Patents

Literature

461results about How to "Improve anti-seepage effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

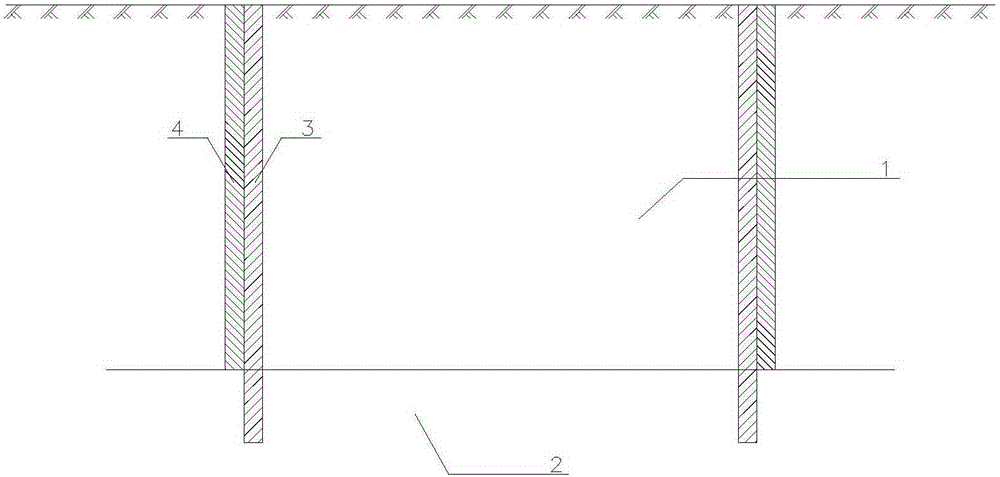

Tunnel connection channel construction method of shield interval

ActiveCN101598027AGood anti-seepageGood reinforcement effectUnderground chambersTunnel liningShield machineLine structure

The invention discloses a tunnel connection channel construction method of a shield interval, which comprises the following steps: 1. an enclosed plain concrete continuous wall which is used as a water sealing curtain is arranged at the periphery of the connection channel ; 2. a mixing pile or grouting is adopted inside of the connection channel area to reinforce soil body; 3. excavating vertical well construction is carried out within the range of a reinforce area; 4. a subsurface excavation method is adopted to carry out excavation and lining construction for the connecting channel from both sides of the vertical well. 5. after the construction of the connecting channel interval is completed and a shield machine entirely passes through a reinforce body, a tube sheet positioned at the connecting channel portal is cut off, the portal waterstop and the portal structure of the connecting channel are constructed; the lining structure of the connecting channel positioned at the vertical well is also constructed and the vertical well is refilled, finally the connecting channel is completed; the stratum reinforce construction method of the connecting channel is high in efficiency and safe, can be promoted and applied to the construction of reinforcing stratum for changing the tool bits of the shield machine, thereby providing reliable guarantee for changing the tool bits of the shield machine.

Owner:CHINA TUNNEL CONSTR GUANGDONG

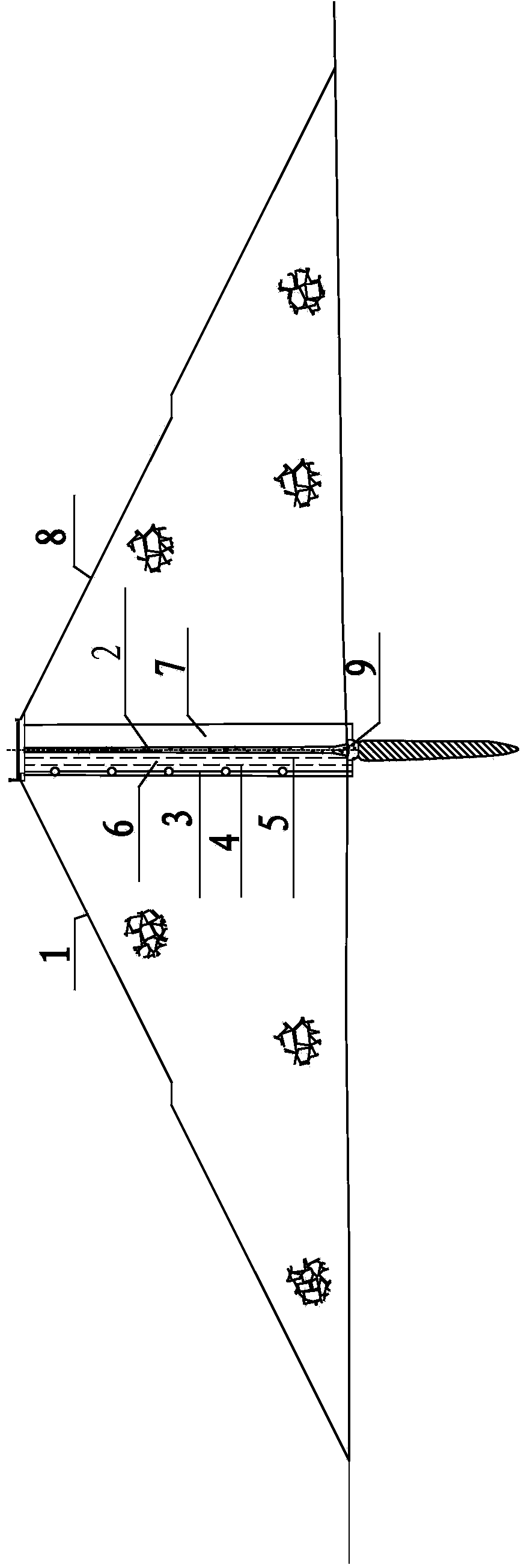

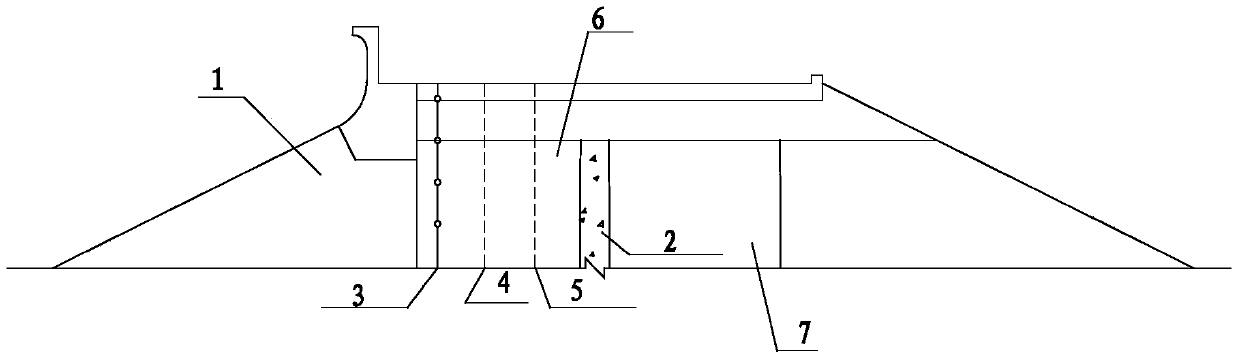

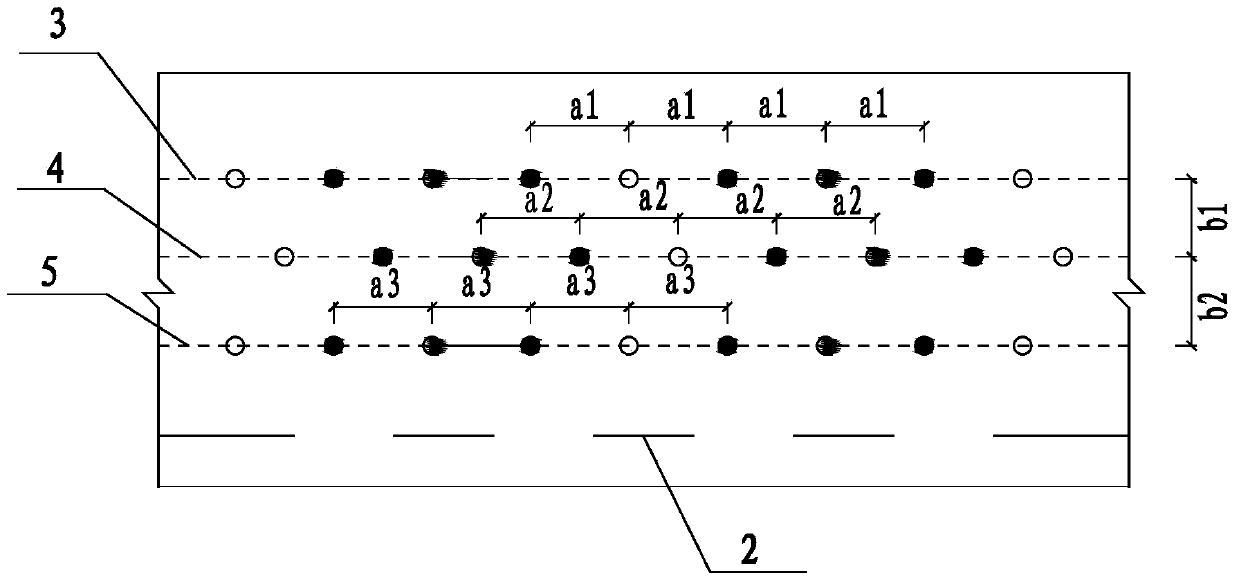

Method for controlling leakage of grouting treatment vertical type asphalt concrete core wall earth-rock dam

ActiveCN103741694ASimple layoutSolve the leakage problemFoundation engineeringProject implementationWater reservoir

The invention discloses a method for controlling leakage of a grouting treatment vertical type asphalt concrete core wall earth-rock dam. The method comprises the steps of first collecting, arranging and analyzing dam technical data, and drawing up a grouting range, grouting hole arrangement and grouting curtain body design indexes; carrying out slurry tests and on-site grouting tests; selecting a device according to slurry test results, manufacturing grouting slurry, performing segmentation and row drilling on an upstream transition layer at a dam crest, and sequentially drilling upstream row grouting holes, middle row grouting holes and downstream row grouting holes in the upstream transition layer from one side of an upstream rockfill material dam shell to an asphalt concrete core wall; and finally performing hole sealing treatment after quality inspection. The method has simplicity in arrangement; under the conditions that a reservoir cannot be emptied, the problem of the leakage of the vertical type asphalt concrete core wall earth-rock dam can be effectively solved, the reservoir can run normally, and dam body safety is guaranteed. Engineering project implementation treatment proves that the method is feasible, safe, reliable and good in leakage treatment effect.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Crack-resistant waterproof cement-based permeable composite repairing material and method for preparing same

InactiveCN101531497AEffective protectionPromotes secondary hydrationSolid waste managementFiberSuperplasticizer

The invention discloses a crack-resistant waterproof cement-based permeable composite repairing material and a method for preparing same. The crack-resistant waterproof cement-based permeable composite repairing material of the invention comprises the following components by the mass fraction: 20% to 40% of Portland cement clinker, 3% to 20% of fly ash, 2% to 10% of gypsum, 2% to 10% of high-alumina cement, 1% to 4% of sodium silicate, 0.1% to 1.5% of high-efficiency naphthalene-based water-reducing agent, 0.1% to 2.0% of sodium carbonate, 40% to 70% of shaping quartz sand, 0.1% to 3.0% of polypropylene staple fiber and 0.05% to 1.0% of sodium carboxymethyl cellulose. The high-performance material of the invention is free from toxicity and pollution, and further has the characteristics of solid cementation, good penetration depth, good waterproof, anti-permeability and crack-resistant effects and the like; and meanwhile, the invention has the advantages of low production cost, simple preparation process and construction method and wide applicable range.

Owner:TIANJIN URBAN CONSTR COLLEGE

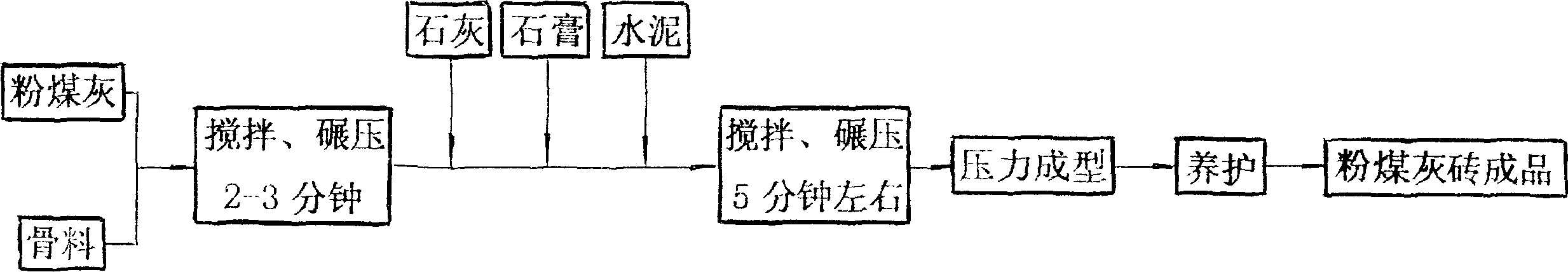

Bricks and mortar made from fly ash and preparation method

InactiveCN1686907AReduce manufacturing costReasonable proportionSolid waste managementFly ash brickBrick and mortar

The present invention belongs to a building brick made of fly ash, mortar and their production method. The raw material composition of brick includes (by wt%) fly ash 70-80, lime 7-13, gypsum 0-1.3, cement 0-5 and the rest is aggregate, and the raw material composition of mortar includes fly ash 70-80, lime 7-13, cement 0-5 and the rest is aggregate. Besides, said invention also provides the concrete steps of their production method.

Owner:韦柳青

Anti-seepage cofferdam structure and construction process

ActiveCN104153380ASimple construction methodSimple structureFoundation engineeringGeomembraneCofferdam

The invention relates to anti-seepage cofferdam structure and a construction process. The cofferdam structure comprises a vertical anti-seepage body arranged in the middle of the end face of a cofferdam, wherein the bottom of the anti-seepage body extends to be embedded into a river bed covering layer, a main body of the anti-seepage body is formed by filling a multi-layer gel and sand gravel mixture, a vertical anti-seepage insulating layer is arranged on one side of the anti-seepage body and is a layer of geomembrane clamped between two geotextiles, a trapezoid cofferdam body is arranged on the other side of the anti-seepage insulating layer, and a lead wire gabion is arranged on the other side of the anti-seepage body. The construction process comprises using a backhoe excavator to remove large stones in a basic region after a temporary cofferdam is built; then using the backhoe excavator to dig a groove with 1.2m width and 3m depth along the cofferdam axis, and back filling the multi-layer gel and sand gravel mixture in layers to construct the anti-seepage cofferdam structure. The anti-seepage cofferdam structure is simple in structural style, the construction method is easy, and the anti-seepage effect is good. A construction period is shortened, fund is saved, and a simple and effective method is provided technically.

Owner:SINOHYDRO BUREAU 11 CO LTD

Synchronous grouting material used for tunnel and preparation method thereof

InactiveCN101928122AUnchangedImprove technical effectSolid waste managementCarboxymethyl celluloseHigh energy

The invention discloses a synchronous grouting material used for a tunnel and a preparation method thereof. The grouting material is the grout which is prepared by taking sediment grout as a main raw material, wherein the sediment grout comprises 30 to 65 percent of clay and fine sand totally and the weight ratio of soil to sand in the sediment grout is 0.1-0.18:1; and adding 80 to 120 kg of cement, 300 to 450 kg of coal ash, 200 to 500 kg of water or mud water and 3 to 10 kg of sodium carboxymethyl cellulose into per cubic meter of the sediment grout, wherein the grout density is between 1.85 and 2.05 g / cm<3> and the grout consistency is between 10.5 and 12 cm. In the preparation method, sediment and the mud water generated in a construction process are adopted as grouting materials, so that the sediment and the mud water can be changed into treasure from waste; and therefore, the preparation method has the characteristics of great reduction of the dosage of high-energy consumption cement, capability of working inside and outside tunnels, and convenient construction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

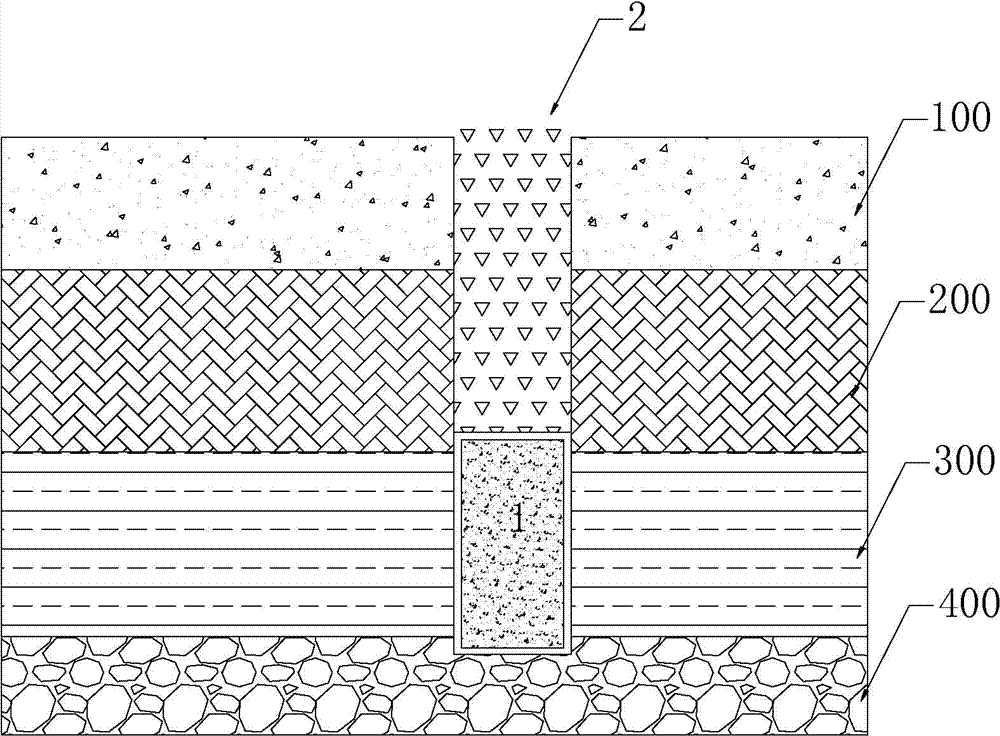

Construction method for processing saline soil roadbed by separation layer

The invention relates to a construction method for processing a saline soil roadbed by a separation layer, comprising the following steps: the separation layer is arranged in a mode that compound geomembranes cover a gravel soil separation layer; the compound geomembranes are laid according to the width of the cross section of the roadbed; firstly, an inner compound geomembrane is laid; then an outer compound geomembrane is laid; the compound geomembranes are flatly laid and tightly adhered to the surface of the roadbed; the gravel soil separation layer is laid on the compound geomembranes and is filled and laminated by layers; the compound geomembranes cover the gravel soil separation layer; gravel soil is filled between the separation layer and the original roadbed surface layer; and the degree of compaction of the top layer is above 97%. According to the construction method disclosed by the invention, the saline soil can be effectively prevented from carrying out salt expansion, corroding and the like on the roadbed, a road surface structure layer can be prevented from damaging, the construction is convenient, the cost of engineering construction can be lowered, the curing cost is reduced, and the stability and the service life of the roadbed can be improved. The practice proves that the scheme brings a better technical effect in the saline soil roadbed construction.

