Patents

Literature

692results about How to "Improve turnover efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Payment control method and system based on credit data

ActiveCN102968715AImprove turnover efficiencyHigh yieldPayments involving neutral partyThird partyUser input

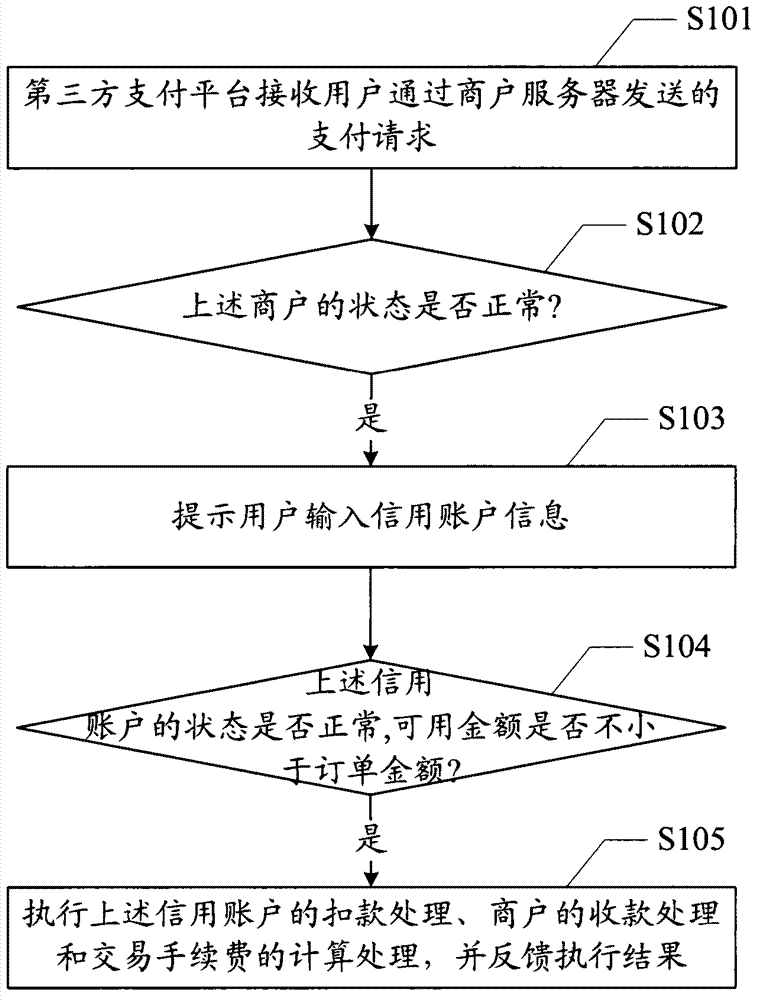

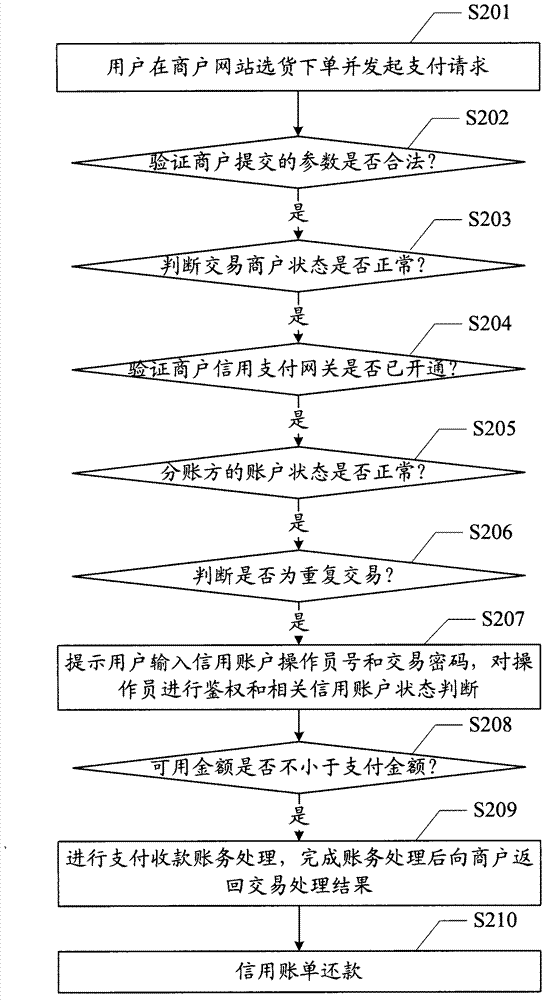

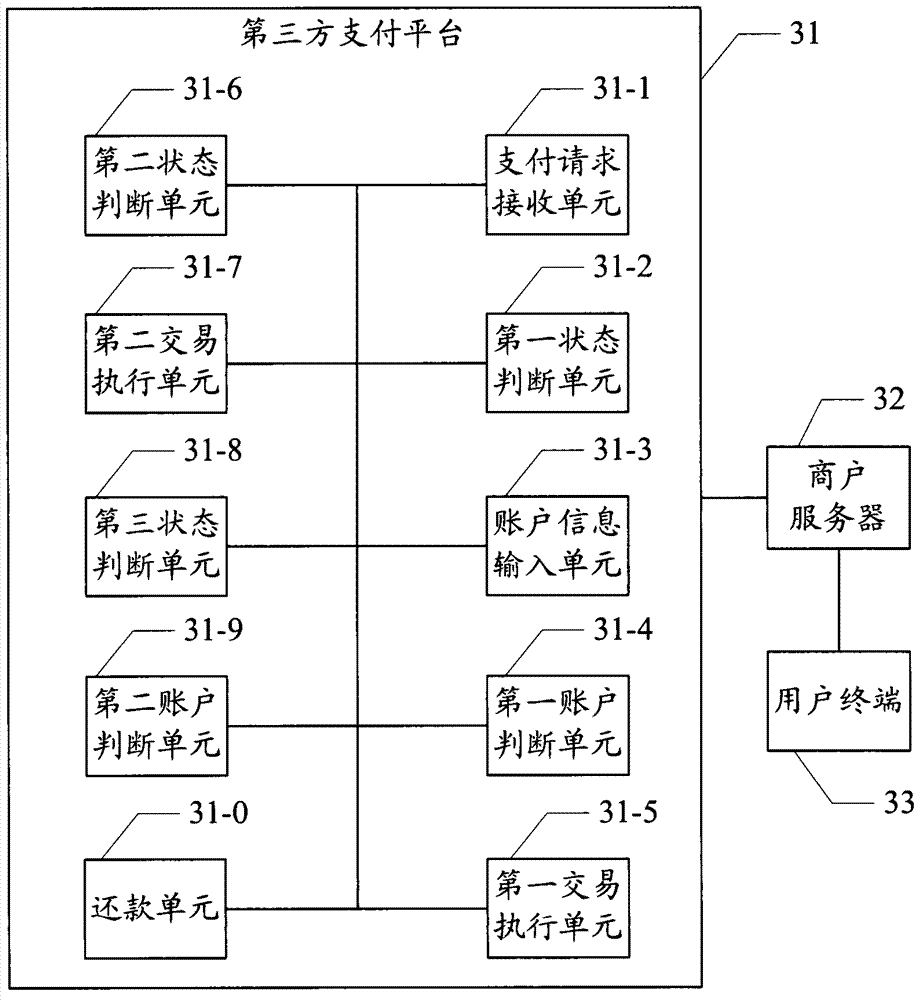

The invention provides a payment control method and a system based on credit data. The method includes that a third-party payment platform receives payment requests sent by a merchant server; whether the state of a merchant is normal is judged, if the state is normal, a user is prompted to input credit account information, whether the state of a credit account is normal and an available amount is larger than or equal to an order amount are judged, if the state is normal and the available amount is larger than or equal to an order amount, deduction treatment of the credit account, collection treatment of the merchant and calculation treatment of transaction procedure fees are performed. The third-party payment platform provides a credit account with a certain amount and a payment day for users at different merchants respectively according to parameter values of users, in an available amount, users can complete safe network transaction in the condition that actual cash payment is produced without banks, and accordingly, the capital turnover efficiency is accelerated, and fund yields of industry chains are improved.

Owner:汇付天下有限公司

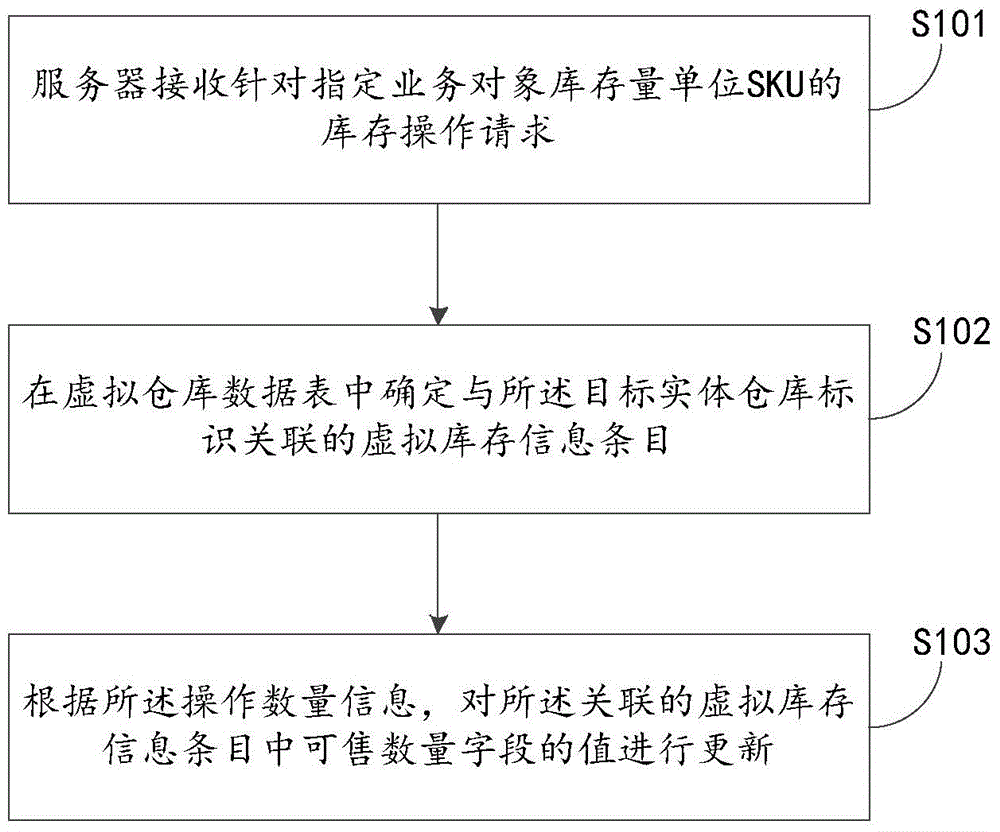

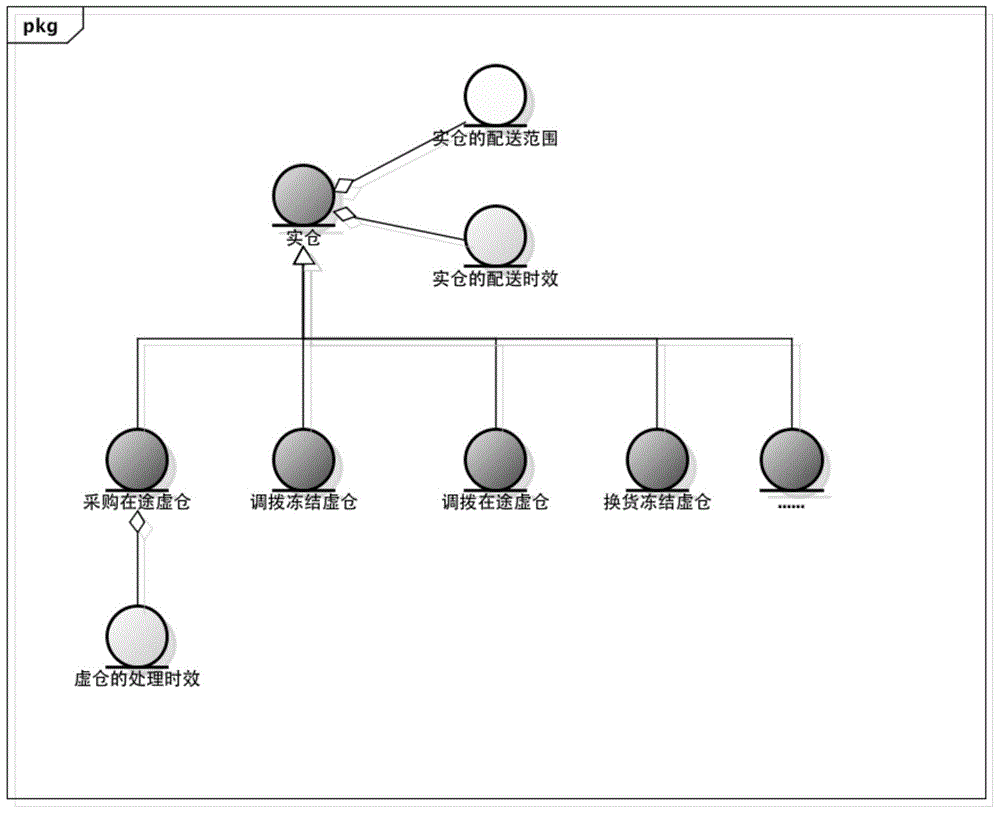

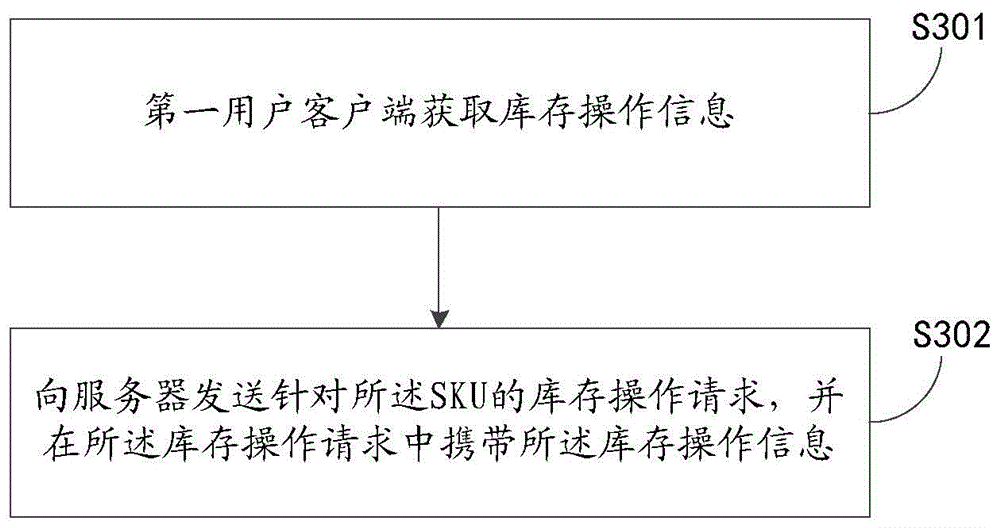

Inventory information processing method and device for business objects

The embodiment of the invention discloses an inventory information processing method and a device for business objects. The method comprises the steps of receiving an inventory operation request for a specified business object inventory unit SKU by means of a server, wherein the inventory operations includes operations conducted on the SKU before the SKU enters a designated target entity warehouse; determining a virtual inventory information entry associated with the identifier of the target entity warehouse in a virtual warehouse data table; according to the number information of the above operations, updating the value of an available number field in the associated virtual inventory information entry so as to provide the available service of the business object SKU according to the value of the available number field in the associated virtual inventory information entry. According to the embodiments of the invention, a user is prevented from missing the selling opportunity, so that the access burden of a sales platform can be reduced. Meanwhile, the waste of network resources is reduced.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

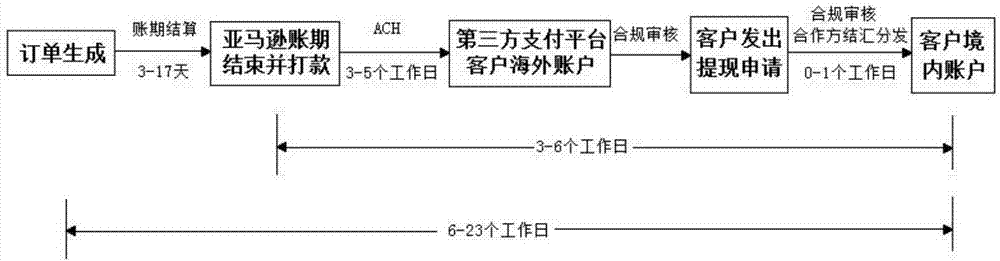

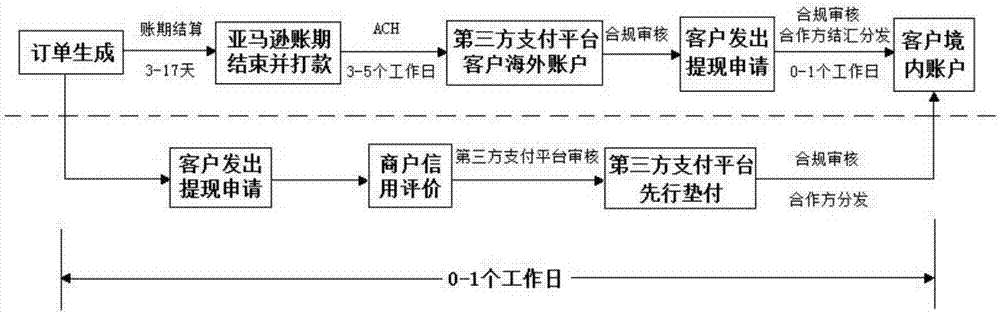

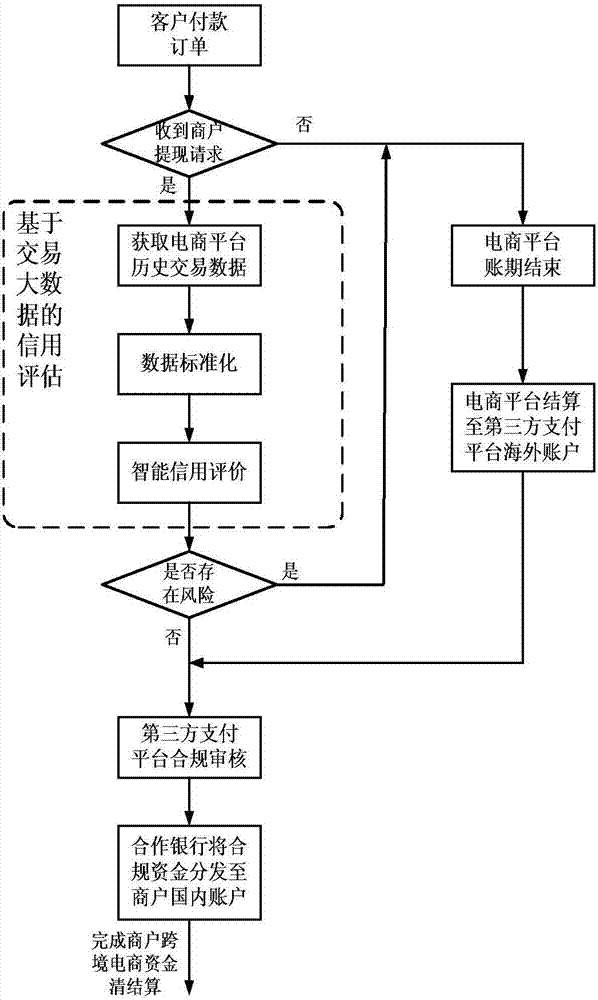

Cross-border payment rapid settling method based on credit big data

InactiveCN107103460AThe risk of advance payment is smallIncrease credibilityFinanceProtocol authorisationThird partyE-commerce

The invention discloses a cross-border payment rapid settling method based on credit big data. Based on the historical transaction big data accumulated on e-commerce platforms by merchants, commodities and users, the method carries out estimation to the transaction risks using the artificial intelligence method. For the transactions whose estimated risks are low, a third-party is used to pay in advance so that the capital settlement is made in advance to the domestic accounts of merchants. This avoids the complicated and tedious procedures of a regular settling mode requiring the transaction completion by the users, e-commerce platform financial period completion, e-commerce settlement to a third party and third-party clearance via banks until to the domestic accounts of merchants. Therefore, under the condition that the pre-paid risk is controlled, the cross-border capital settling procedure for the merchants is simplified, the third-party payment and settlement efficiency is increased; and the capital can be transferred among accounts in shorter time. Therefore, the capital cycling efficiency is increased; the risk change risk incurred from an excessively regular long settlement period is reduced, and the operation risks of the merchants are reduced.

Owner:HANGZHOU PINGPONG INTELLIGENT TECH CO LTD

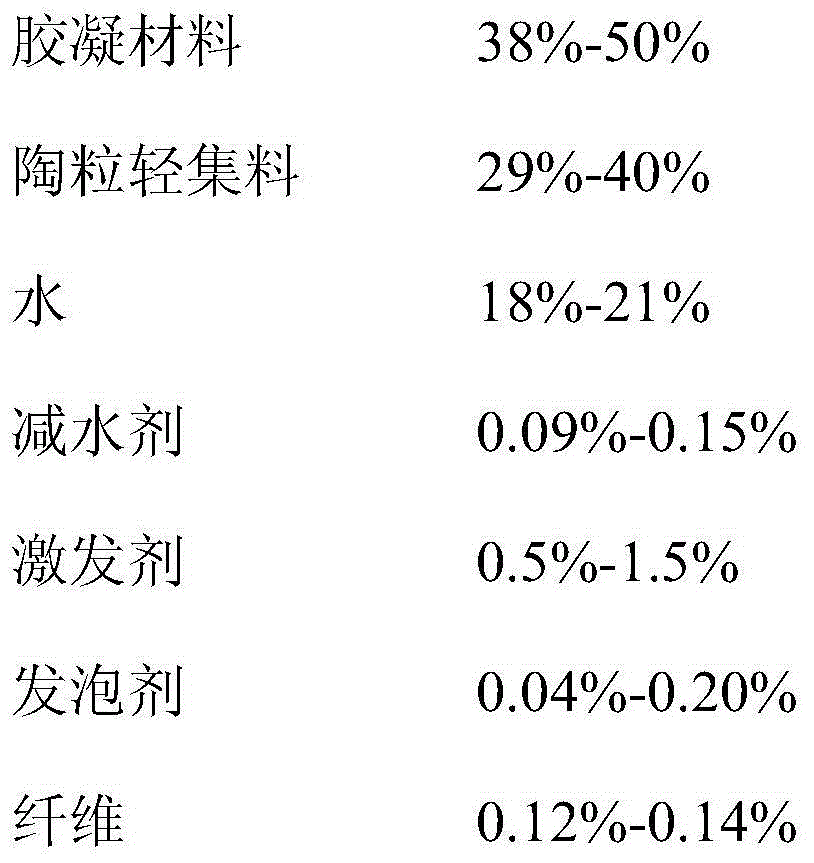

High-volume coal ash ceramsite foam concrete and preparation method thereof

The invention provides a preparation method of high-volume coal ash ceramsite foam concrete. The preparation method of the ceramsite foam concrete comprises the following steps: putting 38%-50% of a binding material, 29%-40% of ceramsite lightweight aggregates, 0.5%-1.5% of an excitant and 0.12%-0.14% of a fiber into a stirrer, and stirring evenly; simultaneously adding 0.04%-0.20% of a foaming agent and foam which is formed by a part of water in a foaming machine and has the particle sizes of 50-1,000mu m, the residual water and 0.09%-0.15% of a water reducer into the stirrer, and stirring with powder evenly to form slurry; adding the foam into the slurry, stirring evenly, and then pouring into a mold to mold; and demolding to prepare the ceramsite foam concrete of which the density is 300-800kg / m<3>. According to the formula provided by the invention, low-cost coal ashes are taken as a main raw material, and the material cost is reduced; meanwhile, the volume-weight of the concrete is reduced by adding the ceramsite lightweight aggregates with different particle sizes; and the mechanical strength and the stability of the concrete are effectively improved.

