U shaped beam three-face punching technique and production device using the technique

A production equipment and punching technology, applied in the field of "U"-shaped beam punching process, can solve the problems of low handling and turning efficiency, large mechanical area, and low production efficiency, etc. The effect of small area and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

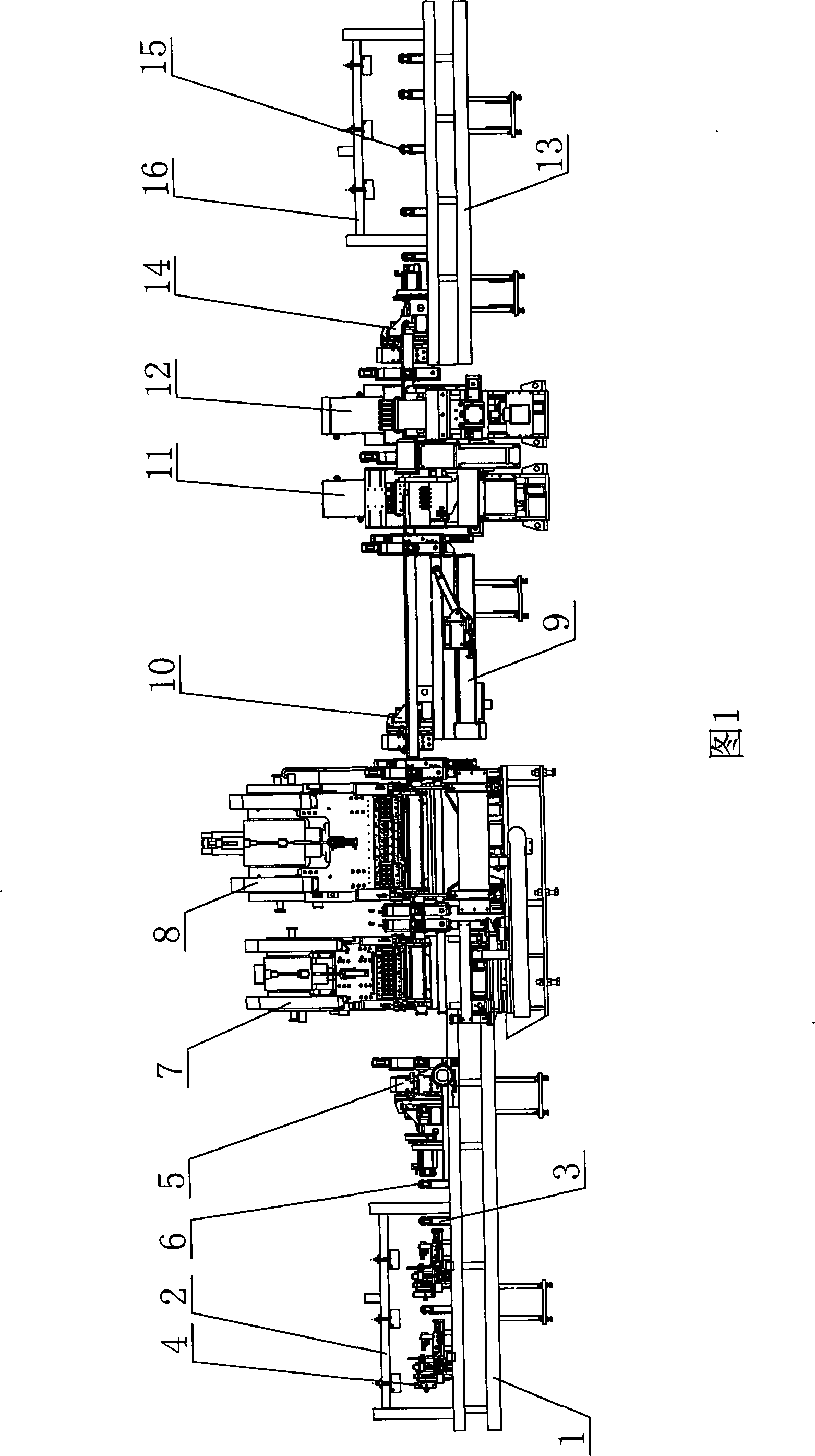

[0020] A kind of " U " shaped beam three-sided punching process of the present invention, its technological process is:

[0021] (1) Place the "U" shaped beam on the loading platform for standby;

[0022] (2) Use the feeding extraction device to suck up the spare "U"-shaped beams in sequence. For the "U"-shaped beams with the opening upwards, they are first hoisted to the automatic turning device, and then placed on the feeding end for support after being automatically turned 180° On the rollers, the "U" shaped beam with the opening downwards is directly hoisted to the supporting rollers at the feeding end;

[0023] (3) The supporting rollers support the "U" beam, and push the "U" beam to the reference positioning roller for positioning;

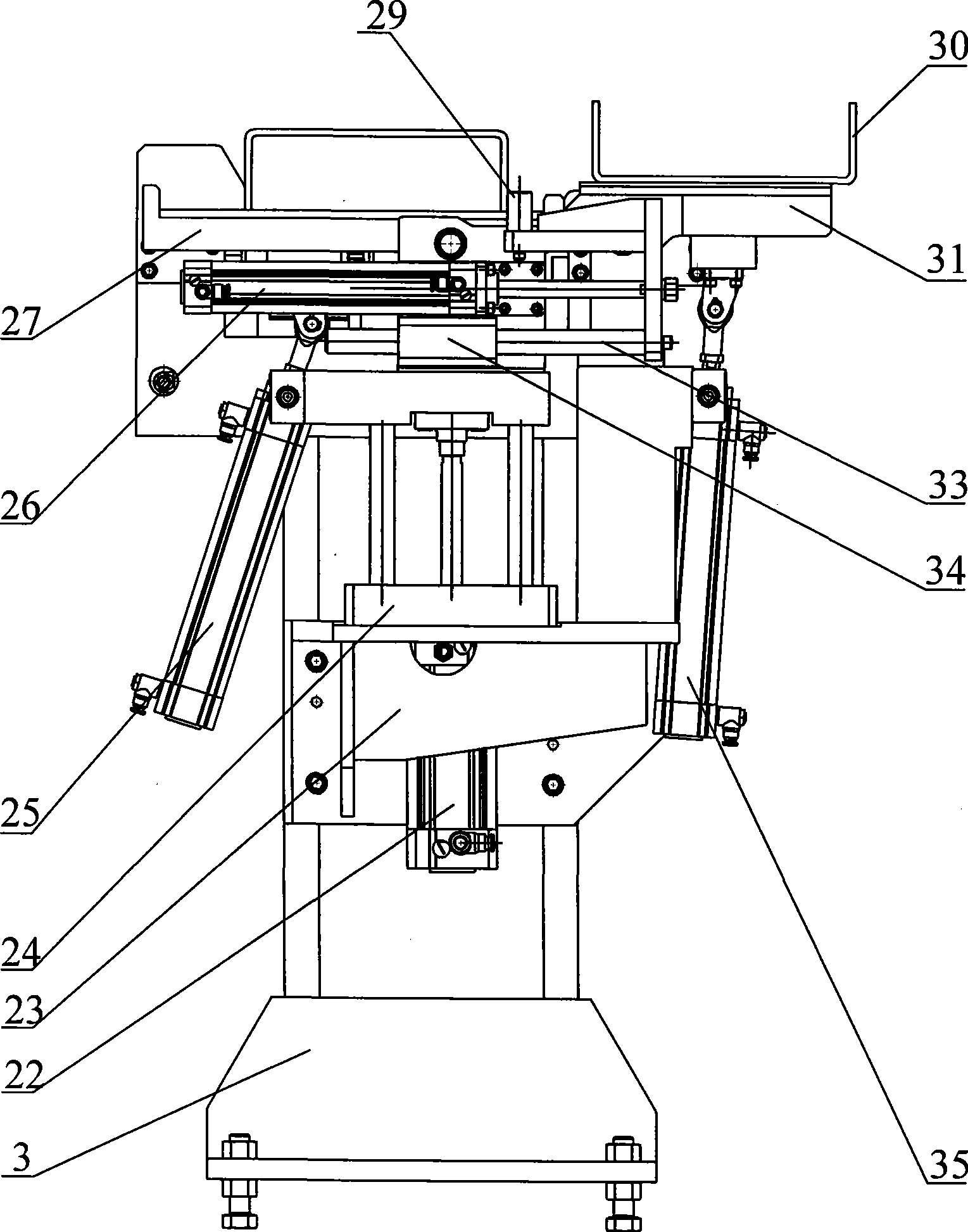

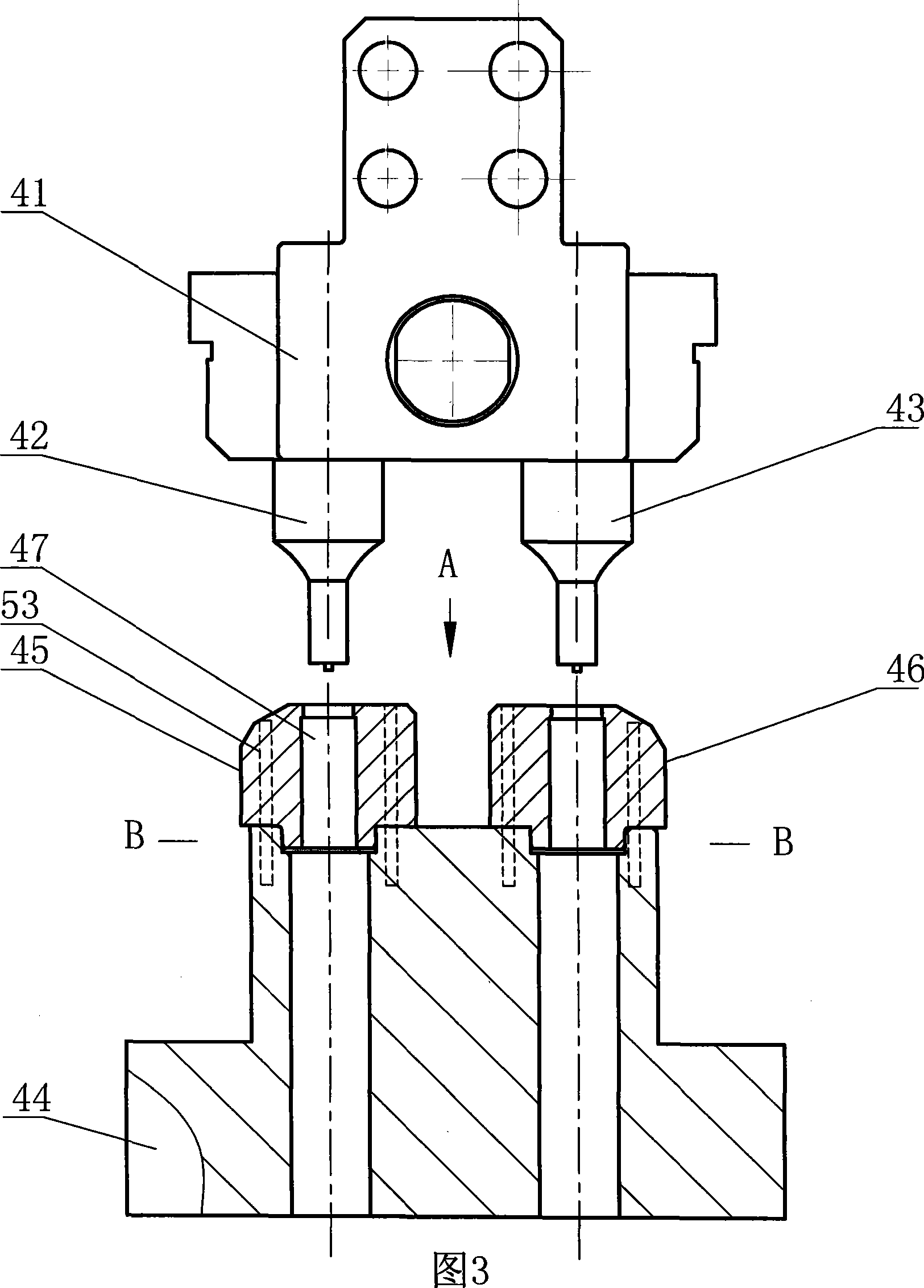

[0024] (4) Use the first feeding and clamping device to clamp the "U"-shaped beam web, and send it to the small abdominal punching machine that can move the X / Y axis and the large abdominal punching machine that can move the Y axis. on sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com