Owner:河南省新开元路桥工程咨询有限公司

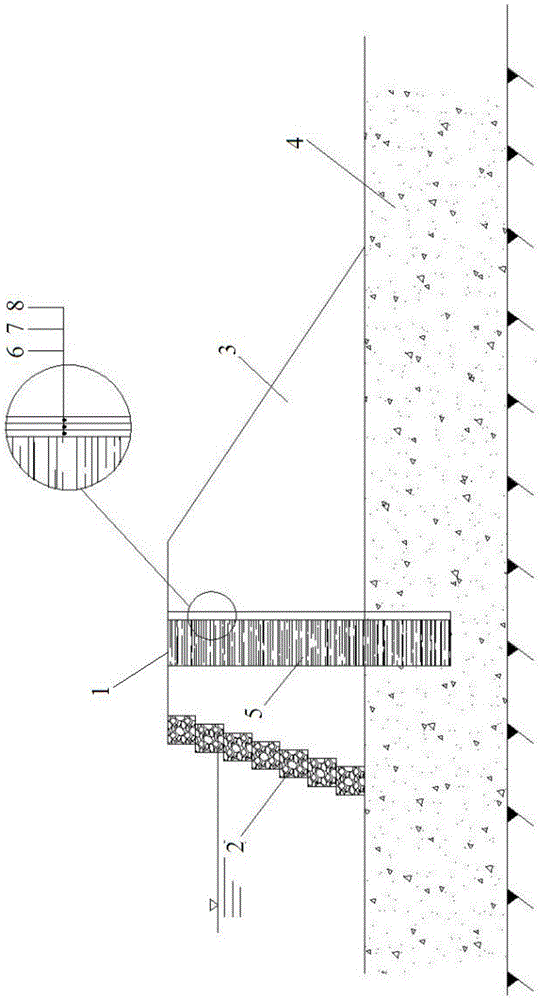

Compound type perpendicular seepage-proofing screen and application thereof

InactiveCN104805871ASolve the problem of circumventionEasy constructionProtective foundationGeomembraneMedicine

The invention discloses a compound type perpendicular seepage-proofing screen which is used for preventing horizontal seepage of pollutants in soil or underground water. The compound type perpendicular seepage-proofing screen comprises a perpendicular flexible seepage-proofing part and a by-pass seepage preventing part, wherein the perpendicular flexible seepage-proofing part comprises a rectangular HDPE (high-density polyethylene) geomembrane; the by-pass seepage preventing part comprises a by-pass seepage preventing supporting part and self-hardening mud which coats the by-pass seepage preventing supporting part; the by-pass seepage preventing supporting part comprises gridding cloth and sodium-based bentonite encapsulated in the gridding cloth, and a groove is formed in the surface of the by-pass seepage preventing supporting part; the bottom of the perpendicular flexible seepage-proofing part is embedded and inserted into the groove of the by-pass seepage preventing supporting part, and the bottom of the perpendicular flexible seepage-proofing part is fixed with the by-pass seepage preventing supporting part through a bolt. The compound type perpendicular seepage-proofing screen has the advantages of being simple in construction, good in seepage-proofing effect, and the like, and can be used for solving the by-pass seepage problem on a joint of the HDPE geomembrane and an underground water-impermeable layer.

Owner:BEIJING GEOENVIRON ENG & TECH

Water stop method for upper-soft and lower-hard water-rich stratum foundation pit engineering retaining structure

The invention discloses a water stop method for an upper-soft and lower-hard water-rich stratum foundation pit engineering retaining structure. The method includes the steps that firstly, a cast-in-situ bored pile is constructed; secondly, on the outer side of the cast-in-situ bored pile, a high-pressure jet grouting pile or a three-shaft stirring pile is constructed; thirdly, a hole is drilled in the center of the high-pressure jet grouting pile or the three-shaft stirring pile, and high-pressure jet grouting or sleeve valve pipe grouting is performed; fourthly, deep hole curtain grouting is performed; fifthly, a first-layer small guiding pit is excavated; sixthly, preliminary-stage supporting is performed on an upright excavation face of the first-layer small guiding pit; seventhly, core soil is reserved during excavation of a first-layer foundation pit; eighthly, a first-layer transverse steel purlin is arranged, and a steel cross brace is erected; and ninthly, when the pre-designed strength of the retaining structure is achieved and the monitored and measured result is accurate, next circulation is performed, and the fourth step, the fifth step, the sixth step, the seventh step and the eighth step are repeated till construction ends. The method is good in main water stop effect and good in flexibility. The technology is simple, the construction risk is small, influences on the environment are small, and adaptability to a complicated stratum is high.

Owner:FUJIAN UNIV OF TECH

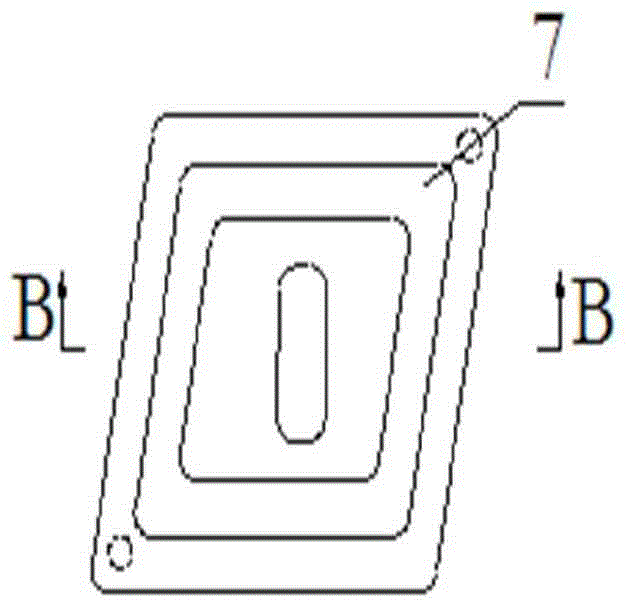

Seepage prevention method and fixture for aerial engine blade rabbet

ActiveCN102978565AImprove anti-seepage effectWill not polluteSolid state diffusion coatingAviationChemical reaction

The invention relates to a seepage prevention method and a fixture for an aerial engine blade rabbet. The seepage prevention method for the aerial engine blade rabbet comprises the following steps of: after heating the cleaned blade rabbet, winding aluminum oxide cotton on the outer surface of the blade rabbet, and clamping the aluminum oxide cotton wound on the blade rabbet by two metal clamps; then putting the blade rabbet wrapped by the aluminum oxide cotton into a metal protective jacket together with the metal clamps; and taking mixtures of ferro-aluminum powders, aluminum-silicon powders and tetra-methylammonium chloride as seepage agents, and carrying out gas aluminizing in a conventional method. The aluminum oxide, used in the invention, can resist corrosive atmosphere, and can not generate any chemical reaction and further generate pollution to a blade. Due to the adoption of the seepage prevention method and the fixture for the aerial engine blade rabbet, seepage layers on the rabbet part can be completely removed by only carrying out processes of wet grit blasting and coloring for one time, the repeated processes of dry grit blasting and the coloring are avoided, the production efficiency is improved for 1-2 times, and 30-40% of cost is saved; and furthermore, the operation is simple, and the seepage prevention effect is good.

Owner:AECC AVIATION POWER CO LTD

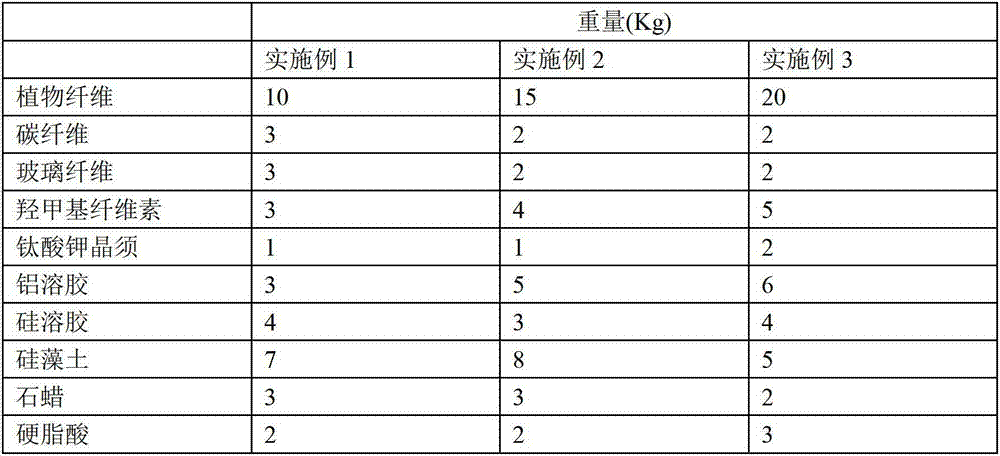

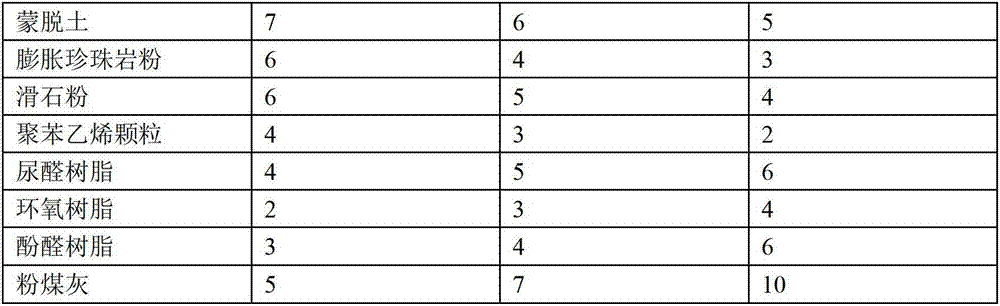

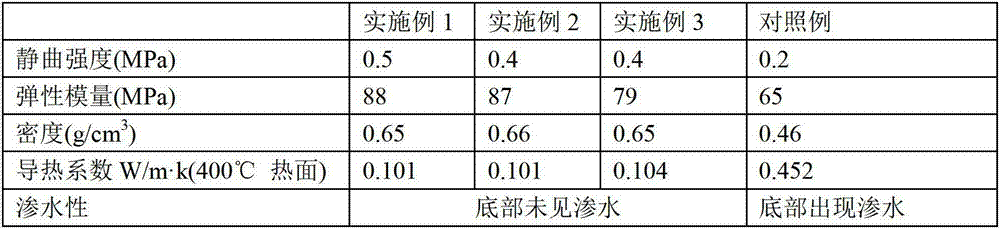

Seepage-proof thermal insulation wall material containing fibrous material

ActiveCN102850032AImprove insulation performanceLow costVegetable fibersSodium carboxymethylcellulose

The invention provides a seepage-proof thermal insulation wall material containing a fibrous material, which belongs to the technical field of building materials. The wall material comprises, by weight, 10 to 20 parts of vegetable fiber, 2 to 3 parts of carbon fiber, 2 to 3 parts of glass fiber, 3 to 5 parts of carboxymethyl cellulose, 1 to 2 parts of potassium titanate whisker, 3 to 6 parts of aluminum sol, 3 to 4 parts of silica sol, 5 to 8 parts of diatomite, 2 to 3 parts of paraffin, 2 to 3 parts of stearic acid, 5 to 7 parts of montmorillonite, 3 to 6 parts of expanded perlite powder, 4 to 6 parts of talcum powder, 2 to 4 parts of a polystyrene particle, 4 to 6 parts of urea formaldehyde resin, 2 to 4 parts of epoxy resin, 3 to 6 parts of phenolic resin and 5 to 10 parts of fly ash. The thermal insulation wall material containing a fibrous material provided by the invention has a small coefficient of heat conductivity, about 0.1 W / m.k, and has good seepage-proof performance.

Owner:苏州市德莱尔建材科技有限公司

Novel rubbish landfill yard anti-seepage material

InactiveCN101456688AAdvantages of anti-seepage materialsNo puncture will occurSodium BentoniteLitter

The invention discloses an impermeable material for a refuse landfill, which is prepared by stirring, paving and rolling a raw material. The thickness of the impermeable material for the refuse landfill is 30 to 50 centimeters, the compactness of the impermeable material for the refuse landfill is more than 90 percent, and the raw material consists of the following components by mass percentage: 60 to 80 percent of semi-rigid material, 3 to 20 percent of bentonite, and 10 to 20 percent of water. Compared with the prior art, the impermeable material for the refuse landfill has the advantages of good impermeable effect, strong anti-puncturing capability, low preparation energy consumption and cost, and simple and convenient construction.

Owner:ZHEJIANG UNIV OF TECH

Construction method of anti-seepage wall of hydropower station

ActiveCN106948354AImprove anti-seepage effectImprove quality controlBlastingExcavationsMaterial resourcesHydropower

The invention discloses a construction method of an anti-seepage wall of a hydropower station. The construction method comprises the steps that first-stage groove section construction and second-stage groove section construction are sequentially carried out on a wall base; first-stage groove sections and second-stage groove sections are arranged in a staggered manner; each groove section is divided into totally three single holes, namely, main holes in the two sides and an auxiliary hole in the middle, and in order to guarantee groove hole type construction, the main holes in the two sides of each groove section are firstly grabbed, and then the auxiliary hole in the middle of each groove section is grabbed; and after hole grabbing is completed, a concrete wall body is poured. Through the adoption of the method, construction difficulty can be reduced, the construction period can be shortened, and manpower and material resource waste can be avoided.

Owner:POWERCHINA XIBEI ENG

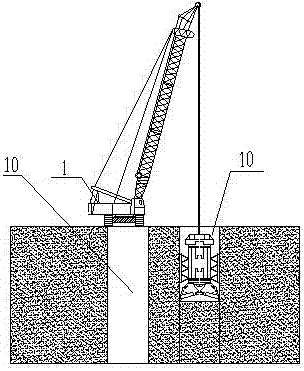

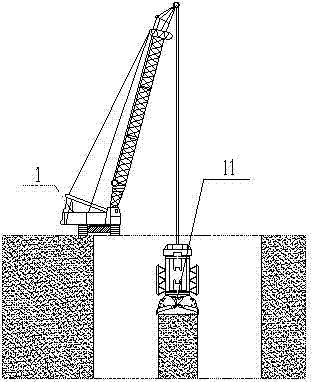

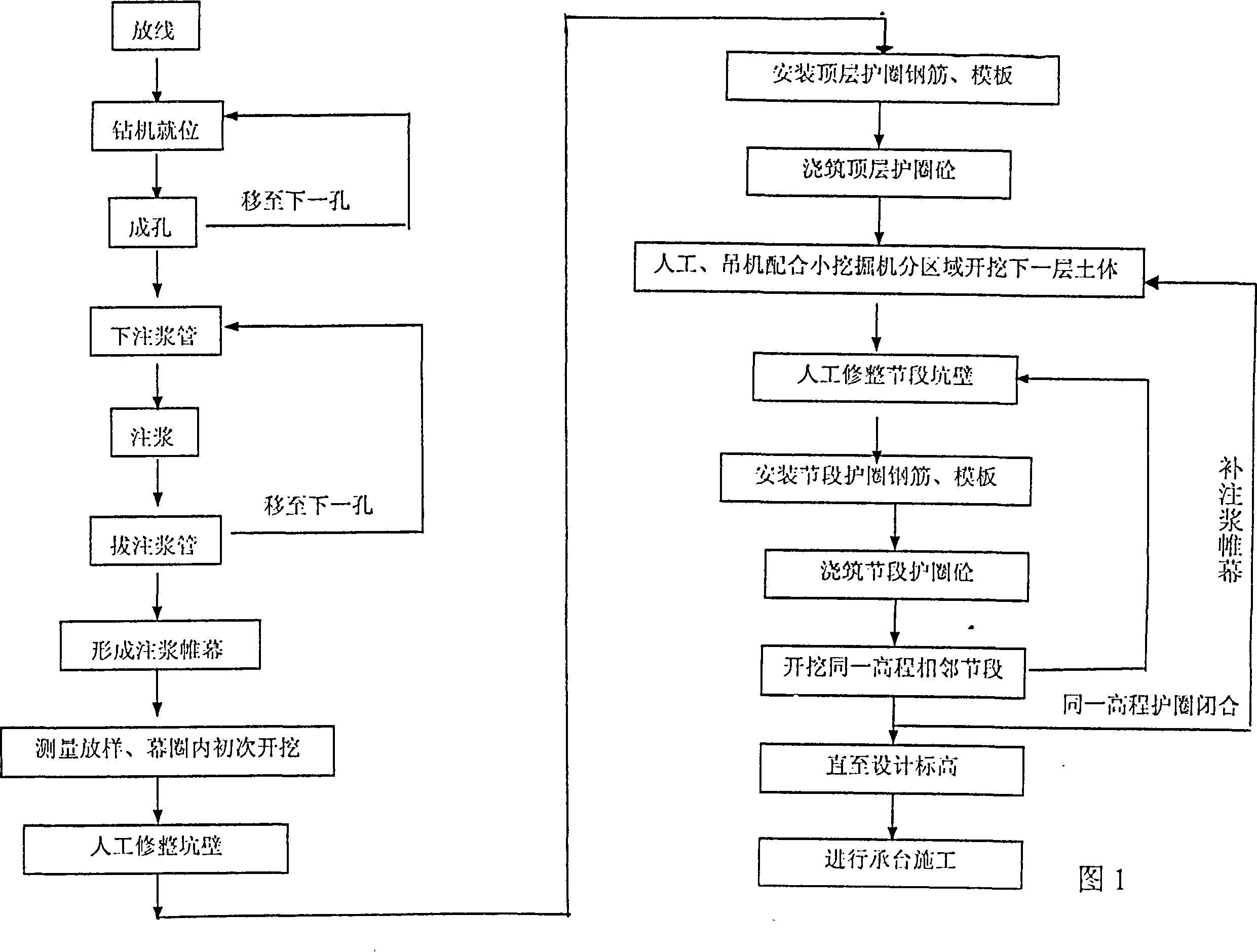

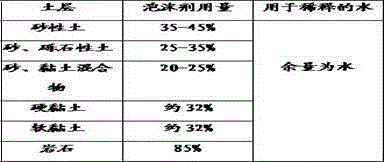

Construction method for grouting curtain combined with steel reinforced concrete guard ring

InactiveCN101200897AReduce thicknessImprove anti-seepage effectSoil preservationReinforced concreteCofferdam

The present invention relates to a construction method by which grout curtains are combined with reinforced concrete cages. The construction of a grout curtain is carried out by an engineering driller and a grouter as the construction of drilled piles is carried out, a foundation ditch is dug layer by layer while the reinforced concrete cages are constructed, the soil body on the periphery of a cofferdam is concreted, stepped excavation and stepped shoring are carried out till the bottom of the foundation ditch, and after the construction of the drilled piles is finished, the construction of a bearing platform is carried out. The curtain formed by grouting is waterproof, the reinforced concrete cages are constructed while the bearing platform foundation ditch is dug, so the soil pressure, water pressure and unbalanced construction load generated by the excavation of the foundation ditch are resisted. The construction of the grout curtain can be carried out as the construction of drilled piles is carried out, the foundation ditch is dug layer by layer while the reinforced concrete cages are constructed, consequently, the construction period is effectively shortened and the construction equipment which is put into use is reduced. The construction by reinforced concrete caissons, steel cofferdams and steel plate piles is difficult, the present invention can easily resolve the problem, and meanwhile, according to the geological conditions, the construction of the bearing platform can apply non-bottom sealing construction, thus saving the cost.

