Patents

Literature

46results about How to "High impermeability level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarboxylic acid series concrete composite water-proof agent and its preparing method

InactiveCN101024566APenetration height ratio is smallReduce autogenous shrinkageAcid waterUltimate tensile strength

The invention relates to a manufacture method for polyocarboxy acid series concrete compound water proof agent that includes polyocarboxy acid water reducing agent 20-80 portions, multihydroxyl carboxyl compounds 1-10 portions, air entraining agent 0.1-1.0 portions. The advantages of the invention are that: it decreases self contraction and dry contraction inner concrete, increasing degree of compaction, decreasing concrete capillary fissure, achieving the ability of water proof and anti-leaking function; the anti-leaking grade is over the other water proof agent; it has slushing pumping, water poof, and constration anticracking function; and has high quality and low price.

Owner:郭震

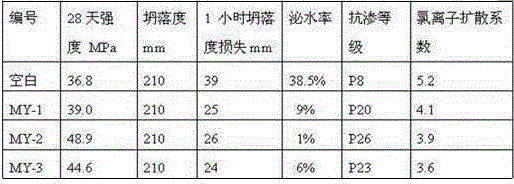

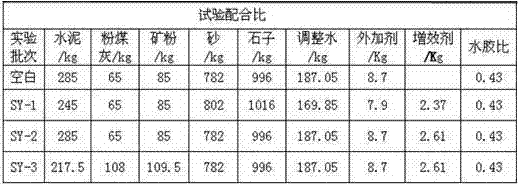

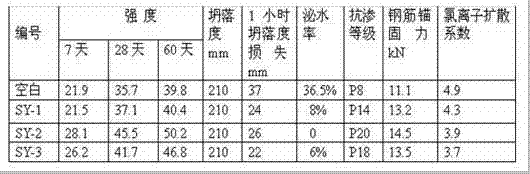

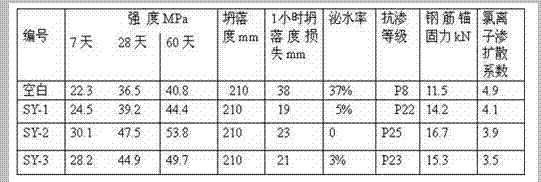

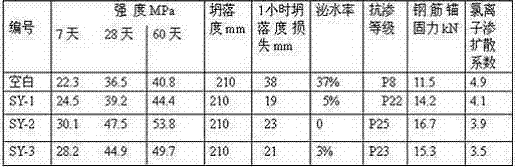

Chloridion-corrosion resistant concrete synergist and production technology thereof

The invention discloses a chloridion-corrosion resistant concrete synergist. The component percentage is anti-bleeding component : anti-permeability waterproof component : enhancing component : dispersing component : entraining component : coordinating component; the anti-bleeding component comprises polysaccharide and / or cellulose ether and / or polyacrylamide, the anti-permeability waterproof component comprises methyl sodium silicate and / or organosilicon waterproofing agent, the enhancing component comprises glycol monoisopropanolamine, composition of the glycol monoisopropanolamine and triethanolamine and triisopropanol, the dispersing component comprises MF and / or TCL and / or NNO, the entraining component comprises dodecyl benzene acid sodium and / or dodecyl benzene sodium sulfate, and the coordinating component comprises polymeric alcohol amine and polymeric polyhydric alcohol. The invention further provides a production technology for the chloridion-corrosion resistant concrete synergist. The chloridion-corrosion resistant concrete synergist is capable of improving the concrete strength, reducing the bleeding rate and reducing the slump loss.

Owner:株洲市中建新材料有限公司

Green rapid-hardening early-strength magnesium phosphate-based healant and preparation method thereof

ActiveCN104909709AImprove compactnessHigh impermeability levelSolid waste managementSilica fumeMagnesium orthophosphate

The invention discloses a green rapid-hardening early-strength magnesium phosphate-based healant and a preparation method thereof. The green rapid-hardening early-strength magnesium phosphate-based healant is composed of a material A and a material B; the material A is prepared via mixing of a phosphate, borax, a toughening ingredient, an accelerating component, a water retention ingredient, a water reducing ingredient, and a grinding aid dispersing agent; and the B material is prepared via mixing of magnesium oxide, flyash, silica fume, ground steel slag, chromium iron tailing slag powder, anhydrite, an expanding agent, and a grinding aid dispersing agent. According to the preparation method, industrial supplementary cementious materials (flyash, silica fume, and ground steel slag) are added into cement, so that cement fluidity and early strength are improved; industrial chromium iron tailing slag powder is added into the green rapid-hardening early-strength magnesium phosphate-based healant as a filling material, so that it is beneficial for cement hydration reaction, set cement compaction rate is increased, and at the same time heavy metal waste solidification is realized. The green rapid-hardening early-strength magnesium phosphate-based healant is capable of achieving balance between magnesium phosphate cement setting time and high early strength, and solving problems that shrinking percentage is large and bonding strength is low.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Preparation method of environment-friendly dry powder pointing agent

InactiveCN101774793AImprove adhesionIncreased durabilitySolid waste managementBrickResource utilization

The invention relates to a preparation method of an environment-friendly dry powder pointing agent taking slag powder as main raw materials, belonging to the technical field of building material preparation processes. The environment-friendly dry powder pointing agent comprises the raw materials in percentage by weight: 55-75 percent of slag powder, 2-10 percent of cement, 10-30 percent of calcite powder, 2-5 percent of re-dispersible emulsoid powder and 0.05-0.3 percent of thickening agent. The environment-friendly dry powder pointing agent has good caking property, good durability and high antiseepage grade, is not in contact with a tapestry brick, generates no cracks, and can effectively inhibit saltpetering. The invention widens a new approach for the resource utilization of the slag powder and has better social efficiency and economic benefit.

Owner:SHANGHAI UNIV +2

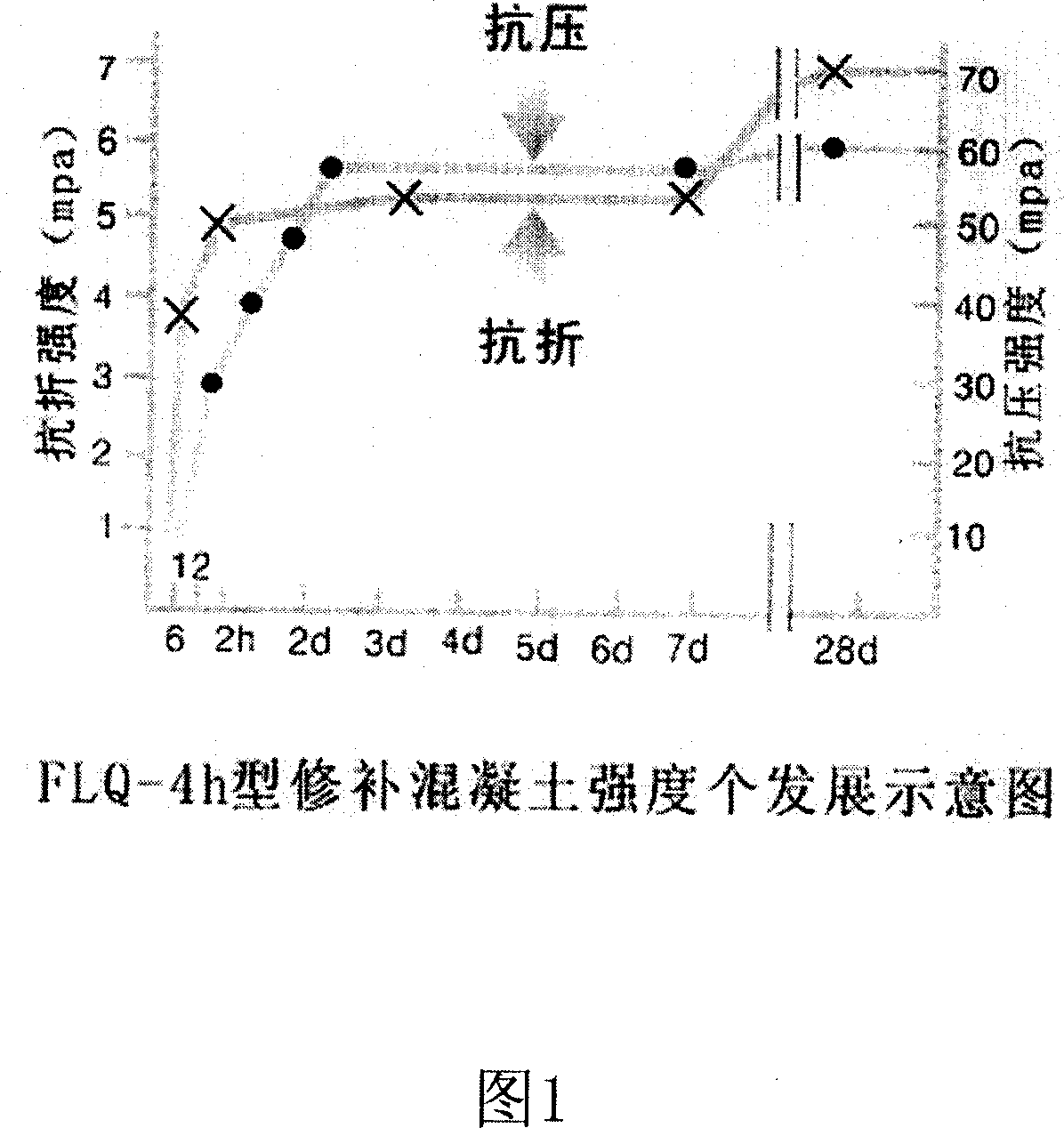

Cement concrete admixture for quickly repairing cement concrete roads

InactiveCN101708969ARapid early strength developmentReduce maintenance traffic timeRoad surfaceMaterials science

The invention belongs to the technical field of cement concrete admixtures. A cement concrete admixture for quickly repairing cement concrete roads consists of the following components in percentage by weight: 70 to 90 percent of inorganic basis material, 10 to 30 percent of early strength admixture, 5 to 20 percent of water reducing agent, 0 to 20 percent of cement-coagulation agent and 0 to 5 percent of rust inhibitor. The admixture can ensure that the traffic opening time of the maintenance of cement concrete pavements is shortened to 8 hours, has the characteristics of high early strength, no shrinkage at later stages, adjustable hardening and setting time, wide applicable temperature range, low mixing amount and the like, and is mainly applicable to the quick construction of engineering maintenance such as various airport runways, concrete pavements of highways, bridges, culverts, tunnels and the like.

Owner:惠州市富力新技术有限公司

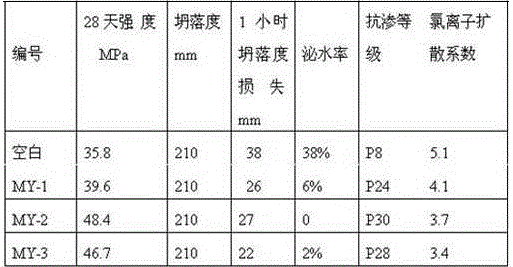

Novel concrete synergist and preparation process thereof

The invention discloses a novel concrete synergist. The percent of the components of the novel concrete synergist is 60% to 80% of anti-bleeding component, 5% to 15% of enhancement component, 2% to 20% of densification component, 0.5% to 10% of dispersion component, 0.2% to 2% of entraining component and 1% to 8% of compounding component; the anti-bleeding component contains polysaccharides and / or cellulose ether and / or polyacrylamide; the enhancement component contains ethylene glycol isopropanolamine and composition of the ethylene glycol isopropanolamine, triethanolamine and triisopropanolamine; the densification component contains nano silicon dioxide and / or colloid silicon dioxide monomers; the dispersion component contains MF and / or TCL and / or NNO; the entraining component contains sodium dodecyl benzene sulfonate and / or sodium lauryl sulfate; the compounding component is polymeric alcohol amine and / or polymer polyol, respectively. The invention further provides a preparation process of the novel concrete synergist. The novel concrete synergist and the preparation process have the flowing technical effects that 1, the strength of concrete can be enhanced; 2, the usage of cement is reduced under the same strength; 3, the permeability coefficient of chloride ions can be reduced, and the slump loss is reduced.

