High-volume coal ash ceramsite foam concrete and preparation method thereof

A technology of foam concrete and fly ash ceramsite, which is applied in the field of building materials, can solve the problems of large usage, achieve the effects of reducing cement consumption, improving mechanical strength and volume stability, and shortening steam curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

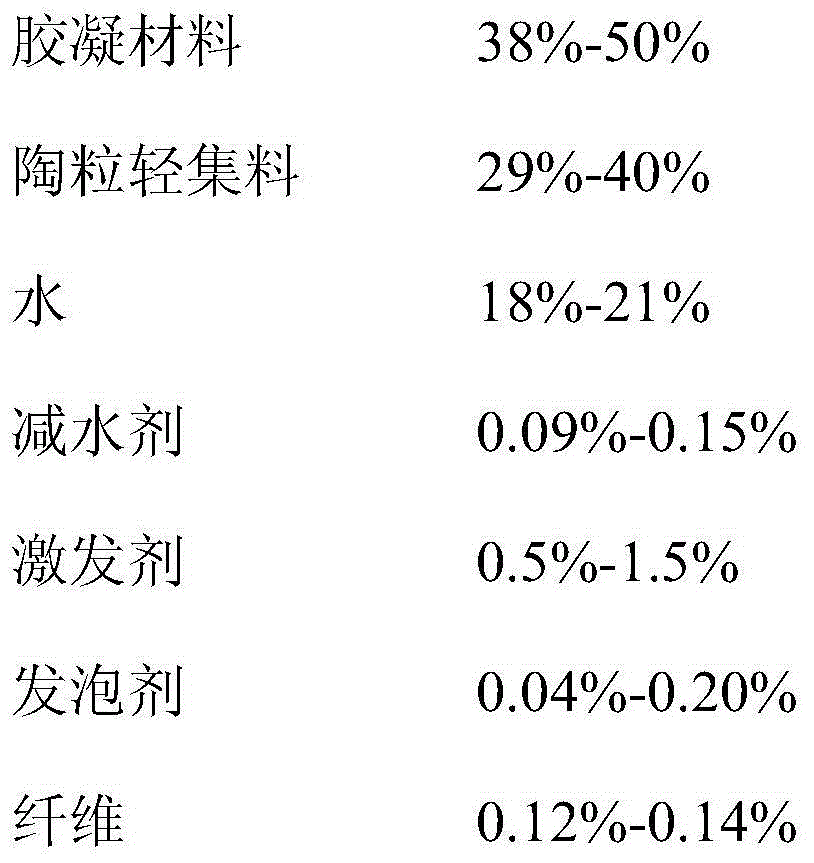

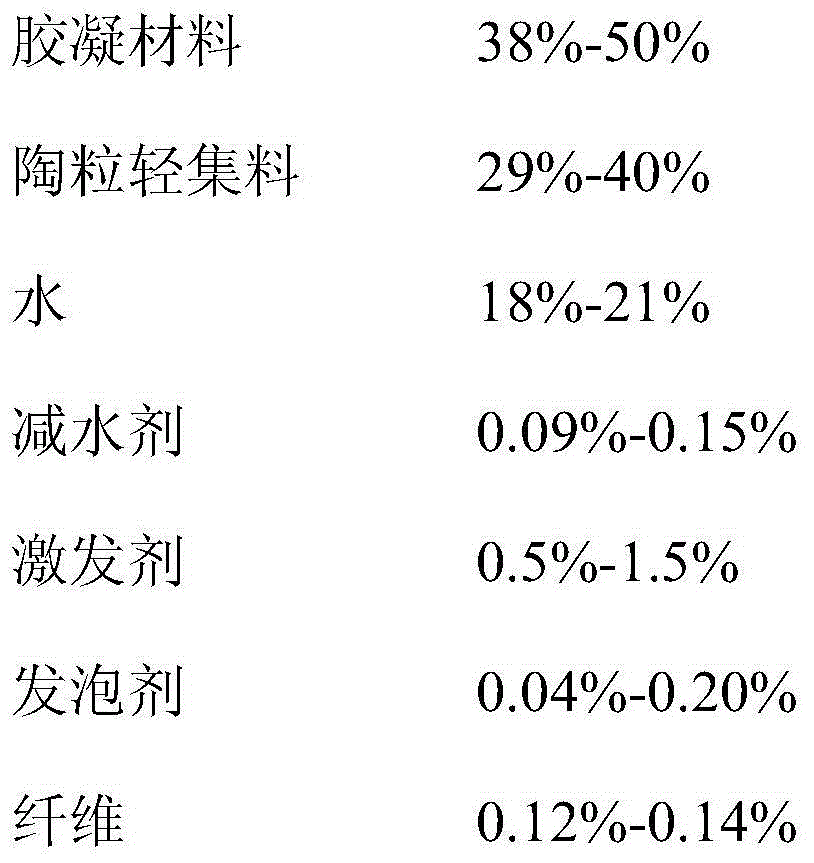

[0028] Example 1: A method for preparing large-volume fly ash ceramsite foamed concrete, its raw material composition and mass ratio of each component are arranged as follows, P.O 42.5 ordinary Portland cement: Class II fly ash: ceramsite light aggregate Material: water: polycarboxylate superplasticizer: aluminum carbonate: protein type KC-16 foaming agent: polypropylene fiber with a length of 8 mm = 190:210:300:180:0.9:5:1.7:1.2, the pottery Light-grained aggregates are compounded with large and small particle sizes of ceramsite. The particle size of large particle size ceramsite is 20-28mm, and the particle size of small particle size ceramsite is 8-15mm. The mass ratio of the two is 180:120.

[0029] The concrete molding steps of above-mentioned foamed concrete are as follows:

[0030] (1) Add P.O 42.5 ordinary Portland cement, Class II fly ash, ceramsite light aggregate, aluminum carbonate, and polypropylene fiber with a length of 8 mm to the mixer for pre-mixing, and the...

Embodiment 2

[0037] A preparation method of a large amount of fly ash ceramsite foam concrete, its raw material composition and the mass ratio of each component are arranged as follows, P.O 42.5 ordinary Portland cement: Class II fly ash: ceramsite light aggregate: tap water: Polycarboxylate