Patents

Literature

351results about How to "Good anti-glare effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

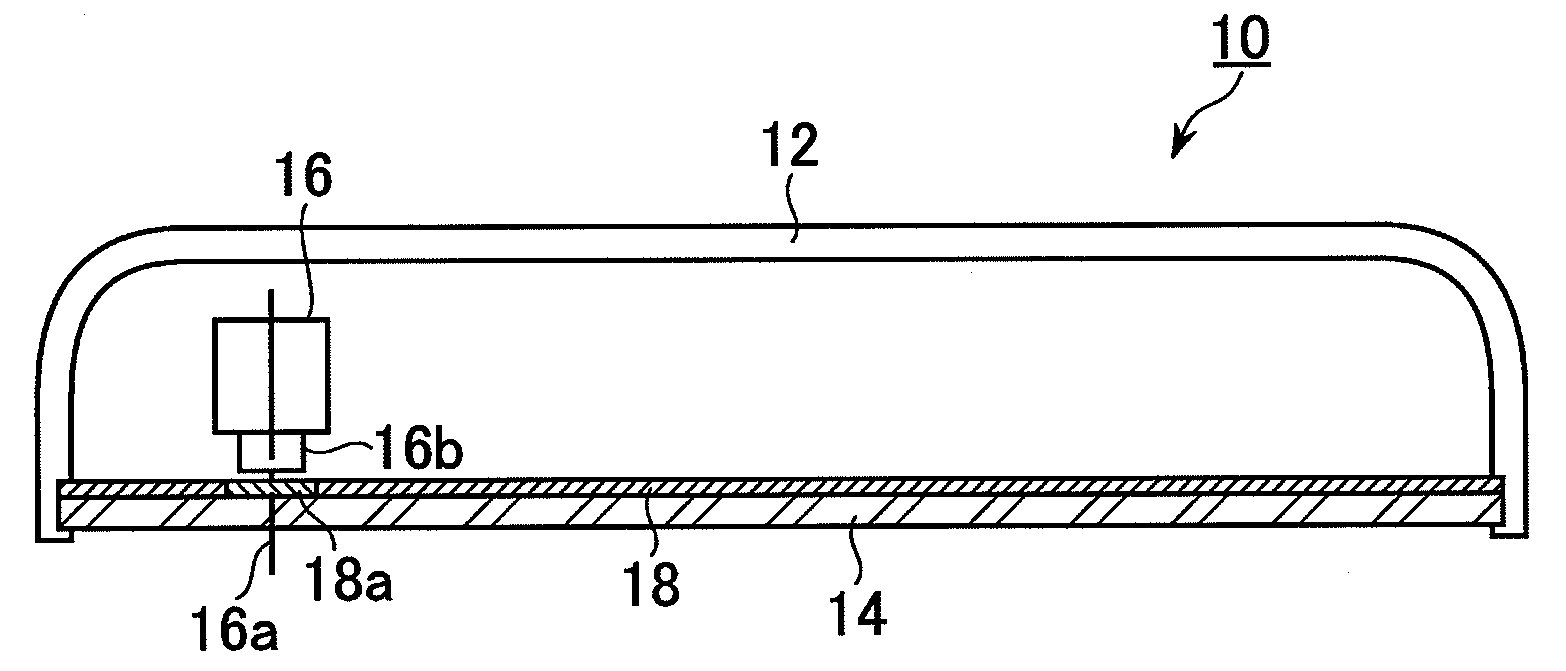

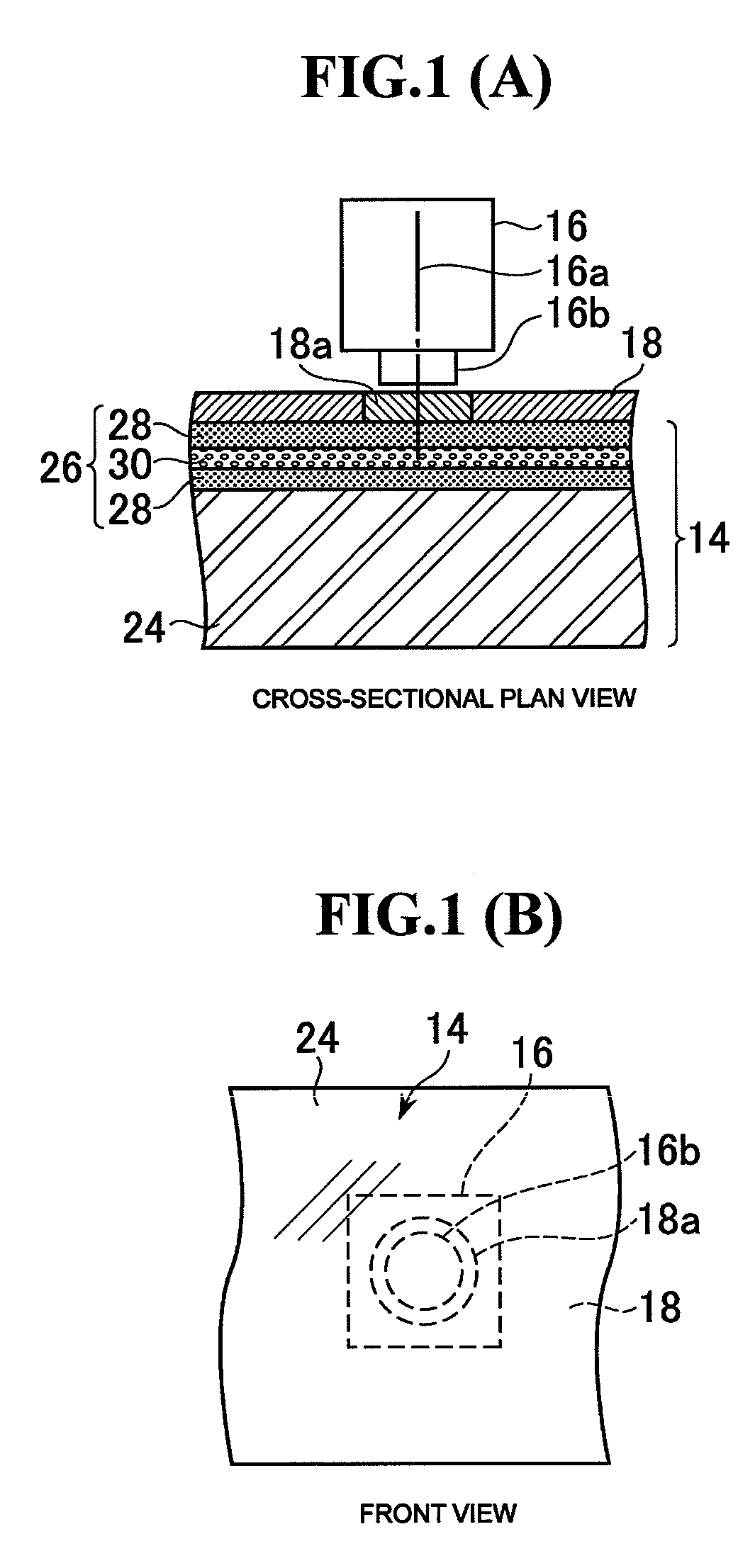

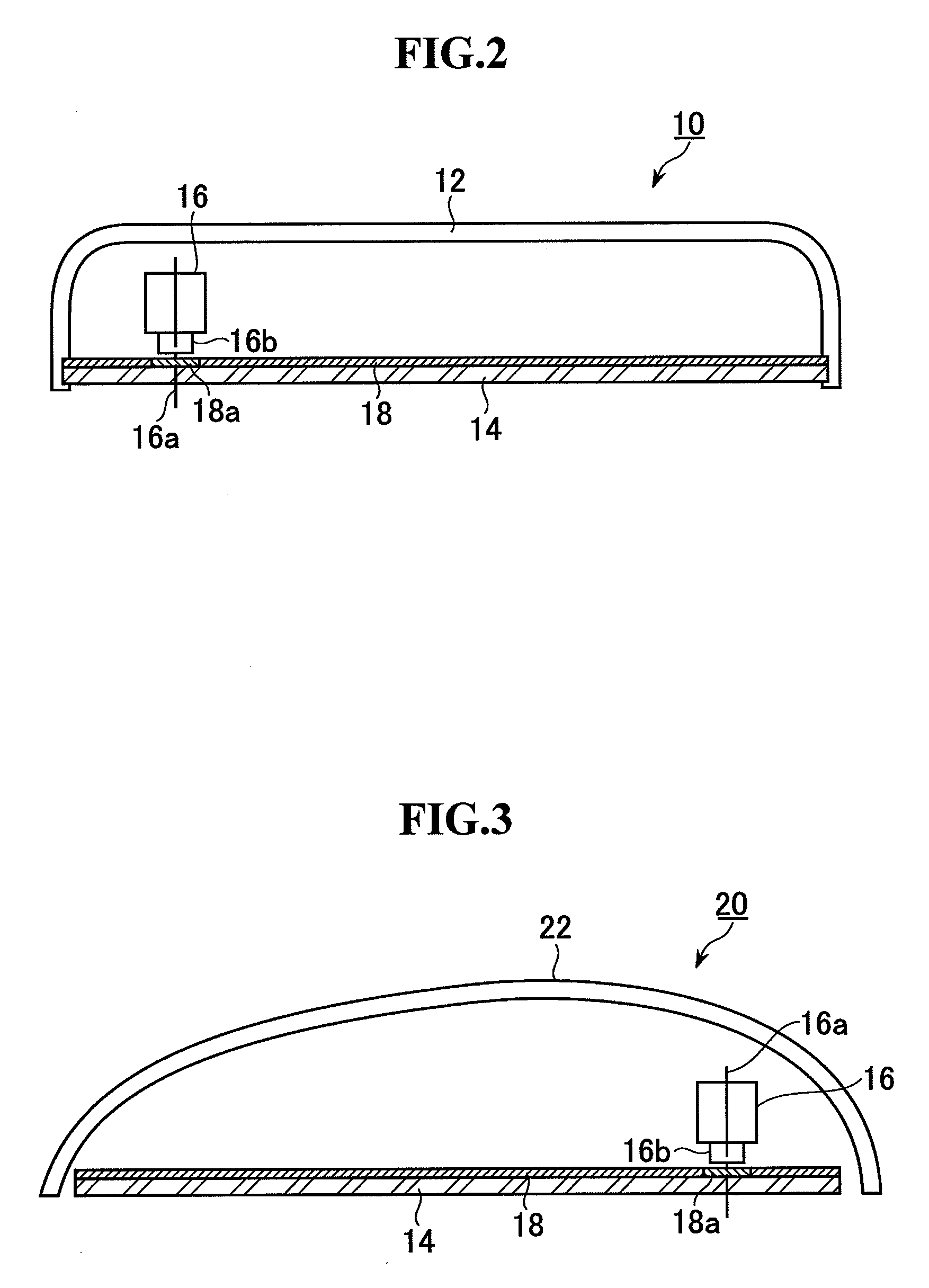

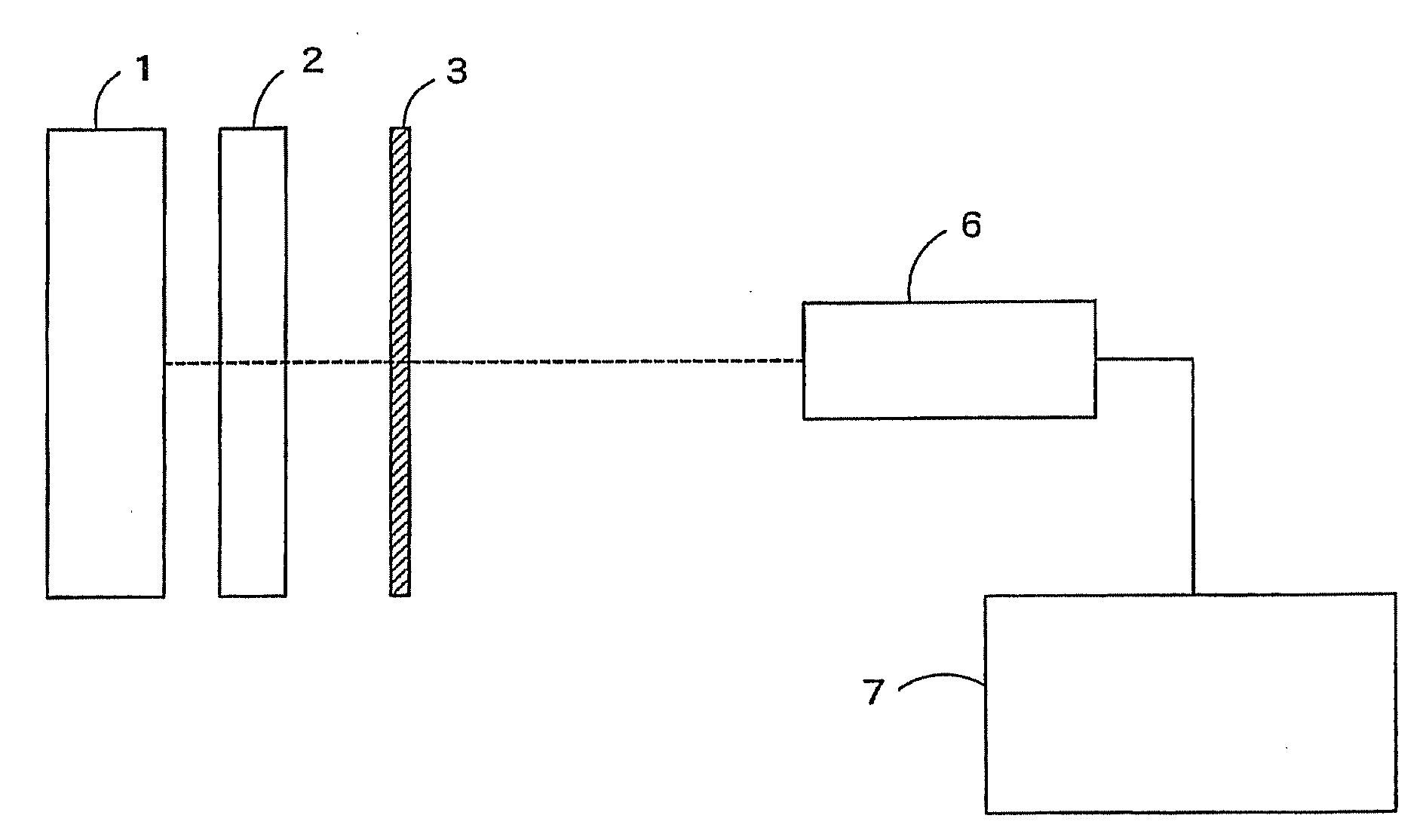

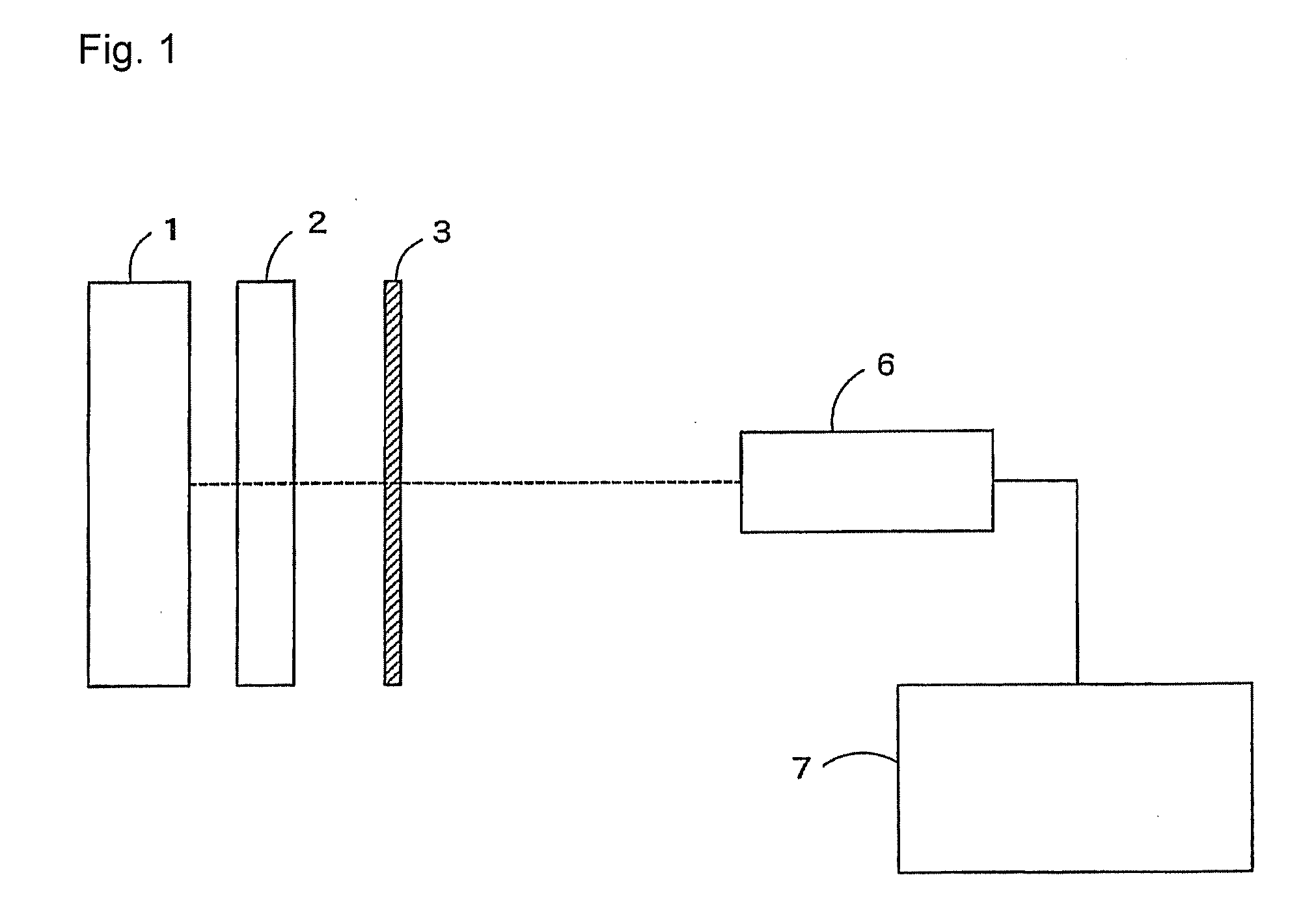

Image pickup device-equipped rear-view mirror

ActiveUS20090040778A1Reduce reflected light intensityGood anti-glare effectOptical signallingTelevision systemsRefractive indexTransmittance

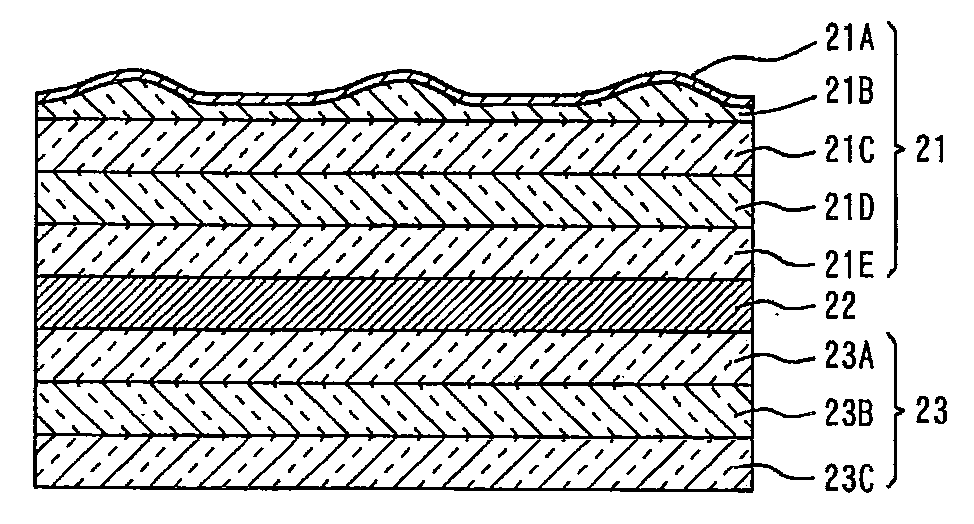

The present invention is intended to provide an image pickup device-equipped rear view mirror with improved image pickup performance, glare prevention and appearance (design) in addition to improved performance as a vehicle mirror. A mirror element is formed by forming a reflecting film consisting of high refractive index material films and a low refractive index material film on a back surface of a transparent glass substrate. The integrating sphere reflectance of the mirror element in the visible range is 40% to 60% and the near-infrared transmittance is no less than 70% for the whole or part of the band belonging to the near-infrared range within the entire sensitive wavelength range of the near-infrared camera. A black mask member is attached to an entire back surface of the reflecting film. The near-infrared camera is arranged behind the black mask member. The region corresponding to the area for the image-pickup by the near-infrared camera within the entire region of the black mask member is formed of a visible-light absorption and near-infrared transmission filter. The near-infrared transmittance of the visible-light absorption and near-infrared transmission filter is no less than 70% for the whole or part of the band belonging to the near-infrared range within the entire sensitive wavelength range of the near-infrared camera.

