Patents

Literature

391results about How to "Won't crush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

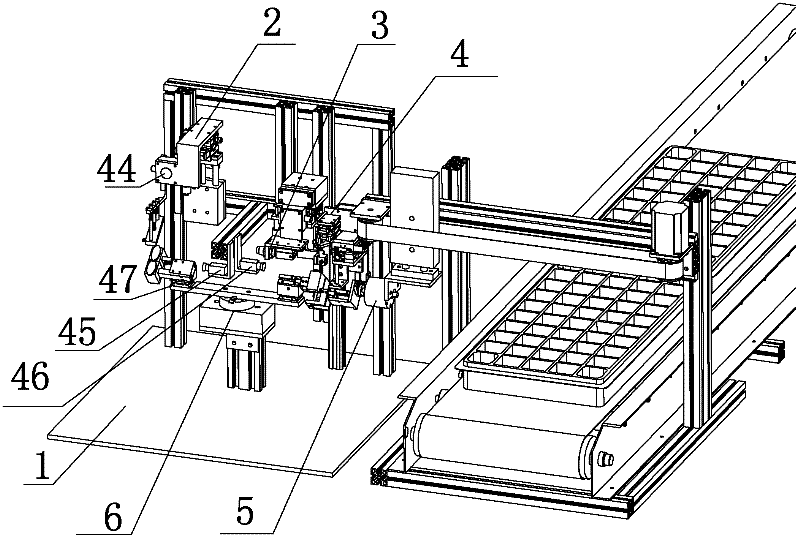

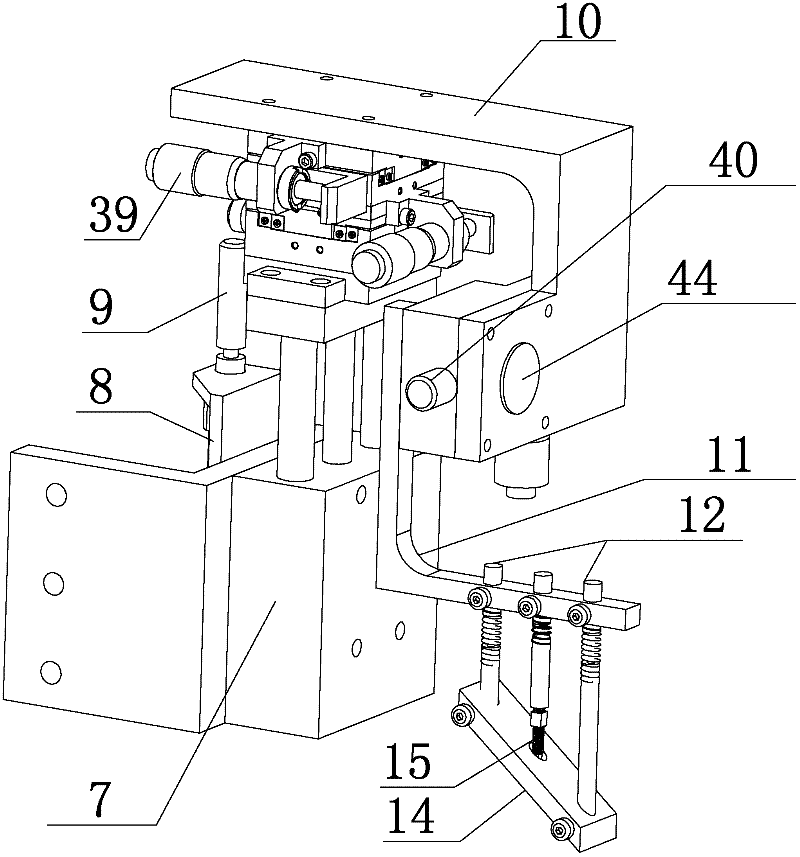

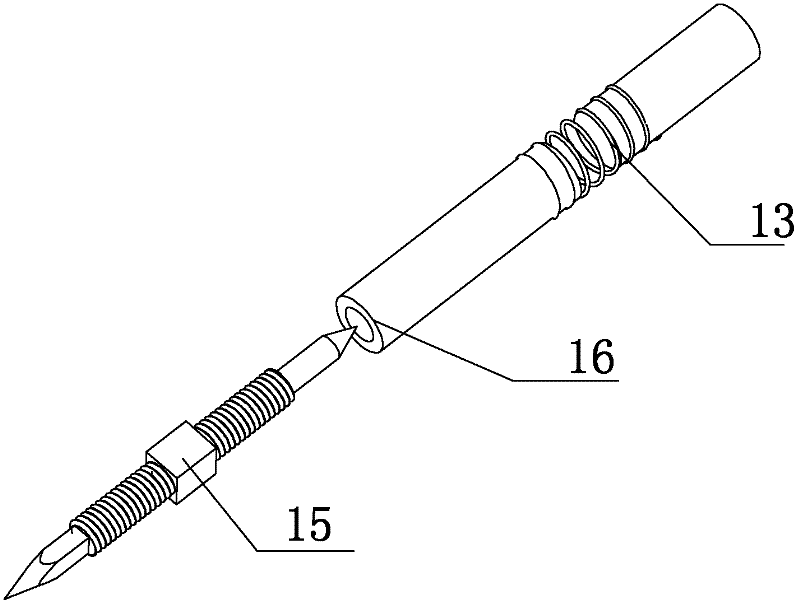

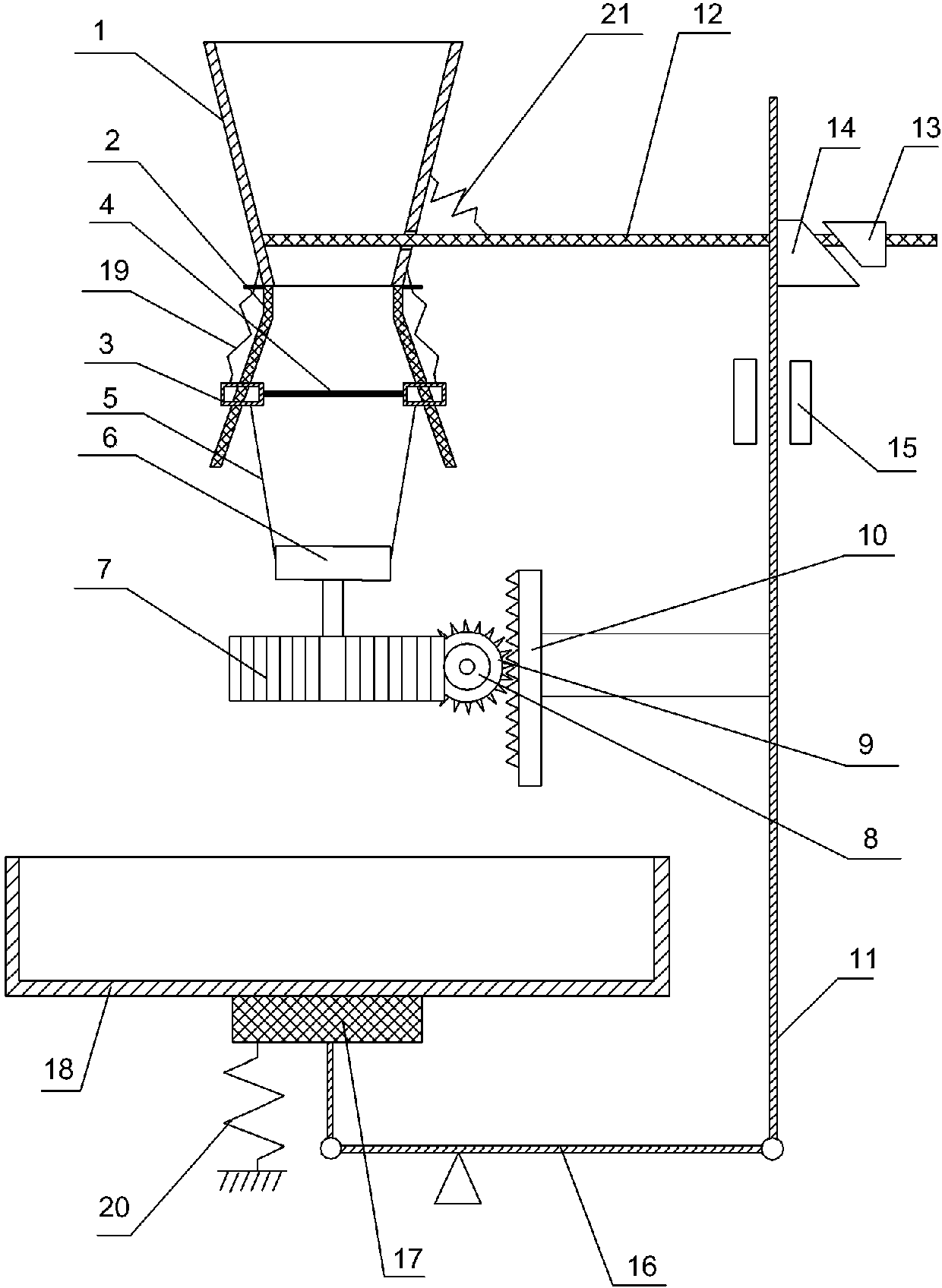

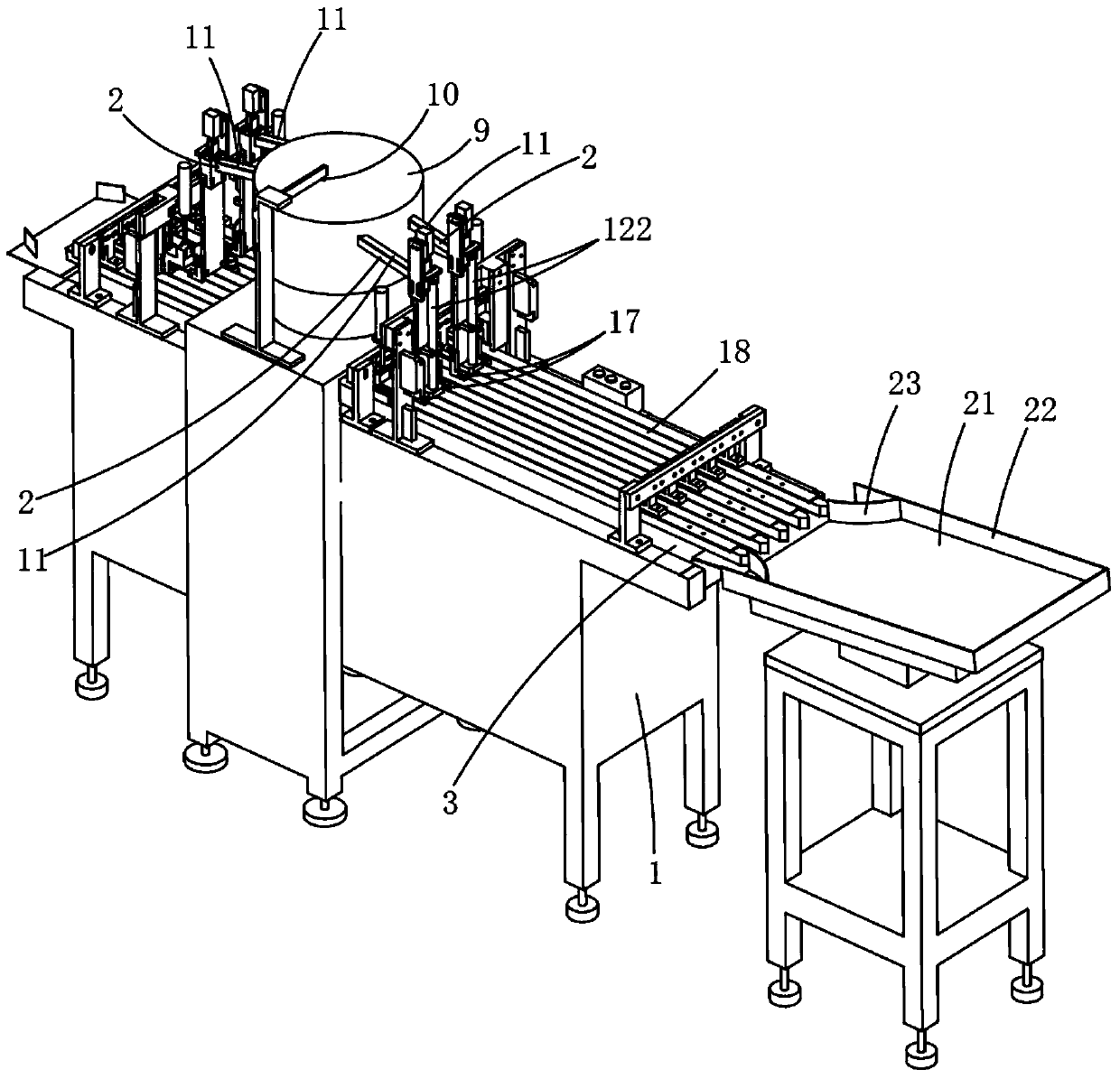

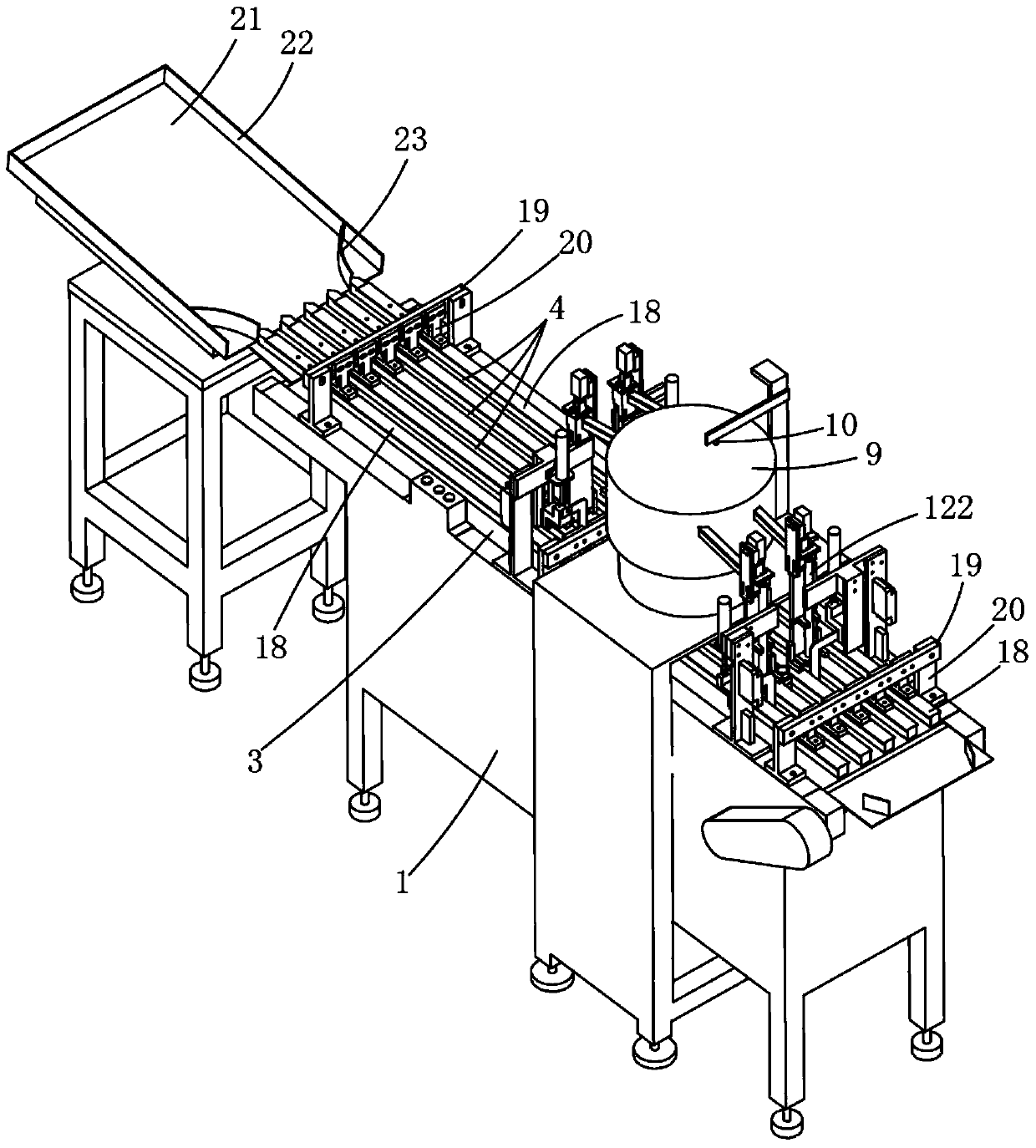

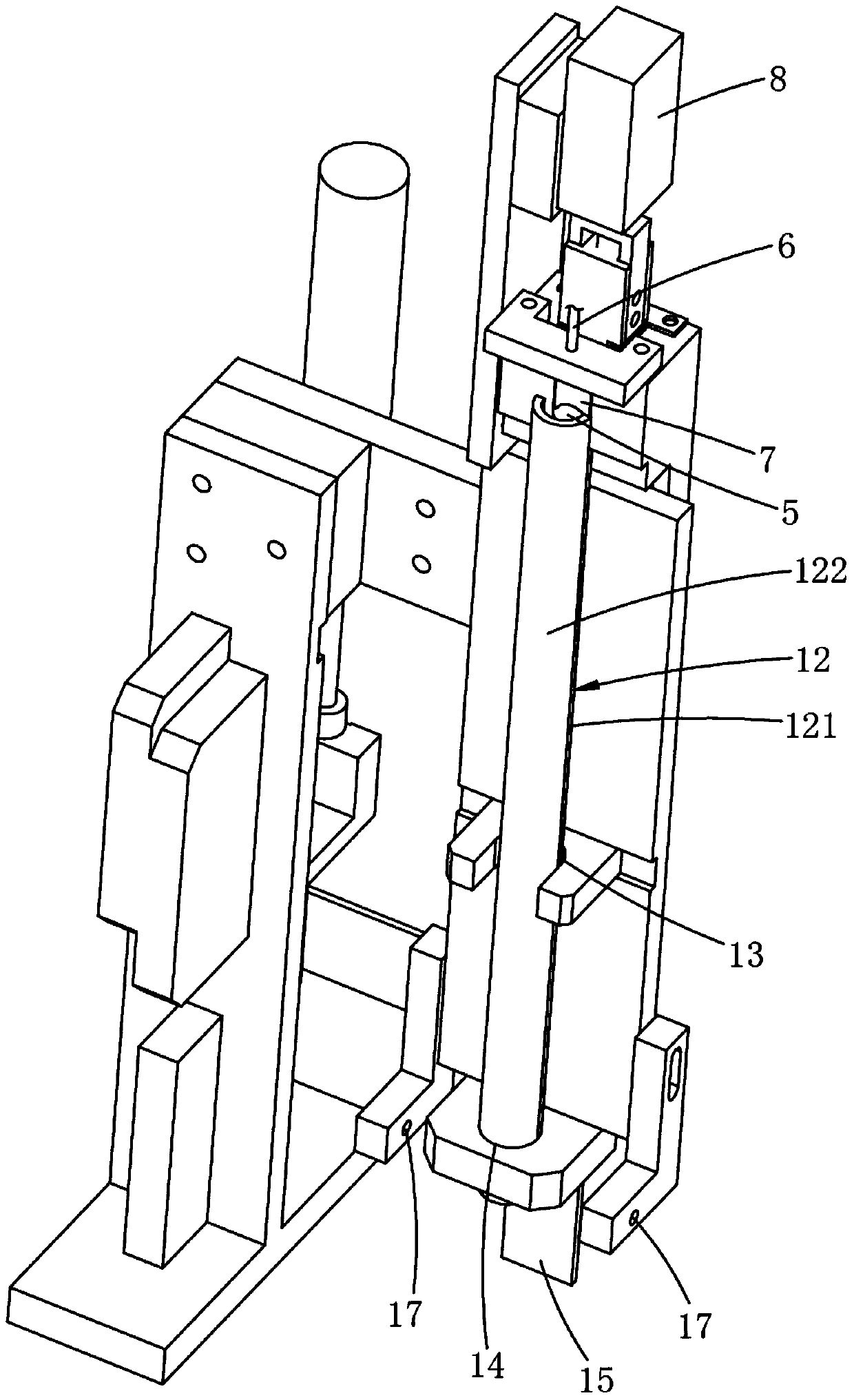

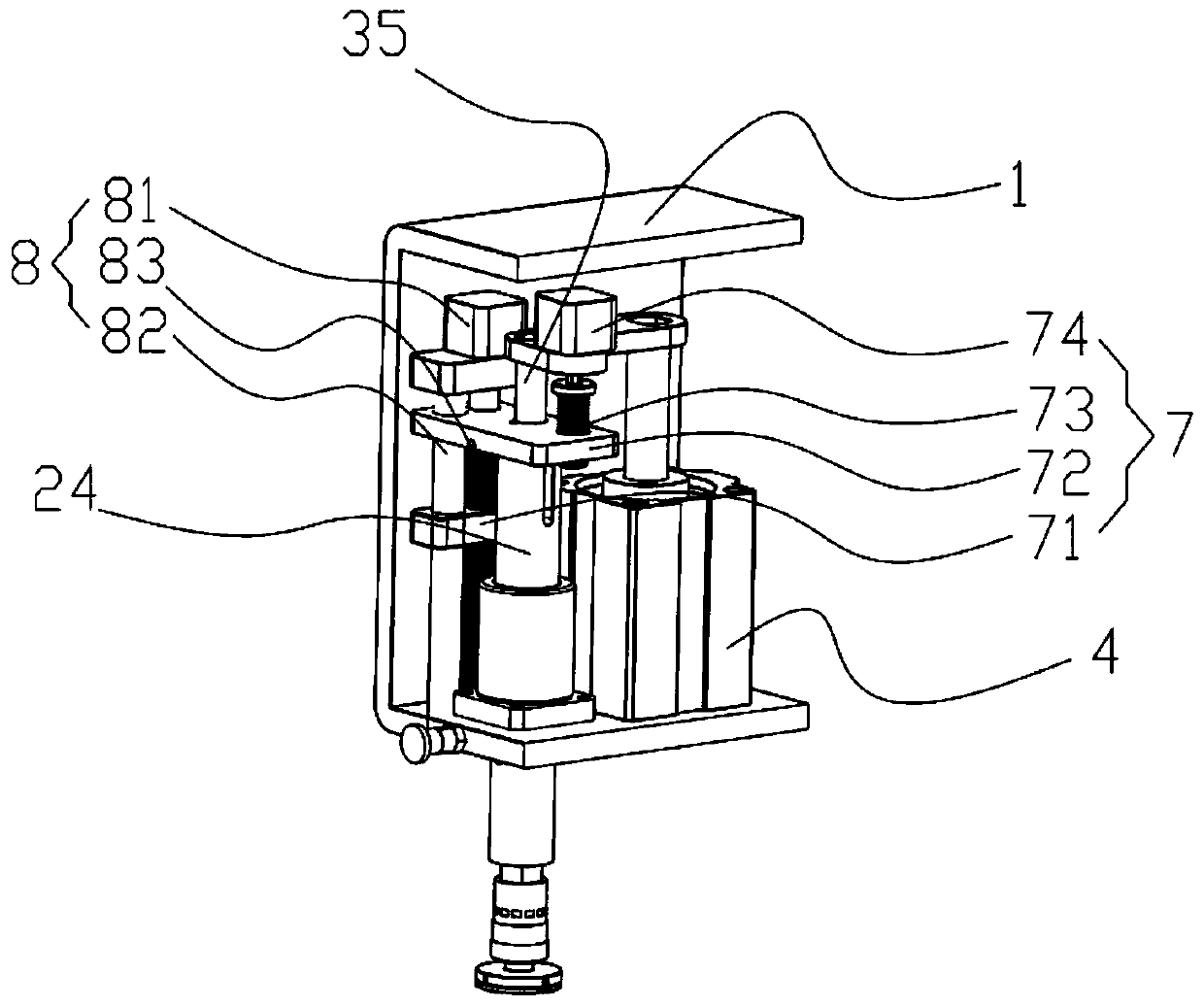

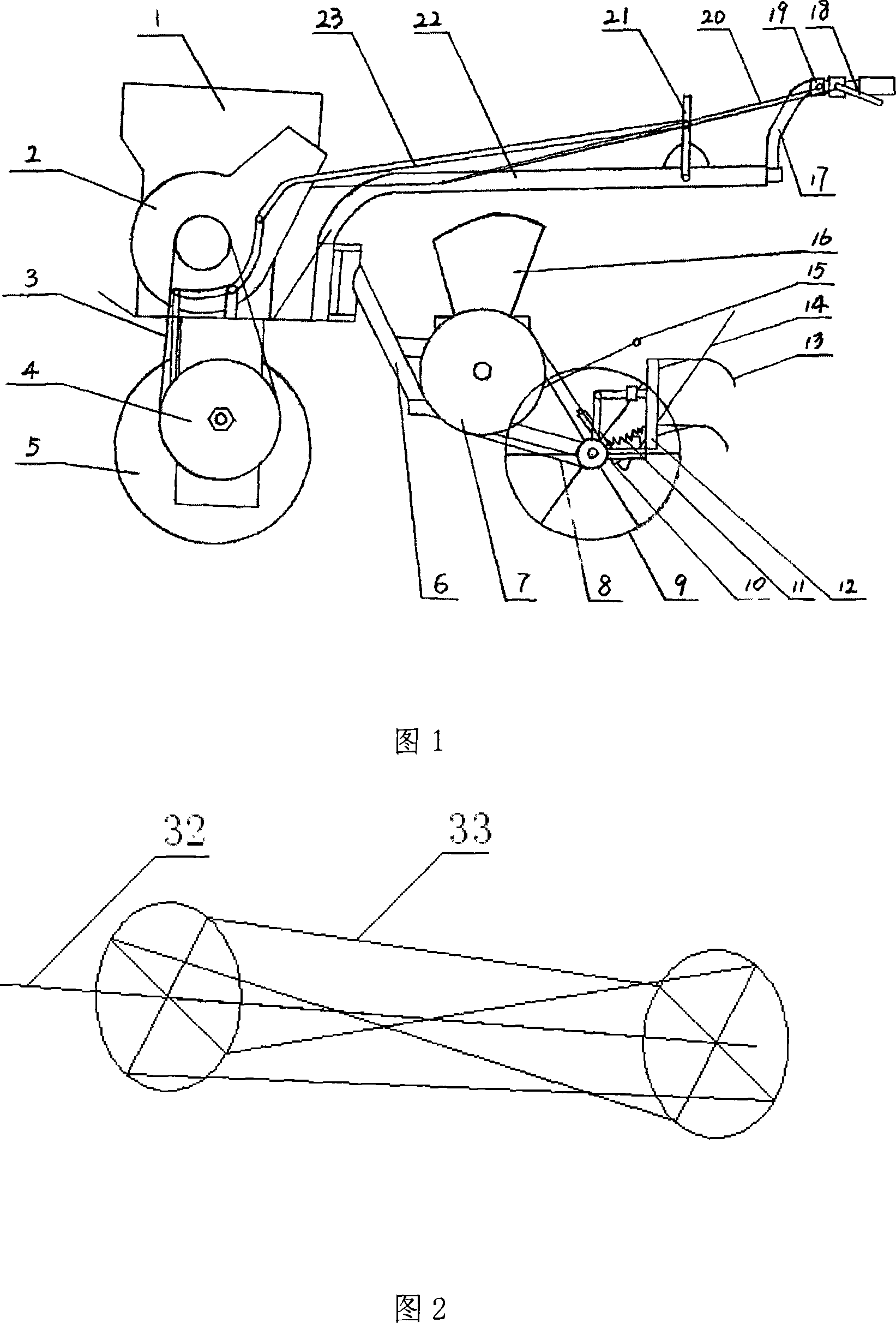

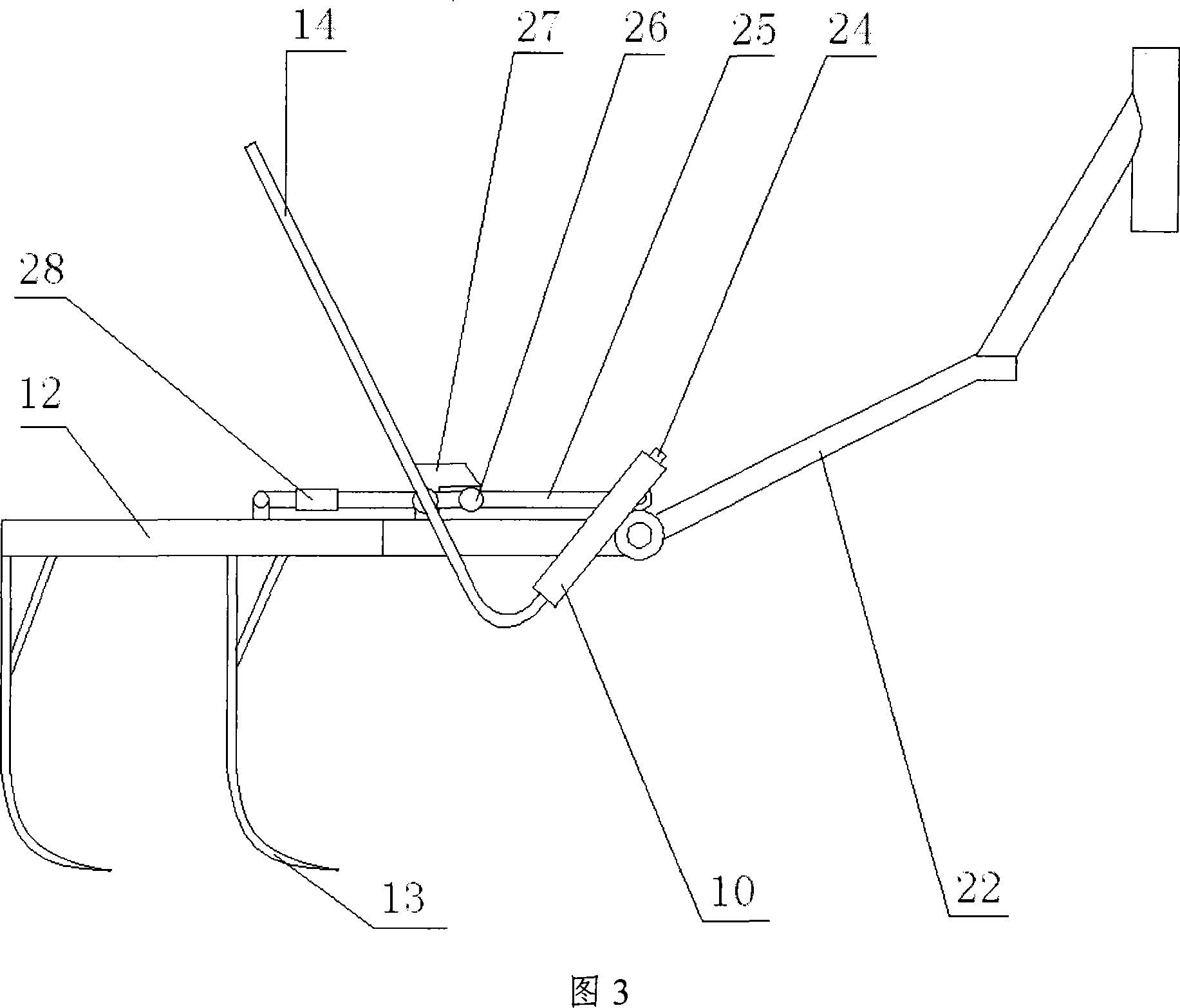

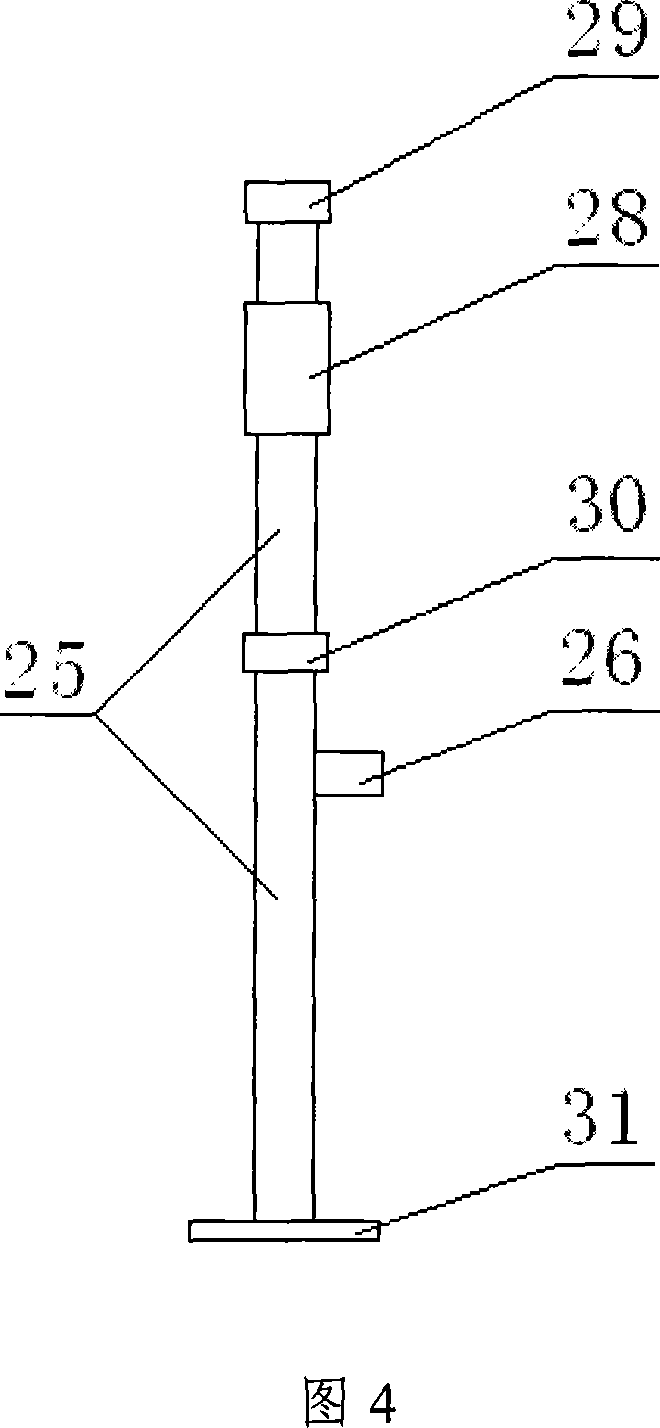

Adjustable oblique-type vegetable grafting device and realization method thereof

InactiveCN102388749AIncrease success rateImprove grafting accuracyHorticultureAgricultural engineeringStructural principle

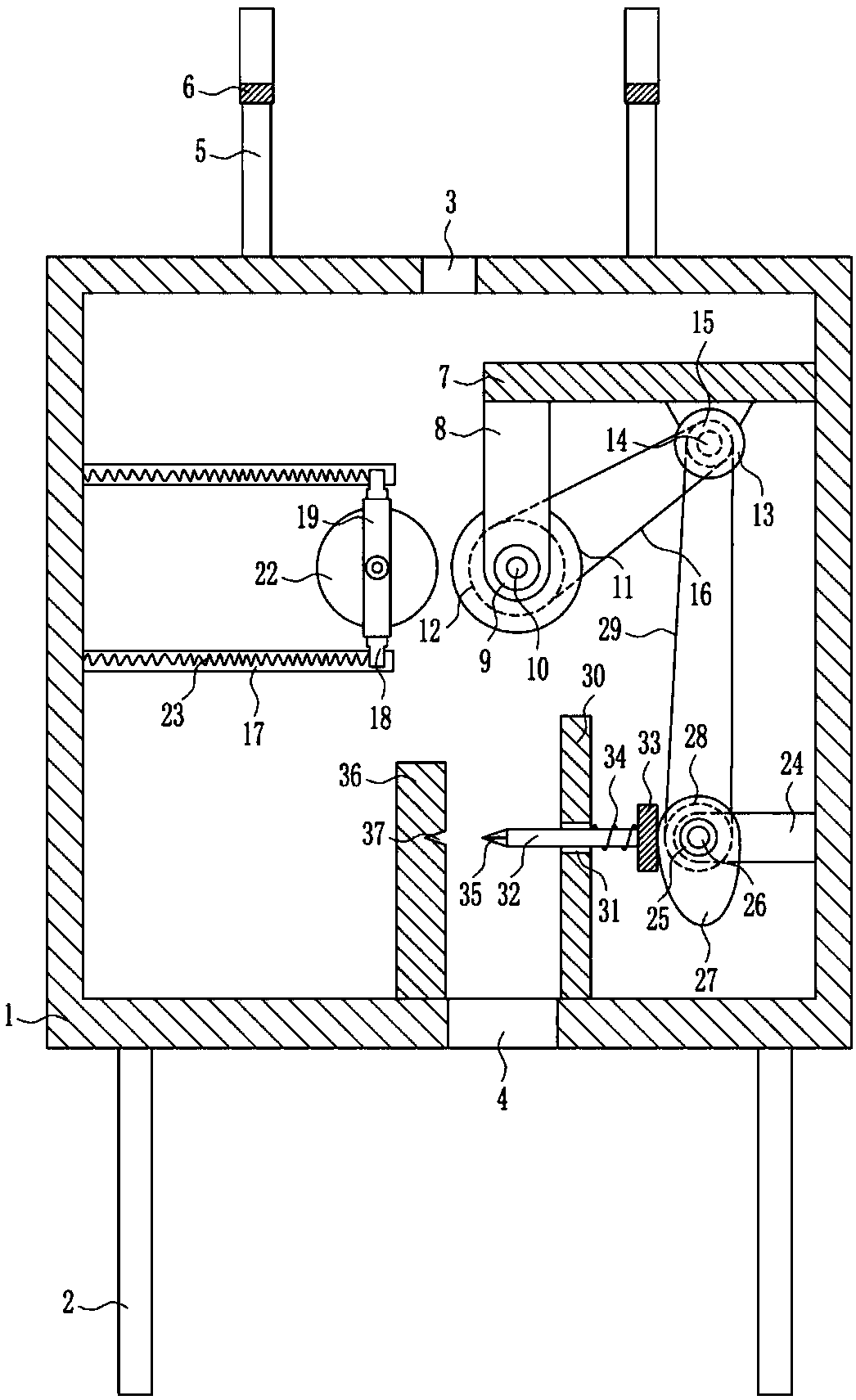

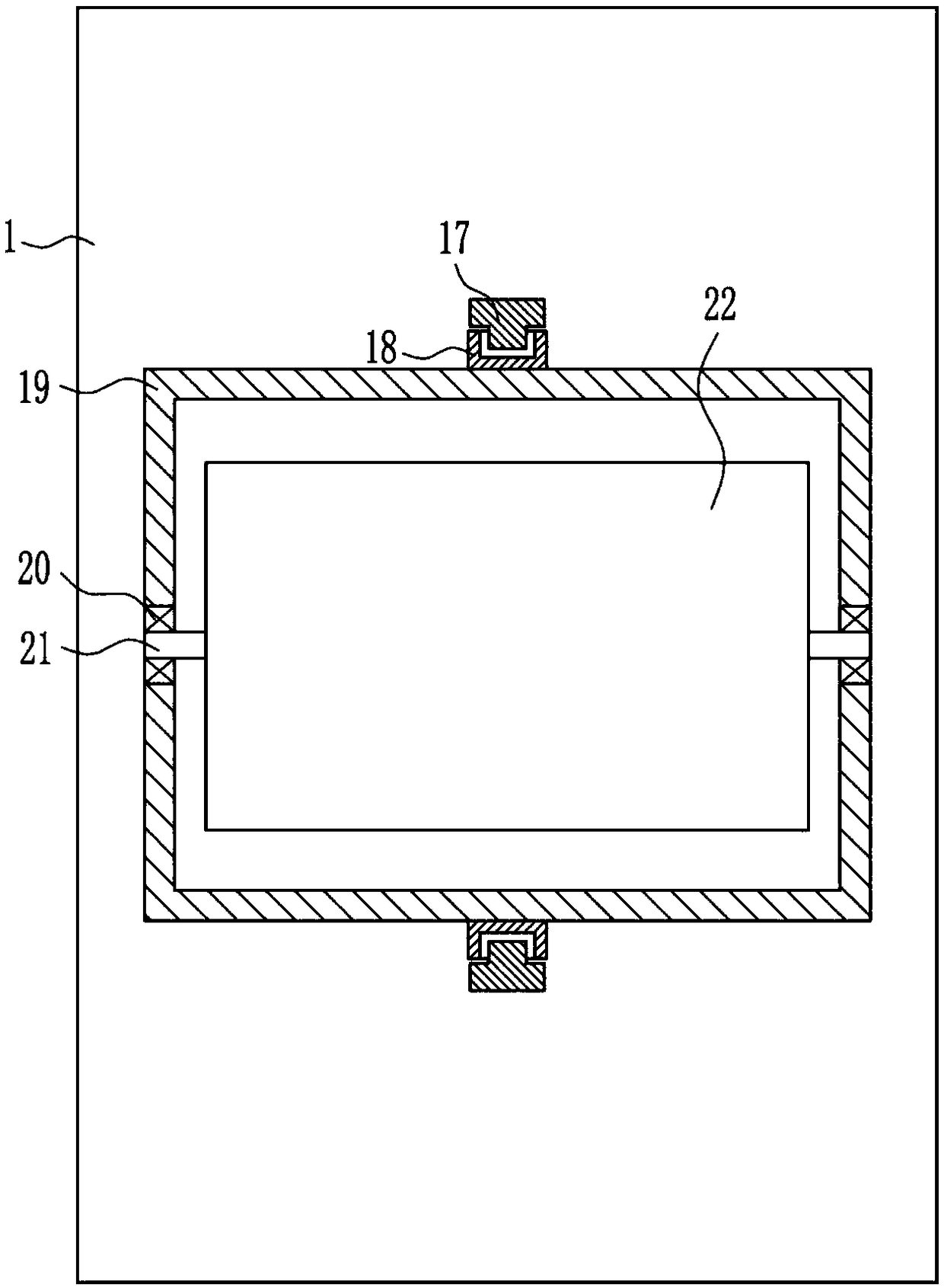

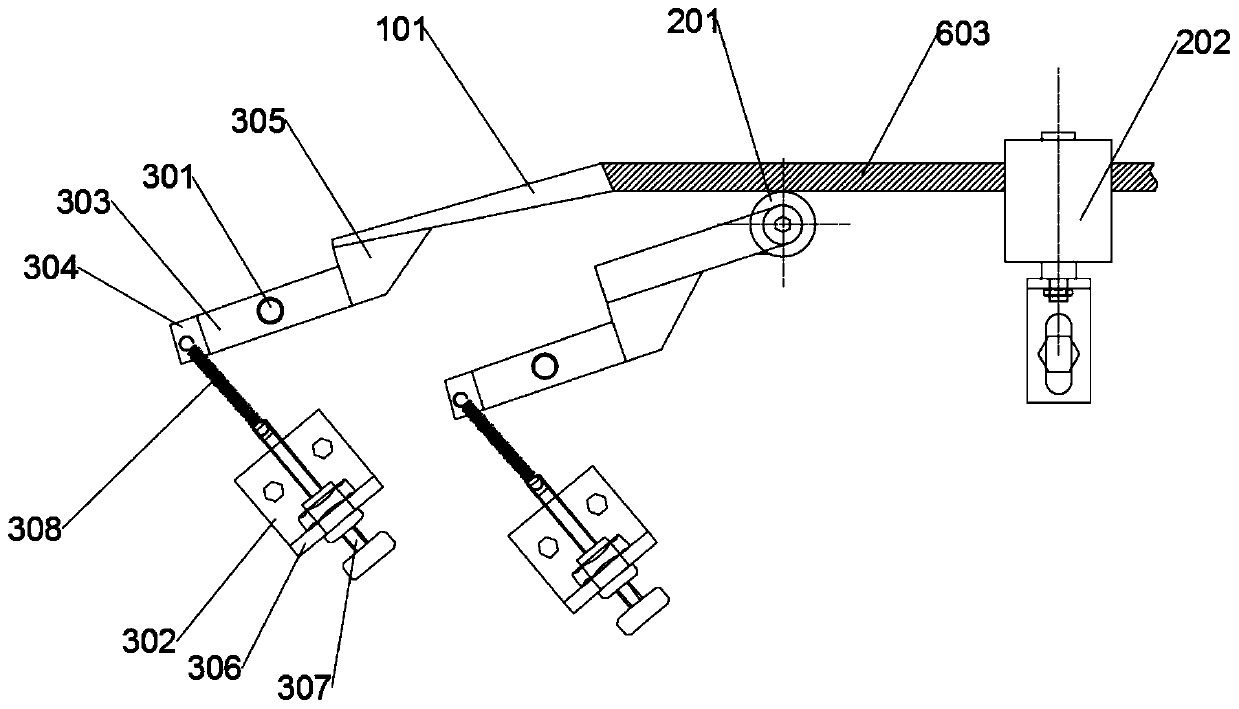

The invention discloses an adjustable oblique-type vegetable grafting device, which comprises a rack, a stock clamping mechanism, a stock hole punching mechanism, a scion clamping mechanism, a scion cutting mechanism, a control mechanism and an automatic back planting mechanism. The invention additionally discloses a realization method of the adjustable oblique-type vegetable grafting device. Theadjustable oblique-type vegetable grafting device overcomes the problems that the requirement on grafting skills is high, the grafting difficulty is great, key parts are inconvenient to adjust, safety protection mechanisms are not complete, the operation difficulty is great, the device is inconvenient to operate, a large quantity of labor force is consumed for seedling back planting and transportation after grafting and the like in the prior art. The adjustable oblique-type vegetable grafting device has the characteristics that the structural principle is simple, the device is convenient to operate, a stock clamp can be fine tuned in real time, the key parts are simple and convenient to adjust, the grafting reliability is high, the safety protection mechanisms are complete, the labor force is saved and the like.