Owner:中冶武汉冶金建筑研究院有限公司

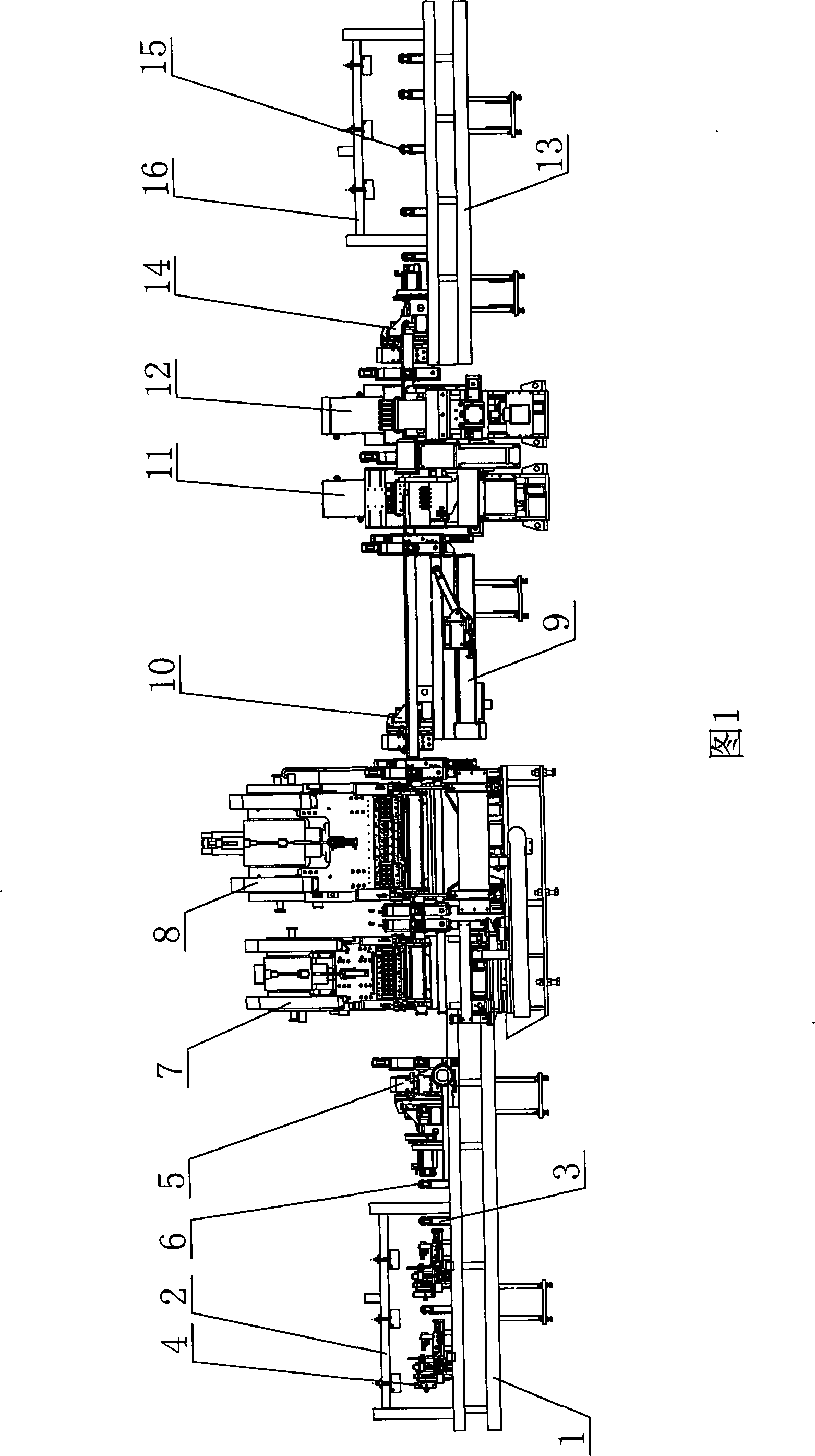

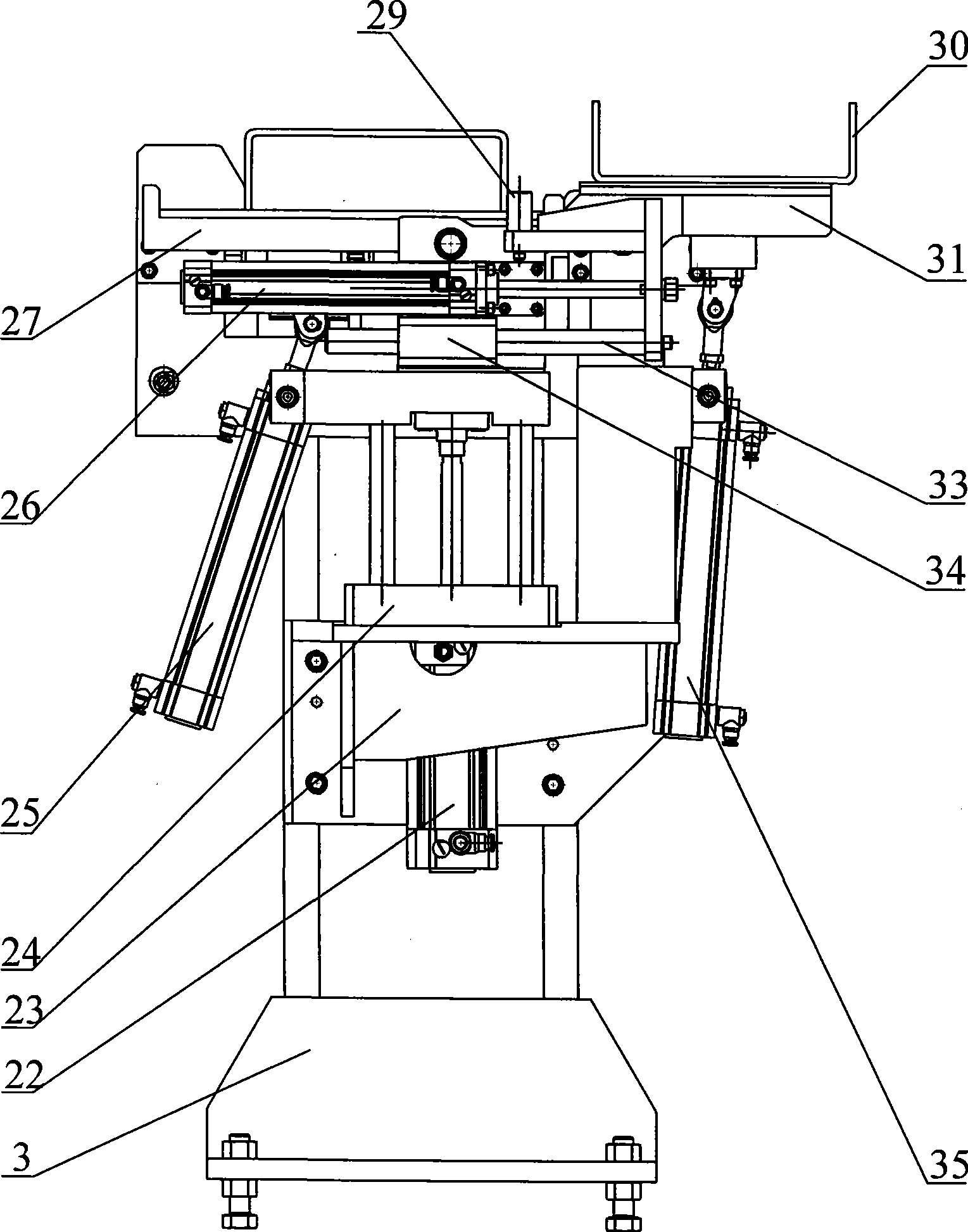

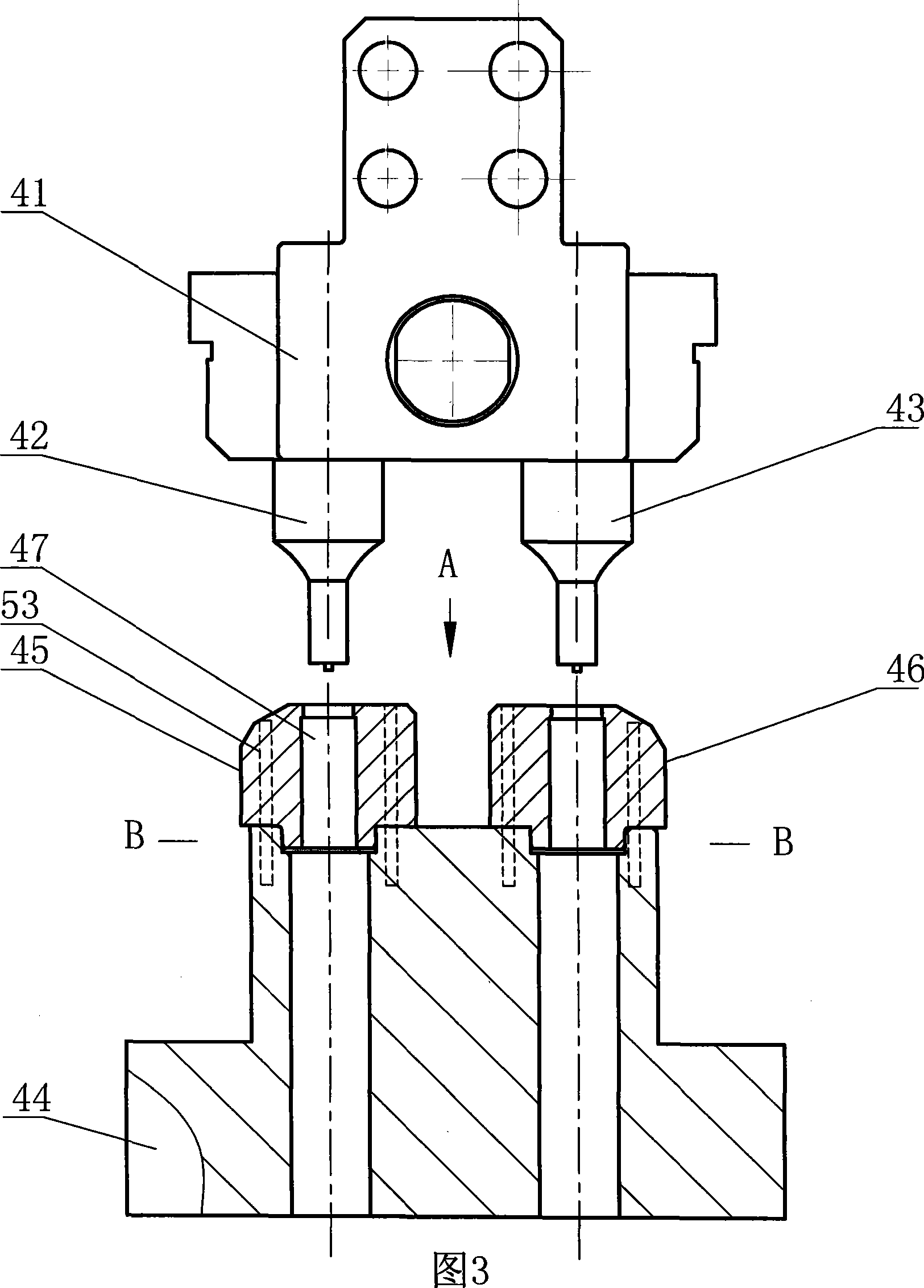

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

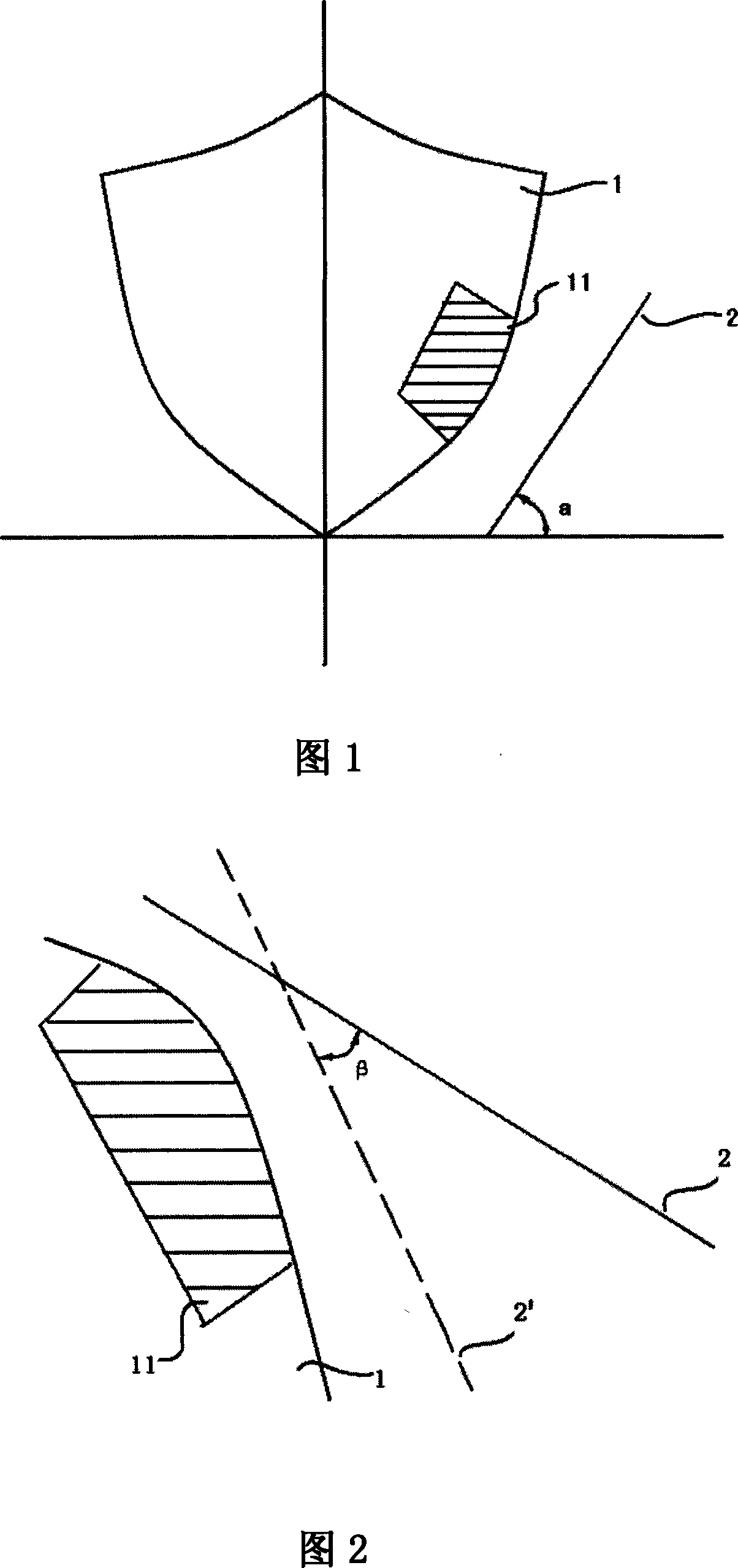

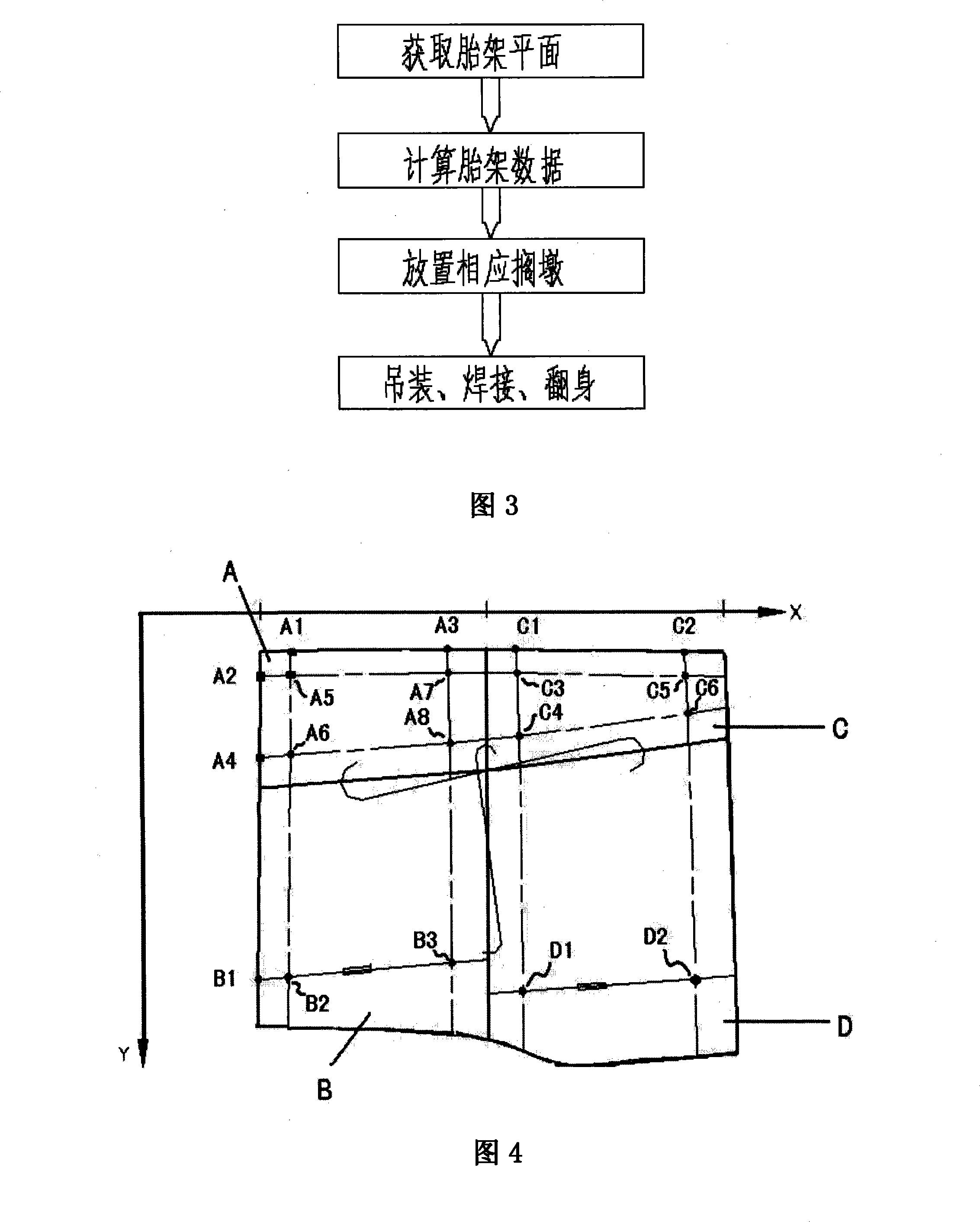

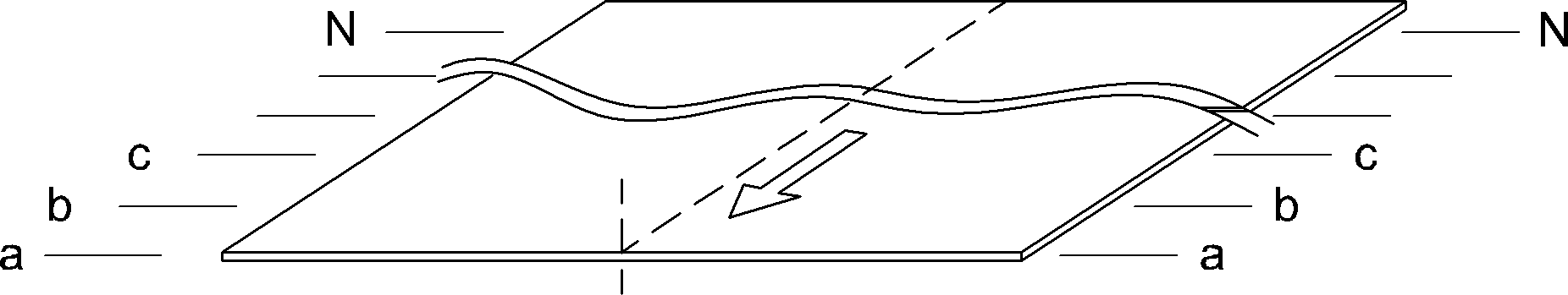

Sectionalized assembling method for ship bow luff part

The invention relates to a total assembly method for the section-dividing of shipping and shipboard parts, used for solving the problems of inconvenient operation and poor precision when the total assembly of a plurality of sections is carried out; the invention comprises the steps that (1) the plurality of sections are seen as an integrated section, and the assembly jig plane is obtained through longitudinal, transverse and oblique cutting on the integrated section; (2) a plurality of key points are obtained on the integrated section, the 3-d coordinates of all key points are found out and the vertical distance from each key point to the assembly jig plane; (3) the ground is taken as the assembly jig plane and supporting columns are correspondingly arranged on the lower part of all the key points; (4) a plurality of sections are respectively and correspondingly hung on the supporting columns for positioning, assembling and welding and overturning, thus implementing the total assembly of all sections. The method of the invention positions all unit sections to be totally assembled according to dimensions, thus reducing energy consumption and improving total assembly efficiency; the process solves the difficulty of large section for total assembly with large bidirectional linear change, thus saving a plurality of assembly jig materials and greatly improving the site turnaround efficiency of the total assembly, and improving the operation environment of the constructors.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

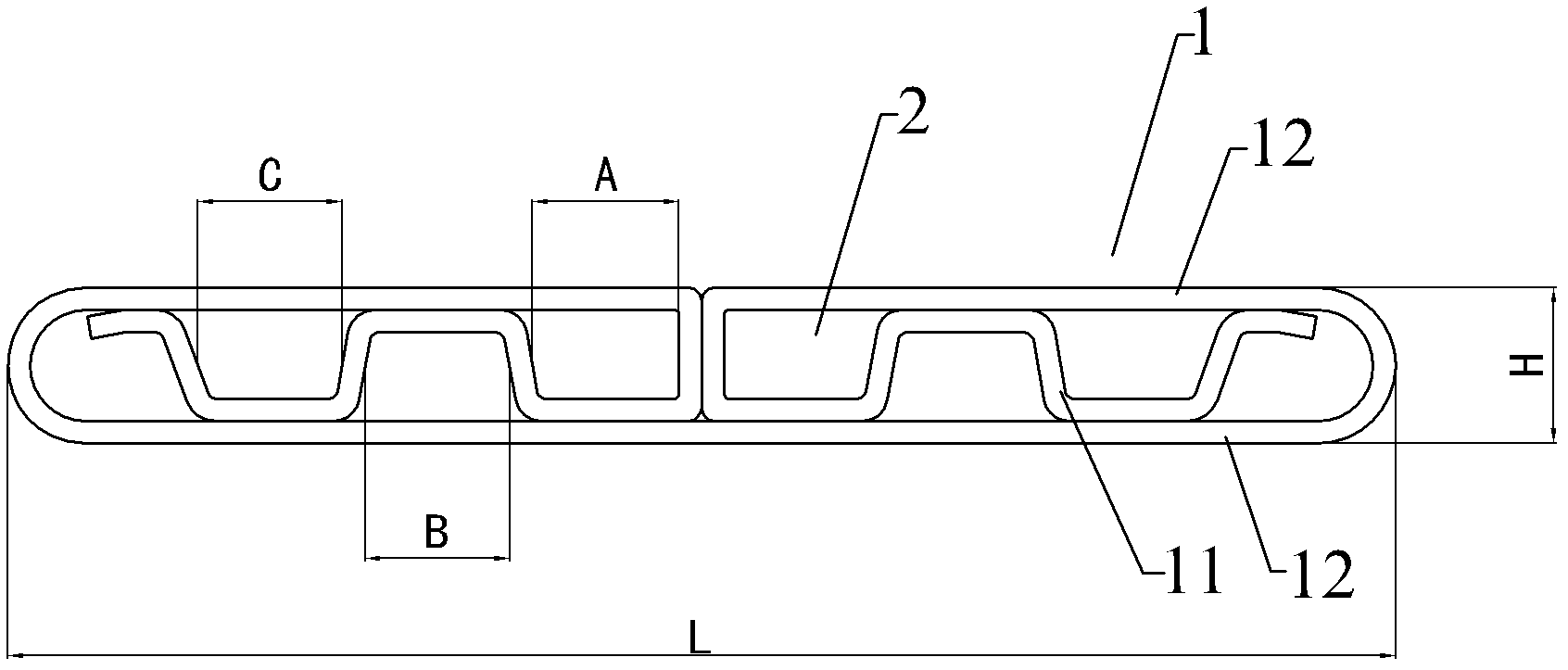

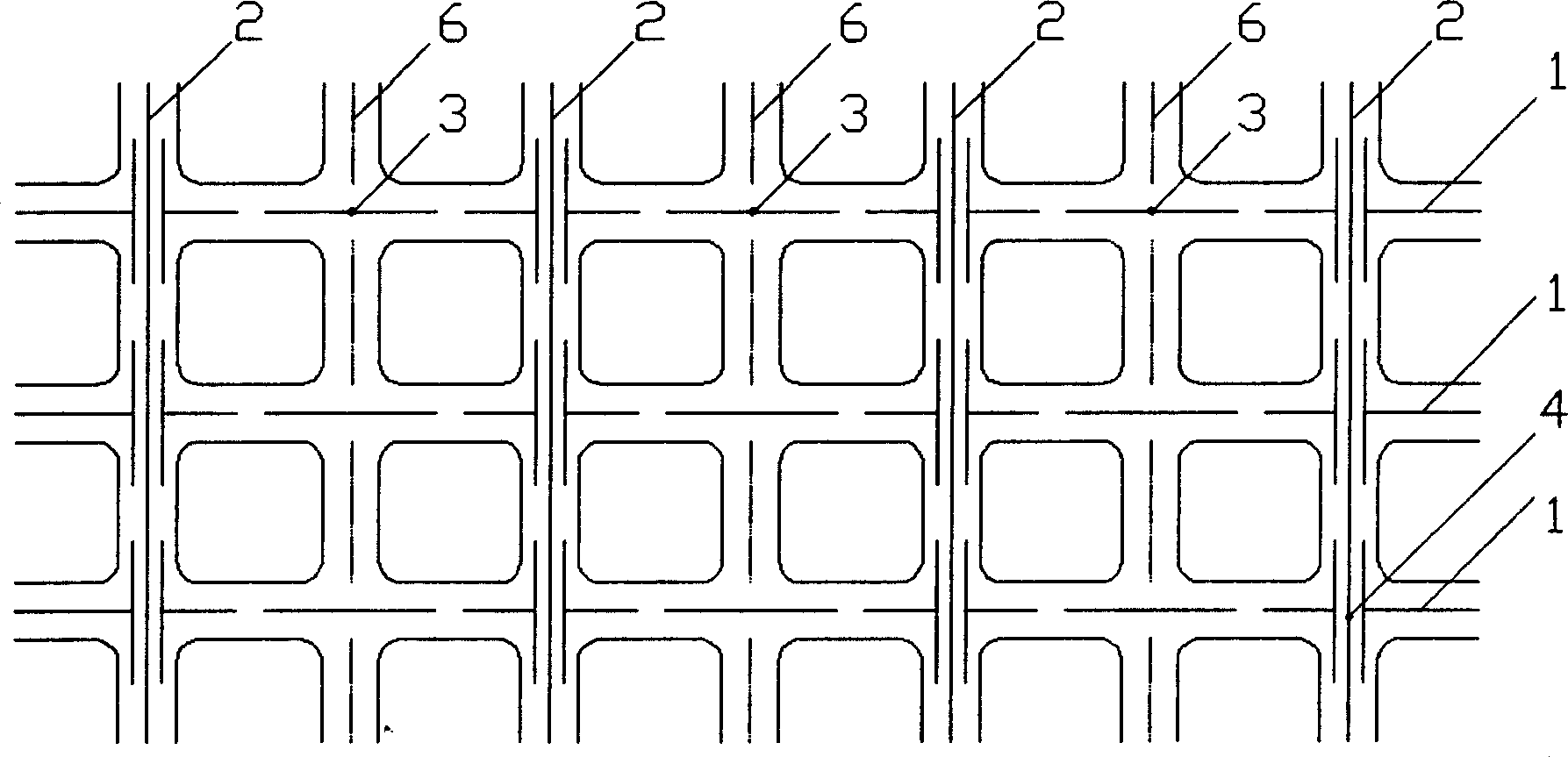

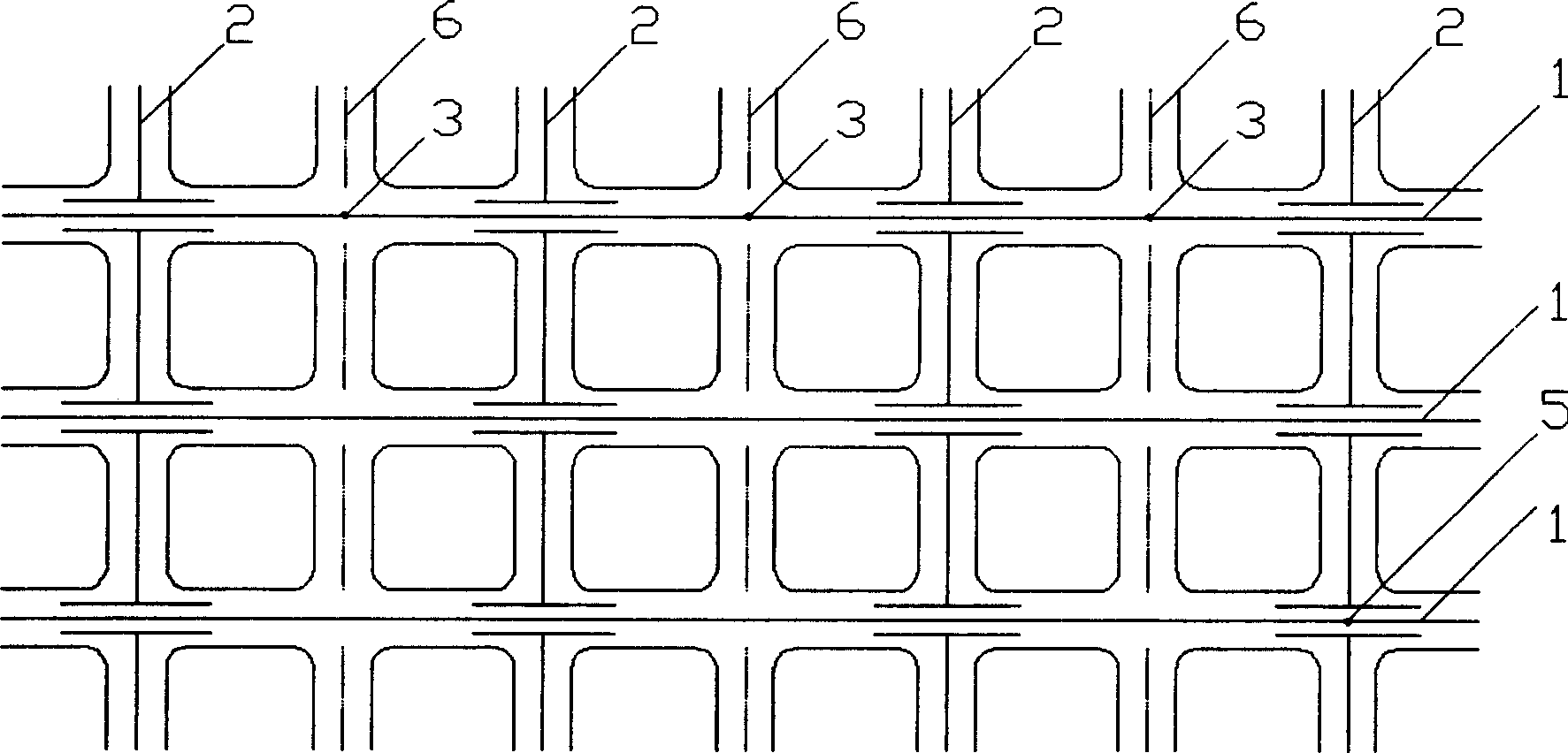

Folding-type microchannel porous flat pipe and molding method thereof

InactiveCN102353294AReduce weightHigh thermal conductivityHeat exchanger casingsTubular elementsControl mannerThin slab

The invention discloses a folding-type microchannel porous flat pipe and a molding method thereof. The flat pipe is formed by subjecting a single thin slab to integral molding, and the single thin slab is sequentially advanced by a mechanical bending mechanism in a multi-point molding control manner, wherein two ends of the single thin slab are respectively bent circuitously, then the circuitously bent parts are vertically bent twice and then horizontally turned and folded once and are butt-jointed at a mesal position of the single thin slab for integral molding, and thus, a porous flat pipe with mutually spaced fine pores is further formed. Compared with the prior art, the invention has the beneficial effects that: 1, the structural form of the flat pipe disclosed by the invention is suitable to being used in a light-weight heat exchanger with light weight and high heat conductivity; 2, the advantages of compact entire structure, high heat exchange efficiency, light weight, firmness, durability, and operation safety and reliability are achieved; 3, by adopting the integral folding and molding structure, the energy consumption of a product production process is low, and the pressure resistance of products is good; and 4, the effect of producing and yield can be achieved through mechanical control, the inventory level is greatly reduced, the product turnover efficiency is increased, and the requirement on lean production can be met.