Owner:MURAKAMI CORP

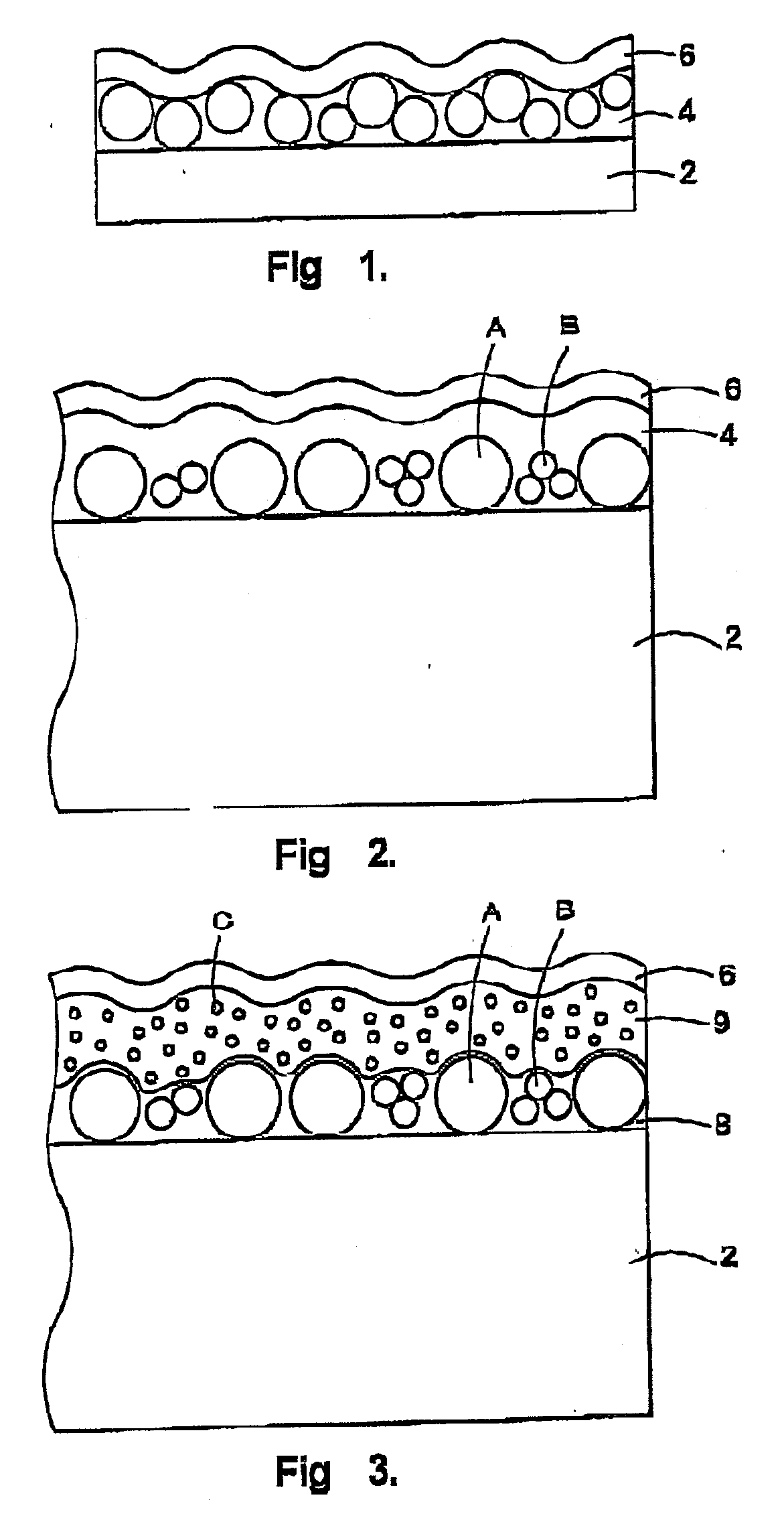

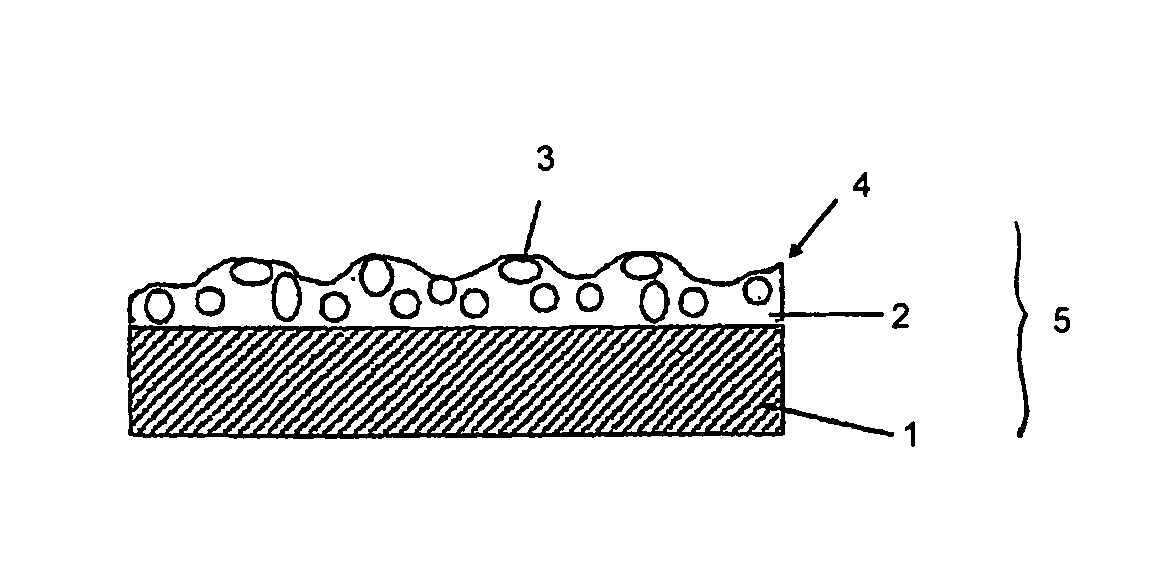

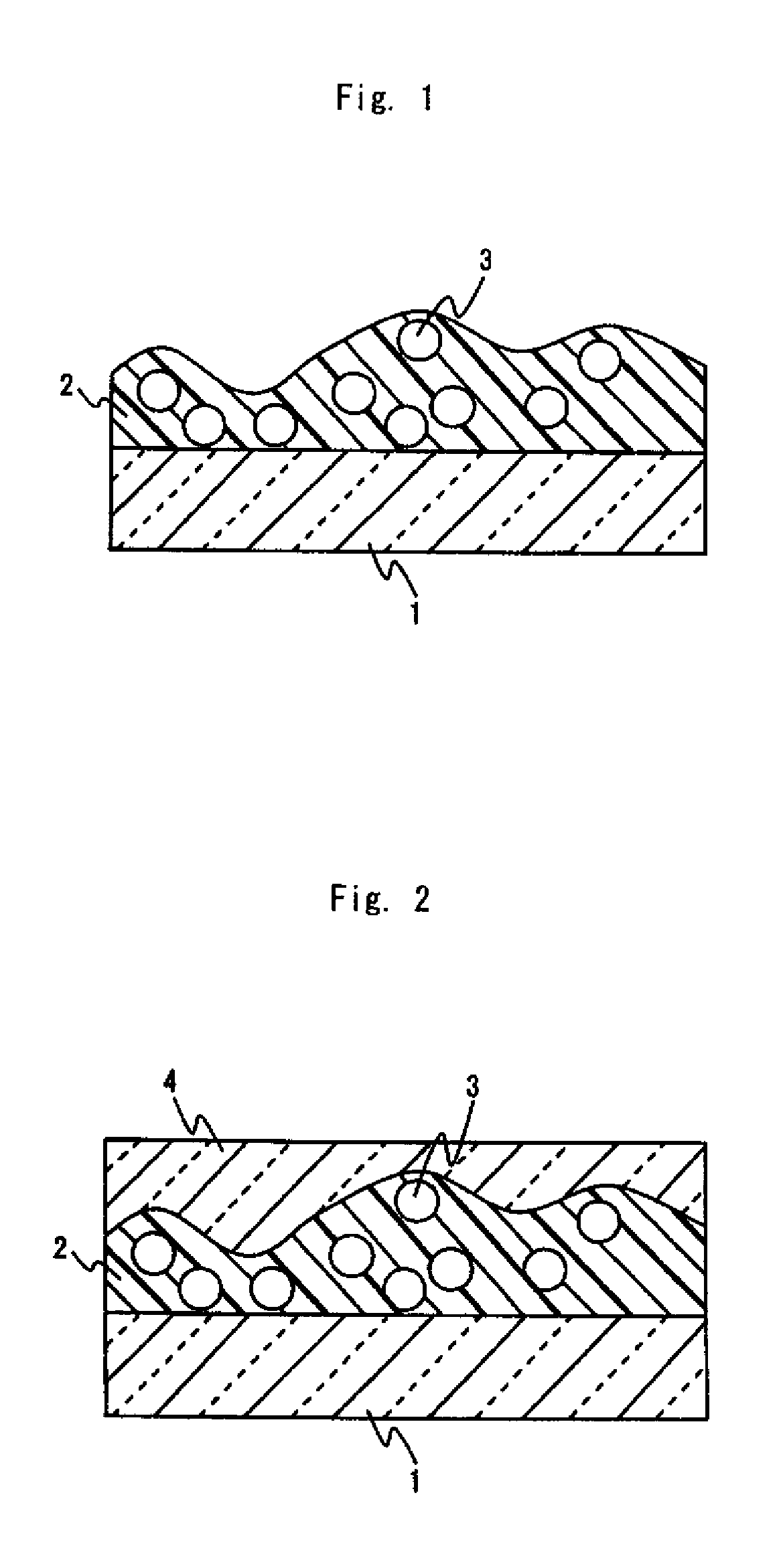

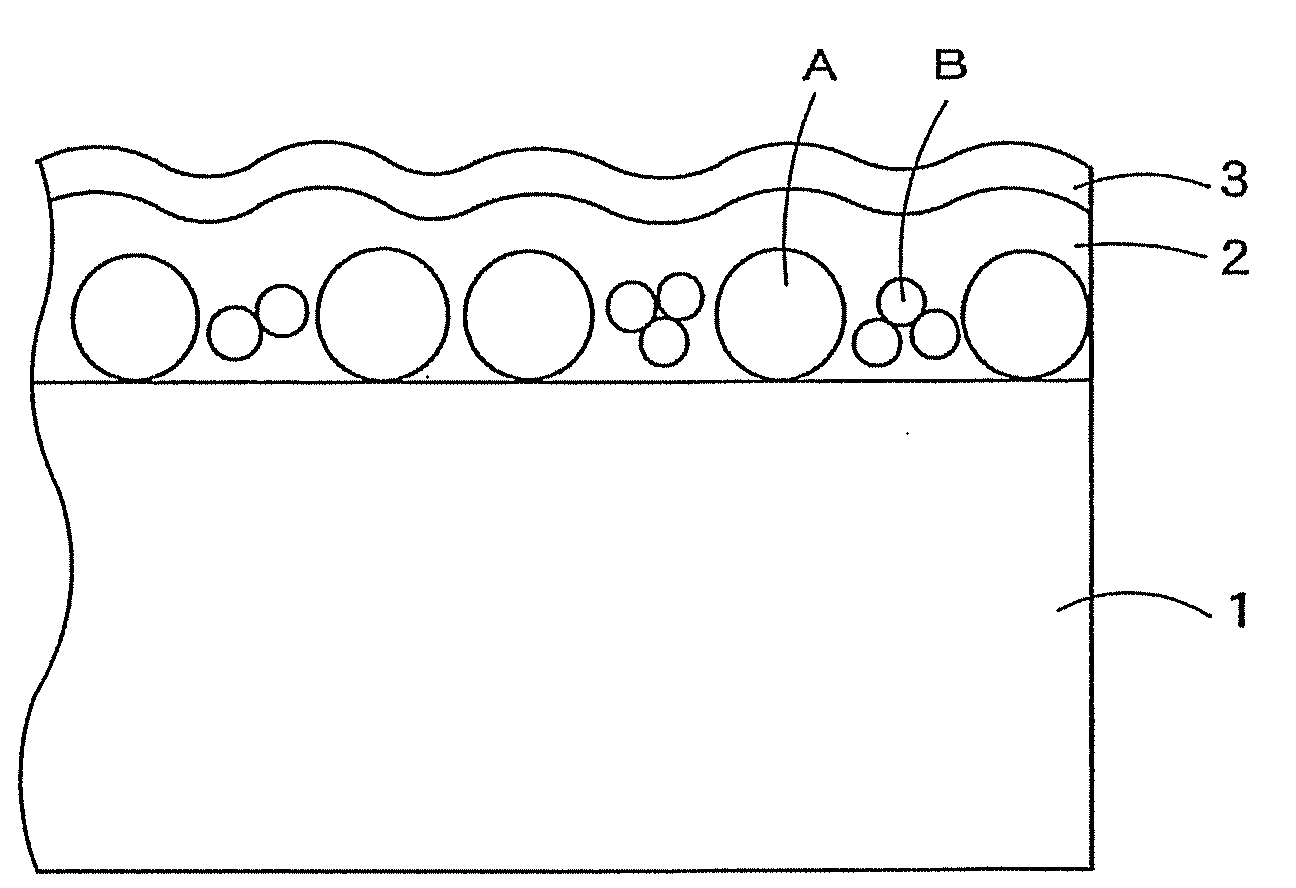

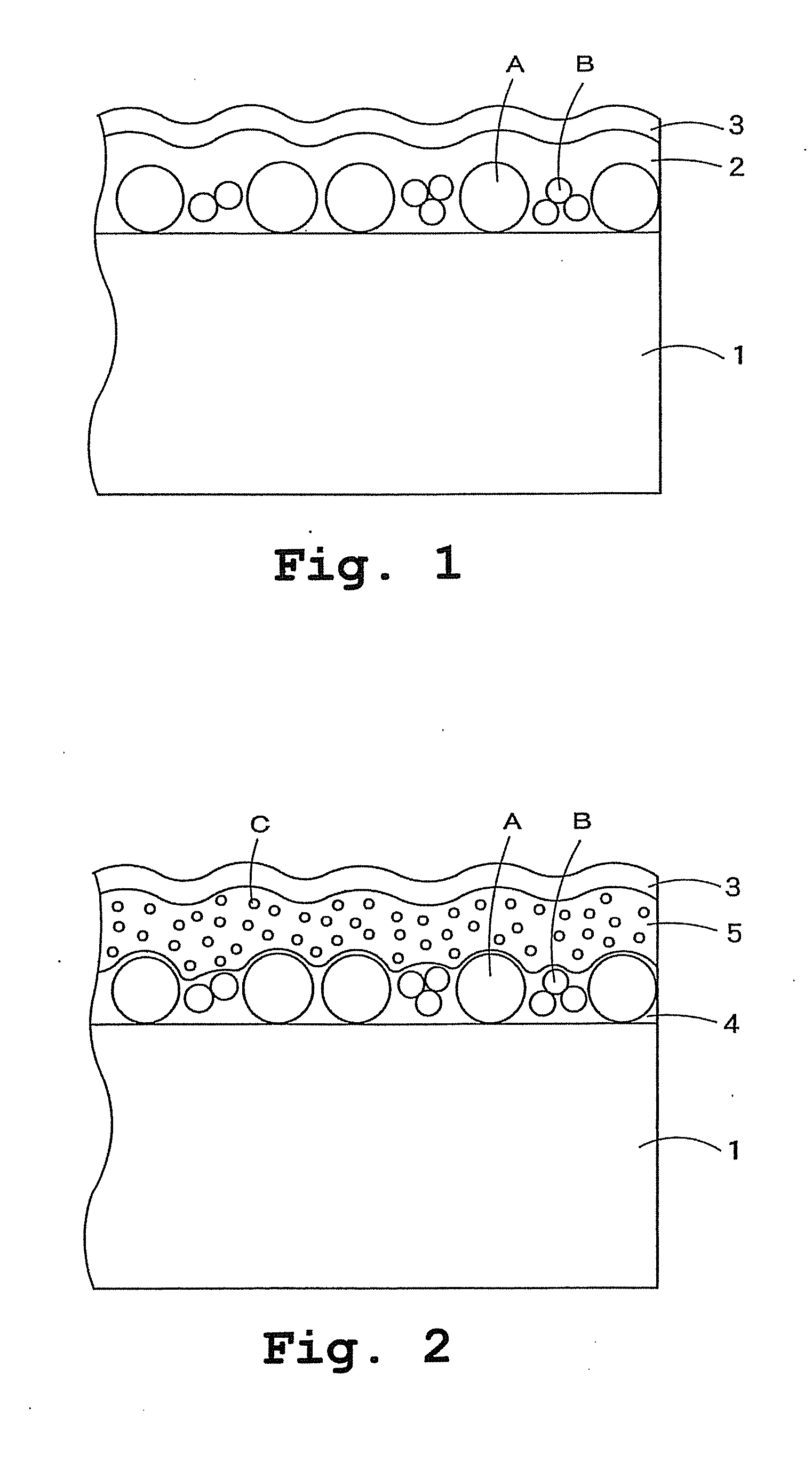

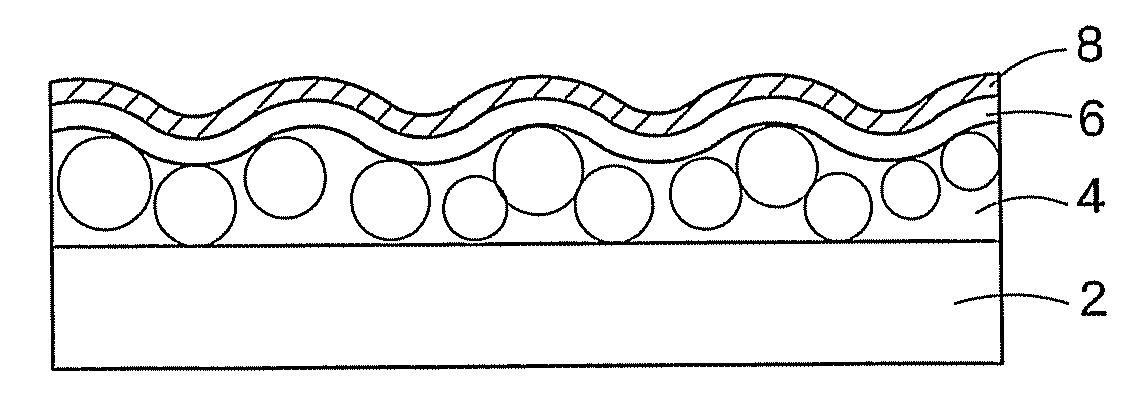

Antiglare laminate

InactiveUS20050255291A1Good anti-glare effectIncrease contrastLayered productsDiffusing elementsOptoelectronicsEngineering

Owner:DAI NIPPON PRINTING CO LTD

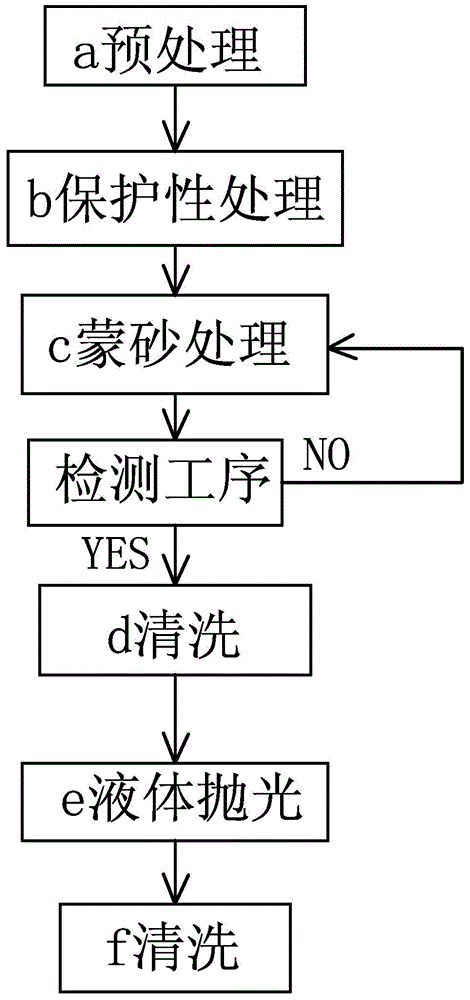

Process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses

The invention discloses a process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses, wherein the method comprises the following steps: (1) weighing the raw materials according to the formula of a frosting liquid, mixing and stirring the raw materials evenly, curing the mixture for 24 -30 hours to prepare the frosting liquid; (2) after cleaning the glass to be frosted, carrying out protective treatment on one surface that is not needed to be frosted; (3) placing the protected glass into a pre-treatment liquor for further cleaning; (4) placing the treated glass into the cured frosting liquid to frost the glass for 30 -200 seconds, taking out the glass and cleaning the glass with water; and (5) placing the frosted glass into a polishing liquid to etch to obtain the anti-glare glass finished product. The invention solves the problem that the high-boron silicon and high-aluminium silicon glasses have large hardness and are difficult to be frosted; the process provided by the invention improves the hardness of the glass while guaranteeing the even frosting degree and good anti-glare effect; the product produced by the process provided by the invention has advantages of acid and alkali resistance and corrosion resistance.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

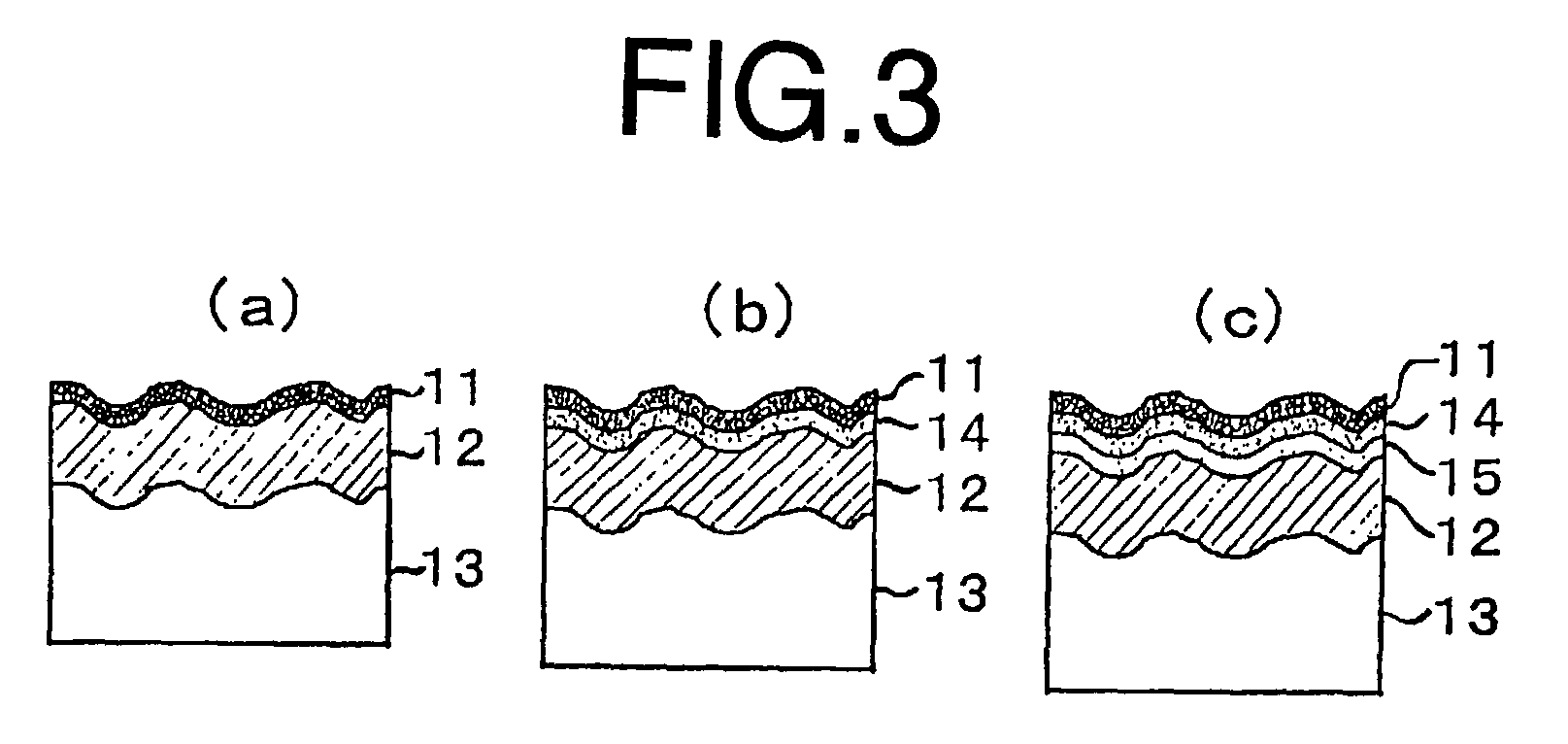

Functional film and display apparatus

InactiveUS20090246415A1High anti-glarenessHigh anti-reflection propertyLiquid crystal compositionsVacuum evaporation coatingRefractive indexComputational physics

Owner:SHARP KK +2

Hard-coated antiglare film, polarizing plate, and image display

InactiveUS20070268587A1Maintain anti-glare propertyIncrease display contrastDiffusing elementsPolarising elementsDisplay contrastOptoelectronics

A hard-coated antiglare film that has excellent antiglare properties, prevents a glare phenomenon from occurring, and prevents white blur from occurring to have excellent display contrast in bright light. The hard-coated antiglare film includes a transparent plastic film substrate and a hard-coating antiglare layer containing fine particles. The hard-coating antiglare layer is formed on at least one surface of the transparent plastic film substrate. The hard-coating antiglare layer has a surface with an uneven structure. The hard-coated antiglare film has a total haze value ht in the range of 40 to 70%. The relationship between the total haze value ht and an inner haze value hi obtained due to scattering inside the hard-coating antiglare layer is a relationship of the total haze value ht≦the inner haze value hi.

Owner:NITTO DENKO CORP

Ultraviolet-cured anti-dazzle hard film and application thereof

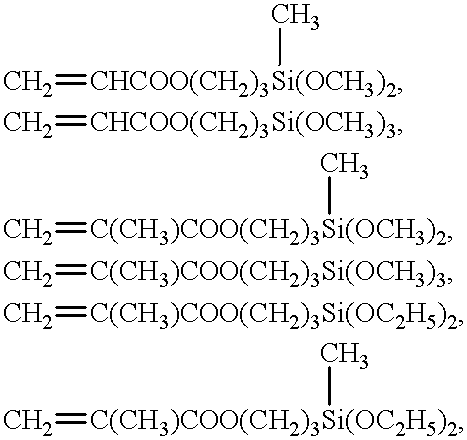

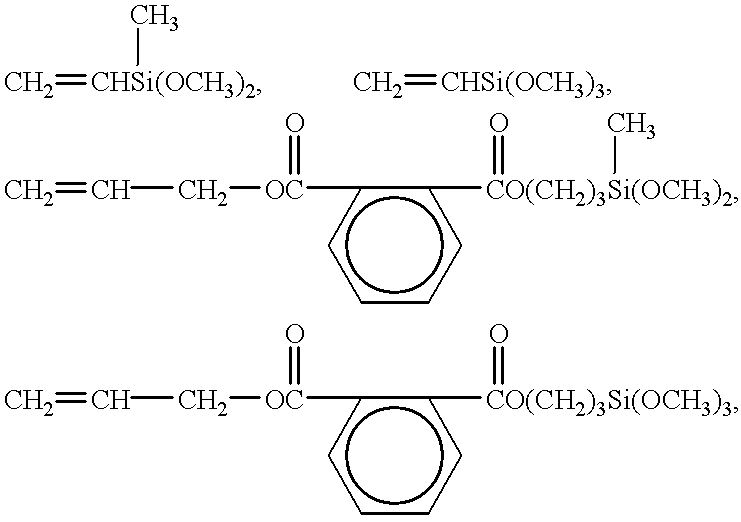

InactiveCN103205190AGood anti-glare effectGood compatibilityPolyurea/polyurethane coatingsPolyester coatingsUltravioletReactive diluent

The invention provides an ultraviolet-cured anti-dazzle hard film and application thereof. The ultraviolet-cured anti-dazzle hard film comprises a transparent supporter and an anti-dazzle hard film coating coated on at least one surface of the transparent supporter. A formula for the coating comprises, by weight, 5 to 90 parts of an ultraviolet-cured resin, 5 to 90 parts of a solvent, 1 to 10 parts of a photoinitiator, 0 to 80 parts of a reactive diluents, 1 to 40 parts of an anti-dazzle particle and 0 to 6 parts of an auxiliary agent. Compared with the prior art, the invention has the following advantages: the ultraviolet-cured resin contains a certain amount of an organic silicon resin, which enables the antifouling property of the surface of the anti-dazzle hard film to be improved; and the selected organic particle has good compatibility with the ultraviolet-cured resin, so transmission loss of light is reduced, which enables clarity of displaying by the anti-dazzle hard film to be improved. The ultraviolet-cured anti-dazzle hard film has good anti-dazzling performance, a good antifouling effect, high hardness, good scratch resistance, excellent flexibility and high resolution.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Antireflection article

InactiveUS6383620B1Good anti-glare effectMaintain resistanceSynthetic resin layered productsRecord information storageElastomerPolymer science

An antiglare-treated article comprising an acrylic resin substrate and a fluorine-containing polymer coating formed on the surface of the substrate, wherein the thickness of the coating is in the range between 0.03 and 0.5 mum, and the fluorine-containing polymer has a refractive index in the range between 1.30 and 1.40 and comprises a block which is compatible with the acrylic resin and a block comprising a fluorine-containing elastomer. This treated article can be stably produced at low costs although it has the same abrasion resistance and antiglare effects as those of conventional antiglare-treated articles, or it has better antiglare effects than conventional antiglare films while maintaining abrasion resistance.

Owner:DAIKIN IND LTD

Anti-dazzling optical laminate

ActiveUS20090268299A1Improving anti-glare propertyIncrease contrastDiffusing elementsRecord information storageBrightness perceptionHaze

Disclosed is an anti-dazzling laminate which has anti-dazzling properties and can realize excellent glare preventive properties and black color reproducibility (gradation rendering of black color at low brightness). The anti-dazzling laminate is an optical laminate comprises a light transparent base material and an anti-dazzling layer provided on the light transparent base material, wherein the outermost surface of the anti-dazzling layer has a concavoconvex shape, and the optical laminate satisfies the following requirements: Ha is more than 0% and less than 90%, Hi is more than 0% and less than 90%, and Hi / Ha is not less than 0.8 and less than 1.0, wherein Ha represents the whole haze value of the optical laminate; and Hi represents the internal haze value of the optical laminate.

Owner:DAI NIPPON PRINTING CO LTD

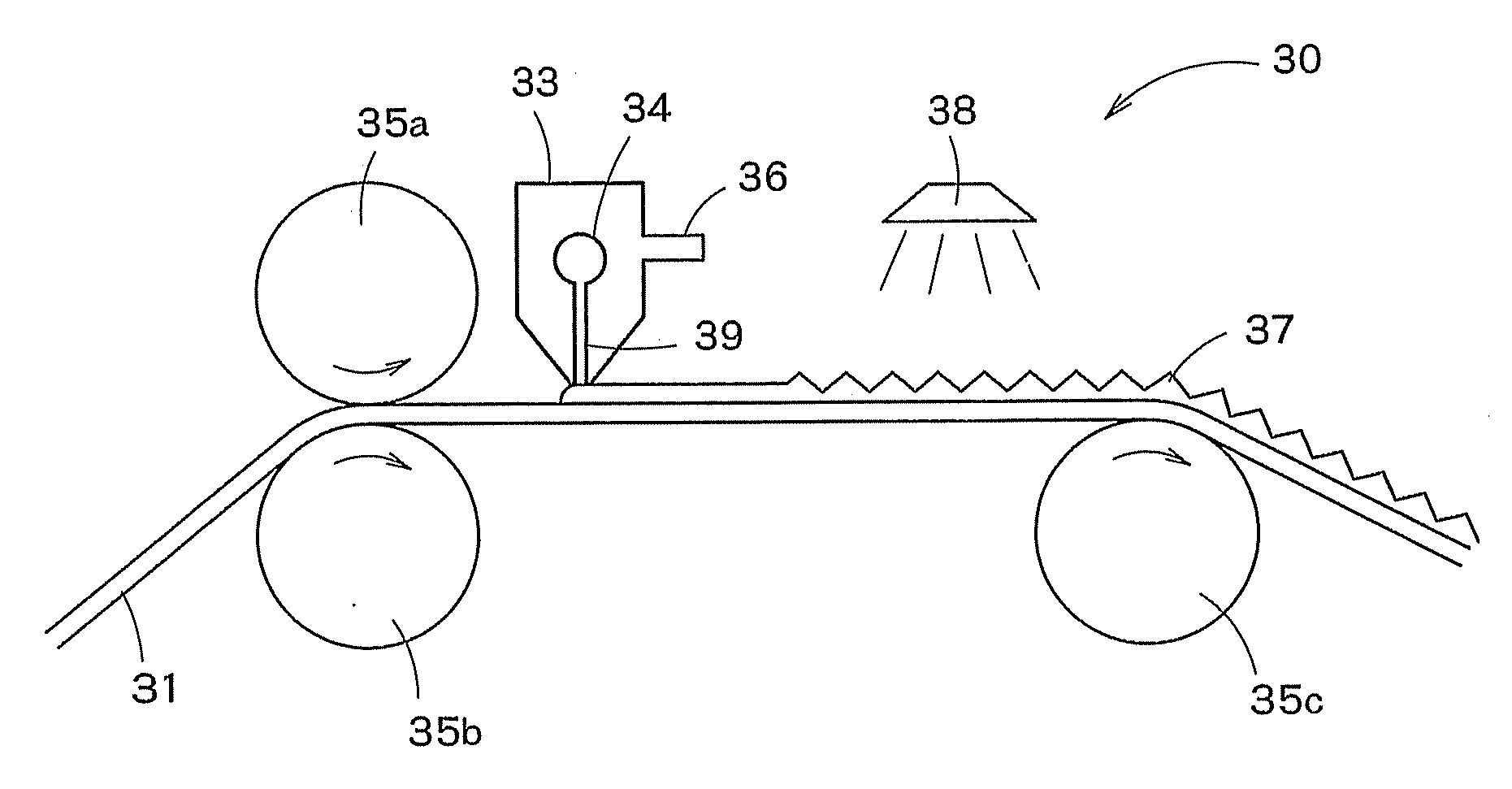

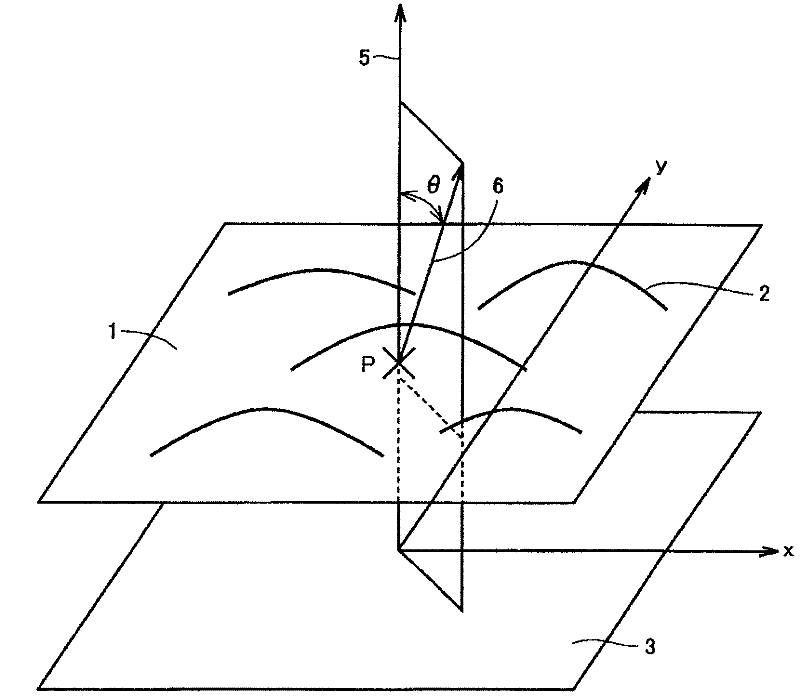

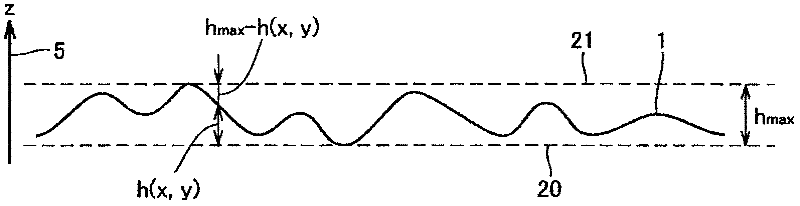

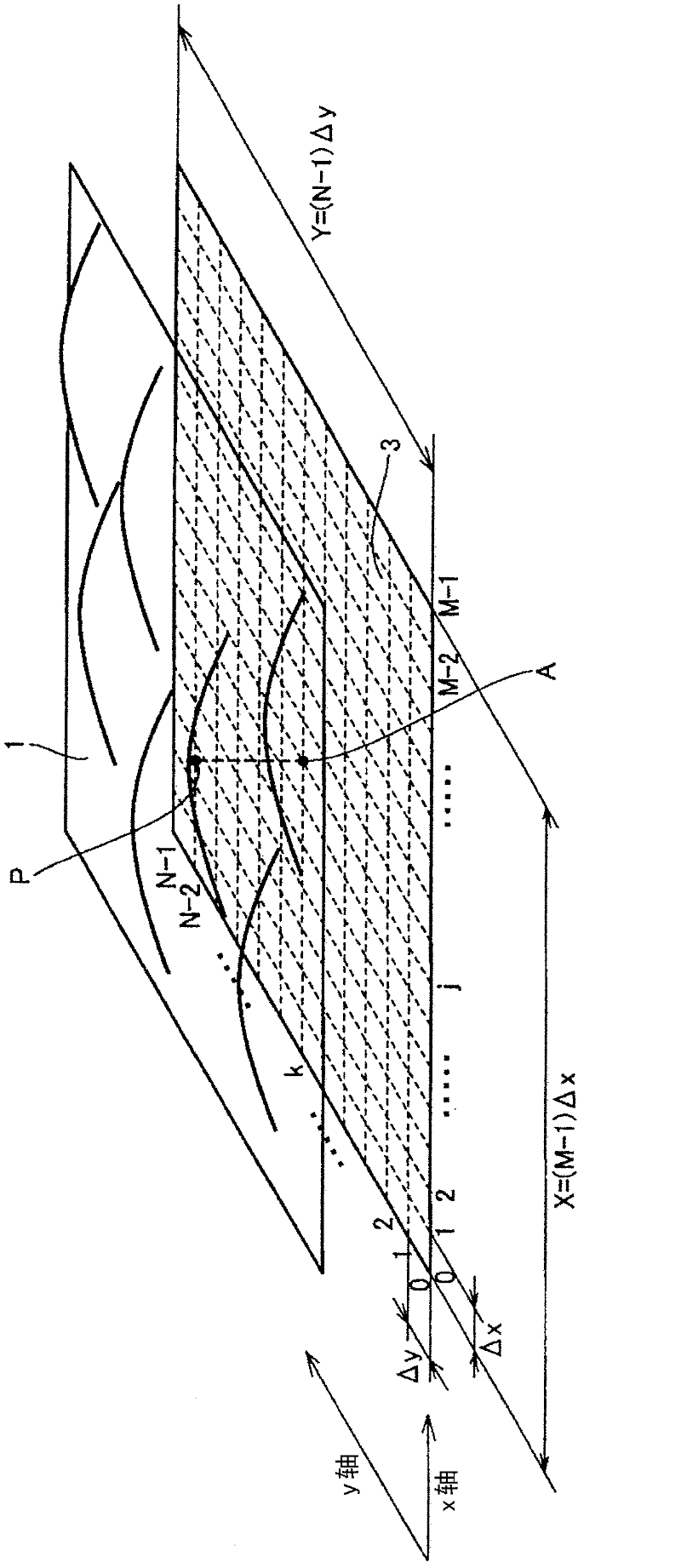

Method and Apparatus For Producing Optical Multilayer Body

ActiveUS20080218865A1Increase contrastImprove propertiesLayered productsDiffusing elementsMetallurgy

Owner:DAI NIPPON PRINTING CO LTD

Anti-reflection film and process for the preparation of the same

InactiveUS7108810B2Reduce glareHigh mechanical strengthMaterial nanotechnologySolid-state devicesRefractive indexSurface roughness

An anti-reflection film comprises a transparent support and a low refractive index coating layer. The low refractive index coating layer has a refractive index lower than a refractive index of the support. The low refractive index coating layer has an essentially uniform thickness, while the layer has a surface roughness in terms of an arithmetic mean (Ra) in the range of 0.05 to 2 μm.

