Patents

Literature

83results about How to "Improve bonding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

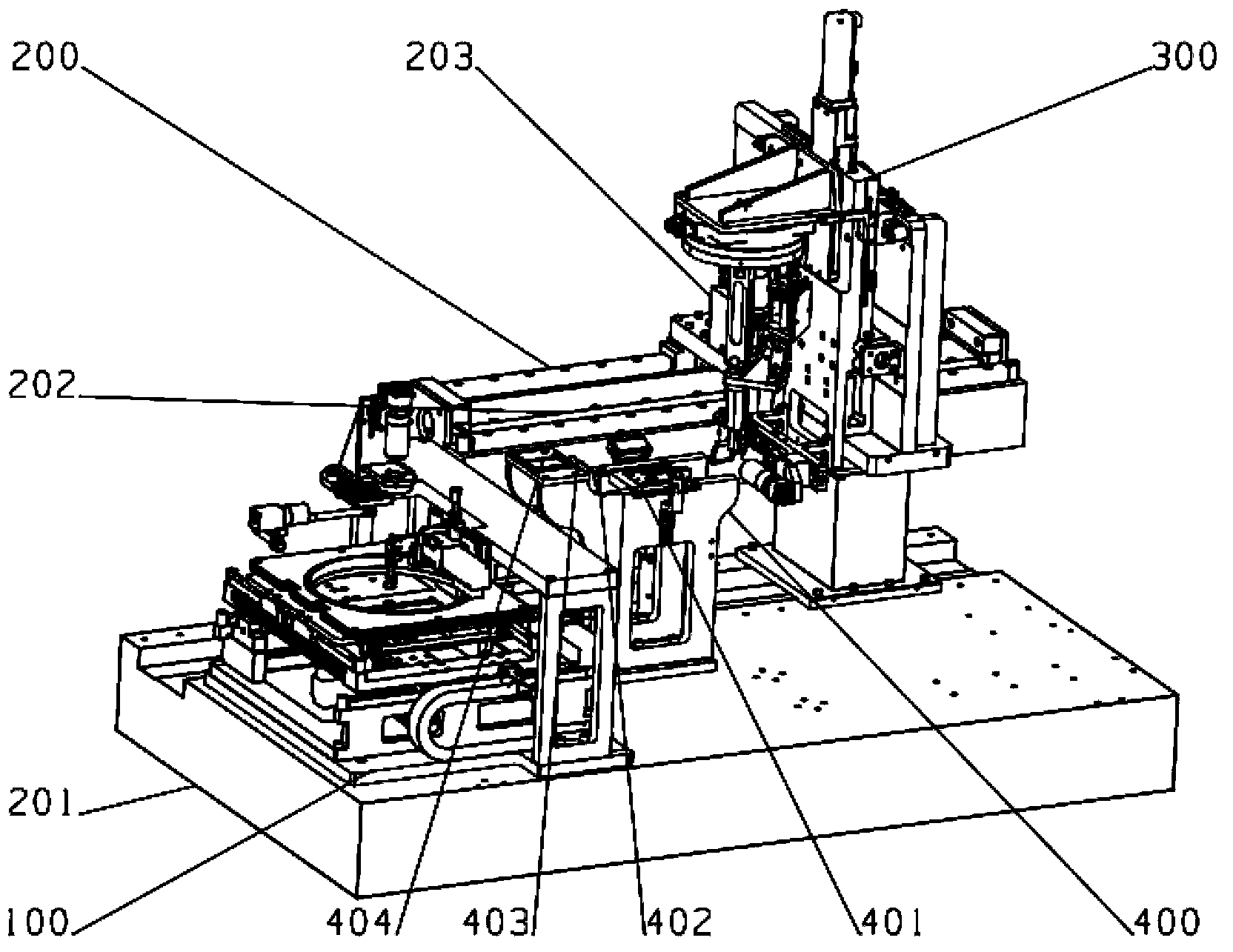

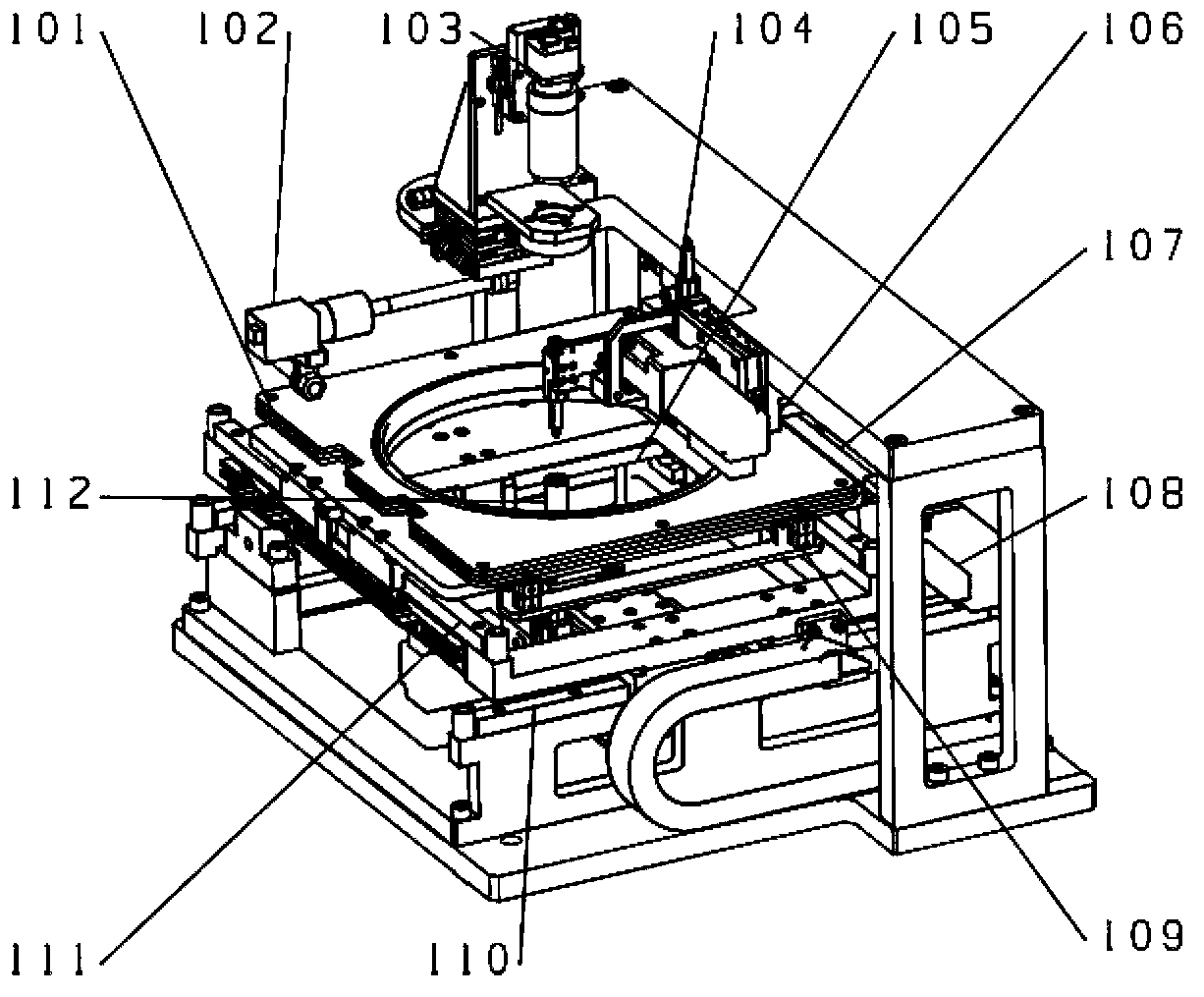

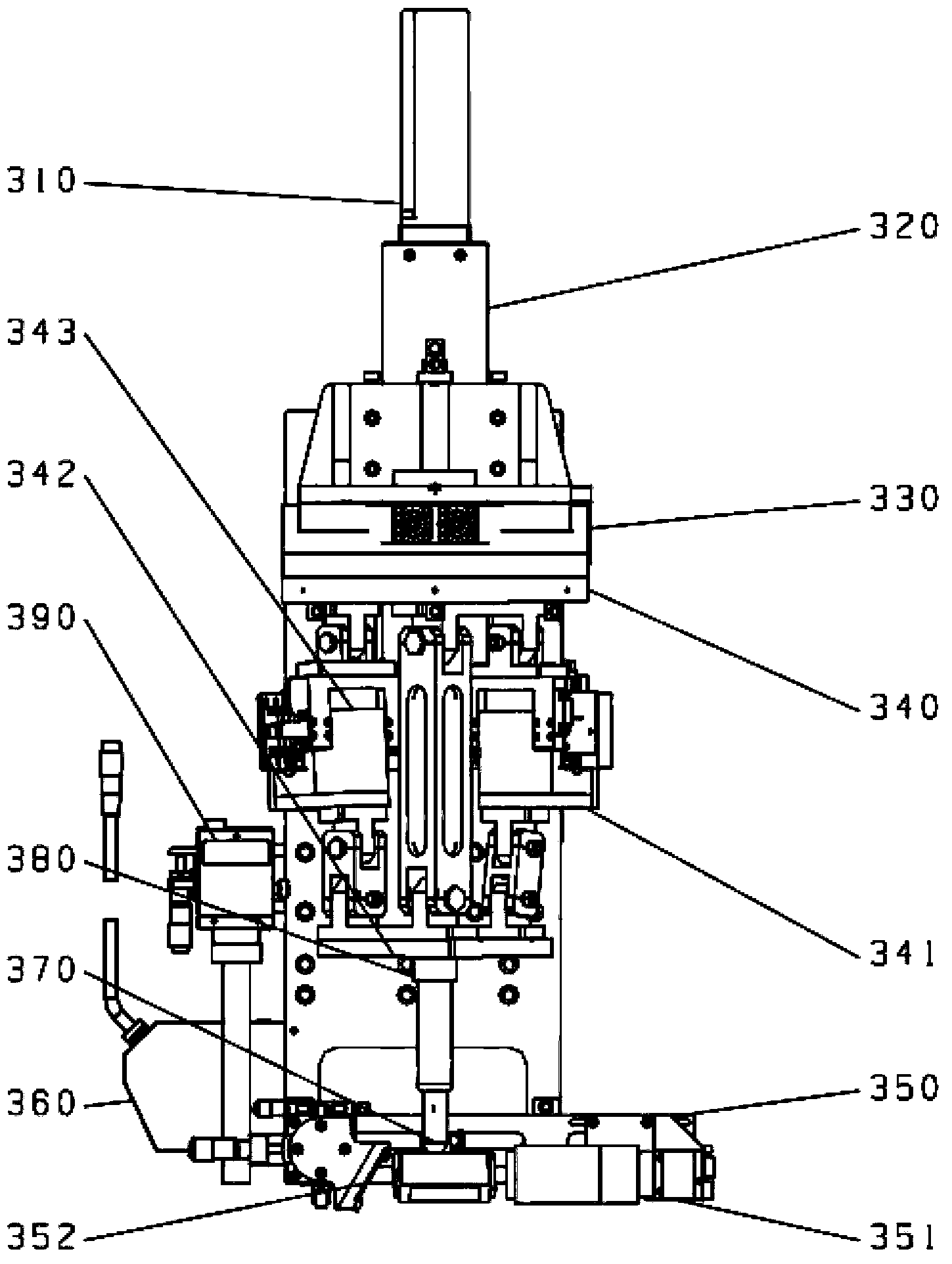

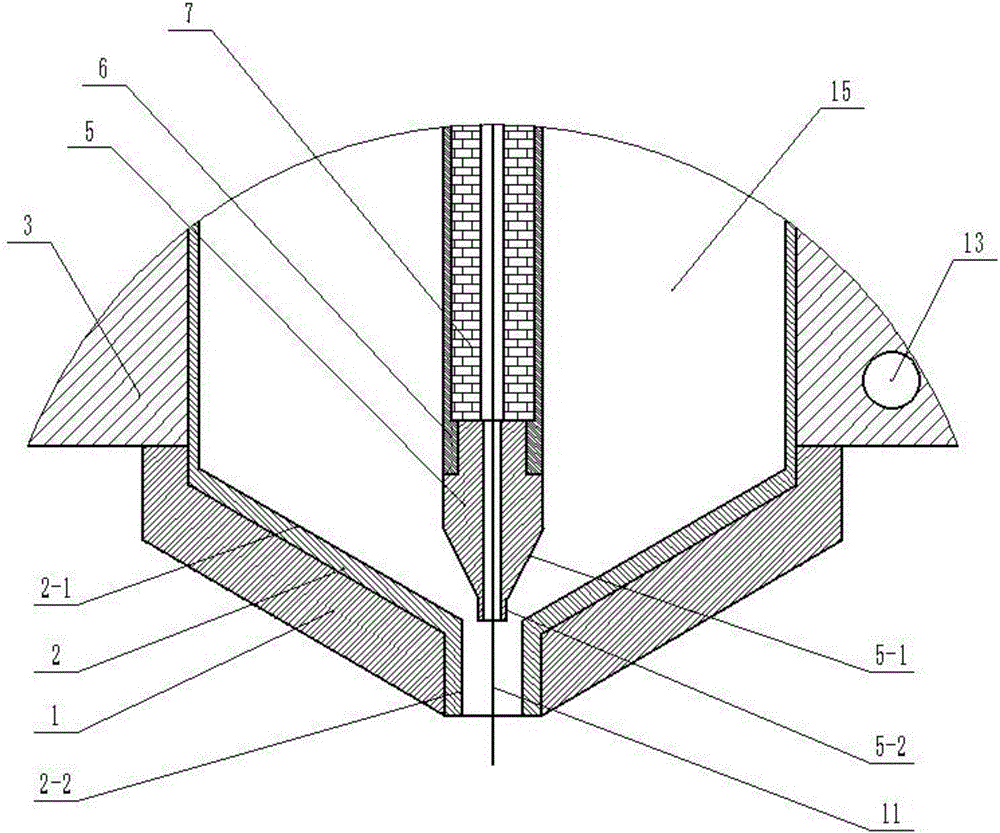

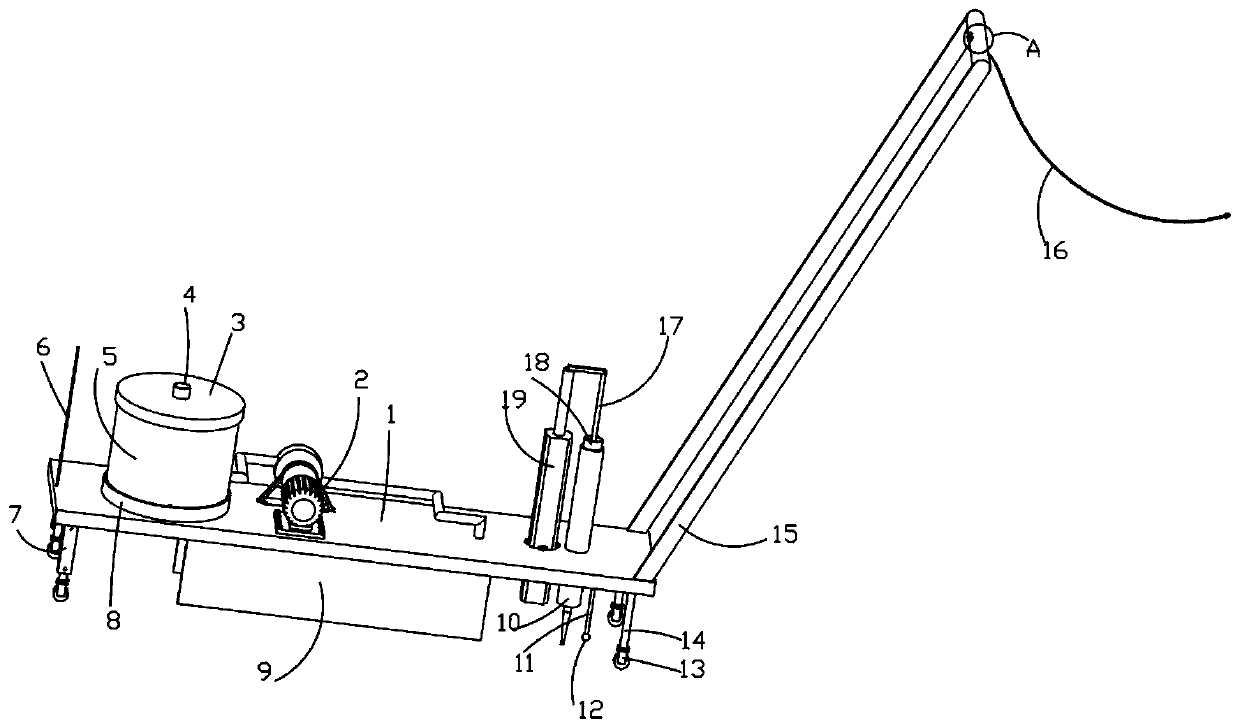

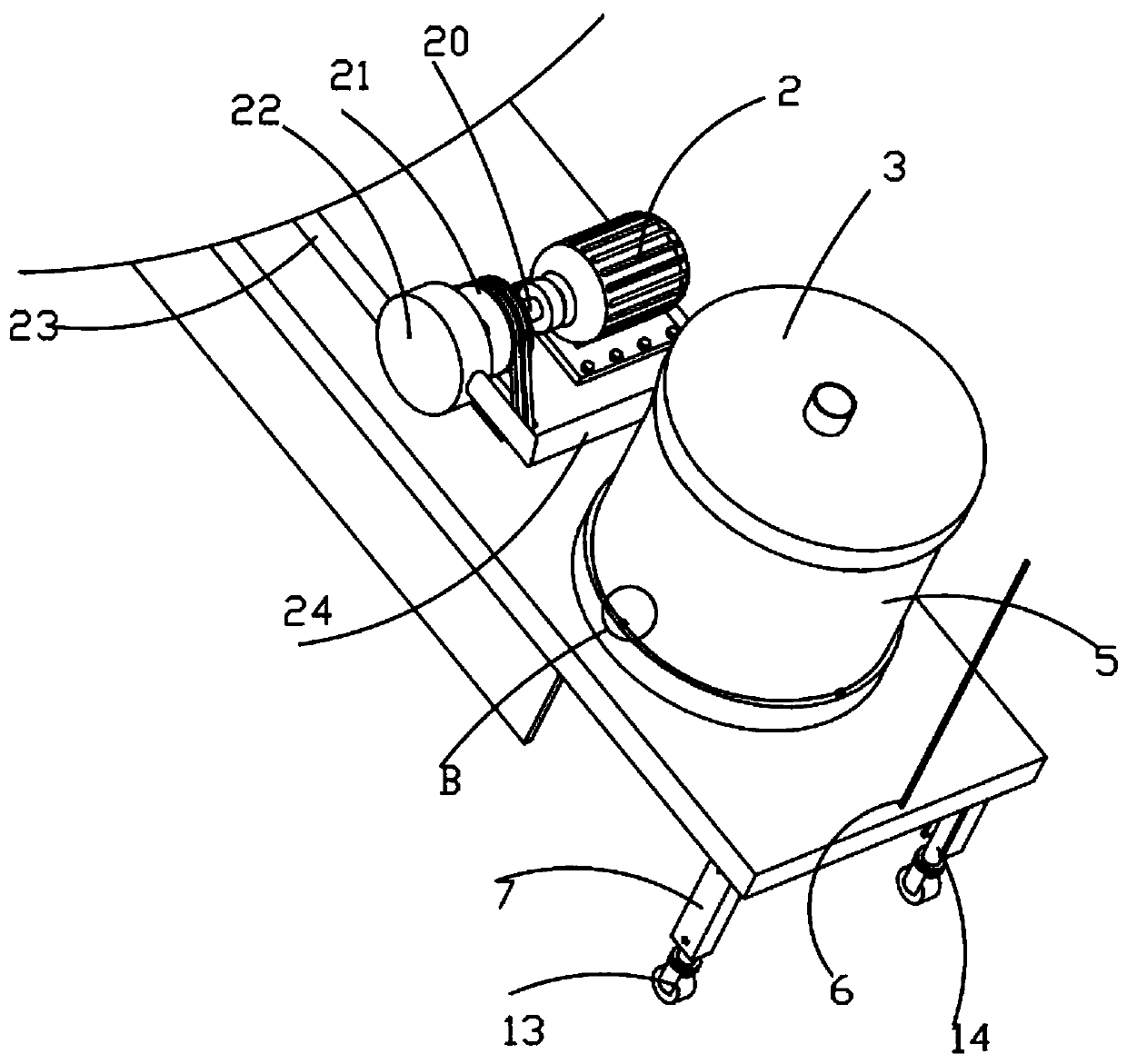

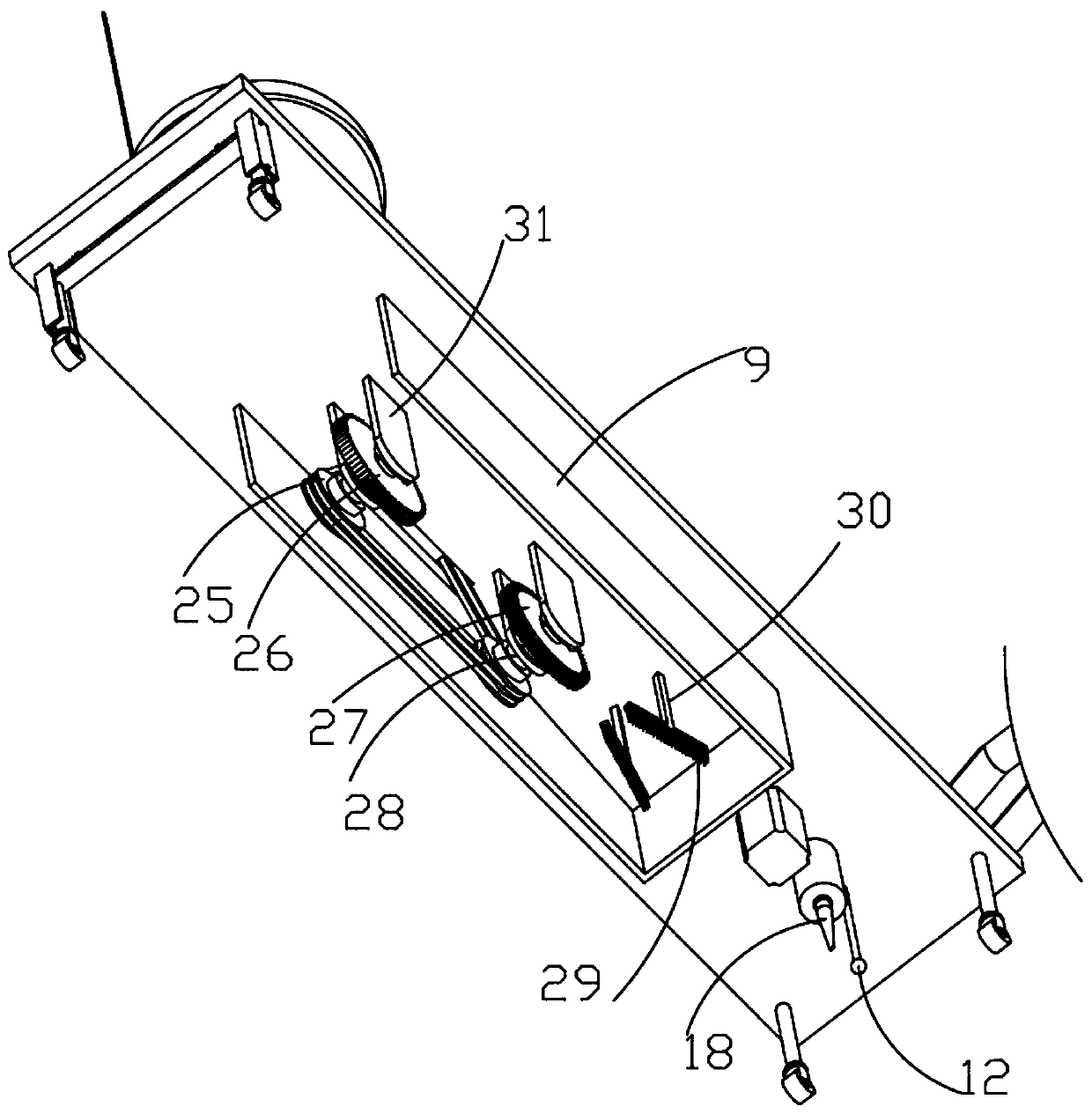

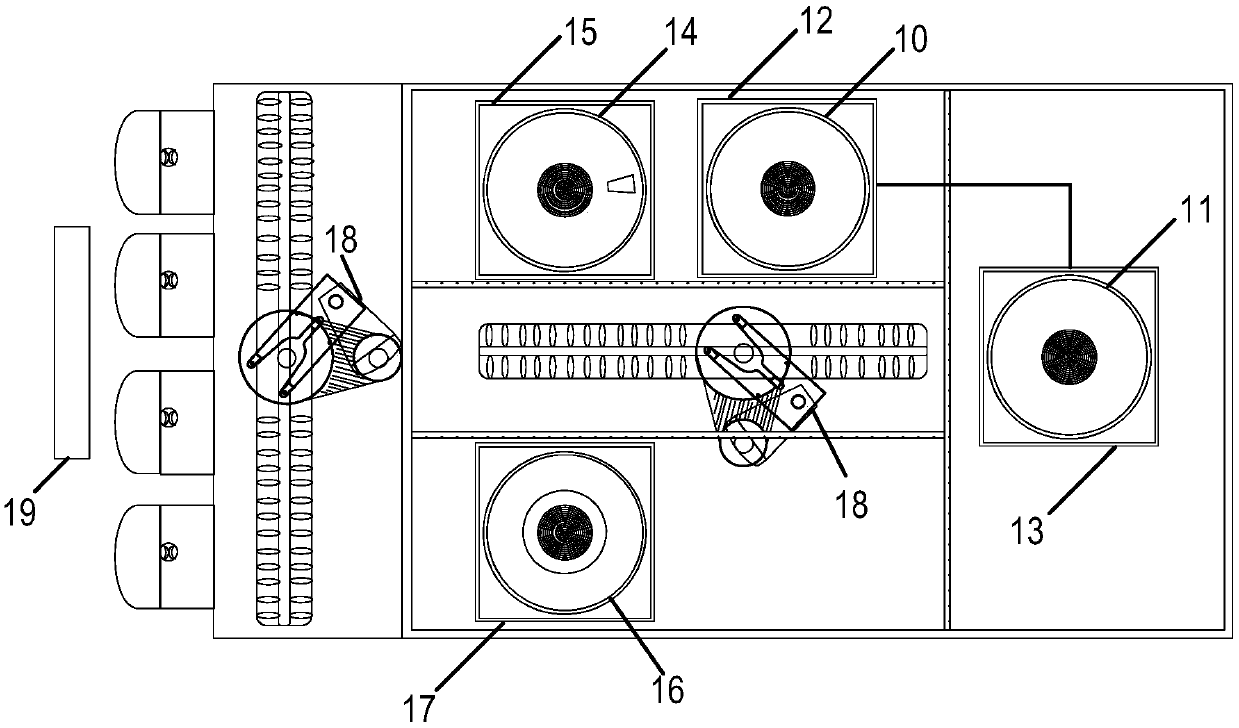

Back bonding platform for superchip

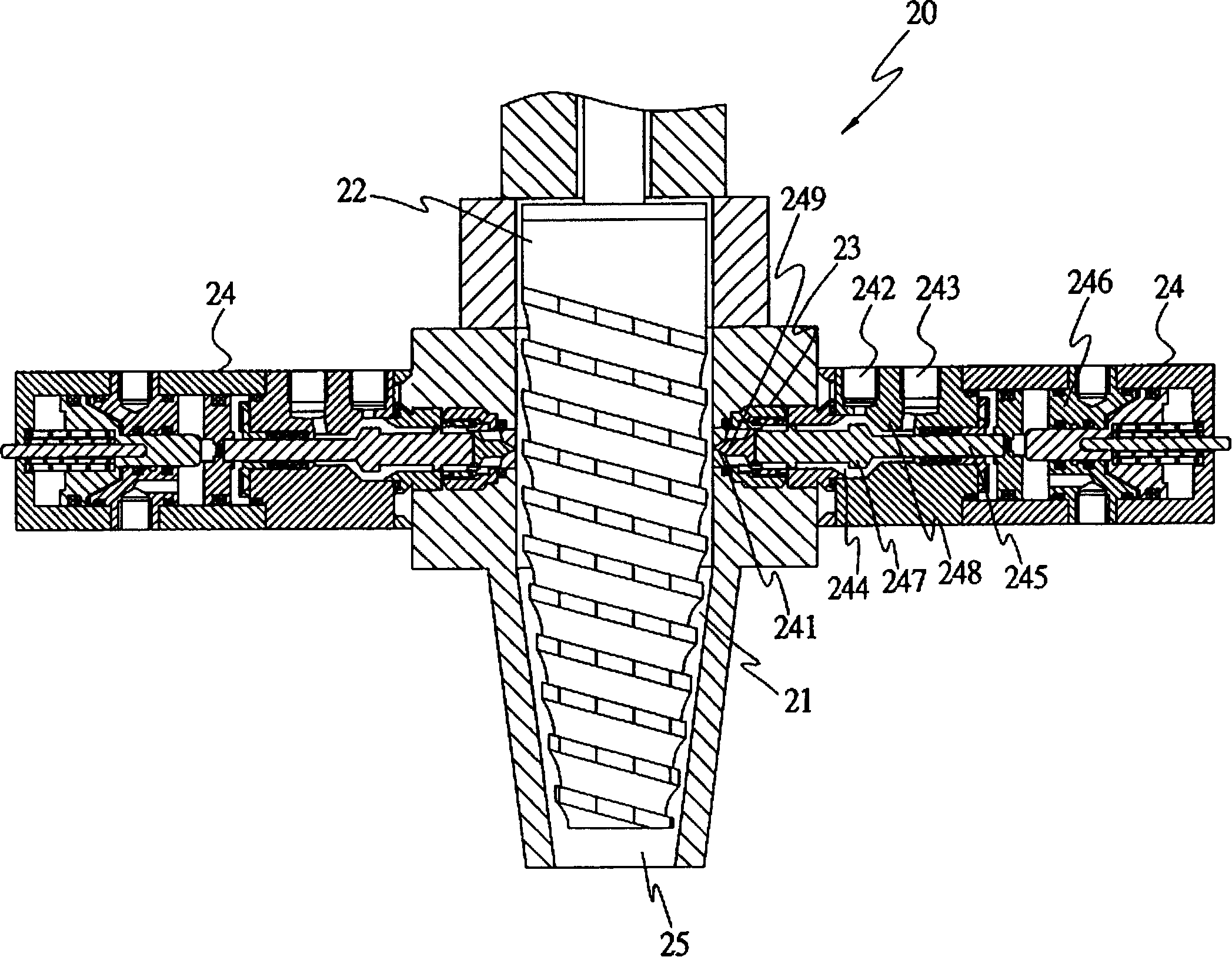

ActiveCN103367208ARigorous processHigh precisionSemiconductor/solid-state device manufacturingCircular discMicrometer

The invention discloses a back bonding platform for a superchip. The back bonding platform comprises a substrate, a chip peeling and overturning unit, an X-Y direction movement unit, a multi-degree of freedom bonding head and a mounting platform unit, wherein the chip peeling and overturning unit is used for respectively peeling and overturning a chip on a wafer disk and sending the chip to a to-be-picked position; the multi-degree of freedom bonding head is arranged on a supporting guide rail of the X-Y direction movement unit in a cantilever mode, and has functions of automatically levelling and aligning; the mounting platform unit is used for adsorbing the substrate and matched with the bonding head, so that the chip and the substrate are mutually positioned. In addition, in order to ensure the high-precision movement or matching of units, a plurality of vision positioning systems are configured in the back bonding platform. The back bonding platform can reach micrometer-level alignment accuracy, has the parallel adjusting accuracy of higher than 0.01 degree, and has the advantages of compact structure, convenience for operation and the like, so that the back bonding platform is particularly suitable for back bonding of the superchip.

Owner:HUAZHONG UNIV OF SCI & TECH

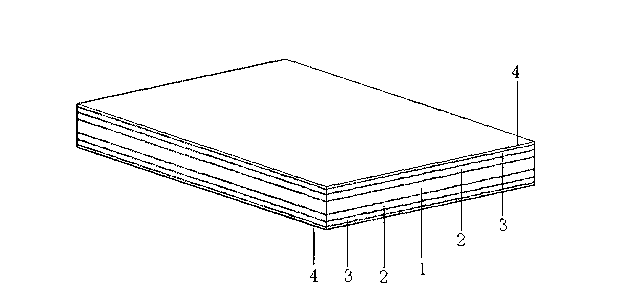

Manufacturing method of melamine ecological plate

InactiveCN103128804AReduce formaldehyde contentReduce production energy consumptionWood veneer joiningEmulsionEngineering

The invention discloses a manufacturing method of a melamine ecological plate. The ecological plate is compounded with a core plate, a middle plate layer, a slab layer and melamine impregnated paper. The core plate is stuck to the middle plate layer after an upper face and a lower face of the core plate are glued. After cold pressing and hot pressing, the core plate is repeatedly maintained, trimmed and sanded, and is glued and stuck to the slab layer. Similarly, after the cold pressing, hot pressing, trimming and sanding, the core plate is glued and stuck to the melamine impregnated paper. The ecological plate manufactured by the method is energy-saving and environment-friendly, and under the condition that energy consumption is not increased, the ecological plate is cold pressed before hot pressing so that a composite structure of the plate is firmer. Furthermore, in the process of pressing and gluing the melamine impregnated paper, emulsion free of formaldehyde is used as binding agent, and accordingly formaldehyde content of the plate is reduced.

