Patents

Literature

46results about How to "Does not reduce hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-Chromium-rare earth co-infiltration process combined with pre-infiltration cold deformation for workpiece

The invention relates to a cold deformation boron - chromium -rare earth coinfiltration process before the work infiltration, which includes performing cloudburst treatment for the work, then adding aquacare and amchlor into the prepared boron - chromium -rare earth coinfiltration agent, evenly mixing and loading into infiltration box, performing rust and grease removal for the work surface after the cloudburst treatment, protecting impervious position with carbite or asbest cord, filling coinfiltration agent on the substratum and top of the infiltration box, embedding the work in the infiltration box filled with powder or granular coinfiltration agent, in which the distance between the work and the box wall should be farther than 30mm; packing the infiltration box with double sodium silicate mastic, then drying at 90-110 DEG C; then heating-up to 840-860 DEG C, filling into heater when reaching the needed temperature and preserving heat for 3.8-4.2 hours, afterwards getting from the furnace to cool, finally performing heat hardening and lonnealing treatment to the work. By this process, the infiltration structure can be improved and the infiltration brittleness can be reduced in the precondition of no reduction of the infiltration layer rigidity, and the attrition resistance of the infiltration layer can also be improved.

Owner:SHANDONG JIANZHU UNIV

Special ceramic cutter material for wire-board or circuit board and preparation method thereof

InactiveCN101157554AImprove impact toughnessImprove wear resistanceTitanium carbideCeramic cutting tool

The invention discloses a ceramic cutting tool and the preparation method thereof special for a smashing line board or a circuit board, and belongs to the art of the smashing equipment. The ceramic cutting tool takes crystal whisker as the plasticizing material; tungsten carbide as the substrate material; titanium carbide as anti-friction agent; carbon as deoxidizing agent; and chromic compound, lanthanum oxide and cerium oxide as additive. The ingredients are evenly blended and directly molded by heat pressing. The raw material is not taken out until being fully mixed, and is then positioned into the sample heat pressing groove of a hot-press machine. The thermo-compression intensity of pressure is 10-40MPa, and the hot-press temperature ranges from 1,480 to 1,600DEG C. The flexible ceramic cutting tool of the invention is provided with good resilience, wearlessness, high rigidity and chemical stability. The technique of the cutting tool is quite simple and the production period is far shorter than the production period of the conventional preparation method that carries the compression molding of the evenly mixed raw materials first and then the sinter molding. The cutting tool material is fit for the cutting tool special for the making of a waste line board and the smashing equipment of the circuit board.

Owner:TSINGHUA UNIV

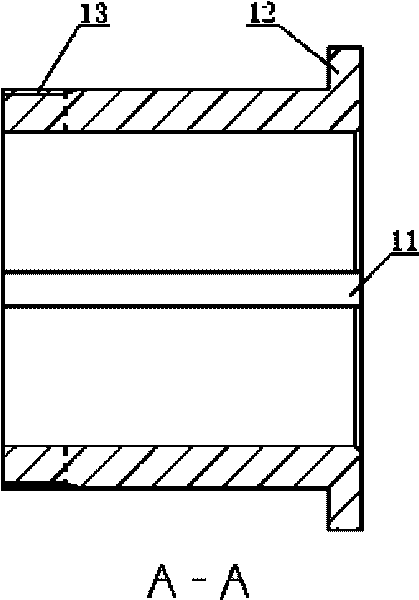

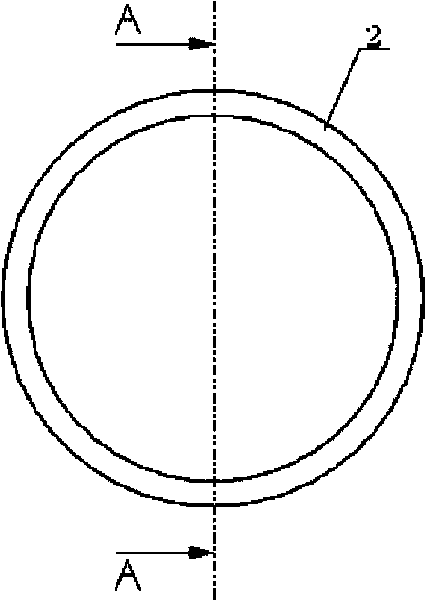

Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

ActiveCN101718297AImprove wear resistanceAccelerated corrosionBearing componentsSliding contact bearingsWater basedCarrying capacity

The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid, which comprises a bearing sleeve, wherein a flange is arranged at one end of the bearing sleeve, and external threads are arranged at the other end of the bearing sleeve; a ceramic shaft sleeve is assembled at the outer layer of the bearing sleeve; a ceramic shaft bushing which comprises a special liquid cavity and a liquid hole structure is arranged outside the ceramic shaft sleeve; a shaft bushing sleeve with the special liquid cavity and the liquid hole structure is assembled at the outer layer of the ceramic shaft bushing; and the bearing of the invention also comprises a bearing end cover, wherein a ceramic ring is assembled at the inner end of the bearing end cover, and internal threads matched with the external threads of the bearing sleeve are arranged on the inner ring of the bearing end cover. The bearing of the invention can improve the wear resistance and the corrosion resistance, can operate in the poor water condition where sandy solid particles are contained, can be lubricated by the water-based lubricating liquid formed by adding other additives into water or water-based liquid; at the same time, the bearing has larger carrying capacity and rigidity, and can ensure a safe and stable operating state, thereby greatly prolonging the operation life.

Owner:TIANJIN UNIV

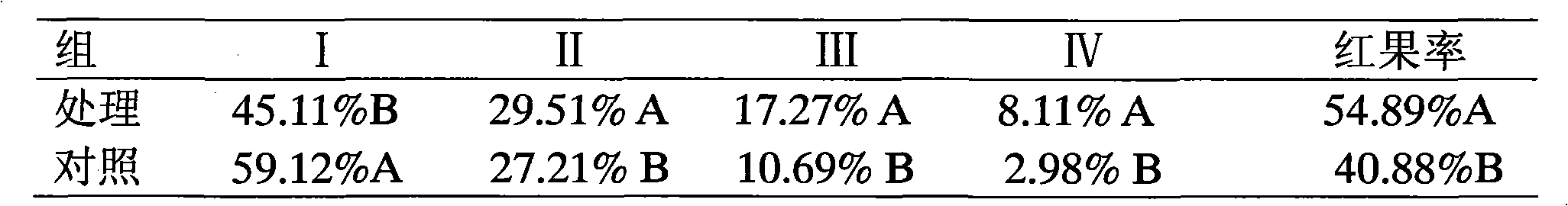

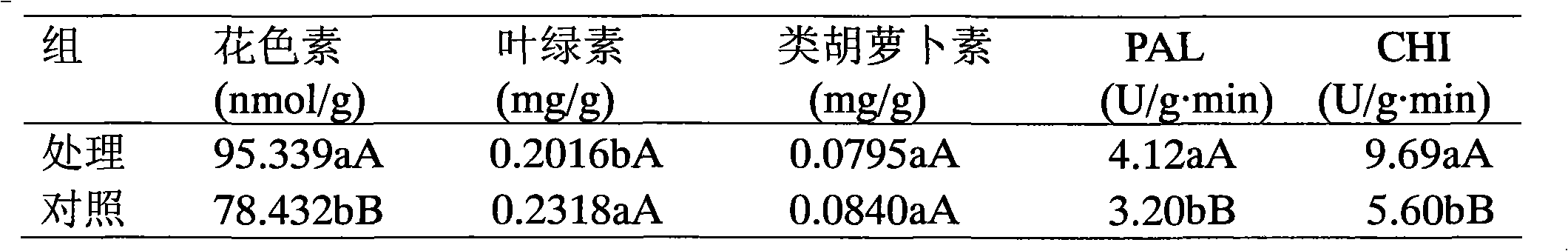

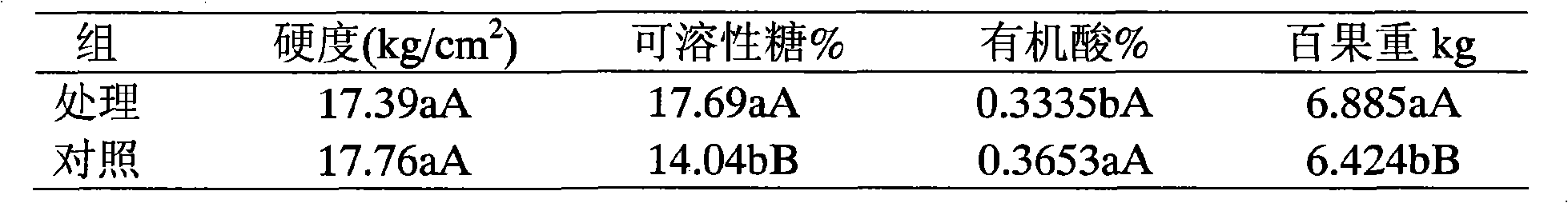

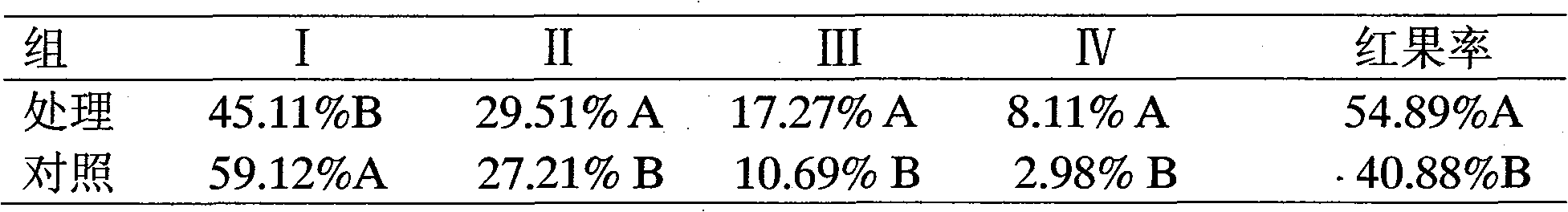

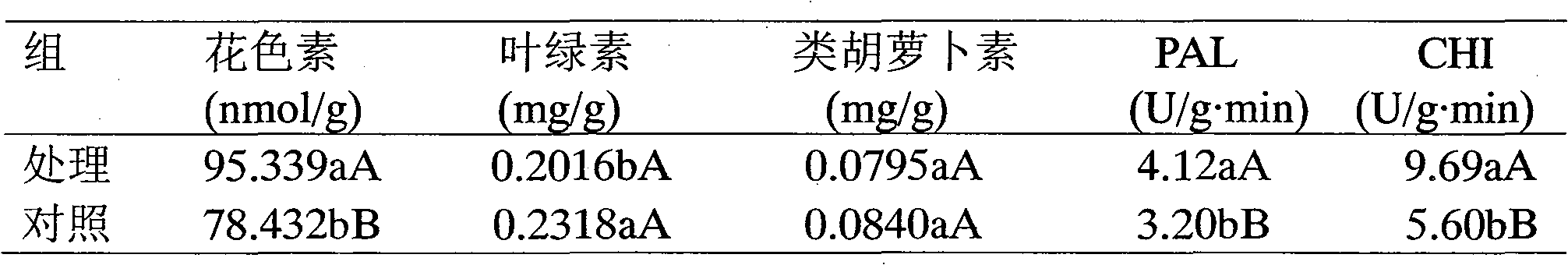

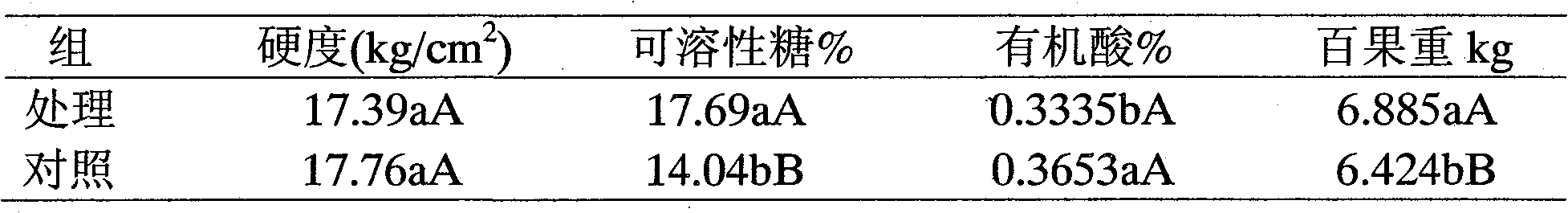

Preparation and producing method for promoting the Nanguo pear coloring

InactiveCN101283685ASolve the problem of coloringIncrease anthocyanin contentBiocidePlant growth regulatorsSucroseTyrosine

The invention relates to an agent for promoting fruit coloration of Nanguo pear. The agent is aqueous and dedicated for Nanguo pear, and can increase the 'red fruit' rate by regulating and controlling the synthesis and metabolism of anthocyanidin in Nanguo pear. The agent contains the following components: uniconazole 0.1g / L, sucrose 1g / L, potassium sulfate 1g / L, calcium chloride 3g / L, levulinic acid 0.1g / L, glutamic acid 1.0g / L, tyrosine 0.3g / L, phenylalanine 0.3g / L, boric acid 0.3g / L, Tween 100 1ml / L, and water in balance. The agent is prepared by the following steps: (1) respectively weighting uniconazole, sucrose, potassium sulfate, calcium chloride, levulinic acid, glutamic acid, tyrosine, phenylalanine, boric acid and Tween 100 at the given ratio; (2) respectively dissolving the materials in water, wherein uniconazole is dissolved with methanol; glutamic acid, tyrosine and phenylalanine are dissolves with distilled water at 100 DEG C; and potassium sulfate and calcium chloride are dissolved with distilled water at 50-70 DEG C; mixing after dilution; adding water until the desired concentration; and stirring thoroughly to obtain the final product. The agent can increase the 'red fruit' rate of Nanguo pear by 14%, and is convenient to use and harmless and innoxious to human body and environment.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

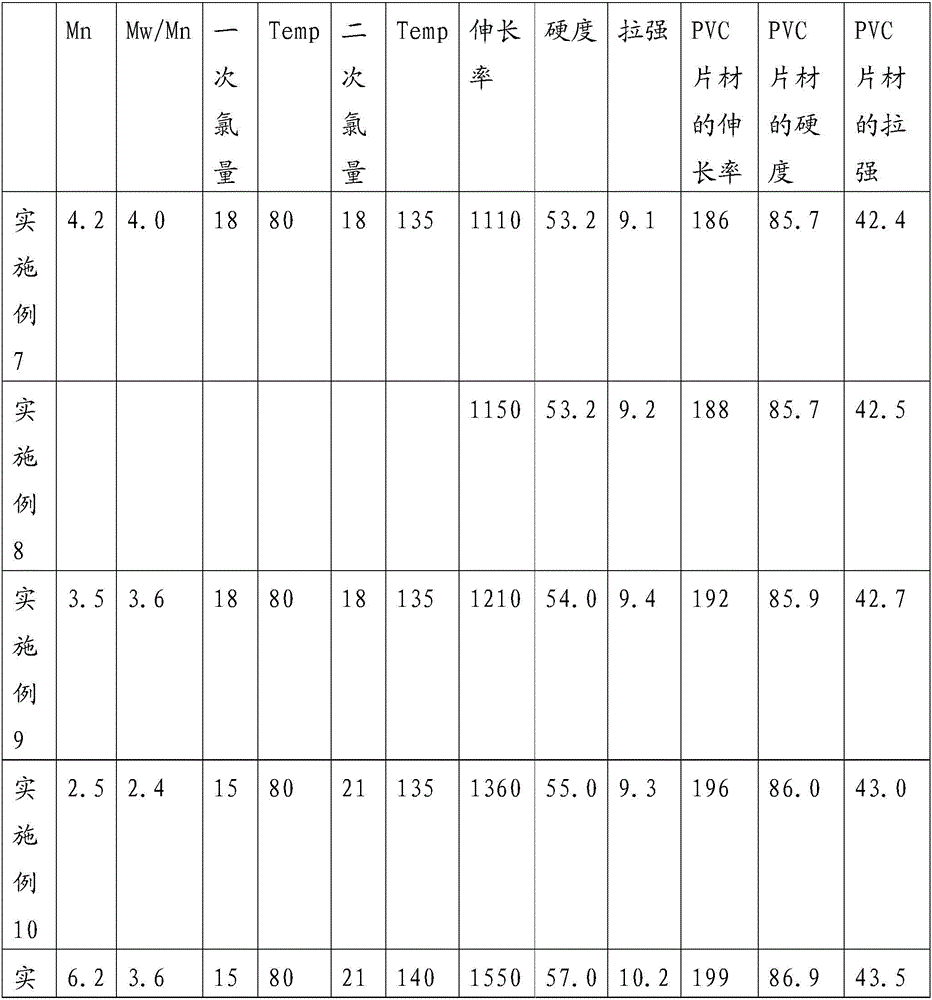

Polyvinyl chloride low temperature toughening modifier and polyvinyl chloride mixture containing same

InactiveCN105693891ADoes not reduce hardnessNo reduction in tensile strengthPolyvinyl chlorideHardness

The invention discloses polyvinyl chloride low temperature toughening modifier and a polyvinyl chloride mixture containing the same. The low temperature toughening modifier is rubber powder with the elongation at break being 1000-1600%, hardness being greater than 53.0%, and tensile strength being greater than 9.0; the polyvinyl chloride mixture comprises, by weight, 100 parts of polyvinyl chloride resin, 1-30 parts of the low temperature toughening modifier, 0.5-5 parts of a stabilizing agent, 0-50 parts of filler, 0-50 parts of wood powder, 0-10 parts of acrylic polymer, 0-20 parts of shock-resistant modifier, 0-5 parts of lubricant and 0-10 parts of pigment. When PVC is modified by the low temperature toughening modifier, on the premise that hardness and tensile strength of the PVC are basically not influenced, the elongation at break of a hard PVC product can be remarkably improved.

