Cement concrete admixture for quickly repairing cement concrete roads

A cement concrete and admixture technology, applied in the field of chemical building materials, can solve the problems of high price and few applications, and achieve the effects of enhancing the anti-cracking ability, improving the impermeability level and reducing the temperature stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

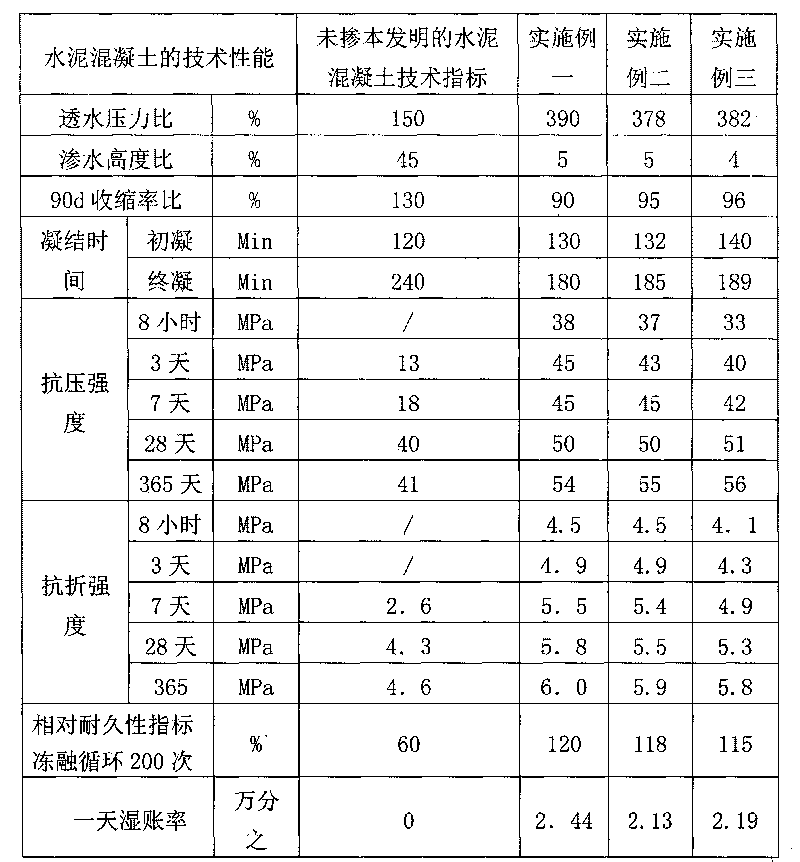

Examples

Embodiment 1

[0029] Weigh each component according to the following weight percentages: 60% of fly ash, 5% of bentonite, 7% of silicon powder, 15% of sodium sulfate, 8% of polycarboxylate water reducer, 3% of citric acid, sodium nitrite 2%, weighed and mixed according to the proportion of the above components and then ground until the specific surface area is greater than 500m 2 / kg.

Embodiment 2

[0031] Weigh each component according to the following weight percentages: 70% of fly ash, 8% of silica fume, 15% of sodium sulfate, 8% of polycarboxylate water reducing agent, 2% of citric acid, 2% of sodium nitrite, according to The proportions of the above components are weighed, mixed and ground until the specific surface area is greater than 500m 2 / kg.

Embodiment 3

[0033] Weigh each component according to the following weight percentage: 80% fly ash, 15% sodium sulfate, 3% polycarboxylate water reducer, 2% citric acid, weigh and mix according to the proportion of the above components and then grind To specific surface area greater than 500m 2 / kg.

[0034] The incorporation of sodium nitrite rust inhibitor can promote the formation of a dense protective film on the surface of the steel bar to prevent the corrosion of the steel bar inside the concrete. It is especially suitable for reinforced concrete. It is of little significance to add a rust inhibitor to the concrete that is not in direct contact with the steel bar; Coagulant is used to regulate concrete setting time, and citric acid of the present invention is retarder, can prolong concrete setting and hardening time appropriately, and early strength agent in the present invention also has the effect of accelerating coagulation in fact, can shorten concrete setting time, and reduce I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com