Owner:江苏福庆木业有限公司

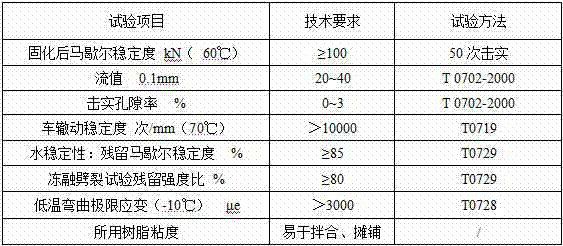

Steel bridge deck pavement cold mixing maintenance material and manufacturing method thereof

ActiveCN103114526AImprove bonding effectImprove interlayer bond strengthIn situ pavingsBridge structural detailsStructural engineeringResin bonding

The invention discloses a steel bridge deck pavement cold mixing maintenance material and a manufacturing method thereof. The maintenance material comprises a resin detritus waterproof layer, a resin bonding layer and a resin concrete pavement layer. The resin detritus waterproof layer is coated on a steel bridge panel required maintenance and is formed by solidifying resin and detritus spread on the surface of the resin. The resin bonding layer is coated on the resin detritus waterproof layer. The resin concrete pavement layer is coated on the resin bonding layer and is formed by solidifying the resin and aggregate in a mixed mode. According to the maintenance material, construction is convenient, influence on construction conditions by temperature is small, performance is excellent, maintenance time is short, production is convenient and rapid, construction period is short and influence on traffic is small.

Owner:江苏苏科建设项目管理有限公司

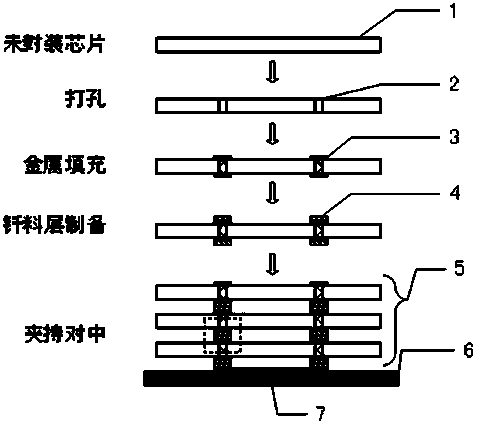

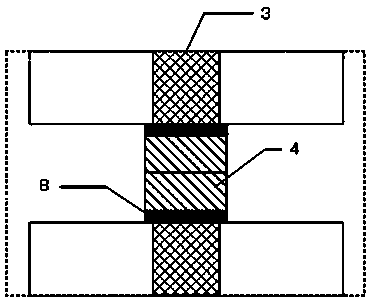

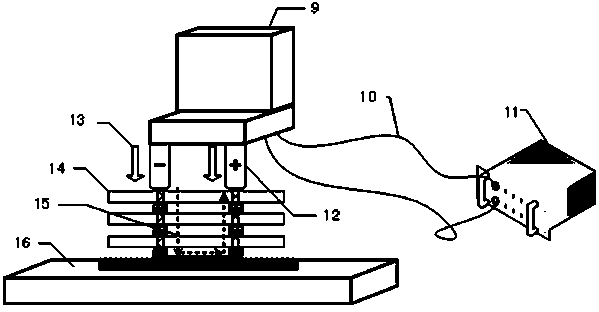

Method for achieving silicon through hole laminated chip interconnection

InactiveCN103972165AQuick bondImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingBonding processEngineering

The invention discloses a method for achieving silicon through hole laminated chip interconnection. The method is used for achieving bonding among multiple layers of stacked silicon through hole chips through the following steps of punching, filling of conductive metal, preparing of a solder layer, clamping and centering, bonding and forming of finished products, wherein in the bonding process, a current joule heat auxiliary bonding technology is adopted for achieving silicon through hole three-dimensional interconnection welding spot bonding. According to the method for achieving three-dimensional packaging and bonding with the assistance of joule heat, under the low temperature and even the normal temperature, fast bonding of full intermetallic compound welding spots can be achieved, and heat damage to a chip is effectively reduced. Under the action of oriented currents, intermetallic compounds in the welding spots are grown preferably and rapidly in an oriented mode, high electrical conductivity and the good comprehensive mechanical property of the welding spots are achieved, and the reliability of the bonding spots is effectively improved. A parallel electrode resistance welding platform is adopted, a hot plate and an ultrasound device are easily integrated, the better bonding effect can be achieved, and the bonding time is shortened.