Owner:FUJIFILM CORP

Hard-coated antiglare film, and polarizing plate and image display including the same

InactiveCN101089659AGood anti-glare effectImprove the display effectDiffusing elementsSynthetic resin layered productsRefractive indexPolarizer

A hard-coated antiglare film is provided that is excellent in antiglare properties and image sharpness and that can prevent glare from occurring. The hard-coated antiglare film includes a transparent plastic film substrate and a hard-coating antiglare layer that is formed on at least one surface of the transparent plastic film substrate and that is formed of fine particles and a curable hard-coating resin. The hard-coating antiglare layer has a thickness in the range of 20 to 30 mum. The fine particles have a weight average particle size in the range of 7 to 15 mum. The difference obtained by subtracting the refractive index of the fine particles from that of the curable hard-coating resin that has been cured is in the range of -0.06 to -0.01 or 0.01 to 0.06.

Owner:NITTO DENKO CORP

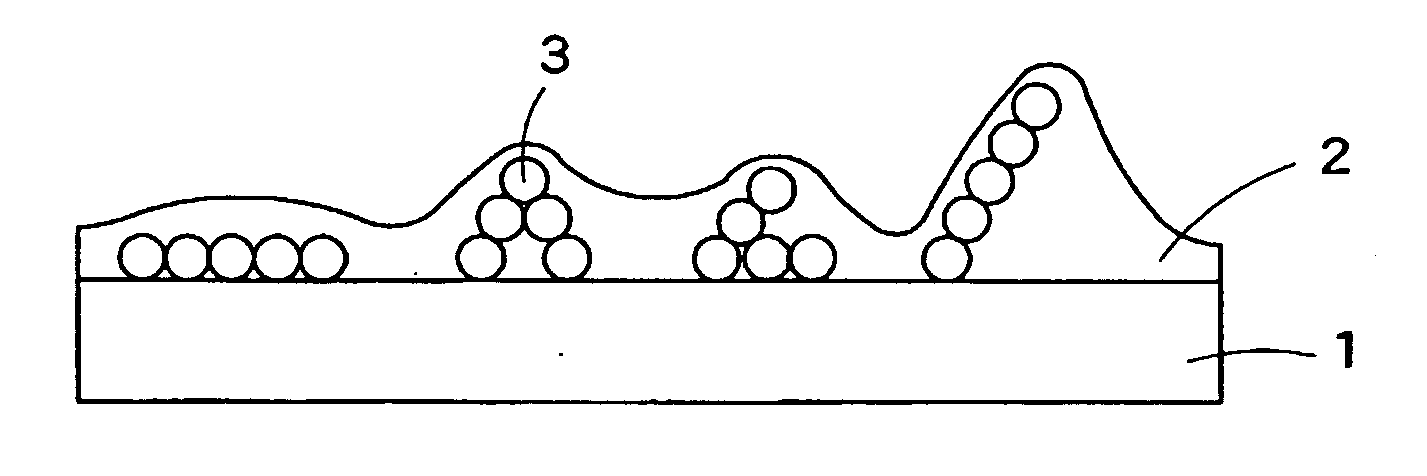

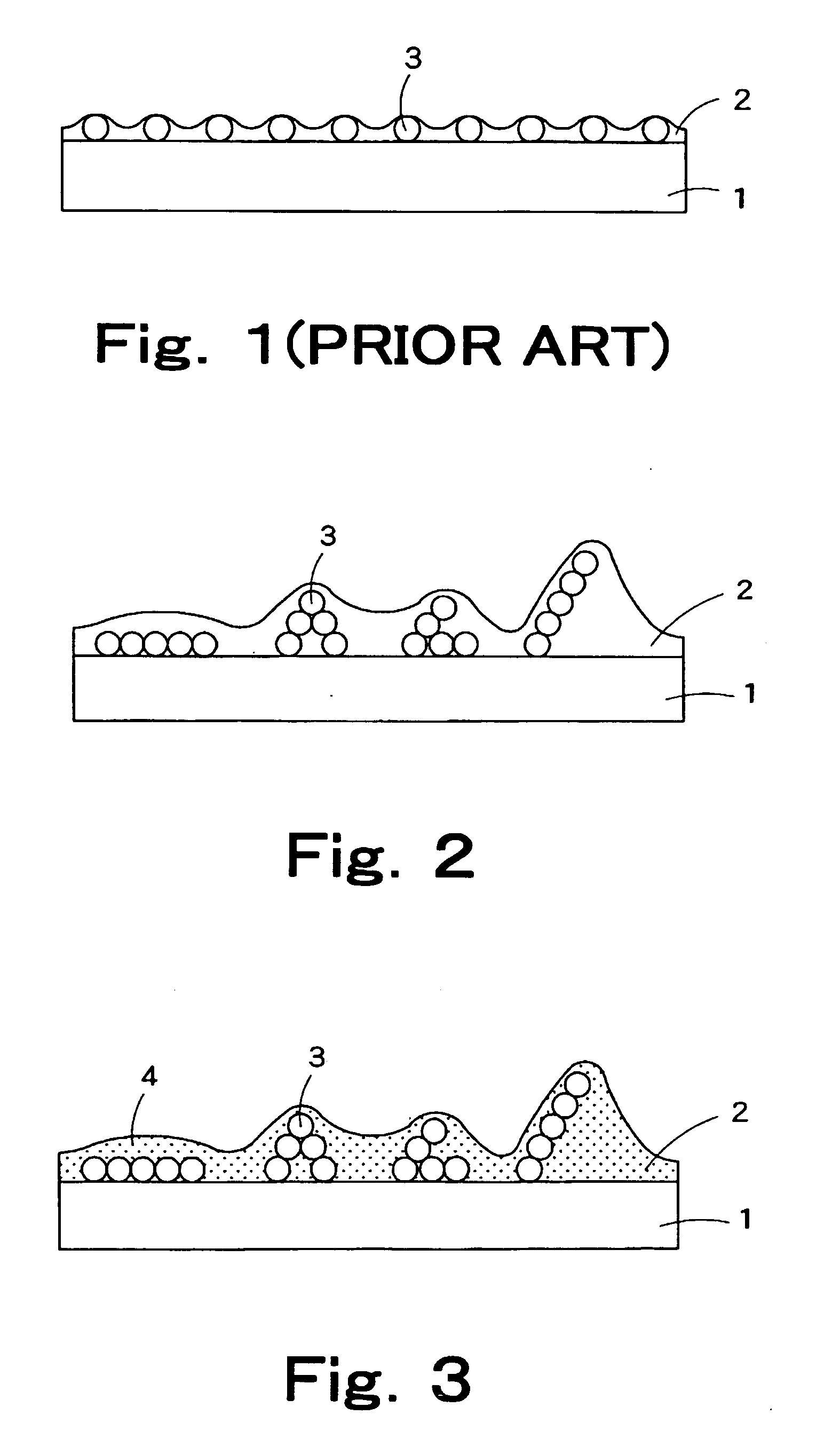

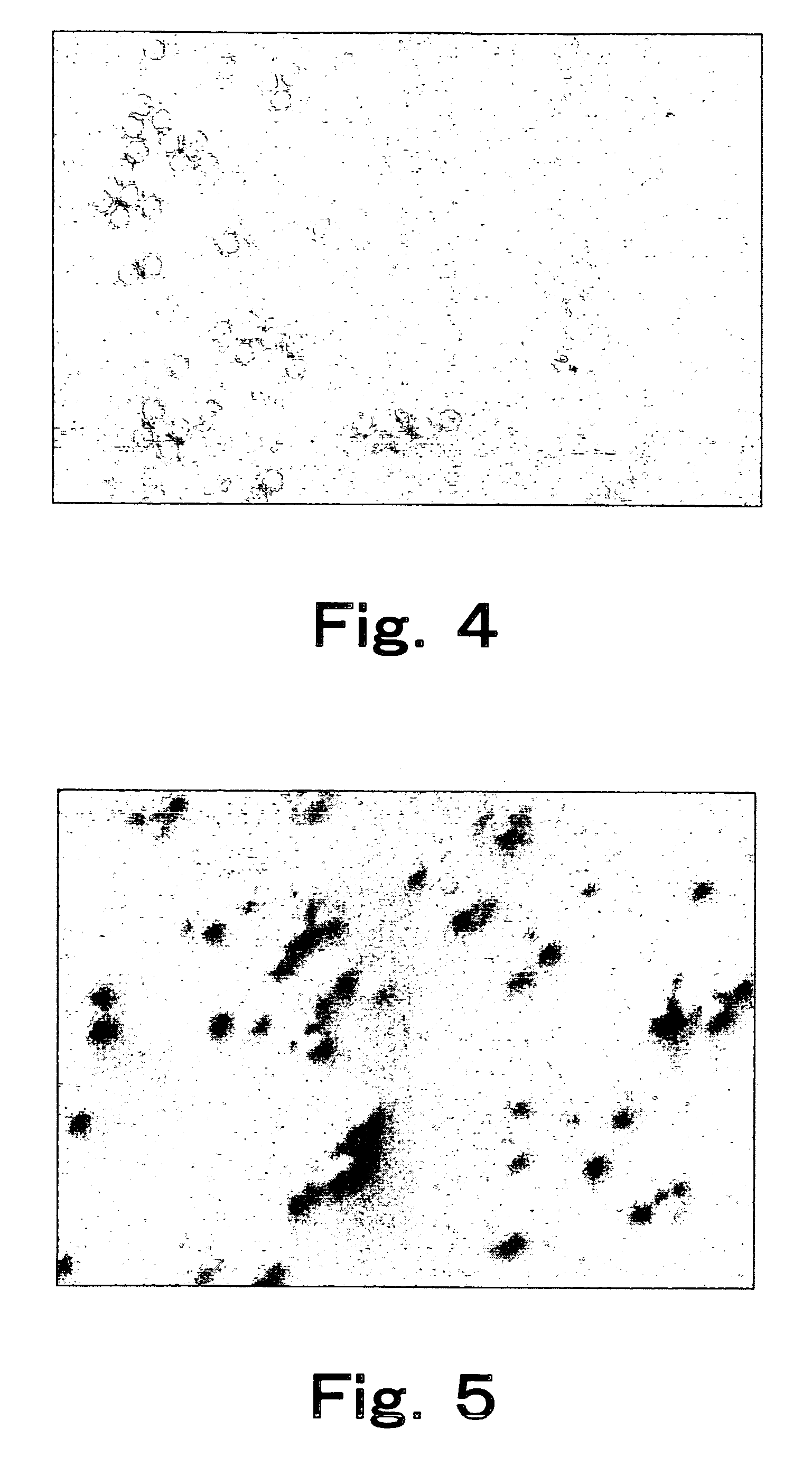

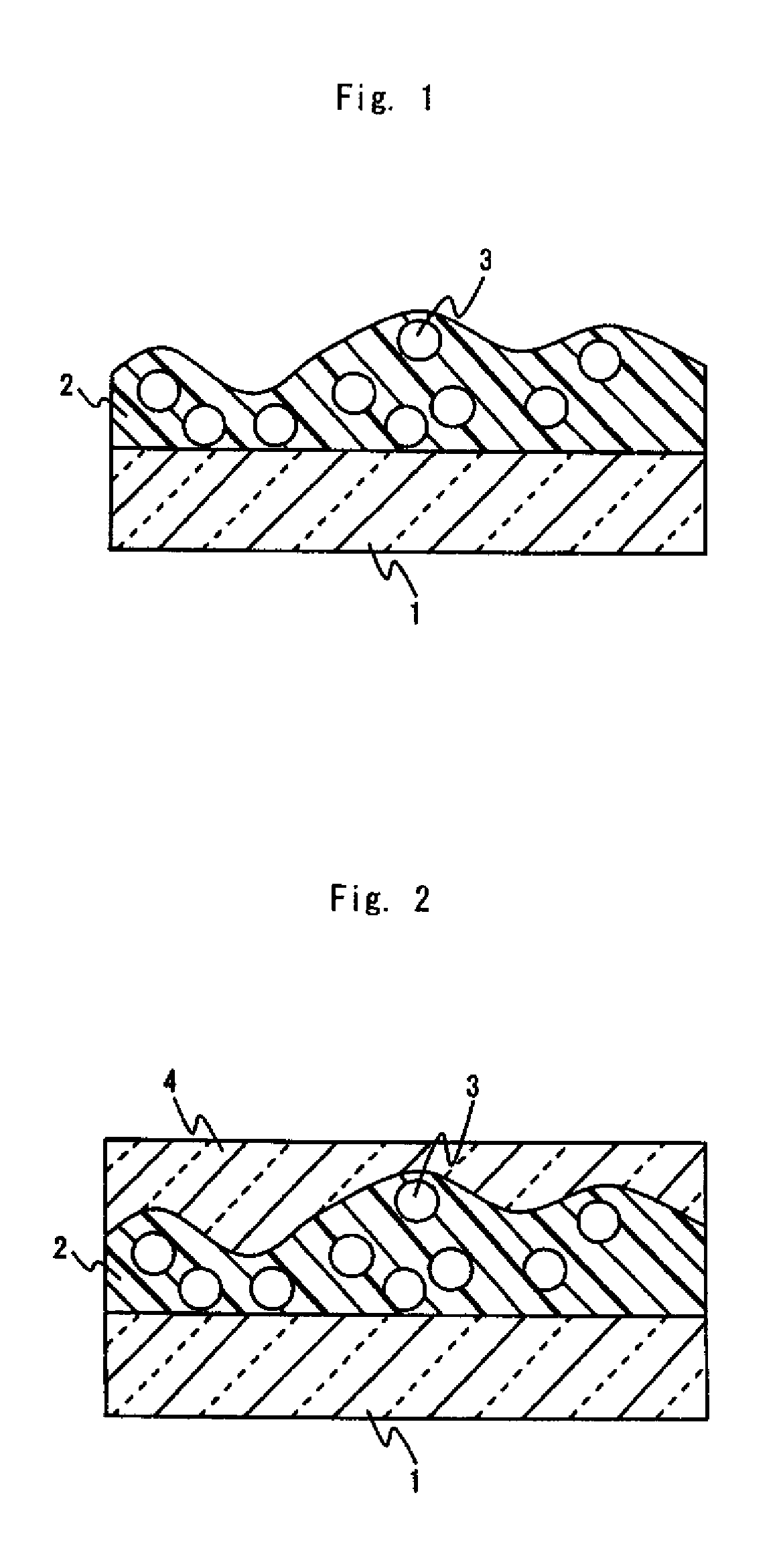

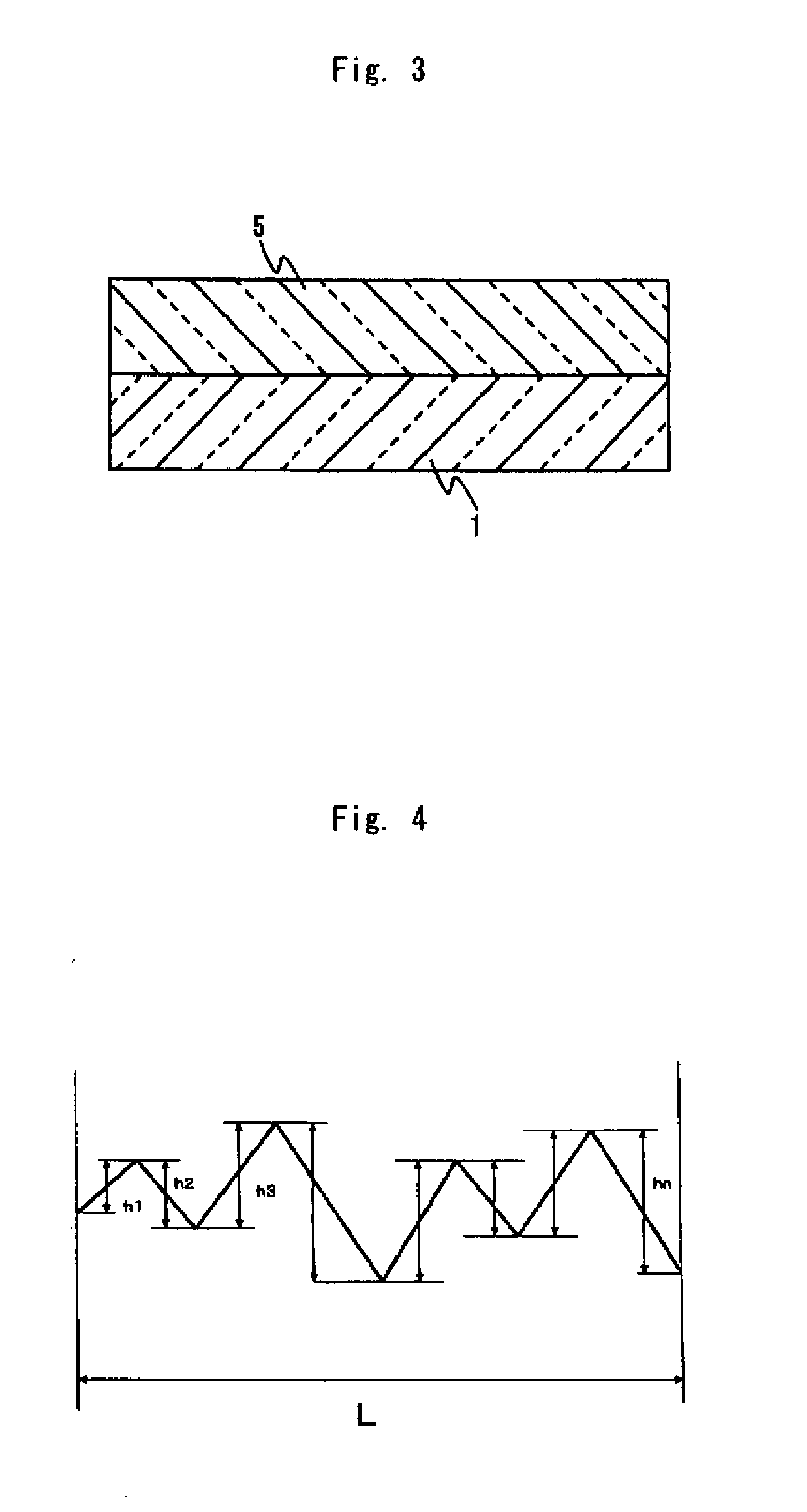

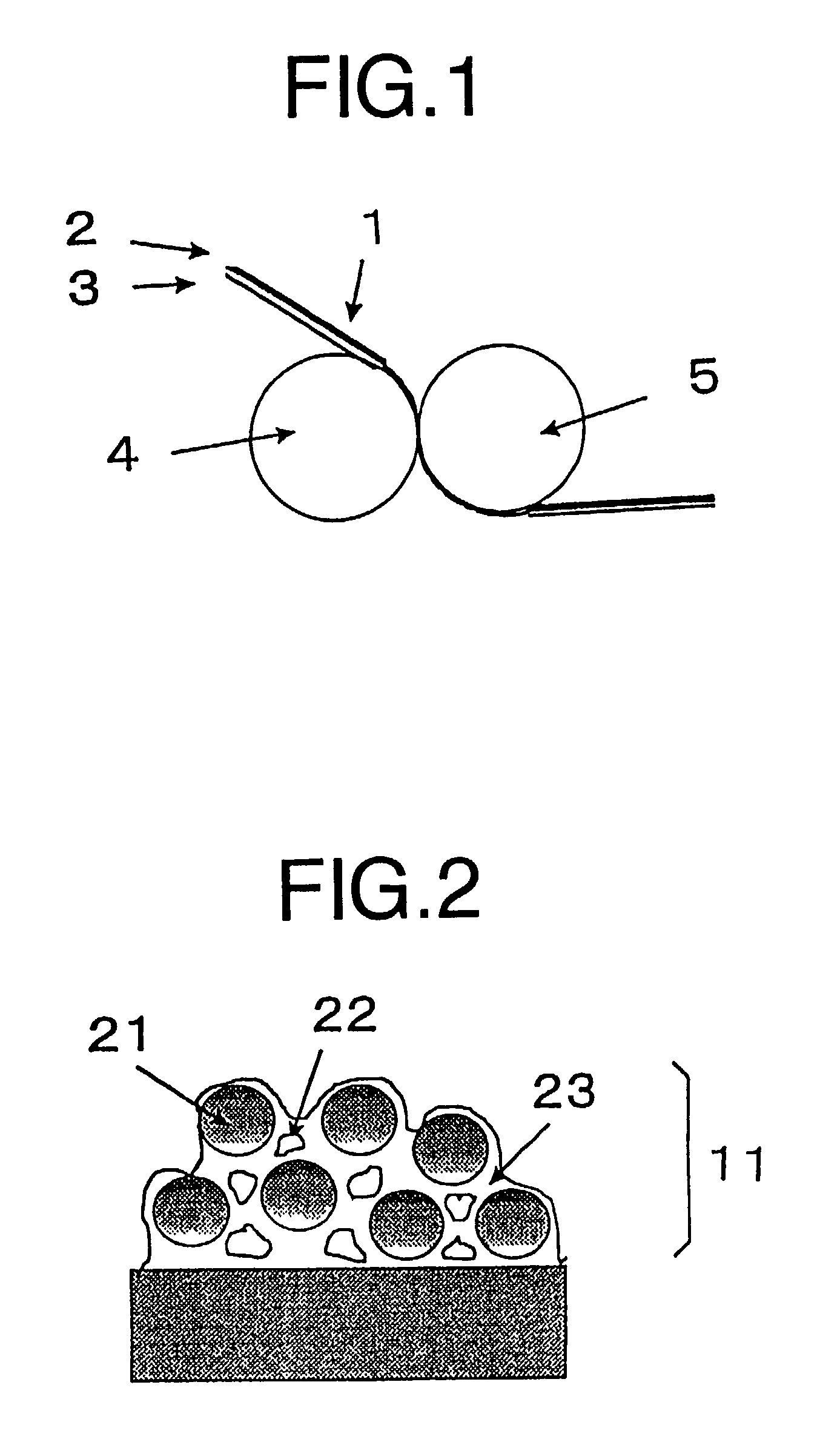