Owner:广州基业长青新材料股份有限公司

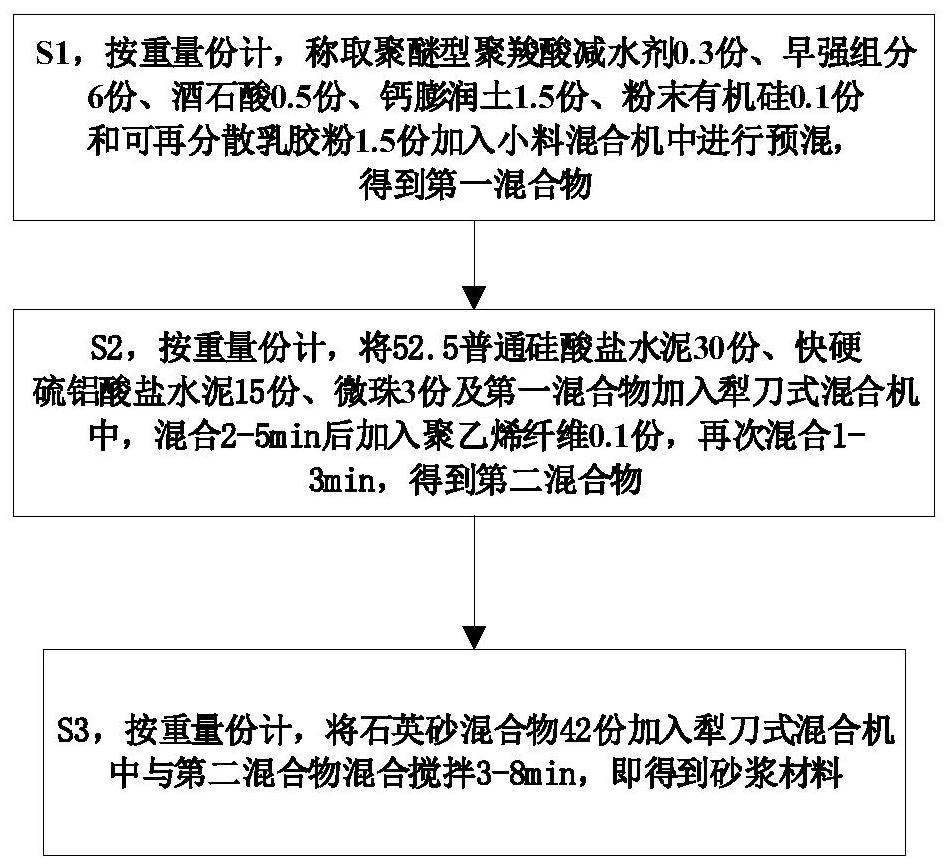

Low-temperature spraying cement-based mortar material for trenchless pipeline repair and preparation method thereof

The invention relates to the technical field of building materials, in particular to a low-temperature spraying cement-based mortar material for trenchless pipeline repair and a preparation method thereof. The mortar material comprises the following raw materials in parts by weight: 30-75 parts of cement, 20-70 parts of a quartz sand mixture, 1-15 parts of mineral powder, 0-1 part of a polycarboxylate superplasticizer, 0-2 parts of fibers, 0-15 parts of an early strength component, 0-5 parts of a retarder, 0-6 parts of a thixotropic agent, 0-0.5 part of a defoaming agent and 0-5 parts of redispersible latex powder, wherein each part of the early strength component is formed by compounding the following components in parts by weight: 1-30 parts of modified nano silicon dioxide, 50-90 parts of dodecacalcium heptaaluminate, 1-15 parts of calcium formate and 1-5 parts of an anti-freezing agent. The mortar material has the characteristics of normal coagulation at a low temperature (-10 DEG C to 5 DEG C), high early, middle and later strength, good adhesive property, good durability, good pumpability and the like, and can be used for effectively repairing a pipeline.

Owner:武汉中地大非开挖研究院有限公司

Sprayable, waterproof, anticorrosive and erosion-resistant high-strength mortar and using method thereof

