Fireworks lead conveying device

A technology for conveying devices and fireworks leads, which is applied in the directions of transportation and packaging, pyrotechnics, and delivery of filamentous materials. The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

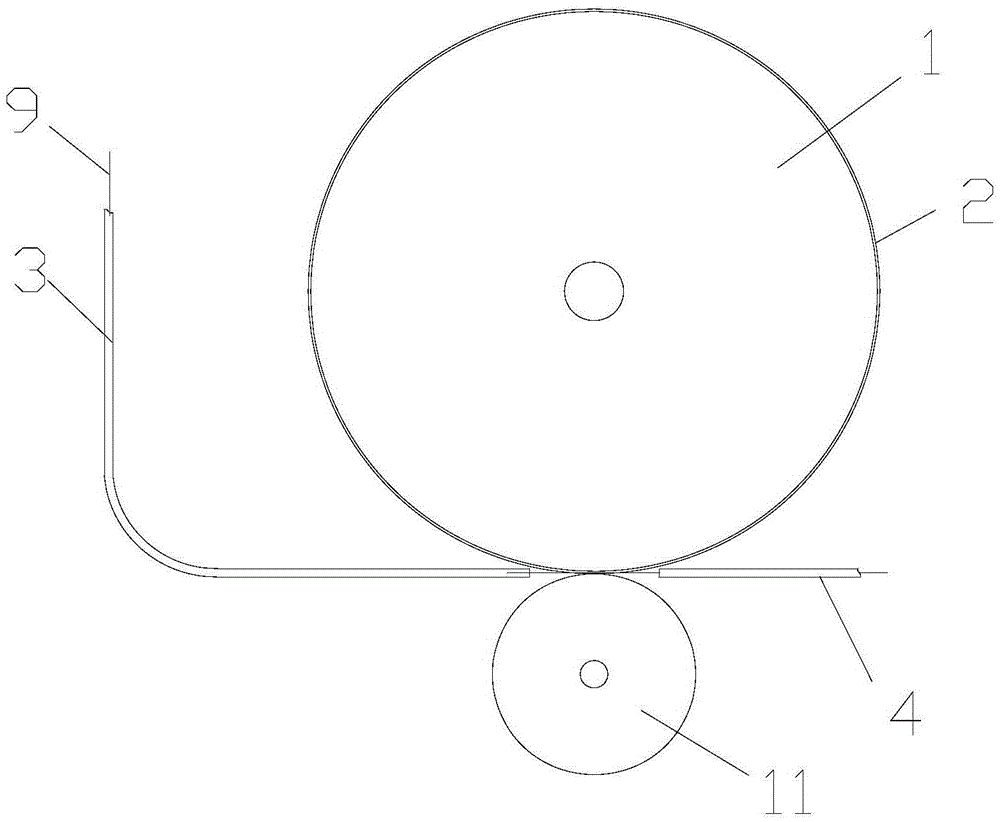

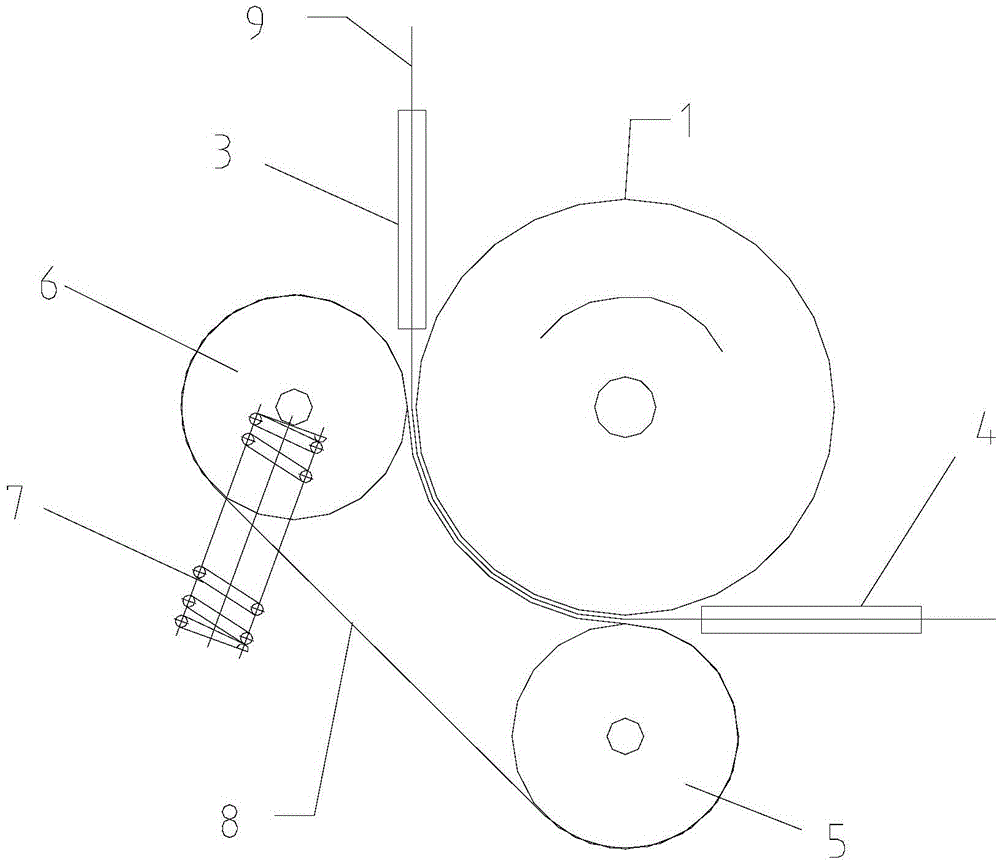

[0033] see Figure 4 and Figure 5 , the firework lead conveying device that the present invention provides, comprises driving wheel 1, is arranged on the circumference of driving wheel 1 and is provided with two O-shaped rubber rings 2, lead wire inlet guide tube 3 and lead wire outlet guide tube 4, also includes a first Roller 5 and a second roller 6, the second roller 6 is installed on the adjustment device 7, a flexible conveyor belt 8 is wound around the first roller 5 and the second roller 6, and the flexible conveyor belt 8 partially wraps the driving wheel 1 The O-shaped rubber ring 2 on the outer periphery of the lead wire inlet guide tube 3 is aligned with the package entrance of the driving wheel 1 and the flexible conveyor belt 8, and the lead wire outlet guide tube 4 is aligned with the package exit of the drive wheel 1 and the flexible conveyor belt 8 The outer circle of the driving wheel 1 is provided with a synchronous gear 101, and the outer side of the flexi...

Embodiment 2

[0035] see Figure 6 and Figure 7 , the firework lead conveying device that the present invention provides, comprises driving wheel 1, is arranged on the circumference of driving wheel 1 and is provided with two O-shaped rubber rings 2, lead wire inlet guide tube 3 and lead wire outlet guide tube 4, also includes a first Roller 5 and a second roller 6, the