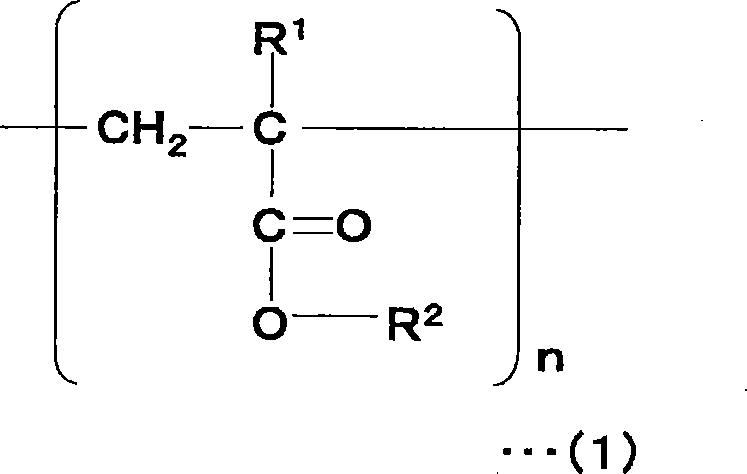

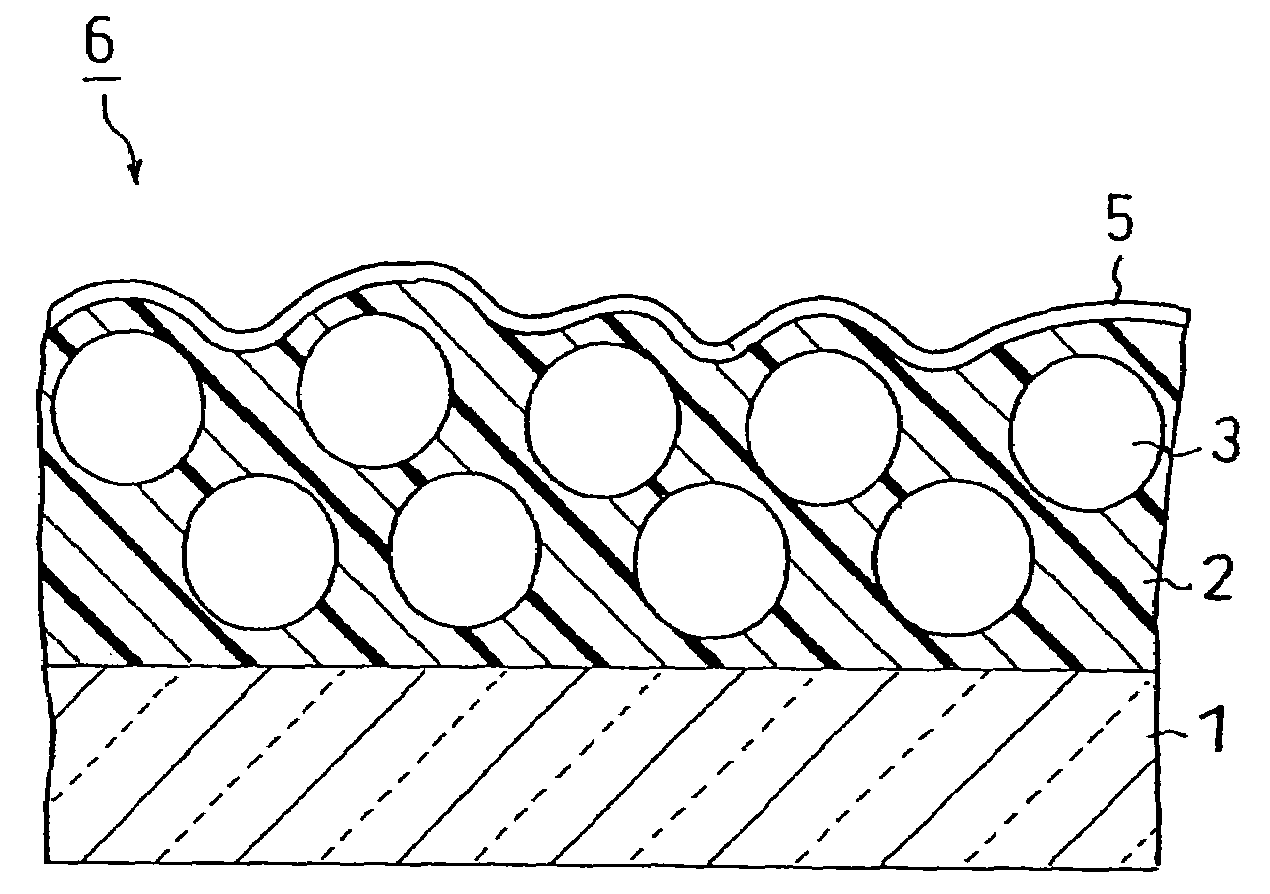

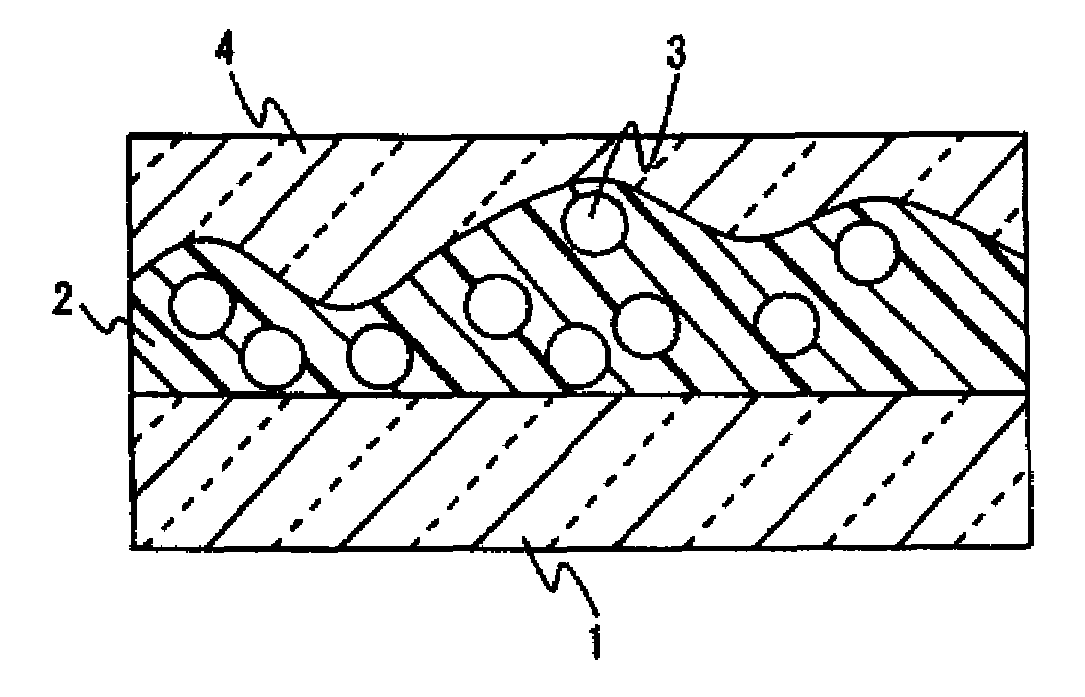

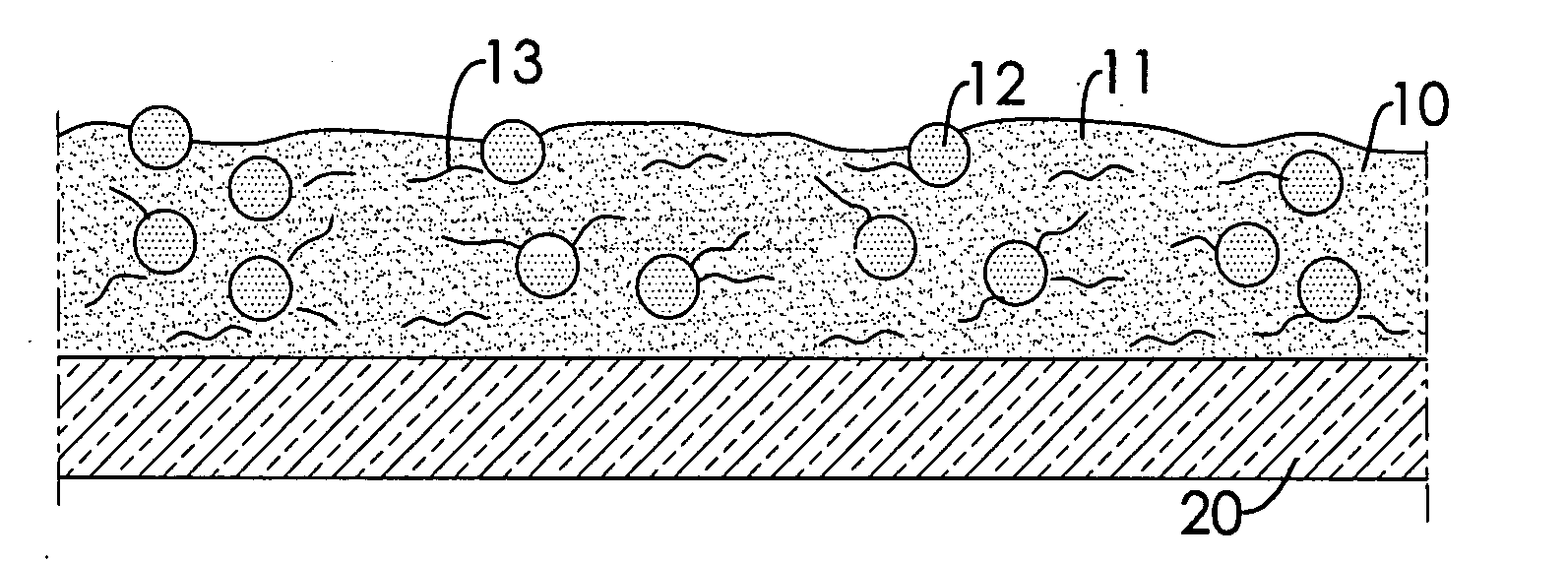

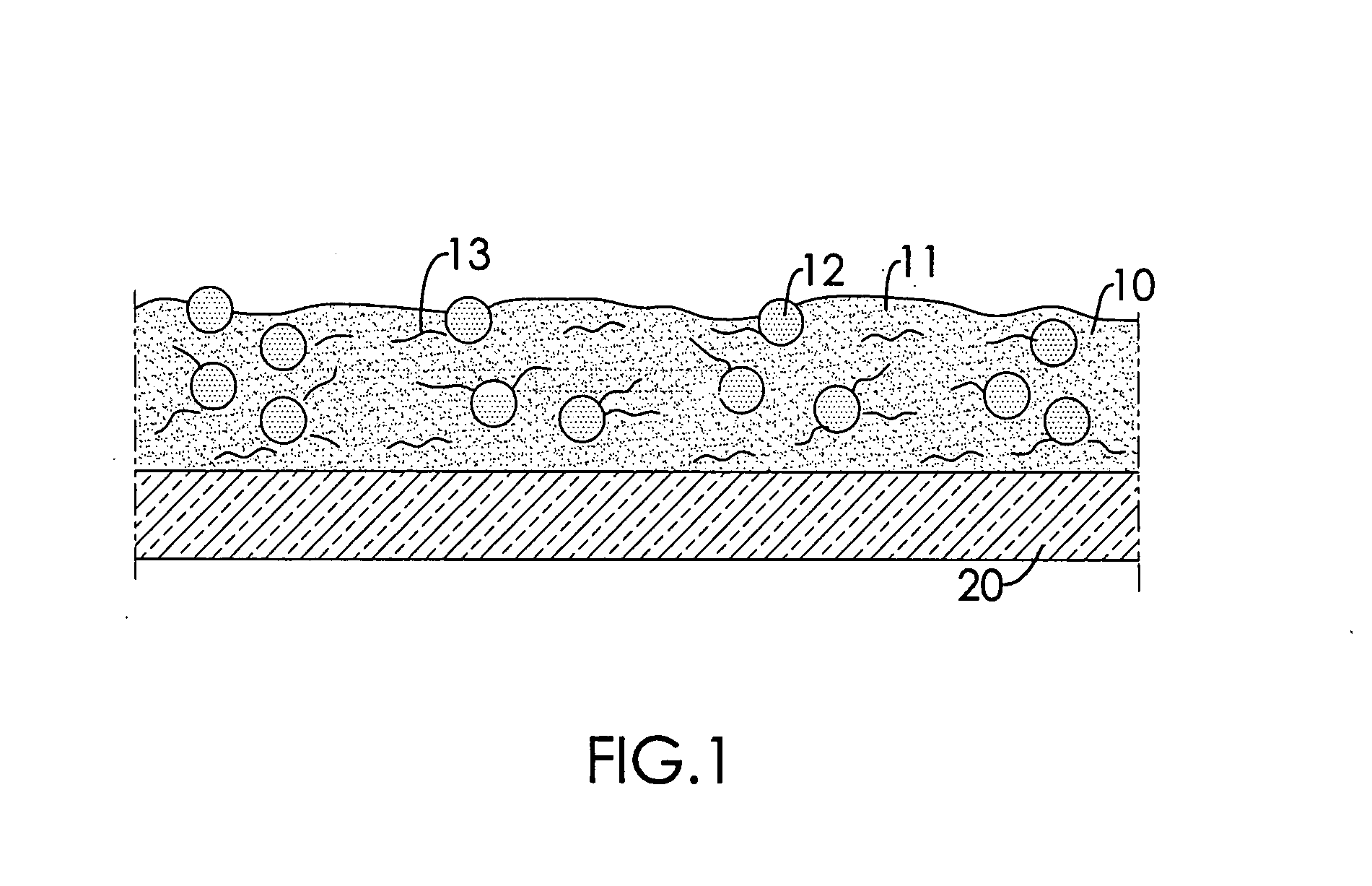

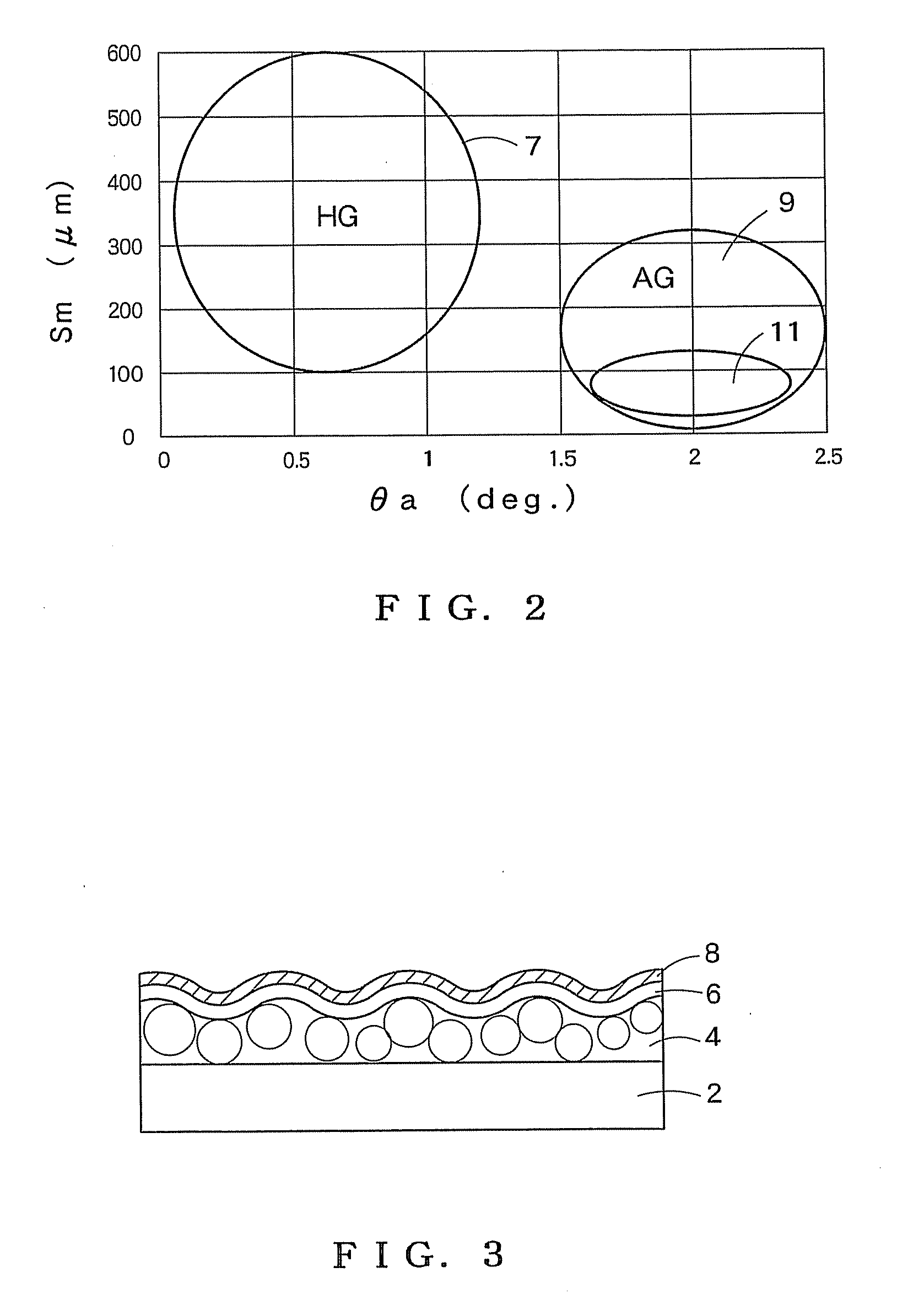

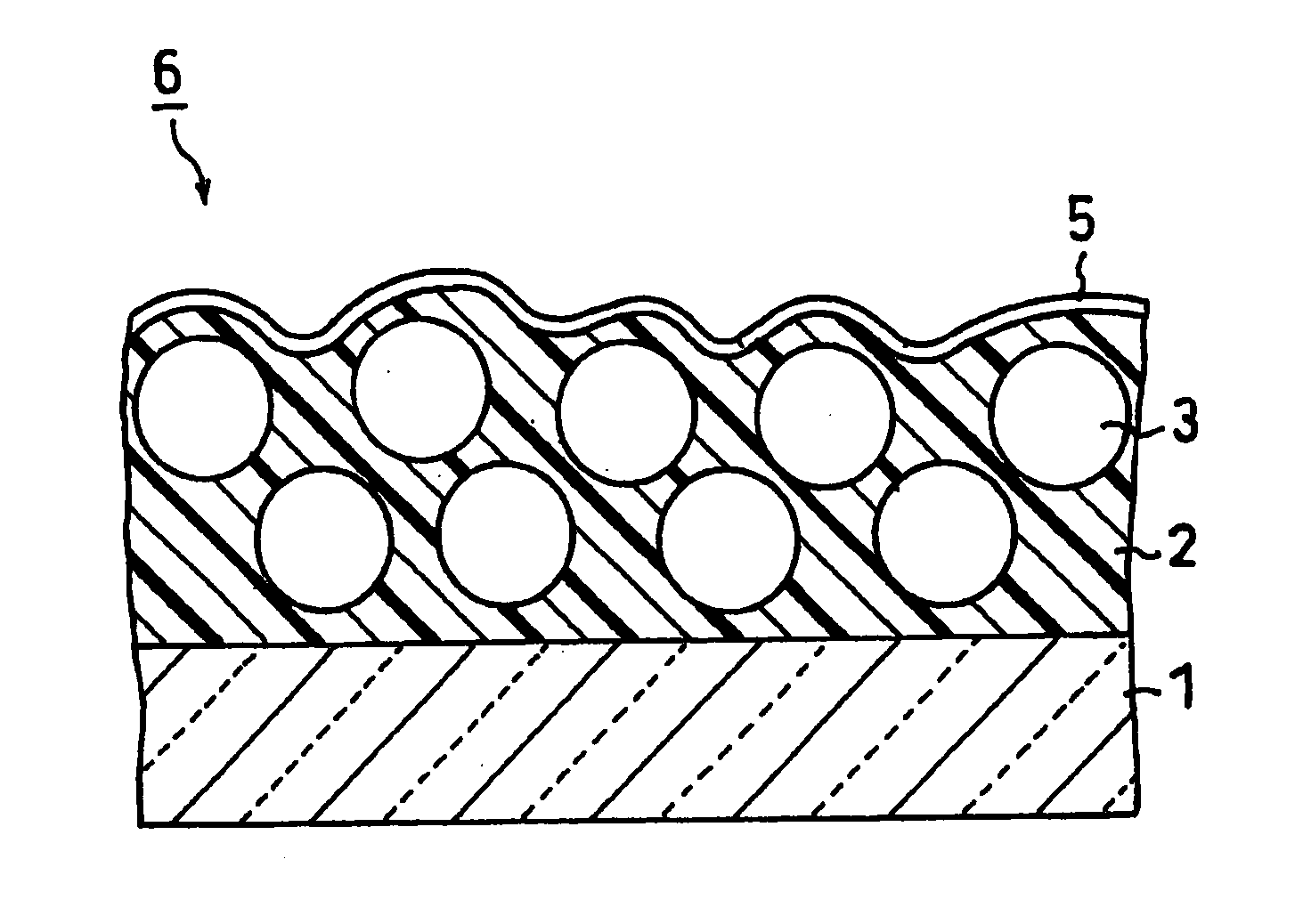

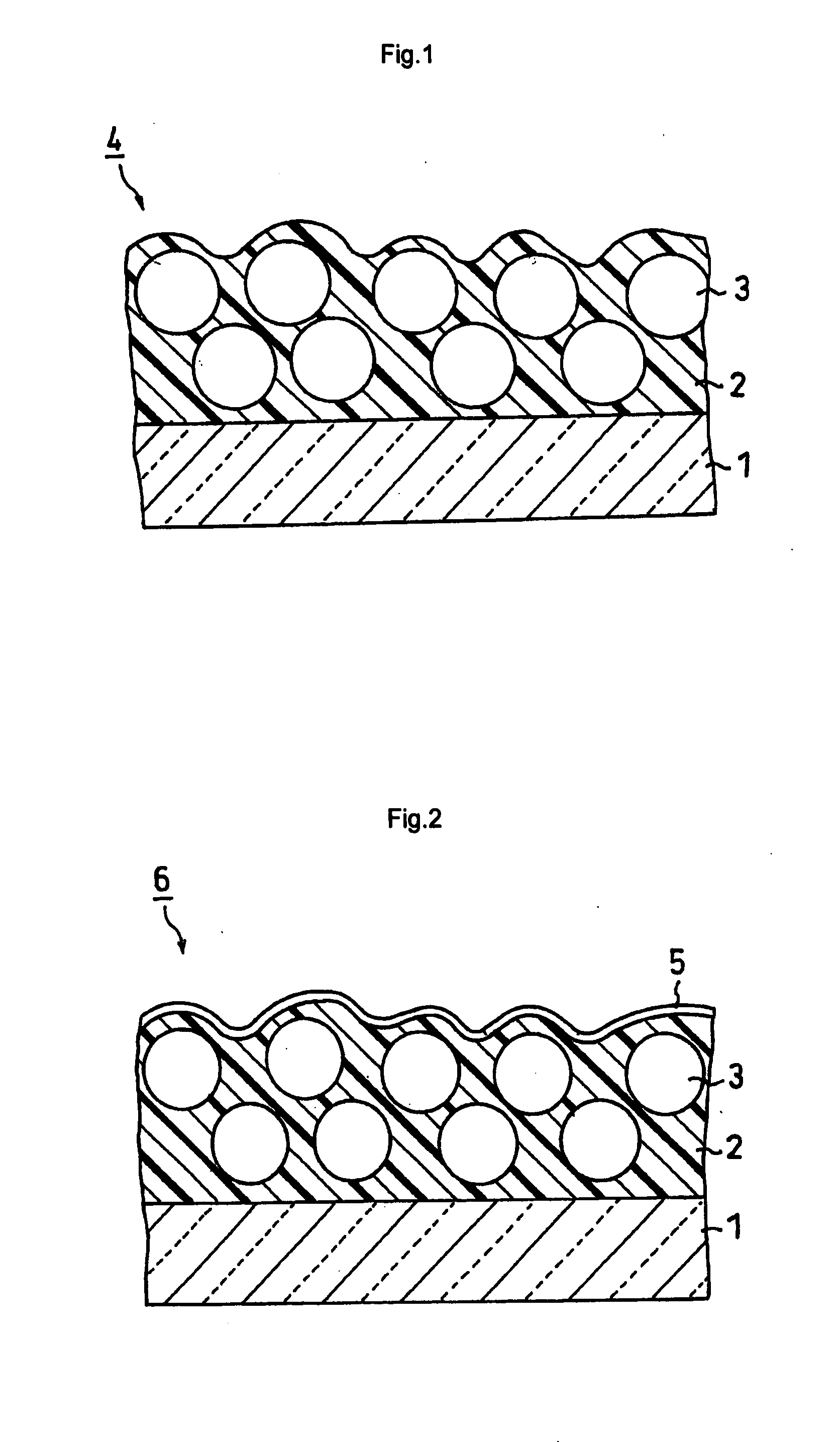

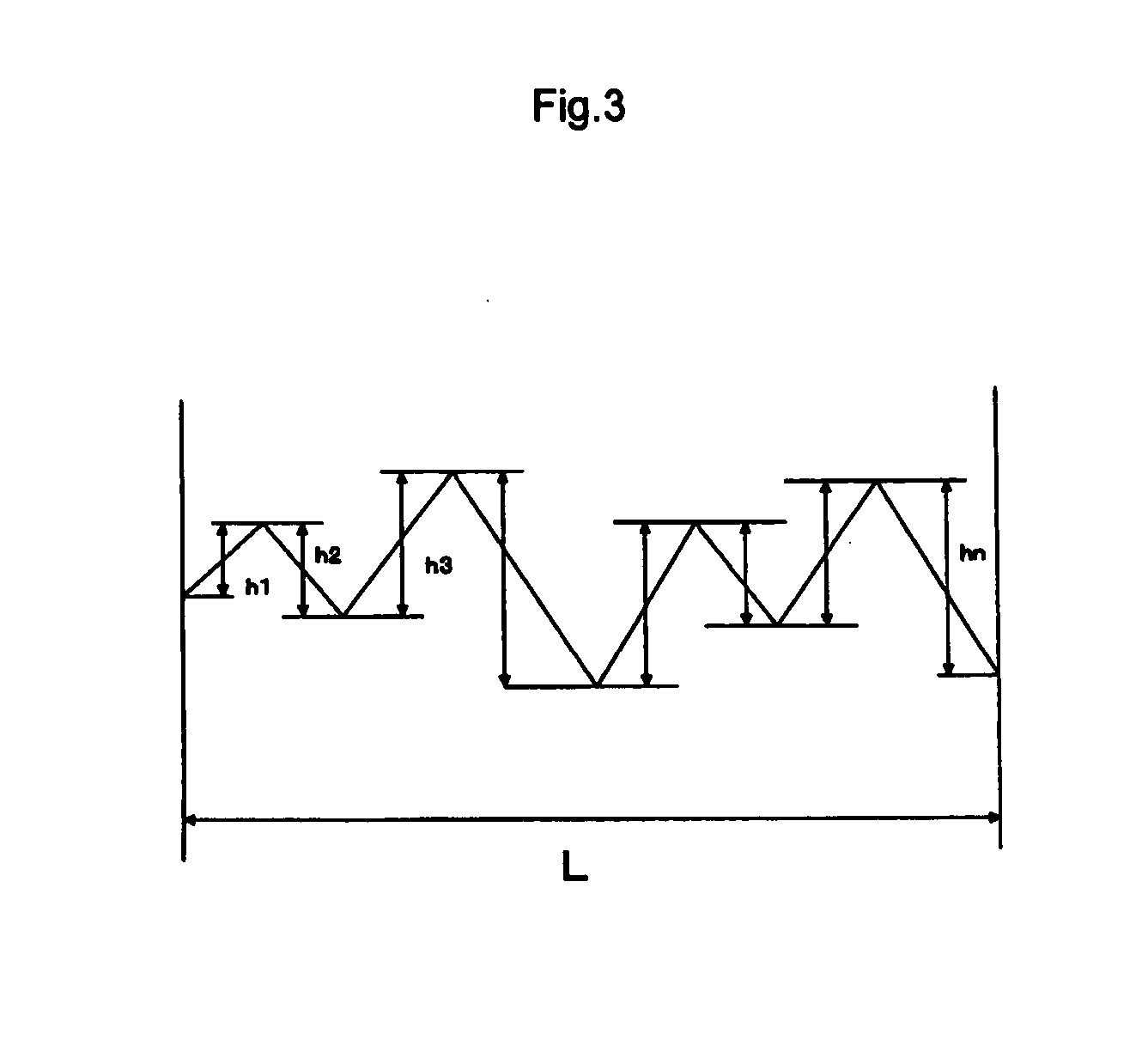

Hard-coated antiglare film and method of manufacturing the same

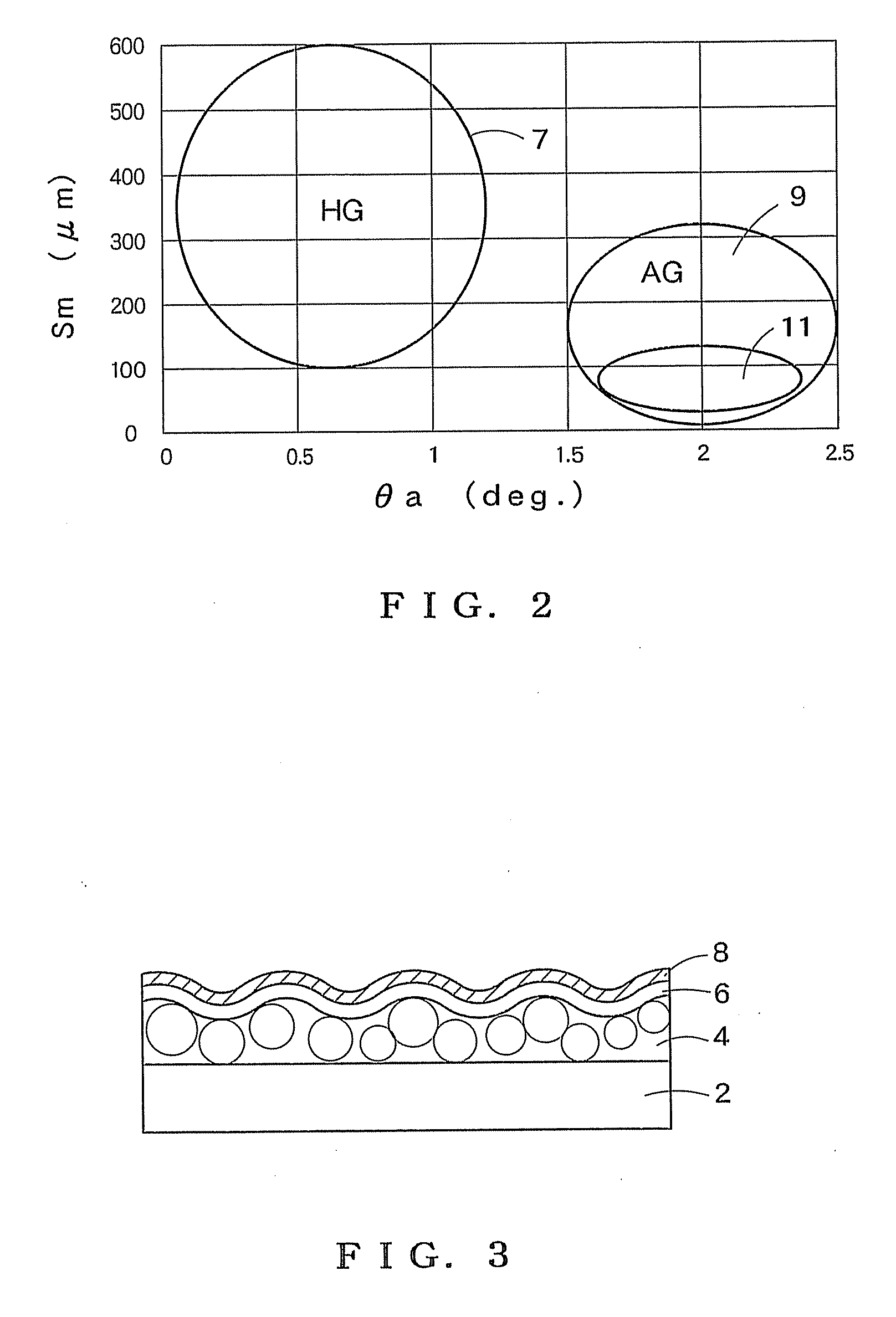

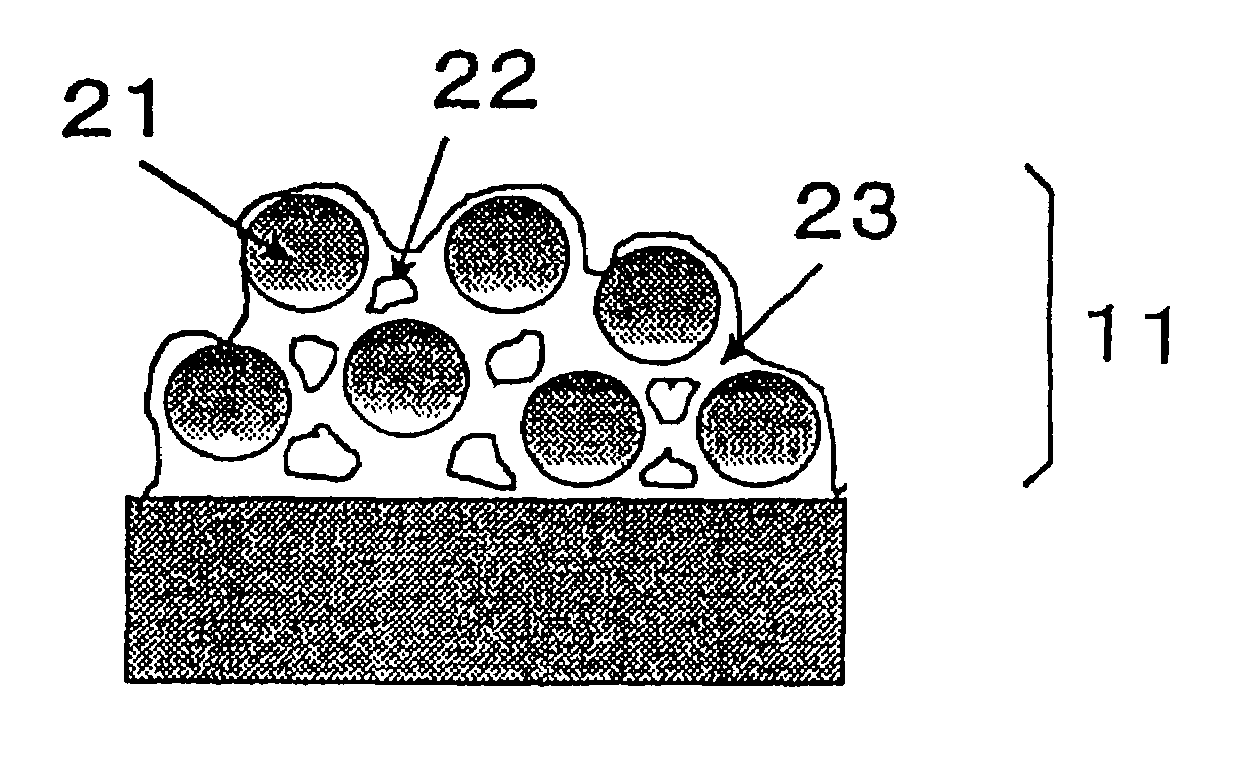

There are provided a hard-coated antiglare film with high hardness, high scratch resistance and good antiglare properties, a method of manufacturing the film, an optical element using the film, and an image display including the film or the optical element. The hard-coated antiglare film of the invention includes a transparent film substrate and a hard-coating layer that contains fine particles and is formed on at least one side of the transparent film substrate, wherein the hard-coating layer has a thickness of 15 μm to 30 μm, the fine particles have an average particle size of 30% to 75% of the thickness of the hard-coating layer, and the fine particles form unevenness with a θa value of 0.4° to 1.5° according to JIS B 0601.