Owner:THE 2ND ENG CO LTD MBEC

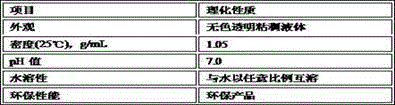

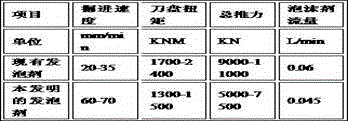

Earth pressure balance shield foaming agent

ActiveCN104946263AImprove plasticityImprove liquidityBuilding constructionsOrganic fertilisersBetaineCocamidopropyl betaine

The invention relates to an earth pressure balance shield foaming agent and a preparation technology thereof. The earth pressure balance shield foaming agent is prepared from 4-15% by weight of sodium dodecyl sulfate, 1-10% by weight of cetyltrimethylammonium chloride, 2-8% by weight of cocamidopropyl betaine, 1-5% by weight of dodecyldimethylamine oxide, 0.1-0.5% by weight of disodium ethylene diamine tetraacetate, 0.1-2.0% by weight of a tackifier and the balance water. The earth pressure balance shield foaming agent has a simple formula and high effects, and utilizes cetyltrimethylammonium chloride with excellent permeability, flexibility, emulsification effects and sterilization performances as a cationic surfactant which can be mixed with other surfactants. The earth pressure balance shield foaming agent is environmentally friendly, has excellent permeability and lubricity and can effectively improve excavated soil fluidity and watertightness.

Owner:XIAMEN NORNS TECH

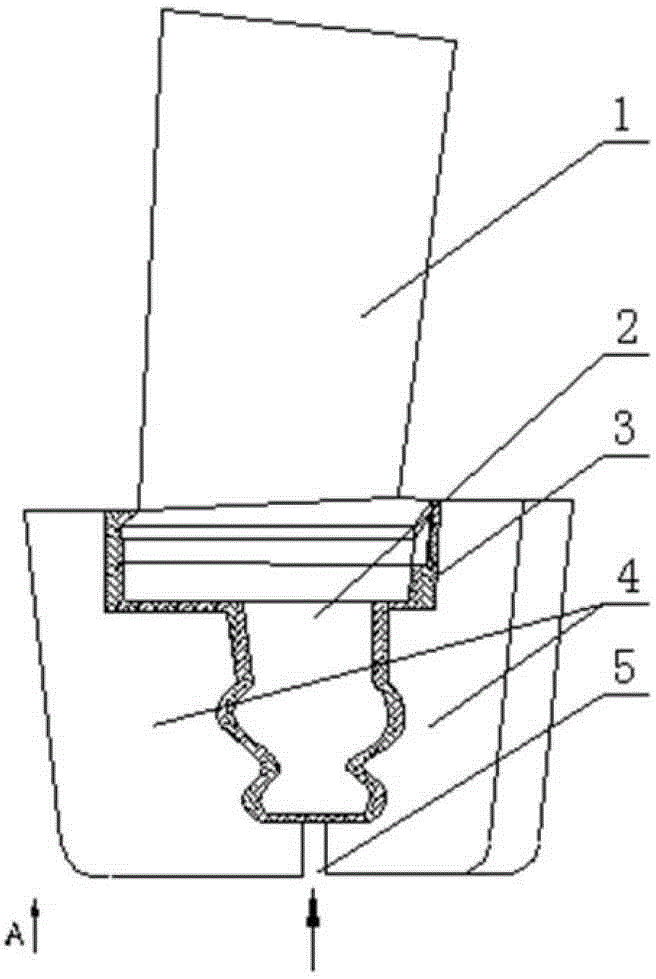

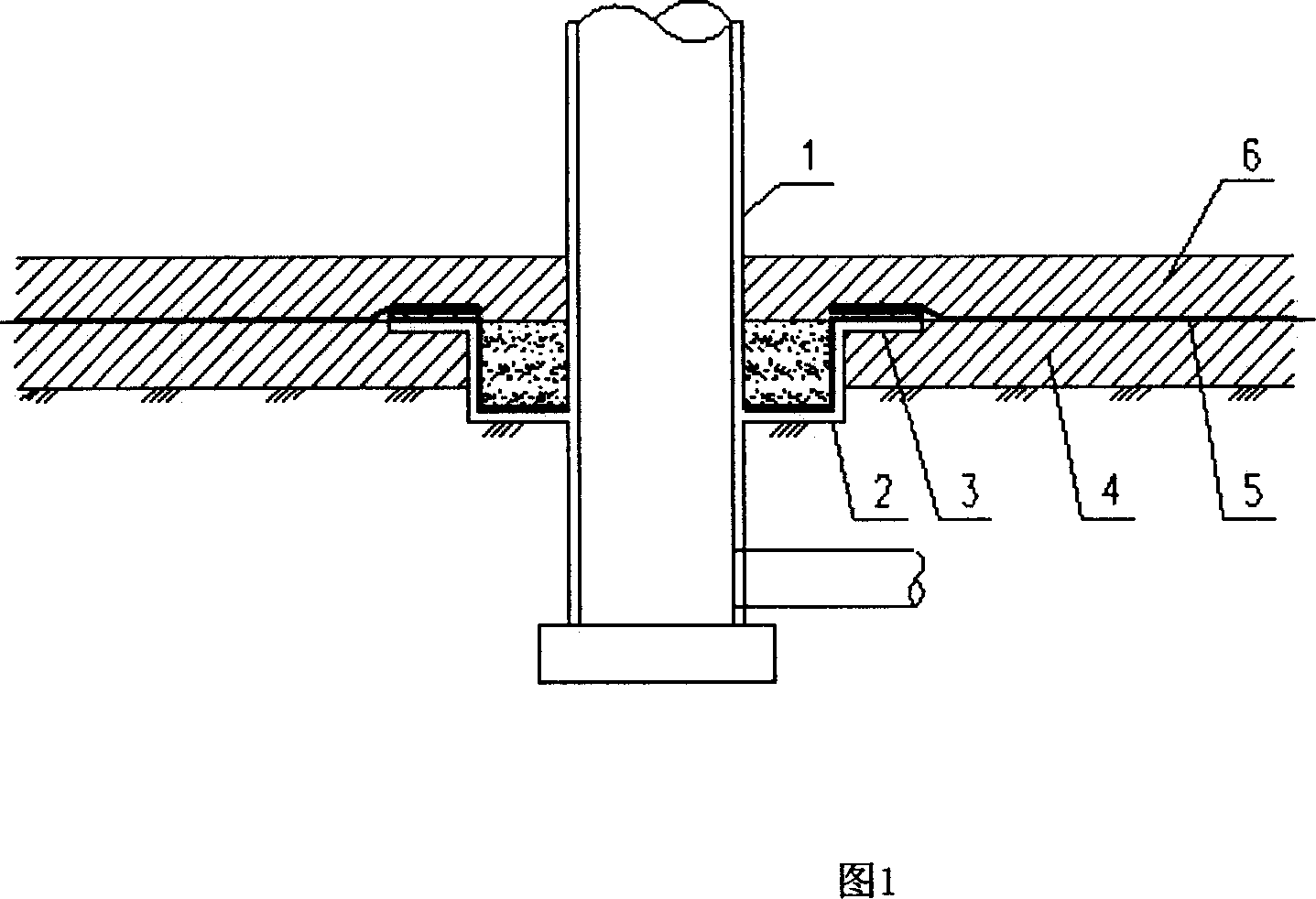

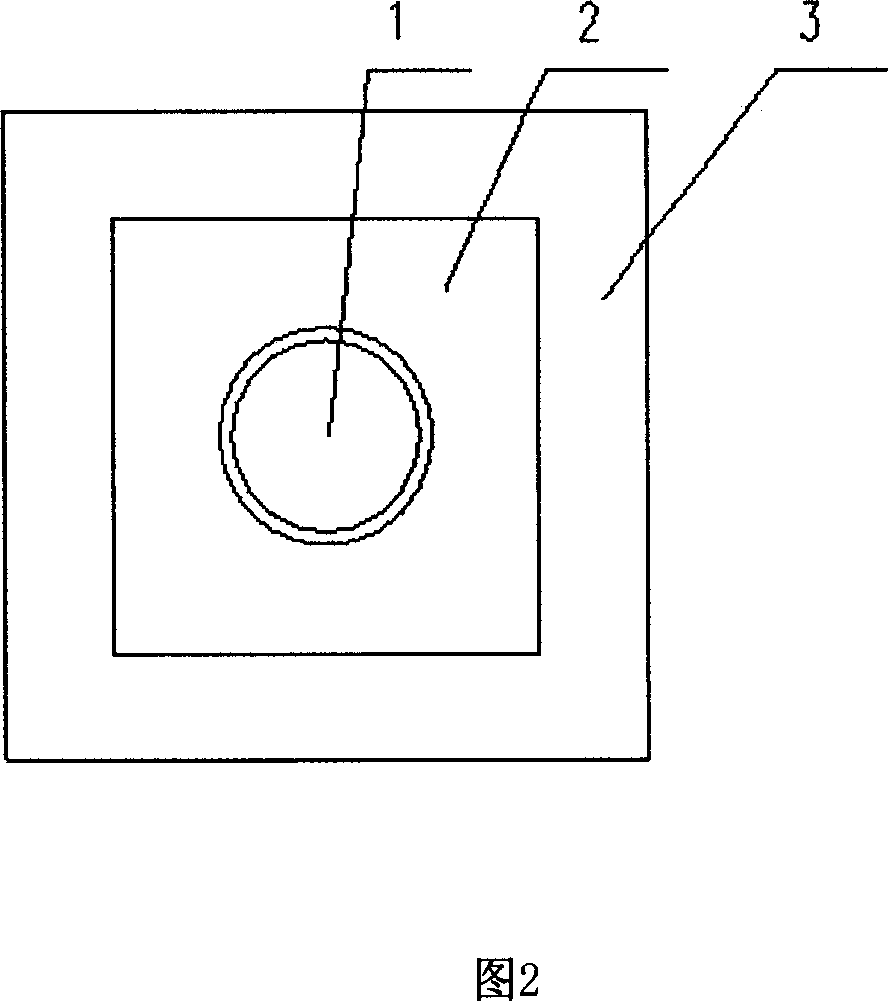

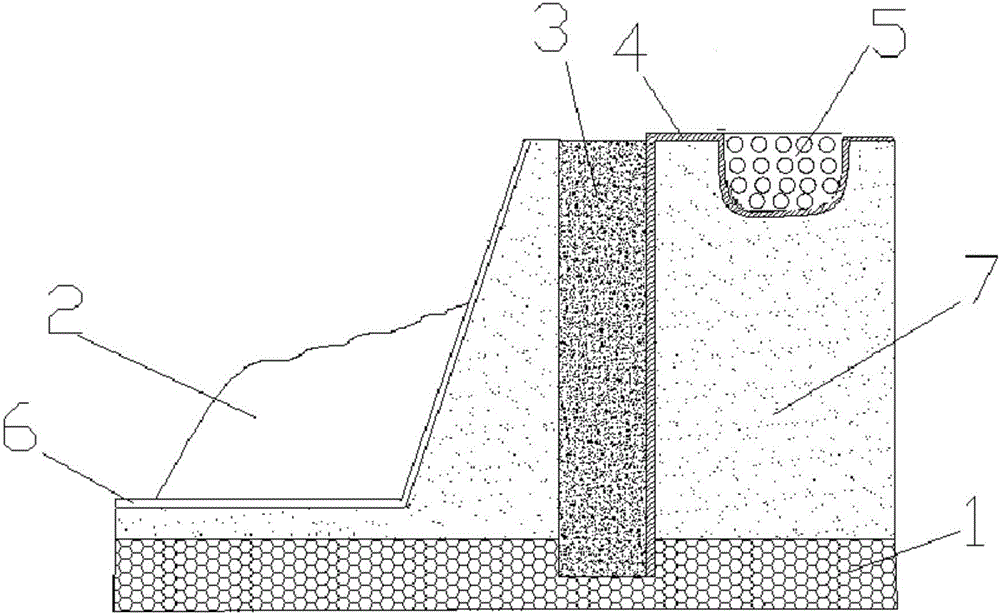

Connecting method and structure for horizontal impervious layer and drainage vertical shaft of red mud yard

ActiveCN1924203AFix the leakSimple construction methodArtificial islandsProtective foundationGeomembraneRed mud

This invention discloses one red earth bump level anti-transparency layer and discharge shaft connection method and its structure, which comprises the following steps: setting concaved tank on discharge shaft and ring edge in concaved tank; then processing level anti-transparency pad layer with top part align to ring edge; then paving compound geomembrane; then drilling concrete into concaved tank; finally processing anti-transparency protection layer.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for improving single-layer oil tank into double-layer oil tank

ActiveCN106239932AReal-time anti-seepage detectionImprove anti-seepage performanceLarge containersDomestic articlesGlass fiberEngineering

The invention relates to a method for improving a single-layer oil tank into a double-layer oil tank. On the basis that the inner wall of the buried single-layer steel oil tank in service is derusted, an anti-corrosion reinforcing coating, a 3D through gap layer and a glass steel inner tank are sequentially manufactured, and the single-layer oil tank is quickly improved into the glass steel double-layer oil tank with a through gap layer space. The 3D through gap layer is communicated with a tank top monitoring well, and sealing performance of the inner tank and the steel outer tank in service can be monitored all day long. The inner surface of the glass steel inner tank is coated with an anti-static layer which makes direct contact with stored liquid, the anti-static layer is connected with an original steel storage tank, and the original steel single-layer storage tank is grounded so that electrostatic hazards can be avoided. The inner tank is made from a glass steel material formed by mixing resin and glass fiber. The oil tank improvement method has the advantages of being good in safety, high in strength, convenient to manufacture and the like, corrosion resistance of the oil tank is improved, the overhaul frequency is reduced, the service life is prolonged, and improvement cost is reduced.

Owner:ZHONGYI GLASS FIBER REINFORCED PLASTICS

GCL vertical anti-seepage wall and preparation method thereof

ActiveCN105672365AGood anti-seepageTightly boundProtective foundationGeotextilesStructural engineeringLow permeability

The invention discloses a GCL vertical anti-seepage wall and a preparation method thereof. The GCL vertical anti-seepage wall comprises a vertical anti-seepage wall body, wherein a sodium-based geosynthetic clay liner is fixed at the outer side of the vertical anti-seepage wall body, and the sodium-based geosynthetic clay liner comprises a vertical anti-seepage structure and a top fixation structure. The anti-seepage wall disclosed by the invention has a low permeability coefficient, and is good in bonding with a soil mass, and high in anti-seepage effect.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

Composite barrier for preventing horizontal diffusion and migration of underground water layer pollutants and application thereof

ActiveCN104499509AEasy to prepareLow raw material costProtective foundationWater soluble polymersPollutant

The invention discloses a composite barrier for preventing horizontal diffusion and migration of underground water layer pollutants and application thereof. The composite barrier is formed by encapsulating expansion clay by a water-soluble polymer film. During the application, the composite barrier is placed into a vertical open groove with a watertight layer arranged at the groove bottom, the filling height of the composite barrier in the vertical open groove is not lower than the upper plane of the underground water layer, wall protecting slurry is removed, and then, soil is filled back into the vertical groove until the vertical groove is flatly filled. The composite barrier has the advantages that the construction is simple, the engineering manufacturing cost is low, the anti-seeping effect is good, and the like. The horizontal migration of pollutants in the underground water layer can be better prevented.

Owner:BEIJING GEOENVIRON ENG & TECH

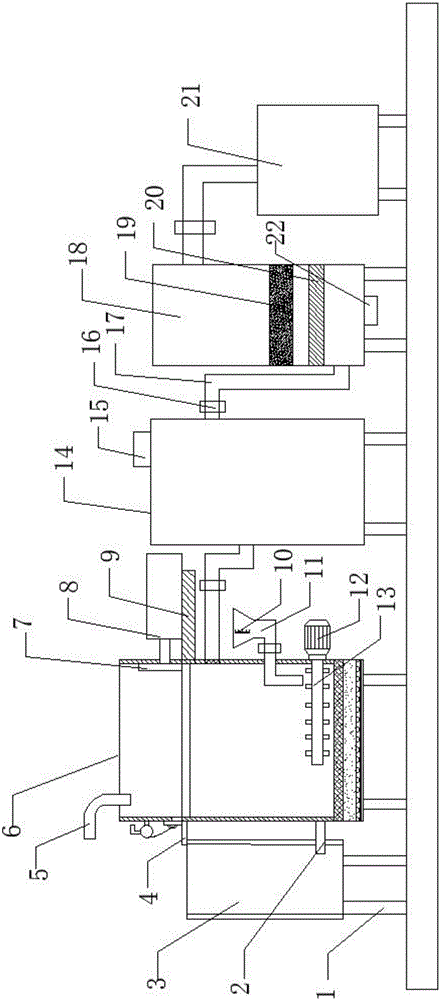

Rainwater collecting and processing device

InactiveCN106193258ATo achieve the treatment effectControl flowFatty/oily/floating substances removal devicesSewerage structuresSludgeRainwater harvesting

The invention discloses a rainwater collecting and processing device. The rainwater collecting and processing device comprises supports, a defouling tank body, a disinfecting tank, a pH-value adjusting tank and a clean water tank, wherein the defouling tank body is connected with a rain water collecting pipe network through a rainwater pipe, the defouling tank body, the disinfecting tank, the pH-value adjusting tank and the clean water tank are all mounted on the supports, and communicate with one another in sequence through a pipeline, a valve is mounted on the pipeline, an impermeable layer is arranged at the bottom of the defouling tank body, a drain outlet is formed in the outer wall of the defouling tank body, a filtering screen is fixedly arranged inside the defouling tank body and in a position below the drain outlet, a mounting plate is arranged on the outer wall, far away from the drain outlet, of the defouling tank body, a telescopic pole is mounted on the mounting plate, a defouling plate is arranged on the filtering screen, the output shaft of the telescopic pole penetrates through the defouling tank body to be connected with the defouling plate, mud and impurities in rainwater can be effectively removed, the rainwater pH-value is adjusted, and the structure is reasonable.

