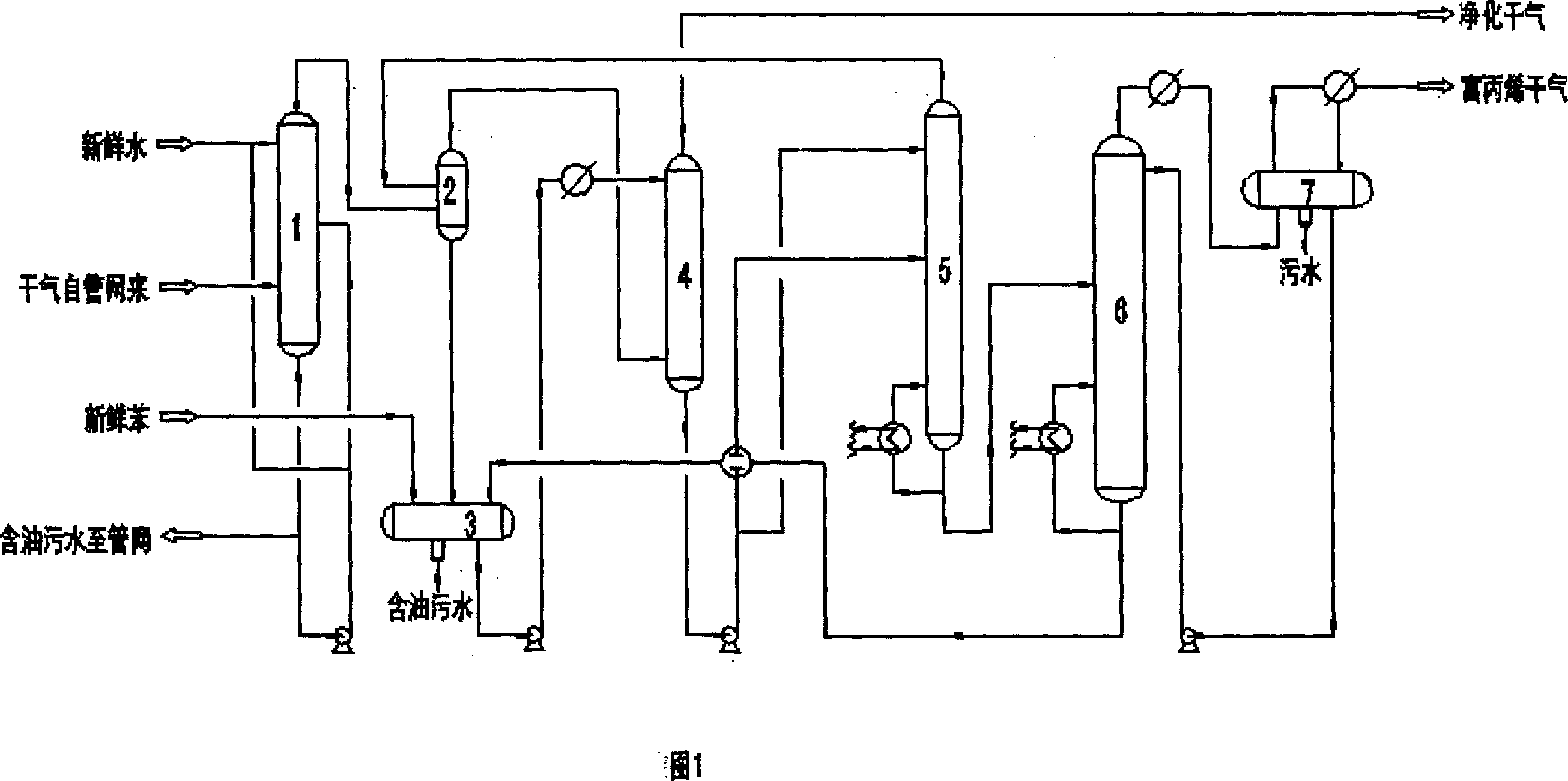

Process flow for raw material pretreatment portion of catalytic dry gas produced phenylethane

A process flow and pretreatment technology, which is applied in the processing of hydrocarbon oil, gas mixture, petroleum industry, etc., can solve the problems of affecting the purity of ethylbenzene products and increasing the consumption of benzene, so as to save absorbent and be beneficial to absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The equipment in the present invention is all the equipment used in the existing technology, and can be ordered or purchased. In the present invention, the dosage of the benzene absorbent varies according to the size of the equipment, but it is sufficient to ensure that the volume ratio of the absorbent to the dry gas is 2-30.

[0026] Catalytic dry gas at 0.6-1.0MPa and 40°C enters the washing tower 1 from the system for washing, and the washing water is recycled as fresh water (with replenishment), most of the MDEA in the dry gas is removed, and the concentration of MDEA in the dry gas after washing is reduced to below 1PPM . The washed dry gas enters the dry gas liquid separation tank 2 and mixes with the circulating dry gas at the top of the deethylene tower 5, then is compressed by the dry gas compressor and then enters the propylene absorption tower 4 at 1.2-1.4 MPa and 40°C. The dry gas purified at the top of the tower enters the alkylation reactor after exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com