Owner:NITTO DENKO CORP

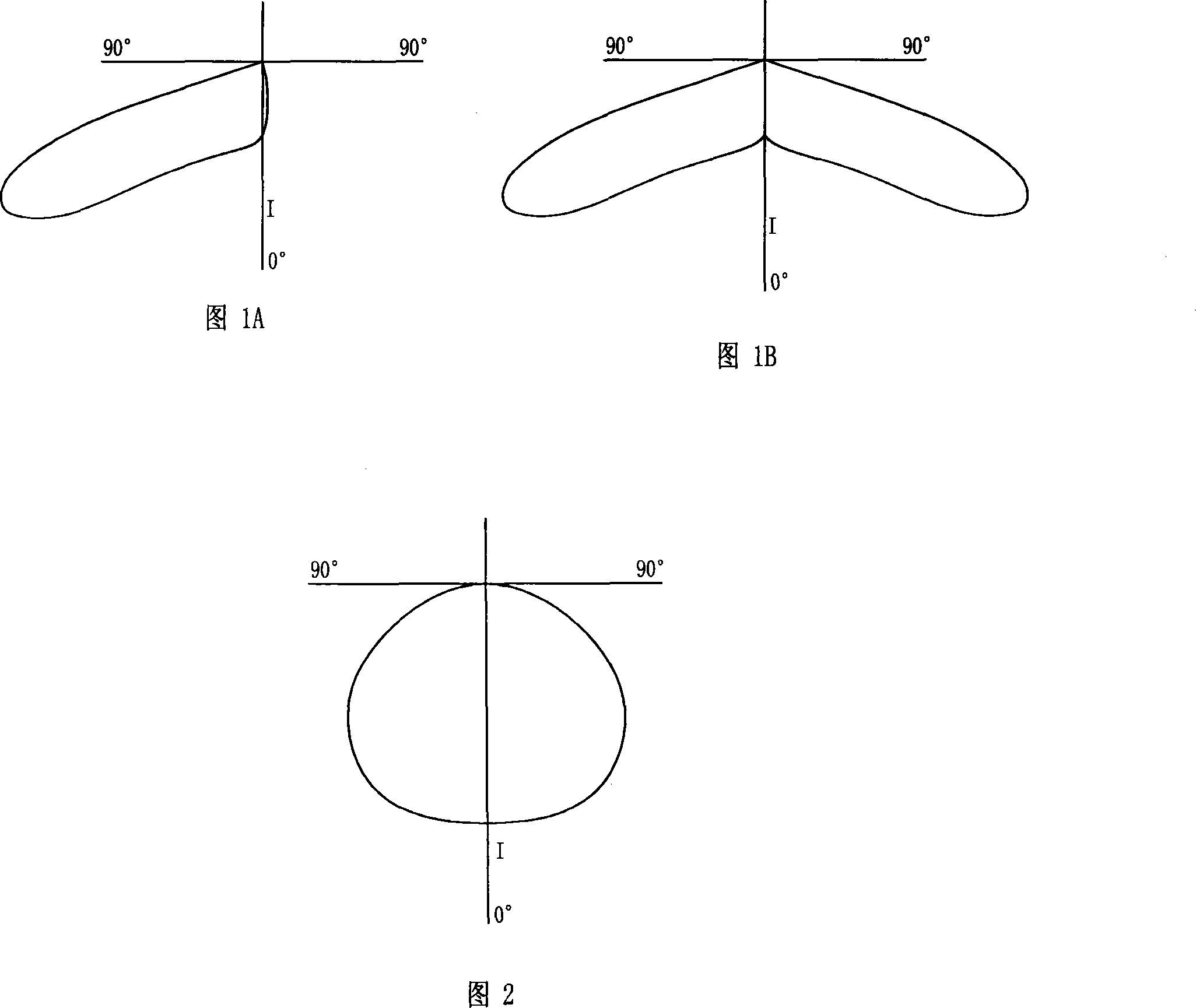

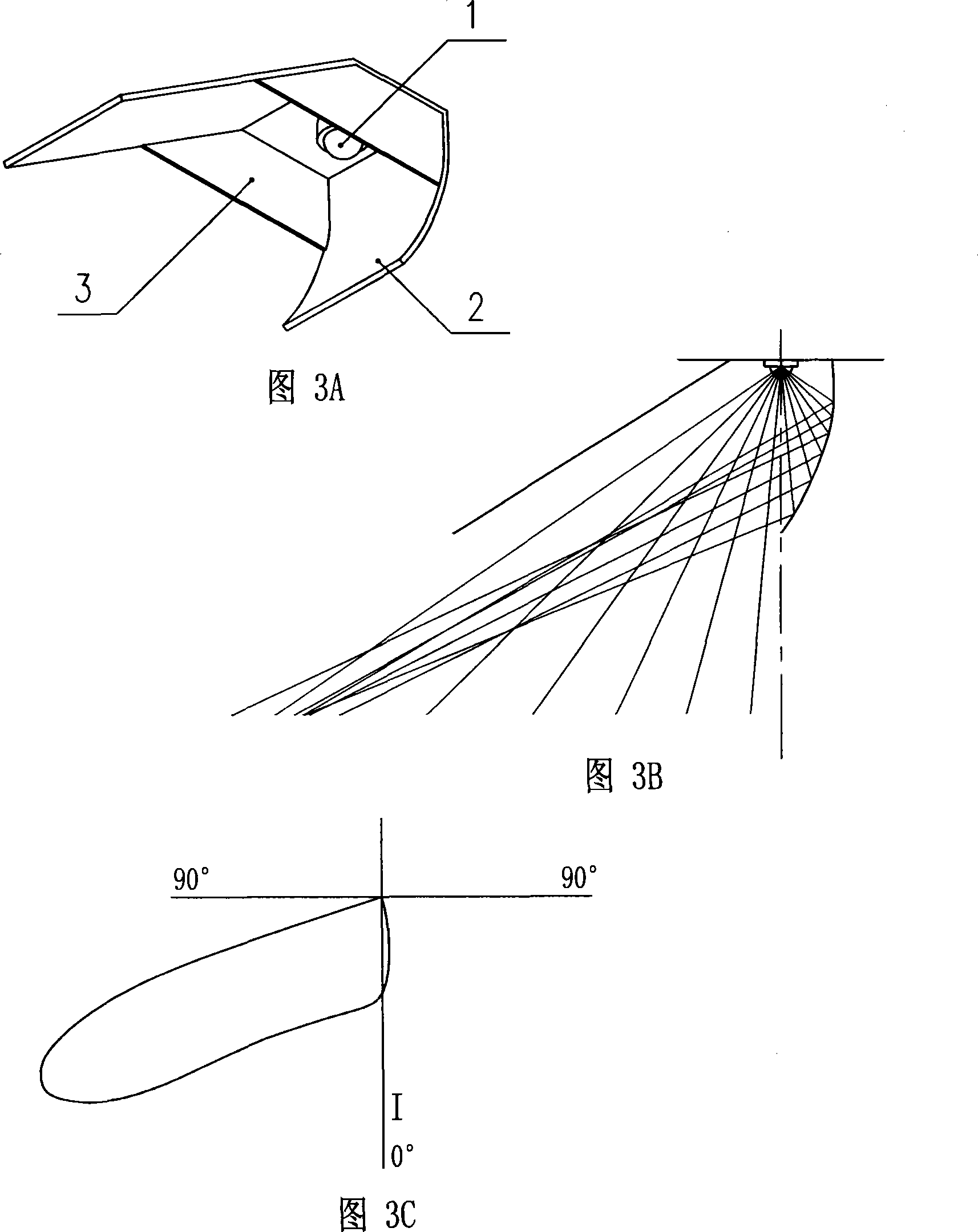

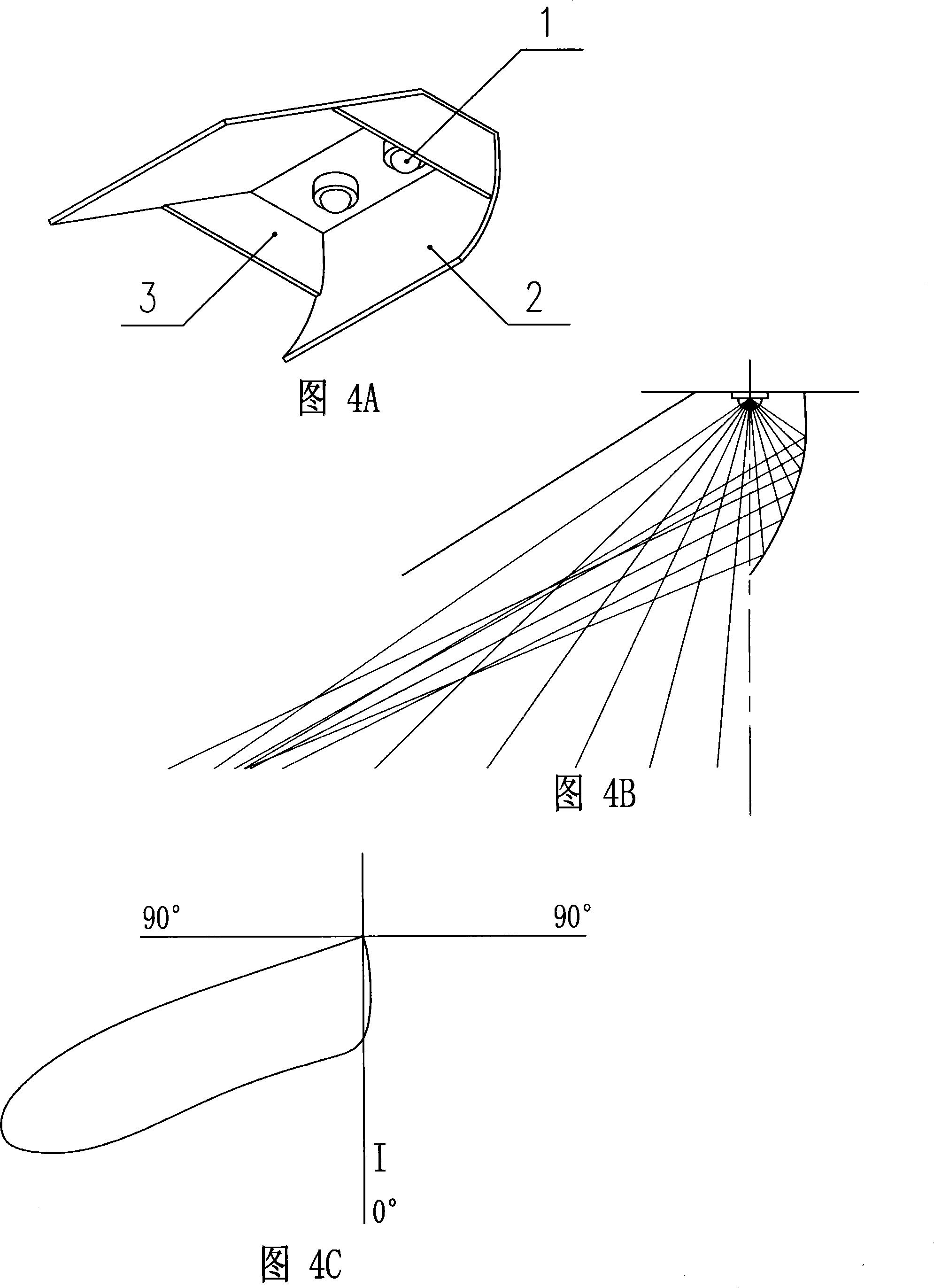

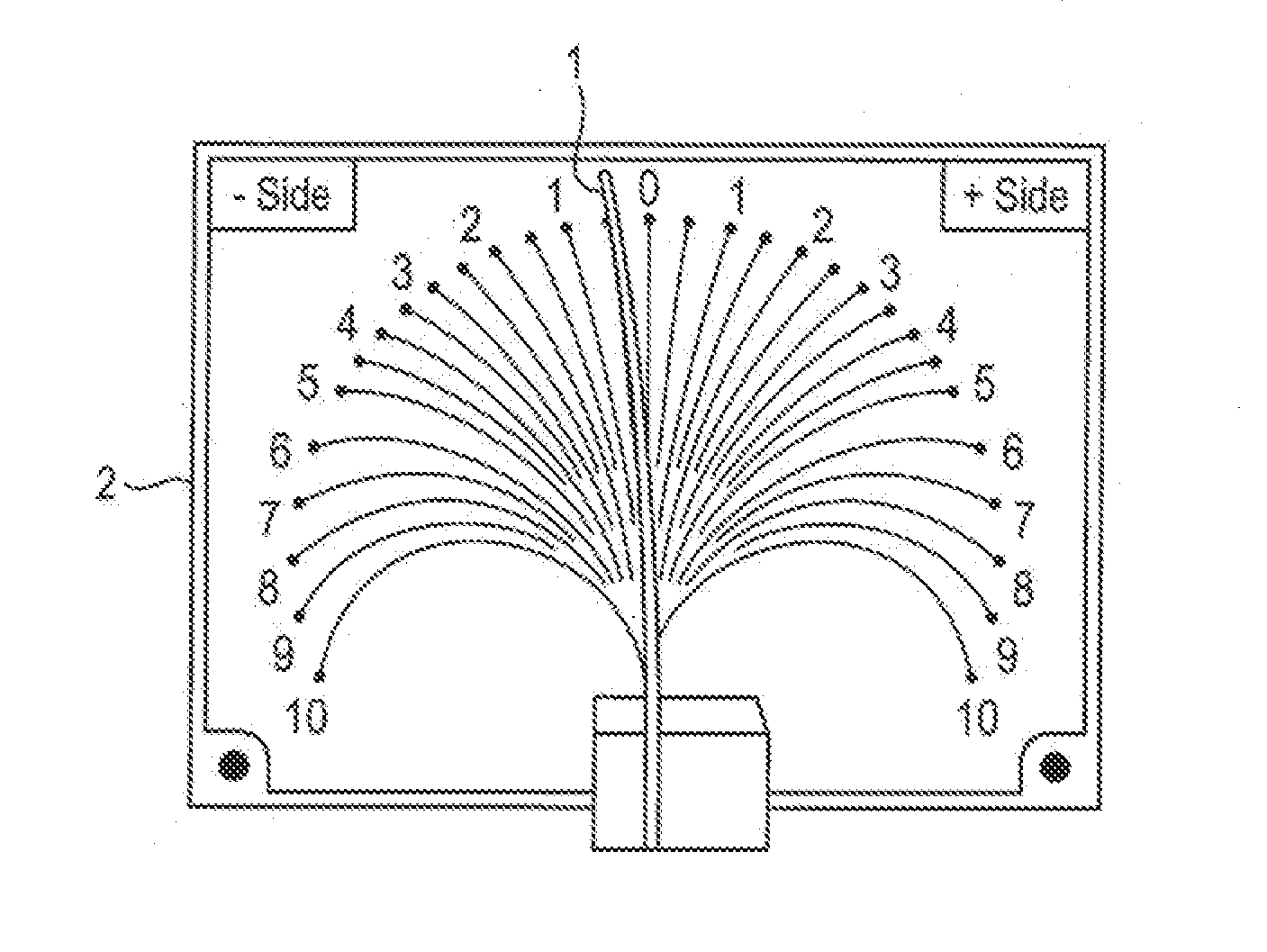

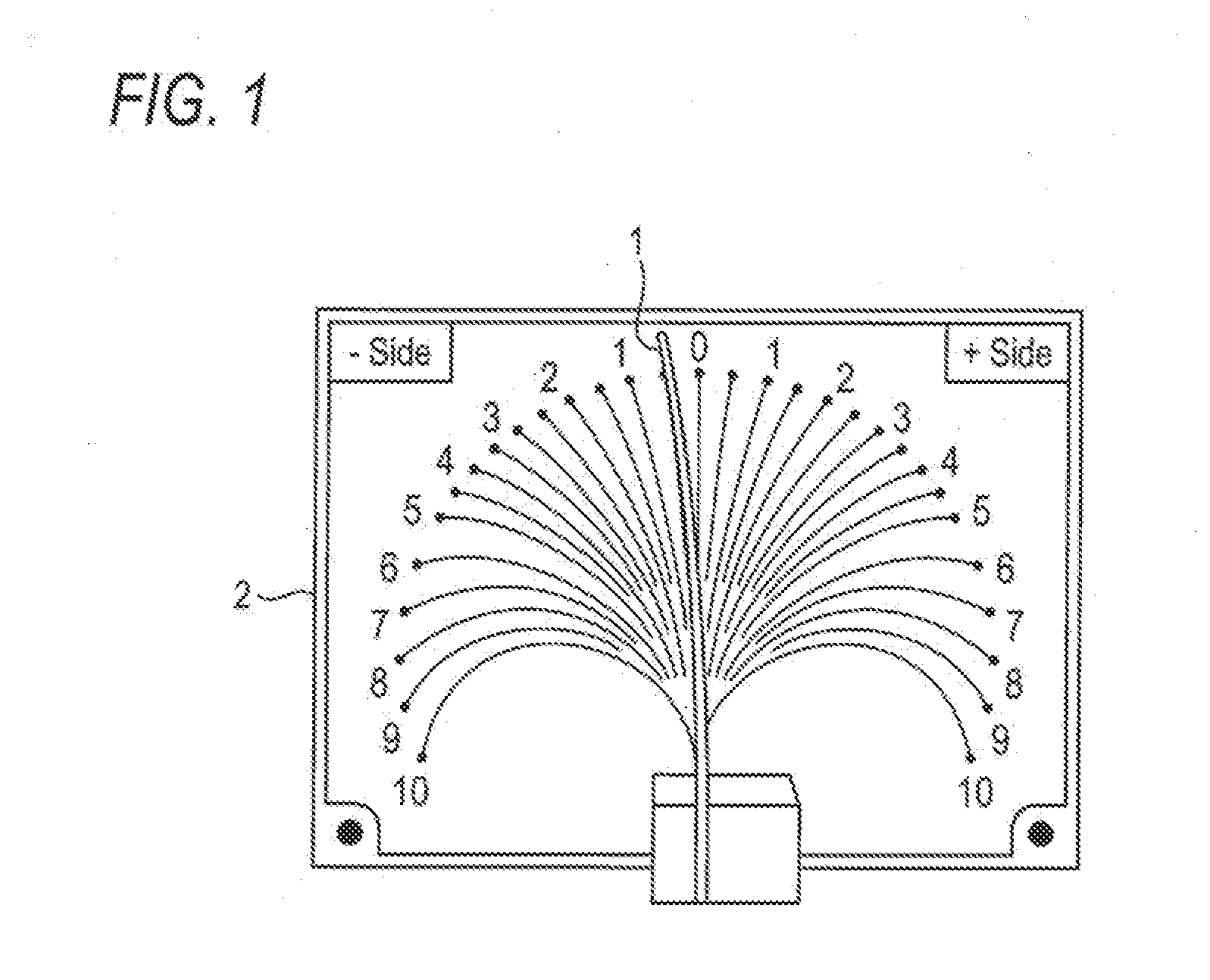

Anti-dazzle LED illumination device

InactiveCN101220928AImprove applicabilityDesign sciencePoint-like light sourceElectric lightingAsymmetric distributionEngineering

An anti-glare LED illuminating apparatus belongs to the semiconductor illuminating technology field and is characterized by being provided with an anti-glare LED illuminating unit U, which comprises an LED light source 1, a combined type reflector 2 and a shielding lace bar 3, or an LED anti-glare illuminating module or an LED anti-glare illuminating die set consisting of the anti-glare LED illuminating unit, the LED light source is arranged between two adjacent shielding lace bars 3, the inner wall of the combined type reflector 2 is an asymmetry reflection plane, optical intensity is distributed asymmetrically along the direction vertical to the combined type reflector 2 axes, a light distribution curve is of lateral wing type, the shielding lace bar 3 limits the glare generated by the LED light source 1 along the axial direction of the combined type reflector 2. The invention has scientific design, reasonable structure, easy production, convenient assembly and good anti-glare effect, reduces the difficulties of manufacturing, processing and assembly and production cost, thus being beneficial to large-scale application.

Owner:史杰

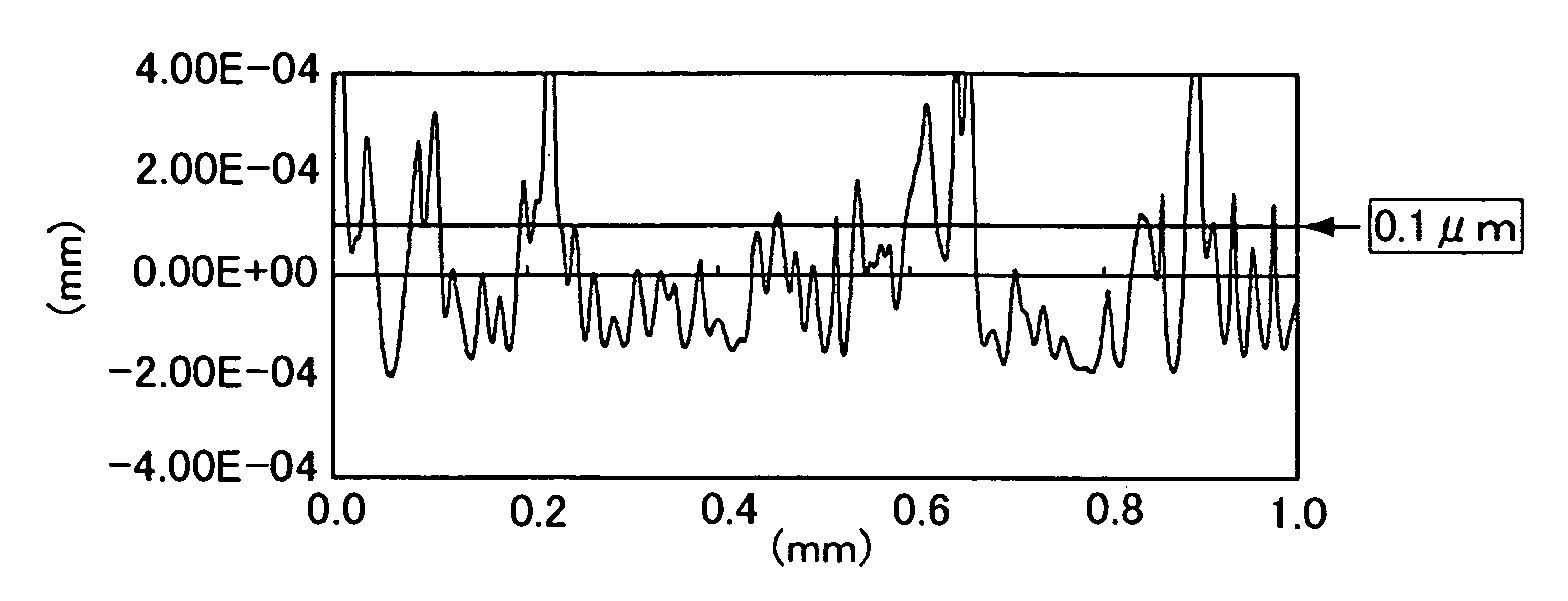

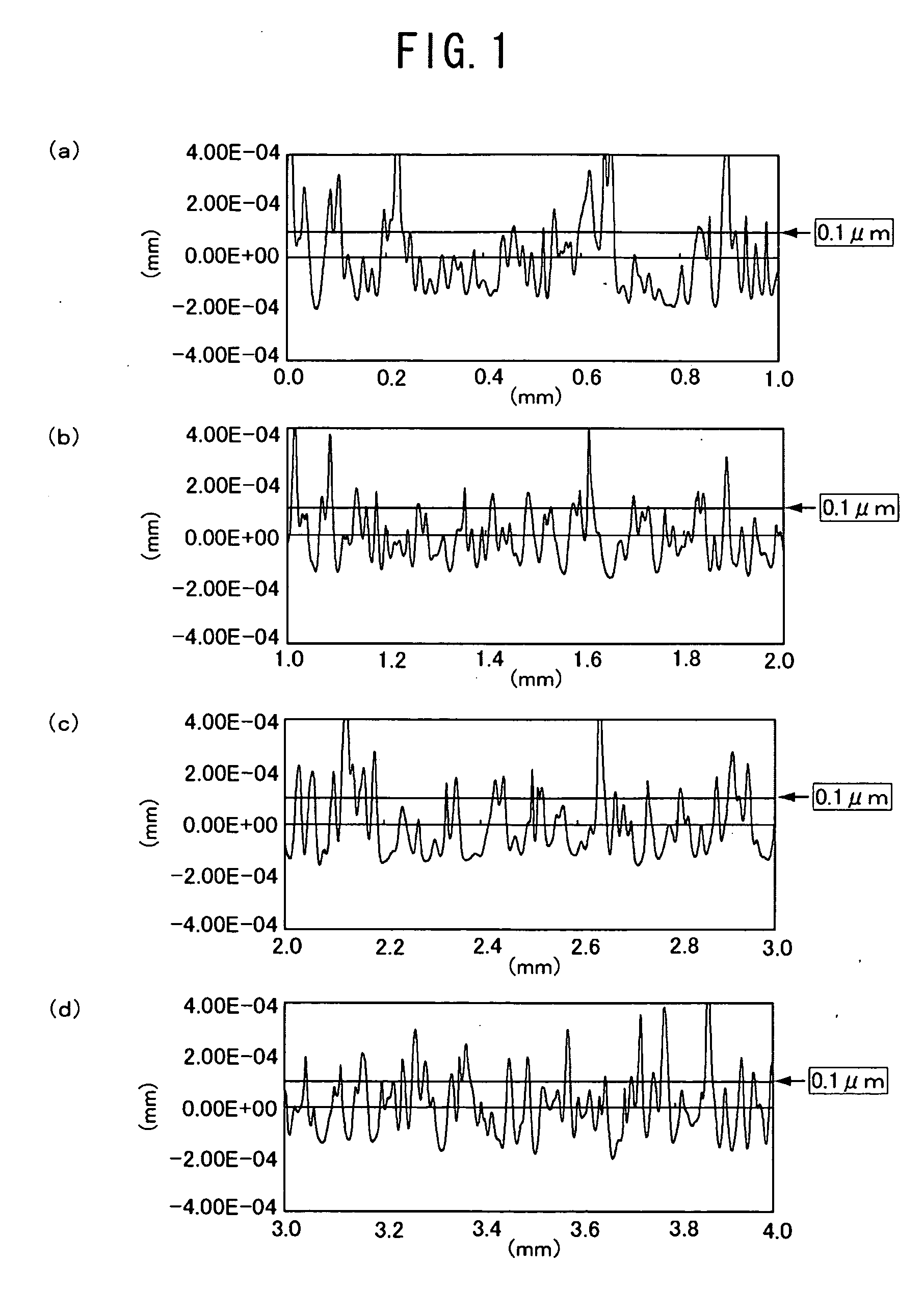

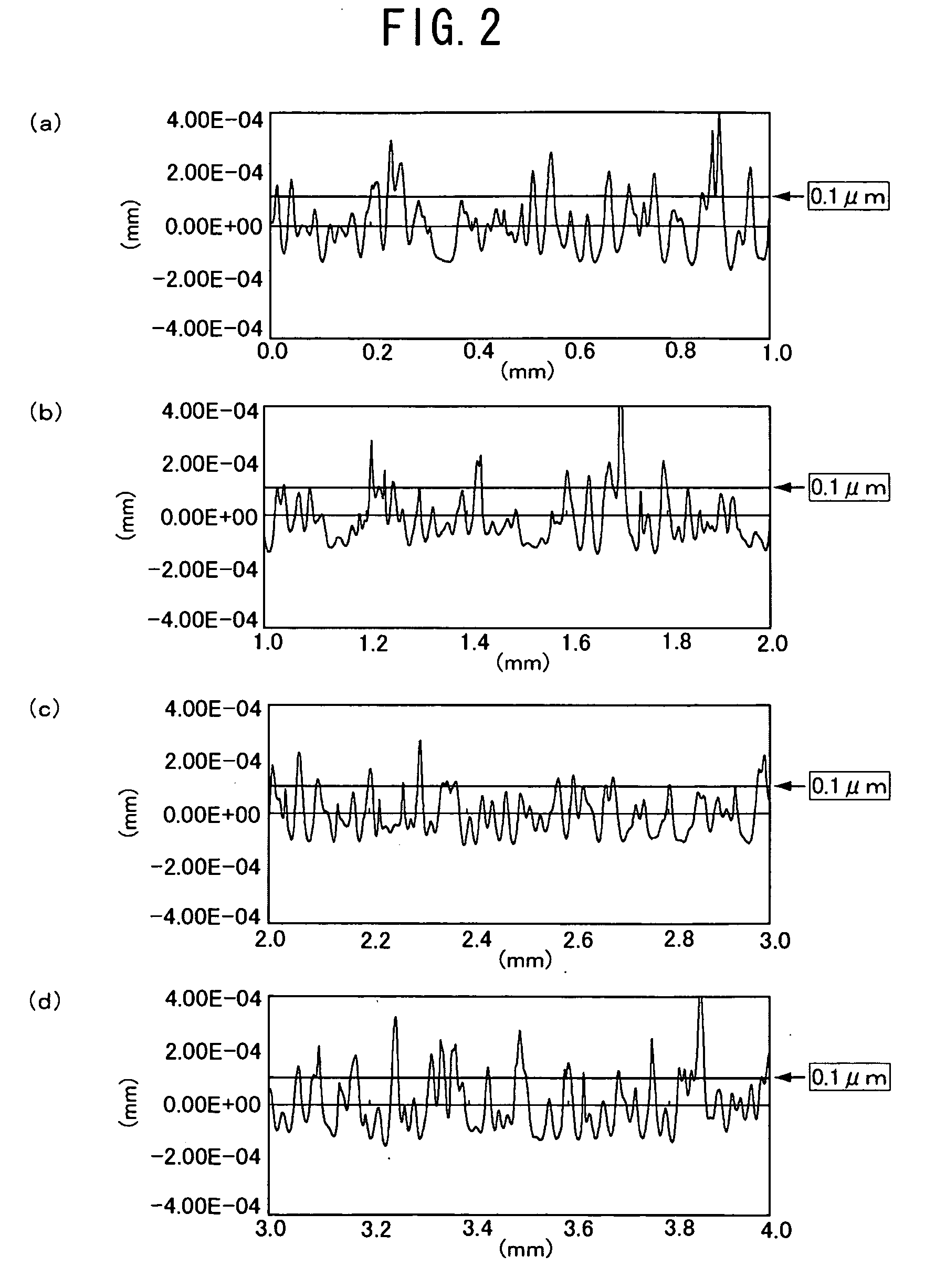

Hard-coated antiglare film, and polarizing plate and image display including the same

ActiveUS20090244710A1Improve bright-dark contrastImprove contrastDiffusing elementsPolarising elementsPlastic filmDisplay device

A hard-coated antiglare film, comprising a transparent plastic film substrate and a hard-coating antiglare layer containing fine particles on at least one surface of the transparent plastic film substrate, wherein an arithmetic average surface roughness Ra (μm) that is defined in JIS B 0601 (1994 version) is in the range of 0.05 to 0.15 μm in an uneven shape of a surface of the hard-coating antiglare layer, and the hard-coated antiglare film includes at least 80 convexities that exceed a roughness mean line of a surface roughness profile in a 4-mm long portion at an arbitrary location of the surface of the hard-coating antiglare layer.

