Patents

Literature

4302results about How to "Improve drilling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

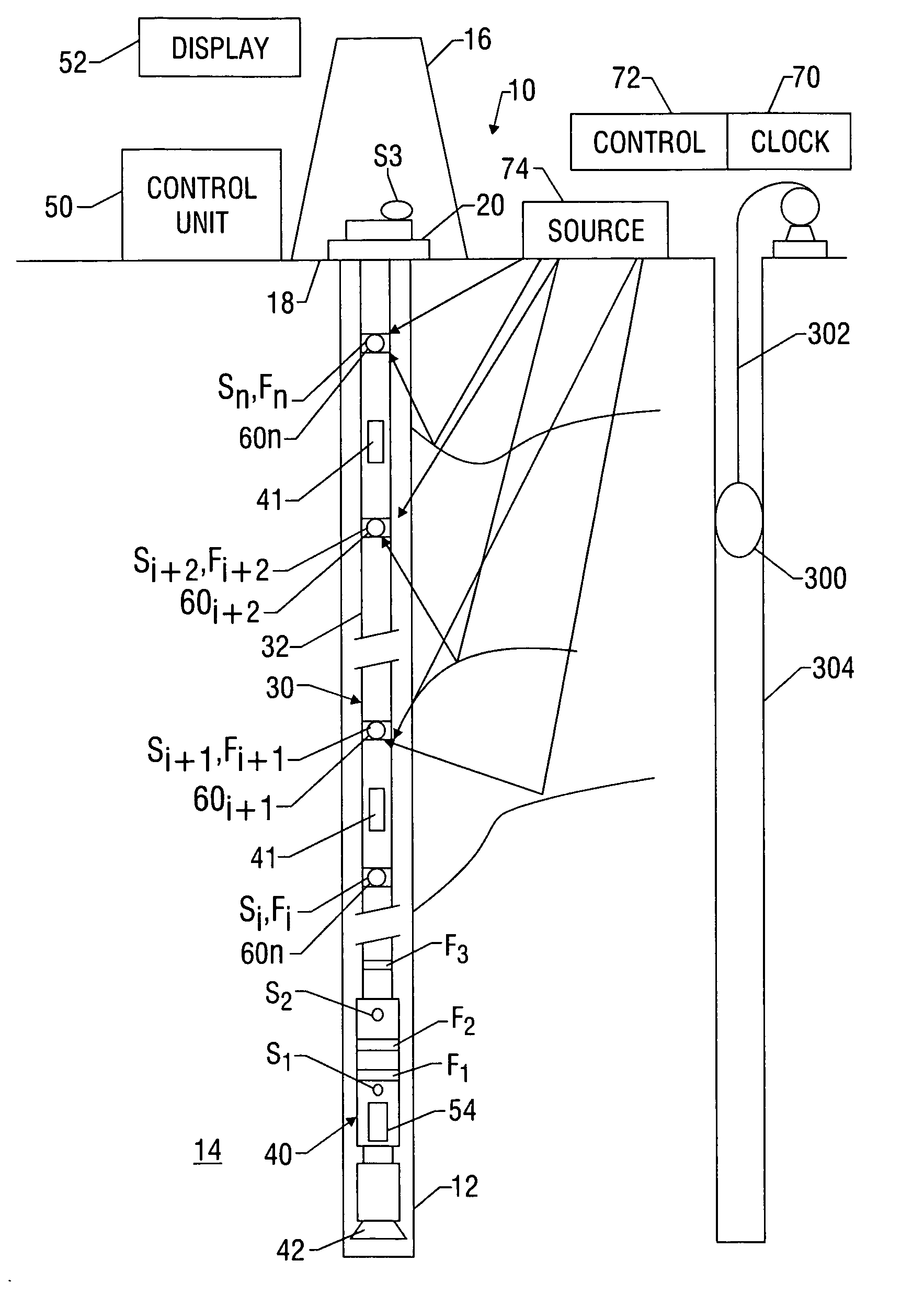

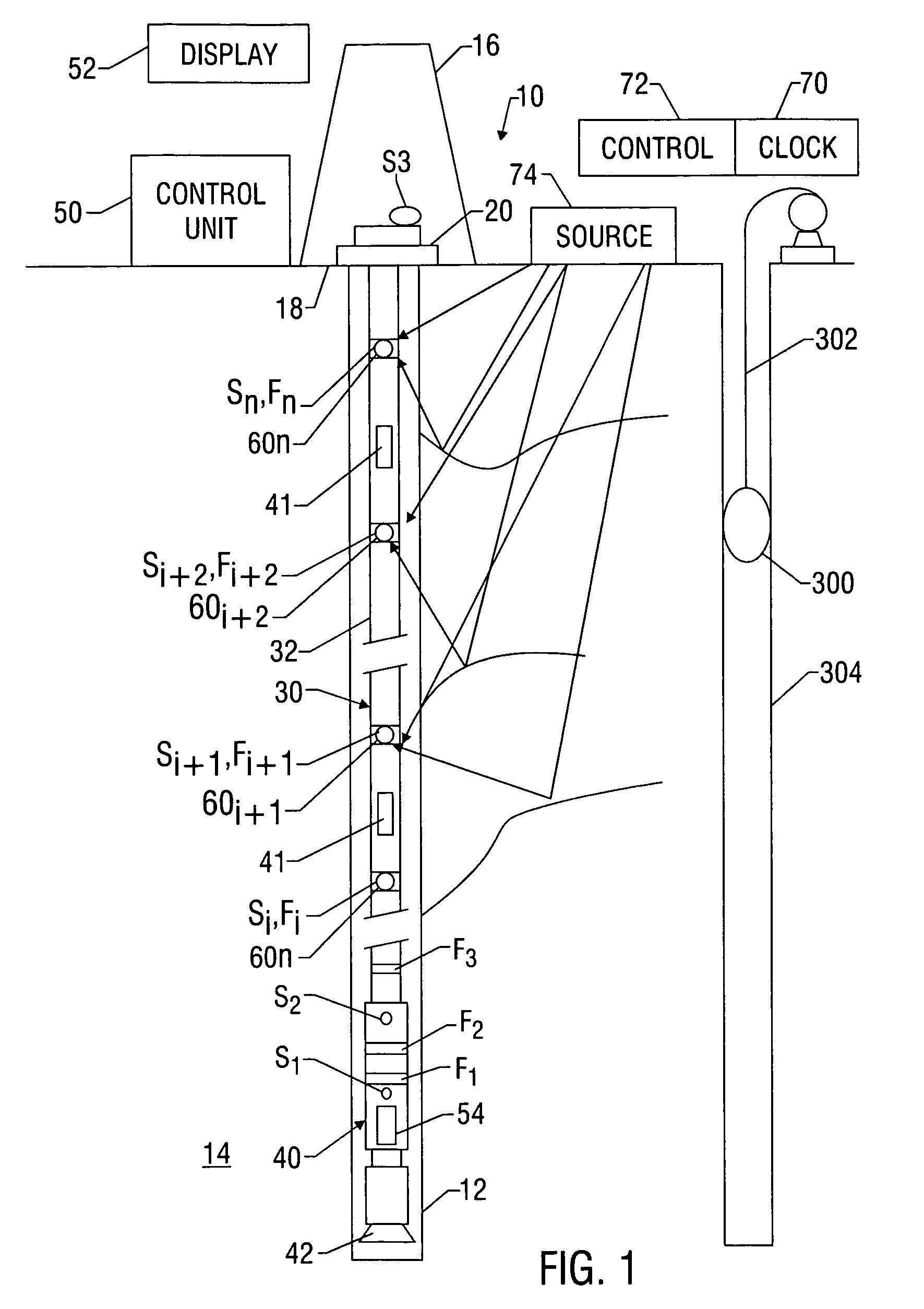

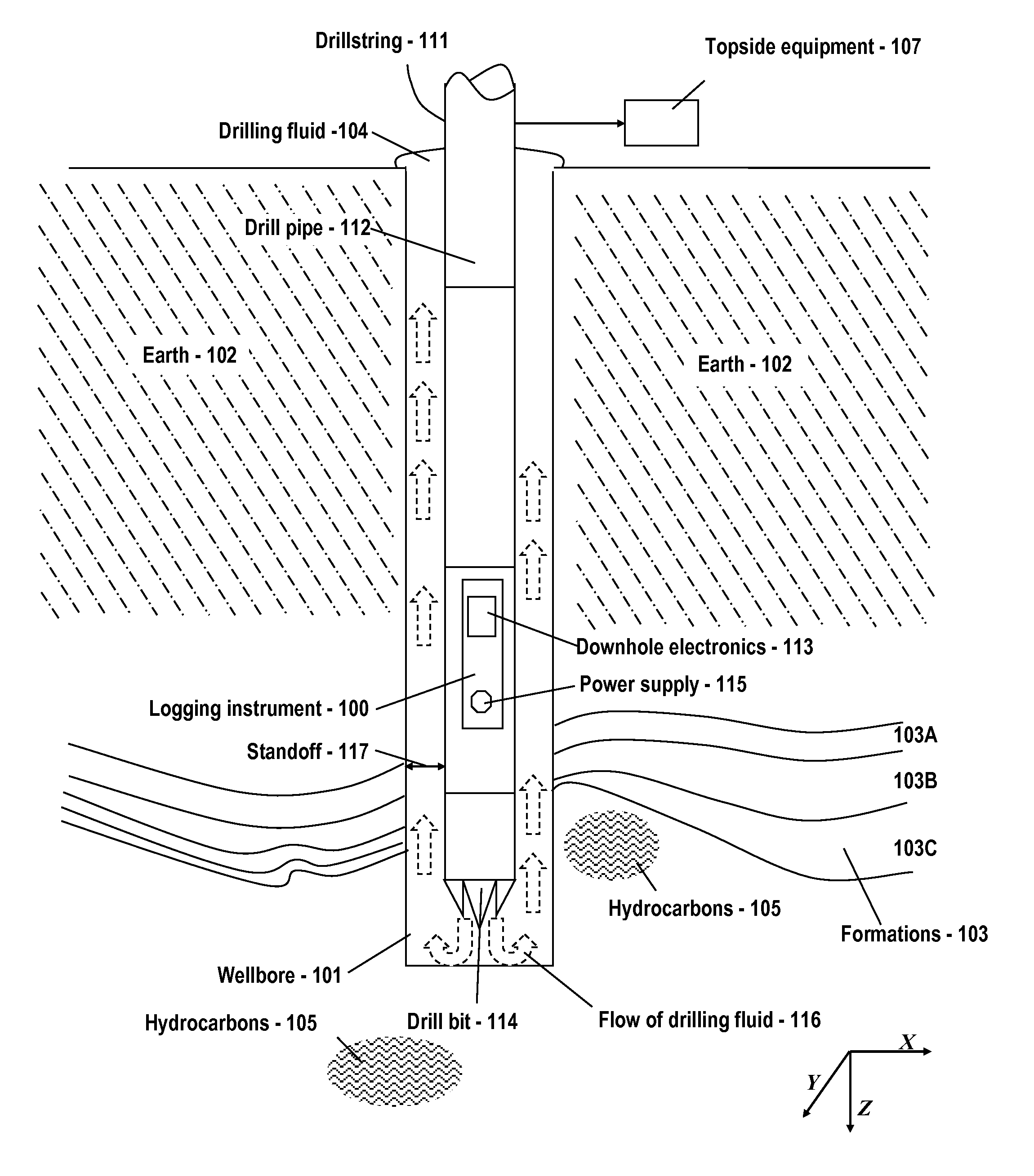

