Patents

Literature

261results about How to "Reduce temperature stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

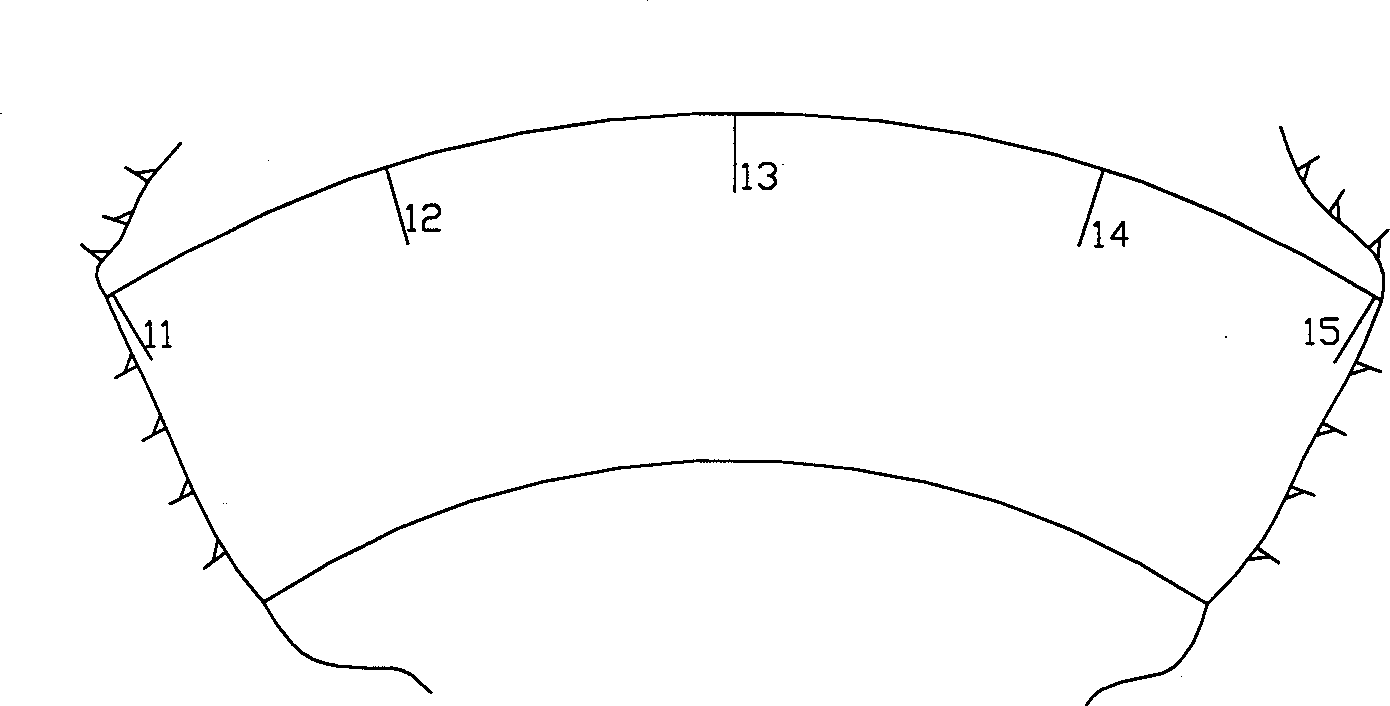

Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

InactiveCN105041336AReduce dosageReduce consumptionUnderground chambersTunnel liningCrack resistanceReinforced concrete

The invention discloses an ultra-high performance hybrid fiber concrete shield segment and a preparation method thereof. The ultra-high performance hybrid fiber concrete shield segment is of a reinforced concrete structure which consists of a steel skeleton and concrete, wherein the reinforcement ratio of used main reinforcements is 0.5%-1.0%, the distances of the main reinforcements are 150-300mm, the grades of steel reinforcements are not less than three, the smallest steel reinforcement distance of distributed reinforcements is 400mm, the biggest steel reinforcement distance of used distributed reinforcements is 2000mm, and the grades of the steel reinforcements are not less than two. The ultra-high performance hybrid fiber concrete shield segment is made from ultra-high performance hybrid fiber concrete, and comprises cementitious materials, sands, crushed stones, steel fibers, synthetic fibers, water reducer, defoamer and water. The ultra-high performance hybrid fiber concrete shield segment is less in dosage of the steel reinforcements and concrete and high in early strength, can prevent steam preservation, reduces energy consumption, and is green, energy-saving and environmentally friendly. The ultra-high performance hybrid fiber concrete shield segment is strong in anti-burst performance when having a fire, excellent in toughness and crack resistance and excellent in durability, enables edge joints not to easily break, and overcomes the defects of traditional segments.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

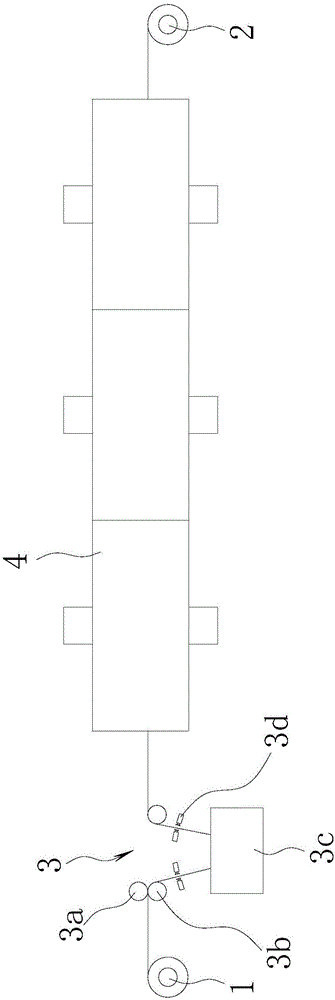

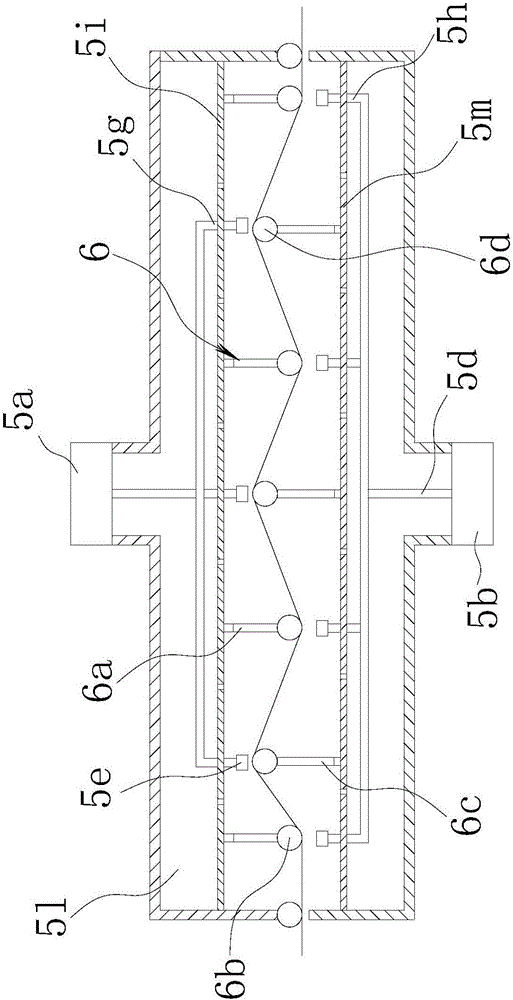

Device for removing copper powder on copper foil and application method of device

ActiveCN105689312ANot easy to damageNot easy to discountCleaning using liquidsHeating arrangementEngineeringCopper foil

The invention discloses a device for removing copper powder on a copper foil and an application method of the device, and belongs to the technical field of copper foil cleaning. The technical points of the device include that a cleaning mechanism and a plurality of drying mechanisms are arranged in order between an unwinding roll and a winding roll along a horizontal direction, and a copper foil orderly passes through the cleaning mechanism and all the drying mechanisms along the horizontal direction. Each drying mechanism is connected with a control unit, and is composed of a housing, a feeding hole and a discharge hole that are separately arranged in two sides of the housing, and an air-floating heating mechanism and a lifting heating mechanism that are arranged in the housing along a housing length direction. The present invention aims at providing the device, which is convenient to use and good in effect, for removing the copper power on the copper foil. The device is used for removing the copper powder on the copper foil.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

ActiveCN102535295AReasonable structural designEasy to laySingle unit pavingsPaving detailsHeat resistancePre stress

The invention discloses a fabricated prestressed heat-resistant cement concrete pavement and a construction process thereof. The pavement is formed by splicing a plurality of fabricated prestressed heat-resistant pavement plates which are parallelly paved and connected into a whole through transverse prestressed steel stranded wires, wherein each fabricated prestressed heat-resistant pavement plate comprises a fabricated prestressed pavement plate which consists of a plurality of pavement plate blocks connected through connecting plates, and a vermiculite concrete heat-resistant paving layer which is paved on the fabricated prestressed pavement plate; each pavement plate block comprises a plurality of common plates which are connected into a whole through longitudinal prestressed steel stranded wires; and the connecting plates and the common plates are cement concrete prefabricated plate blocks. The construction process comprises the following steps of: 1, prefabricating the cement concrete prefabricated plate blocks; 2, transporting the cement concrete prefabricated plate blocks; and 3, paving the pavement. The pavement is reasonable in structural design, convenient to construct, low in input cost and short in construction period, and has heat resistance, construction quality is easy to ensure, and various practical problems of the traditional fabricated cement concrete pavement can be solved.

Owner:CHANGAN UNIV

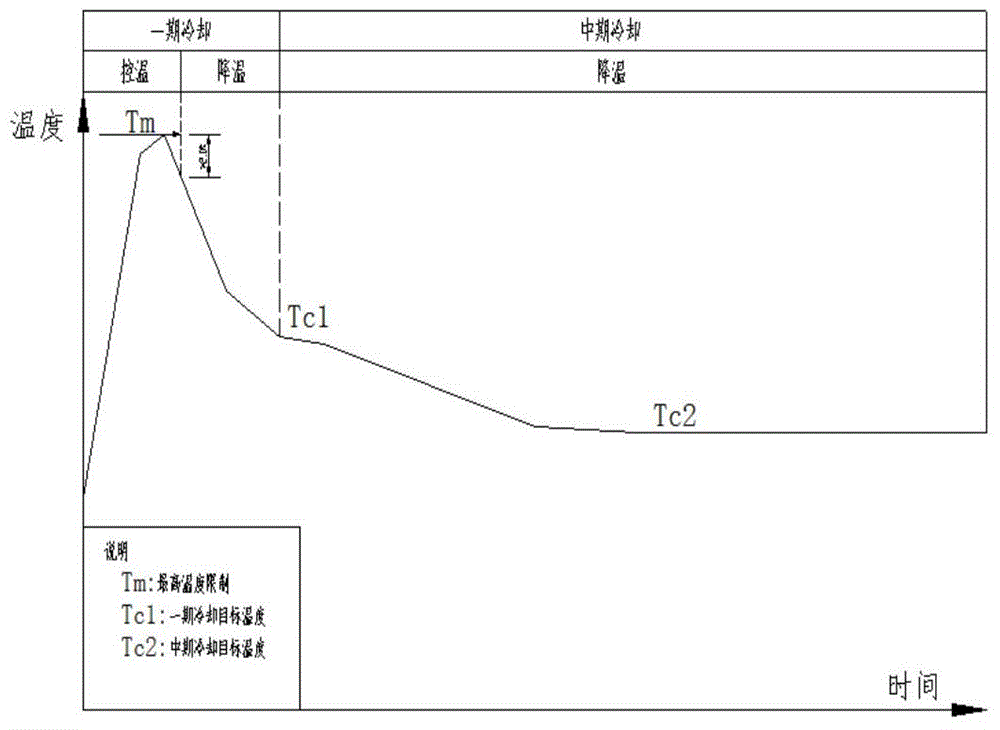

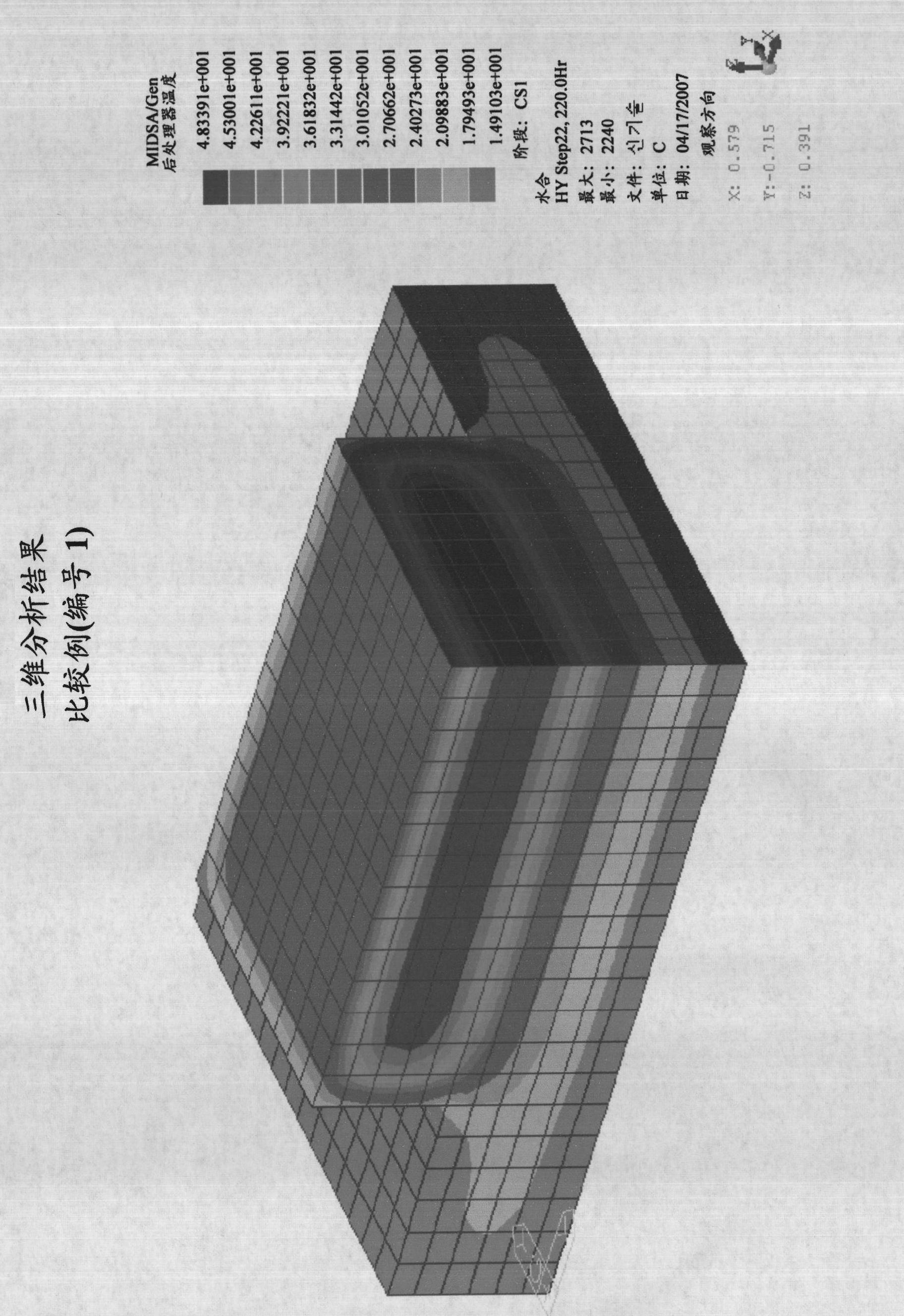

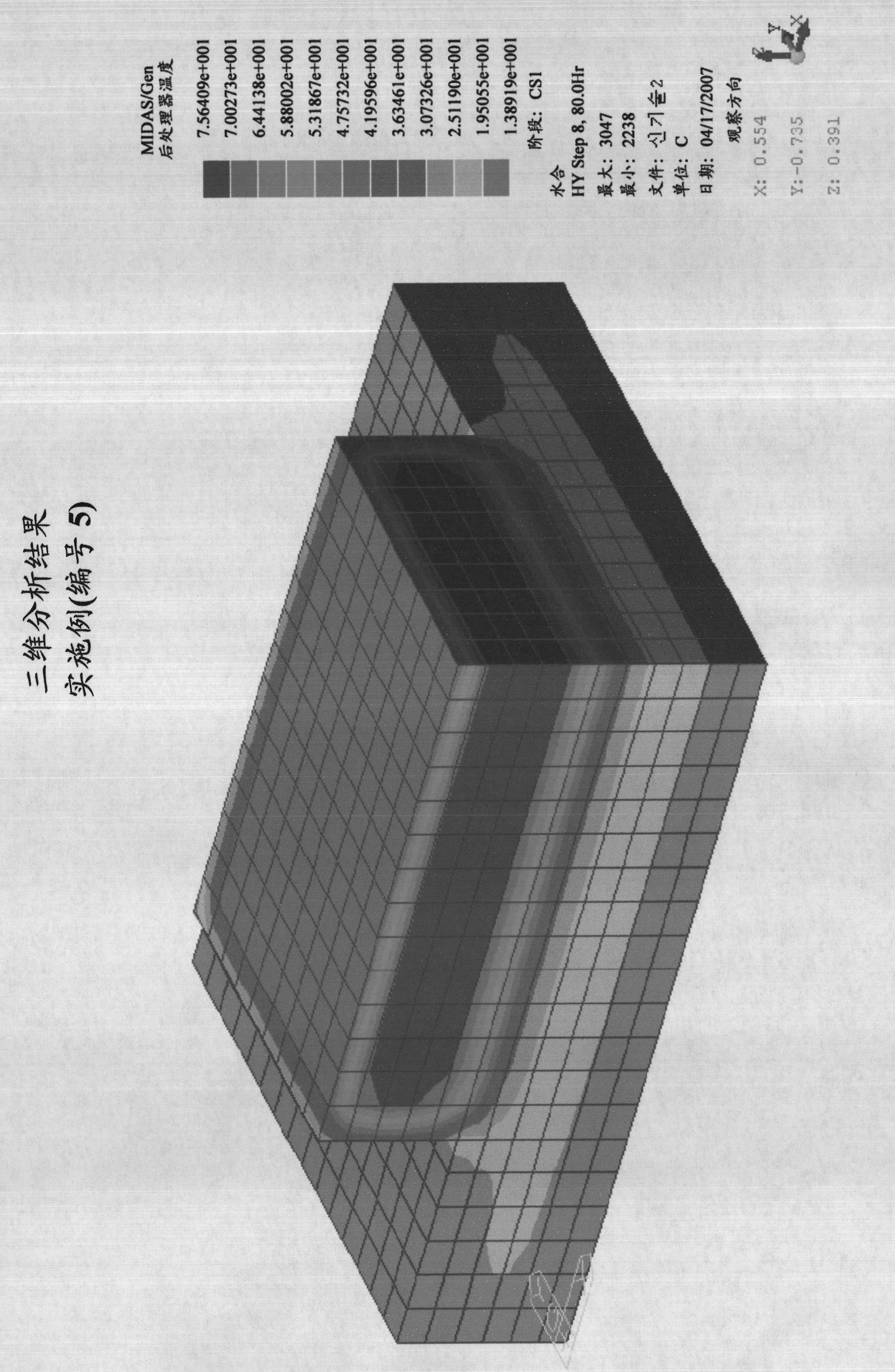

Ideal temperature control curve model of concrete dam and intelligent control method utilizing same

InactiveCN103603312AReduce temperature stressHydraulic modelsAdaptive controlTemperature controlStress distribution

The invention discloses an ideal temperature control curve model of a concrete dam. A finite element simulation analysis method is utilized, the distribution rule of the various dam types of temperature field and thermal stress is researched based on the existing specifications and temperature control practical experience, and the ideal temperature control curve model of concrete which is poured in different portions, different material partitions and different seasons is obtained through simulation calculation, wherein the temperature stress of the ideal temperature control curve model is minimum under the condition of the same temperature control standard. In addition, the invention also provides an intelligent control method utilizing the ideal temperature control curve model of the concrete dam.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

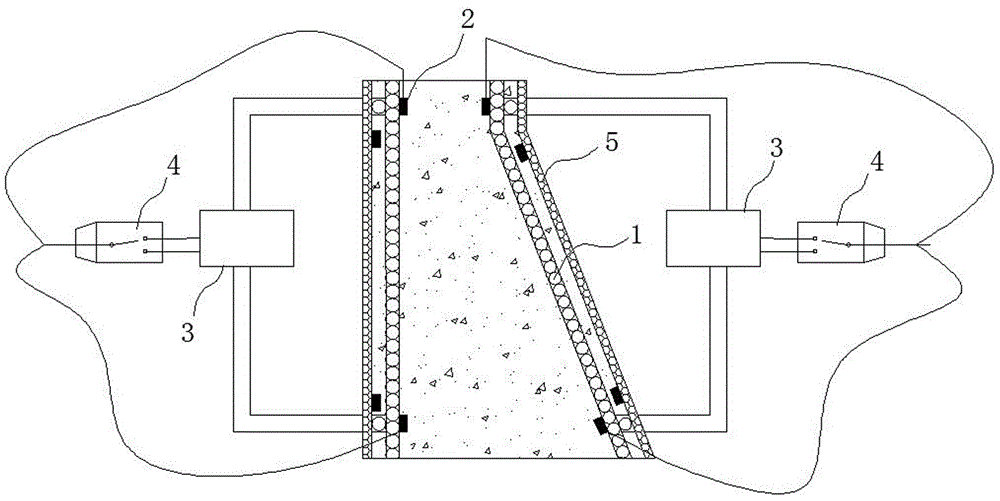

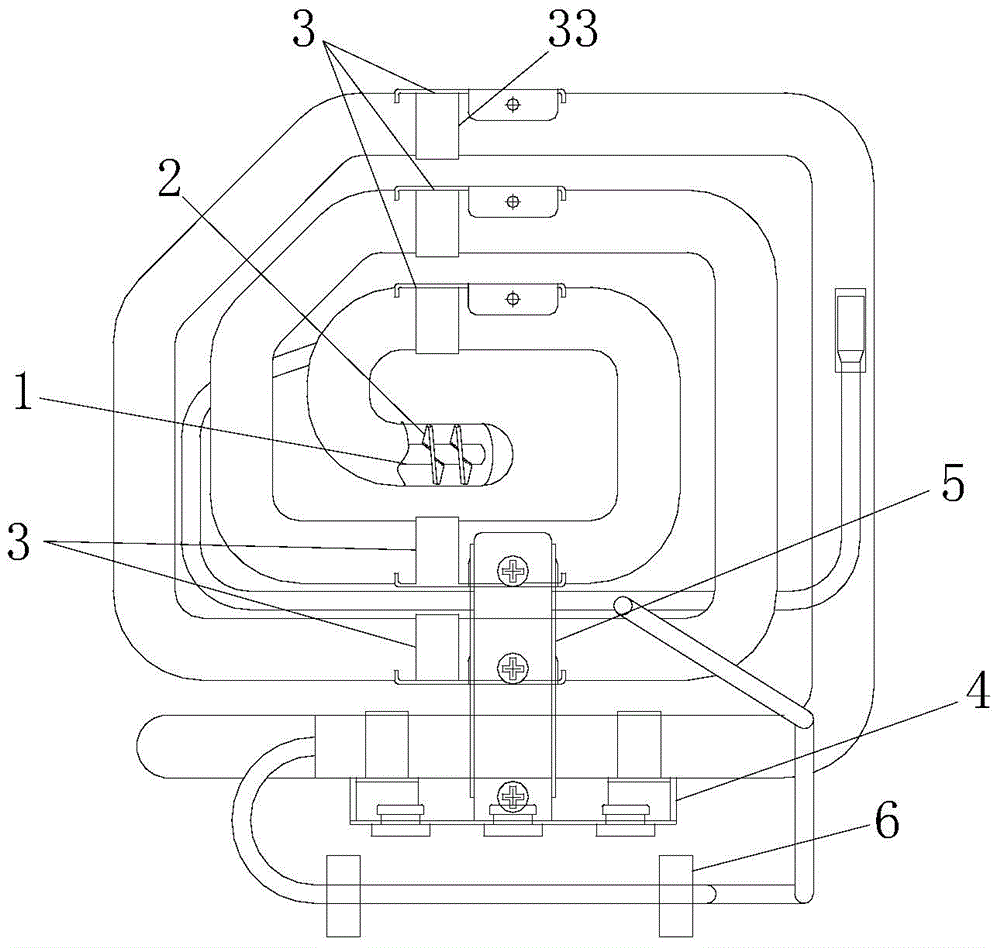

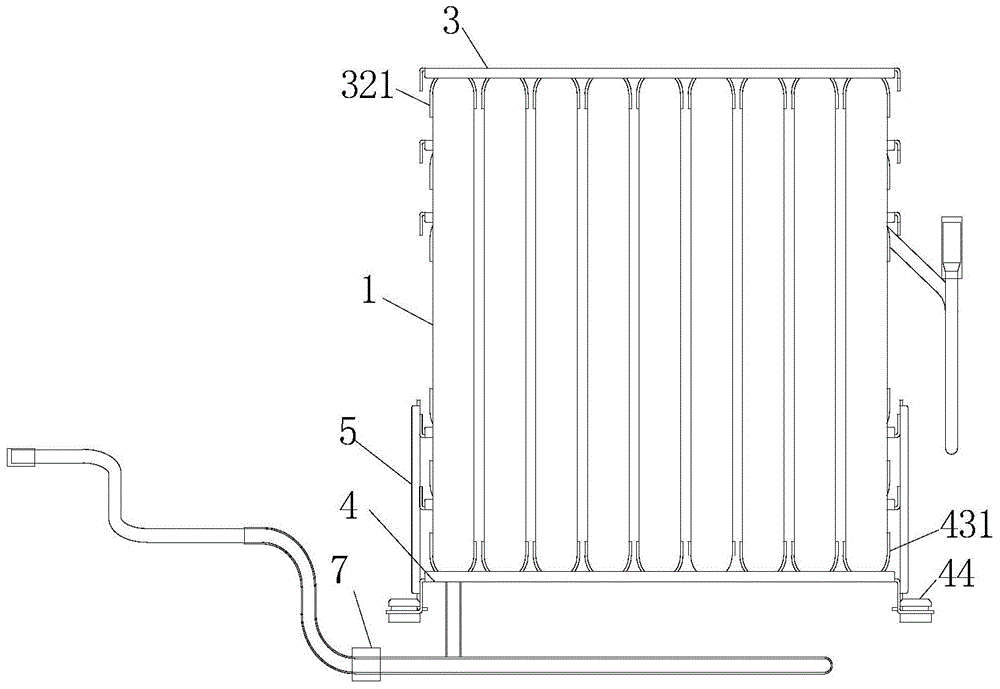

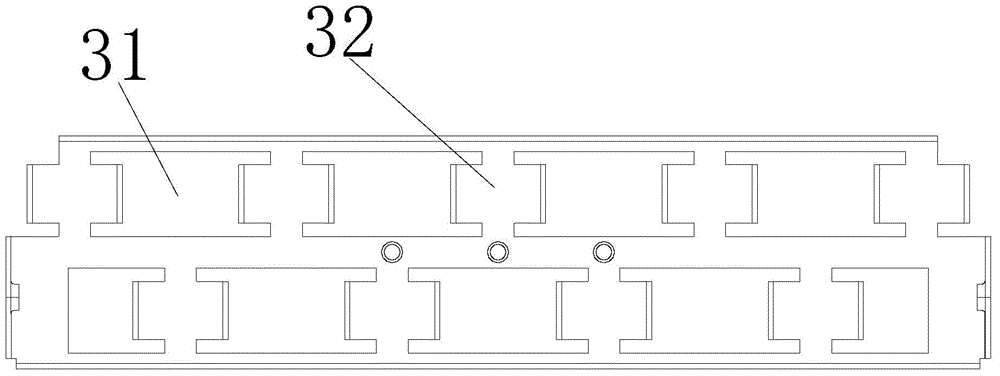

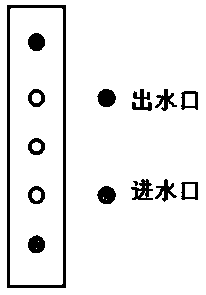

Method and device capable of regulating temperature of concrete dam permanently

ActiveCN106522229AReduce temperature gradientReduce the temperatureDamsFoundation engineeringTemperature controlSurface layer

The invention provides a method and device capable of regulating the temperature of a concrete dam permanently. According to the method, the inside temperature and surface temperature of concrete of a dam body are acquired in real time by cooperatively using an original safety monitoring net of the dam and monitoring equipment buried in the dam, the inner and outer layer temperature difference of the dam is effectively intervened and intelligently regulated, thereby being kept within an allowed range all the time, and manual participation is not needed in the whole process. The device is arranged at the same time of pouring construction of the dam, and temperature control is realized through conveying pipelines which are arranged under the surface layers of concrete of the upstream surface and the downstream surface of the dam in parallel and carry temperature compensation liquid. A novel dam heat preservation mode is created, pure passive heat preservation is changed into active temperature regulation, the dam can automatically operate, the temperature of the concrete dam can be regulated during construction, and the temperature of the concrete dam can be permanently regulated after the dam is constructed and operates. Dam cracks are greatly reduced, and the permanent protection function is achieved.