Owner:NITTO DENKO CORP

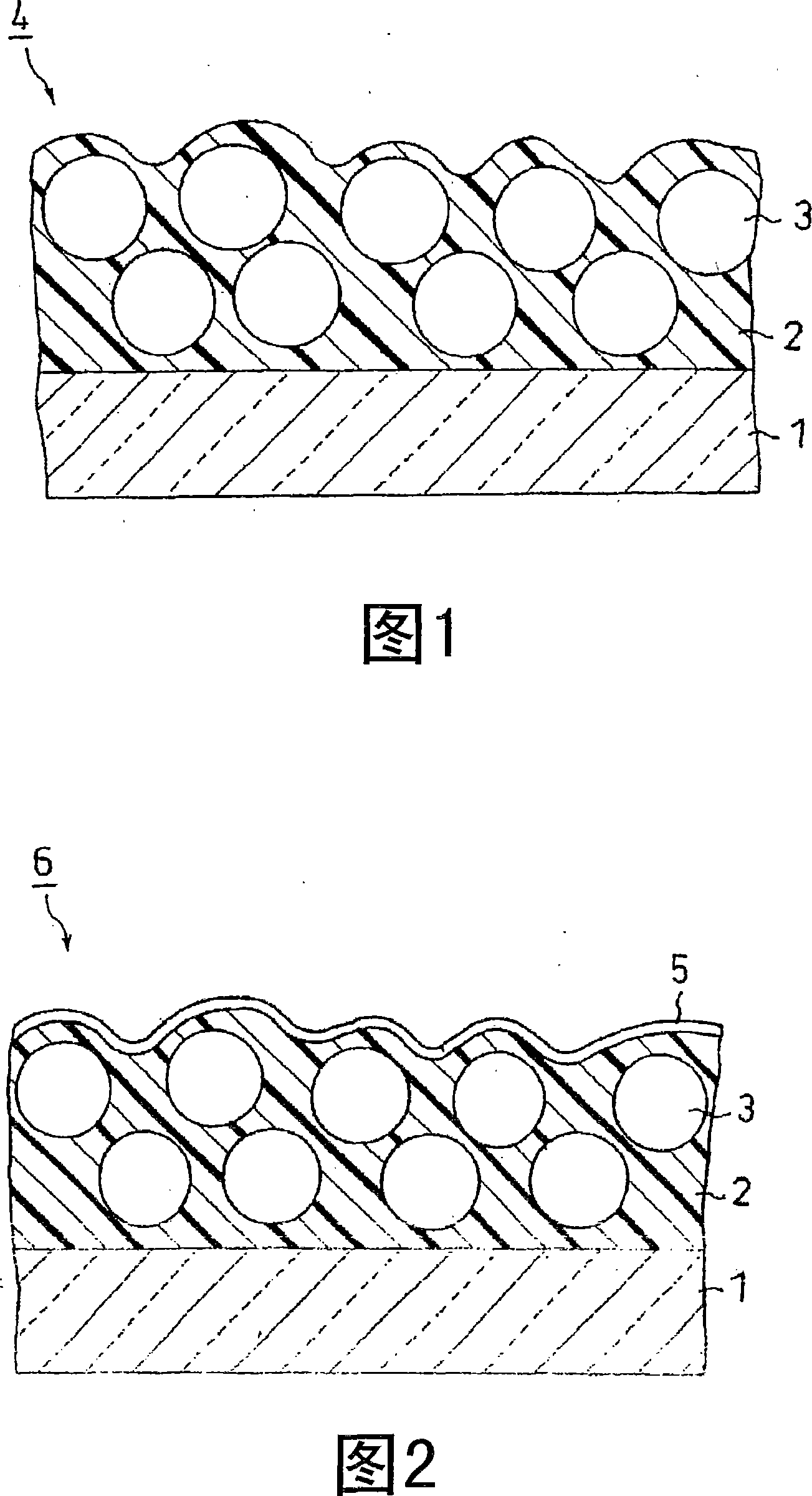

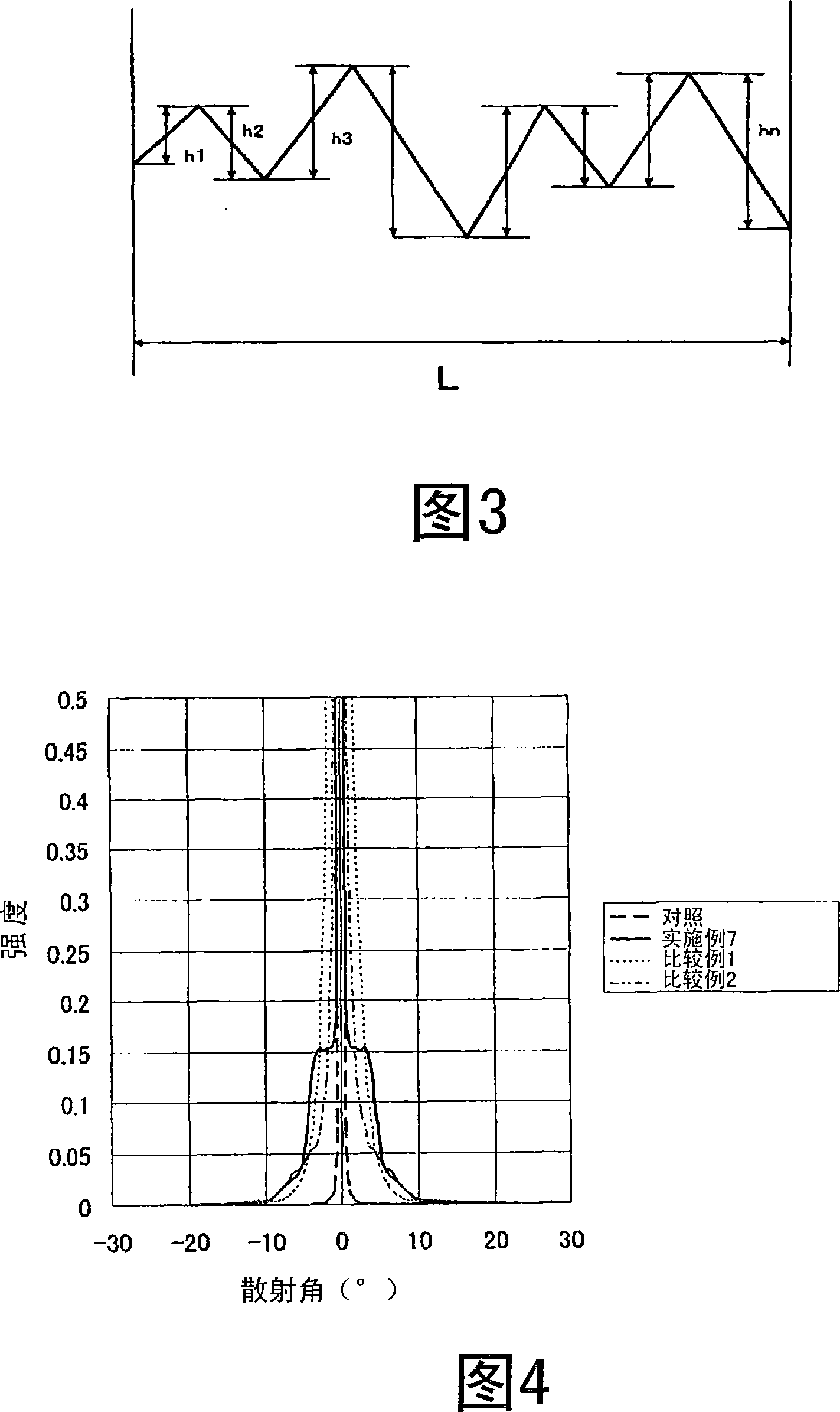

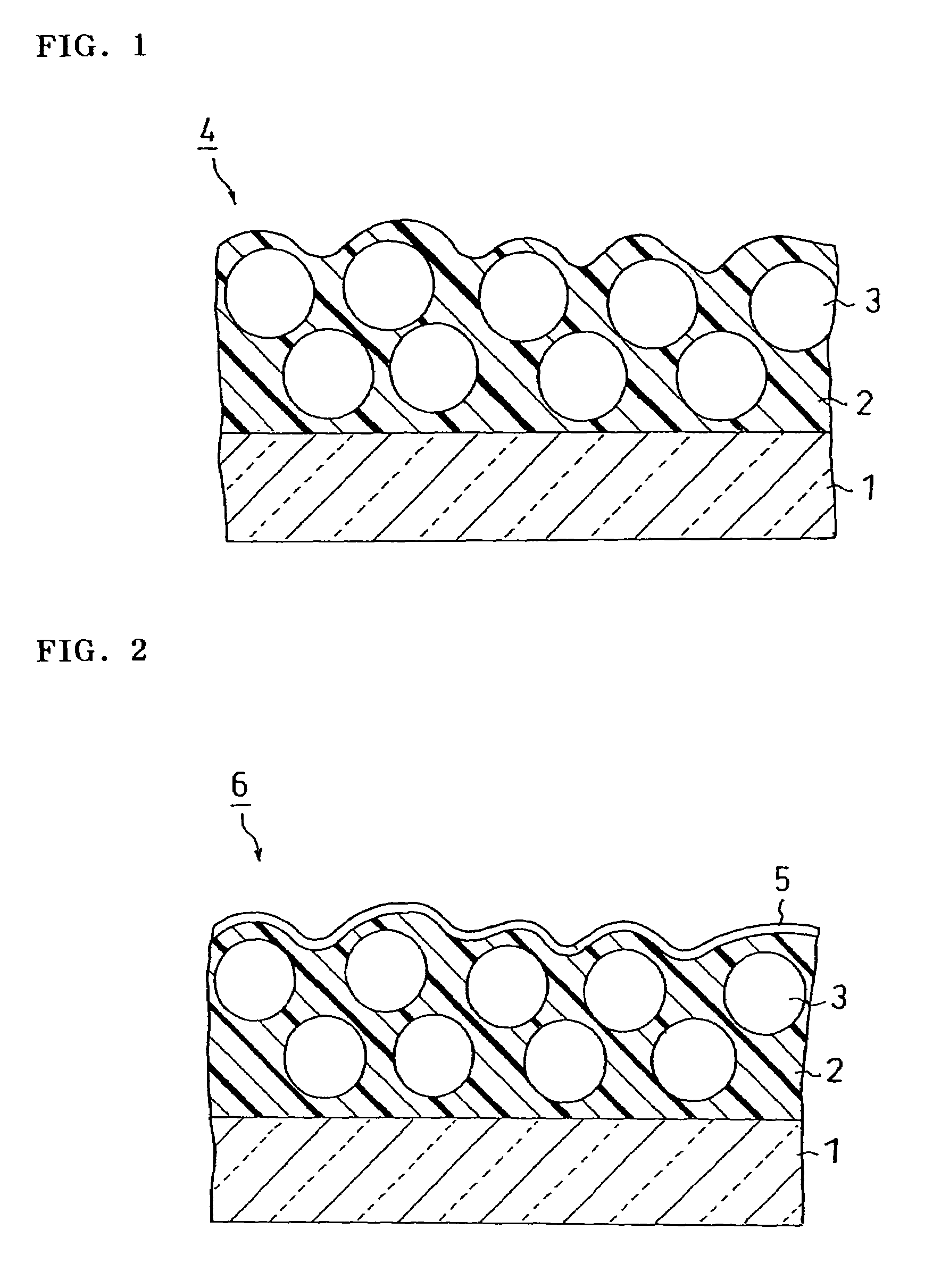

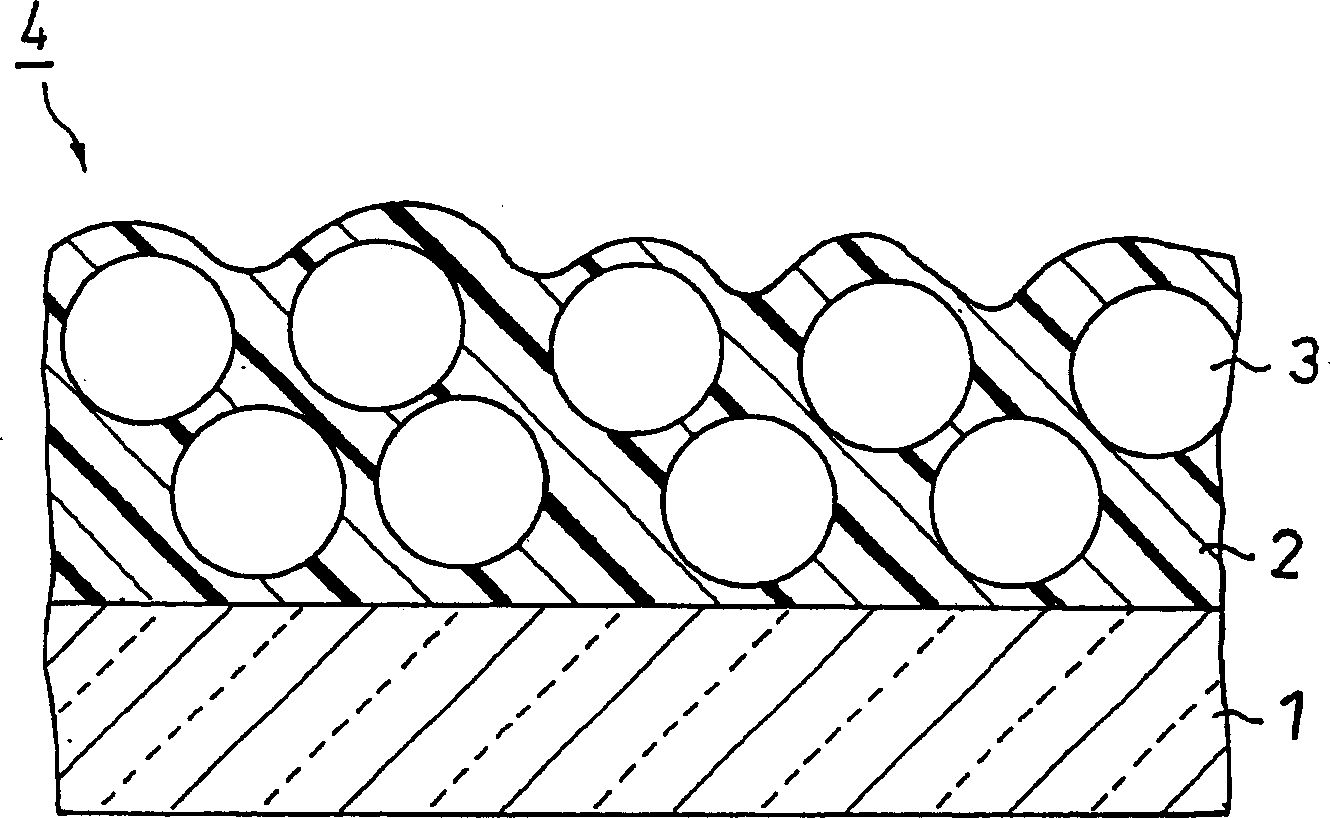

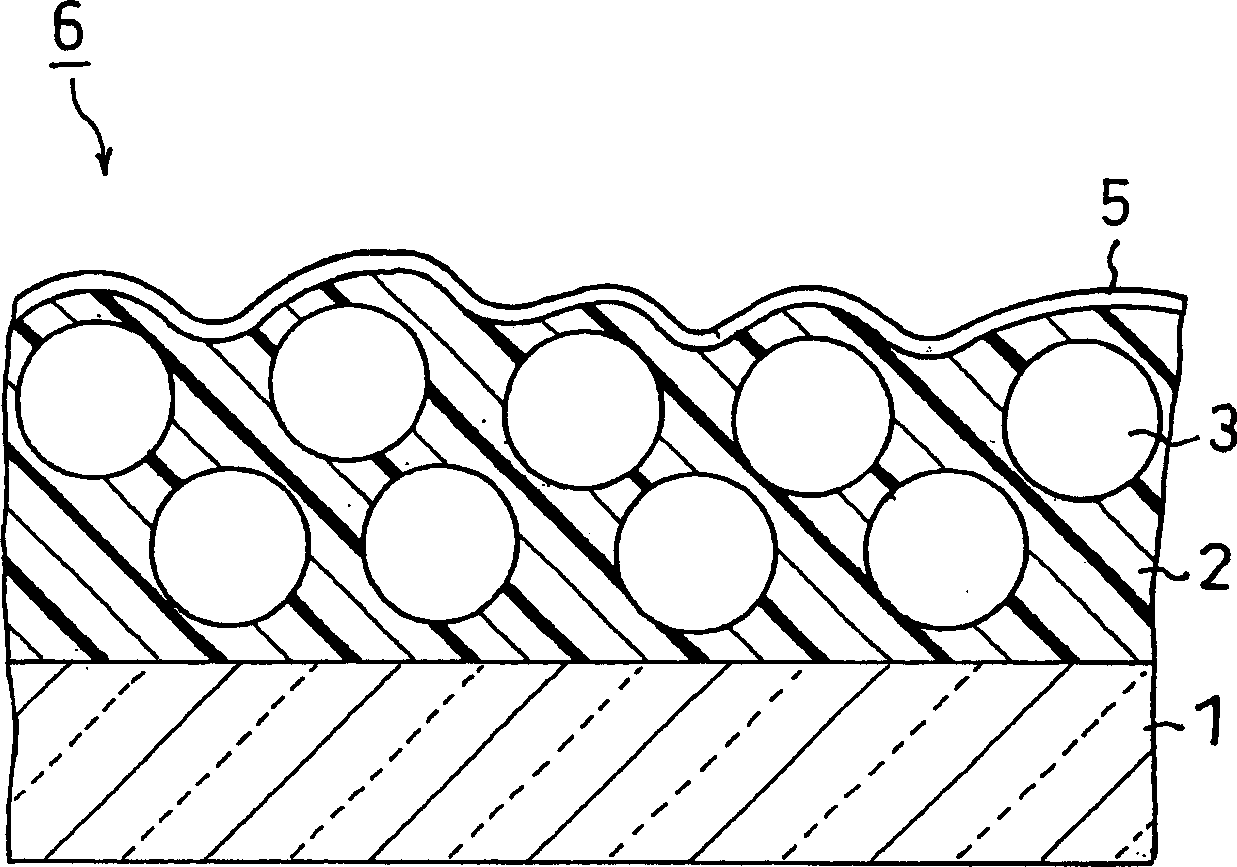

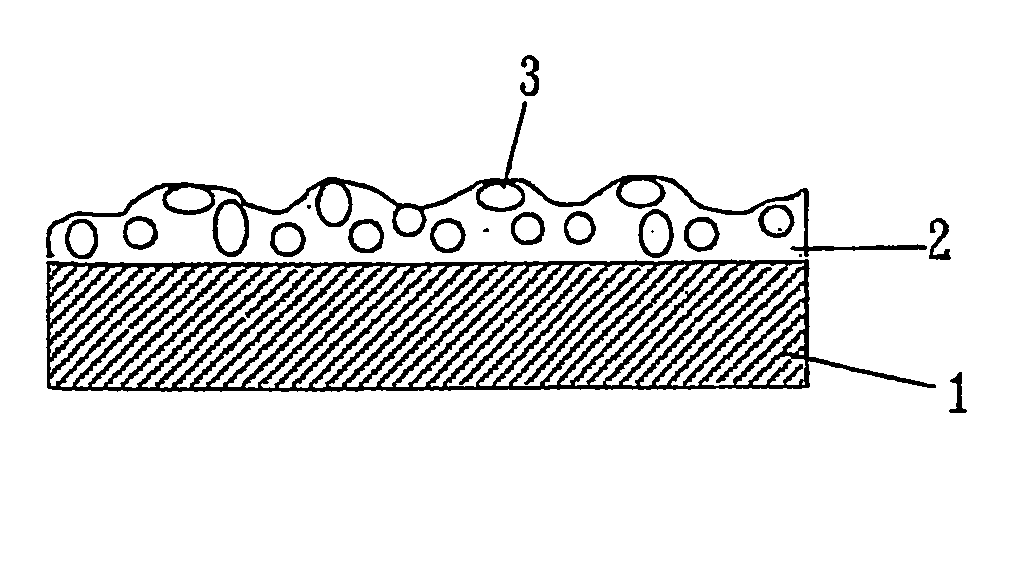

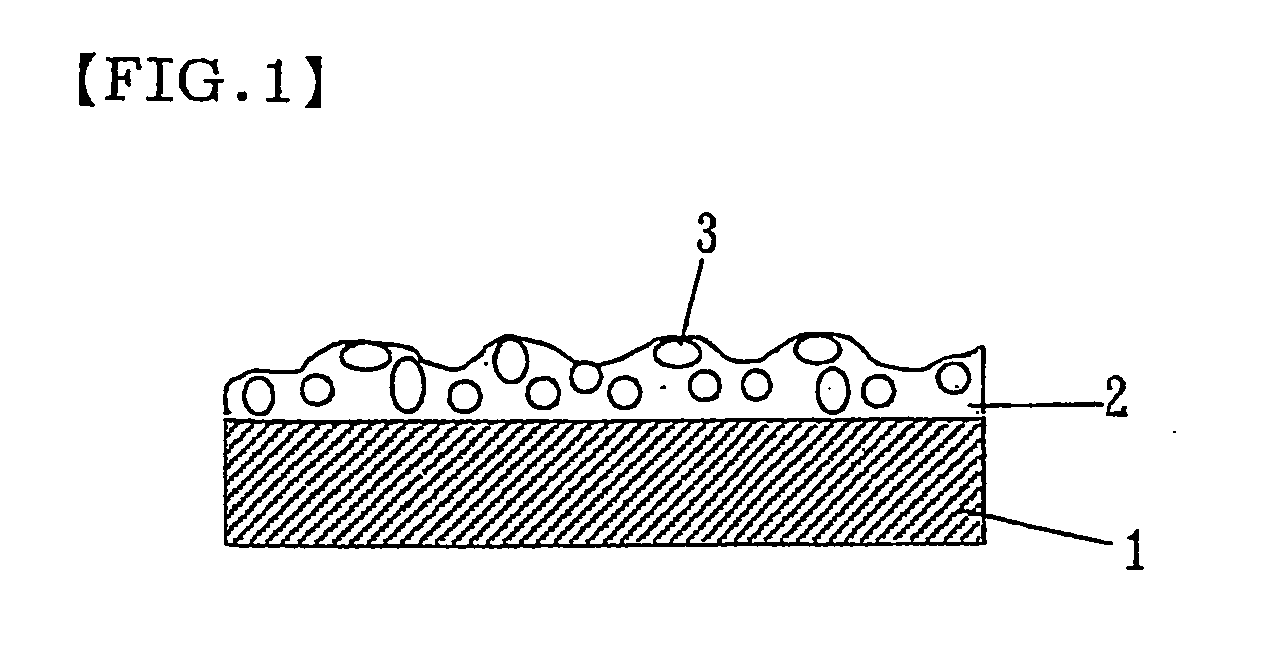

Hard-coated antiglare film and method of manufacturing the same

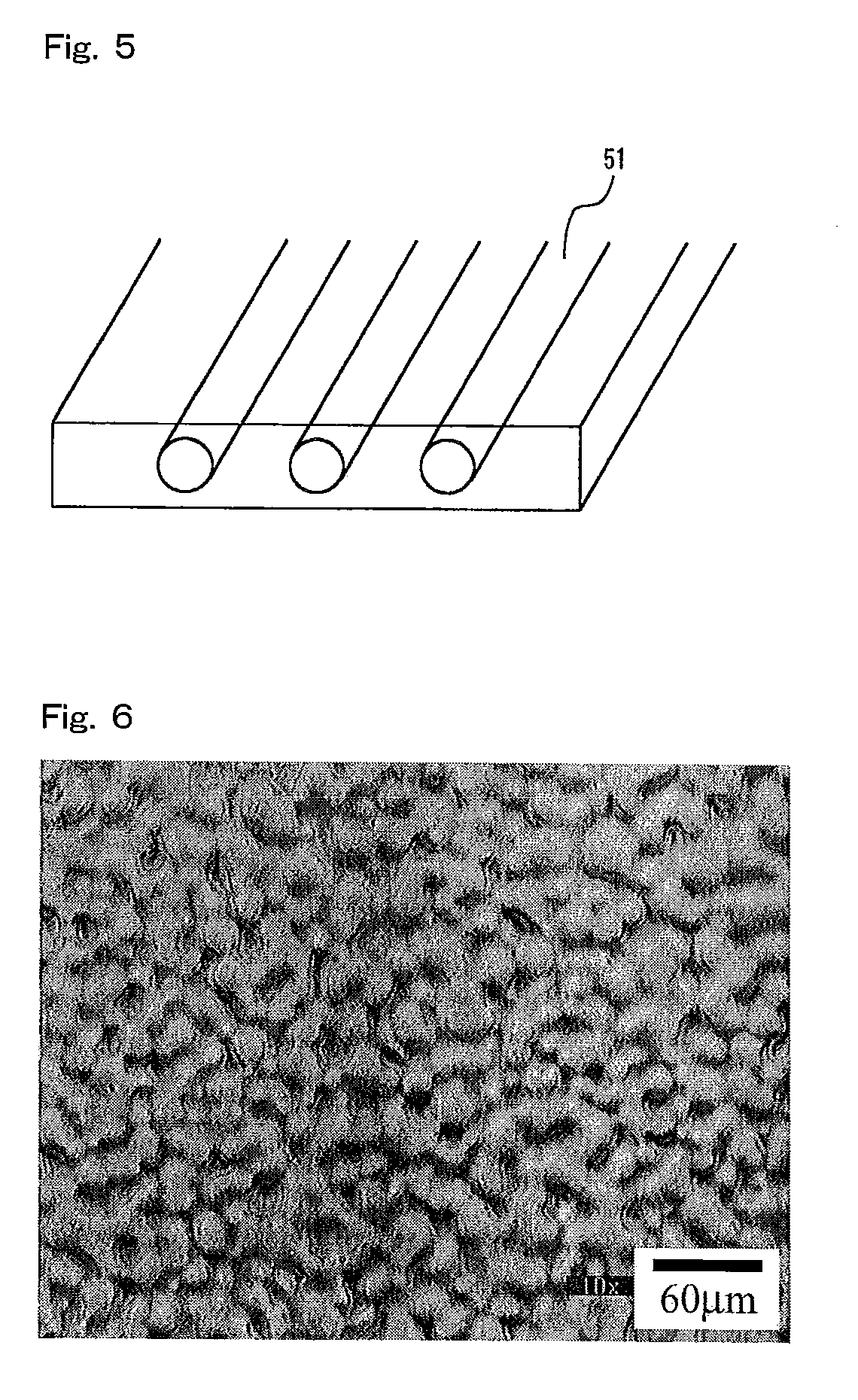

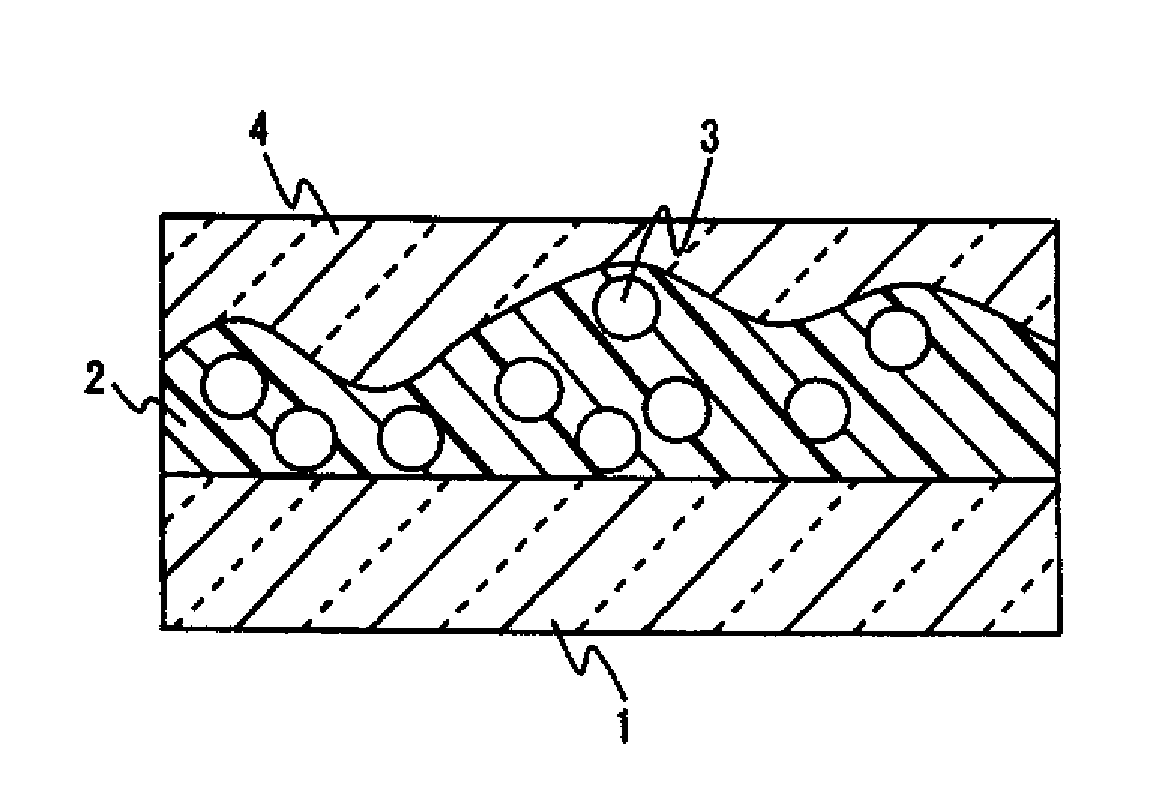

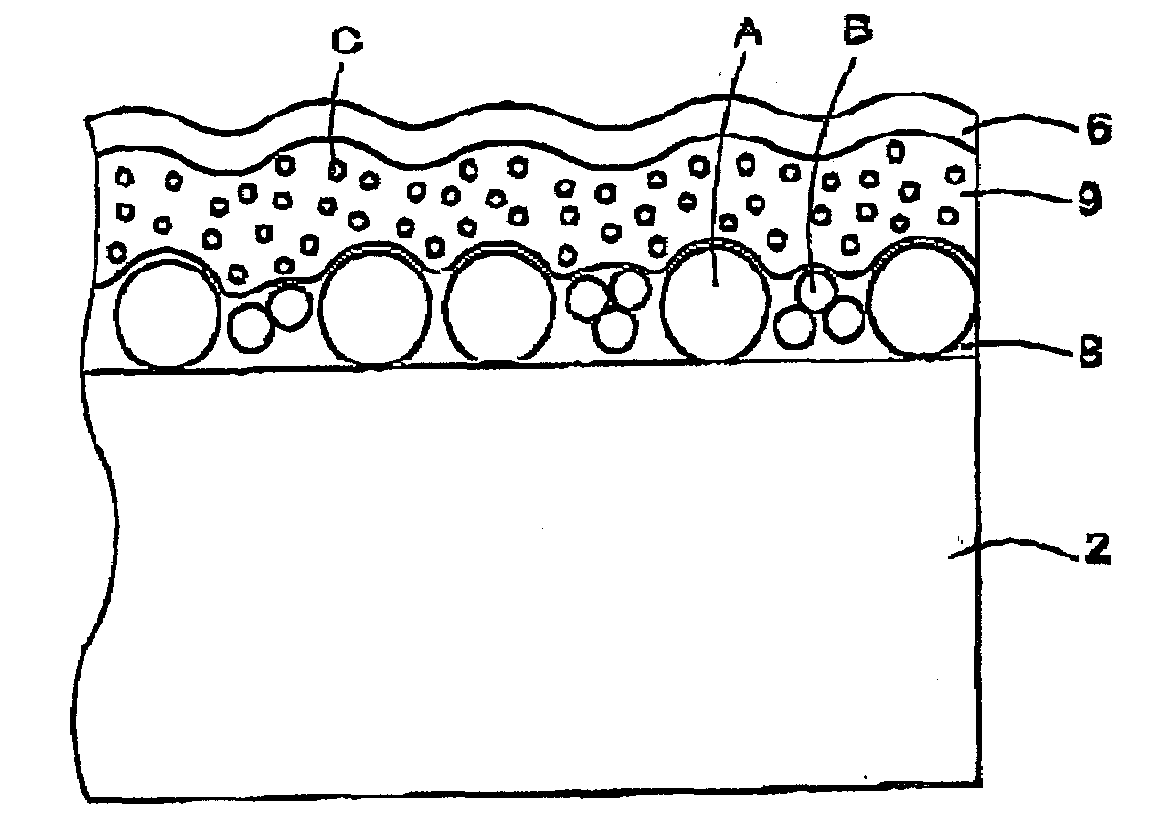

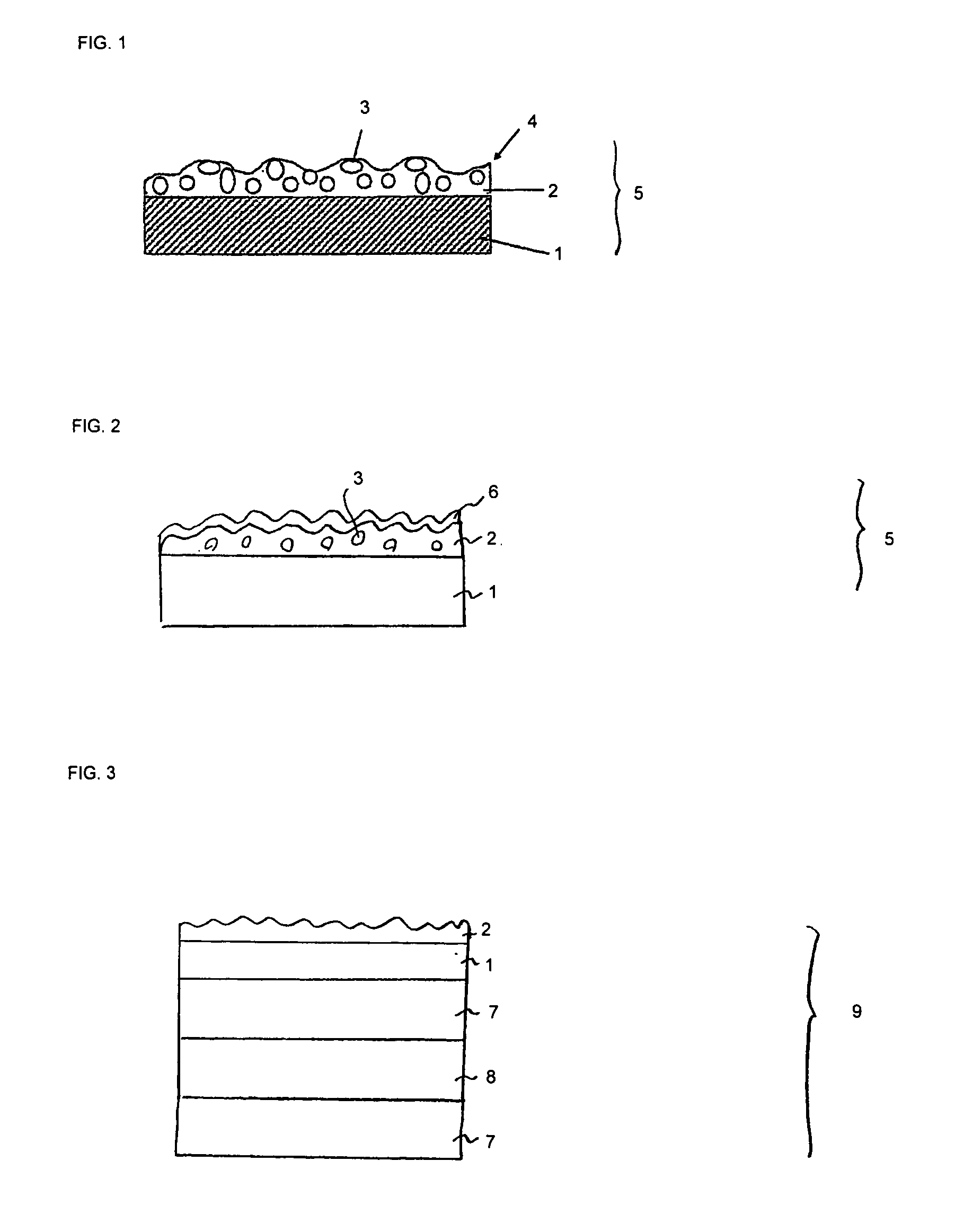

InactiveCN1794016AHigh hardnessGood anti-glare effectDiffusing elementsPolarising elementsHardnessMaterials science

The invention provides an anti-glare hard-coated film (4), which is an anti-glare hard-coated film having a hard coating (2) containing particles (3) on at least one surface of a transparent film substrate (1) (4), the film thickness of the hard coat layer (2) is not less than 15 μm and not more than 30 μm, and the average particle size of the particles (3) is not less than 30% and not more than 75% of the film thickness of the hard coat layer (2). The θa of the concavo-convex shape formed by the microparticles (3) according to JIS B 0601 is 0.4° or more and 1.5° or less. Thereby, an anti-glare hard-coated film excellent in hardness, scratch resistance, and anti-glare property, its production method, an optical element using the same, and an image display device equipped with the same can be provided.

Owner:NITTO DENKO CORP

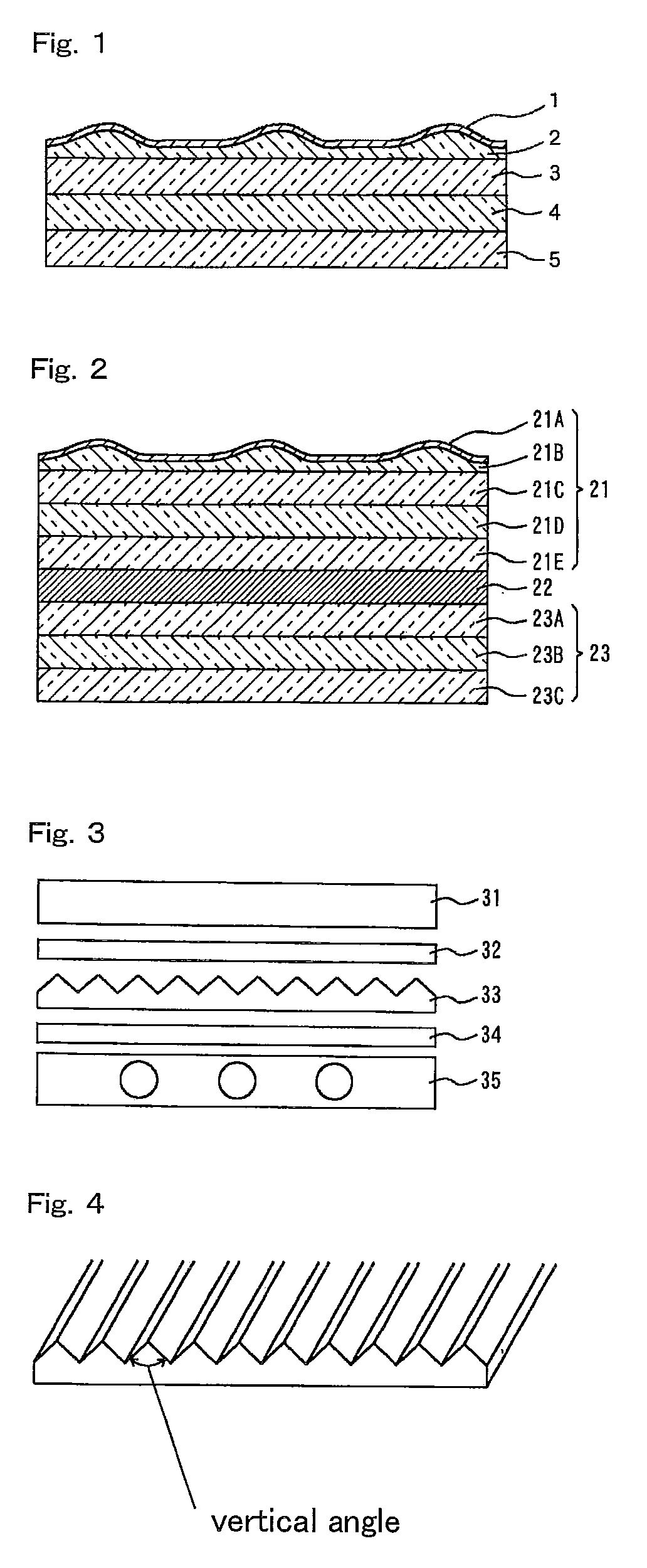

Light diffusing sheet, optical element and image display

InactiveUS7271862B2Glaring blurringLowering image visibilityTelevision system detailsDiffusing elementsVisibilityDisplay device

The present invention, a light diffusing sheet comprising a transparent resin layer having a minute unevenness formed on a surface thereof on at least one side of a transparent substrate, and a haze value of the light diffusing sheet is 30% or more, a ratio (Ra / Sm) of a center-line average surface roughness (Ra: μm) and an average height-depth spacing (Sm: μm) is 0.005 or less, and the Ra satisfies a relationship of 0.1≦Ra≦0.4. The light diffusing sheet enables suppression of glaring of a screen and white blurring, while maintaining antiglare property, having excellent image visibility.

Owner:NITTO DENKO CORP

Hard-coated antiglare film, polarizing plate, and image display

InactiveUS7604358B2Increase display contrastPrevents a glare phenomenon from occurring on the screenDiffusing elementsPolarising elementsDisplay contrastPlastic film

Owner:NITTO DENKO CORP

Anti-dazzling optical laminate

ActiveUS20080260997A1Increase contrastPrevent glareDiffusing elementsRecord information storageOptoelectronicsHaze

There is provided an anti-dazzling laminate which has anti-dazzling properties, has a high level of transparency by virtue of freedom from a milky-white impression caused by light diffusion, and can realize excellent black color reproducibility and scintillation preventive properties. The anti-dazzling laminate is an optical laminate comprising a light transparent base material and an anti-dazzling layer provided on the light transparent base material, wherein the outermost surface of the anti-dazzling layer has a concavoconvex shape, and the optical laminate satisfies the following requirements: Ha is more than 0% and less than 8%, Hi is more than 0% and not more than 6%, and Hi / Ha is not less than 0.013 and less than 0.8, wherein Ha represents the whole haze value of the optical laminate; and Hi represents the internal haze value of the optical laminate.

Owner:DAI NIPPON PRINTING CO LTD

Composition of anti-glare coating

InactiveUS20090142583A1Inhibit aggregationGood anti-glare effectImpression capsMixing methodsMicrometerPolyresin

A composition of an anti-glare coating has a resin, multiple particles and a dispersant. The resin is selected from the group consisting of thermosetting resin and light-curing resin. The particles have a dimension that is from about 30 nanometers (nm) to about 10 micrometers (μm). Because the dispersant stabilizes and keeps a separation distance between each two particles, the particles cannot aggregate in or precipitate out of the anti-glare coating. Thus, the anti-glare coating can be coated easily on the substrate and a surface of the anti-glare film is uniform to provide an improved anti-glare effect. Moreover, the dispersant allows adjustment of haze, gloss and distinctness of image of a substrate coated with the anti-glare coating.

