Patents

Literature

126results about How to "Solve the hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses

The invention discloses a process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses, wherein the method comprises the following steps: (1) weighing the raw materials according to the formula of a frosting liquid, mixing and stirring the raw materials evenly, curing the mixture for 24 -30 hours to prepare the frosting liquid; (2) after cleaning the glass to be frosted, carrying out protective treatment on one surface that is not needed to be frosted; (3) placing the protected glass into a pre-treatment liquor for further cleaning; (4) placing the treated glass into the cured frosting liquid to frost the glass for 30 -200 seconds, taking out the glass and cleaning the glass with water; and (5) placing the frosted glass into a polishing liquid to etch to obtain the anti-glare glass finished product. The invention solves the problem that the high-boron silicon and high-aluminium silicon glasses have large hardness and are difficult to be frosted; the process provided by the invention improves the hardness of the glass while guaranteeing the even frosting degree and good anti-glare effect; the product produced by the process provided by the invention has advantages of acid and alkali resistance and corrosion resistance.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

Method for preparing CMP (Chemically Mechanical Polishing) solution for sapphire substrate material

InactiveCN102010669ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesSurface finishMaterial removal

The invention relates to a method for preparing a CMP (Chemically Mechanical Polishing) solution in a high-precision surface finishing process of a sapphire substrate material. In the method, a nano SiO2 abrasive material is adopted for the polishing solution, wherein the abrasive material has the concentration of 30-50wt% and the particle diameter of 15-100nm so as to benefit material removal and surface leveling. The pH value of the polishing solution is 9-13, which not only benefits effective removal but also guarantees the stability of silica sol; and in a preparation process, a negative pressure stirring preparation method is adopted under a closed system, and pollutions of organic matters, large particles, metal ions and the like brought by the traditional preparation methods of compounding, mechanical stirring and the like are prevented so that the requirement on ultra cleanness is met.

Owner:TIANJIN JINGLING MICROELECTRONIC MATERIALS CO LTD

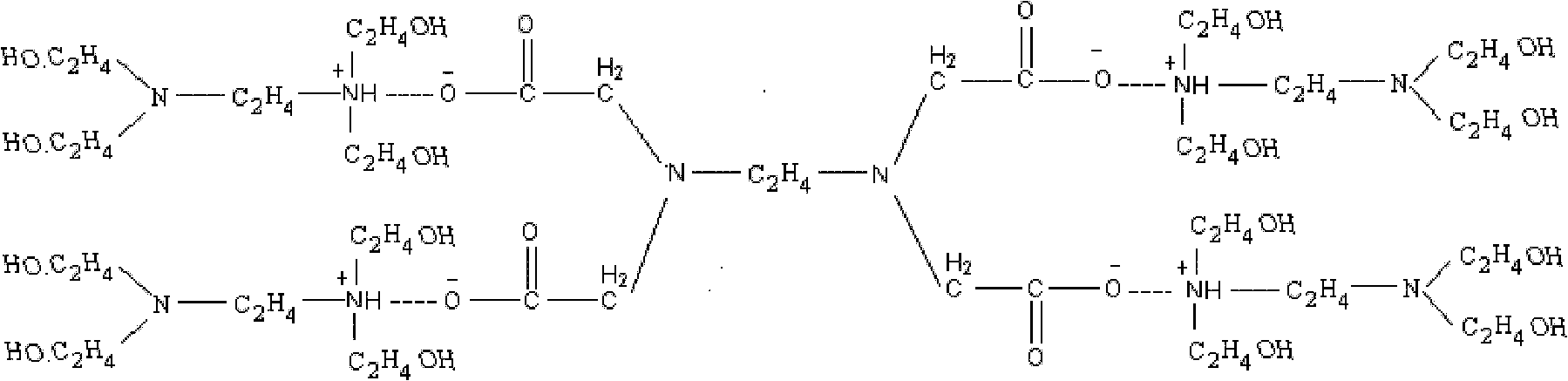

Preparation method for high-hardness waterborne polyurethane dispersion

ActiveCN104231209AImprove water resistanceImprove adhesionPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method for high-hardness waterborne polyurethane dispersion. An inorganic nano material and waterborne polyurethane are grafted through an in-situ polymerization method, so that the hybridization reaction of inorganic materials and the organic materials is realized and complementary advantages are realized. The preparation method comprises the following operation steps: adding polyisocyanate, macromolecule polyol, a catalyst, a chain extender and a silane coupling agent according to certain weight ratio in a flask for reacting to obtain a polyurethane prepolymer; after the reaction is ended, sequentially adding a neutralizer, inorganic nano material dispersion liquid and deionized water under the condition of low-temperature and high-speed stirring; finally, heating under the vacuum condition for removing the solvent to obtain the high-hardness waterborne polyurethane dispersion. Compared with the traditional inorganic and organic blending process, the preparation method has the characteristics that products prepared through the preparation method have the advantages of good stability, excellent water resistance, long-time aging resistance, excellent and high adhesion, high drying speed, high hardness, good fullness, higher light transmittance and the like, and are wide in application range.

Owner:江苏日出化工有限公司

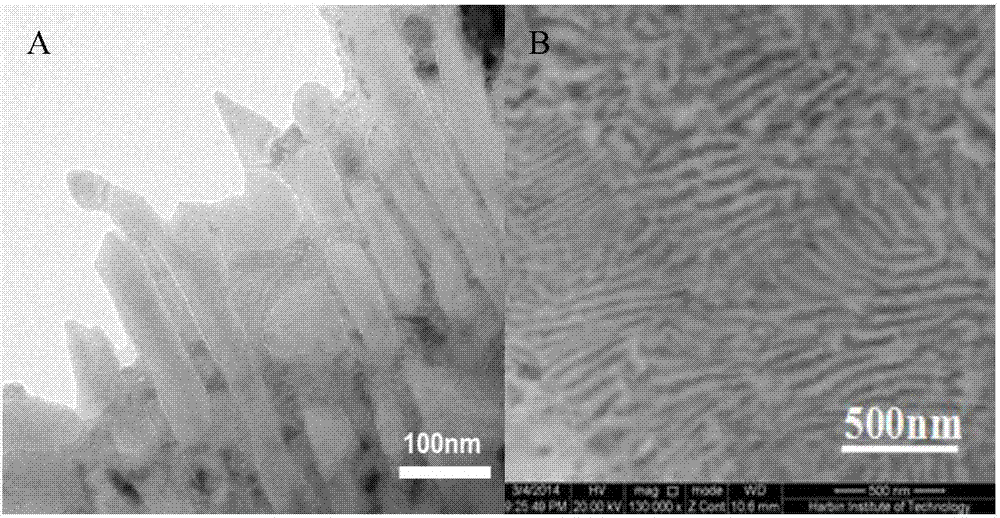

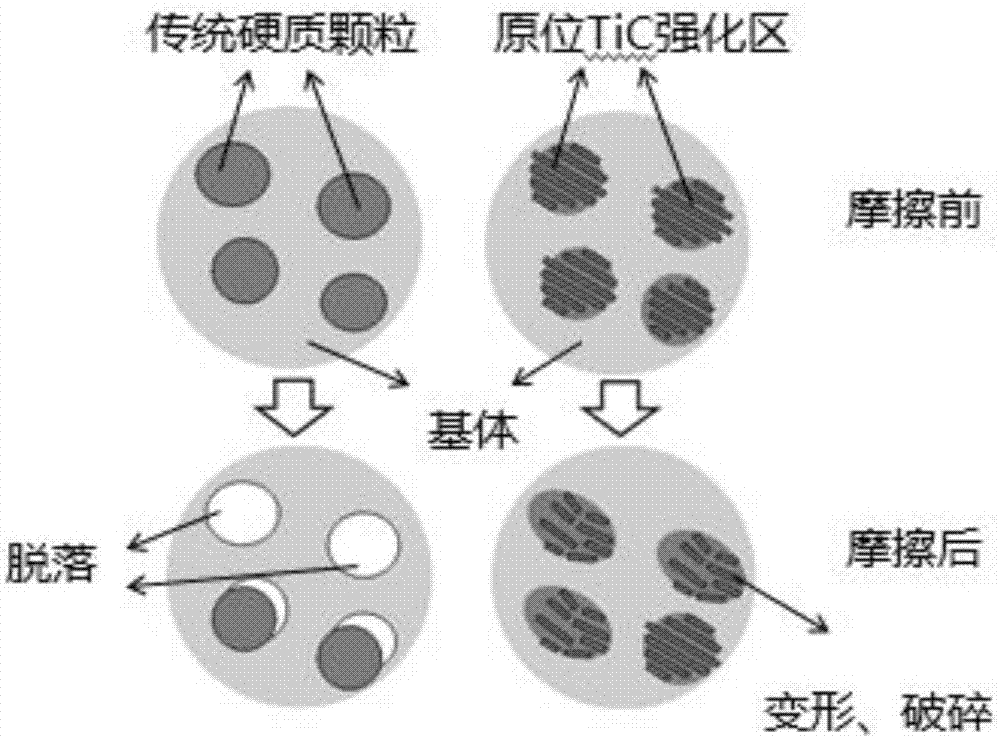

Brake pad material for high-speed railway passenger train and preparing method thereof