Owner:SHANDONG RIKE PLASTIC RUBBER TECH CO LTD

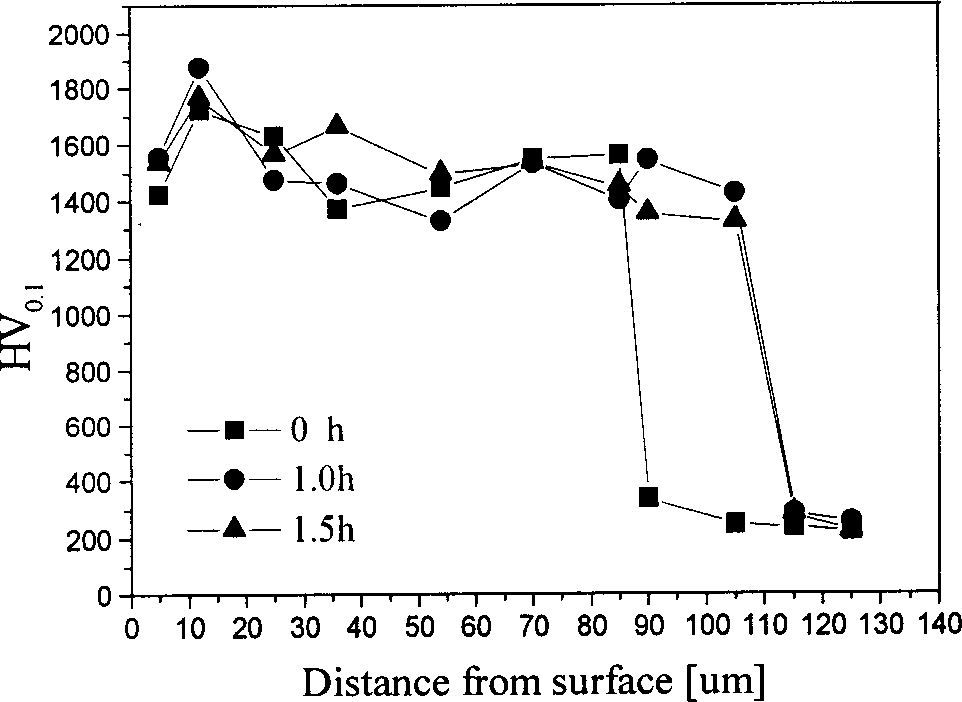

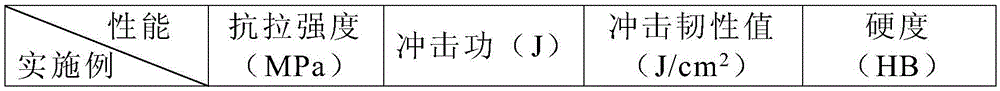

High-toughness high-wear-resistance carbide-containing isothermal quenching nodular cast iron and preparation method thereof

The invention discloses high-toughness high-wear-resistance carbide-containing isothermal quenching nodular cast iron and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The produced nodular cast iron comprises the following chemical components of, by weight (wt%), of 3.3-3.8% of C, 1.3-1.7% of Si, 0.4-0.7% of Mn, 1.0-1.5% of Cr, less than or equal to0.040% of P, less than or equal to 0.007% of S, and the balance Fe. The preparation method comprises the following steps that the surface of a casting is coated with an antioxidant, then the casting is placed into a heat treatment furnace to be heated to 1080-1110 DEG C, undergoes heat preservation for 10-15 minutes, and is discharged out of the furnace to undergo air cooling to reach 300-350 DEGC, then the casting is re-fed into the furnace to be heated to 880-900 DEG C, undergoes heat preservation for 90-150 minutes, then is rapidly taken out to be put into a nitrate solution with the temperature of 250-320 DEG C, undergoes heat preservation for 1-3 hours, and then is taken out to be cooled in the air to reach the room temperature. The impact toughness is improved by 120% or more, and meanwhile, the hardness and the wear resistance are not reduced.

Owner:BEIJING UNIV OF TECH

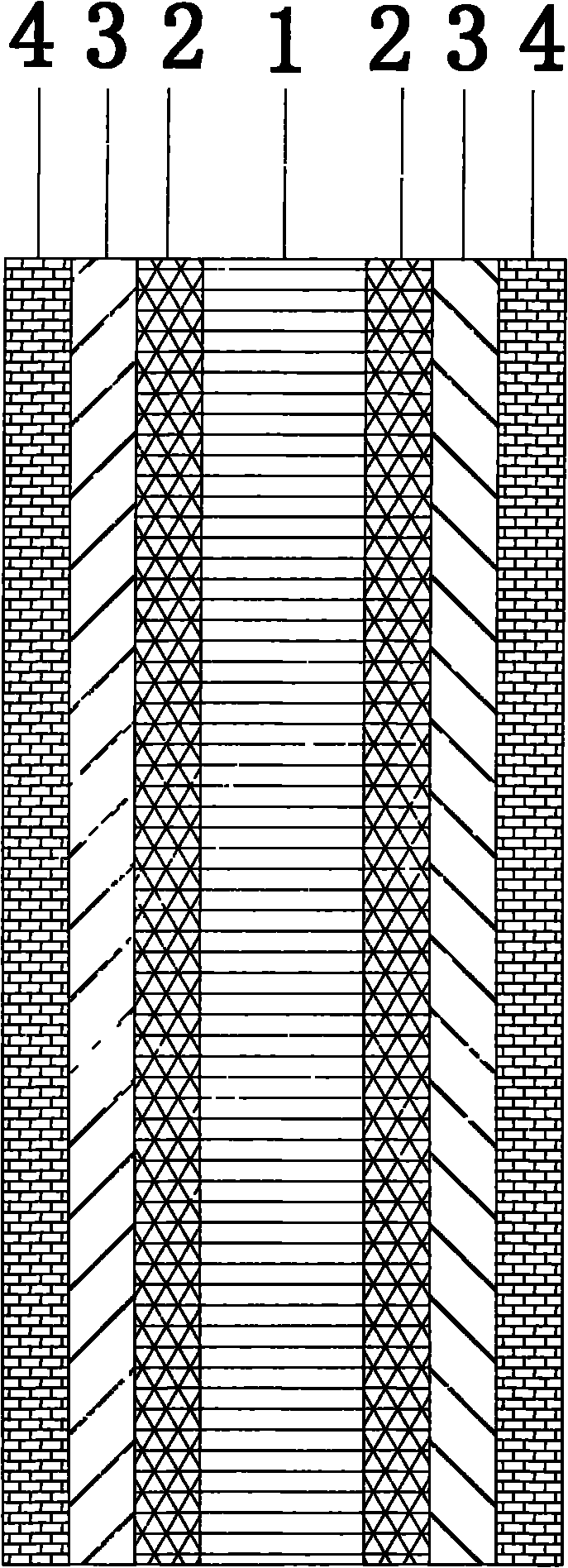

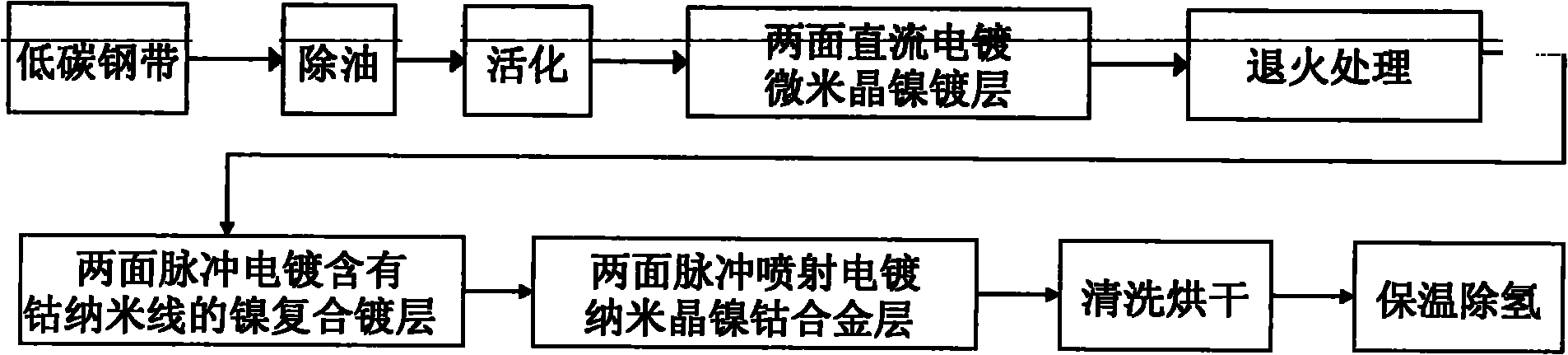

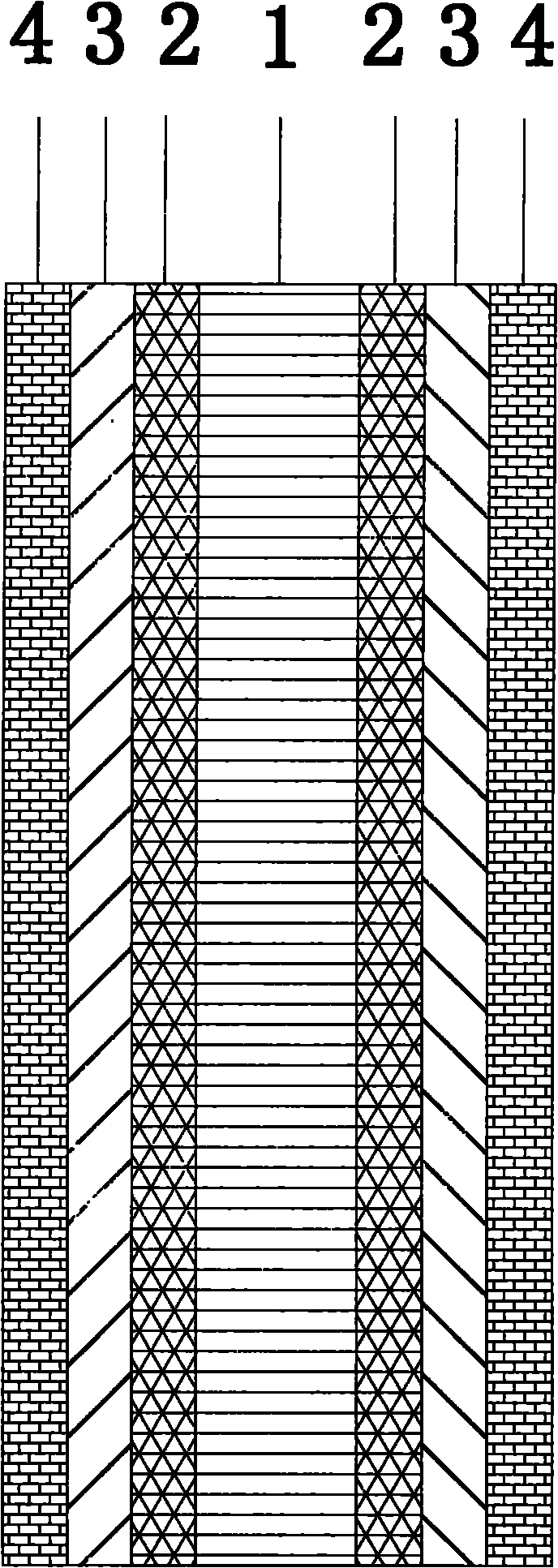

Steel strip plated with composite film containing cobalt nanowires and preparation method thereof

ActiveCN101954762AImprove toughnessDoes not reduce hardnessCell component detailsMetal layered productsLithiumPower battery

The invention discloses a steel strip plated with composite film containing cobalt nanowires and a preparation method thereof. the steel strip of the invention uses a steel strip as the substrate, and the both sides of the steel strip are respectively plated with a multilayer composite film containing cobalt nanowires. The bottom layer of each multilayer composite film containing cobalt nanowiresis a micron crystalline nickle plating, the middle layer is a nickle composite plating containing cobalt nanowires and the surface layer is nanocrystalline nickle-cobalt alloy plating. The invention also provides the preparation method of the steel strip. The preparation method comprises the following steps: degreasing and activating a steel strip, adopting the direct current electroplating mode to prepare a micron crystalline nickle plating on the substrate, annealing, adopting the pulse electroplating mode to prepare a nickle composite plating containing cobalt nanowires on the nickle plating and then adopting the pulse injection mode to prepare a nanocrystalline nickle-cobalt alloy plating on the nickle composite plating containing cobalt nanowires. The steel strip is closely combined by the multilayer composite film containing cobalt nanowires and the low carbon steel strip, has good corrosion resistance, punching property and high load resistance and can be used as the shell material of the lithium ion power battery and high-performance alkaline Zn / MnO2 battery.