Owner:SOUTH CHINA AGRI UNIV

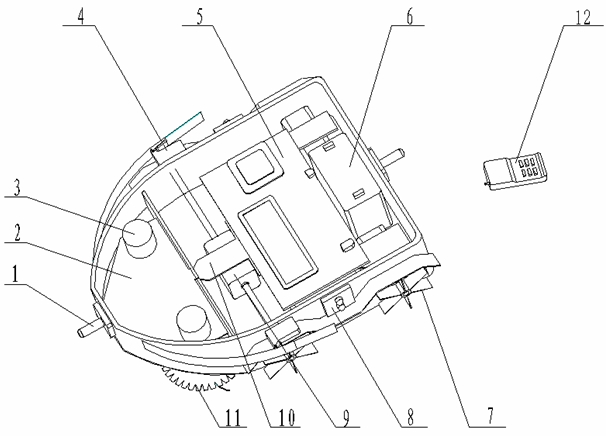

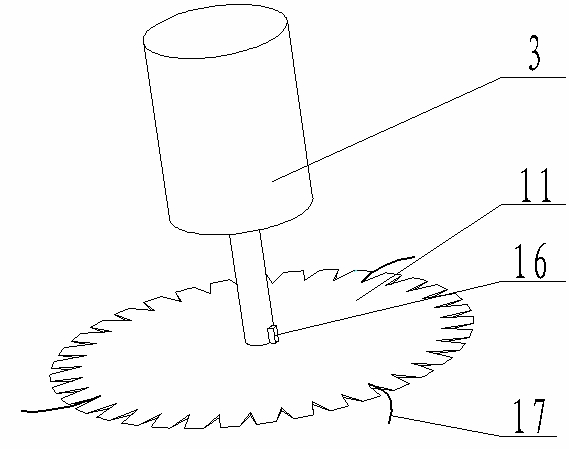

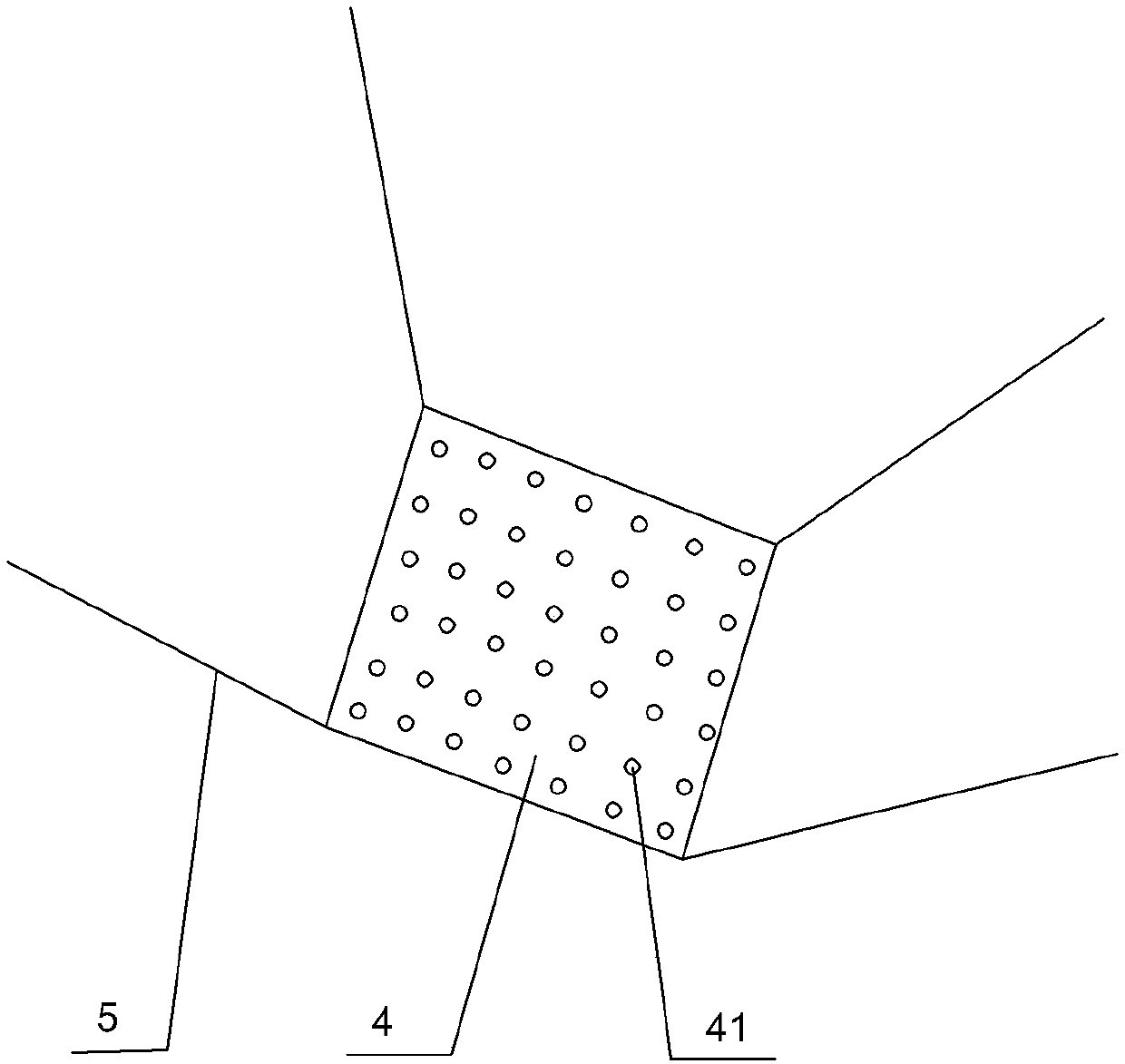

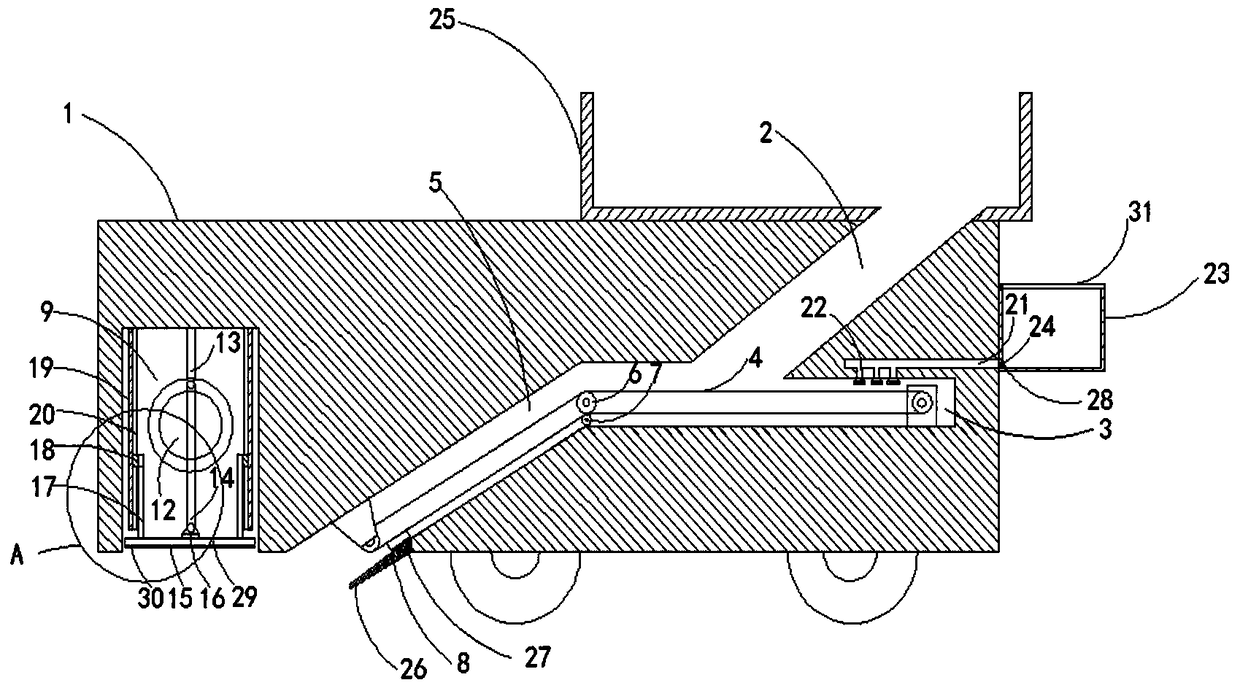

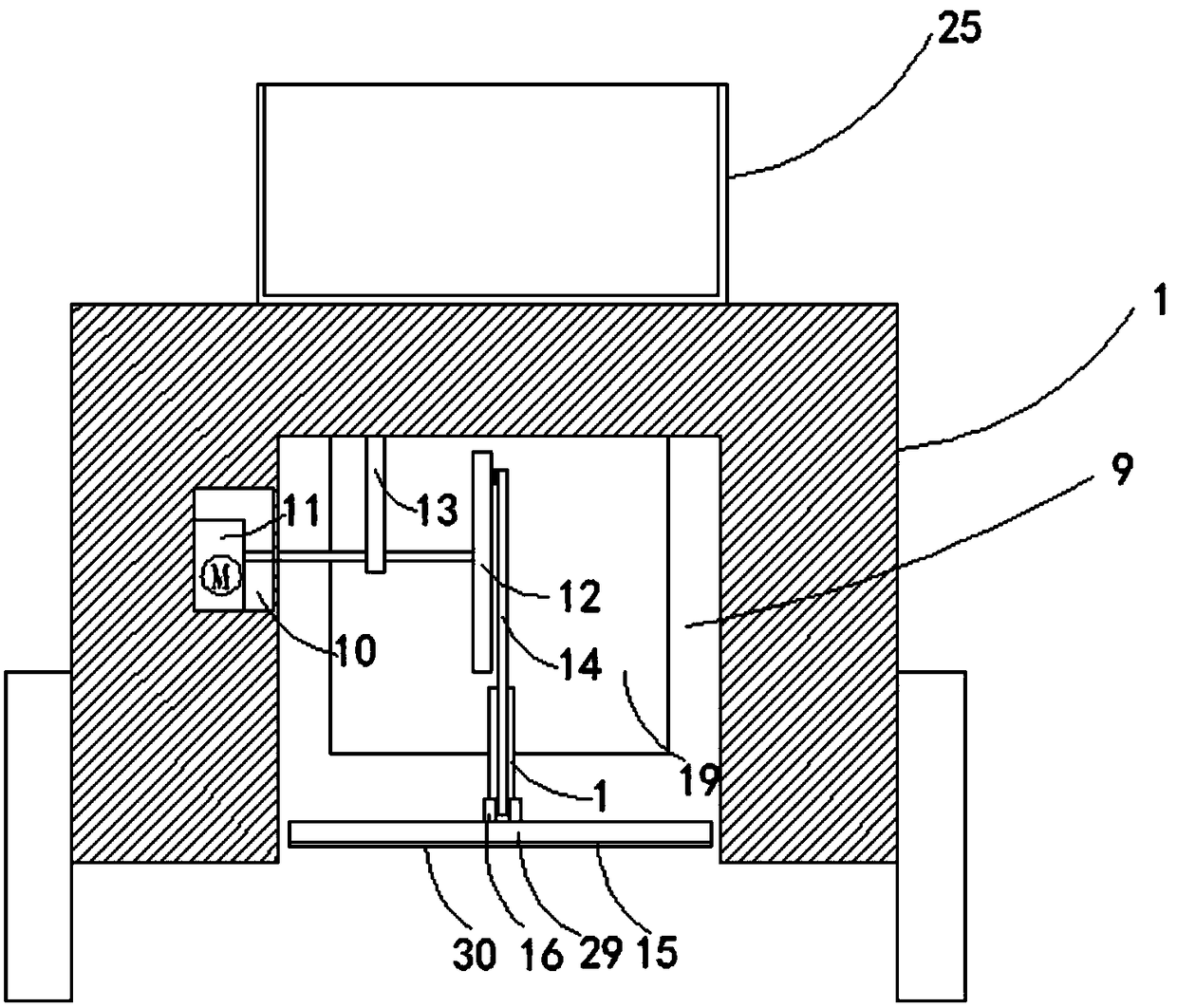

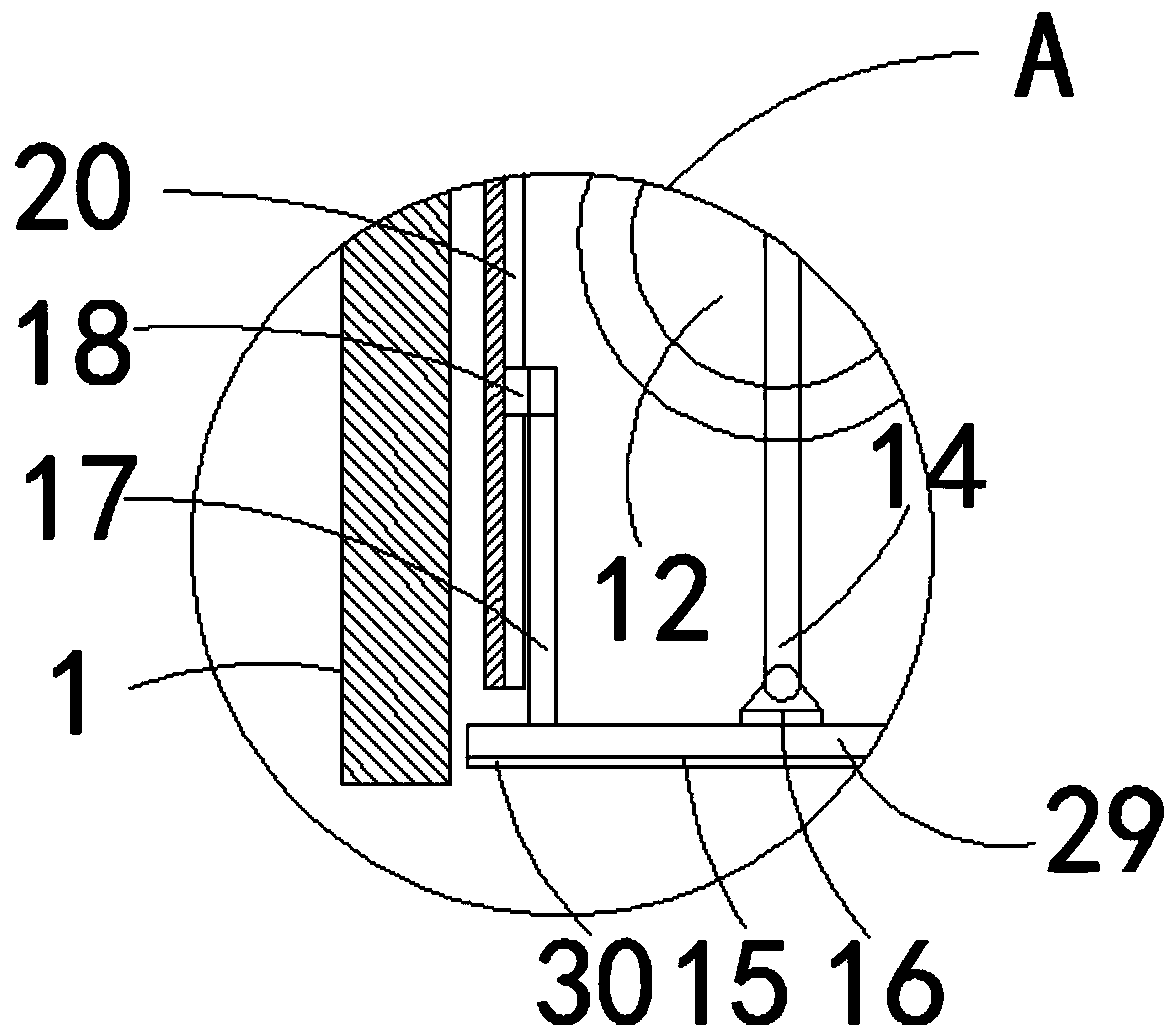

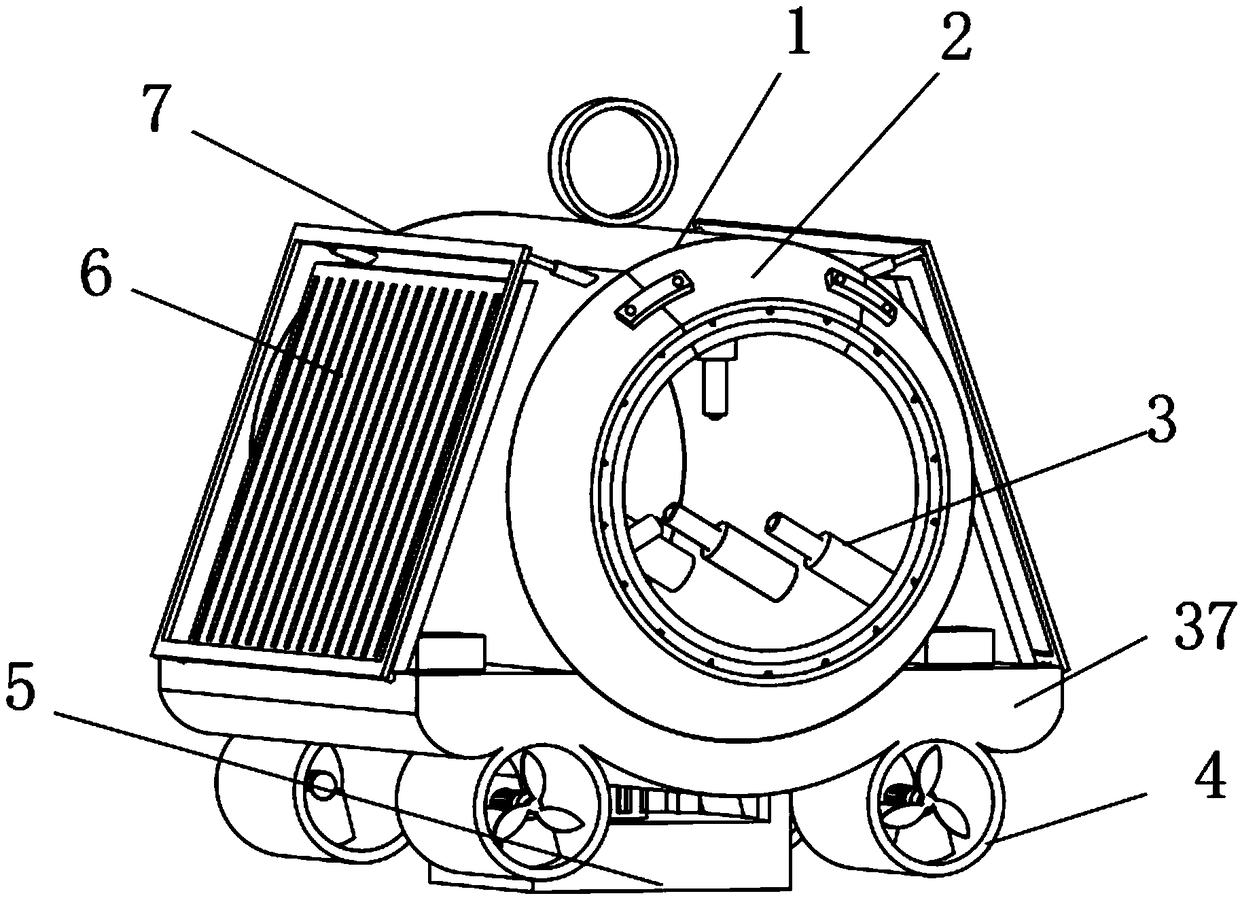

Small-sized inter-row weeding robot for paddy fields

The invention belongs to the field of agricultural robots, in particular to a small-sized inter-row weeding robot for paddy fields, which comprises a chassis, a drive system, a control system, a sensing system, a weeding device and a power source. A drive motor drives a spindle to rotate so as to drive paddle wheels, and the paddle wheels rotate at different speeds to turn the robot. A direct current motor drives a weeding disc blade to rotate to cut off inter-row weeds on a paddy field. Silt generated in travelling of the paddle wheels covers the weeds among plants to inhibit the inter-plant weeds. After a limit switch contacts with rice plants, a single chip microcomputer controls the left motor and the right motor to rotate at different speeds so as to lead the weeding robot to turn and avoid the plants. When a pressure sensor touches a ridge, the single chip microcomputer controls the drive motor to rotate reversely and the weeding robot continues operating in the opposite direction. The sensing system is capable of measuring information such as paddy field water temperature, plant amount and the like. The small-sized inter-row weeding robot for paddy fields is operated in a mechanical weeding mode, so that usage of pesticides and weeding labor are reduced, environment pollution by the pesticides is lessened, and cost is saved. The small-sized inter-row weeding robot for paddy fields is small in size and light in weight.

Owner:JIANGSU UNIV

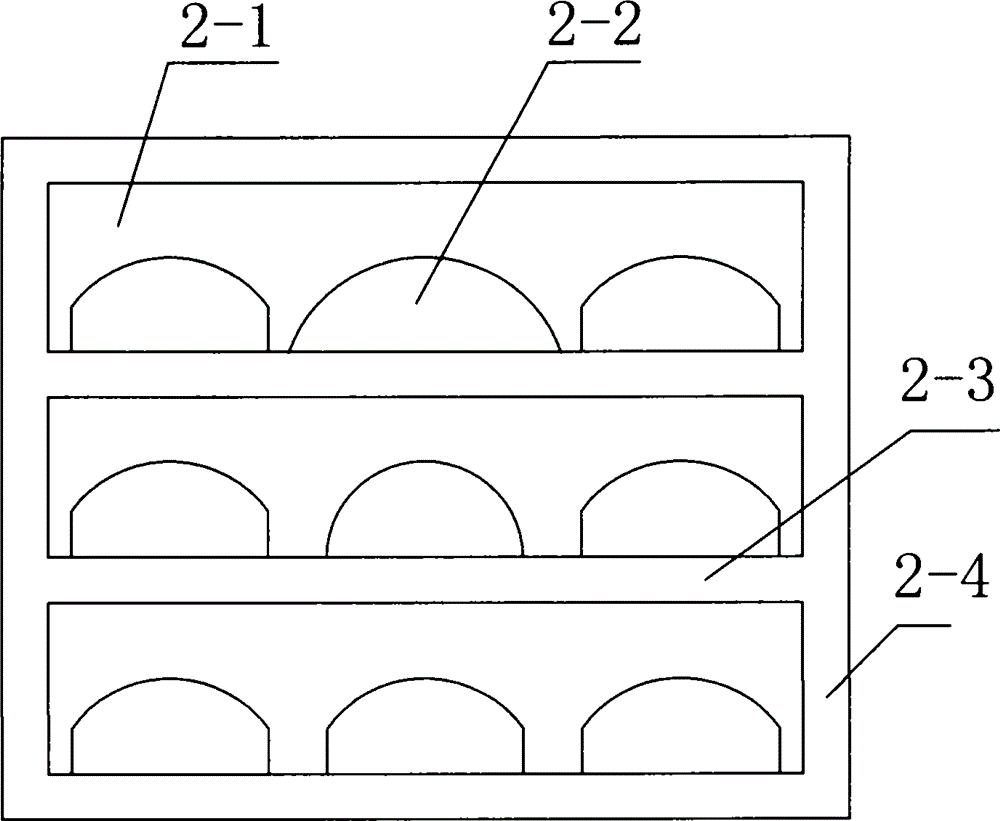

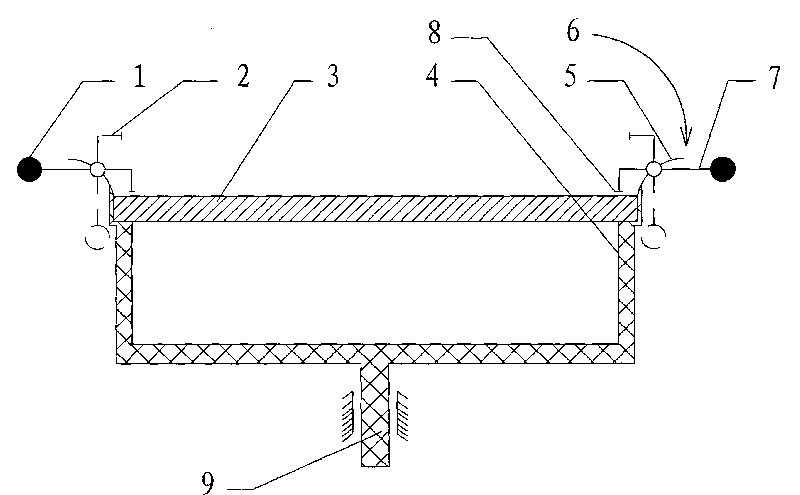

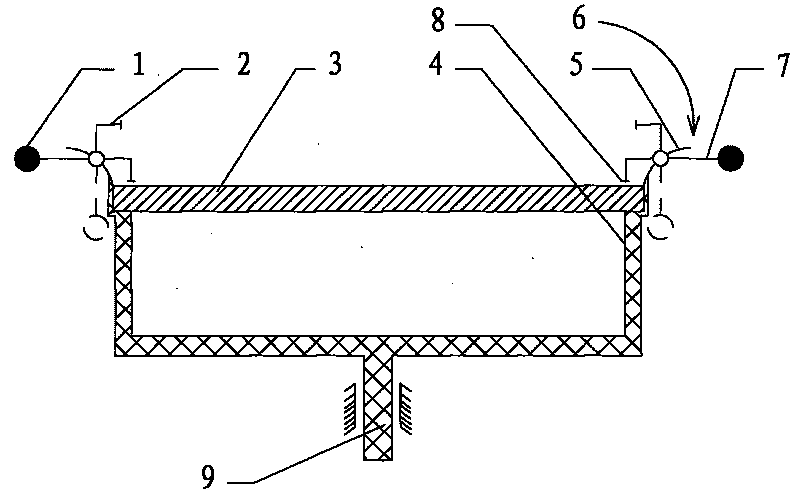

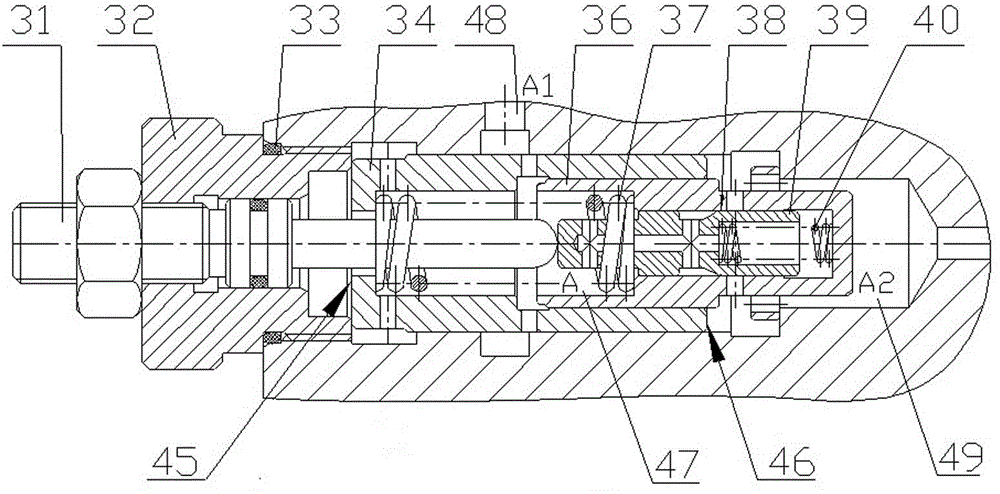

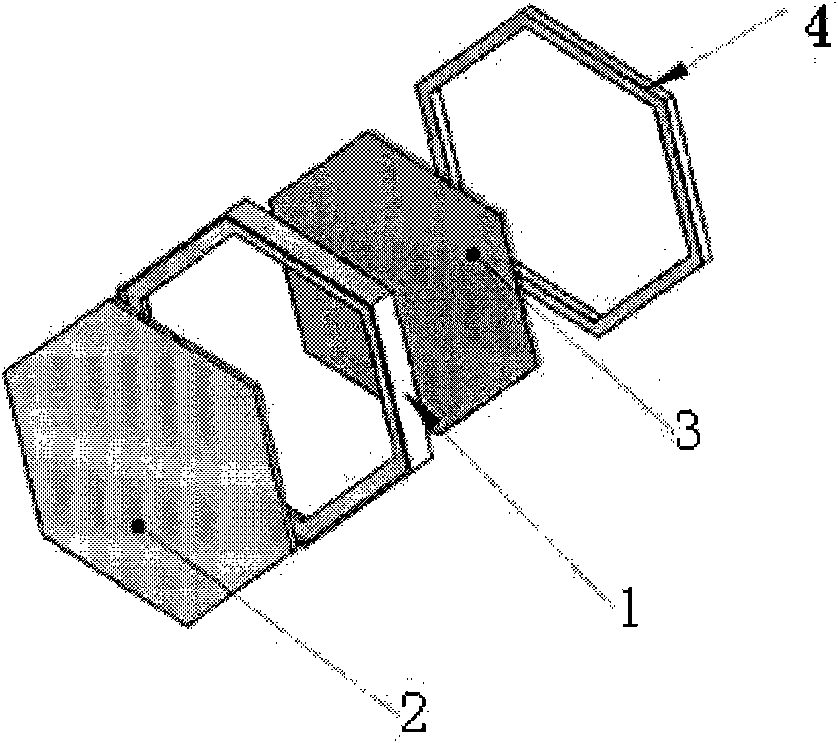

Beehive and auxiliary equipment

The invention discloses a Boya (the name of the product, in Chinese means erudition and elegance) beehive and auxiliary equipment. The Boya beehive and the auxiliary equipment comprise a box, a Boya vent pipe, a Boya functional box, a Boya feeder, a Boya combined frame, a Boya queen bee isolator, a Boya protective table queen bee cage, a Boya honeycomb door, and Boya lantern rings, wherein the Boya vent pipe is arranged in the box to allow ventilation instead of light transmitting; the Boya honeycomb door can isolate the queen bee and can be used for a long time; the Boya functional box can collect the queen bee and drones and guard against theft; the Boya feeder cannot drown bees, occupies a little of space, but is high in capacity; the Boya queen bee isolator can store and isolate the queen bee for a long time; the Boya protective table queen bee cage can protect the table and cage the queen bee for a short time; as for the Boya combined frame, the frame bodies and frame lugs are separately designed, the frame bodies and the frame lugs are connected through the Boya lantern rings, and can be quickly disassembled. The high box is adopted to mount the multilayered frames; the multilayered frames can be changed up and down, so as to prolong the service life of the honeycomb; the frames of the single-queen-bee box, the double-queen-bee box and the mating box can be in common use; insulating layers are arranged in the box body to insulate the heat; in winter, one to two layers of the frames can be only mounted, and the bees under the frame are naturally in groups to pass the winter.

Owner:陈日宝

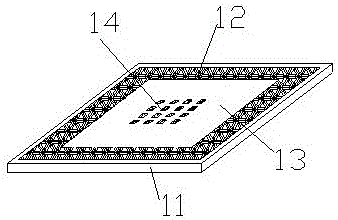

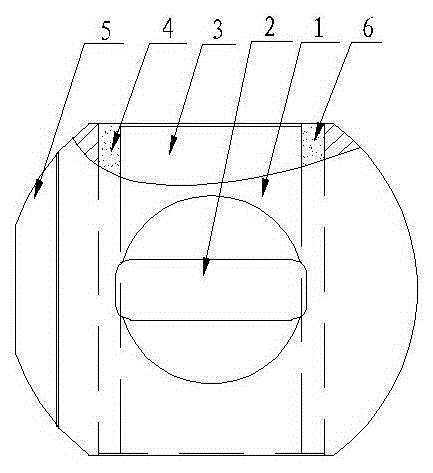

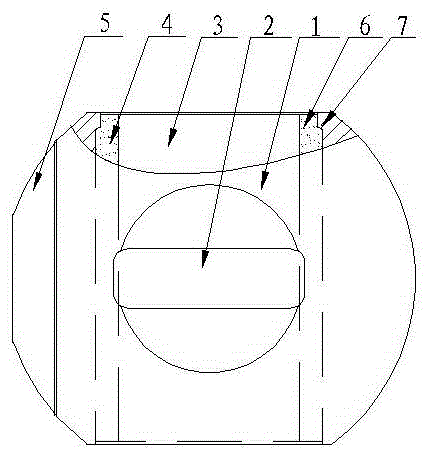

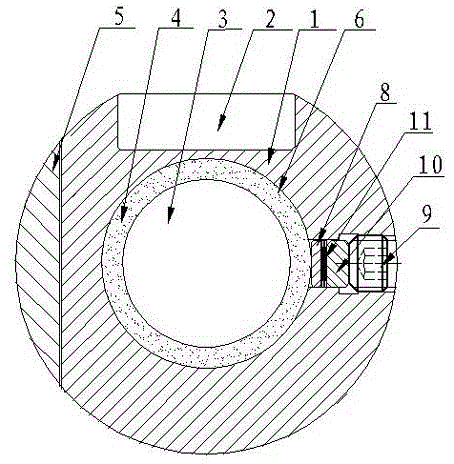

Novel non-vacuum adsorption wafer clamping mechanism

InactiveCN101728300AEasy to fixWon't crushSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention relates to a novel non-vacuum adsorption wafer clamping mechanism belonging to the field of semiconductors. The novel non-vacuum adsorption wafer clamping mechanism is a wafer clamping mechanism arranged on semiconductor equipment and used during the rotating and processing of a wafer and especially used in an occasion which needs to protect the central figure area of the wafer and an occasion which can not supply vacuum or is inconvenient to use vacuum adsorption. The wafer clamping mechanism is provided with a mechanism body and a minitype lever mechanism, wherein the periphery of the mechanism body of the wafer clamping mechanism is provided with the minitype lever mechanism used for clamping the wafer to be processed. When a centrifuge rotates at a high speed, the clamping mechanism tightly clamps the wafer without generating the problems of wafter offset and desquamation during high-speed rotation. The wafer clamping mechanism has wide application range, is almost suitable for wafers in all shapes and sizes and only needs to change the position of the minitype lever mechanism and the size and the shape of a base with an annular bottom surface when the size and the shape of the processed wafer are changed.

Owner:SHENYANG KINGSEMI CO LTD

Method for breeding fragrant pig

ActiveCN107691361AReduce labor costsWon't crushAnimal feeding devicesAnimal housingAnimal scienceLivestock breeding

The invention belongs to the technical field of livestock breeding, and discloses a method for a breeding fragrant pig. The method includes the following steps that (1) a pig house is constructed; (2)feeding is carried out through an automatic feeding device, wherein feed is added into a supplying box, and before the fragrant pig feeds, the fragrant pig treads on a pedal, feed in the supplying box automatically enters a feed trough, and after feeding of the fragrant pig is completed, the fragrant pig leaves the pedal, and the supplying box stops to supply the feed to the feed trough; (3) residual feed in the feed trough is cleaned. By means of the method for breeding the fragrant pig, automatic feeding of the fragrant pig can be achieved, the feed is not required to be artificially added,and the labor cost is saved.

Owner:李柯槿

Capacitive touch screen and manufacture method thereof

InactiveCN102207805AImprove efficiencySuitable for mass productionInput/output processes for data processingGlass coverHigh volume manufacturing

The invention relates to a capacitive touch screen, comprising an ITO (Indium Tin Oxide) glass substrate provided with a printed circuit layer on the front side, wherein a PET (polyethylene glycol terephthalate) film is adhered on the outer side surface of the printed circuit layer. The invention also provides a manufacture method of the capacitive touch screen, which comprises the following steps of: binding: forming the printed circuit layer on the ITO glass substrate, and then binding a flexible circuit board to the ITO glass substrate to be connected with the printed circuit layer; and film sticking: sticking an optical clear resin to the PET film, and cutting the PET film into a small piece matching to the ITO glass substrate in size, and sticking the small PET film to the outer side surface of the printed circuit layer on the ITO glass substrate. In the invention, the traditional glass cover plate is replaced by the PET film, the device and the process operation for the sticking step are simplified; and the invention has low cost and high efficiency and is suitable for the mass production. The sticking of the PET film belongs to the film-glass sticking manner, and the product yield is up to 99%. The image distortion of the product is not easy to occur during using. During assembling, the casing presses against the soft PET film having a good buffer action, and the entire capacitive screen cannot be crushed.

Owner:GANZHOU DPT TECH

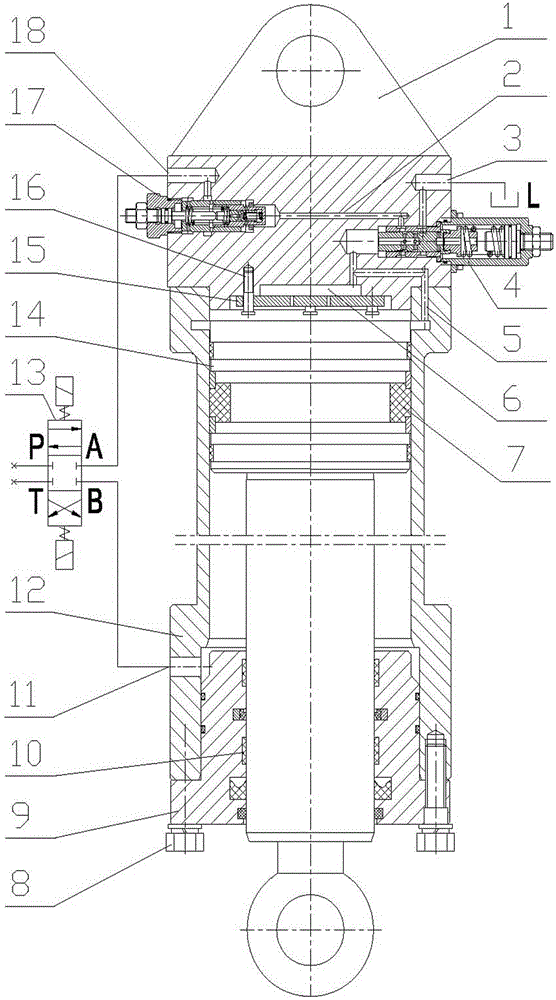

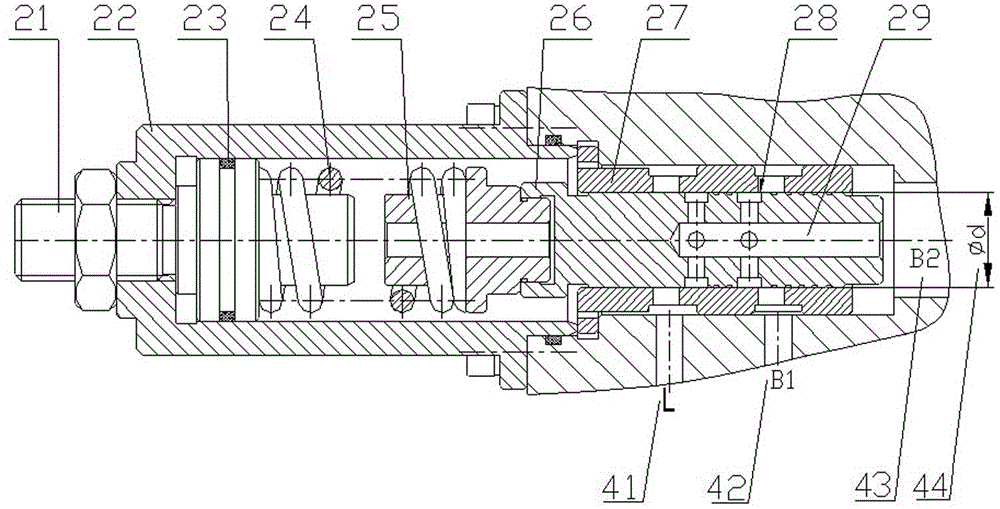

Adjustable-pressure and adjustable-flow buffer hydraulic cylinder, control method and hydraulic system

The invention relates to an adjustable-pressure and adjustable-flow buffer hydraulic cylinder, a control method and a hydraulic system. The buffer hydraulic cylinder comprises a cylinder barrel, an upper cylinder cover, a lower cylinder cover and a piston. A cylinder barrel is connected below the upper cylinder cover. The piston is installed in the cylinder barrel. A piston seal is sheathed on the piston. A lower control oil port is arranged at the lower part of the cylinder barrel. An upper control oil port is arranged on the left side of the upper cylinder cover. A flow adjusting assembly and a pressure adjusting assembly are additionally arranged in the upper cylinder cover. The upper control oil port and the lower control oil port are connected with the hydraulic system through a reversing valve. The hydraulic cylinder control method and the hydraulic system disclosed by the invention have the advantages that the lowering speed and the pressure of a single hydraulic cylinder are adjusted by controlling the lifting and the lowering of a railway track bed sewage blowing and sucking device, four hydraulic cylinders synchronously move to lower down the sewage blowing and sucking device, the blowing and sucking device is guaranteed to move close to the surfaces of rails, supporting wheels are not crushed and impact is not produced during rapid lifting.