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

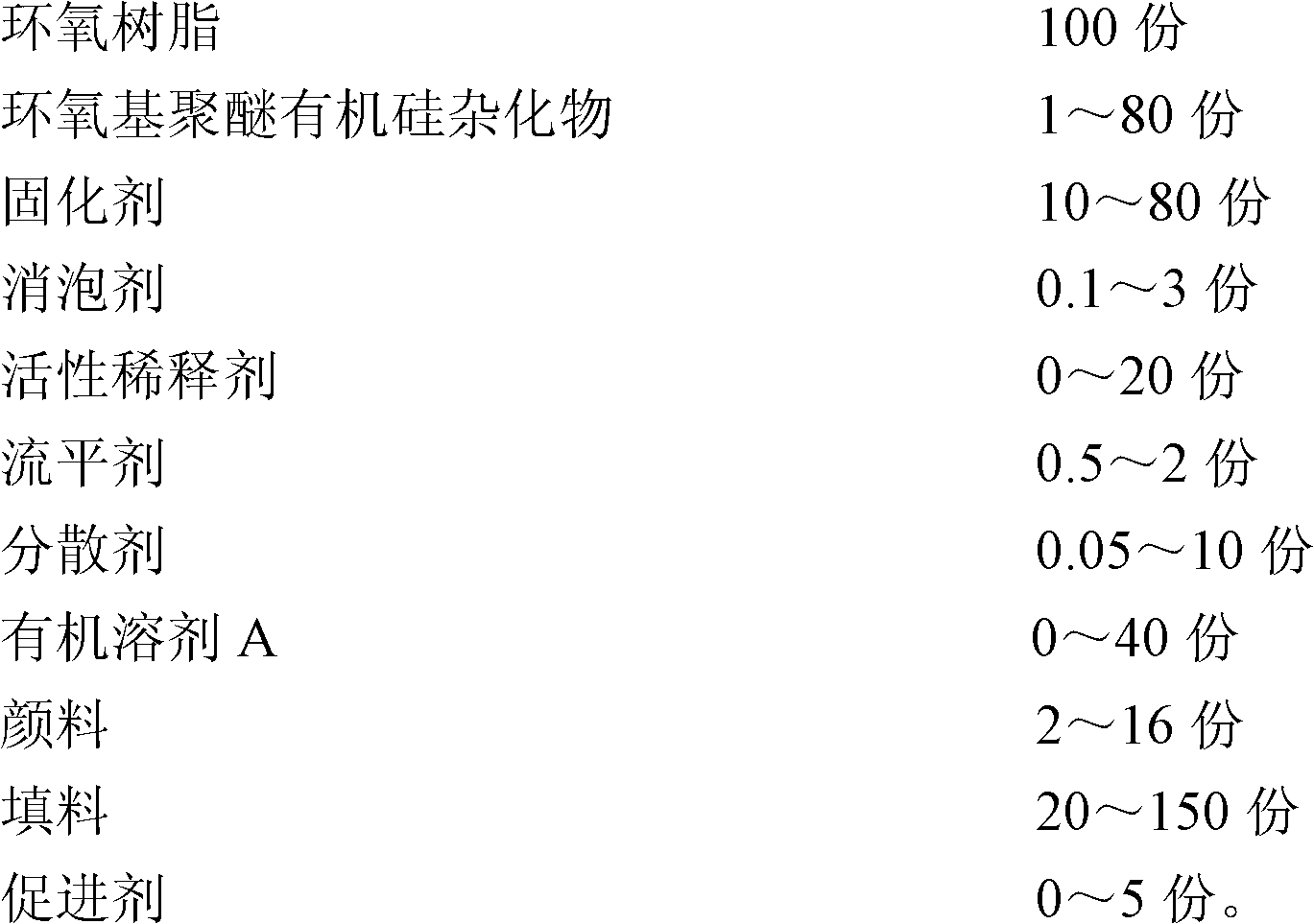

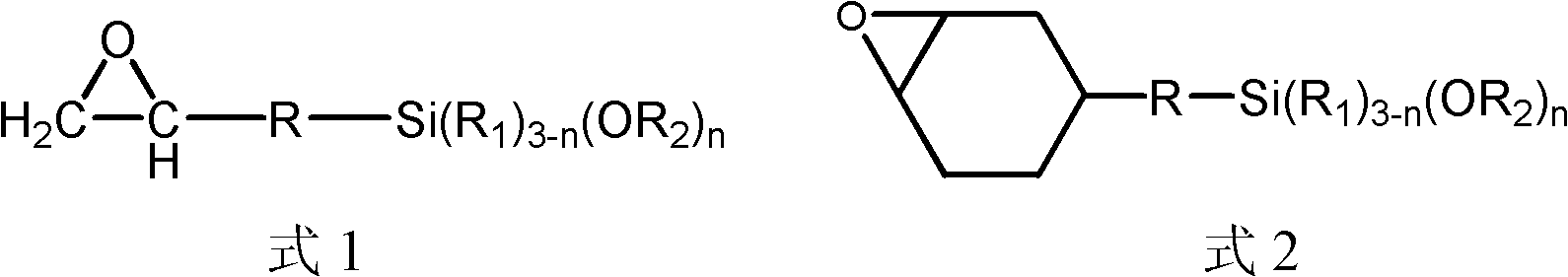

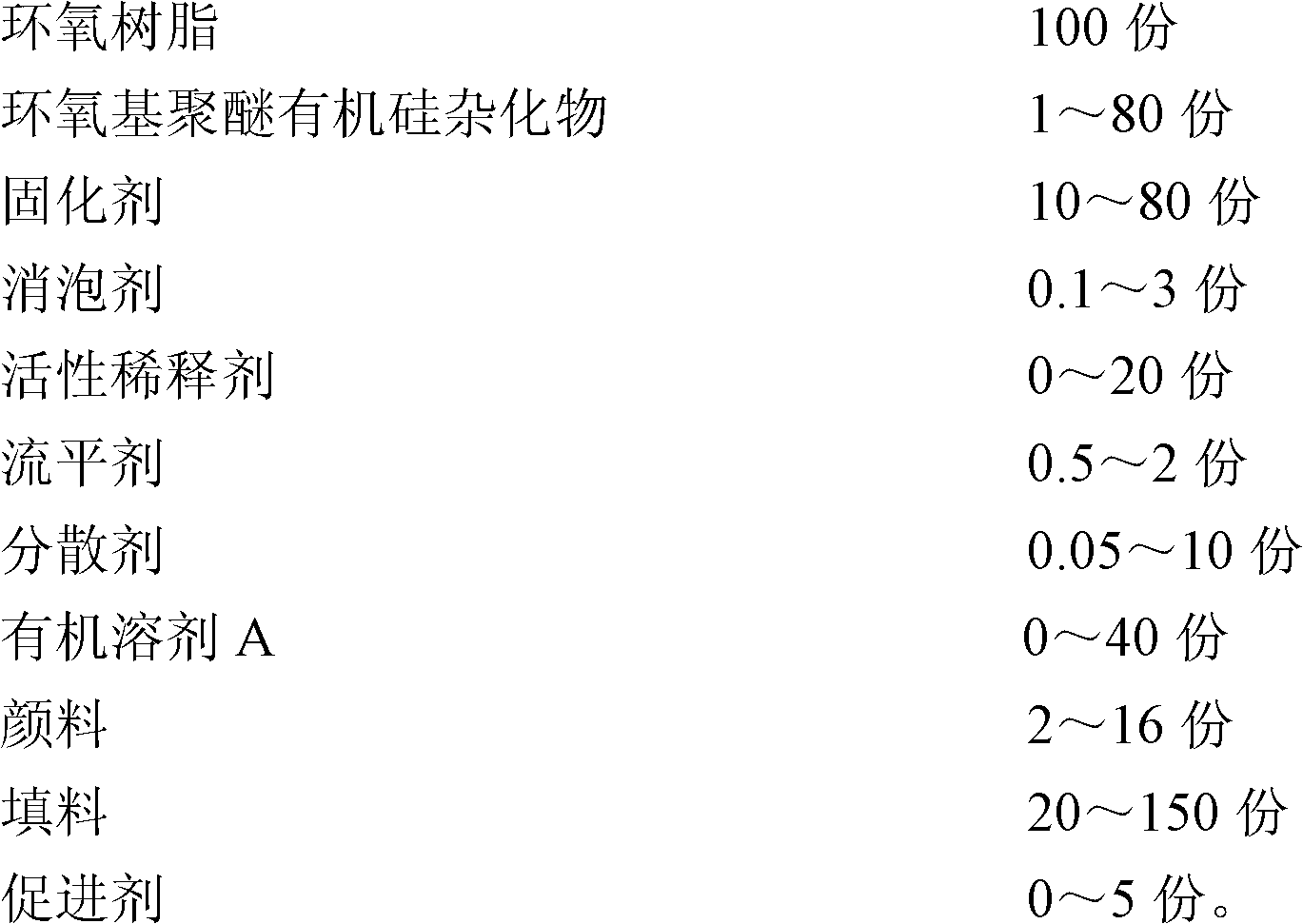

Epoxy floor coating containing epoxy polyether organosilicon hybrid and preparation method thereof

The invention discloses an epoxy floor coating containing epoxy polyether organosilicon hybrid and a preparation method thereof, belonging to the field of building materials. According to the method, the epoxy polyether organosilicon hybrid is prepared through hydrolytic polycondensation, and then 100 parts of an epoxy resin, 10 to 80 parts of a curing agent, 1 part to 80 parts of the epoxy polyether organosilicon hybrid, 0.1 part to 3 parts of an antifoaming agent, 0 to 20 parts of an active diluent, 0.5 part to 2 parts of a leveling agent, 0.05 part to 10 parts of a dispersant, 0 to 40 parts of an organic solvent, 2 to 16 parts of pigments, 20 to 150 parts of a filling material and 0 to 5 parts of a promoter are uniformly mixed so as to obtain the epoxy floor coating. Through modification by the epoxy polyether organosilicon hybrid, the epoxy floor coating provided in the invention has the following advantages compared to conventional epoxy floor coatings: a floor coated by the epoxy floor coating has a high hardness and good wear resistance, stain resistance and heat resistance; the preparation method has the advantages of a simple preparation process, easily available raw materials and convenient implementation, which enables production cost to be reduced and strong practicality to be obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Formula for making colour artificial stone and its production method

The present invention relates to a formula of colour artificial stone and its production process. its formula incldues (wt%) 10-20% of resin, 30-40% of colour cobblestone or colour stone powder, 20-30% of natural stone powder, 10-20% of filling material, 2-3% of hardening accelerator and 2-3% of adjuvant.

Owner:熊二明

Method for manufacturing purple mud pottery

The invention discloses a method for manufacturing purple mud pottery. The method comprises the following steps: selecting drying and crushing kaolin, red porcelain clay and yellow clay, adding water into the mixture, adding screened river sand to prepare mud, molding, drying in the shade, patching, manually manufacturing a mouth, a kettle handle and the like, assembling the mouth, the kettle handle and the like with a kettle body, polishing, performing press polish, drawing, sculpturing, carving, drying in the shade at low temperature, drying at medium temperature, drying at high temperature, firing in a kiln, discharging from the kiln to obtain a finished product. Because the raw material formula is improved, the large-scale kaolin and river sand are added on the basis of the original yellow clay and red porcelain clay, the density of the pottery products is improved, particularly the firing temperature is increased, the problems that the sintering hardness and the density can not be meet during low-temperature firing are solved, the problem that high-temperature firing water seepage can not be realized is solved, and the pottery is bright in color, ideal in air permeability and exquisite in workmanship and is a brand new pottery product.

Owner:SUILING TAOYUAN POTTERY CULTURE & ARTS DEV CO LTD

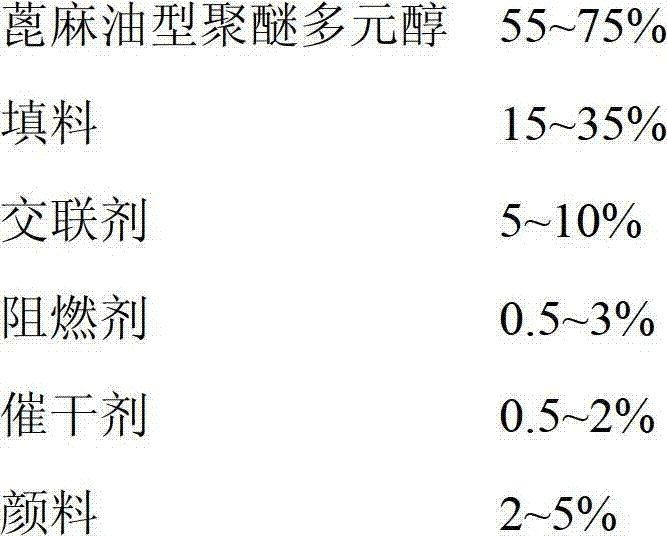

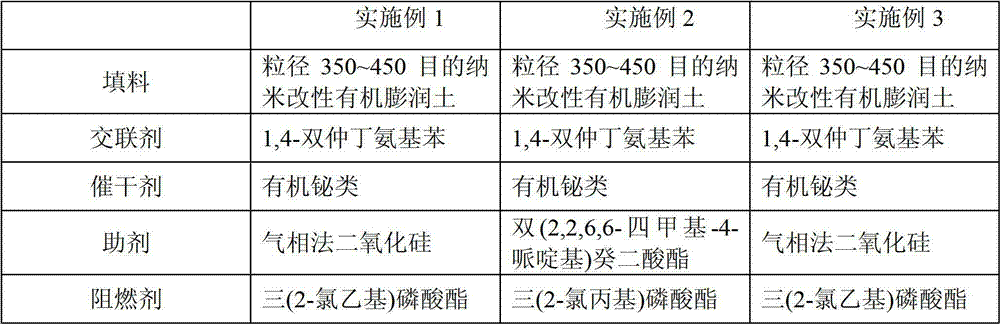

Polyurethane composition for jogging area of plastic venue and preparation method thereof

The invention relates to a polyurethane composition, in particular to a polyurethane composition for the jogging area of the plastic venue and a preparation method of the polyurethane composition. The polyurethane composition comprises the component A and the component B. The component A comprises 55-75% by mass of castor-oil type polyether polyol, 15-35% by mass of filler, 5-10% by mass of cross-linking agent, 0.5-3% by mass of flame retardant, 0.5-2% by mass of drier, 2-5% by mass of pigment, 0.1-2% of additive and 1-5% by mass of foaming agent. The component B comprises 50-60% by mass of castor-oil type polyether polyol and 40-50% by mass of isocyanate. The polyurethane composition solves the problems of high hardness, poor flexibility, low elongation, poor impact absorption performance and low vertical deformation of the conventional jogging area of the plastic venue, can better protect the joints of the athletes in the warm-up process and is beneficial to improving the competition achievements of the athletes. The preparation method of the polyurethane composition is easy and practical and is easy to implement.