Owner:HARBIN INST OF TECH

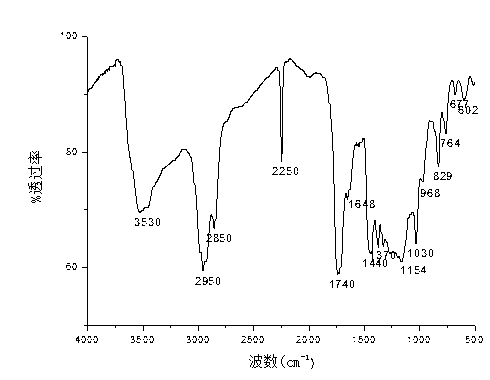

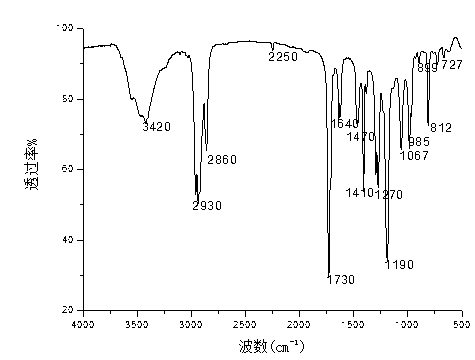

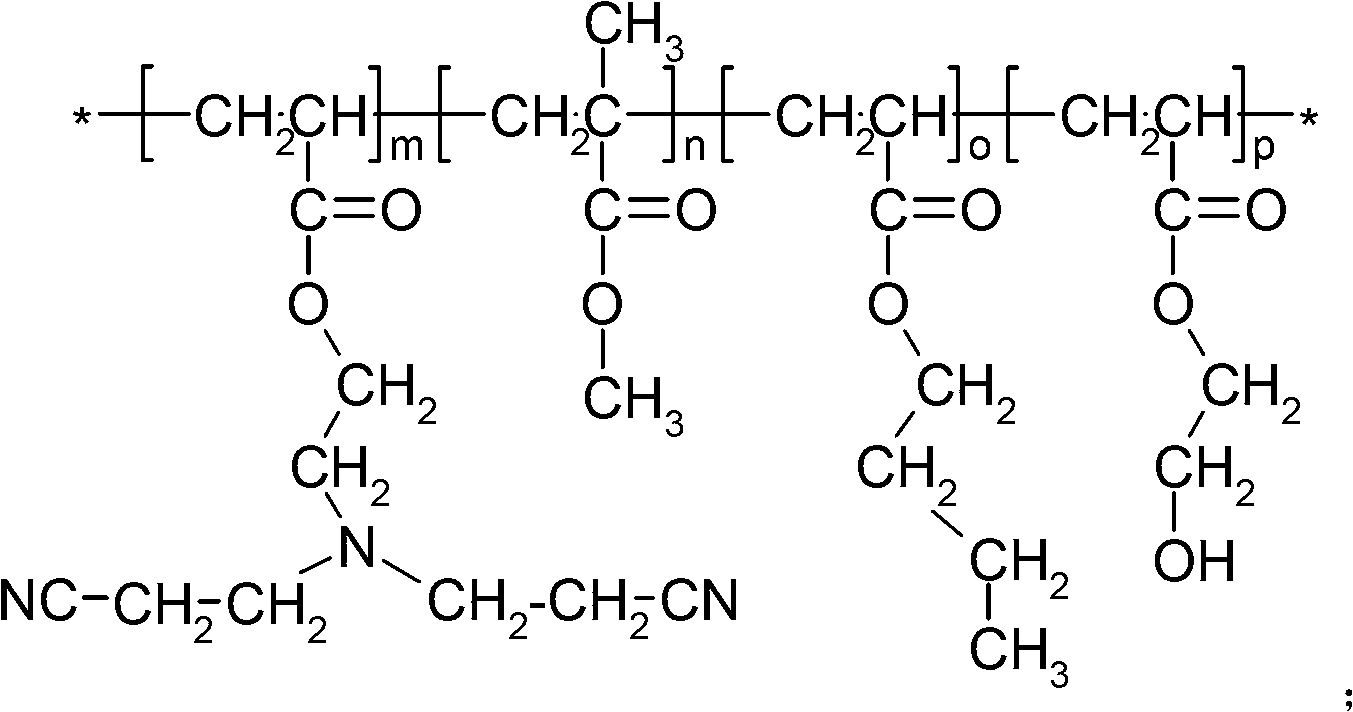

Macromolecule bonding agent and preparation method thereof

InactiveCN102977260AStrong forceThe polymerization reaction is easy to controlCarboxylic acid nitrile preparationOrganic compound preparationChemical synthesisPolymer science

The present invention discloses a macromolecule bonding agent and a preparation method thereof, and belongs to the technical field of chemical synthesis and propellant applications, wherein the obtained product can be adopted as a propellant bonding agent. According to the present invention, N,N-dicyanopropyl aminoethyl acrylate, methyl methacrylate, butyl acrylate and hydroxyethyl acrylate are subjected to copolymerization, wherein a copolymer function chain contains two cyanoalkyl groups, such that an absorption effect is strong; during product preparation, a reactivity ratio of the function monomer is close to reactivity ratios of other copolymerization monomers, such that the reaction is easily controlled; a good bonding effect can be achieved in propellant applications so as to provide a good mechanical property; and advantages of easily-obtained raw materials, easily-achieved preparation process and easy promotion and application are provided.

Owner:SUZHOU UNIV

High-efficiency dust suppressant for urban roads

InactiveCN109082265AImprove bonding effectStrong material strengthOther chemical processesWater contentChemistry

The invention discloses a high-efficiency dust suppressant for urban roads. The dust suppressant consists of the following components in percentage by mass: 0.1-40 % of water retaining agent, 0.1-40 %of adhesive, 0.1-5.0 % of wetting agent, 0.01-5 % of accelerator, and 20-80 % of water. The accelerator and the adhesive contained in the dust suppressant have more reaction sites, wherein the accelerator can react with main effective adhesive substances for curing reaction crosslinking in the process of spraying and drying of the dust suppressant, and thus the bonding effect of the adhesive is enhanced, the acting force between dust is strengthened, and a combination, which finally forms, has stronger material strength, and can resist the shearing force and pressure of vehicles on the road surface to a greater extent, so that the dust suppression effect is enhanced. The water retaining agent in the dust suppression agent is a high-efficiency water-absorbing substance, ensures the road surface to keep a certain water content, and can be matched with the wetting agent to adapt to different environments in different regions and ensure the dust suppression effect of the roads.

Owner:ZHEJIANG UNIV

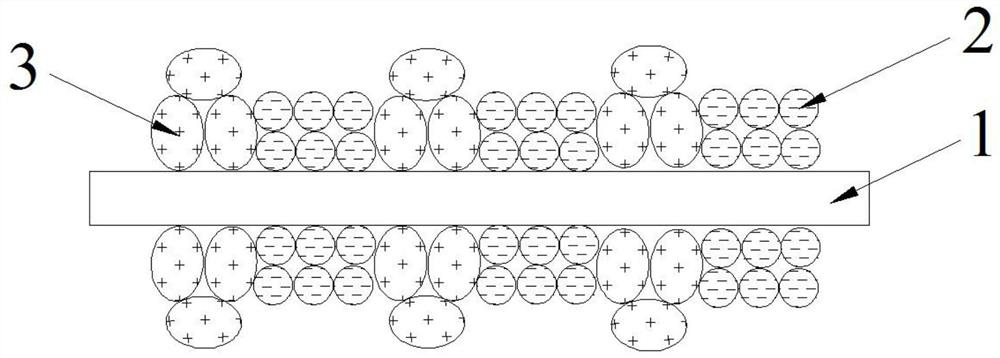

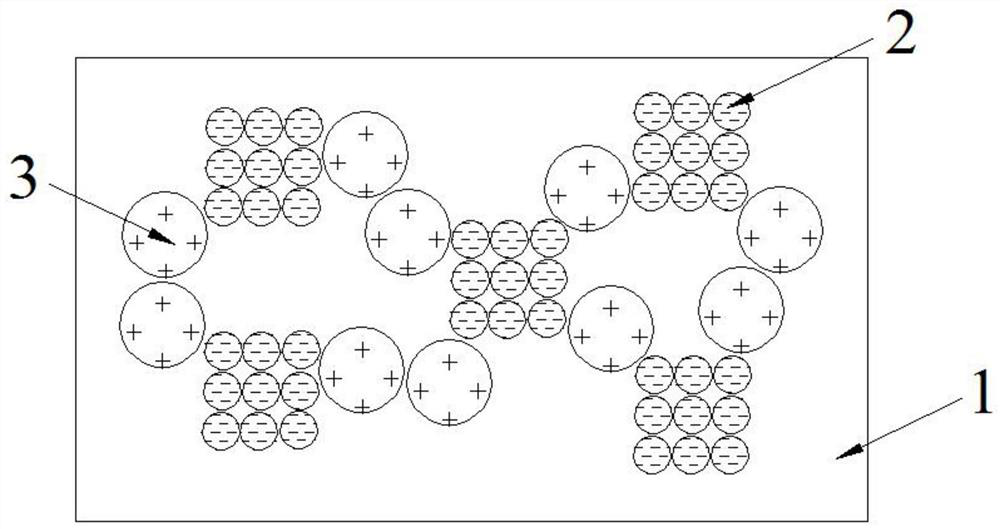

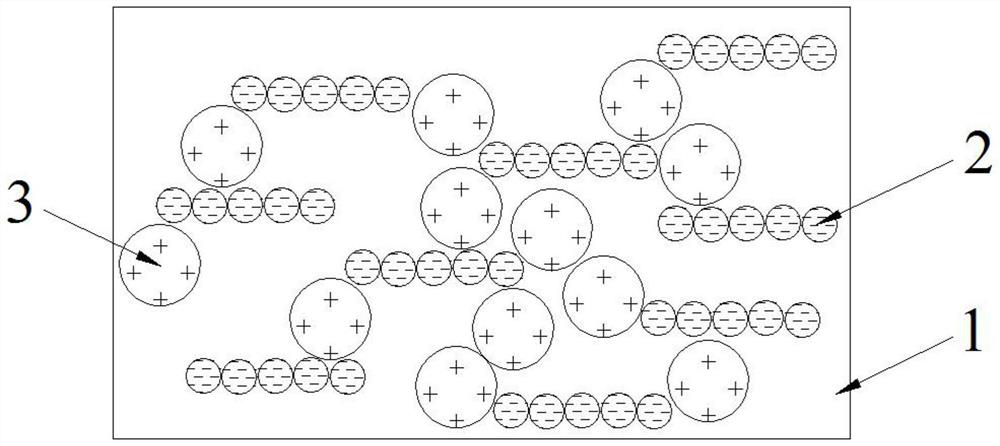

Cold-mixed and cold-laid asphalt mixture, and cold-mixed and cold-laid asphalt mixture wearing layer

ActiveCN108129073AImprove bonding effectReduce driving noiseIn situ pavingsPitch blendeHigh resistance

The invention provides a cold-mixed and cold-laid asphalt mixture, and a cold-mixed and cold-laid asphalt mixture wearing layer, and belongs to the technical field of road engineering. The cold-mixedand cold-laid asphalt mixture comprises coarse aggregates, fine aggregates, high-performance modified emulsified asphalt, a mineral filler, water and a liquid additive. The asphalt mixture prepared from above cold-mixed and cold-laid material components according to a special mineral grading range can be closely bonded to an old asphalt pavement and a cement pavement; and compared with traditionalmicro-surfacing and super-sticky wearing layer materials, the mixture has higher resistance to crack, water and skid and lower driving noises.

Owner:SOUTH CHINA UNIV OF TECH +1

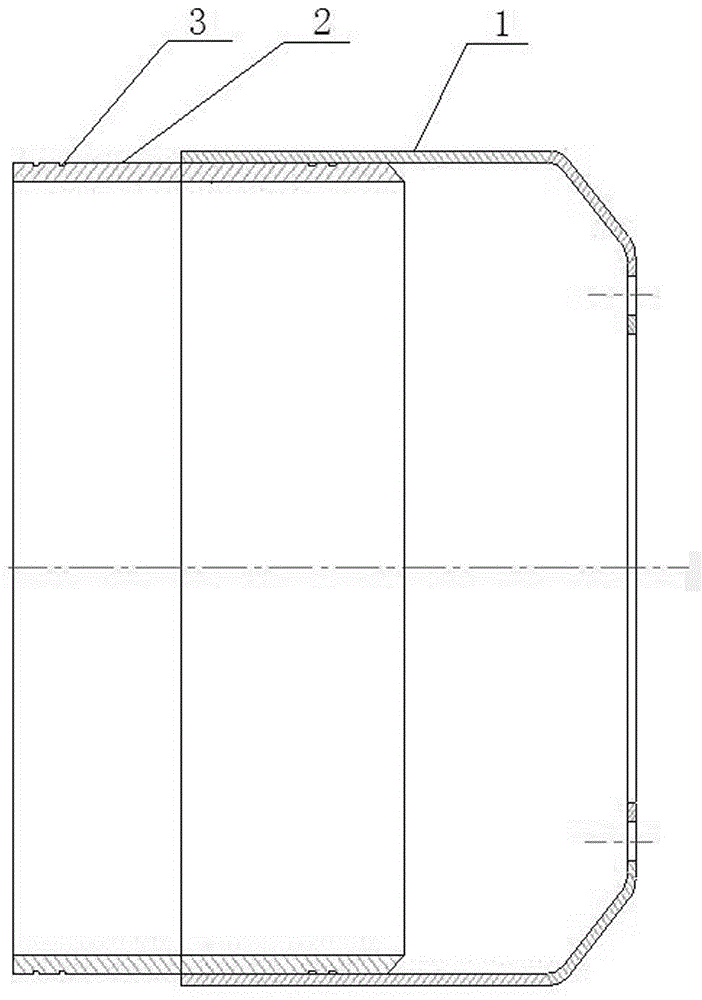

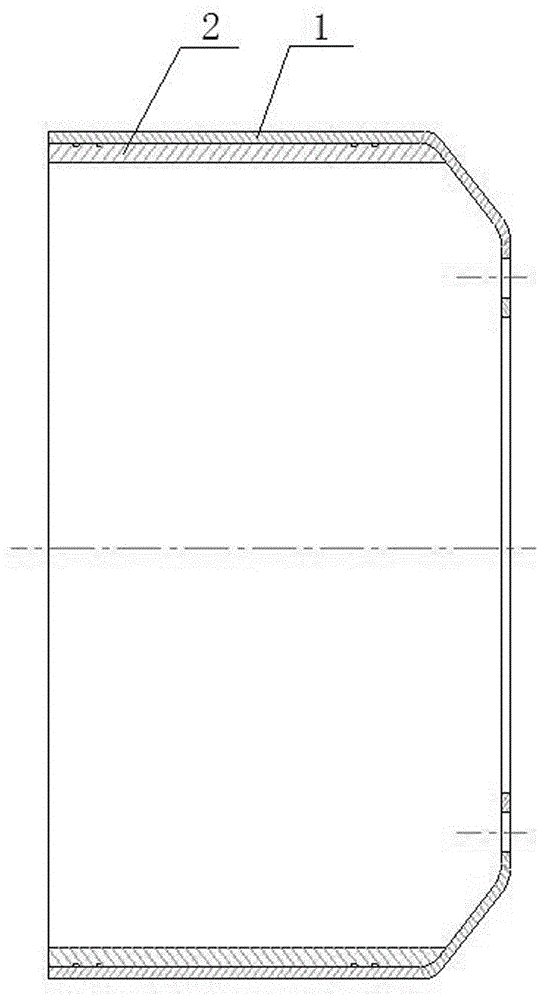

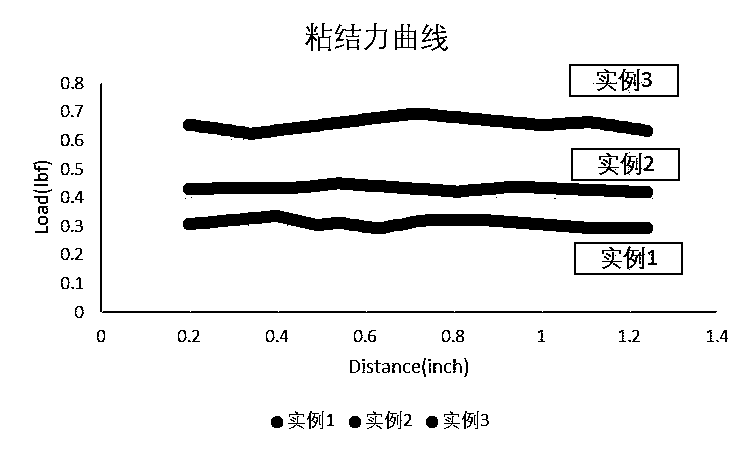

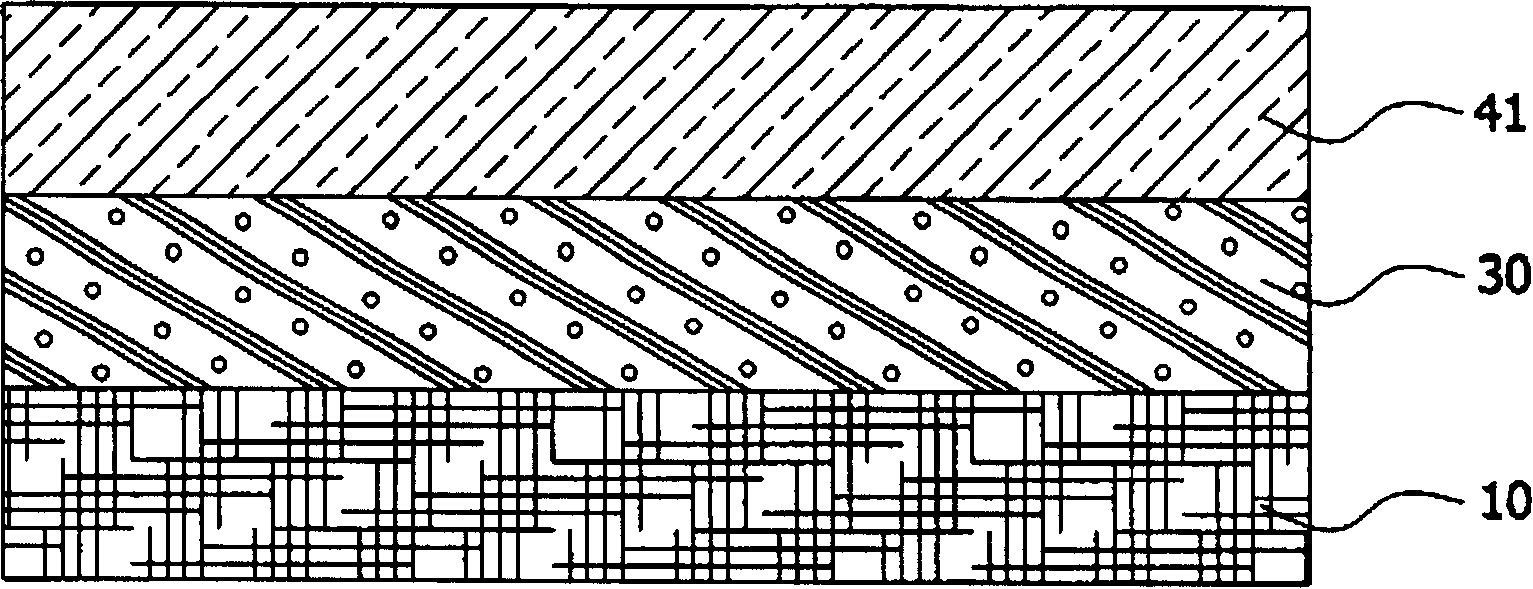

Preparation method of composite diaphragm, composite diaphragm and lithium ion battery

ActiveCN111653717AImprove bonding effectRealize regular arrangementSecondary cellsCell component detailsBond coatingLithium electrode

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a composite diaphragm. The preparation method comprises the following steps:putting inorganic particles into a first solvent to obtain inorganic slurry, coating at least one surface of a base membrane with the inorganic slurry at intervals, and drying to obtain an inorganic heat-stable coating; putting organic particles into a second solvent to obtain organic slurry, and coating the surface of the base film between the inorganic heat-stable coatings with the organic slurry at intervals to obtain an organic bonding coating, wherein the thickness of the organic bonding coating is greater than that of the inorganic heat-stable coating; and drying to obtain the compositediaphragm. According to the invention, the problems that inorganic particles and organic particles cannot be regularly arranged, the organic particles can be buried by the inorganic particles, and thebonding effect of the organic particles, a base film and a pole piece is poor are solved.

Owner:东莞市魔方新能源科技有限公司

Addition heat-conducting self-adhesive silicone rubber and preparation method thereof

InactiveCN105315958AImprove bonding effectPlay a bonding effectNon-macromolecular adhesive additivesSilane couplingSelf adhesive

The invention relates to the field of thermal interface materials, and provides addition heat-conducting self-adhesive silicone rubber which comprises the ingredients of resin, a reinforcing filler, a heat-conducting filler, a silane coupling agent and a titanate coupling agent. The invention further provides a preparation method of the addition heat-conducting self-adhesive silicone rubber. The preparation method comprises the following steps: A, weighing proper quantities of raw materials according to the proportion of the raw materials; B, pretreating the heat-conducting filler with the silane coupling agent and the titanate coupling agent; C, mixing resin and the reinforcing filler in a kneader to obtain a uniform mixture, and grinding the uniform mixture with a grinding machine till the reinforcing filler is dispersed uniformly; D, putting materials obtained in the step B and the step C into the kneader, and carrying out heating, vacuumizing and uniform stirring. The self-adhesive silicone rubber can perform a bonding effect as soon as being directly cured at high temperature during bonding. The preparation method has the advantage that the bonding effect of the silicone rubber is enhanced effectively.

Owner:SUZHOU TIANMAI THERMAL TECH

Forming method of press-fit double-metal compound brake drum

The invention discloses a forming method of a press-fit double-metal compound brake drum, and relates to the technical field of brake drum forming methods. Firstly, a cold drawing stretching method is adopted to manufacture a low-carbon steel pipe as a brake drum cover; a centrifugal casting method is used for manufacturing a cast iron pipe; the cast iron pipe is machined as a certain size; the outer diameter of the cast iron pipe is larger than the inner diameter of a low-carbon steel shell; multiple grooves are machined in the outer wall of the cast iron pipe; epoxy resin adhesive is coated on the outer wall of the cast iron pipe and in the grooves; the cast iron pipe is pressed in the brake drum cover manufactured by the low-carbon steel by a hydropress to form the double-metal compound brake drum compounded by two materials of low-carbon steel and cast iron; and the brake drum can be placed by 24 hours for installation for use. The forming method of the double-metal compound brake drum is simple, is high in efficiency, is firm in combination of two materials of the brake drum, and is safe and durable in product.

