Composite ball core for ball valve

A composite ball and ball valve technology, which is applied in the direction of valve details, valve devices, valve elements and valve seats, etc., can solve the problem that the service life cannot reach the expected goal, it is not perfect, and the local position of the metal substrate is easy to be washed Corrosion and other problems, to avoid liquid corrosion, prolong service life, avoid corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

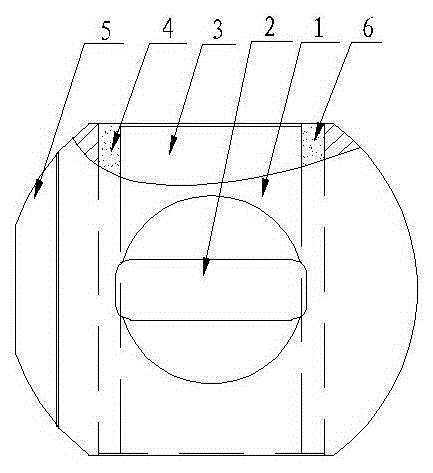

[0025] Embodiment 1, a kind of composite ball core for ball valve, refer to figure 1 , the metal ball core base 1 is provided with a valve stem hole 2 and a flow channel cavity 3, and a ceramic flow channel 4 is fixed in the flow channel cavity 3 close to the cavity wall, and the sealing surface 5 of the metal ball core base 1 is a ceramic sealing surface , which constitutes a structure of the present invention.

Embodiment 2

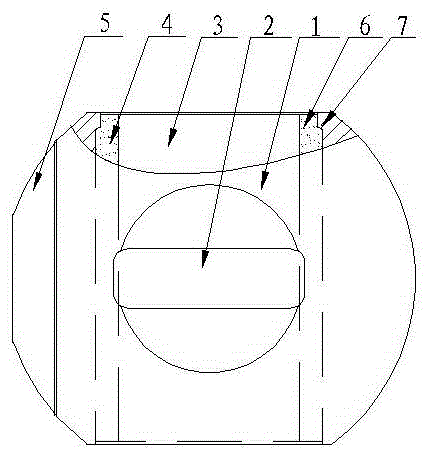

[0026] Embodiment 2, a kind of composite ball core for ball valve, refer to figure 2 On the basis of Embodiment 1, the ceramic flow channel 4 is a ceramic flow channel tube 6, and the ceramic flow channel tube 6 is provided with a shoulder 7 at the end of the fluid outlet direction to prevent the flow channel tube from moving toward the outlet direction, and the others are the same as The embodiments are exactly the same.

Embodiment 3

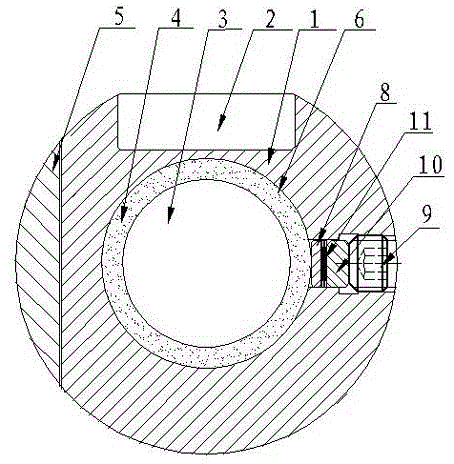

[0027] Embodiment 3, a kind of composite ball core for ball valve, refer to figure 2 , image 3 , on the basis of Embodiment 2, a pressure block 8 is arranged vertically in the metal ball core matrix 1 in the axial direction of the ceramic flow pipe 6, and the compression bolt 9 presses the pressure block 8 to be close to the outer wall of the ceramic flow pipe 6. The pressure block 8 is composed of two pressure pads 10 with a disc spring 11 in the middle, and the others are identical to the embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com