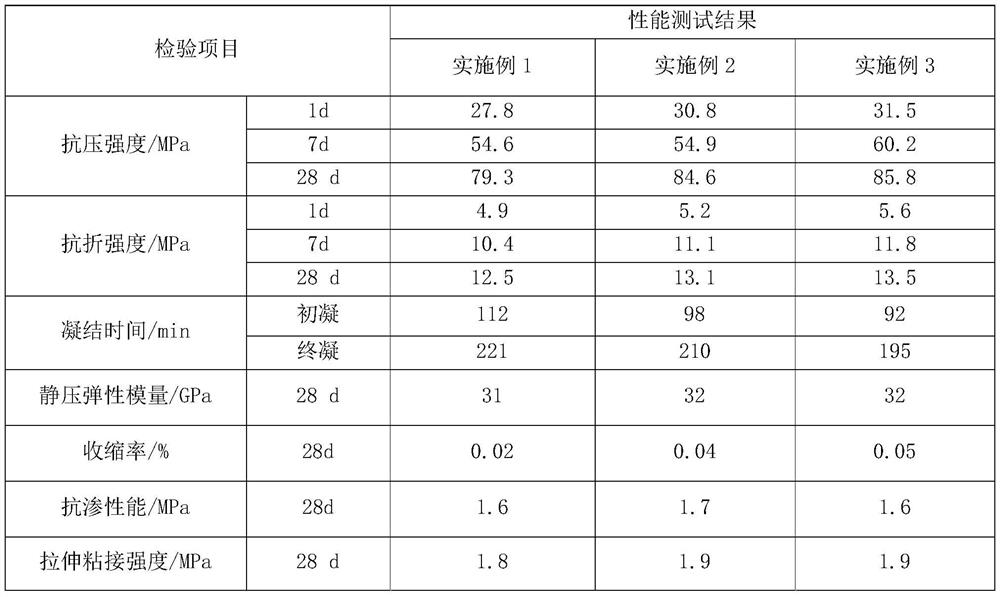

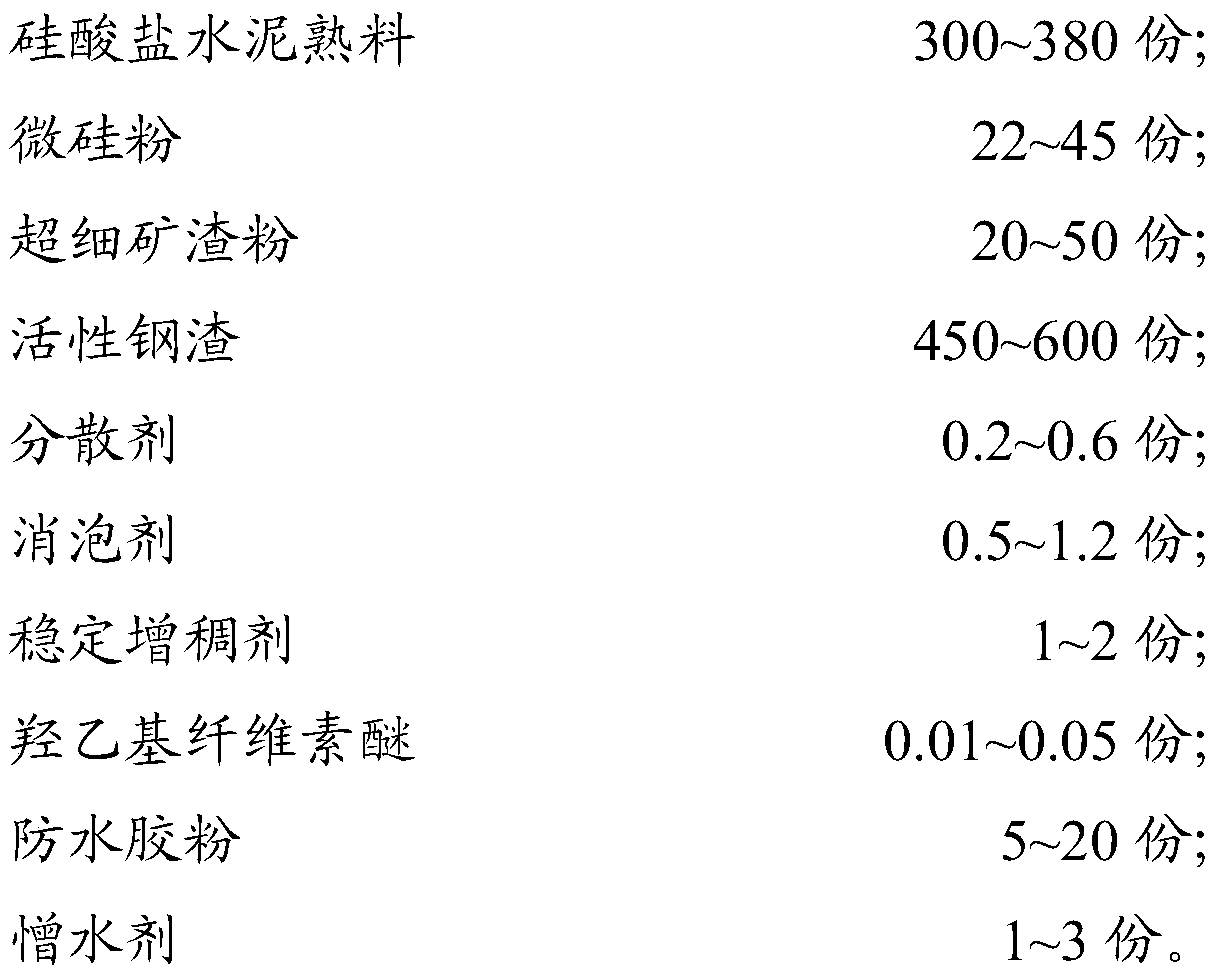

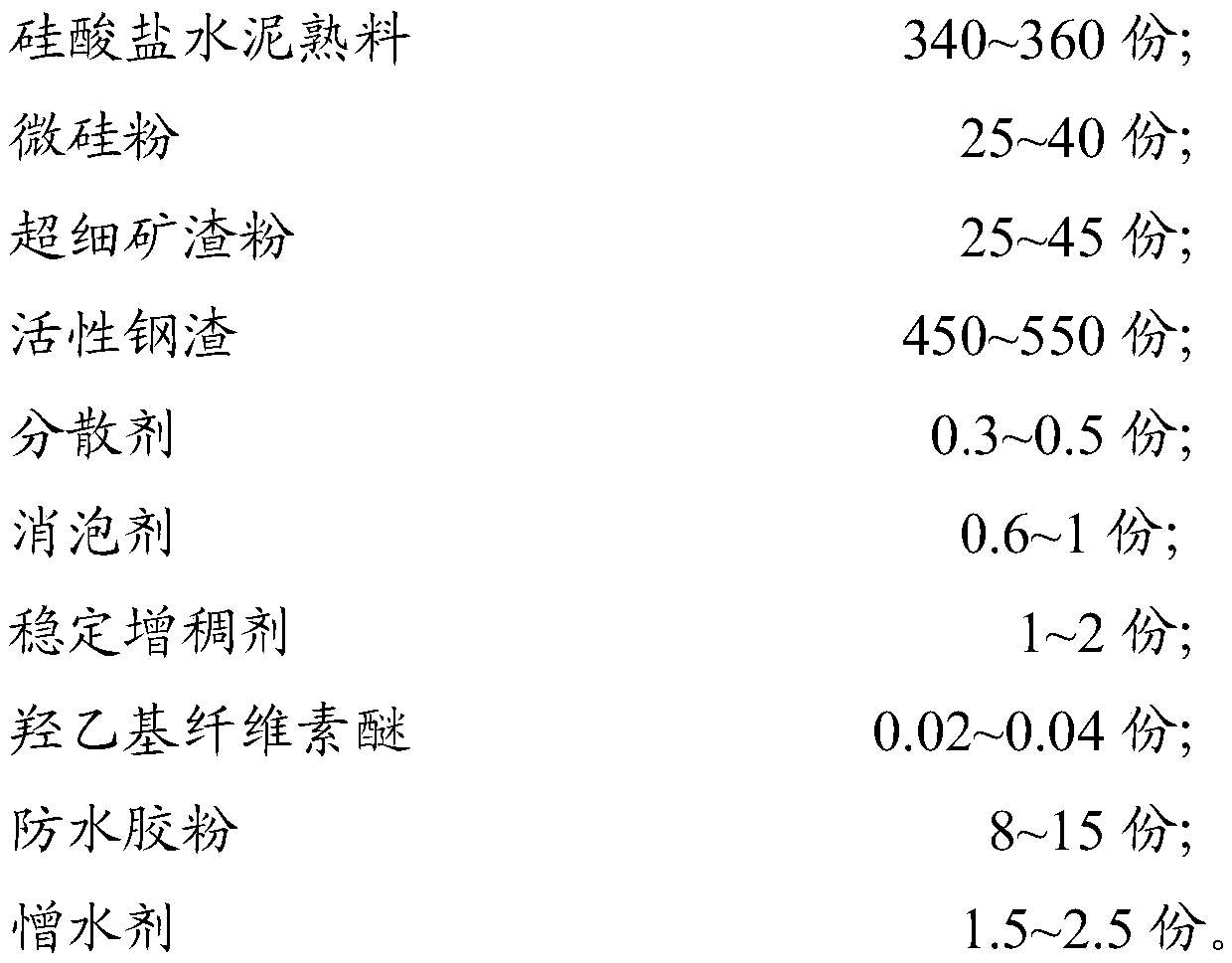

PendingCN110668774AHigh impermeability levelHigh compressive strengthCelluloseHydroxyethyl cellulose

The invention provides a sprayable, waterproof, anticorrosive and erosion-resistant high-strength mortar and a using method thereof, and belongs to the technical field of building materials. The sprayable, waterproof, anticorrosive and erosion-resistant high-strength mortar comprises, by mass, 300-380 parts of a Portland cement clinker, 22-45 parts of silica fume, 20-50 parts of ultrafine mineralslag powder, 450-600 parts of active steel slag, 0.2-0.6 part of a dispersant, 0.5-1.2 parts of an antifoaming agent, 1-2 parts of a stable thickening agent, 0.01-0.05 part of hydroxyethyl cellulose ether, 5-20 parts of waterproof rubber powder and 1-3 parts of a water repellent. The sprayable, waterproof, anticorrosive and erosion-resistant high-strength mortar has the advantages of high impermeability, high compressive strength and bonding strength, excellent alkali resistance, excellent sulfate corrosion resistance, excellent hydrophobicity, low shrinkage rate and good volume stability.

Owner:湖南人健宝固高新科技发展有限公司 +1

Alkali-free setting accelerator and production method thereof

InactiveCN107721240AGreen environmental protection and pollution-free construction environmentStable qualityAluminium saltsShotcrete

The invention provides an alkali-free setting accelerator. The alkali-free setting accelerator contains the following raw materials: aluminum sulfate, a coordination agent, organic alcohol amine and amide matters. The invention further provides a production method of the alkali-free setting accelerator. Compared with the prior art, the alkali-free setting accelerator has the beneficial effects that the accelerator can meet the quick setting requirement of wet spraying concrete, the environment-friendly and pollution-free construction environment can be realized, the stable quality of sprayed concrete is guaranteed, and meanwhile, the long-term strength and impermeability grade of the sprayed concrete can be greatly increased. The alkali-free setting accelerator is long in storage time, canresist temperature change and is totally non-alkaline.

Owner:山东鲁碧环保科技有限公司 +1

High-anti-permeability cement-based repair material for tunnel engineering and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a high-anti-permeability cement-based repair material for tunnel engineering. The repair material consists of portland cement, coal ash, silica fume, steel slag powder, rock powder, tailing sand, quartz sand, attapulgite, acrylate emulsion, cellulose ether, polyacrylamide, PVA fibers, PET fibers, a polycarboxylic acid water reducer and a defoaming agent. The repair material has the characteristics of easy construction, good working performance, good water retention performance, high compressive strength, high anti-permeability level, high toughness and adhesion, excellent durability and the like; and the repair material can be suitable for construction initial protection or engineering later maintenance and repair of lining concrete in the tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Nano-level water proof micro powder product and its preparation method

InactiveCN1513915ADispersedPlay a waterproof roleOther chemical processesNanoparticleMethyltrichlorosilane

A water-proof nanoparticle for building materials, paint, cement, etc is prepared through hydrolysis polymerizing of hydrolytic polymerizing of methyl trichlorosilane or the mixture of methyl trichlorosilane and dimethyl dichlorosilane, trimethyl chlorosilane, ethyl trichlorosilane, phenyl trichlorosilane, or vinyl trichlorosilane at 50-80 deg.C in acidic condition, washing, filtering, dissolving in alkali solution, reacting on acid to generate deposit, washing, filtering and airflow drying. Its advantages are high water-proof effect and low cost.

Owner:闫新育 +1

Cement concrete additive for repairing cement concrete road

InactiveCN101134650AReduced shrinkage performanceHigh impermeability levelSolid waste managementRebarSlag

The present invention relates to one kind of cement concrete admixture for repairing cement concrete road. The cement concrete admixture consists of industrial slag 70-80 wt%, bentonite 10-15 wt% and silica powder 8-15 wt%, and is produced through mixing the materials and grinding to specific surface area greater than 500 sq m / kg. It is added into cement concrete, with the weight ratio between cement and the admixture being 1 to 0.025-0.035. It has the features of high early strength, slight early expansion, no after shrinkage, anticracking and antiseepage, no corrosion to reinforcing bar, etc. It is especially suitable for use in the repair engineering of cement concrete road, bridge, culvert, tunnel, etc.

Owner:邬桂林

Alkali-free concrete accelerator and processing method thereof

The invention discloses an alkali-free concrete accelerator and a processing method thereof. The alkali-free concrete accelerator comprises the following raw materials in parts by weight: 30-65 partsof aluminum sulfate, 2-8 parts of an organic amine, 1-3% of a stabilizer, 1-5 parts of a suspending agent, 20-35 parts of water, 2-5 parts of bentonite and 4-6% of magnesium fluosilicate. In the present invention, the caulking agent for building decoration of prefabricated parts is simple in preparation method, low in cost, is liquid after preparation, can be uniformly mixed with concrete conveniently, contains no alkali or chlorine or pungent smell, is high in safety, is harmless to human body, is excellent in cohesiveness; adding of a stabilizing agent can prolong the storage time, preventdeterioration; magnesium fluosilicate and aluminum sulfate are adopted for cooperative using, so that the resilience value is low, later strength retention rate is high, and impermeability grade is high; adding of the alkali-free concrete accelerator in sprayed concrete is capable of achieving a preferable working environment and considerable market value.