Owner:YANGJIANG BAOMALI AUTO AIR CONDITIONER

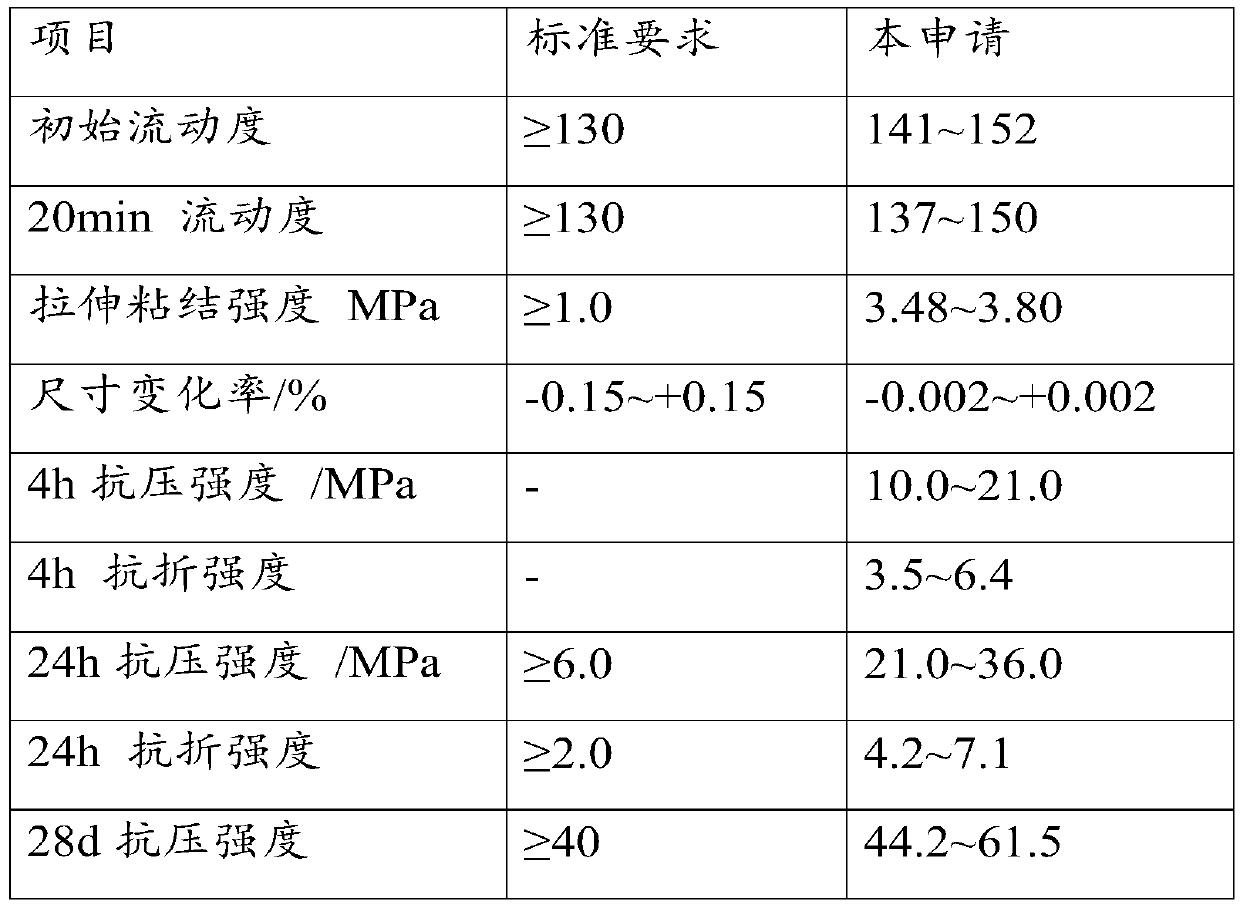

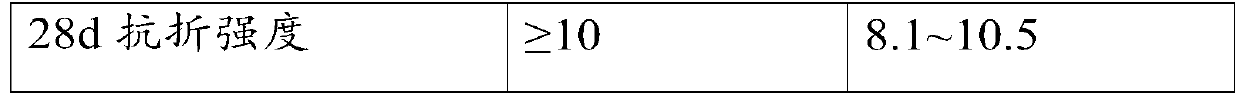

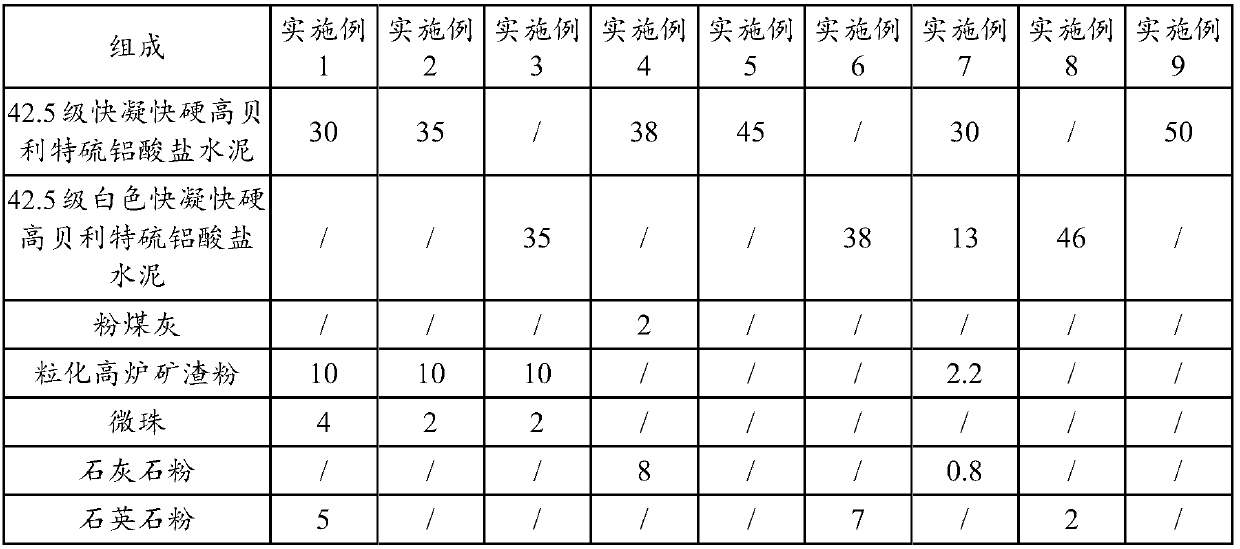

Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

PendingCN109836106AImprove initial fluidityNo significant decrease in fluidity after 20 minutesAcid corrosionSlurry

The invention provides quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and a preparation method, and relates to the field of building materials. The mortar powder comprises the following raw materials in percentage by weight: 30%-50% of quick-cementing and -hardening high-belite sulphoaluminate cement, 46.19%-51.97% of a fine aggregate, 0.15%-0.3% of a waterreducing agent, 0%-0.04% of a thickening agent, 0.05%-0.2% of a defoaming agent, 0.5%-3.5% of latex powder, 0.075%-0.25% of a retarder and 0.15%-0.3% of a coagulation accelerator. The self-leveling mortar has the excellent properties of acid corrosion resistance, small shrinkage, high tensile bonding strength, high setting and hardening speed and the like, and is suitable for self-leveling floors,industrial floors, civil floors, artistic floors and the like in an acid salt environment.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

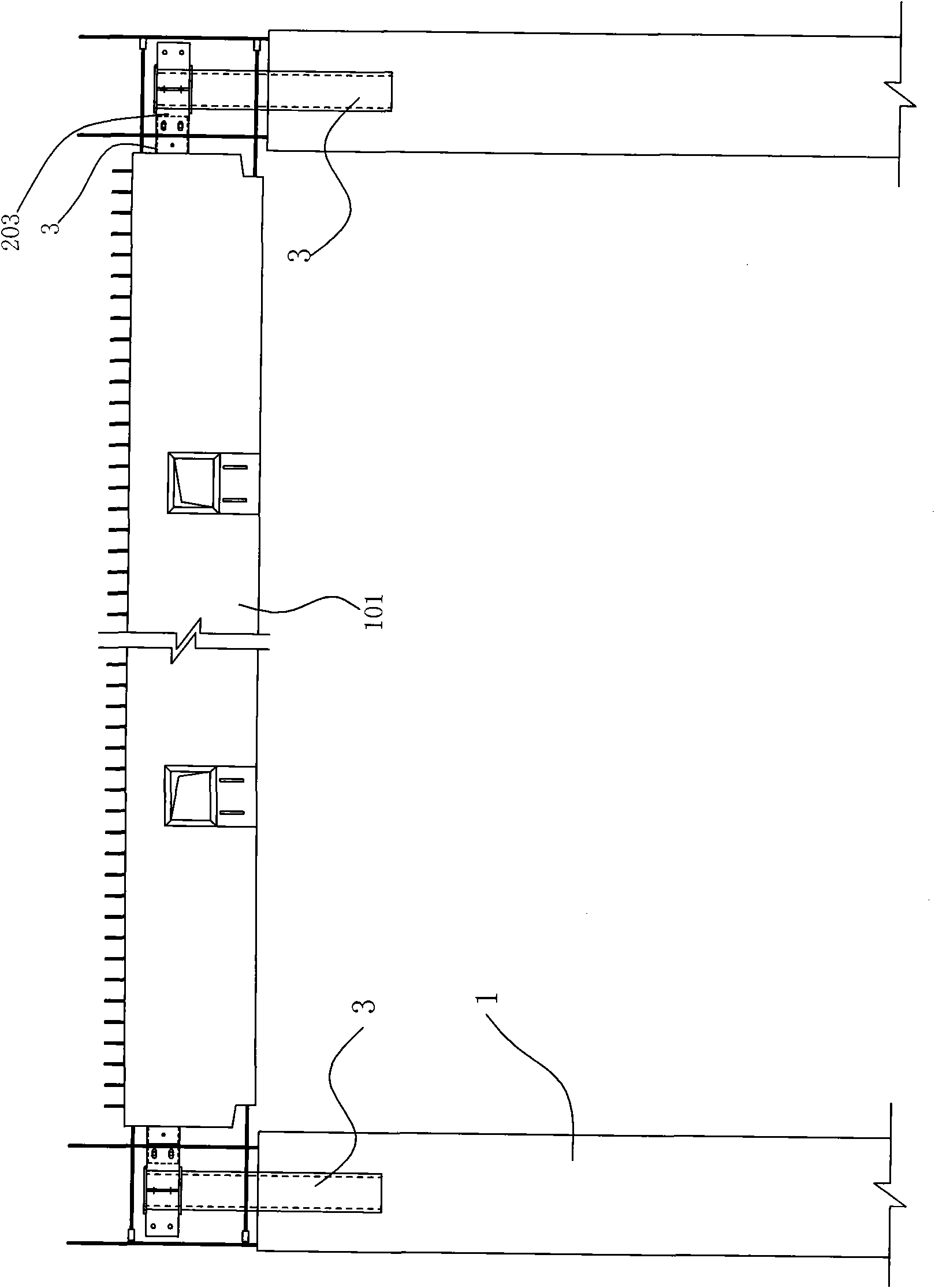

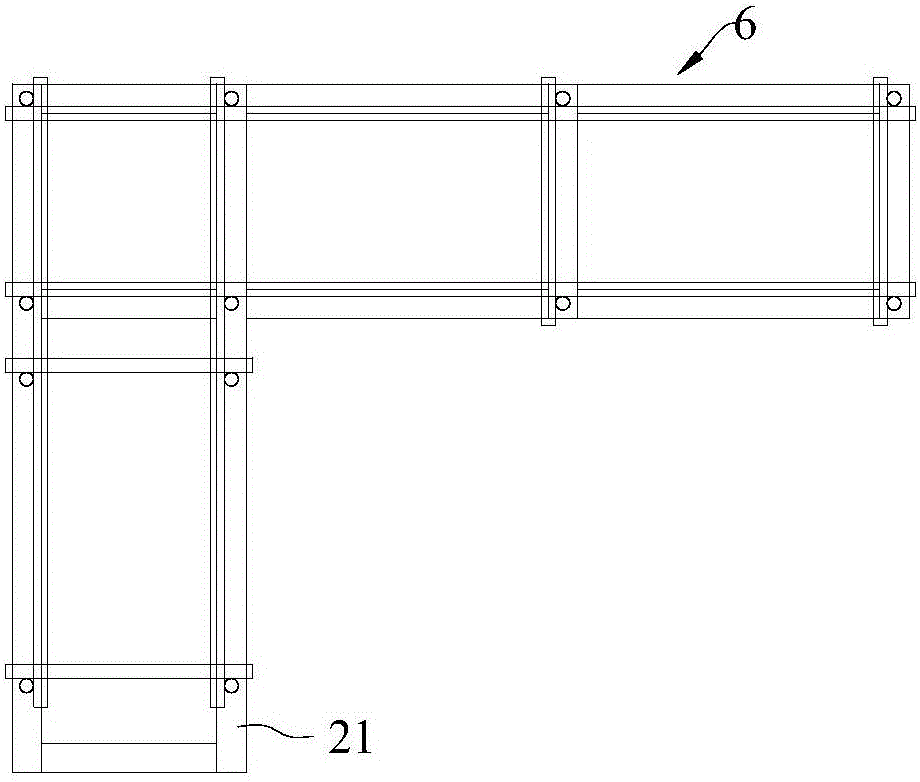

Novel reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386AReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

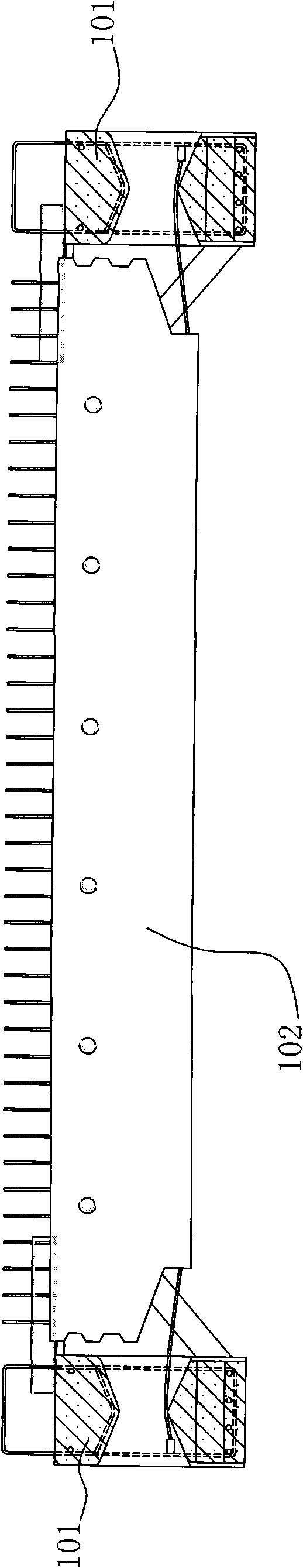

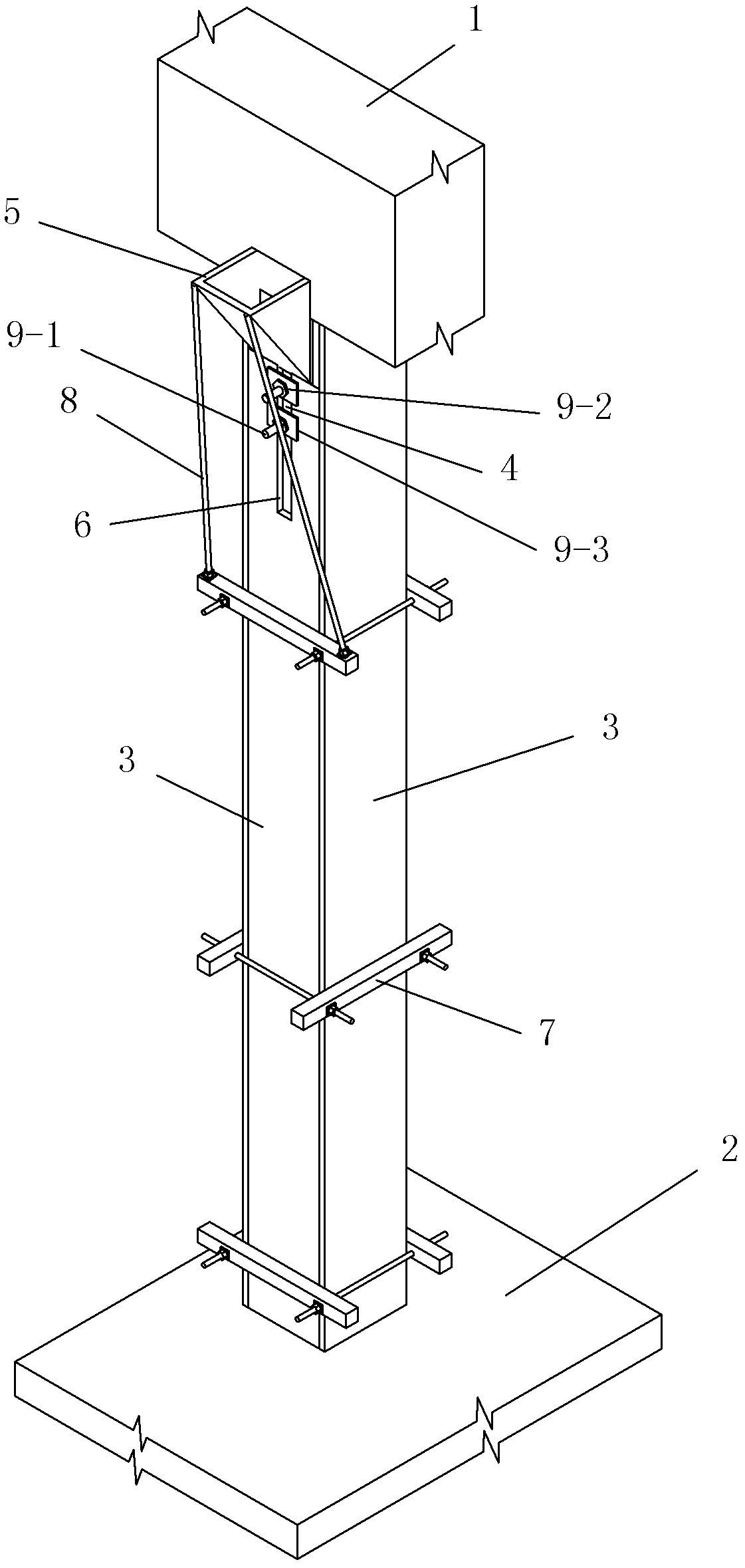

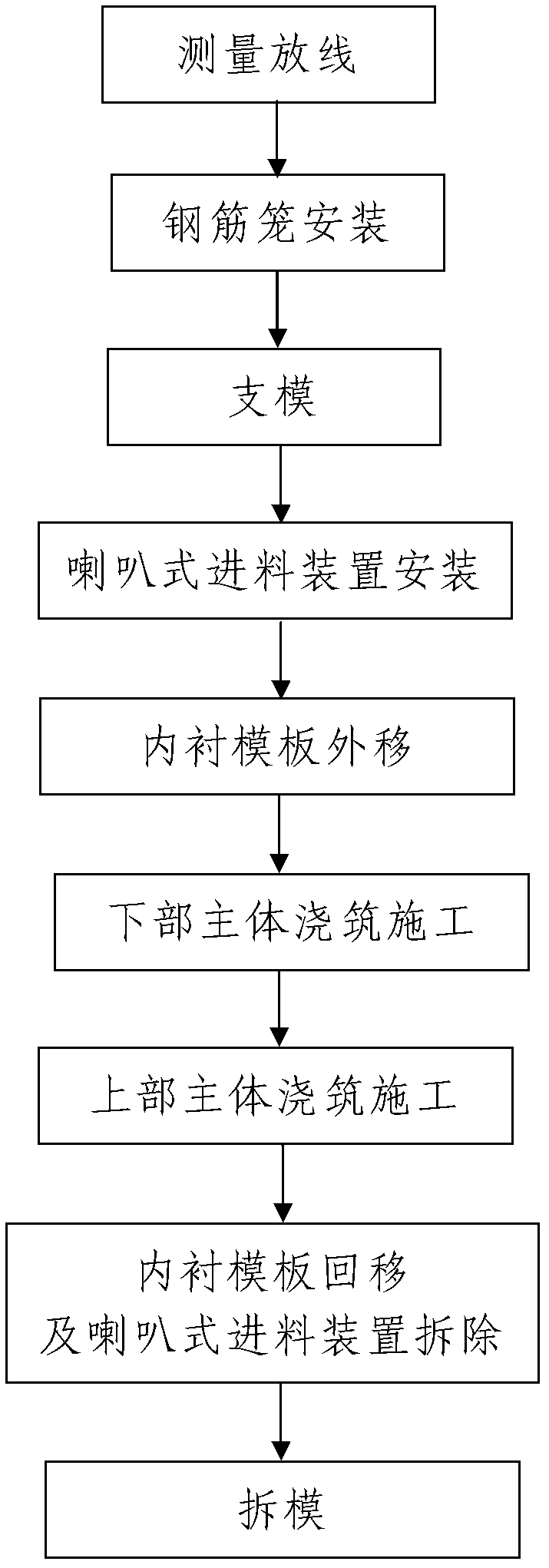

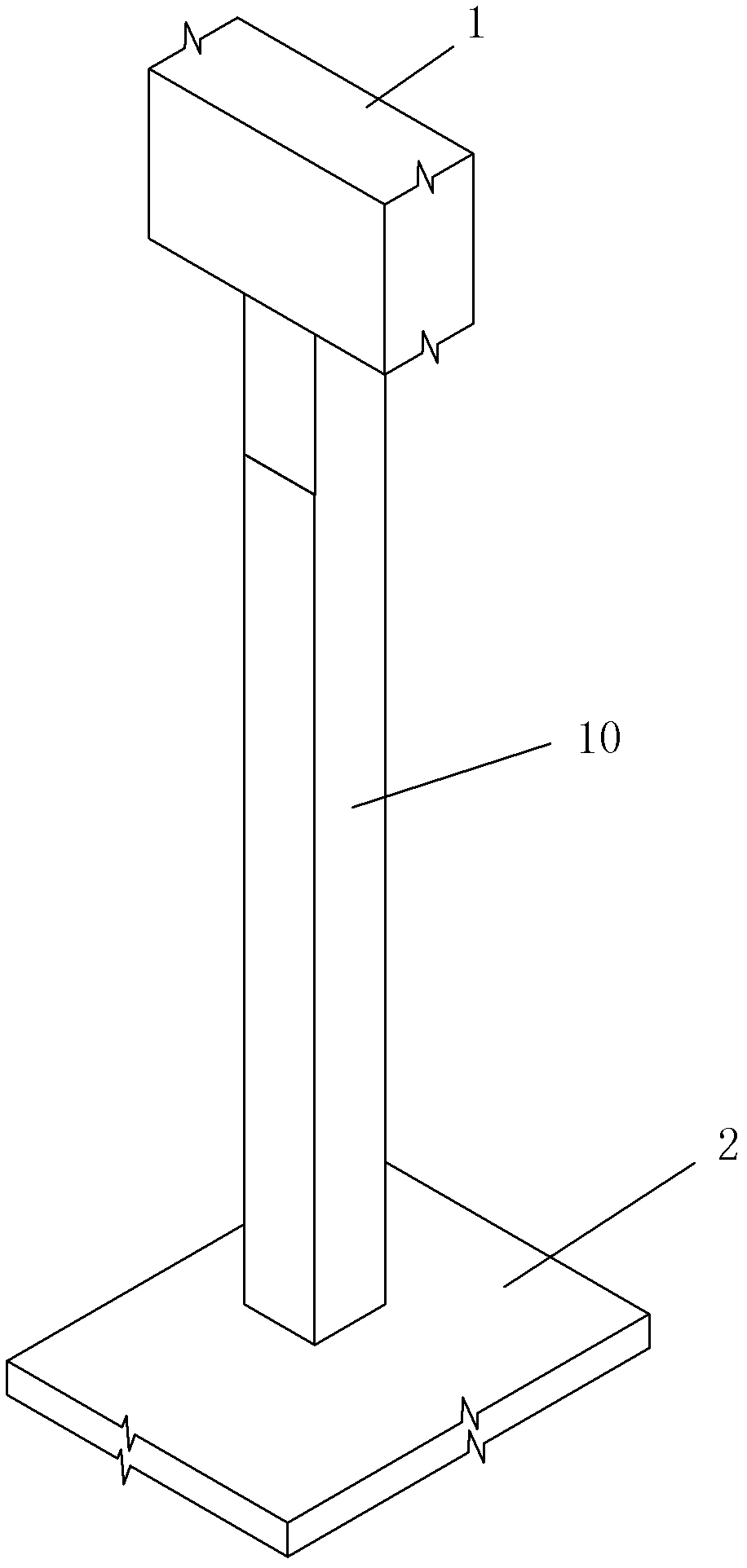

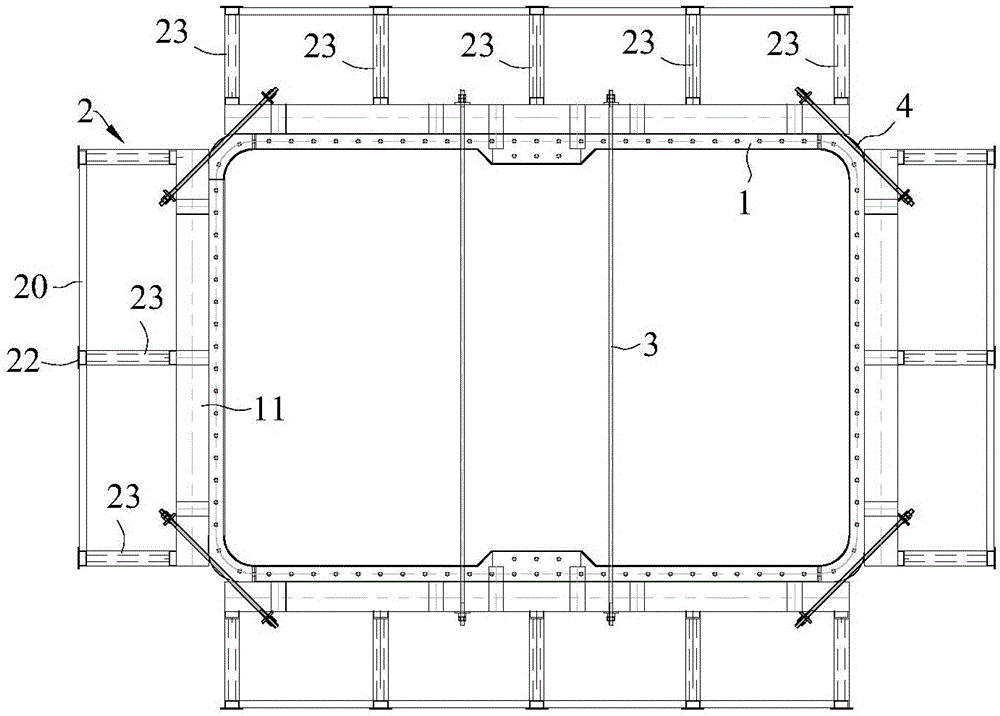

Casting molding template and casting molding process for constructional columns of infilled walls

InactiveCN102561681ASimple structureReasonable designForms/shuttering/falseworksBuilding material handlingMaterials scienceBuilding construction

The invention discloses a casting molding template and a casting molding process for constructional columns of infilled walls. The molding template comprises a lining template and a principal template, wherein the upper end part of the principal template is provided with a lining template installing slot for installing the lining template, the lining template and the principal template are assembled so as to form a constructional column template; and the lining template installing slot is provided with a horn-type feeding device, the lining template is a movable template which can carry out up-and-down motions or left-and-right motions on the inner wall of the principal template, and a template moving component is arranged on the outside surface of the lining template; and the molding process comprises the steps of 1, carrying out survey layout; 2, installing a reinforcement cage; 3, erecting the template; 4, installing the horn-type feeding device; 5, moving the lining template outwards; 6, carrying out casting construction; 7, moving back the lining template and removing the horn-type feeding device; and 8, removing the template. The casting molding template disclosed by the invention is reasonable in structure, simple in operation, economic, practical, time-saving, labor-saving and good in application effect, and can effectively solve various actual problems existing in the current construction on constructional columns of infilled walls.