Owner:TSINGHUA UNIV +3

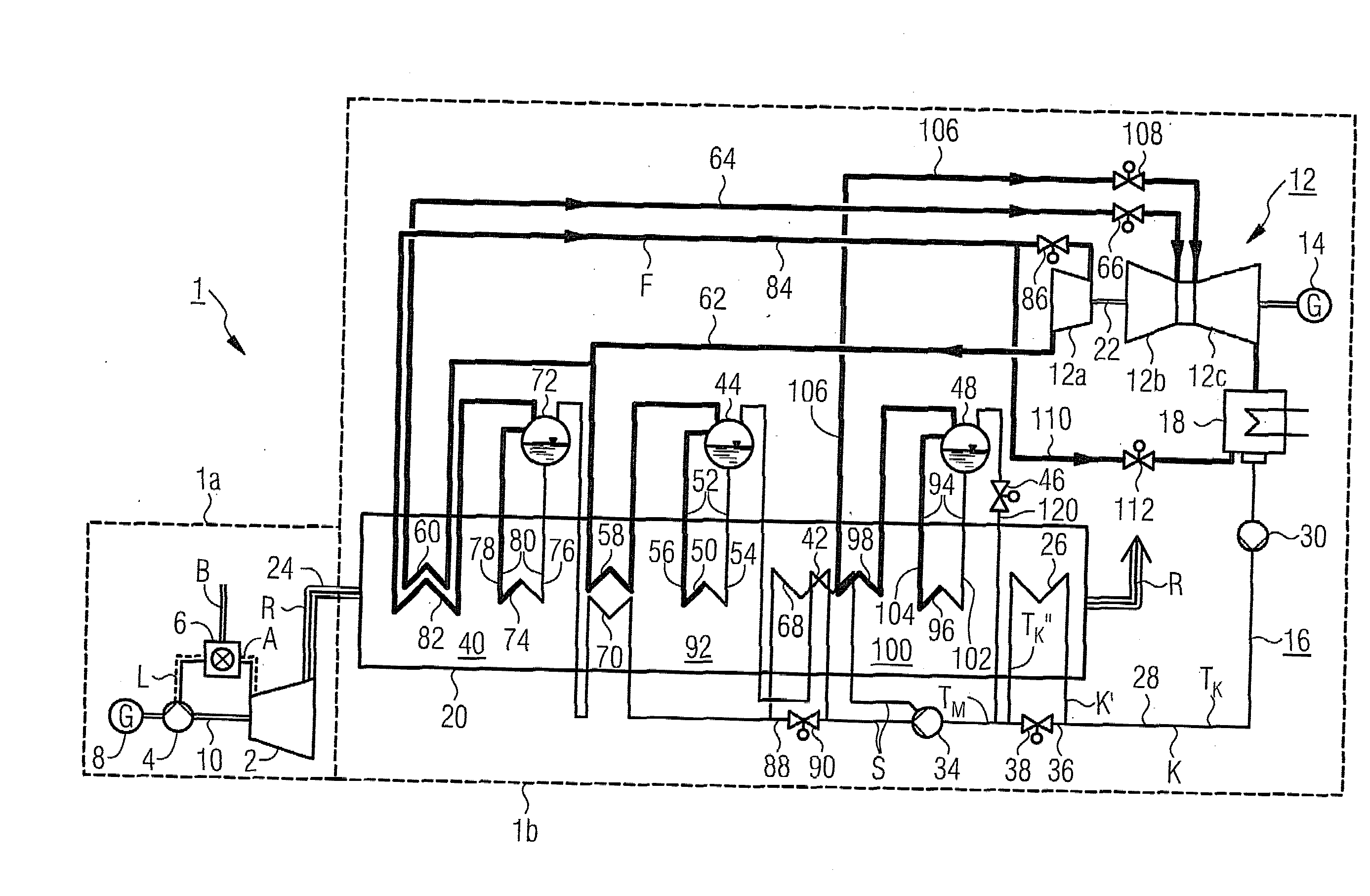

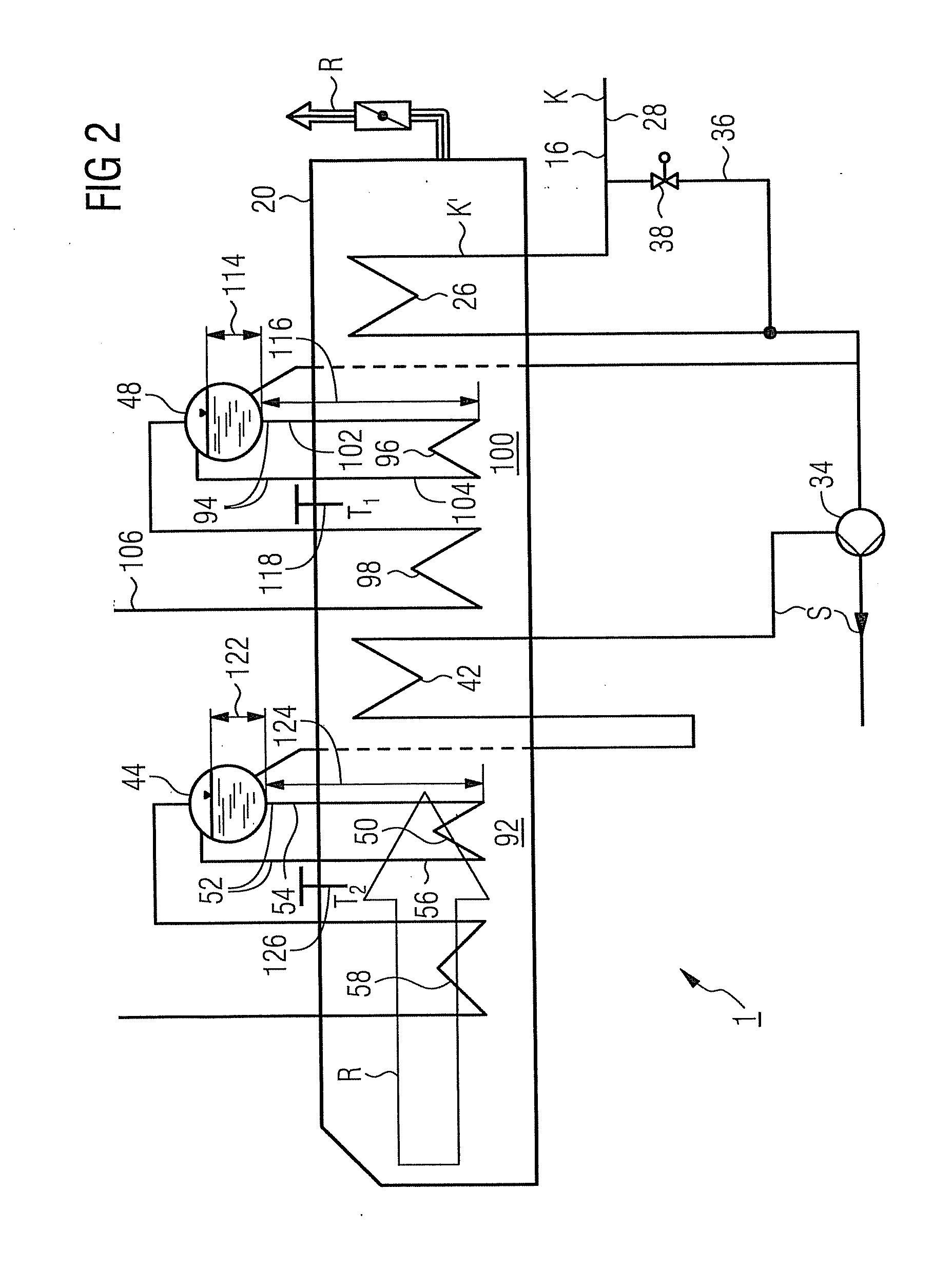

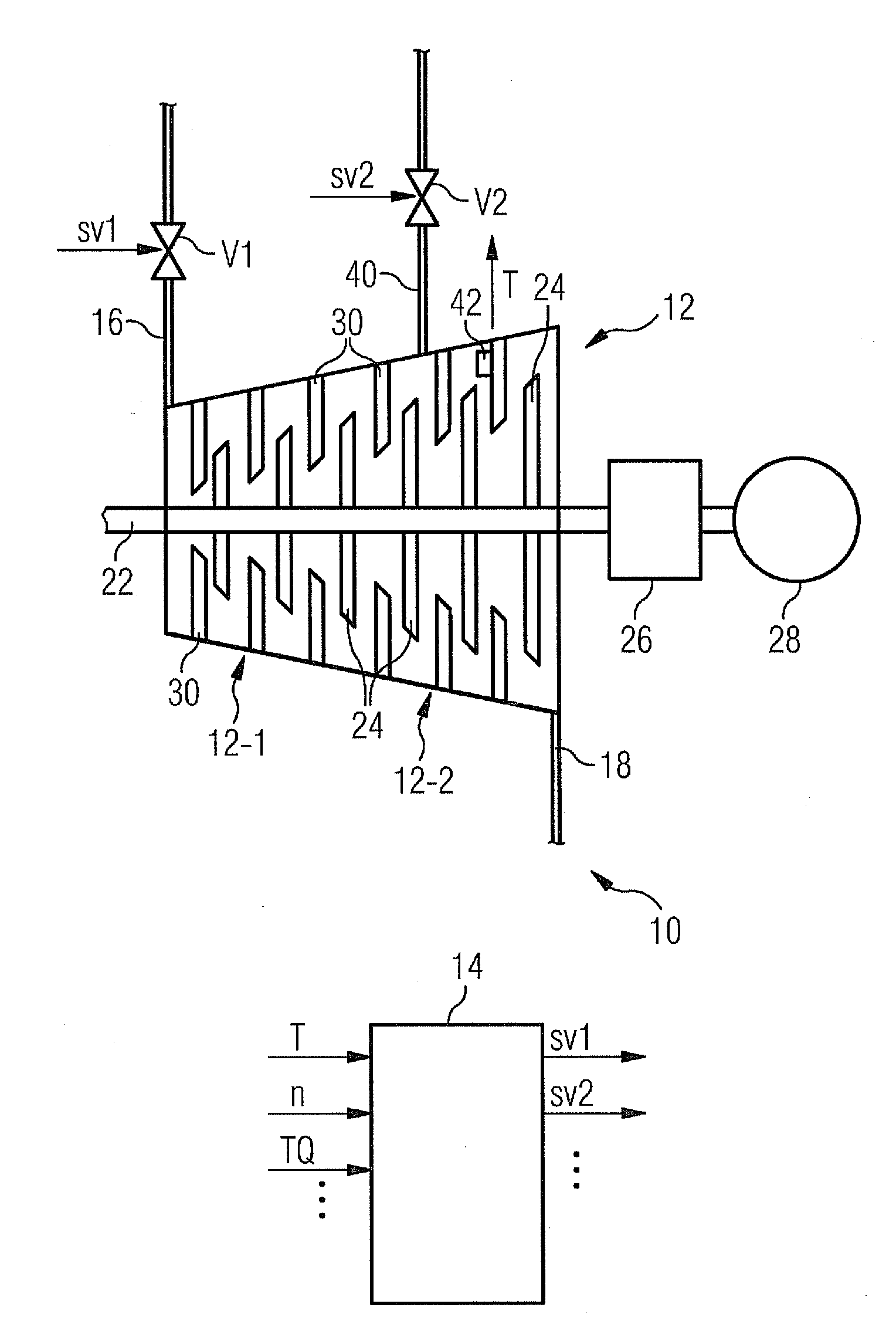

Method for operating a gas and steam turbine plant and a gas and steam turbine plant for this purpose

InactiveUS20100089024A1Improve reliabilityLow cost designGas turbine plantsSteam/vapor condensersFlue gasEngineering

A method for operating a gas and steam turbine plant is provided. In the plant, the flue gas that escapes from a gas turbine is routed through a waste gas steam generator and where a flow medium that is used to drive a steam turbine is conducted in a flow medium circuit that includes several pressure stages. At least one of the pressure stages has an evaporator circuit with a steam collection drum that has a plurality of downpipes connected to the steam collection drum and a plurality of rising pipes downstream of the downpipes that are likewise connected to the steam collection drum and are heated by the flue gas in the waste heat steam generator. The height of the fluid column formed by the flow medium in the downpipes is monitored and a transient dry operation of the evaporator circuit can thus be detected and safeguarded against.

Owner:SIEMENS AG

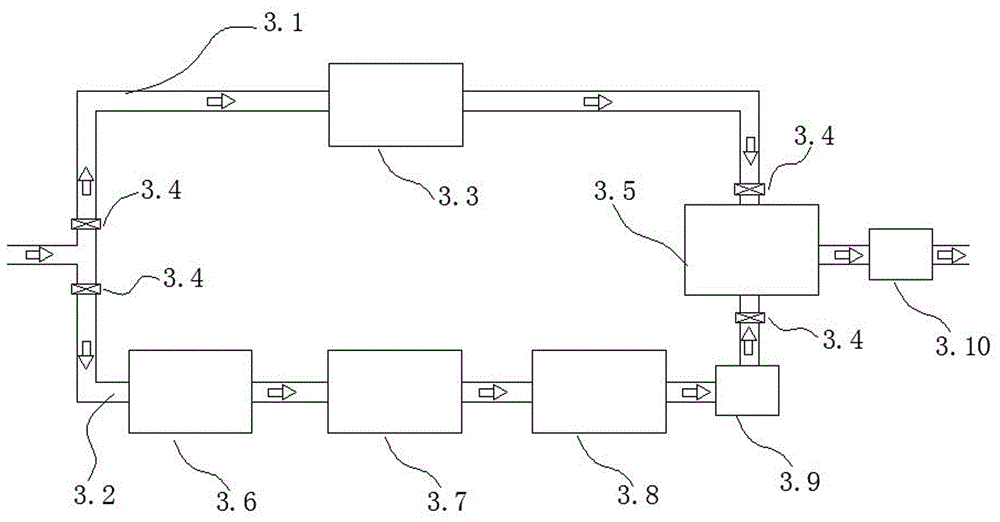

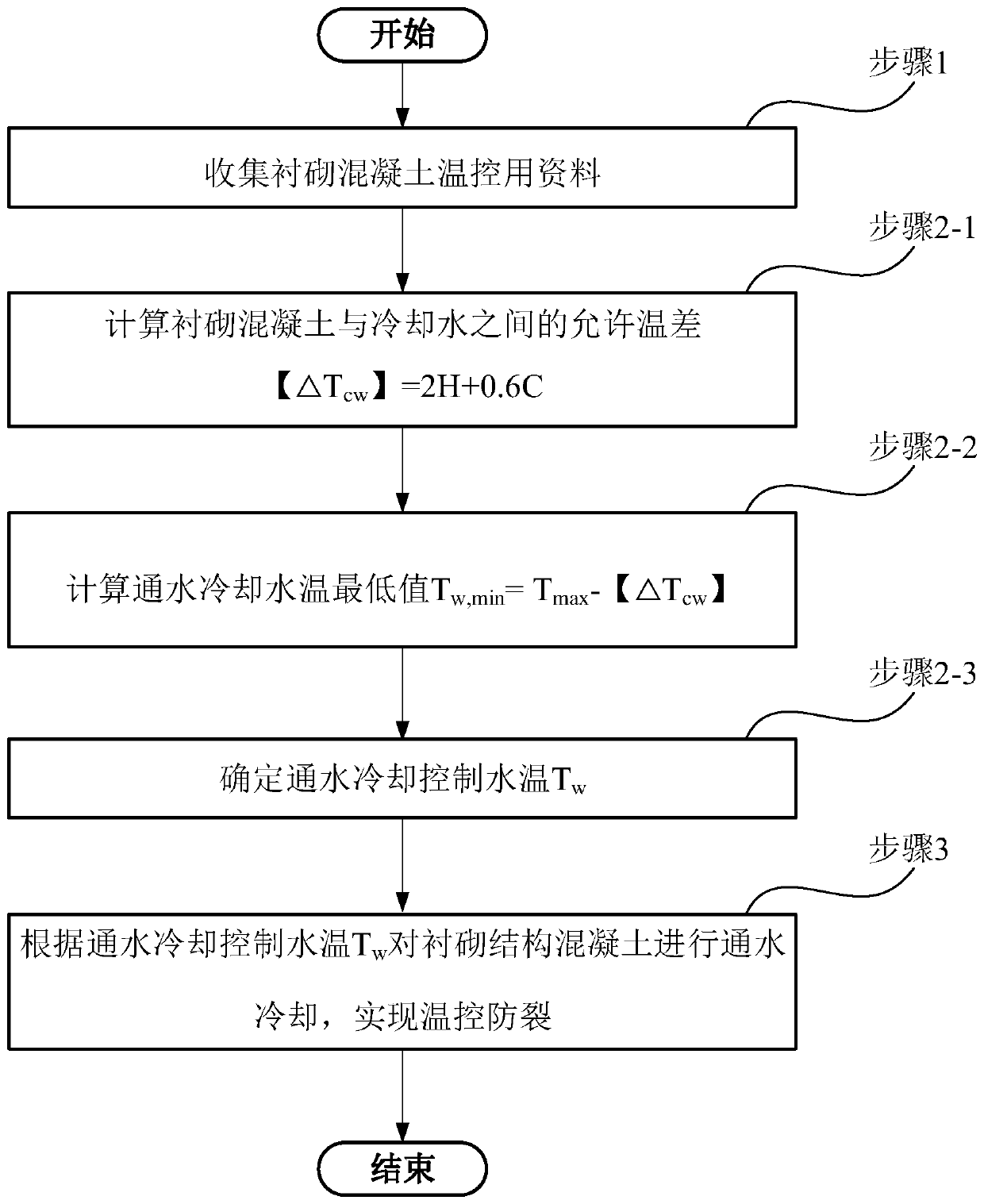

Lining structure concrete water cooling water temperature control method

ActiveCN110409387AAvoid manual control errorsReduce labor intensityWater-power plantsHydro energy generationTemperature controlEngineering

The invention provides a lining structure concrete water cooling water temperature control method. The method comprises the following steps: (1) lining concrete temperature control data is collected;(2) a water cooling control water temperature is calculated based on the collected lining concrete temperature control data, comprising: (2-1) an allowed temperature difference [delta Tcw]=2H+0.6 C between lining concrete and cooling water is calculated by a formula 1; (2-2) a water cooling water temperature lowest value Tw, min=Tmax-[delta Tcw] is calculated; and (2-3) the water cooling control water temperature Tw is determined: according to water temperature conditions in a construction site and the requirements of calculating the water cooling water temperature lowest value Tw, the water cooling control water temperature Tw is determined under the precondition of Tw not smaller than Tw, min; and (3) the water cooling is performed on lining structure concrete according to the water cooling control water temperature Tw to realize the temperature control cracking prevention to prevent cracks at the internals and pipe peripheries due to quicker temperature drop.

Owner:WUCHANG UNIV OF TECH +2

Plasma-sprayed ceramic layer on neodymium-iron-boron permanent magnet material surface and preparation method of plasma-sprayed ceramic layer

ActiveCN107254656AFirmly connectedFast preparationMolten spray coatingPermanent magnet manufactureComposite ceramicAlloy

The invention discloses a plasma-sprayed ceramic layer on a neodymium-iron-boron permanent magnet material surface capable of avoiding the failure phenomena, such as foaming in a protective layer of the neodymium-iron-boron permanent magnet material surface and peeling of the protective layer and a preparation method of the plasma-sprayed ceramic layer. The plasma-sprayed ceramic layer on the neodymium-iron-boron permanent magnet material surface comprises a neodymium-iron-boron machine body, an Al2O3-TiO2 composite ceramic layer and a Ni-Al alloy layer transition layer. The preparation method comprises the steps of (1) pretreating a neodymium-iron-boron matrix; (2) carrying out preheating treatment on the pretreated neodymium-iron-boron matrix in a vacuum environment; (3) preparing the Ni-Al alloy layer transition layer on the surface of the preheated neodymium-iron-boron matrix by adopting plasma spraying; and (4) preparing the Al2O3-TiO2 composite ceramic layer on the surface of the Ni-Al alloy layer transition layer by adopting plasma spraying. According to the plasma-sprayed ceramic layer of the neodymium-iron-boron permanent magnet material surface and the preparation method of the plasma-sprayed ceramic layer, rapid preparation of the high-quality protective layer on the neodymium-iron-boron permanent magnet material surface can be achieved, no by-product exists in the preparation process, and the plasma-sprayed ceramic layer is green, clean and free of pollution.