Owner:何颖

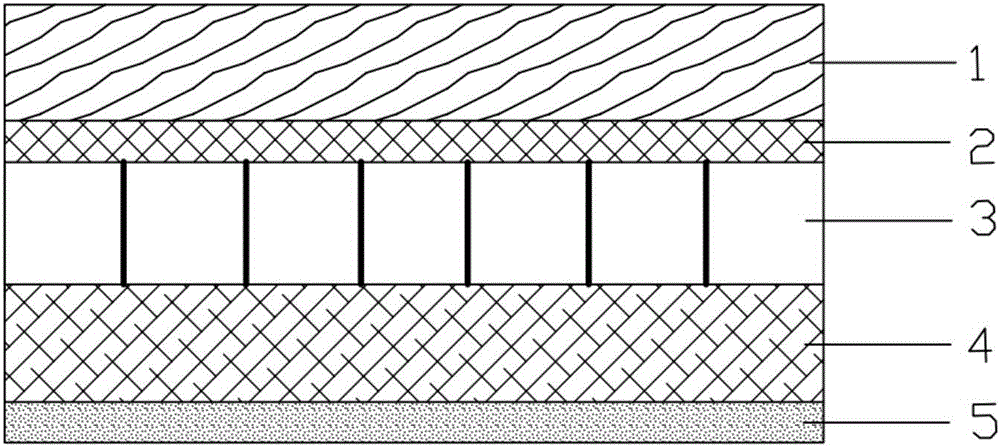

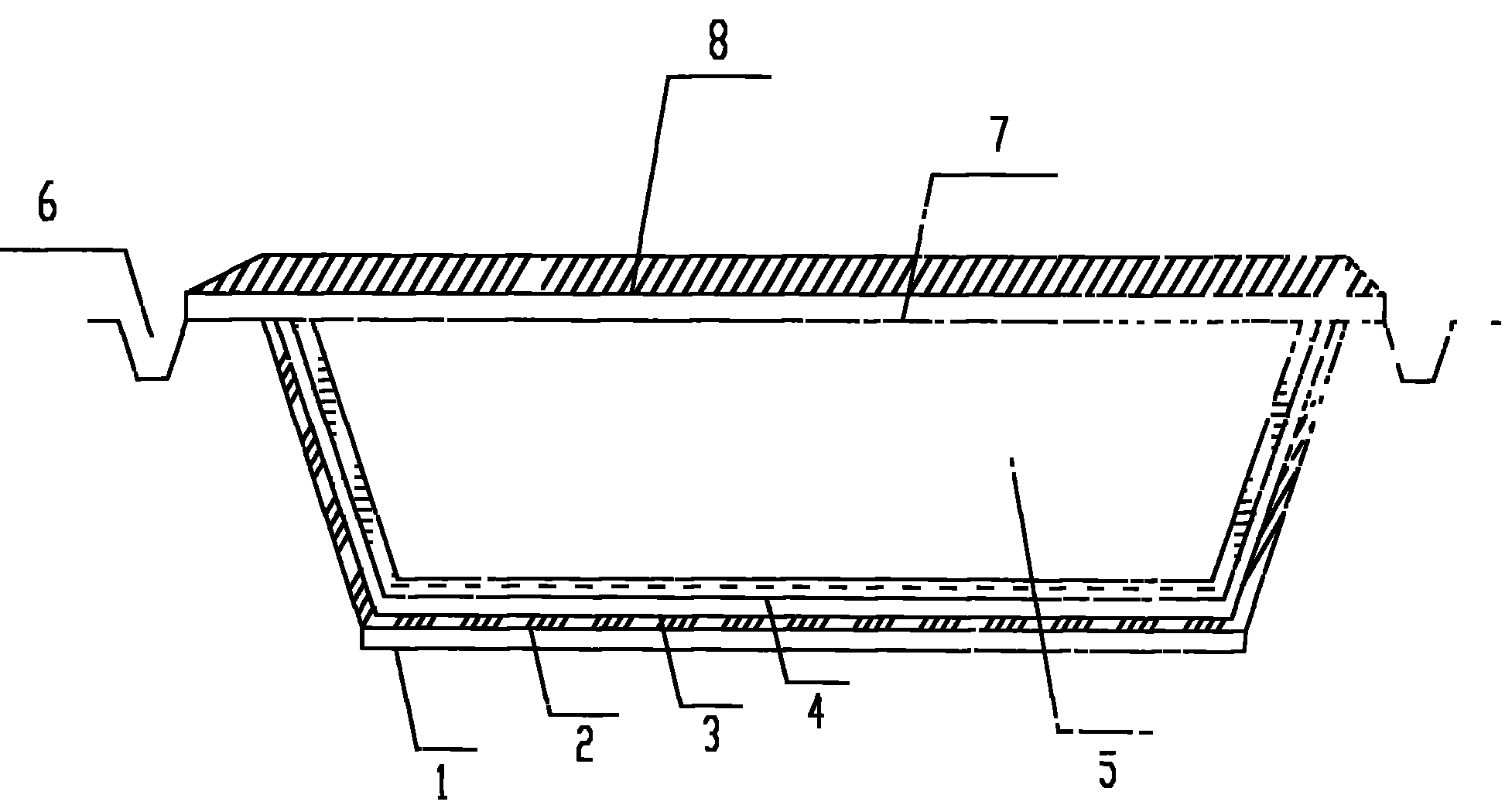

Method for constructing oil drilling waste mud solidification pool

ActiveCN101979781AImprove anti-seepage effectWill not puncture the polyethylene geomembraneArtificial islandsUnderwater structuresGeomembraneWell drilling

The invention provides a method for constructing an oil drilling waste mud solidification pool and relates to the technical field of oil and gas exploration drilling pollution control. A scheme of the method comprises the following steps of: excavating the solidification pool on site, wherein the slope of a pool wall is 45 to 60 DEG, and the pool height is 2.0 to 2.5 m; performing seepage control on a pool bottom by adopting clay-(non-woven geotextile)-(high-density polyethylene geomembrane)-(non-woven geotextile); continuously packaging solid waste to a top part by using the clay-(non-woven geotextile)-(high-density polyethylene geomembrane)-(non-woven geotextile); and capping the top part by using C20 concrete so as to prevent a solidified body from seeping. The process is simple and easy, the cost investment is small, the construction period is short, and the drilling waste mud is propelled to be solidified rapidly and timely so as to effectively prevent the waste mud from overflowing and polluting the environment in the drilling operation process.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Preparation of low-carbon energy-saving modified polyethylene waterproof special material

The invention relates to the preparation of a low-carbon energy-saving modified polyethylene waterproof special material, which belongs to the field of the preparation of high molecular materials. The preparation of the low-carbon energy-saving modified polyethylene waterproof special material solves the problems of low performance and high price of a single raw material of polyethylene; and recovered polyethylene plastics is applied as a modified base material, which conforms to the requirements of energy saving, low carbon and environmental protection and also widens the application field of the recovered material. The low-carbon energy-saving modified polyethylene waterproof special material belongs to a blended modified material and has low manufacturing cost and excellent performance, and various advantages of the low-carbon energy-saving modified polyethylene waterproof special material are incomparable to novel materials. The modified polyethylene waterproof special material has the excellent performances of high tensile strength, large elongation at break, corrosion resistance, ageing resistance, good impermeability and the like; the modified polyethylene waterproof special material is used for manufacturing products, such as impermeable waterproof coiled materials, plates, sheets and the like, and also has the advantage that cold construction can be carried out; and the modified polyethylene waterproof special material is largely used in the engineering of water prevention, corrosion prevention and leakage prevention in various fields of railways, bridges, refuse landfill and the like, and has extensive market.