Owner:湖南加美乐素新材料股份有限公司

Building coating and preparation method thereof

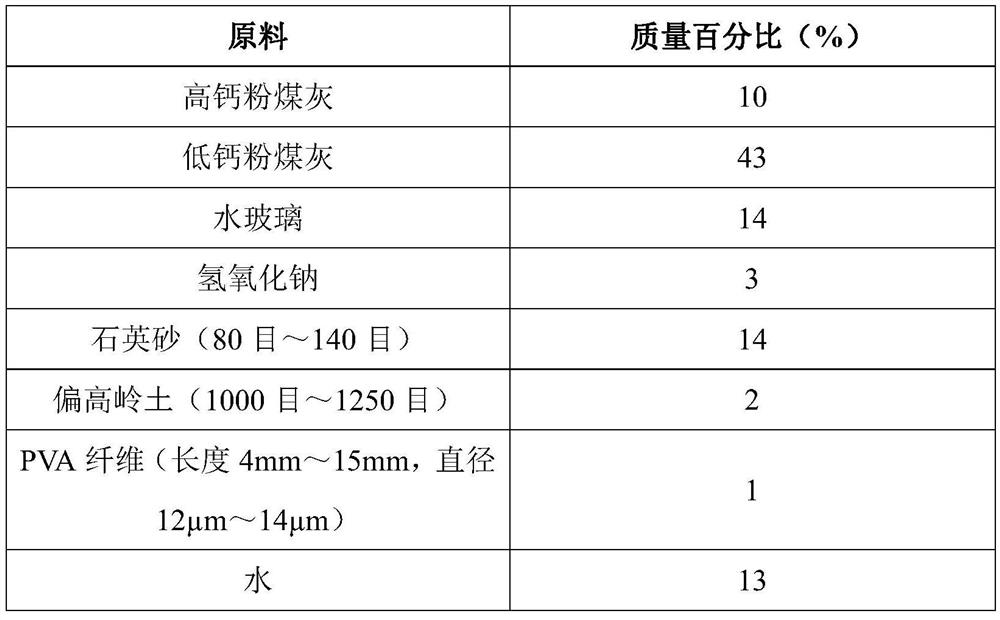

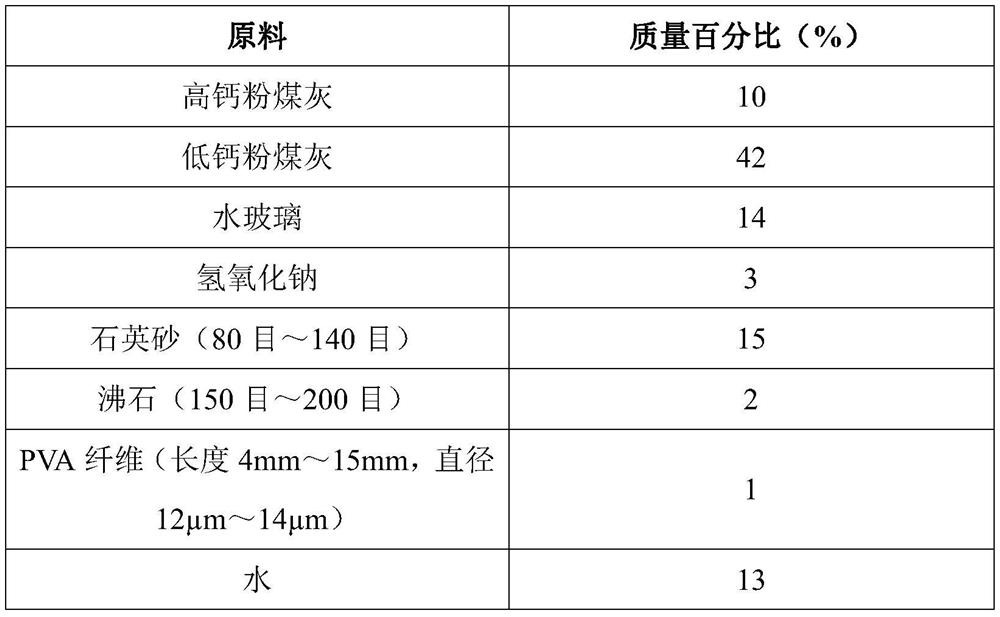

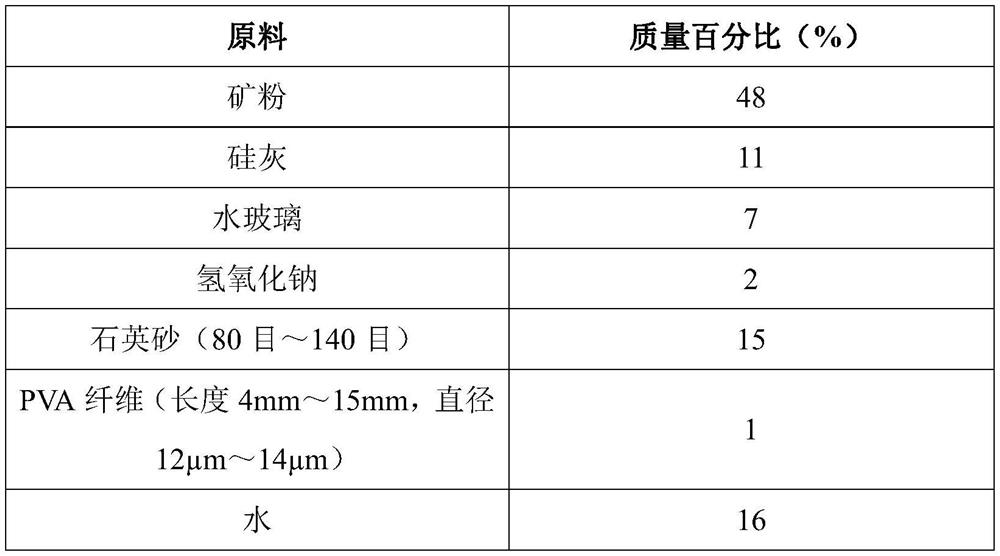

The invention discloses a building coating and a preparation method thereof. The building coating is composed of a cementing material, water glass, sodium hydroxide, quartz sand, metakaolin, zeolite, fibers and water. The preparation method comprises the following steps: mixing the cementing material, the quartz sand, the metakaolin and the zeolite, stirring, adding the water glass, the sodium hydroxide and the water, stirring, adding the fibers, and stirring to obtain the building coating. A coating layer formed by the building coating has ultrahigh toughness and excellent strain hardening characteristics, can still provide protection for a structure or a component matrix after being subjected to large deformation, is high in anti-permeability grade and excellent in bonding performance, and can be widely applied to surface protection of various building structures and components thereof; and the coating can also be used for reinforcing and maintaining aged and damaged building structures.

Owner:SOUTH CHINA UNIV OF TECH

Antibacterial mildew-proof waterproof leakage blockage mortar and manufacturing method thereof

InactiveCN106186950AAntibacterial and antifungalNot easy to reuniteSolid waste managementHigh pressurePolymer

The invention discloses antibacterial mildew-proof waterproof leakage blockage mortar. Nanometer ferriferrous oxide is added and is subjected to organic modification; the surface energy is reduced, so that the surface amphipathicity is realized; by using a three-dimensional protection effect, nanometer particles are uniformly dispersed into the mortar and cannot agglomerate; the pressure-resistant intensity of the product is improved; then, the materials are mutually compounded with polymer styrene acrylic emulsion and polypropylene fiber; through the physical and chemical effects, the surface energy of the polypropylene fiber is improved, so that the bonding force with the mortar is improved; the generation of early-stage micro cracks is well inhibited, so that the seeping resistance performance, the bending resistant intensity and the durability of the product are improved; the boiler ash are modified and are then added into the raw materials to be matched with other effective additives, so that each ingredient o the mortar is uniformly dispersed and cannot easily settle; the waterproof performance of the leakage blockage mortar is obviously improved; the prepared waterproof leakage blockage mortar has the good antibacterial mildew-proof waterproof performance, high seepage resistant stages, high pressure resistant intensity and good anti-aging performance, and has the advantages that the construction is convenient; the cost is low; green and environment protection effects are achieved.

Owner:ANHUI LENCAQI BUILDING MATERIAL

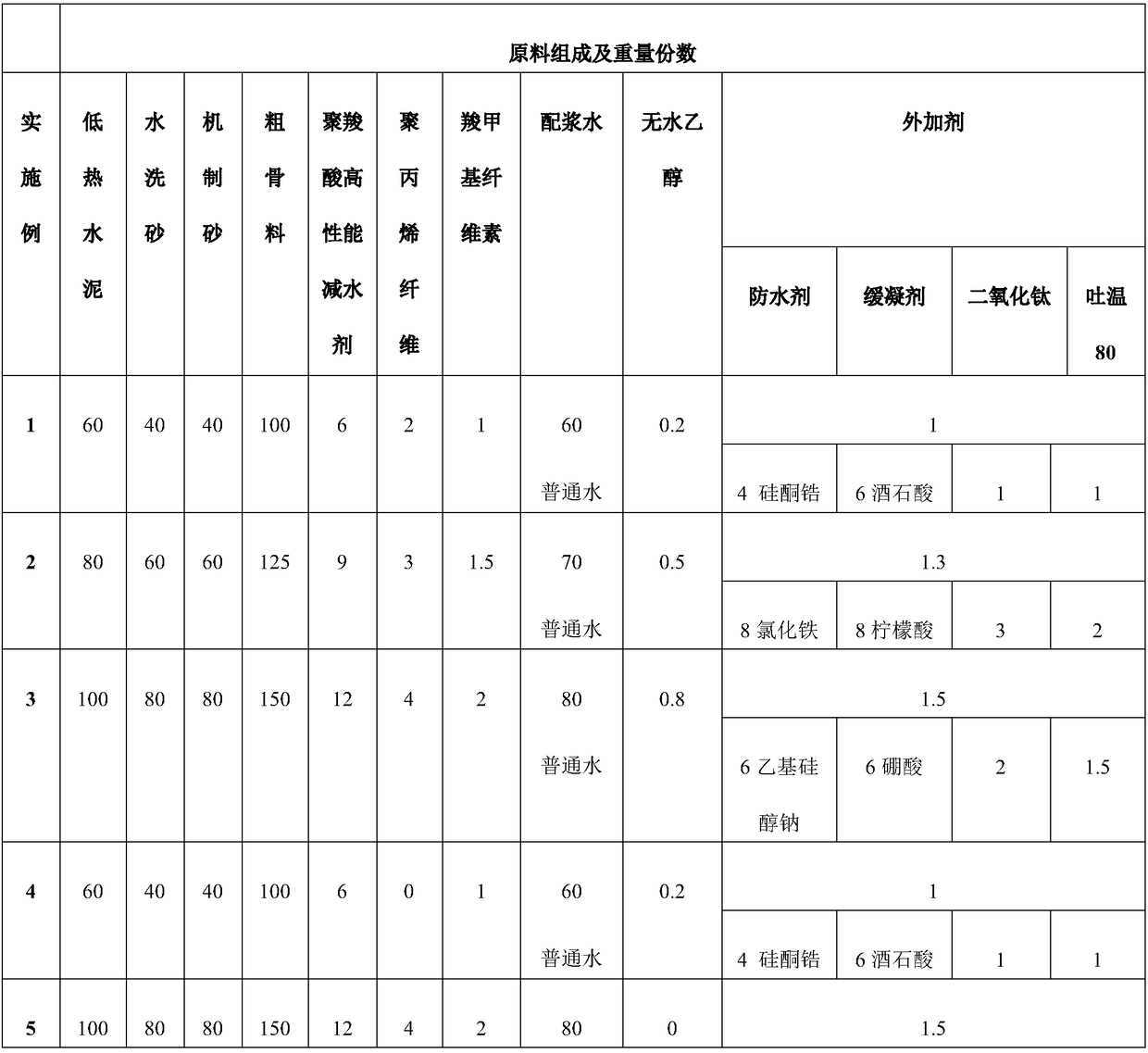

Concrete for long wall engineering and preparation method thereof

The invention belongs to the technical field of concrete preparation and brings forward concrete for long wall engineering and a preparation method thereof. The invention is characterized in that theconcrete is prepared from the following ingredients (by weight): 60-100 parts of low-heat cement, 40-80 parts of washed-out sand, 40-80 parts of machine-made sand, 100-150 parts of coarse aggregate, 6-12 parts of a polycarboxylates high performance water-reducing admixture, 2-4 parts of polypropylene fiber, 1-2 parts of carboxymethyl cellulose, 60-80 parts of water for slurry preparation, 0.2-0.8part of anhydrous ethanol, and 1-1.5 parts of an additive. The low-heat cement is prepared by mixing the following ingredients (by weight): 50-80 parts of Portland cement clinker, 8-12 parts of desulfurized gypsum, 30-40 parts of mineral waste residue, 20-25 parts of steel slag and 40-60 parts of fly ash. Particle size of the machine-made sand is less than 5 mm, and particle size of the coarse aggregate is 5-20 mm. The coarse aggregate is prepared by mixing 80-120 parts by weight of broken stone and 20-30 parts by weight of pebble. The problem that traditional concrete for long wall engineering often produce more cracks which will severely affect use strength, use durability and safety of long walls is solved.

Owner:石家庄金隅混凝土有限公司

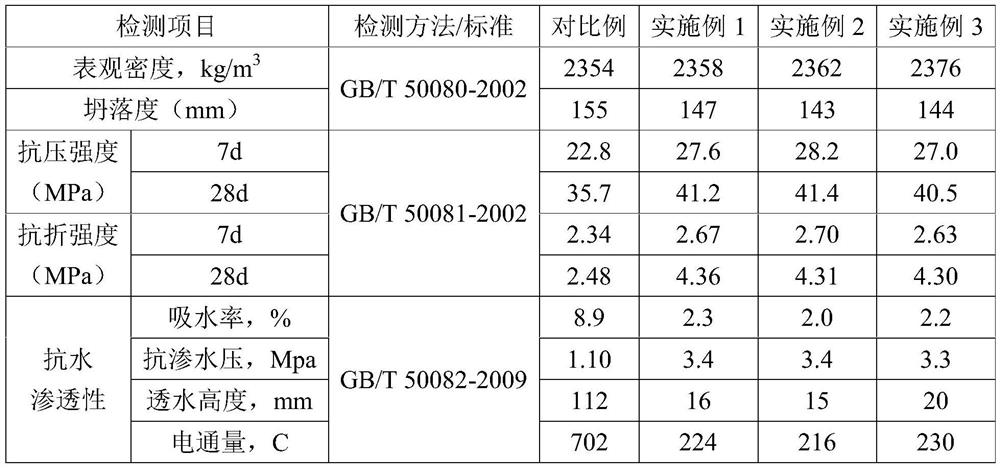

High impermeability cement-based repair material for tunnel engineering and preparation method thereof

The invention belongs to the technical field of building materials, and specifically relates to a high-impermeability cement-based repair material for tunnel engineering, which is composed of Portland cement, fly ash, silica fume, steel slag powder, rock powder, tailings sand, quartz sand, Attapulgite, acrylate emulsion, cellulose ether, polyacrylamide, PVA fiber, PET fiber, polycarboxylate water reducer and defoamer. The invention has the characteristics of easy construction, good workability, good water retention, high compressive strength, high impermeability grade, high toughness, cohesiveness and excellent durability; the product of the invention can be applied to the construction of lining concrete in tunnel engineering Initial protection or post-project maintenance and repair.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Preparation method of antiseepage waterproof mortar