Owner:SHANDONG INOV POLYURETHANE

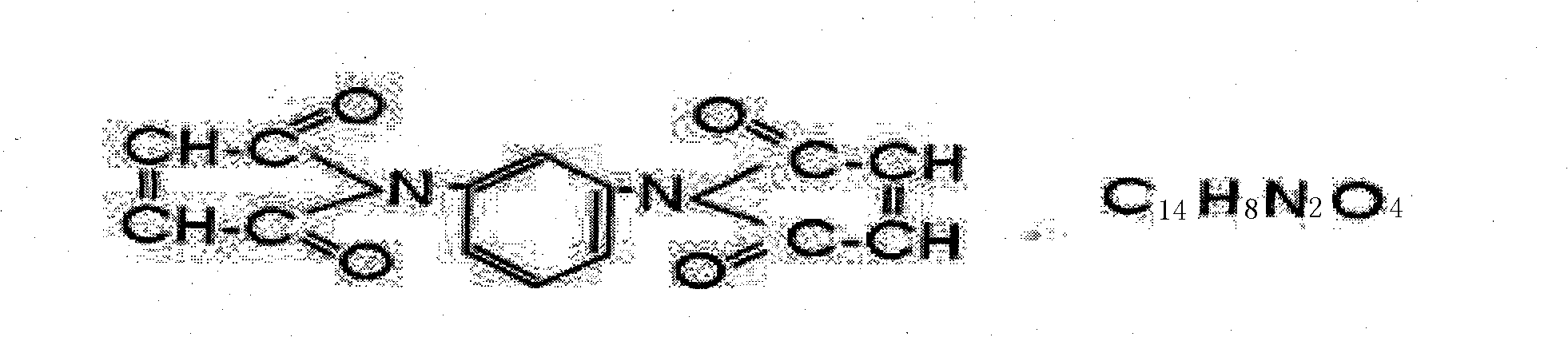

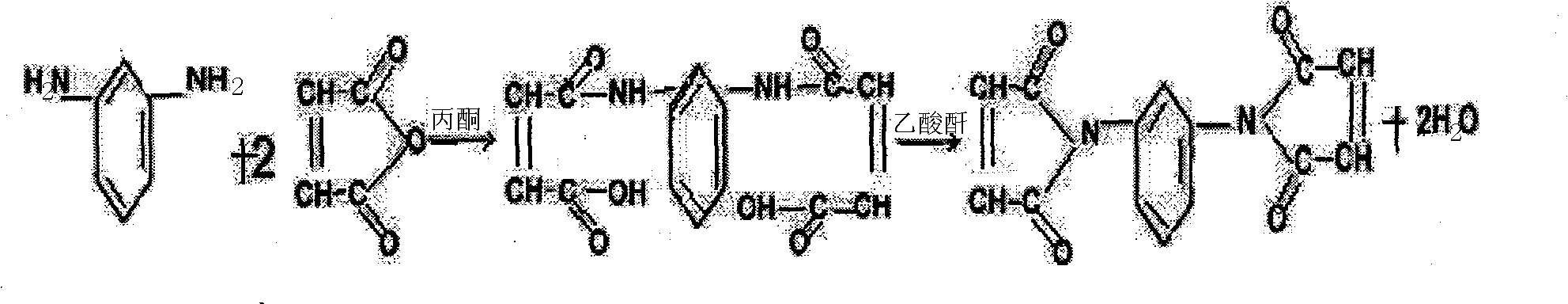

Preparation method of N,N'-m-phenylenebismaleimide

ActiveCN101805280ASolve the hardnessSolving Elasticity ProblemsOrganic chemistryPolymer scienceAcetic anhydride

The invention relates to a preparation method of N,N'-m-phenylenebismaleimide (HA-8). The preparation method is mainly technically characterized by firstly adding m-phenylenediamine in a reaction kettle equipped with a stirrer and a thermometer, then adding a solvent, stirring for fully dissolving the m-phenylenediamine, further adding maleic anhydride, keeping the temperature for 2 hours after completion, then adding acetic anhydride, completing the reaction, further evaporating, recovering the solvent of acetone, finally carrying out centrifugal washing for obtaining a crude product, drying, smashing and obtaining a finished product. The yield is calculated to be 91.5% by taking the m-phenylenediamine as a standard substance. The product is mainly used in natural rubber and various types of synthetic rubber, and can prevent reversion by being matched with sulfur, improve the heat resistance and the anti-aging property, reduce the heat production of the rubber and improve the bonding property between the rubber and metal fabric.

Owner:咸阳三精科技股份有限公司

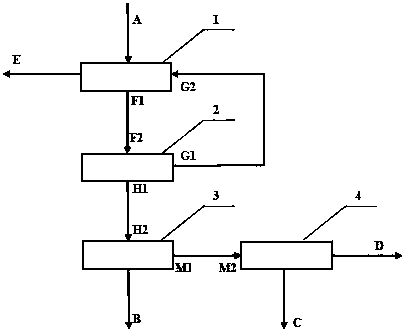

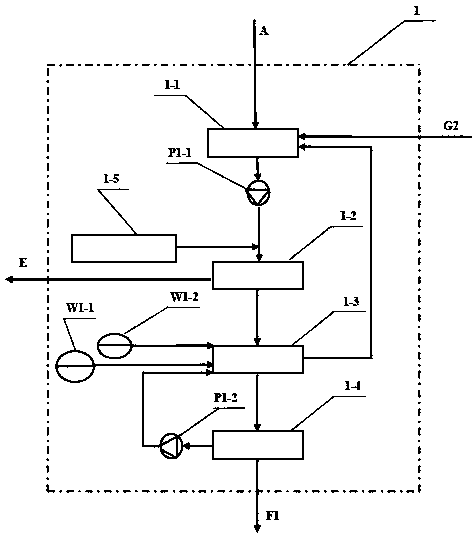

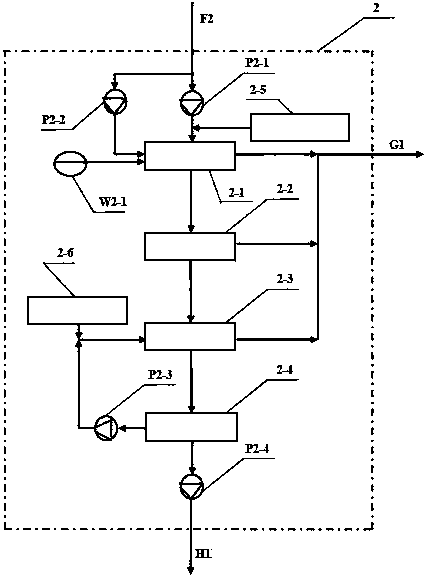

Brine waste water processing reusing device and method

ActiveCN104003569ASolve the hardnessEvaporation energy saving and high efficiencyMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention discloses a brine waste water processing reusing device and method. The structure of the device comprises a preprocessing system 1, an ultrafiltration processing system 2, a reverse osmosis processing system 3 and a negative pressure spray evaporation processing system 4. The device has the advantages that the device can be suitable for water draining, circulating water sewage draining, boiler sewage draining, demineralized water station resin regenerating water draining and the like of brine waste water primary treatment; organic pollutants and hardness in brine waste water are removed, and salinity is lowered; (3) the purposes of reusing and zero emission by efficient evaporating on thick water are achieved; (4) preprocessing, ultrafiltration and reverse osmosis are combined organically; (5) rolling type reverse osmosis and flat plate reverse osmosis are combined, and decrement is concentrated to the maximum degree; and (6) energy is saved, efficiency is high in low-temperature negative-pressure spray evaporation, and the purposes of reusing and zero emission are achieved.