Owner:HENAN UNIV OF SCI & TECH

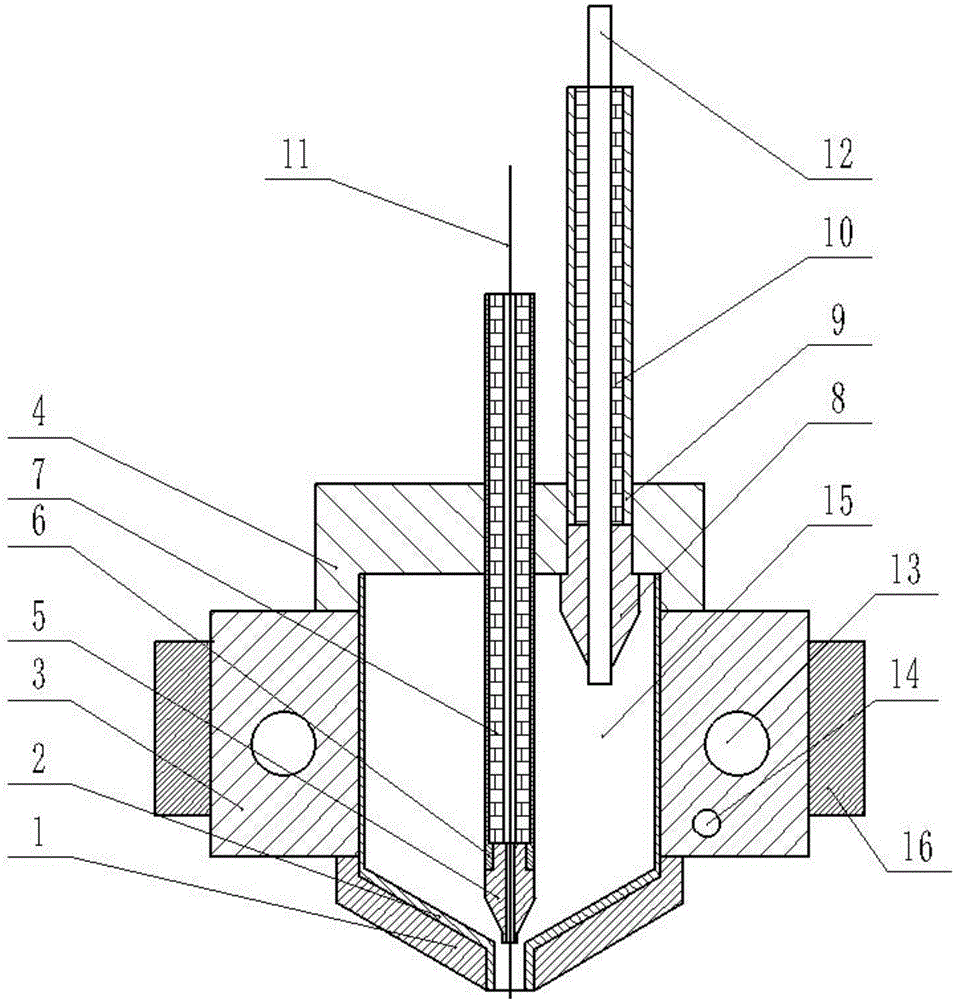

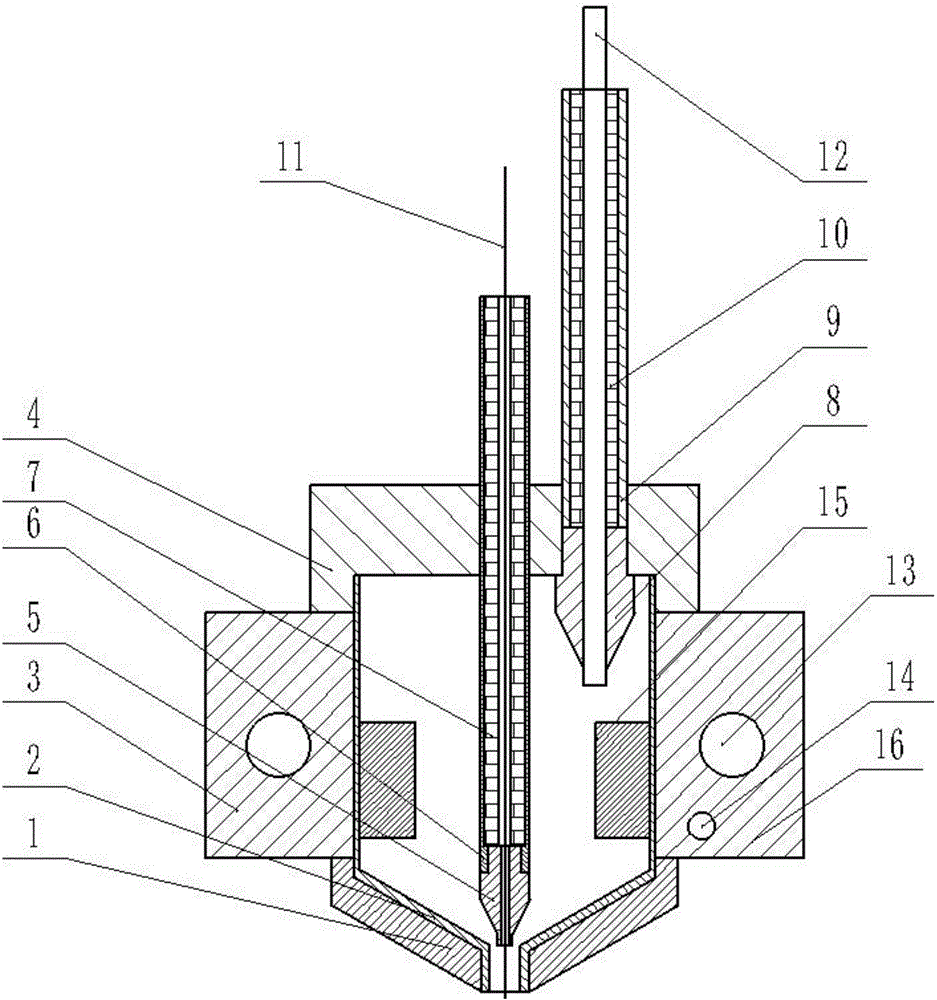

Additive manufacturing sprayer for fiber reinforced composite material based on ultrasonic enhancing

ActiveCN106363905AImprove bonding effectImprove print quality3D object support structuresApplying layer meansUltrasonic generatorPolytetrafluoroethylene

The invention belongs to the field of additive manufacturing and relates to an additive manufacturing sprayer for a fiber reinforced composite material based on ultrasonic enhancing. The additive manufacturing sprayer for the fiber reinforced composite material based on ultrasonic enhancing comprises a sprayer body, an inner cavity, a heat conducting block, a cap, a fiber sprayer body, a fiber throat pipe, a polytetrafluoroethylene pipe I, a resin sprayer body, a resin throat pipe, a polytetrafluoroethylene pipe II, heating rods, temperature sensors and ultrasonic generators, the resin and fiber bonding effect can be improved, sprayer blockage is prevented, and the sprayer body can be conveniently cleaned. The sprayer body is detachably connected to the lower end of the inner cavity and is sleeved with the heat conducting block; the heating rods and the temperature sensors are arranged on the heat conducting block in a nested manner; the upper end of the inner cavity is detachably connected with the cap; the fiber throat pipe and the resin throat pipe are both detachably connected to through holes of the cap; the through hole connected with the resin throat pipe is further detachably connected with the resin sprayer body; the polytetrafluoroethylene pipe I is arranged in the fiber throat pipe in a sleeved manner; the lower end of the fiber throat pipe is detachably connected with the fiber sprayer body; the polytetrafluoroethylene pipe II is arranged in the resin throat pipe in a sleeved manner; and a cavity is formed after the inner cavity is connected with the cap.

Owner:HARBIN INST OF TECH

Decorative plastic surface vacuum-coating film preparation method

InactiveCN103726011AImprove shielding effectNo emissionsVacuum evaporation coatingSputtering coatingFrequency bandChemistry

The invention discloses a method for preparing a decorative plastic surface vacuum-coating film having effects of electromagnetic radiation resistance, static conduction, hardness improvement, color adjustment, wear resistance and worm damage resistance. The method comprises the following steps of a, cleaning the plastic surface and carrying out flattening treatment, b, sealing the plastic surface by an amino airtight resin, c, putting the plastic into a cleaning tank containing diluted acid or diluted alkali, carrying out cleaning and carrying out drying, and d, carrying out film vacuum-coating on the dried plastic surface so that metal is deposited on the plastic surface and forms a continuous and uniform film containing the metal and metal oxides. The plastic product material obtained by the method has electromagnetic shielding effectiveness above 30dB in a frequency band of 30MHz to 1.5GHz and satisfies electromagnetic shielding and static conduction requirements. The method has simple and feasible processes, is environmentally friendly and efficient, can be used at a low temperature and is suitable for industrial large-scale production. Through the film, a plastic surface color can be adjusted according to demands and plastic surface hardening, corrosion resistance, wear resistance and good appearance are realized. The method greatly broadens plastic purposes, improves a plastic grade and realizes efficient plastic utilization.

Owner:WUXI HUIMING ELECTRONICS TECH

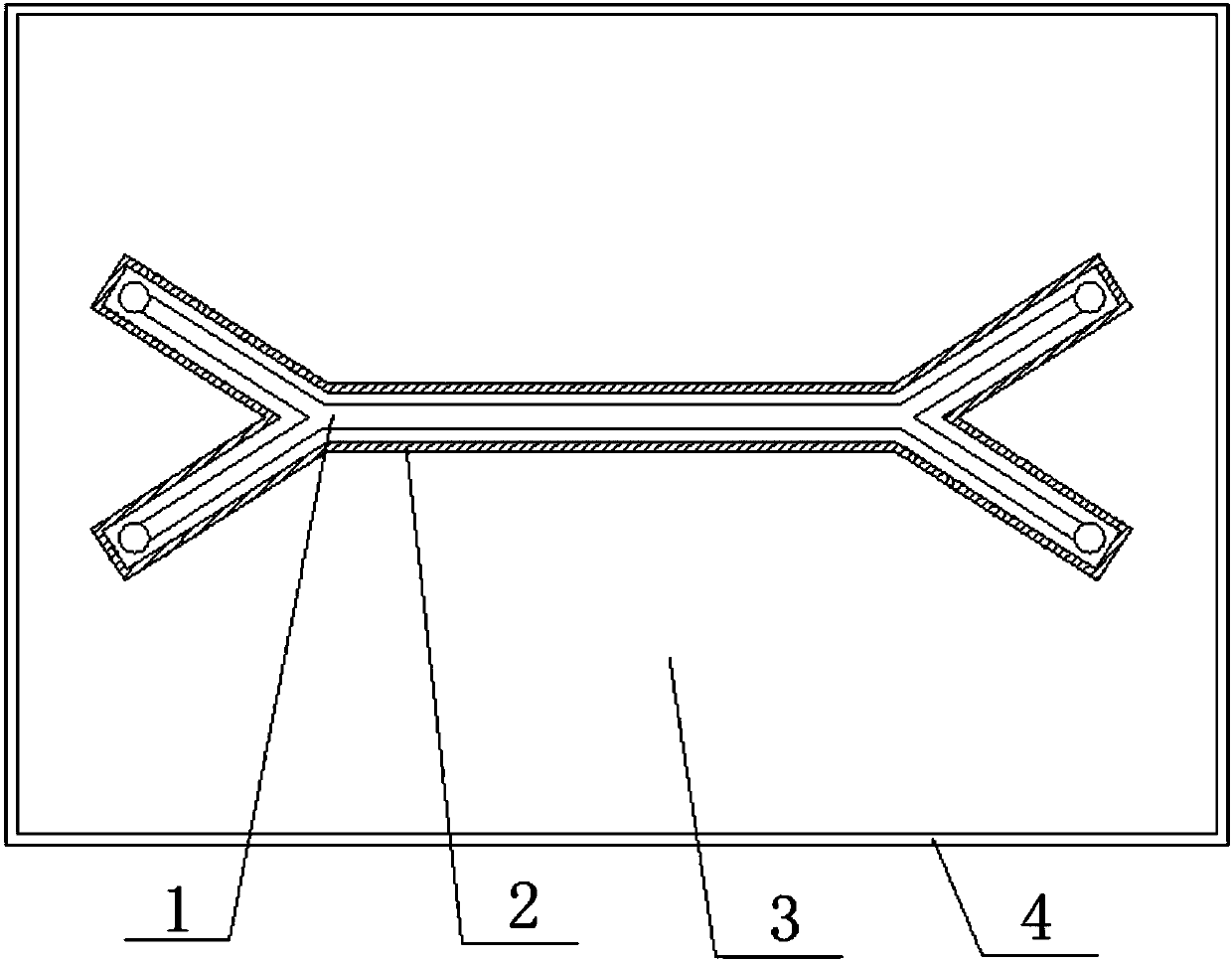

Micro-fluidic chip bonding method and micro-fluidic chip

ActiveCN107775960AGuaranteed stabilityAvoid affecting physical and chemical propertiesLaboratory glasswaresAdhesiveEngineering

The invention relates to the technical field of bioscience micro-total analysis systems, in particular to a micro-fluidic chip bonding method and a micro-fluidic chip. The method includes: providing amicro-fluidic chip substrate, wherein the upper surface of the substrate is provided with a microchannel structure; arranging ultrasonic bonding energy conducting ribs at the edge around the microchannel structure of the upper surface of the substrate or around a position, corresponding to the microchannel structure of the substrate, of a cover plate; adhering a surface pasting double-side adhesive tape on the substrate or the cover plate to glue the cover plate with the substrate; performing ultrasonic bonding on the substrate and the cover plate to enable first-step bonding; applying pressure to fix the chip or hot-pressing the same to enable the substrate and the cover plate which are pasted by the double-side adhesive tape to be firmly bonded. By the method, bonding stability of the micro-fluid chip can be ensured, and own physiochemical properties of the micro-fluidic chip can be avoided being affected, so that detection results are not interfered.

Owner:成都微康生物科技有限公司

Double-component aluminum metal anti-corrosion repairing agent and preparation method thereof

InactiveCN104804692AGood high temperature resistanceImprove bonding effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesActive agentDefoaming Agents

The invention discloses a double-component aluminum metal anti-corrosion repairing agent and a preparation method thereof. The repairing agent comprises the following components in parts by weight: 20 to 25 parts of epoxy resin, 10 to 15 parts of curing agent, 18 to 23 parts of reinforced stuffing, 10 to 15 parts of coupling agent, 5 to 8 parts of micro powder, 3 to 6 parts of active agent, 1 to 3 parts of tackifier, 0.1 to 0.5 part of defoaming agent and 30 to 35 parts of thinning agent. A membrane layer formed by the repairing agent on the surface of an aluminum base material can resist the high temperature of 700 DEG C and has no phenomenon of obvious stripping, burring and the like. The double-component aluminum metal anti-corrosion repairing agent is excellent in water resistance, alkali and acid resistance and weather resistance.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Adhesive for corrugated packaging carton

InactiveCN108504293AImprove bonding effectGood adhesionNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveChemistryAdhesive

The invention discloses an adhesive for a corrugated packaging carton. The adhesive is prepared from, by weight, 20-29 parts of nanometer titania, 16-26 parts of ethyl acetate, 50-80 parts of starch,4-9 parts of methyl methacrylate, 3-10 parts of potassium persulfate persulphate, 6-12 parts of waterborne hydroxyl polyurethane, 60-90 parts of water, 5-12 parts of sodium metasilicate and 3-9 partsof citric acid. In this way, the adhesion effect is remarkably improved by means of the adhesive.

Owner:苏州震嵘包装有限公司

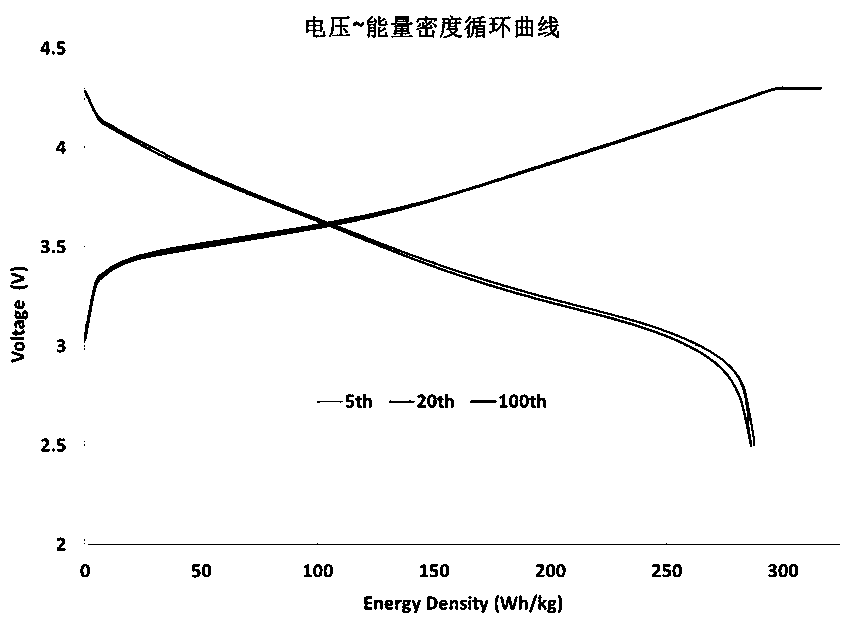

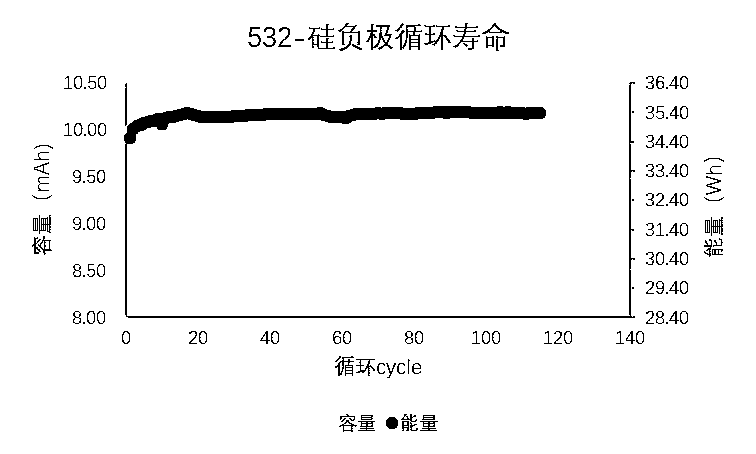

High-proportion silicon negative electrode aqueous composite binder and application thereof

InactiveCN111244454AGood tensile propertiesImprove bonding effectCell electrodesSecondary cellsCyclic stabilityAqueous solubility

The invention relates to a high-proportion silicon negative electrode aqueous composite binder, which is prepared by the following steps: mixing a polymer A, a polymer B and a polymer C into a negative electrode plate, and heating the negative electrode plate in vacuum, wherein the polymer A is water-soluble polyimide (PI), the polymer B is at least one of polyacrylic acid (PAA) or polymethylacrylic acid (PMAA), and the polymer C is water-soluble styrene-butadiene latex (SBR). T the aqueous composite binder combines good cohesiveness of PI, PAA (PMAA) and SBR, shows good tensile property, canform a cross-linked network after heating treatment, improves the bonding effect, can well adapt to expansion of the volume of the silicon negative electrode, and improves the cycling stability of thesilicon negative electrode.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

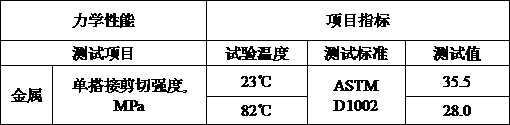

Preparation method for low-temperature curing structure glue film

InactiveCN108395860AHigh bonding strengthImprove bonding effectNon-macromolecular adhesive additivesFilm/foil adhesivesLow temperature curingHot melt

The invention provides a preparation method for a low-temperature curing structure glue film. The low-temperature curing structure glue film is prepared from the following components in parts by weight: 25-50 parts of component A, 25-50 parts of component B, 10-25 parts of component C, 5-40 parts of component D, 10-25 parts of component E and 1-25 parts of component F, wherein the component A is selected from at least one of multifunctional epoxy resins, and the component B is selected from one or more of bisphenol epoxy resins. A resin composition is prepared by uniformly mixing the above components A-F, and 100-400 g / m<2> of the low-temperature curing structure glue film is prepared by performing a hot melting method on the obtained resin composition. The method is capable of effectivelyreducing the internal stress easily generated in a heating curing process, and the prepared low-temperature curing structure glue film has an excellent adhesive property and a good gluing result, andcan be extensively applied to board-board and board-core gluing in metal or composite materials.

