Rail beam ice and snow melting assembly, PC rail beam and laying method of PC rail beam

A track beam, ice and snow technology, applied in the field of PC track beam melting ice and snow, can solve the problems of reduced safety performance, unfavorable environmental protection, train operation delay, etc., to reduce temperature stress and heat loss, easy installation, maintenance and replacement, and simple structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

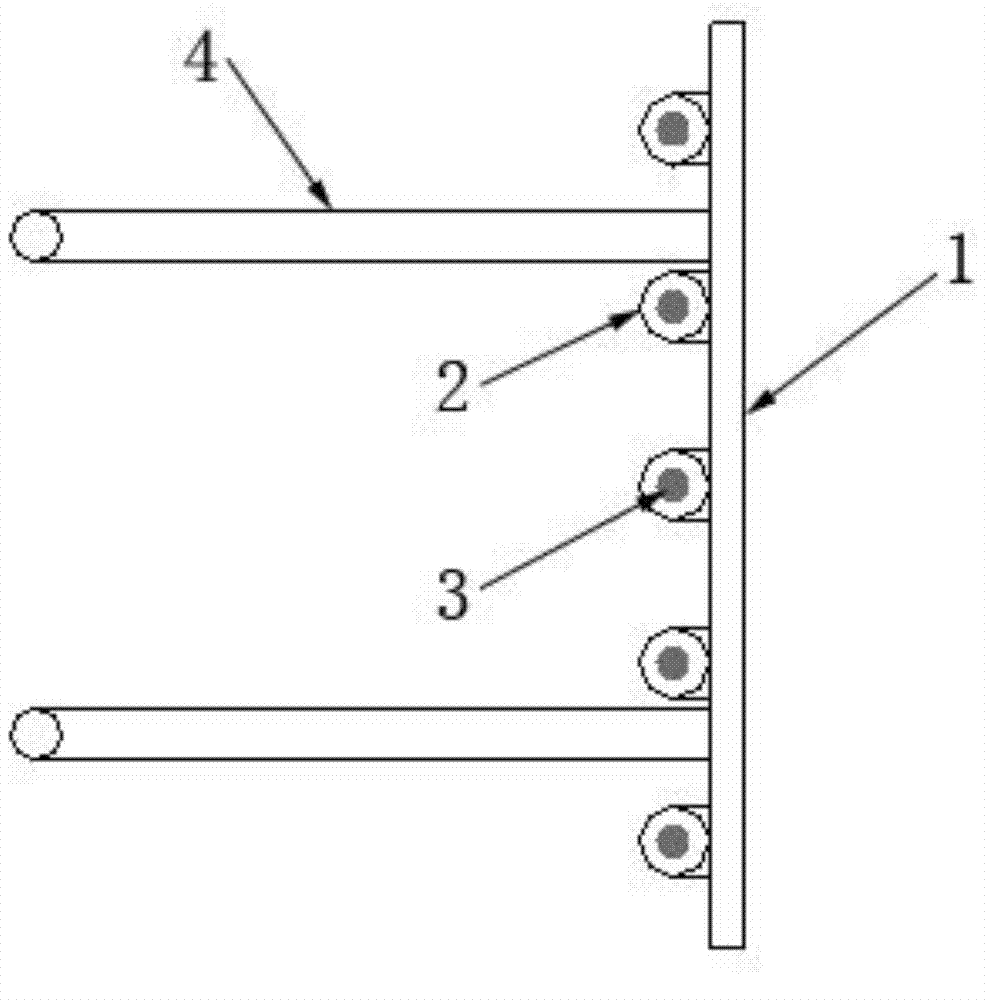

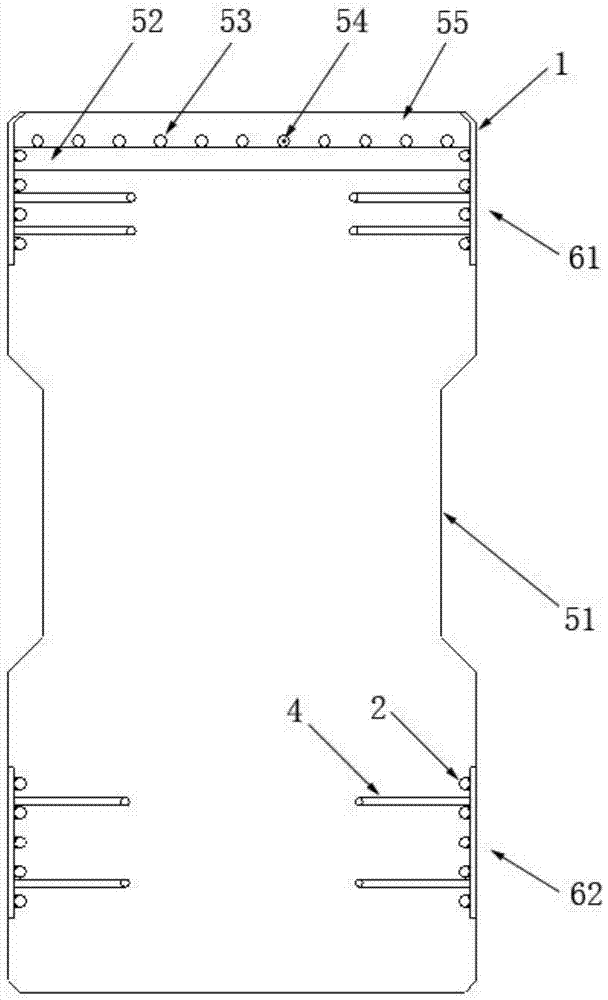

[0035] like figure 2 As shown, the PC track beam of the present invention mainly includes: beam body concrete 51, a heat insulating layer material 52 is laid on the top of the beam body concrete 51, a top heat conducting pipe 53 is laid on the top of the heat insulating layer material 52, and a top heat conducting pipe 53 is arranged inside the top heat conducting pipe 53. For the heating cable 54, surface concrete 55 is laid on the top heat pipe 54, and the track beam ice and snow melting components are respectively laid on the contact part 61 and the contact part 62 of the guide wheel of the beam body concrete 55 and the train.