Owner:GUILIN UNIV OF ELECTRONIC TECH

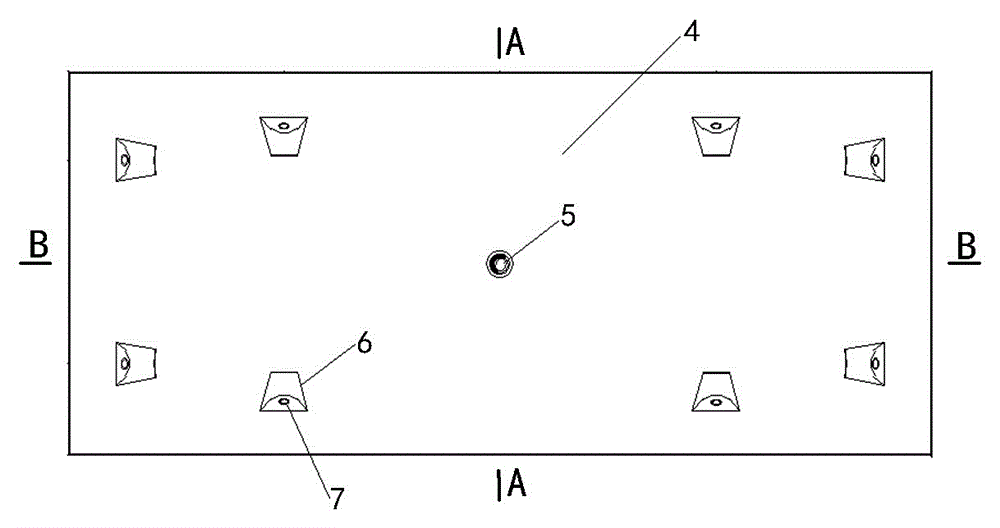

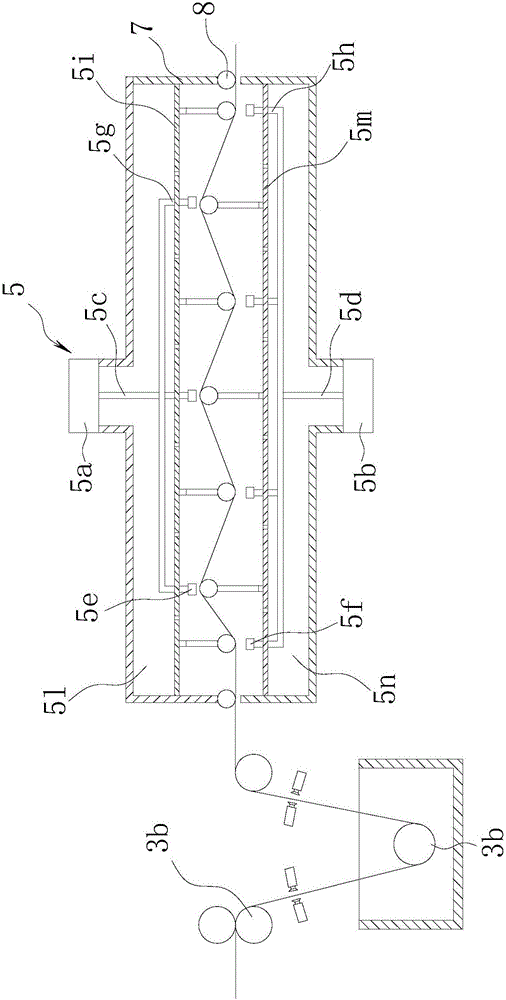

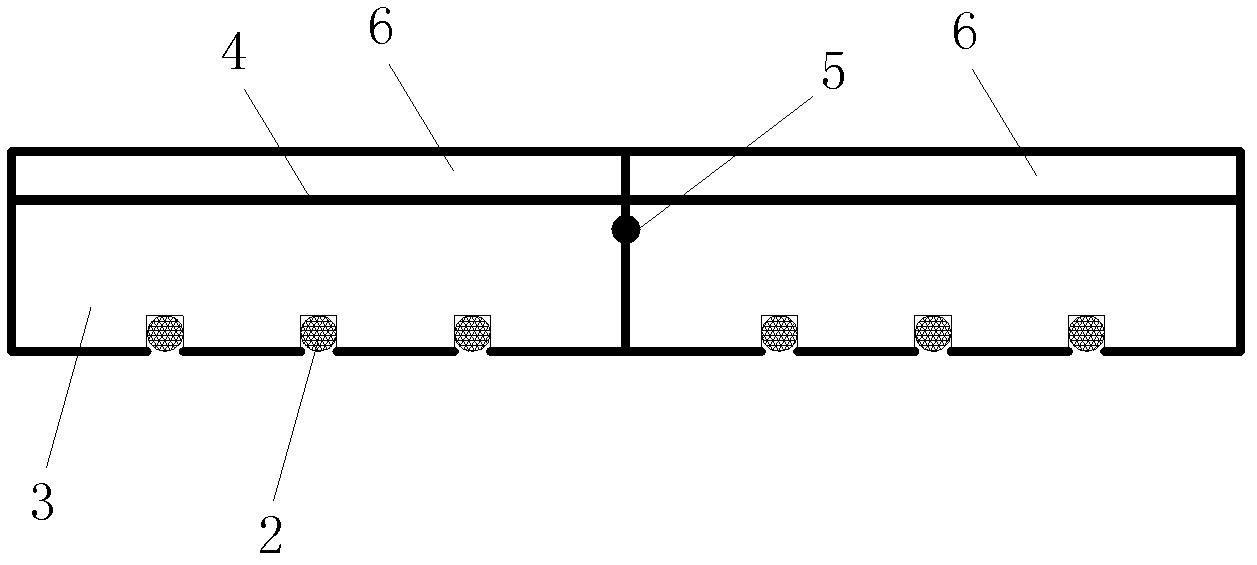

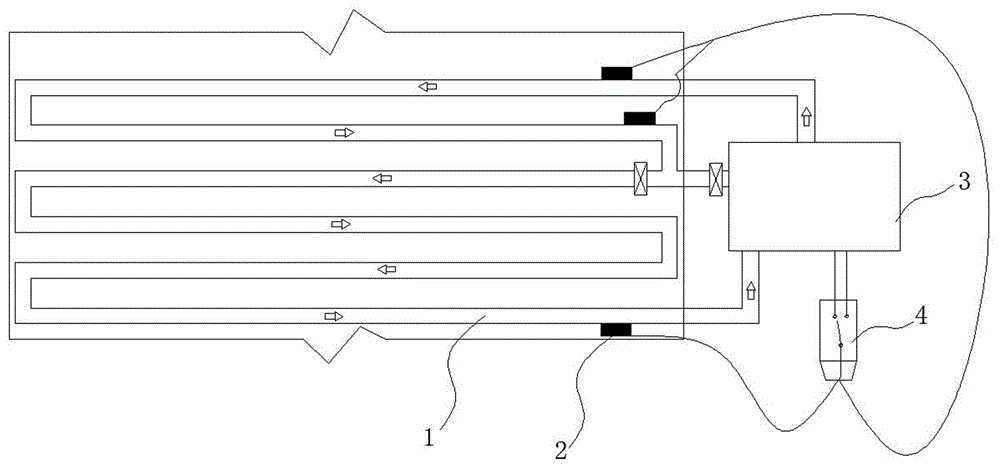

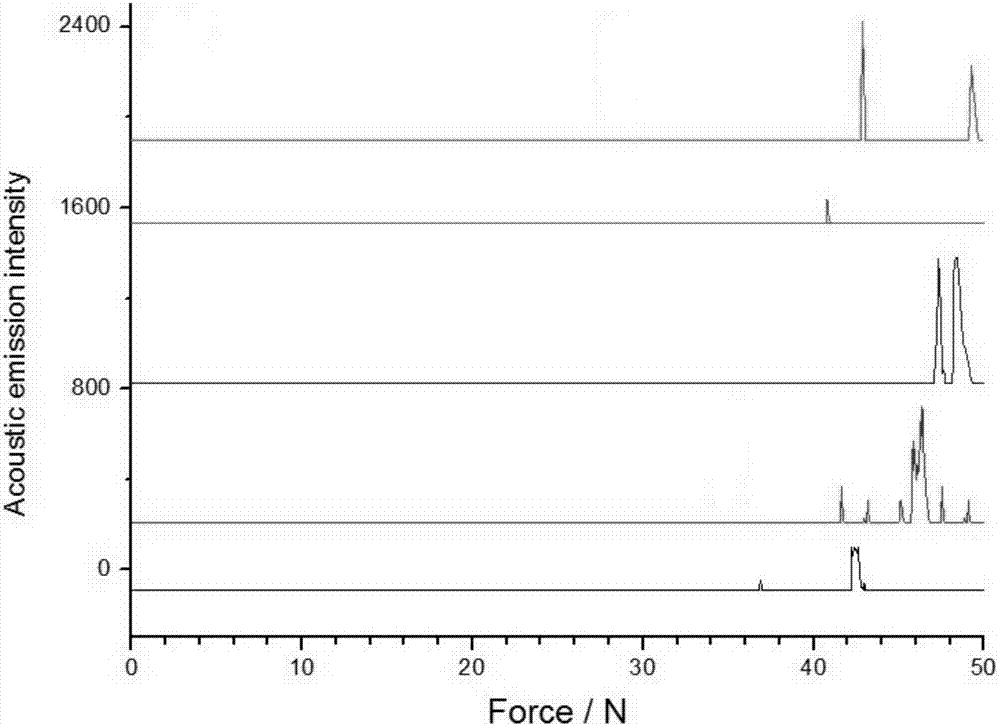

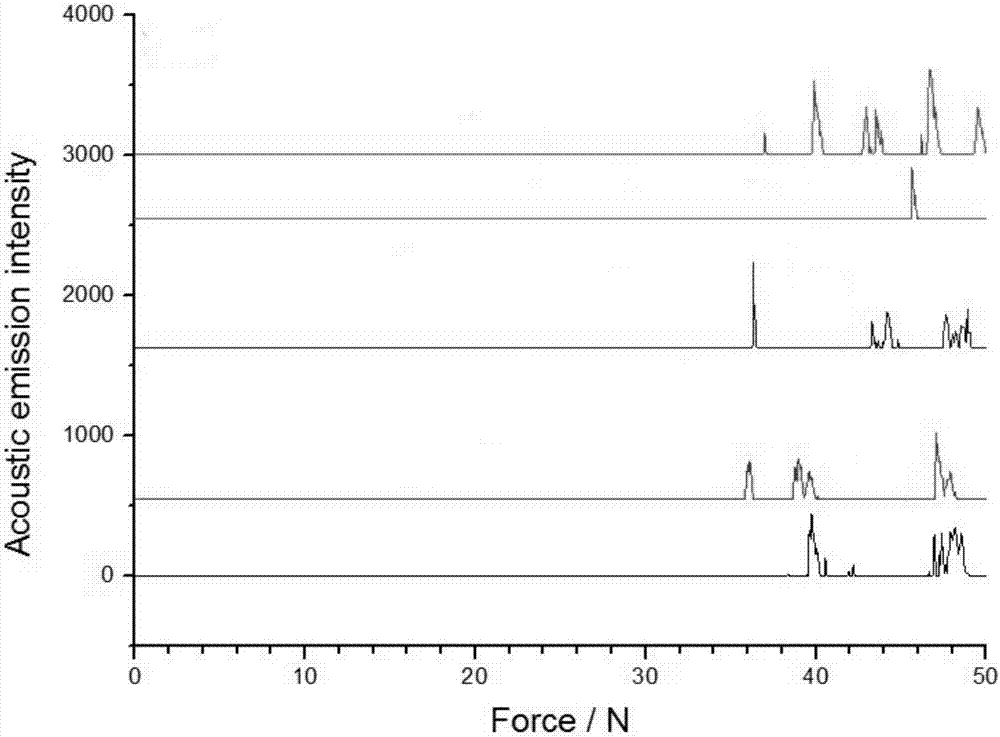

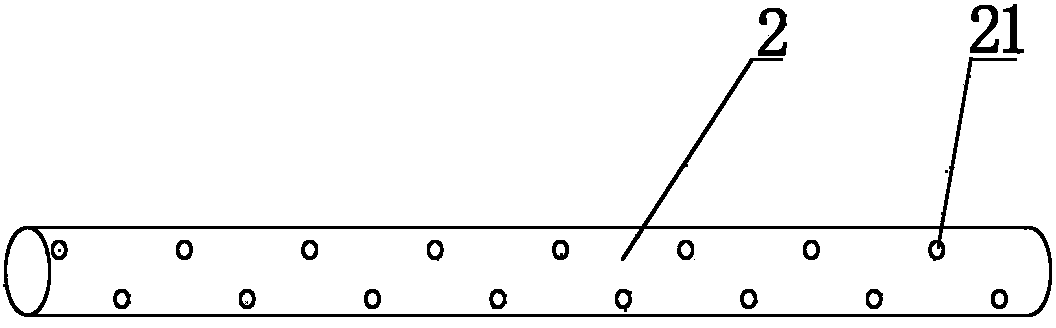

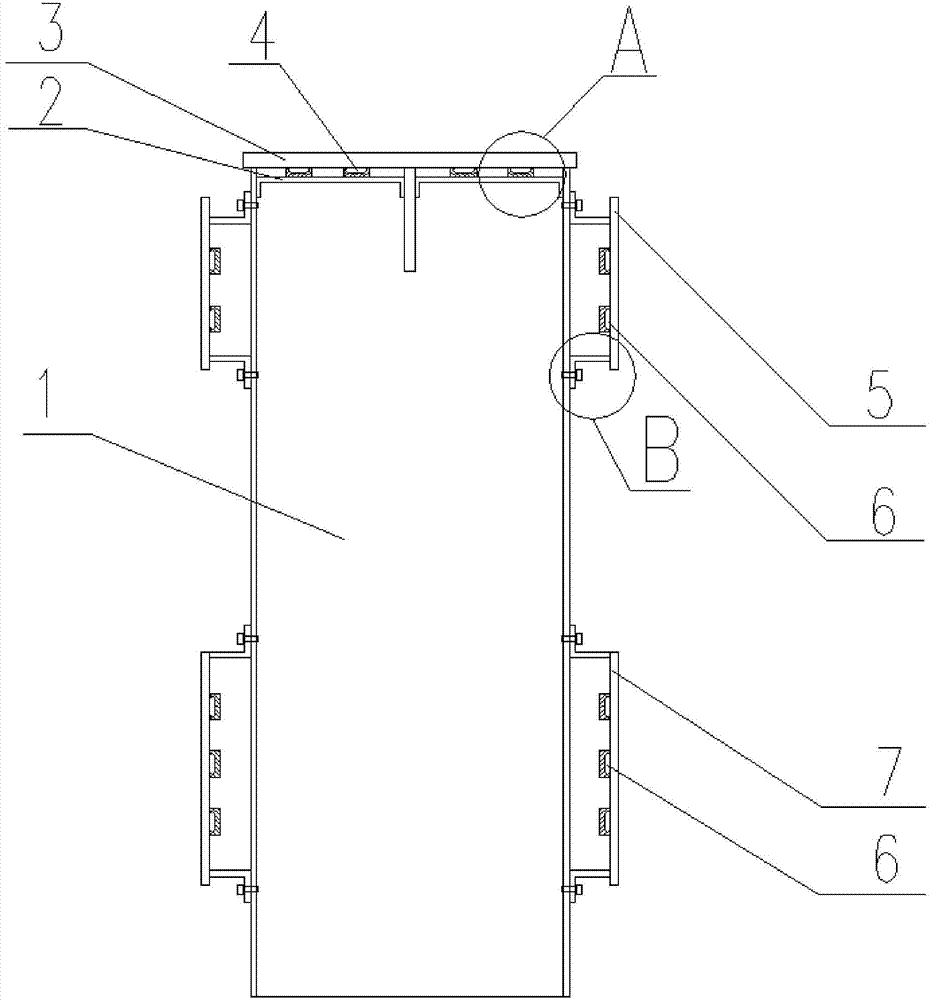

Long-wall structure concrete curing device and curing method thereof

ActiveCN103978547AExpand the scope of influenceReduce temperature stressCeramic shaping apparatusTemperature stressNumerical control

The invention relates to a long-wall structure concrete curing device and a curing method thereof. The curing device comprises a moisturizing device, a heat-preservation device and a temperature measurement device, wherein the moisturizing device comprises a spraying pipe, and the spraying pipe is fixed through a split bolt of a formwork at the top of a wall; the heat-preservation device comprises a plastic film and a heat-preservation material, the spraying pipe and the wall are wrapped with the plastic film, and the plastic film is wrapped with the heat-preservation material; the temperature measurement device comprises a center temperature measurement point and a surface temperature measurement point, the center temperature measurement point and the surface temperature measurement point are buried at the same elevation of the wall, and the center temperature measurement point and the surface temperature measurement point are connected with a numerical control temperature measurement instrument through a temperature measurement line. According to the curing device and the curing method, the outside of the surface of a long-wall concrete structure is provided with the moisturizing device capable of spraying fine water mist slowly and wrapped with the heat-preservatoin device composing of the plastic film and the heat-preservation material, the difference of temperatures inside and outside concrete is controlled, temperature stress in the concrete is reduced, temperature cracks of the concrete are reduced, and the problem of how to control the cracks in long-wall structure construction in the environment with a dry climate and a large temperature difference is solved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

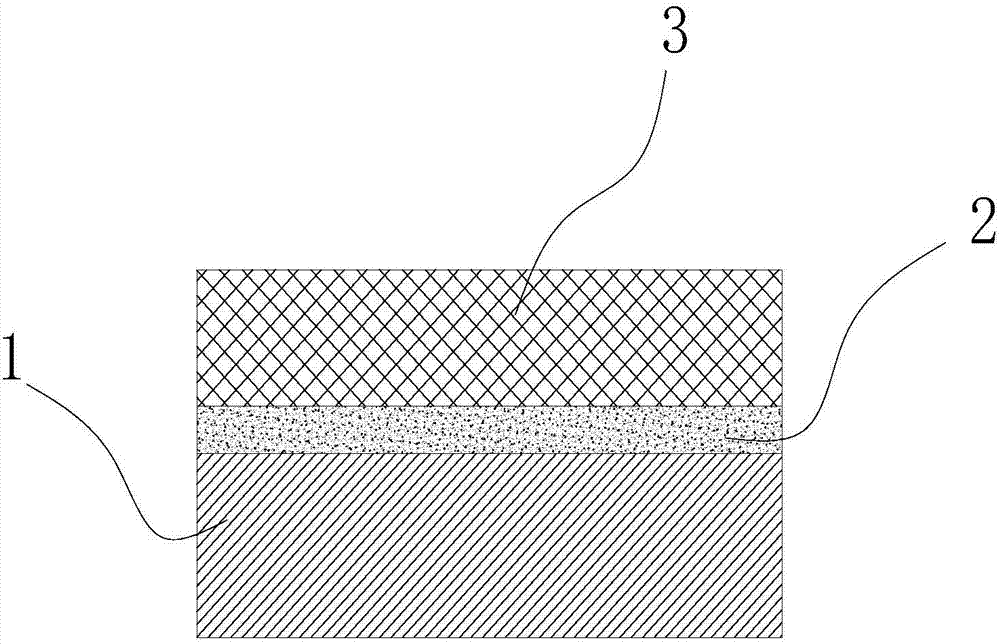

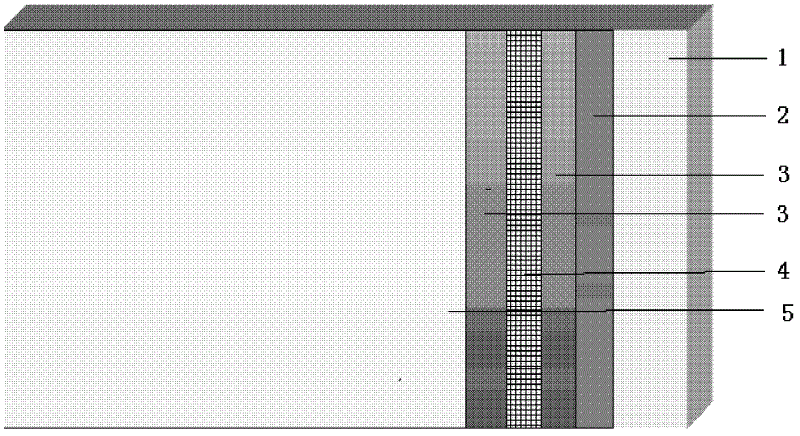

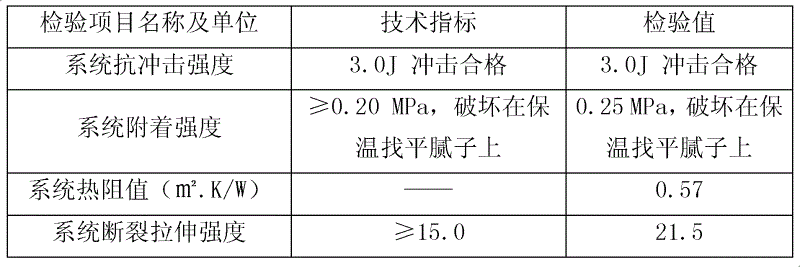

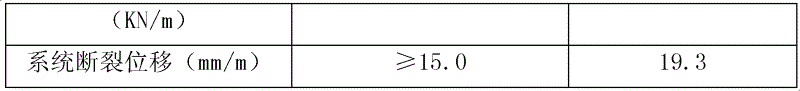

Coating system dedicated for outer wall reflecting and heat-insulating paint and construction method of coating system

InactiveCN102619310ALarge thermal resistanceImprove insulation effectCovering/liningsAntifouling/underwater paintsGlass fiberCoating system

The invention relates to a coating system dedicated for outer wall reflecting and heat-insulating paint and a construction method of the coating system. The coating system is successively provided with heat-insulating leveling putties, an anti-cracking layer, sealing primer and a reflecting and heat-insulating paint finish paint layer from the surface of a base layer wall body, wherein the anti-cracking layer comprises two layers of heat-insulating leveling putties and glass fiber gridding cloth clamped between the two layers of heat-insulating leveling putties. The coating system dedicated for the outer wall reflecting and heat-insulating paint has the functions that the heat-insulating effect is enhanced, the anti-cracking effect is obvious, and the like by regulating the assorting of the base layers and applying the principle design, such as material deformation modulus access, and flexible gradual change.

Owner:上海天补建筑科技有限公司

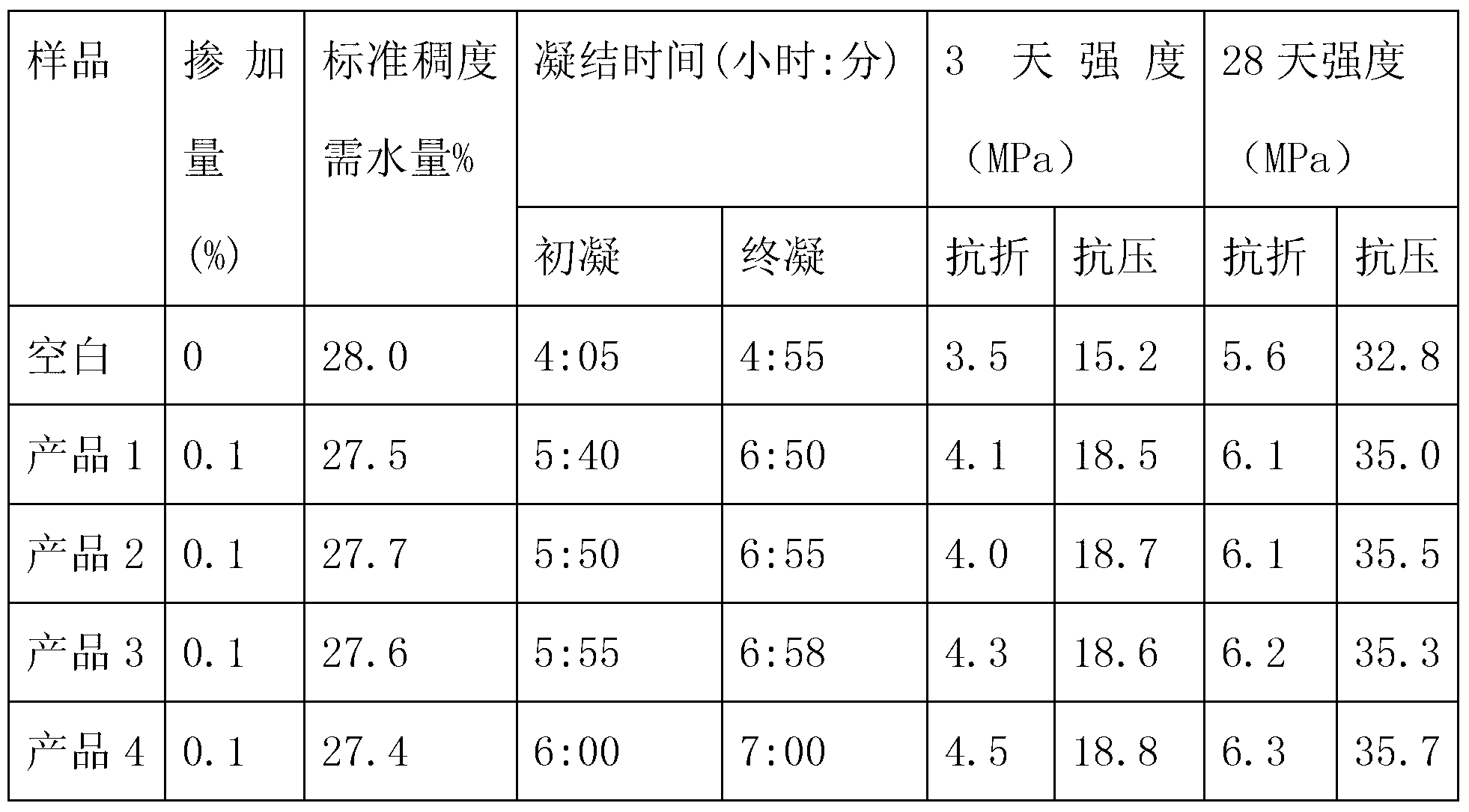

Retarded cement grinding aid and preparation method thereof

ActiveCN103193415AImprove early strengthIncrease late strengthCarboxymethyl celluloseCement grinding

The invention discloses a retarded cement grinding aid and a preparation method thereof. The retarded cement grinding aid comprises 0.01-0.02wt% of sodium carboxymethyl cellulose, 25-30wt% of molasses calcium, 5-10wt% of citric acid and the balance of water, wherein the total percent is 100%. The retarded cement grinding aid provided by the invention has the beneficial effects that the molasses calcium is used instead of the molasses and cane sugar commonly used at present, is a powdery product prepared by neutralizing the molasses with lime, has better water reducing and retarding effects than the molasses and saves the cost; and the hydration and hardening time of the cement is effectively lengthened so that the freshly mixed cement concrete can maintain the plasticity in a longer time, thus adjusting the setting time of the freshly mixed cement concrete.