Owner:大连盖特科技发展有限公司

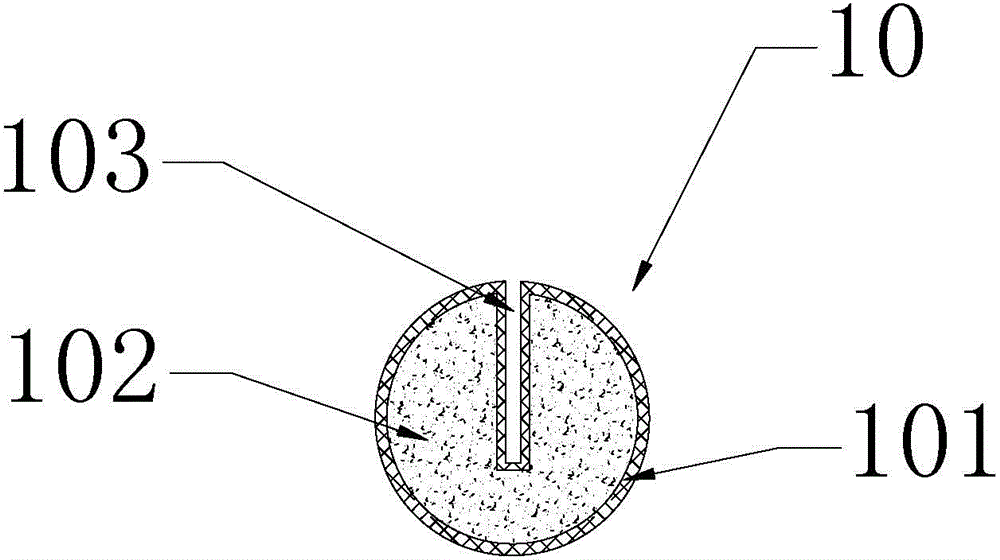

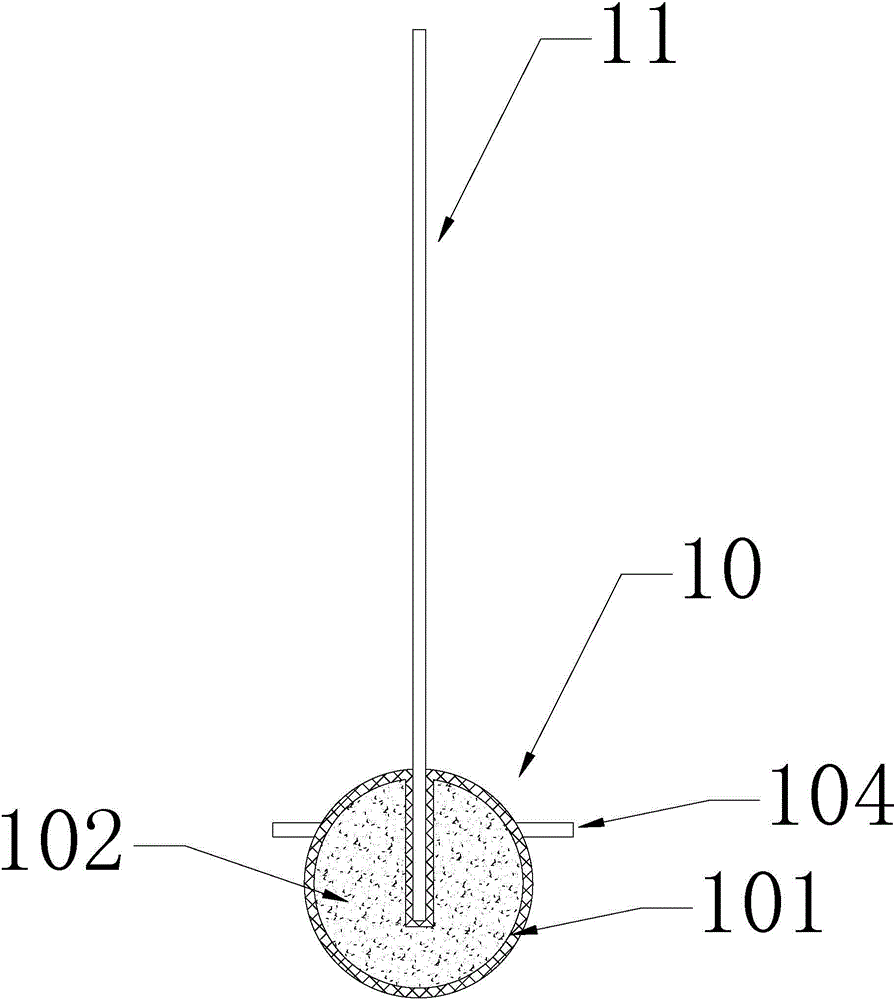

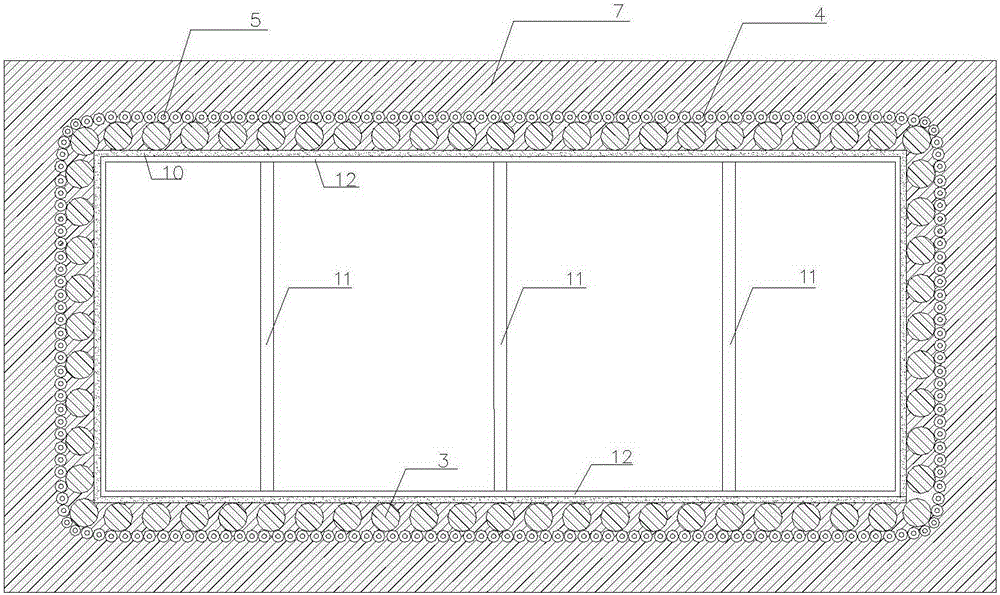

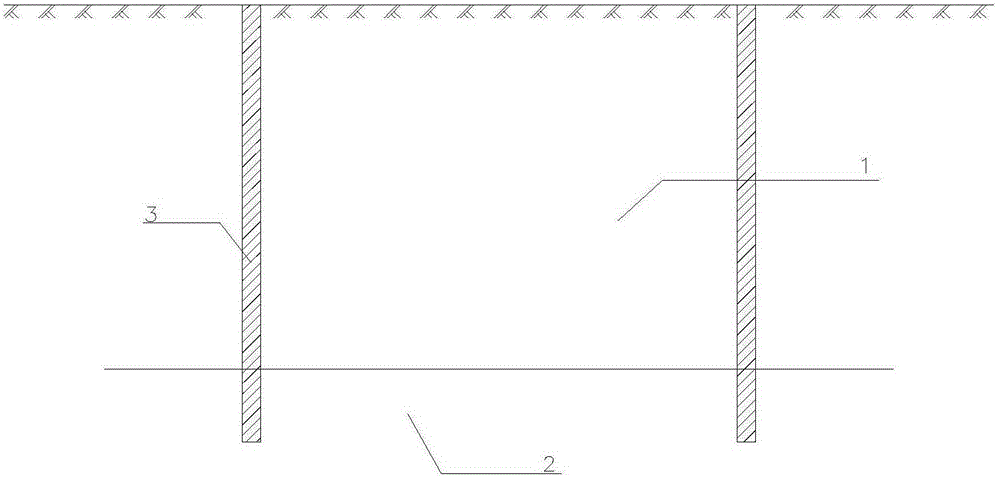

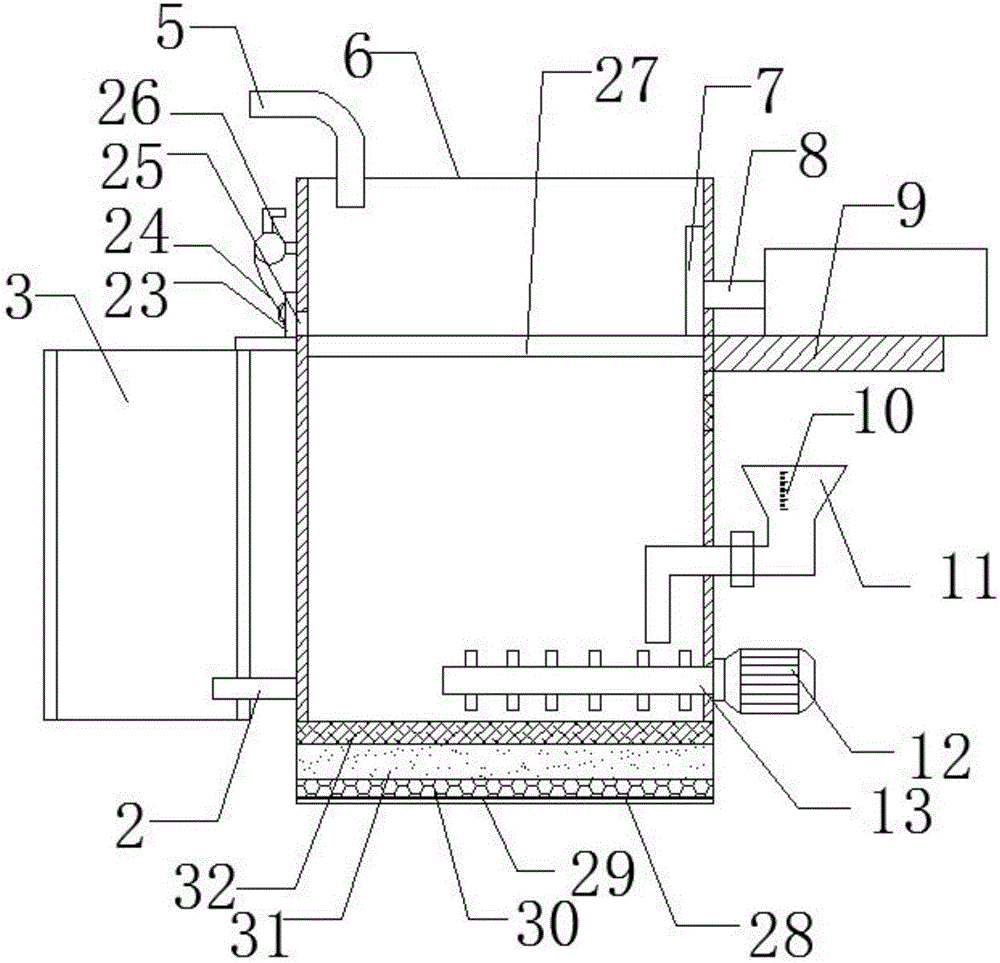

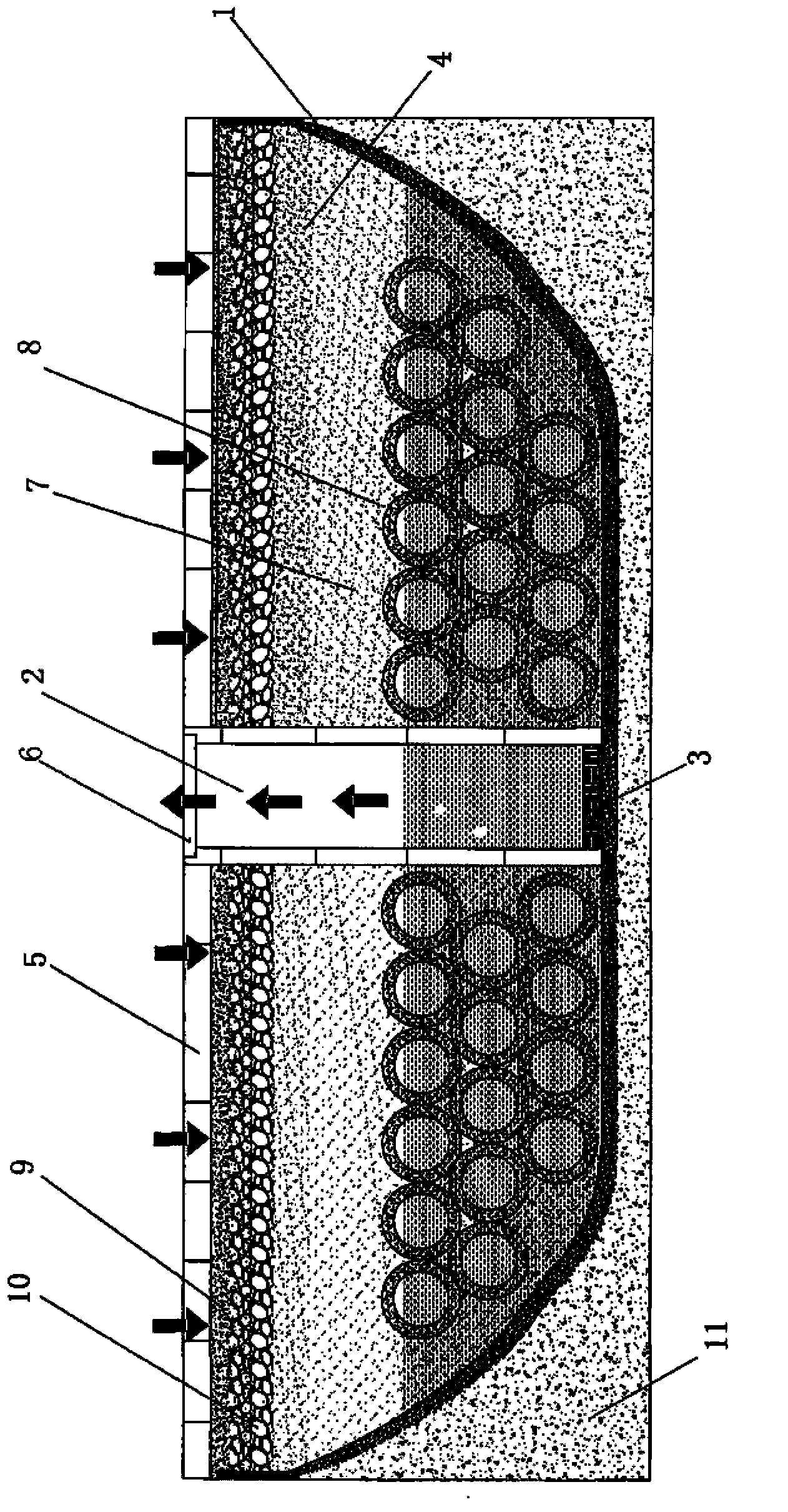

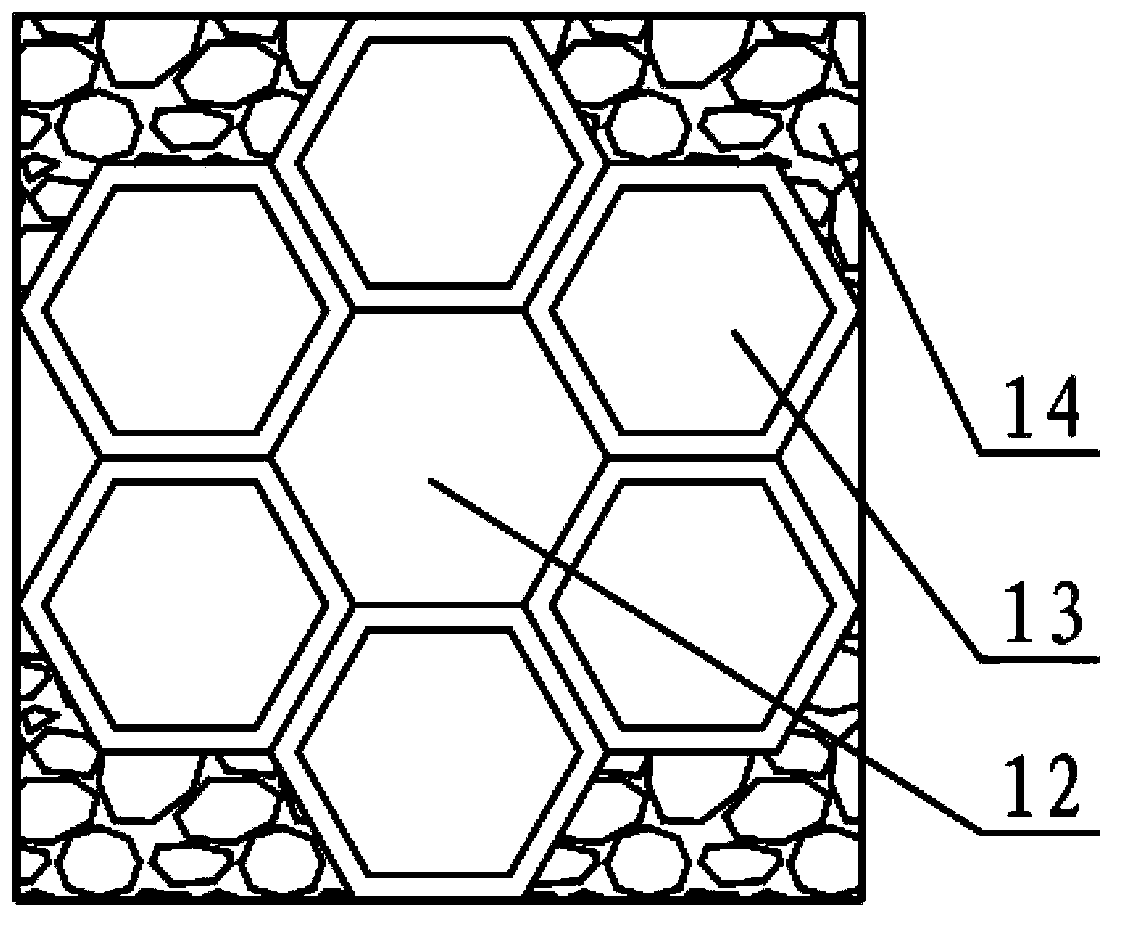

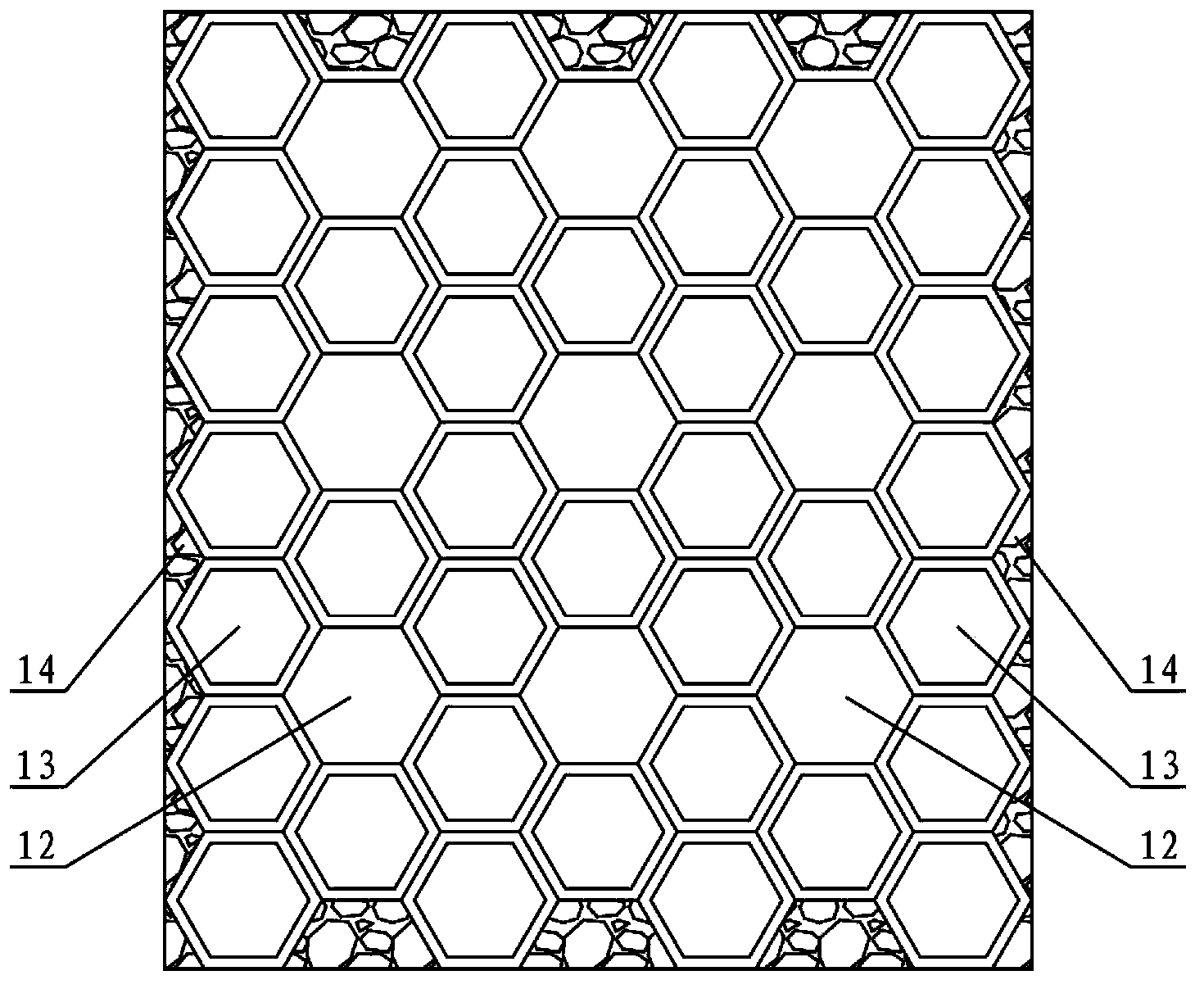

Water purifying and water storing unit, and water purifying and water storing system

ActiveCN103408187AWon't settleWon't spoilGeneral water supply conservationMultistage water/sewage treatmentWater dischargeFiltration

The invention belongs to the field of municipal engineering technologies, and especially relates to a water purifying and water storing unit, and a water purifying and water storing system provided with the water purifying and water storing unit, which are used for collection, filtration, purification treatment and storage of rain water. The container wall of a water container of the water purifying and water storing unit is water resistant; a water discharging well and invisible wells around the water discharging well are arranged in the water container; pervious structures are employed for the well walls of the water discharging well and the invisible wells; spaces between the water discharging well and the container wall of the water container, and spaces between the invisible wells and the container wall of the water container are all filled with a filling material; and a pervious surface bed is arranged on the invisible wells and the filling material. A combination mode of ventilation anti-seepage treatment and concrete floor is employed for the well bottom of the water discharging well and the invisible wells, so that water will not deteriorate, and subsidence of the water discharging well and the invisible wells will not happen; hexagonal honeycomb structures are employed for the water discharging well and the invisible wells, so that the structures are stable, specific surface area is large, carriers are provided for biofiml formation, water processing performance is obtained, and no energy is consumed.

Owner:北京仁创生态科技有限公司

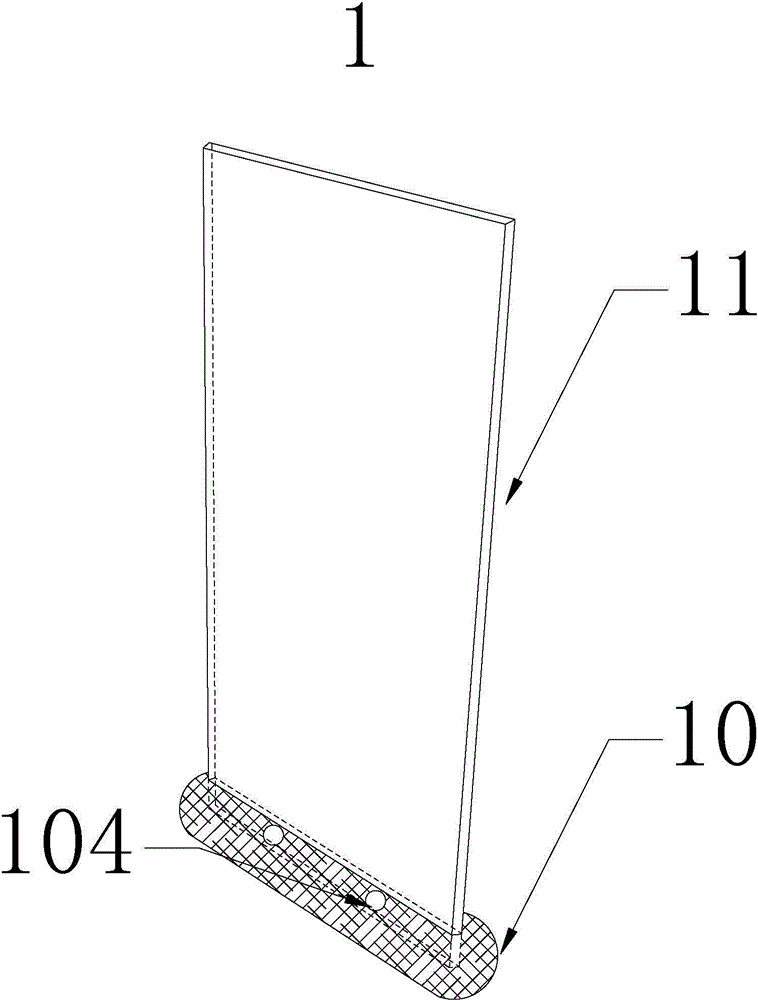

Underground impermeable membrane inserting connector and construction method thereof

PendingCN108867710AImprove anti-seepage effectConstruction is more convenient and efficientProtective foundationEngineeringMembrane configuration

The invention discloses an underground impermeable membrane inserting connector and a construction method thereof. The underground impermeable membrane inserting connector comprises a connector body,one or more grouting grooves or one or more grouting rooms are formed in the connector body, an opening is formed in the side end of the connector body and runs through the grouting grooves, insertingparts are arranged in the grouting grooves and comprise linking segments and installing segments, the linking segments extend out of the connector body from the opening, and the installing segments are movably inserted into the lateral portion of the opening, then extend into impermeable membranes or permeating membranes through the opening, and are connected with the impermeable membranes or thepermeating membranes through the linking segments. The aim that the impermeable membranes are applied to underground anti-seepage treatment construction through inserting is realized, construction quality and efficiency are further improved, and possible pollution caused by construction is reduced.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

