Cement concrete additive for repairing cement concrete road

A technology for cement concrete and road repair, which is applied in the field of cement concrete admixtures and cement concrete admixtures for cement concrete road repair, can solve problems such as the decrease of road surface smoothness, affect the road surface smoothness, reduce the use function, etc., and achieve anti-cracking ability. The effect of enhancing, improving the impermeability level, low shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] 70% industrial waste, 15% silica fume, 15% bentonite.

[0042] The weight percentage ratio of concrete mixed with the present invention is:

[0043] Cement: medium sand: crushed stone: water: the repair agent involved in the present invention = 1:1.30:3.13:0.36:0.03

[0044] The proportion of concrete without the present invention is:

[0045] Cement: medium sand: crushed stone: water = 1: 1.30: 3.13: 0.36

[0046] The technical indicators of cement concrete road quick repair agent concrete produced according to this component are as follows:

[0047]

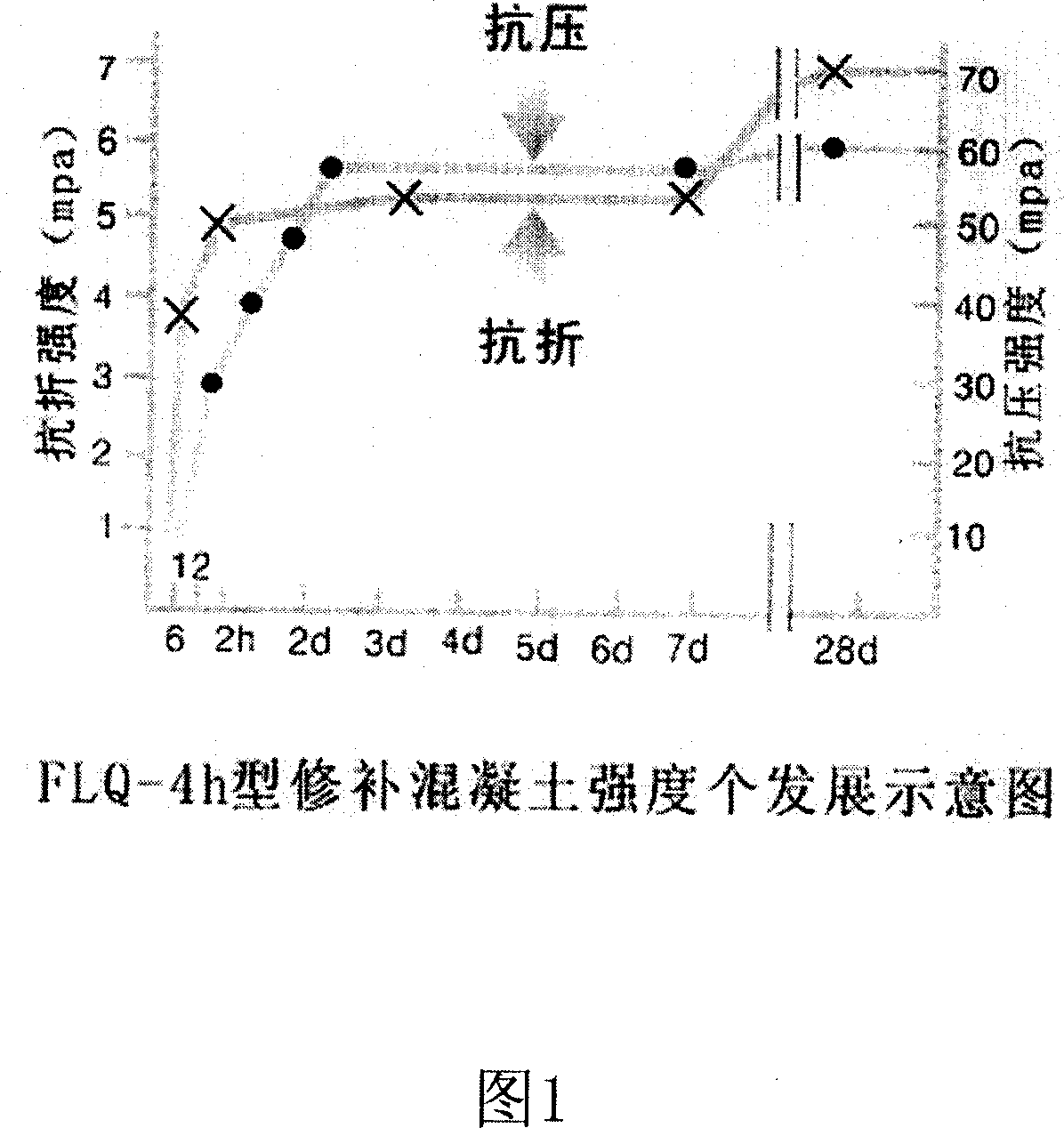

[0048] Intensity

[0049] It can be seen from the data in the comparison table that the present invention has high early strength and does not retreat in late strength; micro-expansion in the early stage and no shrinkage in the late stage; crack resistance and seepage prevention; wear resistance and durability. It is especially suitable for the maintenance of highway concrete pavement and bridges, culvert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com