Underground impermeable membrane inserting connector and construction method thereof

A technology of plug-in joints and construction methods, which is applied in infrastructure engineering, protection devices, buildings, etc., to achieve good anti-seepage effects, convenient and more convenient construction, and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

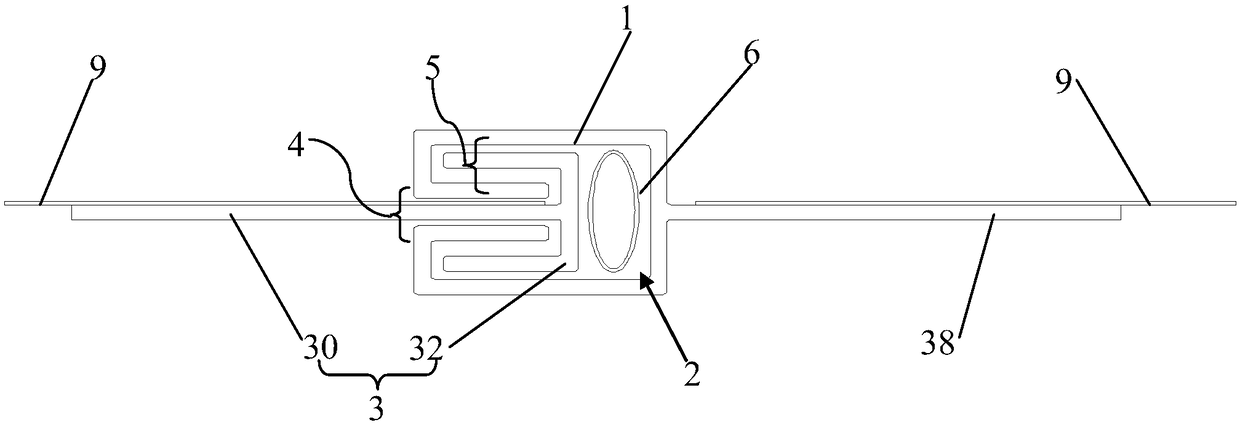

[0039] combine figure 1 with figure 2 As shown, the present invention firstly provides an underground anti-seepage membrane plug joint, including a rectangular joint body 1, a grouting groove / chamber 2 is opened on one side of the joint body 1, and the left side of the joint body 1 The side end is provided with an opening 4 and leads to the grouting tank 2, and the grouting tank 2 is provided with a mountain-shaped connector 3, and the connector 3 includes a connecting section 30 and a mounting section 32. The connecting section 30 extends out of the joint body 1 from the opening 4, and the installation section 32 is movably inserted in the side of the opening 4, and then extends into the anti-seepage membrane or the permeable membrane 9 through the opening 4, The impermeable membrane or the permeable membrane 9 is connected through the connecting section 30 .

[0040] Specifically, both sides of the opening 4 are respectively provided with slots 5 extending straight into t...