Owner:陕西建工集团有限公司

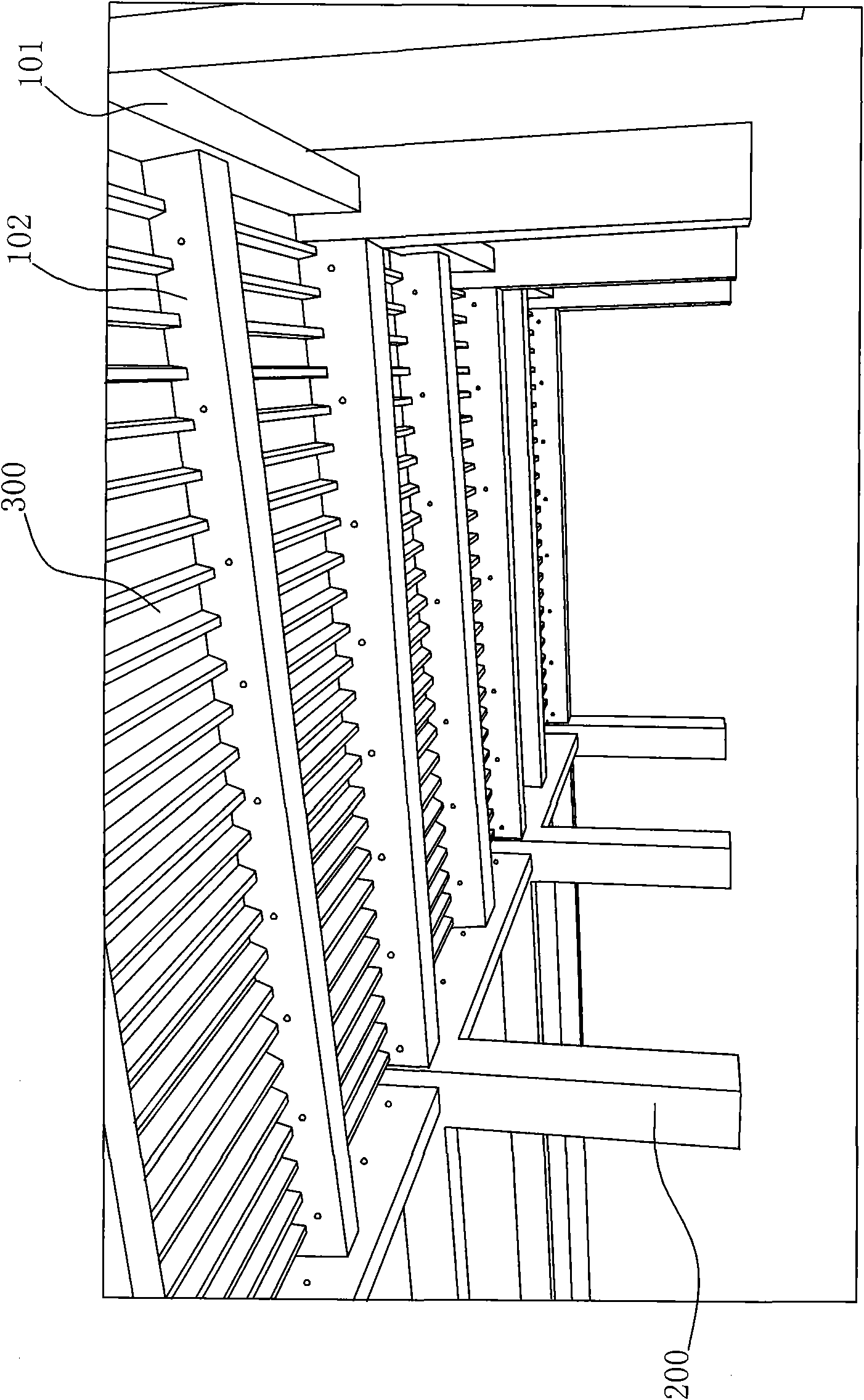

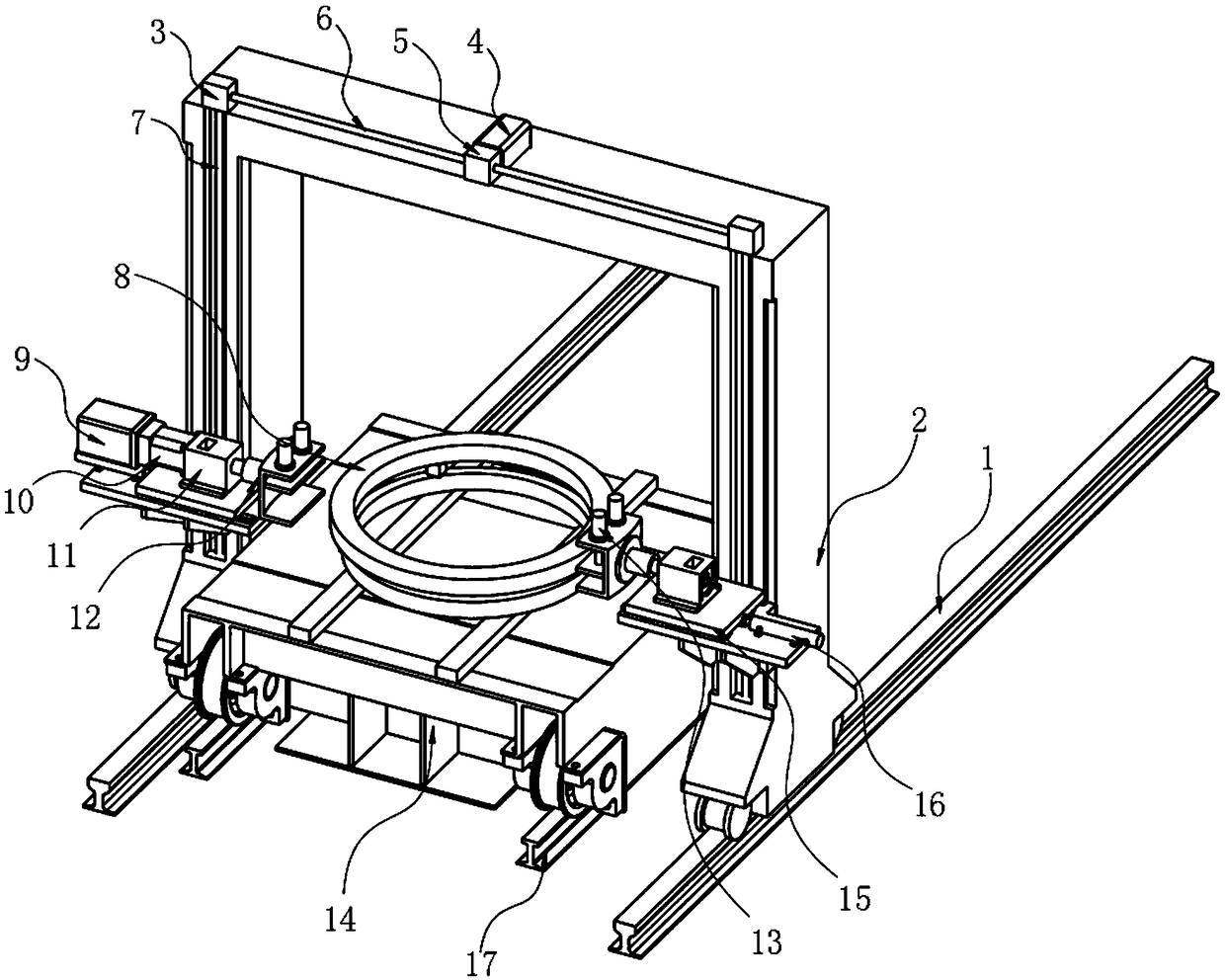

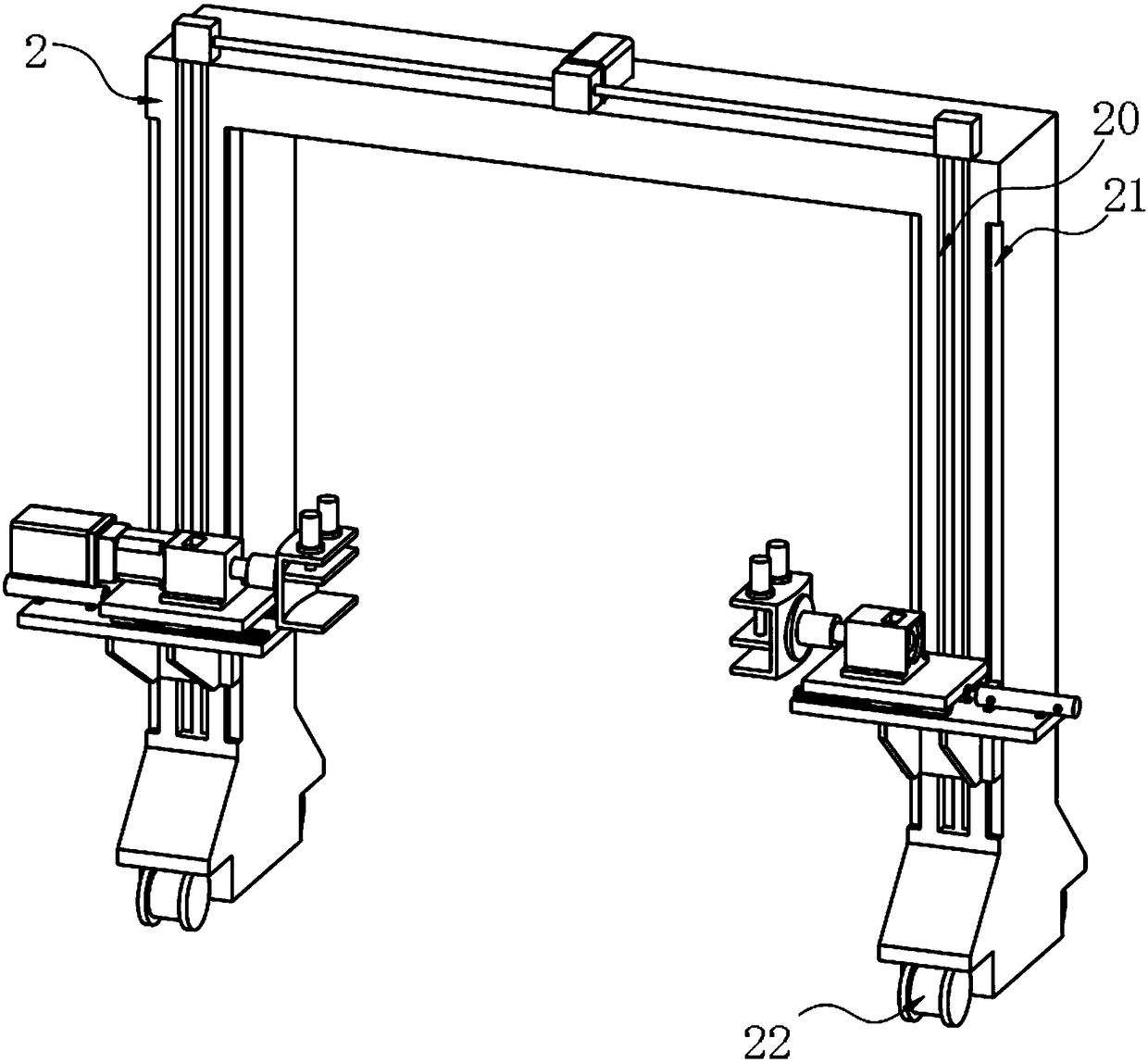

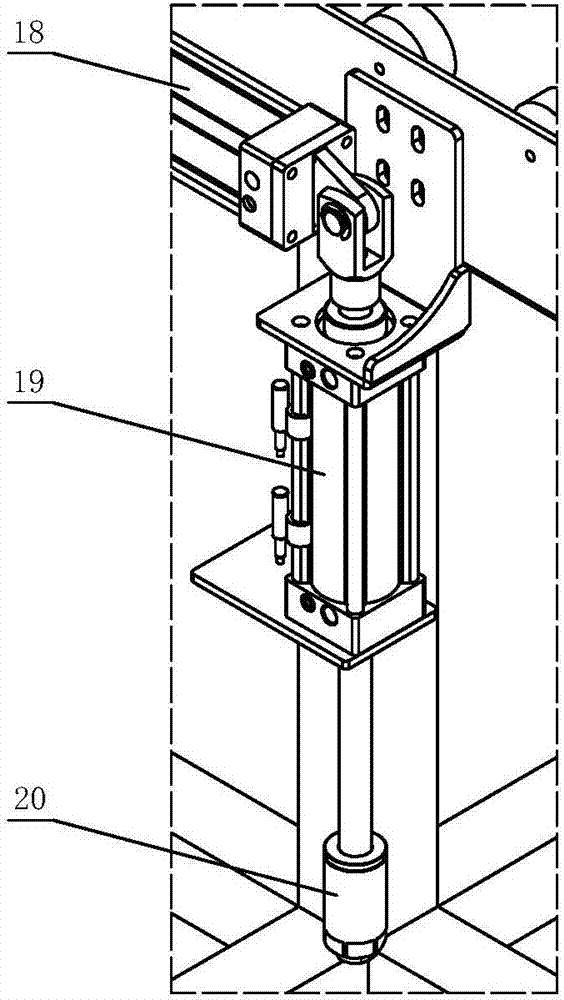

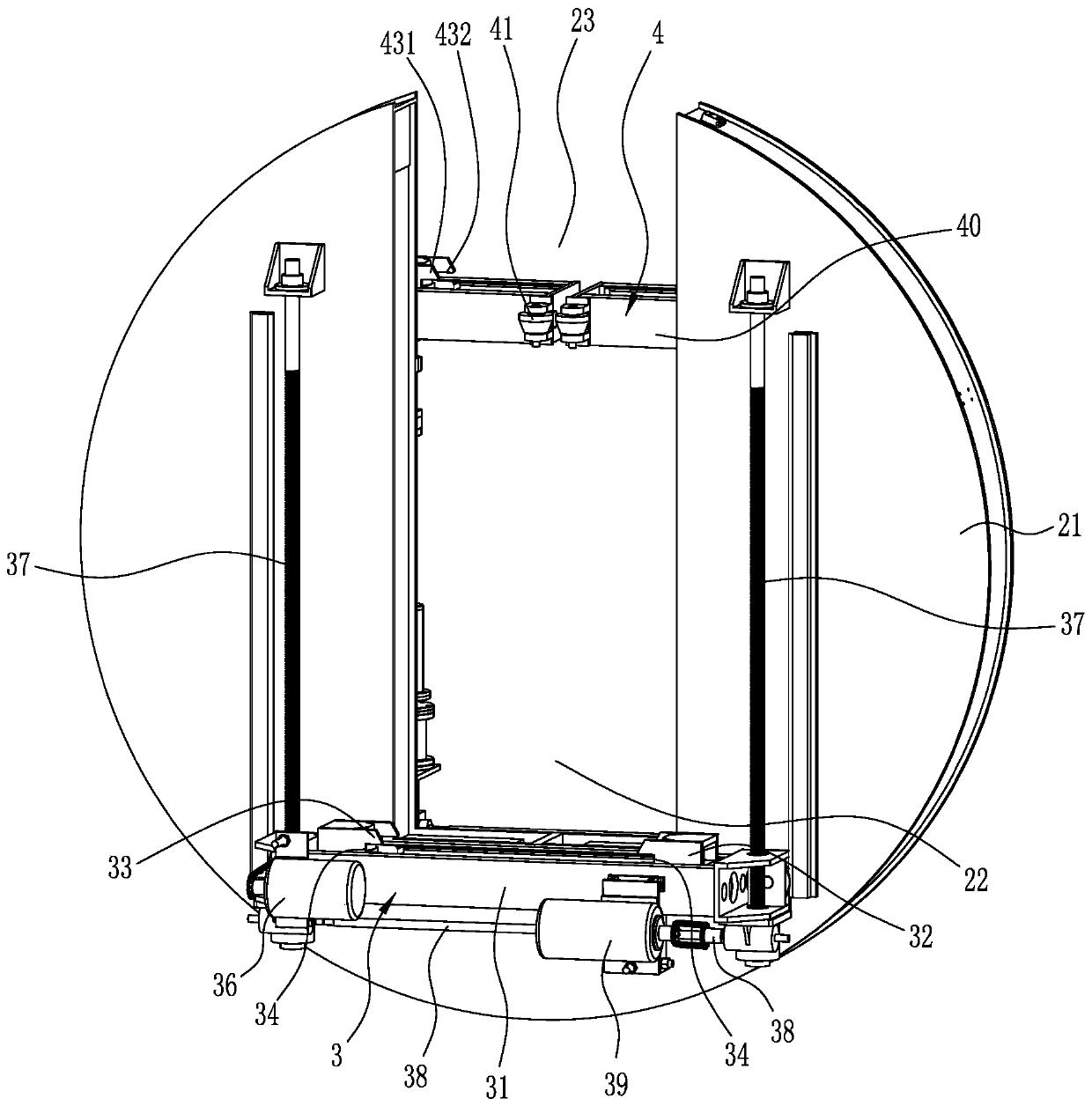

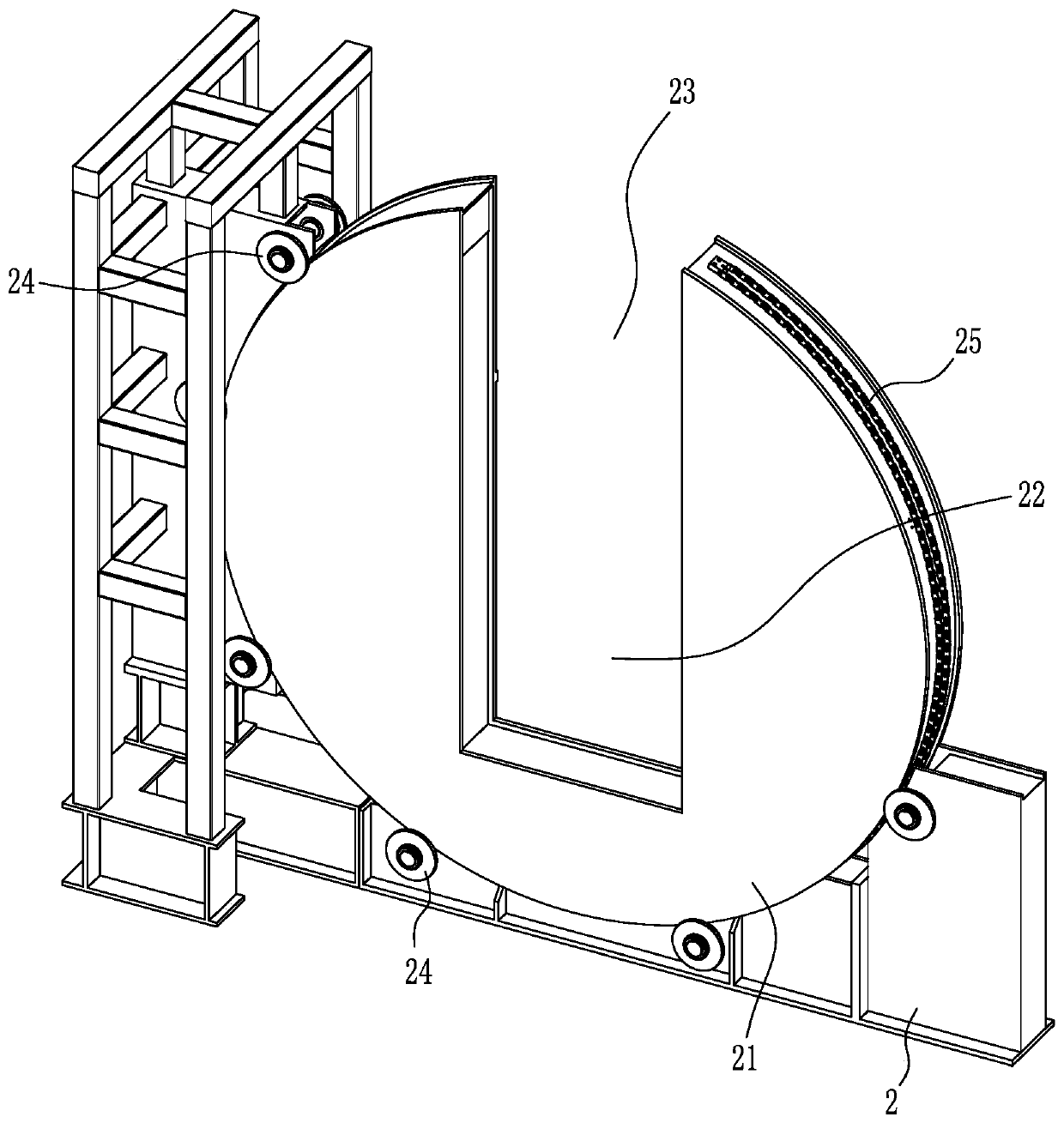

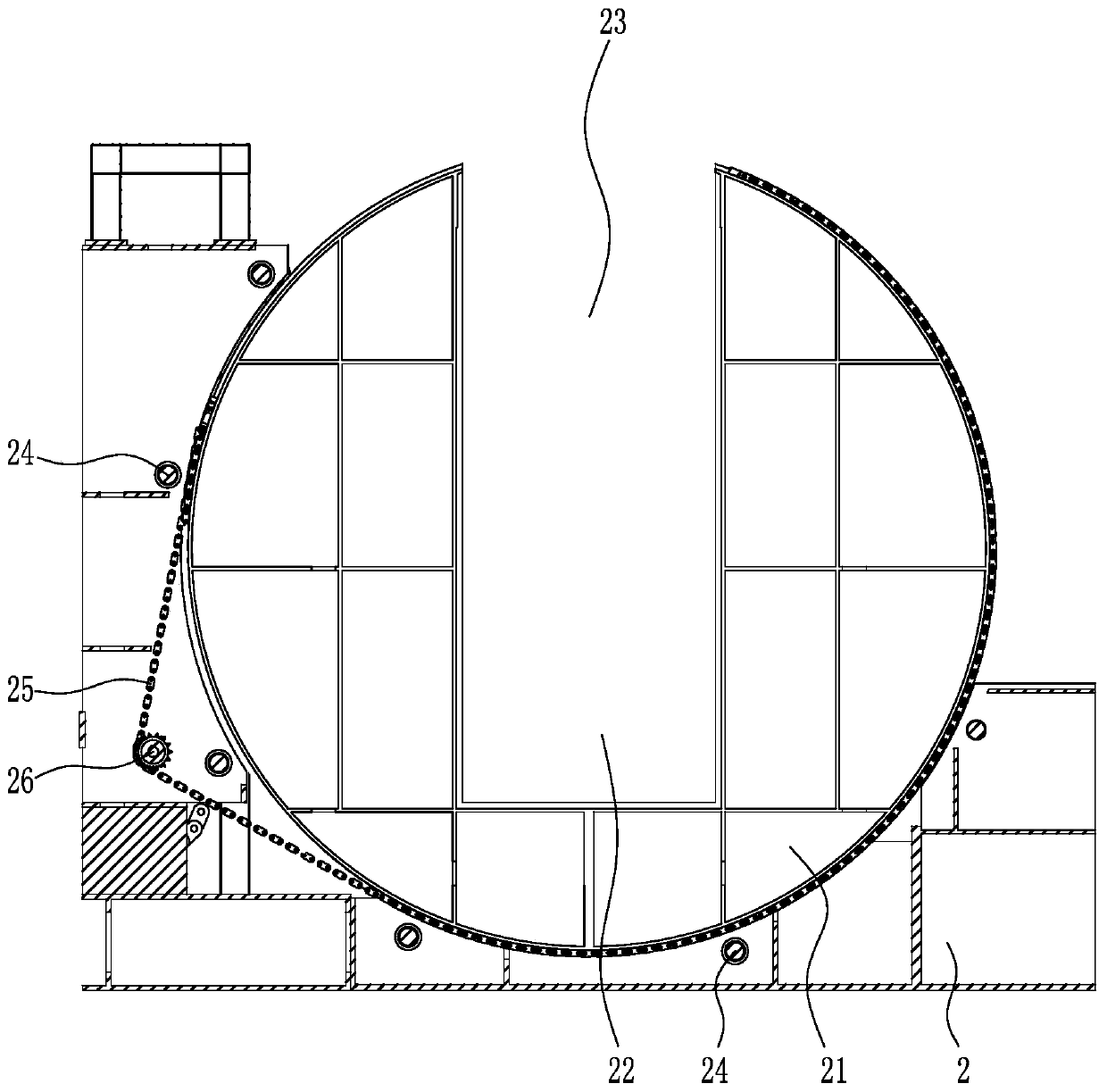

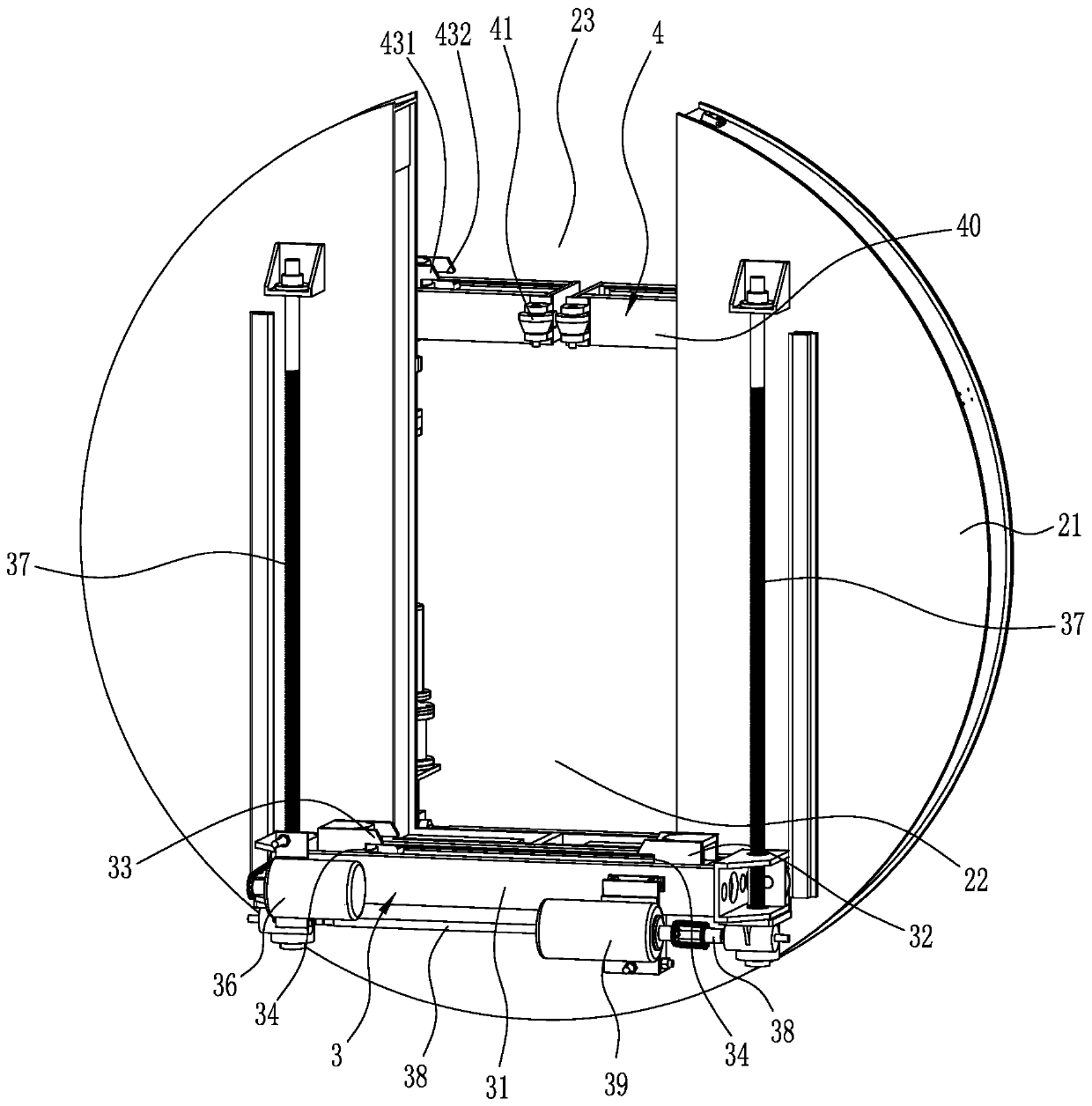

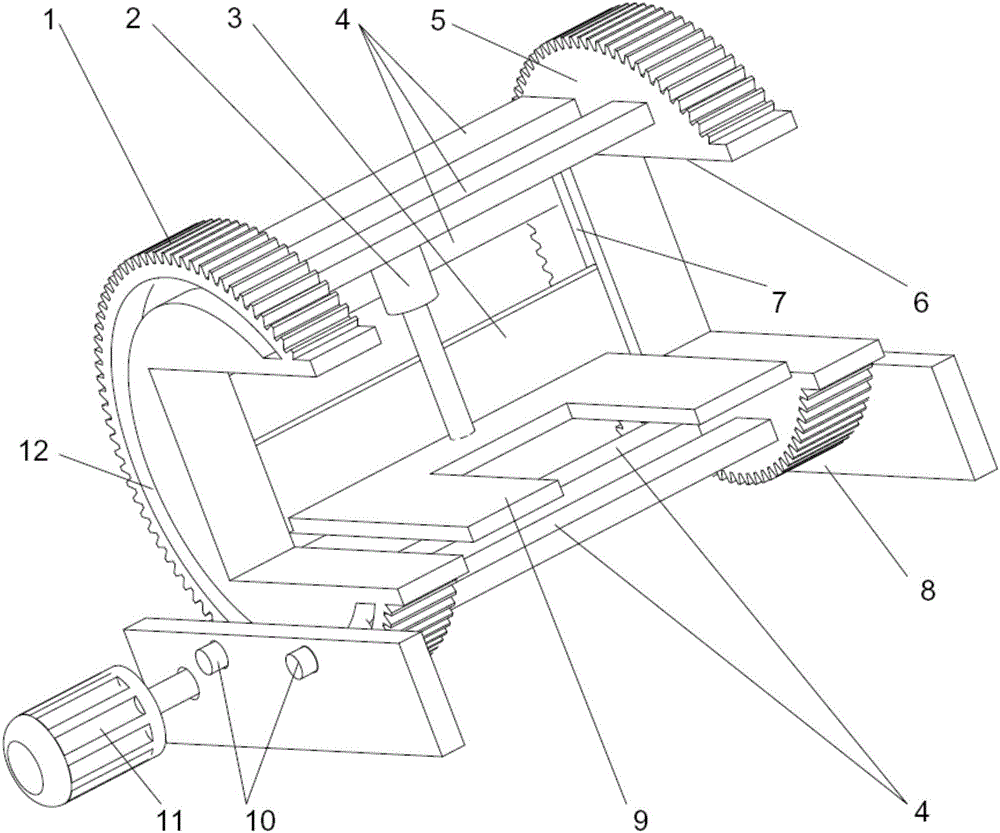

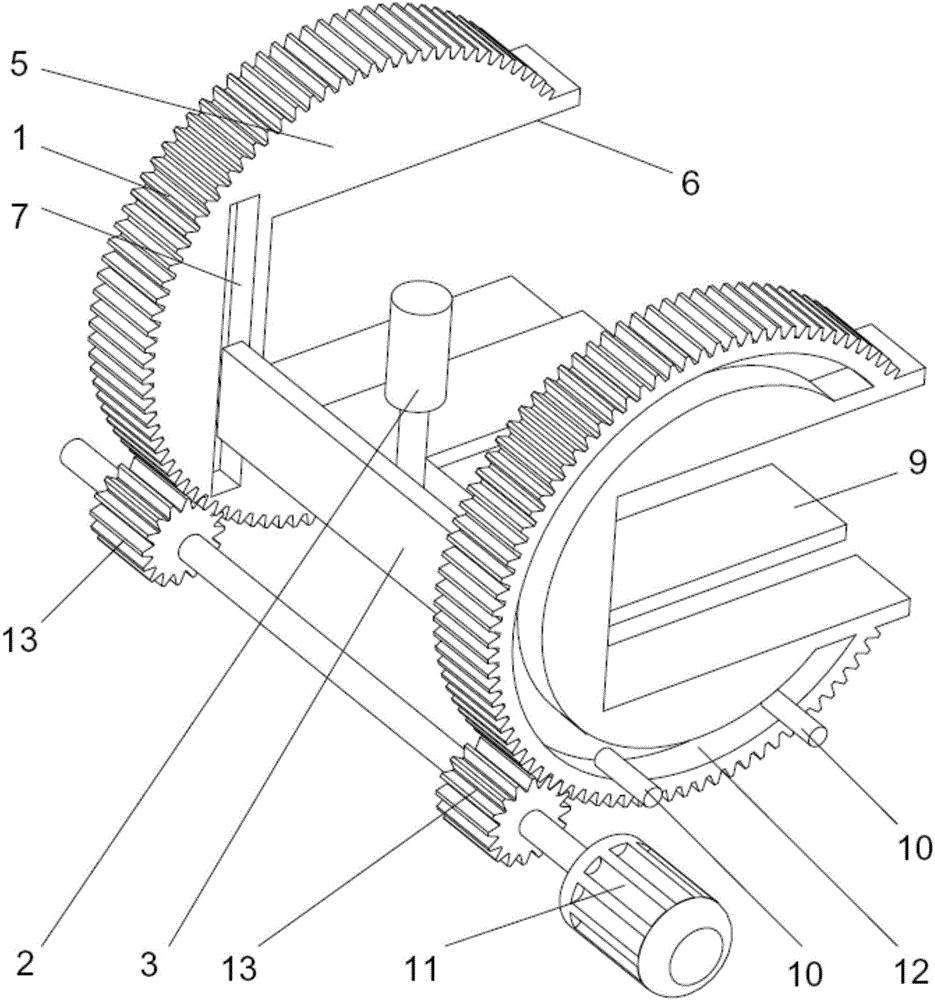

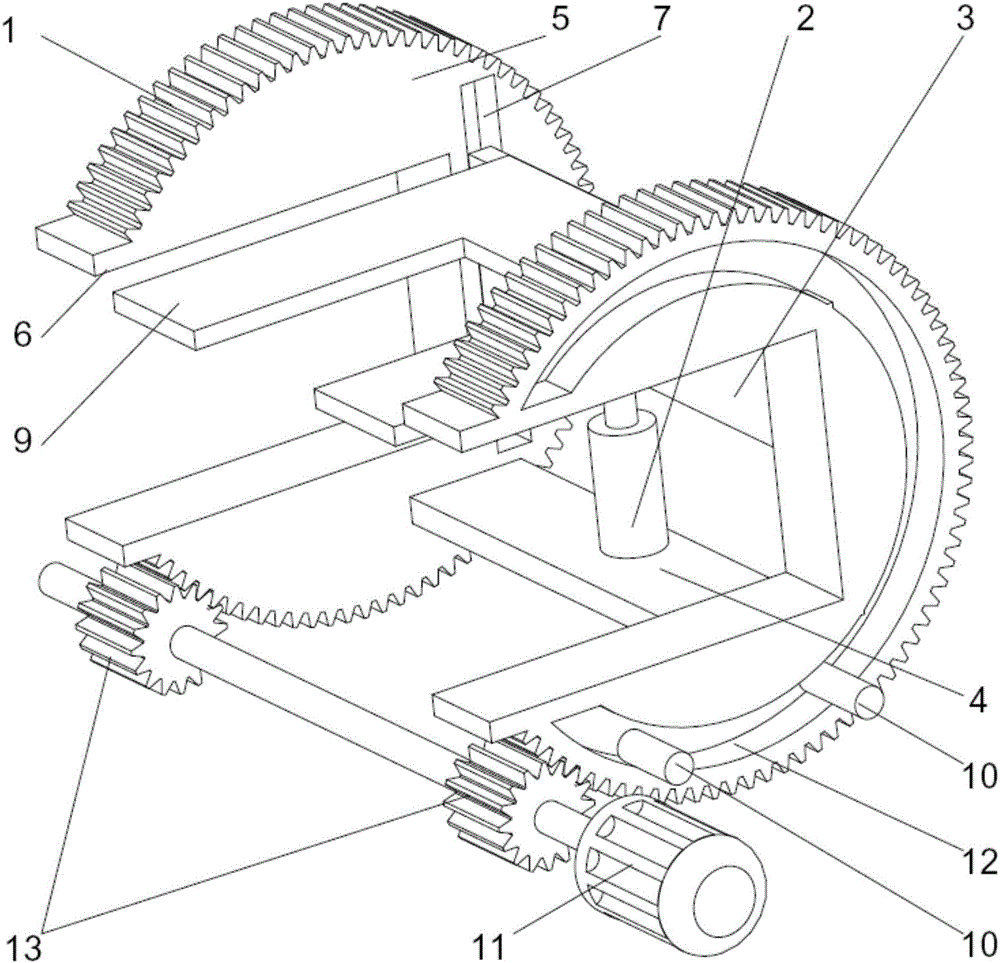

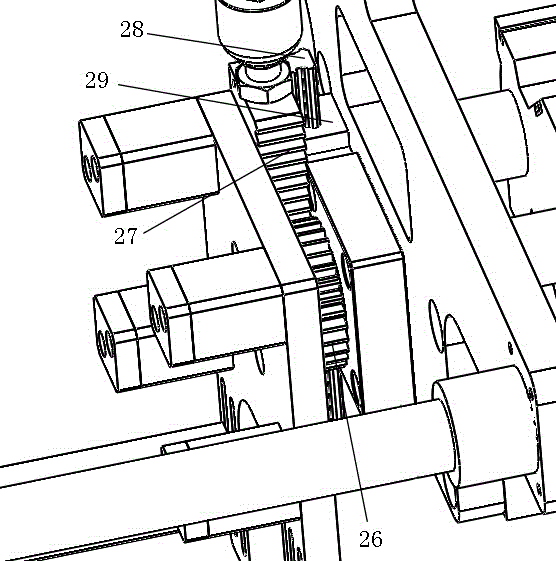

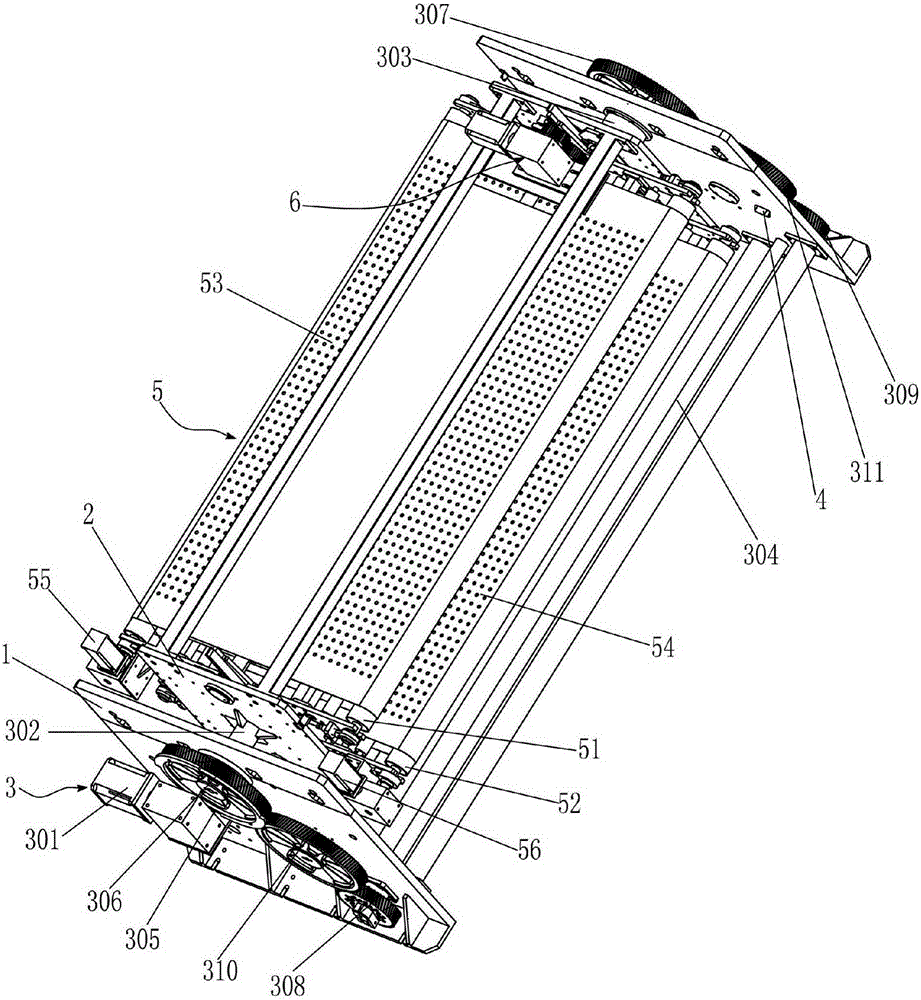

Slewing bearing overturning mechanism

InactiveCN109399109AEasy to processAvoid occupyingBase supporting structuresBraking devices for hoisting equipmentsReduction driveReducer