Owner:NANJING YONGNENG MATERIALS

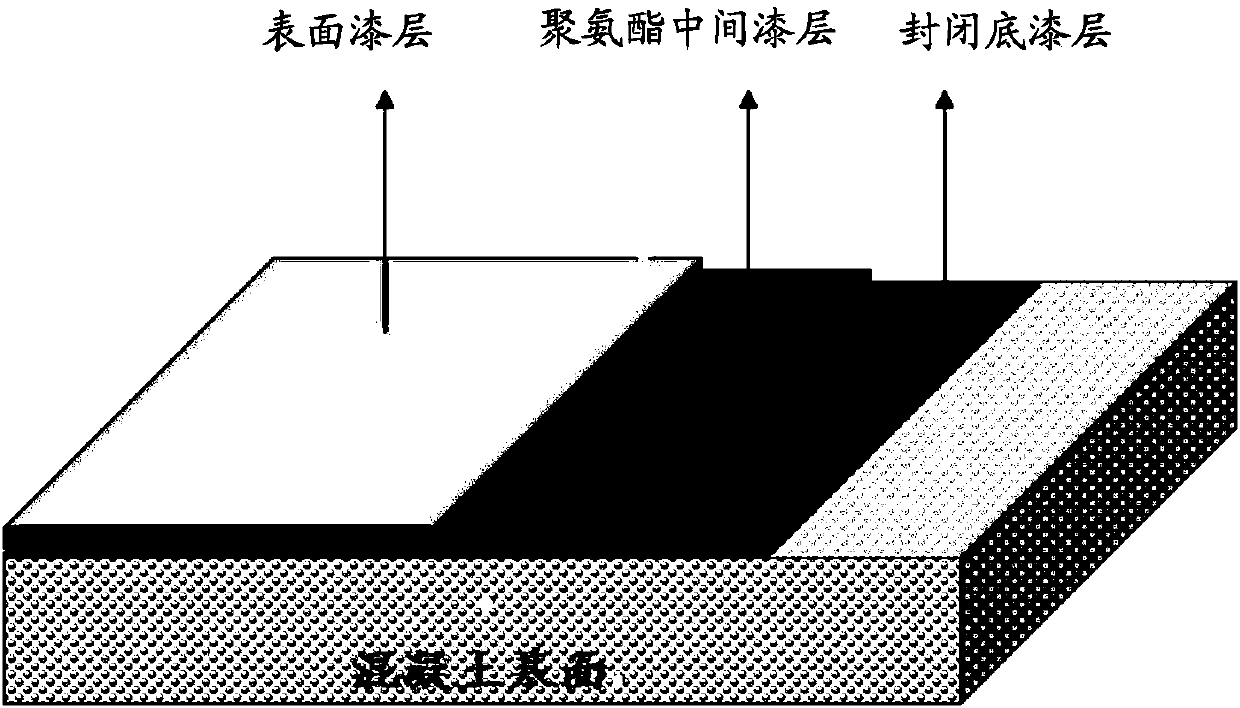

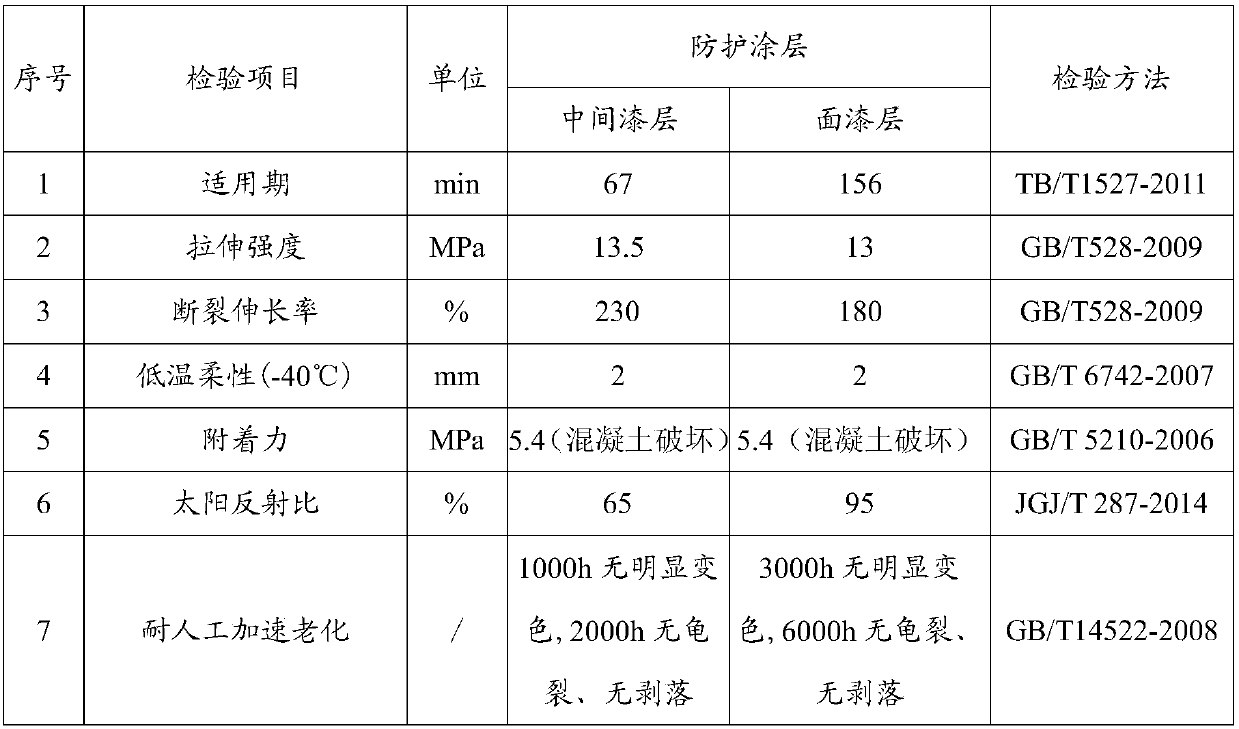

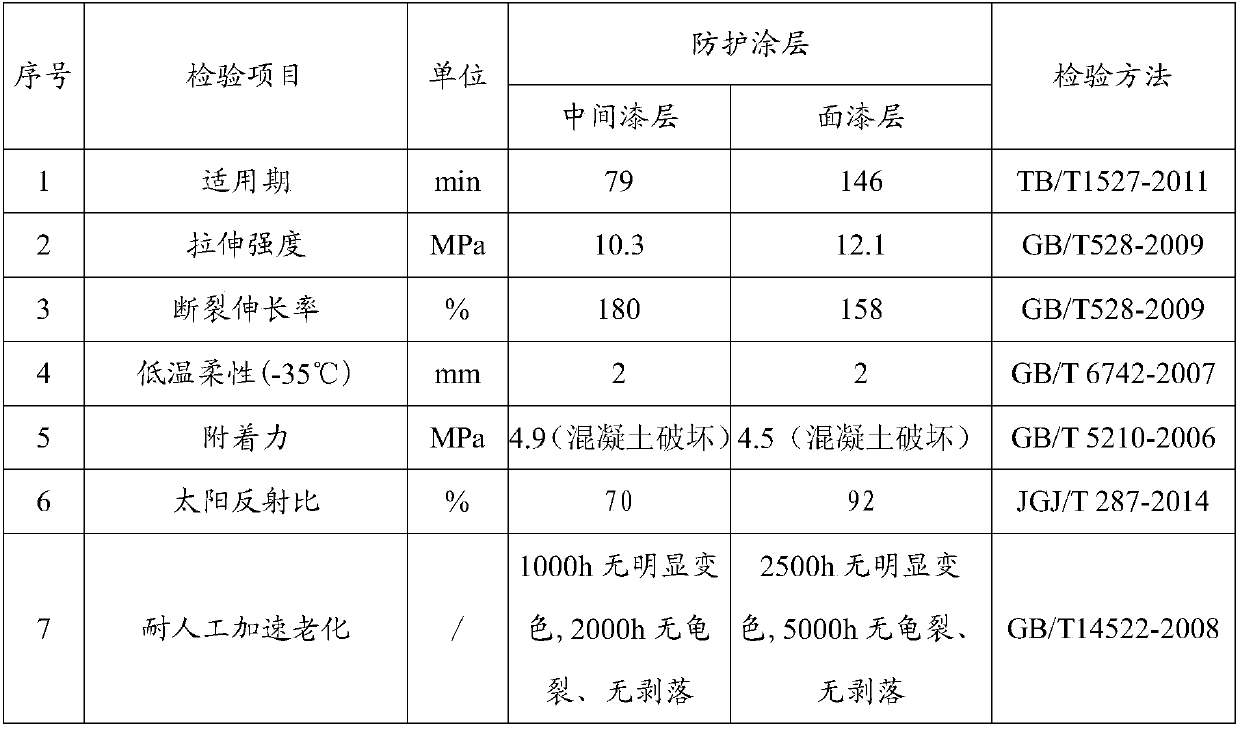

Railway structure concrete protecting coating and preparation method and using method thereof

ActiveCN107603359AImprove adaptabilityImprove aging resistancePolyurea/polyurethane coatingsEpoxy resin coatingsTemperature differenceFluorocarbon

The invention provides railway structure concrete protecting coating and a preparation method and a using method thereof. The protecting coating comprises a sealing primer layer, a polyurethane middlepaint layer and a fluorocarbon finish paint layer. The protecting coating has excellent adhesion; when the protecting coating is used for protecting a railway concrete bridge, the protecting coatingcan avoid occurrence of a situation that the railway concrete bridge cracks first and then is repaired in a special environmental region, significantly improves the durability of the railway concretebridge, prolongs the service life the railway concrete bridge, can achieve an excellent concrete protecting effect in the case of relatively thin concrete bridge coating thickness, and is convenient and fast to use; the protecting coating can also be used for protecting the surface of a ballastless track structure, and when the protecting coating is applied to the surface of a concrete track plateunder a steel rail or the surface of a ballast bed plate, the temperature difference between day and night due to sunlight irradiation can be reduced, the warpage amount of the track plate can be reduced, the open joints of plate corners or upwarp of the ballast bed plate or other damages can be reduced or even eliminated, and the effect of improving the durability of a ballastless track high-speed railway with a strict requirement on the smoothness is relatively good.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +4

Spiral condenser and manufacturing process of spiral condenser

InactiveCN104315760AReduce labor intensityImprove protectionEvaporators/condensersHeat exchanger casingsEngineeringConductor Coil

The invention relates to a spiral condenser, which comprises a heat radiation pipe and fins, wherein the heat radiation pipe forms a cuboid structure through bending and winding, the cuboid structure consists of a plurality of layers of circuitous heat radiation pipe units, the heat radiation pipe units are mutually parallel, in addition, the gap between the heat radiation pipe units is set to be 10mm to 30mm, the fins are spirally arranged on the outer surface of the heat radiation pipe in a winding way and are of a straight sheet type structure, the gap between the adjacent fin blades is set to be 4mm to 10mm, the spiral condenser also comprises a support frame assembly used for supporting and fixing the cuboid structure consisting of the layers of circuitous heat radiation pipe units. The spiral condenser has the characteristics that the cost is low, the manufacturing is simple, the heat radiation effect is good, the refrigeration is fast, and the like.

Owner:CHANGZHOU CHANGZHENG HEAT EXCHANGER TECH

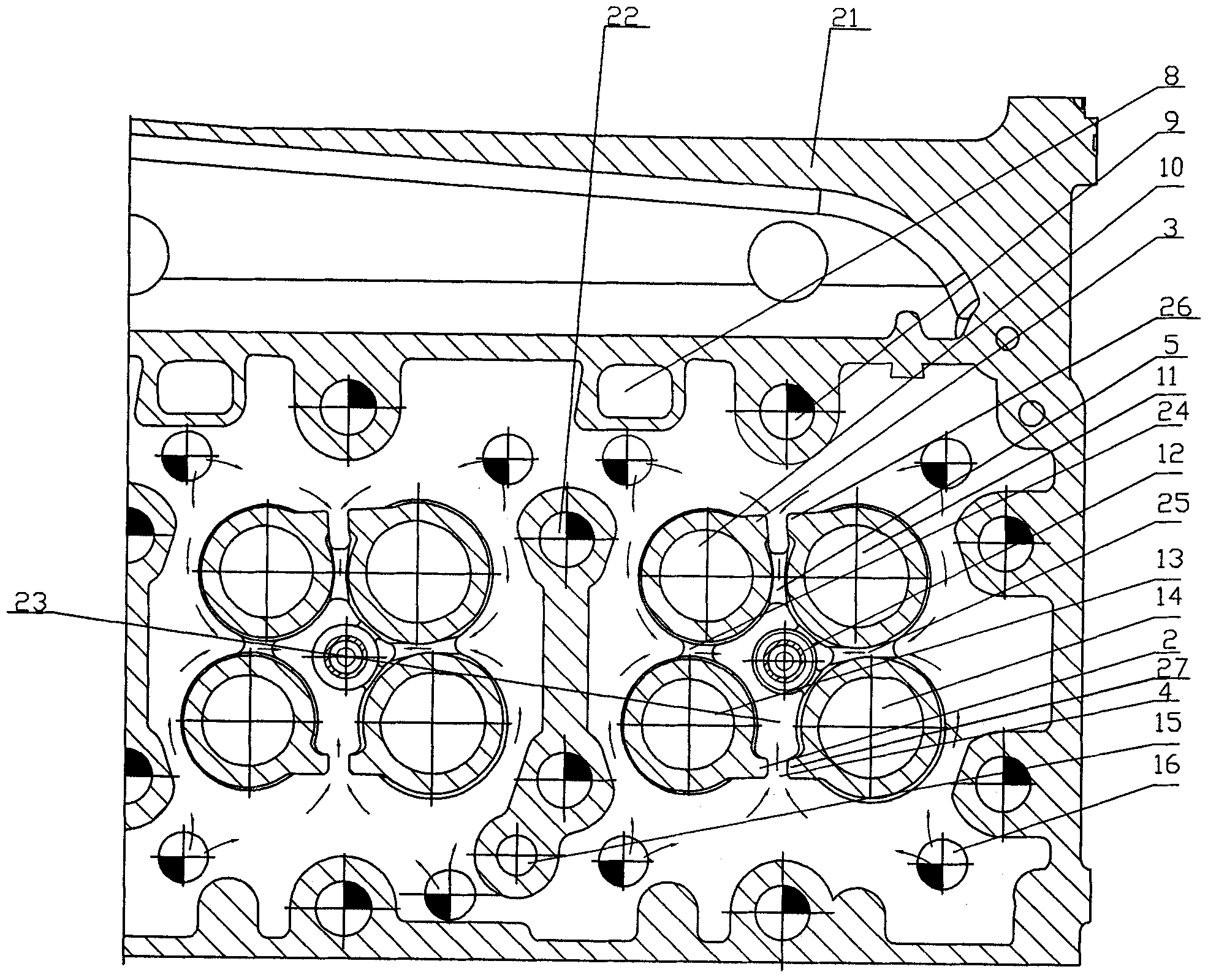

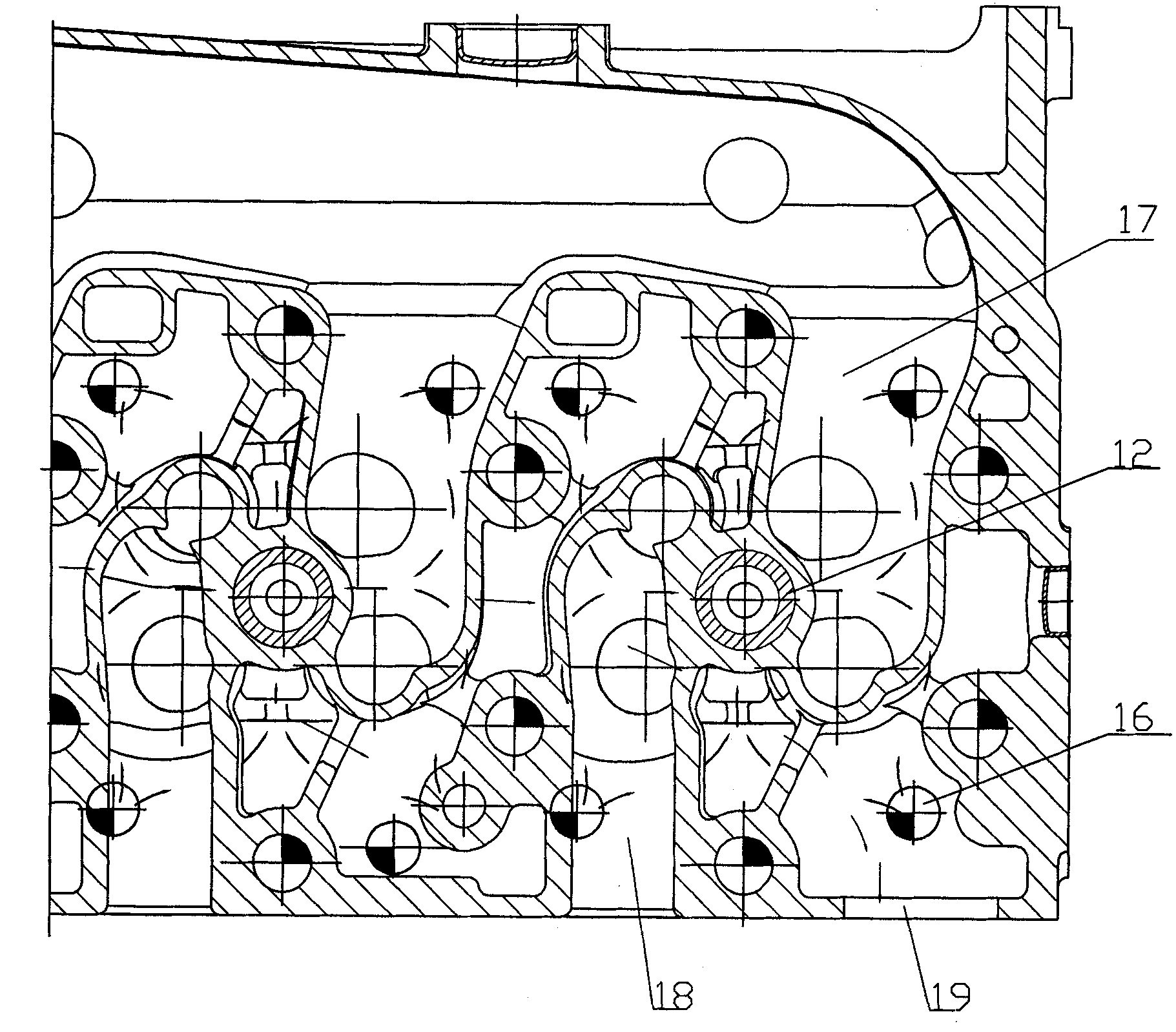

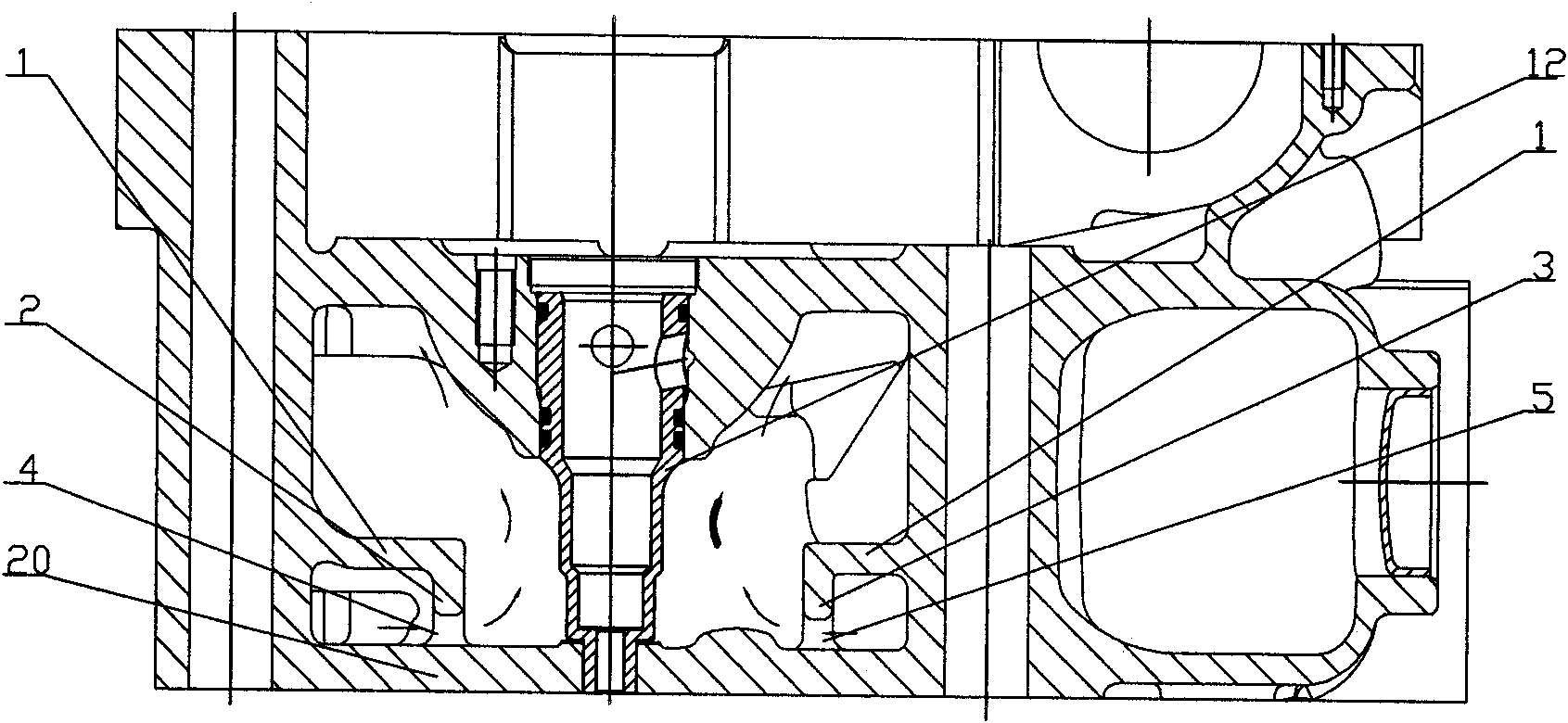

Water channel structure of cylinder cover

InactiveCN101865047AReduce temperature stressCool evenlyCylinder headsCylindersTemperature stressInlet channel

The invention relates to a water channel structure of a cylinder cover, which comprises a first air inlet hole base, a second air inlet hole base, a first vent hole base, a second vent hole base and a fuel injector sleeve arranged on the cylinder cover. A bolt hole, an oil inlet hole and an oil return hole are formed on the cylinder cover; a lower layer water channel and an upper layer water channel are formed in the cylinder cover around a first inlet valve base hole, a first exhaust valve base hole, a second inlet valve base hole, a second exhaust valve base hole, an inlet channel and an exhaust channel; the lower layer water channel is communicated with the upper layer water channel through a communicating water channel; a first intercommunicating pore is formed between the first exhaust valve base hole and the second exhaust valve base hole to communicate the lower layer water channel on one side with the communicating water channel; and a second intercommunicating pore is formed between the first inlet valve base hole and the second inlet valve base hole to communicate the lower layer water channel on the other side with the communicating water channel. The water channel structure of the cylinder cover can reduce temperature stress of the cylinder cover to ensure that an inlet valve base, an exhaust valve base and the fuel injector sleeve are cooled uniformly, avoid capillary cracks and prolong the service lives of the inlet valve base, the exhaust valve base and the fuel injector sleeve.

Owner:WUXI KIPOR POWER CO LTD

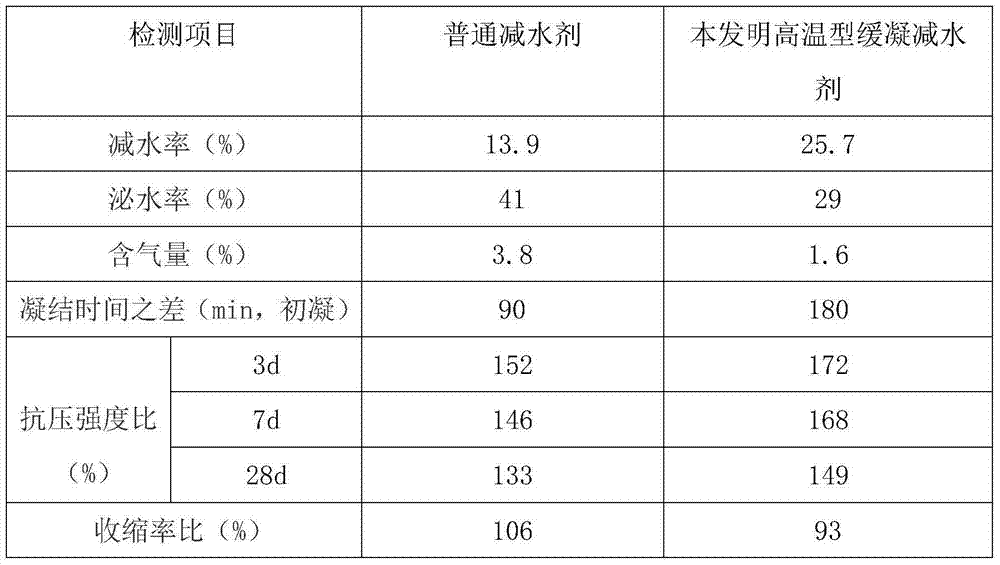

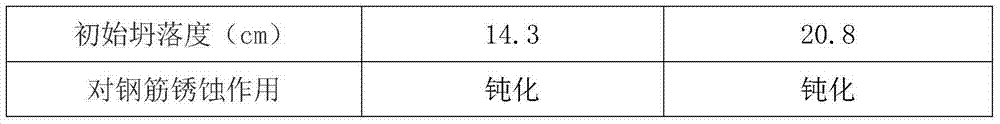

High-temperature retarding and water reducing agent

InactiveCN104119017AImprove high temperature resistanceSuitable for a wide temperature rangeSlagPENTAERYTHRITYL DISTEARATE

The invention discloses a high-temperature retarding and water reducing agent prepared by mixing the following raw materials in parts by weight: 35-45 parts of polycyclic aromatic hydrocarbon sulfonated formaldehyde condensates, 20-30 parts of acyclic hydroxyl sulfonate condensates, 10-15 parts of diethylenetriaminepenta(methylene-phosphonic acid), 8-16 parts of calcium saccharate, 12-18 parts of alunite powder, 5-10 parts of xanthan gum powder, 4-8 parts of barium metaborate, 3-6 parts of sodium lauryl sulfate, 2-4 parts of pentaerythrite di-n-stearate, 6-12 parts of maleic anhydride-styrene sulfoacid copolymers, 10-15 parts of blast furnace slag powder, 5-10 parts of waste saccharide slag powder, 7-13 parts of nekal and 4-7 parts of auxiliary. The water reducing agent disclosed by the invention is excellent in high temperature resistance, relatively wide in applicable temperature range (150-250 DEG C), capable of reducing cement hydration heat release, reducing the temperature stress of the concrete, avoiding generating temperature cracks and completely meeting the construction requirement for high-temperature and high-pressure well cementation, suitable for continuously pouring mass concrete under a high temperature condition, remarkable in water reducing enhancement effect, good in slump loss resistance and wide in market prospect.