Owner:CRCC HIGH TECH EQUIP CORP LTD

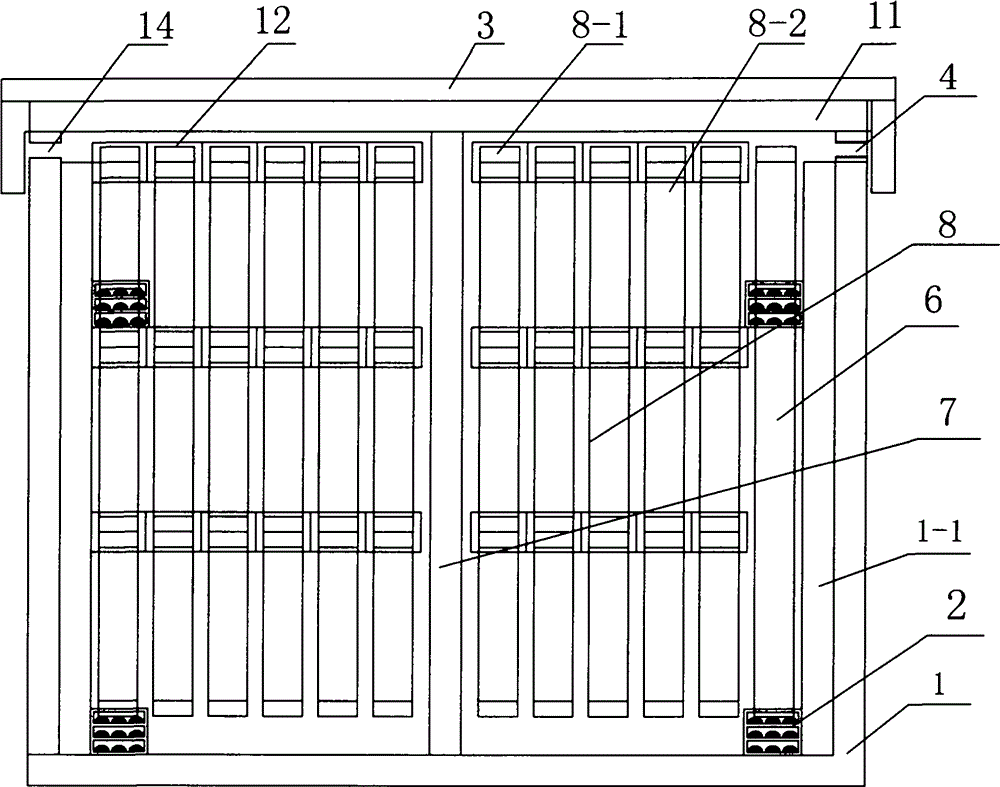

Photovoltaic curtain wall capable of replacing solar battery board and components thereof

The invention relates to the technical field of photovoltaic curtain walls, in particular to a photovoltaic curtain wall capable of replacing a solar battery board and components thereof. The photovoltaic curtain wall capable of replacing the solar battery board comprises a frame, outer glass, a solar battery assembly and an inner frame, wherein the solar battery assembly is pressed in the frame through the inner frame; the outer glass is arranged on the frame by means of an exposed frame or a hidden frame, and positioned in the front of the solar battery assembly. The photovoltaic curtain wall capable of replacing the solar battery board is formed by splicing the components of the photovoltaic curtain wall capable of replacing the solar battery board. The curtain wall and the components thereof have the advantages that: the solar battery assembly is convenient to replace, a pressing frame can be designed to a whole piece to be used as a standard component for manufacturing without re-assembly. When being installed and maintained, the frame is unnecessary to assemble and disassemble, and the assembly is implemented by only using a common tool instead of a special tool. The pressure controllability between the pressing frame and the assembly is high when the curtain wall is installed so as to ensure that the assembly cannot be crushed.

Owner:TRINA SOLAR CO LTD

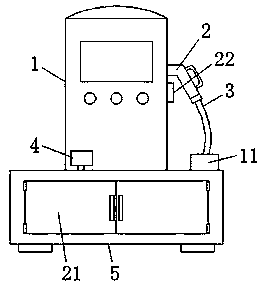

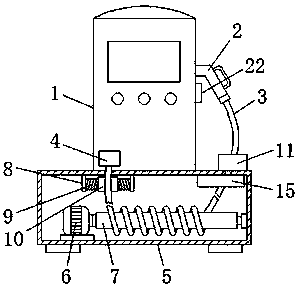

Automobile charging pile wire winding device and method thereof

The invention discloses an automobile charging pile wire winding device and a method thereof. The automobile charging pile wire winding device comprises a charging pile body, a charging gun is arranged on the right side of the charging pile body, a charging wire is movably installed at the bottom of the charging gun, and an infrared sensor is fixedly installed on the portion, corresponding to thecharging gun, of the right side of the charging pile body. According to the automobile charging pile wire winding device and the method thereof, through arrangement of the charging pile body, the charging gun, the charging wire, a bearing block, a supporting base, a motor, a winding shaft, fixing plates, torsional springs, a winding wheel, a fixing frame, connecting springs, baffles and the infrared sensor, the external charging wire can be automatically wound after charging is finished, it is guaranteed that the charging wire can not be ground, and damage is prevented; and meanwhile, the problems that the charging wire is prone to being damaged or electric leakage is prone to occurring due to the fact that the charging wire on the ground is prone to being ground by vehicles when some vehicle owners directly plug a charging head into the charging pile again and neglect the position of the charging wire after charging is completed are solved.

Owner:王秋夫

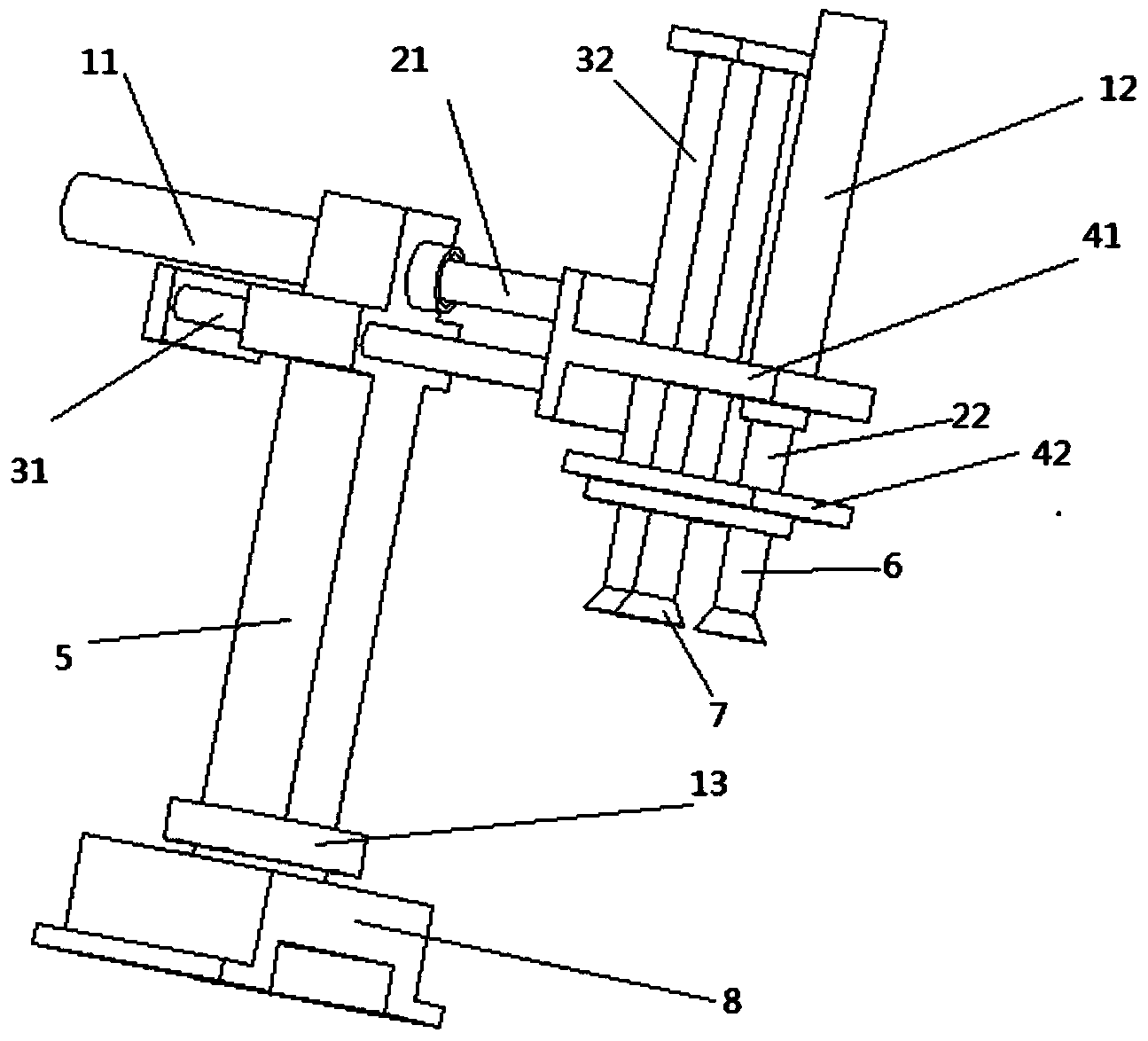

Injection molding blade pickup mechanical hand

The invention discloses an injection molding blade pickup mechanical hand and belongs to injection molding accessory equipment. The injection molding blade pickup mechanical hand consists of a horizontal cylinder, a vertical cylinder, an oscillating cylinder, a cylindrical guide rail, a base, a machine body, a supporting plate, a piston rod, a telescopic pipe and a vacuum chuck, wherein the piston rod moves back and forth in the horizontal cylinder in a reciprocating mode; the front end of the piston rod is connected with the supporting plate; the horizontal cylinder is fixed on the machine body; the cylindrical guide rail is arranged at the lower part of the horizontal cylinder; the piston rod moves up and down in the vertical cylinder in the reciprocating mode; the vertical cylinder is fixed on the supporting plate; the telescopic pipe is arranged below the supporting plate; the telescopic pipe and the vacuum chuck are connected together; the machine body is connected with the base together through the oscillating cylinder. The injection molding blade pickup mechanical hand disclosed by the invention has the beneficial effect that the device can help pick up injection molding blades.

Owner:张圣贤

Turf laying machine for lawn

ActiveCN108739093APromote growthAvoid accidental damageHops/wine cultivationTurf growingNutrient solutionConveyor belt

The invention discloses a turf laying machine for a lawn. The machine comprises a machine body, and a first groove is obliquely formed in the upper end of the machine body; the machine body is internally provided with a first chamber, the top surface of the first chamber is provided with a first opening communicated with the bottom of the first groove, and a conveyor belt is fixedly mounted at thebottom of the first chamber; a second groove is obliquely formed in the lower end of the machine body, the top of the second groove is provided with a second opening communicated with the side wall of the first chamber, and the output end of the conveyor belt is located at an opening of the second groove; the machine body is internally provided with a second chamber; a box body is fixedly connected to the side wall of the machine body, the side wall of the bottom of the box body is provided with a third opening communicated with a fourth groove, and the third opening is filled with a plug; aplacement frame is fixedly connected to the upper end of the machine body, and the bottom of the placement frame is provided with a fourth opening communicated with the first groove. By means of the turf laying machine, turf laying on the large lawn is facilitated, and watering or spraying of a nutrient solution can be conducted at the same time.

Owner:安徽远维建设有限公司

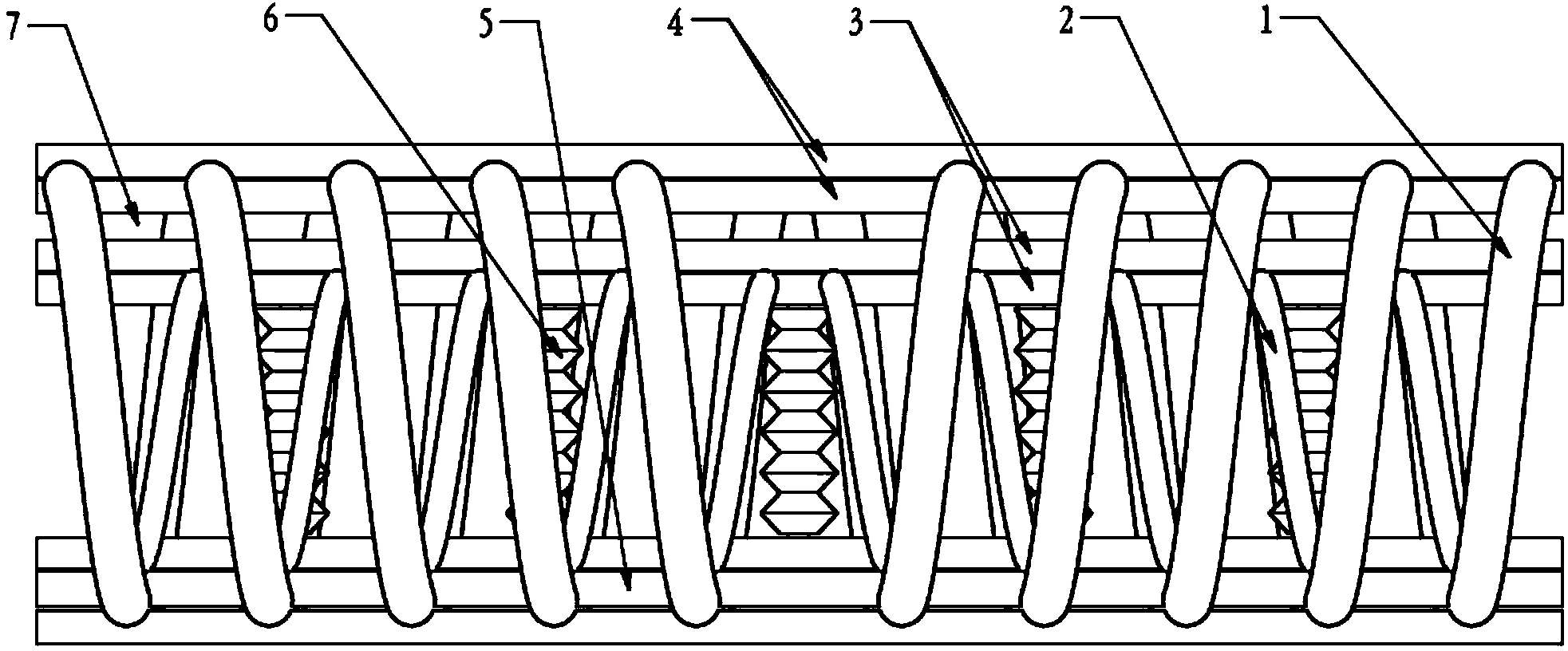

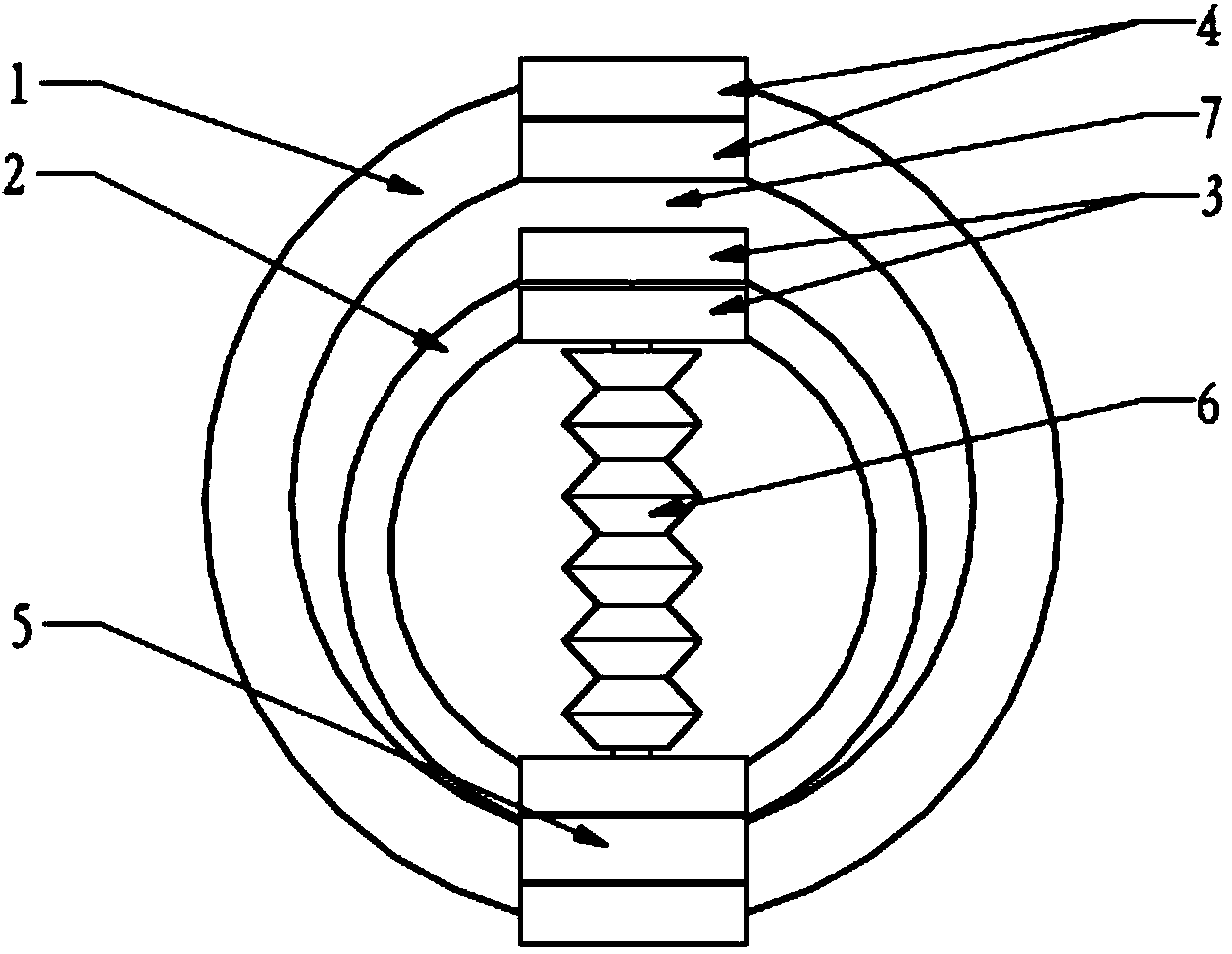

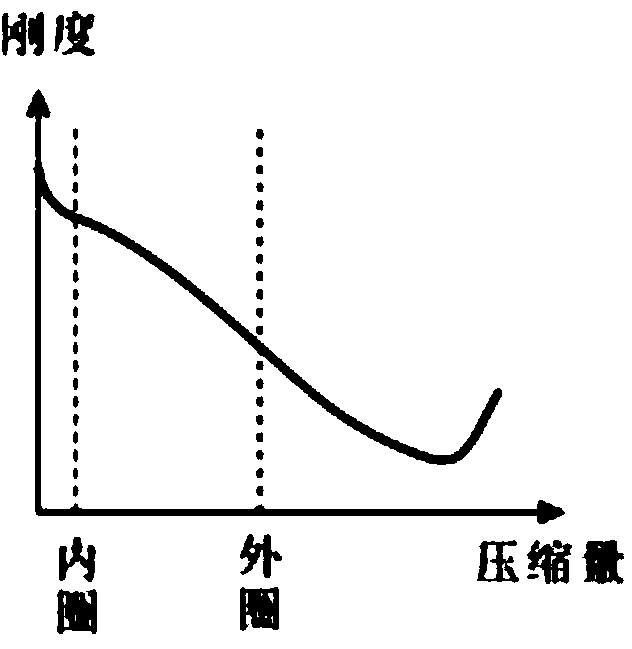

Double-circle steel wire rope shock absorber

ActiveCN103470671AVibration damping works normallyPlay a limiting roleShock absorbersSmall amplitudeBroadband

The invention discloses a double-circle steel wire rope shock absorber, consisting of an outer-circle steel wire rope, an inner-circle steel wire rope, inner-circle upper clamping plates, outer-circle upper clamping plates, a lower clamping plate and a plurality of belleville spring assemblies. The double-circle steel wire rope shock absorber provided by the invention can guarantee the normal exertion of shock absorption performance in the case of large predeformation and guarantee no conquassation under quite great loads; therefore, the safety coefficient and the capability of coping with an accident are improved; the broadband high-attenuation of shock by the shock absorber under the working conditions of precompression and small amplitude (several millimeters) can be realized; in addition, the double-circle steel wire rope shock absorber has the characteristics of long service life, good shock absorption effect and the like.