[0036] Specifically, laying the insulating layer material 52 on the upper part of the beam concrete 51 can concentrate the heat transfer to the surface of the beam, avoiding the heat from spreading to the interior of the beam, thereby ensuring that the surface of the beam concrete 51 can heat up quickly, and achieve better ice and snow melting. Eff...

no. 2 example

[0040] The difference from the first embodiment is that the ice and snow melting components of the track beam are not only laid on the contact parts 61 and 62 of the guide wheels of the beam body concrete 55 and the train, but also can be directly laid on the beam body. Concrete 55 is laid on the top of the beam body concrete 55 at the contact position between the running wheel of the train, and is laid simultaneously at the contact position between the beam body concrete 51 and the running wheel of the train, the contact position 61 of the guide wheel and the contact position 62 of the stability theory. The top heat pipe 53 and the top heating cable 54 in the first embodiment can be omitted, and directly replaced by the heat pipe 2 and the heating cable 3 .

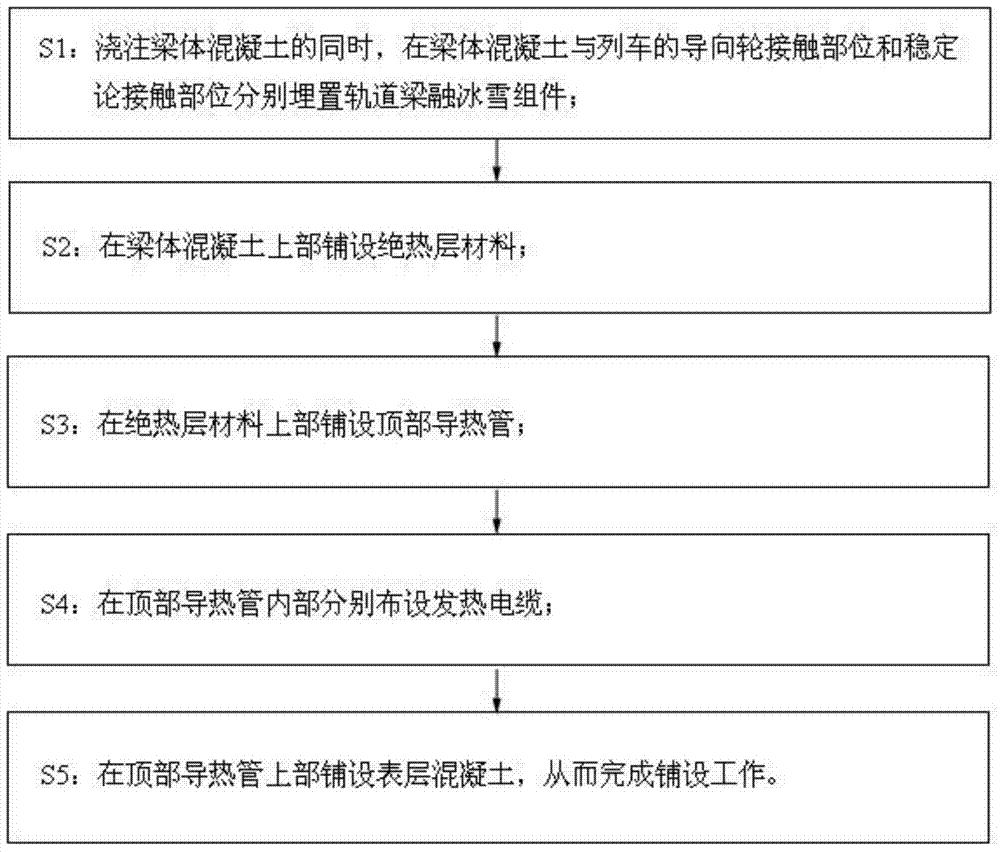

[0041] In addition, if image 3 As shown, the present invention also provides a method for laying the above-mentioned PC track beam, which mainly includes the following steps: S1: While pouring the beam body concrete, at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com