Owner:HENGSHEN

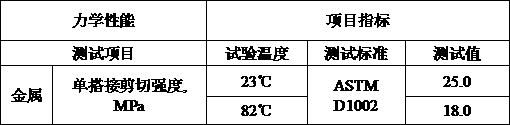

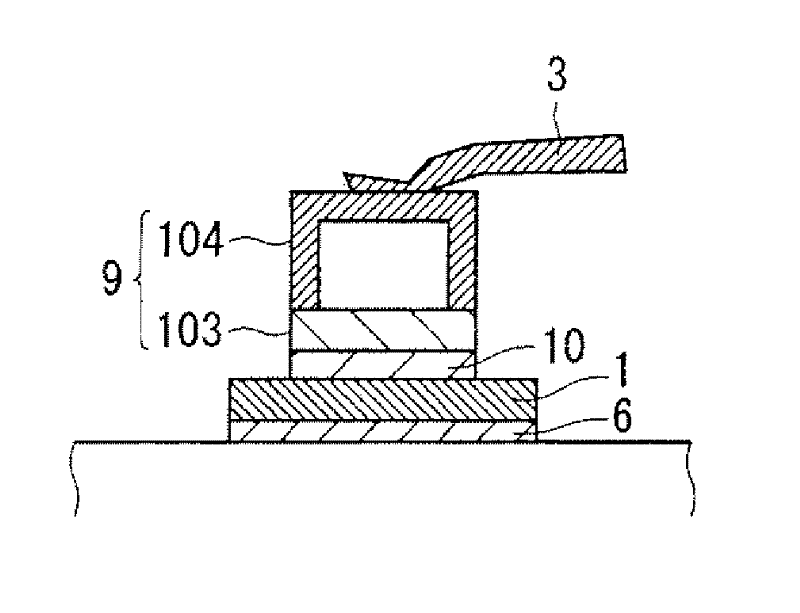

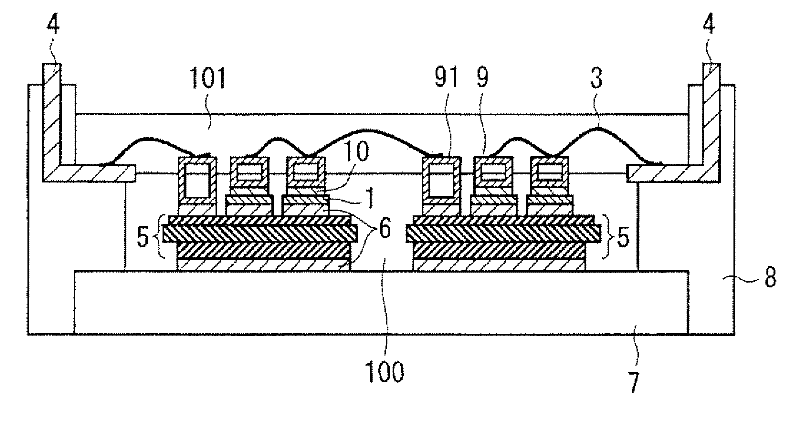

Power module and method for manufacturing same

InactiveCN102446864AInhibition of direct heat transferInhibit thermal stressSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

Provided is a power module that prevents a deterioration of reliability of bonded portions of aluminum wires, and enables a high-temperature operation of a Si or SiC device. A power module according to the present invention includes: insulating substrates (5) arranged in a case (8); power elements (1) bonded on the insulating substrates (5); wiring members (9) as first wiring members which are rectangular tube-like metal, and have first side surfaces bonded to surface electrodes of the power elements (1); aluminum wires (3) as wires connected to second side surfaces of the wiring members (9), which are opposite to the first side surfaces, and a sealing material (2) filled into the case (8) while covering the insulating substrates (5), the power elements (1), the wiring members (9) and the aluminum wires (3).

Owner:MITSUBISHI ELECTRIC CORP

Decorative joint filling device for decoration and using method thereof

ActiveCN111535558AGuaranteed integrityImprove bonding effectDirt cleaningCleaning using toolsBar pressingDrive motor

The invention relates to a decorative joint filling device for decoration and a using method thereof. The decorative joint filling device comprises a bottom plate, a driving motor and an electric pushing rod, wherein the bottom plate is provided with a circular ring, the driving motor, a hollow drum, the electric pushing rod, a mounting cylinder and a push handle; the circular ring is provided with an air filtration structure; the air filtration structure is provided with a hose; the hose is connected to the hollow drum; the hollow drum is provided with a rotating shaft, fan blades and an airinlet pipe; the right end of the air inlet pipe is arranged at the bottom of the bottom plate; the driving motor is connected to the rotating shaft; the rotating shaft is provided with a driving beltpulley; the driving belt pulley is provided with a belt; the belt is provided with a driven belt pulley; the driven belt pulley is provided with a rotating rod; the rotating rods are provided with a cutting disk and a rotating disk; the rotating disk is provided with bristles; the rotating disk is provided with a dust pushing structure; the dust pushing structure is provided with a dust accumulation structure; the mounting cylinder is provided with a decorative joint filler cylinder; the electric pushing rod is provided with an L-shaped pressing rod; the bottom plate is provided with a straight rod; and the straight rod is provided with a pressing ball. The decorative joint filling device for decoration and the using method thereof have the advantages of realizing the cleanliness in cut joints, avoiding the influence of dust in the cut joints on decorative joint filler, improving the bonding effect of the decorative joint filler and tiles, and ensuring the integrity of decorative jointfilling.

Owner:河南瑞隆建设有限公司

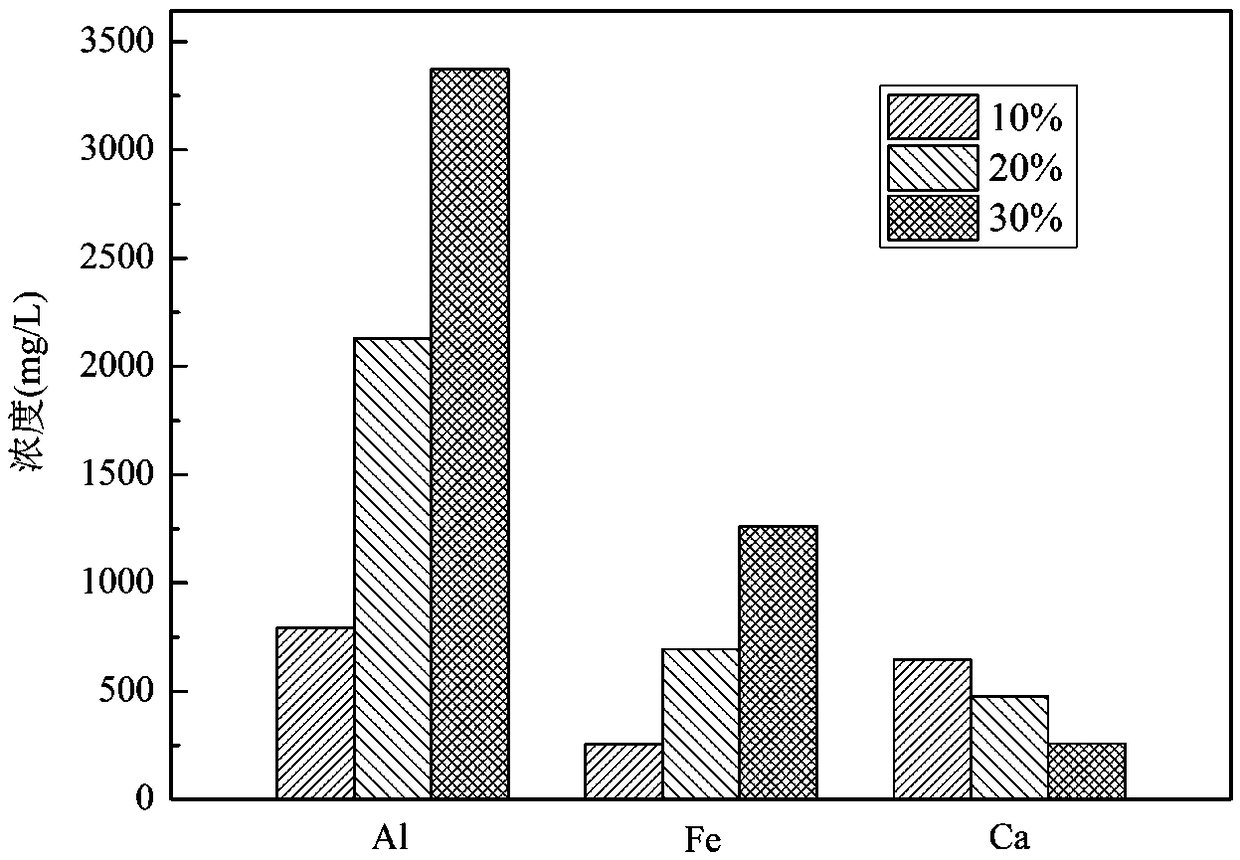

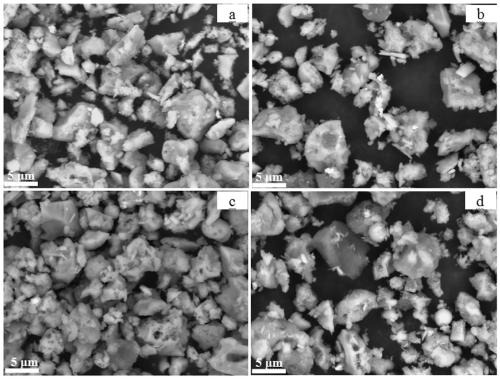

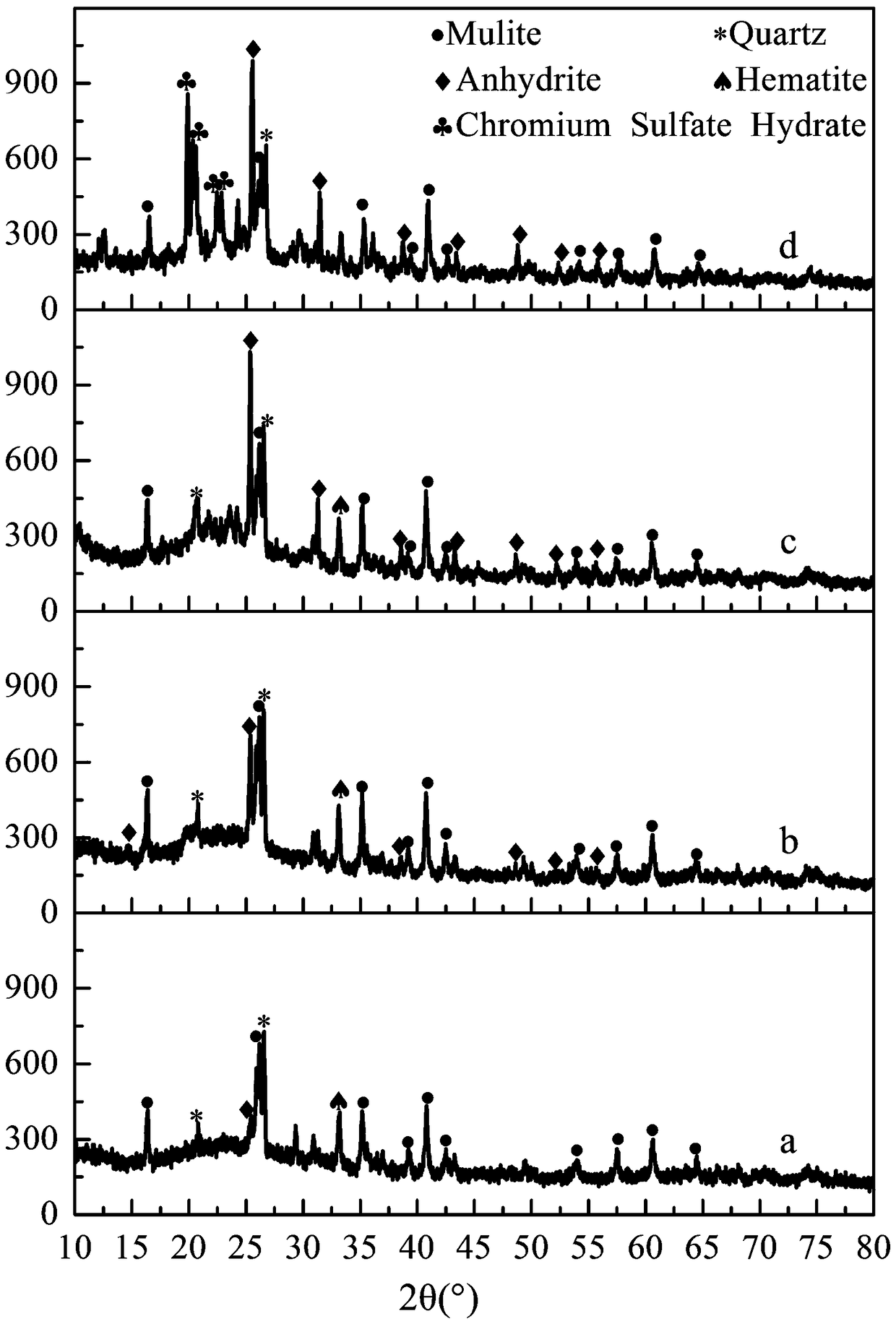

Modified magnesium sulfate cement and preparation method thereof

The invention provides a preparation method of modified magnesium sulfate cement. The method comprises the following steps: (1) weighing concentrated sulfuric acid, ultrafine coal ash, magnesium oxideand water according to a certain proportion for later use; (2) adding the concentrated sulfuric acid into a certain amount of water reserve to prepare a dilute sulfuric acid solution, then adding theultrafine coal ash, and stirring to obtain activated modified ultrafine coal ash; (3) slowly adding 10 to 20 percent of magnesium oxide reserve into the mixture obtained in step (2), and regulating and stirring to fully dissolve the active magnesium oxide in order to obtain a mixture of the coal ash and the magnesium sulfate solution; (4) weighing a certain amount of additive, adding the additiveinto the remaining water, stirring at room temperature for dissolving, adding the solution into the mixture obtained in step (3), continually adding the remaining magnesium oxide, and stirring for 30to 60 minutes to obtain pure thick magnesium sulfate cement slurry. The magnesium sulfate cement can be up to 66.96 MPa in compressive strength after 28 days. Moreover, the preparation method is easyto operate, low in cost, and easy for realizing industrialization.

Owner:SHANXI UNIV

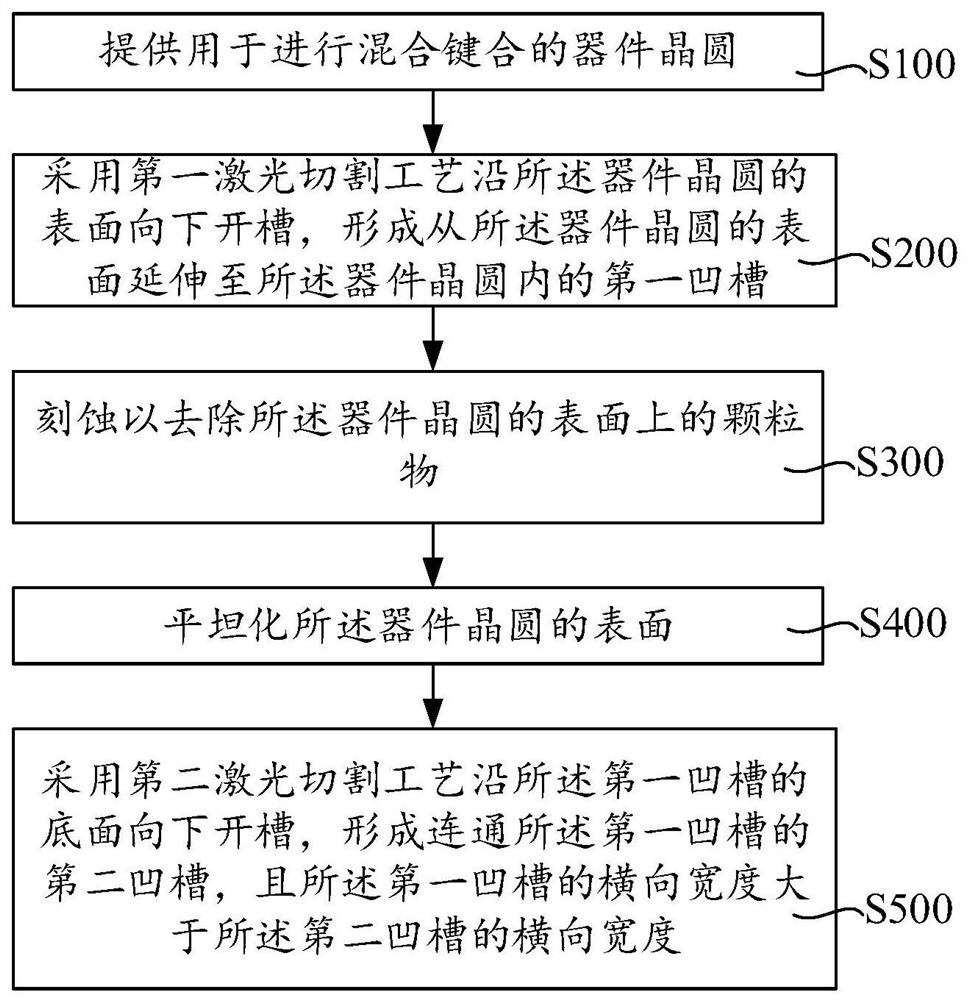

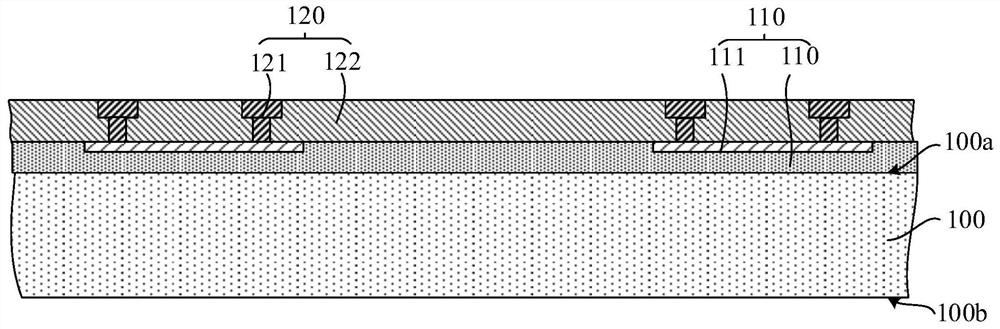

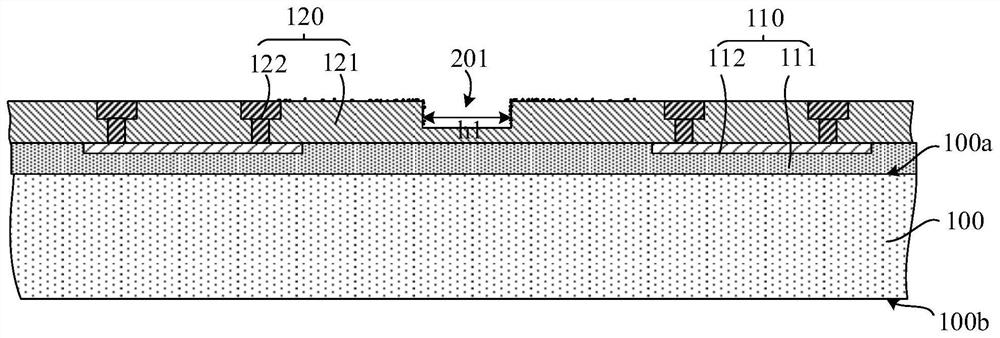

Wafer cutting method

ActiveCN113523597AEnsure smoothness and cleanlinessImprove bonding effectSemiconductor/solid-state device manufacturingLaser beam welding apparatusPhysicsLaser cutting

The invention provides a wafer cutting method. The method comprises the following steps of: firstly, downwards grooving along the surface of a device wafer by adopting a first laser cutting process to form a first groove with larger transverse width, then etching the surface of the device wafer, removing particulate matters which are generated and attached to the surface of the device wafer when the first groove is formed, then flattening the surface of the device wafer, ensuring the cleanliness and flatness of the surface of the device wafer, then adopting a second laser cutting process for grooving downwards along the bottom face of the first groove, and forming a second groove which is communicated with the first groove and is small in transverse width, wherein at the moment, the particles generated by the second laser cutting process are only accumulated in the first groove and the second groove, the cleanliness and flatness of the surface of the device wafer are not affected, the cleanliness and flatness of the surface of a single chip generated after cutting are guaranteed, and the bonding effect of a hybrid bonding process can be improved.