Owner:ZHONGBEI UNIV

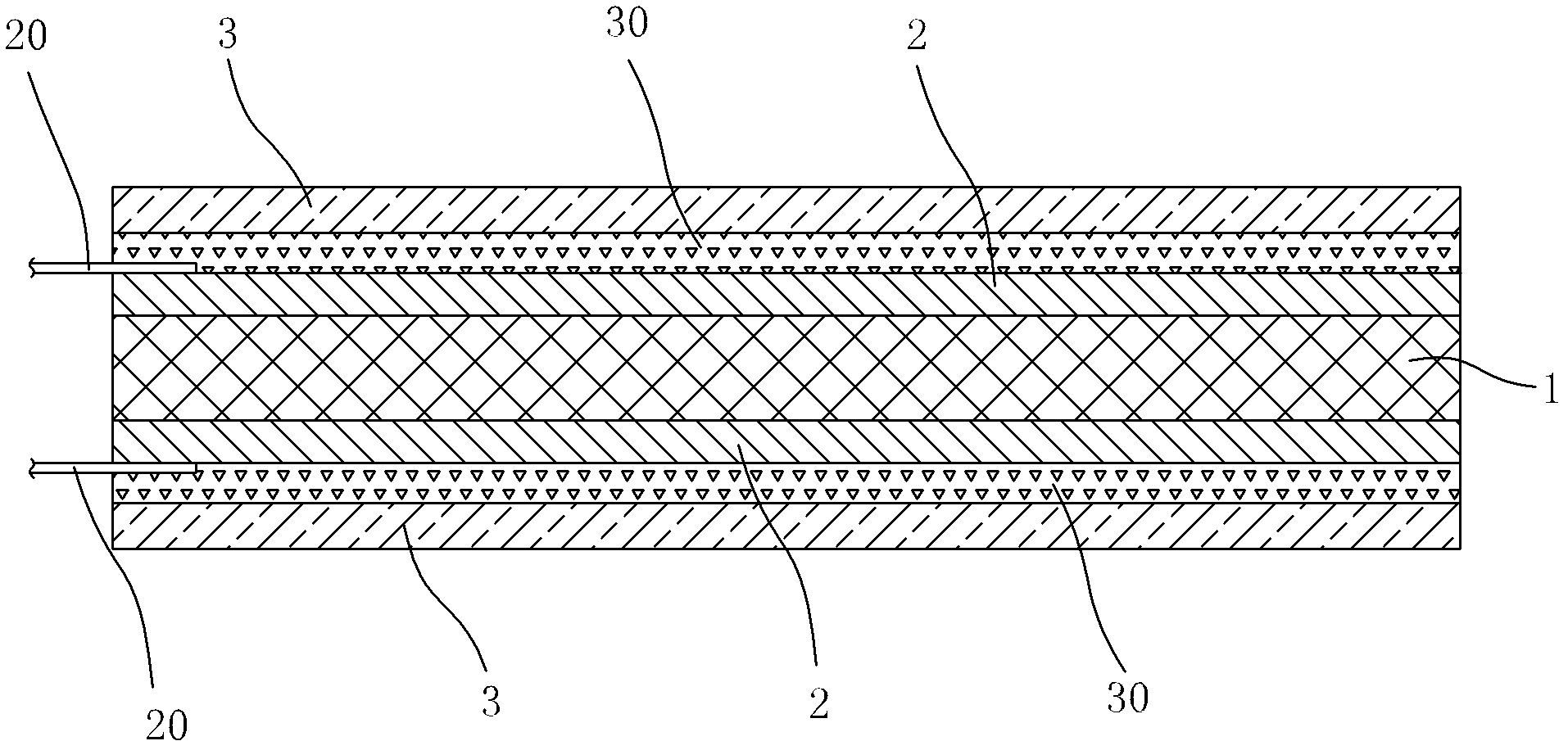

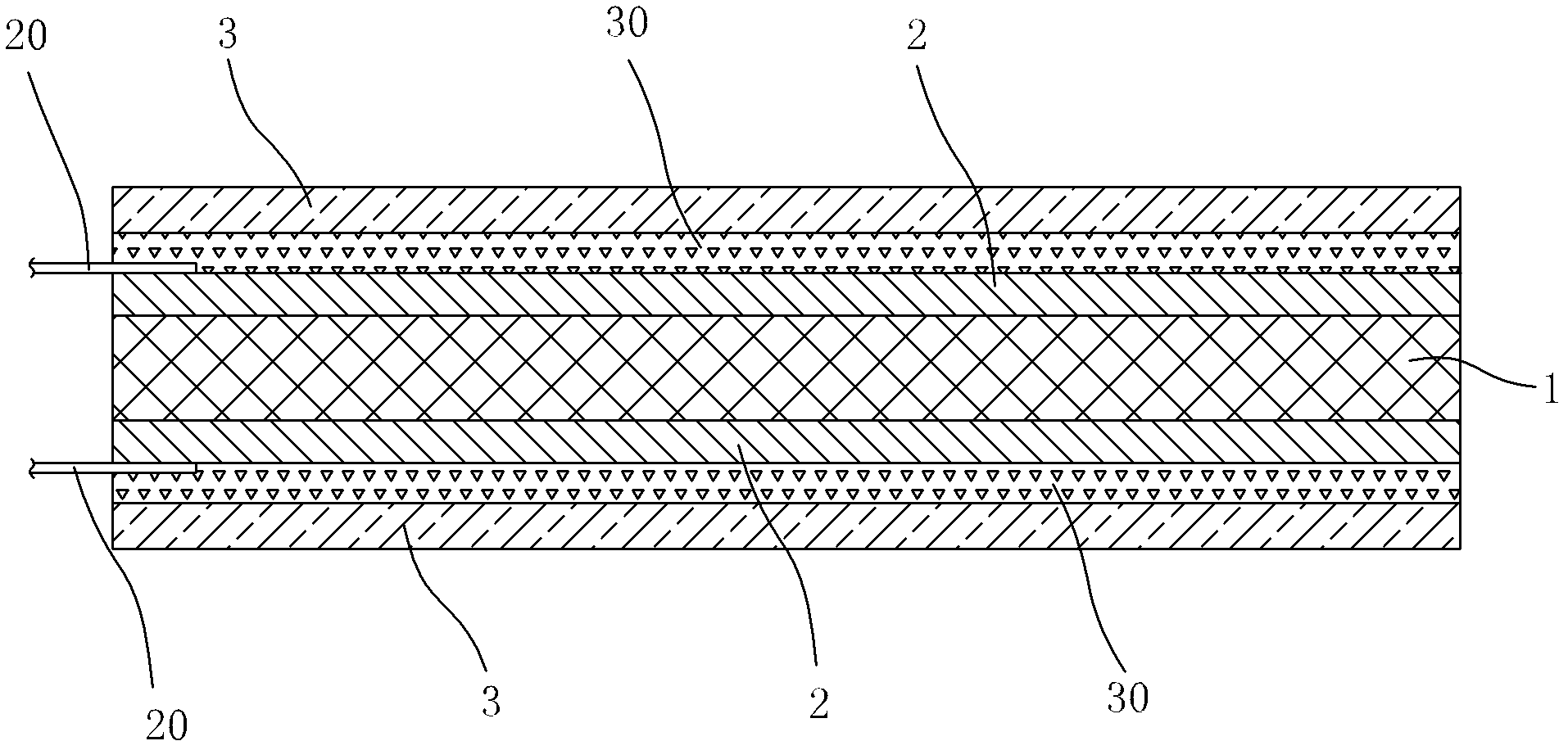

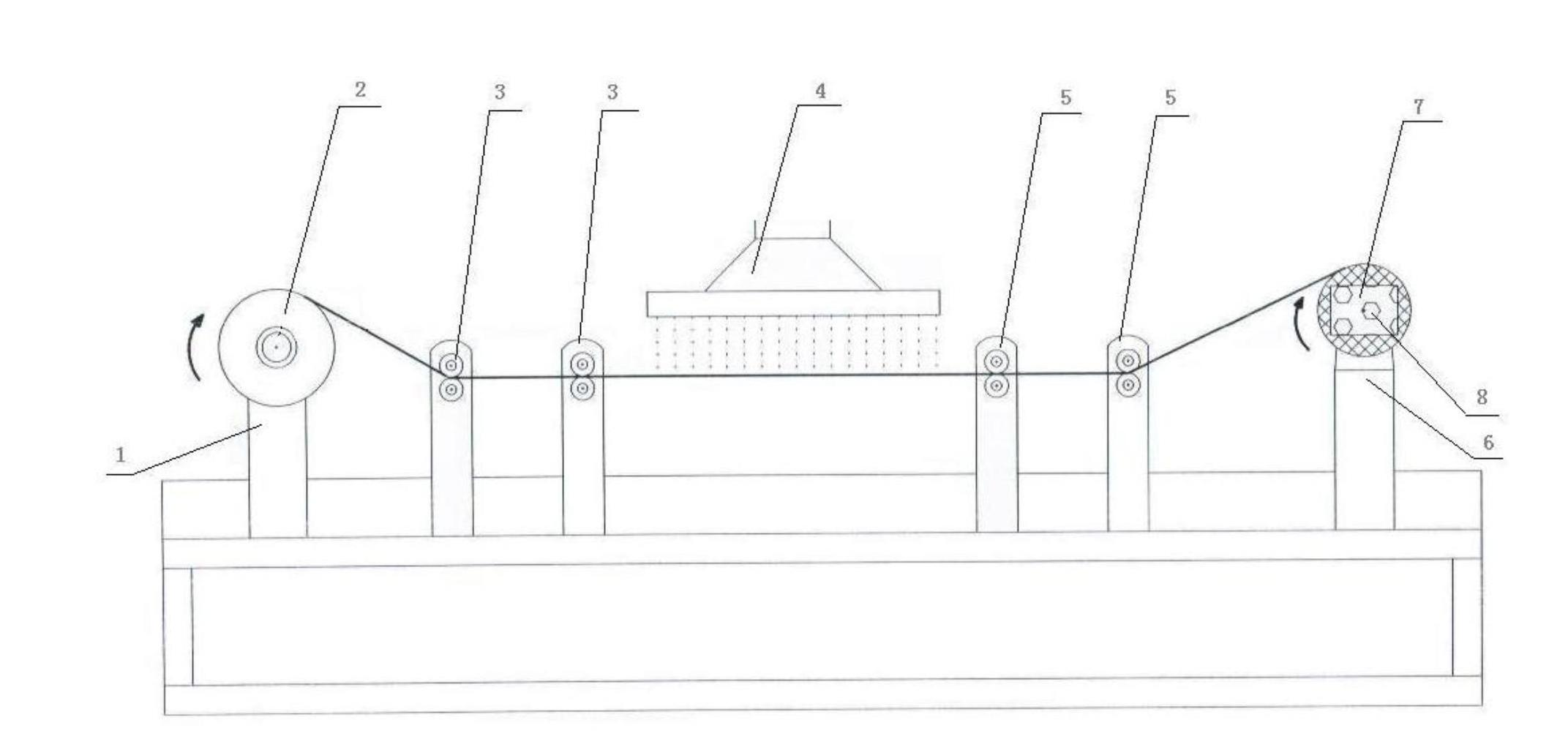

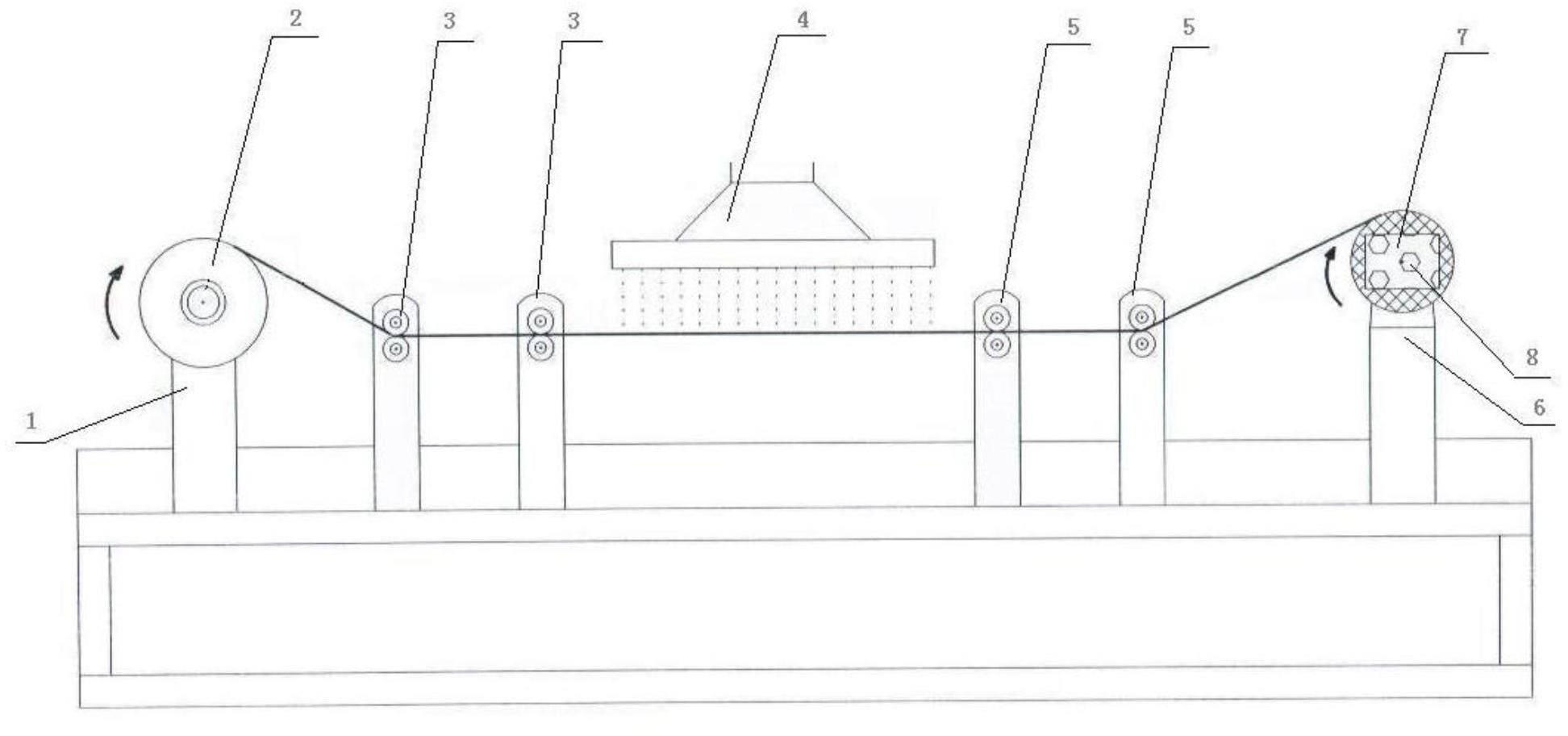

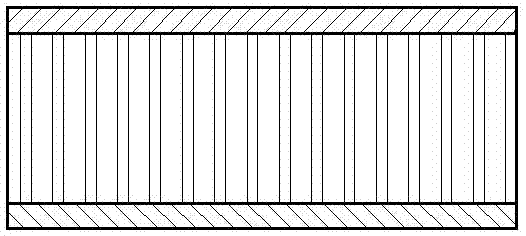

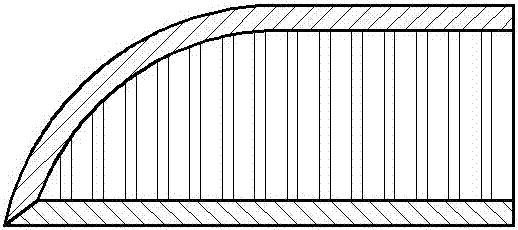

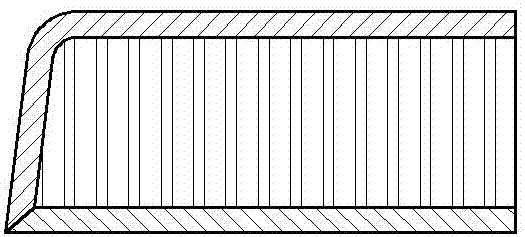

Continuous production method and equipment for composite type sleeper

The invention provides a continuous production method for a composite type sleeper. The continuous production method comprises the following four procedures: (1) spreading: enabling spread glass fiber woven fabric to pass through a supporting-spreading mechanism; (2) soaking: uniformly spraying polyurethane resin on the surface of the glass fiber woven fabric, and then enabling the glass fiber woven fabric to pass through pair rolls, thus forming a flat surface; (3) winding: winding the glass fiber woven fabric on the outer surface of a sleeper inner core, shearing off the glass fiber woven fabric and placing the sheared glass fiber woven fabric in a mold; and (4) molding: aging the polyurethane resin in the mold, removing the mold after the aging is ended, thus obtaining the composite type sleeper. The invention also provides continuous production equipment for the composite type sleeper. The interlayer shearing force of the sleeper produced by the method is cannot be damaged easily, the polyurethane resin in the outer surface of the sleeper produced by the method is distributed uniformly, and continuous and automatic production is realized by virtue of the method.

Owner:BEIJING PANTIAN NEW TECH

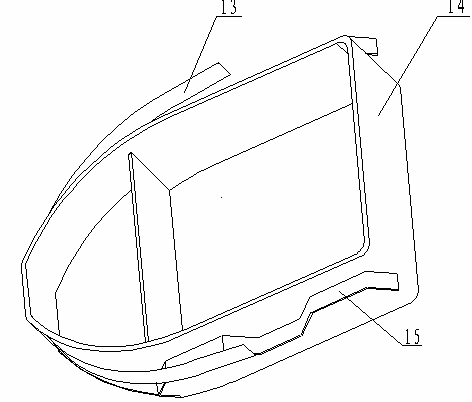

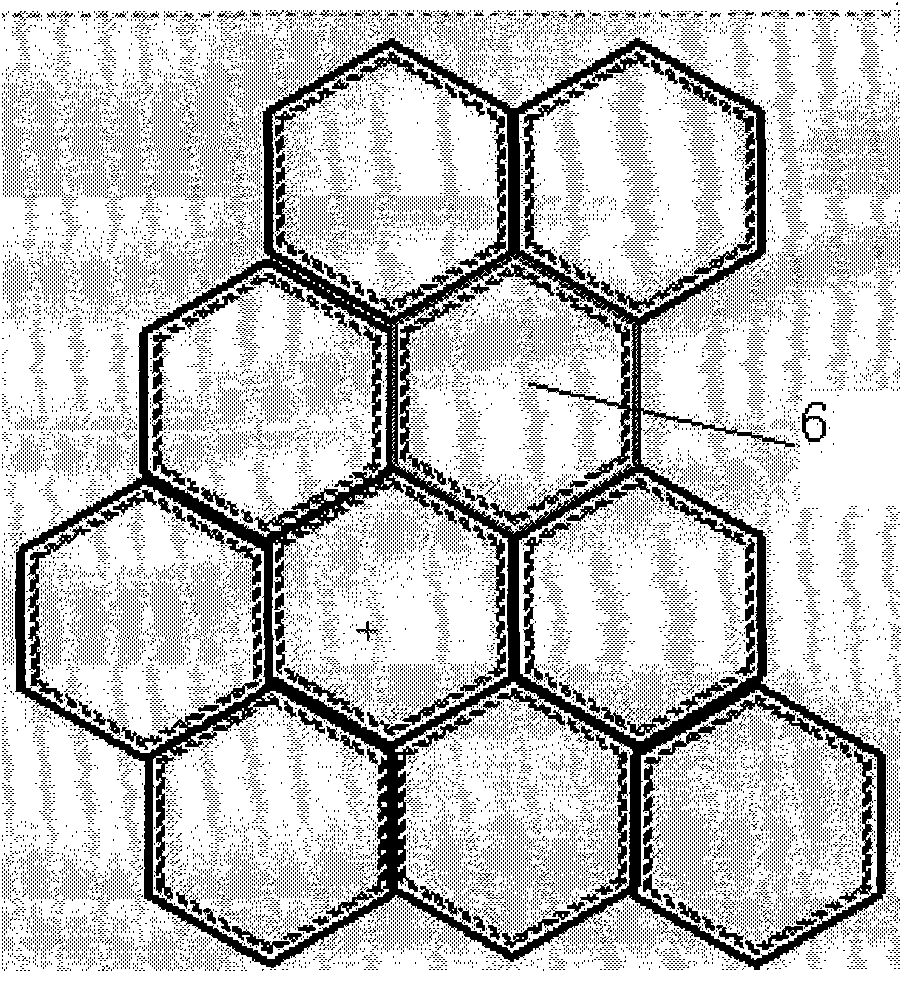

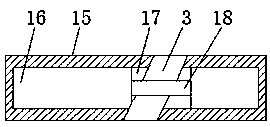

Method for sealing edge of plastic cellular sandwich board and apparatus thereof

ActiveCN107379726AWon't crushImprove side wall strengthLamination ancillary operationsSynthetic resin layered productsSandwich boardMechanical engineering

The invention relates to a method for sealing an edge of a plastic cellular sandwich board and an apparatus thereof. According to the invention, an edge sealing zone is arranged outside the contour of a product, in the edge sealing zone, a high-temperature part is inserted between an upper skin and a lower skin of the edge, honeycomb is removed through fusing, the upper skin and the lower skin are softened, and then the upper skin and the lower skin are turned to a center, so that edge sealing of the product is realized. According to the edge sealing method, the product edge is full and firm, the product edge intensity is enhanced, the problem of edge enclosing of a PPHC material is solved, and an application of the PPHC material on a spare wheel cover plate is promoted.

Owner:宁波正海汽车内饰件有限公司

Pill counting and filling machine

The invention discloses a pill counting and filling machine. A constant pill counting and outputting device comprises a pill stopping device, a second pill delivery pipe and a bottles and cans stopping device, wherein the bottles and cans stopping device is provided with a driving mechanism, a channel and an elastic pressing head, wherein the elastic pressing head is movably placed in the channel, the driving mechanism is connected with an elastic pressing head, and a pill counting sensor is arranged at the adjacent side of the channel; the upper port of the second pill delivery pipe extends to the outlet of the channel, the lower port extends to the position above a conveyor belt which is slightly higher than bottles and cans, and the bottles and cans stopping device is arranged at the rear side of the second oil delivery pipe. According to the pill counting and filling machine, pills are output gradually through the channel, and the pills are elastically pressed by the elastic pressing head so as to stop outputting the pills, so that counting is accurate, the integral design is compact, the volume is smaller, the equipment is minimized, the efficiency is high, the pills can not be squashed, and the equipment can be more flexibly placed.

Owner:曹东华

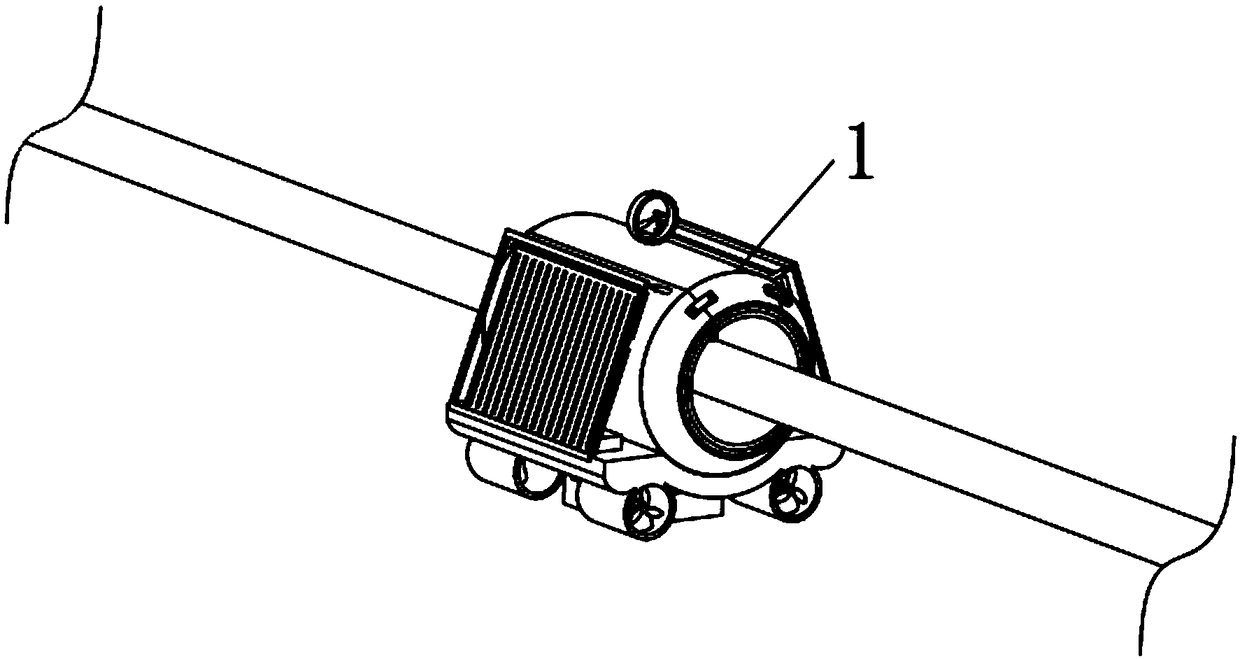

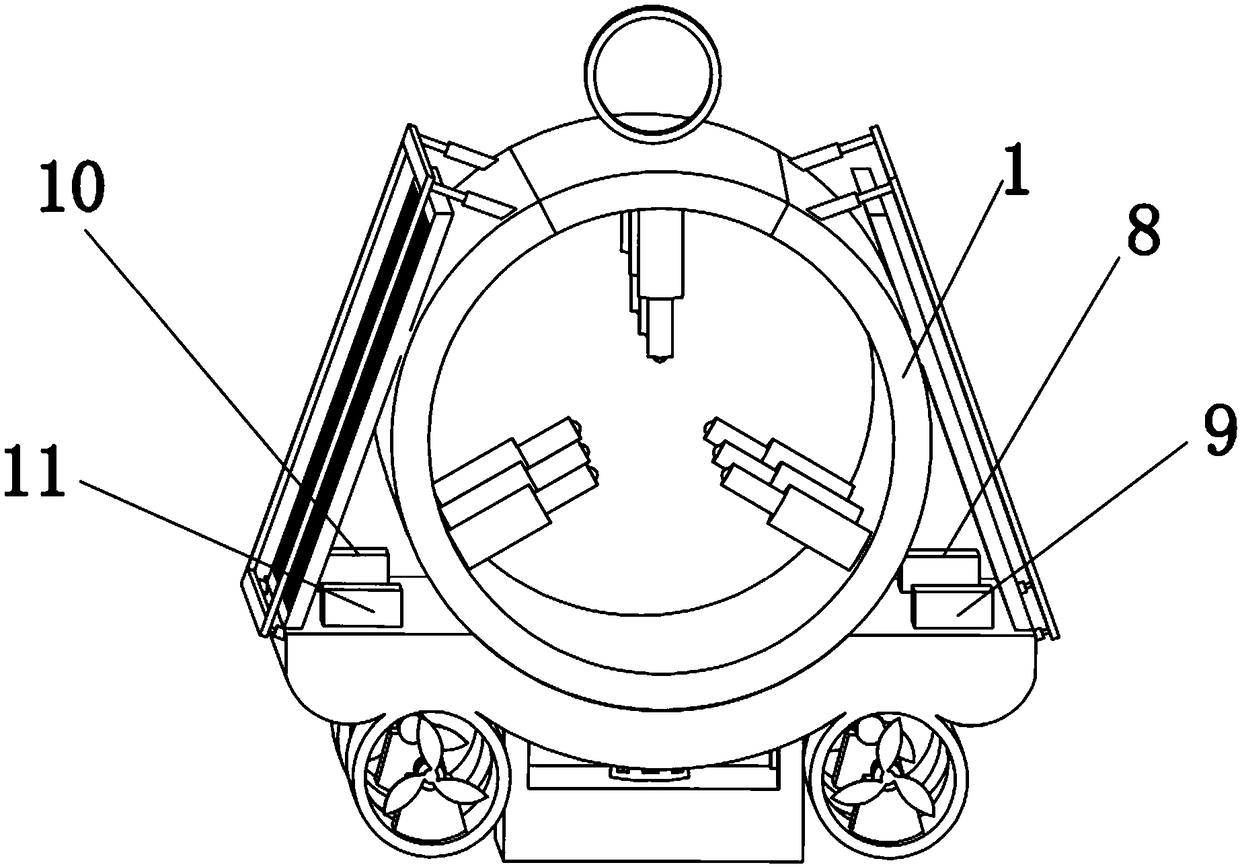

Circuit periodic inspection equipment based on GPS

ActiveCN109212381AEasy to installWon't crushOverhead installationFault location by conductor typesSnow removalEngineering

The invention discloses circuit periodic inspection equipment based on a GPS. The circuit periodic inspection equipment based on the GPS comprises a barrel body, snow removal devices, nine clamping devices, driving devices, a weight losing device, a solar cell panel and a protective device. The snow removal devices are symmetrically fixed at the two ends of the barrel body, the nine clamping devices are arranged in the barrel body, every three clamping devices are annularly and uniformly distributed on the inner wall of the barrel body, and the clamping devices are arranged in three rows of equidistantly. A base is fixed at the bottom of the barrel body, the driving devices are fixed at four corners of the bottom of the base correspondingly, and the orientation of the driving devices located at one end of the base is opposite to the orientation of the driving devices located at the other end of the base. The circuit periodic inspection equipment based on the GPS has high routing inspection speed and high efficiency and can inspect faults when the tiny faults appear in high-tension circuits, preventive measures are taken, power consumption is low, solar power supply is adopted, precision localization is achieved through the GPS after the faults are inspected, and rapid overhauling is achieved.

Owner:南昌保莱科技有限公司

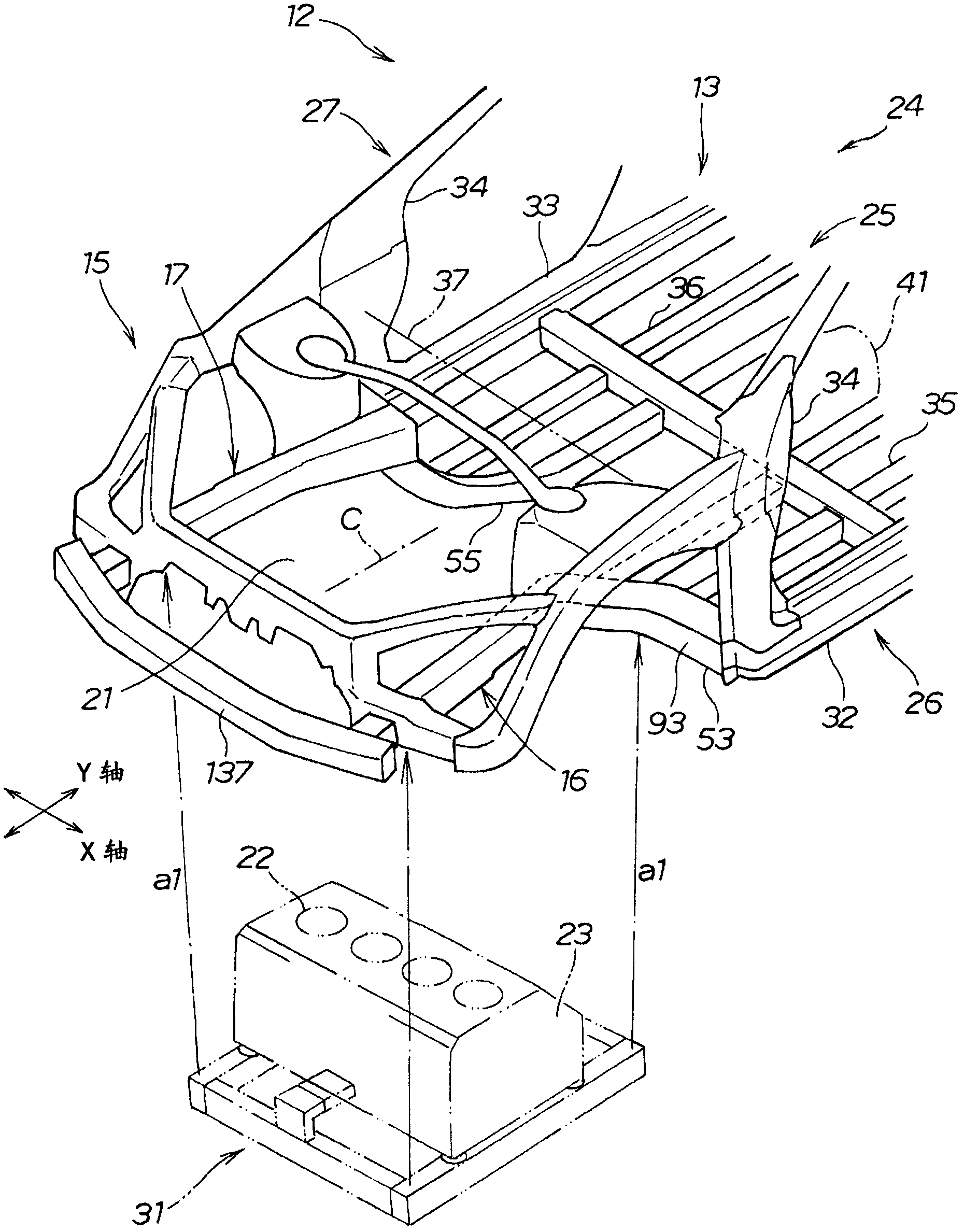

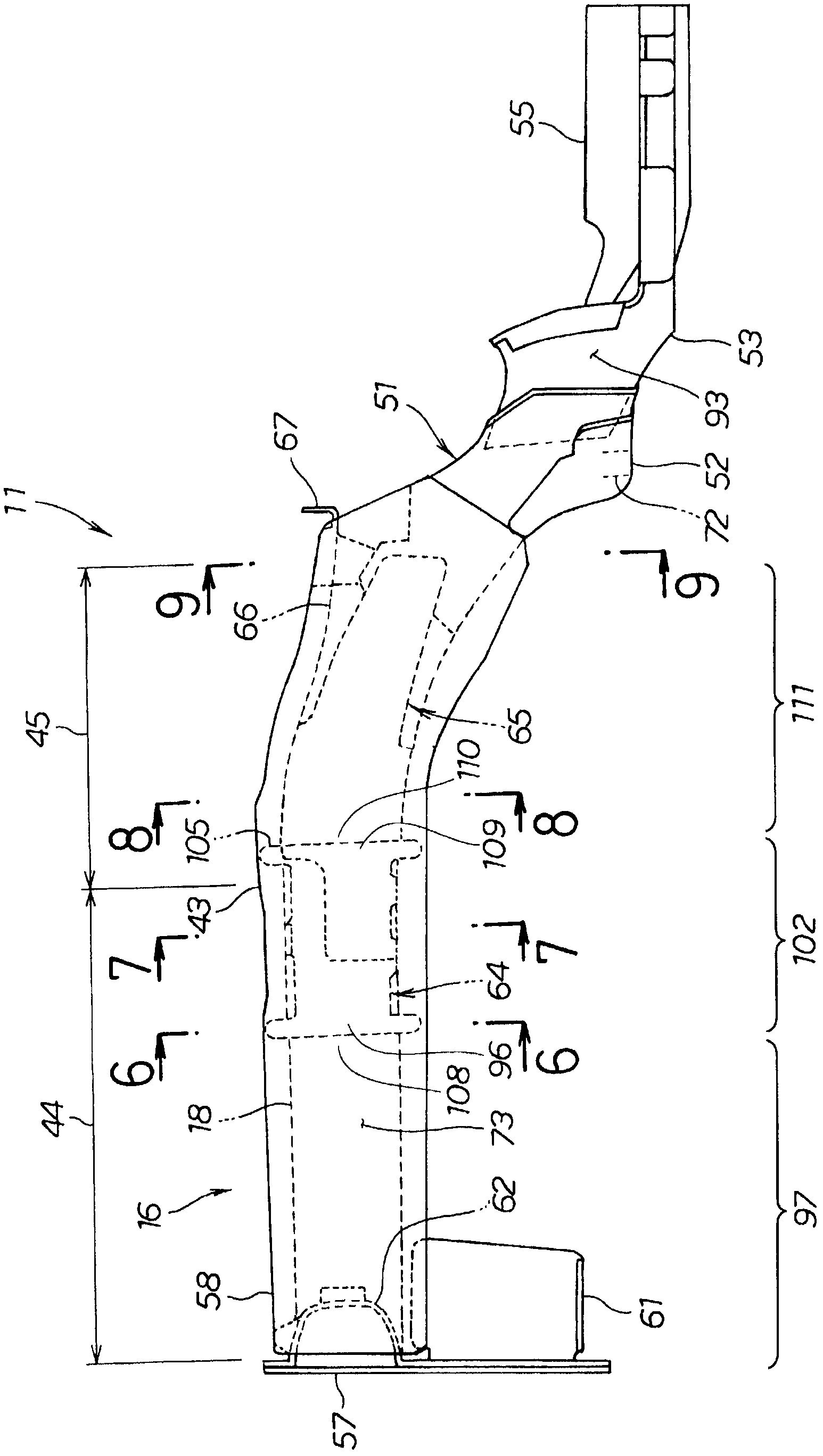

Vehicle body front structure

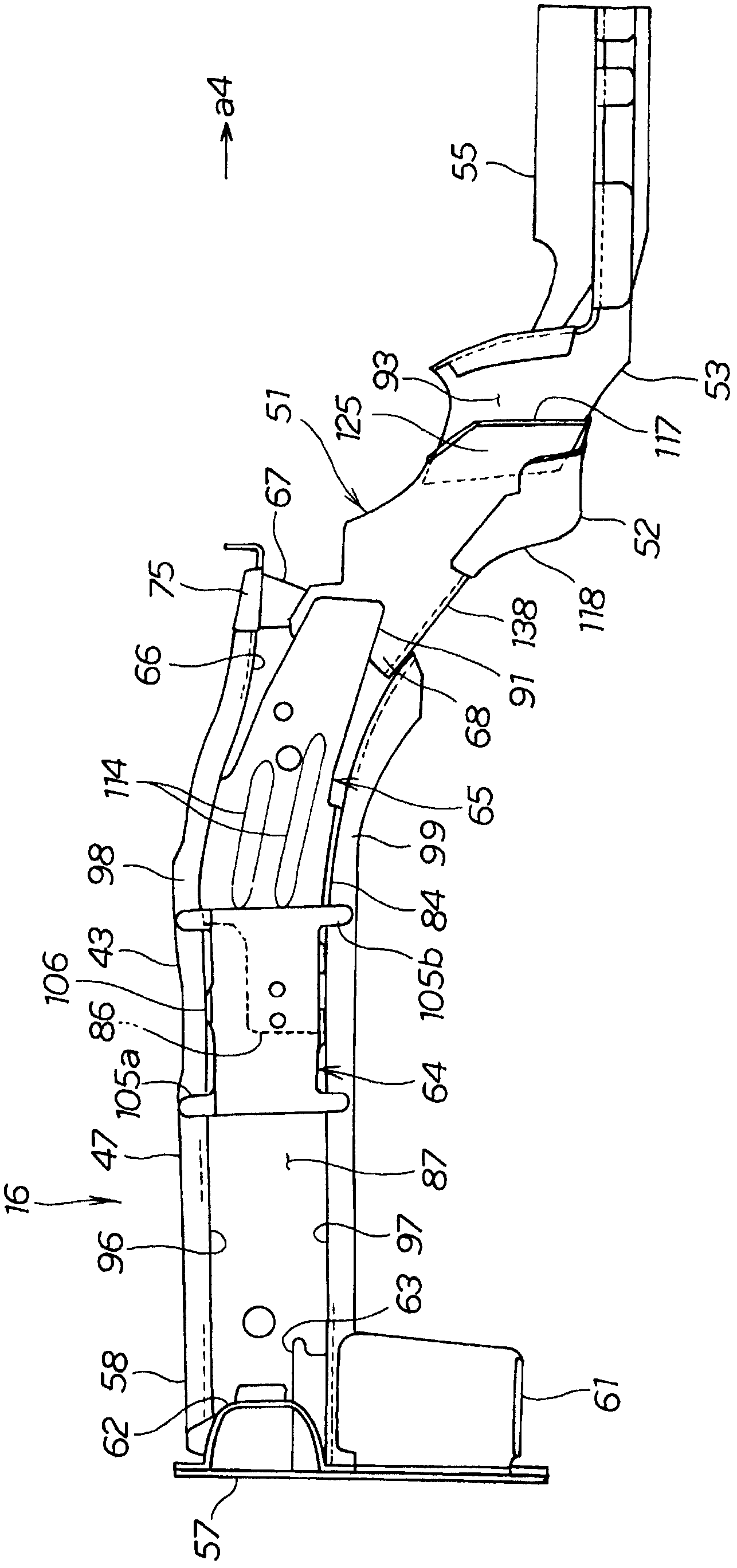

ActiveCN102470901AEasy to manufactureEasy plastic processingUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