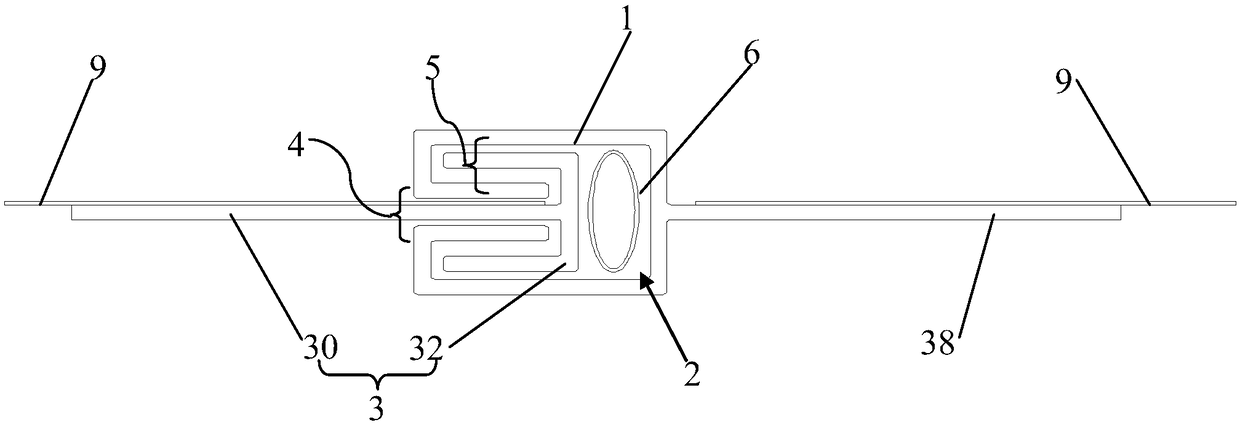

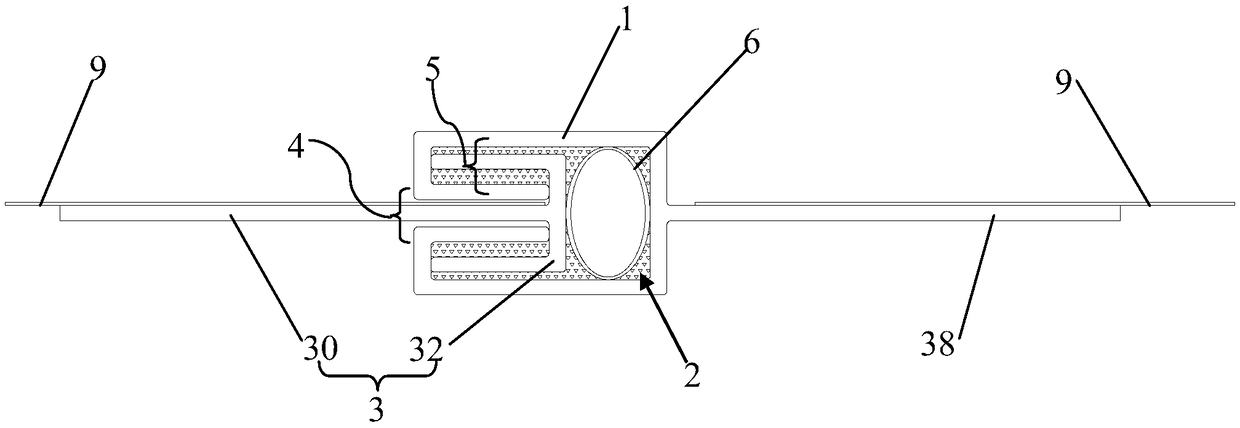

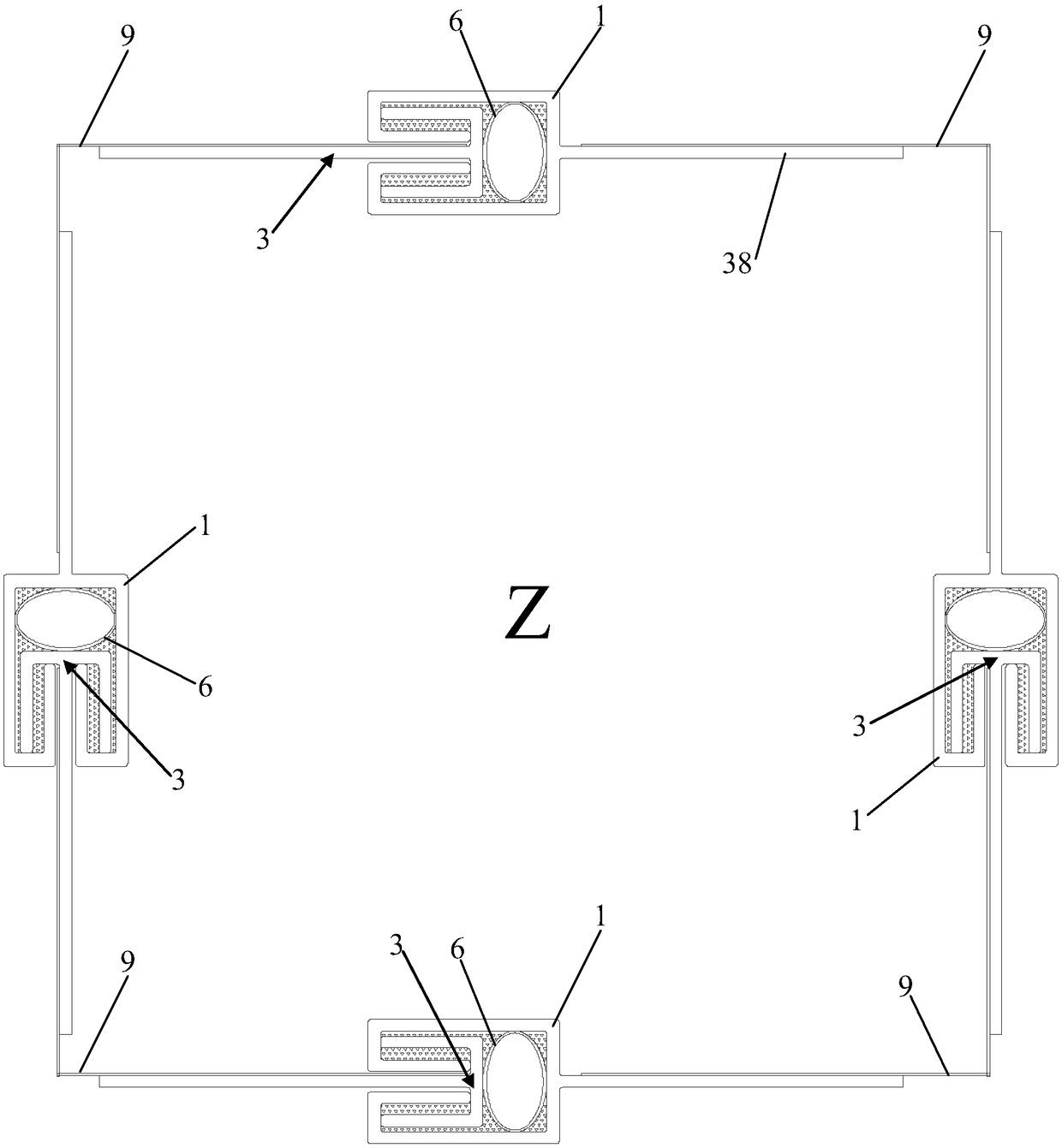

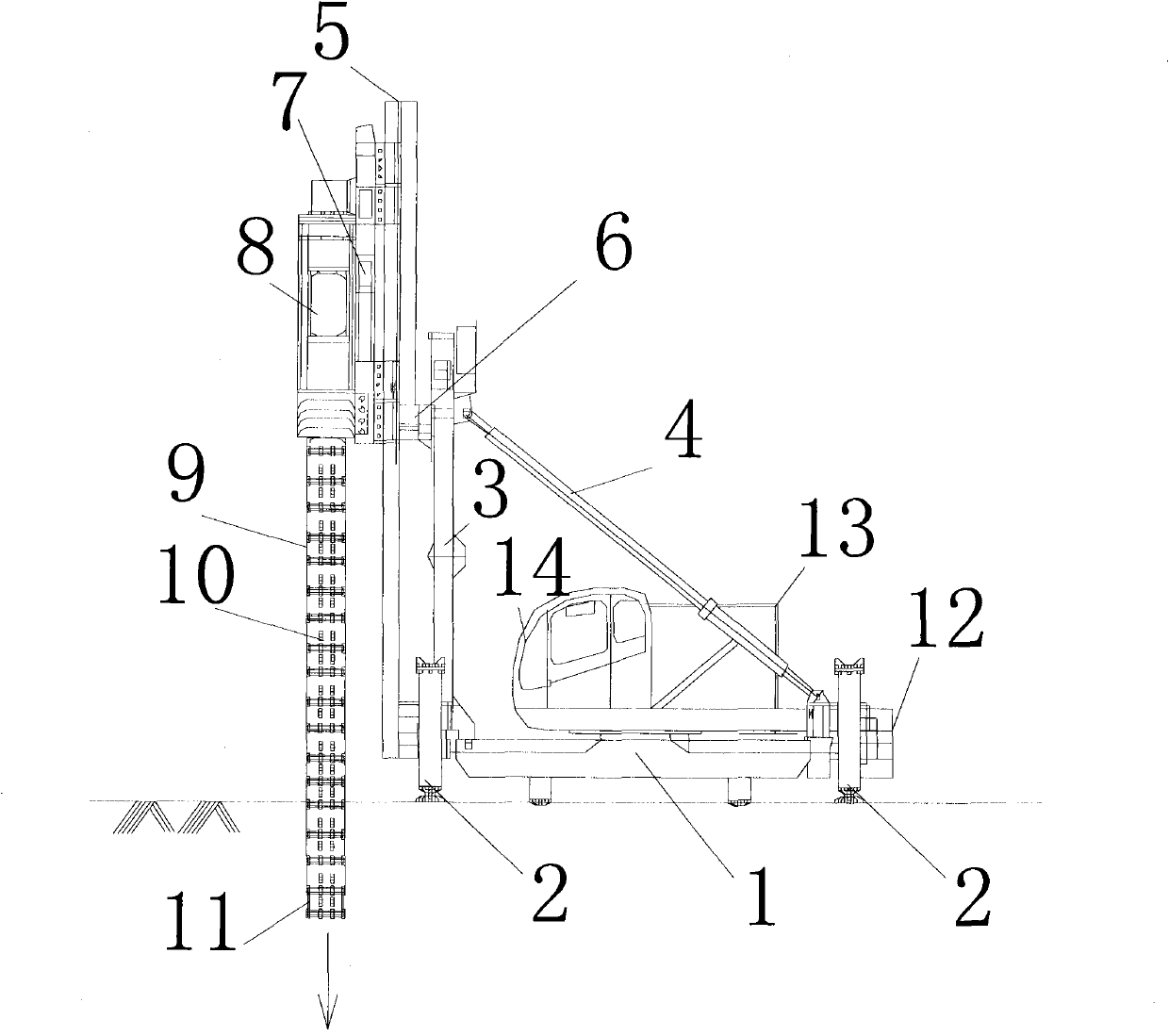

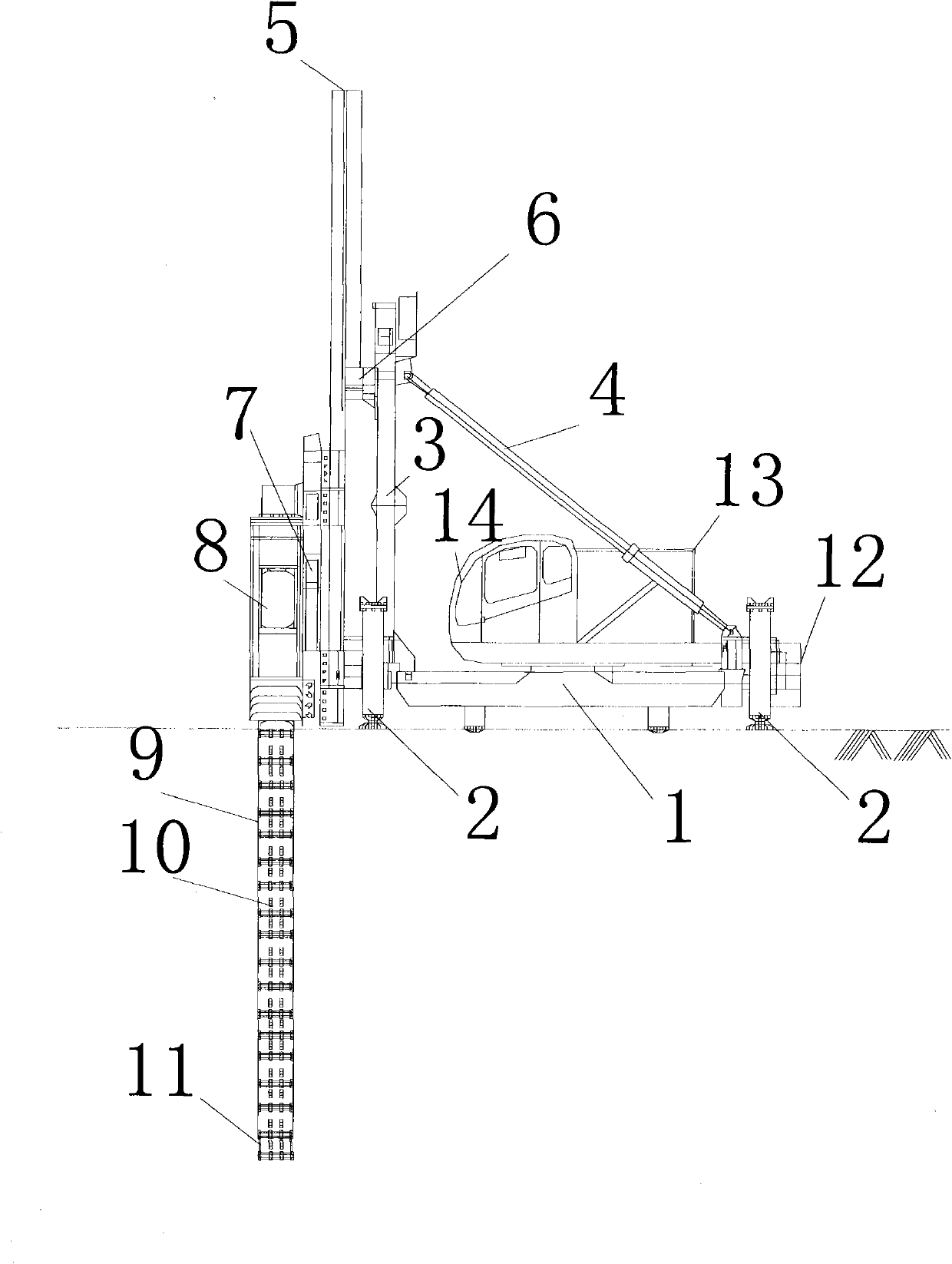

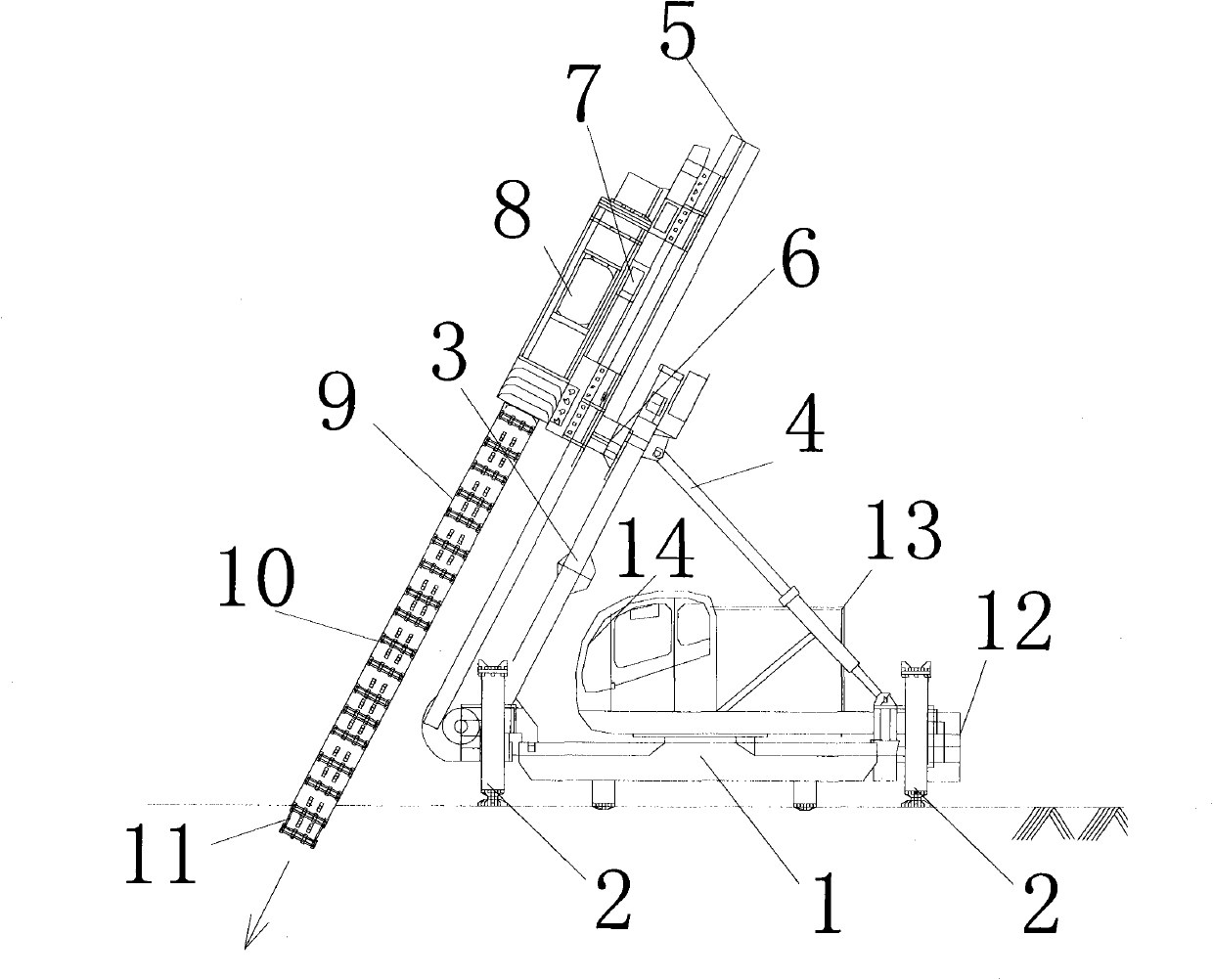

Continuous wall forming machine of underground cement soil impermeable wall

InactiveCN102021920AUniform textureTowards precisionSoil-shifting machines/dredgersAgricultural engineeringKnife blades

The invention relates to a continuous wall forming machine of an underground cement soil impermeable wall. A machine chassis and a hydraulic support form a walking travel mechanism, a frame and an oblique adjusting rod are arranged on the machine chassis, the frame is adjusted to be in a perpendicular or oblique position through the oblique adjusting rod, and a vertical guide rod and a horizontal drive cylinder are arranged on the frame. A cutter drive mechanism and a cutter combination box are connected with a cutter combination chain and a cutter head, and move up and down along the vertical guide rod through a vertical drive cylinder. The cutter combination chain surrounding the two sides of the cutter combination box moves around a position between the cutter drive mechanism and the cutter head. Soil layers are cut and agitated by blades fixed on the cutter combination chain. A non-fence impermeable wall having excellent impermeable effect is really built through the machine, and the continuous impermeable wall has the advantages of uniform texture, accurate advance direction, better impermeable effect and simple technology. The continuous wall forming machine can be used for digging downwards, cutting soil layers and building the cement soil wall in one step.