The invention relates to the technical field of machinery, in particular to a slewing bearing overturning mechanism. The slewing bearing overturning mechanism comprises two ground rails and a travelling trolley, wherein the two ground rails are parallel to each other; the travelling trolley is arranged between the two ground rails and above the two ground rails; a gantry bracket is arranged on thetwo ground rails; a pair of opposite guiding rail sliders is arranged on the side wall of the gantry bracket; a connecting assembly is arranged on the guiding rail sliders; a rotating motor and a third speed reducer are arranged behind the connecting assembly; a rotating device is arranged in front of the connecting assembly; an output shaft of the rotating motor is coaxially connected with an input shaft of the third reducer; and an output shaft of the third reducer is fixedly connected to the rear end of the rotating device through the connecting assembly. By using the slewing bearing overturning mechanism, the inner ring, the outer ring and assemblies of a slewing bearing are automatically overturned to facilitate the machining and assembling of the slewing bearing. The slewing bearingoverturning mechanism has the advantages that the structure is compact, the assembling is convenient, the occupation of a crane is avoided, the safety of workers is ensured, and the overturning efficiency is improved.

Owner:NANJING GONGDA CNC TECH

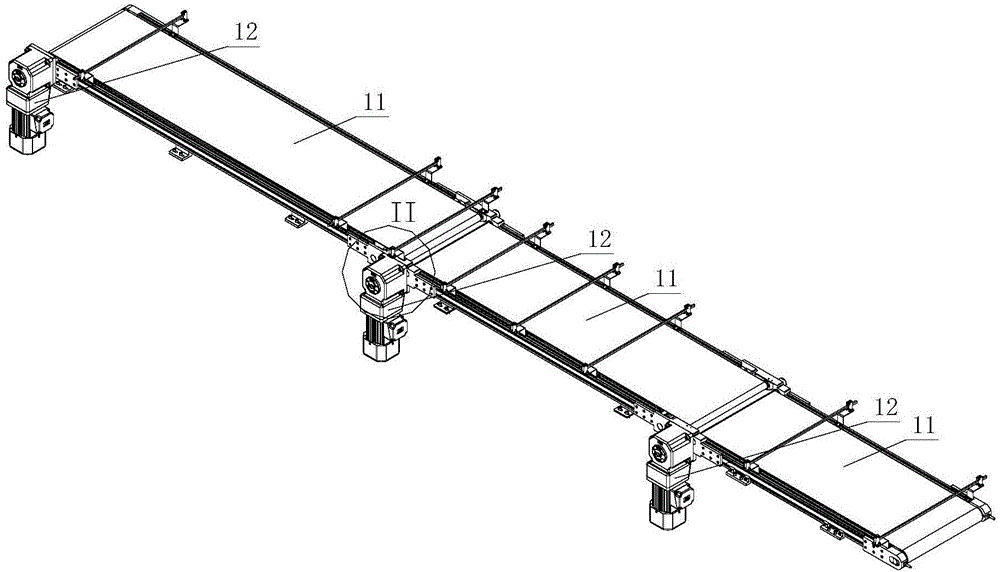

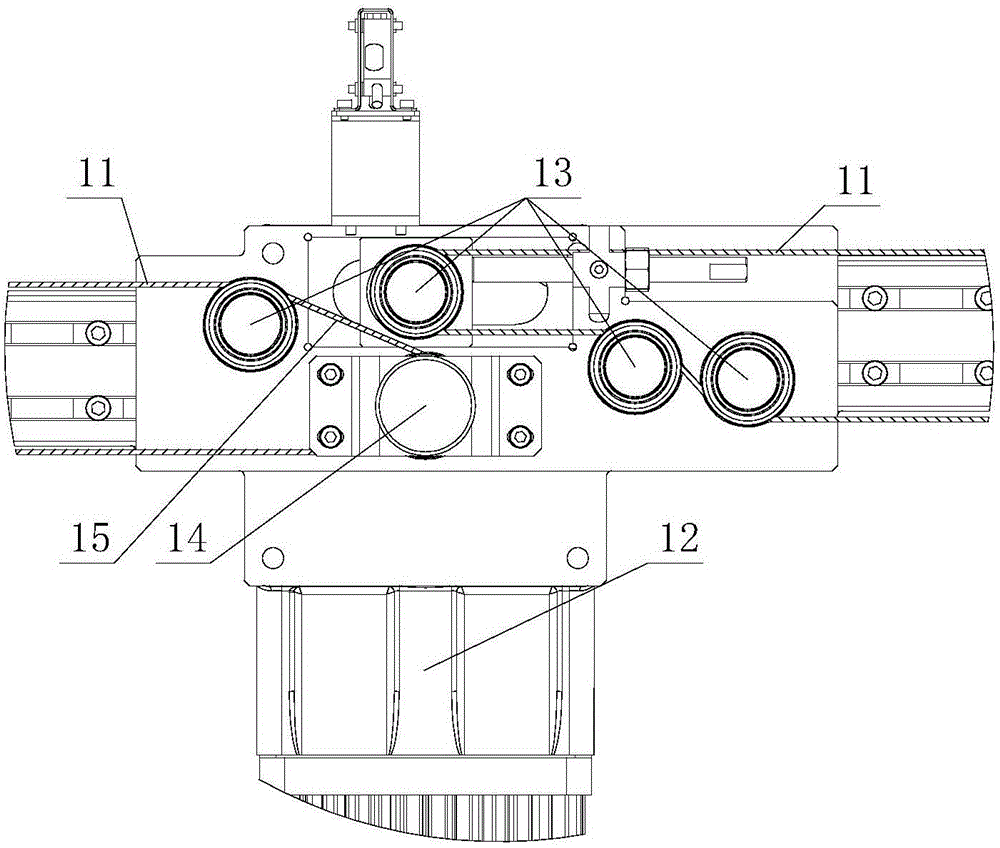

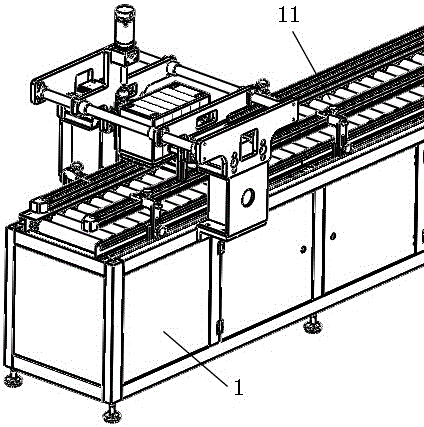

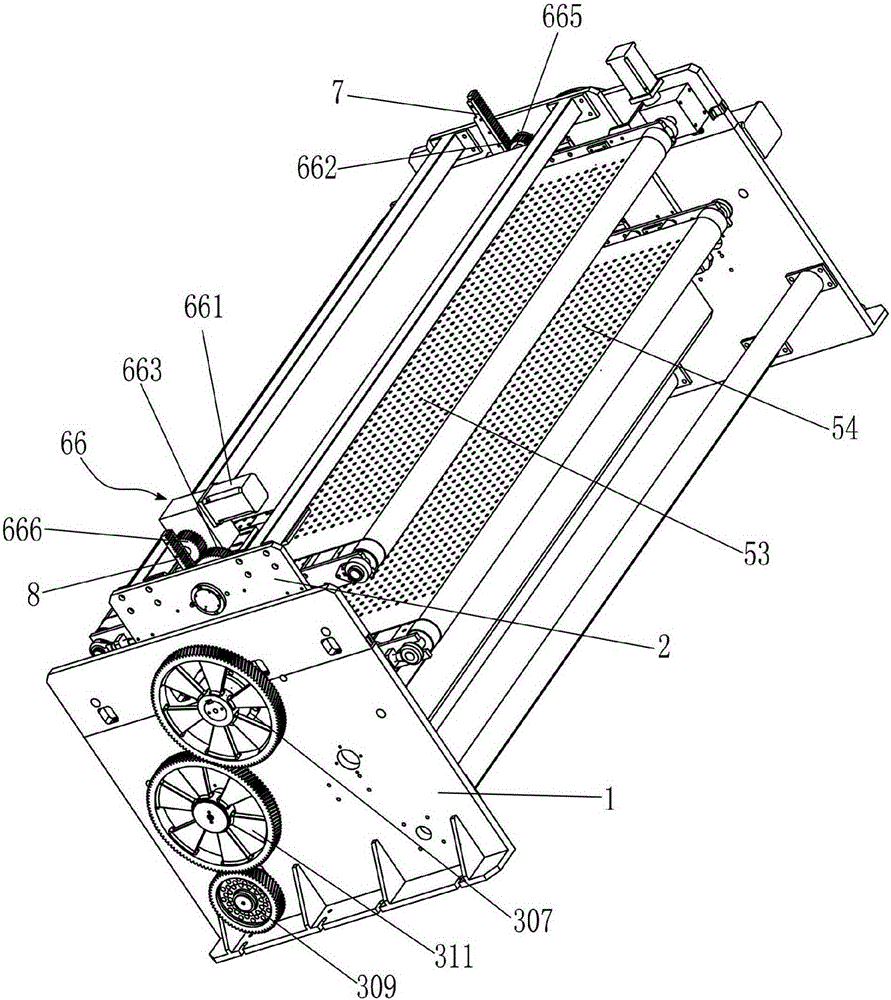

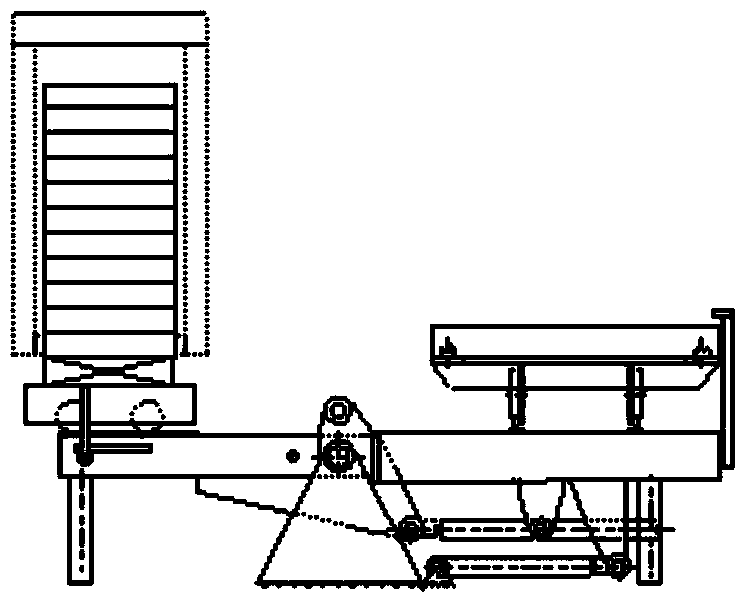

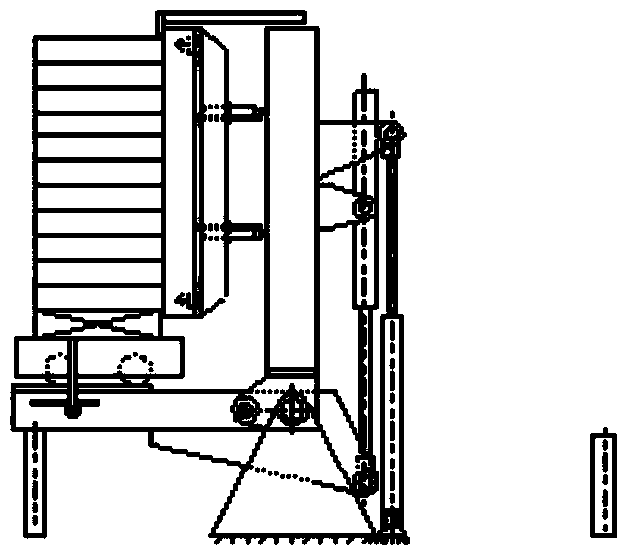

Plate overturning machine and numerical-control cutting production line thereof

PendingCN107954185ASimple structureReduce manufacturing costConveyorsConveyor partsHigh turnoverProduction line

A plate overturning machine comprises an equipment machine frame. An overturning mechanism and a conveying mechanism are arranged on the equipment machine frame. The overturning mechanism comprises anoverturning arm, one or more suction disk assemblies and an overturning drive assembly. One side of the overturning arm is rotationally connected with the equipment machine frame. The suction disk assemblies are assembled on the overturning arm. The overturning drive assembly is arranged on the equipment machine frame and drives the overturning arm to conduct reciprocating overturning between thecorresponding numerical-control cutting machine and the equipment machine frame where the overturning arm is located so that a plate-shaped workpiece on the numerical-control cutting machine can be overturned and placed on a feeding area of the equipment machine frame. The conveying mechanism is located in the feeding area of the equipment machine frame and comprises a conveying chain and a conveying drive assembly, wherein the conveying chain is provided with a stop block, the conveying drive assembly is arranged on the equipment machine frame and drives the conveying chain to operate, and the stop block moves along with the conveying chain and drives the plate-shaped workpiece in the feeding area to be conveyed in the direction of the corresponding numerical-control cutting machine. Theplate overturning machine has the advantages of being reliable and stable in performance, high in overturning efficiency, low in labor intensity and capable of achieving multi-machine combination.

Owner:FOSHAN HAOYANG WOODWORK MACHINERY MFR

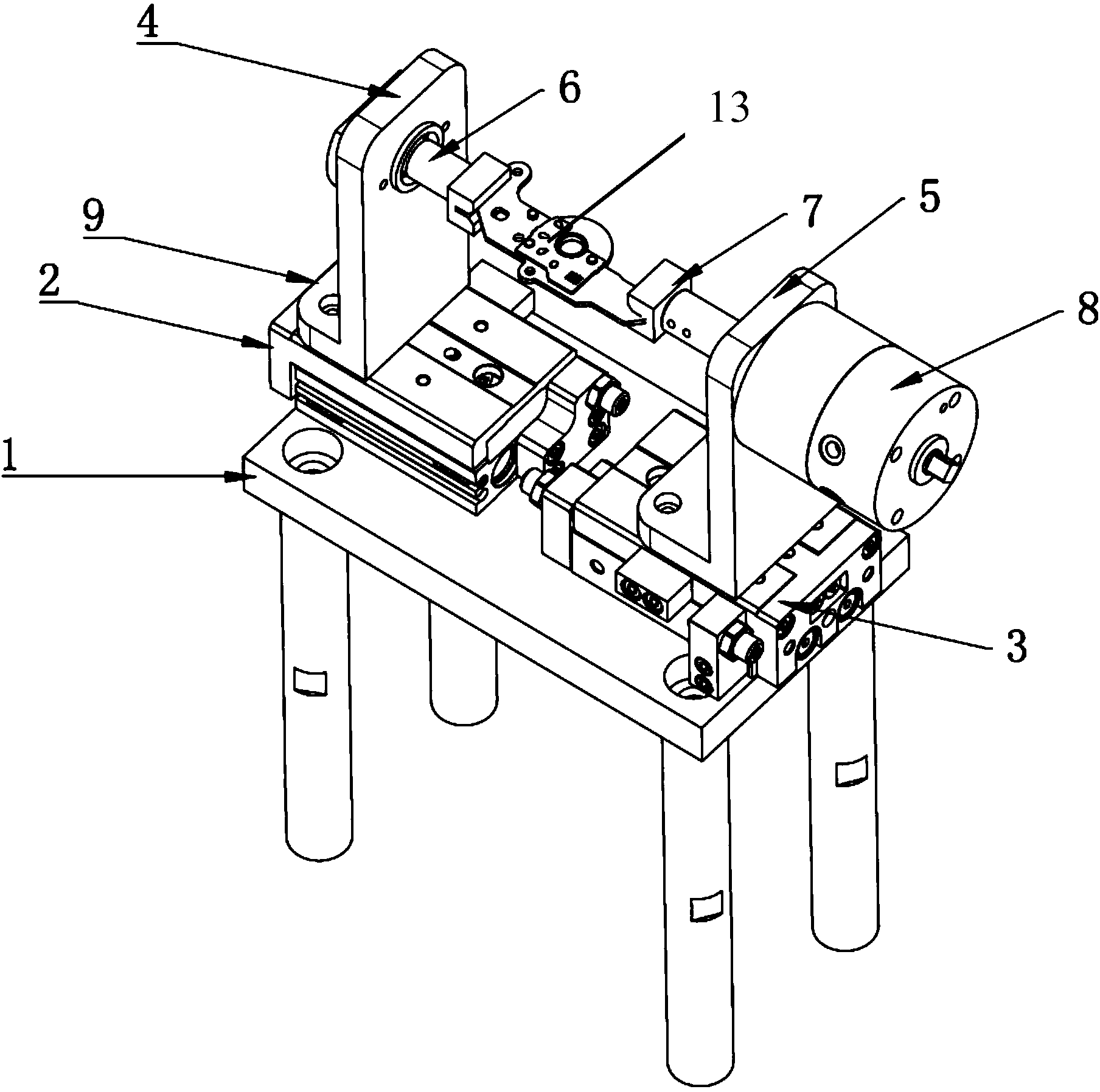

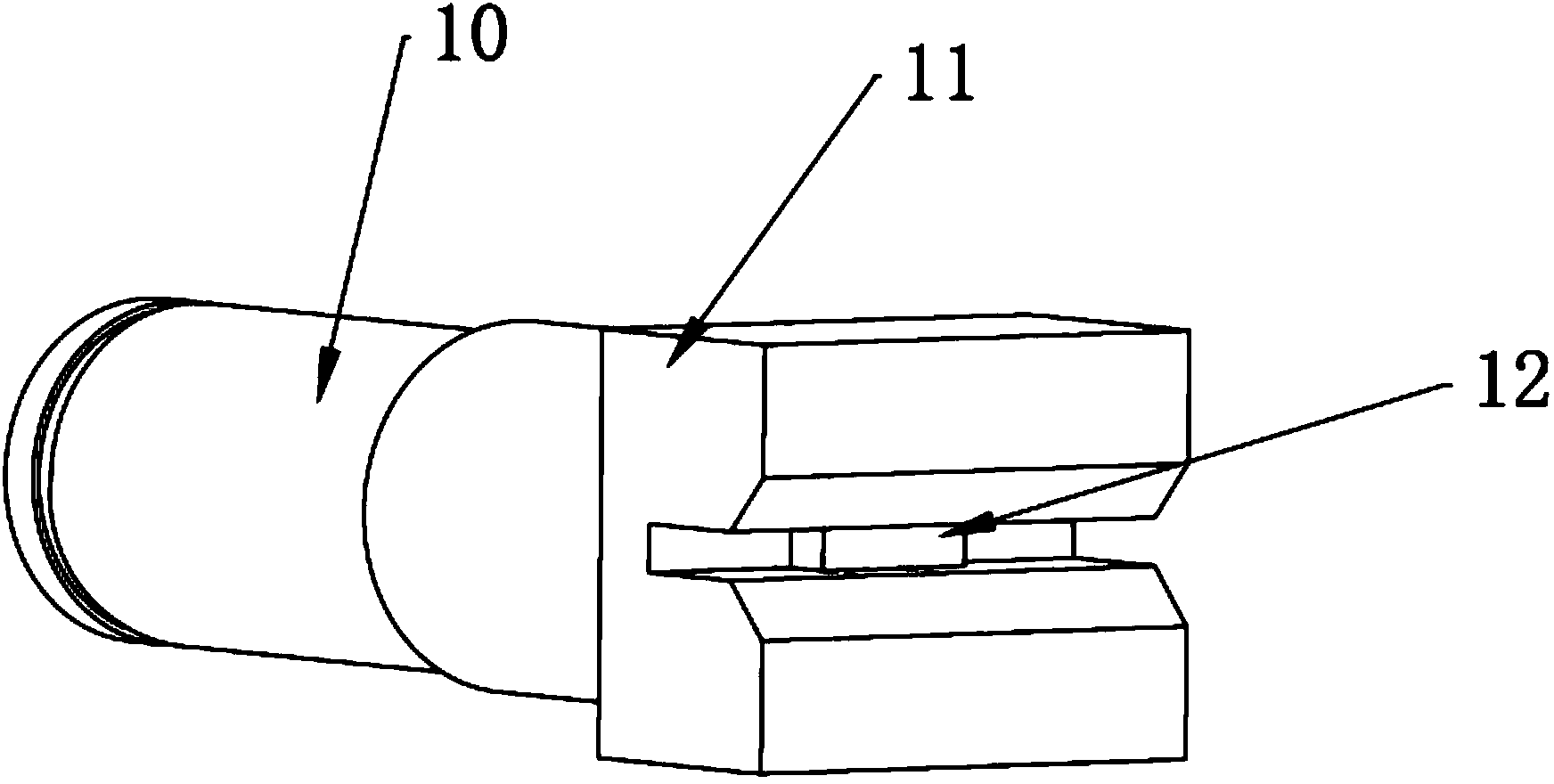

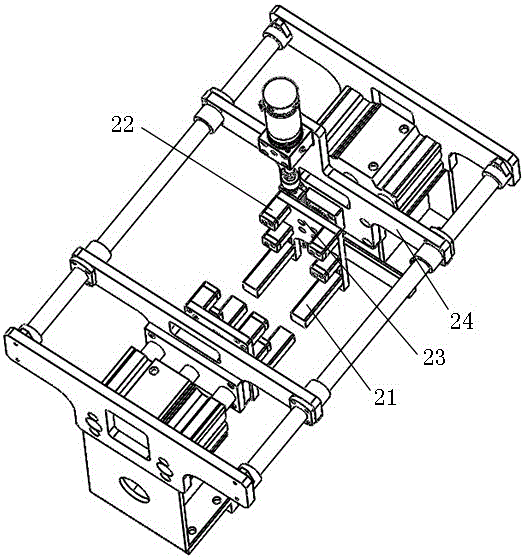

Automatic turnover mechanism

InactiveCN103707120AChange center of gravityHigh precisionMetal working apparatusRotary conveyorsEngineeringSupport plane

The invention discloses an automatic turnover mechanism. The automatic turnover mechanism comprises a base, an ejecting device and a device for clamping workpieces to be machined. The ejecting device is composed of a left ejecting block and a right ejecting block, wherein the left ejecting block and the right ejecting block can horizontally move. Supporting frames are fixed to the left ejecting block and the right ejecting block respectively, and shaft sleeve holes are formed in the supporting frames. The device for clamping the workpieces to be machined comprises a left clamping shaft and a right clamping shaft, one end of the left clamping shaft penetrates through the shaft sleeve hole in the corresponding supporting frame and can horizontally move along with the supporting frame, one end of the right clamping shaft penetrates through the shaft sleeve hole in the corresponding supporting frame and then is connected with a rotating air cylinder, and the right clamping shaft can rotate along with the rotating air cylinder and horizontally move along with the corresponding supporting frame. The rotating axis of the device for clamping the workpieces to be machined is fixed creatively, it is guaranteed that the gravity of the workpieces to be machined does not change after the workpieces to be machined are rotated, and therefore machining accuracy is improved. The automatic turnover mechanism can be turned over at any angle, and turnover efficiency is high. The appearance quality of the workpieces to be machined cannot be affected in the turnover process.

Owner:SANKYO PRECISION HUIZHOU

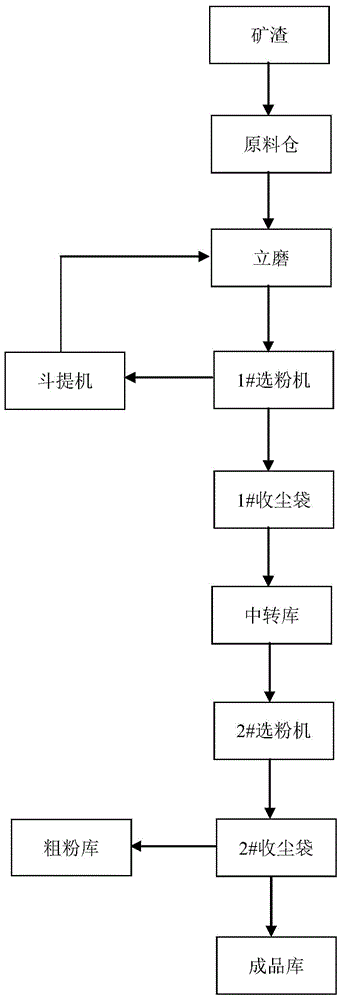

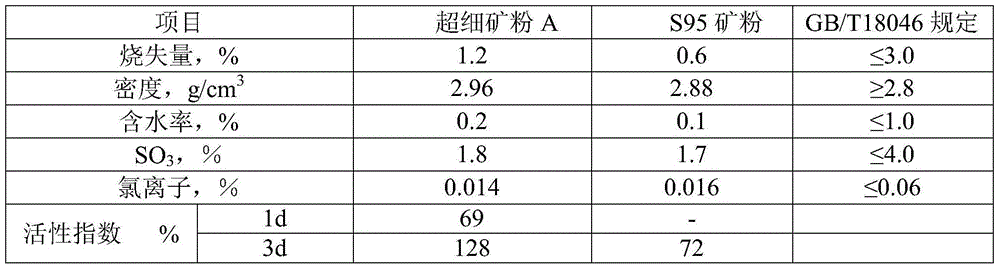

Ultrafine slag powder, and preparation method and application thereof

InactiveCN104478269AImprove finenessHigh activitySolid waste managementSlagUltimate tensile strength

The invention belongs to the field of comprehensive utilization of solid waste resource, and especially relates to an ultrafine slag powder, and a preparation method and application thereof. Vertical-milling grinding and two stages of sorting technologies are combined, a slag pre-grinded material subjected to vertical milling is subjected to a first stage of grading processing, so that a mineral powder with the specific surface area according with a requirement is sorted out, and unqualified slag crude powder falls into a vertical mill for grinding. The slag powder according with the requirement is subjected to a second stage of grading processing, so that a slag powder with the particle size of 20 mu m or less is sorted out, overly grinding phenomenon is avoided, and energy consumption and cost are reduced. The prepared slag powder has relatively high activity, can be applied to concrete as a mineral doping material, is capable of reducing the cost of concrete and concrete products, increasing the strength of concrete and improving the endurance of concrete, and also is applicable to production of pipe sheets and pipe piles. After the concrete is doped with the ultrafine slag powder, the doping amount of a cementing material can be properly reduced, and thus the purpose of saving energy and reducing cost and improving effect are realized.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

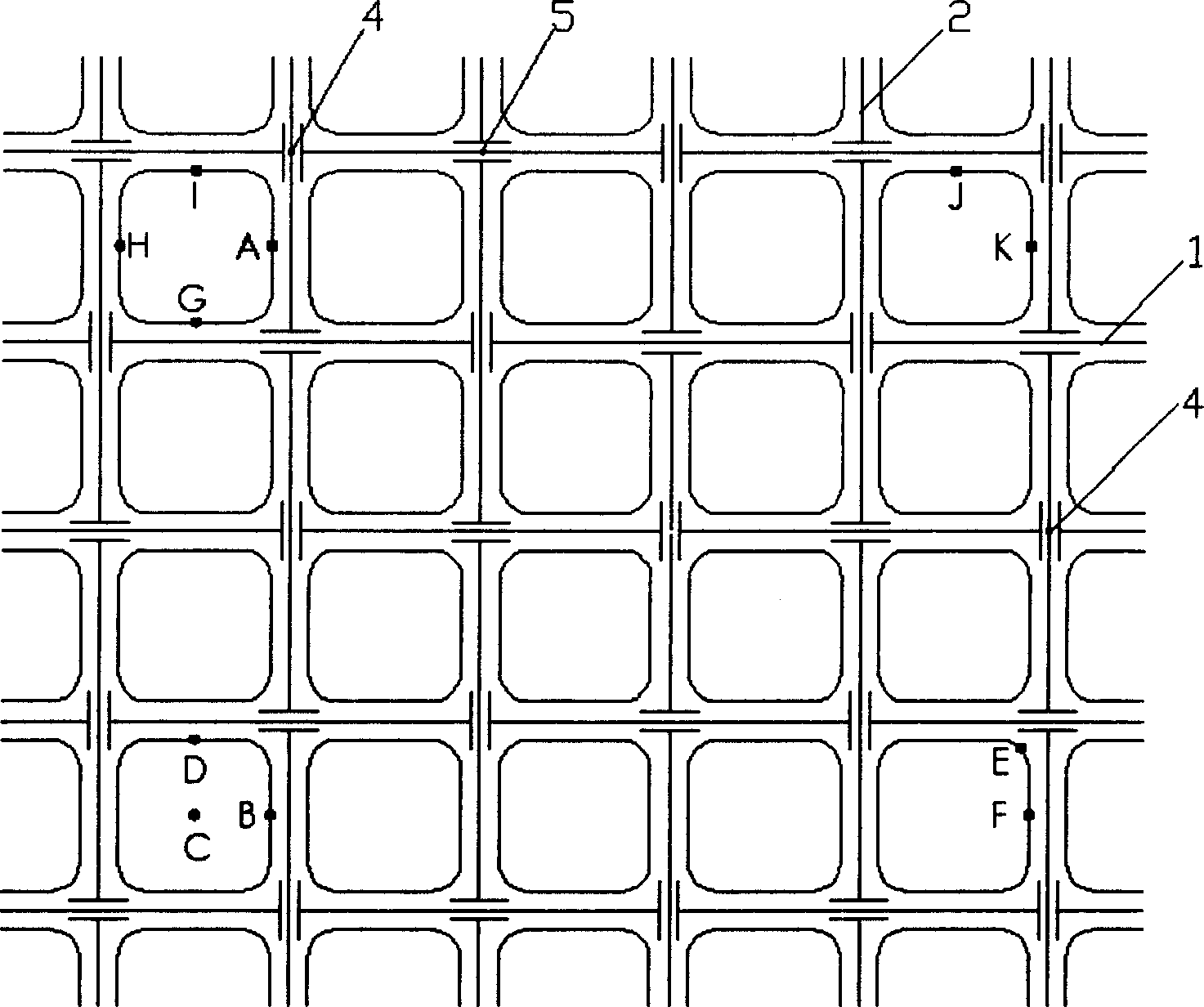

Channel type automatic cigarette-sorting and -storing method and apparatus thereof

InactiveCN1843869AImprove flow and efficiencyReduce errorsStorage devicesAutomatic controlTraffic volume

The invention discloses a channel-type tobacco automatic classify storage method and relative device, which comprises: several layers and several tobacco storage channels (1). The whole process of feeding, storing and discharging are automatically controlled by computer (2). The invention can realize unattended operation of tobacco, to improve efficiency and flux, which replaces the disc unit with tobacco unit as transmission unit, to realize automatic tobacco feeding and selecting. And it can improve the safety of storehouse and reduce the labor intensity of worker.