Owner:HUBEI 3D SEMICON INTEGRATED INNOVATION CENT CO LTD

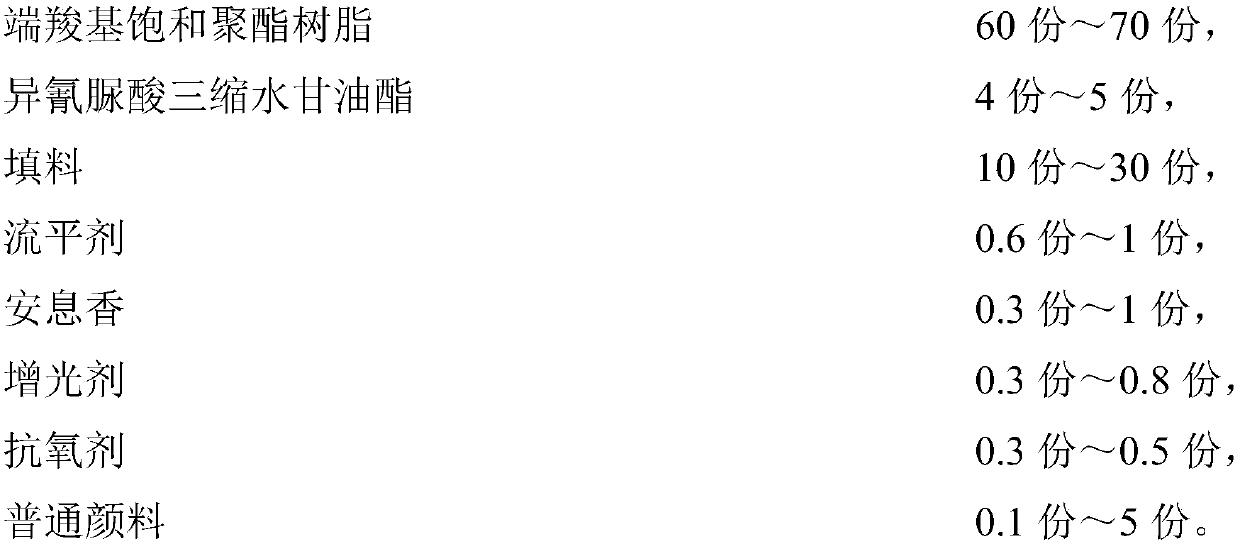

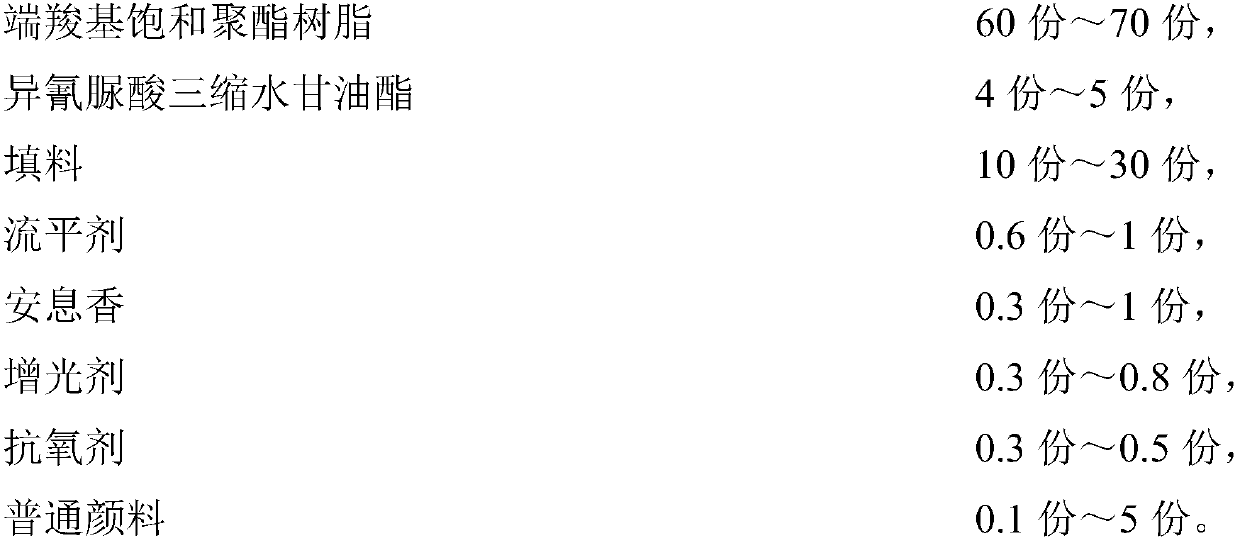

Metal powder coating and preparation method thereof

InactiveCN107858082ATo achieve a shiny effectGood chemical resistancePowdery paintsPolyester coatingsTriglycidyl isocyanurateMelt extrusion

The invention relates to a metal powder coating and a preparation method thereof, belonging to the technical field of powder coating. The metal powder coating is prepared by bonding base powder and aluminum powder, wherein the mass of the aluminum powder is 1-3% of that of the base powder; according to the formula, the base powder is prepared from 60-70 parts of carboxyl terminated saturated polyester resin, 4-5 parts of triglycidyl isocyanurate, 10-30 parts of filler, 0.6-1 part of a leveling agent, 0.3-1 part of benzoin, 0.3-0.8 part of a luster-enhancing agent, 0.3-0.5 part of an antioxidant and 0.1-5 parts of common pigment. The preparation method comprises the steps of mixing the components of the base powder, carrying out melt extrusion, tabletting and crushing, grinding and screening to obtain the base powder; putting the base powder into a bonding machine, adding the aluminum powder, gelatinizing for 200-300s, and bonding to obtain the metal powder coating. The metal powder coating is proper in components and content ratio; the adopted preparation method is good in bonding effect and good in metal twinkling effect; the coating is excellent in chemical resistance and physical and mechanical properties, stable in product quality and good in construction performance.

Owner:HEBEI HANGUANG HEAVY IND

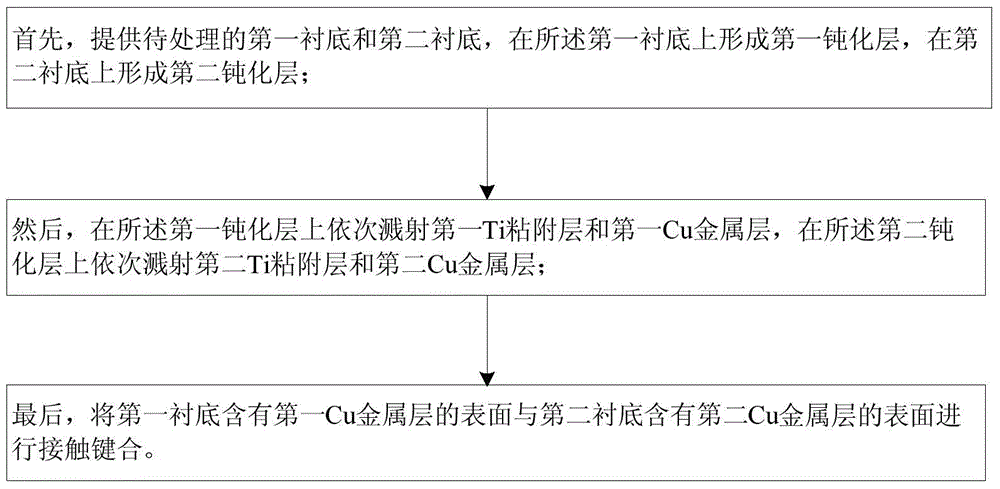

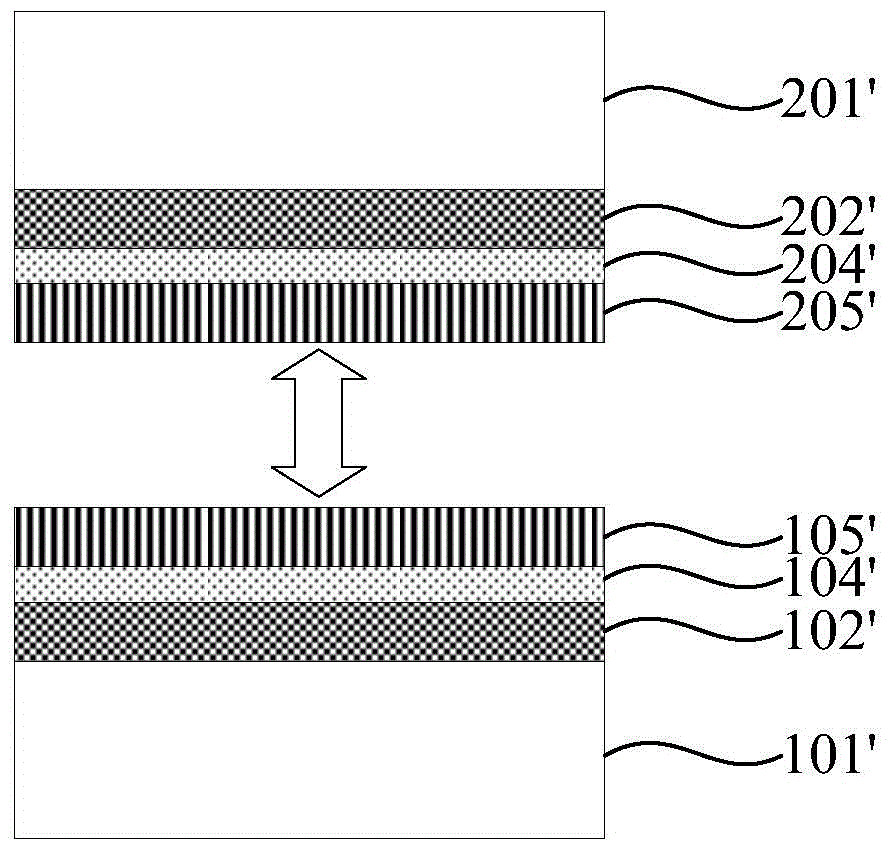

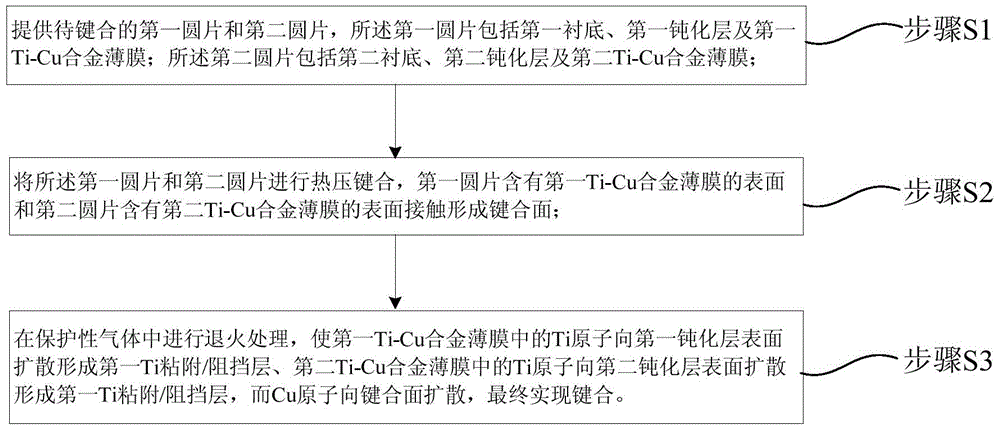

Copper-copper metal thermal pressing bonding method

InactiveCN104465428AGood bonding effectImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveTi-Cu alloy

The invention provides a copper-copper metal thermal pressing bonding method. The method at least comprises the following steps: first of all, providing a first wafer to be bonded and a second wafer to be bonded, wherein the first water comprises a first substrate, a first passivation layer and a first Ti-Cu alloy film, and the second wafer comprises a second substrate, a second passivation layer and a second Ti-Cu alloy film; then, performgin thermal pressing bonding on the surface of the first Ti-Cu alloy film of the first wafer and the surface of the second Ti-Cu alloy film of the second wafer; and finally, performing annealing processing in a protective gas to enable Ti atoms in the first Ti-Cu alloy film to diffuse towards the surface of the first passivation layer and Ti atoms in the second Ti-Cu alloy film to diffuse towards the surface of the second passivation layer so as to finally form Ti adhesive / barrier layers on the surfaces of the first passivation layer and the second passivation layer, and Cu atoms diffusing towards a bonding surface so as to realize bonding. According to the method provided by the invention, before the bonding, what is needed is only to respectively perform co-sputtering on the two substrates for once, such that the sputtering frequency is reduced by half, the process is relatively simple, the reliability is good, the technical cost is quite low, and finally, the Ti adhesive / barrier layer are formed through diffusion after the annealing processing, and the copper bonding effect is better.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