Owner:WUHU SANXING CONCRETE ADMIXTURE

Concrete

InactiveCN105645866AReduced risk of crackingReduce heat of hydrationCrack resistanceFineness modulus

The invention discloses concrete. The concrete is prepared from the following components of ordinary Portland cement, a mineral admixture, a water reducing agent, medium sand, broken stones, an anti-cracking silicone waterproof agent (FQY) and water, wherein the mineral admixture is prepared from pulverized fuel ash and granulated blast-furnace slag; the fineness modulus of the medium sand is 2.3 to 2.9, and the broken stones are continuous graded broken stone particles of which the particle size is 5 to 25 mm. The novel concrete disclosed by the invention has higher performance index on aspects of crack resistance, leakage prevention, working performance and durability.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

Ice and snow melting device for steel track beam

InactiveCN104746394ASolve the problem of rapid melting of ice and snowGuaranteed uptimeClimate change adaptationRailway tracksTemperature stressMetallurgy

The invention relates to the technical field of track traffic, and discloses an ice and snow melting device for a steel track beam. The device comprises a top surface heating strip arranged on the top surface of a beam body of the steel track beam, and side surface heating strips respectively arranged on the two side surfaces of the beam body, wherein the top surface heating strip is used for heating a steel plate on a walking surface of the beam body; the side surface heating strips are used for heating a steel plate on a guide surface and a steel plate on a stable surface of the beam body; the top surface heating strip is bonded with the lower side of the steel plate on the walking surface; the side surface heating strips are respectively bonded with the inner sides of the steel plate on the guide surface and the steel plate on the stable surface; and the top surface heating strip and the side surface heating strips are respectively wrapped with thermal insulating layers for reducing the loss of heat and transferring the heat to the internal of the beam body. The device can quickly and totally melt ice and snow on the steel track beam without generating greater temperature stress, so that the safety performance is guaranteed, and the effects of energy conservation and environmental protection are achieved.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

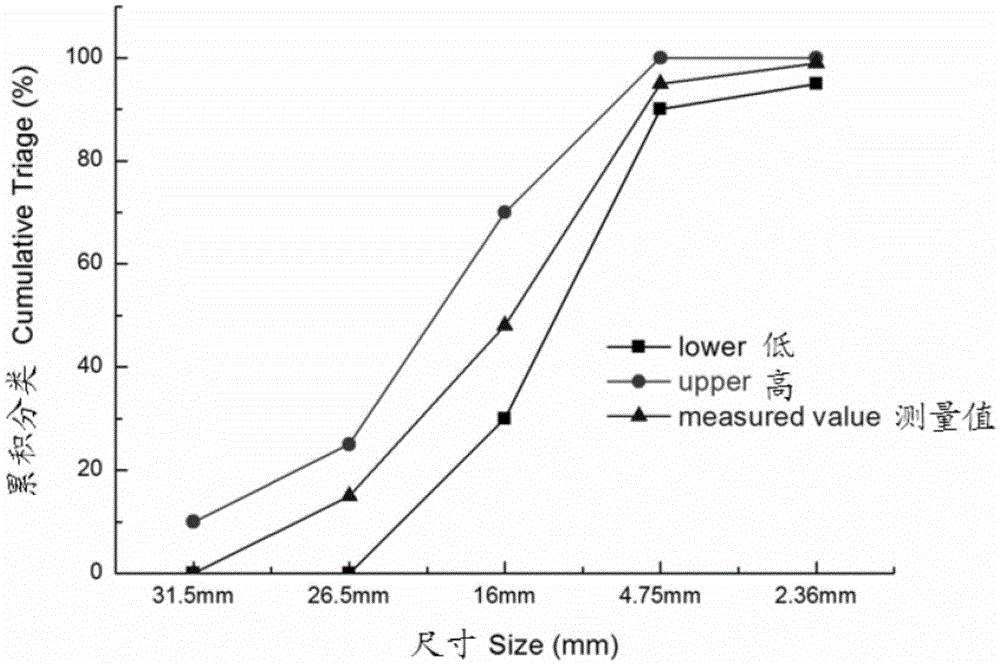

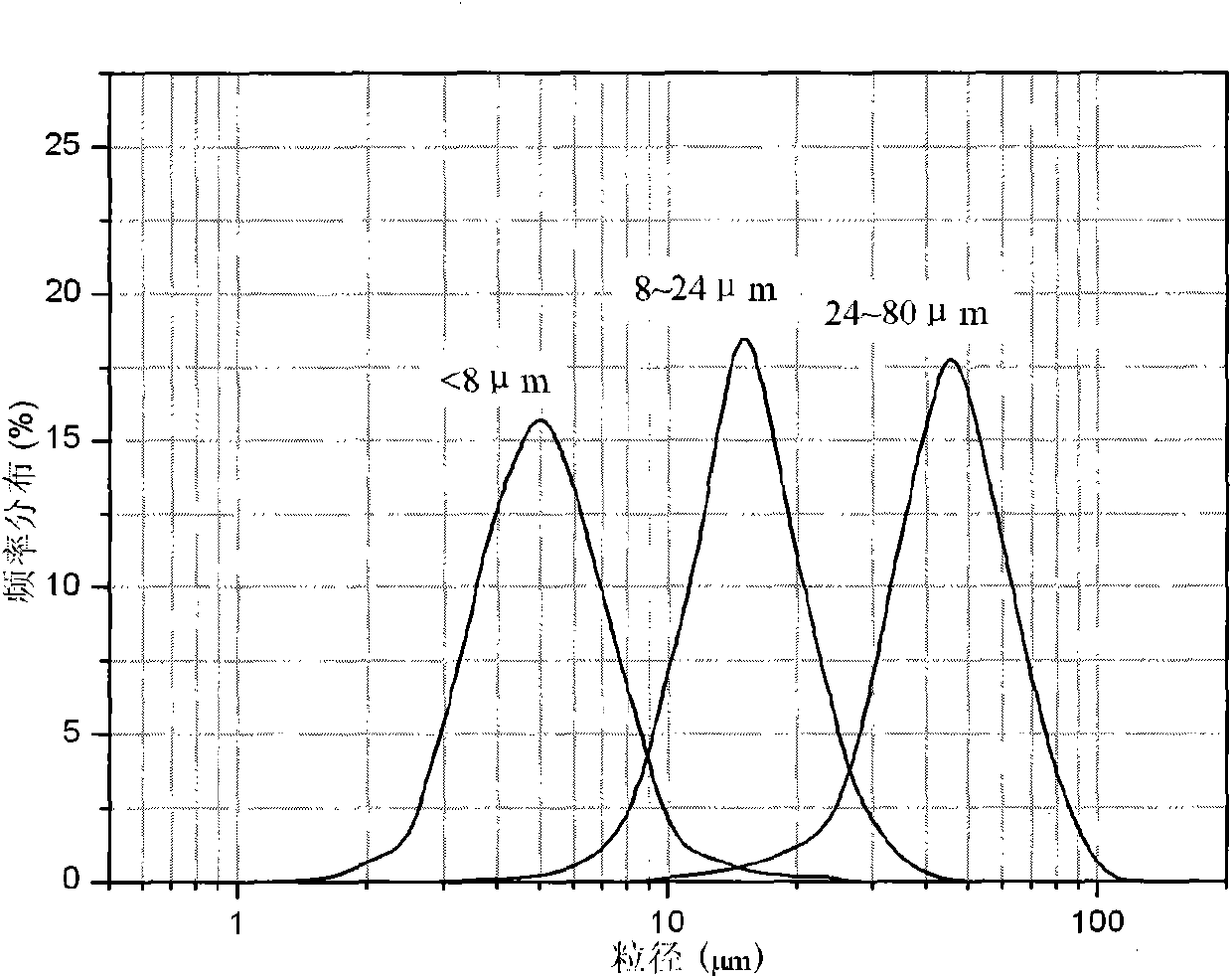

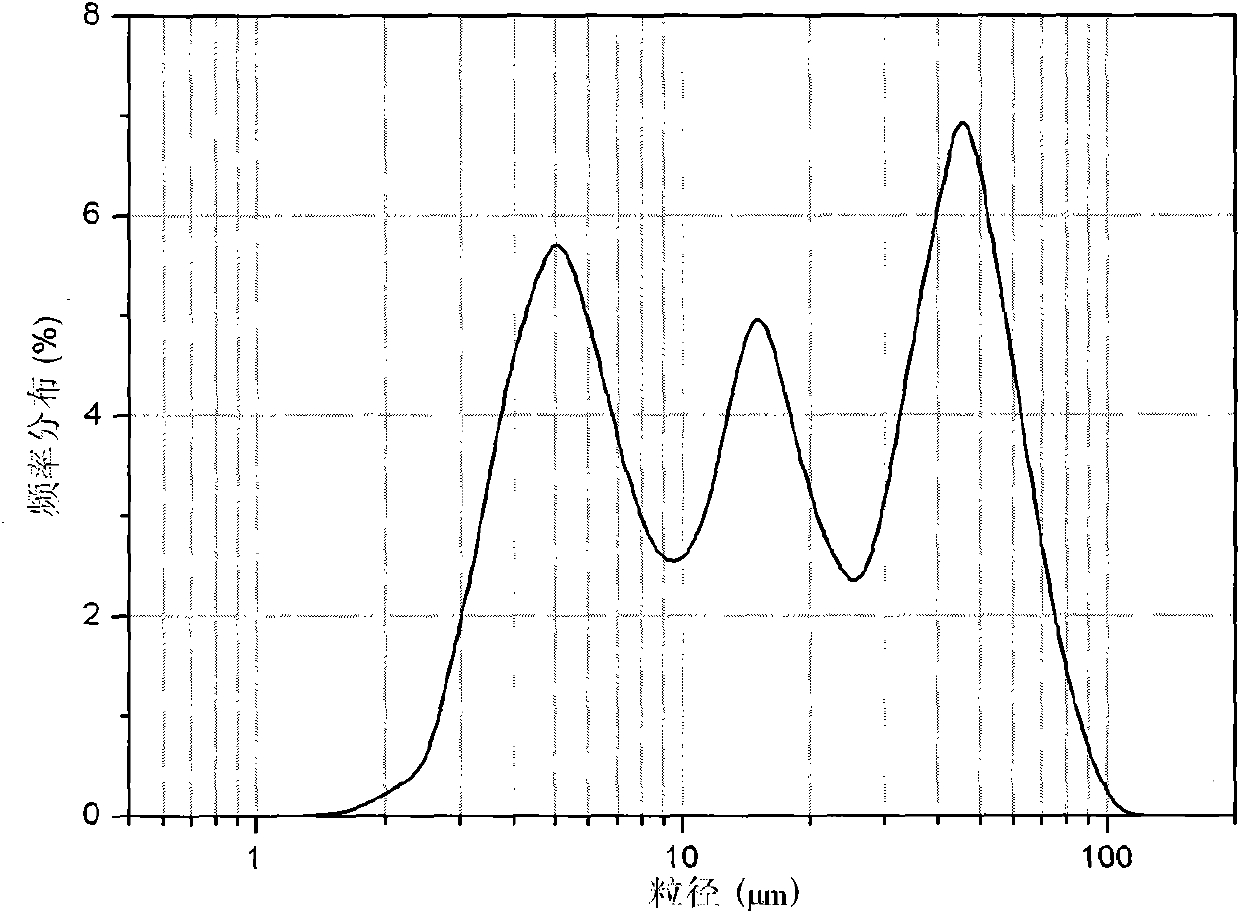

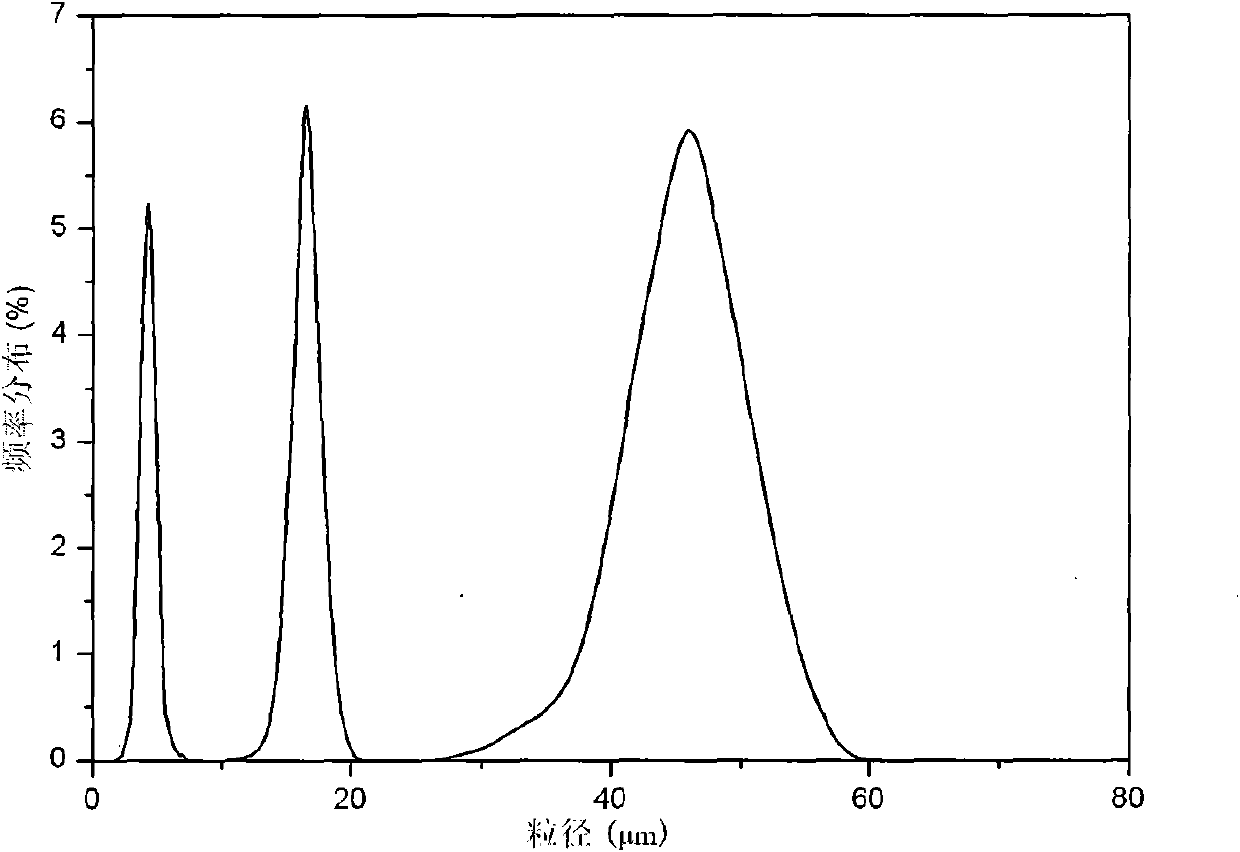

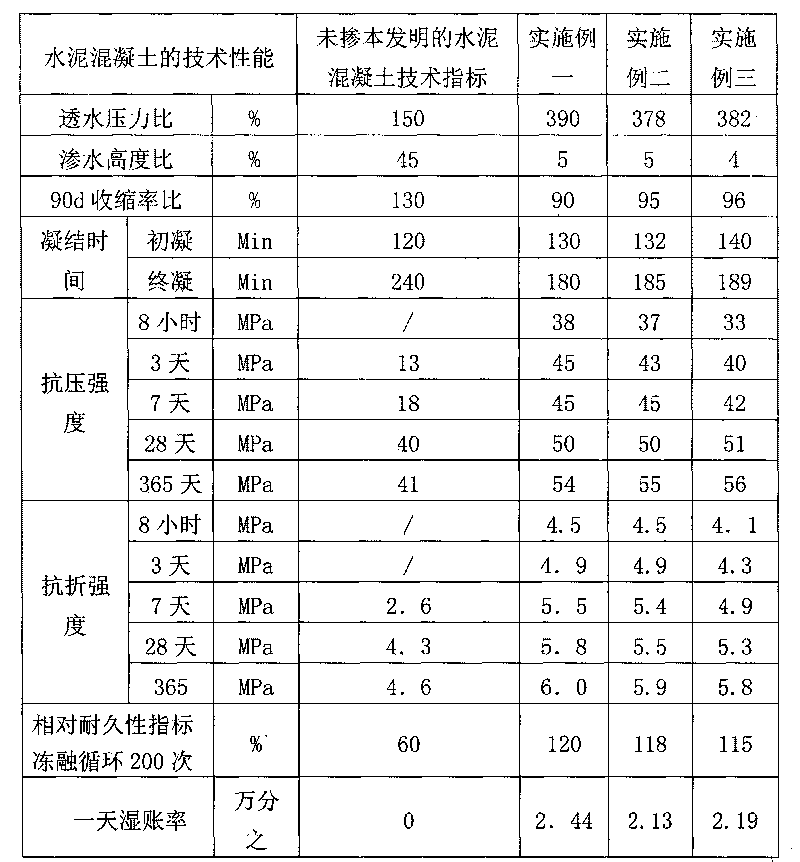

Preparation method of composite cement with low clinker dosage and high flexural compression ratio

The invention discloses a preparation method of composite cement with low clinker dosage and high flexural compression ratio. The preparation method is to mix three size ranges of powder particles and obtain the composite cement. The three size ranges of powder particles are as follows: 1) the grain size of particles is less than 8mu m, the particles are composed of high-activity supplementary cementing material with the grain size; 2) the grain size of particles is 8-24mu m, the particles are composed of cement clinker particles with the grain size; and 3) the grain size of particles is 24-80mu m, and the particles are composed of low-activity supplementary cementing material or inert filler. The volume percentages of the three size ranges of powder particles are 25-40%, 25-30% and 30-45% respectively. The clinker volume percentage of the composite cement is 25-30%, the 28-day compressive strength is up to 35-50MPa, the flexural strength is up to 10-12Mpa, the flexural compression ratio is 1 / 3-1 / 4; and the composite cement has low hydration heat and good anti-cracking capability and can be used in the civil construction / engineering with the demand on the anti-cracking capability.

Owner:SOUTH CHINA UNIV OF TECH

Cement concrete admixture for quickly repairing cement concrete roads

InactiveCN101708969ARapid early strength developmentReduce maintenance traffic timeRoad surfaceMaterials science

The invention belongs to the technical field of cement concrete admixtures. A cement concrete admixture for quickly repairing cement concrete roads consists of the following components in percentage by weight: 70 to 90 percent of inorganic basis material, 10 to 30 percent of early strength admixture, 5 to 20 percent of water reducing agent, 0 to 20 percent of cement-coagulation agent and 0 to 5 percent of rust inhibitor. The admixture can ensure that the traffic opening time of the maintenance of cement concrete pavements is shortened to 8 hours, has the characteristics of high early strength, no shrinkage at later stages, adjustable hardening and setting time, wide applicable temperature range, low mixing amount and the like, and is mainly applicable to the quick construction of engineering maintenance such as various airport runways, concrete pavements of highways, bridges, culverts, tunnels and the like.

Owner:惠州市富力新技术有限公司

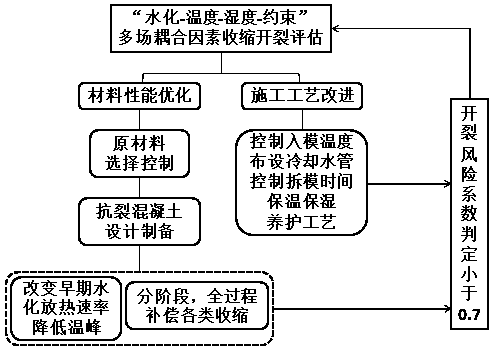

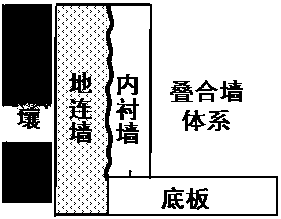

Underground station strong constraint superposed wall lining cast-in-place concrete structure crack control method

ActiveCN110424457AReduce concentrated stressReduce temperature stressArtificial islandsUnderwater structuresPeak valueRisk evaluation

The invention relates to an underground station strong constraint superposed wall lining cast-in-place concrete structure crack control method. The underground station strong constraint superposed wall lining cast-in-place concrete structure crack control method comprises the following steps: performing cracking risk evaluation on the key influence factors of superposed wall lining concrete and calculating the quantitative influence on the cracking risk coefficient by different factors; optimally designing lining C35P8 concrete mixed proportion and burying temperature and deformation sensors in parts with high cracking risk; soaking jointing surface concrete with clean water before pouring, performing high-temperature construction, controlling the concrete casting temperature to be less than 26 DEG C, increasing the temperature of a core part to the highest peak value after concrete pouring is completed, dismantling a template after the temperature is obviously reduced, sticking the surface and the top at once after dismantling the template and covering with heat-insulating and moisturizing maintaining cloth; and after maintaining, observing and counting the surface crack condition. By the method provided by the invention, the cracking risk of the superposed wall lining is reduced, the technical problem that the superposed wall lining is liable to crack is effectively controlled and prevented and construction quality is guaranteed.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD +2

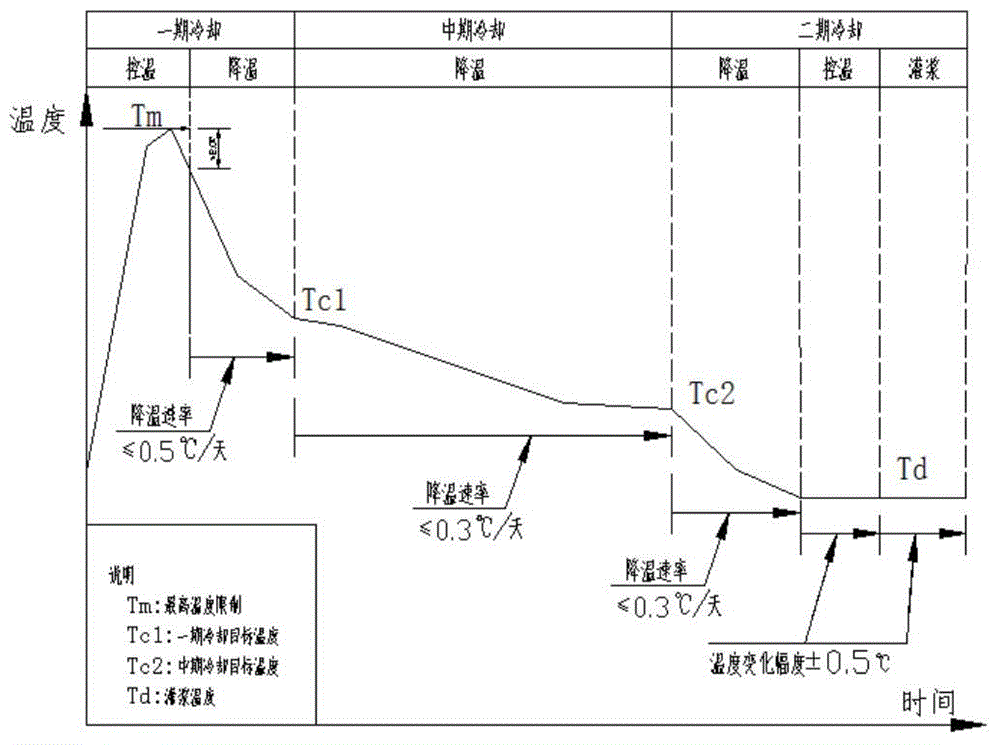

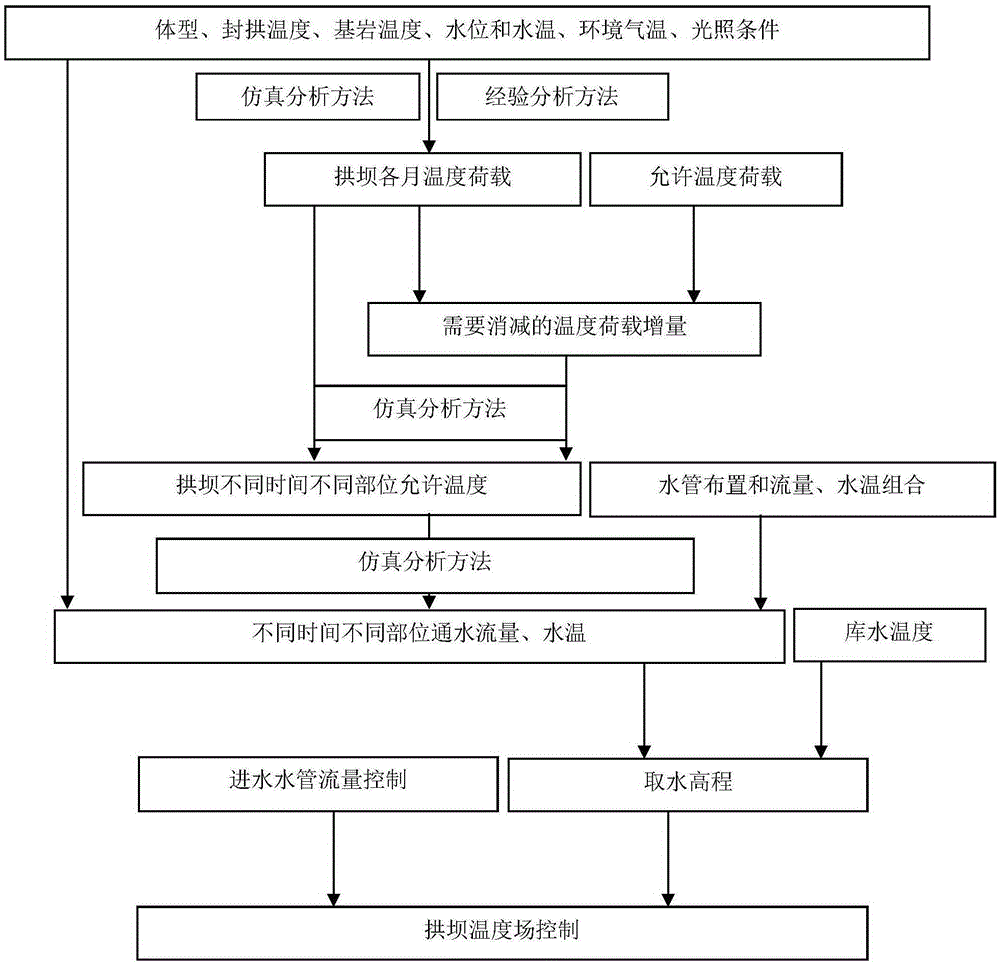

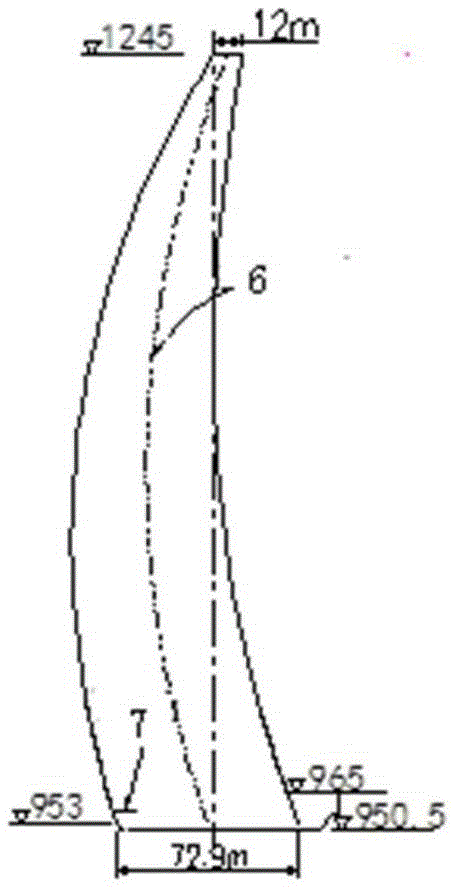

Intelligent adjusting method for temperature loads of arched concrete dam

InactiveCN105421281AReduce temperature stressImprove work performanceHydraulic engineering apparatusArch damsWater pipeEngineering

The invention discloses an intelligent adjusting method for temperature loads of an arched concrete dam. The method is characterized by comprising the following steps that the average temperature load of a dam body in every month is calculated; an allowed temperature load is determined, and temperature load increments, needing to be reduced, at different times and different portions are obtained; according to the allowed temperature load and the temperature load increments needing to be reduced, allowed temperatures at different times and different portions of the dam are inversely calculated; according to temperature values, needing to be reached through control, at different times and different portions and the temperature distribution condition of upstream reservoir water, by considering temperature control requirements during the operation period, the arrangement of cooling water pipes during the construction period is optimized, the cooling water pipes are reserved, and water passing temperatures and flows of the water pipes during the operation period are determined; a water fetching elevation range is determined; and water passes according to the determined water fetching elevation range, and temperature control is conducted by controlling the flows in the water pipes. According to the intelligent adjusting method, part of the cooling water pipes in the construction period are reserved, intelligent water passing is carried out during the operation period to control the temperature of the dam body, the temperature loads are reduced, and the working condition of the dam body is improved; safety stock is increased, and durability is improved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