Owner:GUIYANG PUTIAN LOGISTICS TECH

Film-coating method for glass fiber yarn cluster

ActiveCN106586060ATransport impactImprove coating efficiencyWrapper folding/bending apparatusWrapping with article rotationGlass fiberYarn

The invention discloses a film-coating method for a glass fiber yarn cluster, and belongs to the technical field of glass fiber production equipment. The invention aims to provide the film-coating method for the glass fiber yarn cluster, and the coating method is relatively good in coating effect and is high in film-coating efficiency. The film-coating method comprises the following steps: step I: conveying yarn clusters; step II: grabbing the yarn clusters; step III: pressing the yarn clusters; step IV: coating a film, wherein a coating film is pushed to a specific position through a film feeding device, a gas blowing tube of a film cutting mechanism of the film feeding device works to blow the coating film; and the coating is adhered on the yarn cluster in a sticky mode, and the coating film is pressed onto the yarn cluster through a film-pressing thin sheet of the film pressing device; a clamping rotating device drives the yarn cluster to rotate, the coating film is continuously guided out and is coated on the cluster yarn; and the film is cut off through a blade of a film cutting mechanism; step V: pushing a film, wherein the film pressing device moves upwards and the film pressing device works to level the coating film exceeding the upper end surface of the yarn cluster to the upper end surface of the yarn cluster; and step VI: outputting finished products. The film-coating method is a film-coating method suitable for coating a layer of film outside the glass fiber yarn cluster.

Owner:福德机器人(成都)有限责任公司

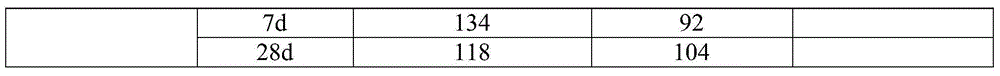

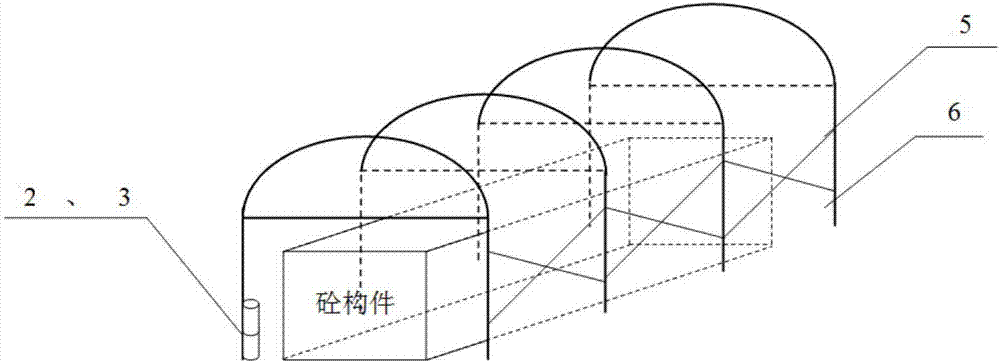

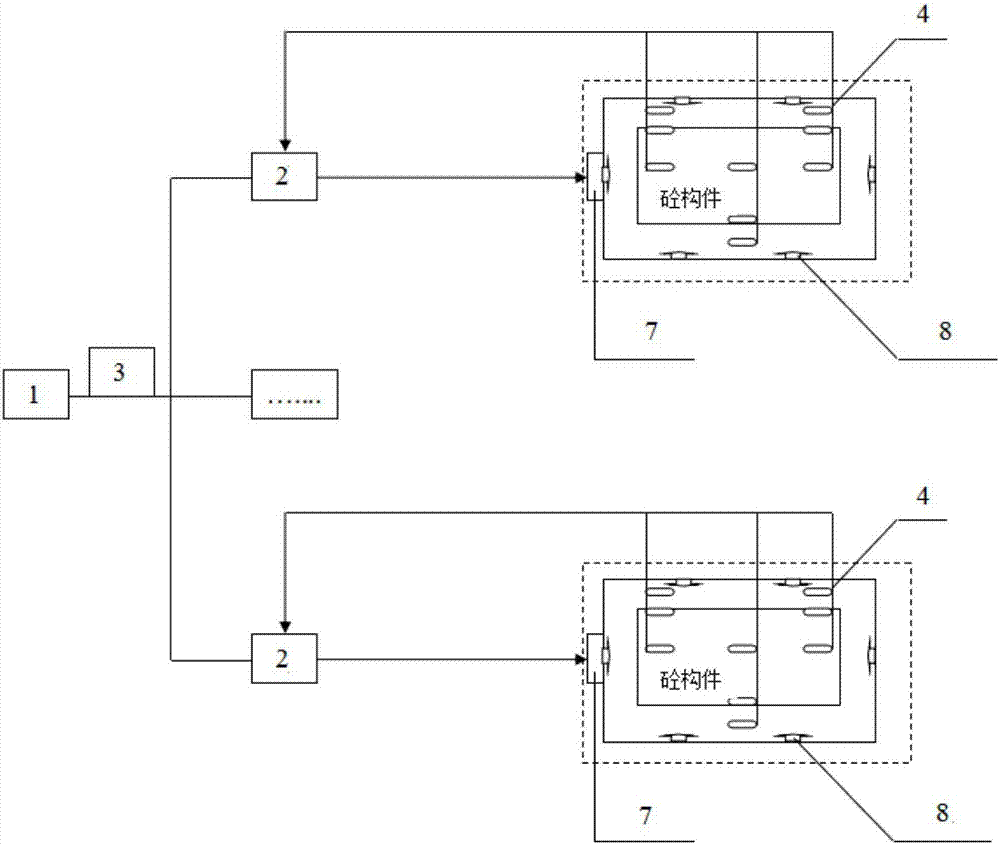

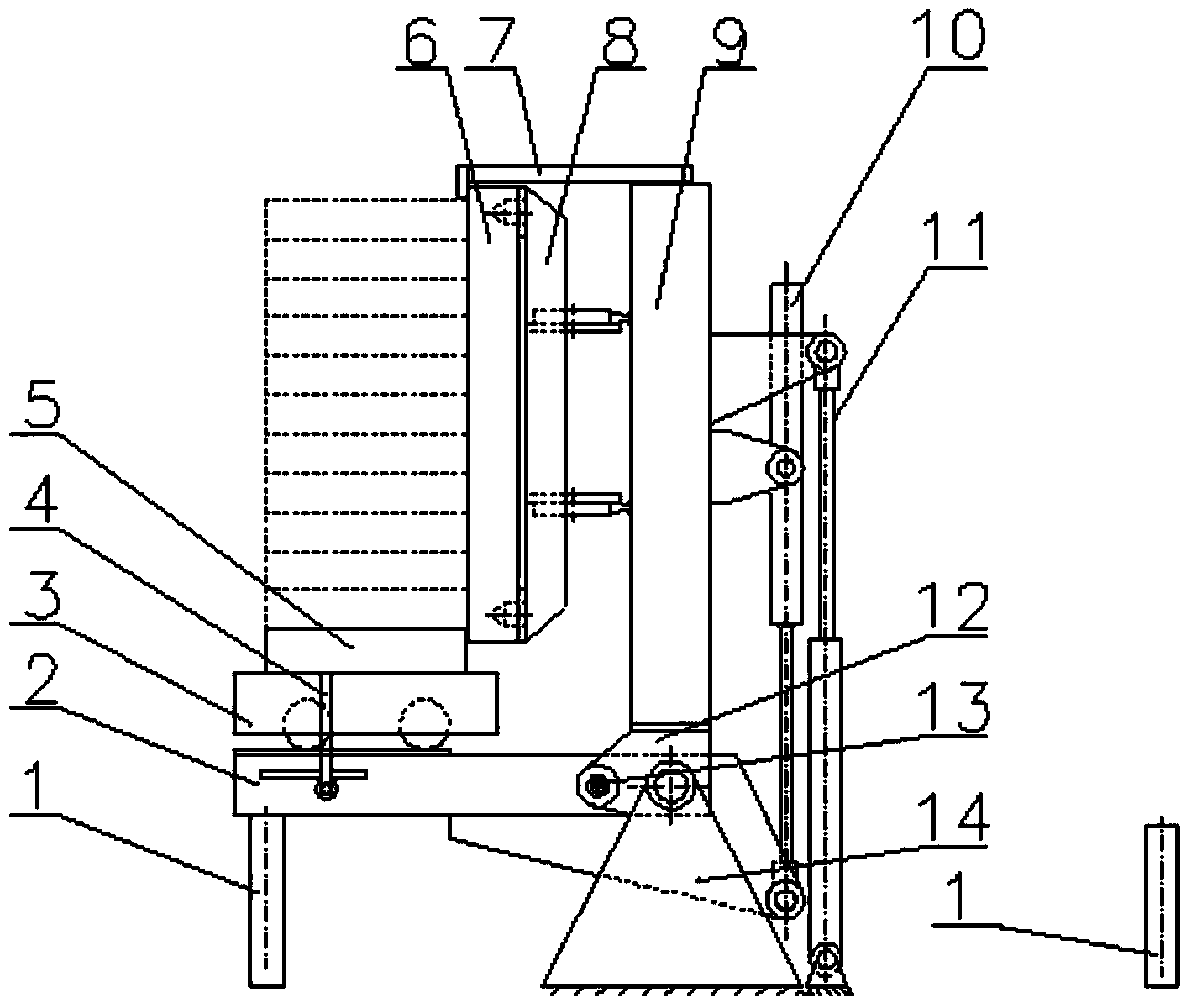

Remote intelligent type maintenance system for prefabricated concrete components

InactiveCN106891429AShorter dismantling timeImprove turnover efficiencyCeramic shaping apparatusTemperature controlSocial benefits

A remote intelligent type maintenance system for prefabricated concrete components comprises an intelligent monitoring system and maintenance system bodies. The intelligent monitoring system comprises a master monitoring device, distributed type data collecting and controlling devices, a wireless data receiving and transmitting device and a plurality of temperature sensors. Each maintenance system body is composed of a telescopic framework, heat preservation canvas, a temperature-control heating and water storing device and a spraying device. The remote intelligent type maintenance system for the prefabricated concrete components can relieve the labor intensity of workers, improve the maintenance efficiency of the prefabricated concrete components, shorten the formwork removal time of the concrete components, effectively lower the risks of cracks and other defects of the prefabricated concrete components and significantly improve the durability of concrete and has great economic and social benefits.

Owner:YUNNAN INST OF BUILDING RES +2

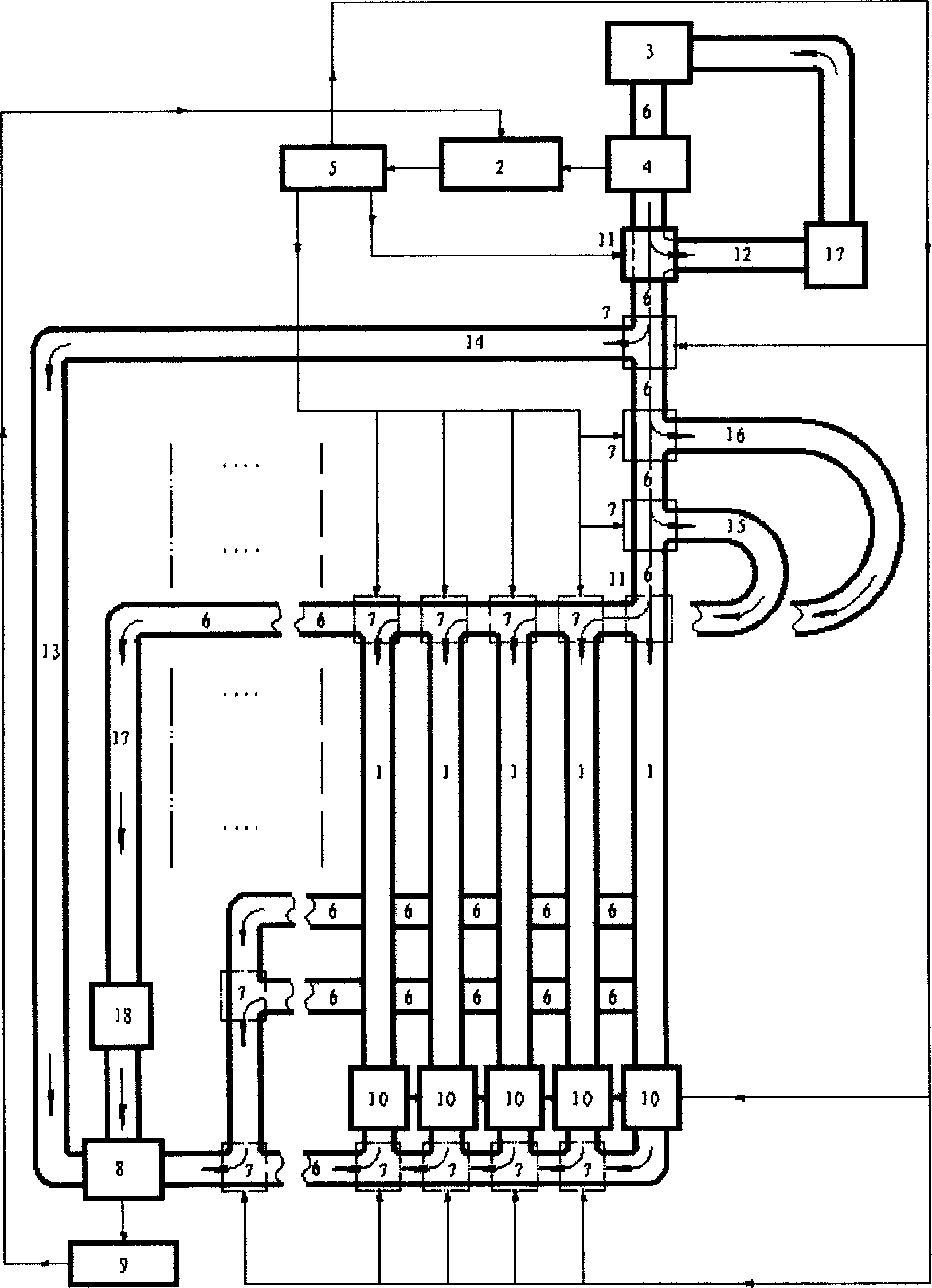

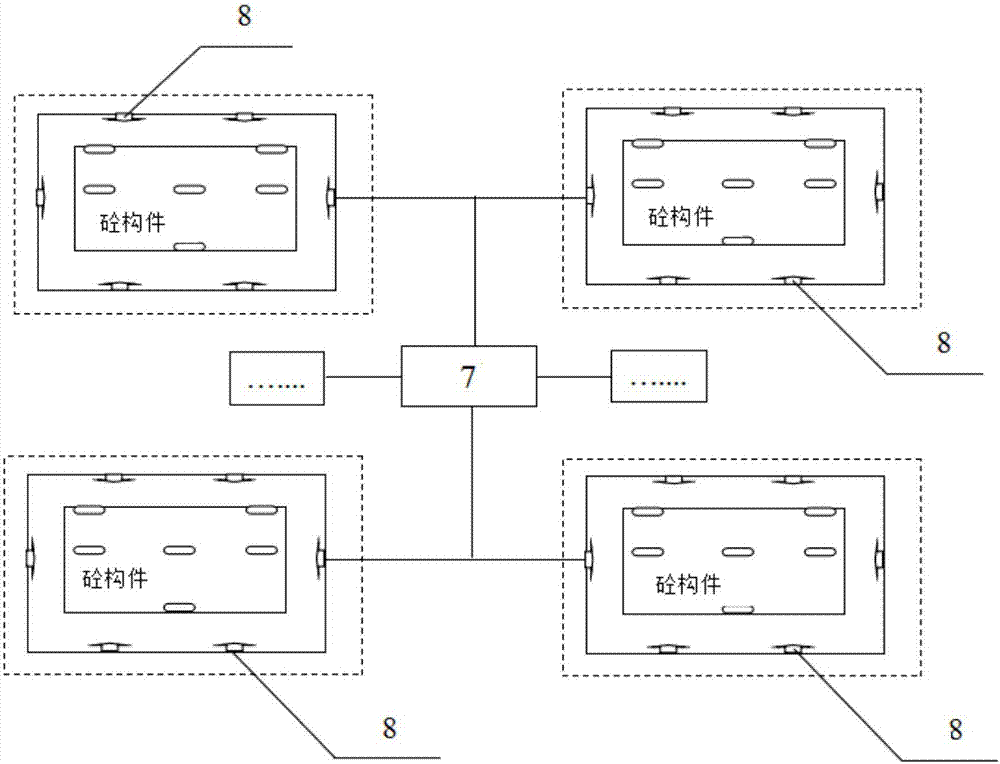

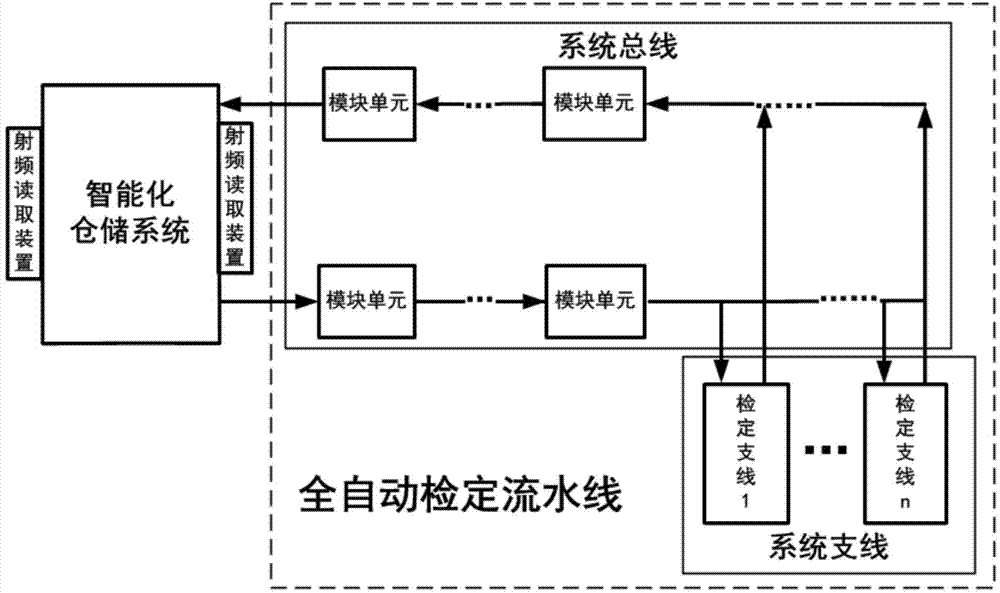

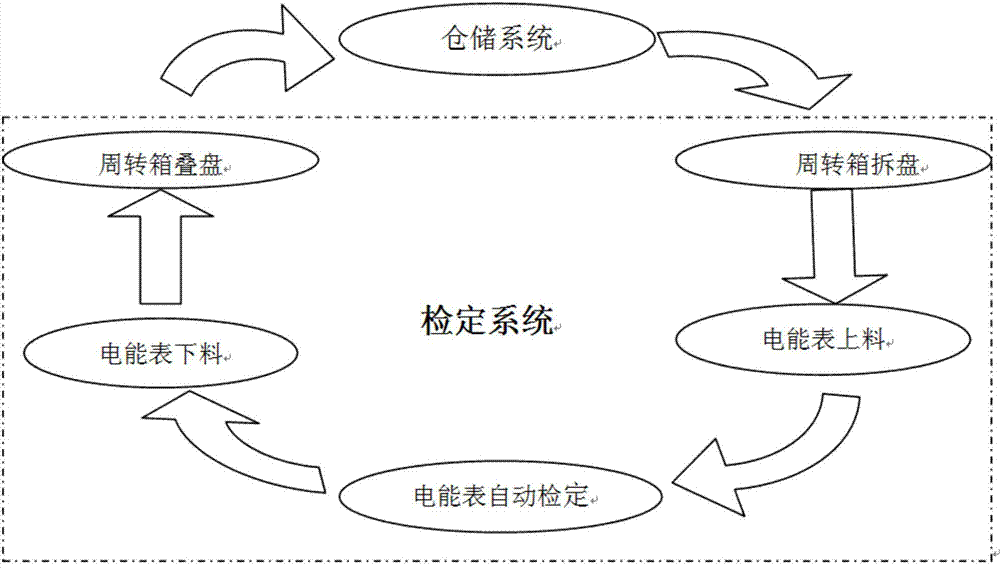

Automated operating device for storage and verification of electric energy meter of electric power system and operating method thereof

ActiveCN103489092AOptimizationImprove management toolsSensing record carriersLogisticsModularityRadio frequency

The invention discloses an automated operating device for storage and verification of an electric energy meter of an electric power system and an operating method thereof. The automated operating device comprises an intelligent warehousing system, an RFID (radio frequency identification) property recognition system and a full-automatic verification assembly line, wherein the intelligent warehousing system comprises a high level three-dimensional good shelf and a physical distribution transport system, the RFID property recognition system comprises a radio frequency chip arranged on the electric energy meter to be verified and a radio frequency read device arranged in the intelligent warehousing system, the full-automatic verification assembly line comprises a system bus and a system branch line, the system bus is combined by modularized units which are connected with each other in series, and the system branch line comprises a plurality of verification branch lines which are connected in parallel. The automated operating device for storage and verification of the electric energy meter of the electric power system and the operating method have the advantages of realizing automated storage and verification of the newly purchased electric energy meter from the process of warehousing and verification to the process of delivery, and improving intelligent management level in metering storage and verifying production.

Owner:STATE GRID CORP OF CHINA +1

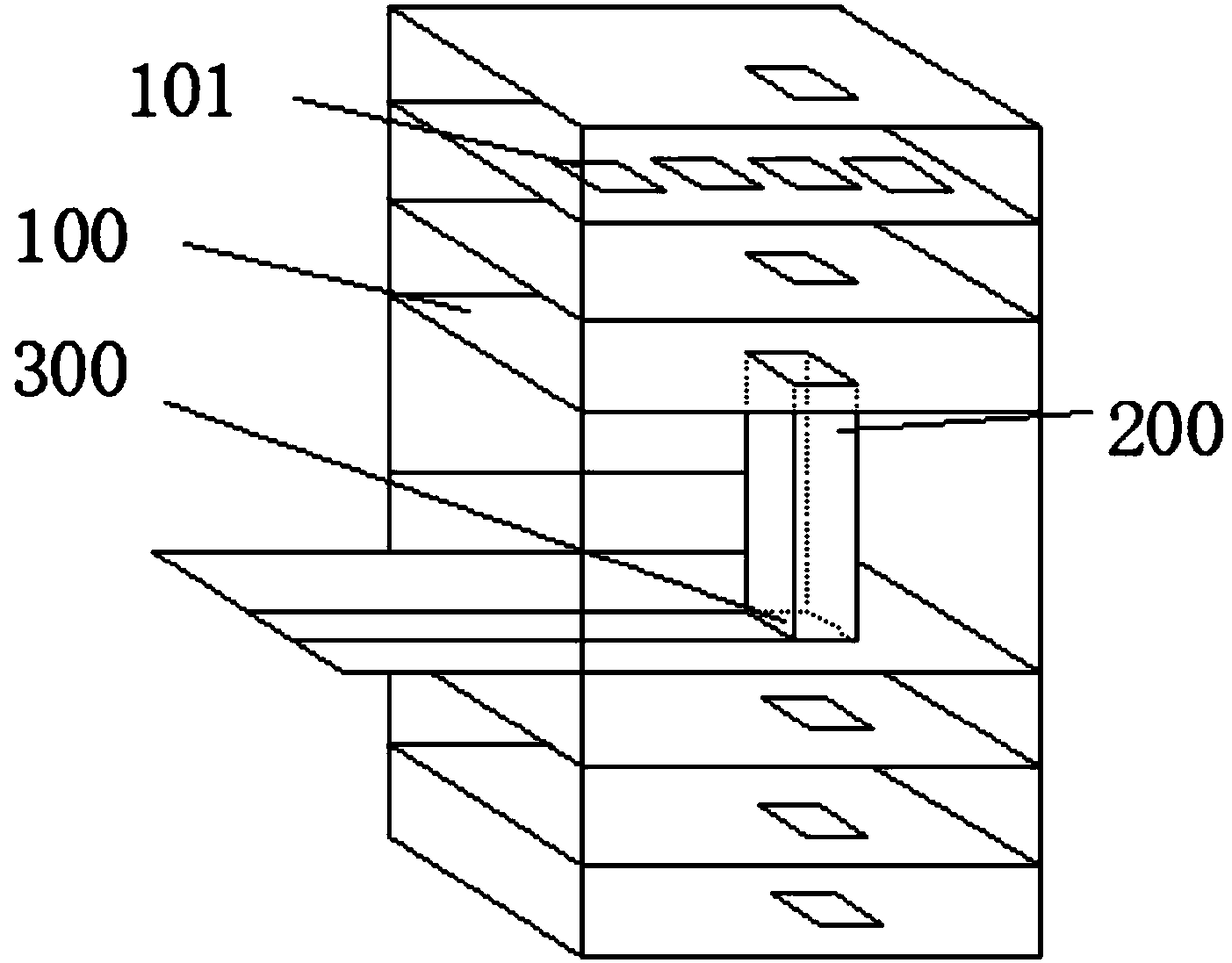

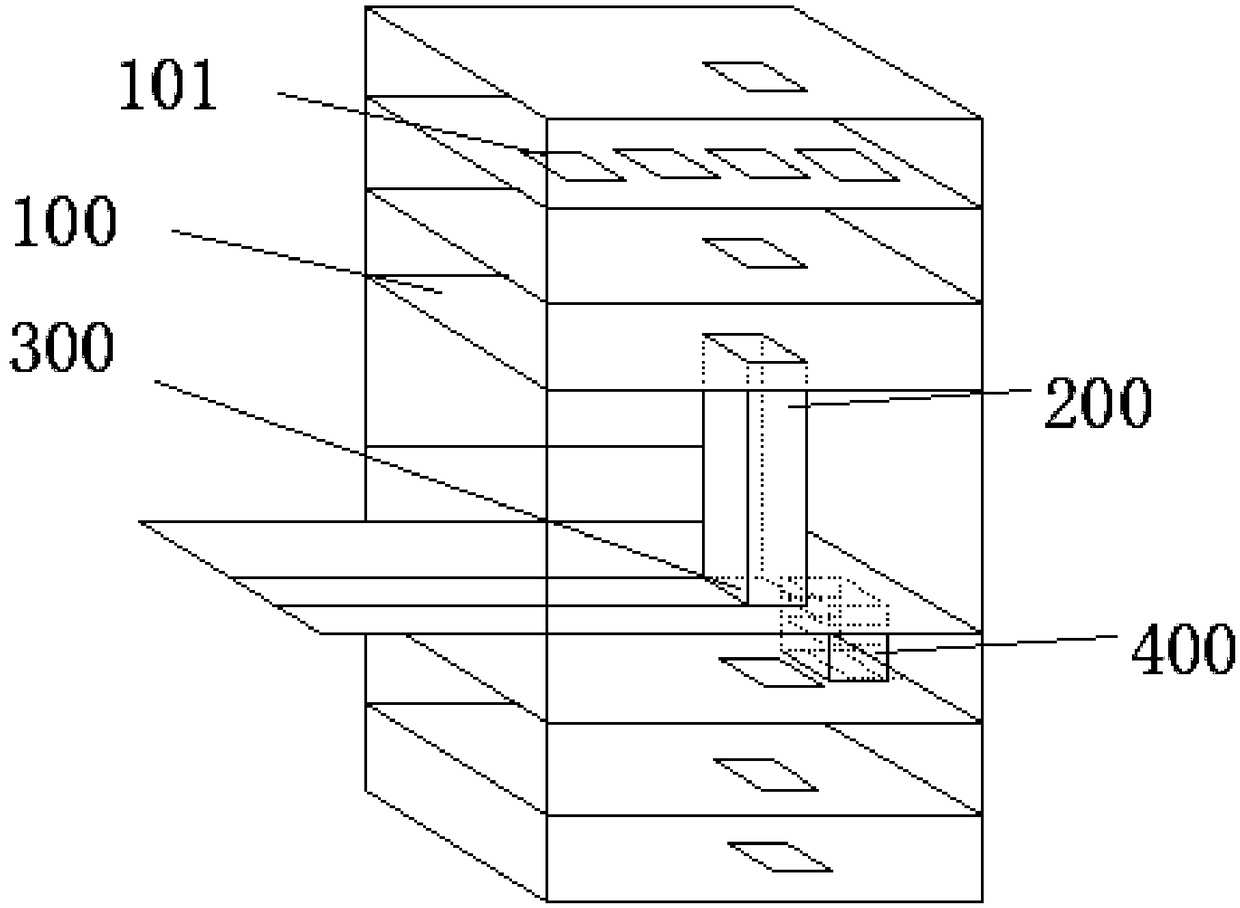

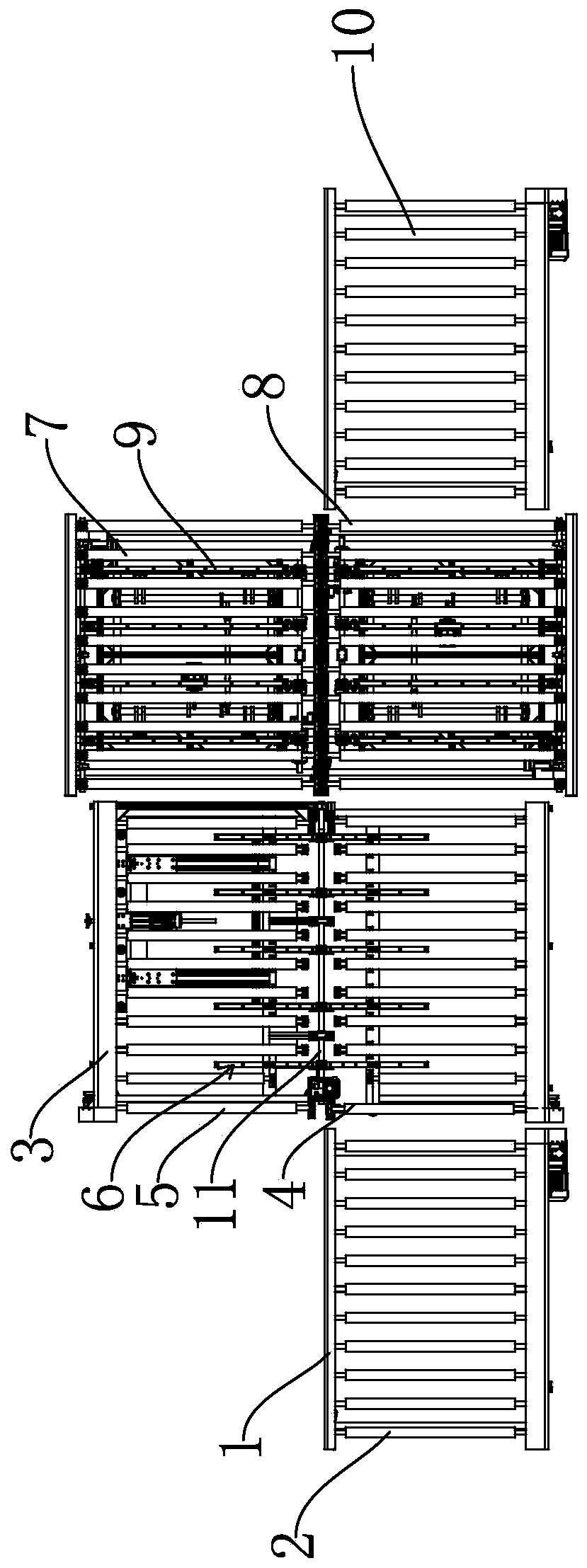

Three-dimensional logistics storage turnover system

PendingCN109110363AImprove space utilizationImprove turnover efficiencyStorage devicesHigh turnoverLogistics management

