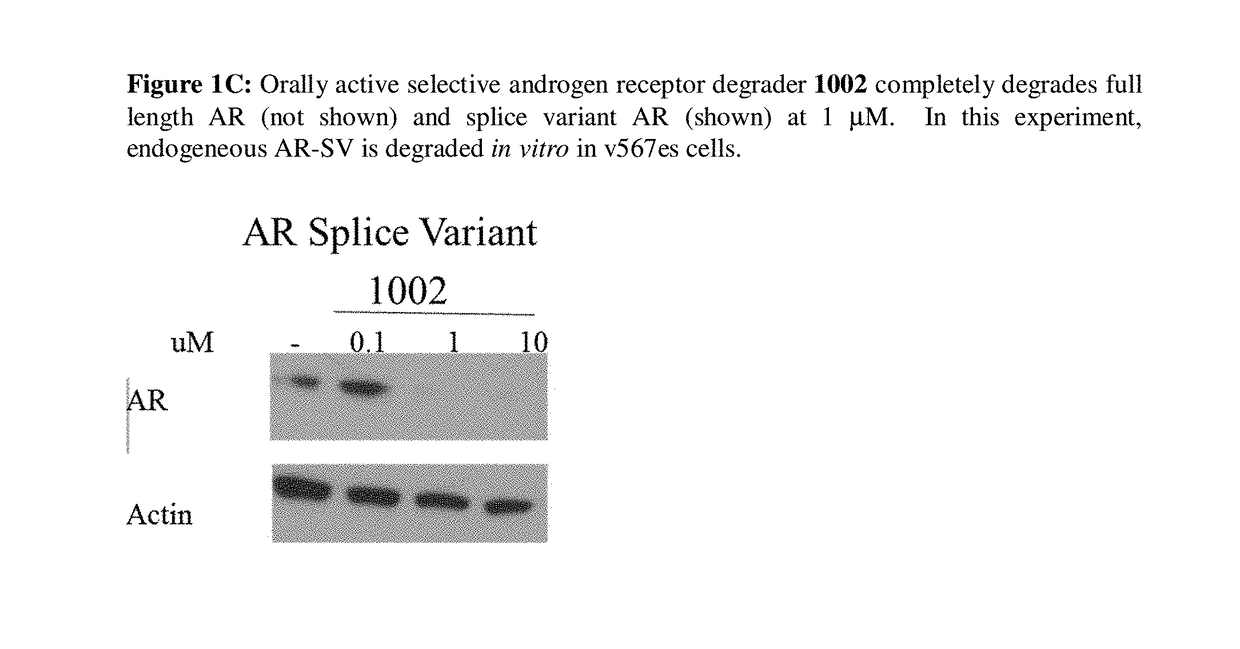

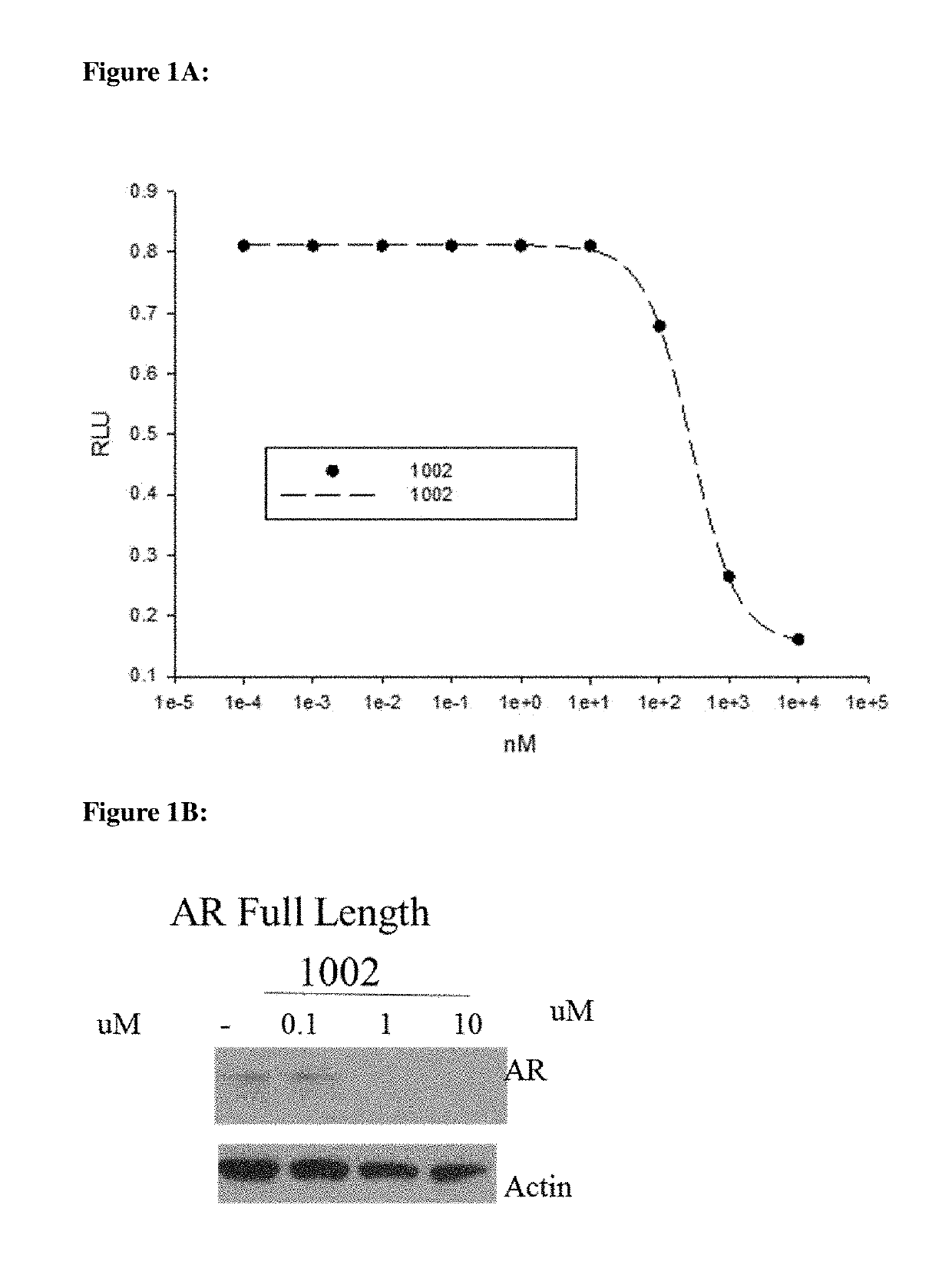

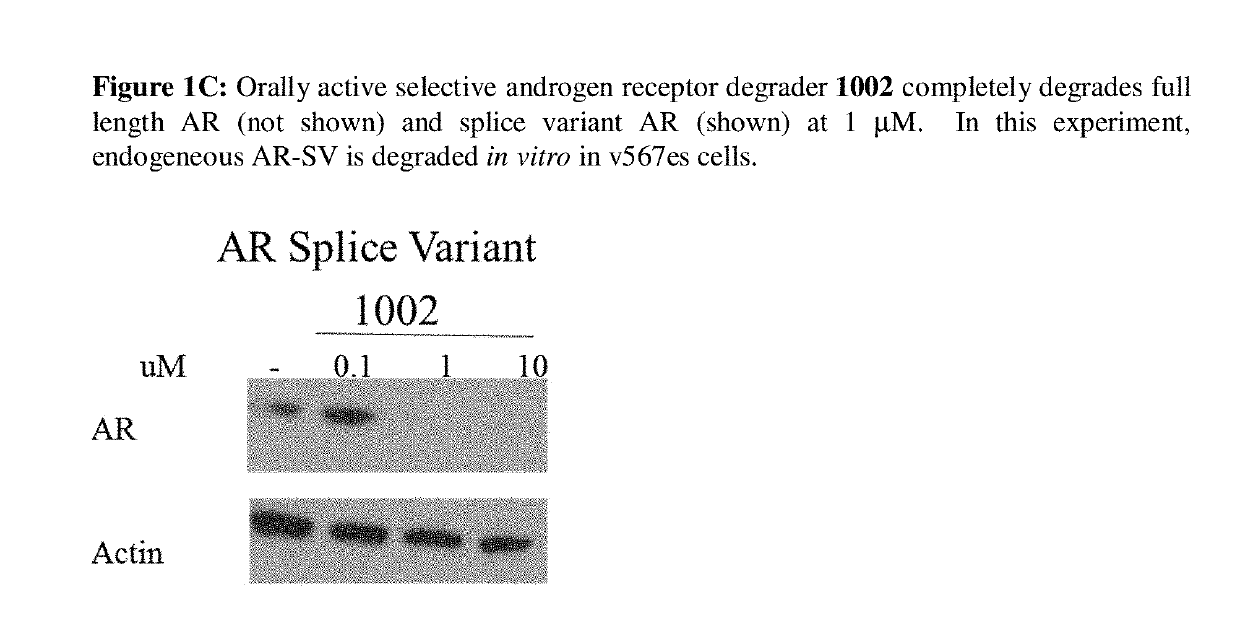

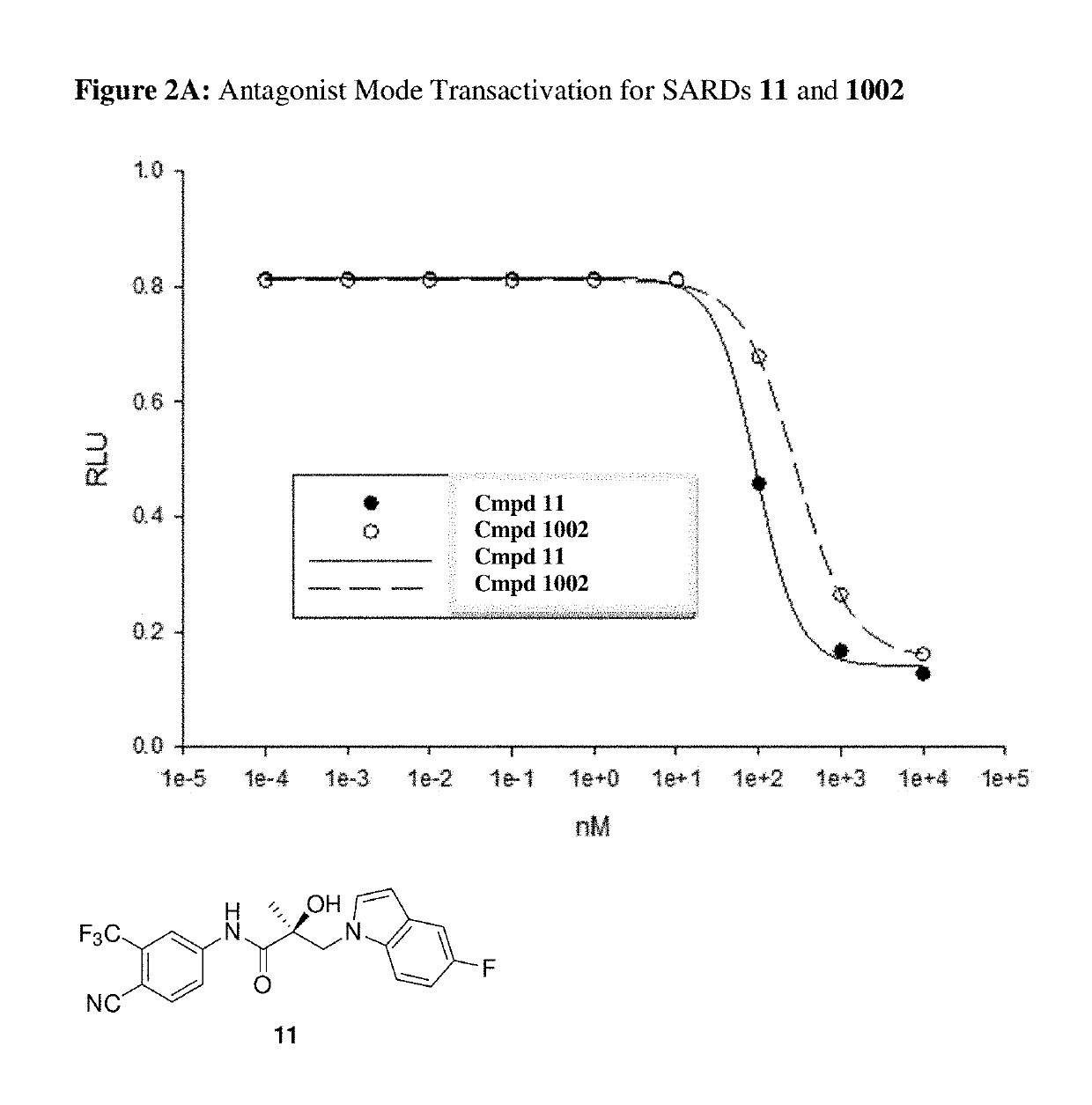

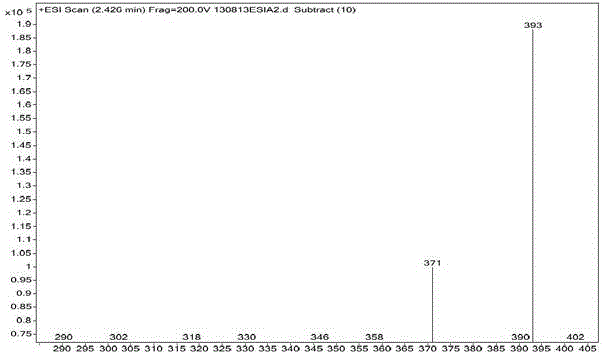

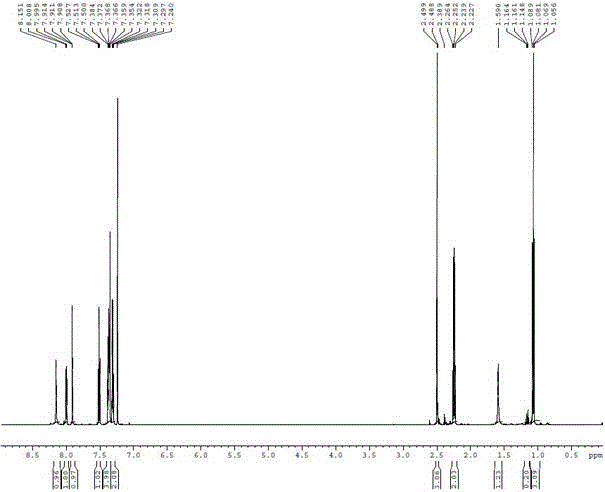

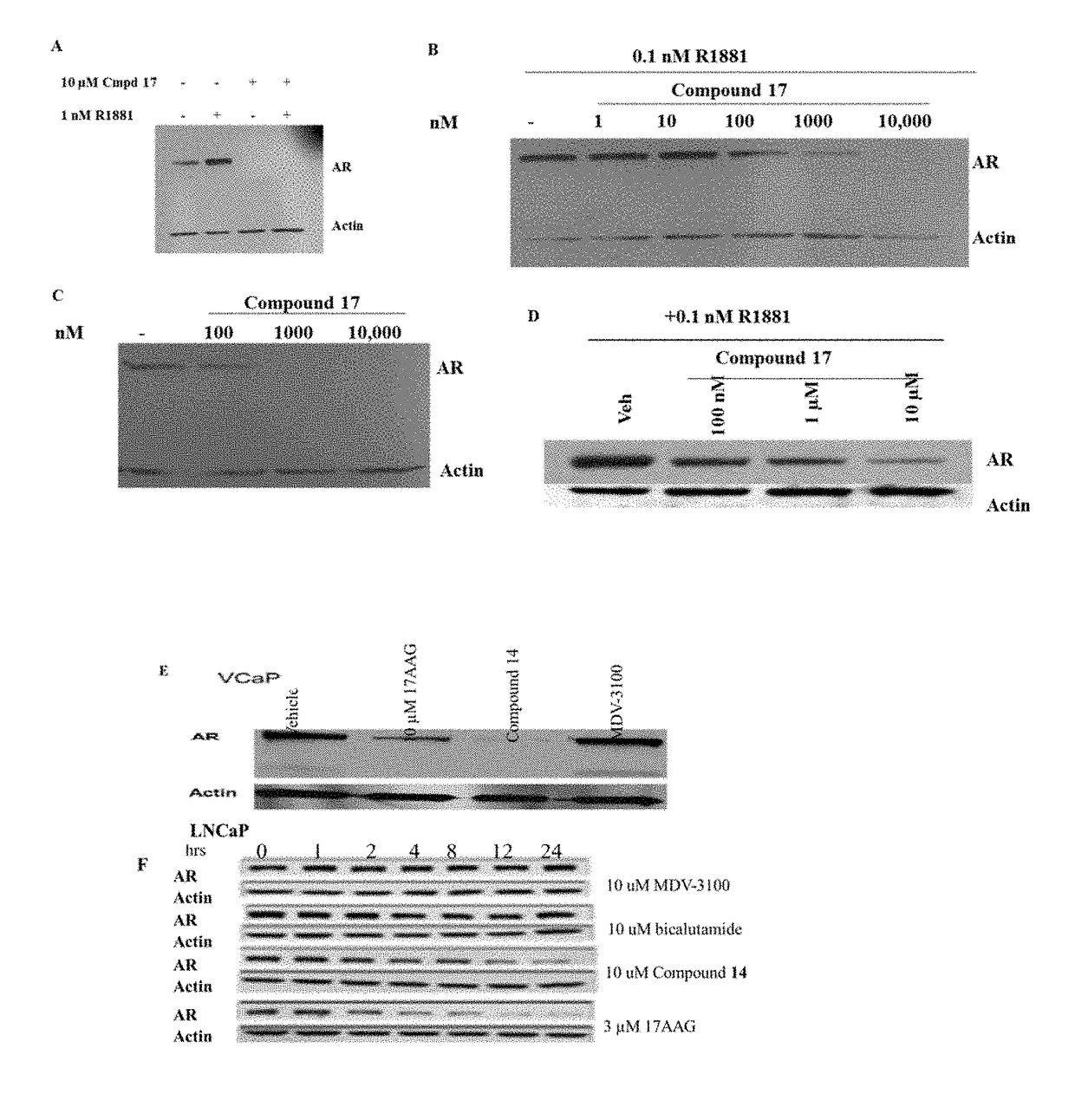

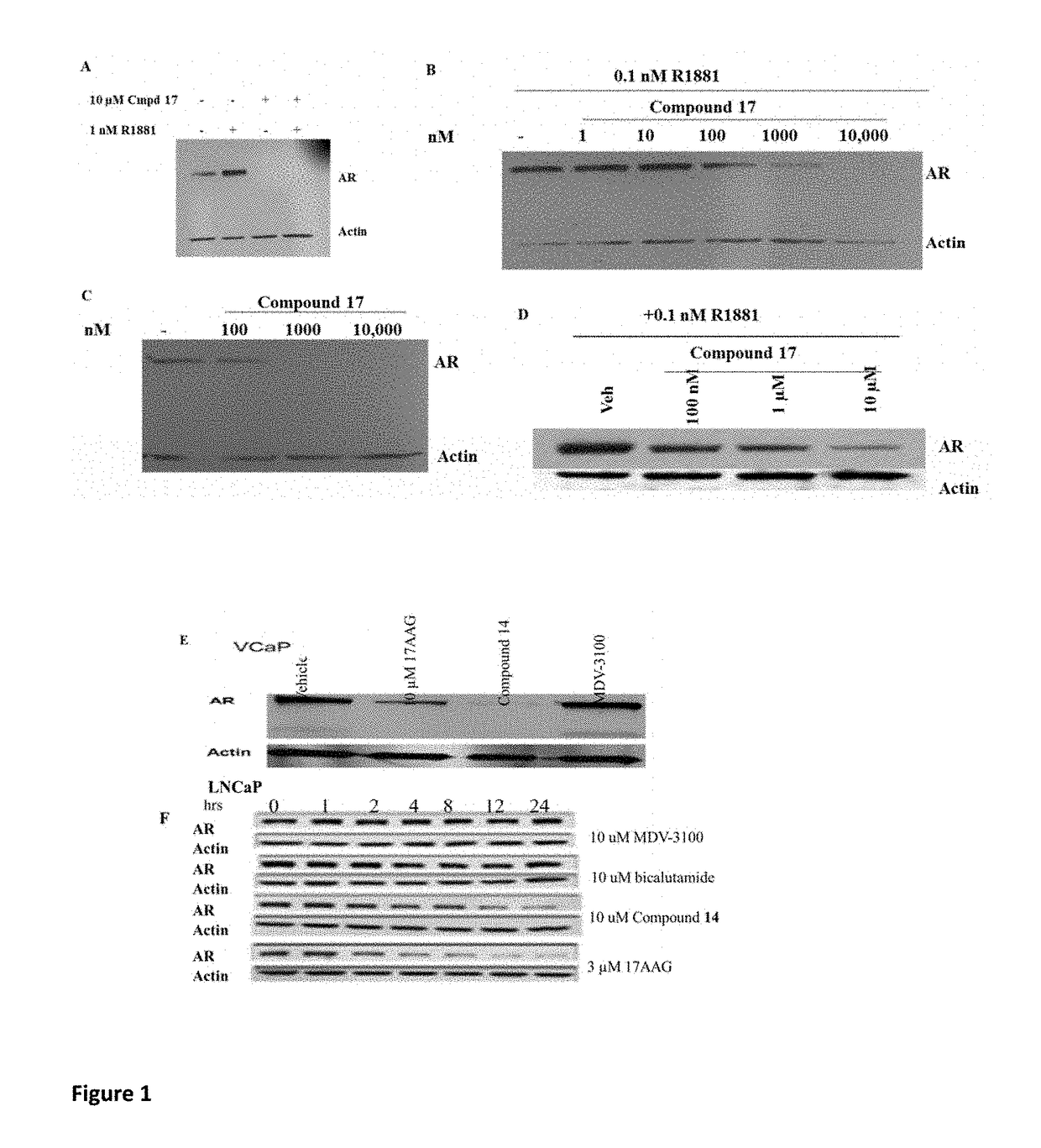

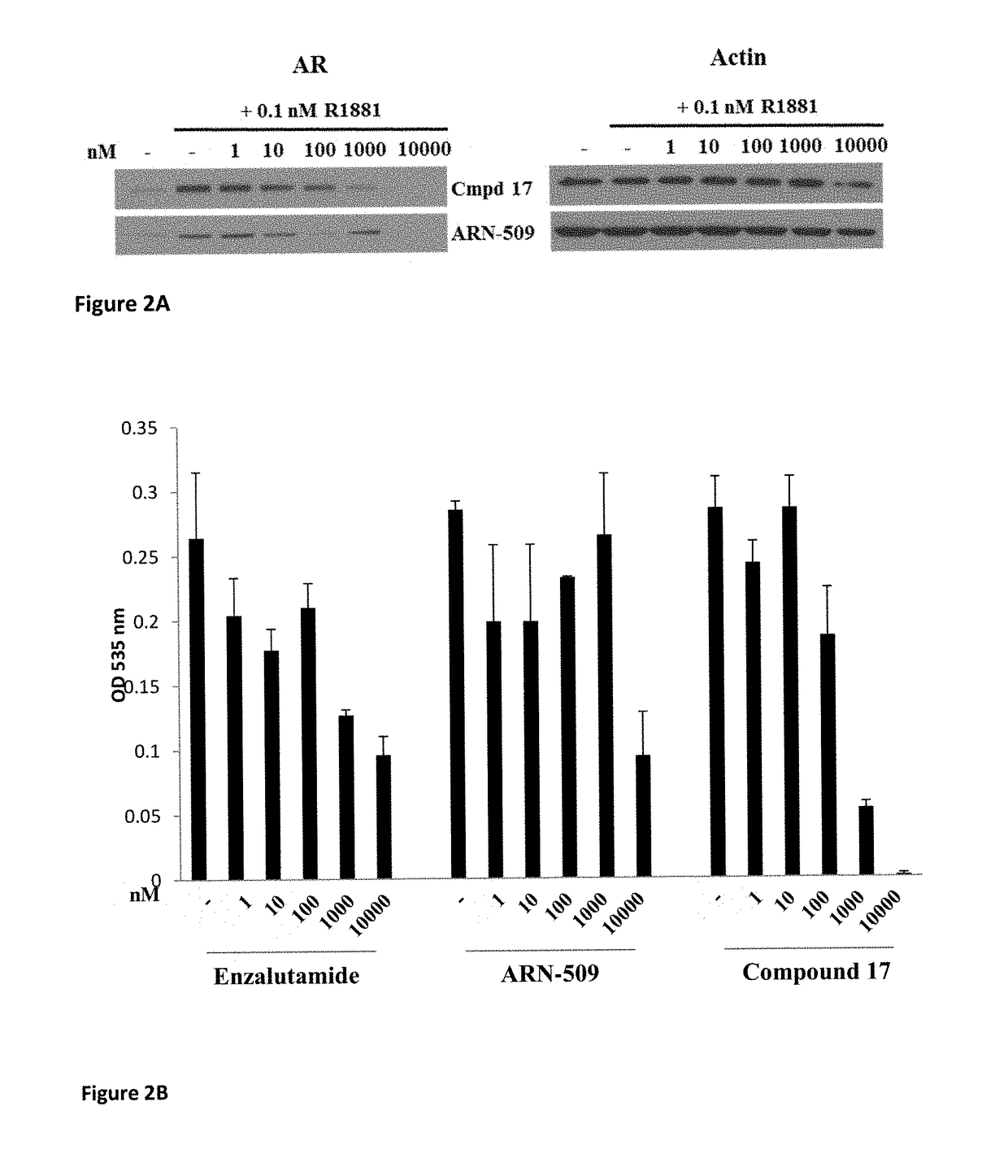

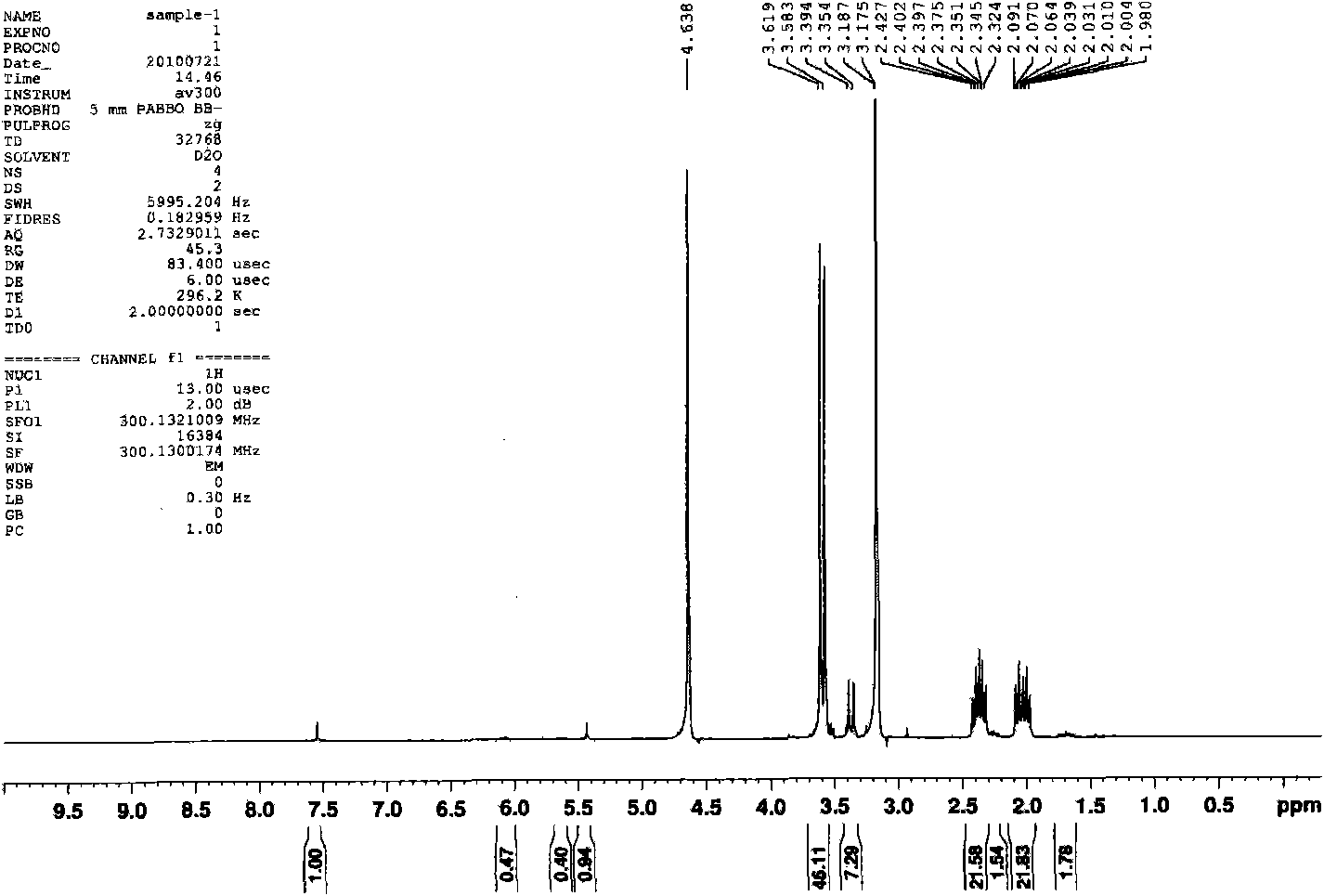

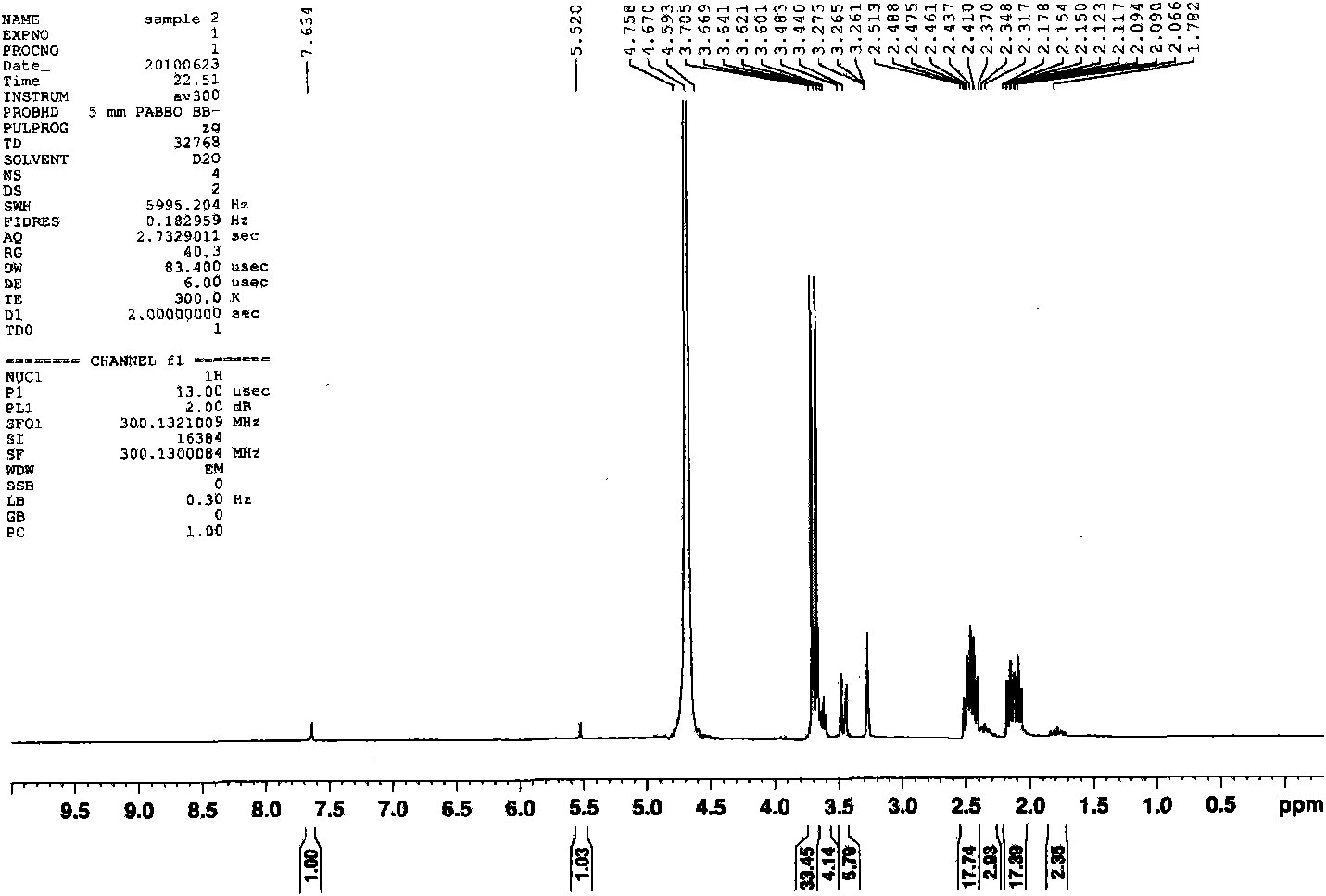

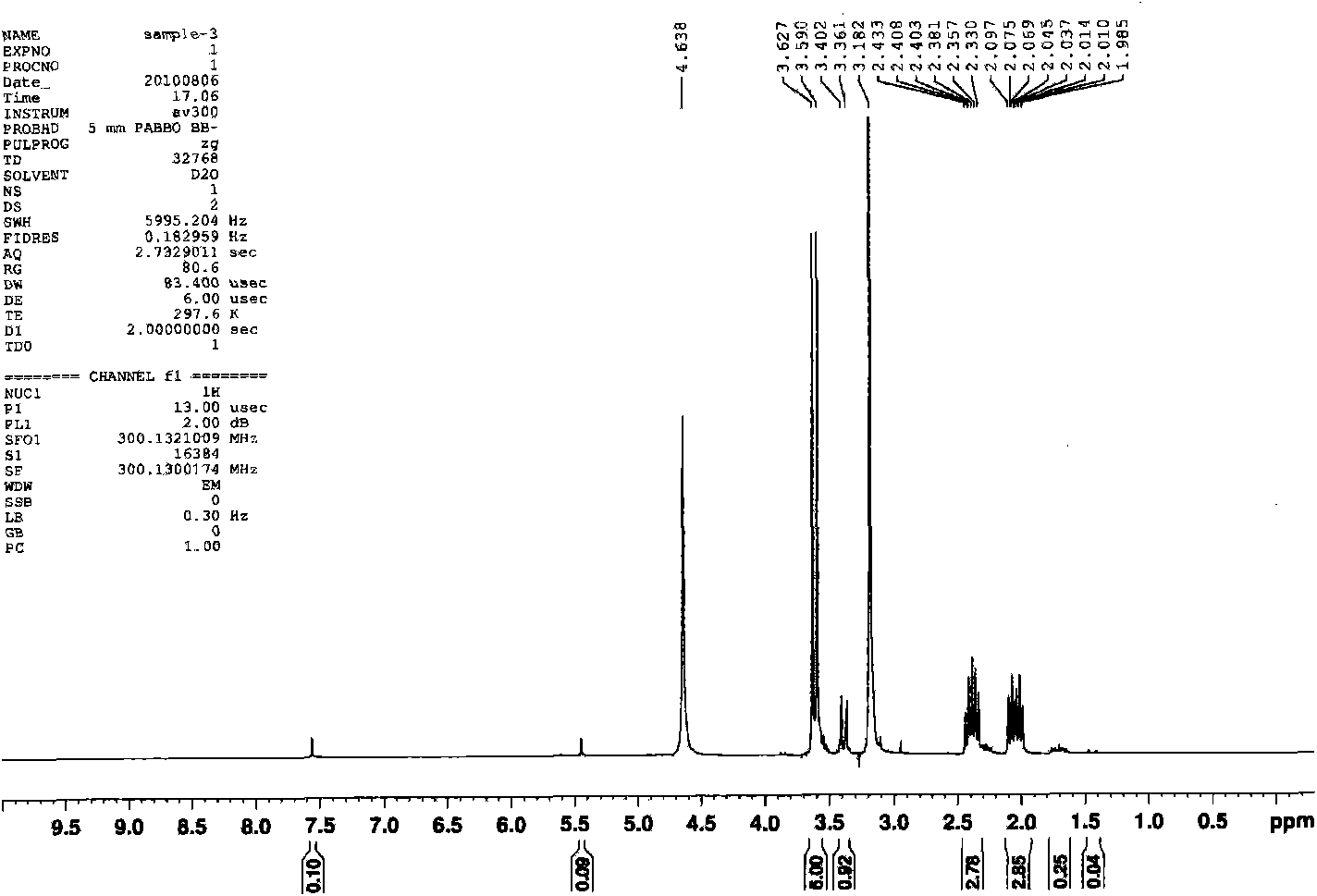

Selective androgen receptor degrader (SARD) ligands and methods of use thereof

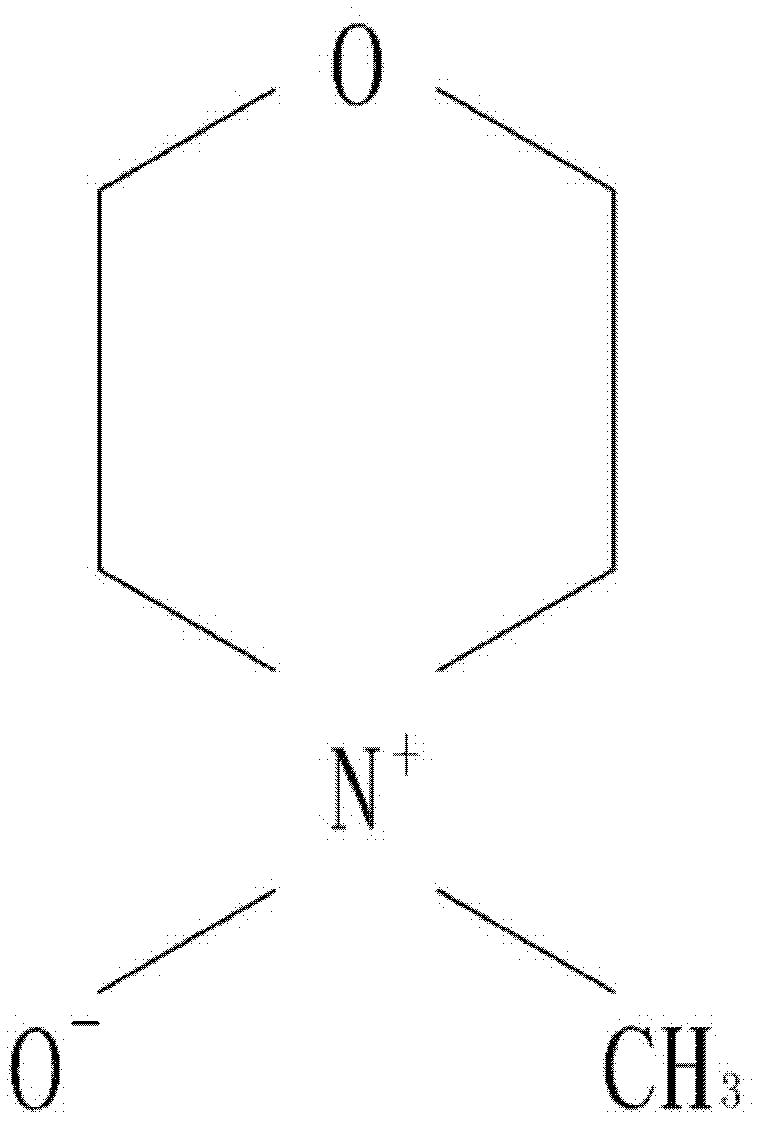

ActiveUS20180273487A1Lower Level RequirementsShorten the lengthOrganic chemistryPharmaceutical delivery mechanismMorpholineResistance mutation

