Stamping processing equipment for automobile aluminum pieces

A technology for stamping and aluminum parts, which is applied in the field of stamping and processing equipment for automobile aluminum parts, can solve the problems of irregular shape of aluminum parts, reduce production efficiency, affect punching quality, etc., achieve stable punching action, avoid drill bit damage, The effect of avoiding the deviation of the punching position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

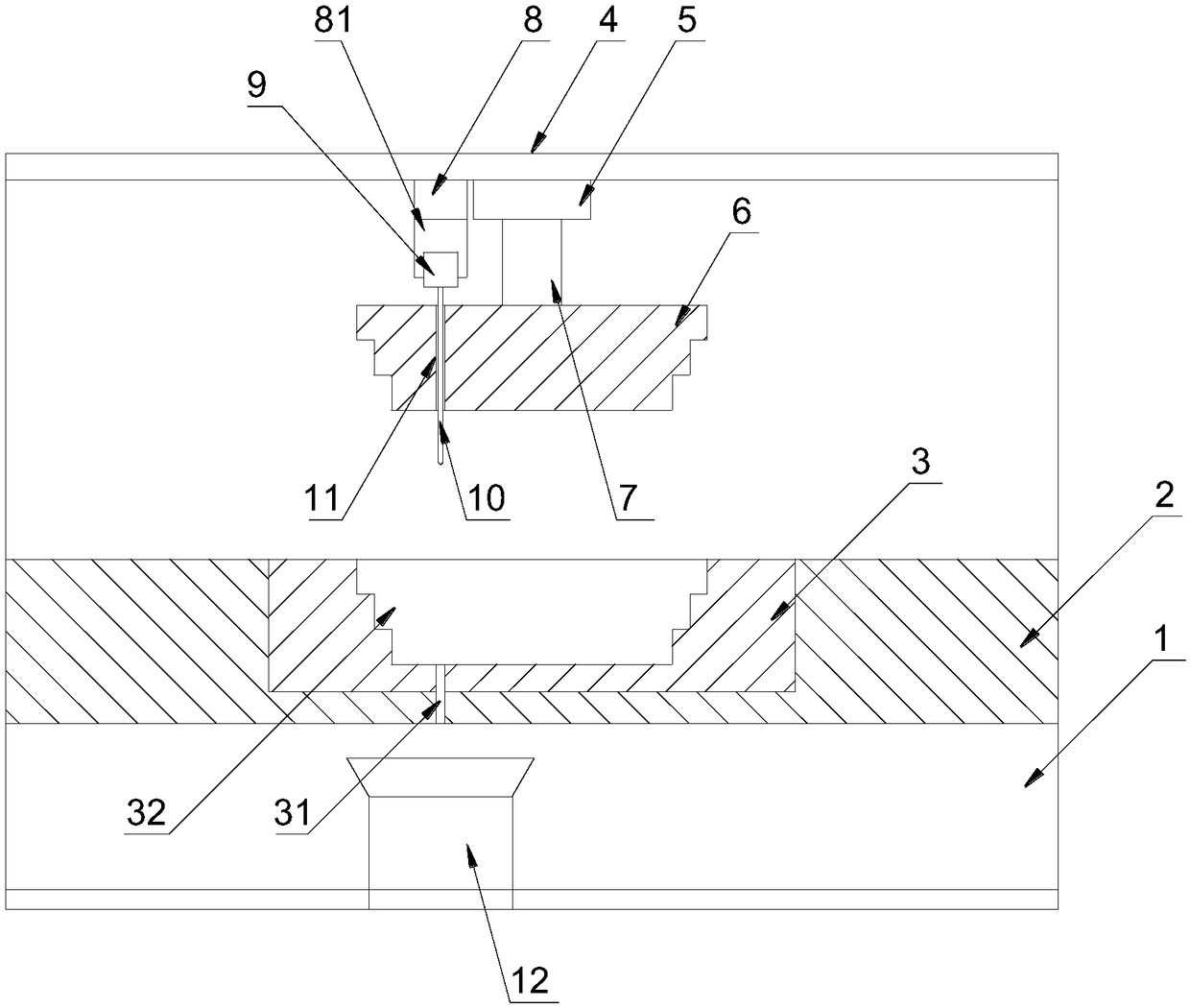

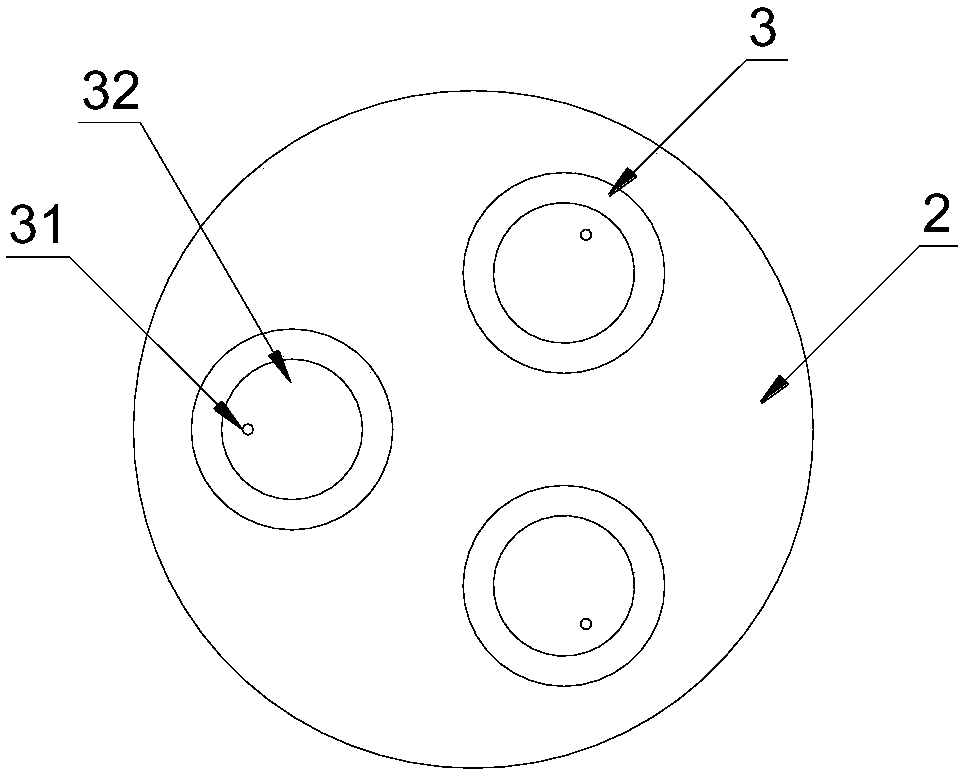

[0019] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a stamping processing equipment for aluminum parts of automobiles proposed by the present invention; figure 2 It is a partial structural schematic diagram of the stamping processing equipment for automobile aluminum parts proposed by the present invention.

[0020] refer to figure 1 , a stamping processing equipment for automobile aluminum parts proposed by the present invention, including a base 1, a workbench 2, a mold 3, a first driving mechanism 5, a first telescopic rod 7, a stamping head 6, a second driving mechanism 8, a second telescopic Rod 81, drilling machine 9, drill bit 10 and frame 4;

[0021] The workbench 2 is set on the base 1, and a placement groove is arranged on the workbench 2; the mold 3 is fixed in the placement groove; the mold 3 is provided with a cavity 31, and the bottom of the cavity 31 is provided with a discharge hole for the drill bit 10 to pass through vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com