The invention discloses a preparation method of an antiseepage waterproof mortar, and belongs to the technical field of waterproof mortar preparation. The preparation method comprises following steps: chlorella and a sodium hydroxide solution are mixed, and are subjected to repeated freezing and thawing so as to obtain a cell lysis solution, the cell lysis buffer is subjected to centrifugation so as to obtain a supernate and a precipitate; the precipitate is extracted, an obtained precipitate extracted solution is mixed with the supernate, and proteins are removed so as to obtain antibacterial polysaccharides; materials such as AEO and polyethylene glycol are delivered into a beaker respectively, and sodium methyl silicate is added after ultrasonic dispersion so as to obtain a waterproof emulsion via stirring; Portland cement, borax, and the like are delivered into a mixer for mixing so as to obtain a mixed slurry; the waterproof emulsion, guar gum, and the like are added for high speed stirring so as to obtain the antiseepage waterproof mortar. The preparation method is simple; the obtained antiseepage waterproof mortar is high in adhesion stress, and compressive strength; the surfaces of buildings obtained via pouring of the antiseepage waterproof mortar possess excellent water resistance; and the preparation method is suitable for large scale popularization and application.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

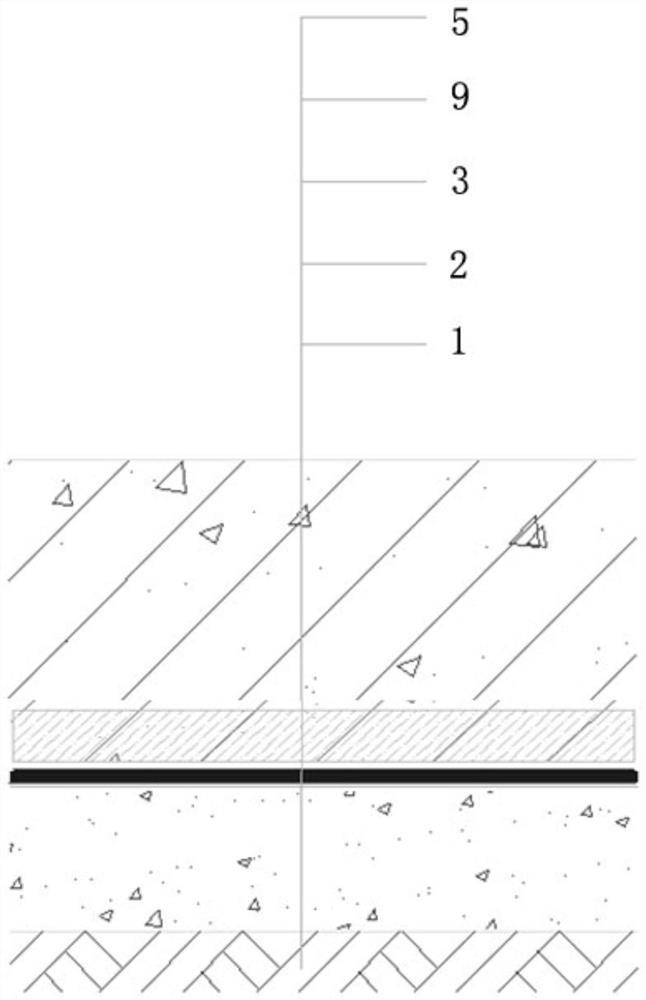

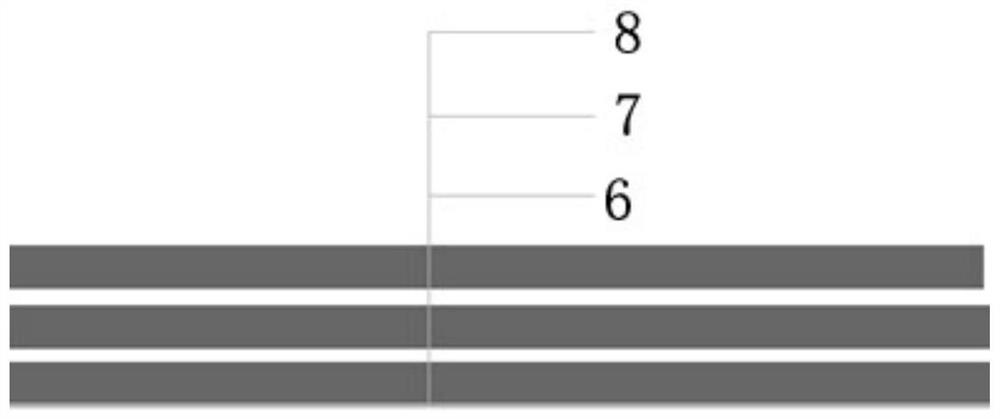

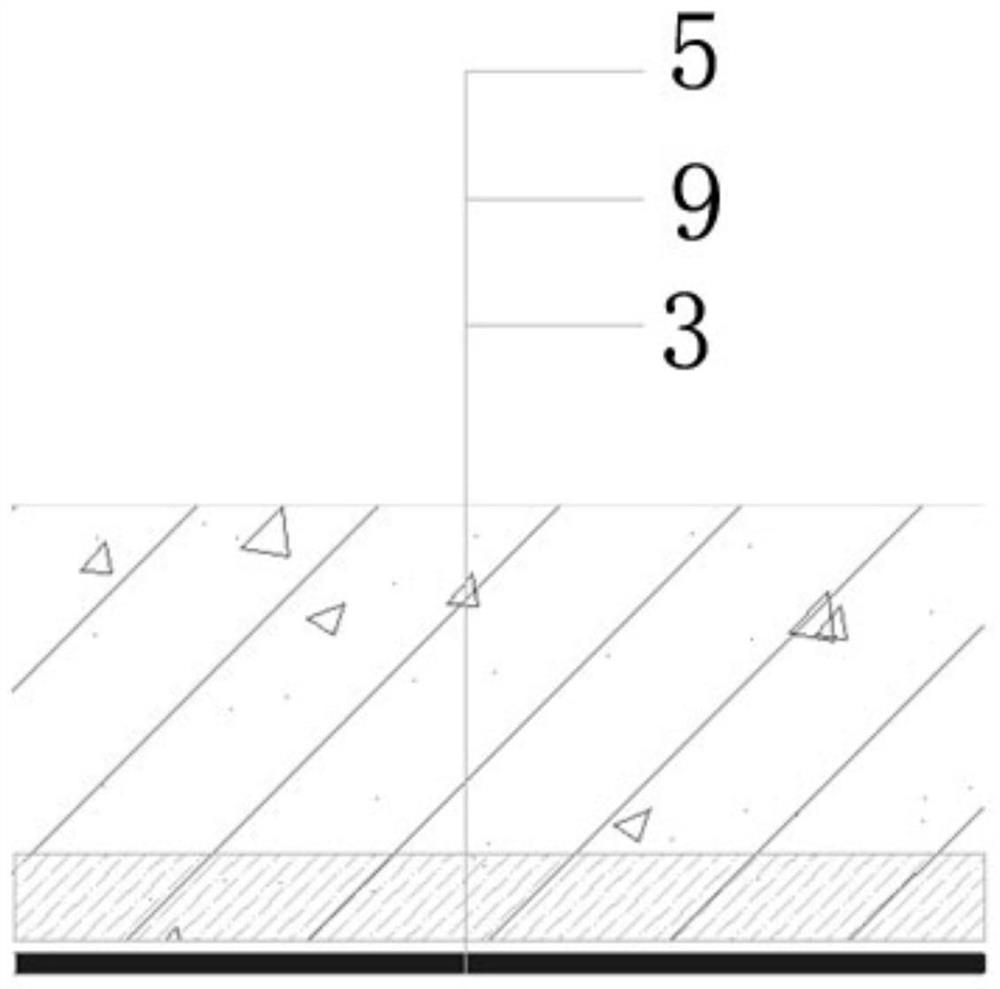

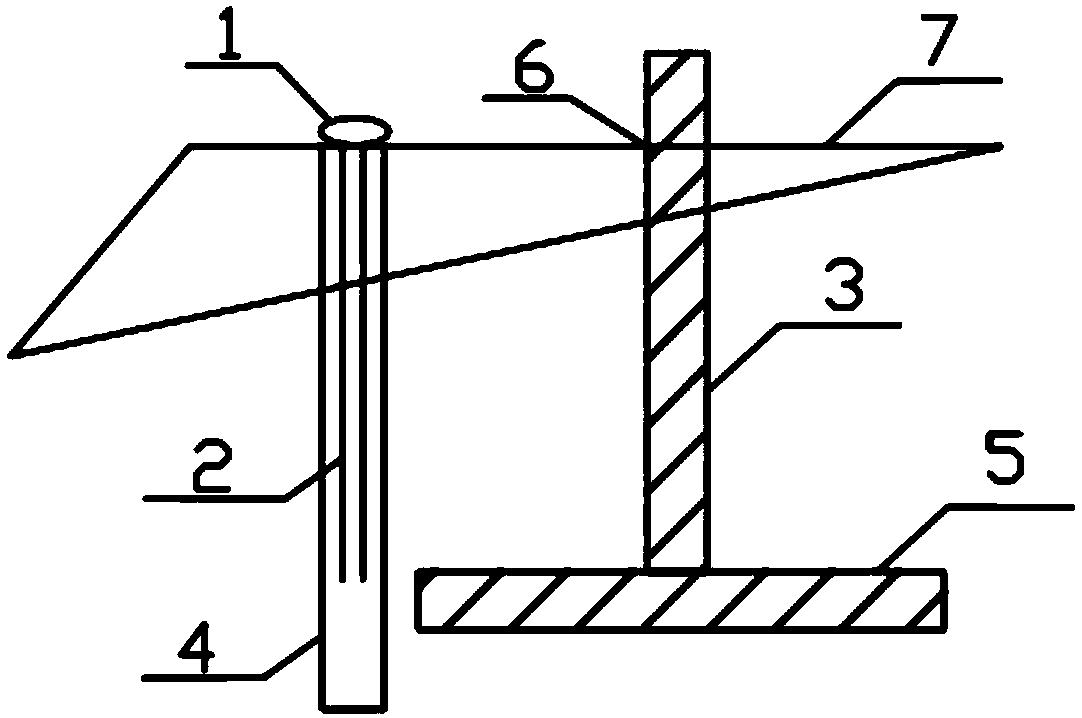

Pre-paving anti-sticking waterproof structure and construction method

PendingCN114150712AGood anti-channeling performanceGood water channeling resistanceProtective foundationWaterproofingStructural engineering

The invention belongs to the technical field of building waterproofing, and discloses a pre-paving anti-sticking waterproof structure and a construction method. The structure sequentially comprises a concrete cushion layer, a pre-laid polymer waterproof roll layer, an anti-seepage self-repairing waterproof layer and an anti-seepage concrete layer from bottom to top. According to the waterproof structure, the rigid-flexible design principle is adopted, the deformation resistance and crack resistance of the waterproof structure are achieved by means of high extension and high strength of the pre-laid polymer waterproof coiled material, meanwhile, the dry-spread cement-based capillary crystalline waterproof material can improve the local anti-seepage grade and compressive strength of the anti-seepage concrete, an anti-seepage self-repairing waterproof layer is formed, and the anti-seepage performance of the waterproof structure is improved. And the dry-spread cement-based capillary crystalline waterproof material also has the capability of improving the self-repairing capability of the concrete in a water leakage environment.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