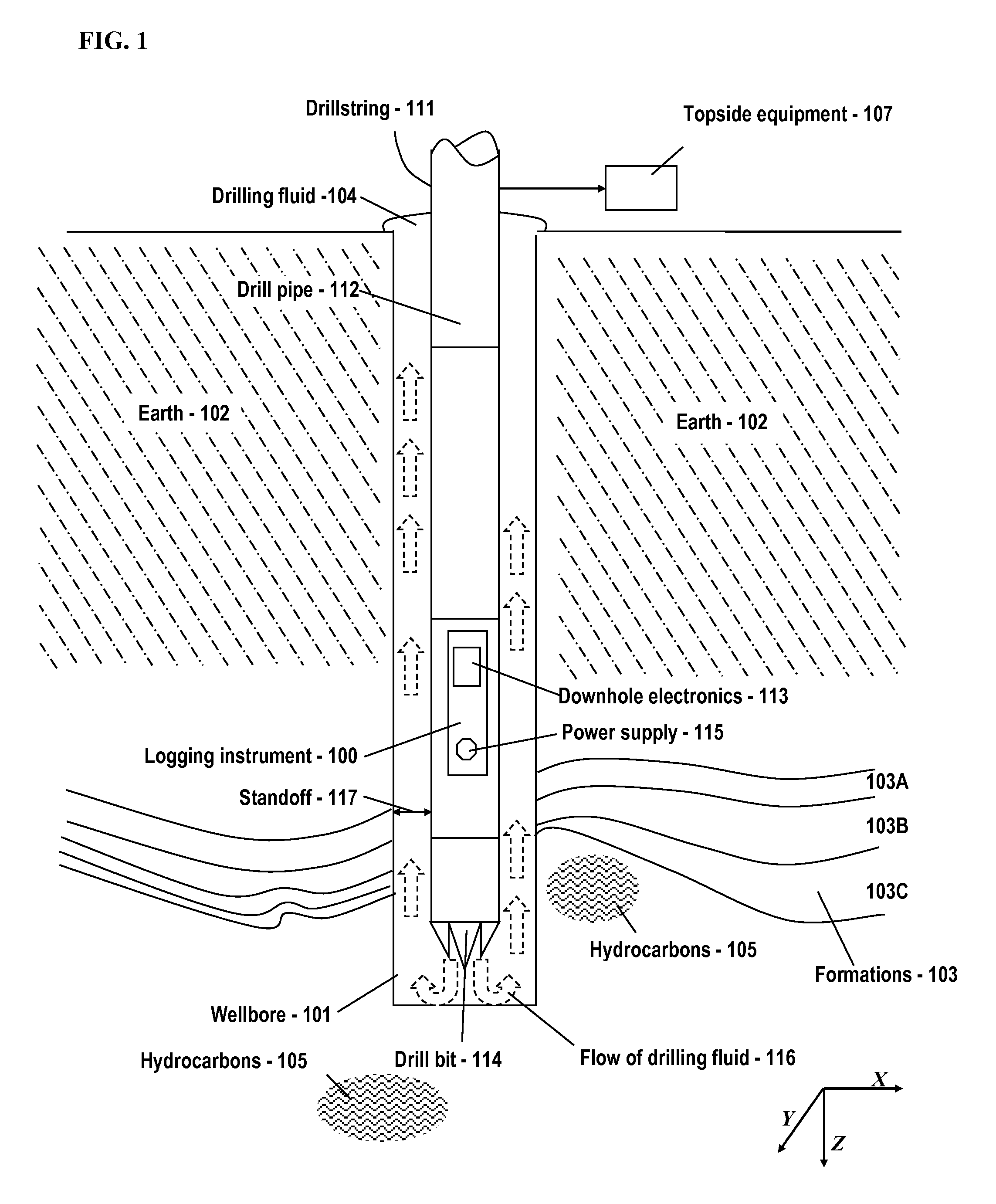

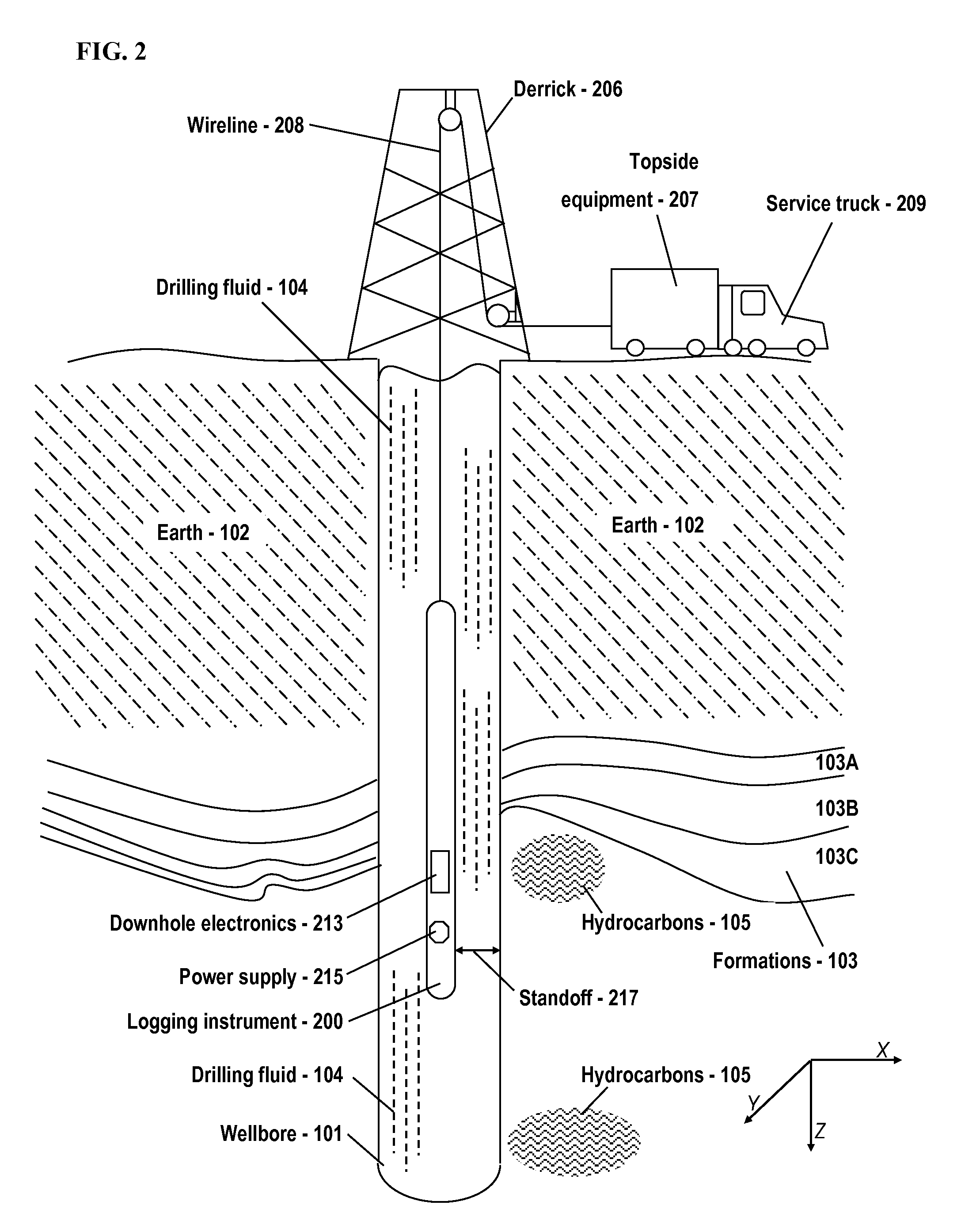

Drilling wellbores with optimal physical drill string conditions

ActiveUS20050279532A1Improve efficiencyEnhance reliabilitySurveySeismic signal processingSubmarineGraphical user interface