Owner:安徽森诺膜技术有限公司

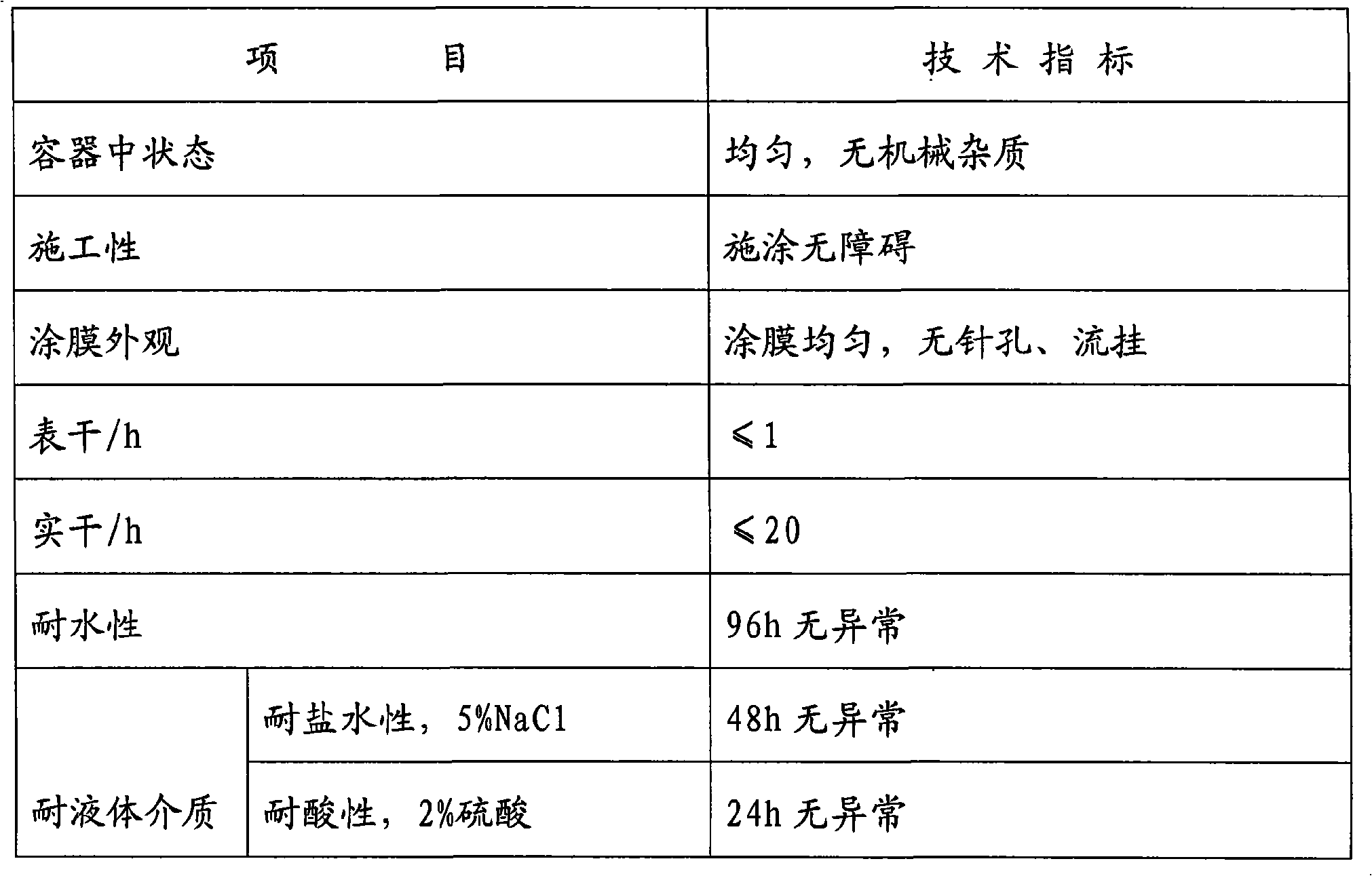

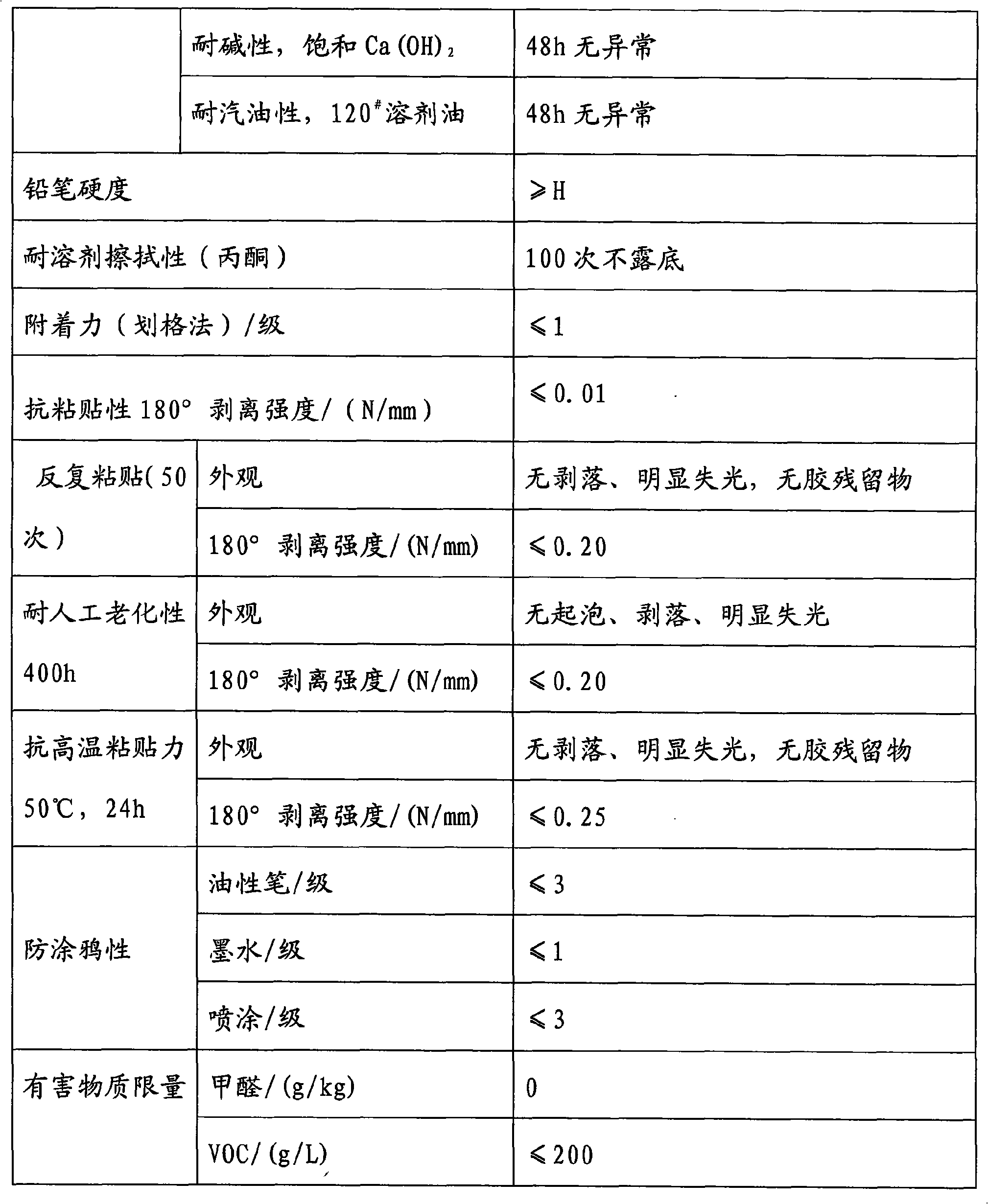

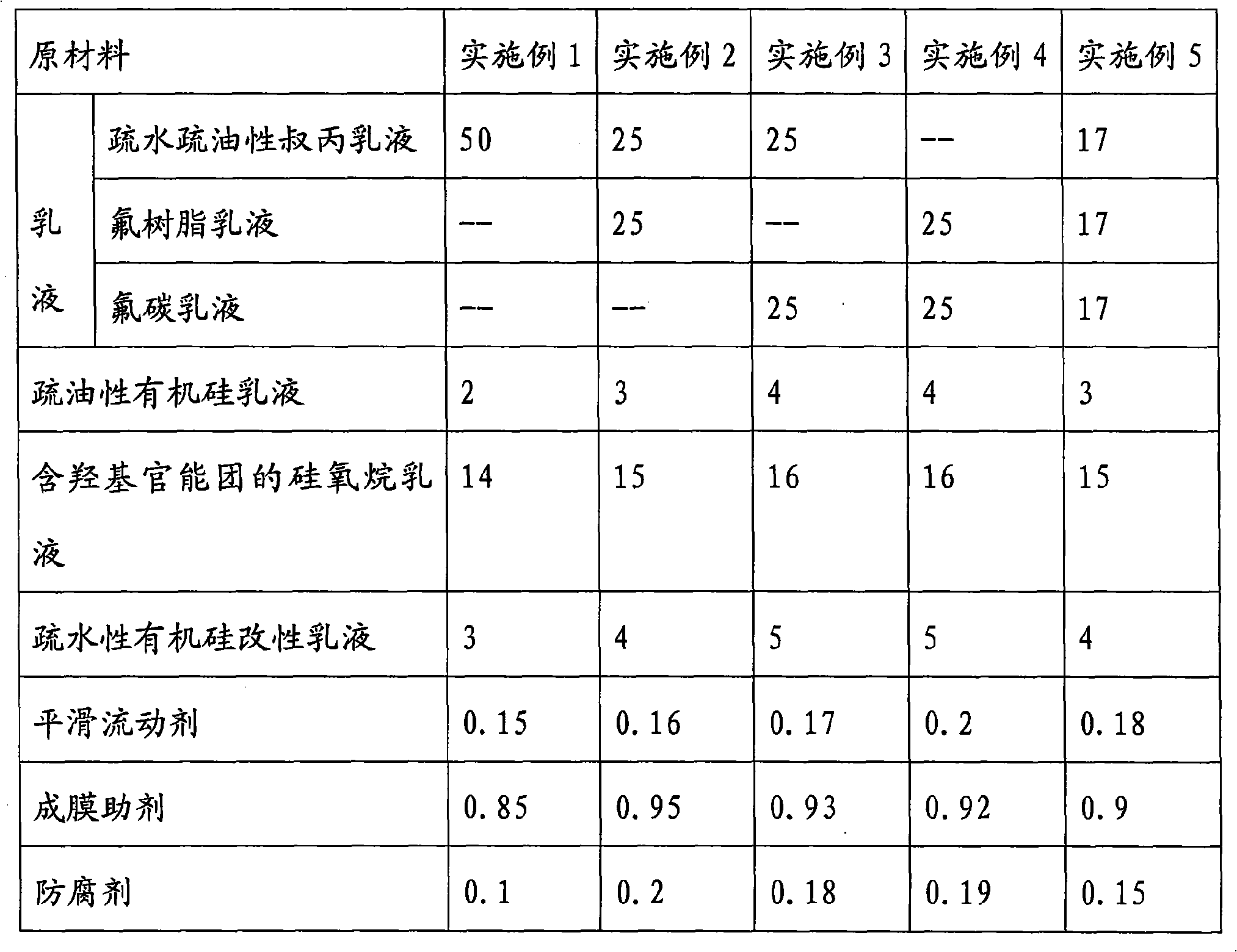

Aqueous anti-graffiti adhesion resistant paint and preparation method thereof

InactiveCN101585990AIncrease elasticityGood resistance to acid, alkali and saltCoatingsEmulsionPreservative

The invention discloses aqueous anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. The paint consists of the following components by weight portion: 50 to 55 portions of emulsion, 2 to 4 portions of organic silicon emulsion, 14 to 16 portions of siloxane emulsion containing hydroxy functional group, 3 to 5 portions of hydrophobic organic silicon modified emulsion, 0.15 to 0.2 portion of smooth flow agent, 0.85 to 0.95 portion of film forming assistant, 0.1 to 0.2 portion of preservative, 0.1 to 0.2 portion of mildew preventive, 0.8 to 1 portion of ethylene glycol, 5 to 7 portions of hydrophobic agent, 0.1 to 0.2 portion of thickening agent, and 23 to 25 portions of deionized water. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has zero formaldehyde, benzene and heavy metals, has low VOC, and is typical environment-friendly paint.

Owner:LANZHOU XUNMEI PAINT IND TECH

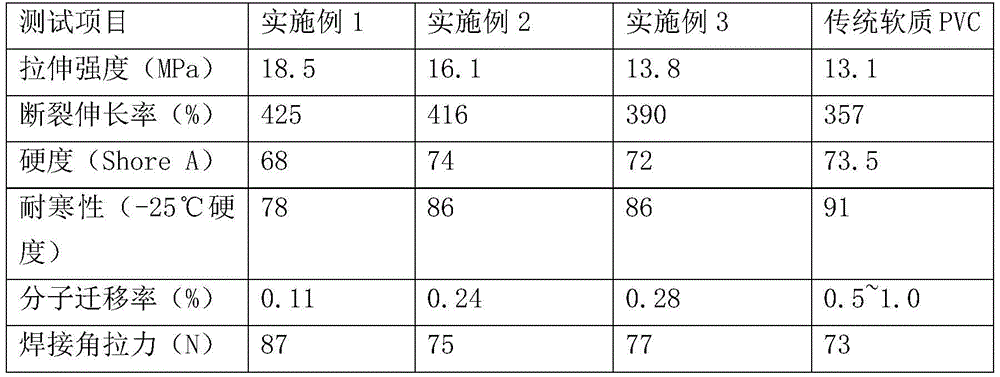

Modified polyvinyl chloride door seal and preparation method thereof

The invention belongs to the technical field of door seal materials, and relates to a modified polyvinyl chloride door seal and a preparation method thereof. The door seal is prepared from, by weight, 40-50 parts of polyvinyl chloride resin powder, 5-15 parts of anti-yellowing thermoplastic elastomer, 0-5 parts of 1,2-cyclohexane dicarboxylic acid di-isononyl ester, 5-20 parts of trioctyl trimellitate, 0-5 parts of dioctyl adipate, 5-10 parts of epoxidized soybean oil, 5-10 parts of polyester oligomer, 10-15 parts of filler, 1-3 parts of a stabilizer, 1-3 parts of a compatilizer, 1-3 parts of a lubricating agent and 0.1-1 part of pigment. Fat diisocyanate is two of hexamethylene diisocyanate (HDI), isophorone diisocyanate (IPDI) and hexamethylene diisocyanate (HMDI). The defects that the hardness of a traditional soft PVC door seal is sharply increased at low temperature and elasticity becomes poor are overcome, the tensile strength and the breaking elongation of the door seal are improved, the welding angle pull force of the door seal is increased, and the service life of the door seal is prolonged.

Owner:QINGDAO NEW MATERIAL TECH IND PARK DEV

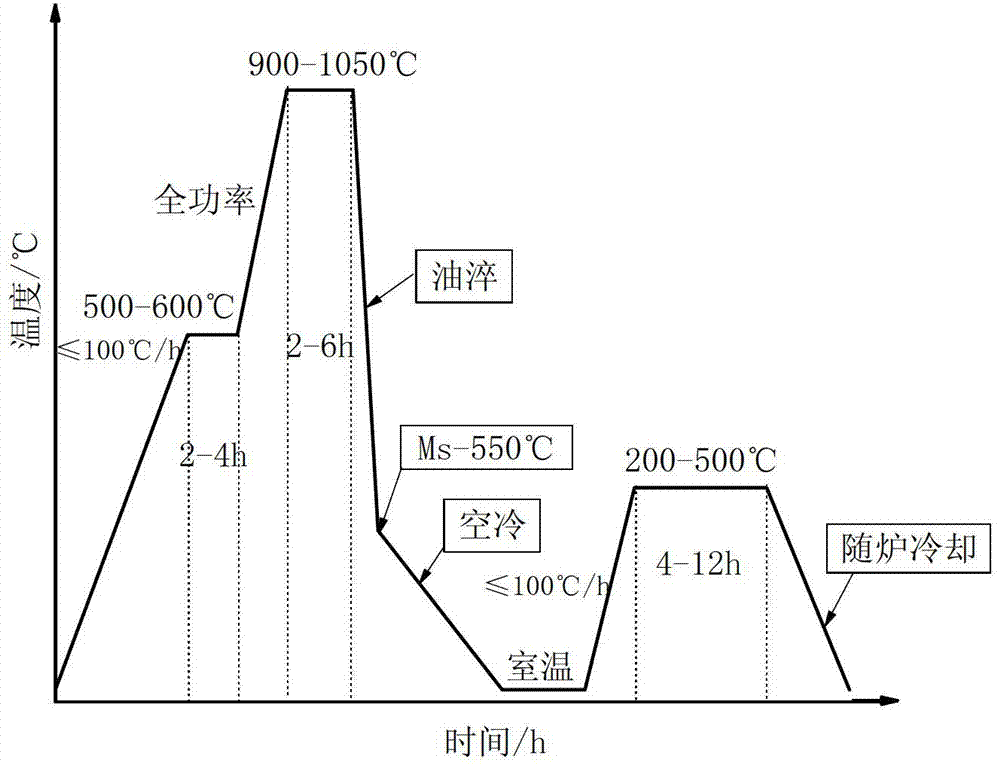

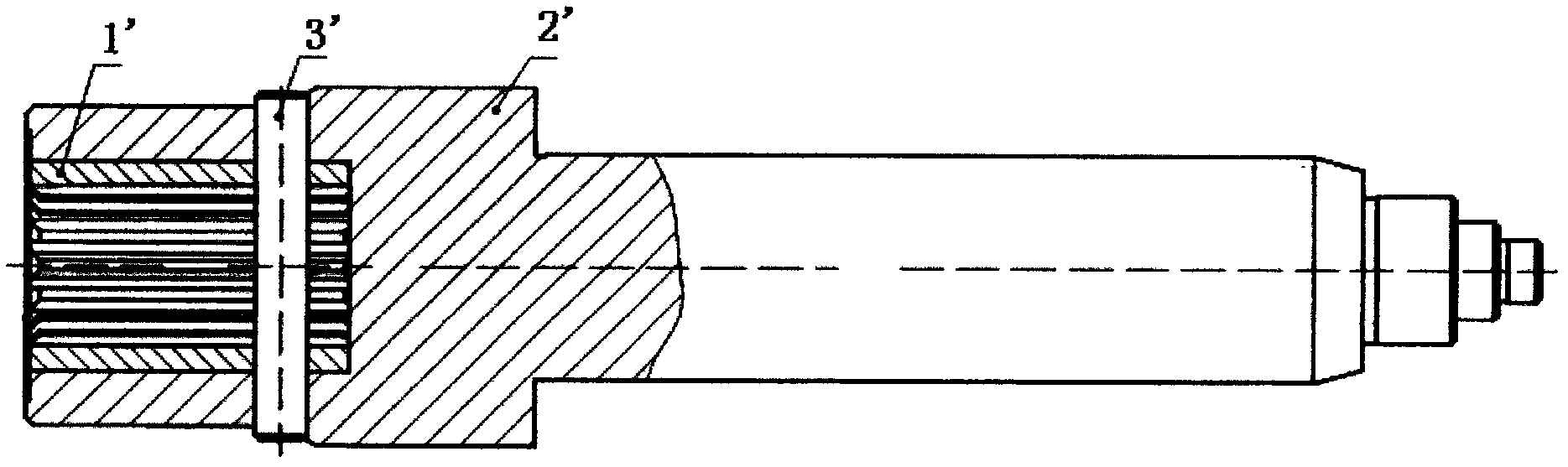

Two-stage quenching heat treatment process method of crusher combined hammer head and special device thereof