second roller 6 is installed on the adjustment device 7, a flexible conveyor belt 8 is wound around the first roller 5 and the second roller 6, and the flexible conveyor belt 8 partially wraps the driving wheel 1 The O-shaped rubber ring 2 on the outer periphery of the lead wire inlet guide tube 3 is aligned with the package entrance of the driving wheel 1 and the flexible conveyor belt 8, and the lead wire outlet guide tube 4 is aligned with the package exit of the drive wheel 1 and the flexible conveyor belt 8 The outer circle of the driving wheel 1 is provided with a synchronous bull gear 102, the outer circle of the fi...

Embodiment 3

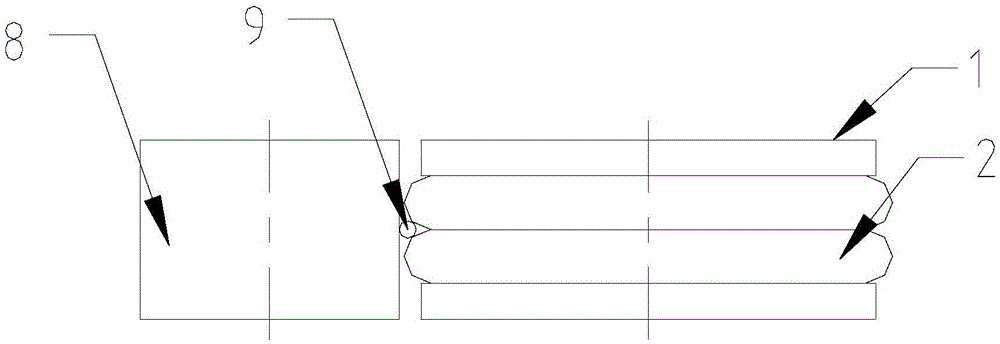

[0037] see Figure 8 , the firework lead conveying device that the present invention provides, comprises driving wheel 1, is arranged on the circumference of driving wheel 1 and is provided with two O-shaped rubber rings 2, lead wire inlet guide tube 3 and lead wire outlet guide tube 4, also includes a first Roller 5 and a second roller 6, the second roller 6 is installed on the adjustment device 7, a flexible conveyor belt 8 is wound around the first roller 5 and the second roller 6, and the flexible conveyor belt 8 partially wraps the driving wheel 1 The O-shaped rubber ring 2 on the outer periphery of the lead wire inlet guide tube 3 is aligned with the package entrance of the driving wheel 1 and the flexible conveyor belt 8, and the lead wire outlet guide tube 4 is aligned with the package exit of the drive wheel 1 and the flexible conveyor belt 8 The driving wheel 1 is coaxially provided with a large synchronous wheel 103, the first roller 5 is coaxially provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com