This invention is directed to pyrrole, pyrazole, imidazole, triazole, and morpholine based selective androgen receptor degrader (SARD) compounds including heterocyclic anilide rings and their synthetic precursors, R-isomers, and non-hydroxylated and / or non-chiral propanamides, and pharmaceutical compositions and uses thereof in treating prostate cancer, advanced prostate cancer, castration resistant prostate cancer, triple negative breast cancer, other cancers expressing the androgen receptor, androgenic alopecia or other hyperandrogenic dermal diseases, Kennedy's disease, amyotrophic lateral sclerosis (ALS), abdominal aortic aneurysm (AAA), and uterine fibroids, and to methods for reducing the levels of androgen receptor-full length (AR-FL) including pathogenic or resistance mutations, AR-splice variants (AR-SV), and pathogenic polyglutamine (polyQ) polymorphisms of AR in a subject.

Owner:UNIV OF TENNESSEE RES FOUND

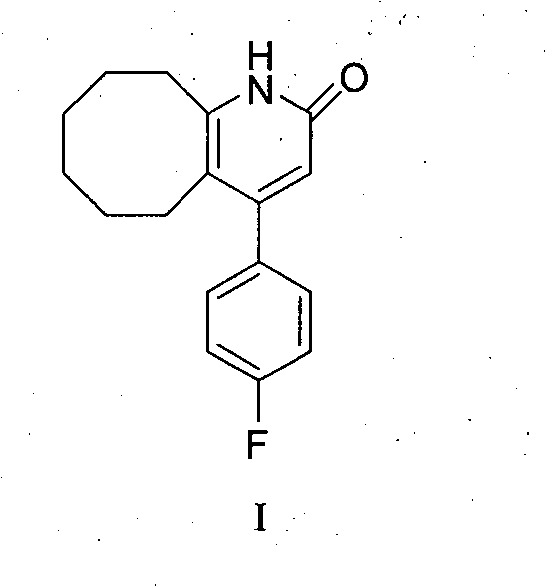

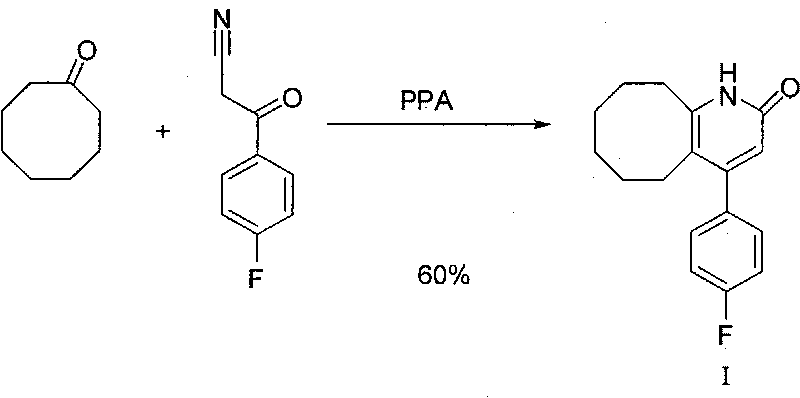

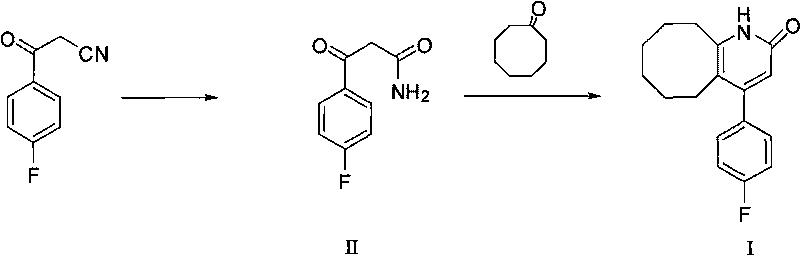

Preparing method of blonanserin intermediate

The invention discloses a preparing method of blonanserin intermediate. The method is processed according to the following two steps of: (a) producing 3-(4-fluorophenyl)-3 oxo-propanamide through the reaction of 3-(4-fluorophenyl)-3 oxypropionitrile; and (b) obtaining 4-(4-fluorophenyl)-5,6,7,8,9,10-hexahydro cyclooctane pyridine-2-(1H)-ketone through the reaction between the 3-(4-fluorophenyl)-3 oxo-propanamide and cyclooctanone. The yield coefficient of the 4-(4-fluorophenyl)-5,6,7,8,9,10-hexahydro cyclooctane pyridine-2-(1H)-ketone prepared by using the method is increased to about 80 percent from 17 percent.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD +1

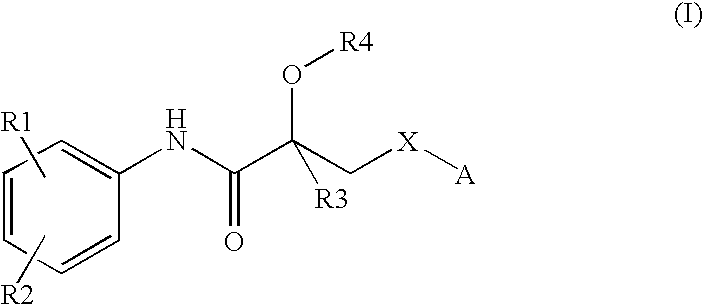

Arylpropionamide, arylacrylamide, arylpropynamide, or arylmethylurea analogs as factor xia inhibitors

The present invention provides compounds of Formula (I):or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, L1, M and R11 are as defined herein. The compounds of Formula (I) are selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors or dual inhibitors of fXIa and plasma kallikrein. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