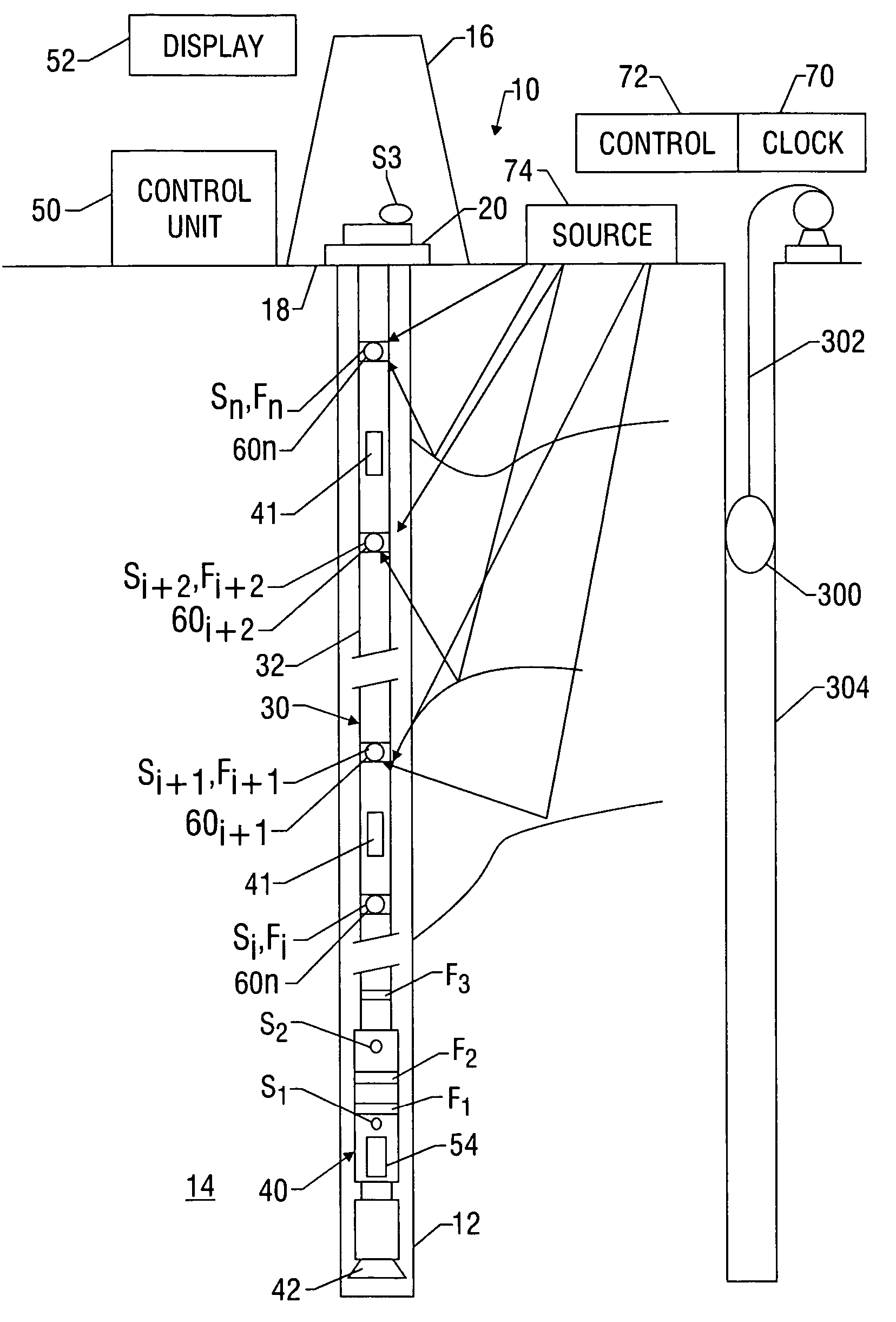

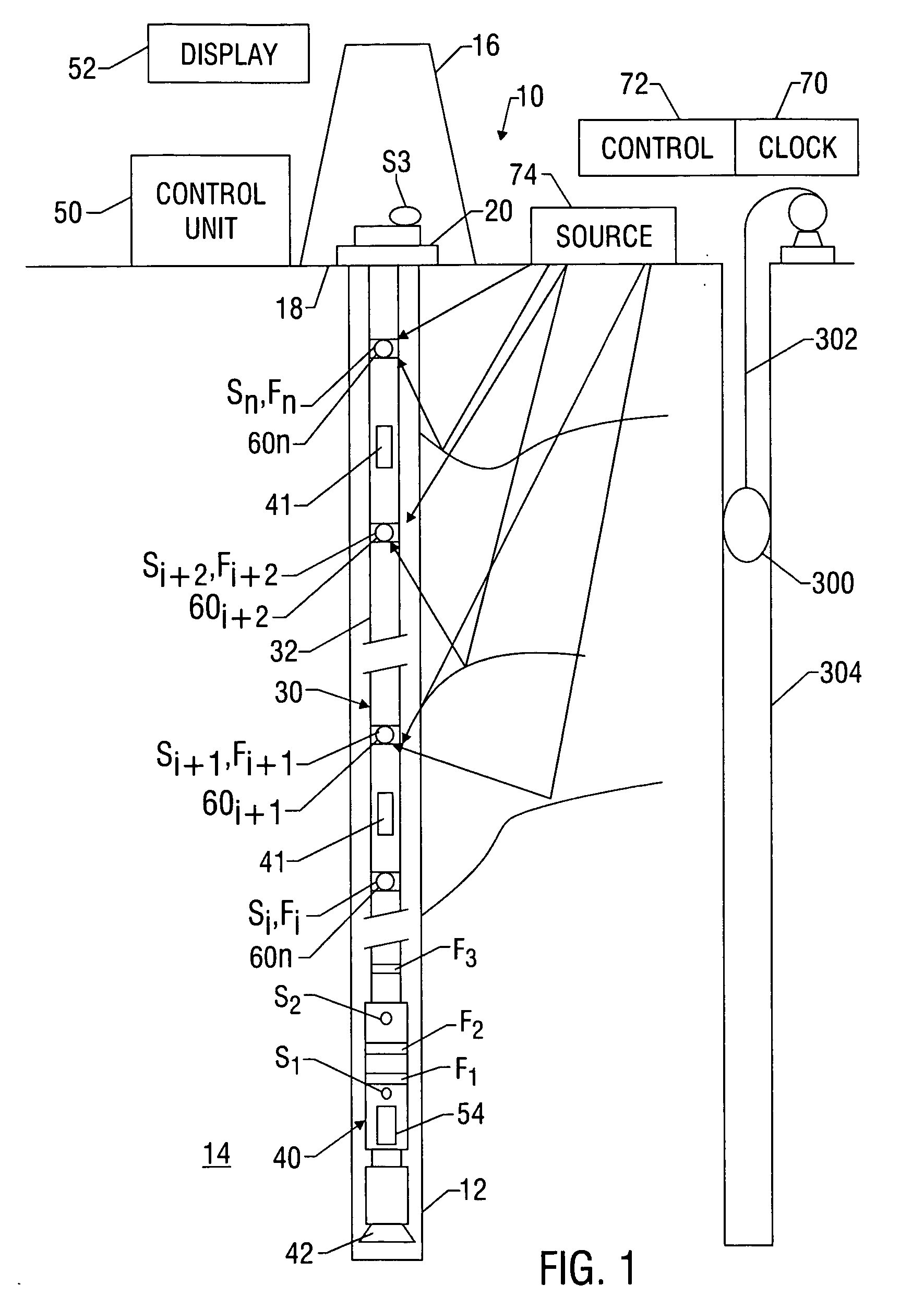

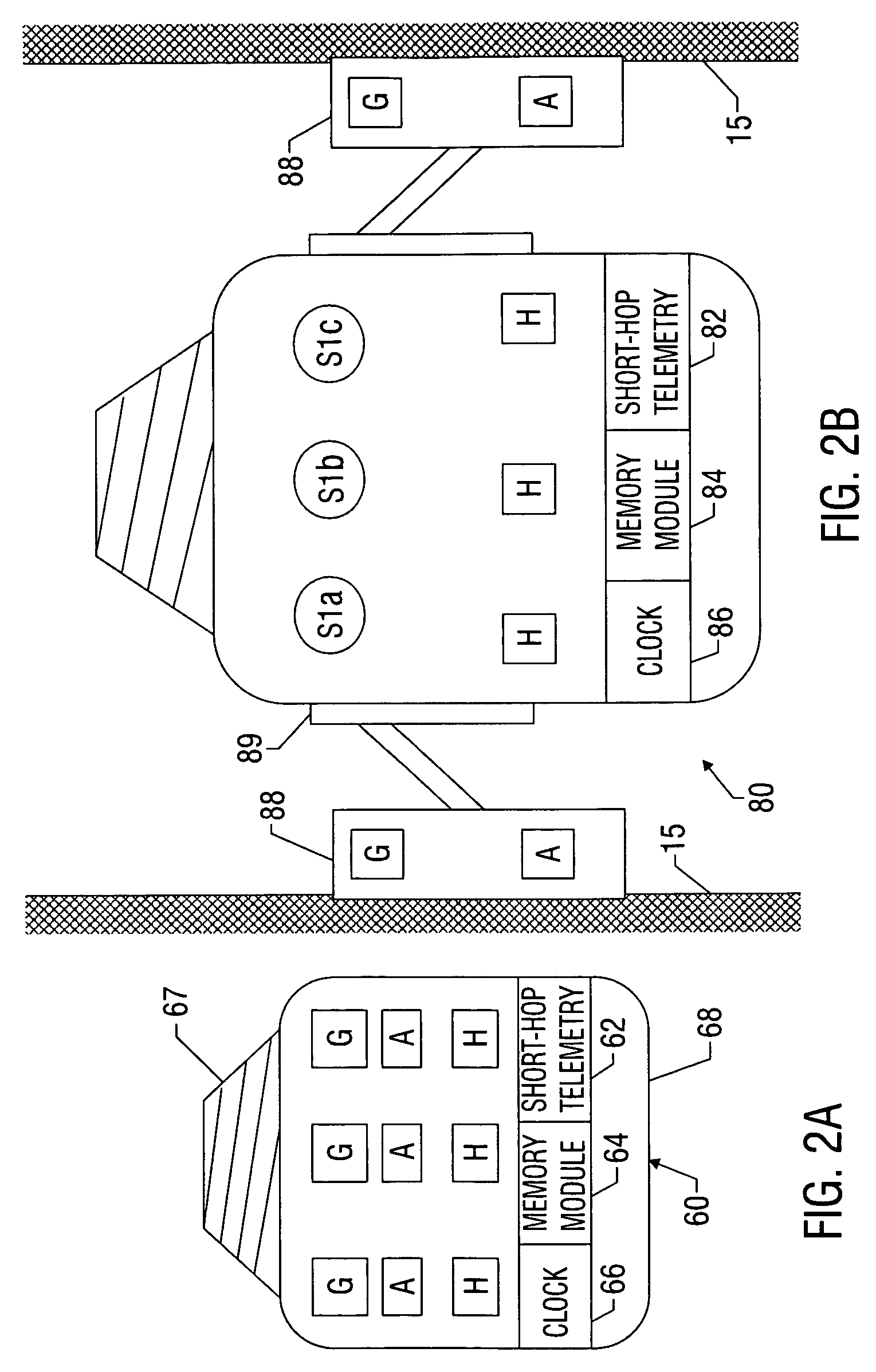

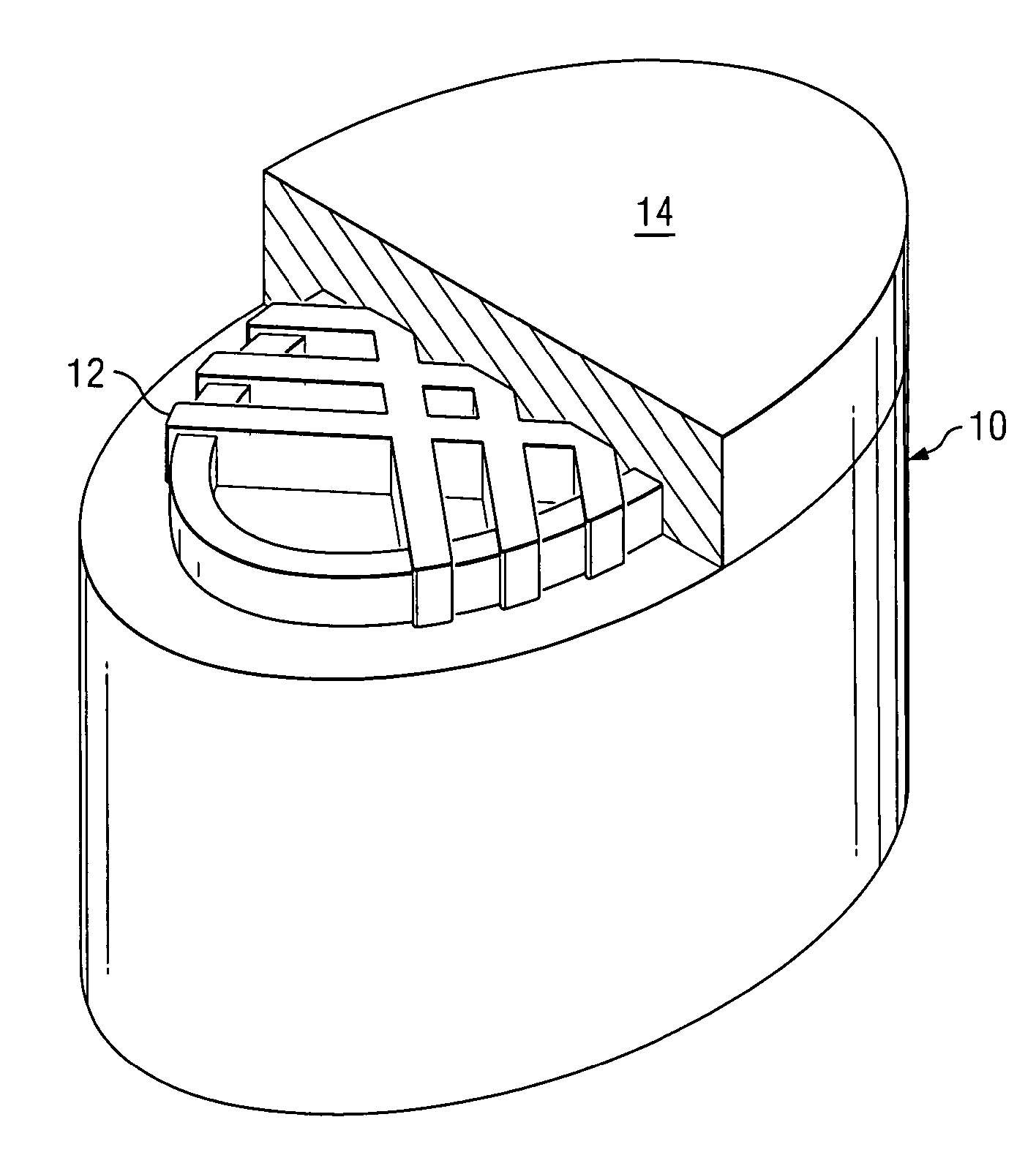

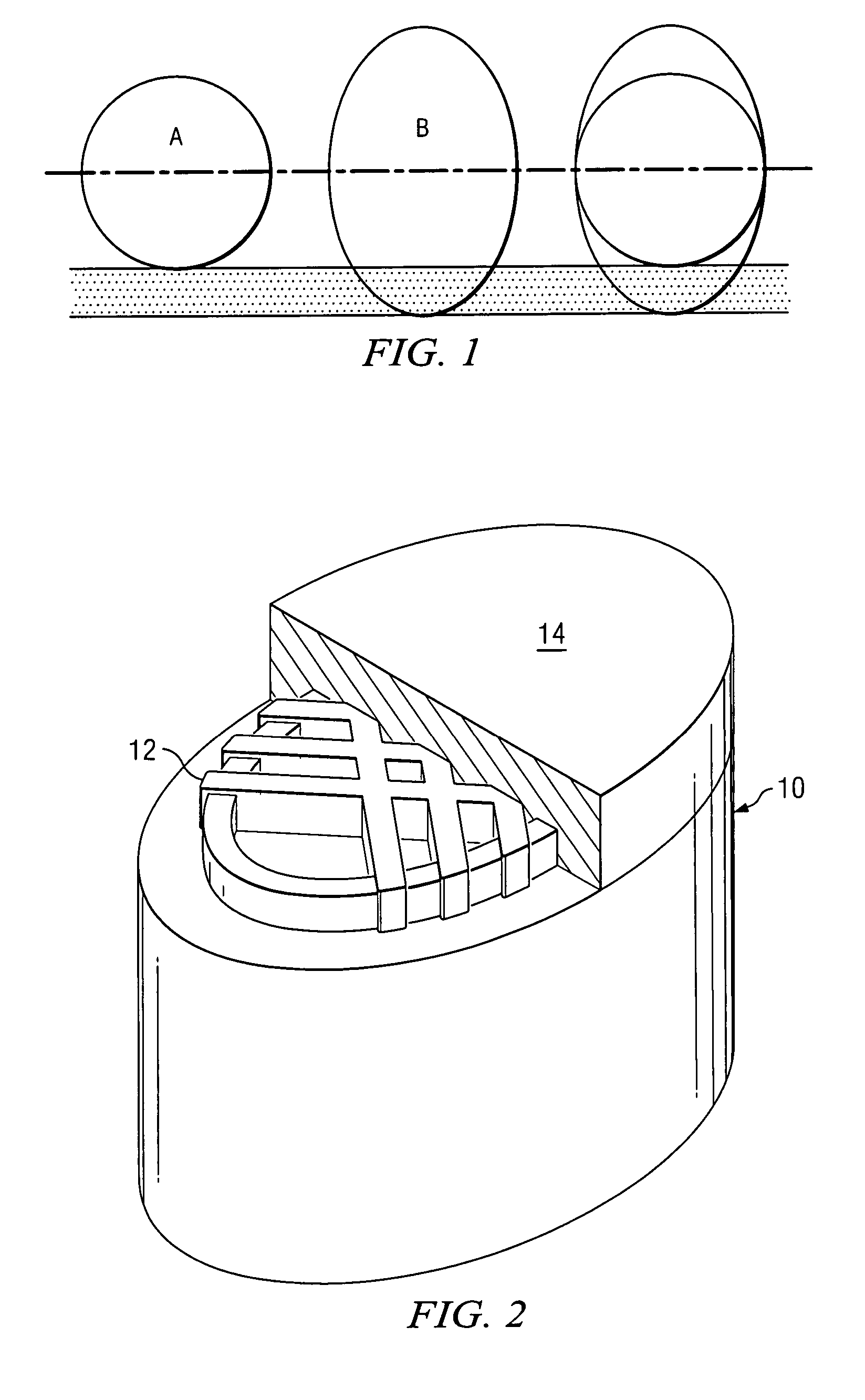

A drilling system includes a control unit and a bottomhole assembly (BHA) coupled to a drill string. The control unit uses measurements from sensors distributed throughout the drill string and BHA to determine the physical condition of the drill string and BHA and to determine whether drilling can be optimized. The drill string sensors are housed in receiver subs and optionally can be positioned on extensible members. The receiver sub also can include a short-hop telemetry module, a processor module, and a clock module. In one embodiment, the receiver subs include seismic sensors for enabling vertical seismic profiling. During operation, the processor visually presents to the operator via one or more graphical user interfaces a dynamically updated pictorial image representing the drilling system. The image is annotated with an appropriate visual signal to indicate a determined physical condition at a given location or component. The processor can also display recommended adjustments to drilling parameters for increasing drilling rates, improving tool life, and more precise steering.