Owner:陶为

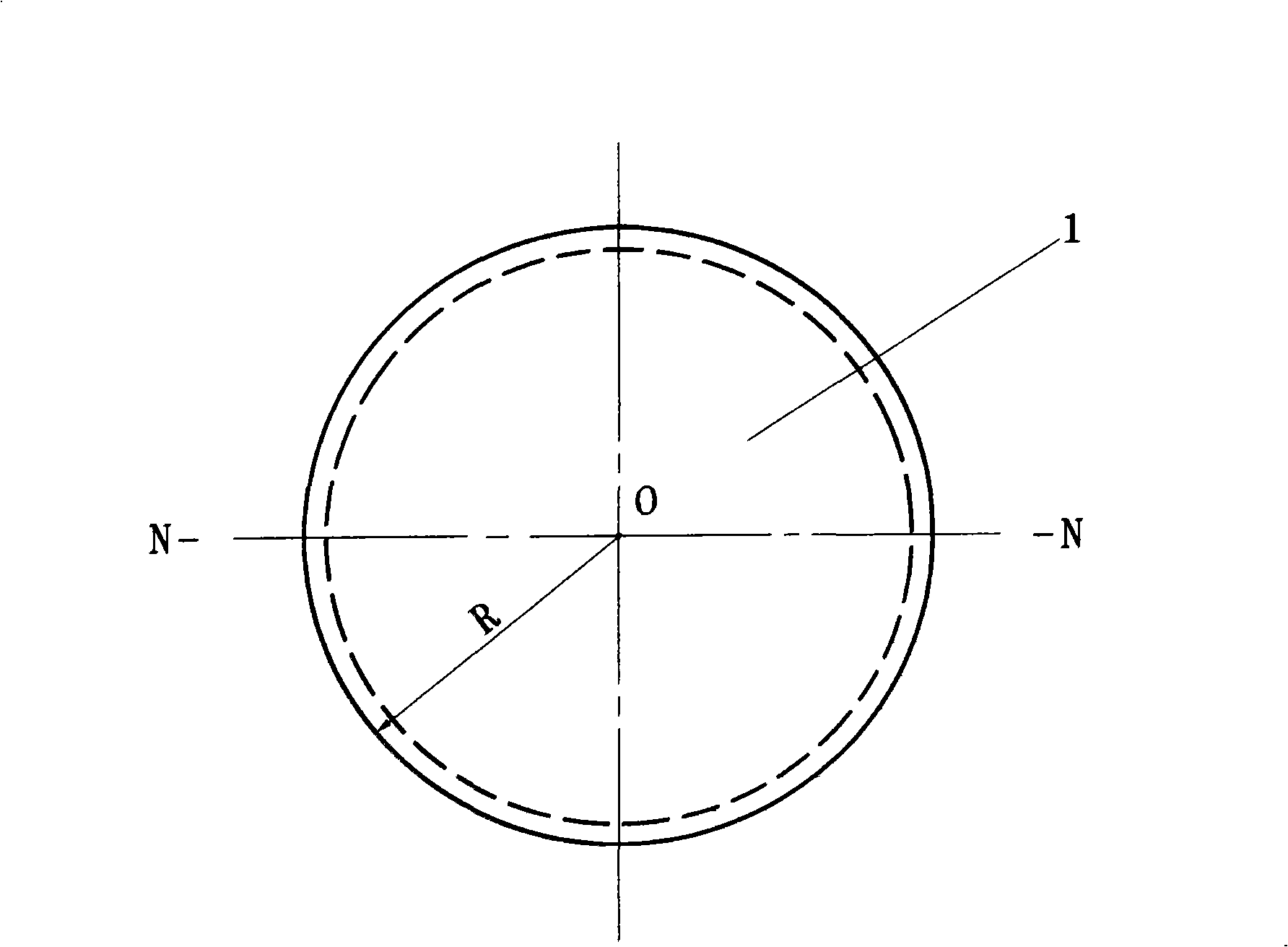

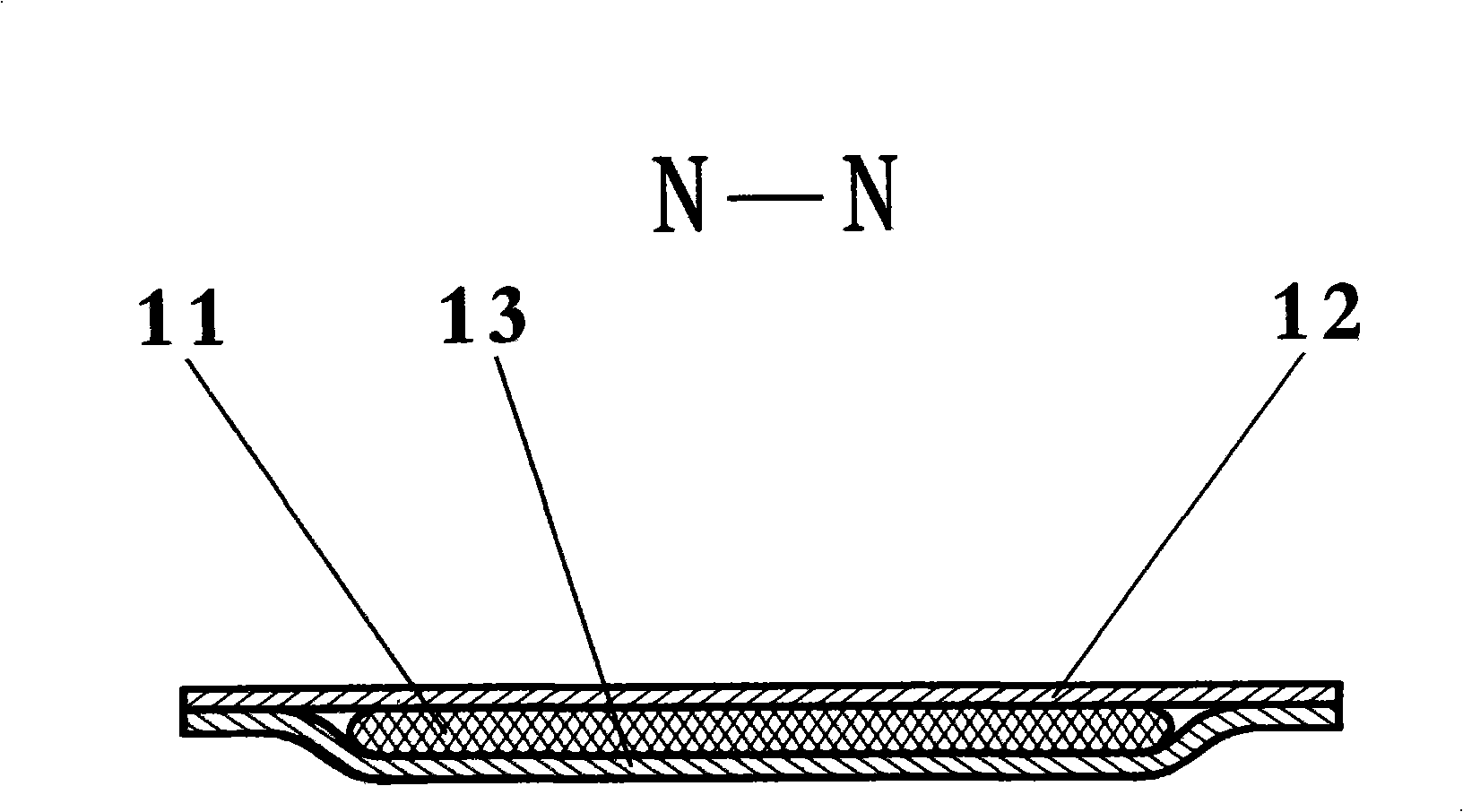

Adjustable attaching type breast pad

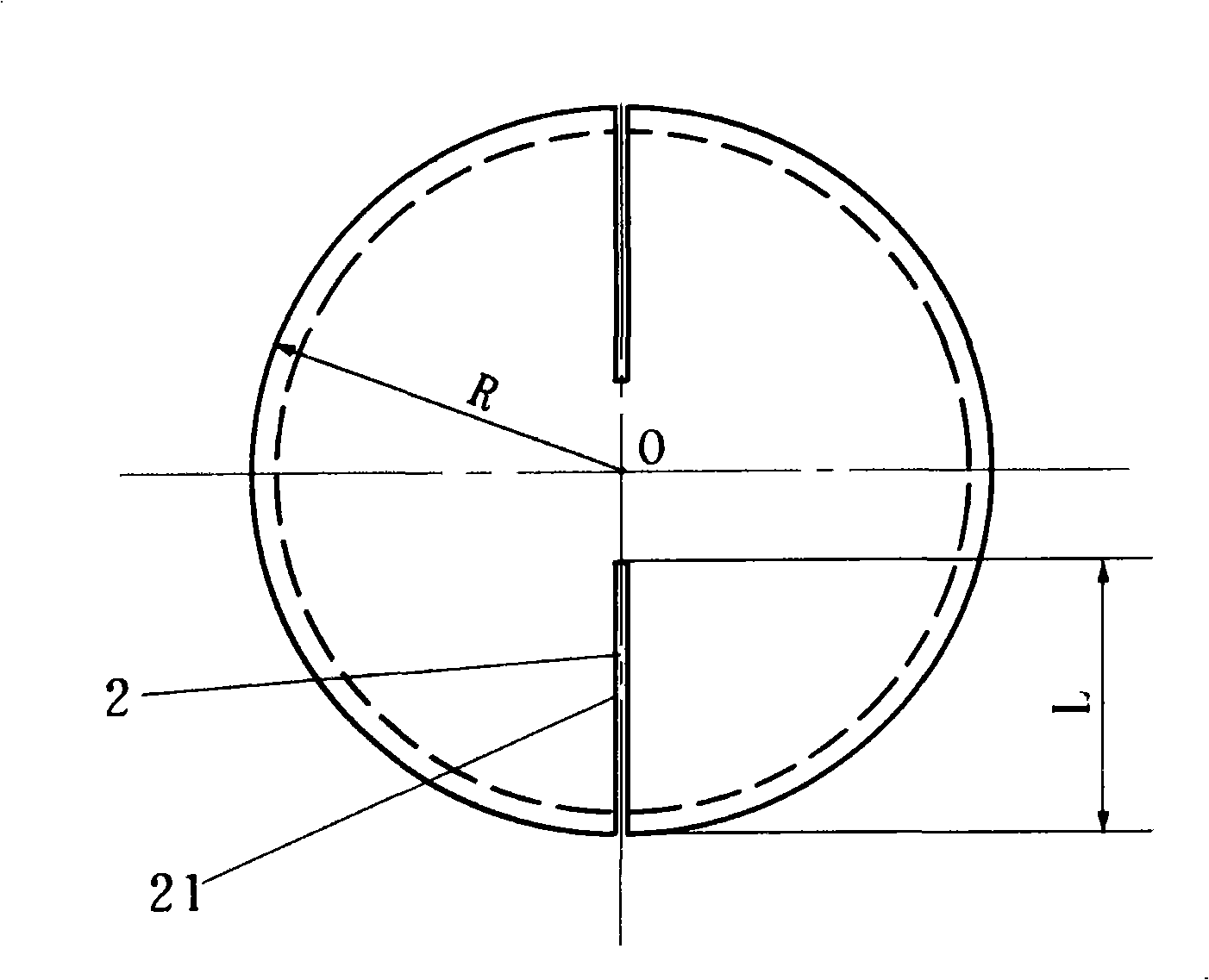

The invention relates to an adjustable attached type breast cushion which is held between underclothes such as brassiere, and the like and breasts of breastfeeding mothers and can effectively absorb the overflowing or spraying latex of breastfeeding women. The foldable breast cushion is arranged on a plane circular main body formed by an absorbing body for absorbing latex, a ventilating waterproof material arranged at the outer side of the absorbing body, and a breast protecting and moisture absorbing material arranged on the inner layer of the absorbing body. The center of the circle is taken as reference, and N commissures are cut from the center of the circle to the circumference. The length of each commissure L is less than or equal to the radius R of the plane circular main body, the N commissures are folded inwards to be jogged, tape or glue is adopted to stick the abutted seam, and the adjustable attached type breast cushion is formed. The foldable breast cushion has the advantages that the breast cushion has good texture, has no seepage leak, and is good in anti-leaking property; and the size of the breast cushion can be adjusted by wearers when the breast cushion is used.

Owner:叶正瑜

Grouting method of waterproof curtain of burnt rock covering on working surface to be mined of coal mine

ActiveCN108843343AImprove anti-seepage performanceImprove anti-seepage effectUnderground chambersDrainageGeomorphologySlurry

The invention belongs to the technical field of water control of mine shafts, and particularly relates to a grouting method of a waterproof curtain of burnt rock covering on a working surface to be mined of a coal mine so as to solve the problems existing in the prior art that slurry between grouting holes is difficult to sufficiently diffuse and overlap, the leakproof effect of a grouting curtainof the burnt rock is poor, and the water shutoff rate is not high. The technical scheme adopted by the invention lies in that the grouting method comprises the steps of (1) performing hole drilling arrangement on the curtain; (2) grouting inner-row curtain holes; and (3) grouting outer-row curtain holes.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP +1