ActiveCN103243210AHigh hardnessCool evenlyFurnace typesHeat treatment furnacesRoom temperatureHardness

The invention relates to a heat treatment technology of an abrasion-resistant material, and particularly relates to a two-stage quenching heat treatment process method of a crusher combined hammer head and a special device thereof. The two-stage quenching heat treatment process method comprises the following steps of: orderly hanging hammer heads with the same spacing on the special device; uniformly charging into a furnace, heating to 900-1050 DEG C, keeping temperature for 2-6 hours, and then fast placing into an oil groove which contains quenching oil with 2-5 times hammer head weight sum (small batch) or hammer head weight and special device weight sum (large batch) for oil quenching; when the surface temperature of the head parts of the hammer heads enters the temperature interval of Ms-500 DEG C, taking out and air-cooling to room temperature; and carrying out medium and low temperature tempering at 200-500 DEG C so that the hardness of the head part material high-chromium cast iron of the crusher combined hammer head more than 60 HRC (Rockwell hardness). The two-stage quenching heat treatment process method disclosed by the invention successfully solves the technical problems of cracking, extremely low air-cooling hardness, and the like of the traditional oil quenching in the actual production of the crusher combined hammer head by dint of the special heat treatment device, adopting an oil cooling-air-cooling two-stage quenching method and controlling the weight proportion of a quenching medium and a workpiece.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Superfine glass fiber cotton felt for photocatalytic air purification and preparation method thereof

ActiveCN111892330AImprove filtration efficiencySmall filter resistanceGlass making apparatusDispersed particle separationGlass fiberNanoparticle

The invention relates to a superfine glass fiber cotton felt for photocatalytic air purification and a preparation method thereof, and belongs to the technical field of functional composite materials.The superfine glass fiber cotton felt consists of the following components in percentage by mass: 83 to 92 weight percent of superfine glass fiber, 6 to 8 weight percent of photocatalytic nanoscale particles and 1 to 3 weight percent of bonding system. The invention also relates to a preparation method of the superfine glass fiber cotton felt for photocatalytic air purification. The preparation method comprises the following steps: uniformly atomizing and spraying turbid liquid containing photocatalytic nanoparticles and a bonding system on the surface of the superfine glass fiber prepared bya flame blowing method, and drying to obtain the superfine glass fiber cotton felt for photocatalytic air purification. Compared with a traditional glass fiber filter cotton felt, the superfine glassfiber cotton felt for photocatalytic air purification has the advantages that the function of eliminating bacteria and volatile organic compounds (TVOC) in air is added, the superfine glass fiber cotton felt is rapidly decomposed under visible light, the filtering efficiency is higher, the filtering resistance is lower, and the machining strength is better.

Owner:CHONGQING UNIV OF ARTS & SCI

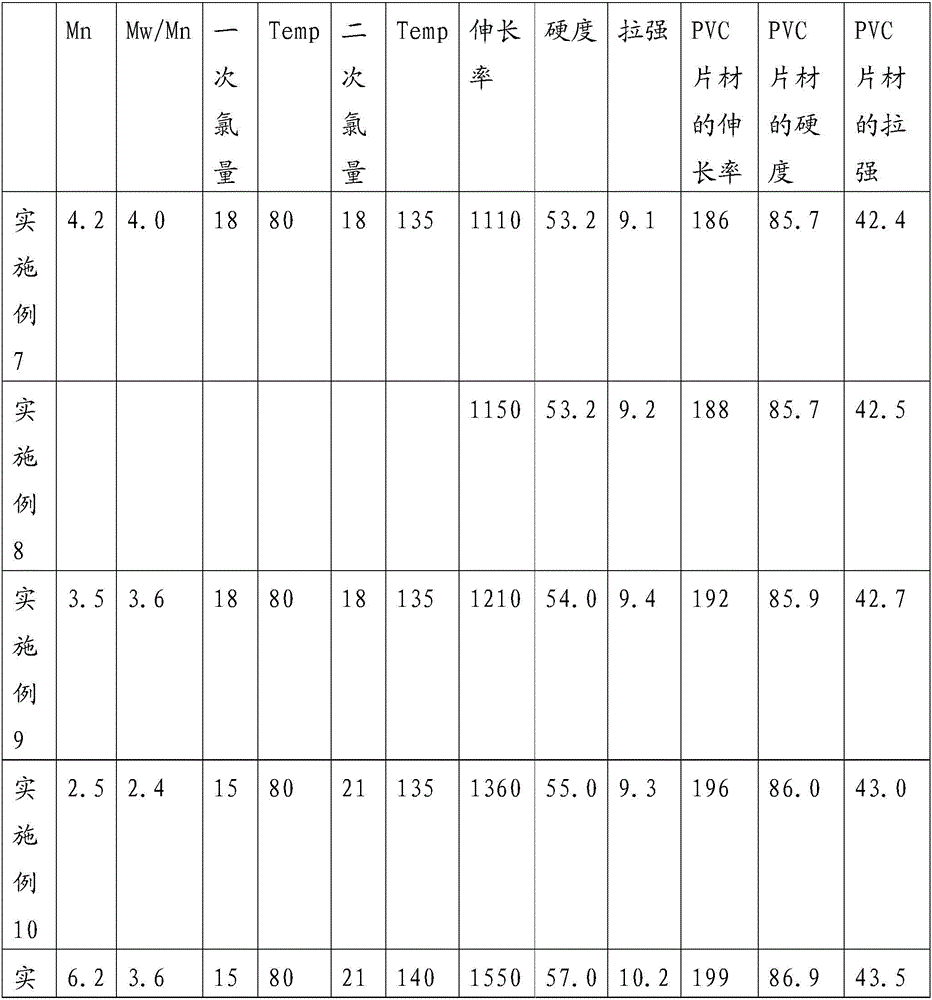

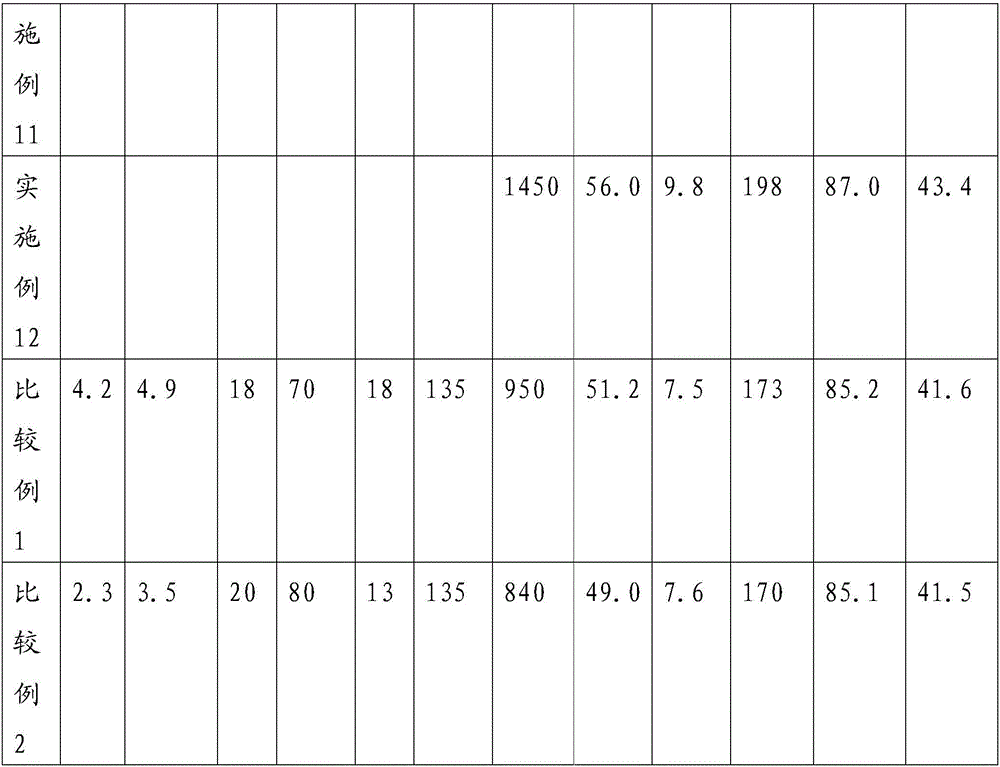

Polyvinyl chloride low temperature toughening modifier and polyvinyl chloride mixture containing same

InactiveCN105693891ADoes not reduce hardnessNo reduction in tensile strengthPolyvinyl chlorideHardness

The invention discloses polyvinyl chloride low temperature toughening modifier and a polyvinyl chloride mixture containing the same. The low temperature toughening modifier is rubber powder with the elongation at break being 1000-1600%, hardness being greater than 53.0%, and tensile strength being greater than 9.0; the polyvinyl chloride mixture comprises, by weight, 100 parts of polyvinyl chloride resin, 1-30 parts of the low temperature toughening modifier, 0.5-5 parts of a stabilizing agent, 0-50 parts of filler, 0-50 parts of wood powder, 0-10 parts of acrylic polymer, 0-20 parts of shock-resistant modifier, 0-5 parts of lubricant and 0-10 parts of pigment. When PVC is modified by the low temperature toughening modifier, on the premise that hardness and tensile strength of the PVC are basically not influenced, the elongation at break of a hard PVC product can be remarkably improved.