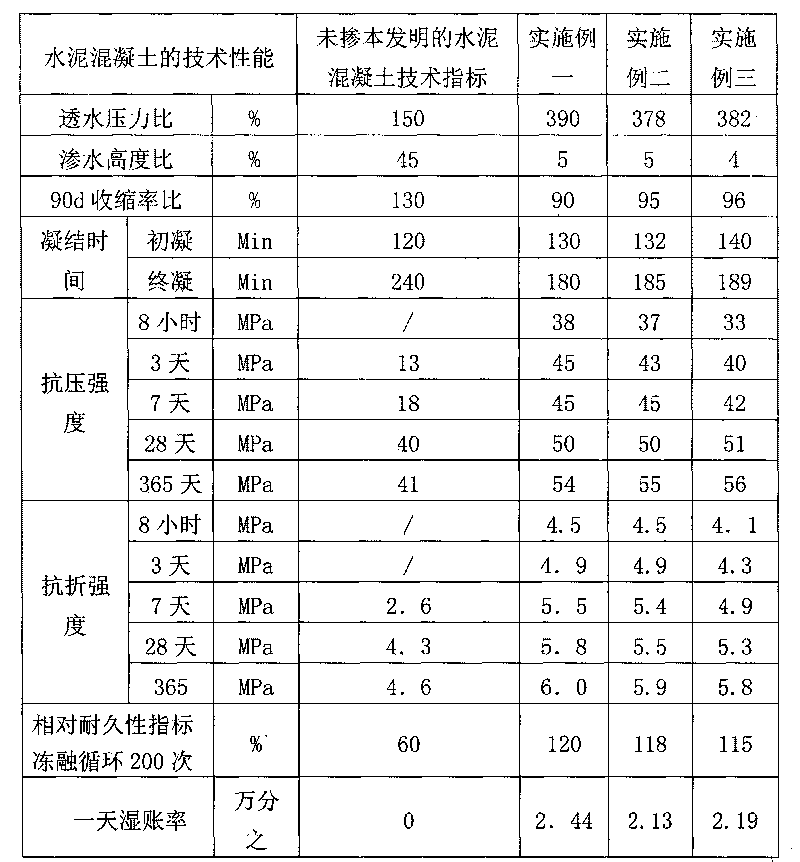

Rigid self-compacting waterproof concrete for underground engineering building construction and preparation method thereof

The invention relates to rigid self-compacting waterproof concrete for underground engineering building construction and a preparation method of the rigid self-compacting waterproof concrete. The concrete is mainly prepared from water and the following components in parts by weight: 300-330 parts of Portland cement, 1050-1100 parts of coarse aggregate, 680-720 parts of fine aggregate, 80-90 partsof precoated sand, 18-20 parts of silica fume, 5.2-5.6 parts of an additive and 0-25 parts of an expanding agent, wherein the ratio of water to binder is 0.36 to 0.40; the precoated sand takes fine sand as a core, and the surface of the fine sand is coated with a siliceous film layer formed by an organic silicon material and a powder layer mainly formed by a waterproof admixture. The rigid self-compacting waterproof concrete mixture has the advantages of good workability, uniform and compact concrete structure, high mechanical strength and good impermeability and waterproofness; compared withcommon waterproof concrete, the rigid self-compacting waterproof concrete mixture is high in impermeability grade, good in durability, wide in raw material source and suitable for underground engineering building construction operation.

Owner:GUANGZHOU CITY POLYTECHNIC

Fabricated element concrete special-purpose kitchen and bath waterproof agent

The invention discloses a fabricated element concrete special-purpose kitchen and bath waterproof agent. The fabricated element concrete special-purpose kitchen and bath waterproof agent comprises, byweight, 10 to 15 parts of modified silicon emulsion, 1 to 2 parts of a zirconium compound, 3 to 6 parts of a organic silicone surfactant, 10 to 15 parts of water-soluble polyurethane resin emulsion,0.1 to 0.4 part of an air entraining agent, 2 to 5 parts of a water reducer, and 1 to 4 parts of a thickening time control agent. According to a preparation method of the fabricated element concrete special-purpose kitchen and bath waterproof agent, organic compounds including the organic silicone surfactant and the water-soluble polyurethane resin emulsion are adopted, and are combined with the air entraining agent, the zirconium compound, the water reducer, and the thickening time control agent to prepare the composite waterproof agent. Compared with convention waterproof agent, the advantages of the composite waterproof agent are that: construction is simple; the composite waterproof agent is safe, and is friendly to the environment, possesses extremely excellent water resistance, is capable of reducing concrete water glue ratio, improving concrete workability and compactness, reducing concrete shrinkage rate further, filling concrete internal pores, and achieving impervious grade increasing, pressure resistance, and high strength.

Owner:湖南加美乐素新材料股份有限公司

Hydrophobic polymer emulsion and its application

The invention provides a hydrophobic polymer emulsion and its application. An emulsification system having little influence on the cement performances including setting time, compressive strength and flexural strength and functional monomers are synthesized into a hydrophobic polymer emulsion for a polymer cement base waterproof material by an emulsion polymerization method; and then on the basis of the hydrophobic polymer emulsion, the polymer cement base waterproof material can be manufactured. The material has excellent waterproof and moisture-proof performances, can be used for water and moisture prevention of toilet, wall, roofing and basement of buildings, and bridge and tunnel; and the material has good affinity with cement mortar, and the waterproof layer surface can be directly coated with the cement mortar, without affecting the bond behavior.

Owner:沈南生

Method for repairing draught fan concrete foundation cavity through high polymers

InactiveCN109056698AThe final setting time can be adjustedControllable health periodSoil preservationEngineeringHigh pressure

The invention discloses a method for repairing a draught fan concrete foundation cavity through high polymers. The method comprises the following steps of 1, appearance analysis and detection, 2, closed circuit television detection, 3, cavity connectivity high-pressure gas detection, 4, injection tube cap manufacturing, 5, injection tube cap installation and 6, high-pressure injection of the highpolymers, thereby completing repairing of the draught fan concrete foundation cavity through the high polymers. The non-excavation rapid maintenance method not requiring a draught fan to stop runningis provided in order to solve implicit diseases such as disengagement in a wind power large-size concrete structure and looseness of a foundation ring, and the method has a low degree of constructiondisturbance, high efficiency and remarkable technical advantages and economic and social benefits as well as broad application prospects.

Owner:南方工程检测修复技术研究院

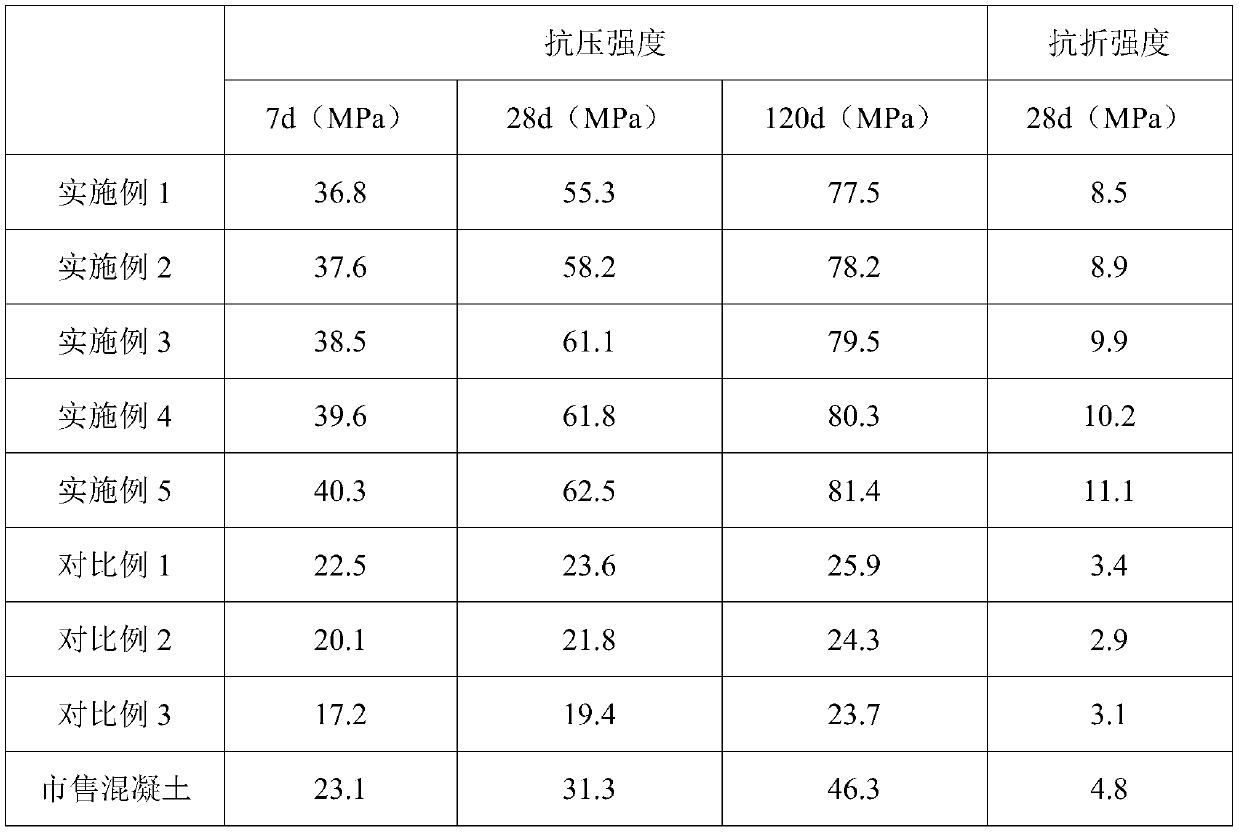

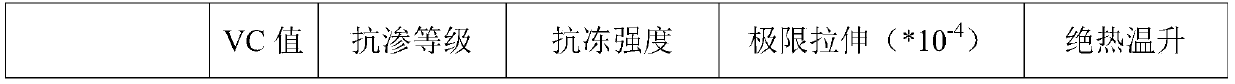

High-wear-resistant building material and preparation method and application thereof