A vehicle body front structure provided with left and right front side frames (16, 17). The left front side frame (16) has a rectangular closed cross-sectional shape. The front side frame (16) is provided with a rectilinear section (front half frame section) (44) extending rectilinearly from the front end (58) to the center section (43), and also with a moment receiving section (rear half frame section) (45) continuing from the rectilinear section (44) and extending in a curved form toward the inner side in the widthwise direction of the vehicle. A first ridge line section (78) is a portion which forms a corner (78) among the corners (78) of the rectilinear section (45), said corner (78) being located on the inner side in the widthwise direction of the vehicle. A second ridge line section (84) is connected to the first ridge line section (78) at a position inside the moment receiving section (45). A stiffener (65) is connected to the rear end (66) of the front side frame (16).

Owner:HONDA MOTOR CO LTD

Self-adaptive brush coating device

InactiveCN106000775AEfficient and accurate completionSave labor costLiquid surface applicatorsCoatingsSheet steelEngineering

The present invention provides an adaptive brush device, including a fixed unit, an adaptive adjustment unit, and a brushing unit. The fixed unit includes a cylinder and slide.The cylinder can drive the sliding platform to move up and down; the adaptive adjustment unit consists of the slider, slider and baffle on the fixed seat, which plays the connection between connecting the fixed unit and the brushing unit;The sliding rail is freely moved; the brushing unit includes the glue brush mechanism and the holding seat, which is set on the slider of the adaptive unit of the adaptive unit.In the paint glue.The adaptive brush device of the present invention can have no time limit for cycle, which greatly saves processing manpower and time costs. In addition, the invention has an adaptive structure and can complete the task of sticking steel sheets more efficiently and accurately.

Owner:KUN SHAN POWER STENCIL

Wire harness cutting-off equipment for instrument production

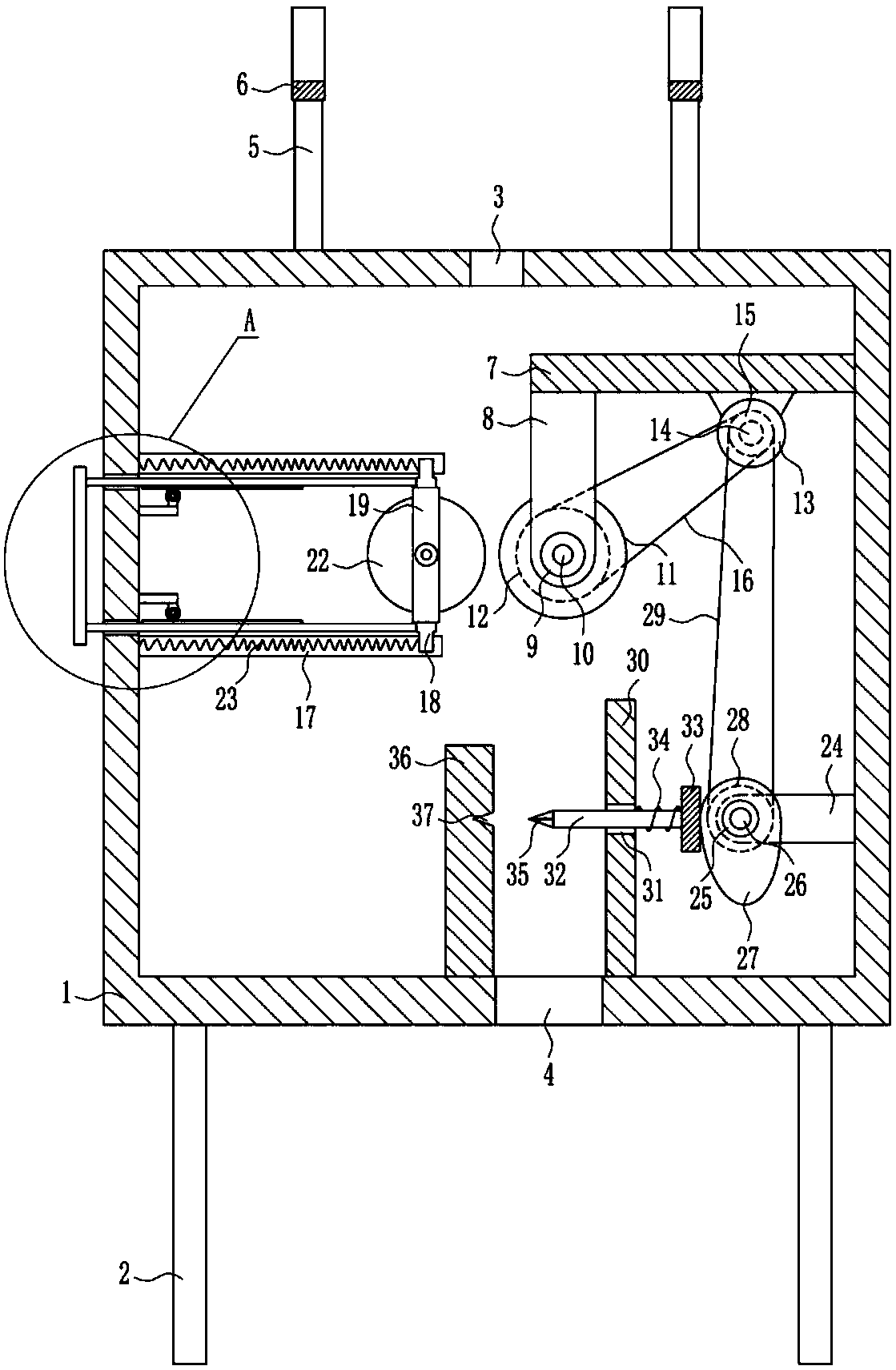

The invention relates to cutting-off equipment, in particular to wire hardness cutting-off equipment for instrument production. According to the technical aims, the wire hardness cutting-off equipmentfor instrument production is high in cutting-off speed and uniform in cutting-off. The wire hardness cutting-off equipment for instrument production comprises a tank, supporting legs, supporting boards, arc-shaped boards, a first transverse board, a first vertical board, a first bearing pedestal, a first rotary shaft, a first roller, a first belt wheel and the like. The supporting legs are installed at four corners of the bottom of the tank; a feeding inlet is formed in the middle of the top of the tank; a discharging outlet is formed in the middle of the bottom of the tank; the two supporting boards are installed on the top of the exterior of the tank; and the feeding inlet is located between the two supporting boards. A first motor is used as a driver to drive the first roller to rotate, so that wire harnesses are driven to move downwards; and a cam drives a cutter to cut off the wire harnesses, a movable plate and a fourth spring are also arranged, so that the cut-off wire harnesses are not stacked, and the effects that the wire harnesses are cut off fast and uniformly are achieved accordingly.

Owner:常州中端电器有限公司

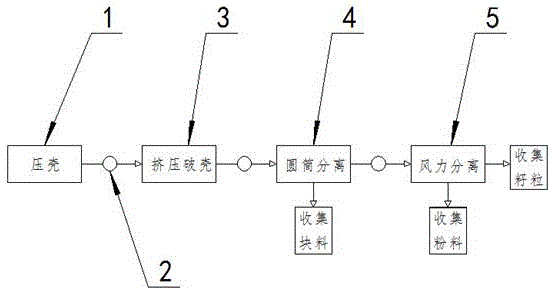

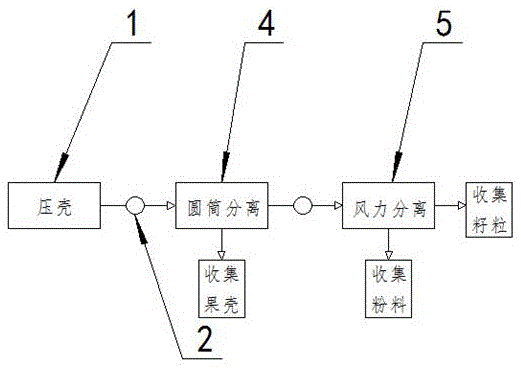

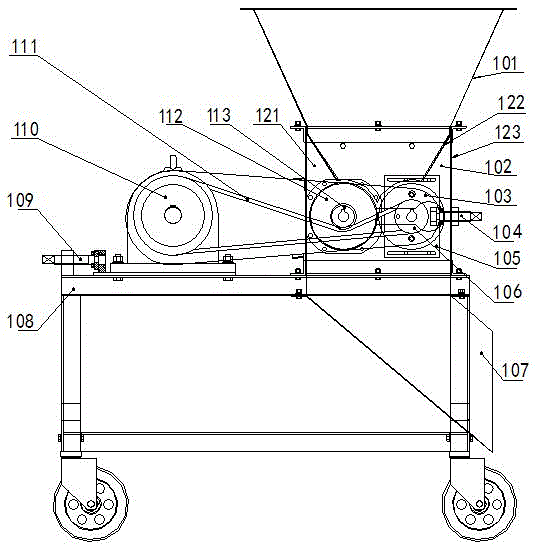

Poppy fruit preliminary processing integrated device and processing method

ActiveCN105583060ASave raw materialsSo as not to damageGas current separationHuskingEngineeringMachining process

The invention discloses a poppy fruit preliminary processing integrated device and a processing method. The device comprises a poppy fruit shell breaking machine, an extrusion shell breaking machine, a cylinder separation device and a wind force separation device. A discharging port of the poppy fruit shell breaking machine is connected with a feeding port of the extrusion shell breaking machine through a conveying device. A discharging port of the extrusion shell breaking machine is connected with a feeding port of the cylinder separation device through a conveying device. A discharging port of the cylinder separation device is connected with a feeding port of the wind force separation device through a conveying device. Whole-process mechanical work for poppy fruit preliminary processing is achieved, the requirement for processing two kinds of poppy fruits can be met by connecting or bypassing the extrusion shell breaking machine, poppy fruit shells of the poppy fruits can be crushed, and seeds, the fruit shells and powder of the poppy fruits can be separated and collected according to processing requirements, and in addition, the fruit shells can be processed into blocks with the diameter of 2-14 mm; and the production efficiency and the processing quality are greatly improved, the seeds are not damaged in the processing process, raw materials of the poppy fruits are saved, and the production cost is reduced.

Owner:JIUQUAN OK SEED MACHINERY

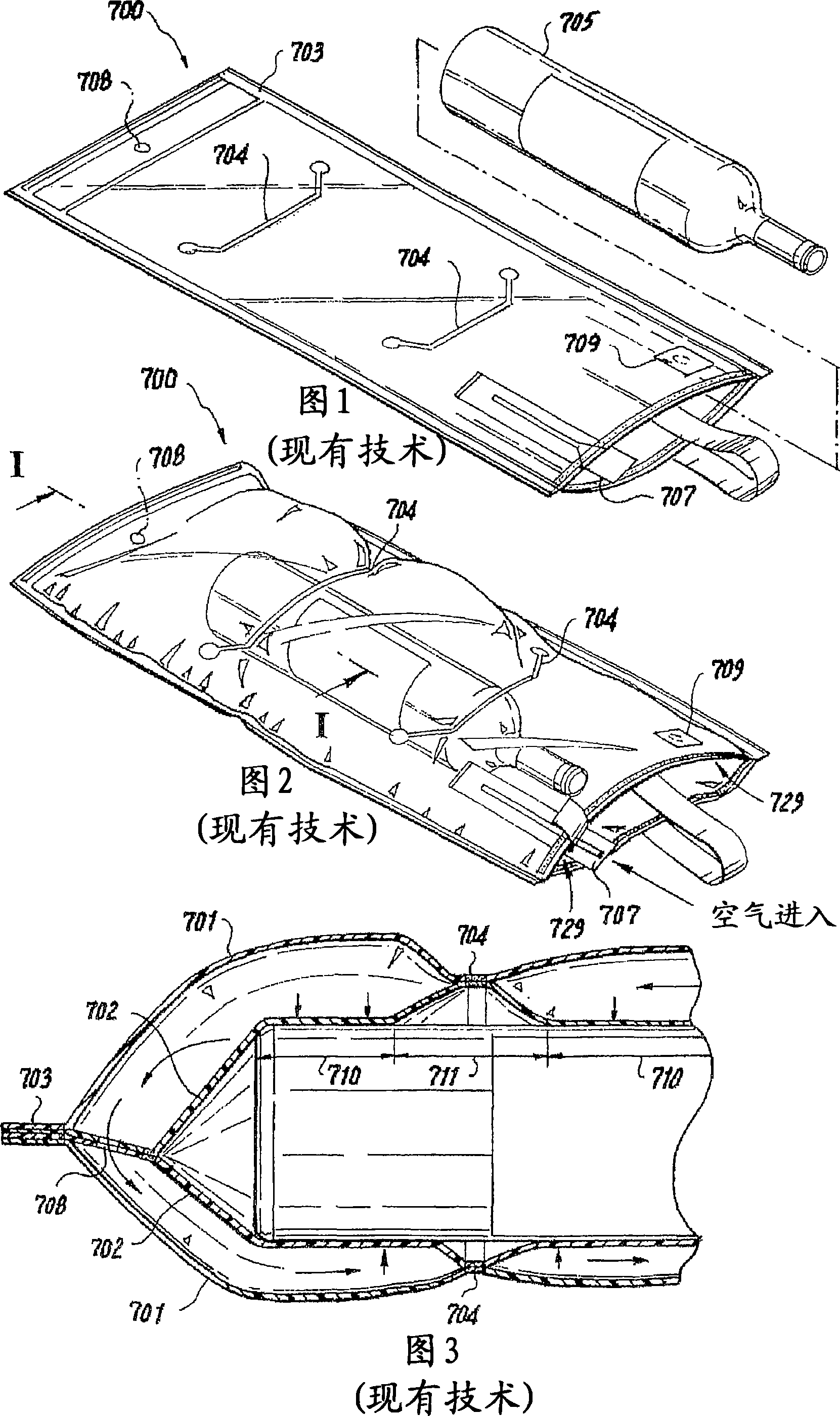

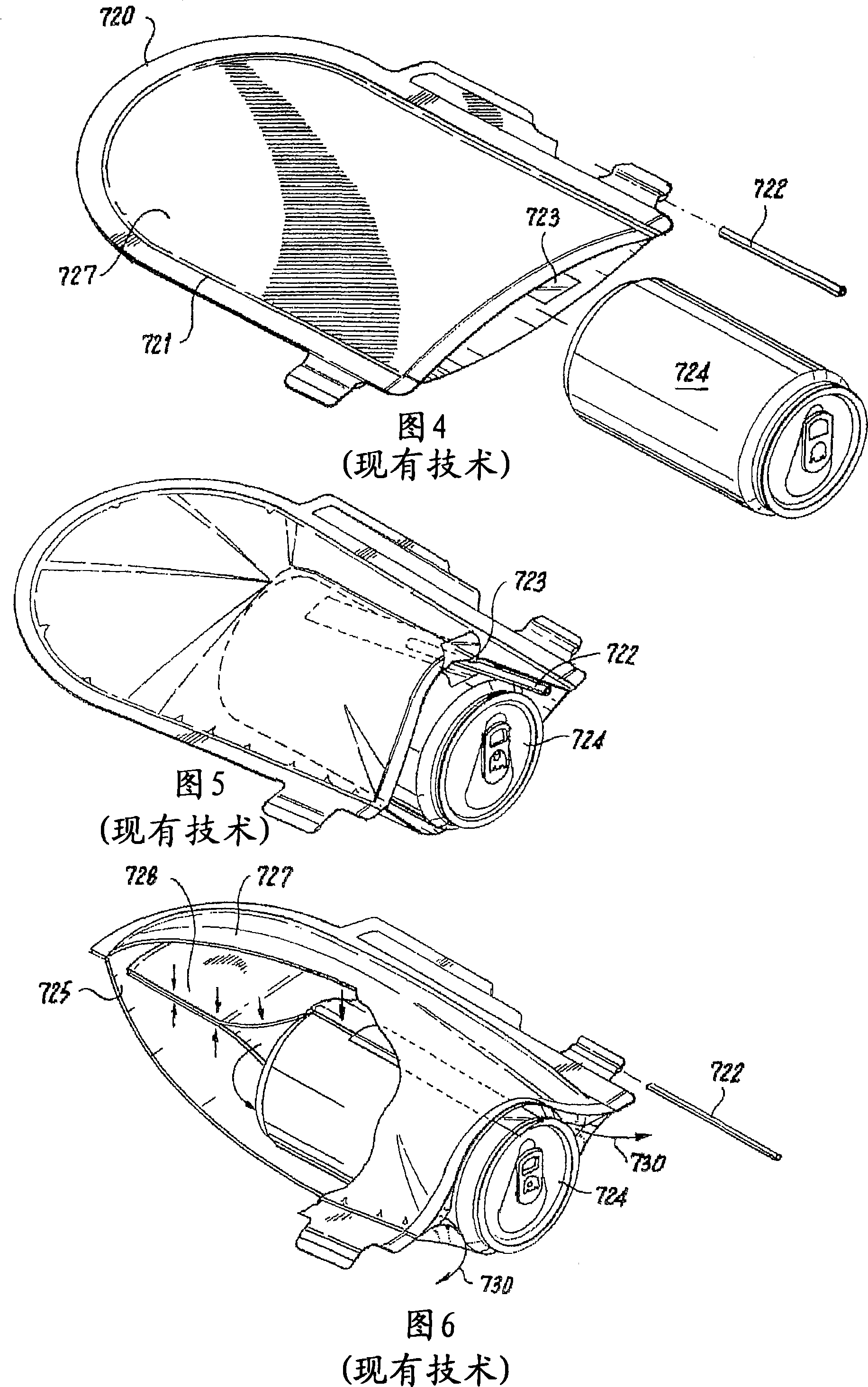

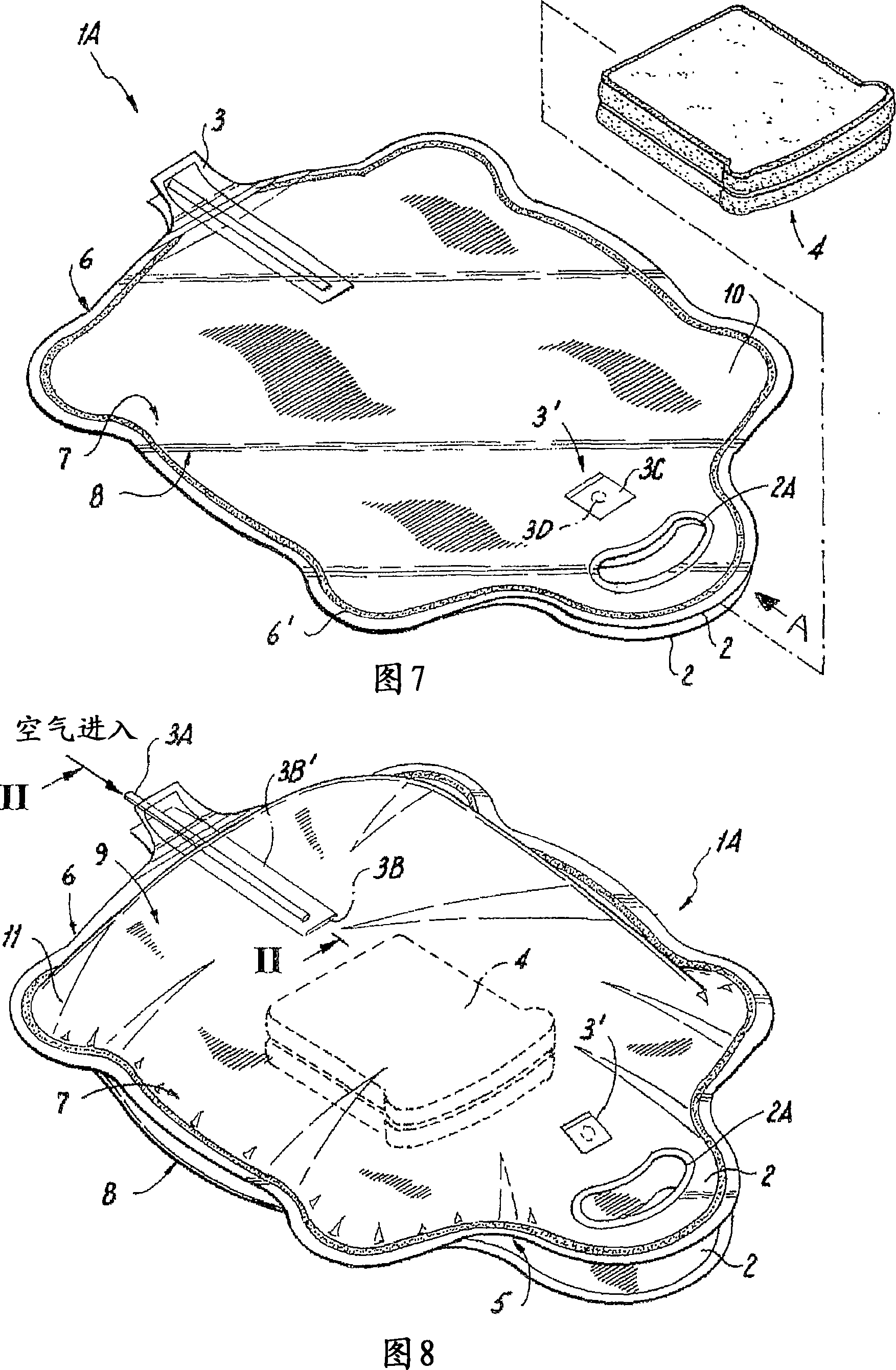

Carry device

In one embodiment a carry device includes a first inner carry pouch made from a first material and an outer bounding pouch or layer made from a second material defining at least one cavity therebetween. An access port may include a release and inflation actuator and provides volumetric access to the at least one cavity allowing passage of a pressurizing atmosphere or temperature effecting medium, or combination thereof. A sealable access is provided, and a common pressure is applied to an outer uniform-pressure region of a non-rigid or rigid item being carried thereby preventing damage and crushing thereof through high contact pressure gradients. In another embodiment handles are inflatable to aid sealing the inner carry pouch and provide a comfortable grip.