Owner:BAKER HUGHES INC

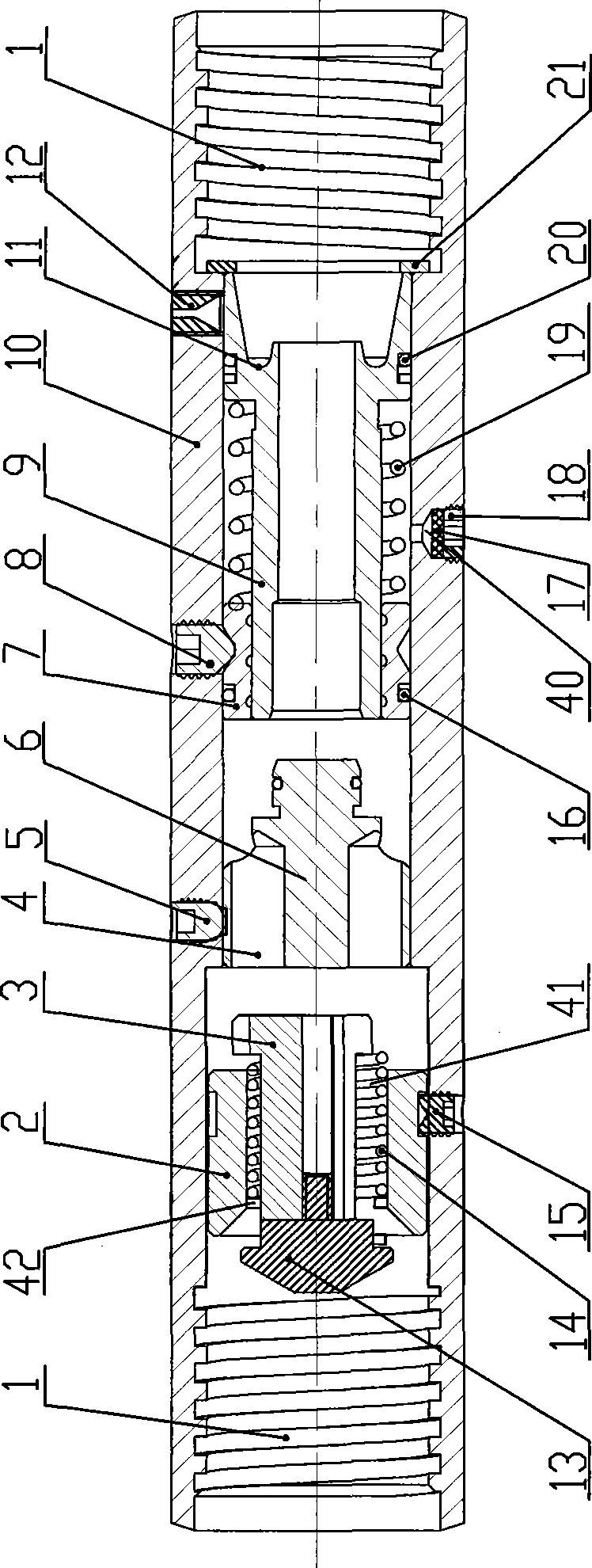

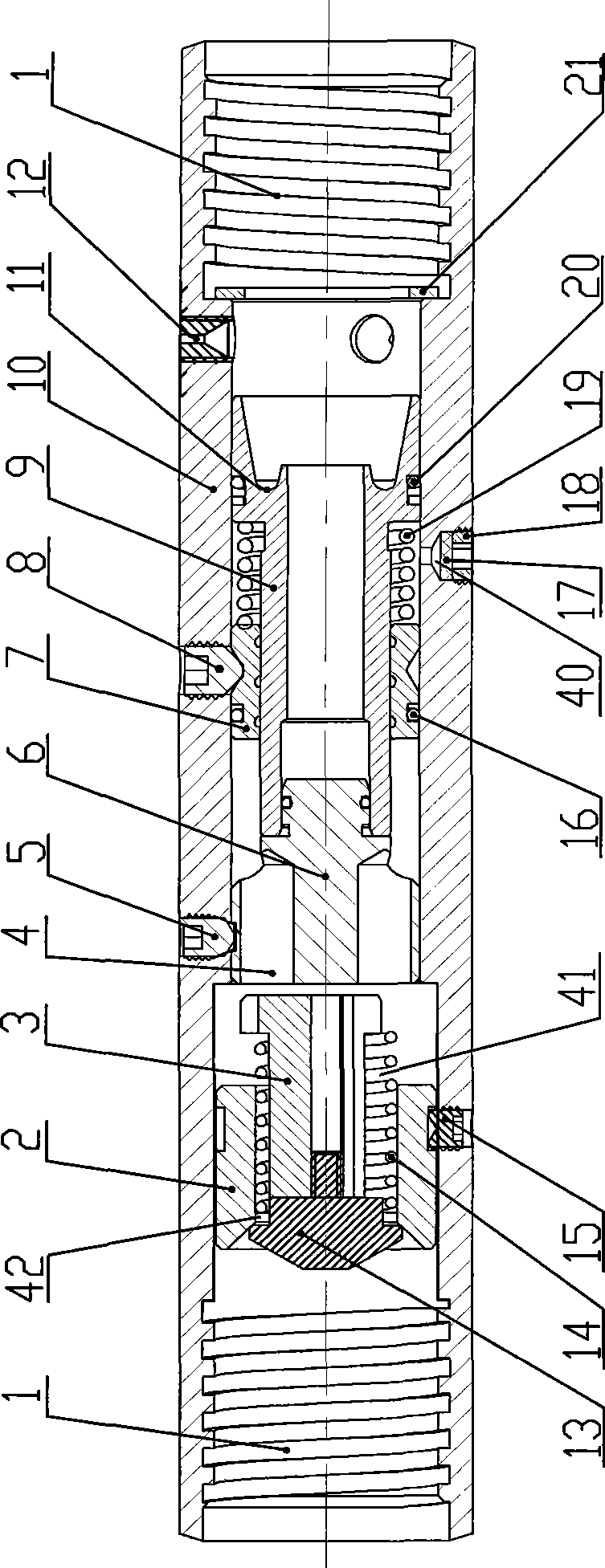

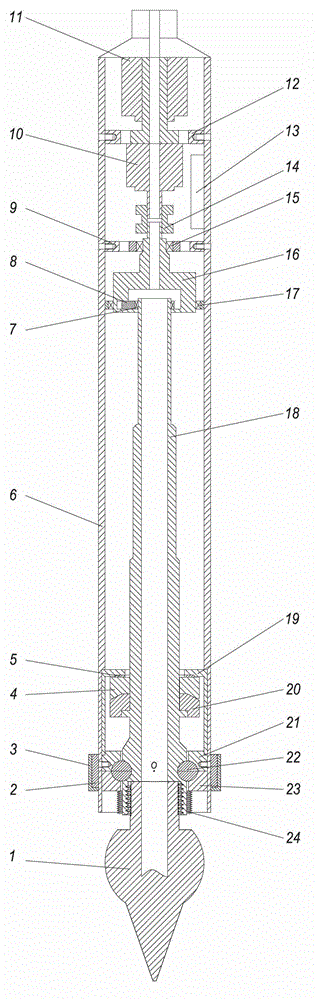

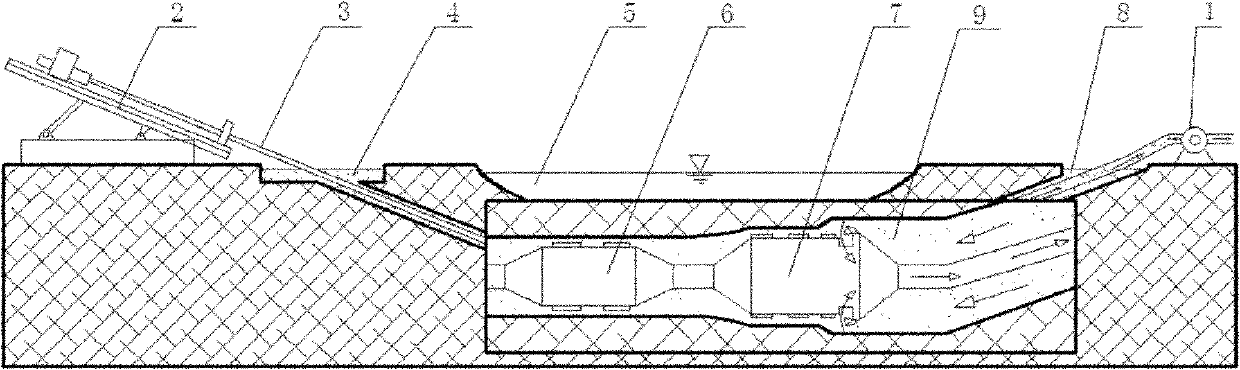

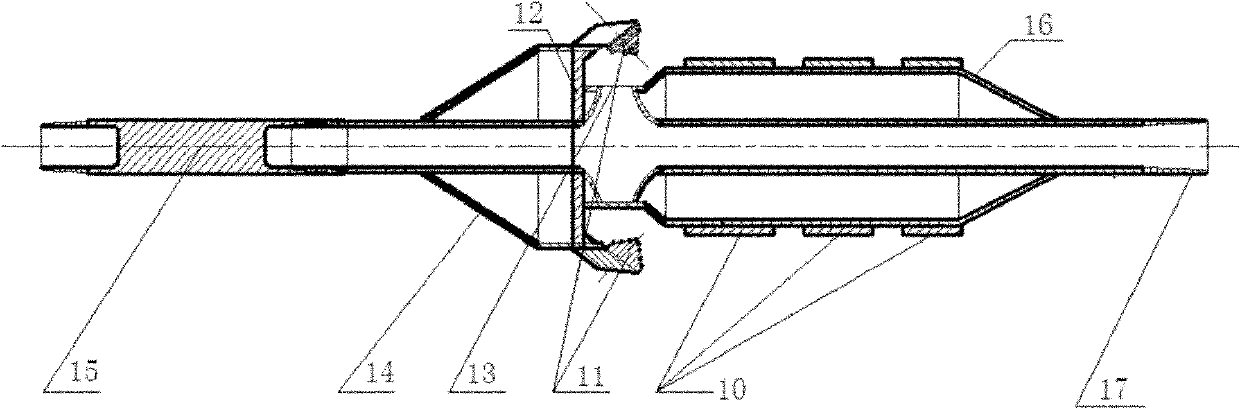

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

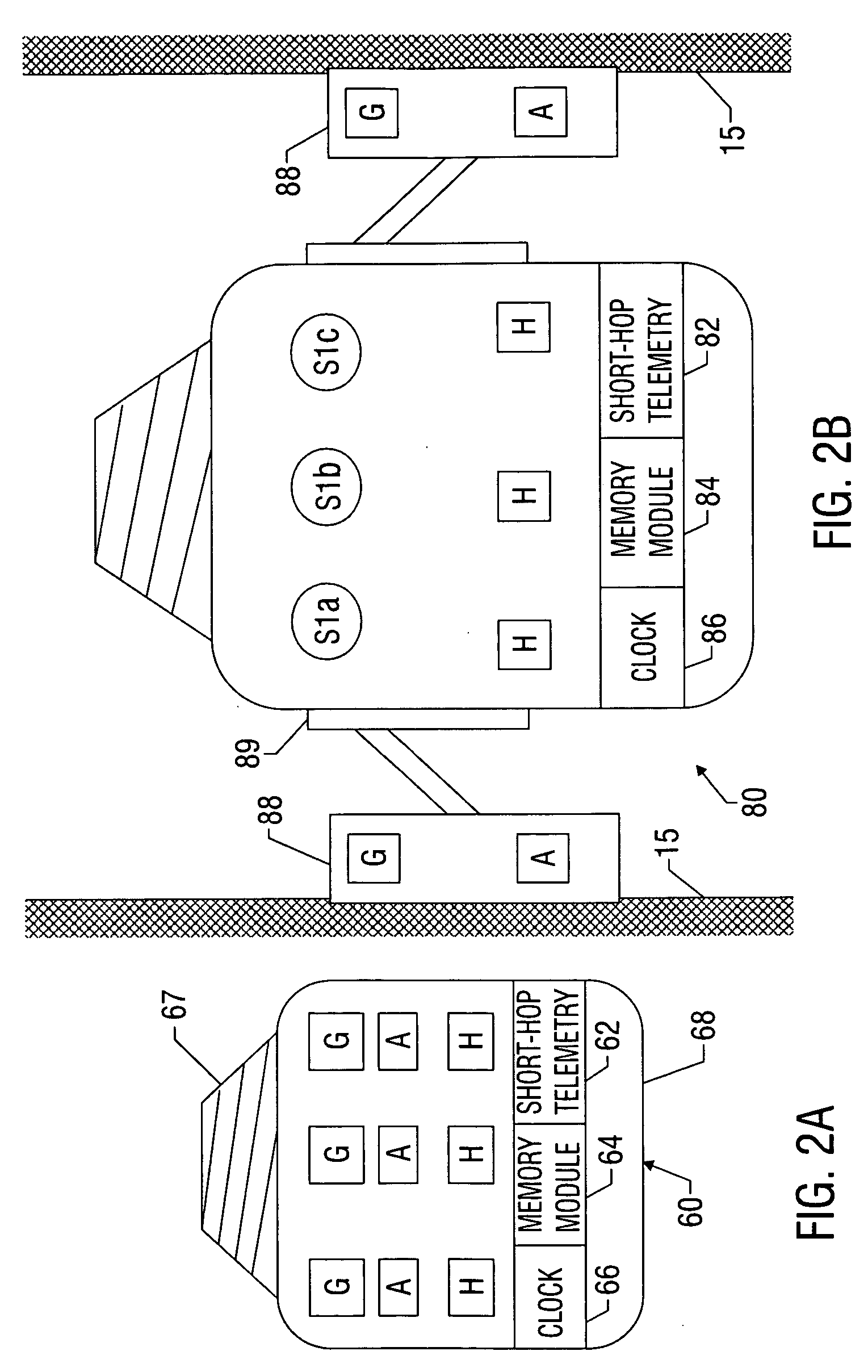

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

Drilling wellbores with optimal physical drill string conditions

ActiveUS7730967B2Improve reliabilityImprove accuracySurveySeismic signal processingVisual presentationControl cell

A drilling system includes a control unit and a bottomhole assembly (BHA) coupled to a drill string. The control unit uses measurements from sensors distributed throughout the drill string and BHA to determine the physical condition of the drill string and BHA and to determine whether drilling can be optimized. The drill string sensors are housed in receiver subs and optionally can be positioned on extensible members. The receiver sub also can include a short-hop telemetry module, a processor module, and a clock module. In one embodiment, the receiver subs include seismic sensors for enabling vertical seismic profiling. During operation, the processor visually presents to the operator via one or more graphical user interfaces a dynamically updated