Slewing bearing overturning mechanism

A technology of turning mechanism and slewing bearing, applied in the field of machinery, can solve the problems of worker operation, low work efficiency, hidden dangers, etc., and achieve the effect of compact structure, convenient assembly, and guarantee of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

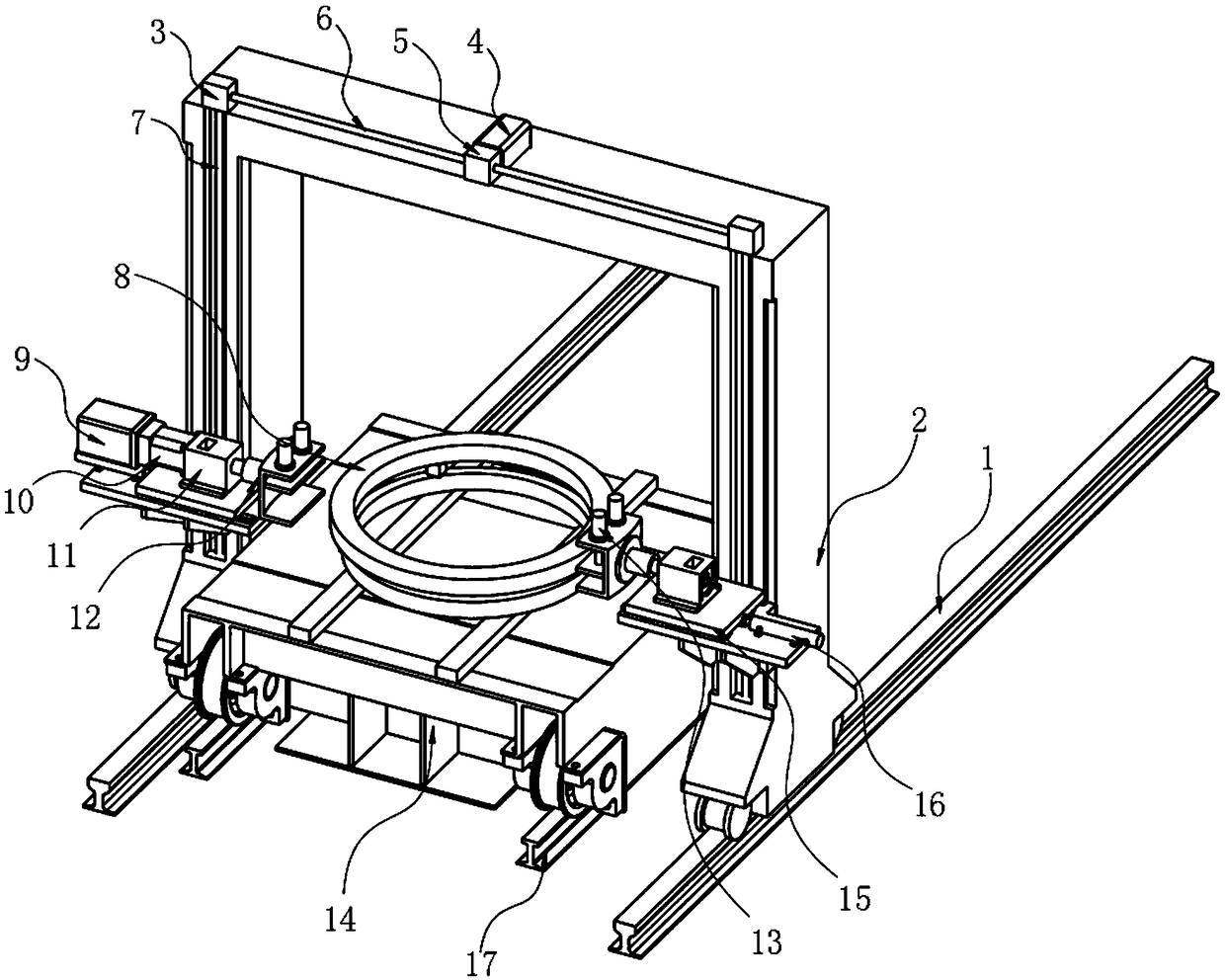

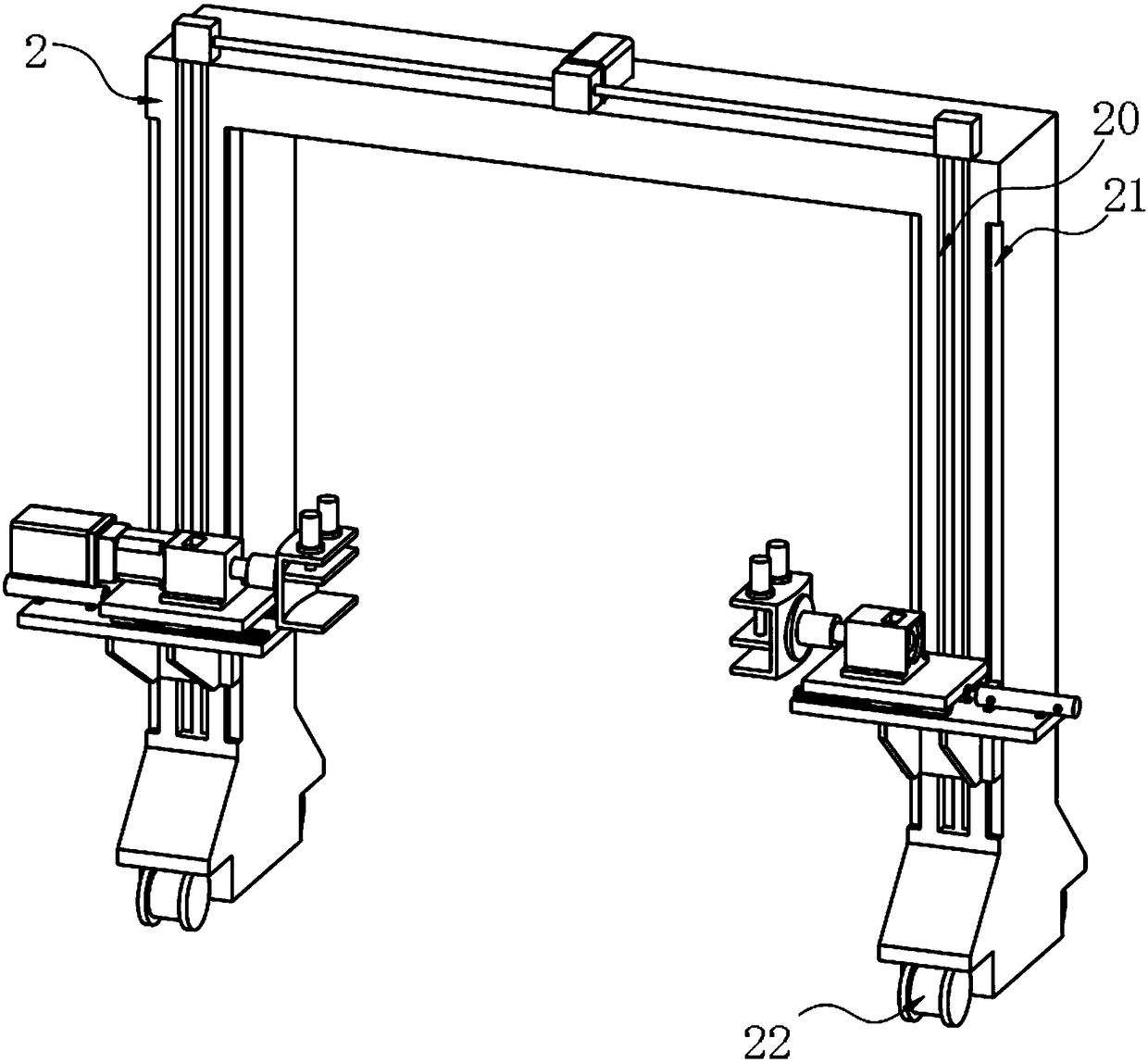

[0028] A slewing bearing turning mechanism, such as Figure 1-5 As shown, two ground rails 1 parallel to each other are included, a mobile trolley 14 is arranged between the two ground rails 1 and above it, a gantry bracket 2 is arranged on the two ground rails 1, and the side walls of the gantry bracket 2 A pair of opposite guide rail sliders 15 are arranged on the top, and a coupling assembly 11 is installed on the guide rail slider 15. A rotating motor 9 and a third reducer 10 are arranged behind the coupling assembly 11, and a rotating device 12 is provided in front of the coupling assembly 11. , the output shaft of the rotating motor 9 is coaxially connected with the input shaft of the third reducer 10, the output shaft of the third reducer is fixedly connected with the rear end of the rotating device 12 through the coupling assembly 11, and the slewing bearing 8 is placed on the moving trolley 14 .

[0029] In this embodiment, the top of the gantry support 2 is provided...

Embodiment 2

[0035] In specific use, in order to facilitate the movement of the whole device and the convenient adjustment of the position of the slewing bearing 8, the inventor made an improvement on the basis of Embodiment 1. As a preference, first Roller 22, the first roller 22 is clamped on the ground rail 1 and can roll back and forth on the ground rail 1, the bottom end of the mobile trolley 14 is symmetrically equipped with a second roller 140, and the bottom end of the second roller 140 is provided with a rail 17 , the second roller 140 is clamped on the rail 17 and can roll back and forth on the rail 17, so that the whole gantry bracket 2 can be moved to adjust the position, and the mobile trolley 14 can be set to roll back and forth. 8 for processing, greatly improving work efficiency.