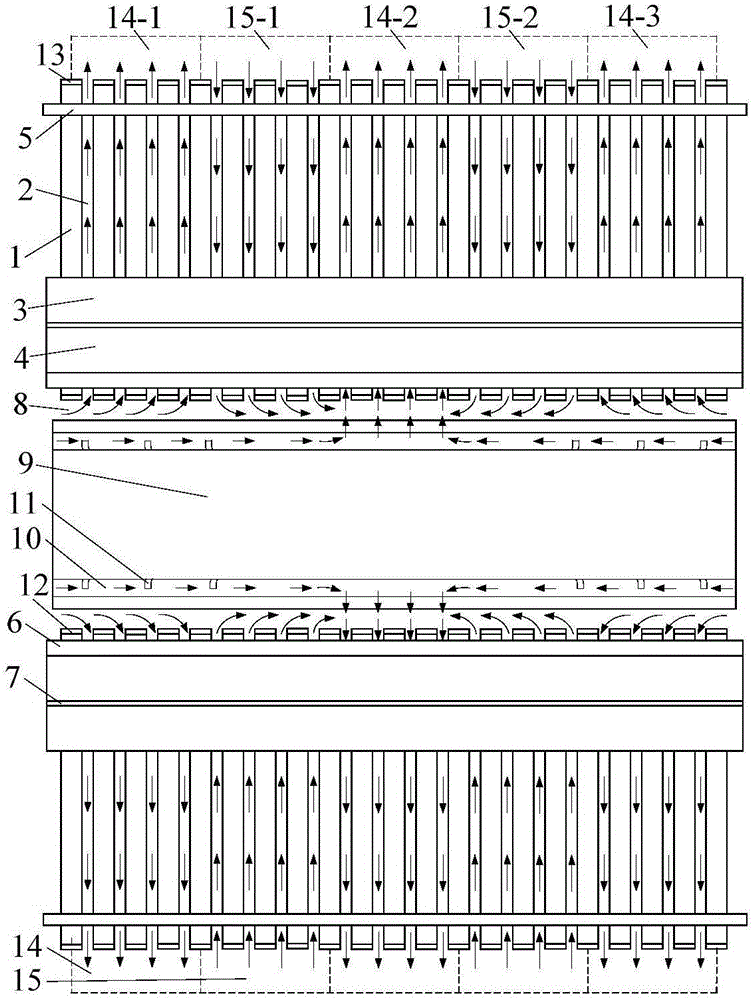

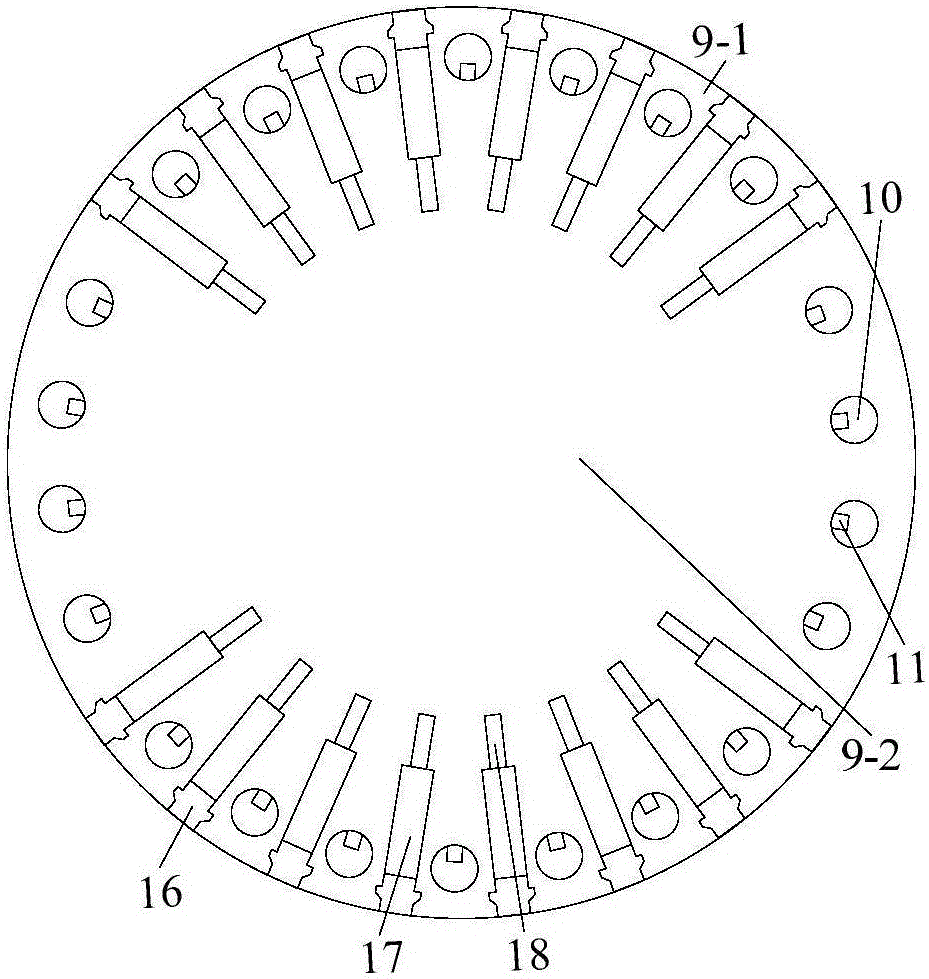

Turbonator cooling system provided with water cooling stator and inner fan type rotor

ActiveCN106026450AEfficient take awayReduce the temperatureMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringFan blade

The invention discloses a turbonator cooling system provided with a water cooling stator and an inner fan type rotor and relates to a field of motors. According to the invention, by adding an in-stator loop type water channel and an out-of-stator loop type water channel at a tooth top part and a yoke back part of an iron core segment of the stator respectively, arranging a rotor axial ventilating duct in rotor teeth and arranging rotor self-cooling fan blades in the rotor axial ventilating duct, the heat dissipation capability of a rotor area and a stator area is enhanced effectively, the utilization rate of cooling fluid in the turbonator is improved, the highest temperature of the stator area and the stator area are reduced substantially and the capability of safe and stable operation of the turbonator is improved.

Owner:HARBIN UNIV OF SCI & TECH

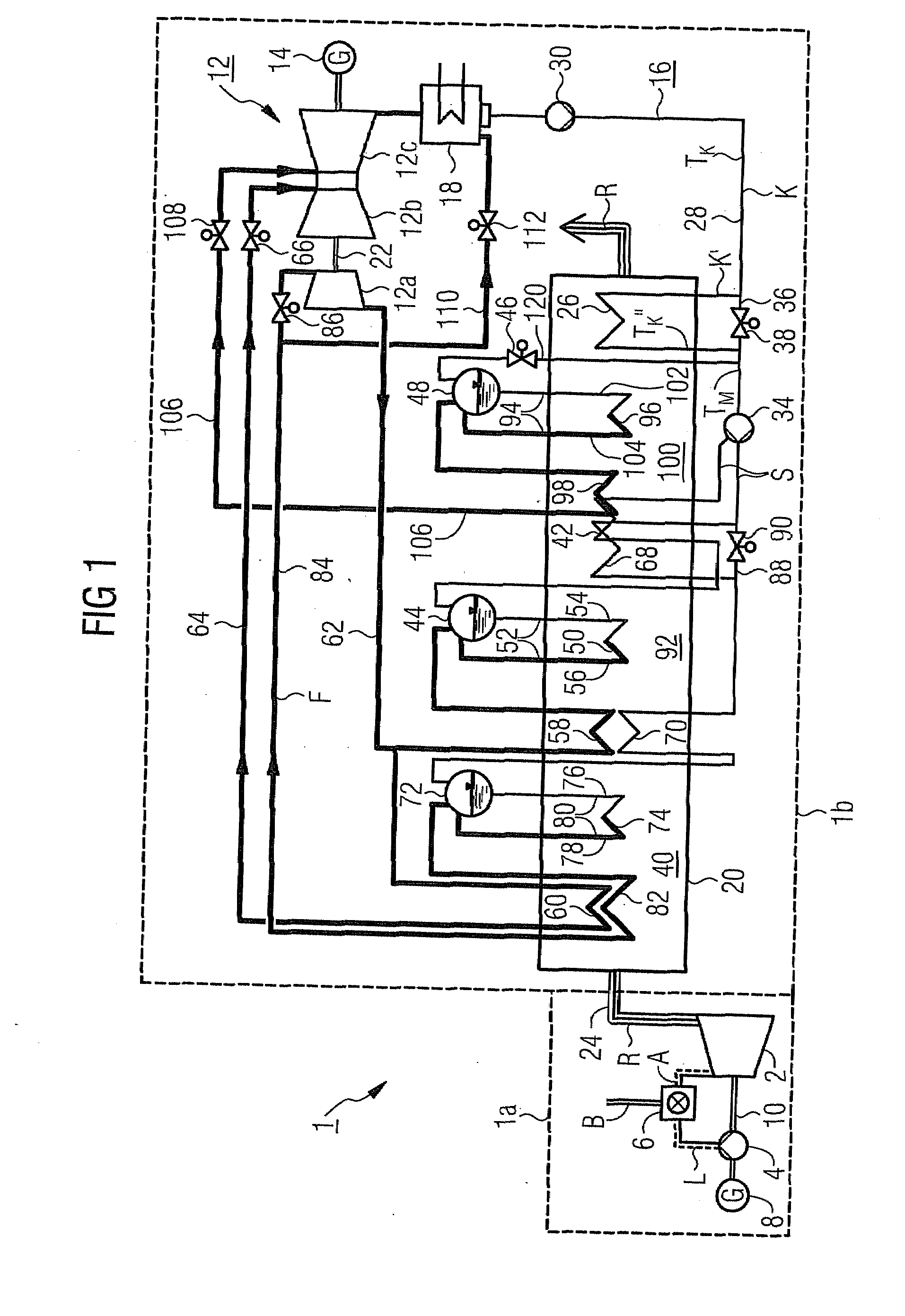

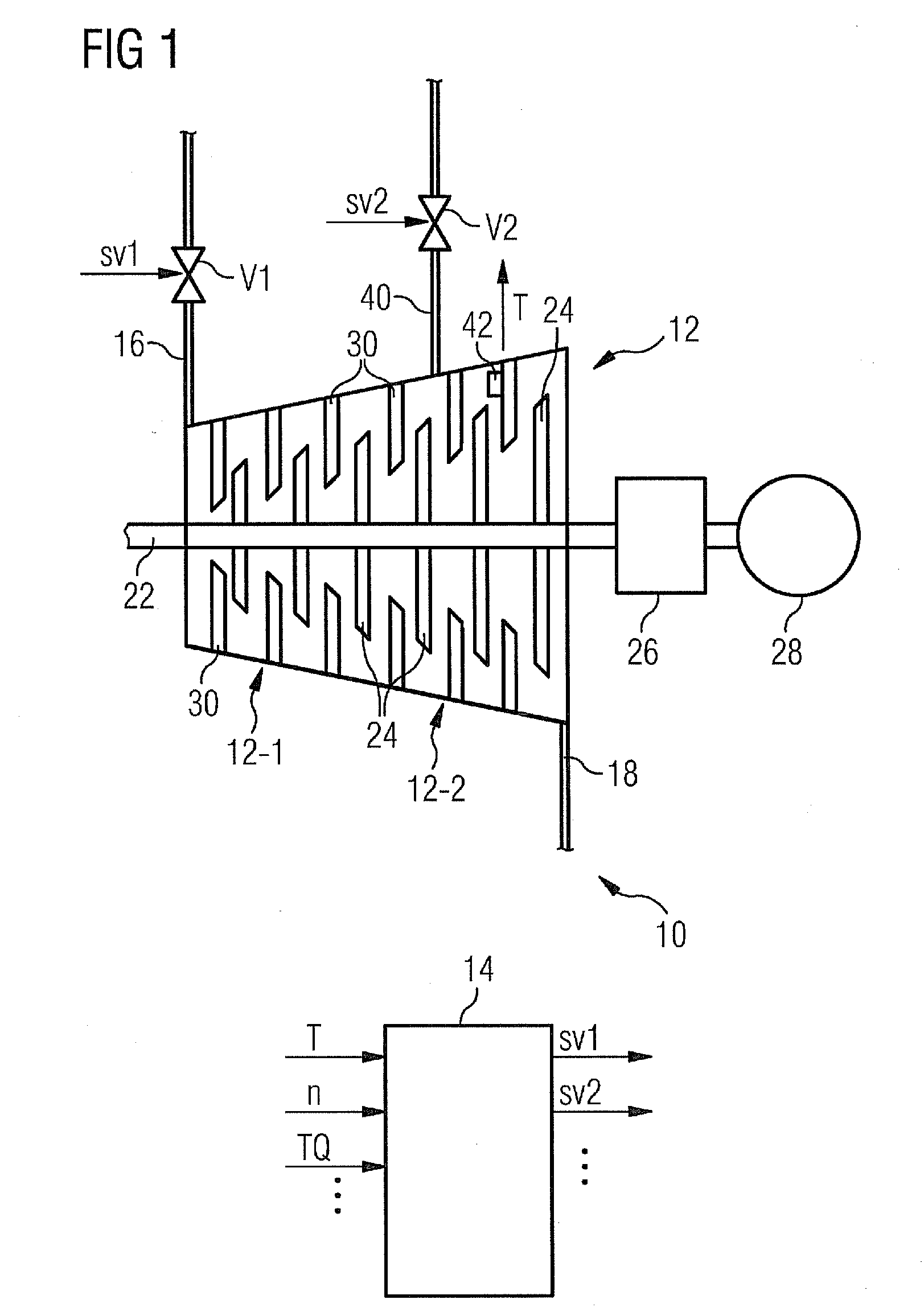

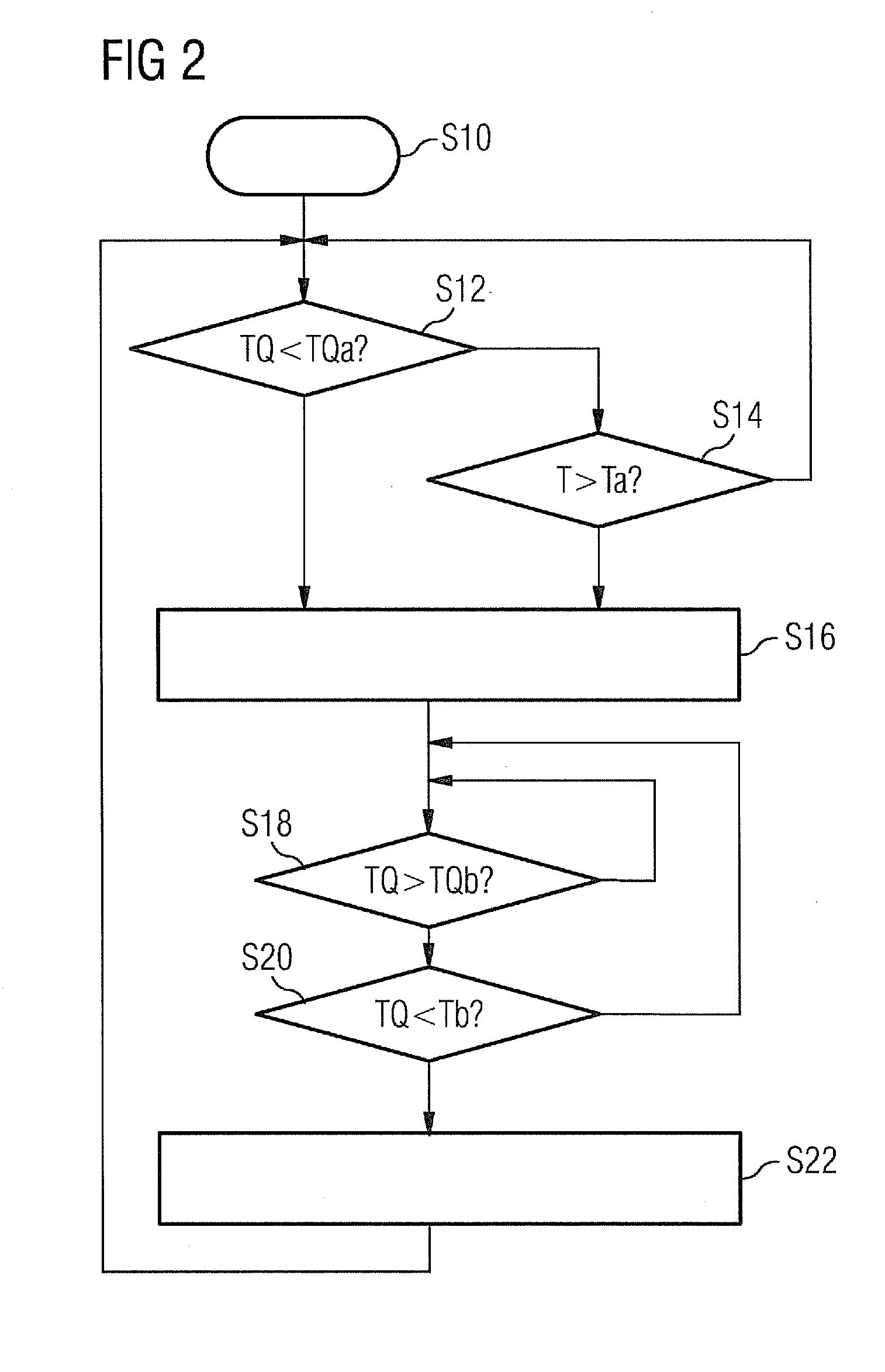

Steam turbine system and method for operating a steam turbine

ActiveUS20110185732A1Excess temperatureExcess ventilationEngine fuctionsEngine controlEngineeringHigh pressure

A steam turbine system including a steam turbine is provided. The steam turbine system includes a high-pressure side steam inlet device, a low-pressure side steam device, and a control device for controlling the steam turbine. An additional steam inlet device is also included arranged between the high-pressure side steam inlet device and the low-pressure side steam device. The control device control a supply of steam via the additional steam inlet device as a function of operating parameters detected at the steam turbine system.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

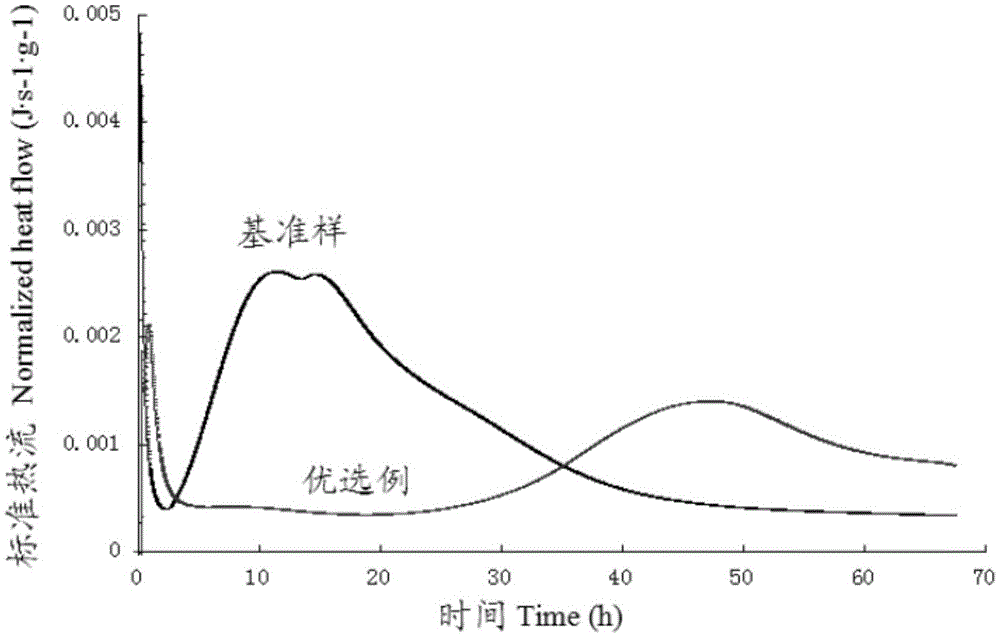

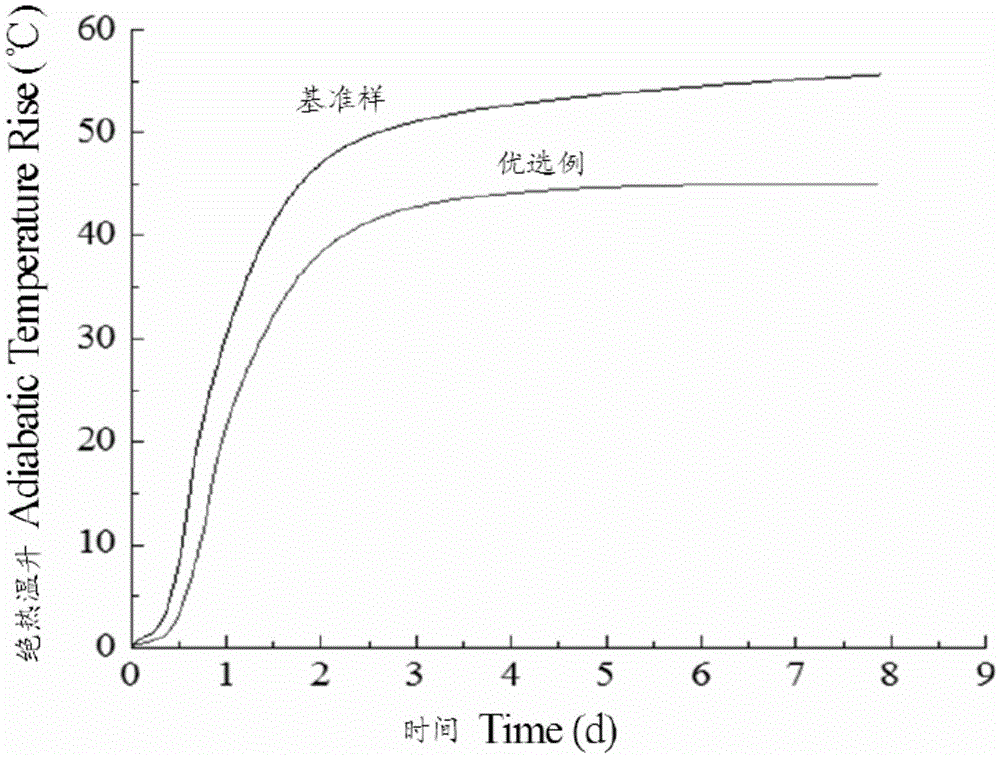

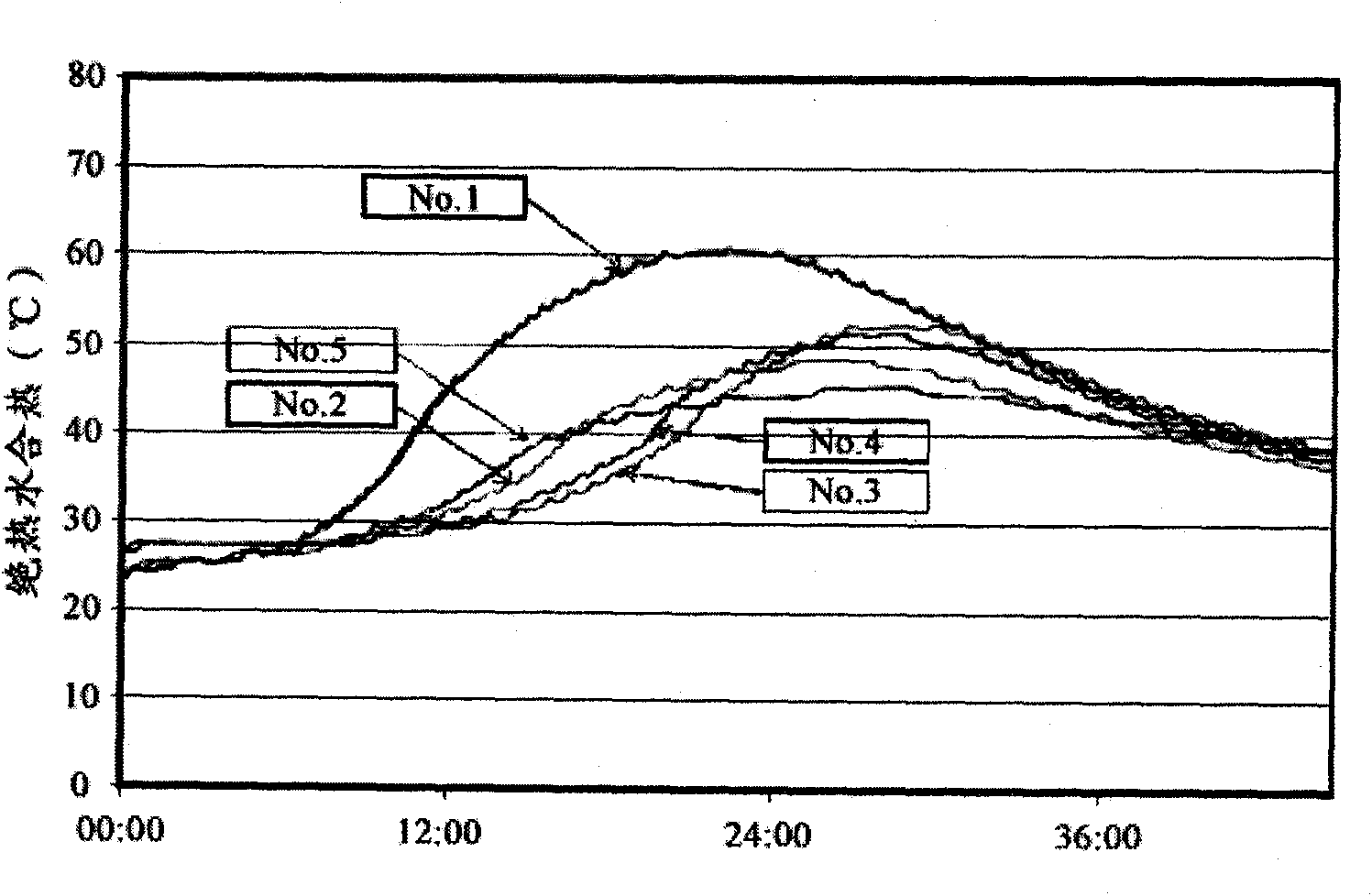

Ultralow-heat binder composition with high-temperature type latent-heat compound and method for lowering hydration heat of concrete by using same

The invention relates to an ultralow-heat binder composition with a high-temperature type latent-heat compound and a method for lowering the hydration heat of concrete by using the ultralow-heat binder composition with the high-temperature type latent-heat compound, wherein the ultralow-heat binder composition is prepared by mixing an inorganic latent-heat compound having the phase transition temperature of 60 DEG C or higher, with a concrete binder through a premixing method. The invention provides the ultralow-heat binder composition which is prepared by mixing a 0.5-10 wt% compound selected from strontium-based latent-heat compound [Sr(OH)2 8H2O], barium-based latent-heat compound [Ba(OH)2 8H2O], magnesium-based latent-heat compound [Mg(NO3)2 6H2O] and ferrum-based latent-heat compound [Fe(NO3)2 6H2O], with a 100wt% ternary binder through the premixing method, wherein the ternary binder consists of 20-70 wt% I type ordinary Portland cement (OPC), 20-60 wt% blast furnace slag (BFS) and 10-60 wt% fly ash (FA); and the invention further provides the method for controlling the hydration heat of the concrete.