Owner:TAIFLEX SCI

Anti-dazzle processing method for electronic product glass display screen

ActiveCN104829140AEliminate sharp cornersGood optical performanceFlexible article cleaningCleaning using toolsMegasonic cleaningEngineering

The invention provides an anti-dazzle processing method for an electronic product glass display screen and belongs to the technical field of display screen processing technology. The anti-dazzle processing method includes rinsing and dedusting the glass display screen in a rinsing tank and subjecting the rinsed and dedusted glass display screen to ultrasonic cleaning in an ultrasonic cleaner; sticking corrosion-resistant plastic protective films on four side faces and the back face of the glass display screen; heating frosting liquid to 20-26 DEG C, and soaking the glass display screen in the heated frosting liquid for 60-120 seconds; removing the protective films on the glass display screen; filling a jetting machine with a polishing solution, fixing the glass display screen, and jetting the polishing solution to the front face of the glass display screen through a spray head of the jetting machine for 180-300 seconds. The anti-dazzle processing method for the electronic product glass display screen has the advantages that the anti-dazzle processing method solves the technical problems of poor surface quality, bad hand feeling, weak anti-dazzle capability and the like of anti-dazzle glass manufactured by an existing anti-dazzle processing method for the display screen; microcosmic sharp corners are eliminated by means of adopting a unique high-pressure jetting and polishing mode, so that anti-dazzle capability is improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

Light diffusing sheet, optical element and image display

InactiveUS20050128379A1Glaring blurringLowering image visibilityTelevision system detailsDiffusing elementsVisibilityDisplay device

The present invention, a light diffusing sheet comprising a transparent resin layer having a minute unevenness formed on a surface thereof on at least one side of a transparent substrate, and a haze value of the light diffusing sheet is 30% or more, a ratio (Ra / Sm) of a center-line average surface roughness (Ra:μm) and an average height-depth spacing (Sm:μm) is 0.005 or less, and the Ra satisfies a relationship of 0.1 ≦Ra ≦0.4. The light diffusing sheet enables suppression of glaring of a screen and white blurring, while maintaining antiglare property, having excellent image visibility.

Owner:NITTO DENKO CORP

Anti-glare hard coat film

InactiveUS6896960B2Decreasing highly fine qualityGood anti-glare effectDiffusing elementsSynthetic resin layered productsDisplay deviceHardness

An anti-glare hard coat film comprising an anti-glare hard coat layer disposed on at least one face of a transparent substrate film, wherein the anti-glare hard coat layer comprises (A) a resin cured by an ionizing radiation and, per 100 parts by weight of the cured resin, 0.2 to 10 parts by weight of (B) fine particles of silica and 1 to 20 parts by weight of (C) fine particles of a silicone resin. When this film is used for various displays, the excellent anti-glare property can be provided without decreasing the highly fine quality of displayed images. This film is also advantageously used as a protective film having a great surface hardness.

Owner:LINTEC CORP

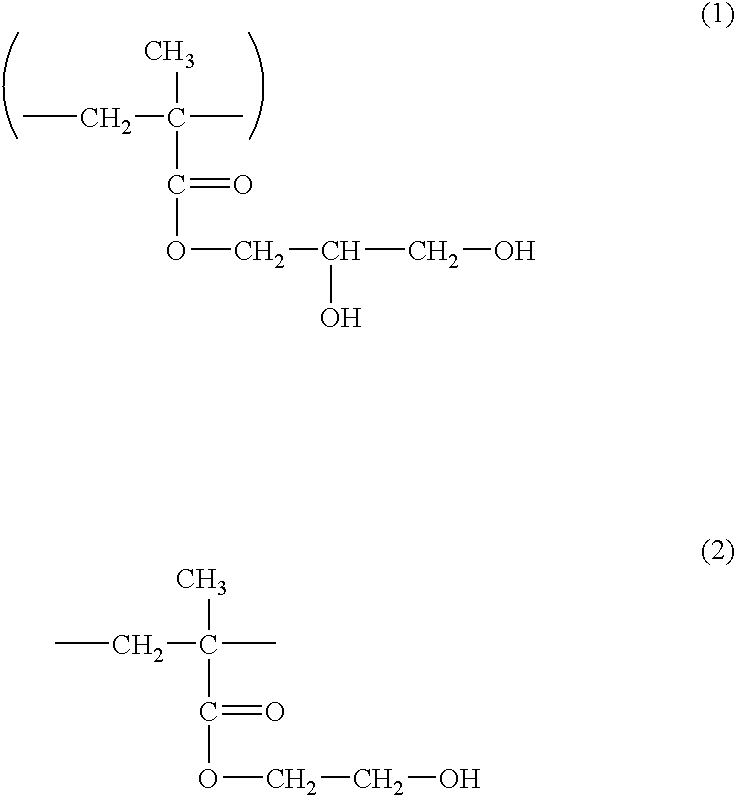

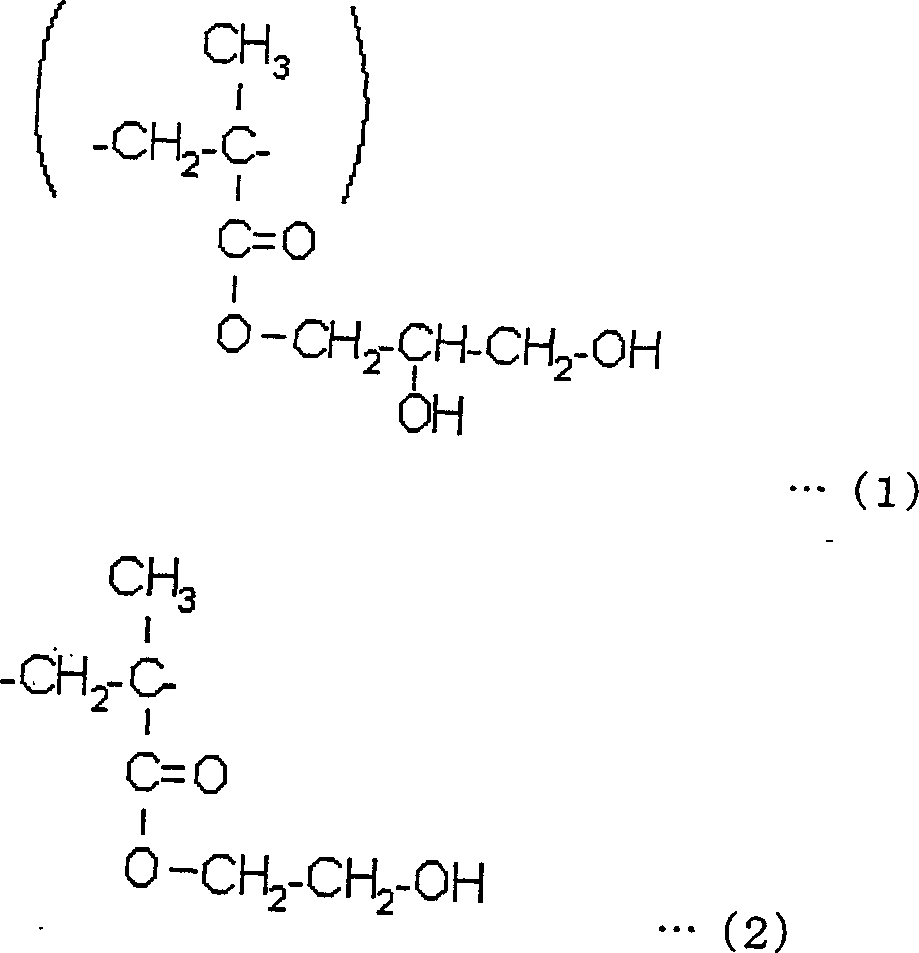

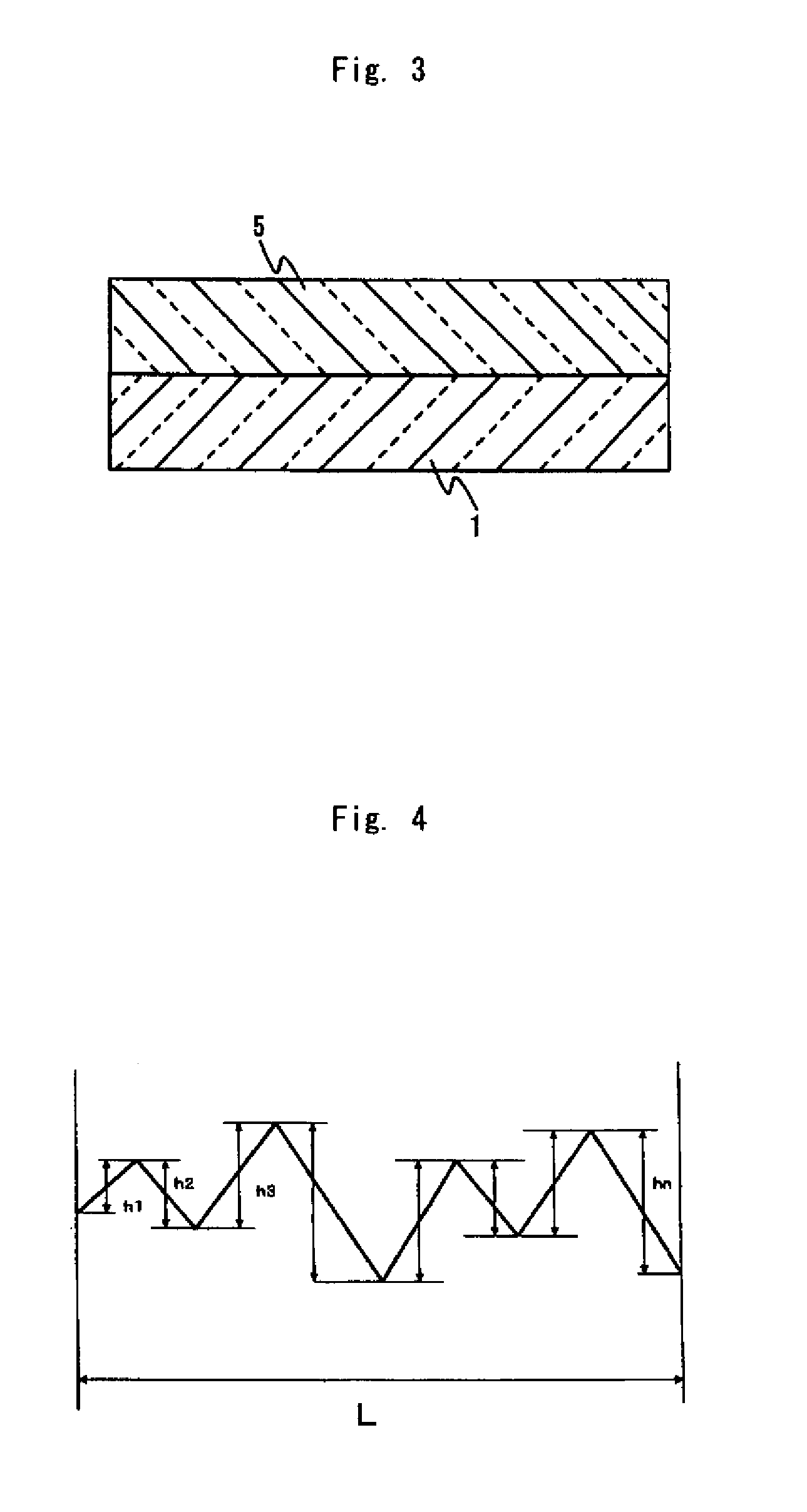

Material for forming antiglare hard coat layer and antiglare hard coat film

InactiveUS20060099385A1Highly fine antiglare propertyOptical properties are stableSynthetic resin layered productsRecord information storageCoated membranePolymer science

A material for forming an antiglare hard coat layer which comprises (A) a polymerizable compound of an active energy beam curing type, (B) a thermoplastic resin, (C) a good solvent for (A) and (B), and (D) a poor solvent for (B), wherein the ratio of amounts by weight of (A) to (B) is 100:0.3 to 100:50 and the ratio of amounts by weight of (C) to (D) is 99:1 to 30:70; and an antiglare hard coat film which comprises an antiglare hard coat layer comprising a layer of an active energy beam-cured resin formed by using the above material and disposed on a substrate film. The hard coat film contains no fine particles or a decreased amount of fine particles for providing the antiglare property and exhibits highly fine antiglare property, stable optical properties and excellent scratch resistance.