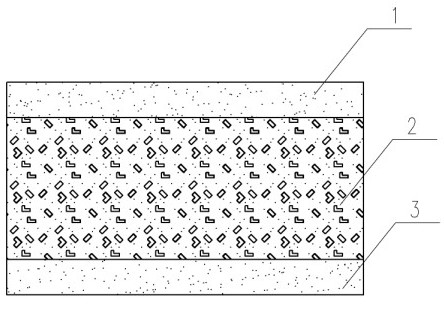

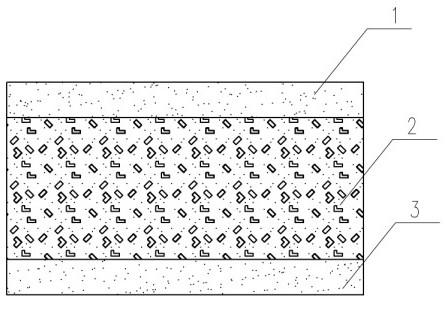

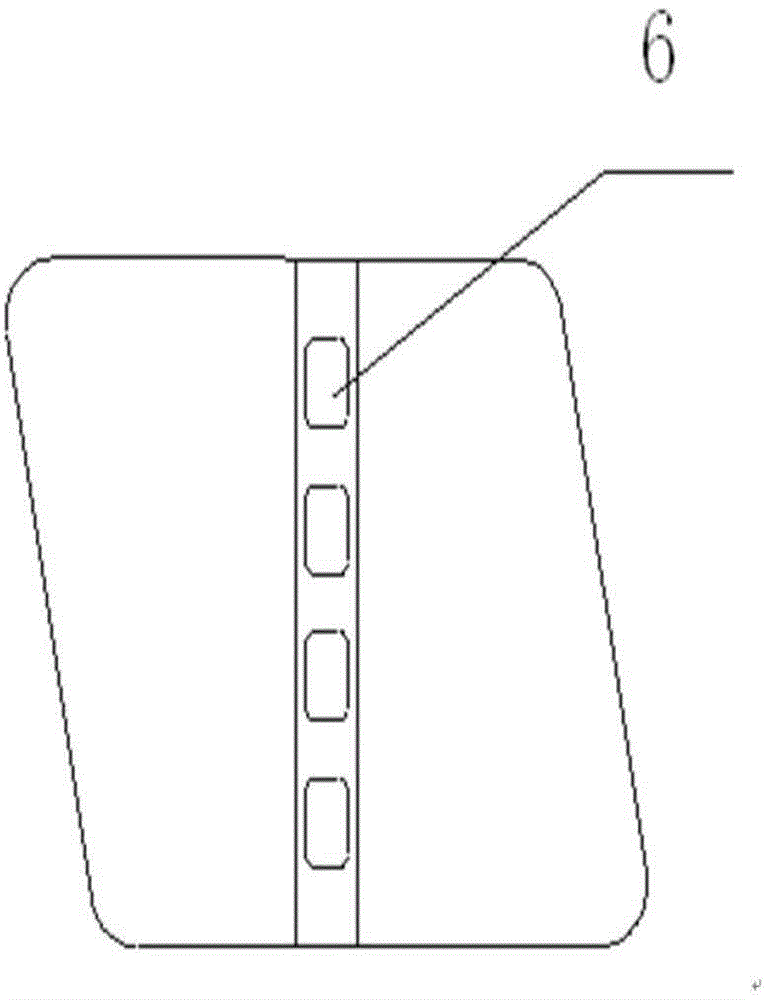

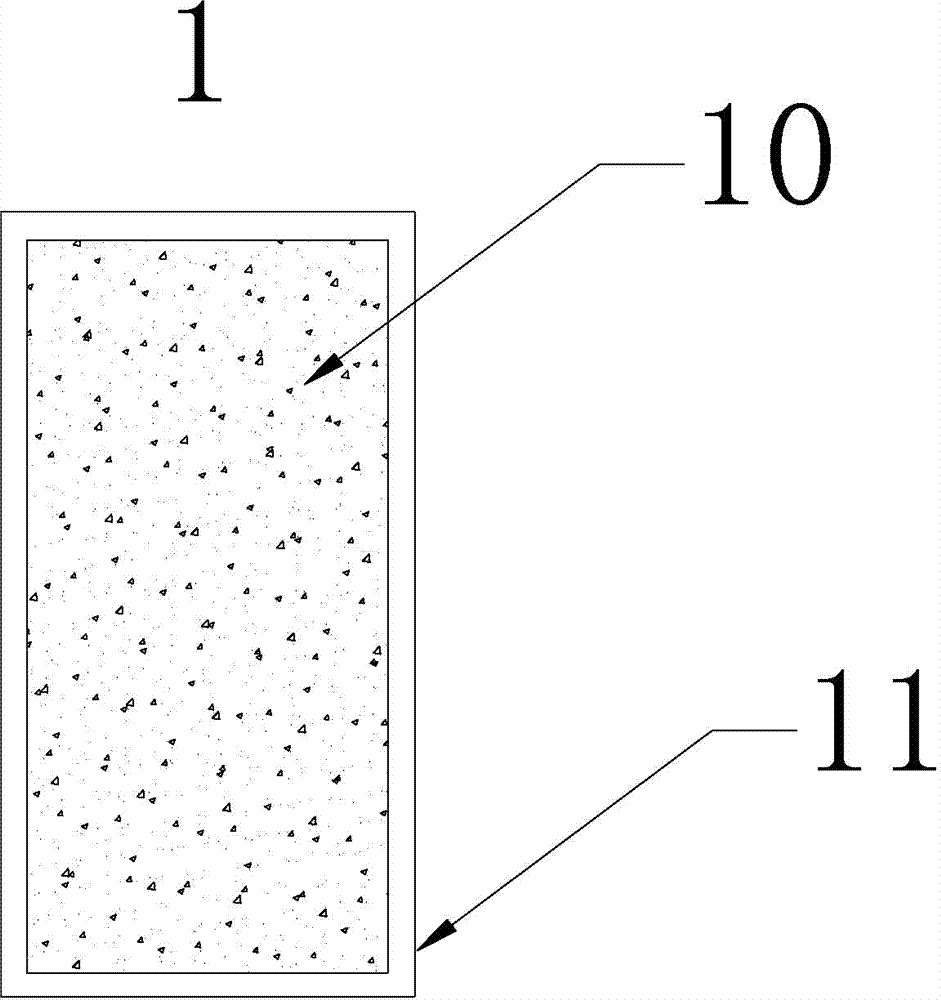

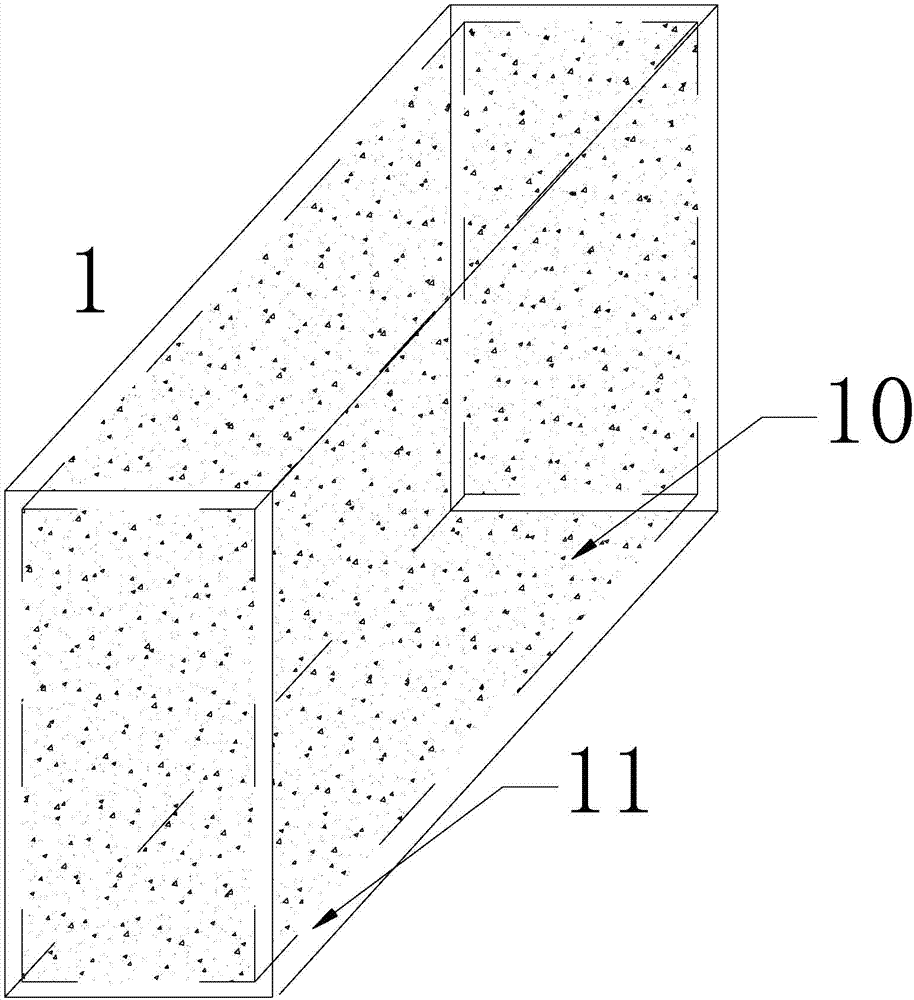

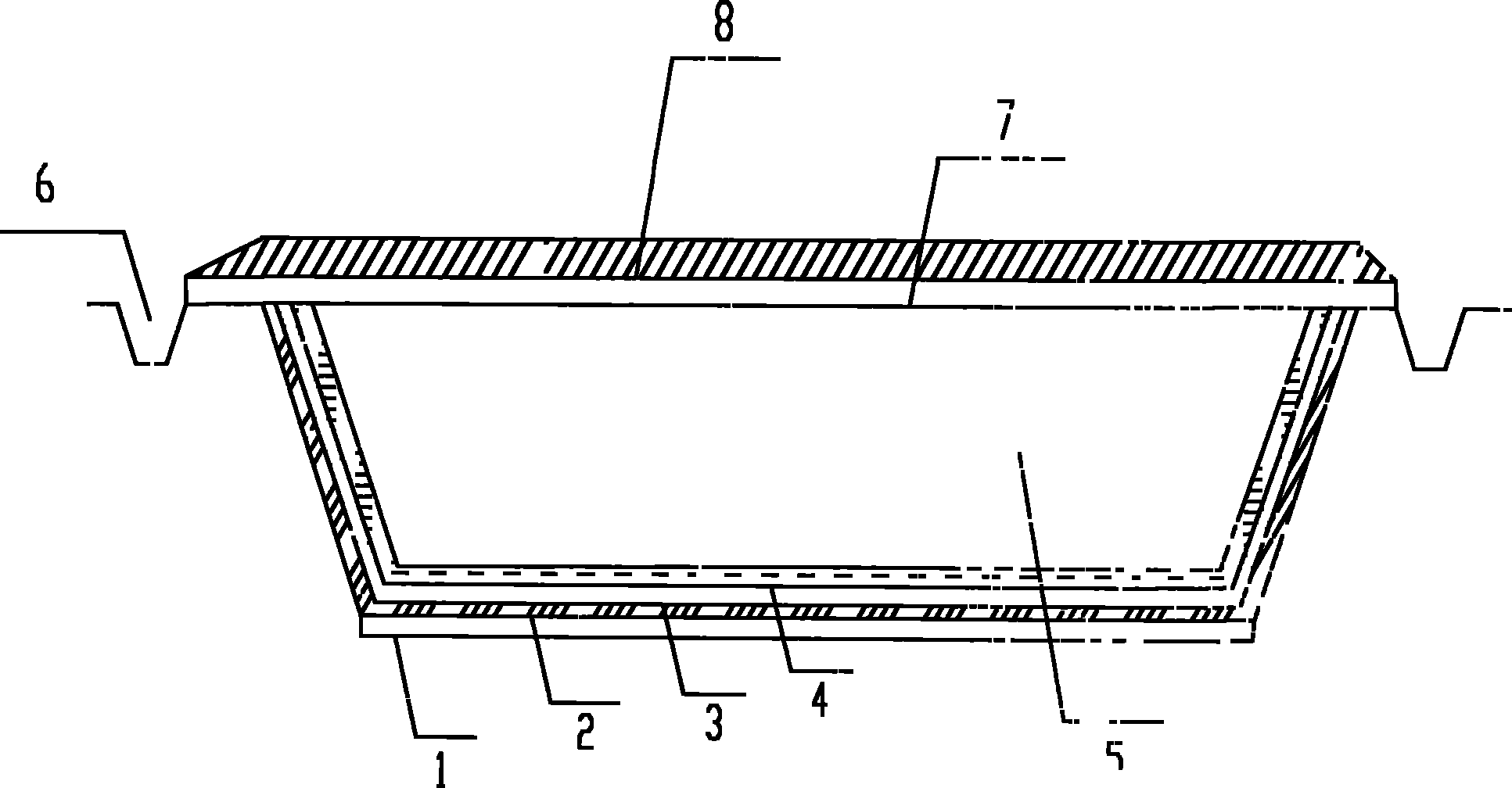

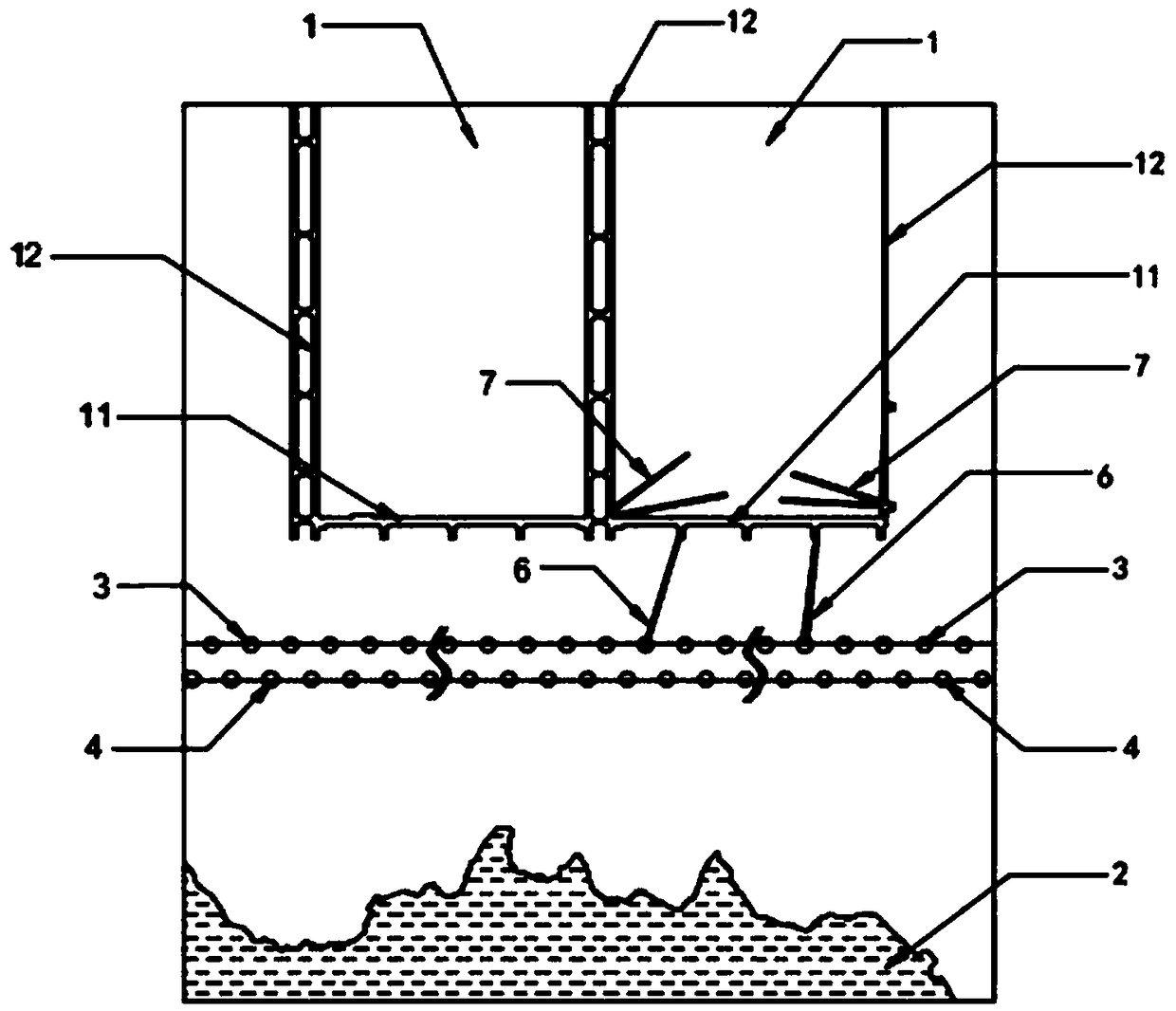

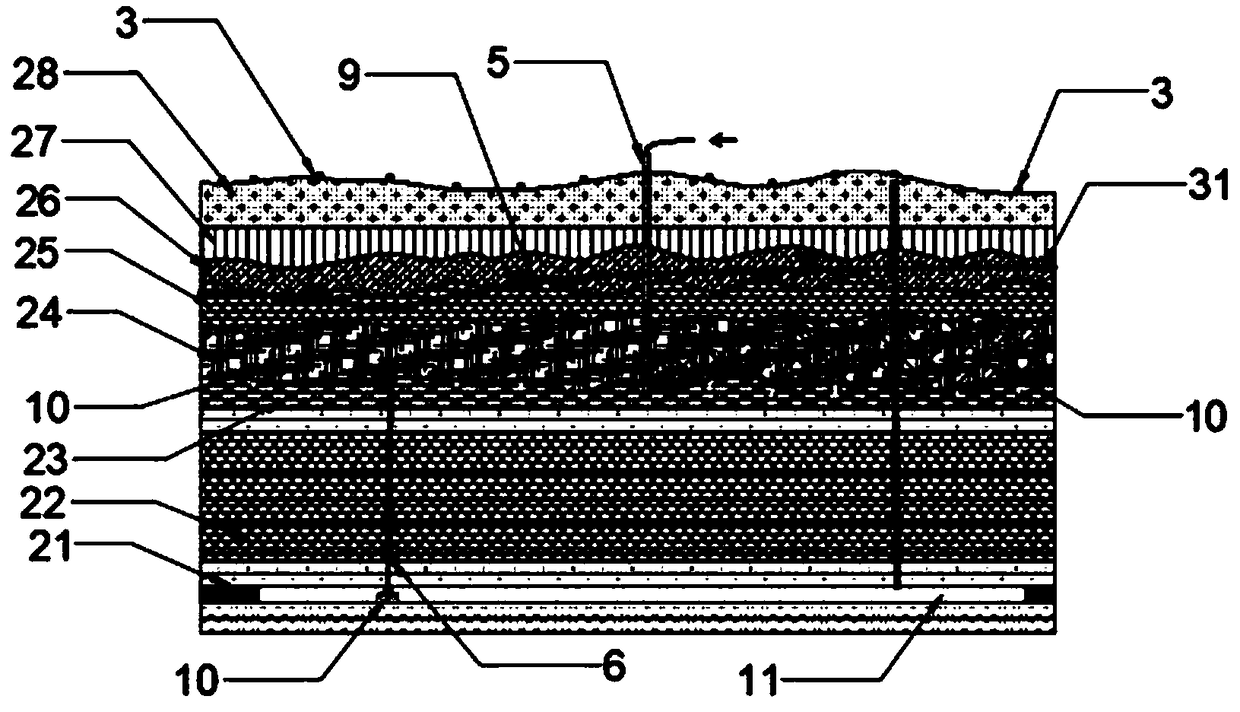

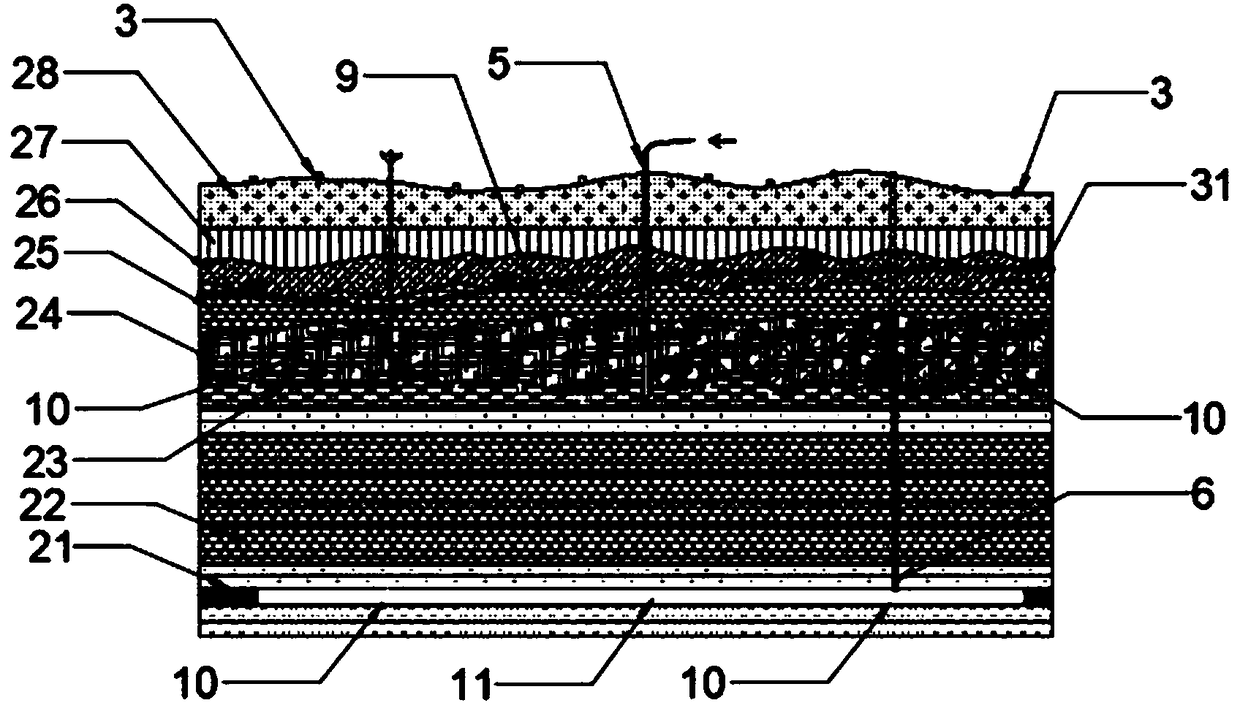

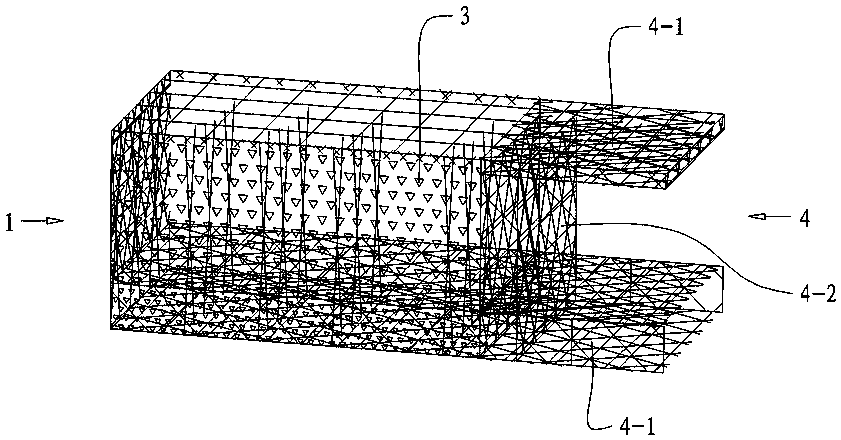

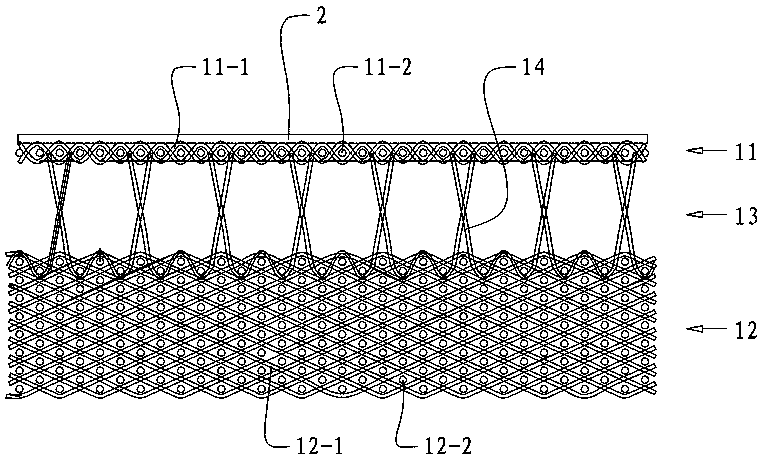

Three-dimensional multilayer-hollow fiber-reinforced concrete blanket capable of achieving lap joint

PendingCN107675831AGood toughening effectHigh strengthConstruction materialBuilding reinforcementsReinforced concreteLap joint

The invention relates to a three-dimensional multilayer-hollow fiber-reinforced concrete blanket capable of achieving lap joint and belongs to the technical field of building materials. The three-dimensional multilayer-hollow fiber-reinforced concrete blanket comprises a three-dimensional hollow-multilayer fabric, a top layer packaging fabric and active dry powder concrete; one side edge or multiside edges of the three-dimensional hollow-multilayer fabric are manufactured into a U-shaped lap-joint part, and the three-dimensional hollow-multilayer fabric comprises a first layer, a second layerand a middle layer; the first layer forms a two-dimensional structure through warp and weft intertwining, and the second layer forms a three-dimensional multilayer structure through warp and weft intertwining; a plurality of grid holes are formed in the first layer, and a three-dimensional hollow structure is formed on the middle layer; vertical warps weave the first layer, the second layer and the middle layer into a three-dimensional integral structure; and the three-dimensional hollow structure is filled with the active dry powder concrete through the grid holes, and the top layer packaging fabric and a first layer package are composited into a whole. The three-dimensional multilayer-hollow fiber-reinforced concrete blanket is a composite concrete blanket which is of a reinforced structure and is high in integrality, reinforced, toughed, resistant to bending and cracking, convenient to use and capable of quickly achieving high-property and low-cost lap joint in the construction process.

Owner:林通泉

Closed isolation composition applied to treatment of gangue hill and implementation method thereof

The invention provides a closed isolation composition applied to the treatment of a gangue hill and an implementation method thereof, and belongs to the technical field of environmental treatment andmine ecological restoration. The closed isolation composition comprises inorganic substances, a polymer, fiber, an additive and water, the weight ratio of the inorganic substances is 20-75%, the weight ratio of the polymer is 0.2-5%, the weight ratio of the fiber is 0.05-5%, the weight ratio of the additive is 0.05-2%, and the weight ratio of the water is 20-75%; the above materials are mixed according to a certain ratio to prepare a mixed slurry, the slurry is sprayed on the surface of the gangue hill for sealing of the gangue hill and isolation from a vegetation area to completely eliminatethe hazard of the gangue hill, and the disturbance influence of vegetation on the gangue hill is eliminated. The closed isolation layer has the advantages of airtightness, seepage resistance, heat insulation, firmness and durability, the used materials are all environmentally friendly, the construction is simple, the efficiency is high, and the cost is low.

Owner:山西智德生态环保股份有限公司

Nano material modified fluorocarbon resin stone waterproof coating

The invention discloses a nano material modified fluorocarbon stone stone waterproof coating. The coating includes the following raw material components: resin raw material consisting of vinylidene fluoride resin and acrylic resin, multi-layer graphene oxide, a silane coupling agent, dibutyltin dichloride and solvent oil. The hardness, wear resistance and permeability resistance of the nano material modified fluorocarbon stone stone waterproof coating can be greatly improved by two-dimensional nanomaterial technology on the premise of guaranteeing of the transmittance and glossiness of the stone waterproof coating, and the protection life and the protection effect of the stone waterproof coating are greatly improved.

Owner:云浮华云创新设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com