Embodiment 2

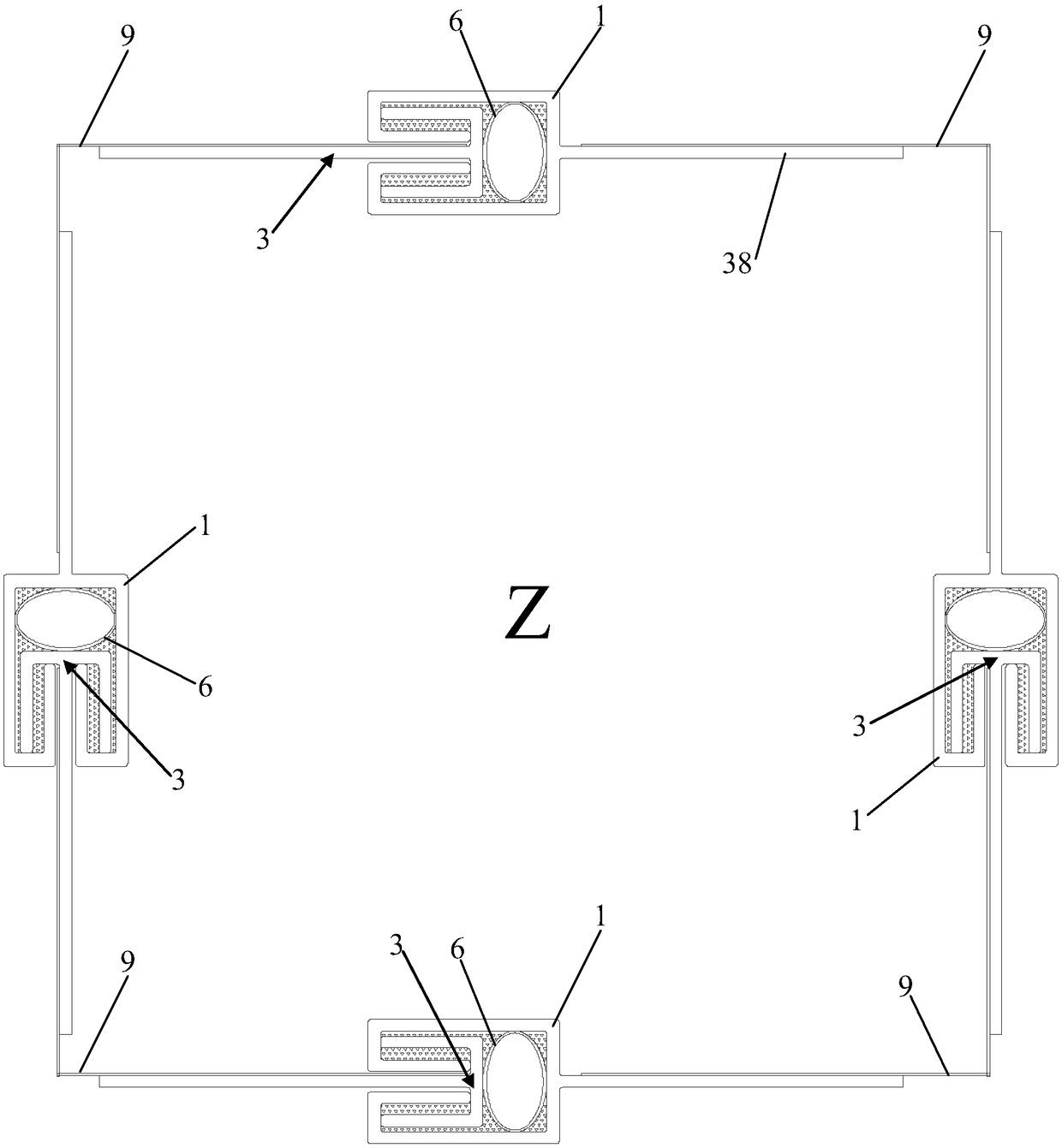

[0050] Such as Figure 4 As shown, on the basis of Embodiment 1, this embodiment further improves the plug joint of underground anti-seepage membrane. The grouting groove / chamber 2' and the connector 3', and the two side ends of the joint body 1' respectively have two openings 4'. In this way, it is convenient for a plurality of said anti-seepage membranes or said permeable membranes 9' to be connected end-to-end to said anti-seepage membrane plug joints.

[0051]More preferably, the middle part of the rectangular joint body 1' has a spacer layer with a certain thickness to fully space the grouting grooves 2' on the left and right sides, and also ensure the structural strength of the joint body 1'.

[0052] Other structures and construction methods are basically the same as those in Embodiment 1, so they will not be repeated here.

Embodiment 3

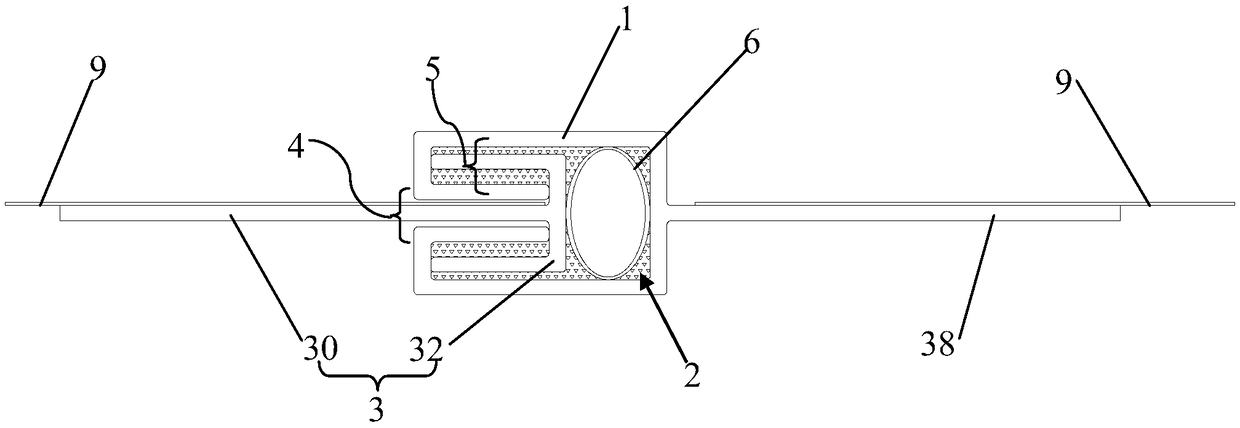

[0054] Such as Figure 5 As shown, on the basis of Example 1, this embodiment further improves the plug joint of underground anti-seepage membrane. The shape of the extension wall 50 of the slot is also triangular and adapted to the shape of the mounting arm 320. In this way, the structural strength of the connector insertion is increased.

[0055] Other structures and construction methods are basically the same as those in Embodiment 1, so they will not be repeated here.

[0056] After completing the above-mentioned implementation process, the following characteristics of the present invention should be reflected:

[0057] 1) The structure is simple and convenient for construction.

[0058] 2) The connection between the membrane and the joint is firmer and the service life is long by means of flexible insertion.

[0059] 3) Good anti-seepage effect, avoiding secondary pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com