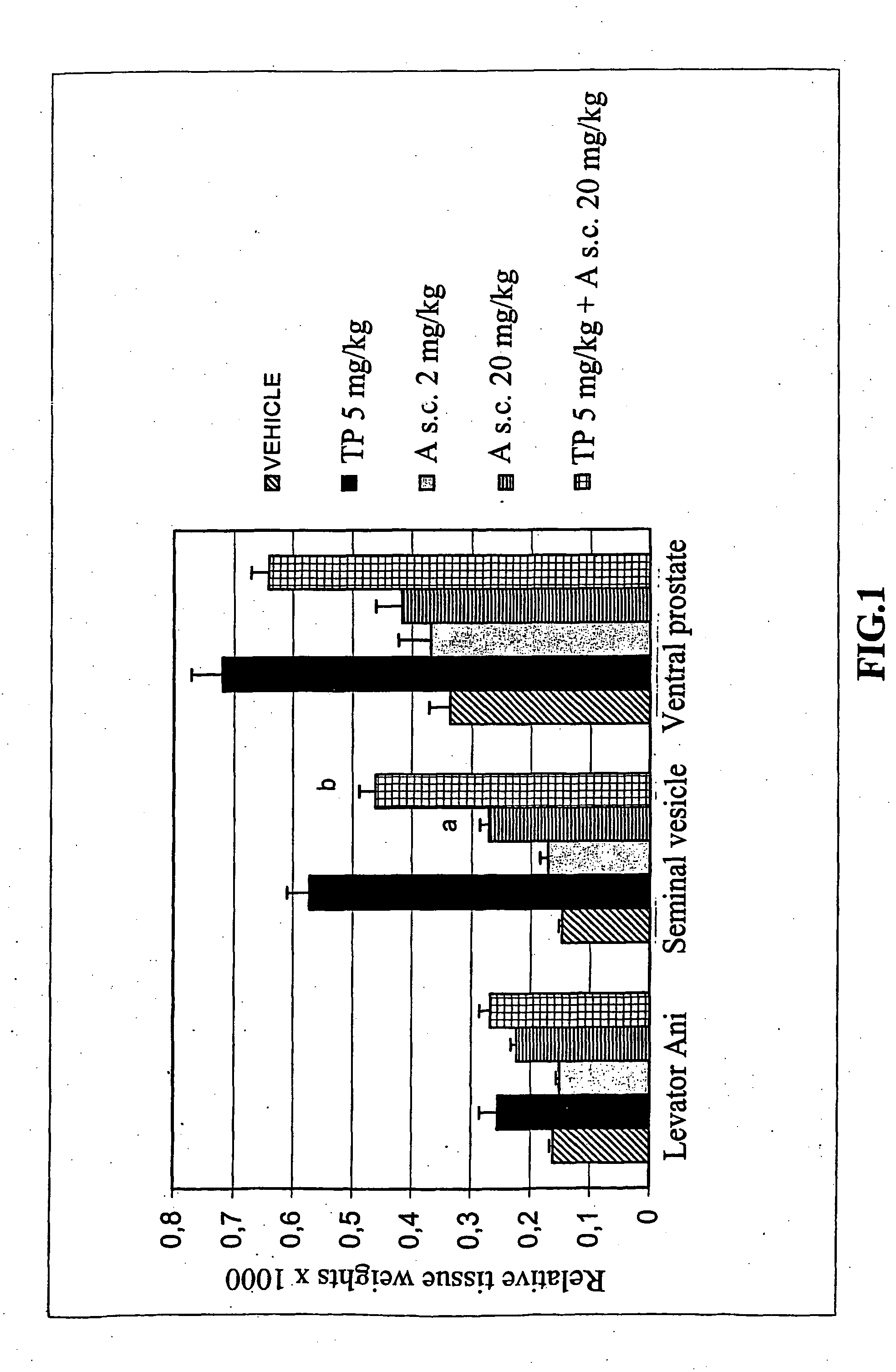

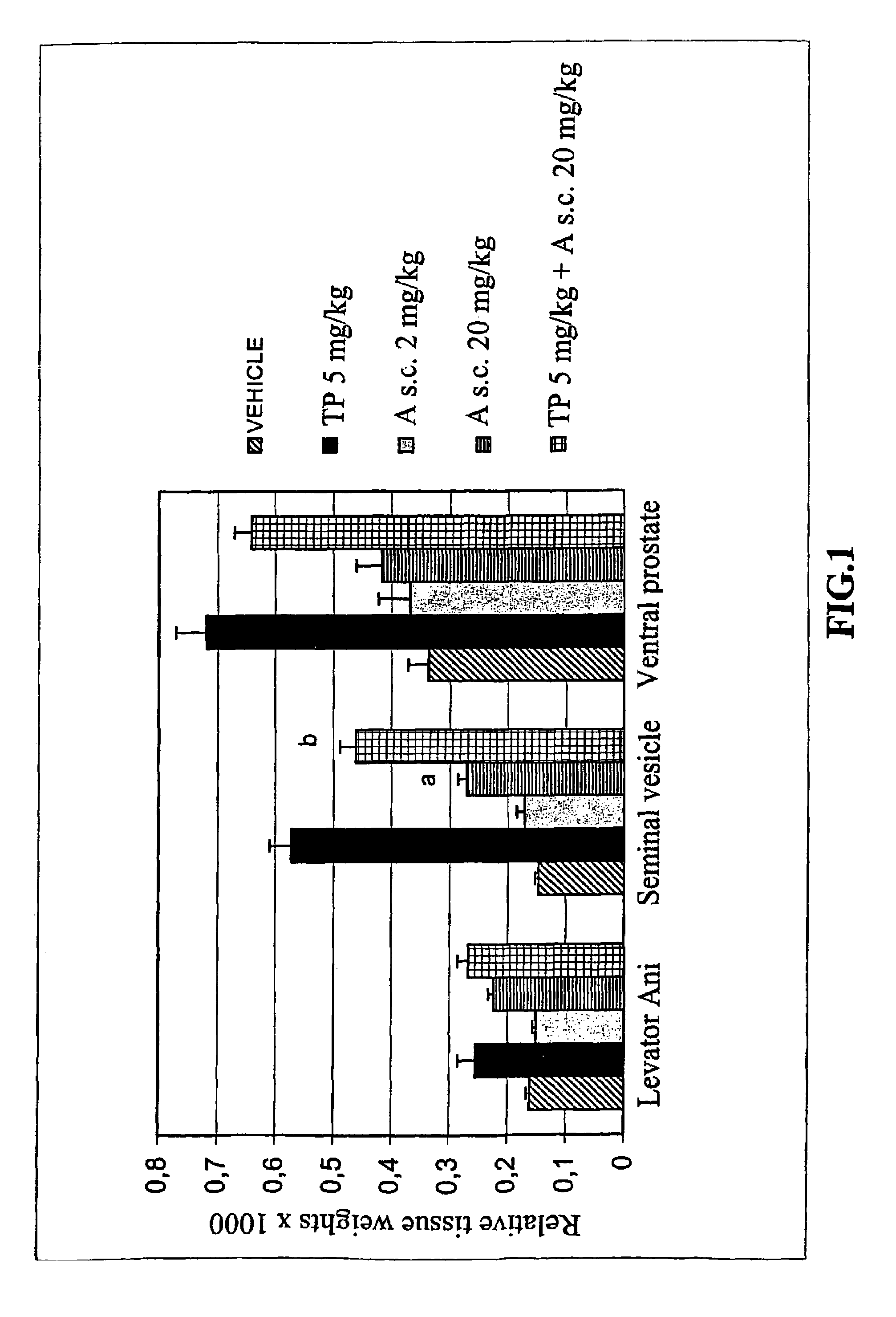

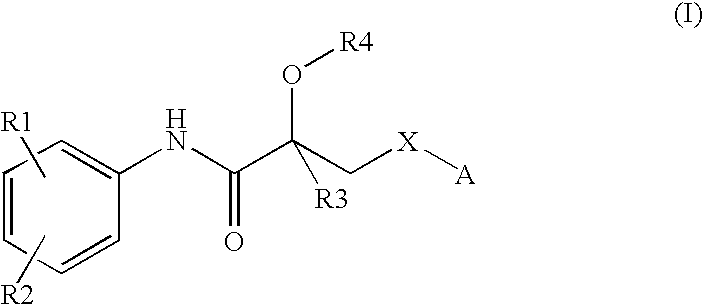

Propionamide derivatives useful as androgen receptor modulators

InactiveUS20070123512A1High activityHigh affinityBiocidePeptide/protein ingredientsSelective androgen receptor modulatorHormone Receptor Modulators

Compounds of formula (I) wherein R1 to R4, X and A are as defined in the claims and pharmaceutically acceptable salts and esters thereof, are disclosed. The compounds of formula (I) possess utility as tissue-selective androgen receptor modulators (SARM) and are useful in hormonal therapy, e.g., in the treatment or prevention of male hypogonadism and age-related conditions such as andropause.

Owner:ORION CORPORATION

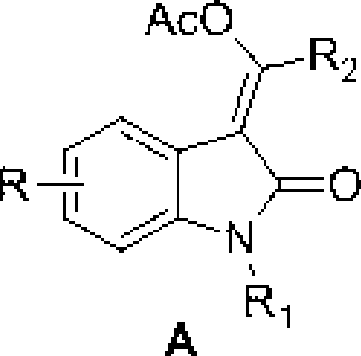

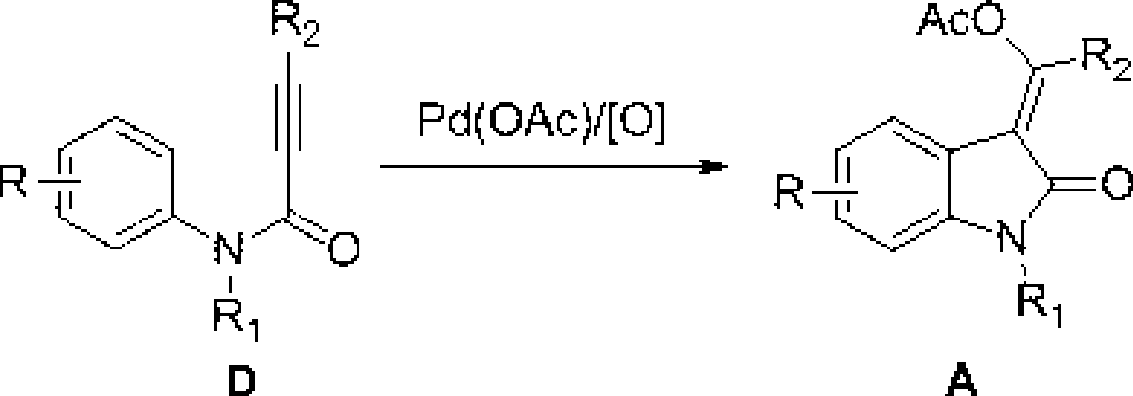

3-methylene-indol-2-one derivates and preparation method thereof

The invention relates to a 3-methylene-indole-2-ketone derivative and a preparation method thereof. The derivative is synthesized by taking N-methyl-N-phenyl-hydrocinnamamide or N-aryl phenylpropargyl acylamide and phthalic imide as substrates through tandem reactions such as C-H activation / acetylene hydrocarbon palladinization / cross coupling and so on, based on the catalysis of Pd<II> / Pd<IV> under the coaction of a palladium catalyst and an oxidizing agent, then ethyl acetate is added, the mixture is scrubbed by common salt, an aqueous phase is then extracted by the ethyl acetate, an organic layer is collected, and the 3-methylene-indole-2-ketone derivative is prepared through drying, condensation and column chromatography. The preparation method has the advantages of simple and convenient reaction operation, short reaction steps, simple conditions, short time, low cost, and high yield, and is worthy to be popularized and applied.