pictorial image representing the drilling system. The image is annotated with an appropriate visual signal to indicate a determined physical condition at a given location or component. The processor can also display recommended adjustments to drilling parameters for increasing drilling rates, improving tool life, and more precise steering.

Owner:BAKER HUGHES INC

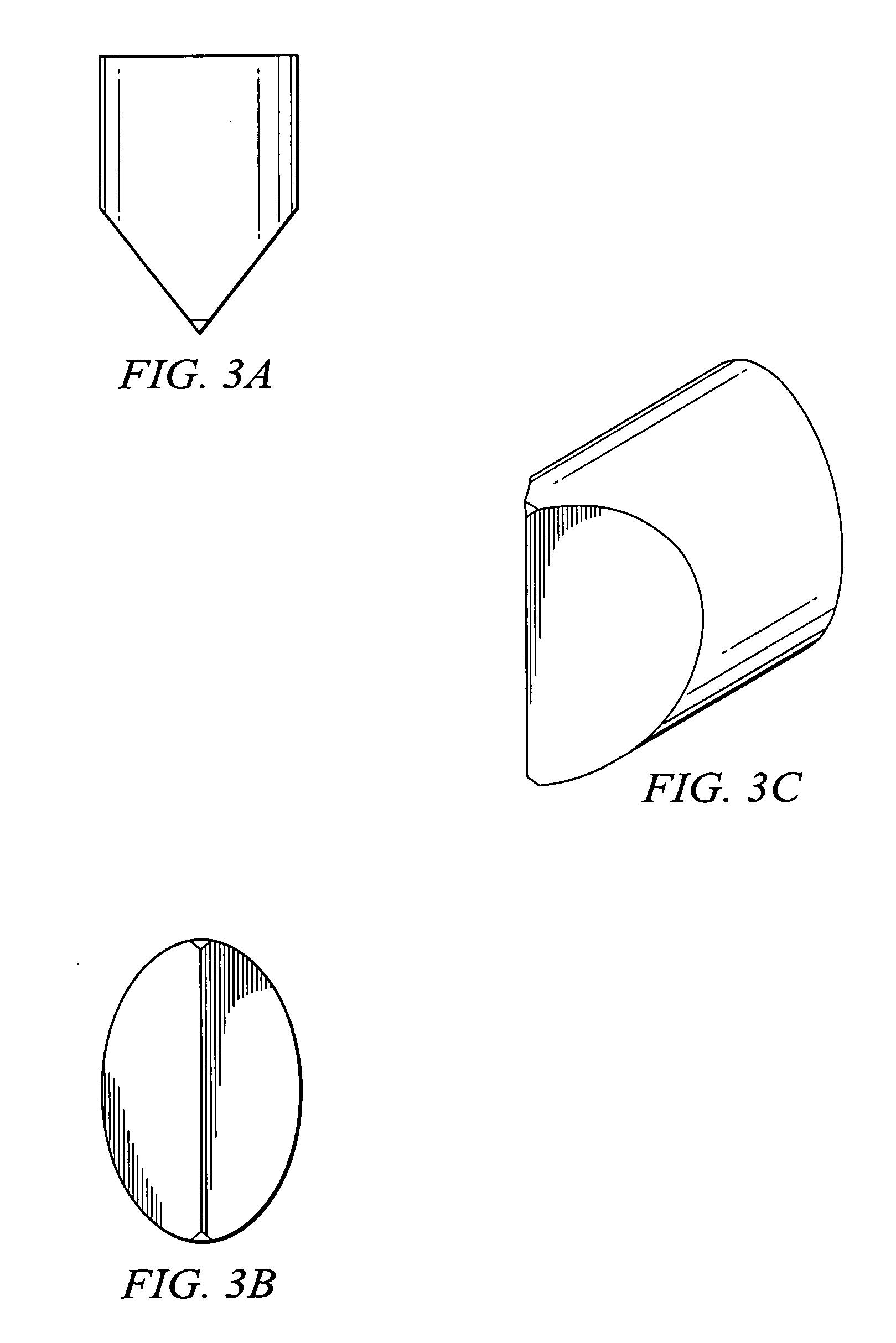

PDC cutter for high compressive strength and highly abrasive formations

InactiveUS20070235230A1Reduce wearReduce crackingDrill bitsConstructionsCompressive strengthUltimate tensile strength

A PDC cutter utilizes the combination of an elliptical shape with higher thermal resistance obtained through leaching to provide a cutter which is more effective than a cutter using either concept alone. The PDC cutter includes a tungsten carbide portion with protrusions extending from a surface thereof in a pattern. The diamond volume is mounted to the surface wherein the protrusions allow for the diamond volume to be larger about a perimeter edge of the cutter and smaller / shallower in a center region of the cutter. The protrusions providing surfaces for the diamond layer (table) to bond to the underlying tungsten carbide portion. With this configuration, diamond volume is maximized around the edge of the cutter.