The invention discloses a three-dimensional logistics storage turnover system and belongs to the technical field of storage equipment. The system comprises one or more storage layers, an elevator, a driving system and a doorway; each storage layer is provided with one or more berths; the elevator penetrates through the one or more storage layers and moves up and down among the one or more storagelayers; the driving system is used for driving cargoes to move from the elevator to the one or more berths and move from the one or more berths into the elevator and is used for driving the cargoes tobe moved among the berths; and the doorway communicates with the elevator and is used for storing the cargoes when depositing and taking out the cargoes. The system adopts the three-dimensional design, the space is utilized sufficiently, the cargoes are stored and taken automatically, and the system has the higher turnover efficiency.

Owner:青岛华通石川岛停车装备有限责任公司

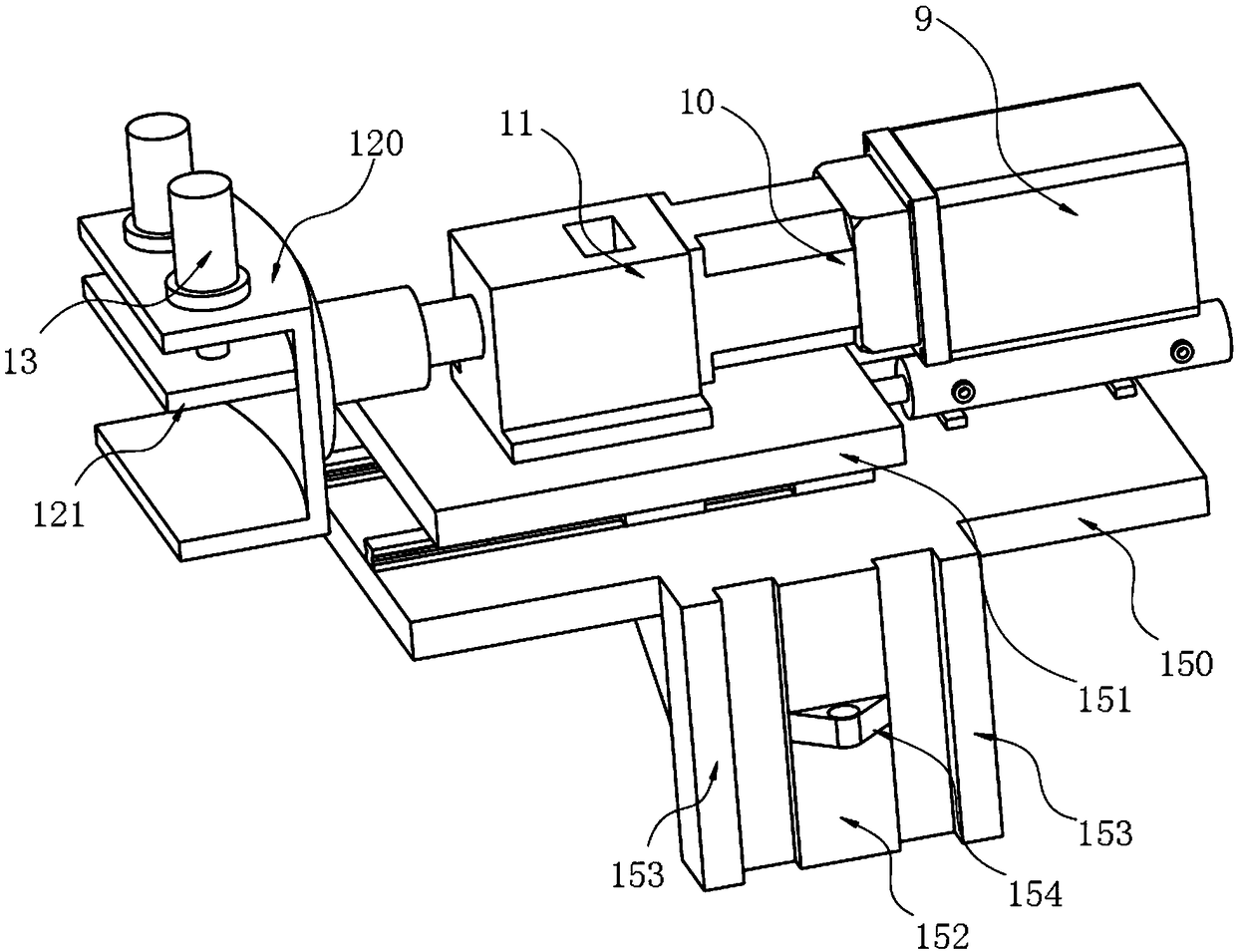

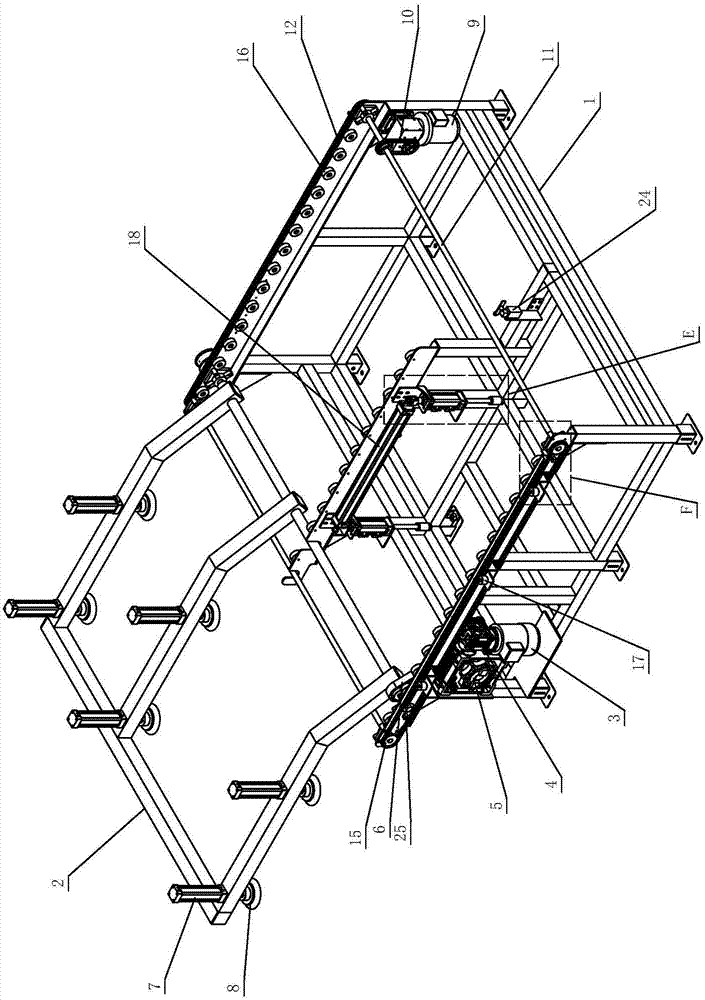

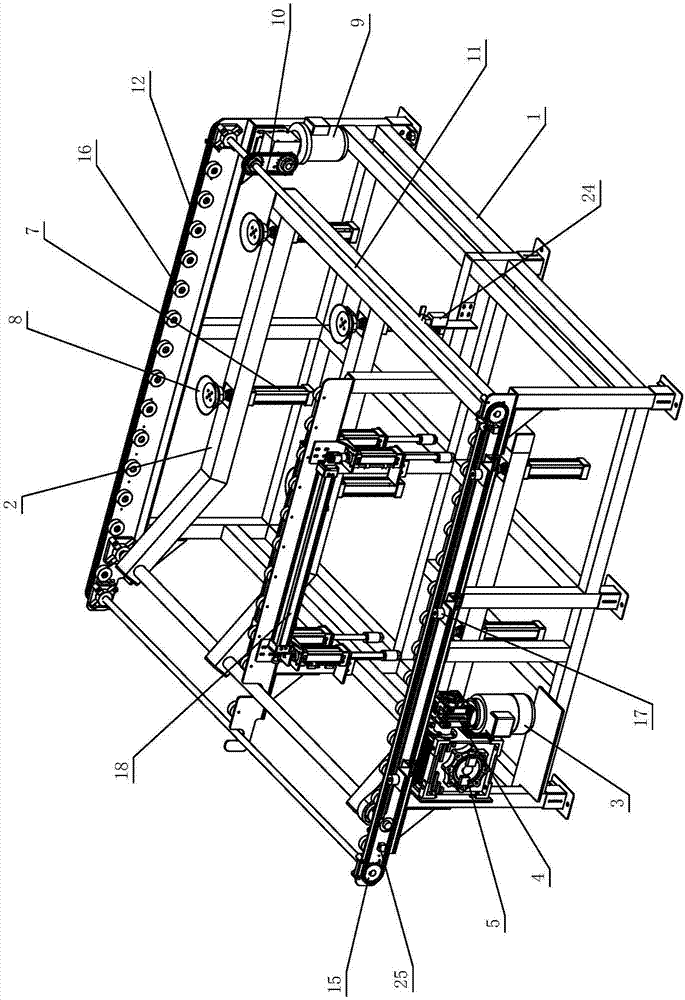

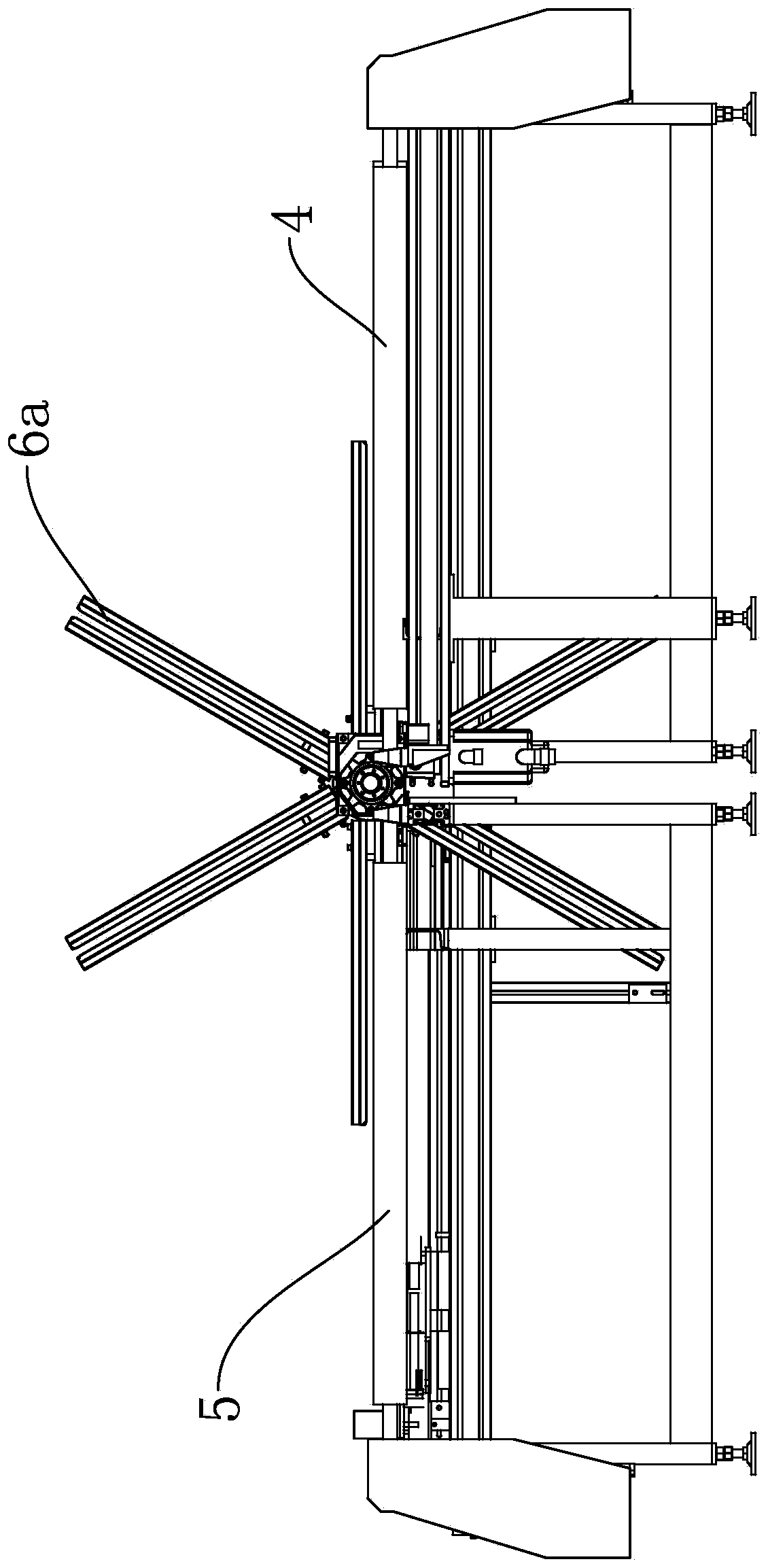

Automatic reversing, butting and assembling device for profile steel

PendingCN110497141AConducive to the realization of welding continuous productionRealize welding continuous productionWelding/cutting auxillary devicesAuxillary welding devicesAssembly lineEngineering

The invention discloses an automatic reversing, butting and assembling device for profile steel. The automatic reversing, butting and assembling device comprises a profile steel reversing rack and a wing plate feeding device which is arranged at one side of a welding assembly line; a profile steel reversing strut is vertically and rotationally installed on the profile steel reversing rack; the profile steel reversing strut is provided with a profile steel avoiding through opening and a profile butting passage, wherein the profile steel butting passage is positioned between the top of the profile steel avoiding through opening and the outer circumferential surface of the profile steel reversing strut; the profile steel reversing strut comprises a standby feed station, a wing plate butting station and a butting output station; a rotary supporting device and a replacement driving device are arranged between the profile steel reversing strut and the profile steel reversing rack; the part,positioned at the profile steel avoiding through opening, of the profile steel reversing strut is provided with a T-shaped steel feeding and butting device; and the profile steel butting passage is provided with a wing plate receiving and butting device. The automatic reversing, butting and assembling device disclosed by the invention can implement on-line quick reversion work, can implement automatic butting with another wing plate in a reversion process, and is beneficial for realizing continuous production of welding of the profile steel, high in reversion efficiency and high in safety.

Owner:ZHIMAIDE CO LTD

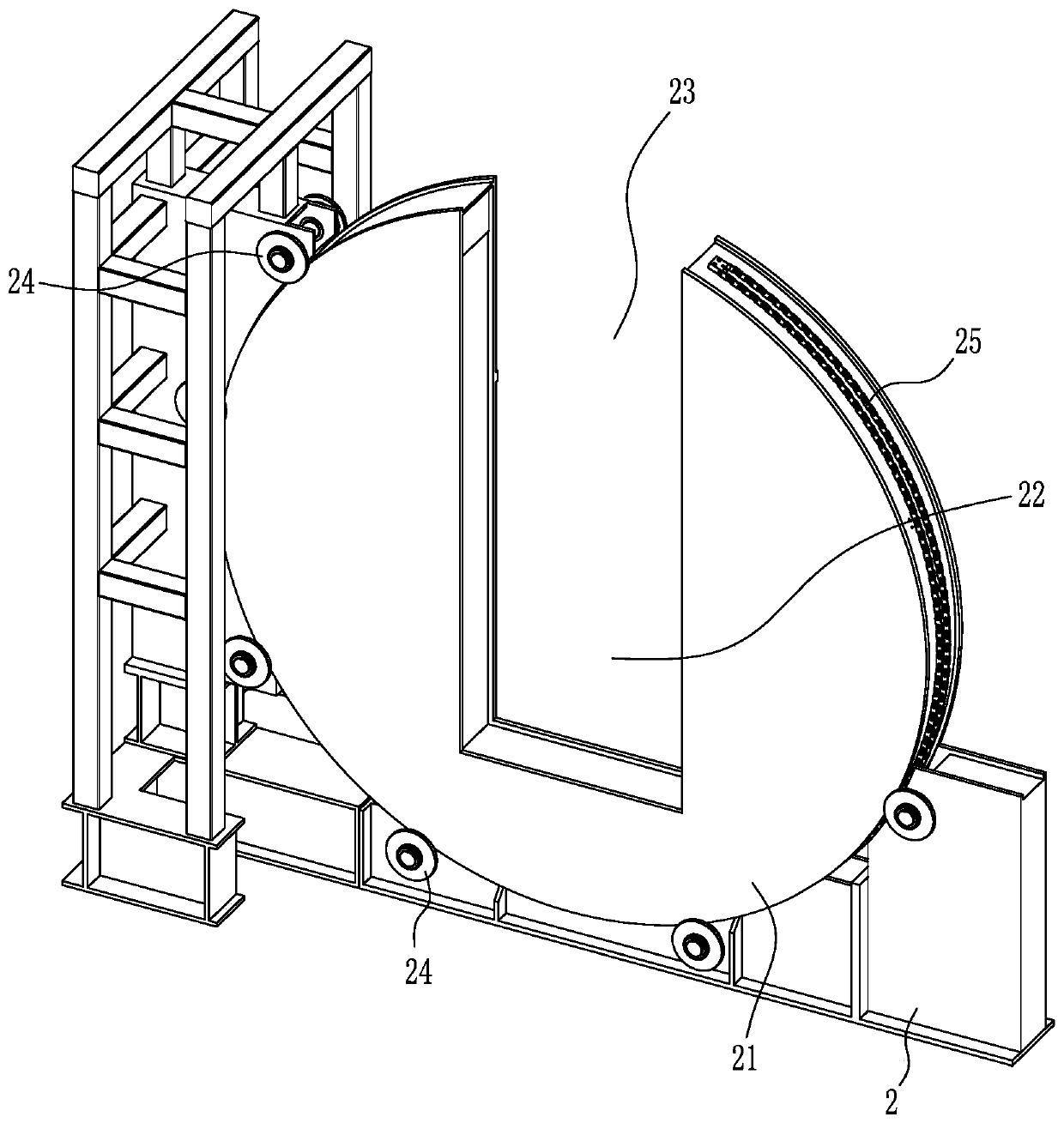

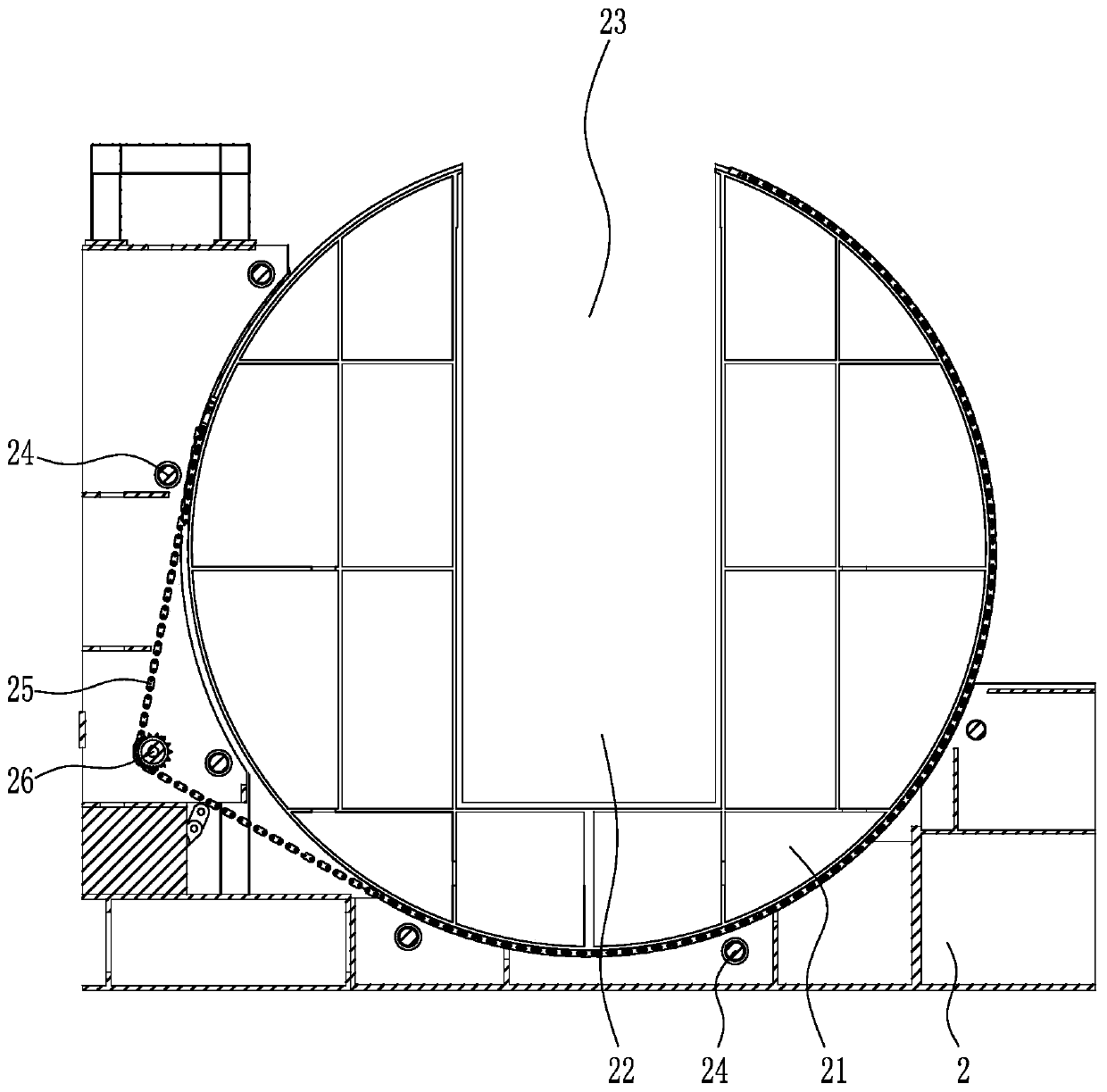

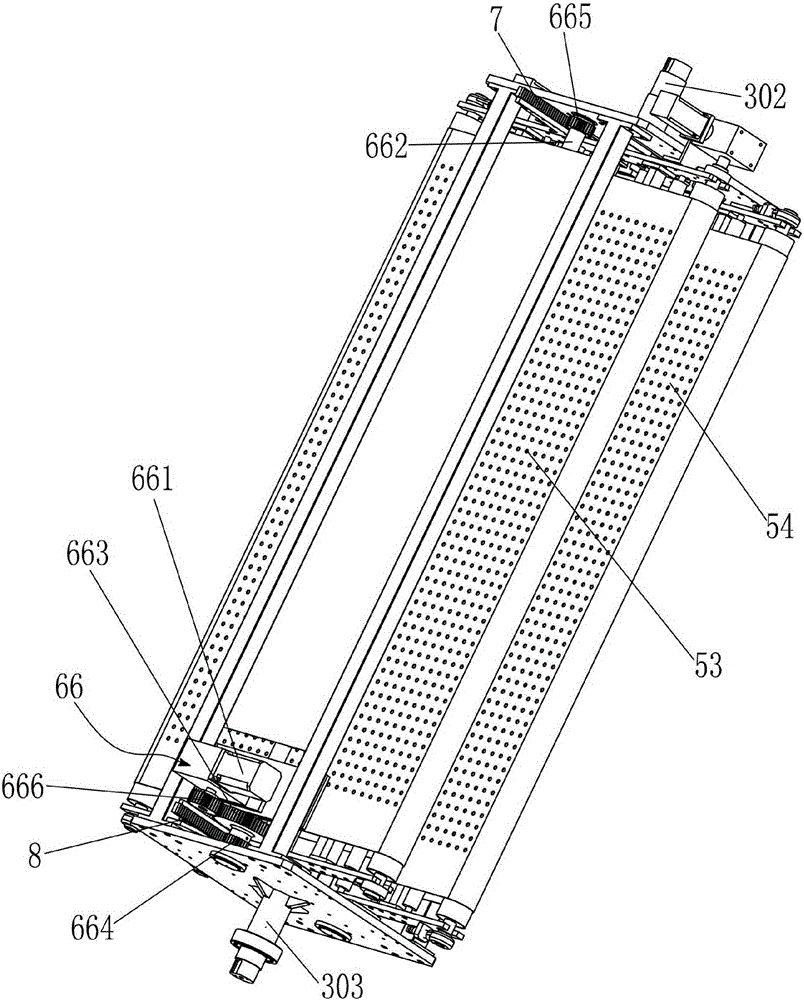

Automatic structural steel overturning device

PendingCN110449818ARealize welding continuous productionImprove turnover efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyMaterials science

The invention discloses an automatic structural steel overturning device. The device comprises a structural steel overturning machine frame which is welded at a welding streamline portion, wherein thestructural steel overturning machine frame is rotatably provided with a structural steel overturning support seat in the vertical direction; the structural steel overturning support seat is providedwith a structural steel clearance passing port, a port top and a structural steel butting channel, wherein the port top is arranged at the structural steel clearance passing port, and the structural steel butting channel is arranged between the outer circumferential surfaces of the structural steel overturning support seat; the structural steel overturning support seat comprises a standby receiving station, a wing plate butting station and a butting output station, wherein a rotating support device and a transposition driving device are arranged between the structural steel overturning supportseat and the structural steel overturning machine frame; and the portion, located at the structural steel clearance passing port, of the structural steel overturning support seat is provided with a T-shaped steel receiving butting device, and the portion located at the structural steel butting channel is provide with a wing plate receiving butting device. According to the automatic structural steel overturning device, on-line quick overturning work can be completed, and during the overturning process, automatic butting with the other wing plate can be facilitated, so that structural steel welding continuous production is achieved, and overturning efficiency as well as safety are high.

Owner:ZHIMAIDE CO LTD

City motor vehicle road system with no conflicting point

InactiveCN1888312AIncrease travel speedFast shippingBallastwayTraffic signalsRoad T junctionCongenital deficiency

The present invention relates to a non-conflicting urban motor-vehicle road system. It is characterized by using ground road as basis, changing all the motor-vehicle road intersections into non-conflicting intersections and remaking the traditional urban-road system composed of high-speed road, main road, secondary road and branch road into a high-speed urban-road system so as to solve the problem of traffic block.