water reducer: sodium aluminate: rosin-type KC-15 foaming agent: polyethylene fiber with a length of 10mm=215:215:290:170:1.3:13:0.4:1.2. The ceramsite light aggregate is compounded with ceramsites with large and small particle sizes. The particle size of the large particle size ceramsite is 15-20mm, and the particle size of the small particle size ceramsite is 3-10mm. The mass ratio is 200:90.

[0038] The concrete molding steps of above-mentioned foamed concrete are as follows:

[0039] (1) Add P.O 42.5 ordinary Portland cement, Class II fly ash, ceramsite light aggregate, sodium aluminate, and polyethylene fiber with a length of 10 mm into the mixer for pre-mixing, and stir The speed is 17r / min, a...

Embodiment 3

[0046] A method for preparing large-volume fly ash ceramsite foamed concrete, its raw material composition and the mass ratio of each component are as follows, P.O 42.5 ordinary Portland cement: II grade fly ash: S95 grade granulated blast furnace slag powder: pottery Lightweight aggregate: water: polycarboxylate superplasticizer: sodium aluminate: protein foaming agent: polyvinyl alcohol fiber with a length of 6-9mm = 180:220:30:290:170:1.3:13:1.7: 1.2. The ceramsite light aggregate is compounded with ceramsite with large and small particle sizes, the average particle size of large particle size ceramsite is 22-26mm, and the average particle size of small particle size ceramsite is 8-11mm, The mass ratio of the two is 190:100; the water is tap water meeting the water standard for concrete, and the protein foaming agent can be a commercially available common protein foaming agent.

[0047] The concrete molding steps of above-mentioned foamed concrete are as follows:

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com