Owner:HUNAN YONGSHENG NEW MATERIALS

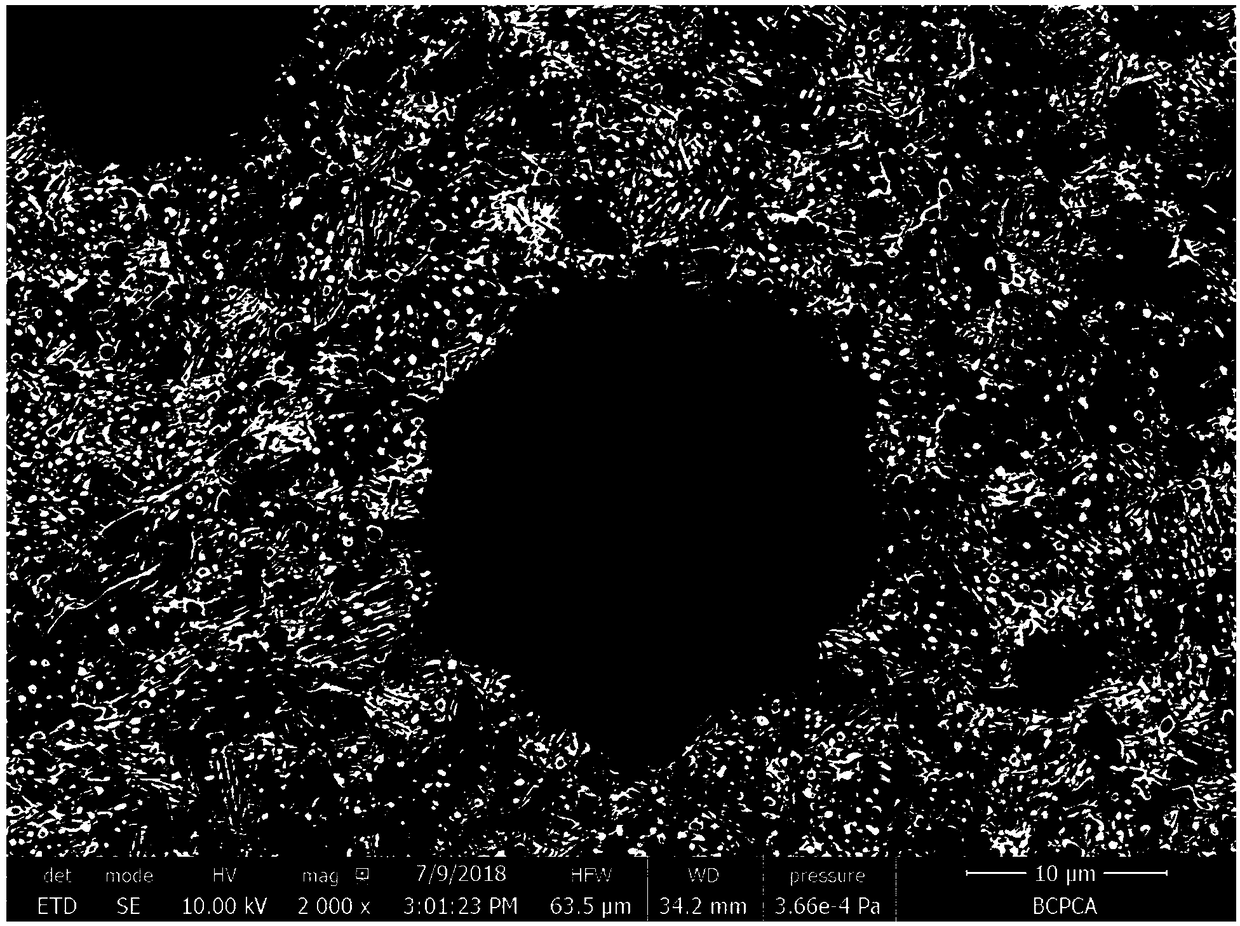

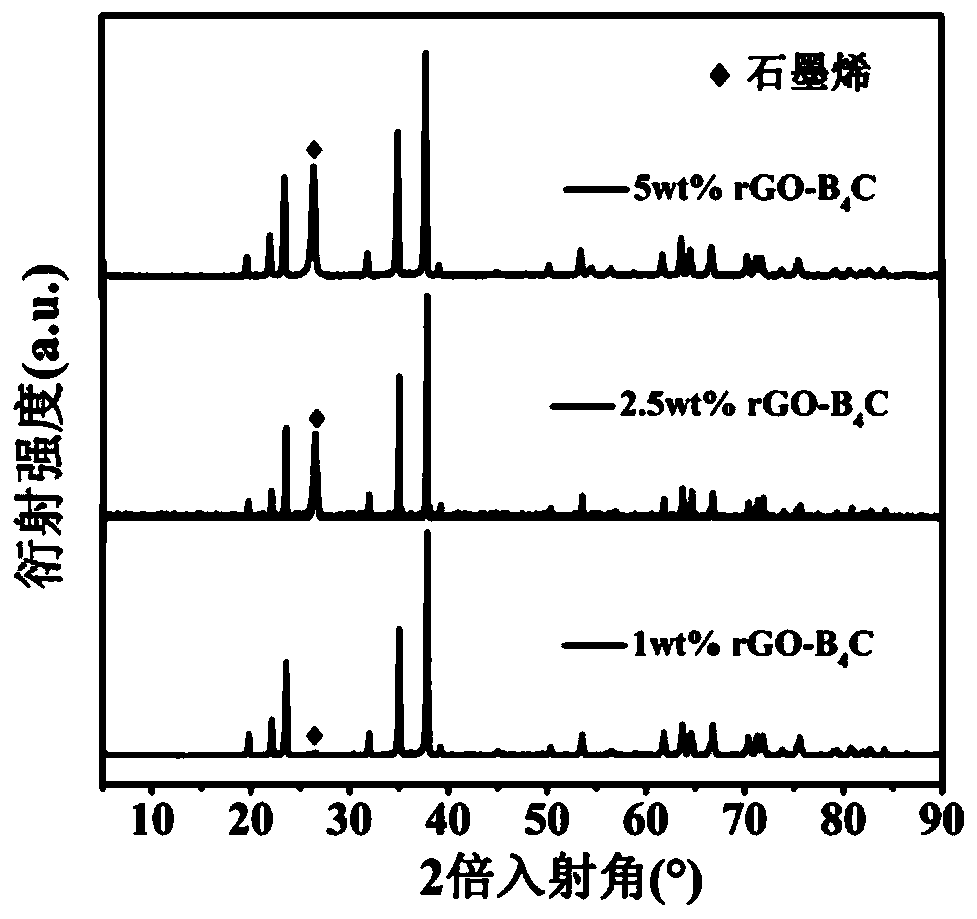

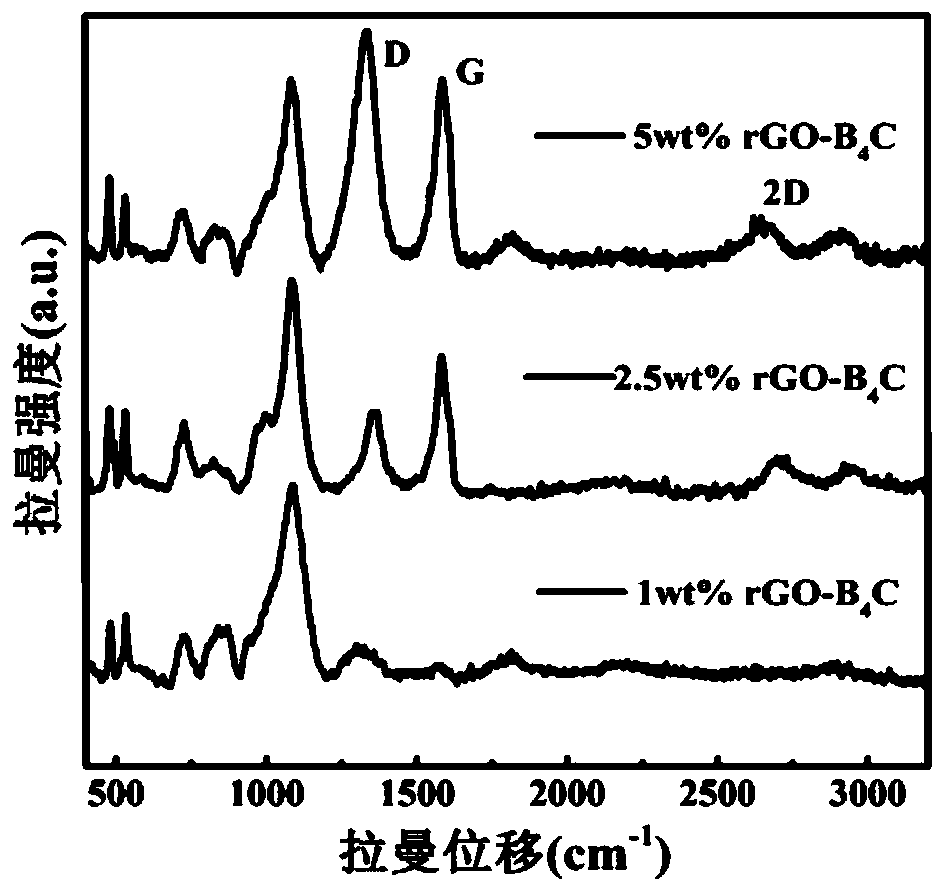

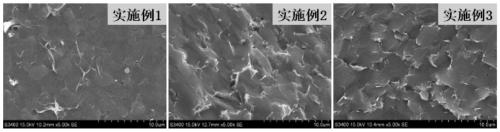

Self-assembled boron carbide-graphene composite ceramic and preparation method thereof

The invention relates to self-assembled boron carbide / graphene composite ceramic and a preparation method thereof, and the preparation method comprises the following steps: adding boron carbide micropowder into an acrylamide solution, mixing the acrylamide solution with a graphene oxide dispersion liquid, putting the obtained mixed solution into a constant-temperature water bath kettle, heating to 60-70 DEG C, adding an initiator, a cross-linking agent and a chelating agent, heating to 80-90 DEG C, reacting for 2-5 hours, and separating out solid boron carbide / graphene mixed powder, and carrying out heat treatment on the boron carbide / graphene mixed powder in an inert atmosphere, then placing the boron carbide / graphene mixed powder in a discharge plasma sintering furnace, and sinteringin under vacuum or an argon atmosphere to obtain the self-assembled boron carbide / graphene oxide composite ceramic. The self-assembled boron carbide / graphene composite ceramic provided by the invention is high in density and high in bending strength, and moreover, reduced graphene oxide is uniformly dispersed in a matrix, so that the fracture toughness of the ceramic matrix is improved.