Owner:WENZHOU UNIVERSITY

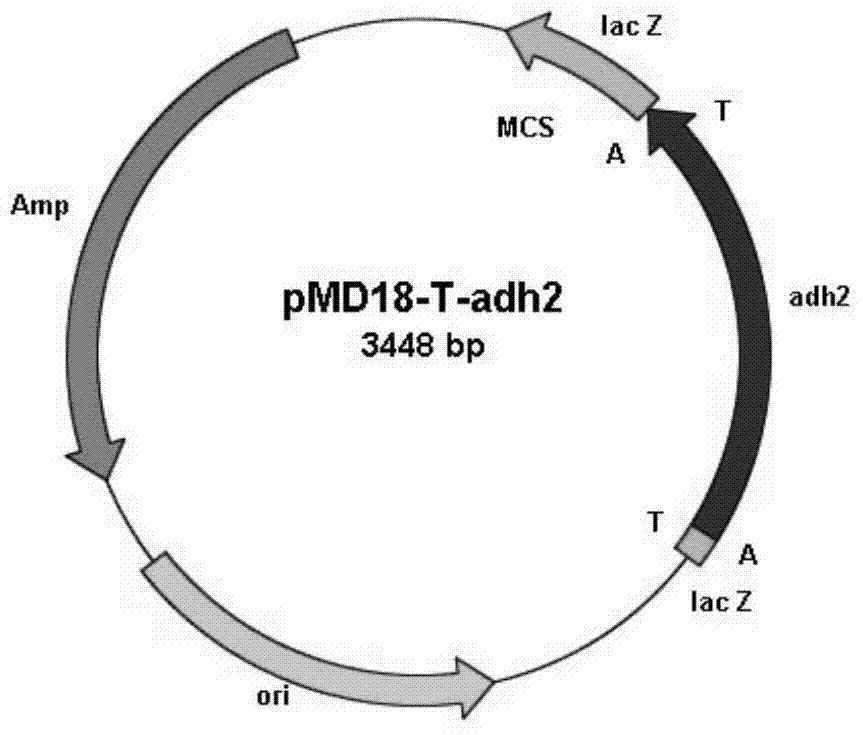

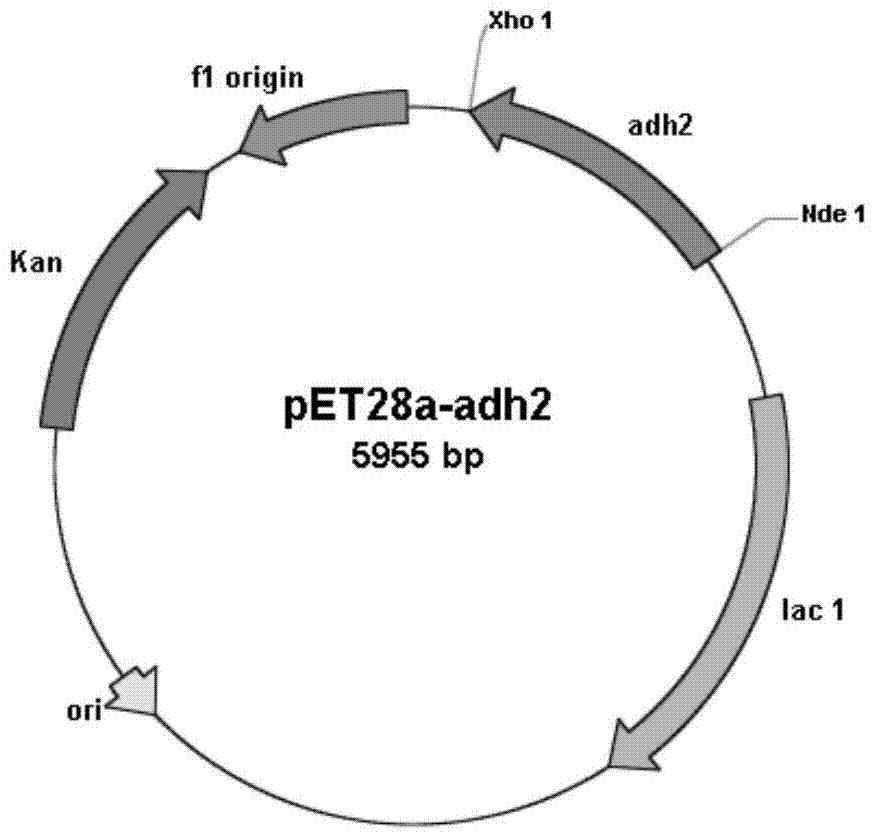

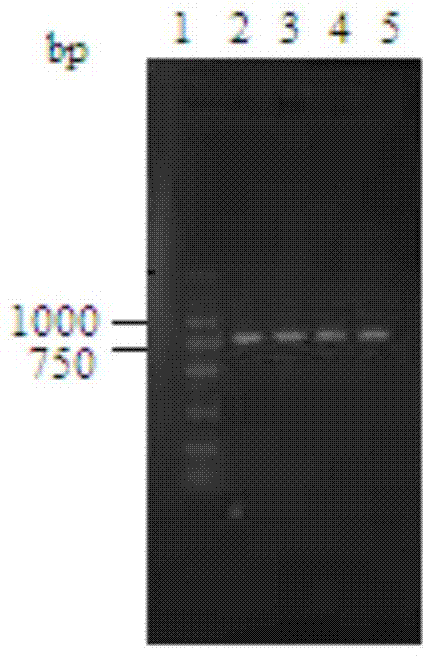

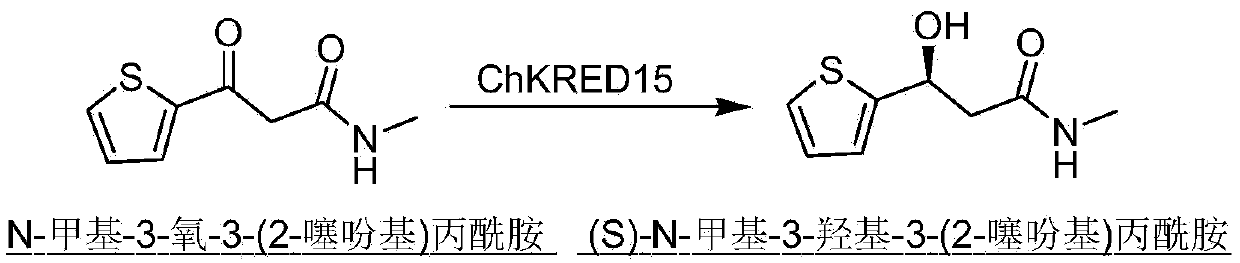

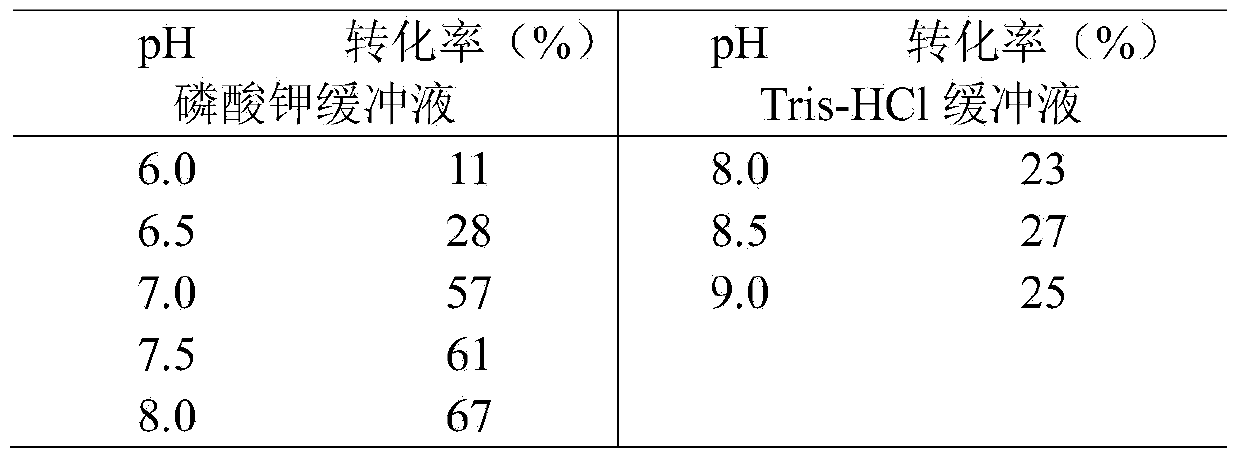

Carbonyl reductase gene, codase, vector, engineering bacterium and application thereof

InactiveCN104263742AHigh enantioselectivityImprove conversion rateBacteriaMicroorganism based processesKetoneEthyl acetate

The invention discloses a recombinant carbonyl reductase derived from Burkholderia gladioli ZJB-12126 and a coding gene thereof, a recombinant vector containing the gene, a recombinant gene engineering bacterium converted from the recombinant vector and application in preparing the recombinant carbonyl reductase.2-benzoylaminomethyl-3-one butyrate, N,N-bis-methyl-3-one-3-(2-thienyl)propanamide, ethyl 4-chloroacetoacetate (COBE) and tert-butyl (R)-6-cyano-5-hydroxy-3-carbonylhexanoate used as substrates are subjected to biological catalytic reaction to prepare high-optical-purity (2S,3R)-2-benzamidomethyl-3-hydroxybutyrate, (S)-N,N-bis-methyl-3-hydroxy-3-(2-thienyl)propanamide, ethyl (S)-4-chloro-3-hydroxybutyrate and tert-butyl 6-cyano-(3R,5R)-dihydroxyhexanoate.

Owner:ZHEJIANG UNIV OF TECH

Selective androgen receptor degrader (SARD) ligands and methods of use thereof

ActiveUS20170368003A1Lower Level RequirementsShorten the lengthHalogenated hydrocarbon active ingredientsNervous disorderMorpholineResistance mutation

This invention is directed to pyrrole, pyrazole, imidazole, triazole, and morpholine based selective androgen receptor degrader (SARD) compounds including heterocyclic anilide rings and their synthetic precursors, R-isomers, and non-hydroxylated and / or non-chiral propanamides, and pharmaceutical compositions and uses thereof in treating prostate cancer, advanced prostate cancer, castration resistant prostate cancer, triple negative breast cancer, other cancers expressing the androgen receptor, androgenic alopecia or other hyperandrogenic dermal diseases, Kennedy's disease, amyotrophic lateral sclerosis (ALS), abdominal aortic aneurysm (AAA), and uterine fibroids, and to methods for reducing the levels of androgen receptor-full length (AR-FL) including pathogenic or resistance mutations, AR-splice variants (AR-SV), and pathogenic polyglutamine (polyQ) polymorphisms of AR in a subject.

Owner:UNIV OF TENNESSEE RES FOUND

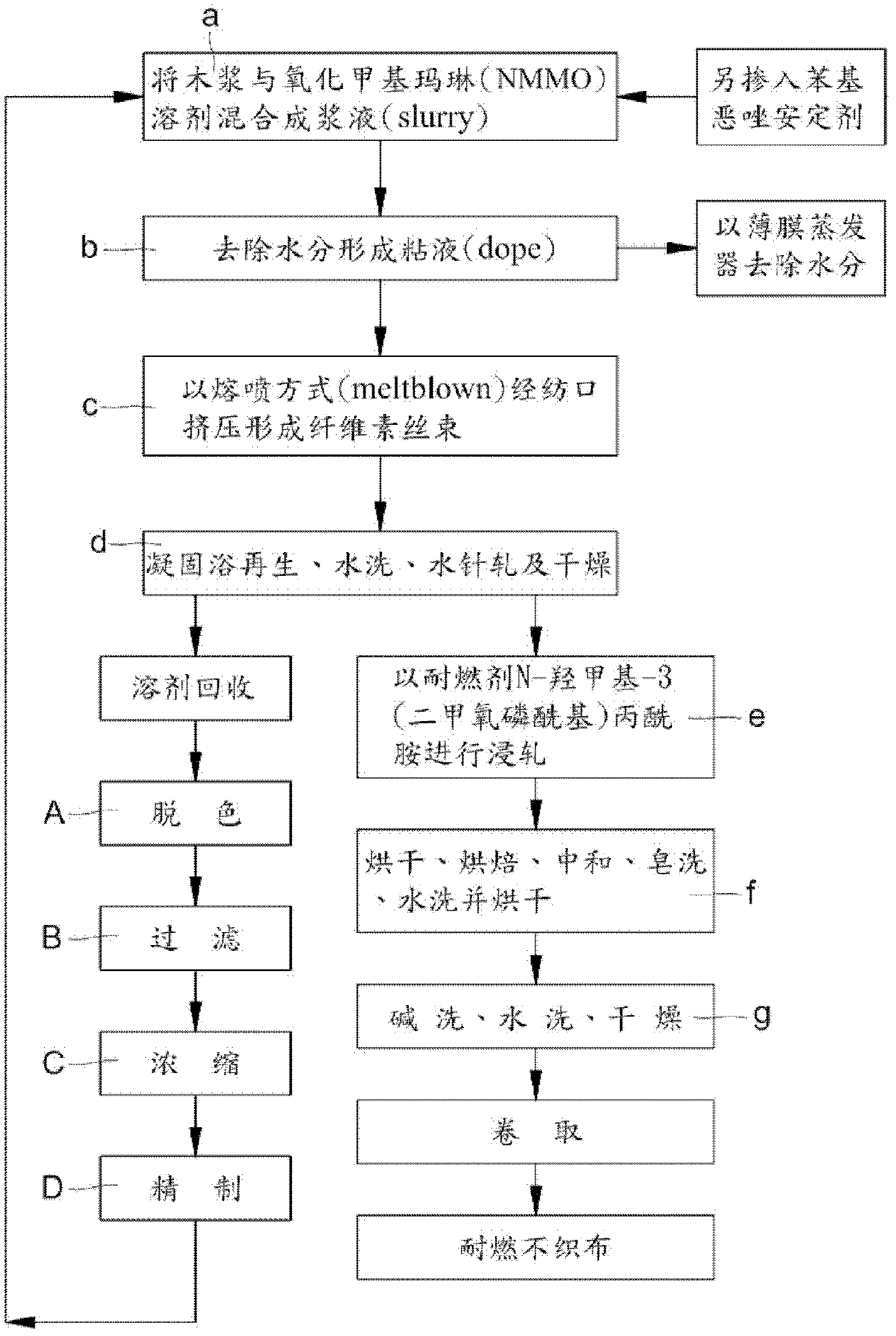

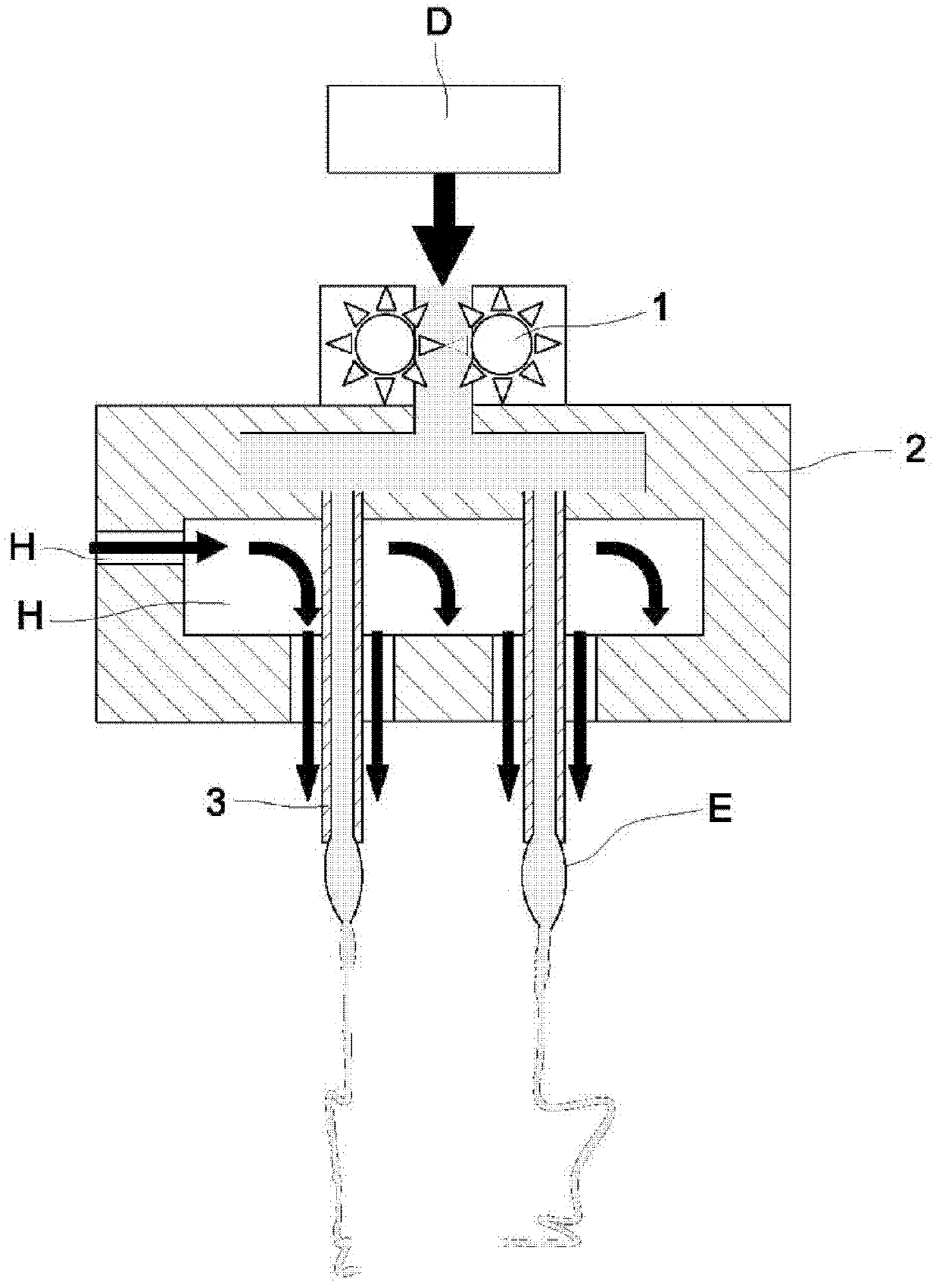

Preparation method for natural cellulose melt-blown non-woven fabric with burning-resistant function

ActiveCN103290682ALow costNo pollutionMonocomponent cellulose artificial filamentDry-cleaning apparatus for textilesCelluloseMorpholine

The invention relates to a preparation method for a natural cellulose melt-blown non-woven fabric with a burning-resistant function. The preparation method comprises the following steps of: mixing wood pulp with a methyl morpholine oxide solvent to form a pulp solution; removing water by a vacuum film evaporator to form a spinning adhesive solution; extruding the adhesive solution from a spinning hole in a melt-blowing way to form a cellulose tow; solidifying, regenerating, washing by water, rolling by a water needle and drying to prepare a natural cellulose non-woven fabric; carrying out pad-rolling on the natural cellulose non-woven fabric and a burning-resistant agent namely N-hydroxymethyl-3-(dimethoxy phosphoryl) propanamide; drying, baking, neutralizing, soaping, washing by the water and drying in sequence; finally washing by alkali, washing by water, drying and rolling to prepare the natural cellulose non-woven fabric with the long-acting burning-resistant function. According to the preparation method, the natural cellulose non-woven fabric and the burning-resistant agent namely N-hydroxymethyl-3-(dimethoxy phosphoryl) propanamide can produce a special crosslinking reaction in the preparation process, the burning-resistant effect of the natural cellulose melt-blown non-woven fabric completely conforms with the test standards of ASTM (American Society for Testing Material) D6413-1999 and ASTM D2863-1995, and the natural cellulose melt-blown non-woven fabric can be naturally decomposed after being used and thrown away, so that the natural cellulose melt-blown non-woven fabric becomes an environment-friendly material harmless to the natural environment.