[0036] Specifically, both the ground rail 1 and the vehicle rail 17 are installed on the ground or the workbench by bolts to ensure their stability.

Embodiment 3

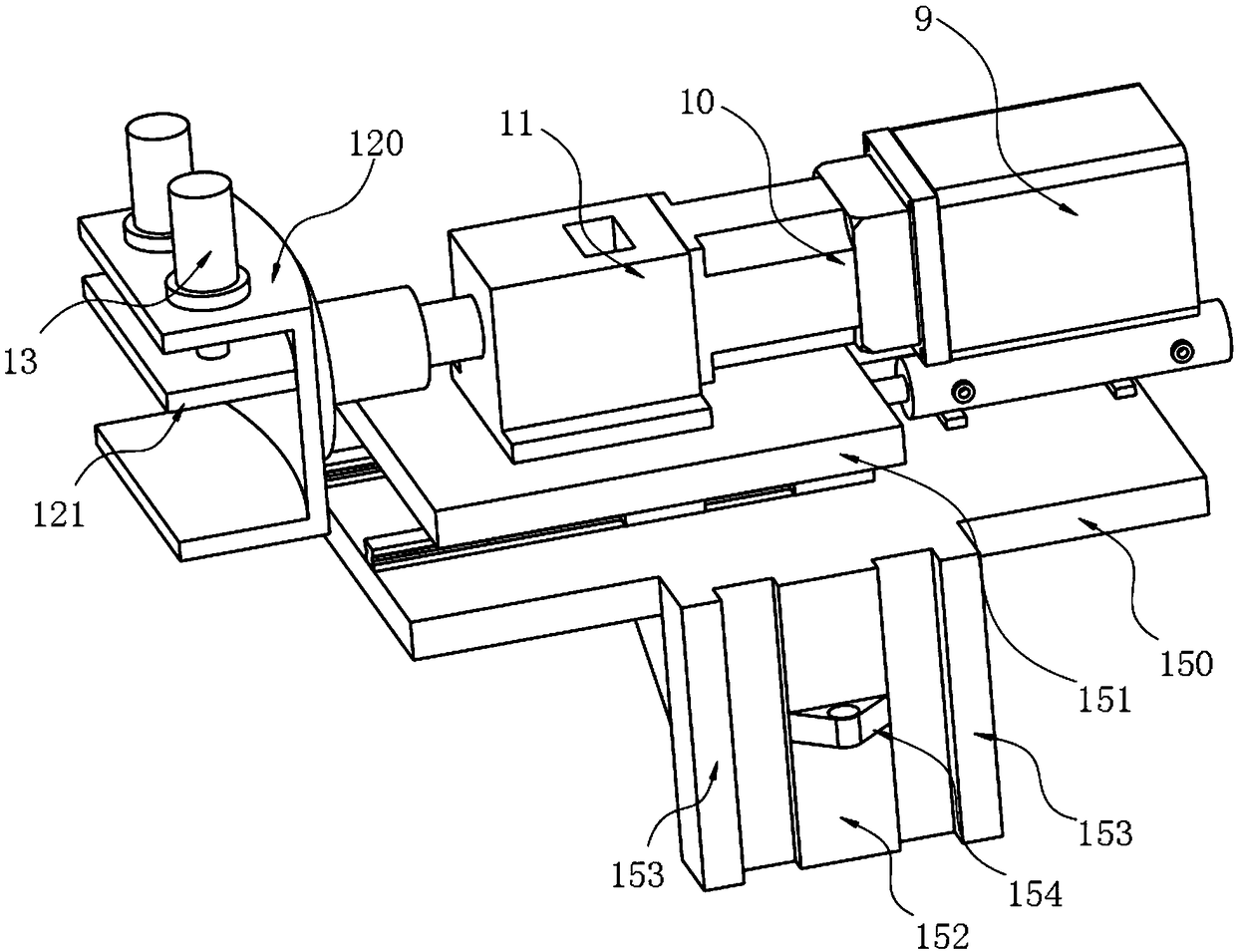

[0038] In order to improve the accuracy and stability of the rotating device 12 during rotation, the inventors made improvements on the basis of Embodiment 1, as a preference, as Figure 6 As shown, the coupling assembly 11 includes a bearing seat 110, and a coupling 111 is provided inside the bearing seat 110, and the coupling 111 is coaxially fixedly connected with the output shaft of the third reducer 10, and the main shaft of the jaw 120 passes through the bearing seat 110 is connected coaxially with the shaft coupling 111, and is locked and fixed by the lock nut 112. A pressure plate 113 is provided at the joint between the lock nut 112 and the inner wall of the bearing seat 110, and the main shaft of the jaw 120 and the inner wall of the bearing seat 110 They are rotationally connected by a plurality of bearings 114, preferably three in this embodiment, and the cooperation between the bearing housing 110 and the coupling 111 makes the third reducer 10 more stable and accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com