Forming method of press-fit double-metal compound brake drum

A composite braking and forming method technology, applied in the direction of brake drums, etc., can solve the problems of popularization and application, complicated production process, fracture and scrapping, etc., and achieve the effect of broad application prospect, simple production process and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

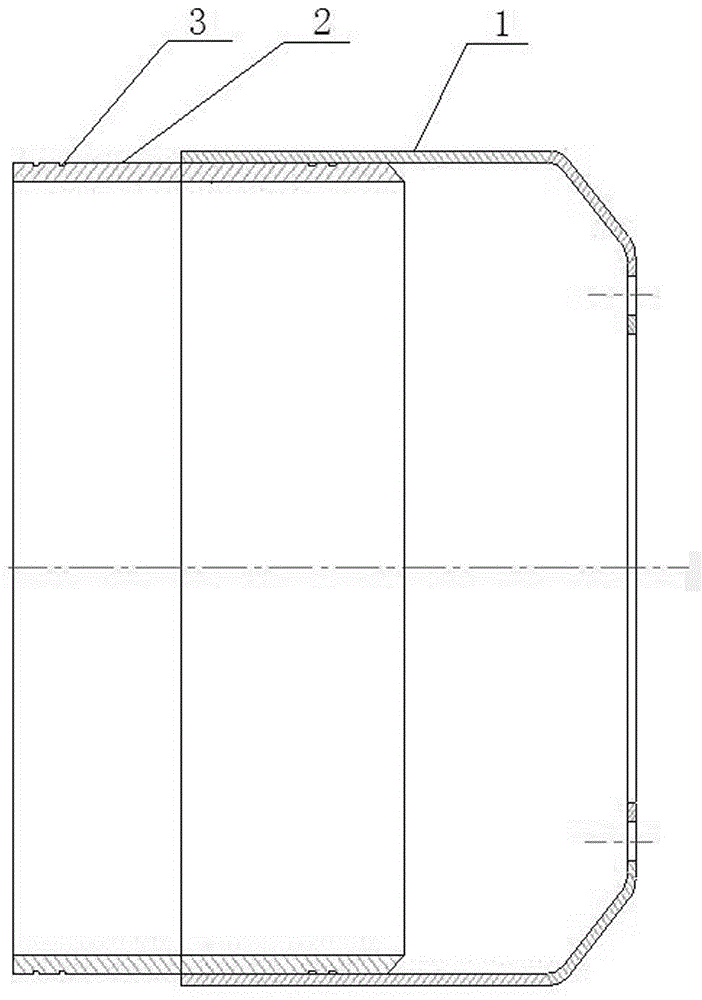

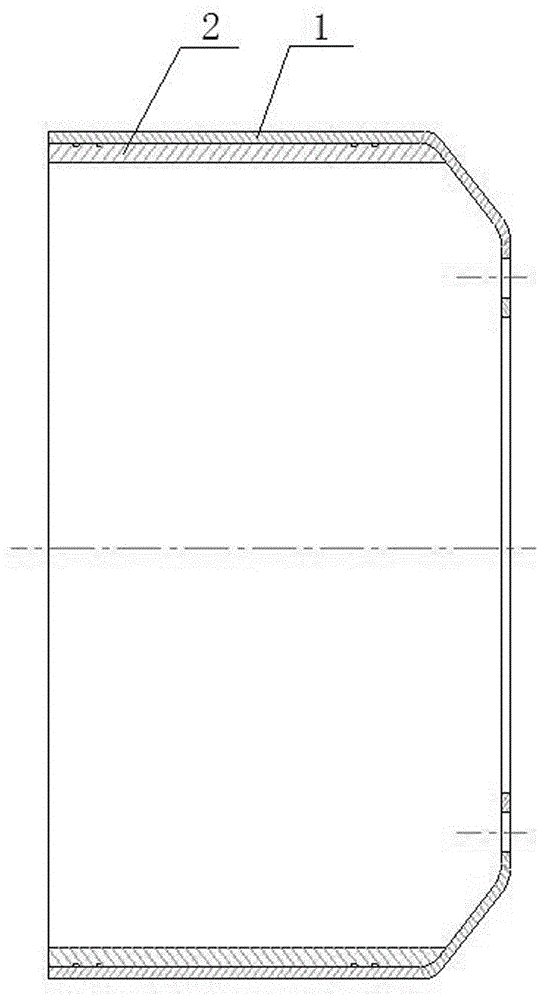

[0022] A method for forming a press-fit bimetal composite brake drum, comprising the following steps:

[0023] (1) Use the method of cold drawing and stretching to make a low-carbon steel pipe with a wall thickness of 7mm into a low-carbon steel shell with a wall thickness of 4mm, a height of 330mm, and a maximum outer diameter of 483mm, as a brake drum jacket ;

[0024] (2) Melt the molten iron, keep the molten iron at 1280~1290°C, and use a horizontal centrifugal casting machine to cast the molten iron into a cast iron pipe; wherein, the rotating speed of the horizontal centrifugal casting machine during the casting process is 600~750r / min;

[0025] (3) Process the finished cast iron pipe into an inner diameter of 460mm, a thickness of 8mm, and a height of 300mm, so that the outer diameter of the cast iron pipe is larger than the inner diameter of the low-carbon steel shell, and several grooves are processed on the outer wall of the cast iron pipe ;

[0026] (4) Fix the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com