Owner:特里波德株式会社 +1

Method for determining mass concrete cooling rate dynamic limit value

PendingCN112067794ARealize no crackingReduce cooling rateMaterial testing goodsThermometer applicationsSite monitoringMechanics

The invention discloses a method for determining a mass concrete cooling rate dynamic limit value. The method comprises the following determination steps: S1, obtaining external constraint stress anda relative deformation value of a concrete pouring body according to the thickness, the length and the age range of the concrete pouring body, and calculating the equivalent temperature of the relative deformation value; S2, according to the equivalent temperature of the external constraint stress and the relative deformation value, obtaining the comprehensive cooling difference increment of the concrete pouring body at different lengths and different ages S3, obtaining the cooling rates of different lengths and different ages by integrating the cooling difference increment and the ages; and S4, making a list of concrete cooling rate limit values at different lengths and different ages, and drawing a concrete cooling rate limit value curve graph. The concrete cooling rate standard can be formed, a visual chart is provided for on-site constructors, the constructors can take positive intervention measures conveniently, an on-site monitoring system is optimized, and intelligent development of construction engineering construction can be promoted.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +3

Ice and snow preventing device of steel track beam

InactiveCN104746393AGuarantee normal operationSimple constructionClimate change adaptationRailway tracksSteel platesSheet steel

The invention relates to the technical field of track traffic, and discloses an ice and snow preventing device of a steel track beam. The ice and snow preventing device comprises heat tracking belts and ice and snow preventing coatings, wherein the heat tracing belts are arranged on the top face of a beam body of the steel track beam, and the ice and snow preventing coatings are arranged on the two side faces of the beam body; the heat tracing belts are used for heating walking face steel plates of the beam body; and the snow preventing coatings are used for preventing ice and snow from being attached to guide face steel plates and stabilizing face steel plates of the beam body. The heat tracing belts are attached to the lower side of the walking face steel plate, and remaining portions of the heat tracking belts are wrapped by a heat insulation layer; and the heat insulation layer is used for reducing heat losses and preventing heat from being transmitted to the interior of the beam body. According to the device, whole-line ice and snow melting of the steel track beam can be rapidly carried out, large temperature stress cannot be generated, safety performance of the device is ensured, and the construction difficulty is simplified.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

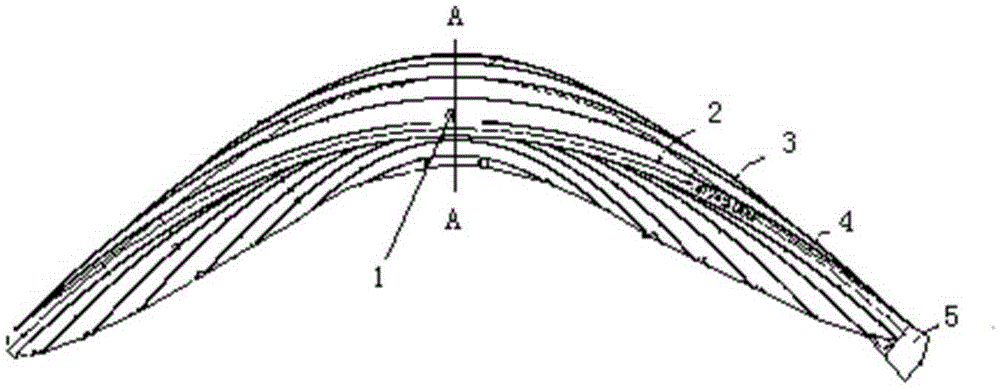

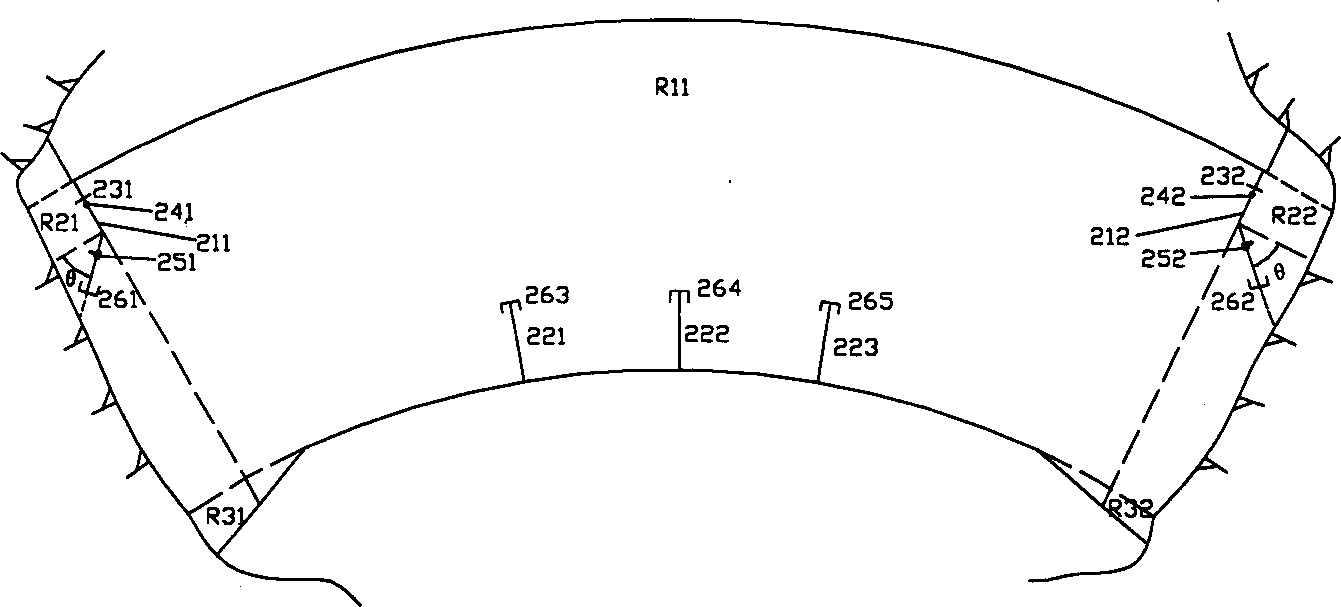

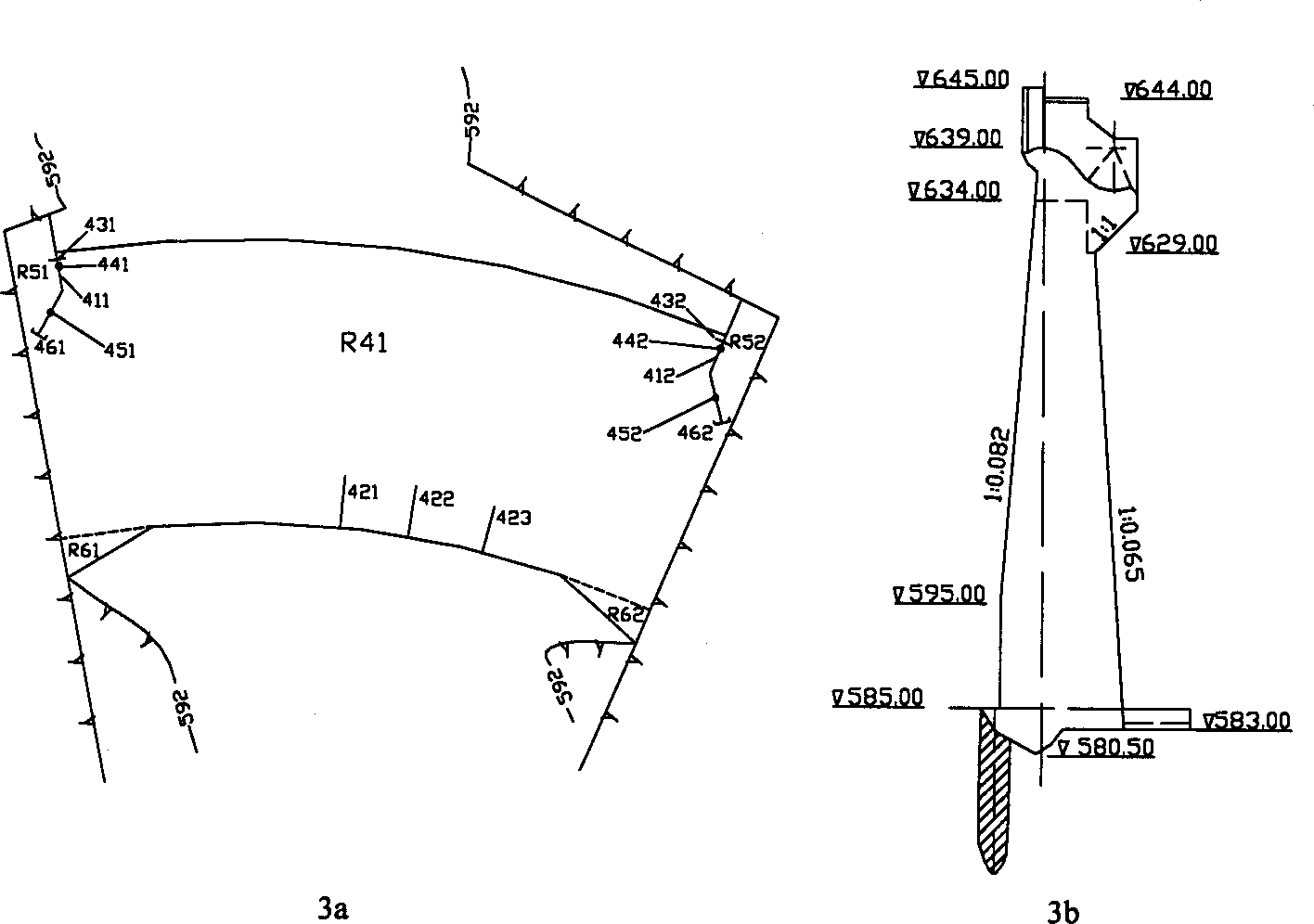

Artificial short-seam structure of rolled concrete arch dam

InactiveCN1336466ASpeed up pouring progressRealize water storageArch damsRoller-compacted concreteTemperature stress

Owner:TSINGHUA UNIV

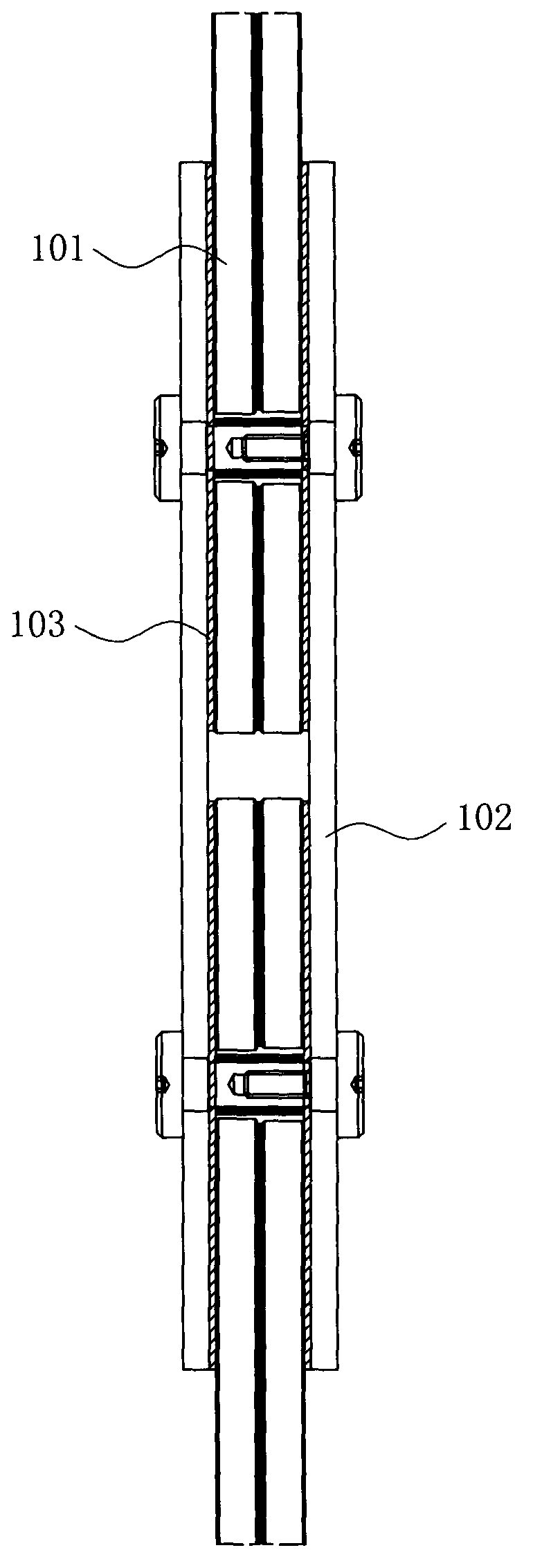

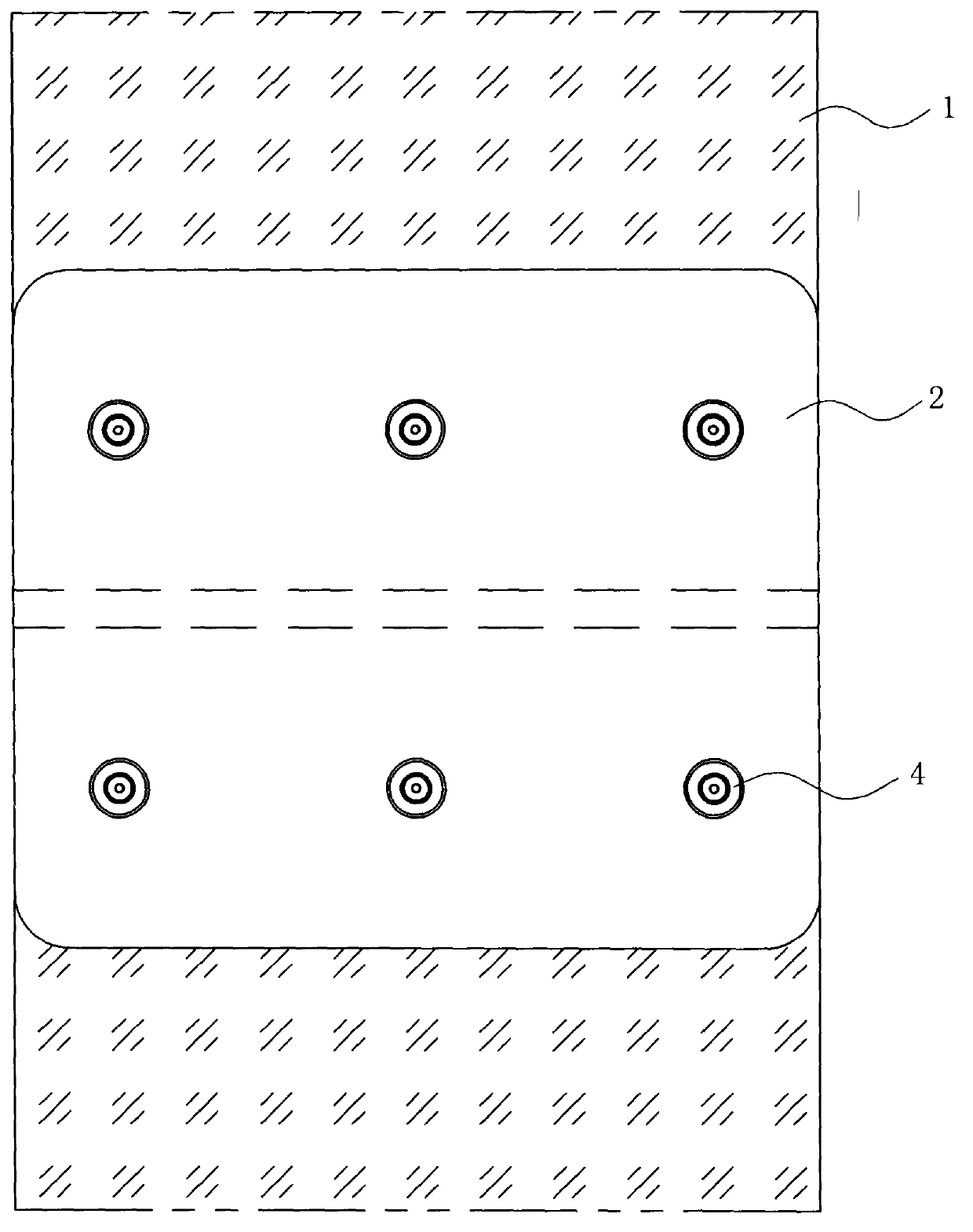

Glass rib splicing structure and construction method thereof

ActiveCN103132637AImprove stabilityReduce temperature stressWallsBuilding material handlingAdhesiveArchitectural engineering

The invention discloses a glass rib splicing structure. The glass rib splicing structure comprises outer connecting plates covered on two sides of spliced ends of adjacent glass ribs, a viscose layer and bolt pins, wherein the viscose layer is positioned between the connecting plates on two sides and a middle glass rib, and the bolt pins penetrate through the glass ribs and the outer connecting plates on two sides. The glass rib splicing structure is characterized in inner steel plates are respectively arranged between the viscose layer and the outer connecting plates and on two sides of a spliced end of every glass rib. A method for the glass rib splicing structure comprises a first step of drilling connecting holes at the spliced end of every glass rib; a second step of respectively arranging bolting holes on the small inner steel plates and the outer connecting plates corresponding to every connecting hole; a third step of adhering the inner steel plates to two sides of the spliced end of every glass rib respectively through adhesive; and a fourth step of respectively enabling the outer connecting plates to be covered on two sides of two adjacent glass ribs with the inner steel plates, and fixing the outer connecting plates by enabling the bolt pins to penetrate through the outer connecting plates, the bolting holes on the inner steel plates and the connecting holes on the glass ribs. By arranging the inner steel plates, splicing firmness of the glass ribs is improved, future maintenance is facilitated, and using cost is reduced.

Owner:苏州苏明装饰股份有限公司

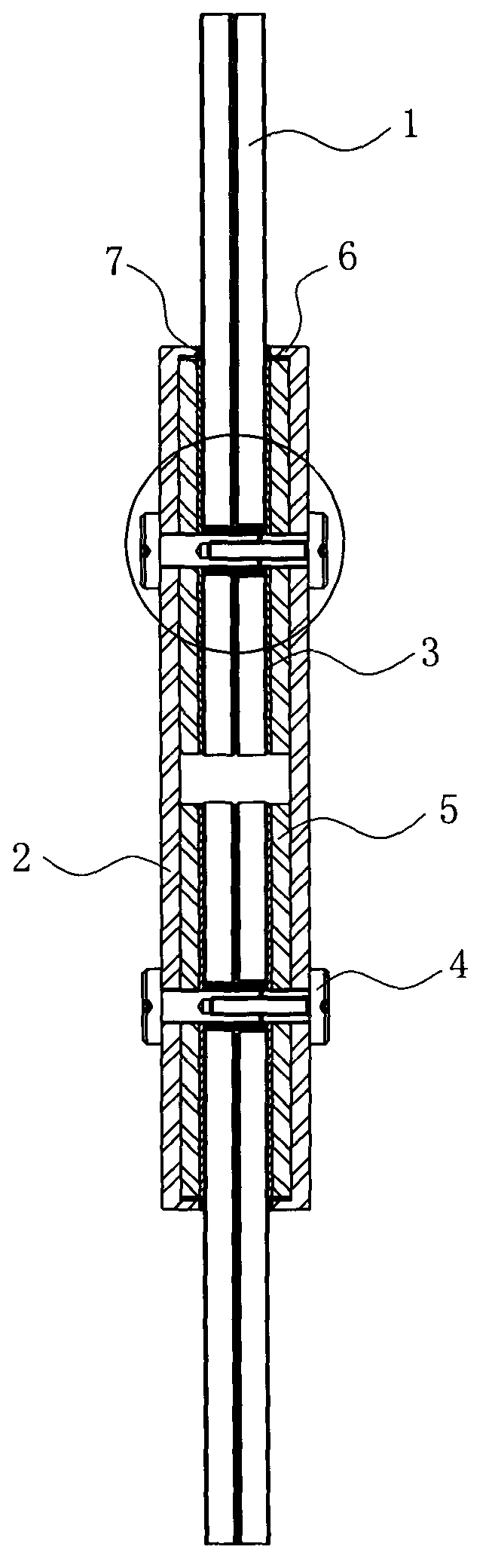

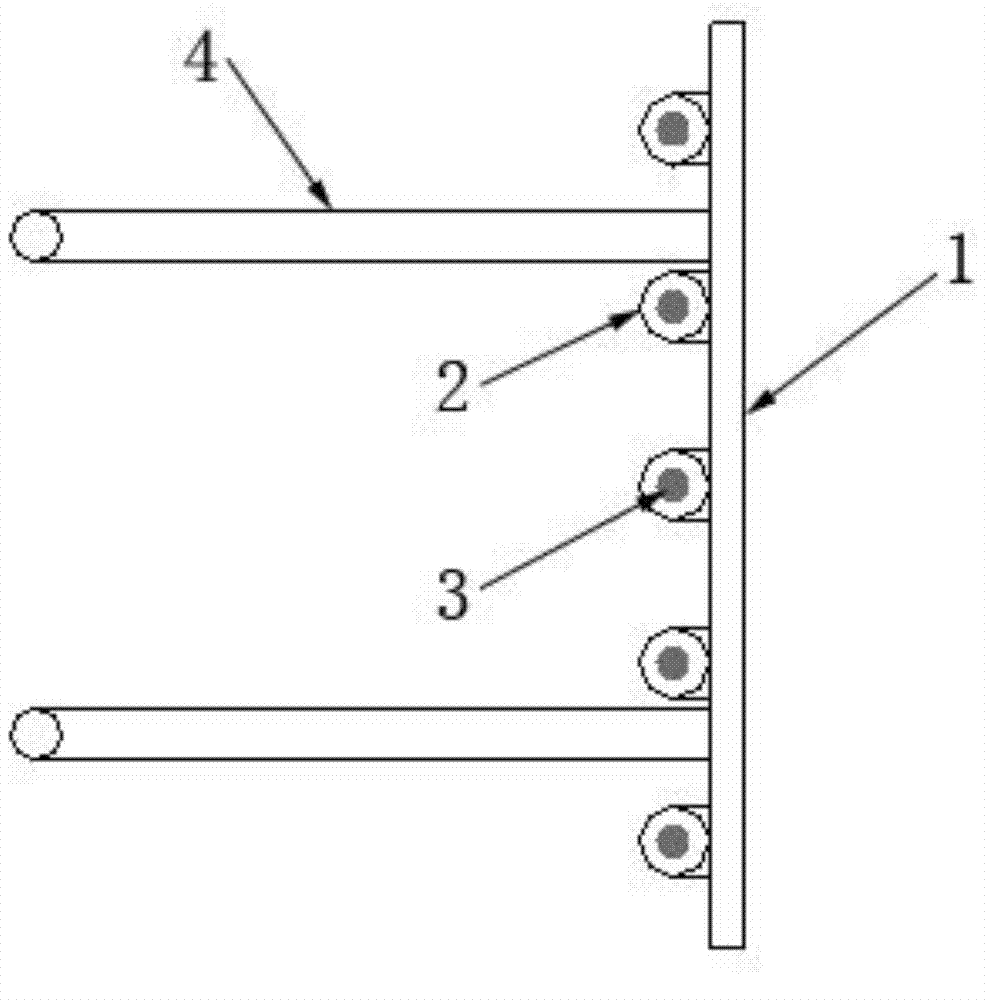

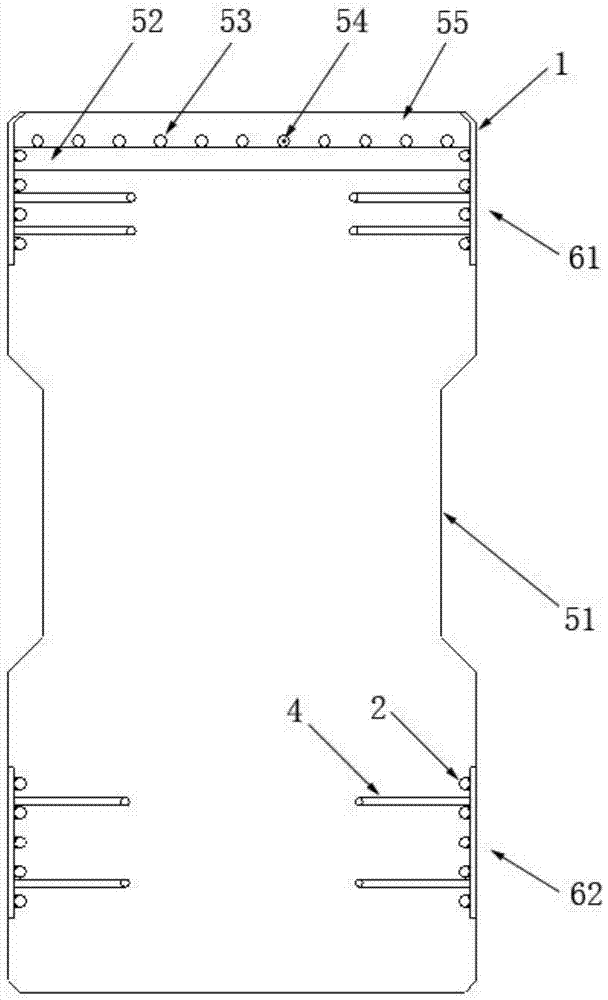

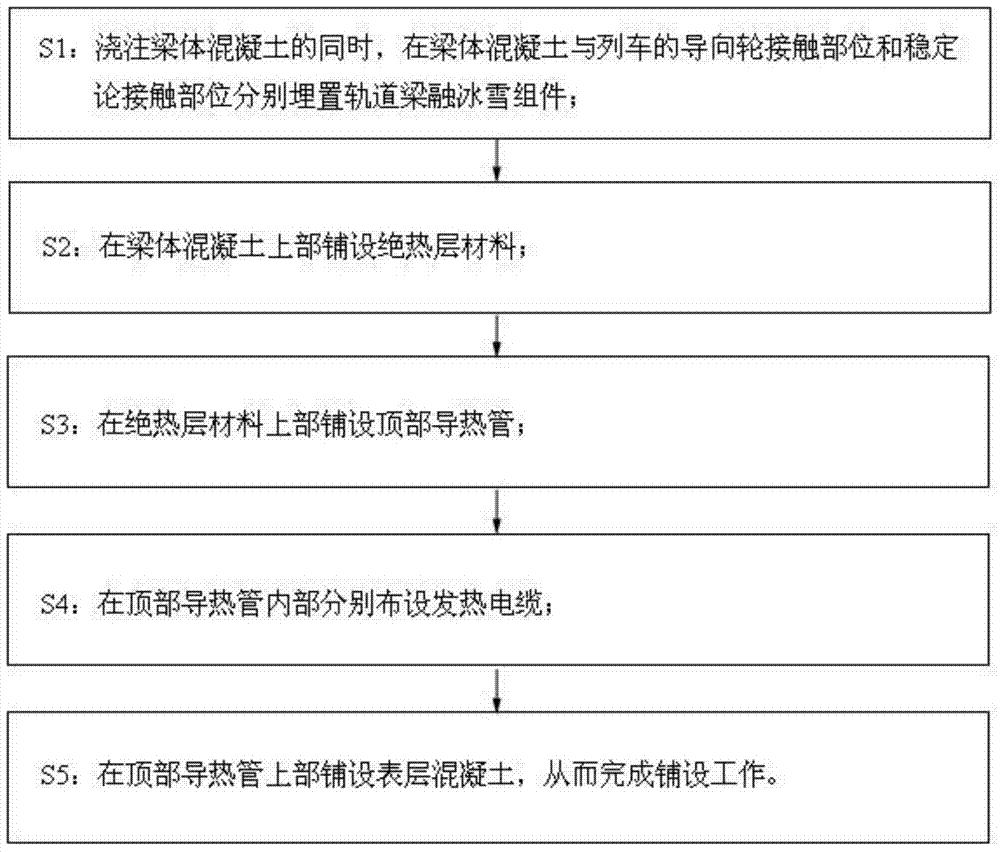

Rail beam ice and snow melting assembly, PC rail beam and laying method of PC rail beam