Owner:纽约布伊尔特股份有限公司

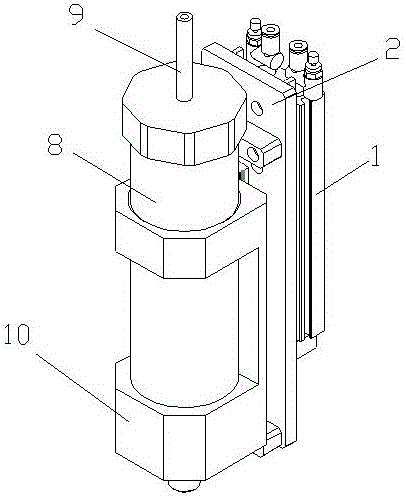

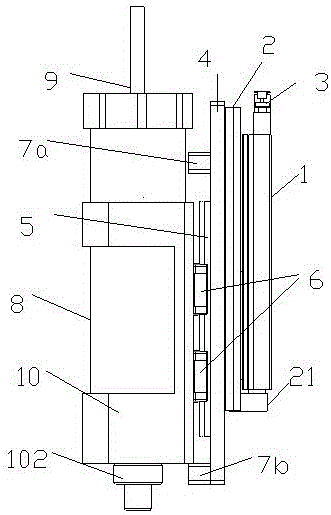

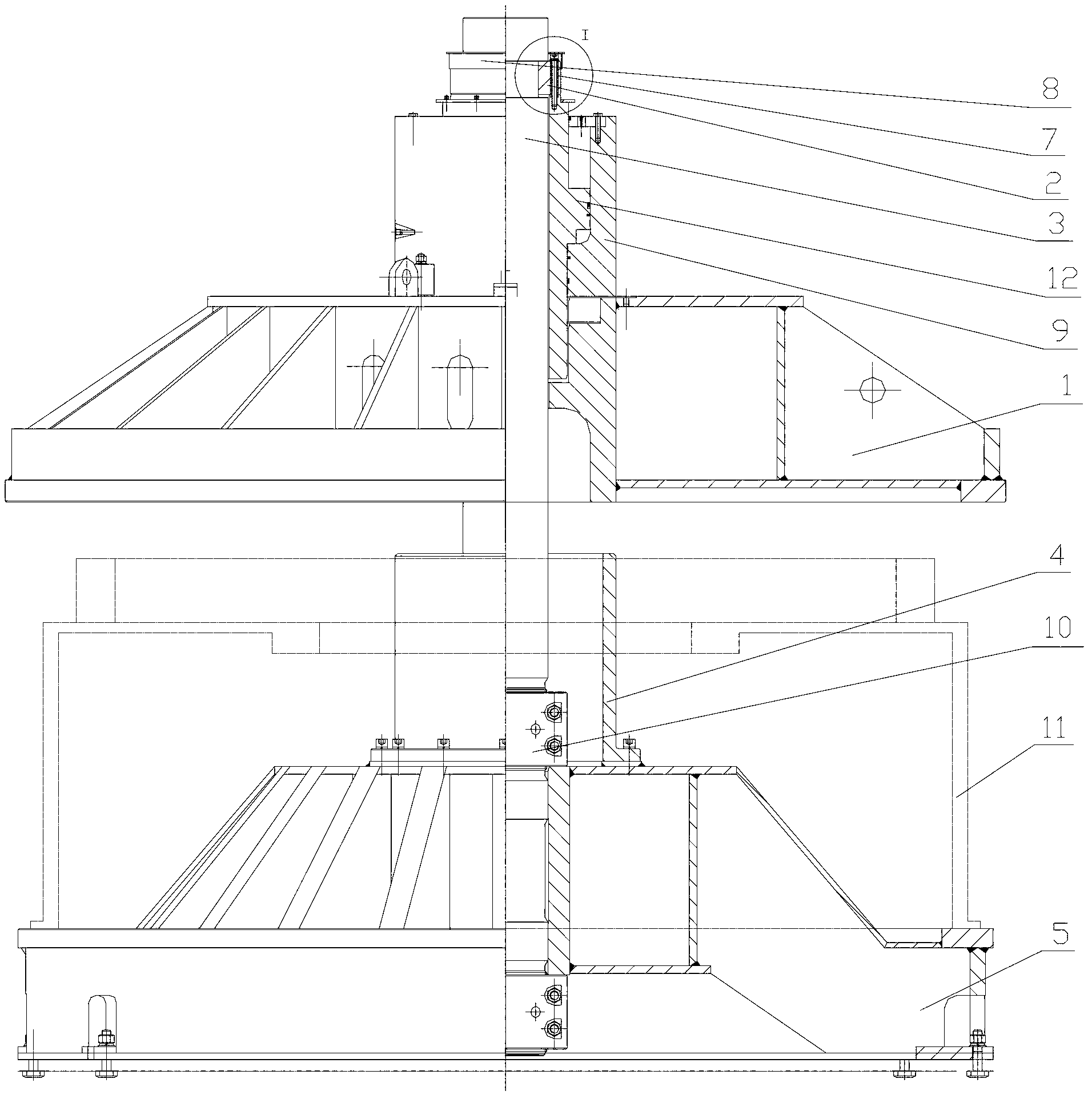

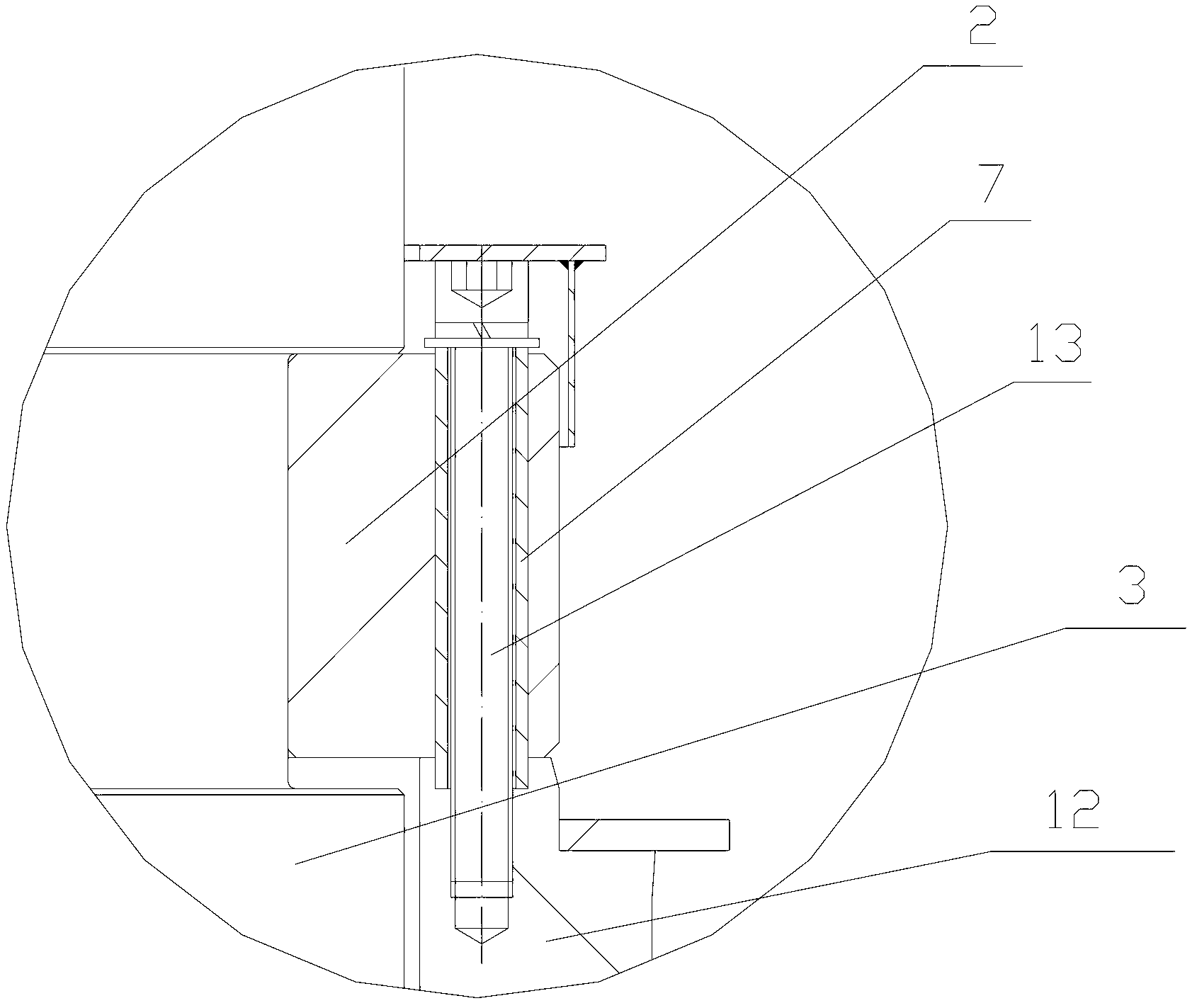

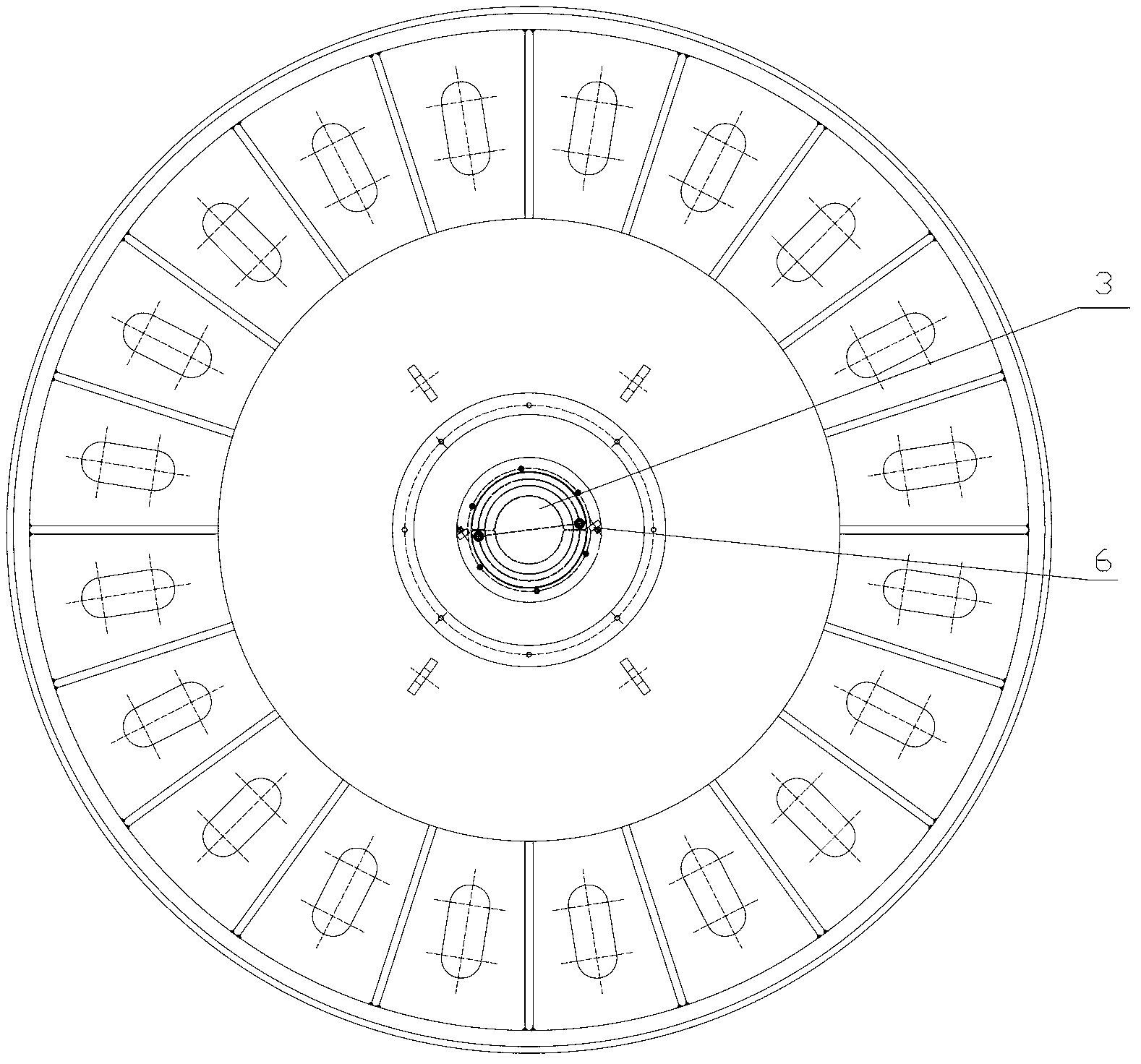

Motor stator iron core pressing hydraulic machine

InactiveCN103326522AReduce manufacturing costReduce laborManufacturing stator/rotor bodiesEngineeringPiston rod

The invention relates to a motor stator iron core pressing hydraulic machine which comprises an upper pressing plate, a pull rod, a lower pressing plate and a main oil cylinder. The lower pressing plate is fixed on the ground through T shaped screws and is connected with a limit sleeve. The lower end of the pull rod in the limit sleeve is fixedly connected with the lower pressing plate through a locking nut. The upper part of the pull rod is fixedly connected with a piston rod of the main oil cylinder through a clamping ring. The main oil cylinder is fixedly connected with the upper pressing plate. The motor stator iron core pressing hydraulic machine has the advantages of simple structure and convenient installation and connection, two working stations can be arranged through division when the motor stator iron core pressing hydraulic machine is in use, the versatility is good, the tooling production cost is low, the labor amount is small, the resources are saved too, and the efficiency and pressing quality of the machine are effectively raised.

Owner:TIANJIN TIANDUAN PRESS CO LTD

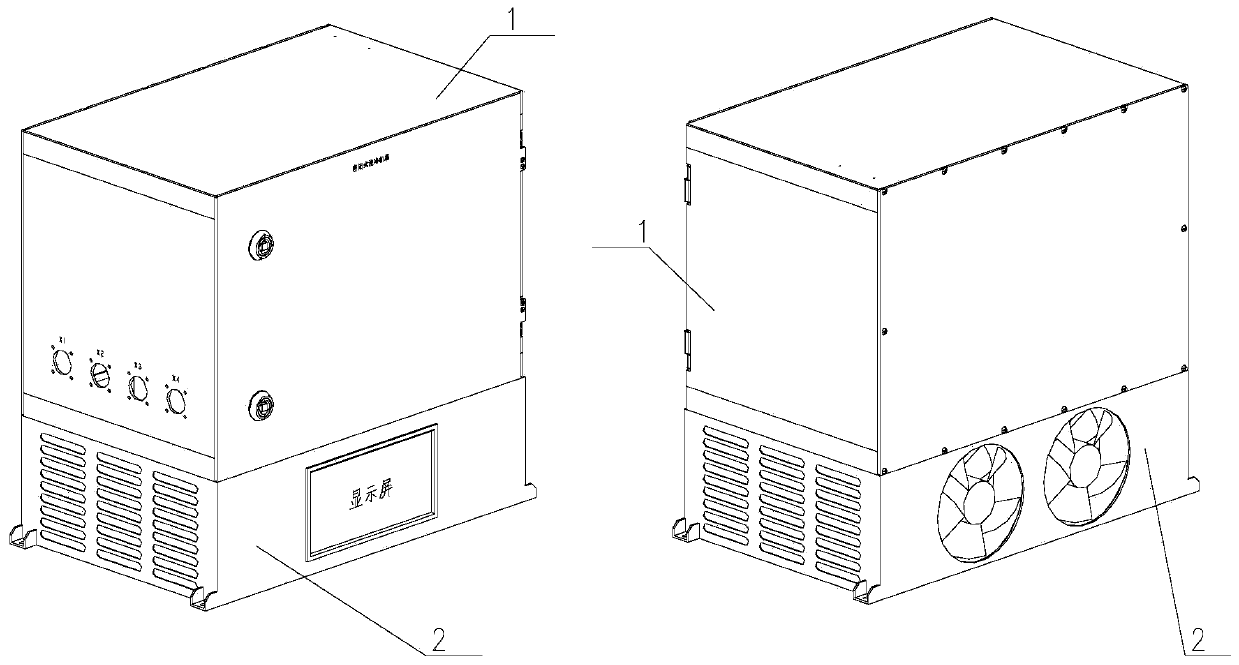

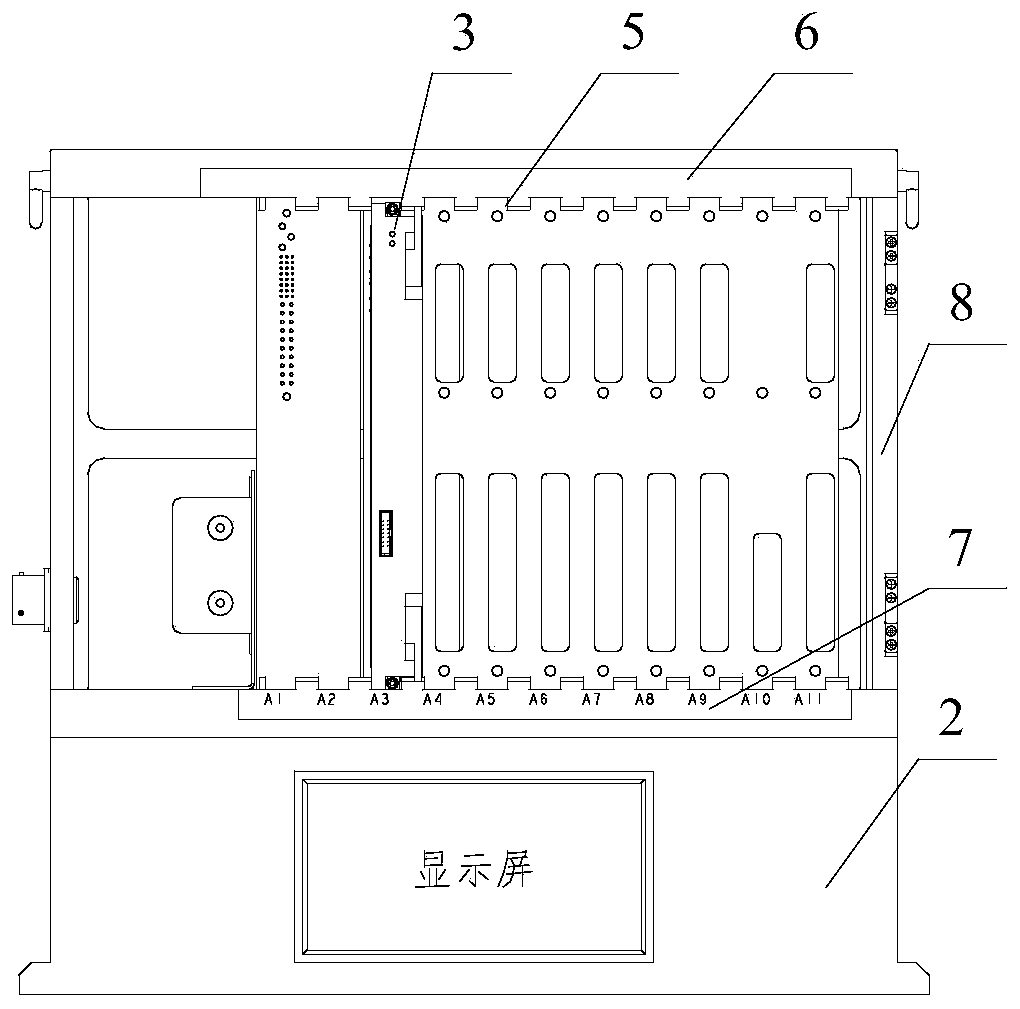

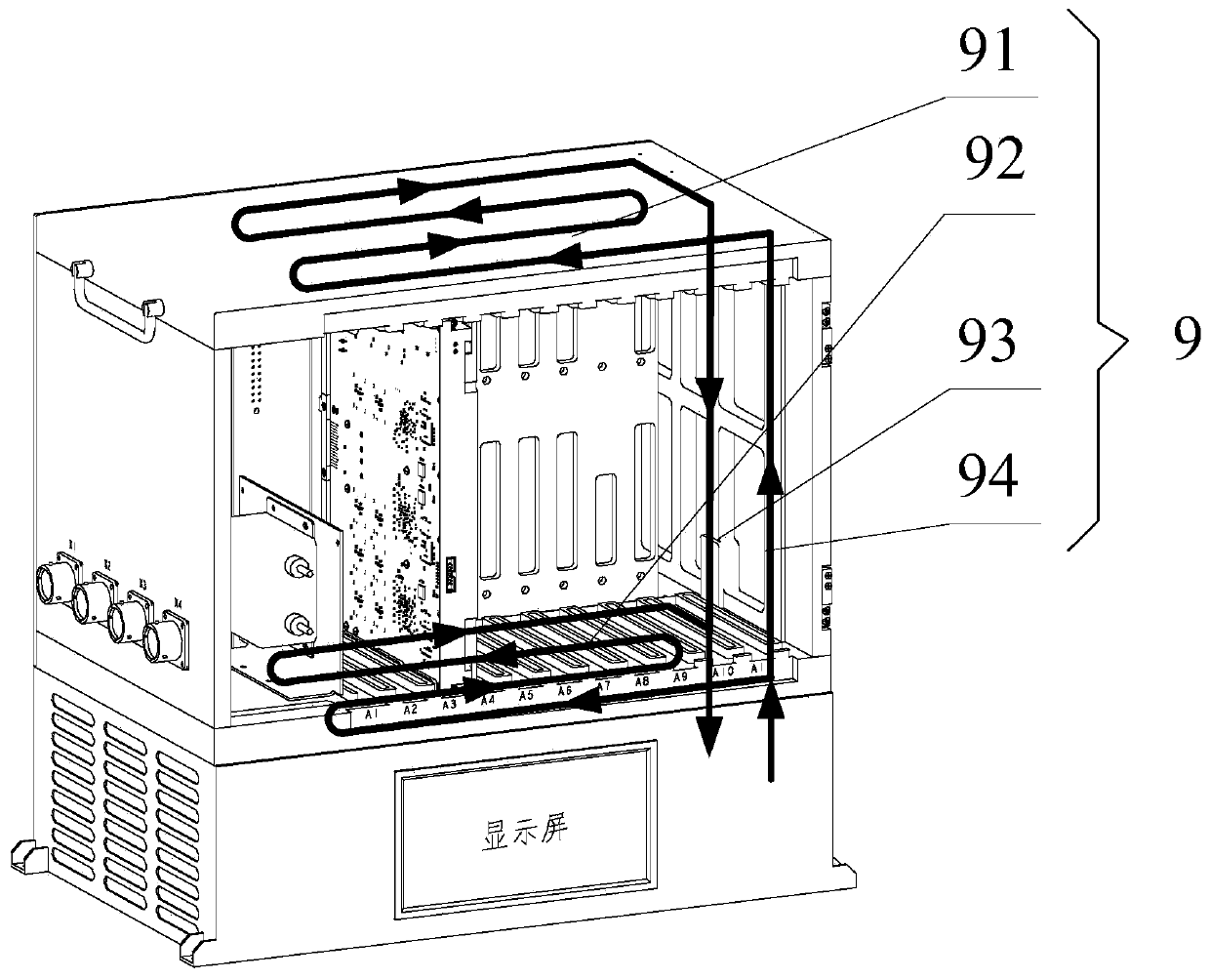

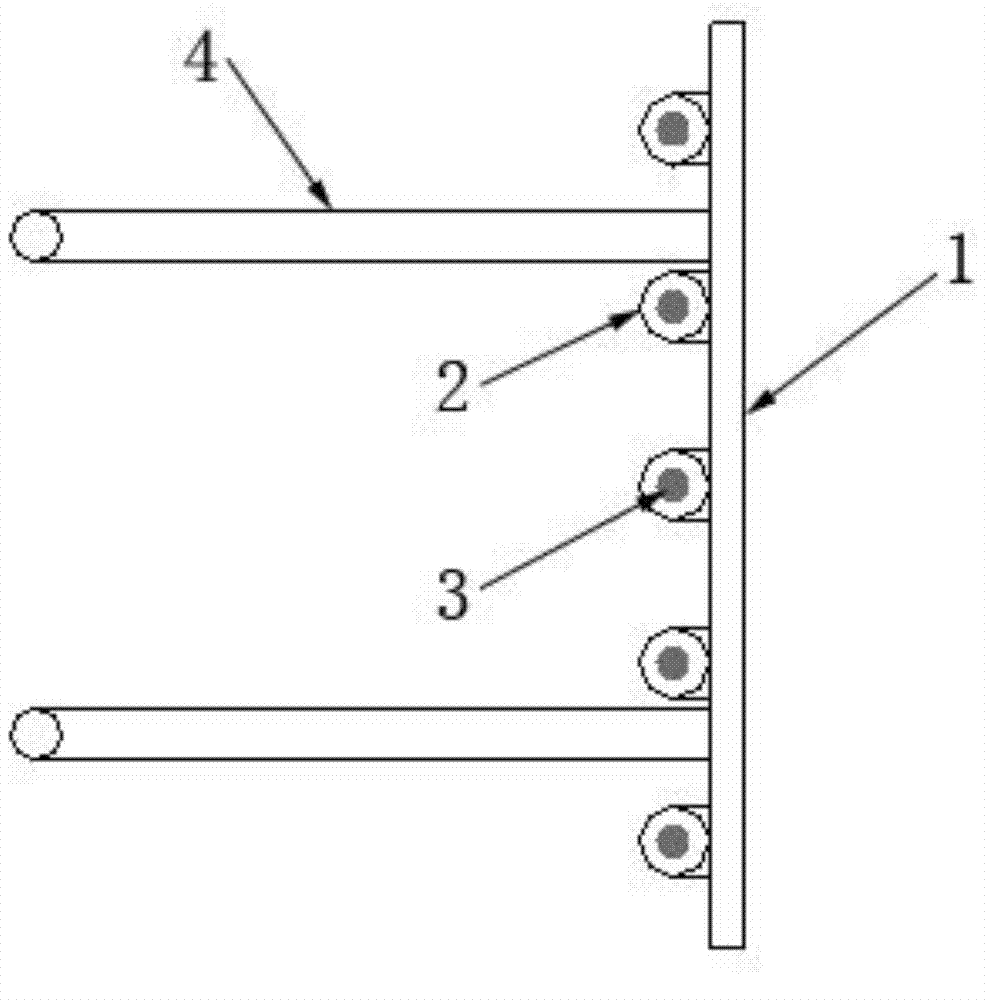

Integrated liquid cooling machine box based on two-phase heat transfer and two-phase heat transfer method thereof

InactiveCN110213942AImprove heat transfer efficiencyGood isothermModifications using liquid coolingSingle phaseIntegrated circuit

The invention relates to an integrated liquid cooling machine box based on two-phase heat transfer and a two-phase heat transfer method thereof. The integrated liquid cooling machine box comprises a machine box shell, a two-phase liquid cooling source and a plug-in cold guide plate, wherein flow channels which are communicated with each other are arranged in the top wall and the bottom wall of themachine box shell; the upper end and the lower end of the plug-in cold guide plate are fixedly connected with the top wall and the bottom wall of the machine box shell respectively, and are used forfixing electronic plug-in components; the two-phase liquid cooling source is fixedly connected with the machine box shell; and each flow channel has a flow channel inlet and a flow channel outlet which are communicated with the two-phase liquid cooling source through pipelines. The two-phase liquid cooling source is fixedly connected with the machine box shell and does not need to depend on an external liquid cooling source. The two-phase liquid cooling source is adopted, and a working medium is subjected to liquid state and gaseous state conversion in a pipeline system; the cooling working medium absorbs the heat of electronic equipment in the flow channels and is changed from the liquid state into the gaseous state, so that heat exchange efficiency is far higher than that of single-phasefluid heat exchange; and the cooling working medium phase change is performed in an isothermal process, so that the isothermal performance of the top wall and the bottom wall of the machine box shellis superior to that of the single-phase fluid heat exchange.