Owner:张文波

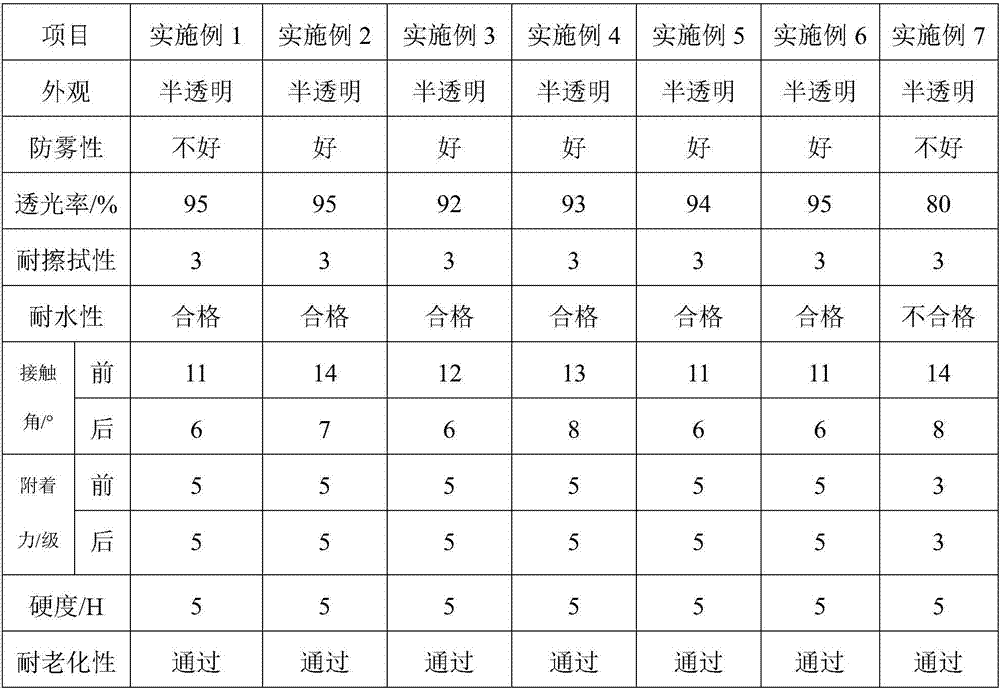

Anti-fog coating material and preparation method thereof

InactiveCN107267060AGood anti-fog performanceGood anti-glare effectPolyurea/polyurethane coatingsEpoxy resin coatingsArchitectural glassEpoxy

The invention discloses an anti-fog coating material and a preparation method thereof. The anti-fog coating material comprises the following components, in parts by mass: 20-40 parts of acrylic resin, 15-25 parts of alkyd resin, 10-20 parts of epoxy resin, 5-15 parts of sodium aliphatate, 10 parts of a binary block copolymer containing propanamide and hydroxyethyl ester, 5-25 parts of a surfactant, 8-12 parts of inorganic nanometer particles, 0.3-0.6 part of an antifoaming agent, 0.1-3 parts of a coupling agent and 1-3 parts of essence. According to the anti-fog coating material disclosed in the invention, the hydrophilicity is high, fog resistance and bright-light resistance are good, and the stability is high, and the coating material mainly used in the fields which need long-efficiency and high-quality fog resistance such as architectural glass, automobile window decorations, ocean ships, and port glass facilities, and practicability and security of devices can be effectively increased.

Owner:YIXING HONGTAI CHEM

Carbonyl reductase, gene thereof, and application thereof in preparing Duloxetine chiral intermediates

The invention discloses a carbonyl reductase (i)Ch ( / i) KRED15 derived from Chryseobacterium ((i) Chryseobacterium ( / i) (i) ( / i) sp. CA49), and a coding gene thereof; the invention also discloses application of the carbonyl reductase as a biocatalyst in preparing a Duloxetine chiral intermediate ((i) S ( / i))-N-methyl-3-hydroxy-3-(2-thienyl) propanamide. The enantiomer excess of products is greater than 99.9%. 20 g / L of substrate can be catalyzed by Ch( / i) KRED15 crude enzyme (2U / mL), and the conversion rate of over 99% can be obtained in 2 hours; a coenzyme circulation system is simple, and has large industrial application prospect.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

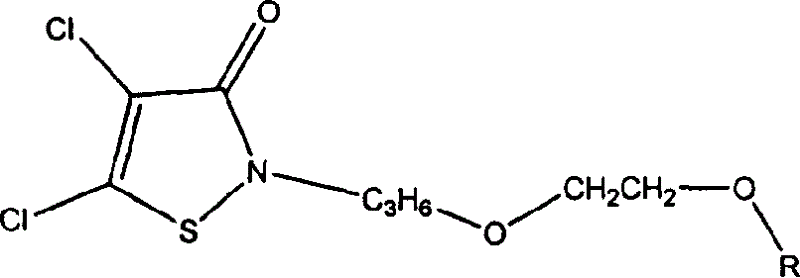

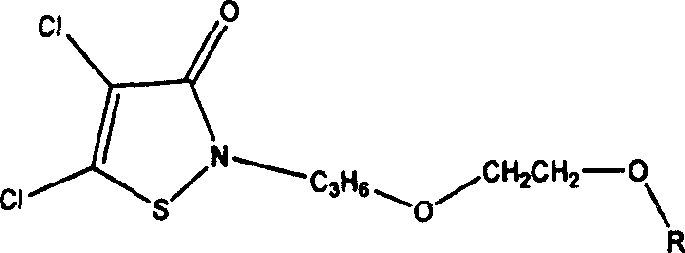

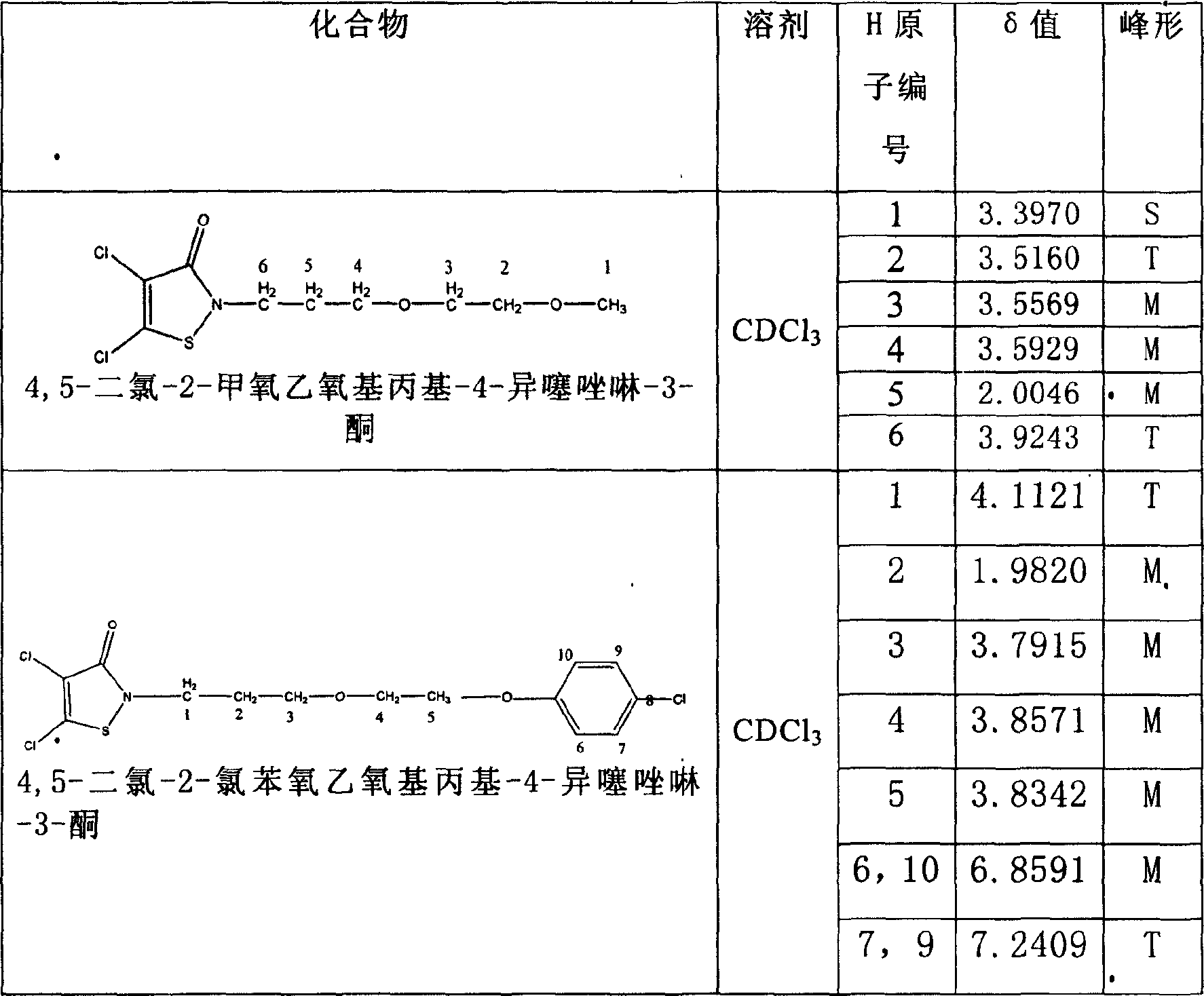

Alkoxy ethoxy propyl isothiazolinone and its preparation process and use

Disclosed is an alkoxy ethoxy propyl isothiazolinone, whose molecule formula is C8H10Cl2NO3SR, the preparation comprises reacting Na2Sx with acrylic methyl ester to obtain dithiodipropionic dimethyl ester, then reacting with alkoxy ethoxy alanine to obtain N, N'-dialkoxy ethoxy propyl dithioamides, and the latter further reacting with sulfuryl chloride. The invention can realize an antifouling agent for rapid degradation in the environment, very small influence to the biological availability for sea creatures can be achieved.

