Temperature control method and system of electronic atomization device

A technology of an electronic atomization device and a temperature control method, which is applied in the application, tobacco, and smoker's products, etc., can solve the problem of no user providing taste experience, etc., and achieve the effect of good experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

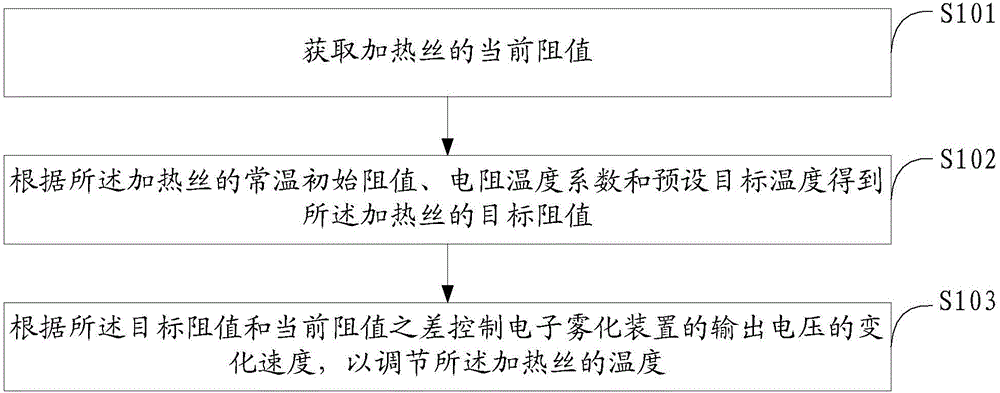

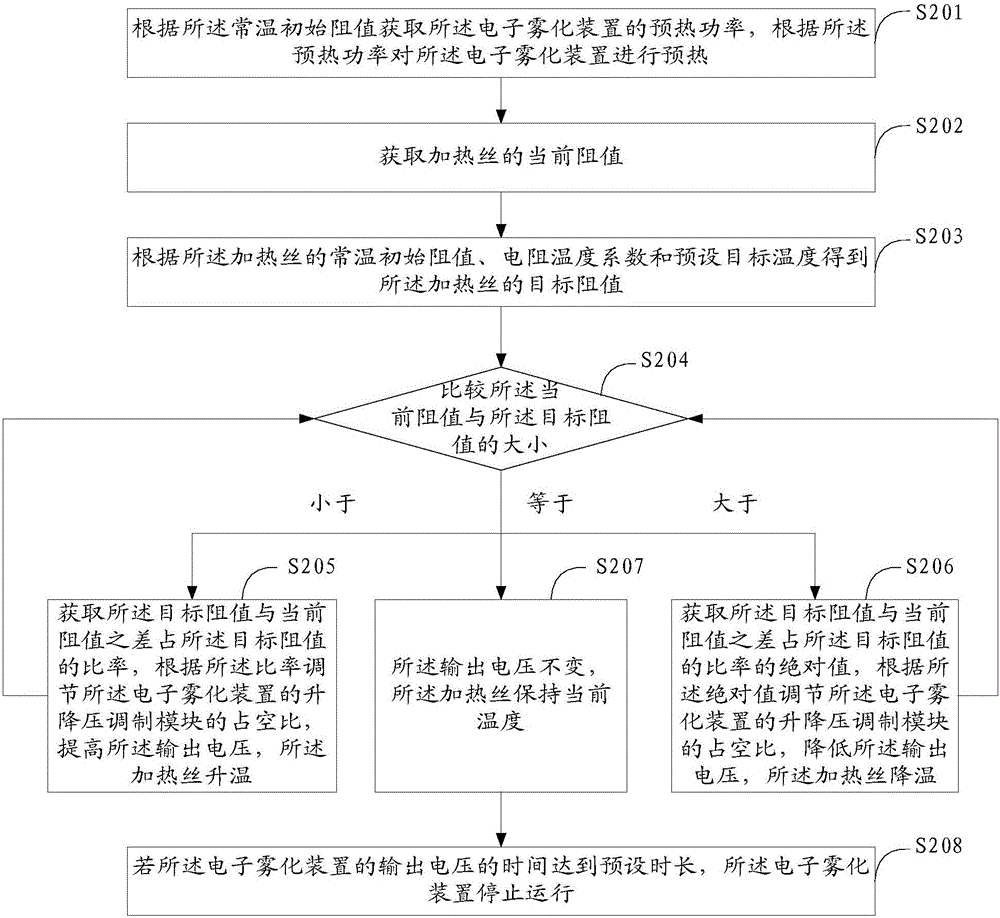

[0022] see figure 1 , figure 1 It is a flowchart of a temperature control method for an electronic atomization device in an embodiment.

[0023] S101. Obtain the current resistance value of the heating wire.

[0024] A heating wire, an atomizer and a battery are arranged inside the electronic atomization device, and an oil guide body is arranged inside the atomizer, and the oil guide body is in contact with the heating wire. During the working process of the electronic atomization device, the e-liquid is dripped on the oil guide body, and the battery provides electric energy for the heating wire to heat up, and the heating wire transfers its heat to the e-liquid through the oil guide body, and the e-liquid passes through High-temperature atomization produces smoke, and the user inhales the smoke to simulate the smoking process.

[0025] S102. Obtain a target resistance value of the heating wire according to the initial resistance value of the heating wire at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com