Owner:BEIJING INST OF RADIO MEASUREMENT

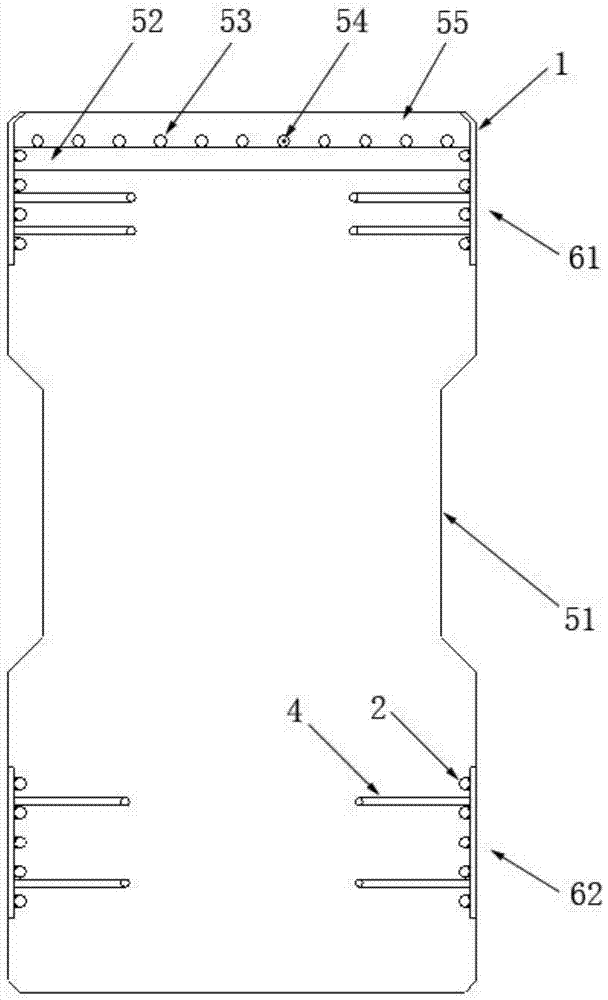

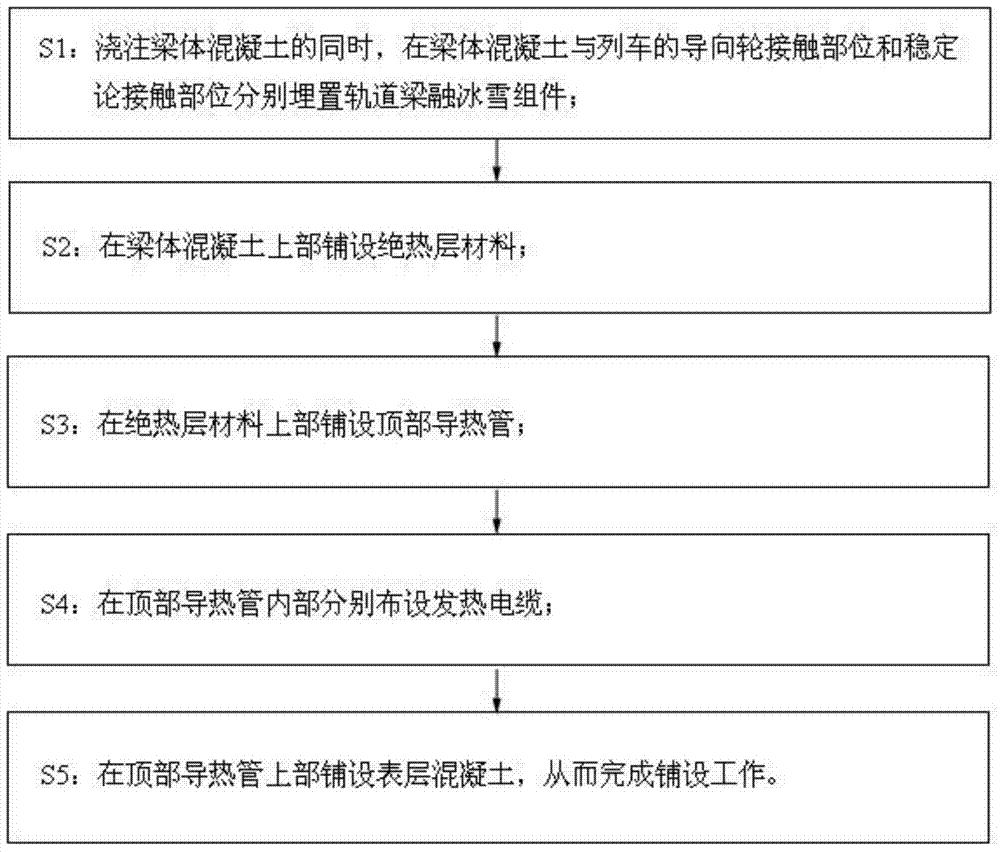

Rail beam ice and snow melting assembly, PC rail beam and laying method of PC rail beam

ActiveCN104711906AAdjustable temperatureHeating fastClimate change adaptationRailway tracksSurface layerSnow melting

The invention discloses a PC rail beam which comprises a rail beam ice and snow melting assembly. The rail beam ice and snow melting assembly comprises a surface layer heat conduction plate, heat conduction pipes which are located at the bottom of the surface layer heat conduction plate and fixedly connected with the surface layer heat conduction plate, heating cables laid in the heat conduction pipes, and a plurality of anchor bars which are fixedly arranged at the bottom of the surface layer heat conduction plate and used for fixedly connecting the surface layer heat conduction plate and beam body concrete. By means of the rail beam ice and snow melting assembly, ice and snow which freeze on the PC rail beam can be rapidly and efficiently processed, and therefore the normal running of trains can be ensured, and obvious social and economical benefits are achieved. In addition, the invention further discloses the rail beam ice and snow melting assembly forming the PC rail beam and a laying method of the PC rail beam.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

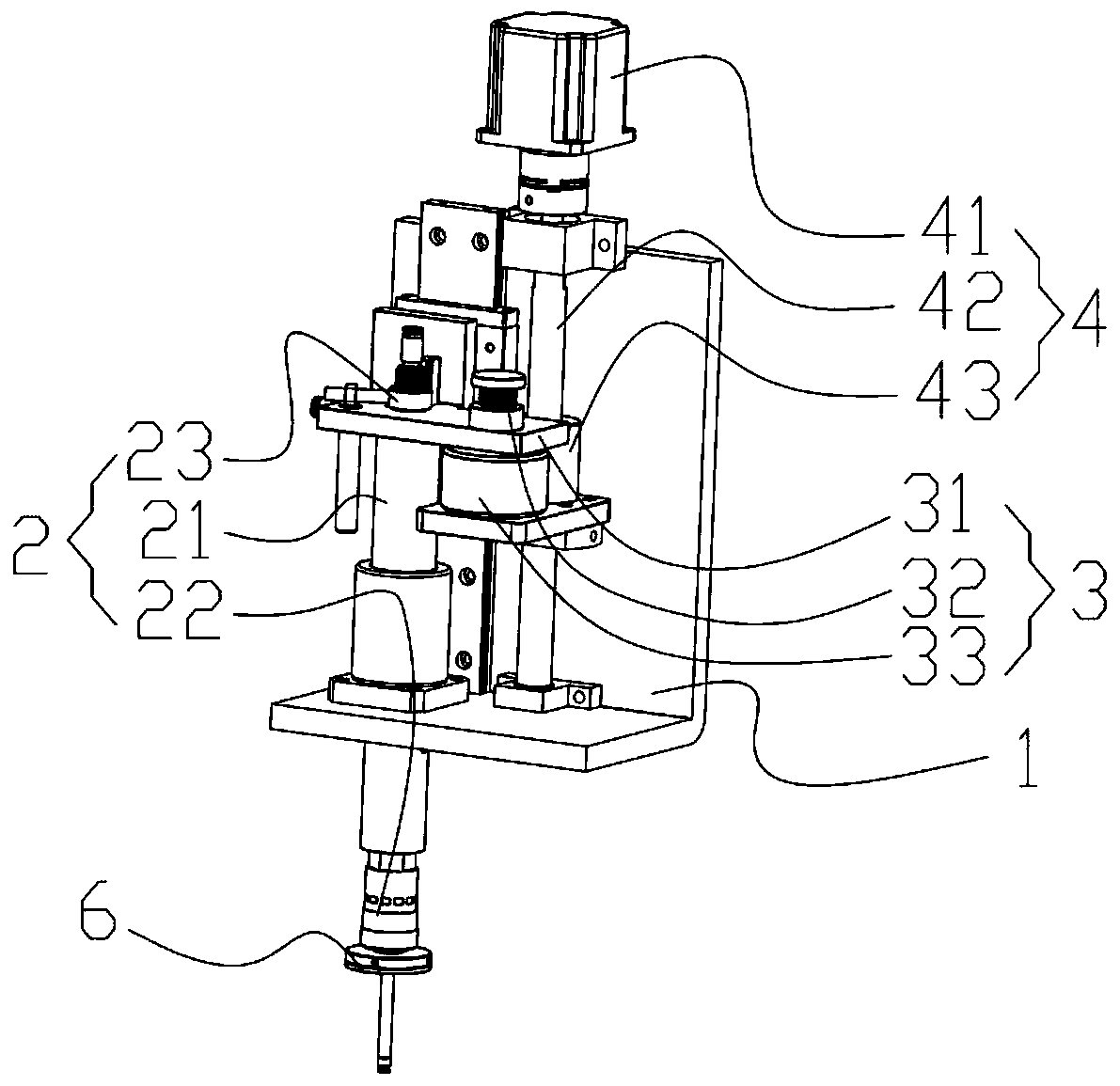

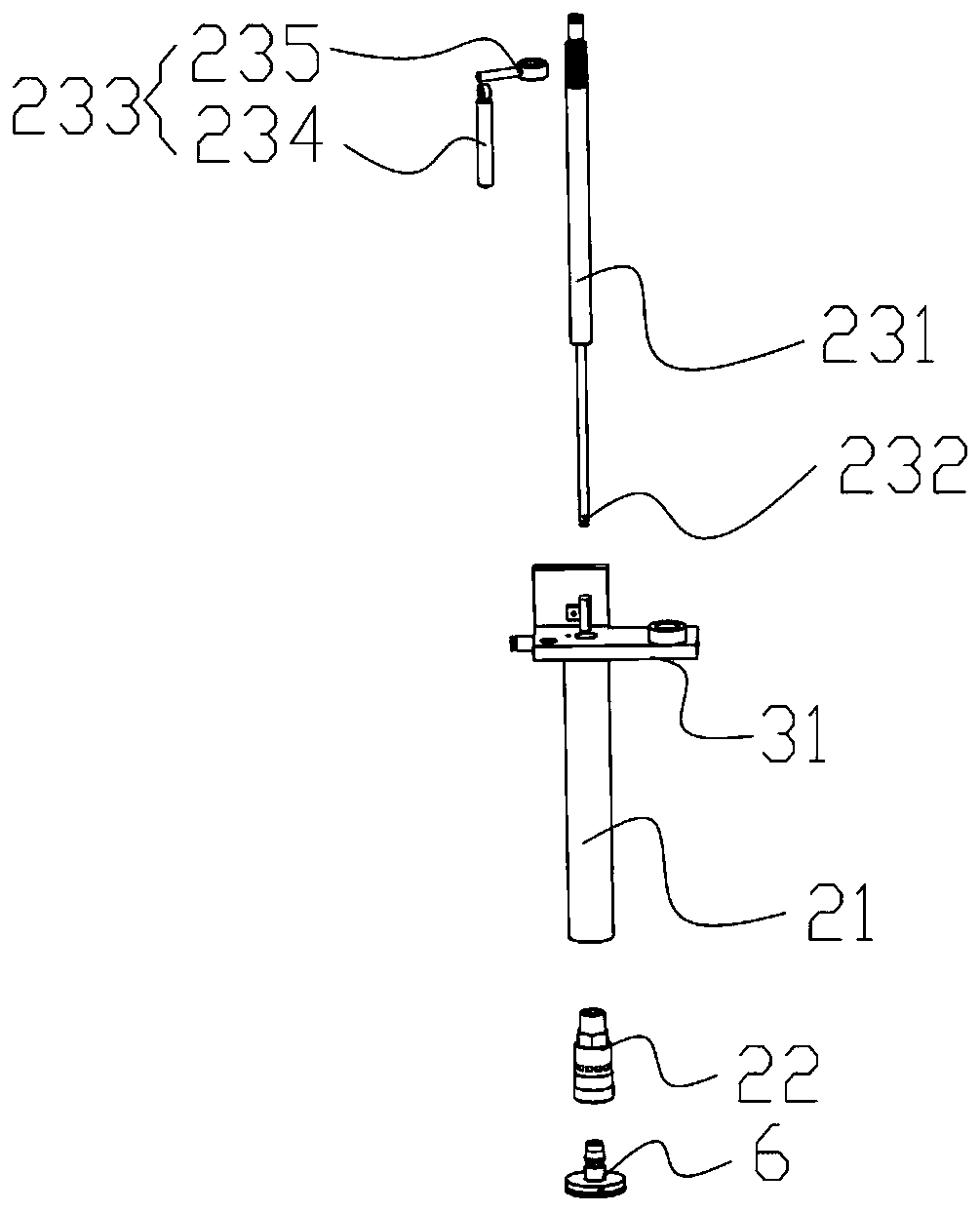

Glass taking and placing mechanism

PendingCN110231770AWon't crushImprove securityRepair toolsGlass productionEngineeringAtmospheric pressure

The invention relates to the technical field of glass transportation, in particular to a glass taking and placing mechanism. The glass taking and placing mechanism comprises a base, an air guiding mechanism, a buffering mechanism, a lifting mechanism and a suction cup used for sucking glass; the lifting mechanism is arranged on the base; the lifting mechanism is used for driving the air guiding mechanism to ascend and descend; the air guiding mechanism is connected to the output end of the lifting mechanism through the buffering mechanism; the buffering mechanism is used for absorbing an impact force between the suction cup and the glass; and the input end of the air guiding mechanism is externally connected with an air source; and the suction cup is arranged at the output end of the air guiding mechanism. By changing an air pressure, specifically sucking and pulling up the glass by the suction cup, the effect of taking away the glass from a shell nonviolently is realized; and meanwhile, due to the arrangement of the buffering mechanism, it is guaranteed that the air guiding mechanism and the suction cup do not descend excessively to crush the glass, so that the safety of dismounting the glass is improved.

Owner:杨少宏

Composite ball core for ball valve

InactiveCN104806782AAvoid corrosionPrevent tamperingPlug valvesValve member-seat contactsCavity wallMaterials science

The invention discloses a composite ball core for a ball valve. The composite ball core is composed of a metal ball core substrate, a valve rod hole and a flow channel cavity and is characterized in that a ceramic flow channel is fixed in the flow channel cavity and close to the cavity wall, and a ceramic sealing surface is used as the sealing surface of the metal ball core. The composite ball core has erosion resistance and pressure resistance when being comparable with a full ceramic ball.

Owner:YANTAI KINGWAY SCI & TECH

Tilling and seeding machine

The tilling and seeding machine includes a machine frame, a handlebar, a power assembly and a working assembly. The power assembly consists of diesel engine, speed variator, front wheel and other parts; the working assembly consists of towing frame, balancing wheel, deep plough, plough elevator and other parts. The tilling and seeding machine features the working assembly with also one material homogenizer, the diesel engine providing the front wheel with power and possessing rotation speed regulated by means of the varying handlebar and varying rod, etc. The machine of the present invention has tilling, seeding, fertilizing and other functions, and possesses the advantages high operation efficiency, stepless speed variation, light weight and easy control.

Owner:张咏麦

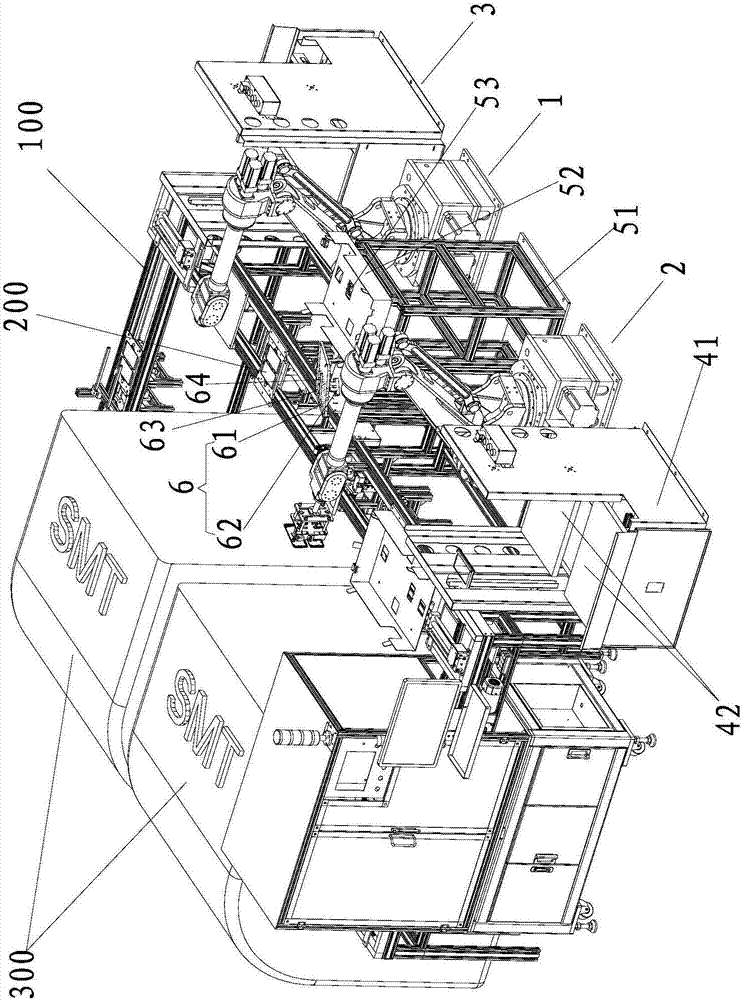

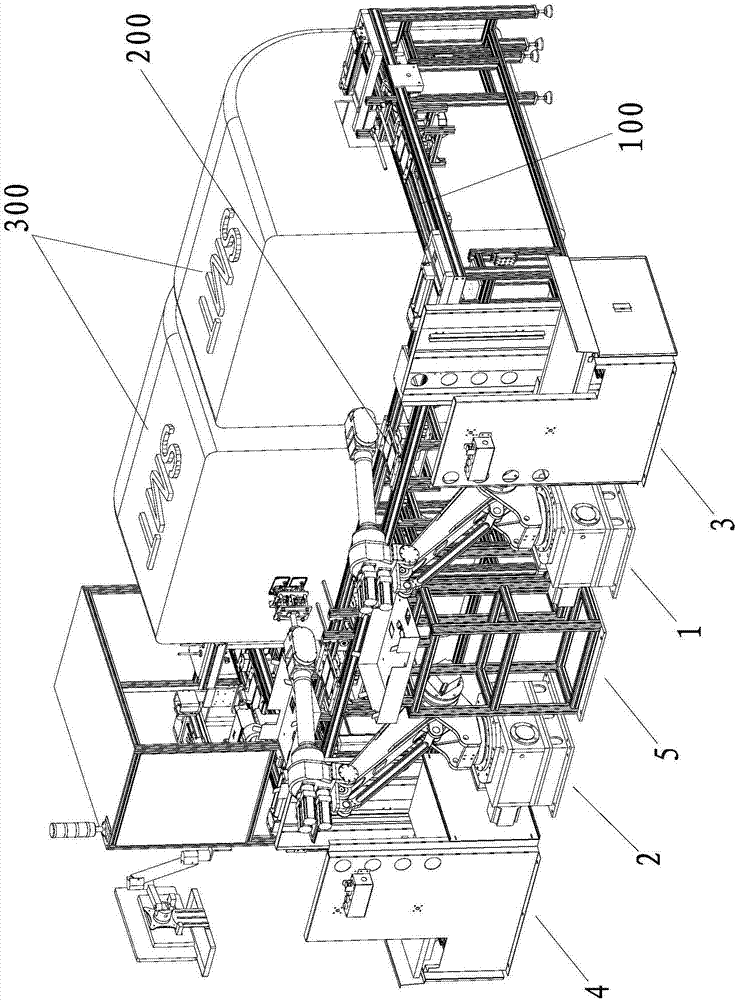

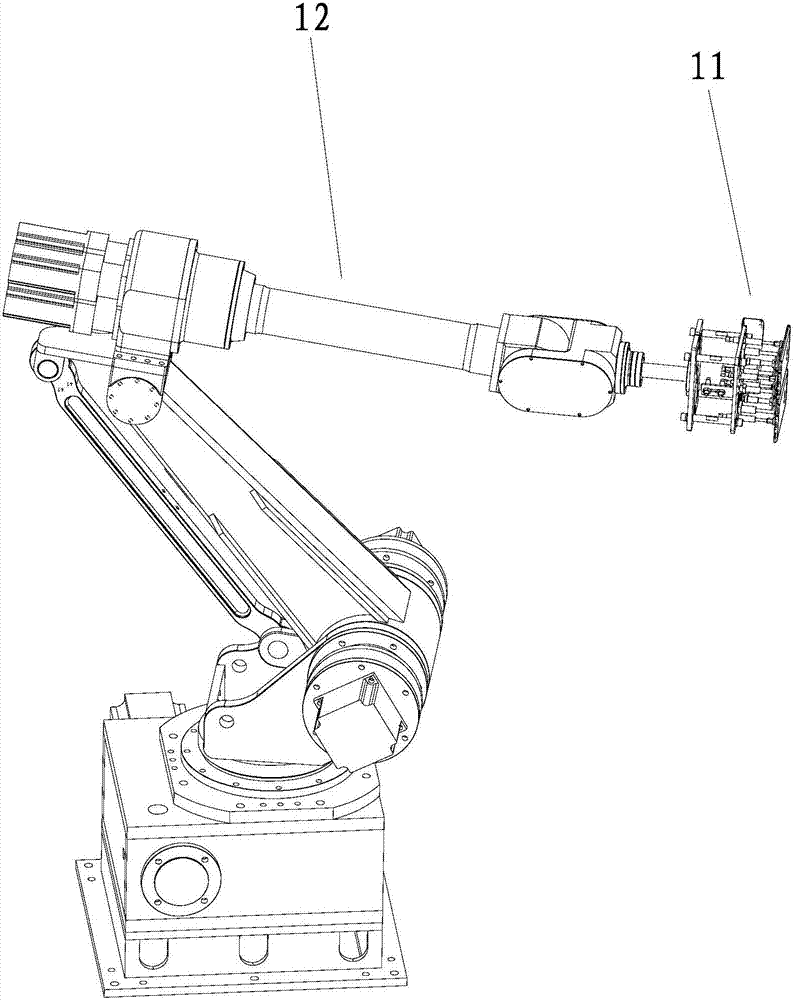

Automatic loading and unloading system of copper coil placement equipment

ActiveCN107416522APlay a protective effectWon't crushConveyor partsStructural engineeringCopper coil

The invention provides an automatic loading and unloading system of copper coil placement equipment. The automatic loading and unloading system comprises a conveying device, a workpiece tray, a loading mechanism, an unloading mechanism, a loading placement device, an unloading placement device, a foam board transfer device and an alignment device, wherein the loading mechanism and the unloading mechanism are used for absorbing and releasing a rear cover of a mobile phone and a foam board; the loading placement device and the unloading placement device are used for placing a stack of foam boards; the foam board transfer device is used for placing one foam board; the alignment device is used for placing the rear cover of the mobile phone, straightening, aligning and correcting the rear cover of the mobile phone; the unloading placement device, the unloading mechanism, the foam board transfer device, the loading mechanism and the loading placement device are positioned in the conveying direction of the loading and unloading station side along the conveying device and are arranged at intervals side by side in sequence; the alignment device and the foam board transfer device are arranged side by side; and the alignment device is positioned between the conveying device and the foam board transfer device. Compared with the prior art, the automatic loading and unloading system has the beneficial effects that the rear cover of the mobile phone is loaded and unloaded in a mechanical automation manner with no need for manual operation; and the automatic loading and unloading system has the advantages of fast loading and unloading speed, low labor intensity of workers, good loading effect and ensuring the placement quality of a copper foil of the rear cover of the mobile phone.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

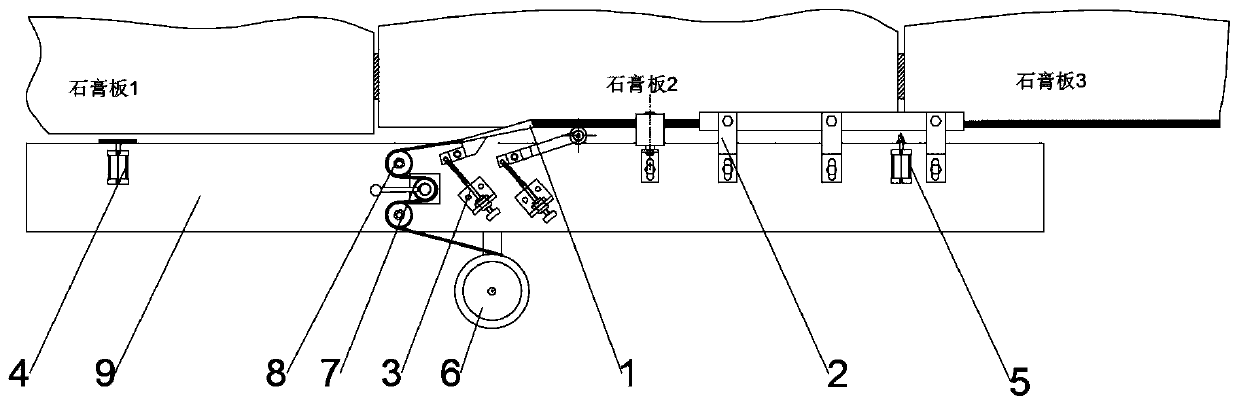

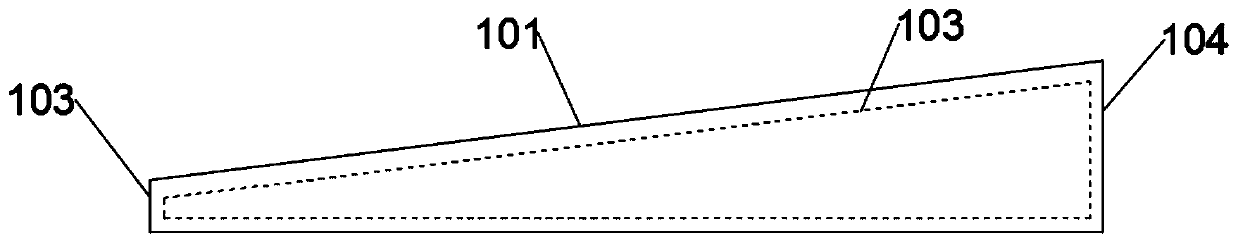

Paperbacked plasterboard edge sealing device

ActiveCN110480822AImprove toughnessAvoid breakingAuxillary shaping apparatusEngineeringOff phenomenon

An embodiment of the invention discloses a paperbacked plasterboard edge sealing device which is arranged on two sides of a plasterboard. The paperbacked plasterboard edge sealing device comprises a rack, wherein an edge sealing band paper outlet device, a water supply device, a paper folding device, a positioning device and a cut-off device are arranged on the rack; the paper folding device comprises a paper folding board; the positioning device comprises an end part positioning roller, side positioning rollers and a positioning brush, the end part positioning roller is opposite to the end part of the plasterboard, the two side positioning rollers are opposite to two sides of the end part of the plasterboard; the positioning brush is in a U-shaped structure in the side direction and is fixed on the rack through a support frame. One group of edge sealing press rollers are adopted to realize the edge sealing positioning effect, the positioning brush is adopted to apply pressure to stickan edge sealing band on a board, three groups of edge sealing press rollers in the prior art are replaced, pressure of the plasterboard is reduced while a good edge sealing effect is realized, core air holes in the edge sealing position of the end part of the plasterboard are prevented from being damaged by pressing, and the paper taking-off phenomenon is prevented.

Owner:HUAINAN BEIXIN BUILDING MATERIAL +1

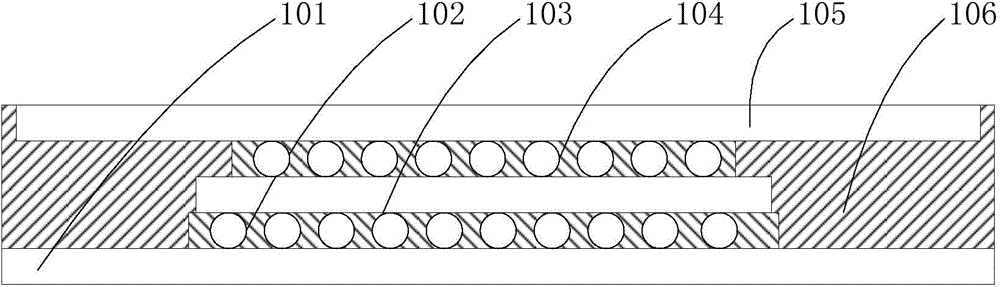

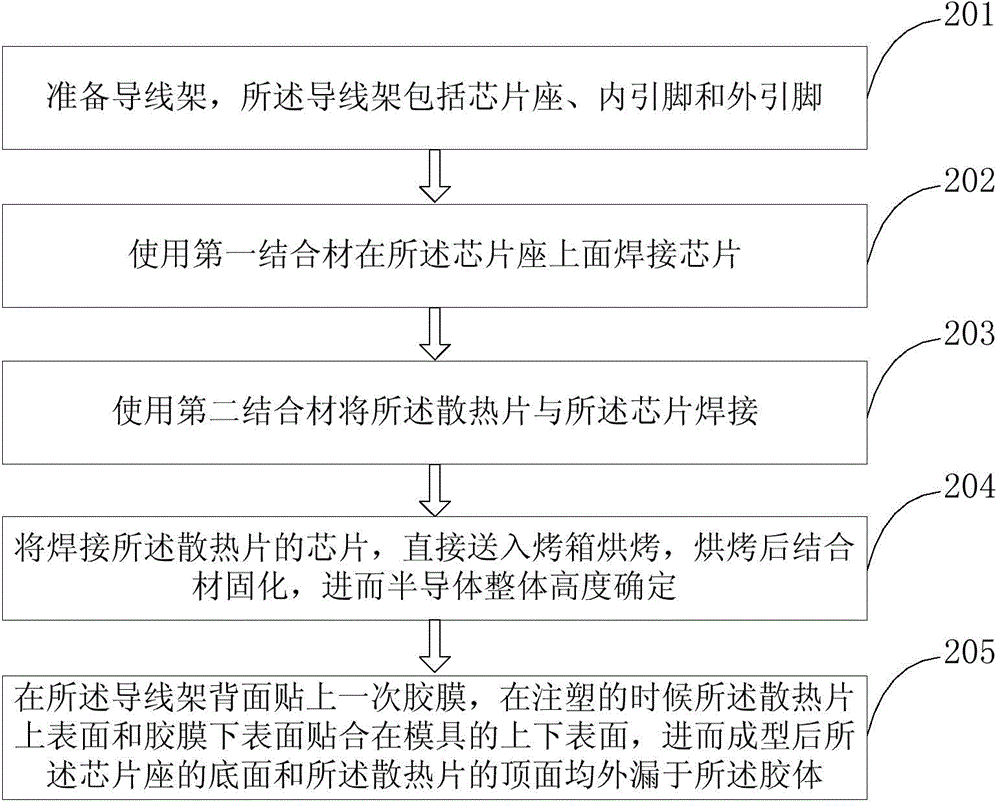

Packaging structure and method of double-sided radiating semiconductor

ActiveCN104600041AWill not cause package overflowWon't crushSemiconductor/solid-state device detailsSolid-state devicesAdhesiveColloid

The invention discloses packaging structure and method of a double-sided radiating semiconductor. The packaging structure of the double-sided radiating semiconductor comprises a lead frame, a first combining material, a chip, a second combining material and a radiating plate which are arranged in a rubber coating by wrapping from bottom to top in a sequence; the first combining material and the second combining material are equipped with high temperature resistant balls with the same diameter. The packaging method of the double-sided radiating semiconductor comprises the steps of preparing the lead frame; welding the chip on the upper surface of a chip seat through the first combining material; welding the radiating plate to the chip through the second combining material; directly drying the lead frame welded with the radiating plate through a drying oven; adhering an one-off adhesive film on the rear surface of the lead frame; the bottom surface of the chip seat and the top surface of the radiating plate expose from the adhesive after forming; the first combining material and the second combining material are equipped with the high temperature resistant balls with the same diameter; the overall thickness of the lead frame, the chip and the radiating plate can be accurately controlled before packaging.

Owner:GREAT TEAM BACKEND FOUNDRY (DONGGUAN) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com