ActiveCN104711906AAdjustable temperatureHeating fastClimate change adaptationRailway tracksSurface layerSnow melting

The invention discloses a PC rail beam which comprises a rail beam ice and snow melting assembly. The rail beam ice and snow melting assembly comprises a surface layer heat conduction plate, heat conduction pipes which are located at the bottom of the surface layer heat conduction plate and fixedly connected with the surface layer heat conduction plate, heating cables laid in the heat conduction pipes, and a plurality of anchor bars which are fixedly arranged at the bottom of the surface layer heat conduction plate and used for fixedly connecting the surface layer heat conduction plate and beam body concrete. By means of the rail beam ice and snow melting assembly, ice and snow which freeze on the PC rail beam can be rapidly and efficiently processed, and therefore the normal running of trains can be ensured, and obvious social and economical benefits are achieved. In addition, the invention further discloses the rail beam ice and snow melting assembly forming the PC rail beam and a laying method of the PC rail beam.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

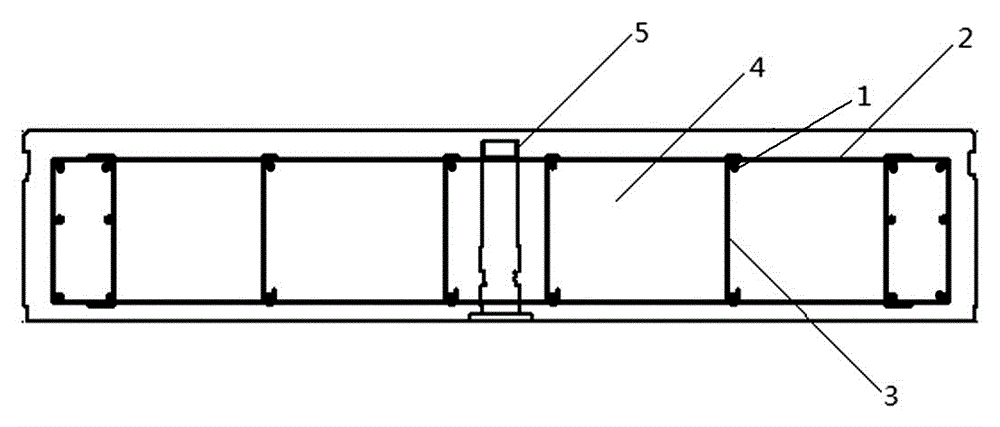

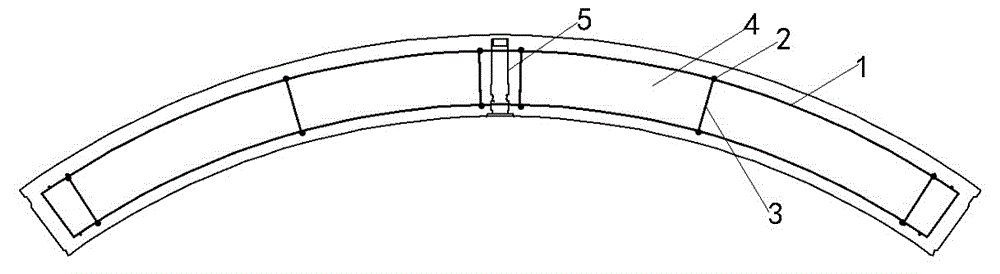

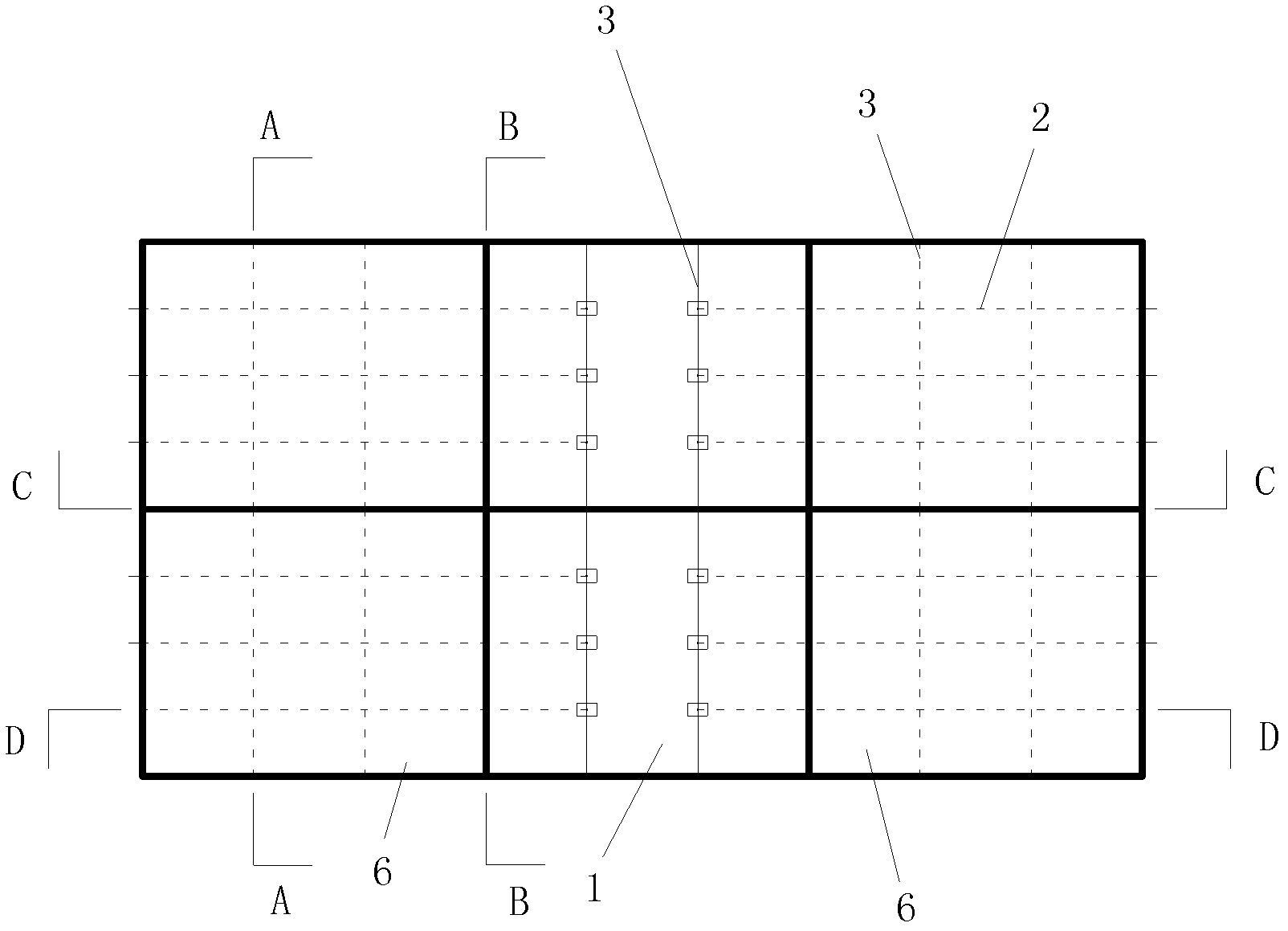

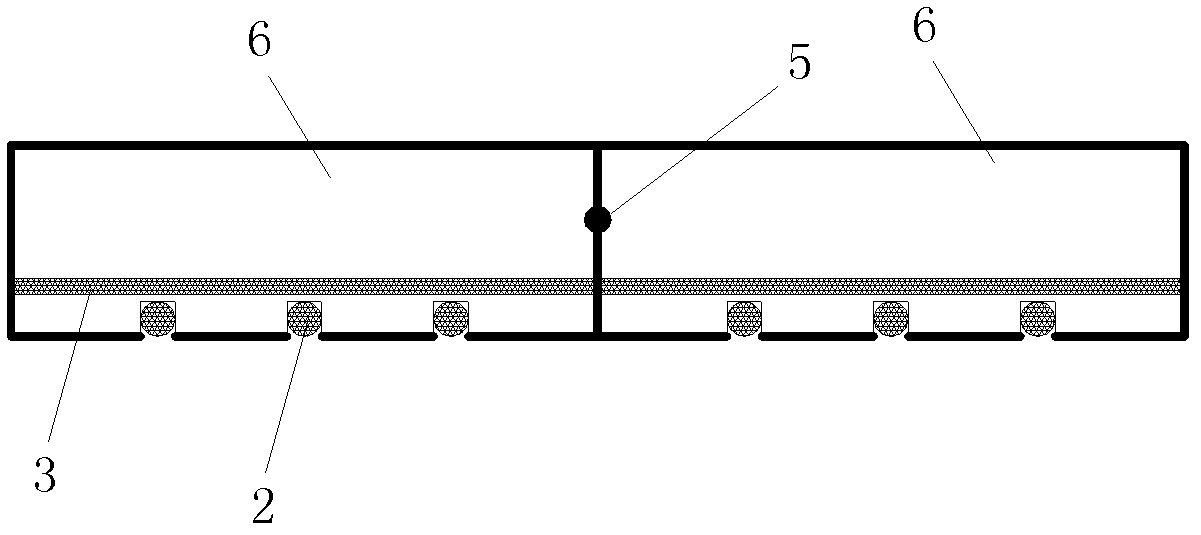

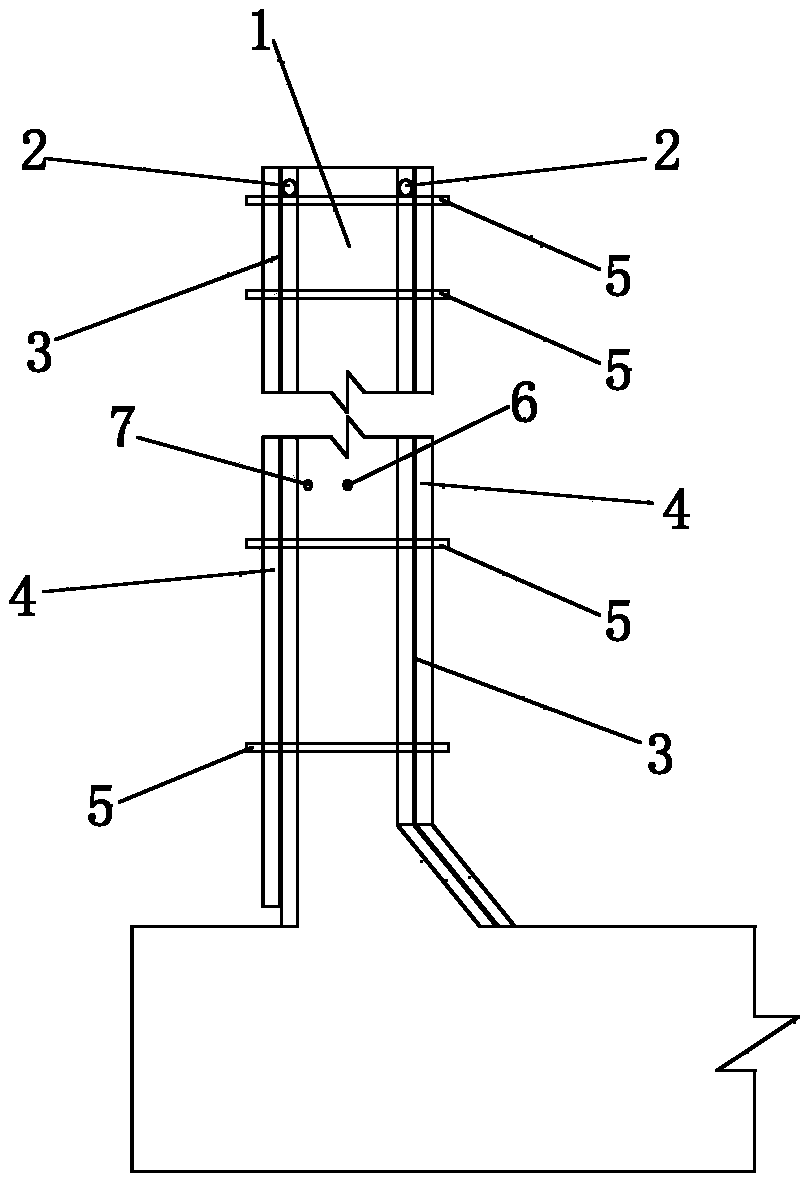

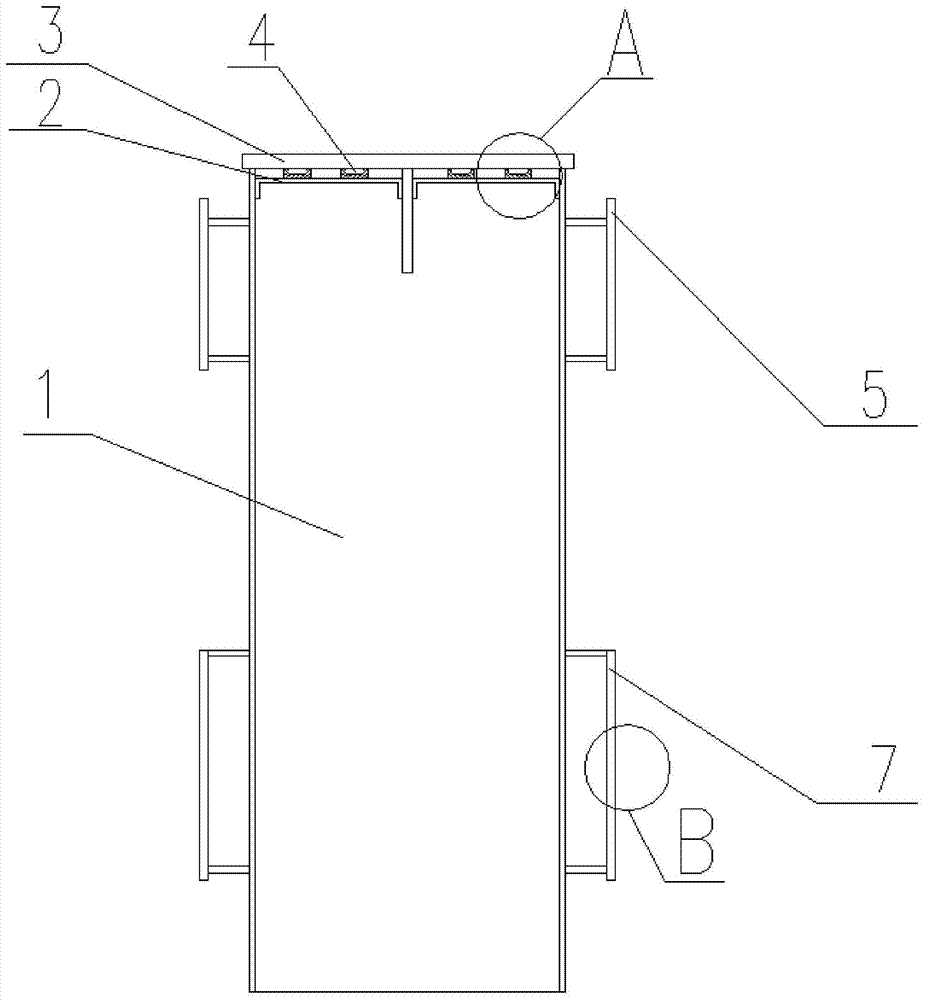

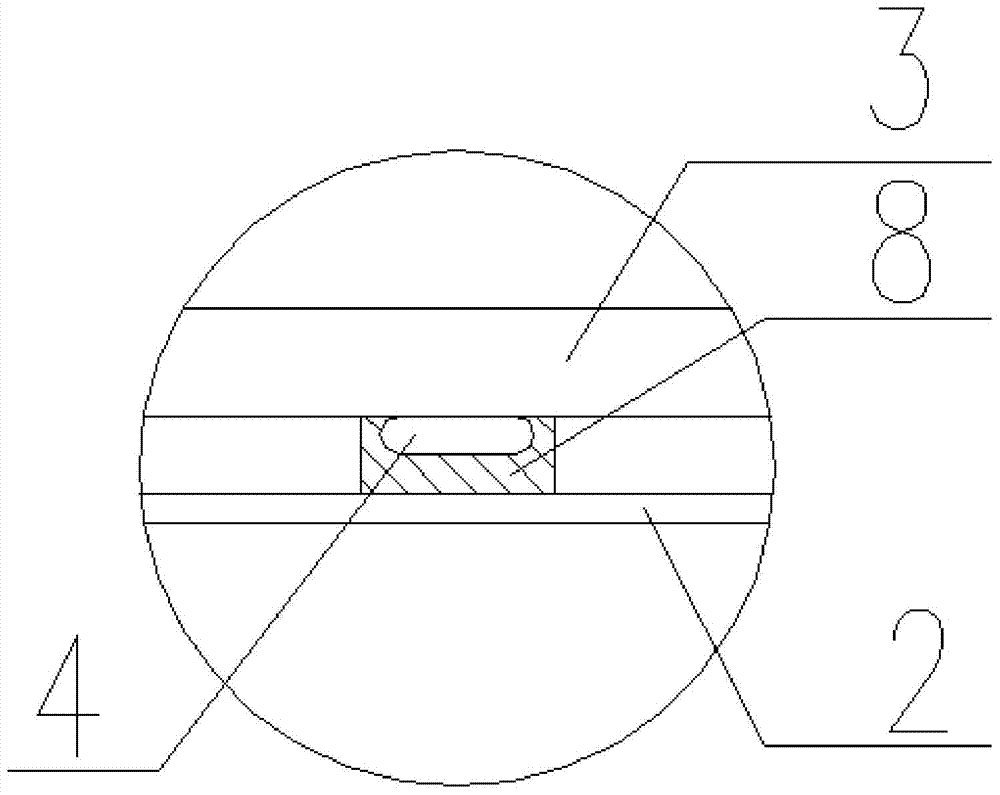

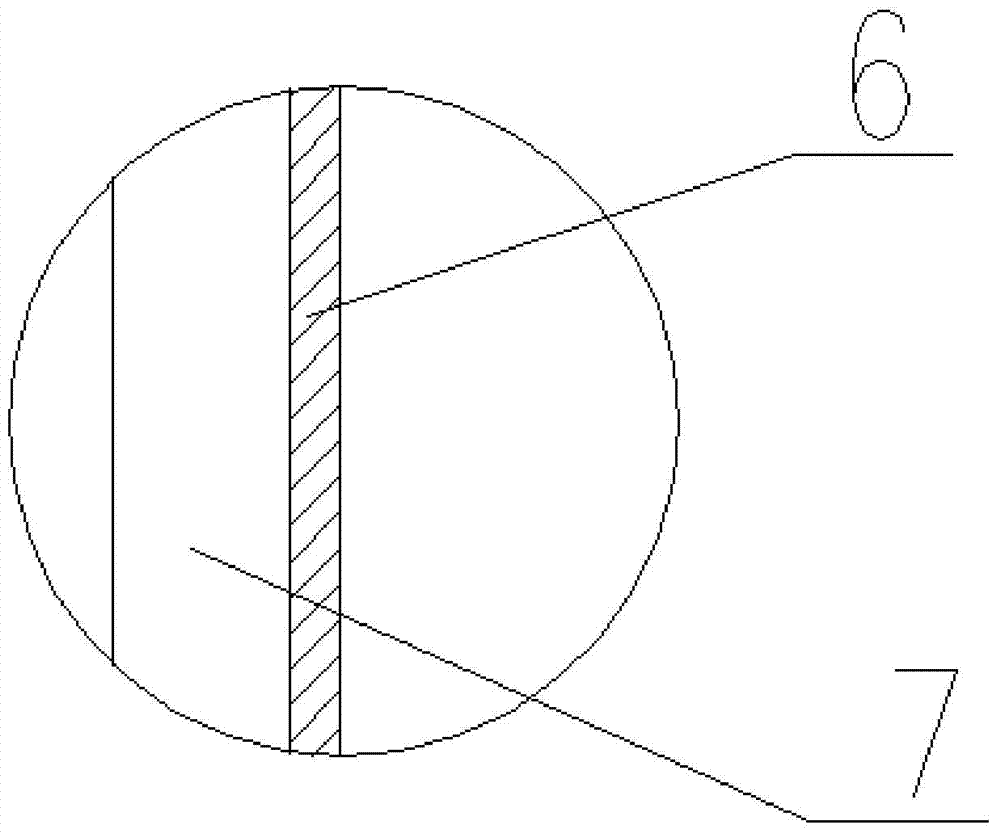

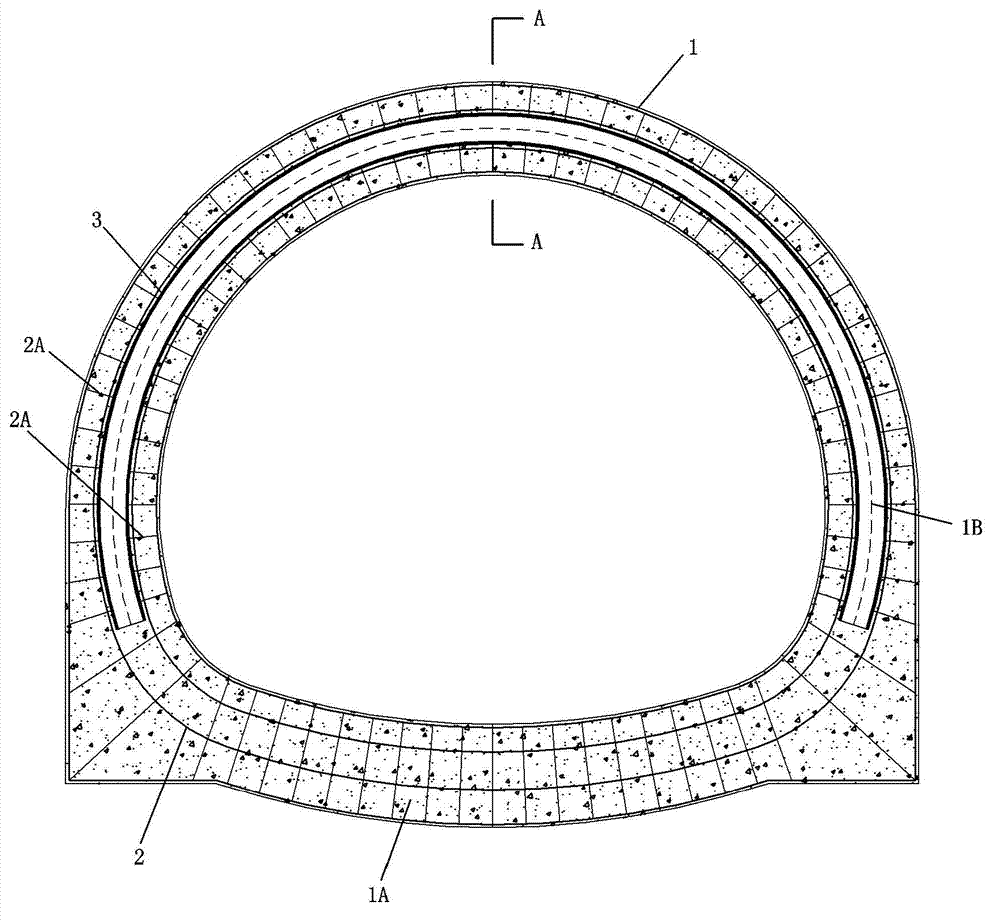

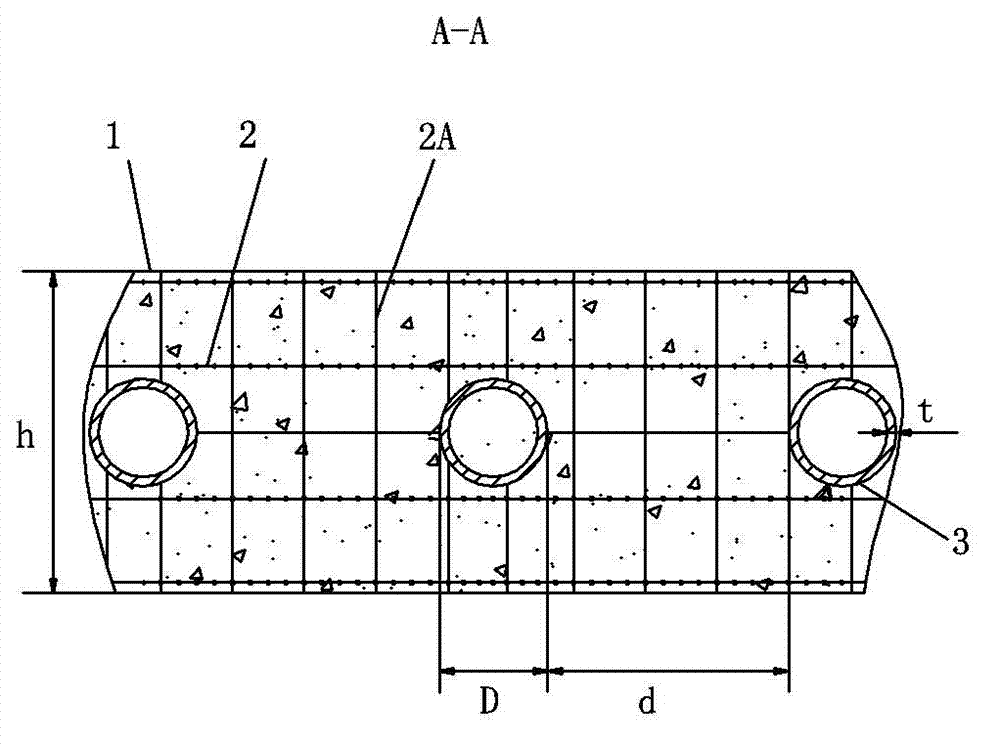

Construction method of annually-perforated long-span mass concrete tunnel lining structure

ActiveCN103046935AImprove thermal conductivityFast temperature transfer rateUnderground chambersTunnel liningShear capacityRebar

The invention discloses a construction method of an annually-perforated long-span mass concrete tunnel lining structure. The method includes: a, erecting a formwork and binding lining steel bars (2) at a construction position of a lining (1); b, welding arc-shaped steel pipes (3) on erection bars (2A) in the lining steel bars (2), wherein the central axis of each arc-shaped steel pipe (3) is coincident with an annular axis (1B) of the lining (1) above an inverted arch (1A), and the arc-shaped steel pipes (3) are distributed longitudinally along a tunnel at an equal interval; and c, pouring concrete. The long-span mass concrete tunnel lining structure construction by the method is high in shear capacity and flexural capacity, high in safety and reliability, simple to construct and easy to popularize.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com