Owner:SHANDONG RIKE PLASTIC RUBBER TECH CO LTD

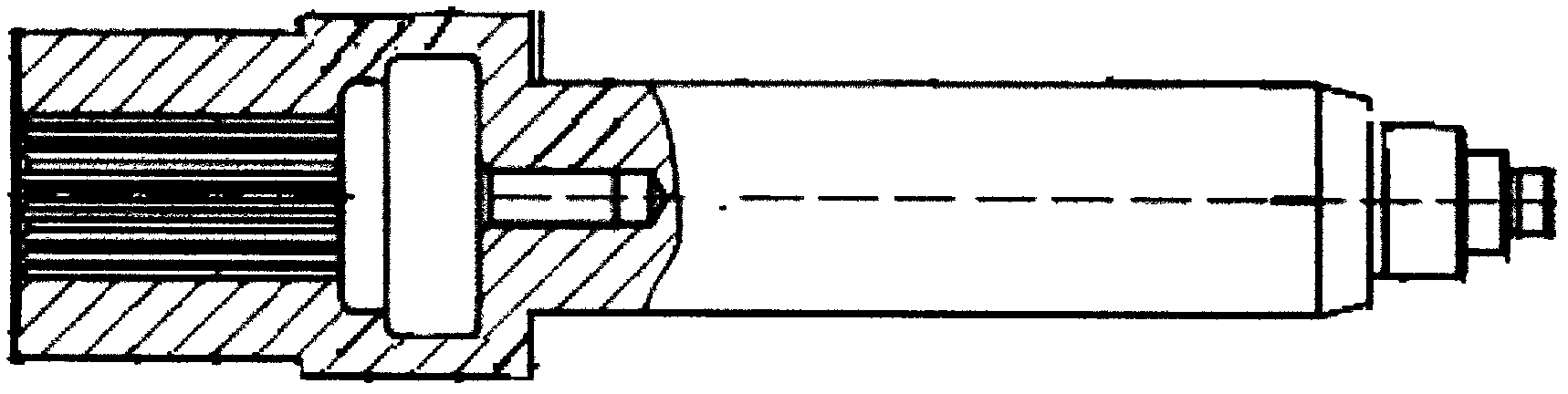

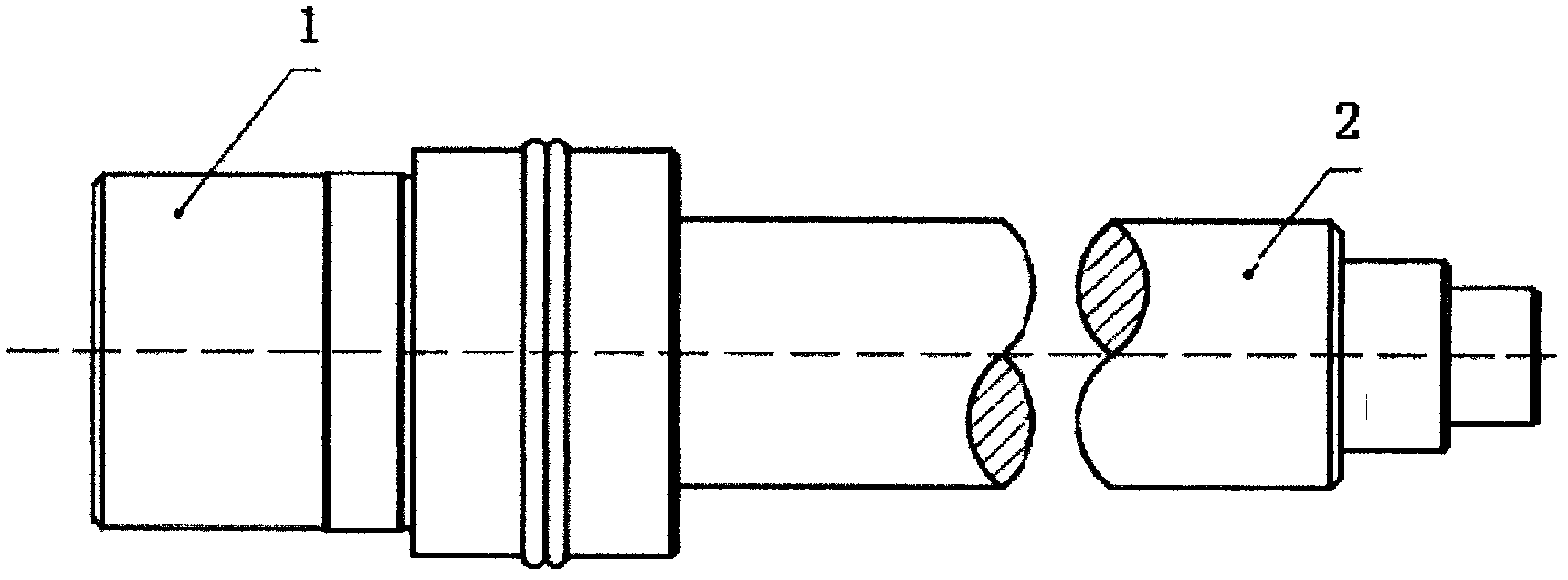

Internal spline shaft and preparation method thereof

The invention discloses an internal spline shaft and a preparation method thereof. The internal spline shaft comprises a head part and a tail part, and the head part and the tail part are connected through friction welding. The preparation method comprises the following steps of: preparing a head part blank of the internal spline shaft by using alloy steel subjected to hardening and tempering; carrying out nitriding or carburizing treatment on the head part blank; pressing a core shaft in an internal spline of the head part blank to carry out coarse grinding; preparing a tail part blank of the internal spline shaft by using alloy steel; carrying out friction welding on the head part blank and the tail part blank so as to form an integral structure; and pressing a core shaft into an internal spline of the head part of the integral structure, and then carrying out cylindrical grinding processing on the integral structure by using a double-centre method so as to obtain a finished product. The internal spline shaft disclosed by the invention is obtained directly by way of two-section friction welding; the internal spline shaft is simpler in process, high in precision and long in service life; the preparation method is high in production efficiency, and a spline tooth is processed by using a broaching machine, thereby effectively ensuring the precision of the spline; and the heat treatment mode of the internal spline shaft is a nitriding or carburizing mode, so that the contradiction between the surface hardness and the core strength of the spline tooth is solved.

Owner:NINGBO JIECHENG AXLE TRADE

Natural wood dyeing method and natural wood dyeing dye

InactiveCN107699053AImprove permeabilitySolve the colorability of dyeingWood treatment detailsPulp and paper industryTannin

The invention discloses a natural wood dyeing method and a natural wood dyeing dye. According to the present invention, the dyeing solution of the present invention and tannin contained in wood are subjected to a chemical reaction, such that the dyed color is natural, the texture are clear, and the penetration depth of the color is 1.0-2.0 mm; the oxidation color of the dyed wood has advantages ofdelayed fading, beautiful outlook and applicability; and with the method and the dye, the technical problems of poor physical properties such as coloring, dyeing uniformity, dimensional stability, hardness and the like of the wood dyeing in the prior art can be solved, and the upgrading of the low-grade wood is promoted.

Owner:张萱

Method for obtaining micro-nano SiO2 particle containing coating on surface of aluminium and aluminium alloy

ActiveCN102899644ASolve the hardnessSolve wear resistanceLiquid/solution decomposition chemical coatingMicro nanoChemical plating

A method for obtaining a micro-nano SiO2 particle containing coating on a surface of aluminium and aluminium alloy. Samples are firstly subjected to alcohol immersing, chemical removing for oil and alkali, acid erosion, water washing and zinc dipping, and finally pre-treated by acetone and alcohol ultrasonic cleaning; SiO2 nanometer particles are placed in a non-ionic surface active agent OP-21 to immerse; and then the samples are subjected to composite chemical plating and washed by cold water to obtain the finished product. The method is reasonable in technology and easy to operate, can produce the coating just by using equipment of traditional nickel-phosphorous chemical plating technology, and has relatively good economic benefit and popularization prospect. The obtained coating is compact and firm, and has advantages of good combinability, uniform surface, high hardness, wear resistance, heat resistance and high comprehensive properties; and hardness and wear resistance of the obtained coating are all higher than that of single nickel-phosphorus coatings. The active agent is nontoxic, environmentally-friendly, highly-efficient, simple in formula, easy to operate and low in cost.

Owner:柳州一阳科技股份有限公司

Potato whole flour and staple food prepared by employing same

InactiveCN104886504AReasonable retention of nutrientsKeep the quality reasonablyFood preparationPotato starchHardness

The invention belongs to the technical field of food processing. In order to solve the problems that the existing potato whole flour is relatively high in processing cost and relatively complex in processing step while the existing potato whole flour which is used for manufacturing staple food products is hard to mold, is great in hardness and is not resistant to cooking, the potato whole flour is low in content, the cost for manufacturing a potato food made of flour is high and the like, the invention provides potato whole flour and staple food prepared by employing the potato whole flour. The preparation method of the potato whole flour comprises the following steps: choosing raw materials; cleaning and peeling the raw materials; selecting the raw materials; cutting the raw materials into slices; blanching the raw materials; cooling and drying the raw materials; and pulverizing the raw materials. The potato whole flour is mixed with oat flour to prepare steam buns; the potato whole flour is mixed with wheat flour and potato starch to prepare noodles; the potato whole flour is mixed with wheat flour to prepare cakes; the potato whole flour is mixed with potato starch to prepare dough and dumpling wrappers; and the potato whole flour is mixed with oat flour and potato starch to prepare Helaomian (a kind of noodles). The staple food preparation process is time-saving, simple and convenient and the prepared food is suitable for the public to eat, the popularization is facilitated, and the potato flour is industrially produced and is stable in quality; the staple food is easy to mold, is tenacious, is complete in nutrition and is good in taste.

Owner:SHANXI SHUYAN FOOD

Novel printing technology of low-temperature bright golden pattern paper

InactiveCN104553407ANo pollutionLow costDuplicating/marking methodsOther printing apparatusEngineeringTemperature resistance

The invention discloses a novel printing technology of low-temperature bright golden pattern paper. The novel printing technology is characterized in that aiming at the defect of traditional bright golden pattern paper and the recent development trend of the bright golden pattern paper, a substitute of golden paste is researched to reduce the production cost and the product price; a substitute of pigment containing harmful heavy metal objects such as lead, cadmium and lithium and the recycling of byproducts during printing are researched to avoid resource waste; low-temperature enamel firing adhesion is researched to reduce energy source consumption, the breakage rate of attached objects and atmospheric pollution; a driving roller which is used for carrying out heat sealing on a heat-sealed material is appropriate in hardness, is good in elasticity and toughness and can be kept smooth in a long time, and the heat-sealed material is enabled to be uniformly heated. According to the novel printing technology disclosed by the invention, through the design concept of energy conservation and emission reduction, environment protection and low carbon economy, the defect in a traditional technology is improved, and the performance of products in aspects such as abrasion resistance, high temperature resistance and safety is effectively increased.

Owner:LUZHOU JINXIN PRINTING

Hard alloy with gradient cobalt content and preparation method thereof

The invention belong to the technical field of hard alloy production and discloses a hard alloy with gradient cobalt content and a preparation method of the hard alloy. The method comprises the following steps of performing ball milling and spray drying respectively on a mixture A and a mixture B for granulation, and then simultaneously performing press molding and sintering treatment on the mixture A and the mixture B to obtain the hard alloy with gradient cobalt content. The problems that a product cannot keep good hardness, wear resistance or toughness at the same time can be effectively solved by the hard alloy with gradient cobalt content and the preparation method of the hard alloy by means of adjusting the composition and proportion of raw materials, changing the traditional pressing forming mode, formulating a corresponding production process and using hard alloy combination raw materials with different particle sizes and cobalt content.

Owner:株洲金韦硬质合金有限公司

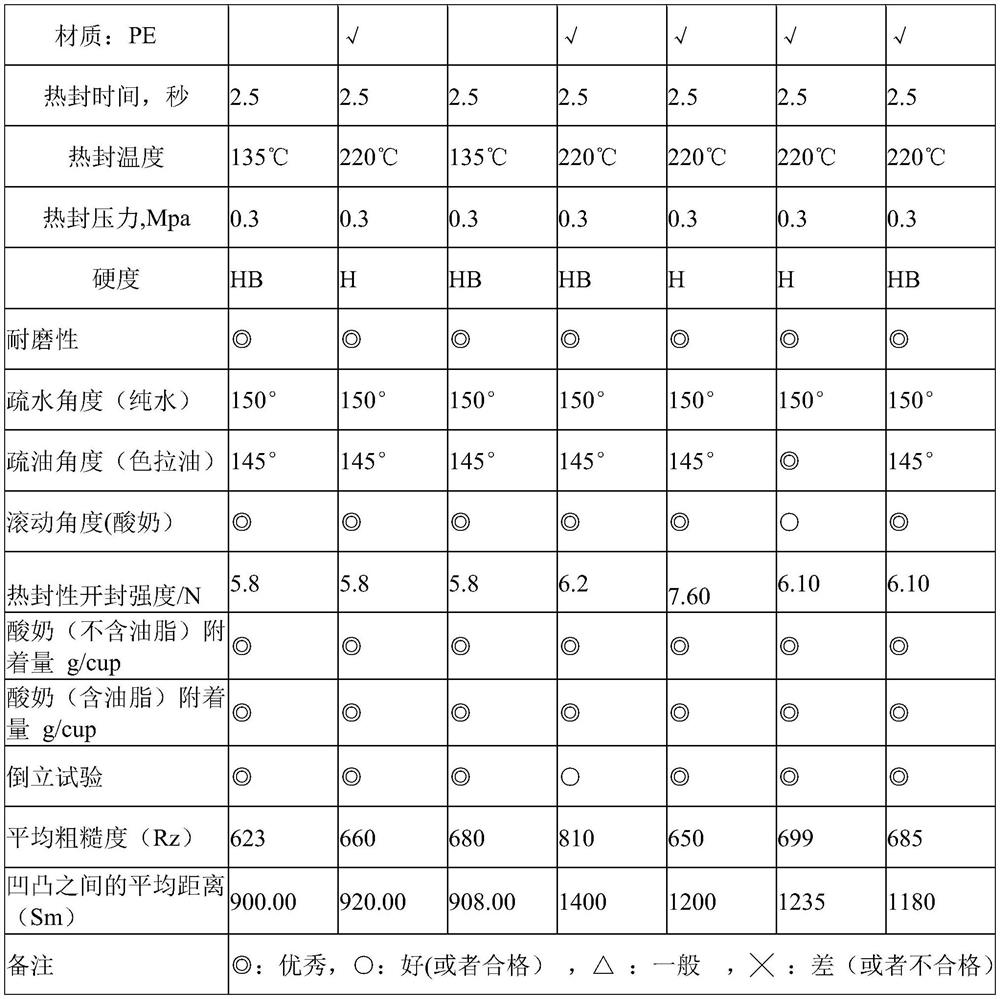

Wear-resistant food-grade super-hydrophobic nano-coating without adhesion to yoghourt