Owner:LINTEC CORP

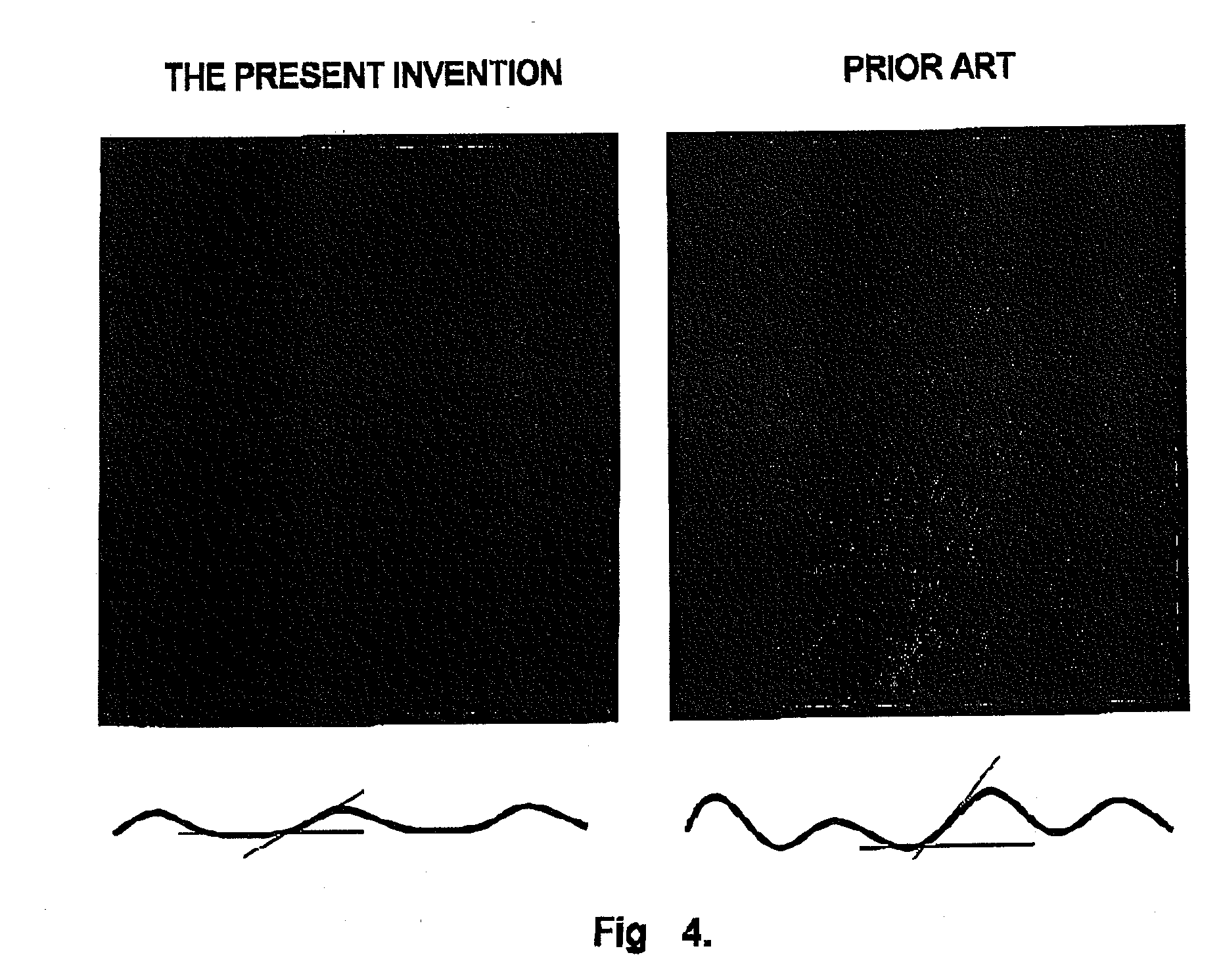

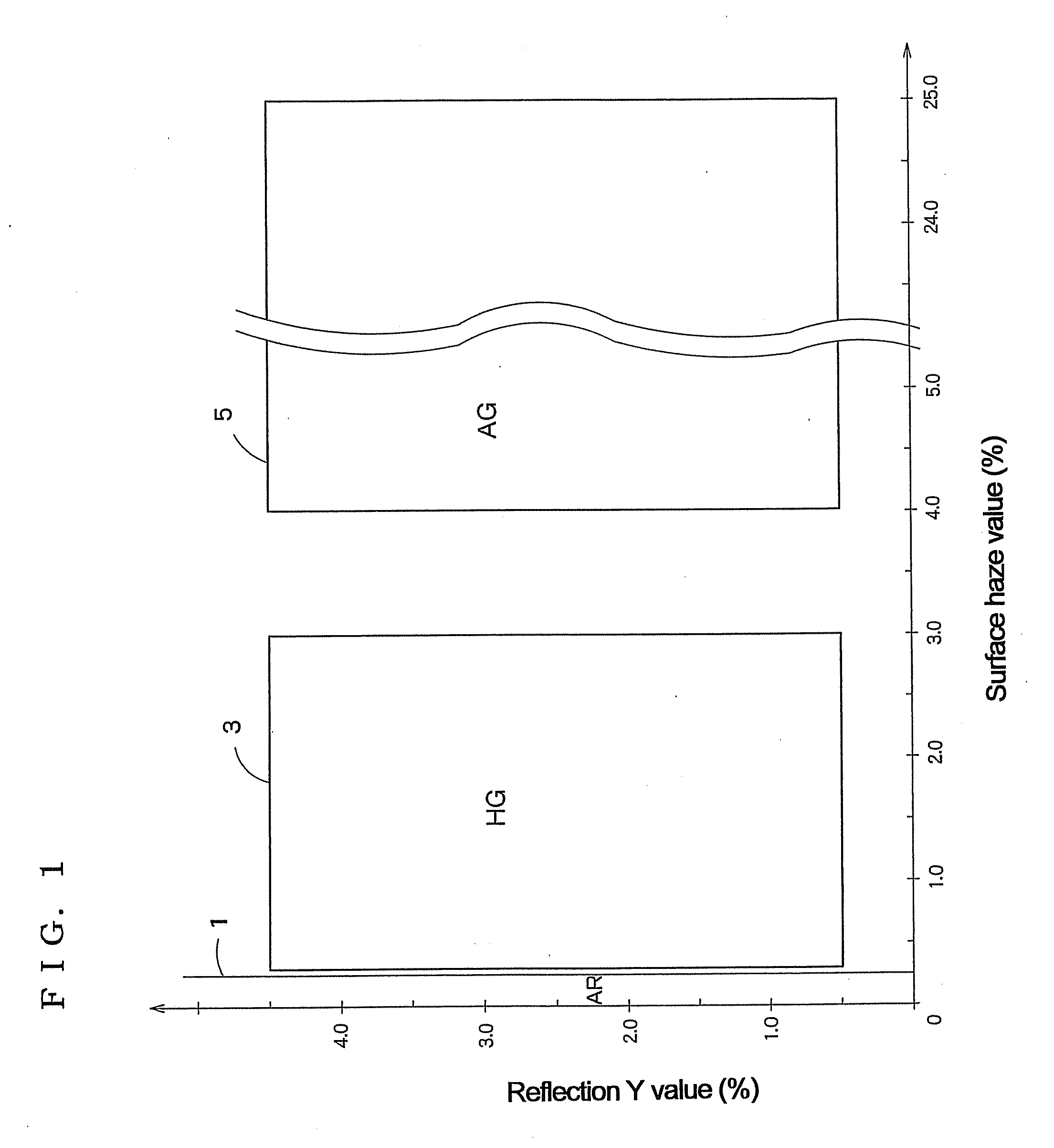

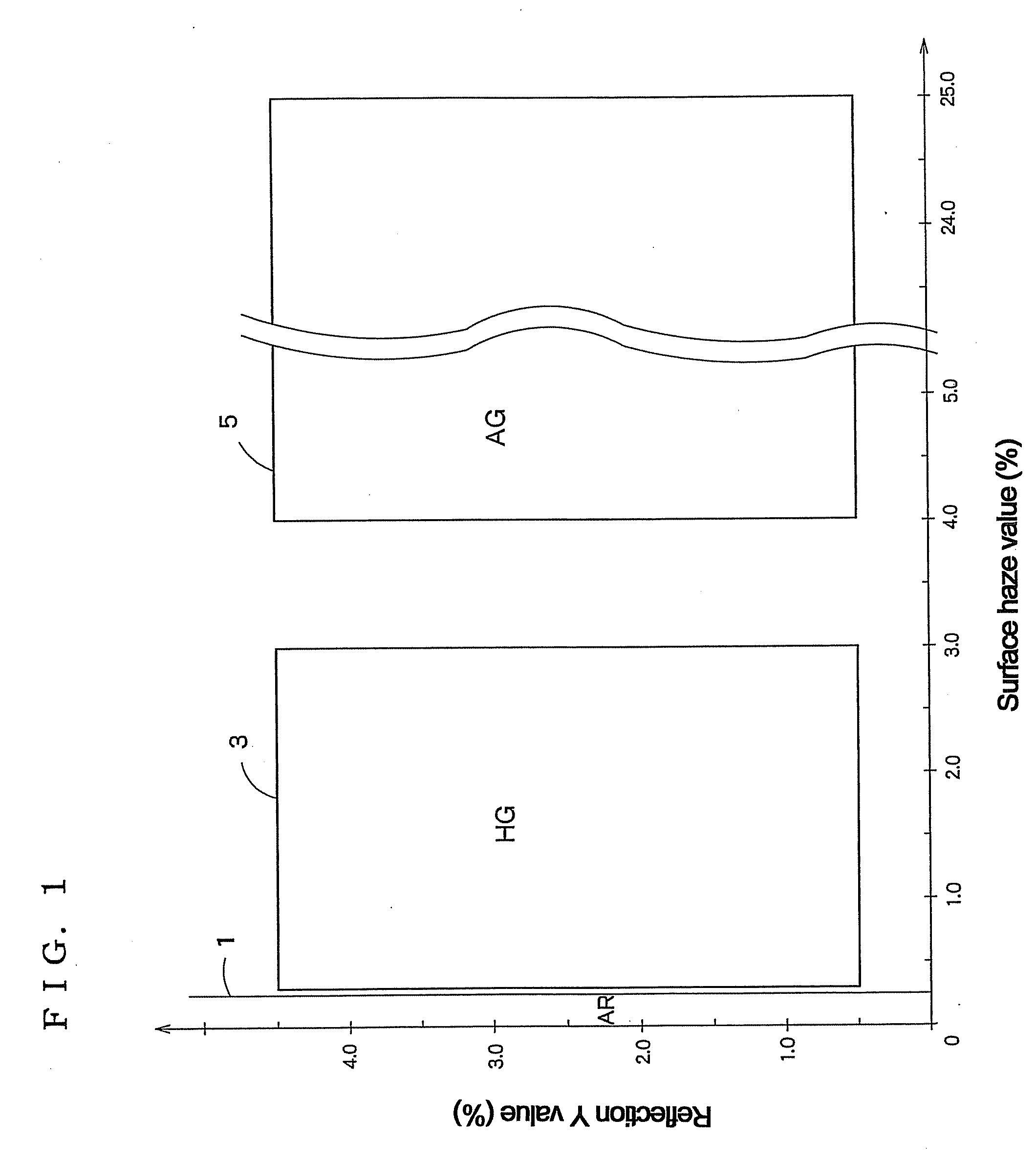

Glare-Proofing Optical Laminate

ActiveUS20090002831A1Low surface haze valueImprove clarityDiffusing elementsLayered productsImage resolutionOptoelectronics

An anti-dazzling laminate made of an optical laminate including a light transparent base material and an anti-dazzling layer having a concavoconvex shape provided on the material. The laminate simultaneously satisfies formulae: 0≦G100≦15 (I), 0.1≦Hs≦5.0 (II), 0.3≦Rz≦1.8 (III) wherein G100 represents a scintillation value which is a standard deviation of a variation in brightness distribution at a resolution of 100 ppi measured on the surface of the laminate; Hs represents the surface haze value of the laminate; and Rz represents the average roughness of the concavoconvex shape of the anti-dazzling layer.

Owner:DAI NIPPON PRINTING CO LTD +1

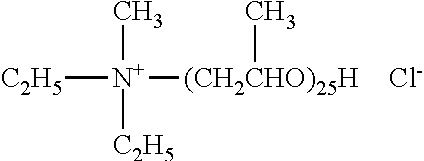

Antiglare film, method for producing the same, polarizing plate and image display device

InactiveUS20130258481A1Good anti-glare effectHigh densityDiffusing elementsPolarising elementsOrganic solventChemical compound

An antiglare film includes an antiglare layer having a thickness of from 3 to 10 μm and a transparent support having a thickness from 20 to 70 μm, and the antiglare layer is formed by applying a composition containing the following components (A) to (D) on the transparent support, drying and curing the applied composition: (A) a resin particle having an average particle size of from 1.0 to 3.0 μm, (B) a curable compound having two or more curable functional groups in a molecule, (C) a smectite clay organic complex in which a smectite clay is intercalated with a quaternary ammonium salt represented by the formula (1) as defined herein, and (D) a volatile organic solvent.

Owner:FUJIFILM CORP

Anti-dazzle Thin Film And Liquid Crystal Display Device

ActiveCN102401915AGood anti-glare effectIncrease contrastDiffusing elementsOptical articlesLiquid-crystal displayRefractive index

The invention provides an anti-dazzle thin film and a liquid crystal display device. The anti-dazzle thin film comprises a transparent supporting body and an anti-dazzle layer, wherein the anti-dazzle layer, formed upon the transparent supporting body, comprises a minuteness concave-convex surface having minor concavo and convex at the side opposite to the transparent supporting body. The anti-dazzle thin film is characterized in that: the internal haze is below 1% while the surface haze is between 0.4% and 10%; the imagine plane, incoming from the main normal direction of the mean surface of the minuteness concave-convex surface and containing the points having highest level, is parallel to the mean surface of the concave-convex surface, that is, the wavelength ejected by the highest level surface is 550nm; the plural amplitude of the highest level surface can be calculated via the level of the minuteness concave-convex surface and the refractive index of the anti-dazzle layer; and when the one-dimensional power spectrum of the plural amplitude is employed as a graph to indicate the intensity of the spatial frequency, there are two break points within the spatial frequency range of 0.032 micron-1 to 0.064 micron-1.

Owner:SUMITOMO CHEM CO LTD

Optical Multilayer Body

ActiveUS20090061165A1Improve clarityMaintain good propertiesDiffusing elementsLayered productsOptoelectronicsBrightness perception

The present invention provides an anti-dazzling laminate which has anti-dazzling properties and can realize excellent glare preventive properties and black color reproducibility (gradation rendering of black color at low brightness). The optical laminate comprises a light transparent base material and an anti-dazzling layer provided on the light transparent base material. The outermost surface of the anti-dazzling layer has a concavoconvex surface, and the average spacing S determined by calculation based on data obtained by measuring a roughness curve of a concacoconvex shape of the anti-dazzling layer is not less than 0.04 mm and not more than 0.30 mm.

Owner:DAI NIPPON PRINTING CO LTD

Hard-coated antiglare film, method of manufacturing the same, optical device, polarizing plate, and image display

InactiveUS20070242362A1High hardnessGood anti-glare effectLiquid crystal compositionsLiquid surface applicatorsCoated surfaceDisplay device

A hard-coated antiglare film is provided that has high hardness, high scratch resistance, and good antiglare properties. In the hard-coated antiglare film of the present invention including a transparent plastic film substrate, a hard-coating layer containing fine particles is formed on at least one surface of the transparent plastic film substrate, the hard-coating layer has a thickness in the range of 15 to 30 μm, the fine particles have a weight average particle size of 30 to 75% of a thickness of the hard-coating layer, the average tilt angle θa of the unevenness of the hard-coating layer surface is in the range of 0.4° to 1.5°, and the hard-coating layer is formed using a resin for forming the hard-coating layer containing three specific resin components.

Owner:NITTO DENKO CORP

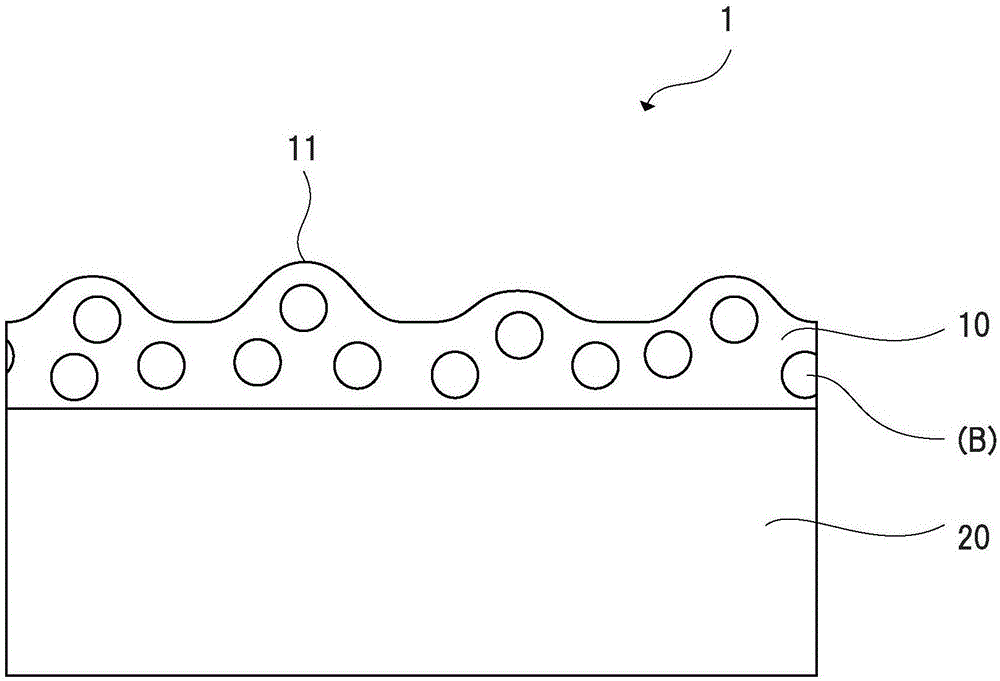

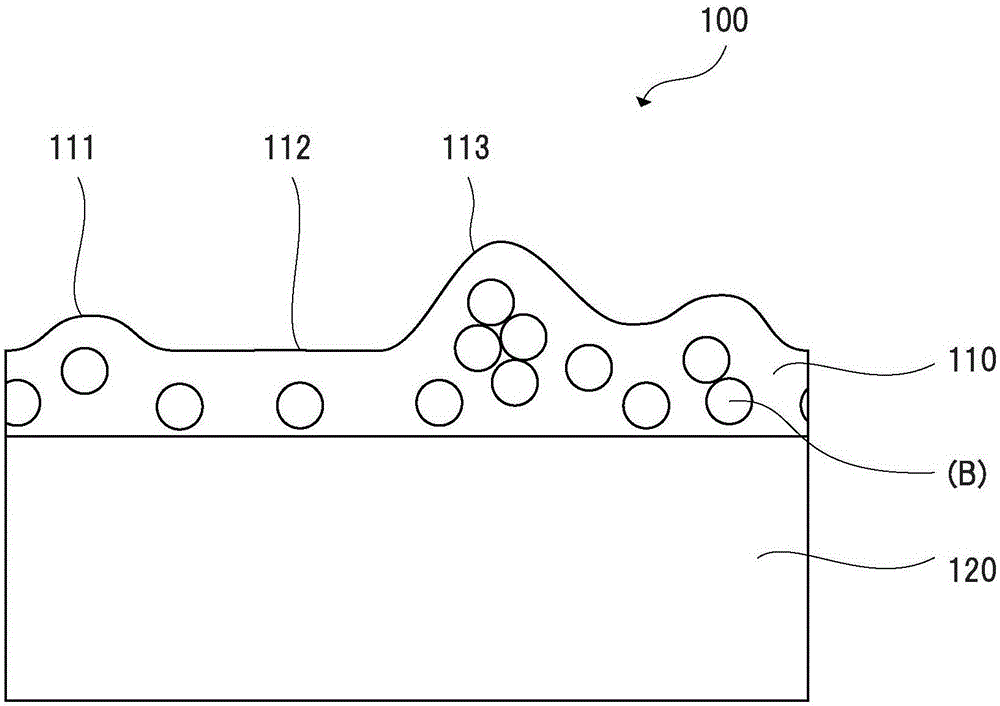

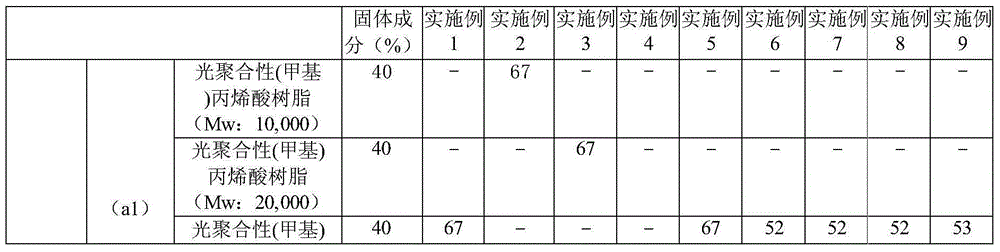

Photocurable resin composition, cured coating film, anti-glare film, method for manufacturing the same, and image display device

InactiveCN105388704AGood anti-glare effectPhotosensitive materials for photomechanical apparatusOptical elementsAcrylic resinMicroparticle

The invention provides a photocurable resin composition, a cured coating film, an anti-glare film, a method for manufacturing the same, and an image display device, and the advantages of the above comprise good anti-glare property and uneven brightness. The photocurable resin composition contains photopolymerizable compositions (A), microparticles (B) and photopolymerization initiators (C), the photocurable resin composition is characterized in that: the photopolymerizable compositions (A) contains more than 10000 weight-average molecular weight of photopolymerizable(methyl)acrylic resin (a1), the microparticles (B) contains more than 1.0[mu]m and less than 2.8[mu]m of organic microparticles and / or inorganic microparticles, and the viscosity is more than 1mPa.s and less than 1000 Pa.s at 23 DEG C below.

Owner:CHUGOKU MARINE PAINTS

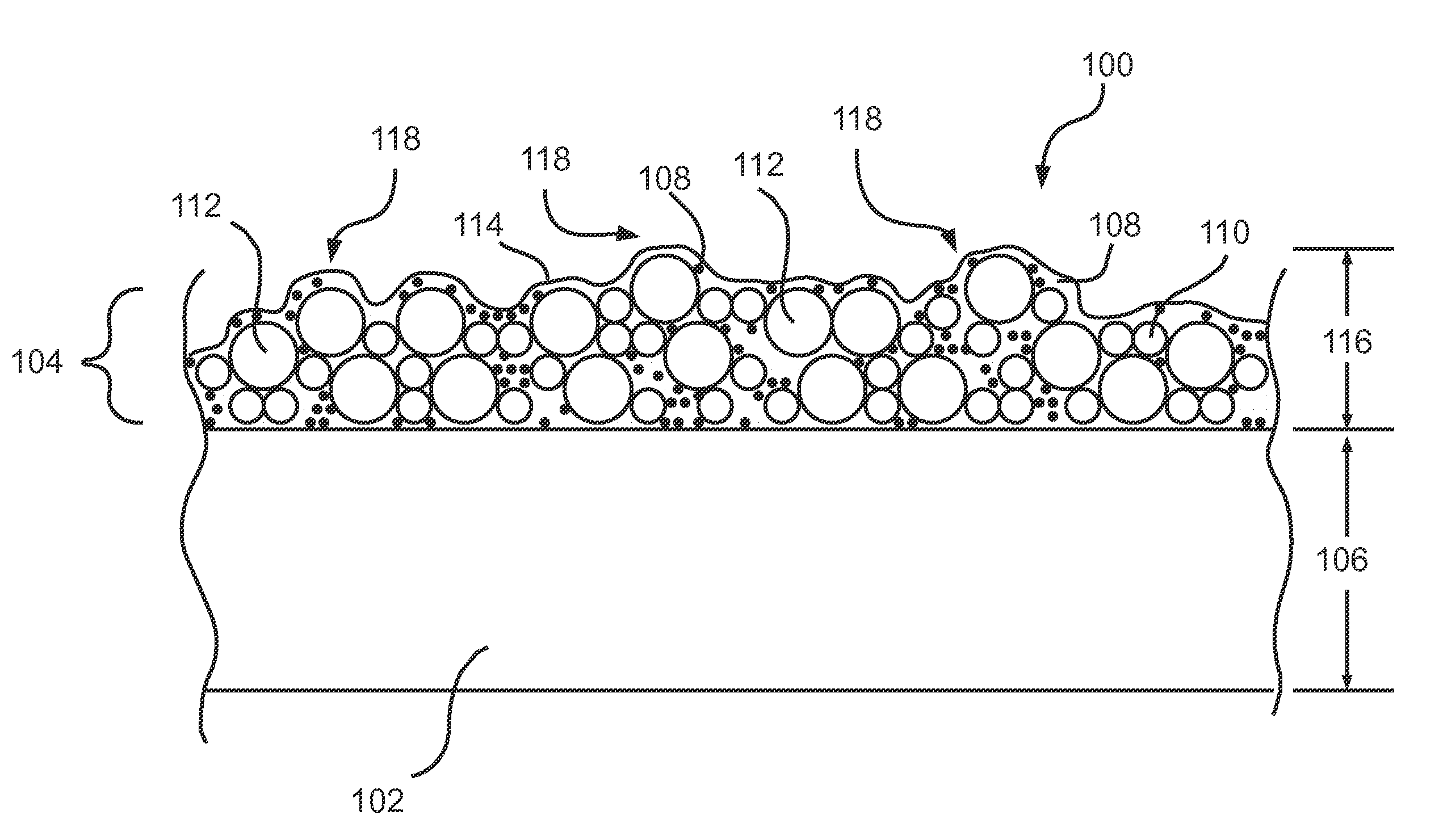

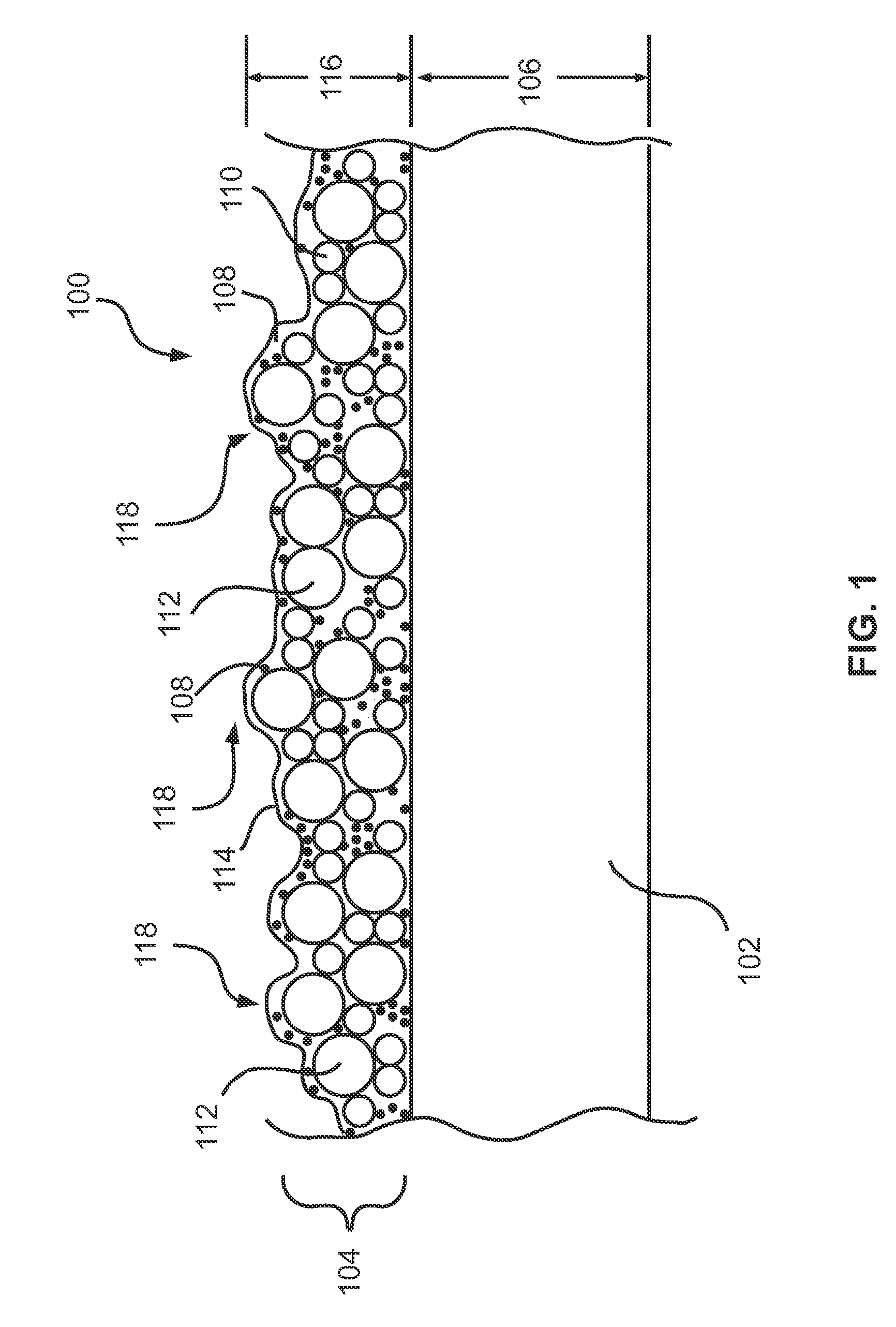

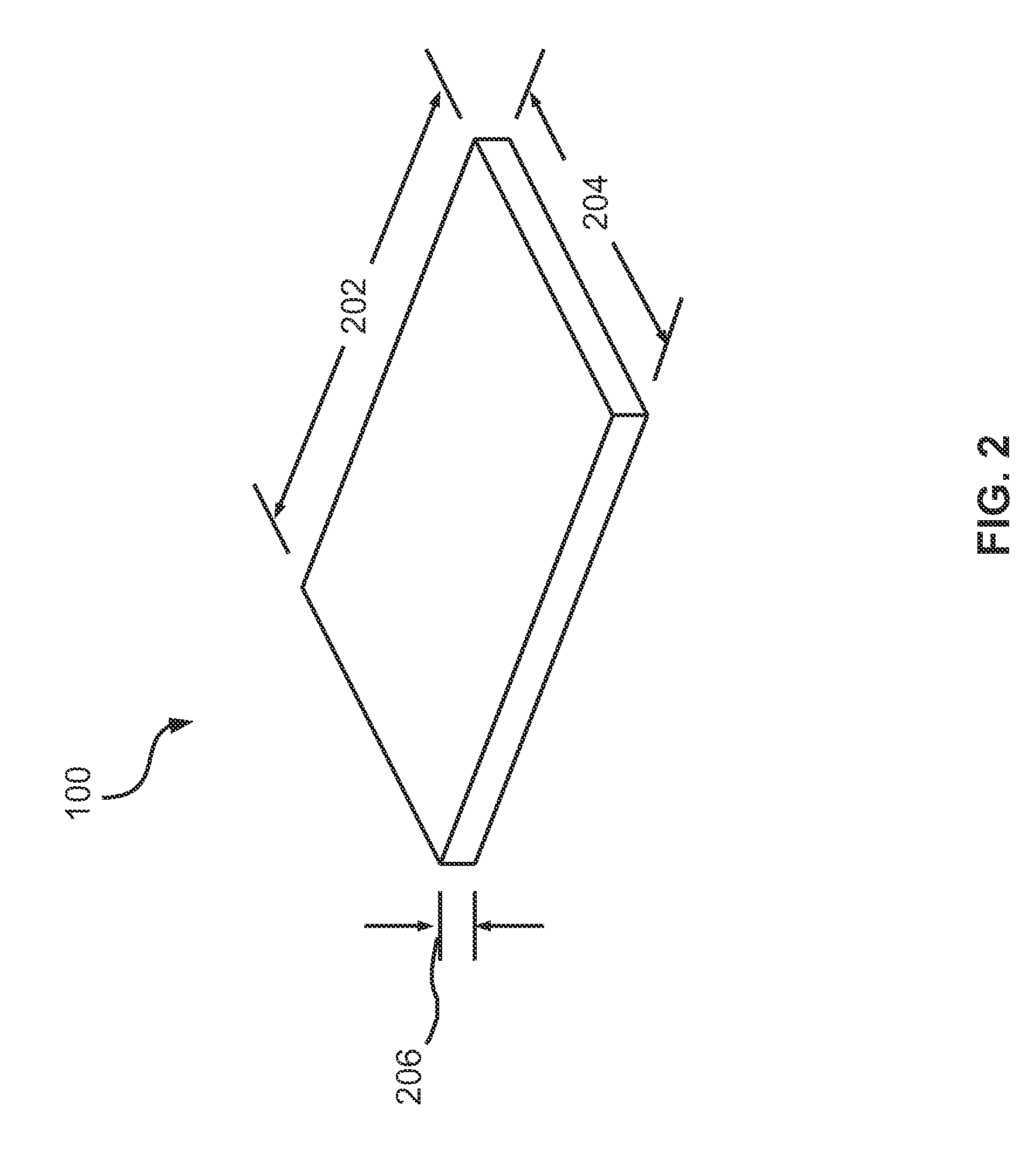

Optical coatings with plate-shaped particles and methods for forming the same

Embodiments provided herein describe optical coatings, panels having optical coatings thereon, and methods for forming optical coatings and panels. A transparent substrate is provided. An optical coating is formed on the transparent substrate. The optical coating includes a plurality of plate-shaped silicon dioxide particles.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com