Owner:OCEAN UNIV OF CHINA

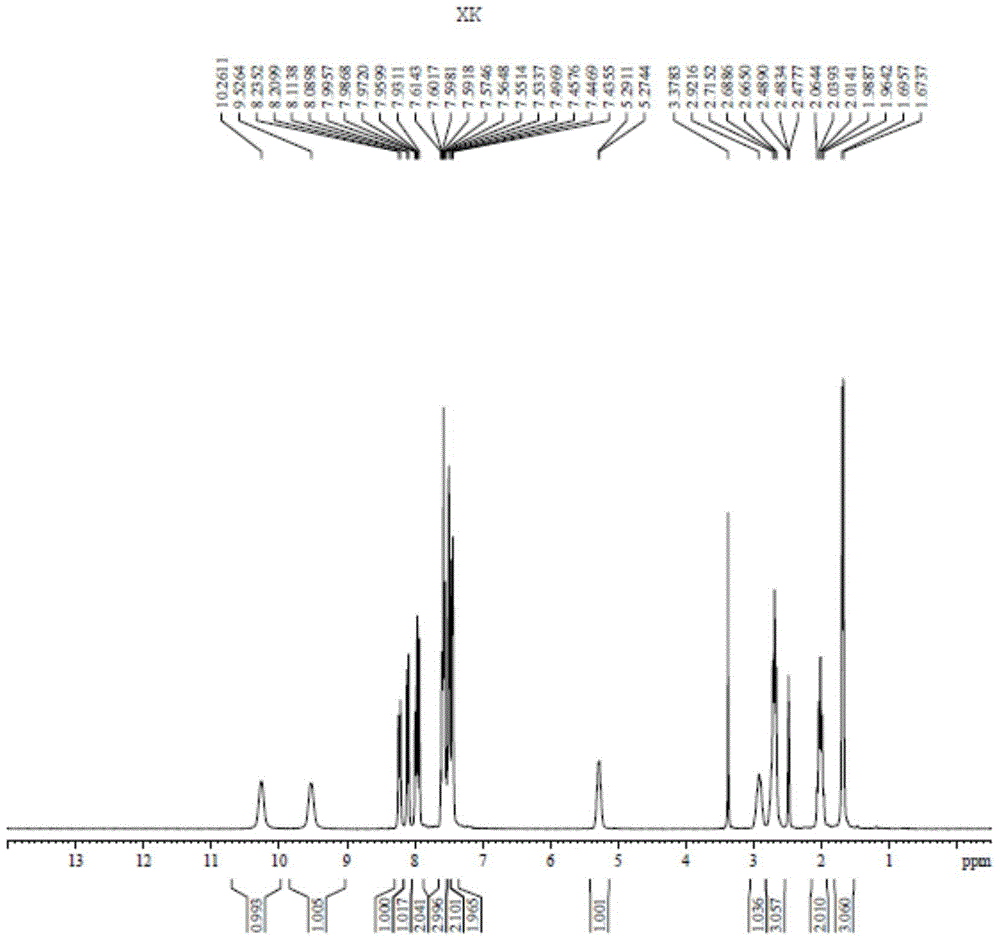

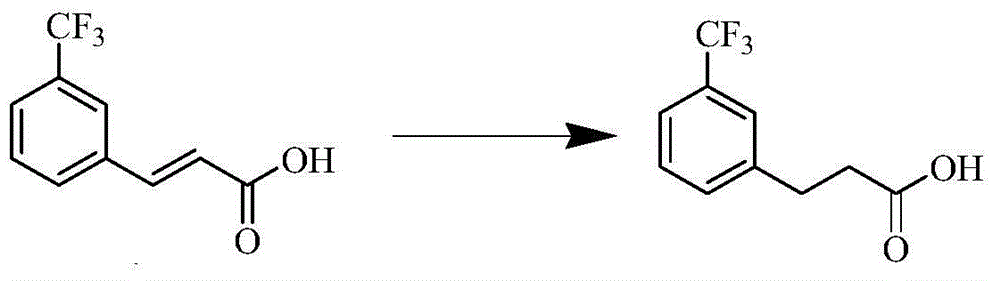

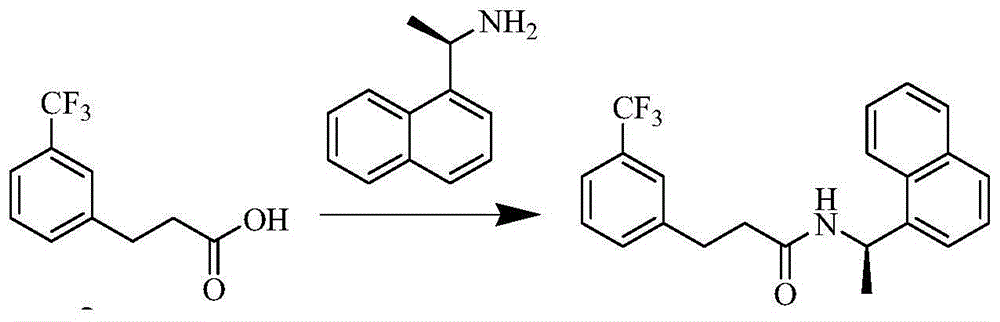

Cinacalcet hydrochloride preparation method

InactiveCN104478736ALow impurity contentNo pollution in the processOrganic compound preparationAmino compound preparationPalladium on carbonCinacalcet Hydrochloride

The invention provides a cinacalcet hydrochloride preparation method which comprises the following steps: (A) by taking trifluoromethylcinnamic acid as a raw material and palladium on carbon as a catalyst, performing hydrogenation reduction to obtain m-trifluoromethylbenzoic acid; (B) performing condensation reaction on the m-trifluoromethylbenzoic acid and R-(1) naphthylethylamine, thus obtaining (R)-N-(1-(naphthalen-1-yl)ethyl)-3-(trifluoromethyl)phenyl)propanamide; (C) performing catalytic reduction on the (R)-N-(1-(naphthalen-1-yl)ethyl)-3-(trifluoromethyl)phenyl)propanamide to obtain cinacalcet; and (D) reacting the cinacalcet and hydrochloric acid to obtain cinacalcet hydrochloride. The method has the advantages of thorough reaction, high yield, no pollution in the reaction process and the like.

Owner:CHENGDU QITAI PHARMA TECH

Preparation method and application of ionic liquid for absorbing SO2

InactiveCN103071367AImprove gas efficiencyLow costDispersed particle separationN dimethylformamideLithium chloride

The invention provides a preparation method of an ionic liquid for absorbing SO2, and an application of the ionic liquid in absorbing SO2. The preparation method of the ionic liquid comprises the steps of uniformly mixing one of aluminium chloride, zinc chloride, lithium chloride, aluminum sulfate, zinc sulfate, lithium sulfate, aluminium nitrate, zinc nitrate and lithium nitrate with one or two of urea, propanamide, butyramide, caprolactam, N,N-dimethylformamide and N,N-dimethylacetamide at a molar ratio of 1:(1-10) or 1:(0.5-3):(1-7), conducting reaction for 1-10h at 70-150 DEG C, conducting vacuum drying on an obtained solution at 40-60 DEG C, and obtaining the ionic liquid. The ionic liquid is mainly used for quickly and efficiently absorbing SO2. With the adoption of the ionic liquid as an SO2 absorbent, requirements on equipment required for absorbing SO2 are simple, the operational conditions are mild, the absorption efficiency is high, the cost is low, the ionic liquid can be recycled, and waste liquid and waste water discharge and other problems do not exist, and the ionic liquid is suitable for industrial production, meets the requirements of green chemical development of the contemporary society, and has good economic and social benefits.

Owner:SHIJIAZHUANG UNIVERSITY

Selective androgen receptor degrader (SARD) ligands and methods of use thereof

ActiveUS10314797B2Halogenated hydrocarbon active ingredientsNervous disorderMorpholineResistance mutation

This invention is directed to pyrrole, pyrazole, imidazole, triazole, and morpholine based selective androgen receptor degrader (SARD) compounds including heterocyclic anilide rings and their synthetic precursors, R-isomers, and non-hydroxylated and / or non-chiral propanamides, and pharmaceutical compositions and uses thereof in treating prostate cancer, advanced prostate cancer, castration resistant prostate cancer, triple negative breast cancer, other cancers expressing the androgen receptor, androgenic alopecia or other hyperandrogenic dermal diseases, Kennedy's disease, amyotrophic lateral sclerosis (ALS), abdominal aortic aneurysm (AAA), and uterine fibroids, and to methods for reducing the levels of androgen receptor-full length (AR-FL) including pathogenic or resistance mutations, AR-splice variants (AR-SV), and pathogenic polyglutamine (polyQ) polymorphisms of AR in a subject.

Owner:UNIV OF TENNESSEE RES FOUND

Viscosity stabilizer for oil-displacing polymer solution and preparation method of stabilizer

PendingCN110724513AGood viscosity stabilityEliminate the effect of viscosityDrilling compositionPropanoic acidAntioxidant

The invention discloses a viscosity stabilizer for an oil-displacing polymer solution and a preparation method of the viscosity stabilizer. The stabilizer composition includes a solvent and additives;the additives are at least two selected from the group consisting of an antioxidant, an anti-salt agent and a bactericide; the antioxidant is at least one selected from the group consisting of thioethanol, thiourea, thiodipropionic acid, sodium thiosulfate, potassium iodide, 2-hydroxyethylamine and acetone; the anti-salt agent is at least one selected from the group consisting of ethylenediaminetetraacetic acid or a salt thereof, 1-hydroxyethylidene-1,1-diphosphonic acid or a salt thereof, polyacrylic acid and sodium citrate; and the bactericide is at least one selected from the group consisting of N,N-dimethyldithiocarbamic acid sodium salt, methylene dithiocyanate, 2,2-dibromo-3-cyanoacetamide, 2-nitro-2-bromo-1,3-propanediol, glutaraldehyde and isothiazolinone. The stabilizer solves the problem of large viscosity loss of the polymer solution during polymer displacement.

Owner:DAQING PETROLEUM ADMINISTRATION +2

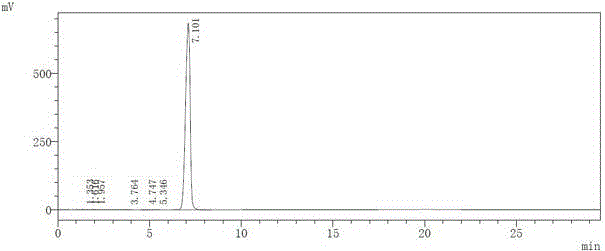

Synthetic method of parecoxib sodium impurity

ActiveCN104557756APrecise positioningQualitative highOrganic chemistryParecoxib sodiumStandard samples

The invention discloses a synthetic method of a parecoxib sodium impurity, namely N-[[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl]propanamide, belonging to the technical field of chemical pharmacy; the parecoxib sodium impurity is obtained by carrying out sulfonation reaction, amination reaction and propionylation reaction by taking 5-methyl-3,4-diphenyl isoxazole as the raw material; the synthesized high-purity parecoxib sodium impurity can be used as an impurity standard sample in detection and analysis of parecoxib sodium finished products; therefore, the accurate positioning property and the qualitative diagnosis to impurities in detection and analysis of parecoxib sodium finished products are increased; control of the impurity is strengthened easily, so that the quality of the parecoxib sodium finished products is increased; the synthetic method disclosed by the invention is cheap and available in raw materials and simple to operate; the yield of the prepared parecoxib sodium impurity is 85+ / -5%; and the HPLC (High Performance Liquid Chromatography) purity is more than or equal to 98%.

Owner:CHENGDU CLIMB PHARMA TECH

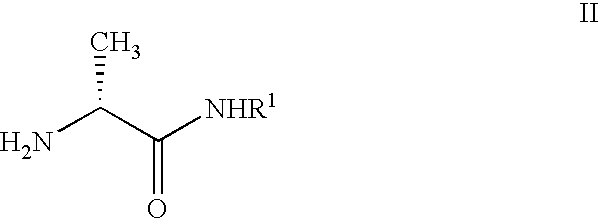

Selective androgen receptor degrader (SARD) ligands and methods of use thereof

ActiveUS9834507B2Improve survivalReduce morbidityOrganic chemistry methodsPharmaceutical delivery mechanismAmyotrophic lateral sclerosisAndrogen

This invention provides novel 3-amino propanamide selective androgen receptor degrader (SARD) compounds, pharmaceutical compositions and uses thereof in treating prostate cancer, advanced prostate cancer, castration resistant prostate cancer, androgenic alopecia or other hyperandrogenic dermal diseases, Kennedy's disease, amyotrophic lateral sclerosis (ALS), and uterine fibroids, and to methods for reducing the levels of androgen receptor-full length (AR-FL) including pathogenic or resistance mutations, AR-splice variants (AR-SV), and pathogenic polyglutamine (polyQ) polymorphisms of AR in a subject.

Owner:ONCTERNAL THERAPEUTICS INC +1

Method for preparing N-hydroxymethyl-3-(dimethoxyphosphoryl) propionamide

ActiveCN102060873AIncrease concentrationReduce usageGroup 5/15 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalDimethyl phosphite

The embodiment of the invention discloses a method for preparing N-hydroxymethyl-3-(dimethoxyphosphoryl) propionamide, which comprises the following steps of: leading acrylamide, dimethyl phosphite and a catalyst to react in a solvent to obtain dimethyl (3-amino-3-acyl propyl) phosphonate, wherein the catalyst is a nonacid compound of alkaline earth metal; leading dimethyl (3-amino-3-acyl propyl) phosphonate to react with formaldehyde to obtain the N-hydroxymethyl-3-(dimethoxyphosphoryl) propionamide. In the invention, the nonacid compound of alkaline earth metal is used as the catalyst. Because the nonacid compound of alkaline earth metal is solid matter, the reactants including acrylamide and dimethyl phosphite can be in good contact with the solid catalyst. Meanwhile, the surface of the solid catalyst has high catalyst concentration to ensure that the catalyst is easy to initiate the reaction. Thus, the preparation method provided by the invention ensures short reaction time and high reaction efficiency.

Owner:UNIV OF SCI & TECH OF CHINA

Propionamide derivatives useful as androgen receptor modulators

InactiveUS7390923B2High activityHigh affinityBiocideOrganic compound preparationSelective androgen receptor modulatorHormone Receptor Modulators

Compounds of formula (I)wherein R1 to R4, X and A are as defined in the claims and pharmaceutically acceptable salts and esters thereof, are disclosed. The compounds of formula (I) possess utility as tissue-selective androgen receptor modulators (SARM) and are useful in hormonal therapy, e.g., in the treatment or prevention of male hypogonadism and age-related conditions such as andropause.

Owner:ORION CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com