The invention discloses a wear-resistant food-grade super-hydrophobic nano-coating without adhesion to yoghourt. The invention aims to disclose the wear-resistant food-grade super-hydrophobic nano-coating without adhesion to yoghourt. The coating that coats a composite PE film or a composite EVA film in a roller coating manner has super-hydrophobic property, good hardness, strength, wear resistance, good heat sealability, no powder falling, no adhesion to yoghourt and the like, and is particularly suitable for the current food packaging industry without equipment modification, and the aim of the invention can be fulfilled by adopting conventional roller coating equipment for construction. According to a technical scheme in the invention, the coating comprises a bottom coating and a surfacecoating. The bottom coating comprises the following components in parts by weight: 4-12 parts of heat-sealing resin of modified ethylene-vinyl acetate copolymer resin, 2-12 parts of organic polysilazane resin, 0.5-4 parts of a hydrogenated styrene-butadiene segmented copolymer elastomer, 1-2 parts of chlorinated polypropylene resin, 5-15 parts of modified nanoparticles, 2.5-7.5 parts of zinc oxide whiskers, 0.25-1 part of a catalyst and 50-80 parts of a mixed organic solvent. The surface coating comprises the following components in parts by weight: 5-10 parts of a low-surface-energy substance and 90-95 parts of ethanol.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

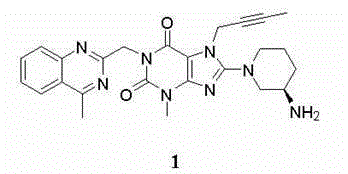

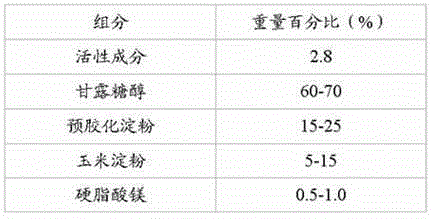

Granisetron hydrochloride orally disintegrating tablets

InactiveCN101095679ADisintegrates quicklyHigh dissolution releaseOrganic active ingredientsDigestive systemOrally disintegrating tabletFreeze-drying

The invention relates to granisetron hydrochloride mouth slaking tablet and the formula and preparing process. The process employs rotary oscillating granulator to produce said slaking agent through direct sheeting method after heat extrusion by melting and gradient cooling. When compared with mouth slaking agent produced with normal melting method, the mouth slaking agent in this invention is characterized by faster slaking speed, higher dissolution rate, intact tablet outlook, stronger rigidity and good taste. If compared with current freeze drying, vacuum drying, spray drying technique, the invention is characterized in that it needs no special production device and condition, no special package, the production process is simple, quality is stable and suitable for industrial production. It provides new products for patients that is dysphagia and bedridden, for old people and children, especially for patients suffering tumor chemotherapy and radiotheraphy.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

Flame-retardant inorganic interior wall coating and preparation method thereof

PendingCN110396311AIncrease flame retardancyReduce surface temperatureFireproof paintsAntifouling/underwater paintsCrack resistanceHydroxyethyl cellulose

The invention provides a flame-retardant inorganic interior wall coating and a preparation method thereof. The coating is prepared by mixing the following components comprising, by weight, 250-315 parts of deionized water, 3-5 parts of hydroxyethyl cellulose, 0.5-2 parts of bentonite, 3-8 parts of a stabilizer, 1-5 parts of a defoaming agent, 1-2 parts of a preservative, 100-250 parts of magnesiumhydroxide, 90-190 parts of titanium dioxide, 30-80 parts of calcined kaolin, 50-80 parts of 800# heavy calcium carbonate, 150-230 parts of inorganic potassium silicate, 50-100 parts of a styrene-acrylic emulsion and 2-5 parts of a thickener. The paint has the characteristics of flame retardancy, compactness, multicolor, scratch resistance, cracking resistance, dew formation resistance, mildew resistance, stain resistance, easiness in scrubbing and good storage stability.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

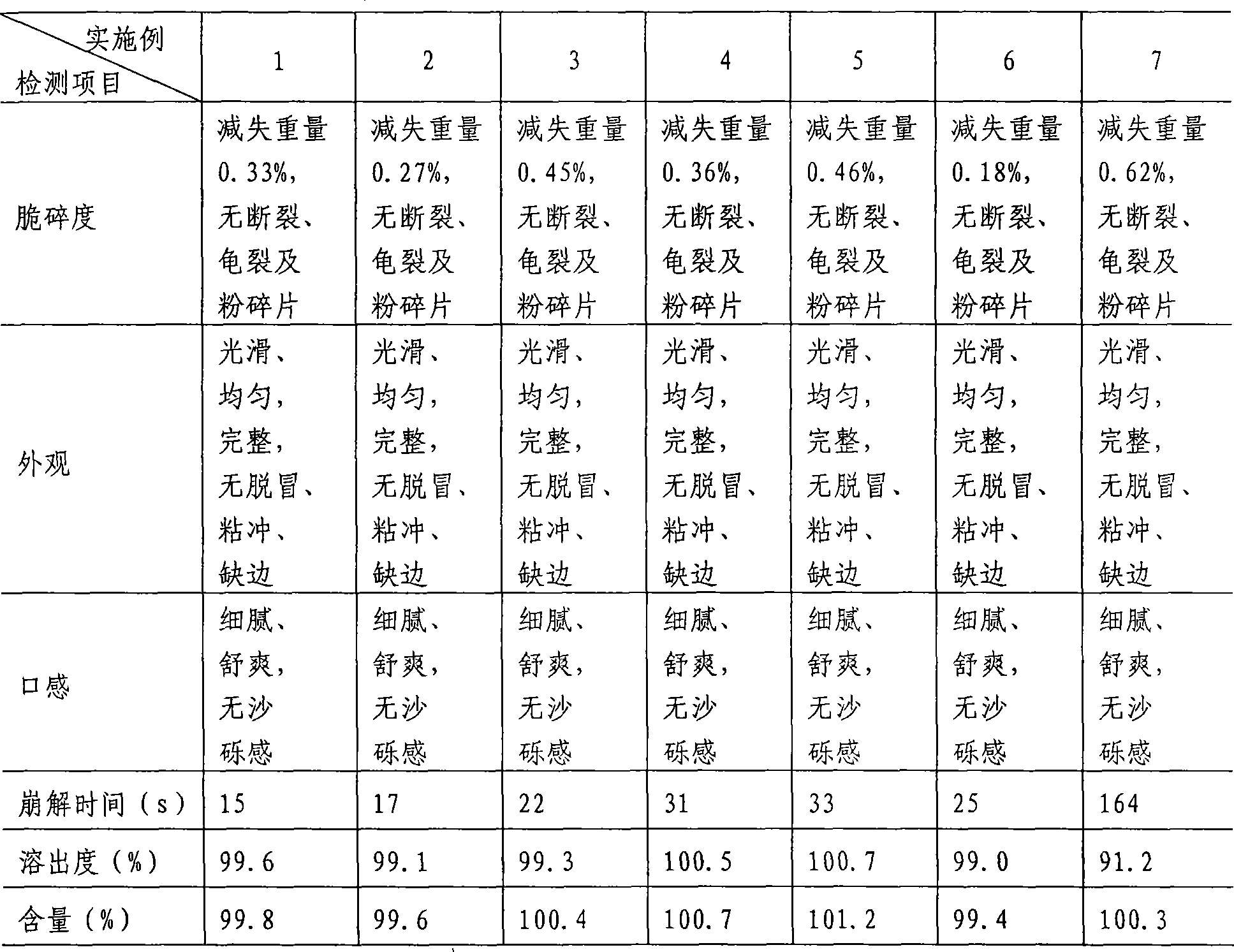

Dipeptidyl peptidase IV inhibitor pharmaceutical composition, use and preparation method thereof

ActiveCN105456270AReduce typesLow costMetabolism disorderPharmaceutical non-active ingredientsStarch cornMagnesium stearate

The invention discloses a pharmaceutical composition containing a dipeptidyl peptidase IV inhibitor linagliptin, use and preparation method thereof. The linagliptin containing pharmaceutical composition provided by the invention consists of linagliptin or a salt thereof serving as the active ingredient, and pharmaceutical excipients mannitol, pregelatinized starch, corn starch and magnesium stearate. The linagliptin containing pharmaceutical composition provided by the invention reduces the types of excipients, increases the stability of the preparation, reduces the cost of raw materials, and solves the hardness and friability problems of linagliptin tablets by controlling the particle size of the key excipient mannitol. The obtained table has all indicators especially the dissolution rate in line with the drug quality standards, and the process is simple, thus being more suitable for large scale production.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

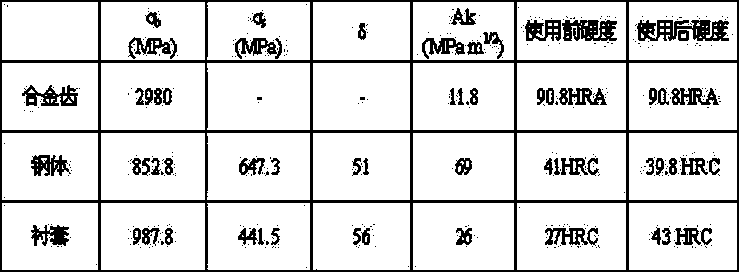

Process for inlaying alloy teeth of rock drilling bit

ActiveCN103850652AReduces the chance of broken (broken) teethLarge joint surfaceDrill bitsInterference fitAlloy

The invention discloses a process for inlaying alloy teeth of a rock drilling bit. The process comprises the steps of 1, selecting a good-quality high manganese round steel and processing the good-quality high manganese round steel into a liner bushing; 2, carrying out vacuum water quenching, tempering and heat preservation on the processed liner bushing, and then carrying out air-cooling treatment; 3, carrying out finish machining on an inner hole of the linear bushing; 4, performing thermal treatment on the linear bushing machined with the inner hole, and pressing the alloy teeth into the linear bushing under appropriate conditions; 5, performing high-speed shot blasting treatment on the teeth-inlaid linear bushing; 6, accurately grinding the outer circular surface of the teeth-inlaid linear bushing; 7, enabling the teeth-inlaid linear bushing to be in interference fit with teeth holes. The process for inlaying the alloy teeth of the rock drilling bit has the advantages that the liner bushing is arranged to sleeve the alloy teeth, so that the holding force is enhanced by enlarging the effective combination surface by increasing the length, and the magnitude of interference can be reduced appropriately without increasing the alloy cost, and therefore, the teeth can be fixed firmly, and also the drilling bit body and the alloy teeth can be protected against damage; meanwhile, under the protection action of the liner bushing, because the stress is basically eliminated in the process of inlaying the teeth in the linear bushing, the phenomena of alloy tooth breakage and steel body collapse are reduced remarkably, and the service life of the drill bit is prolonged.

Owner:ZHUZHOU SUNSHINE CEMENTED CARBIDE TOOLS

Titanium/titanium alloy surface oxygen permeation method

InactiveCN103789717AHigh hardnessSolve the hardnessSolid state diffusion coatingHigh surfaceTitanium

The invention discloses a titanium / titanium alloy surface oxygen permeation method. The titanium / titanium alloy surface oxygen permeation method comprises the process steps of (1) putting titanium and a titanium alloy in an electric furnace, carrying out heat treatment on the titanium and the titanium alloy at the temperature of 750-900 DEG C for 3-20 hours; and (2) taking out the titanium or the titanium alloy treated in the first step, rapidly putting the titanium and the titanium alloy in cold water for quenching treatment to obtain the titanium or the titanium alloy with a black oxygen permeation layer. The titanium / titanium alloy surface oxygen permeation method has the effects and the beneficial effects that (1) an oxygen permeation modified layer with high hardness can be obtained, the highest surface hardness of the oxygen permeation modified layer is higher than 800Hv, thus overcomes the defects of the titanium / titanium alloy, such as low surface hardness and poor abrasive resistance; (2) since a thin black titanium alloy oxide layer remains on the surface of the oxygen permeation layer obtain by virtue of the method, the extinction requirements of military and optical instruments can be satisfied; (3) the method is simple in the process and does not need to be carried out by professionals; and (4) the cost is low, air is adopted as an oxygen permeation agent, water is adopted as a quenching medium, and no other extra materials are needed.