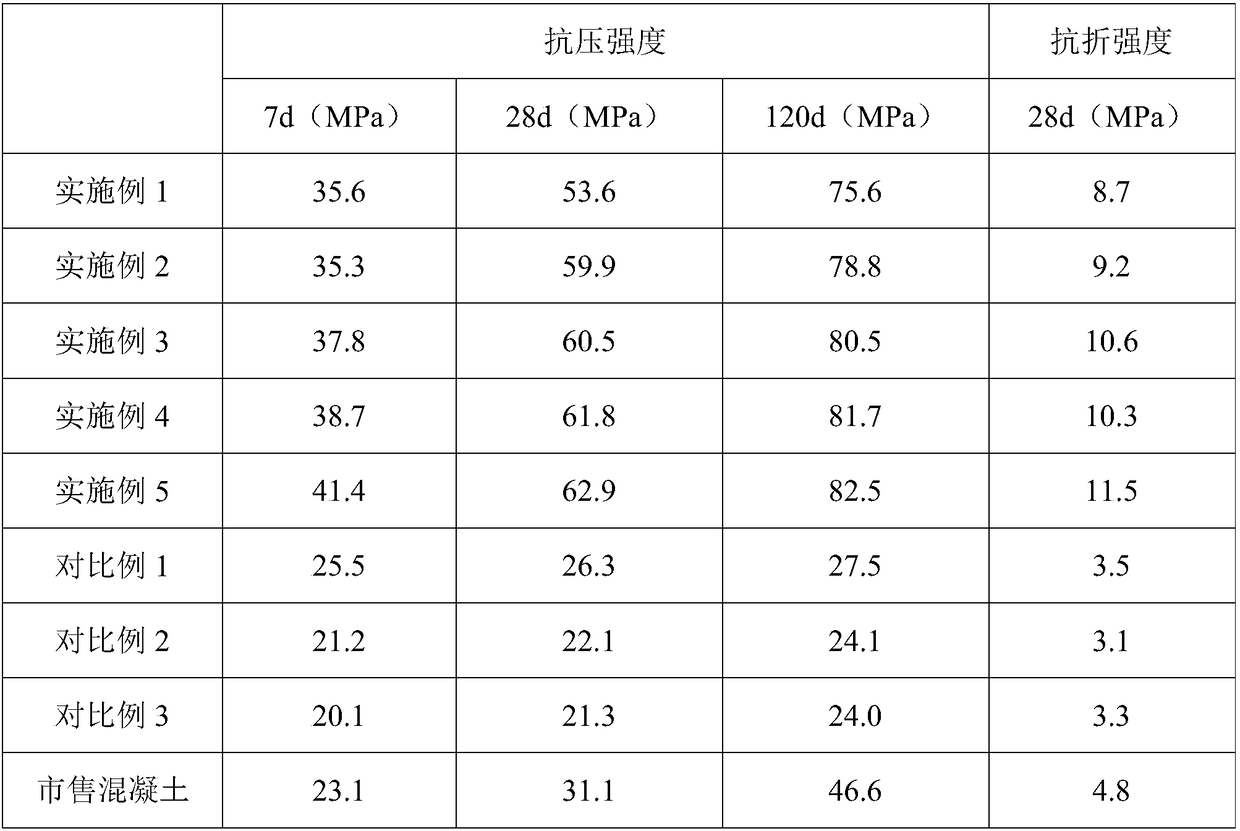

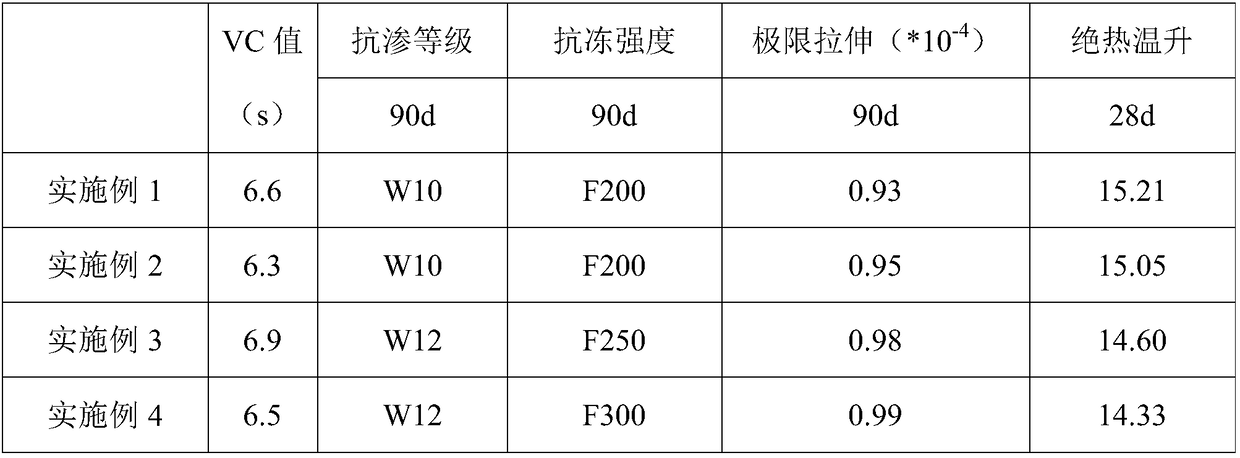

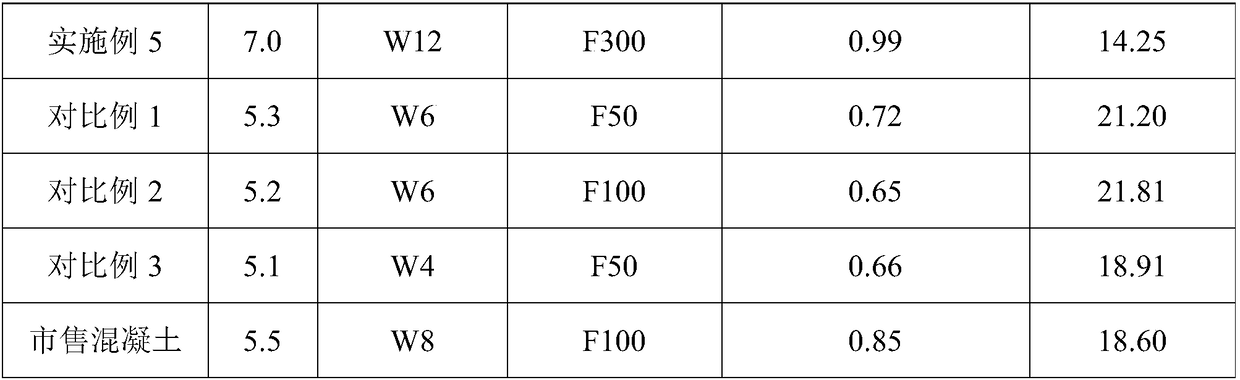

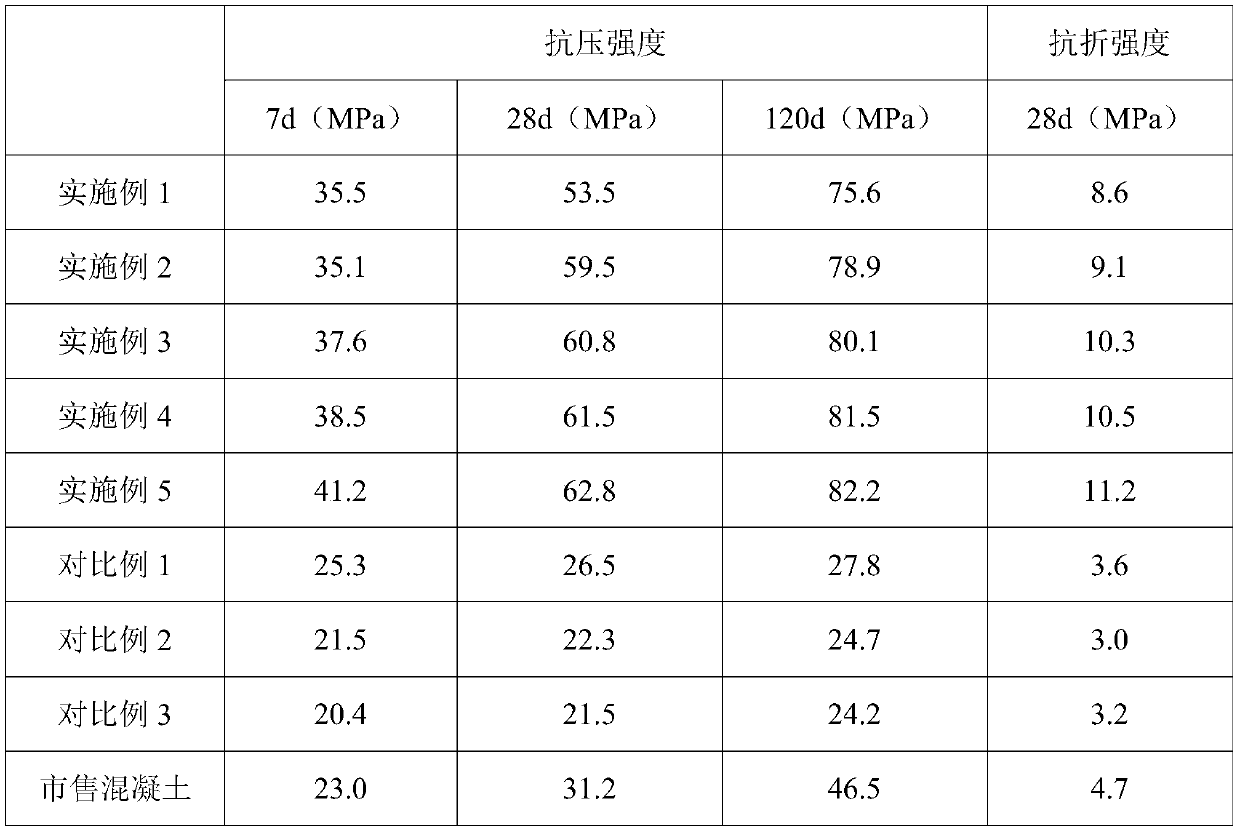

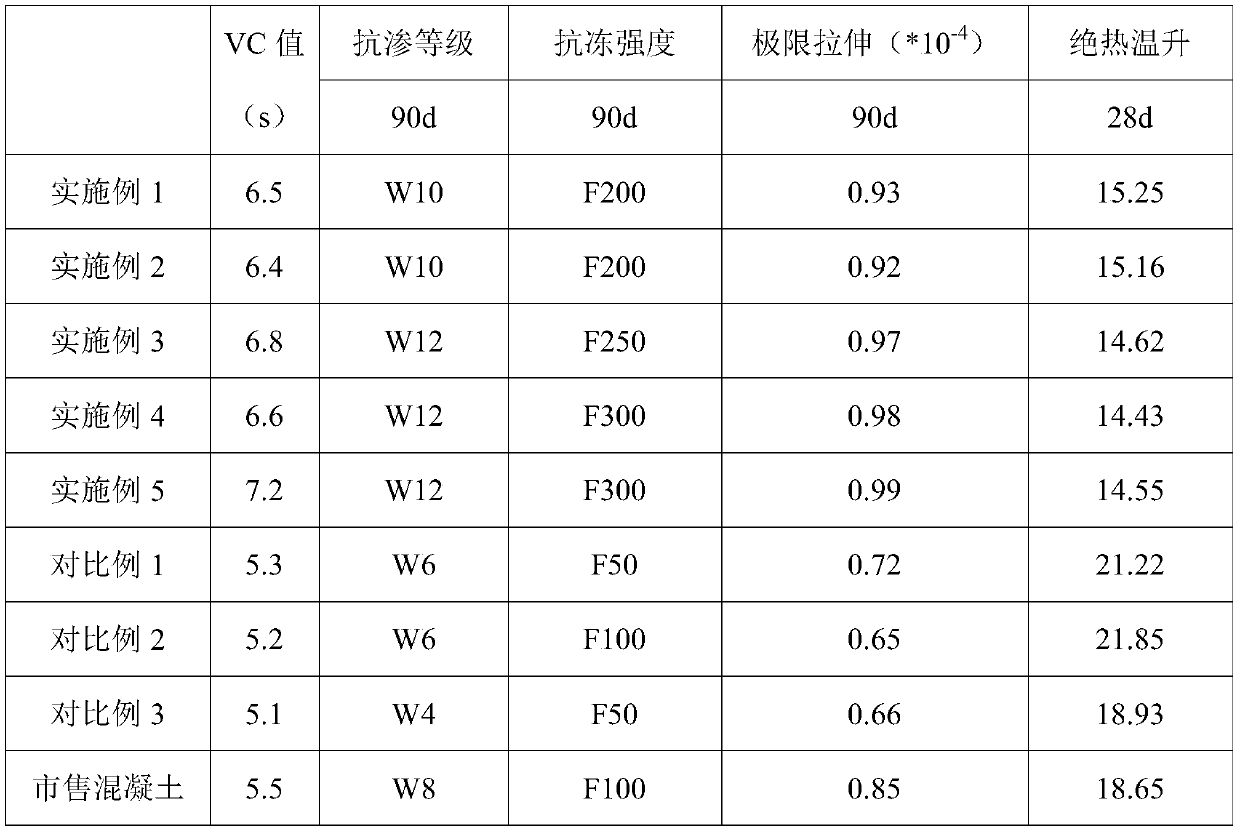

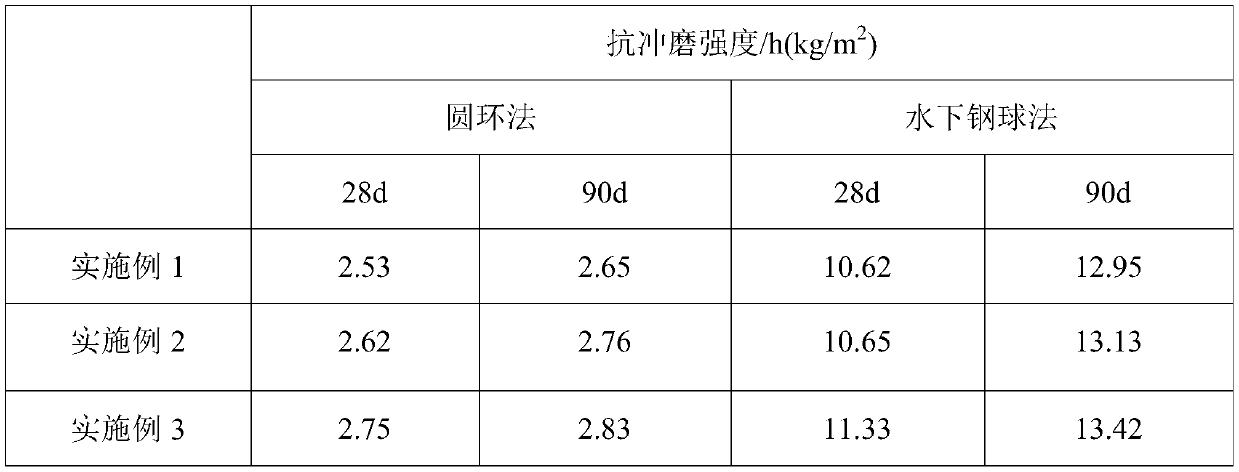

The invention discloses a high-wear-resistant building material and a preparation method and application thereof. The high-wear-resistant building material comprises the following raw materials in parts by weight: 45-55 parts of portland cement, 20-30 parts of fine sand, 12-20 parts of guar gum, 16-24 parts of vermiculite and 7-15 parts of ethanol amine. The preparation method comprises the following steps: mixing and grinding vermiculite; mixing the ground vermiculite with an ethanol amine solution; performing heating, sealing and stirring for 2.2-2.4 h; performing centrifugal separation; taking a deposit; washing and then drying the deposit; adding guar gum; performing ball-milling; mixing with portland cement and fine sand; performing uniform stirring; and performing casting, vibrationand maintenance to obtain the high-wear-resistant building material. The high-wear-resistant building material is higher in compressive strength and rupture strength, and is remarkably improved in VCvalue, seepage resistance grade, anti-freezing strength, ultimate tensile property, adiabatic temperature rise, chemical corrosion resistance and the like, the erosion and abrasion resistance is effectively improved, the crack resistance is improved, and the high-wear-resistant building material is particularly suitable for environments such as hydraulic drainage buildings, which demand more on the erosion wear resistance and the crack resistance of concrete.

Owner:兰州新华恒混凝土有限责任公司

Anti-freezing concrete and preparation method thereof

InactiveCN112174598AReduce heat of hydrationReduce thermal cracksCrushed stoneStructural engineering

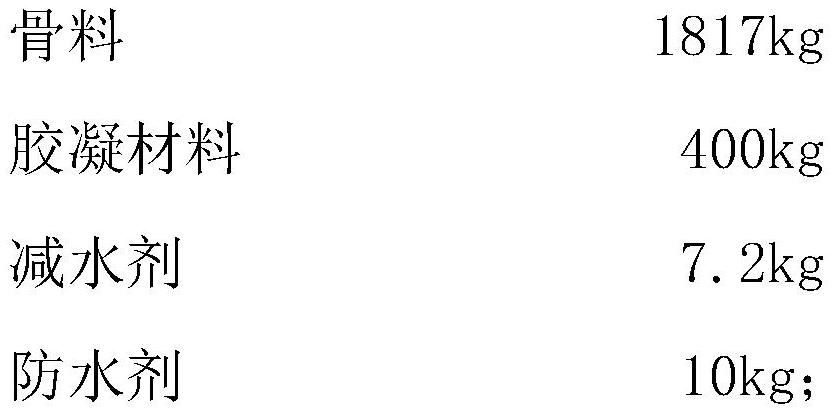

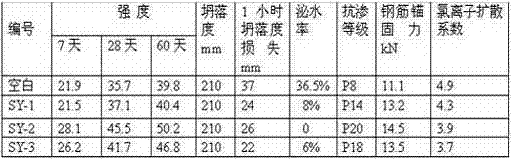

The invention discloses anti-freezing concrete and a preparation method. The anti-freezing concrete is composed of aggregate, a cementing material, a water reducing agent, a waterproof agent and water, each cubic meter of the anti-freezing concrete contains 18-17kg of the aggregate, 400kg of the cementing material, 7.2kg of the water reducing agent and 10kg of the waterproof agent, the content ofwater is calculated according to the weight ratio of water to cementing material of 0.44: 1, the aggregate is composed of medium sand and broken stone, the broken stone is formed by continuously proportioning broken stone with the particle size D of greater than or equal to 5mm and less than 20mm and broken stone with the particle size D of greater than or equal to 20mm and less than or equal to 40mm in two stages. The preparation method comprises the steps of adding water accounting for 1 / 3-1 / 2 of the total volume into the water reducing agent, uniformly mixing the obtained water reducing agent aqueous solution with the cement, the II-grade fly ash and the waterproof agent, adding the medium sand, the gravels and the residual volume of water, controlling the rotating speed to be 80-100r / min, and stirring for 60-180 seconds, thereby finally obtaining the anti-freezing concrete with high compactness, small shrinkage and excellent anti-freezing property.

Owner:SHANGHAI CONSTR NO 1 GRP

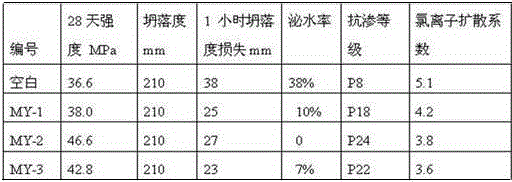

Novel concrete synergist and its manufacturing process

ActiveCN104844060BLow permeability coefficientHigh impermeability levelColloidal silicaChloride ion penetration

Owner:广州基业长青新材料股份有限公司

Concrete for construction in underground contaminated environment

The invention belongs to the technical field of construction materials, and provides concrete for construction in an underground contaminated environment in order to solve the problems that the existing concrete has a poor effect in resisting corrosion, cracking and water simultaneously, and cannot resist the geology in the contaminated environment effectively, and consequently, the concrete and steel bars are corroded, resulting in poor durability of reinforced concrete. The concrete for construction in the underground contaminated environment is prepared by mixing common portland cement, silicon dioxide, calcium carbonate, calcium oxide, aluminum oxide, iron oxide, magnesium oxide, sulfuric anhydride, a polycarboxylate high performance water reducing agent, water, anhydrous calcium sulphoaluminate and anhydrous calcium sulfate according to a certain proportion. The cement has high quality, and is improved in impermeability grade and lowered in cracking area and corrosion rate by addition of the anhydrous calcium sulphoaluminate and the anhydrous calcium sulfate, thereby improving the water-proof, anti-crack and anti-corrosion performance; the concrete can resist the damage of various gaseous, liquid-state and solid-state corrosive mediums in the underground contaminated environment.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