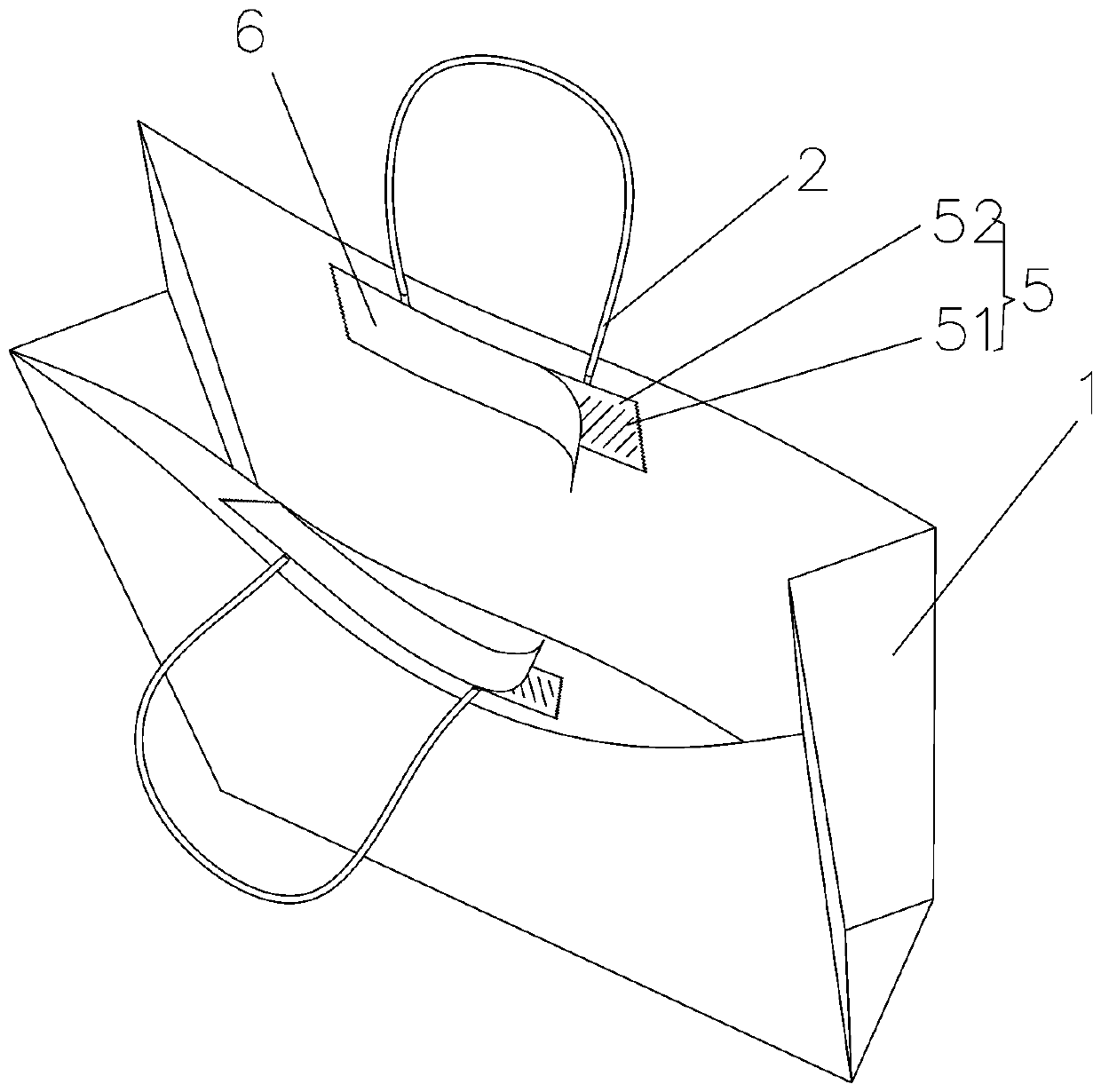

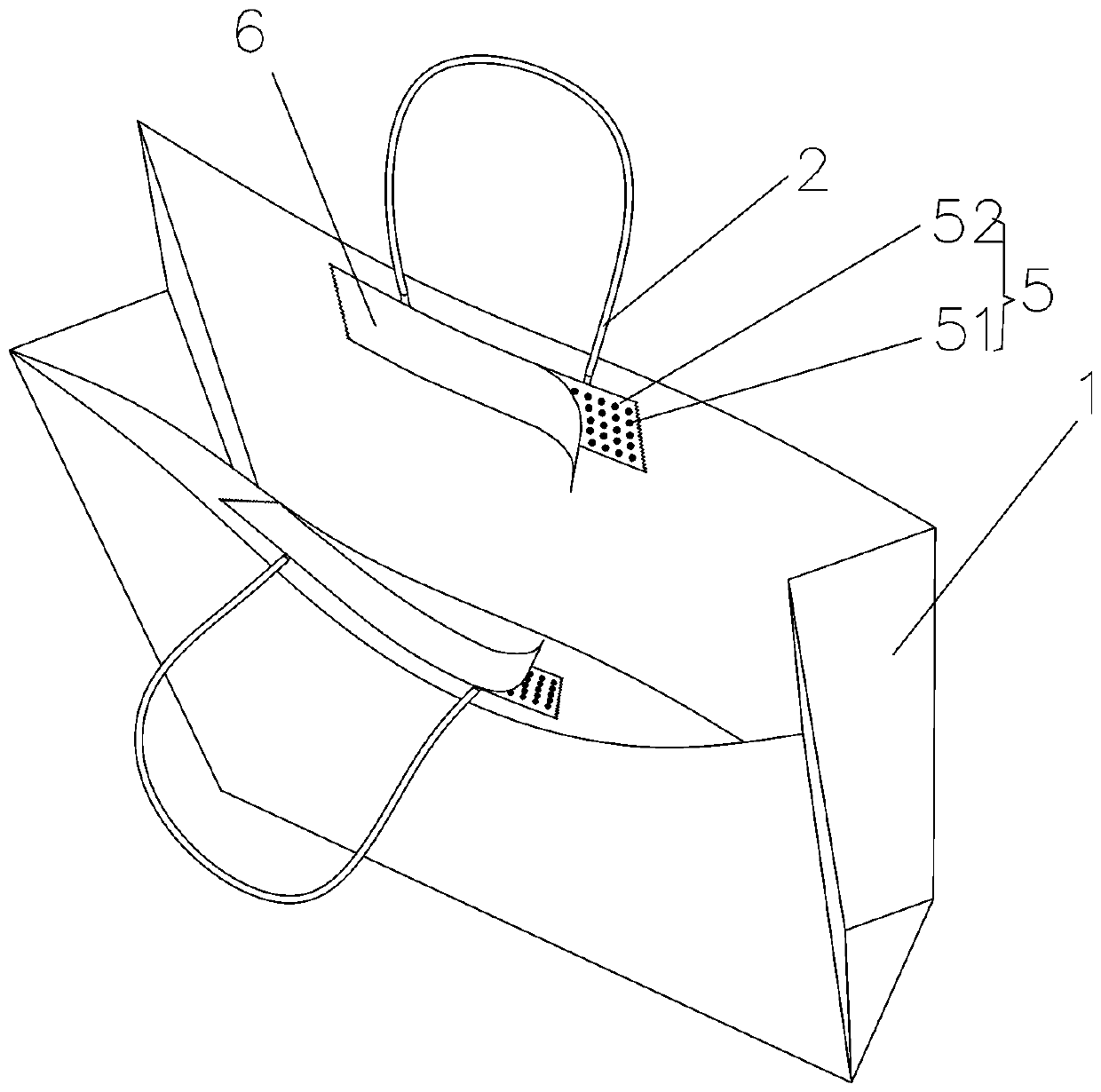

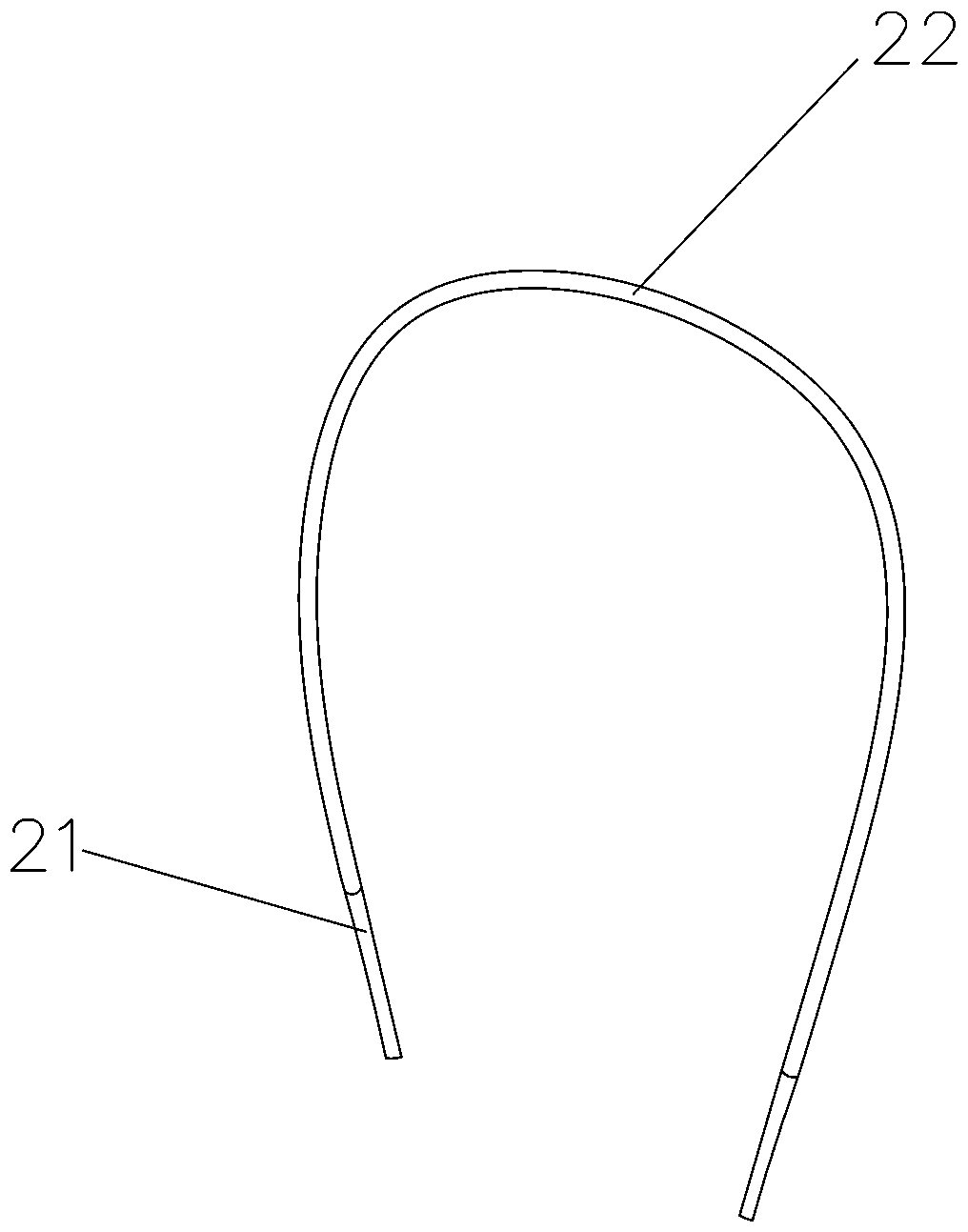

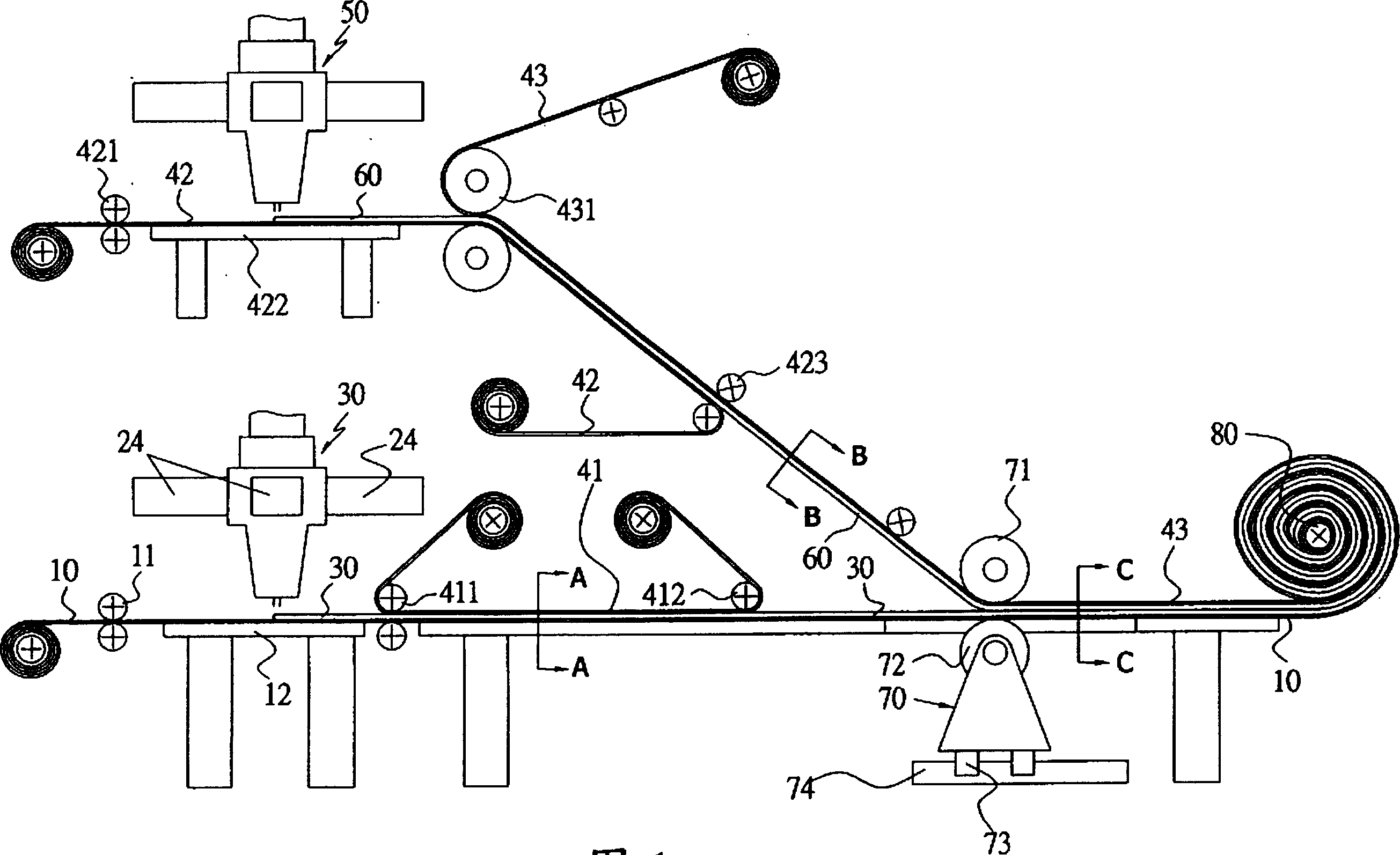

Hand bag

The invention discloses a hand bag which comprises a bag body with a bag opening, a hand lifting rope, a first adhesive layer, a sticker, a second adhesive layer and release paper. Two ends of the hand lifting rope are respectively provided with a bonding part with a flat structure, the middle section of the hand lifting rope is a handle part, the sticker is arranged near the bag opening, the outer side surface of the sticker and the bonding part of the hand lifting rope are adhered to the corresponding inner side surface of the bag body through a first adhesive layer, the inner side surface of the sticker is coated with a second adhesive layer, and the second adhesive layer is covered with release paper. According to the hand bag, the bonding parts at the two ends of the hand lifting ropeare designed to be flat; the stability of the contact face is good, operation is convenient during bonding, the sticker and the bonding part can be directly bonded to the corresponding inner side face of the bag body together through the first bonding layer, the outer contour of the bonding part can be completely wrapped without a too thick bonding layer, and therefore the good bonding effect isachieved. Compared with the prior art, a layer of sticker and a layer of adhesive layer are omitted, so that the material cost is saved, and meanwhile, the production process is simplified.

Owner:XIAMEN JIHONG TECH CO LTD

Manufacture of synthetic leather with one-step formed coating and substrate

InactiveCN1260427CReduce processSave plant equipment and manpower and material resourcesTextiles and paperMaterial resourcesEngineering

A synthetic leather manufacturing method in which a base material and a skin are formed at one time, which utilizes two sets of injection mixing devices to manufacture a PU plastic foam layer and a skin layer at the same time, and make both of them half-reacted but not completely hardened. In order to achieve the effect of one-time molding, the present invention overcomes the shortcomings of the known technology that the base material and the dough must be manufactured separately, and the space for storage and accumulation of materials is wasted, thereby shortening the manufacturing process and saving plant equipment. And manpower, electricity and material resources, as well as reducing production costs, no air, water pollution, and has the advantages of a wider range of uses.

Owner:吴清发

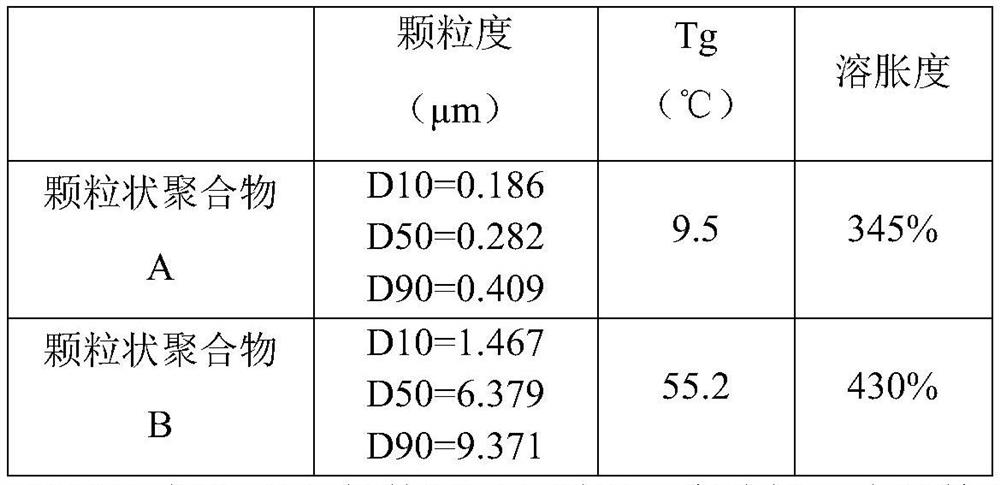

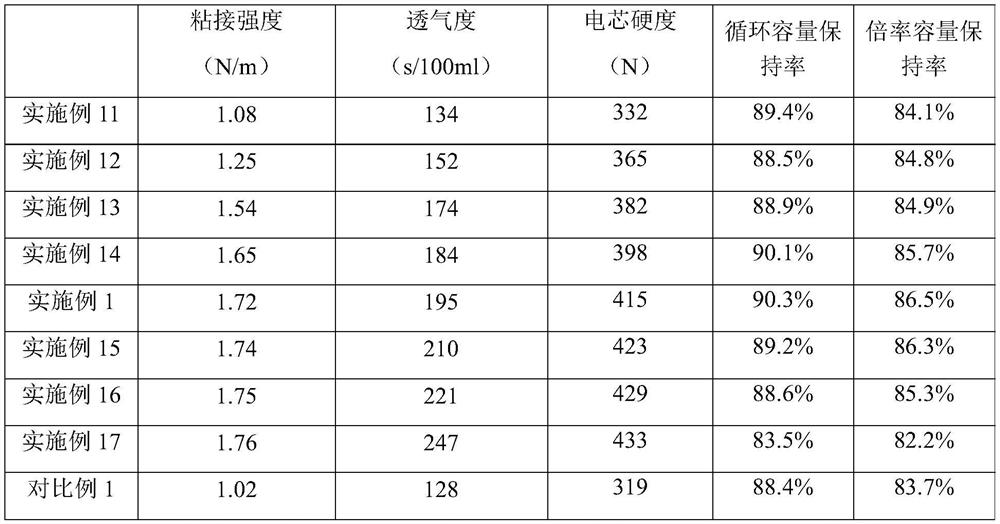

Water-based paint for lithium ion battery composite diaphragm, lithium ion battery composite diaphragm and lithium ion battery

InactiveCN112940650AImprove bonding effectGuaranteed bonding effectNon-macromolecular adhesive additivesNitrile polymer adhesivesLithium electrodeBonding strength

The invention relates to water-based paint for a lithium ion battery composite diaphragm, the lithium ion battery composite diaphragm and a lithium ion battery. The water-based paint comprises a binder and non-conductive inorganic particles, the binder comprises a granular polymer A and a granular polymer B, the glass transition temperature of the granular polymer A is lower than that of the granular polymer B, the granularity D50 of the granular polymer A is 0.05-1.0 [mu]m, and the granular polymer B has the granularity D10 of 1.0-5.0 [mu]m, the granularity D50 of 2.0-10 [mu]m, and the granularity D90 of 3.0-20 [mu]m. The particle size D50 of the non-conductive inorganic particles is smaller than the particle size D50 of the particulate polymer B. The water-based paint has the advantage of high bonding strength, the prepared composite diaphragm is good in air permeability, not prone to mutual bonding and easy to roll and store, and the lithium ion battery applying the composite diaphragm is excellent in comprehensive performance and long in cycle storage life.

Owner:深圳好电科技有限公司

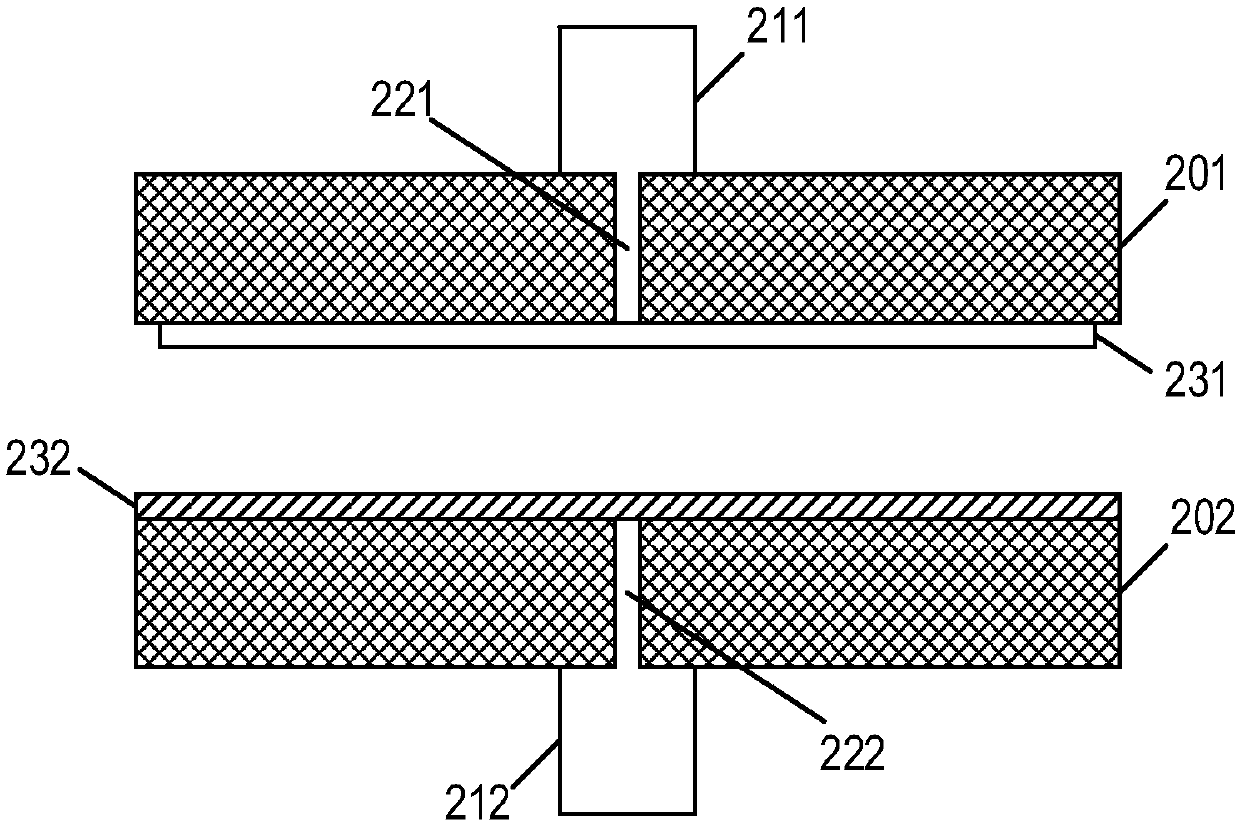

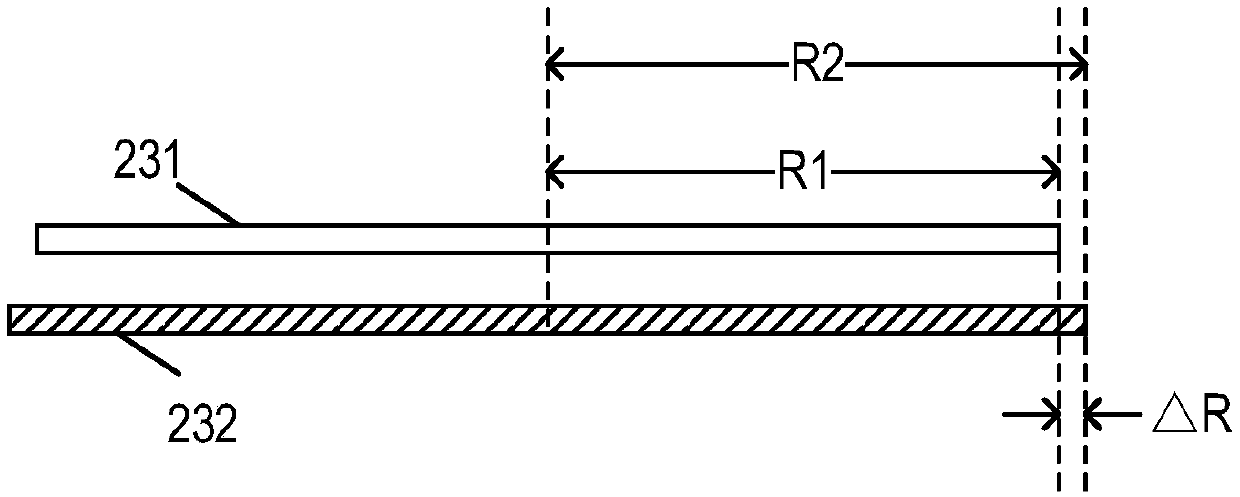

Wafer bonding device and wafer bonding method

ActiveCN109585346AImprove alignment accuracyImprove bonding effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention relates to the technical field of semiconductor manufacturing, and in particular to a wafer bonding device and a wafer bonding method. The wafer bonding device comprises: a measuring module, used for respectively acquiring sizes of two wafers to be bonded; and a bonding module, connected to the measuring module, and used for bonding the two wafers and adjusting the bonding pressure applied to the two wafers according to the relative sizes of the two wafers, so that the bonding pressure applied to the smaller wafer is greater than that applied to the larger wafer. The invention, by increasing the alignment precision between two wafers to be bonded, improves the bonding effect, and improves the performance of the semiconductor product.