Owner:WUHAN UNIV OF TECH

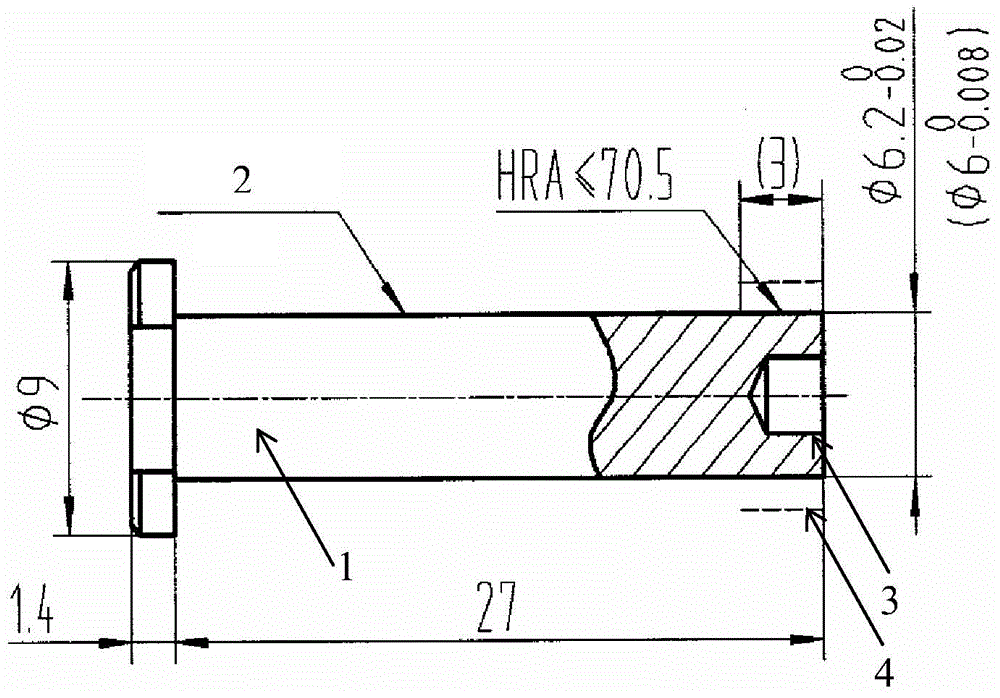

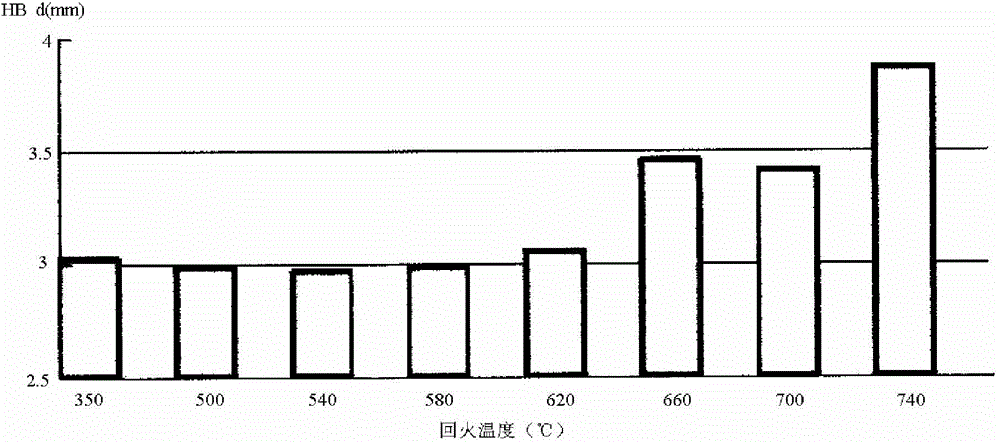

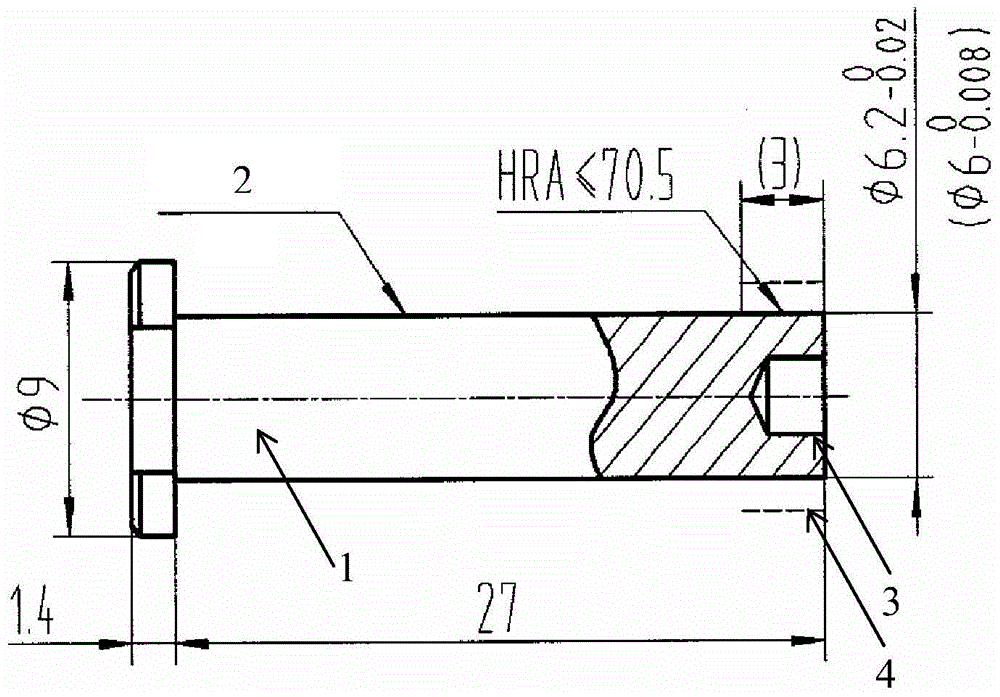

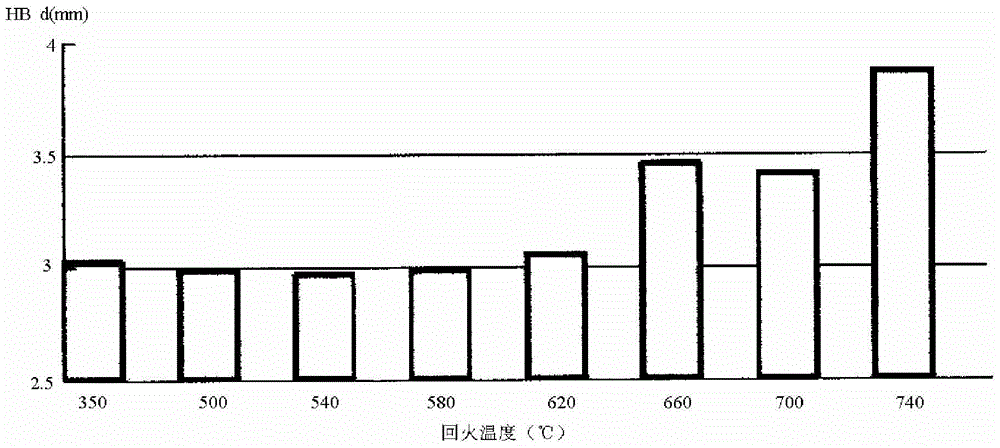

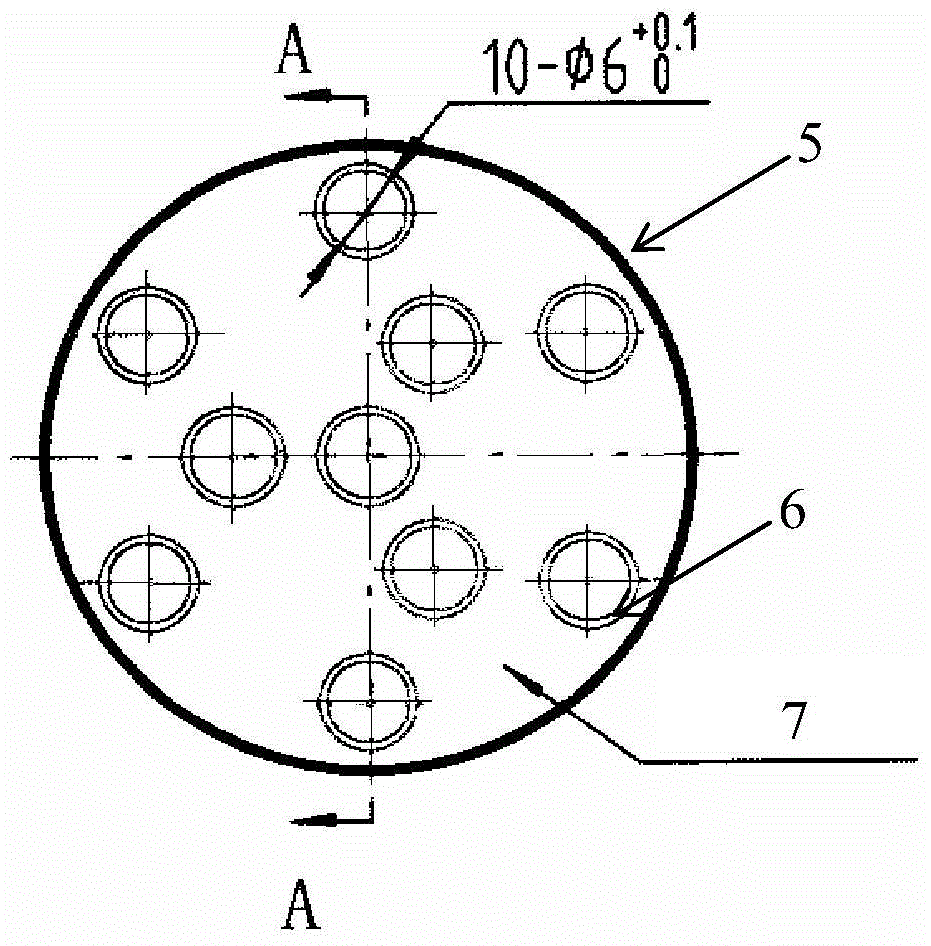

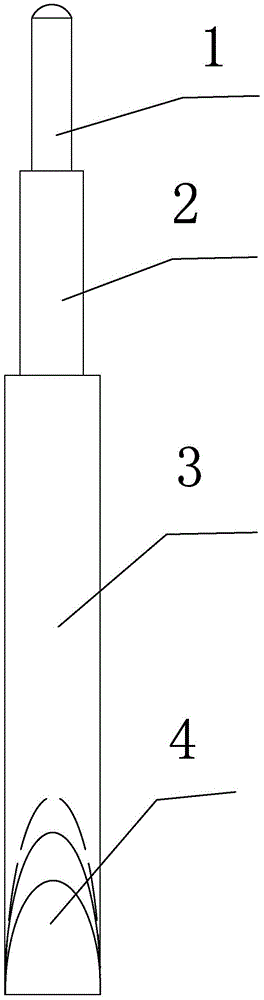

Local softening method of high-strength alloy steel carburized parts

The invention relates to the field of local annealing heat treatment of carburized parts and specifically relates to a local softening method of high-strength alloy steel carburized parts. The local softening method can be applied to manufacturing the carburized parts having different requirements on the hardness of the high-strength steel. A carburized locking pin is locally heated by use of fused salt in a salt-bath furnace; the locking pin is made of martensitic steel 16Cr3NiWMoVNbE; an annealing heat-protective fixture is adopted for performing heat protection on the carburized surface of the locking pin part, and the local annealing part is heated till a temperature above 600 DEG C for softening. The local softening method of the high-strength alloy steel carburized parts is capable of reducing the hardness of the flaring positions of the parts and preventing the parts from cracking in the flaring process under the condition of guaranteeing the hardness of the carburized surfaces. According to the local softening method, the method of rapid heating annealing by use of protective salt bath is adopted for performing annealing treatment on the gear locking pin, so that the high strength of the carburized surface and the base body of the part can be prevented from reduction, and the hardness of the portion needing to be deformed can be reduced, and as a result, the cracking problem in the flaring deformation process of the part is solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Dendritic polymer dispersant-added waterborne coating ink

The invention relates to dendritic polymer dispersant-added waterborne coating ink and belongs to the field of coatings. The waterborne coating ink comprises the following components in parts by weight: 1-3 parts of dendritic polymer, 80-150 parts of waterborne resin, 8-12 parts of toner and 11-22 parts of a solvent. The waterborne coating ink has the beneficial effects that 1, the industrial production is achieved, the process is simple and the batch promotion can be achieved; 2, the property of the coating can be increased, the process effect is improved and such mechanical properties of the coating as adhesive force, flexibility, hardness, wear resistance and the like cannot be decreased; 3, the waterborne coating ink can be universal for dispersion of azo and quinacridone organic pigments, compared to conventional dispersants, the dendritic dispersant disclosed by the invention has significant advantages of final evaluation indicators, namely, viscosity and fineness over the conventional dispersants, the addition is less than those of the conventional dispersants, the overall advantages are prominent and purposes that the cost is saved and the process effects is improved can be achieved.

Owner:WEIHAI CY DENDRIMER TECH +1

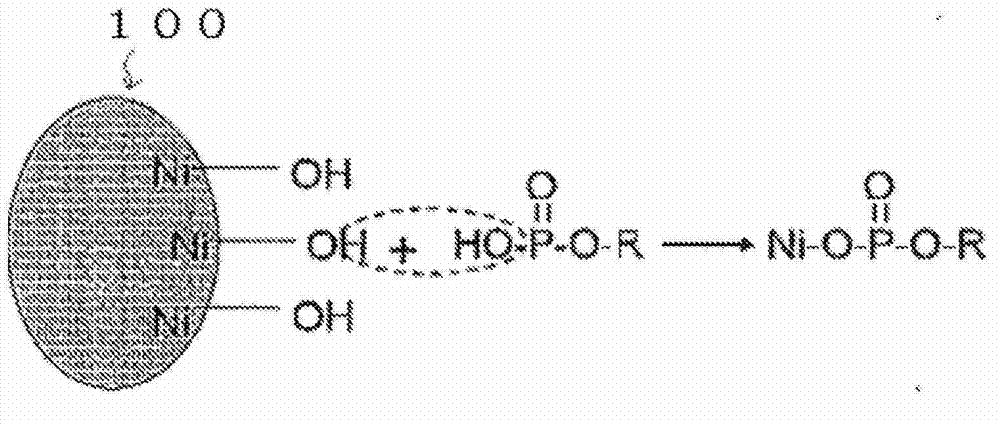

Conductive particle, method for producing same, anisotropic conductive film, assembly and connection method

ActiveCN102792386APrevent oxidationDoes not reduce hardnessNon-insulated conductorsTransportation and packagingAnisotropic conductive filmCore Particle

A conductive particle comprises a core particle and a conductive layer formed on the surface of the core particle. The core particle is formed from at least a resin or a metal. The surface of the conductive layer has a phosphorus-containing hydrophobic group.

Owner:DEXERIALS CORP

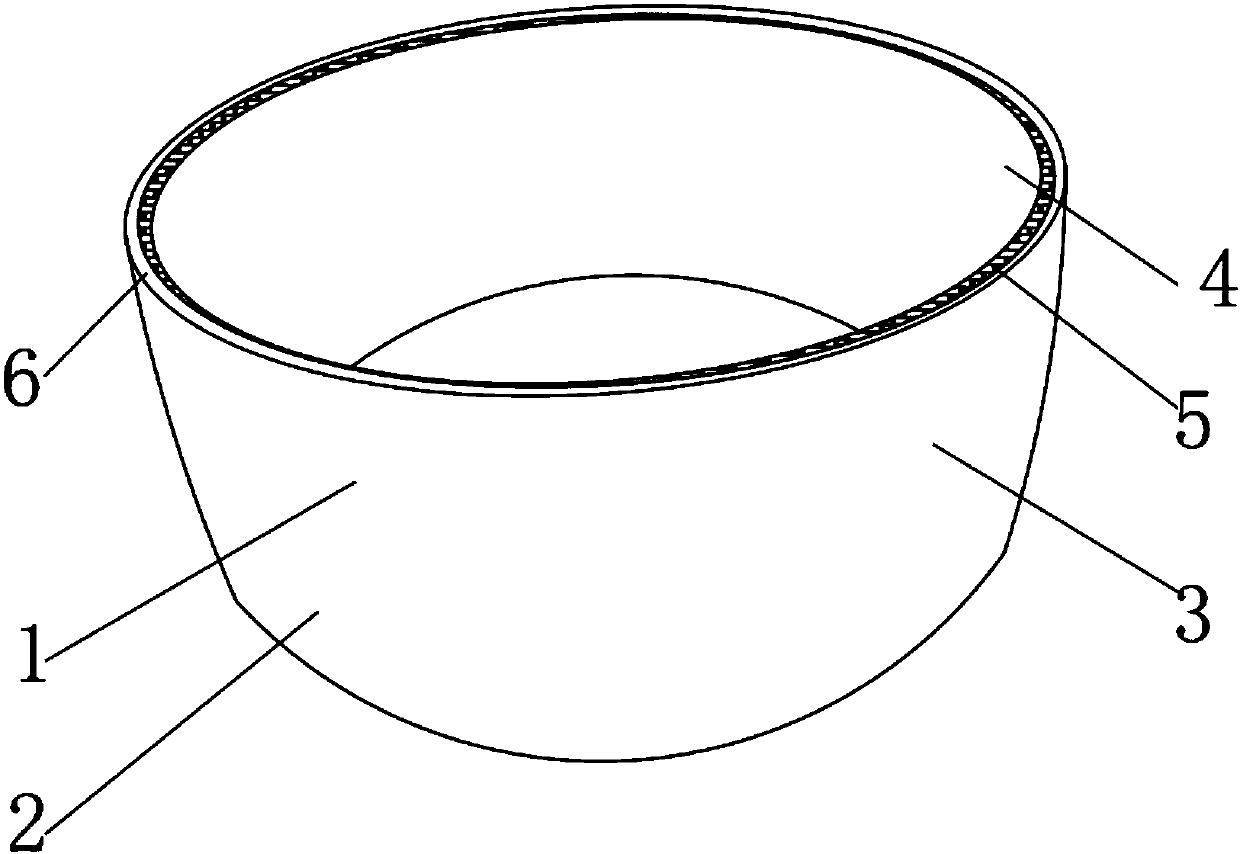

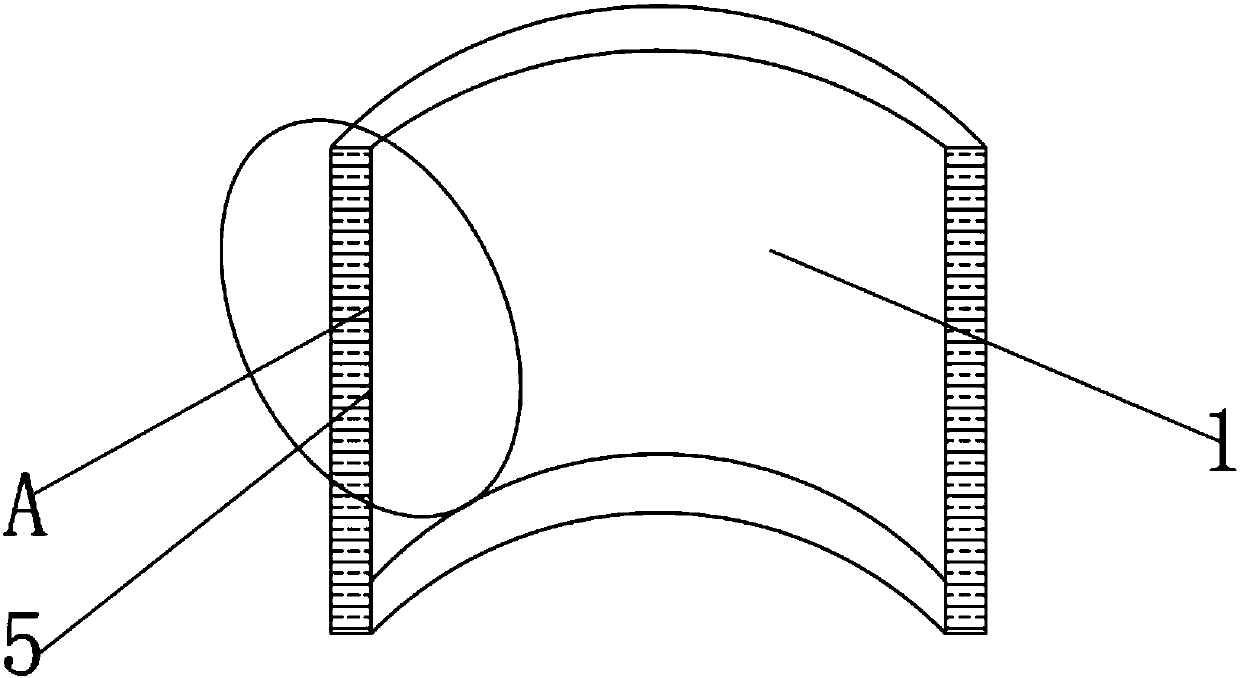

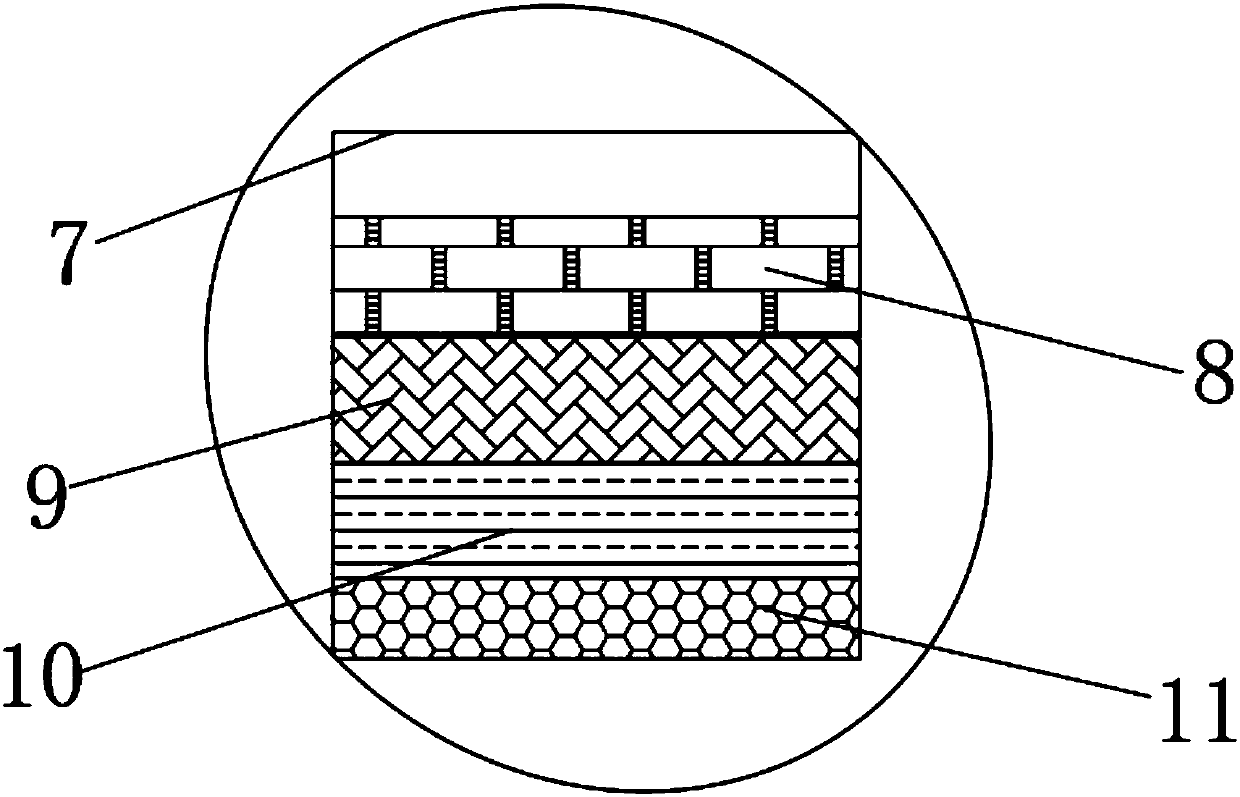

Quartz crucible excellent in heat preservation effect

InactiveCN110302854AImprove insulation effectHigh melting pointAfter-treatment apparatusPolycrystalline material growthHoneycombPolystyrene