A kind of high wear-resistant concrete material and its preparation method and application

InactiveCN107986717BSmall drying shrinkageHigh compressive strengthCompressive resistanceCellulose diacetate

The invention discloses a high-wear-resistant concrete material as well as a preparation method and application thereof. The concrete material is prepared from the following materials in parts by weight, 45 to 55 parts of silicate cement, 23 to 31 parts of fine sand, 11 to 19 parts of polystyrene resin, 7 to 15 parts of cellulose diacetate, 15 to 25 parts of dimethyl sulfoxide, and 18 to 26 partsof vermiculite. The preparation method comprises the steps that the vermiculite and cellulose diacetate are mixed and crushed, and then mixed with a dimethyl sulfoxide solution, heated and sealed forstirring, a precipitate is collected by centrifugation, pretreated vermiculite is obtained by washing and drying the precipitate; the precipitate is added with a polystyrene resin to conduct ball milling, mixed with silicate cement and fine sand, and evenly mixed; pouring, vibrating, and curing are conducted. The high-wear-resistant concrete material has higher compressive strength and flexural strength, has significant improvement in VC value, impermeability grade, freeze-thaw strength, ultimate tensile, adiabatic temperature rise, chemical attack resistance and the like, effectively improvesimpact resistance, effectively improves resistant to erosion and abrasion, effectively reduces shrinkage deformation of concrete, improves crack resistance, and has excellent overall performance.

Owner:大足朝野混凝土有限公司

A kind of application method of architectural paint for surface protection of building structure

The invention discloses an application method of architectural paint for surface protection of building structures. The architectural coating of the present invention is composed of cementitious material, water glass, sodium hydroxide, quartz sand, metakaolin, zeolite, fiber and water, and the preparation method includes the following steps: mixing cementitious material, quartz sand, metakaolin and zeolite , stir, then add water glass, sodium hydroxide and water, stir, then add fiber, stir, that is, the architectural coating. The coating formed by the architectural coating of the present invention has ultra-high toughness and excellent strain hardening properties, can still provide protection for the structure or component substrate after being subjected to large deformation, the coating has a high impermeability level and excellent bonding performance, and can It is widely used in the surface protection of various building structures and their components, and can also be used for reinforcement and maintenance of building structures after aging and damage.

Owner:SOUTH CHINA UNIV OF TECH

A kind of concrete material with anti-abrasion and its preparation method and application

The invention discloses a washout-resistant concrete material as well as a preparation method and the application thereof. The concrete material comprises the following raw materials in parts by weight: 45-55 parts of Portland cement, 20-30 parts of fine sand, 12-20 parts of vinyl acetate resin, 16-24 parts of montmorillonite, 1-5 parts of dioctyl(maleate)tin and 7-15 parts of levulinic acid. Thepreparation method comprises the following steps: mixing and grinding the dioctyl(maleate)tin and the montmorillonite, further mixing with a levulinic acid solution, heating, carrying out sealed stirring treatment for 2.2-2.4 hours, carrying put centrifugal separation so as to obtain precipitate, washing and drying the precipitate, further adding the vinyl acetate resin, carrying out ball milling,further mixing with the Portland cement and fine sand, uniformly stirring, and carrying out casting, vibration and maintenance. The concrete material is relatively high in compression strength and breaking strength, is remarkably improved on aspects such as VC values, anti-permeability grades, anti-freezing strength, extreme tension, adiabatic temperature rise and chemical corrosion resistance, is effectively improved in impact wearing resistance and cracking resistance, and is particularly applicable to environments such as hydraulic drain structures with relatively high requirements on washout resistance and cracking resistance.

Owner:东阳市华能新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com