Three-dimensional multilayer-hollow fiber-reinforced concrete blanket capable of achieving lap joint

A three-dimensional multi-layer, fiber-reinforced technology, applied in the direction of building reinforcements, building components, structural elements, etc., can solve the problems of insufficient performance such as tensile resistance, bending resistance, puncture resistance, and wear resistance, uneven material distribution, and stress bearing and other problems, to achieve the effect of fast and simple construction process, high volume stability and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

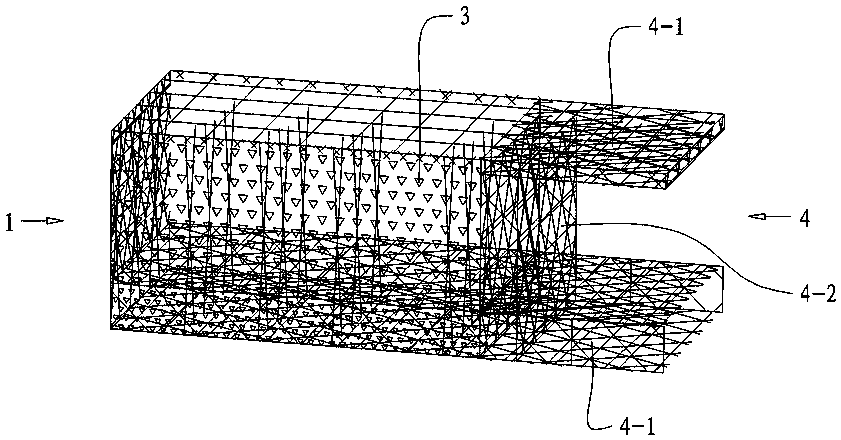

[0049] The three-dimensional multi-layer-hollow fiber reinforced concrete blanket that can be lapped in this embodiment, such as figure 1 and figure 2 As shown, it includes a three-dimensional hollow-multilayer fabric 1, a top layer of encapsulating fabric 2 and an active dry powder concrete 3 filled in the three-dimensional hollow-multilayer fabric. One or more sides of the three-dimensional hollow-multi-layer fabric 1 are made into U-shaped overlapping edges 4 that can be overlapped with adjacent concrete blankets.

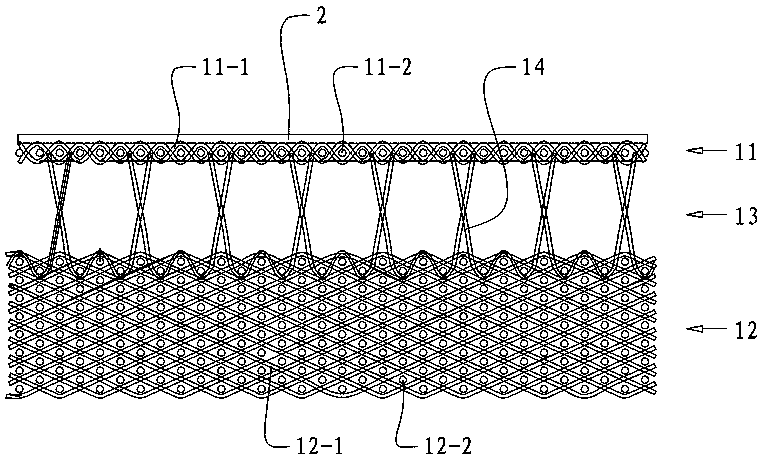

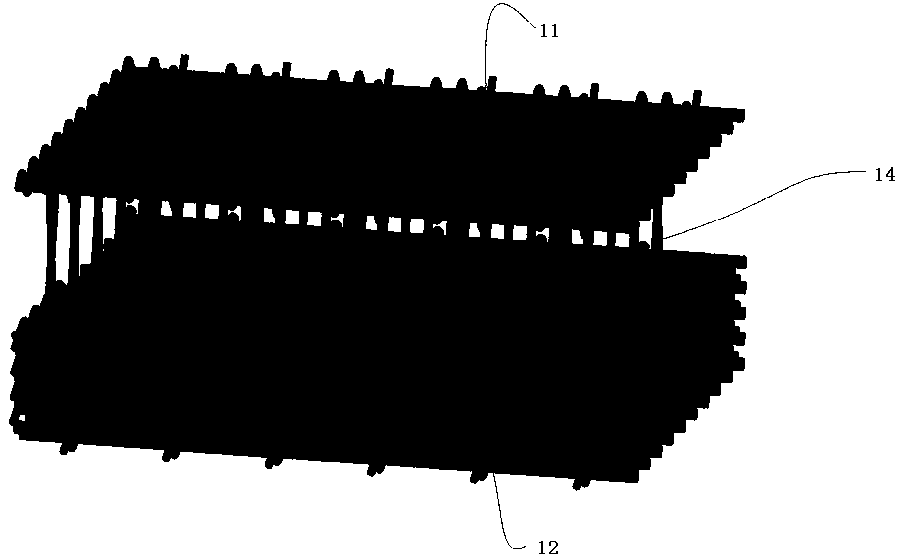

[0050] Such as figure 2 and image 3 As shown, the three-dimensional hollow-multilayer fabric 1 includes a first layer 11, a second layer 12 and an intermediate layer 13 between the first layer and the second layer.

[0051] The first layer 11 is interwoven with first warp yarns 11-1 and first weft yarns 11-2 to form a two-dimensional structure. The two-dimensional organization is formed by interweaving according to the changes of the three original organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com