The invention discloses a quartz crucible excellent in heat preservation effect. The quartz crucible comprises a quartz crucible body and is characterized a crucible bottom is fixedly mounted at the lower end of the quartz crucible body, a crucible body part is arranged in the middle of the quartz crucible body, the inner surface of the crucible body part is provided with an inner wall, the outersurface of the inner wall is provided with an outer wall, a graphite heat preservation sleeve is fixedly mounted on the outer surface of the outer wall, and a position, close to the inner surface of the inner wall, inside the outer wall is provided with a transparent layer. The quartz crucible has the advantages that the quartz crucible is provided with the graphite heat preservation sleeve, an extruded polystyrene board and a honeycomb core, so that the quartz crucible is resistant to high temperature, and the heat preservation effect of the quartz crucible is improved; meanwhile, graphite heat preservation sleeve dampness can be prevented at the same time to prolong the service life of the graphite heat preservation sleeve; the weight of the graphite heat preservation sleeve is reduced while hardness lowering is avoided; the quartz crucible is convenient for people to use and promising in application prospect.

Owner:连云港科拓信息科技有限公司

Insert for metal cutting

InactiveCN1718334ADoes not reduce hardnessReduce wearVacuum evaporation coatingSputtering coatingMetal machiningEdge strength

The present invention relates to a coated cutting insert for metalworking, especially machining of low-chip materials, etc., comprising a tungsten carbide substrate having a binder-phase-rich surface region, having at least one rake face and at least one clearance face, intersecting Form the cutting edge. The binder phase-rich surface region is at least partially absent from the rake face comprising at least a portion of the surface extending from the cutting edge. The strength and wear resistance of the cutting edge can thus be optimized.