Owner:VAREL INT IND

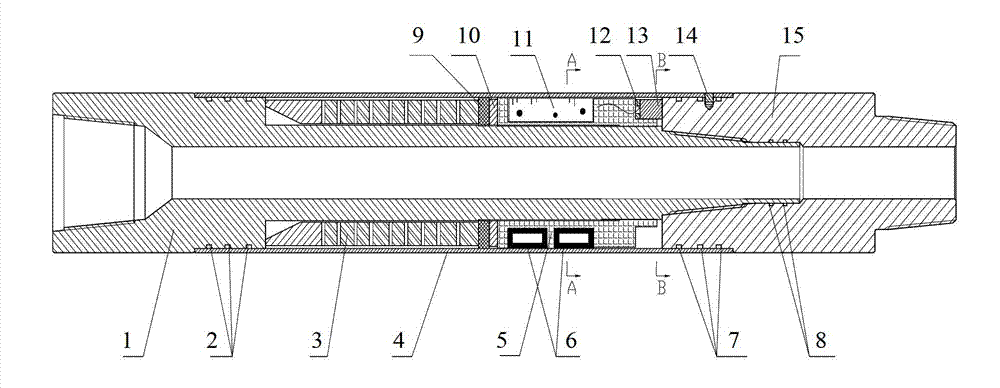

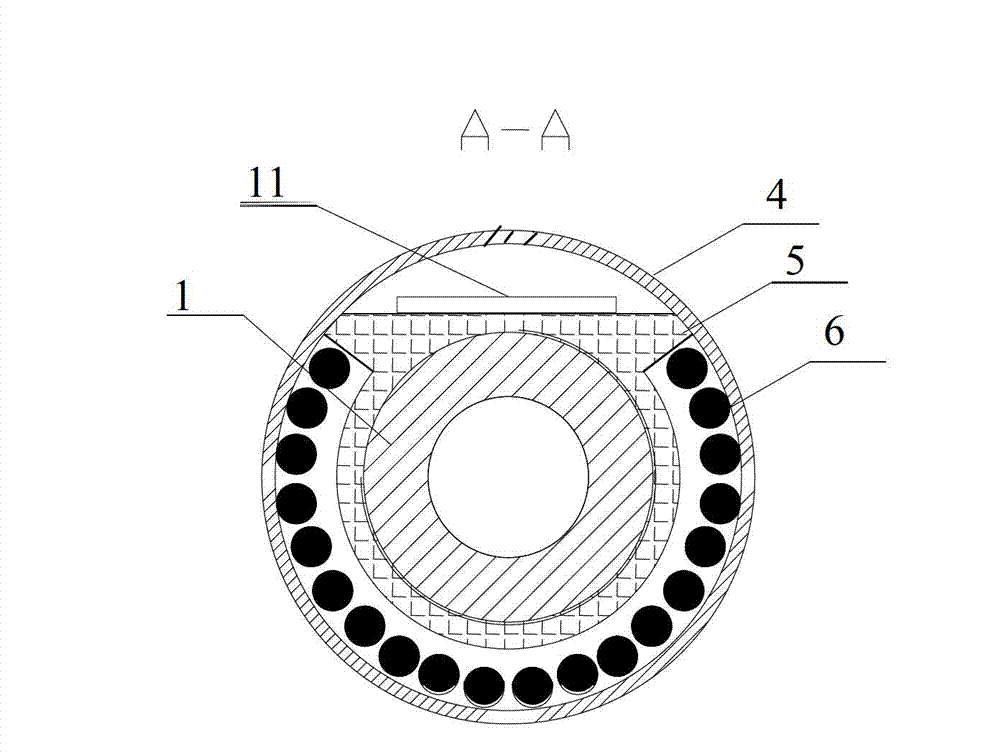

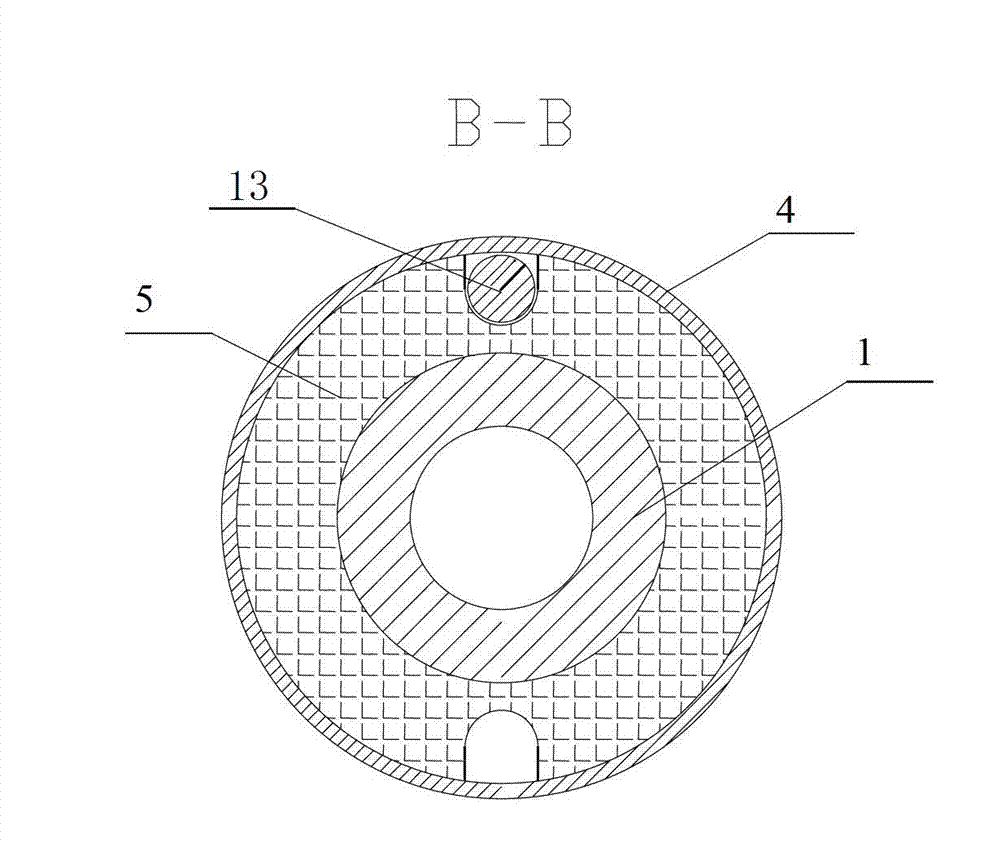

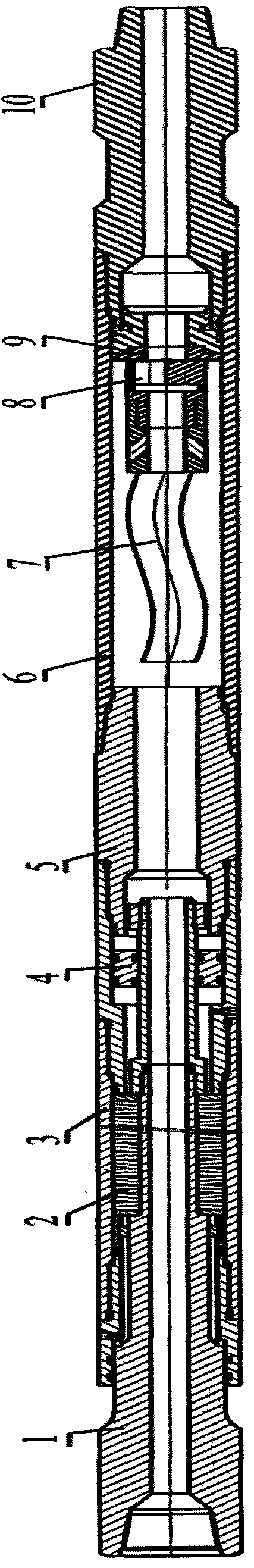

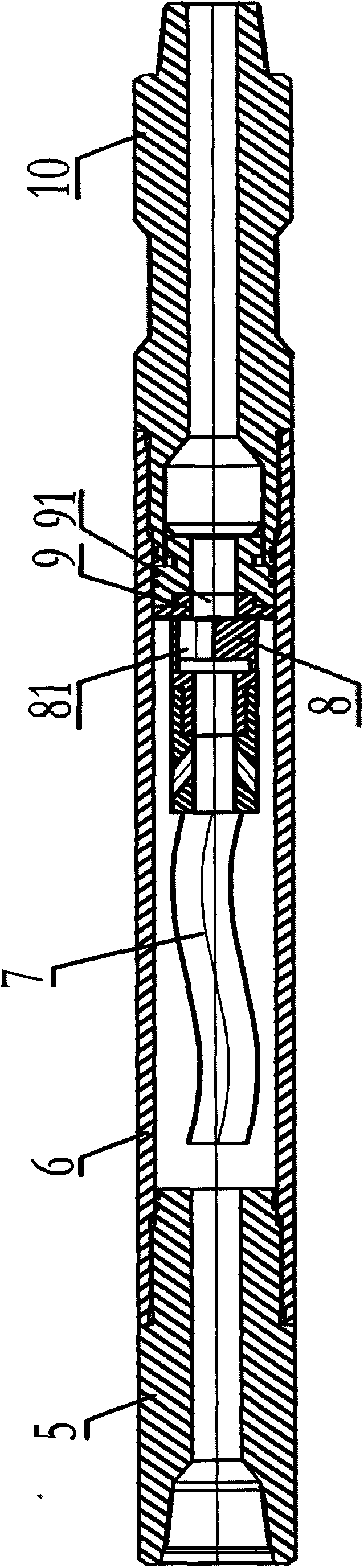

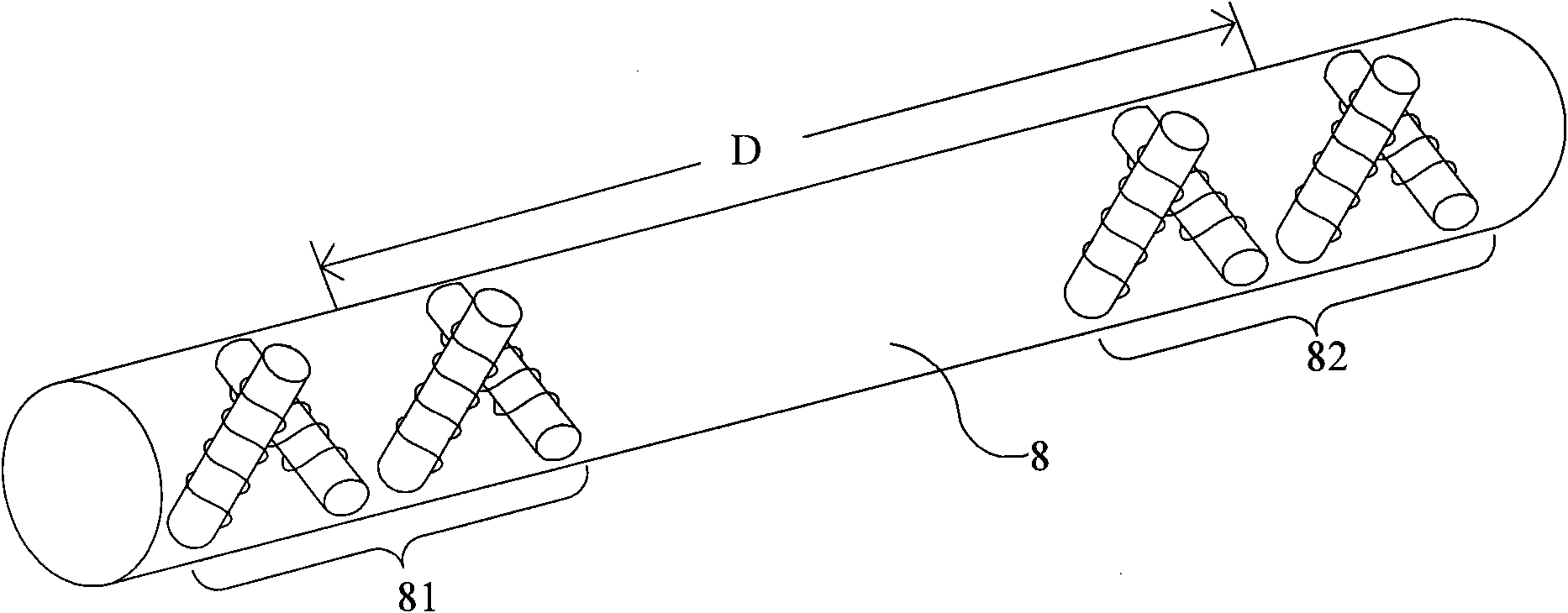

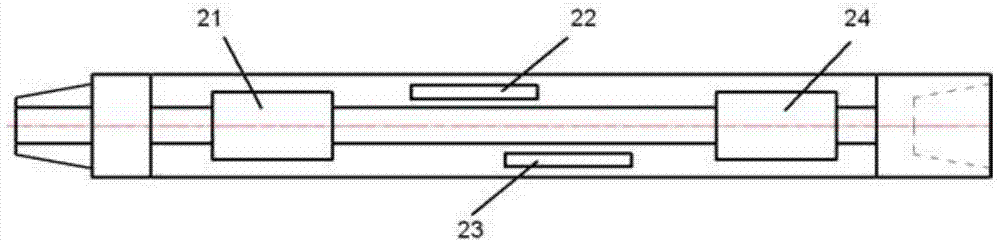

Well drilling information acoustic wave transmission relay device based on drilling string information channel

ActiveCN102733799AReduce distractionsImprove versatilitySurveyWell drillingSurface acoustic wave sensor

The invention relates to a drilling information transmitting device in the field of petroleum and natural gas drilling engineering, in particular to a well drilling information acoustic wave transmission relay device based on a drilling string information channel. The well drilling information acoustic wave transmission relay device comprises an acoustic wave