Owner:SHENYANG LIGONG UNIV

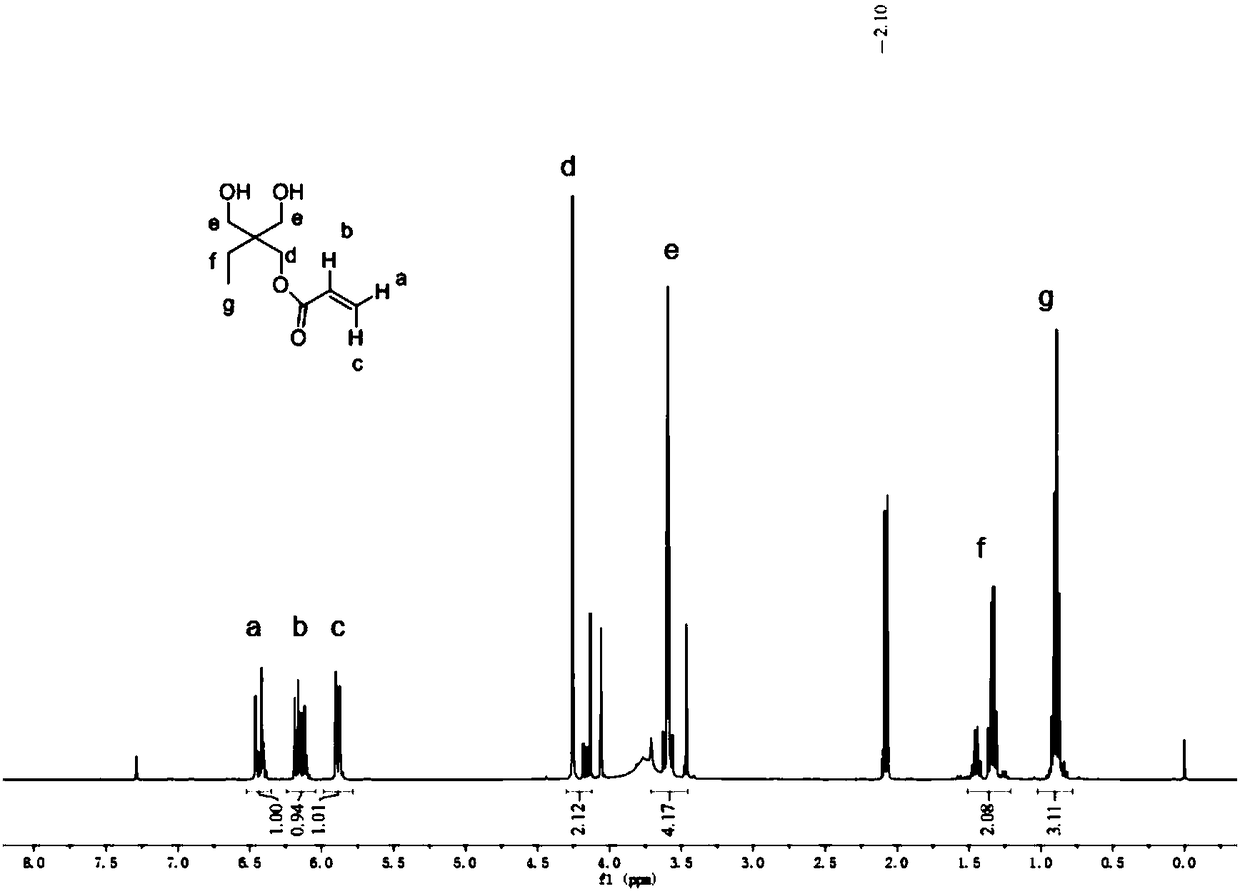

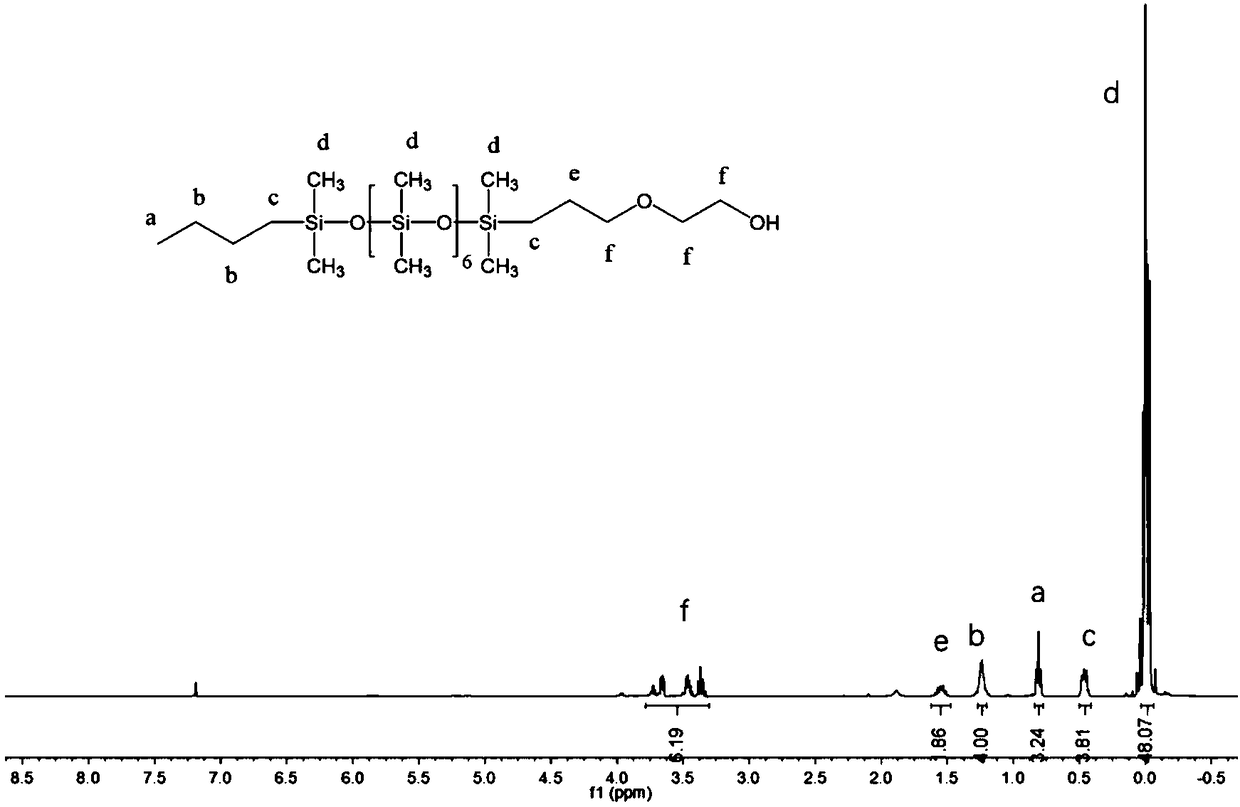

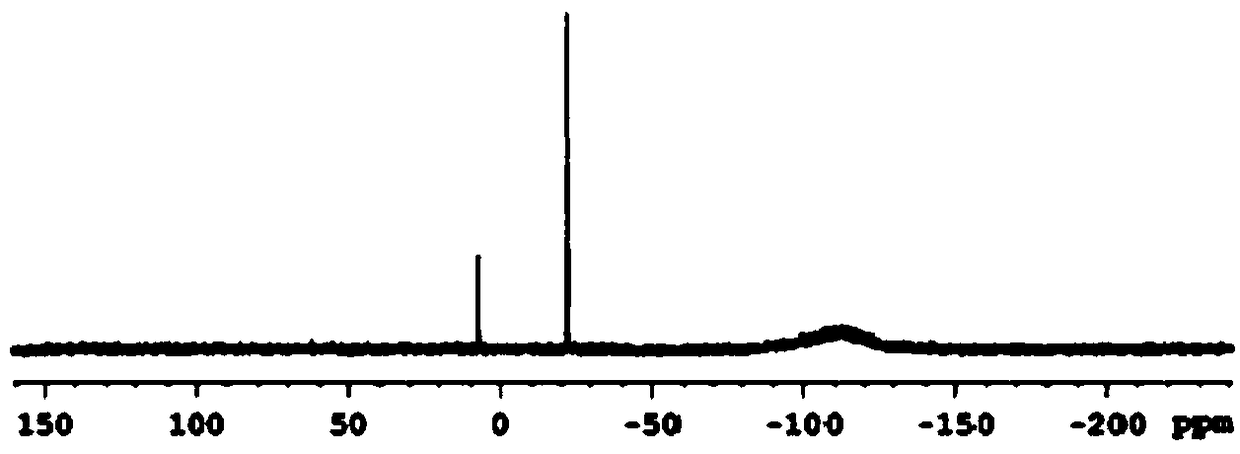

Method for preparing photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and composition thereof

The invention discloses a method for preparing a photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and a composition thereof. The method is based on the shortcomings of the current photopolymerizable organosilicon polyurethane acrylate aqueous oligomer, and the method comprises the following steps: synthesizing 2,2-bis(hydroxymethyl) butyl acrylate (HBA), and introducing thematerial into the oligomer molecule to make the polymer side chain is rich in unsaturated carbon-carbon double bonds; synthesizing one-terminated hydroxypolydimethylsiloxane (Si-OH), and introducing the substrate to the end of a main chain of the aqueous polyurethane acrylate oligomer so that the substrates facilitate enrichment on the surface of the material. Through the above molecular design, the problems of poor water resistance and low hardness of the aqueous photocurable material caused by the low double bond content and low crosslink density of the photocurable material are effectivelysolved, and the disadvantages that silicone chain is easily wrapped by the crosslinked network when is in the middle of the main chain so that the silicone is not enriched at the surface of the material, so that the surface hydrophobicity of the material can be effectively increased.

Owner:安庆北化大科技园有限公司

Dual-curing light guide glue for display screen backlight modules and preparation method of dual-curing light guide glue

InactiveCN106497498AHigh peel strengthImprove dispersion uniformityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyMethacrylate

The invention discloses dual-curing light guide glue for display screen backlight modules. The dual-curing light guide glue comprises a component A and a component B, wherein the component A is prepared from a light-curing monomer, polybutadiene dimethacrylate, aliphatic polyurethane acrylate, epoxy resin, a activated diluent, a crosslinker, a leveling agent, a dispersant, a coupling agent and light guide powder by means of mixing and reacting; the component B is prepared from a light initiator, epoxy resin-modified aliphatic amine, a defoaming agent, light guide powder and a rheological agent by means of reaction. The invention further relates to a preparation method of the dual-curing light guide glue for the display screen backlight modules. The preparation method has the advantages of short process flow and low cost. The dual-curing light guide glue prepared by the method has the advantages of excellent peel strength, storage stability, impact resistance, high luminance and uniformity and the like.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

High-strength and high-toughness graphene composite ceramics

The invention discloses high-strength and high-toughness graphene composite ceramic. The high-strength and high-toughness graphene composite ceramic comprise a green body and a glaze material, whereinthe green body is prepared from ferric oxide, anorthite, potassium feldspar, attapulgite, spodumene, graphene, nanometer titanium dioxide fiber powder, silicon carbide crystal whiskers, barium sulfate and glass microbeads; and the glaze material is prepared from kaolin, graphene, nanometer titanium dioxide fiber powder, bamboo charcoal powder, silicon carbide crystal whiskers, barium sulfate, glass microbeads, potassium feldspar, quartz sand, talcum powder, olivine, bamboo charcoal powder, ferric oxide, aluminum oxide, magnesium oxide, zirconium silicate, zinc oxide and lutetium oxide. A fiber reinforcing technology is introduced, use of the graphene is combined, and the barium sulfate and the glass microbeads are compounded, so that the dispersibility of the graphene is improved; according to proper proportion, the components can exert a remarkable synergistic effect and obviously enhance the strength and the toughness of the ceramic; furthermore, the obtained ceramic material has aremarkable adsorbing and removing ability on air pollutants and has excellent corrosion resistance; and the application range is wide, and the preparation method is simple and suitable for industrialized production.

Owner:林荣铨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com