Owner:SECO TOOLS AB

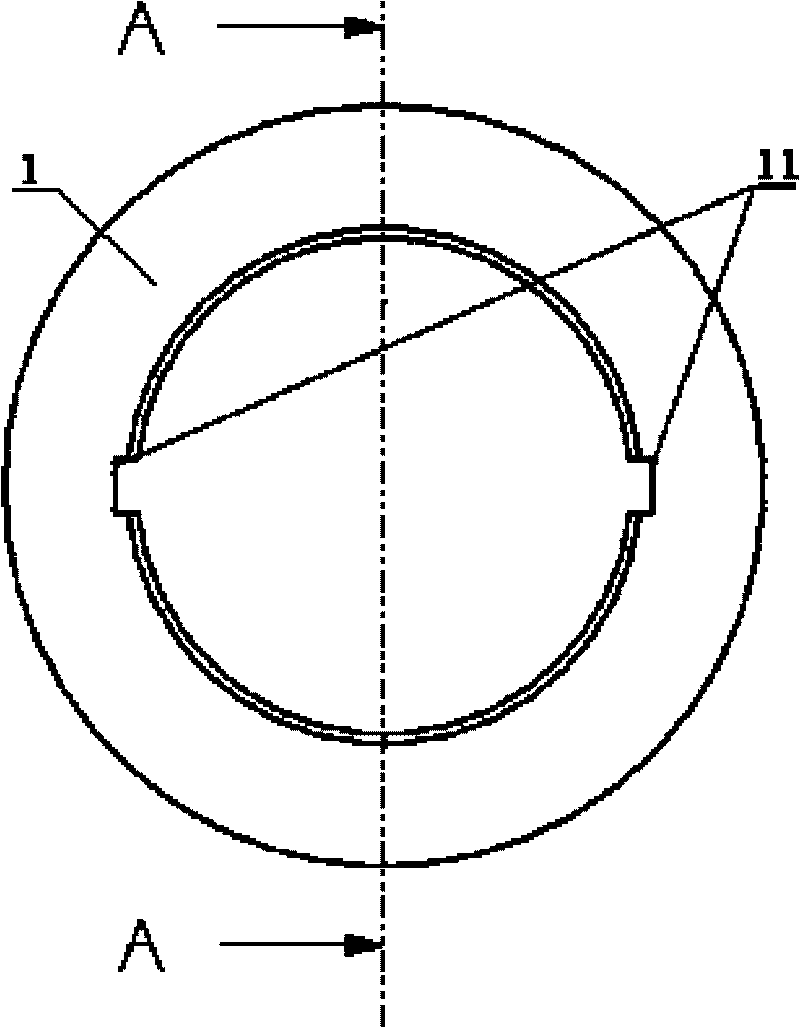

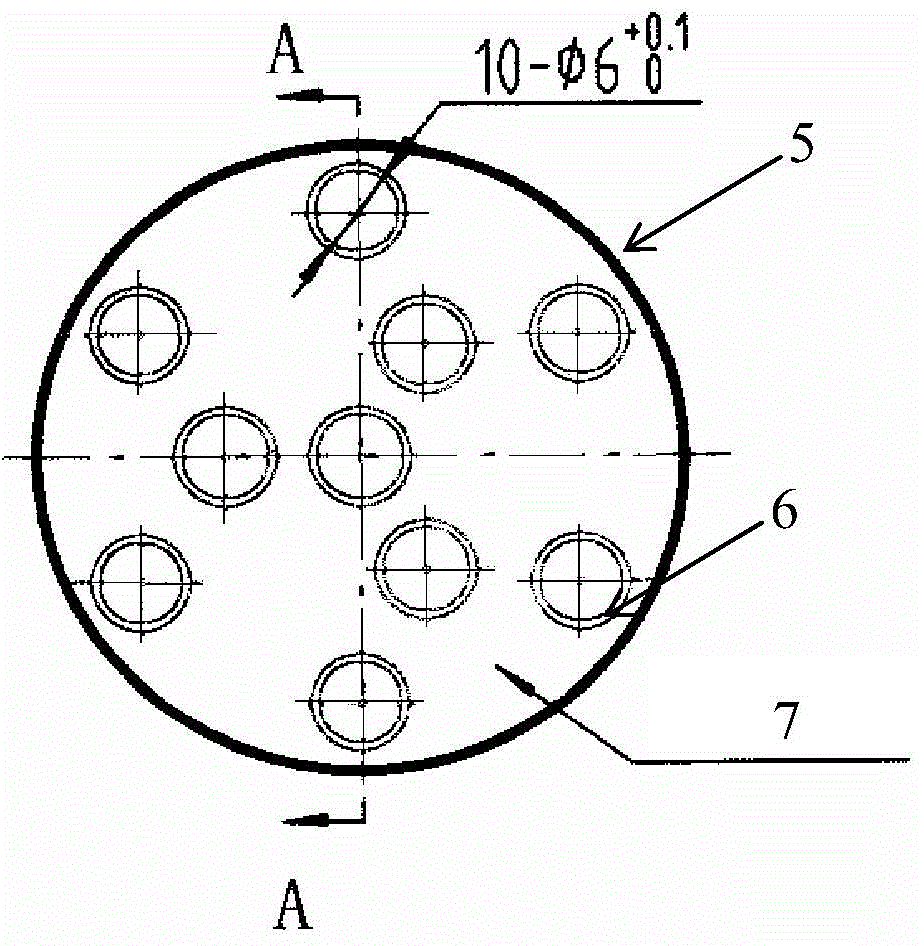

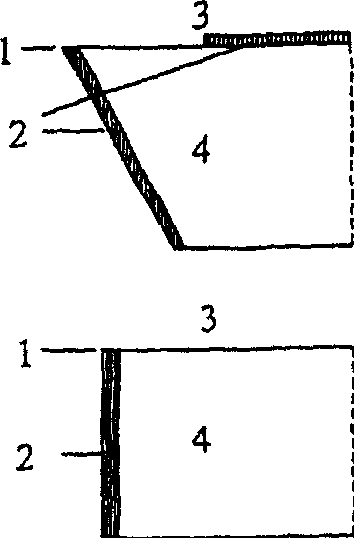

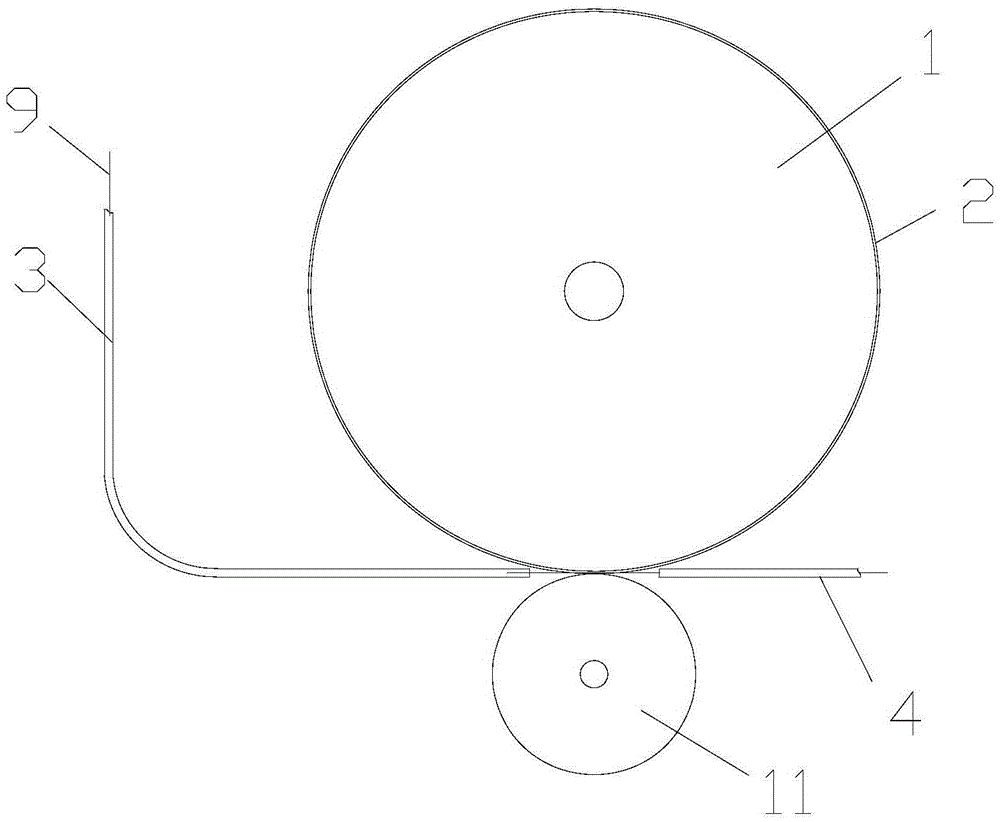

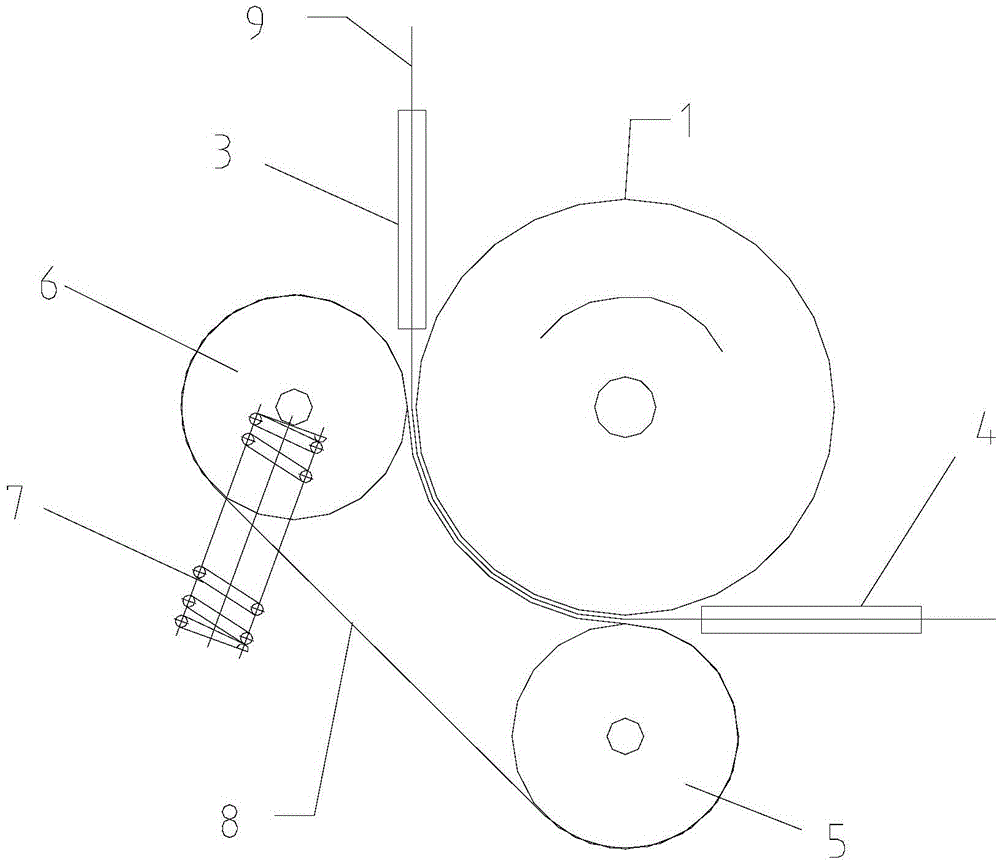

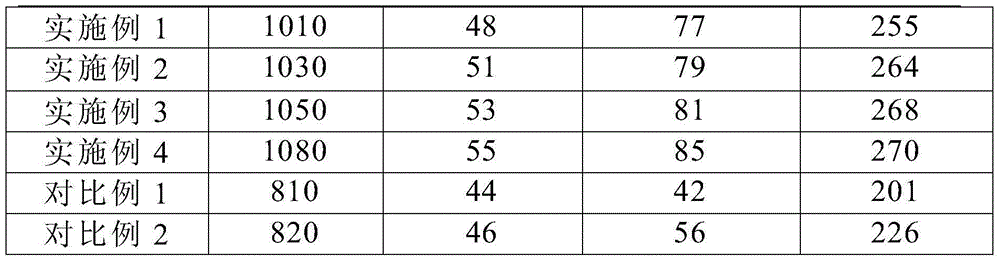

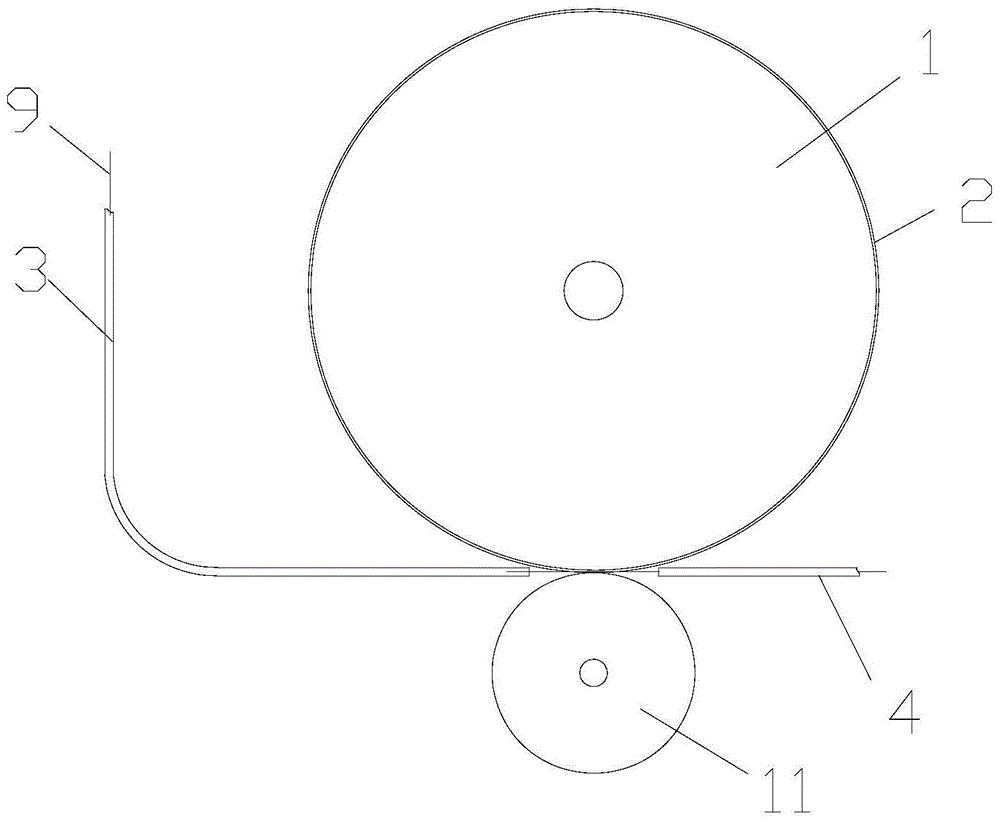

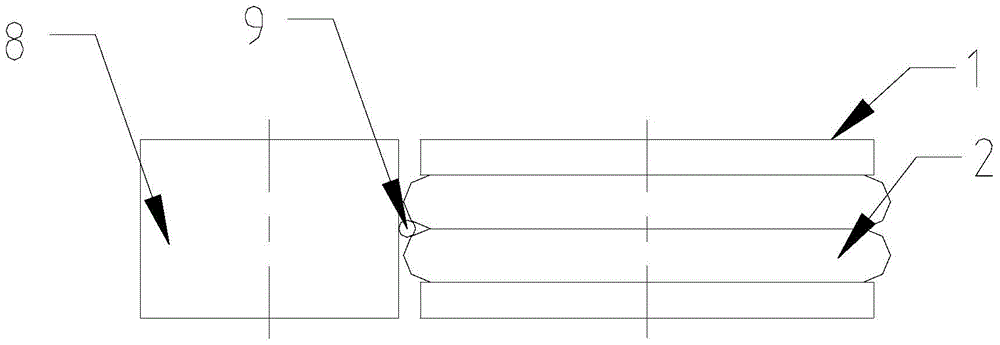

Fireworks lead conveying device

ActiveCN105547052AGuaranteed reliabilityEliminate potential safety hazardsFilament handlingFireworksEngineeringCombustion

The invention discloses a fireworks lead conveying device. The fireworks lead conveying device comprises a driving wheel (1), a lead inlet guiding pipe (3), a lead outlet guiding pipe (4), a first roller (5) and a second roller (6), wherein a flexible conveyer belt (8) is mounted on the first roller (5) and the second roller (6) in a wrapping manner and partly wraps the periphery of the driving wheel (1); the lead inlet guiding pipe (3) is aligned with the wrapping inlet of the driving wheel (1) and the flexible conveyer belt (8), and the lead outlet guiding pipe (4) is aligned with the wrapping outlet of the driving wheel (1) and the flexible conveyer belt (8). The fireworks lead conveying device disclosed by the invention can maintain the quality of a lead and does not change the combustion efficiency of the lead.

Owner:浏阳市丰田烟花制造有限公司

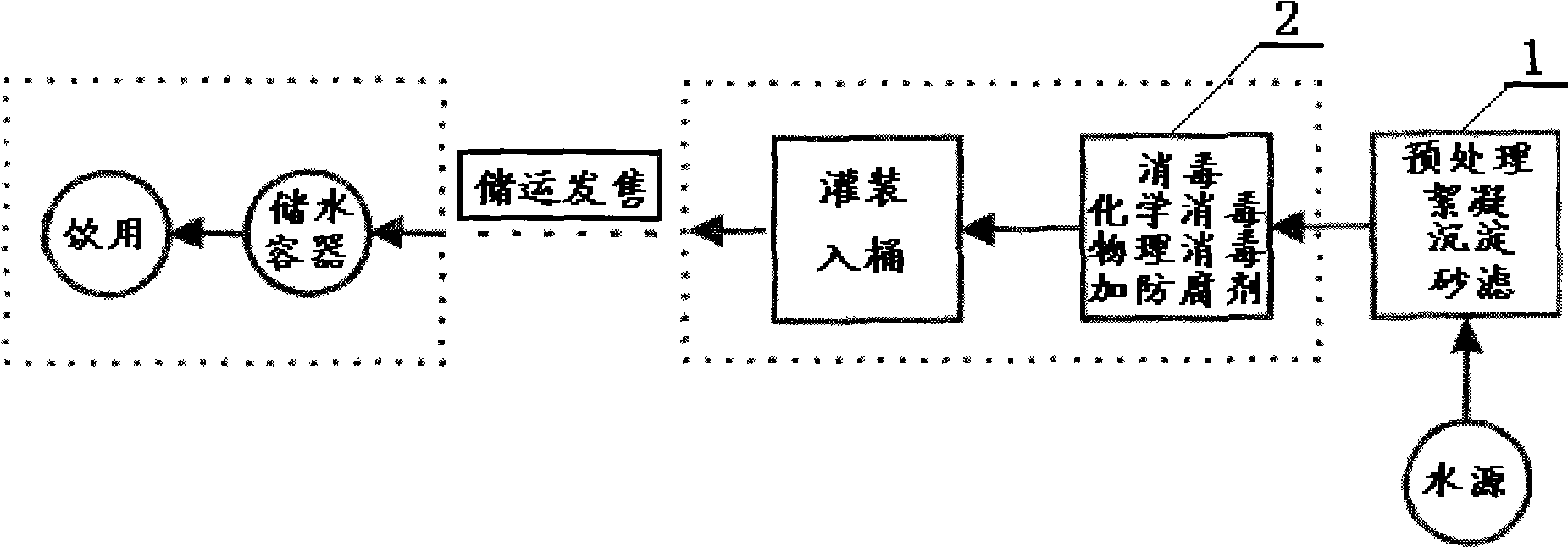

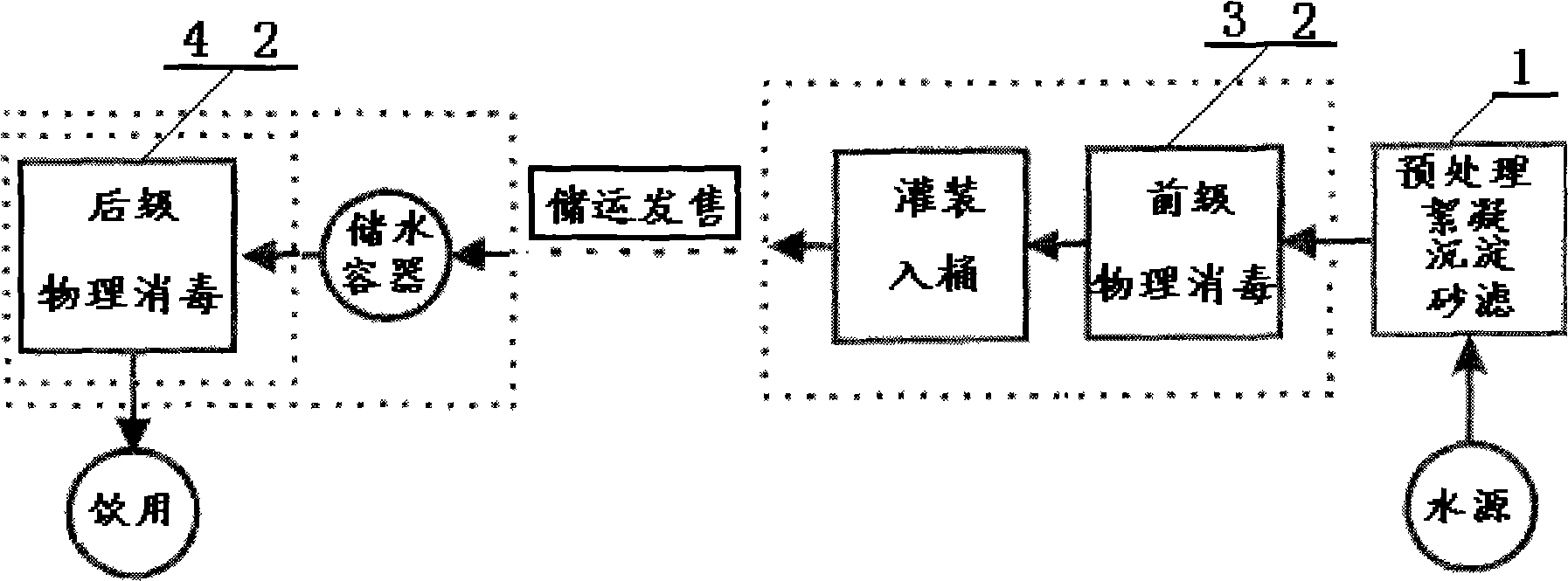

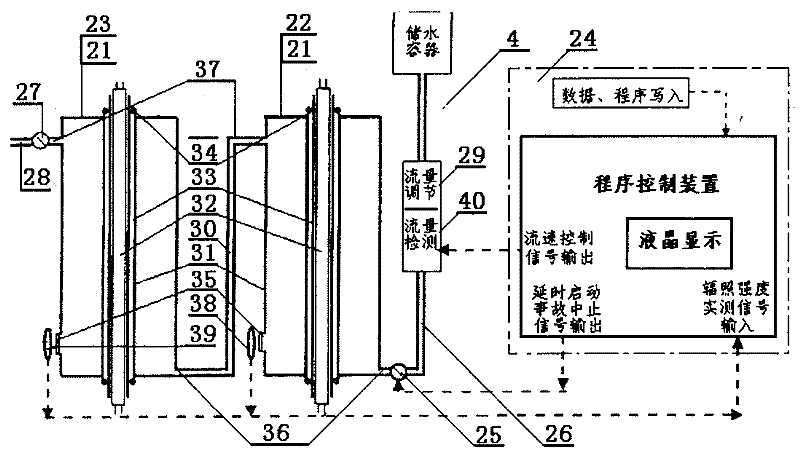

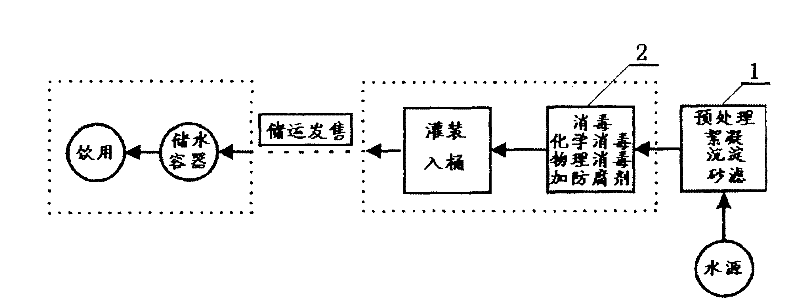

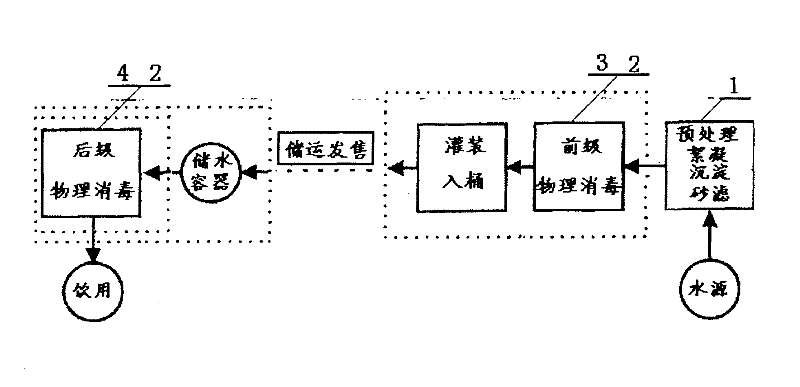

Composite and separable physical disinfection method and device of barreled drinking water

InactiveCN101531431AOvercoming the difficulty of no disinfection persistenceWill not reduce the contentWater/sewage treatment by irradiationMultistage water/sewage treatmentWater productionDisinfection methods

The invention relates to a composite and separable physical disinfection method and a device of barreled drinking water; full physical disinfection technology without any chemical sanitizing agent and any chemical preservative is utilized; a disinfection system consists of a forward series connection type ultrafiltration membrane filter system in a water production factory and backward series connection type ultraviolet radiation disinfection systems respectively set at all user ends; a disinfection safety automatic detection control device is also configured; more than 99.99 percent of viruses in the original water and more than 99.9 percent of other pathogenic microbes can be killed; more than 99.9 percent of generated reproduction bacteria caused by barrel wall stemming and water gas mixing during storage and transportation after the barreled drinking water is packed and during the operation can be killed; meanwhile, any disinfection by-product can not be generated; the drinking water of good quality and with remained quantity property can be obtained; the method can practically solve the problems that the disinfection by-product is generated in the current chemical technology and the current physical disinfection technology is short of disinfection durative and safety; the view having been generally recognized by the water production industry for a long time is changed that the physical disinfection technology cannot be used separately and can be combined with the chemical disinfection method; thus, the method of the invention has strong practicability.

Owner:李杰

Novel nitriding process

InactiveCN106367711AReduce brittlenessReduce hardnessSolid state diffusion coatingMicro structureRoom temperature

The invention discloses a novel nitriding process. The novel nitriding process comprises the following steps that a cleaned part is placed in a nitride furnace and subjected to preoxidation for 1-2 hours at the temperature of 350-400 DEG C, then ammonia gas and an energizing reagent are injected, exhausting is carried out, the temperature is increased to 520-650 DEG C, then the ammonia gas and the energizing reagent continue to be injected, insulating nitriding is carried out for 12-18 hours at the temperature of 520-650 DEG C, and then the part is cooled to be at the room temperature, specifically, the flow of the injected ammonia gas is 1.4-2.0 m<3> / h, the flow of the injected energizing reagent is 2-4 ml / min, and during insulating nitriding, the pressure of the nitride furnace is 0.4-1.0 kPa, and the ammonia gas resolution ratio is 20%-70%. The nitriding process is simple, the effective hardening layer depth of the obtained part is higher, and the micro-structure of a permeating layer is better; and according to the product subjected to nitriding treatment, deformation is tiny, the dimension precision and the mechanical strength index meet the product design requirements, and perfect combination of the surface hardness, effective hardening layer depth and deformation with the process cycle is achieved.