Owner:董国良 +4

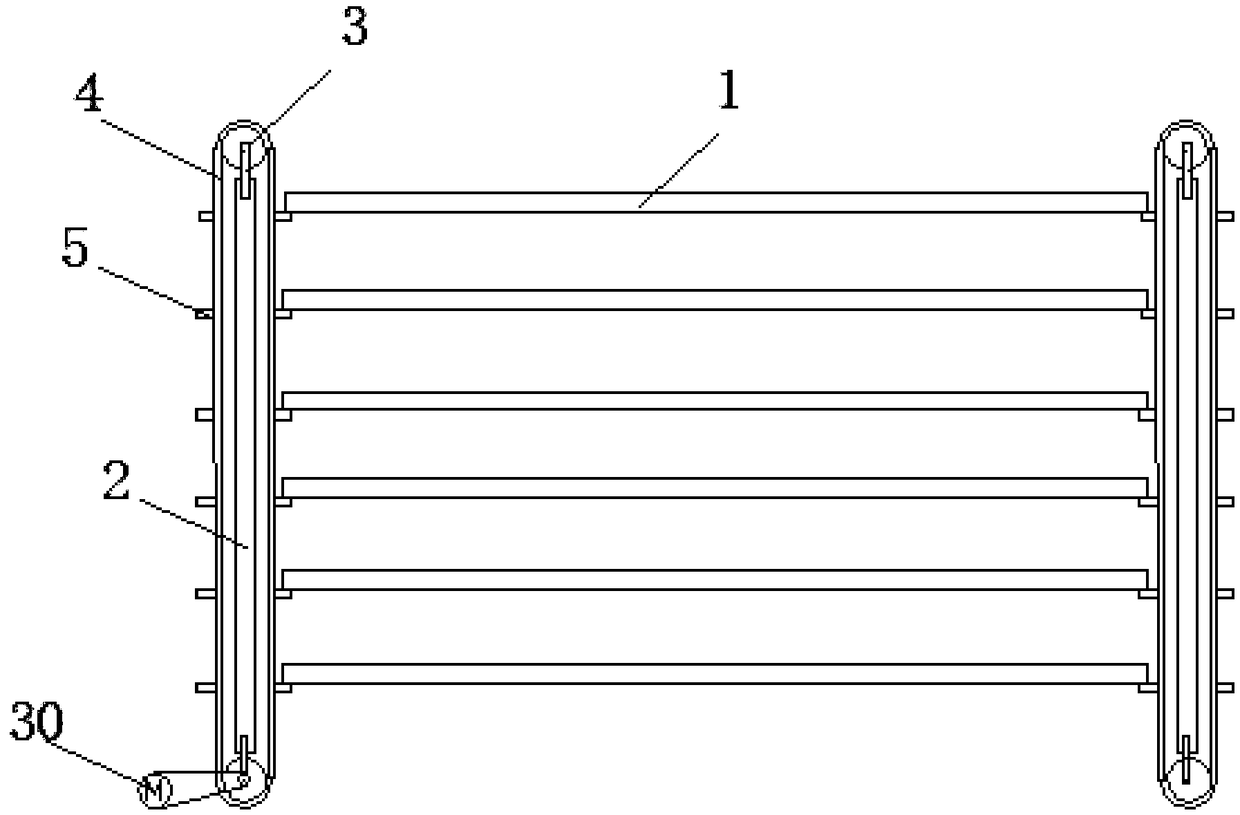

Turnover frame for stacked wooden boards

InactiveCN106271944AImprove turnover efficiencyReasonable structureGrinding feedersGrinding work supportsHydraulic cylinderVertical edge

The invention discloses a turnover frame for stacked wooden boards. The turnover frame comprises C-shaped wheel carriers of two board block bodies movably erected on a base, wherein the arch back surfaces of the C characters of the C-shaped wheel carriers are arc-shaped wheel surfaces; wheel surface gears are arranged on the wheel surfaces; the concave parts of the C characters are square dent type wheel carrier gaps; arc-shaped slot type roller limiting guide rails are arranged on the deviating surfaces of the two C-shaped wheel carriers; guide slots are formed in the vertical edges of the wheel carrier gaps in the deviating surfaces of the two C-shaped wheel carriers; the two C-shaped wheel carriers are spaced from each other in a mirror image manner; the opposite surfaces of the C-shaped wheel carriers are connected through a plurality of connection rods; a movable locking plate is inserted between the two guide slots; the lower edge of the movable locking plate is vertically connected with a movable clamping plate; a hydraulic cylinder is arranged between the movable clamping plate and the connection rods located at the upper edges of the wheel carrier gaps; a motor is connected with the wheel surface gears through a transmission rod and pinions in a transmission manner; the C-shaped wheel carriers are movably connected with the base through the cooperation between cylindrical rollers and roller limiting guide rails. The turnover frame has an optimized structure, is safer and more reliable, and is higher in turnover efficiency.

Owner:福建省宝龙环球装饰材料有限公司

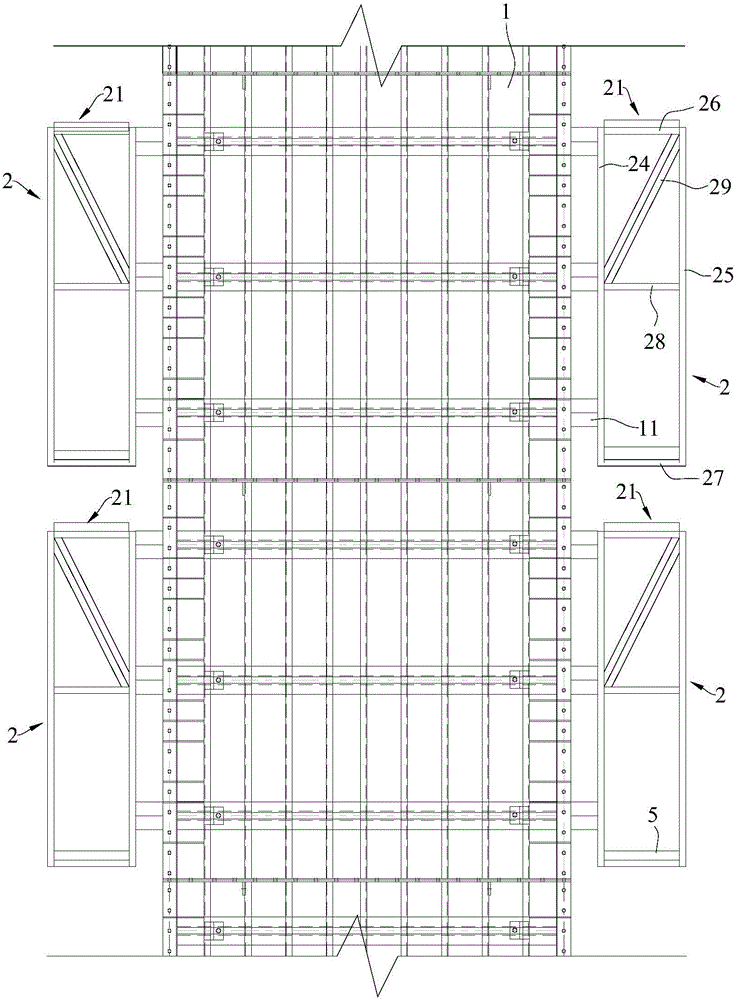

Railway high pier body template and scaffold integrated turnover formwork segmental construction method

InactiveCN105887685AAvoid safety hazardsFast constructionBridge structural detailsBridge erection/assemblyFalseworkRebar

The invention discloses a railway high pier body template and scaffold integrated turnover formwork segmental construction method, which is used for the technical field of bridge construction. The method comprises the following steps: prefabricating pier body templates and a shaping scaffold; erecting a first-layer steel bar bound scaffold; binding first-section pier body steel bars; after setting a guy cable, detaching the first-layer steel bar bound scaffold; hoisting the pier body templates, wherein at least three sections of the pier body templates are arranged from bottom to top; after detaching the guy cable, pouring first-section pier body concrete; after reaching required strength, detaching the pier body templates except the pier body template of the topmost section; hoisting on the pier body template of the topmost section to form a steel bar bound scaffold and binding the pier body steel bars; after setting the guy cable, detaching the steel bar bound scaffold; mounting the first detached pier body templates on the pier body template of the topmost section to form a turnover formwork; detaching the steel bar guy cable, pouring secondary-section pier body concrete; continually carrying out turnover formwork construction on the residual sections of a pier body and finishing pier body construction. The railway high pier body template and scaffold integrated turnover formwork segmental construction method has remarkable characteristics and advantages of convenience for mounting and dismounting, simplicity in operation, safety and reliability and short construction period.

Owner:CHINA RAILWAY PORT & CHANNEL ENG GRP +1

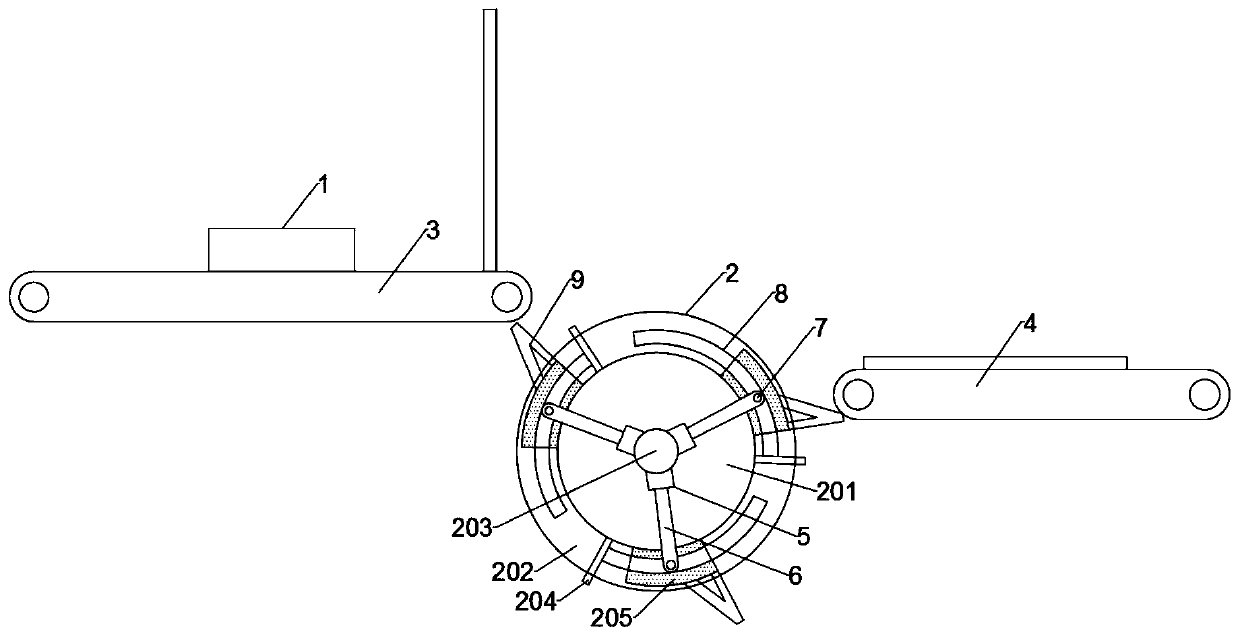

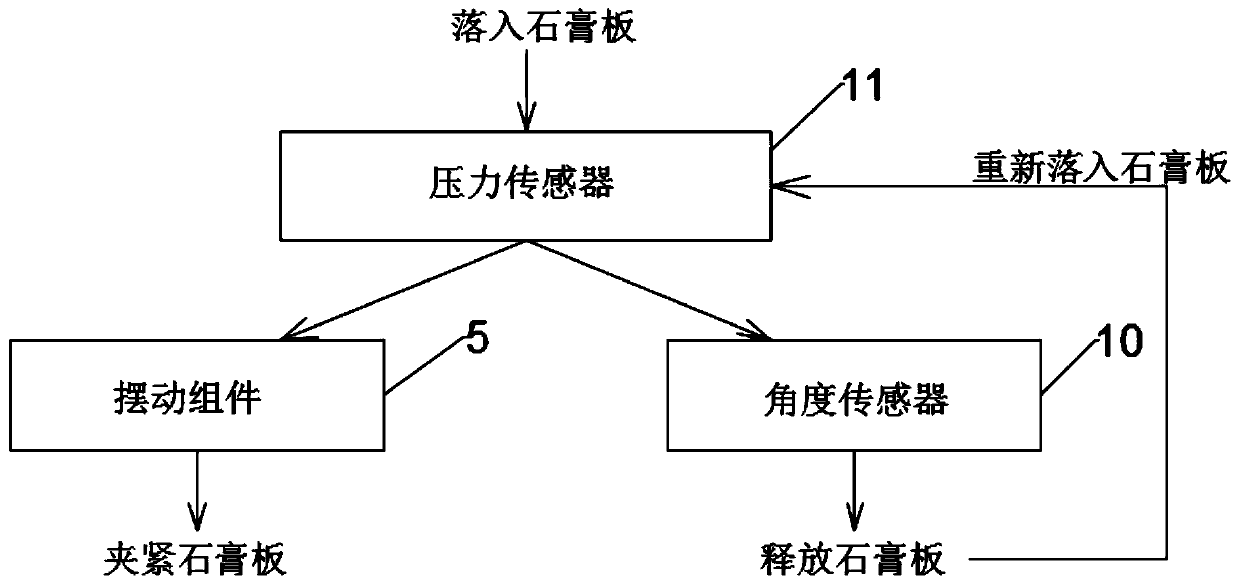

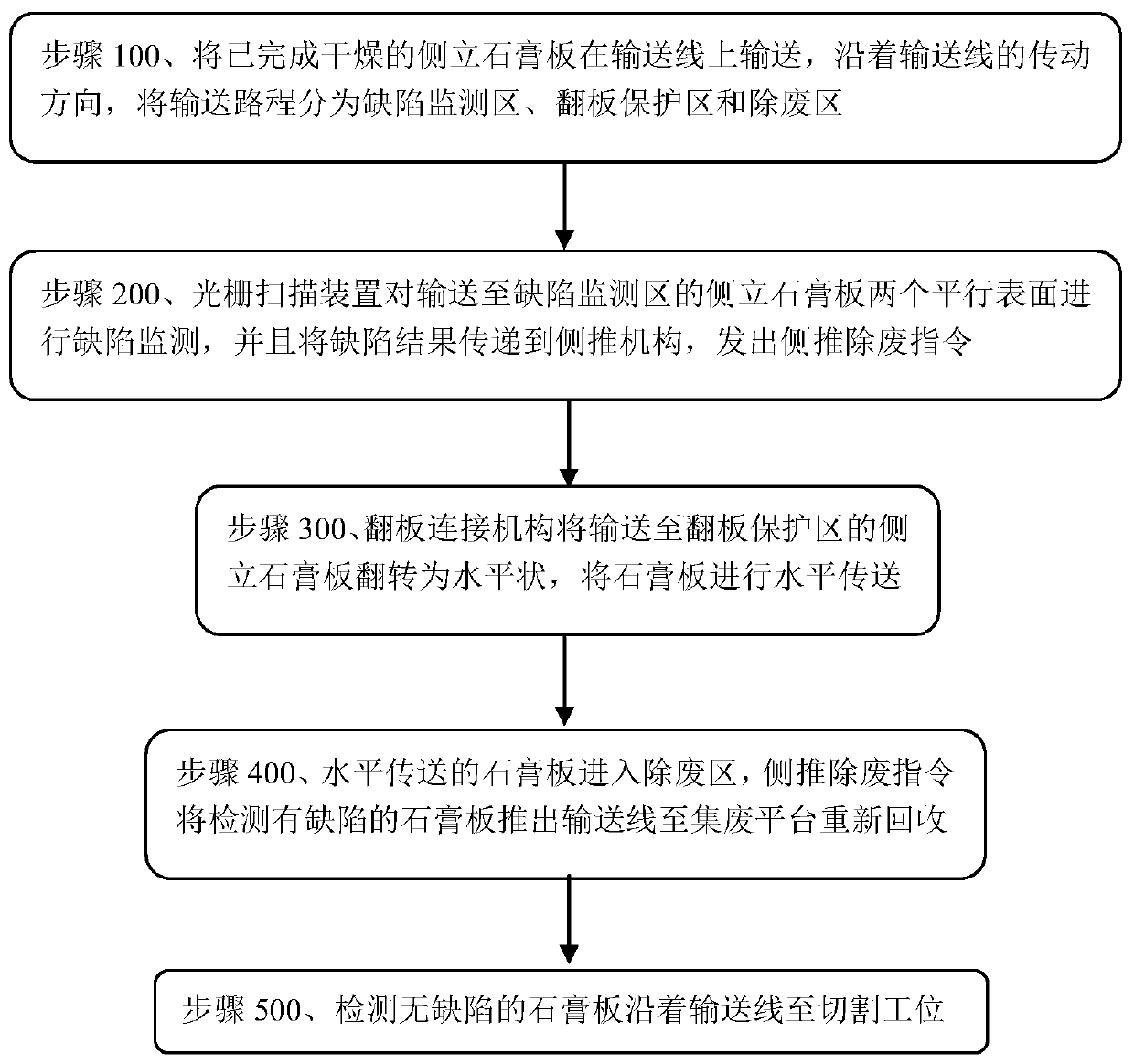

Gypsum board defect automatic monitoring system and monitoring method

ActiveCN110530890AGuaranteed placementConvenient disposal operationMaterial analysis by optical meansSortingGratingMonitoring system

The embodiment of the invention discloses an automatic gypsum board defect monitoring system. The system comprises a conveying line used for conveying a gypsum board output by a drying machine to a next stacking station. A grating scanning device for scanning and identifying the surface of the gypsum board standing laterally is arranged between the drying machine and the stacking station, a boardoverturning and connecting mechanism and a lateral pushing mechanism are sequentially arranged between the grating scanning device and the stacking station, and the lateral pushing mechanism pushes adetected defective gypsum board away from the conveying line to be collected in a centralized mode. A monitoring method comprises a step of dividing a conveying path into a defect monitoring area, a turning board protection area and a waste removal area, a step of performing defect monitoring on two parallel surfaces of the gypsum board standing laterally conveyed to the defect monitoring area, astep of horizontally overturning and converying the gypsum board standing laterally conveyed to the turning board protection area, a step of pushes the detected defective gypsum board away from the conveying line according to a side push waste removal instruction, and a step of conveying a detected gypsum board without defects to the stacking station along the conveying line. According to the scheme, the secondary damage probability of the gypsum board caused by a board overturning mechanism can be effectively reduced.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Glass rotary overturning device

PendingCN110304432AGood effectImprove turnover efficiencyConveyorsControl devices for conveyorsPeripheralRotating disc

The invention provides a glass rotary overturning device, and belongs to the technical field of machinery. The glass rotary overturning device comprises a frame; a feeding mechanism, a rotary overturning mechanism, a steering mechanism and a discharge mechanism are arranged on the frame in sequence; the rotary overturning mechanism comprises an overturning roller table, multiple second conveying rollers and multiple third conveying rollers; the overturning roller table is transversely provided with a rotating shaft; the multiple second conveying rollers are longitudinally arranged on one sideof the rotating shaft in parallel at equal intervals; the multiple third conveying rollers are longitudinally arranged on the other side of the rotating shaft in parallel at equal intervals; the second conveying rollers and the third conveying rollers are symmetrically arranged about the transverse center line of the overturning roller table; and a second driving mechanism capable of driving the second conveying rollers to rotate is arranged on the overturning roller table. A third driving mechanism capable of driving the third conveying rollers to rotate is arranged on the overturning rollertable; the rotating shaft is sleeved with multiple overturning brackets; the overturning brackets comprise rotating discs; and multiple overturning forks are arranged on the outer peripheral surfacesof the rotating discs. The glass rotary overturning device has the advantage of improving the overturning efficiency.

Owner:FLAT GLASS GROUP CO LTD

Overturning mechanism of storage battery

InactiveCN106185261AWide adaptabilityImprove work efficiencyConveyor partsElectrical and Electronics engineeringEngineering

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

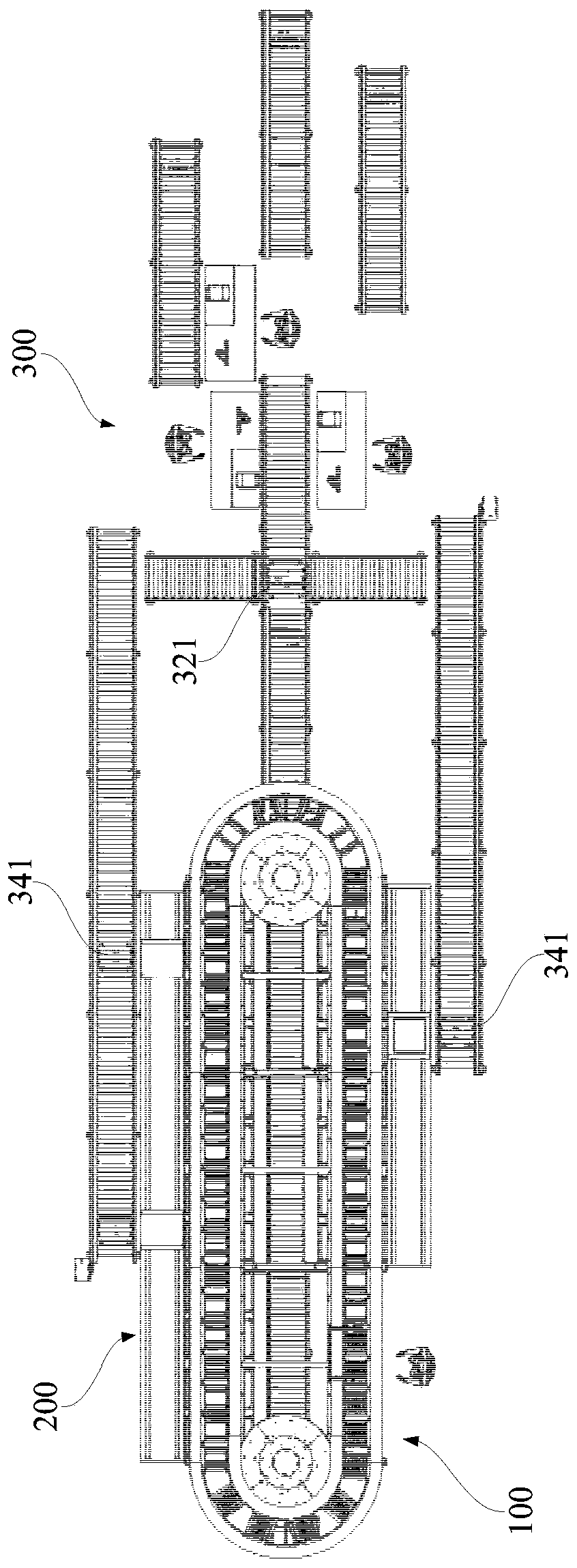

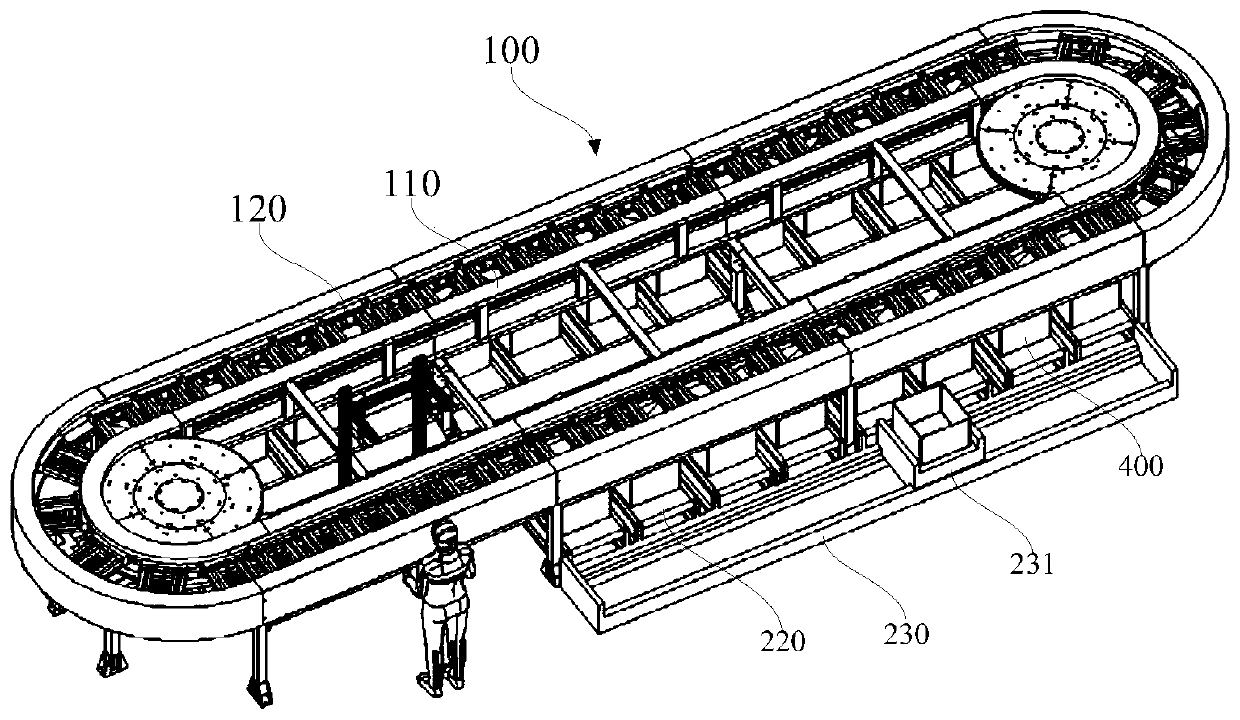

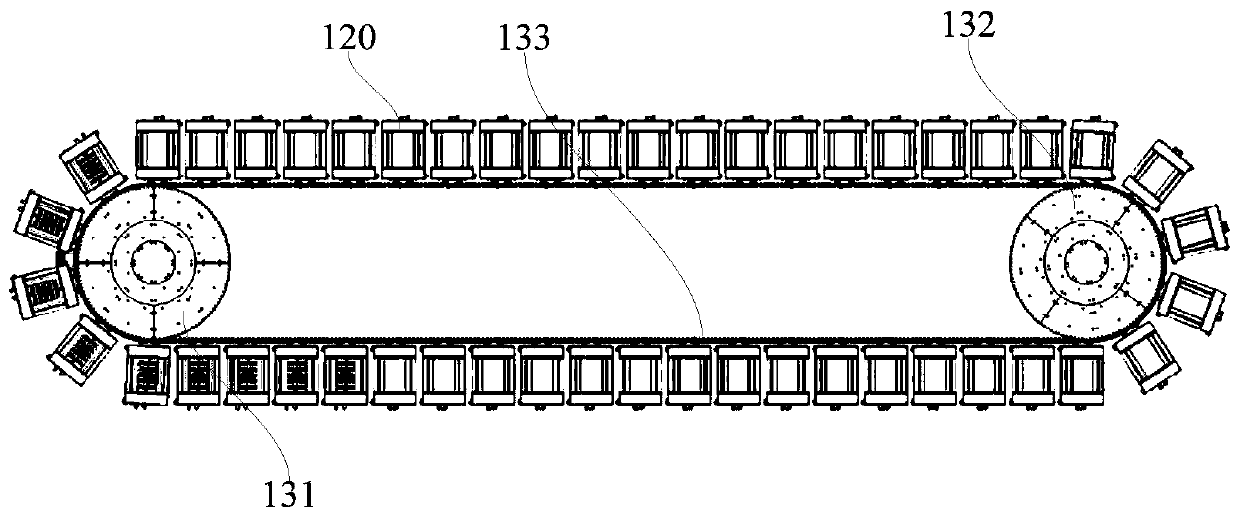

Bag falling type sorting system

PendingCN110090807AConvenient packing workImprove sorting efficiencySortingTransfer systemEngineering

The invention discloses a bag falling type sorting system. The bag falling type sorting system comprises a tray system, a transferring system and a sub-packaging system; the tray system comprises an annular support, a chain transmission mechanism and a plurality of supporting platforms; each supporting platform comprises two openable supporting plates, the first sides of the two supporting platesare connected through a connecting rod mechanism, the second side closing parts of the two supporting plates are lapped on the supporting part of a swinging hook, and the upper end part of the swinging hook is rotationally arranged on a frame of the supporting platforms; the transferring system comprises a goods delivery line, two sides of the goods delivery line are correspondingly provided witha plurality of conveying platforms, and the conveying platforms are provided with a sorting basket for receiving articles falling from the supporting platforms; a transferring platform is arranged onthe outer side of the conveying platforms; the sub-packaging system comprises a goods receiving conveying line and three goods distribution conveying lines, wherein one side of each goods distributionconveying line is correspondingly provided with a box loading operation table, and an empty basket conveying line is arranged between the other side of the goods distribution conveying line and the transferring platform; and a plurality of supporting plate opening mechanisms are arranged on the annular support, and the supporting plate opening mechanisms are positioned above the conveying platforms.

Owner:陈宇

Corrugated board turnover machine

The invention discloses a corrugated board turnover machine. The corrugated board turnover machine comprises a rack, a rotating support arranged in the rack, a rotating device which is arranged on the rack and used for driving the rotating support to rotate, a detection device which is arranged on the rack and used for detecting the height of corrugated boards, a conveying device which is arranged on the rotating support and used for conveying the corrugated boards and a clamping and loosening device which is arranged on the rotating support and used for driving the conveying device to conduct clamping or loosening movement; the detection device is in communication connection with the clamping and loosening device, and the rotating device can drive the rotating support to rotate and drive the clamping and loosening device to conduct rotating movement. After the corrugated boards are counted and packed through a counting machine, board faces of the packed corrugated boards are normally upward, and the multiple packed corrugated boards are conveyed in a spaced turning mode, so that the board faces of every two adjacent packed corrugated boards are opposite to each other for stacking, the corrugated board turning efficiency is improved, and unmanned and automatic board turning is achieved.

Owner:广东勤善美智能装备股份有限公司

Finished product building block overturning table

ActiveCN103640086AGuaranteed smooth productionImprove turnover efficiencyLifting devicesAuxillary shaping apparatusPiston rodHydraulic drive system

The invention discloses a finished product building block overturning table which comprises a rotating supporting base, a small overturning frame, a large overturning frame and a fixed support. The large overturning frame and the small overturning frame are hinged to the rotating supporting base, the large overturning frame is hinged to a piston rod of a hydraulic transmission mechanism of an overturning device, an oil cylinder of the hydraulic transmission mechanism of the overturning device is hinged to a ground foundation, the large overturning frame is hinged to an oil cylinder of a hydraulic transmission mechanism of a rotating device, and a piston rod of the hydraulic transmission mechanism of the rotating device is hinged to the small overturning frame. According to the technical scheme, the requirements of overturning kettle-entering steam-cured aerated concrete building blocks through 90 degrees after movement out of a kettle and lifting the aerated concrete building blocks in aerated concrete building block production and the requirements of recycling steam-cured flat plates can be met, the finished product building block overturning table runs reliably and is accurate in motion, overturning efficiency of finished product building blocks can be improved, and the aerated concrete building blocks can be produced smoothly.

Owner:ANHUI KEDA IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com