Owner:YANGTZE MEMORY TECH CO LTD

Production method of environment-friendly composite polyurethane synthetic leather

InactiveCN110616571AImprove bonding effectImprove bonding performancePolyureas/polyurethane adhesivesTextiles and paperPolyurethane adhesivePrepolymer

The invention discloses a production method of environment-friendly composite polyurethane synthetic leather. The production method sequentially includes: producing front-side leather, producing rear-side leather, preparing a water-borne compositing agent, and compositing the front-side leather and the rear-side leather to obtain the double-sided leather. A preparation method of the water-borne compositing agent includes the steps of firstly, preparing epoxy resin composite water-borne polyurethane prepolymer; secondly, preparing a silane coupling agent modified epoxy resin composite water-borne polyurethane emulsion; thirdly, preparing a silane coupling agent modified epoxy resin composite water-borne polyurethane adhesive. The production method has the advantages that the adhering effectof the double-sided leather is increased, and the double-sided leather is free of environment pollution, noncombustible, nontoxic, wide in adaptability, environmentally friendly, suitable for being popularized and used and the like.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

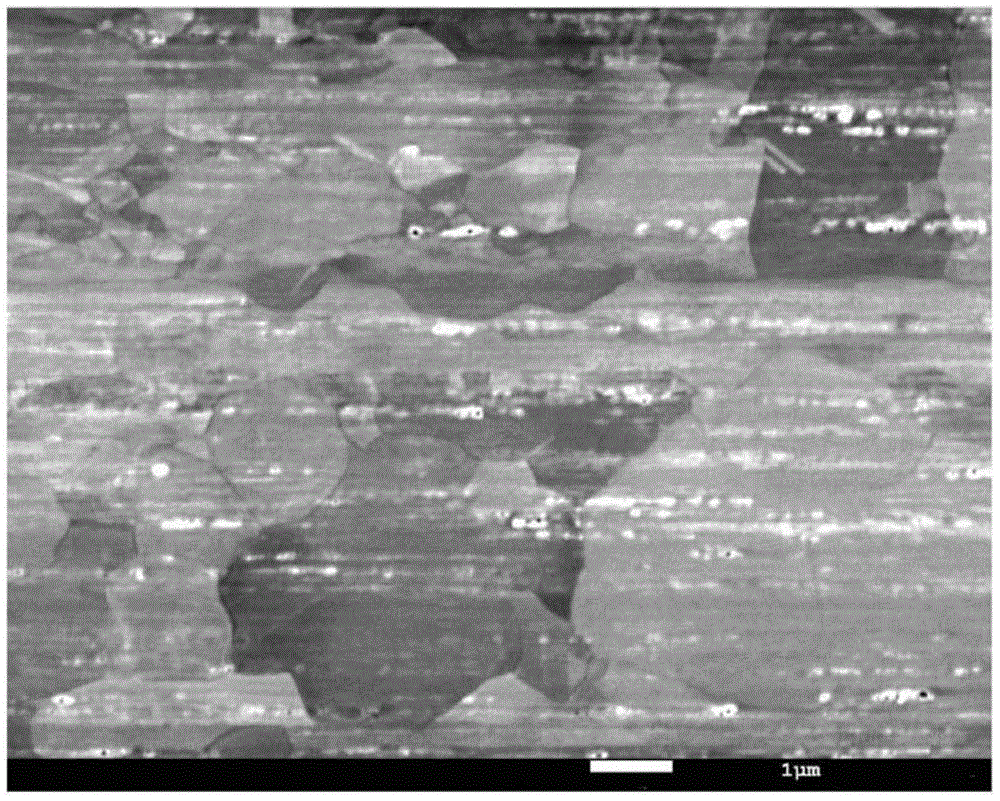

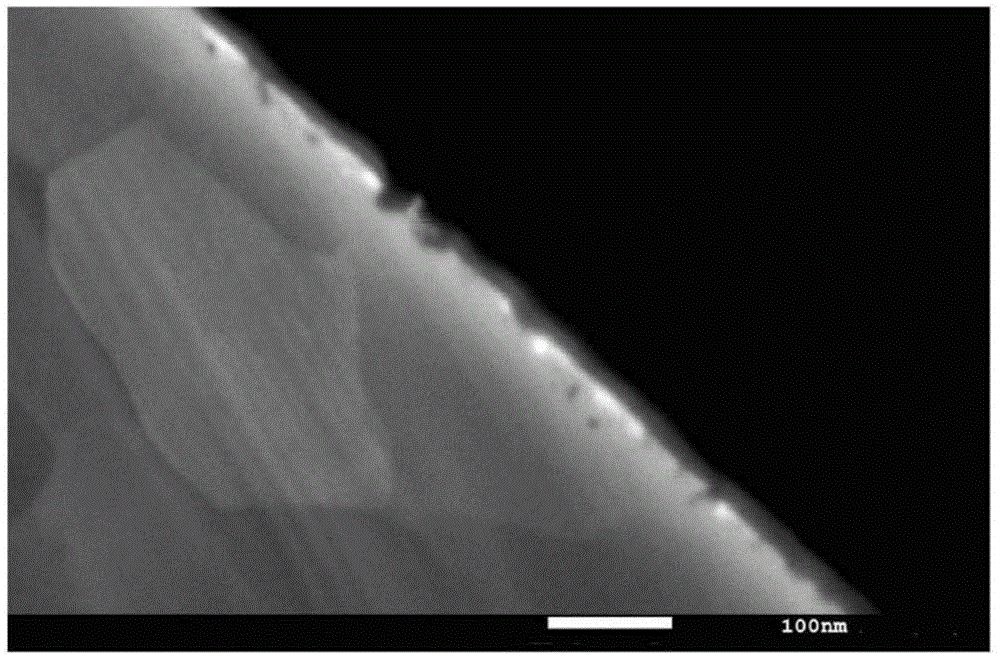

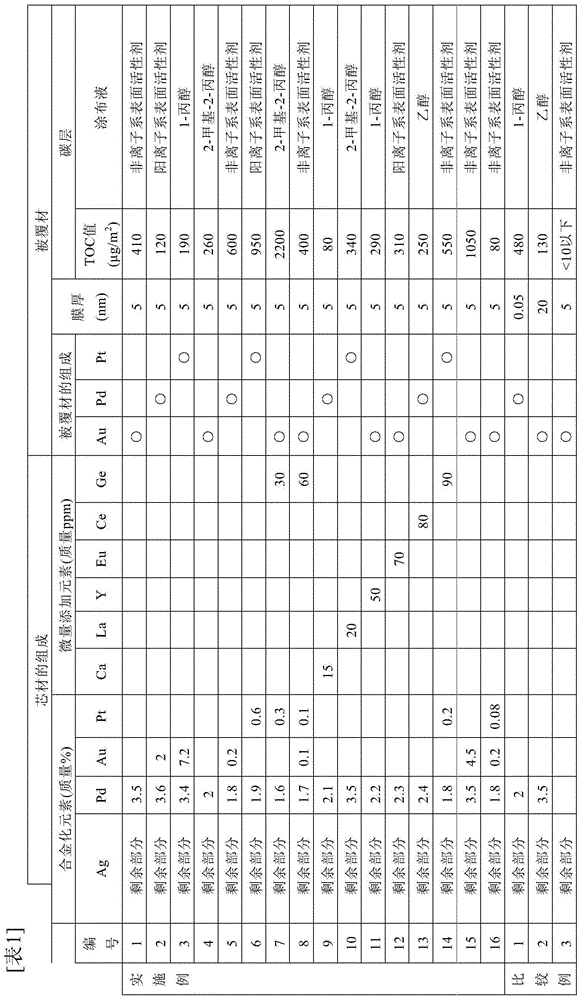

Structure of surface-modified silver-palladium alloy wire

InactiveCN105321917AImprove bonding effectPrevent oxidationSemiconductor/solid-state device detailsSolid-state devicesAlloySilver-palladium alloy

The invention relates to a structure of a surface-modified silver-palladium alloy wire. The surface-modified silver-palladium alloy wire is composed of a core and a surface-modified layer. The core is made of Ag-Pd alloy or Ag-Pd-Au(Pt) alloy prepared from Ag and Au respectively with the purity being more than 99.99 mass% and Pd with the purity being more than 99.9 mass%, wherein the mass ratio of the Ag and Pd of the Ag-Pd alloy is 100:(1-5), and the mass ratio of the Ag, Pd and Au(or Pt)of the Ag-Pd-Au(Pt) alloy is 100:(1-5):(0.05-10). The surface-modified layer is composed of Ag, Pd and Pt respectively with the purity being more than 99.99 mass% and alloys thereof. The structure of the surface-modified silver-palladium alloy wire is characterized in that the wire surface and the grain boundary of the core form cross dark rings with the interval being 20-30 [mu]m in the long side direction of the wire, and the surface morphology of the surface-modified layer is embedded in uneven-sized longitudinal grooves of the core.

Owner:TANAKA DENSHI KOGYO KK

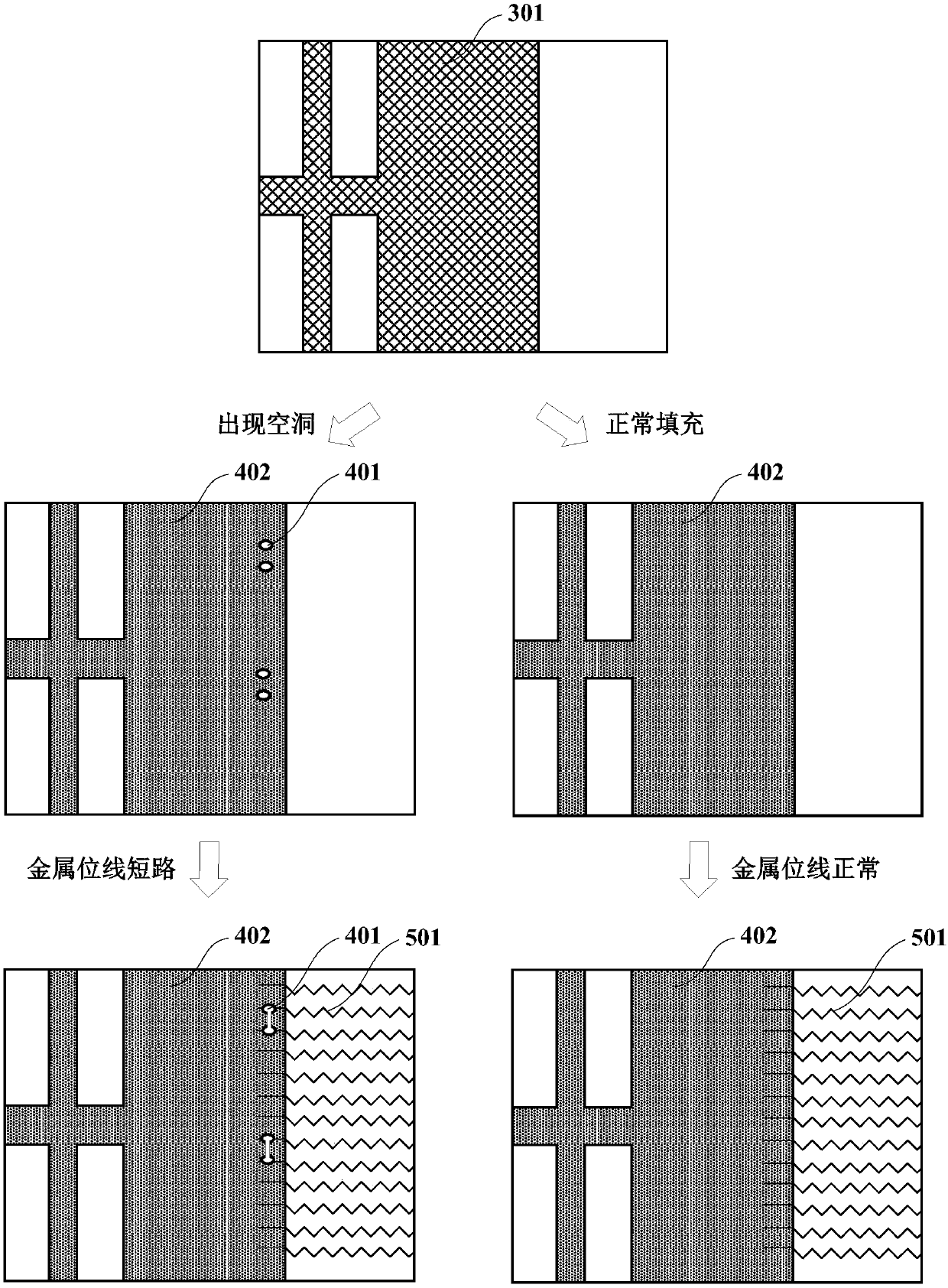

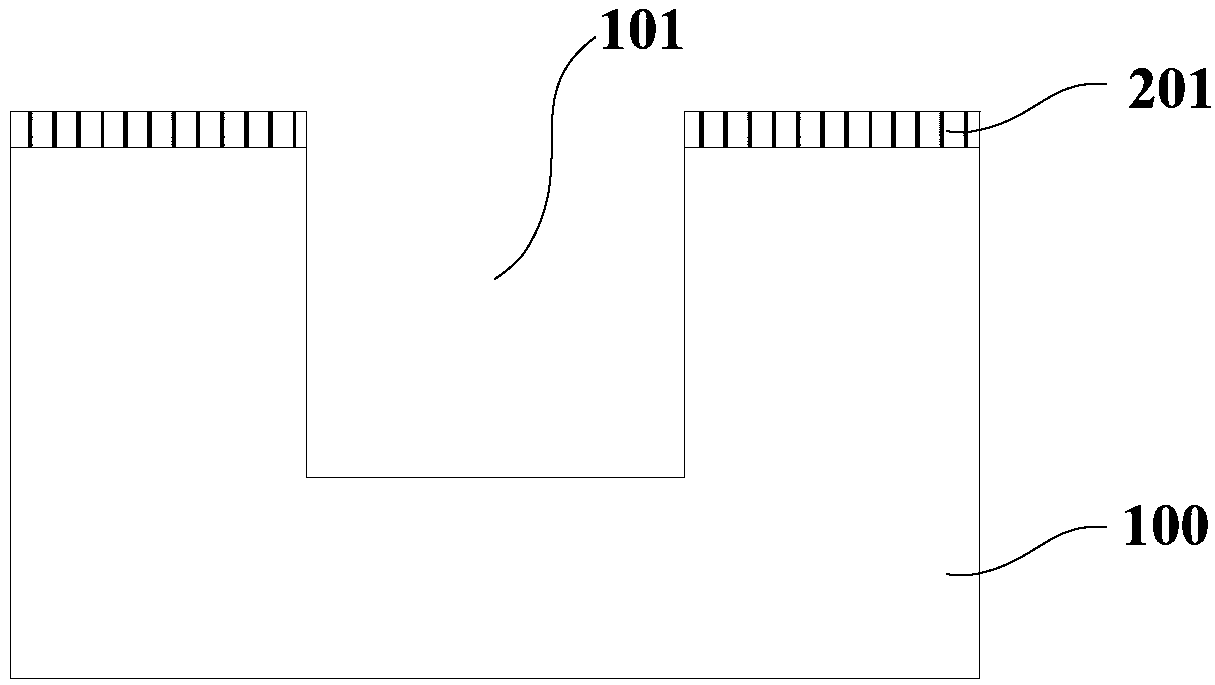

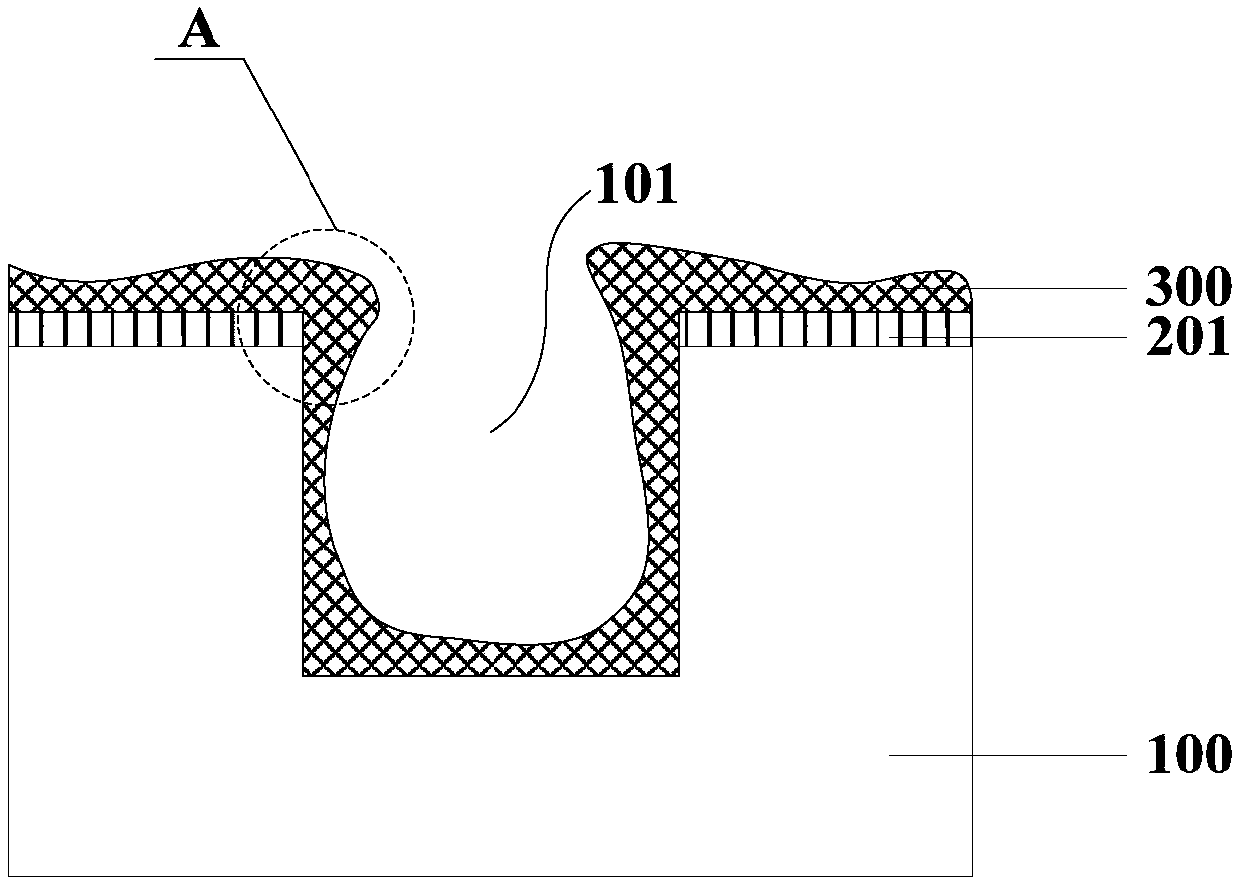

Isolation trench film filling structure, semiconductor memory device and preparation method

PendingCN107706145AEasy to shapeGuaranteed integritySemiconductor/solid-state device manufacturingEtchingHigh density

The invention provides an isolation trench film filling structure, a semiconductor memory device and a preparation method. The preparation method of the isolation trench film filling structure comprises the steps that a semiconductor substrate with a peripheral groove is provided; a prefabricated filling material is formed on the semiconductor substrate, and the upper surface of the semiconductorsubstrate and the sidewall and the bottom of the peripheral groove are covered to form a neck; the prefabricated filling material is pre-etched to remove the neck; a high-density plasma oxide materialis formed on the semiconductor substrate; the prefabricated filling material is covered, and the peripheral groove is filled; and extra high-density plasma oxide material and prefabricated filling material are removed to acquire a high-density plasma oxide material layer and a prefabricated filling layer in the peripheral groove. According to the invention, the shape of the prefabricated fillinglayer is improved through pre-etching; voids between the high-density plasma oxide material and the prefabricated filling material are prevented; and device failure caused by short circuit caused by asubsequently formed metal bit line is prevented.

Owner:CHANGXIN MEMORY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com