Owner:CHONGQING TIEMA IND GRP

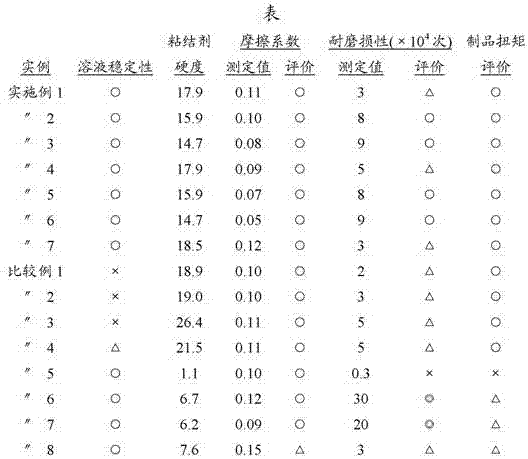

Surface treatment agent for vulcanized rubber

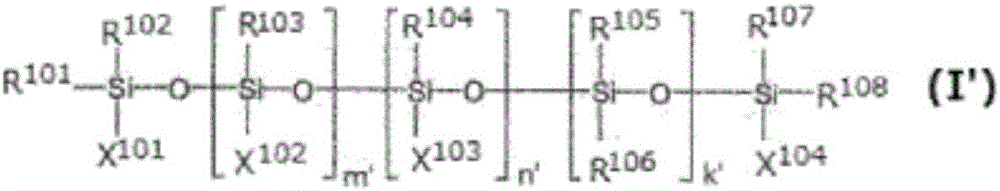

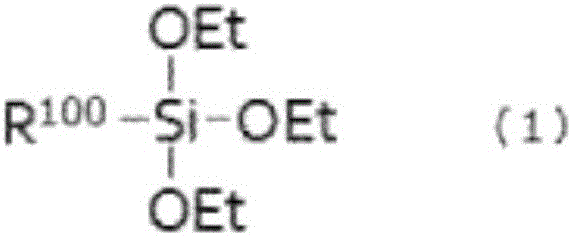

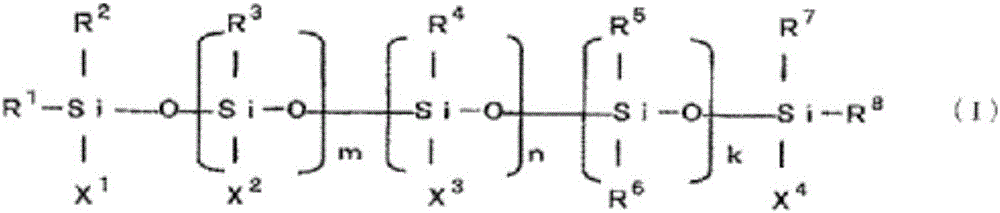

ActiveCN107108975AReduce hardnessDoes not reduce hardnessEngine sealsSynthetic resin layered productsOligomerOrganic solvent

A surface treatment agent for vulcanized rubber, comprising an organic solvent solution containing fluororesin particles in a ratio of 10-160 parts by weight with respect to 100 parts by weight in terms of solid content of a 1,2-polybutadiene containing an isocyanate group, the organic solvent solution using as a dispersing agent 2.5-20 parts by weight of a fluorine-containing surfactant based on an oligomer containing a perfluoroalkyl group. This surface treatment agent for vulcanized rubber has enhanced liquid stability of the organic solvent solution and enhances product torque evaluation and additional hardness and abrasion resistance overall in a coating film formed therefrom, and is effective for use as a coating agent or the like a seal lip part of an oil seal.

Owner:NOK CORP

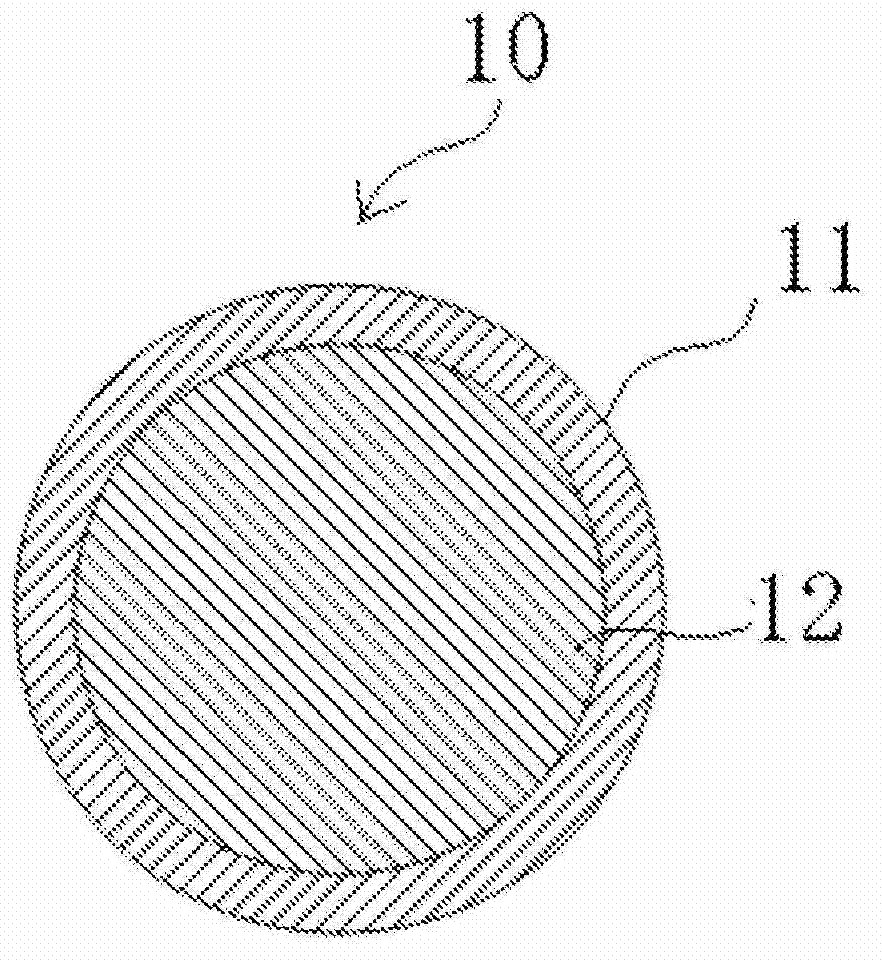

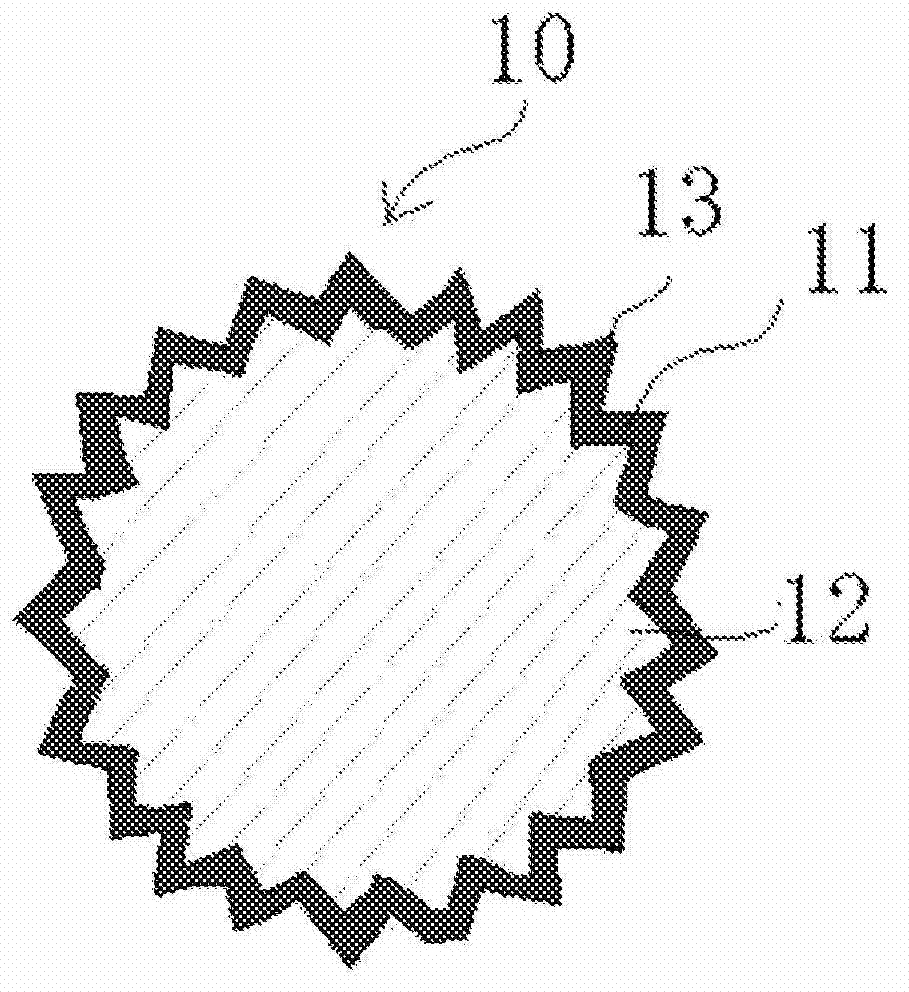

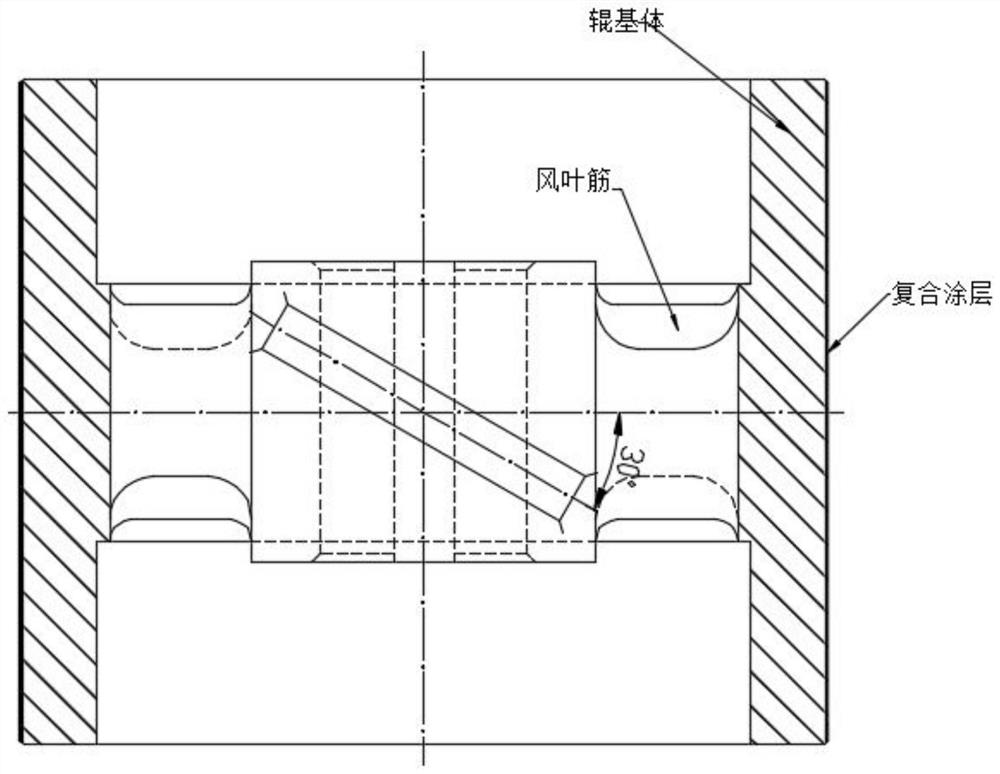

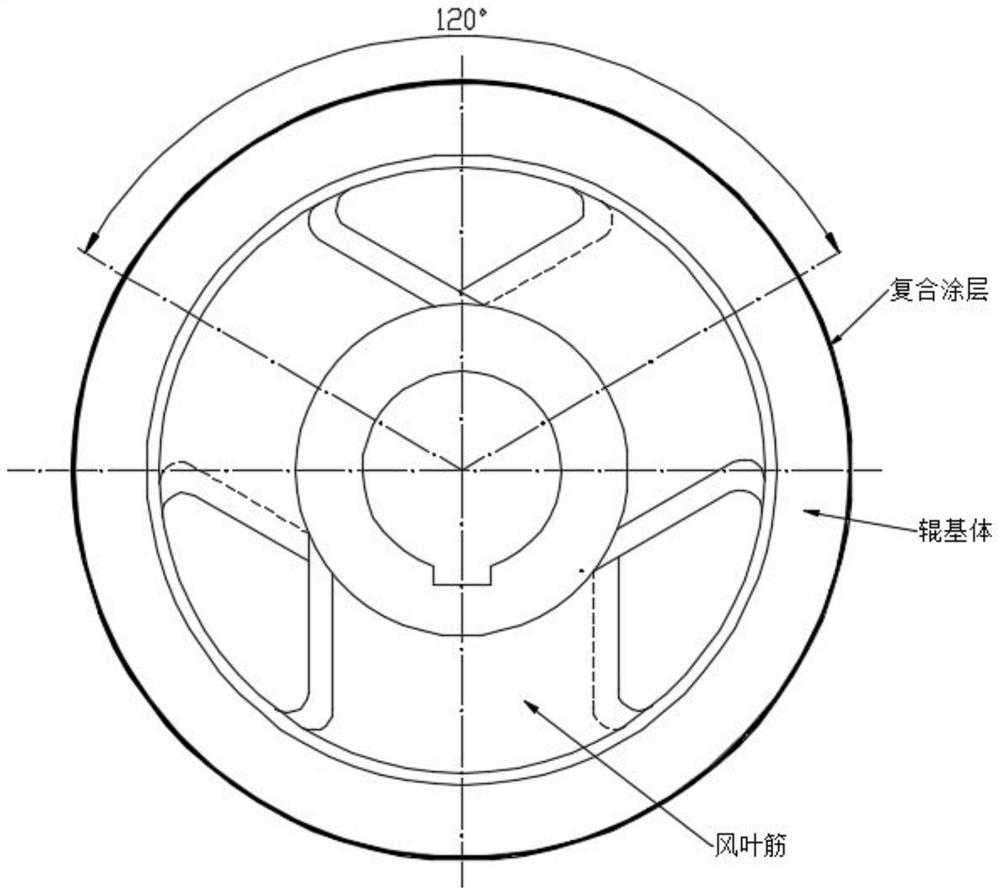

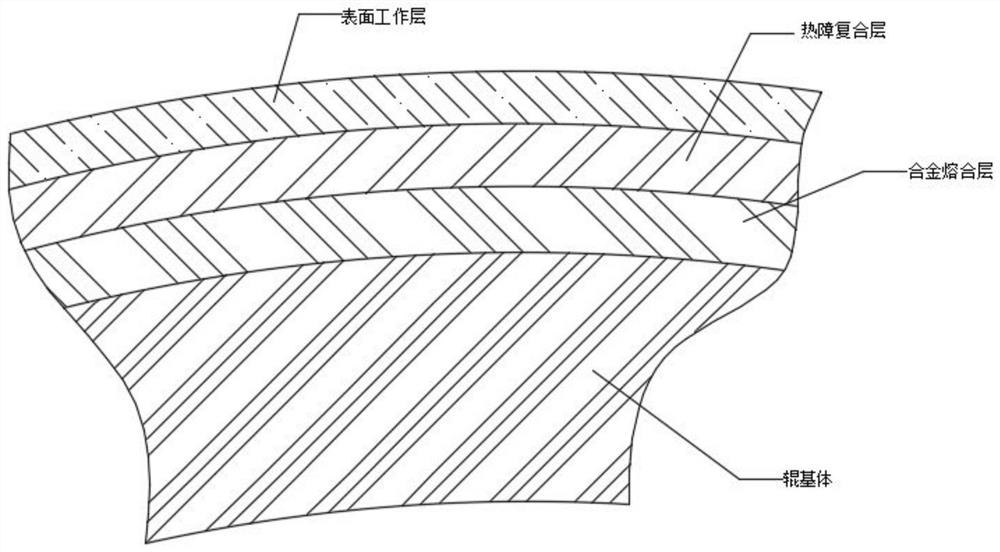

Novel wear-resistant superhard metallurgical frequency conversion roller structure and manufacturing process of frequency conversion roller

PendingCN114226473AExtended service lifeExtend working lifeMolten spray coatingMetal rolling arrangementsFrequency conversionEngineering

The invention discloses a novel wear-resistant superhard metallurgical variable-frequency roller structure and a production process, and belongs to the field of metallurgical rollers for rolled steel conveying. Comprising a roller base body; a plurality of fan blade ribs are circumferentially distributed in the roller base body at equal intervals, the fan blade ribs are arranged in the axial direction of the roller base body in a vortex mode, a composite coating is arranged on the outer side face of the roller base body, and an alloy fusion layer, a thermal barrier composite layer and a surface working layer are sequentially arranged on the composite coating from inside to outside. A composite coating is additionally arranged on the surface of the frequency conversion roller according to needs, and if smooth spraying is not beneficial to combination with the surface coating, the surface of a roller base body is modified as follows: a spiral coarsening structure is arranged on the outer side face of the roller base body. After spiral roughening treatment, the contact area between the roller base body and the composite coating is increased, the roller base body and the composite coating can be effectively combined, and the bonding strength between the roller base body and the composite coating is guaranteed.

Owner:马鞍山市恒泰重工机械有限公司

Rubber composition and pneumatic tire using same

The invention provides a rubber composition which achieves higher silica dispersibility without lowering workability and hardness, while having excellently low fuel consumption properties; and a pneumatic tire which uses this rubber composition. A rubber composition which is obtained by blending 5-200 parts by mass of (B) silica relative to 100 parts by mass of (A) a diene rubber, 1-20% by mass of (C) a silane coupling agent relative to the silica, and 1-20% by mass of (D) a glycerol mono-fatty acid ester relative to the mass of silica, said glycerol mono-fatty acid ester being derived from a fatty acid having 8-24 carbon atoms. With respect to this rubber composition, 10 parts by mass or more in 100 parts by mass of the component (A) has a heteroatom-containing functional group in the main chain and / or at an end.

Owner:THE YOKOHAMA RUBBER CO LTD

Heat treatment process for high-carbon-chromium bearing steel pipe

InactiveCN108504839ADecompose fullyImprove conversion rateFurnace typesQuenching agentsHigh carbonRoom temperature

The invention relates to a heat treatment process for a high-carbon-chromium bearing steel pipe. The heat treatment process comprises the following steps that the high-carbon-chromium bearing steel pipe is heated in a quenching furnace to 850-890 DEG C, and heat preservation is conducted; after being washed and dried, the high-carbon-chromium bearing steel pipe is placed into a vacuum cooling oilfurnace to be cooled to 76-82 DEG C, and heat preservation is conducted for 2-5 min; the high-carbon-chromium bearing steel pipe is placed into a tempering furnace to be heated to 165-190 DEG C, heatpreservation is conducted for 1.5-2.5 h, and then the high-carbon-chromium bearing steel pipe is placed into the vacuum cooling oil furnace to be cooled to 80-95 DEG C, taken out to be washed and dried, and cooled in air to be the room temperature; and tempering treatment operation is repeated, and the high-carbon-chromium bearing steel pipe is subjected to secondary tempering treatment. The high-carbon-chromium bearing steel pipe produced by the heat treatment process is high in hardness, uniform in structure, good in abrasion resistance and high in toughness.

Owner:ZHEJIANG JIANLI CO LTD

Special ceramic cutter material for crushing wire-board or circuit board and preparation method thereof

InactiveCN100569699CSimple preparation processImprove fracture toughnessTitanium carbideCeramic cutting tool

The invention discloses a special ceramic cutter material for circuit board powder or circuit board crushing and a preparation method thereof, belonging to the technical field of crushing equipment. The ceramic cutter uses whiskers as toughening material, tungsten carbide as base material, titanium carbide as wear-resistant agent, carbon as deoxidizer, chromium-containing compound, lanthanum oxide and cerium oxide as additives, and the above components are uniform After mixing, it is directly molded by hot pressing. After the raw materials are fully mixed, they are taken out and placed in the sample hot-pressing tank of the hot-pressing machine for direct hot-pressing. The pressure during hot-pressing is 10-40MPa, and the hot-pressing temperature is 1480-1600°C. The special tough ceramic cutter developed by the invention has good impact toughness, wear resistance and chemical stability, and simultaneously has high hardness. The tool material not only has a simple preparation process, but also has a production cycle much shorter than the conventional preparation method in which mixed raw materials are first pressed into shape and then sintered into shape. The cutter material is not only suitable for making special cutters for waste circuit boards / circuit board crushing equipment.

Owner:TSINGHUA UNIV

Preparation and producing method for promoting the Nanguo pear coloring

InactiveCN101283685BSolve the problem of coloringIncrease anthocyanin contentBiocidePlant growth regulatorsBiotechnologySucrose

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

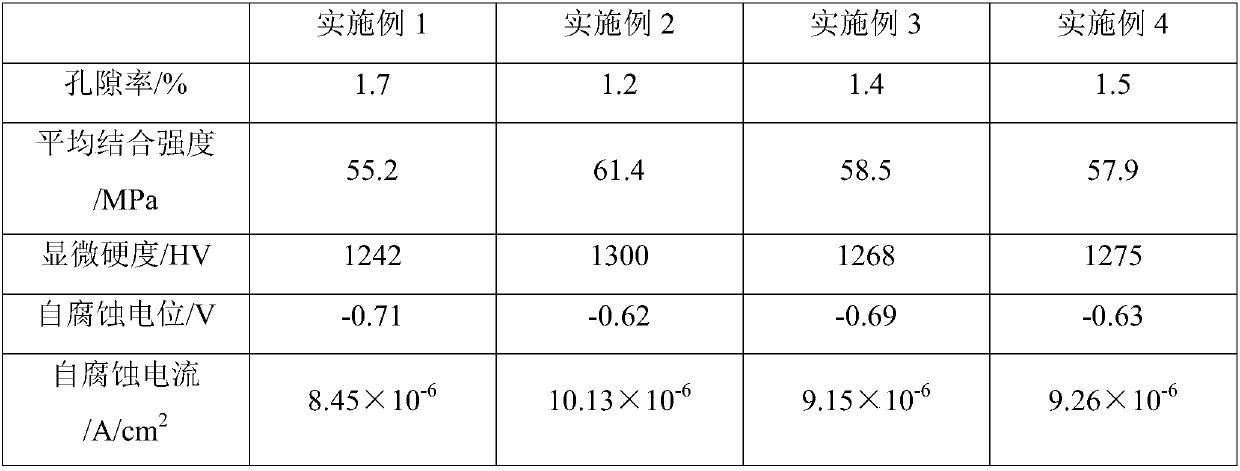

Aluminum-based amorphous nano composite powder core wire material and preparation method thereof

The invention discloses an aluminum-based amorphous nano composite powder core wire material and a preparation method of the aluminum-based amorphous nano composite powder core wire material. The wirematerial is made of a powder core wrapped with pure aluminum belt outer skin, and by mass percentage, the powder core accounts for 40-48% of the powder core wire material. The powder core is formed by mixing following alloy powder, and the powder core comprises, by mass percentage, 4-8% of chromium, 2-7% of silver, 2-6% of nickel, 1.5-6% of nano silicon carbide, 3-12% of nano alumina, 1-7% of nano magnesium oxide and the balance iron. Compared with the prior art, the aluminum-based amorphous nano composite powder core wire material and the preparation method have the following beneficial effects that the aluminum-based amorphous nano composite powder core wire material easily forms an oxide passivation film on the surface in a corrosive medium, and the corrosion resistance of the coatingis improved effectively while the overall hardness of the coating is not lowered; and the preparation process of the aluminum-based amorphous nano composite powder core wire material is simple, the time is short, and the efficiency is high.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

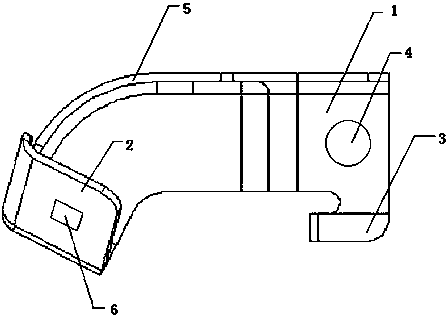

Lightweight fixing bracket for car engine and car body

InactiveCN109209637APrevent follow-up phenomenonImprove rigidityMachines/enginesEngine componentsEngineeringFlanging

The invention discloses a lightweight fixing bracket for a car engine and a car body. The lightweight fixing bracket comprises a bracket body, the bracket body is of an L-shaped structure, comprises an upper side face and a lower side face, and the upper side face is vertically connected with the lower side face; an installation hole and a stop rotating edge are further arranged on the bracket body, the installation hole is formed in the center of the upper side face in a penetrating mode, the stop rotating edge is arranged at one end of the upper side face, the stop rotating edge is perpendicular to the upper side face, a flanging is arranged on the edge of the bracket body, the flanging is vertically connected with the bracket body, an arc included angle is formed at the connection, andthe stop rotating edge and the convex ends of the flanging have the same orientation. The rigidity of the fixing bracket is improved, and the rotating following phenomenon during installation is prevented.

Owner:JINGJIANG XINCHENG VEHICLE PARTS

A method for modifying nanocarbon materials to strengthen epoxy resin matrix composites

ActiveCN108219368BDoes not reduce hardnessNo reduction in fracture toughnessEpoxyResin-Based Composite

Owner:常州嘉晖新材料科技有限公司

A method for local softening of high-strength alloy steel carburized parts

The invention relates to the field of local annealing heat treatment of carburized parts and specifically relates to a local softening method of high-strength alloy steel carburized parts. The local softening method can be applied to manufacturing the carburized parts having different requirements on the hardness of the high-strength steel. A carburized locking pin is locally heated by use of fused salt in a salt-bath furnace; the locking pin is made of martensitic steel 16Cr3NiWMoVNbE; an annealing heat-protective fixture is adopted for performing heat protection on the carburized surface of the locking pin part, and the local annealing part is heated till a temperature above 600 DEG C for softening. The local softening method of the high-strength alloy steel carburized parts is capable of reducing the hardness of the flaring positions of the parts and preventing the parts from cracking in the flaring process under the condition of guaranteeing the hardness of the carburized surfaces. According to the local softening method, the method of rapid heating annealing by use of protective salt bath is adopted for performing annealing treatment on the gear locking pin, so that the high strength of the carburized surface and the base body of the part can be prevented from reduction, and the hardness of the portion needing to be deformed can be reduced, and as a result, the cracking problem in the flaring deformation process of the part is solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Formula and preparation method of toughened epoxy resin

The preparation method comprises the following steps: putting 70-85% of bisphenol A epoxy resin, 1-10% of polyethylene glycol, 10-25% of benzyl alcohol and 0.1-5% of an epoxy silane coupling agent into a reaction kettle, carrying out a heating reaction for 6 hours, stirring at 60 DEG C, dropwise adding a sodium hydroxide aqueous solution, adding benzene, heating to 55-75 DEG C, adding acetic acid for neutralization, and carrying out cooling to room temperature; under the condition that the hardness, the glass transition temperature TG and the transparency are not reduced, the adhesive density is improved, the flexibility is enhanced, the mechanical strength is strengthened, meanwhile, the dilution effect of the epoxy resin is good through reaction of multiple systems, and the toughness effect in an epoxy resin curing system is well improved.

Owner:广州惠利电子材料有限公司

Automatic jump connector for street lamp

InactiveCN105490054AImprove high temperature performanceLight in massCoupling contact membersRare-earth elementEngineering

The invention relates to an automatic jump connector for a street lamp, and belongs to the technical field of alloy materials. The connector sequentially comprises cylindrical lower end part, middle part and upper end part from bottom to top, wherein the diameter of the lower end part is greater than that of the middle part; the diameter of the middle part is greater than that of the upper end part; a section cutting plane is arranged at the bottom end of the lower end part; the cutting direction of the section cutting plane inclines from the external surface of the lower end part to the center of the lower end part from top to bottom; an urgent surface is a cambered surface; the lower end of the urgent surface is flush with the bottom surface of the lower end part; the connector comprises a ceramic filling part and a metal layer; the metal layer is arranged on an outer layer of the ceramic filling part and is a tin-phosphor bronze layer; and the metal layer is prepared from the following components in percentage by weight: 2.7%-3.3% of Zn, 3.5%-4.5% of Sn, 0.01%-0.03% of P, 0.01%-0.05% of Fe, 0.5%-1% of Ni, 0.05%-0.1% of Si, 0.1%-0.5% of a rare earth element, less than 0.02% of Pb, less than 0.002% of Al, less than 0.002% of Sb, less than 0.002% of Bi and the balance of Cu and inevitable impurity elements. The connector has relatively high conductivity, excellent strength, high-temperature usability, wear-resisting property, thermal fatigue resistance, stress relaxation resistance and the like.

Owner:宁波市鄞州永佳连接器件厂(普通合伙)

Fireworks Lead Conveying Device

ActiveCN105547052BDoes not affect strengthDoes not reduce hardnessFilament handlingFireworksDrive wheelCombustion

The invention discloses a fireworks lead conveying device. The fireworks lead conveying device comprises a driving wheel (1), a lead inlet guiding pipe (3), a lead outlet guiding pipe (4), a first roller (5) and a second roller (6), wherein a flexible conveyer belt (8) is mounted on the first roller (5) and the second roller (6) in a wrapping manner and partly wraps the periphery of the driving wheel (1); the lead inlet guiding pipe (3) is aligned with the wrapping inlet of the driving wheel (1) and the flexible conveyer belt (8), and the lead outlet guiding pipe (4) is aligned with the wrapping outlet of the driving wheel (1) and the flexible conveyer belt (8). The fireworks lead conveying device disclosed by the invention can maintain the quality of a lead and does not change the combustion efficiency of the lead.

Owner:浏阳市丰田烟花制造有限公司

Composite and separable physical disinfection device of barreled drinking water

InactiveCN101531431BOvercoming the difficulty of no disinfection persistenceWill not reduce the contentWater/sewage treatment by irradiationMultistage water/sewage treatmentUltrafiltrationWater production

The invention relates to a composite and separable physical disinfection device; full physical disinfection technology without any chemical sanitizing agent and any chemical preservative is utilized; a disinfection system consists of a forward series connection type ultrafiltration membrane filter system in a water production factory and backward series connection type ultraviolet radiation disinfection systems respectively set at all user ends; a disinfection safety automatic detection control device is also configured; more than 99.99 percent of viruses in the original water and more than 99.9 percent of other pathogenic microbes can be killed; more than 99.9 percent of generated reproduction bacteria caused by barrel wall stemming and water gas mixing during storage and transportation after the barreled drinking water is packed and during the operation can be killed; meanwhile, any disinfection by-product can not be generated; the drinking water of good quality and with remained quantity property can be obtained; the method can practically solve the problems that the disinfection by-product is generated in the current chemical technology and the current physical disinfection technology is short of disinfection durative and safety; the view having been generally recognized by the water production industry for a long time is changed that the physical disinfection technology cannot be used separately and can be combined with the chemical disinfection method; thus, the method of the invention has strong practicability.

Owner:李杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com