sensor, a modulator circuit, a power source and a transmitting transducer assembly, wherein the modulator circuit receives electric signals outputted from the acoustic wave sensor; effective data are obtained after the electric signals are processed, and are transmitted to the transmitting transducer assembly; and the power source is used for supplying power for the acoustic wave sensor, the modulator circuit and the acoustic wave transmitting transducer assembly. The well drilling information acoustic wave transmission relay device can effectively work in an underground complex environment for a long time, the transmission distance of acoustic waves in a drilling string is lengthened, effective detection and directional signal transmission are ensured, and interference of a ring is decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

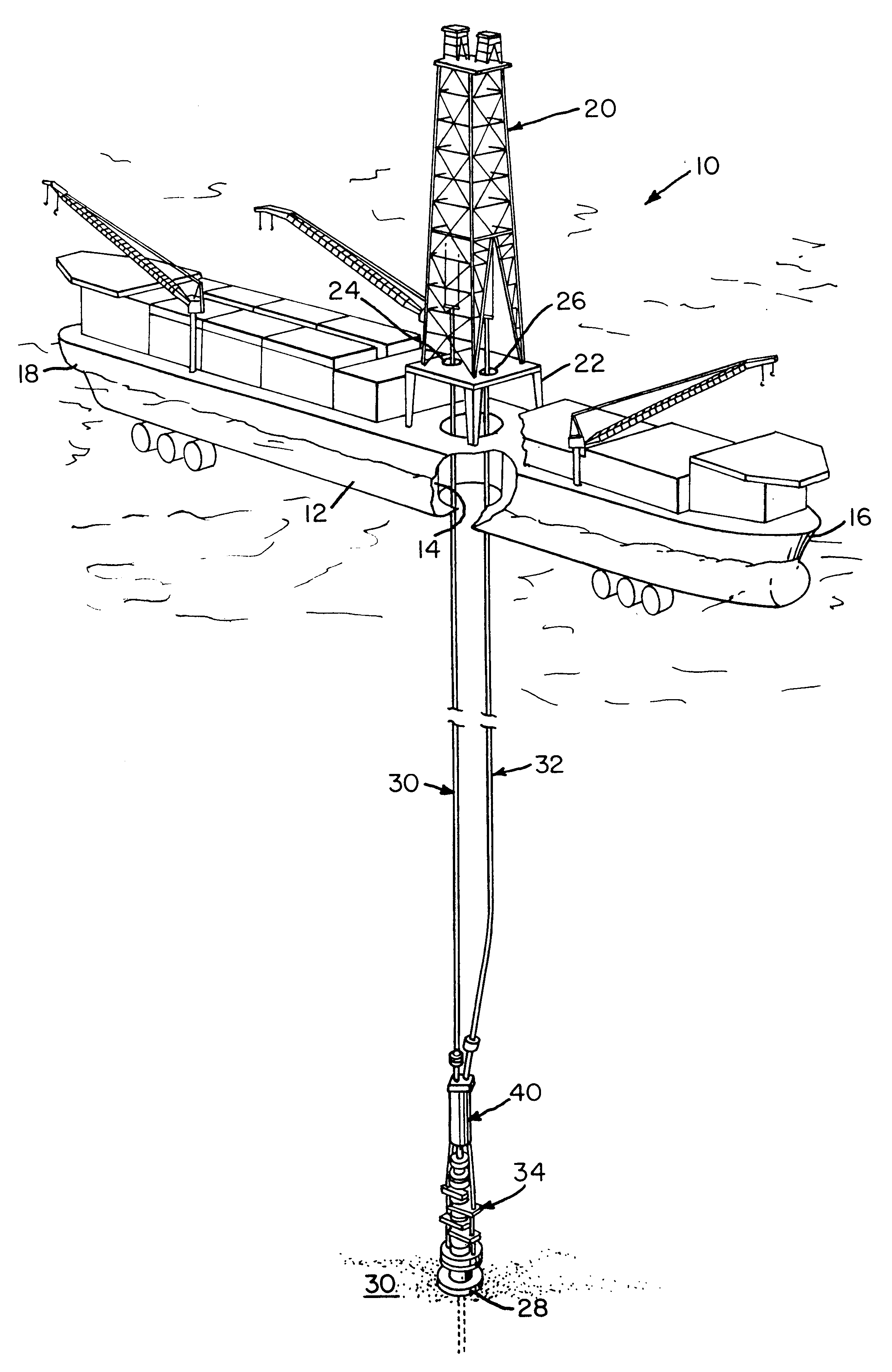

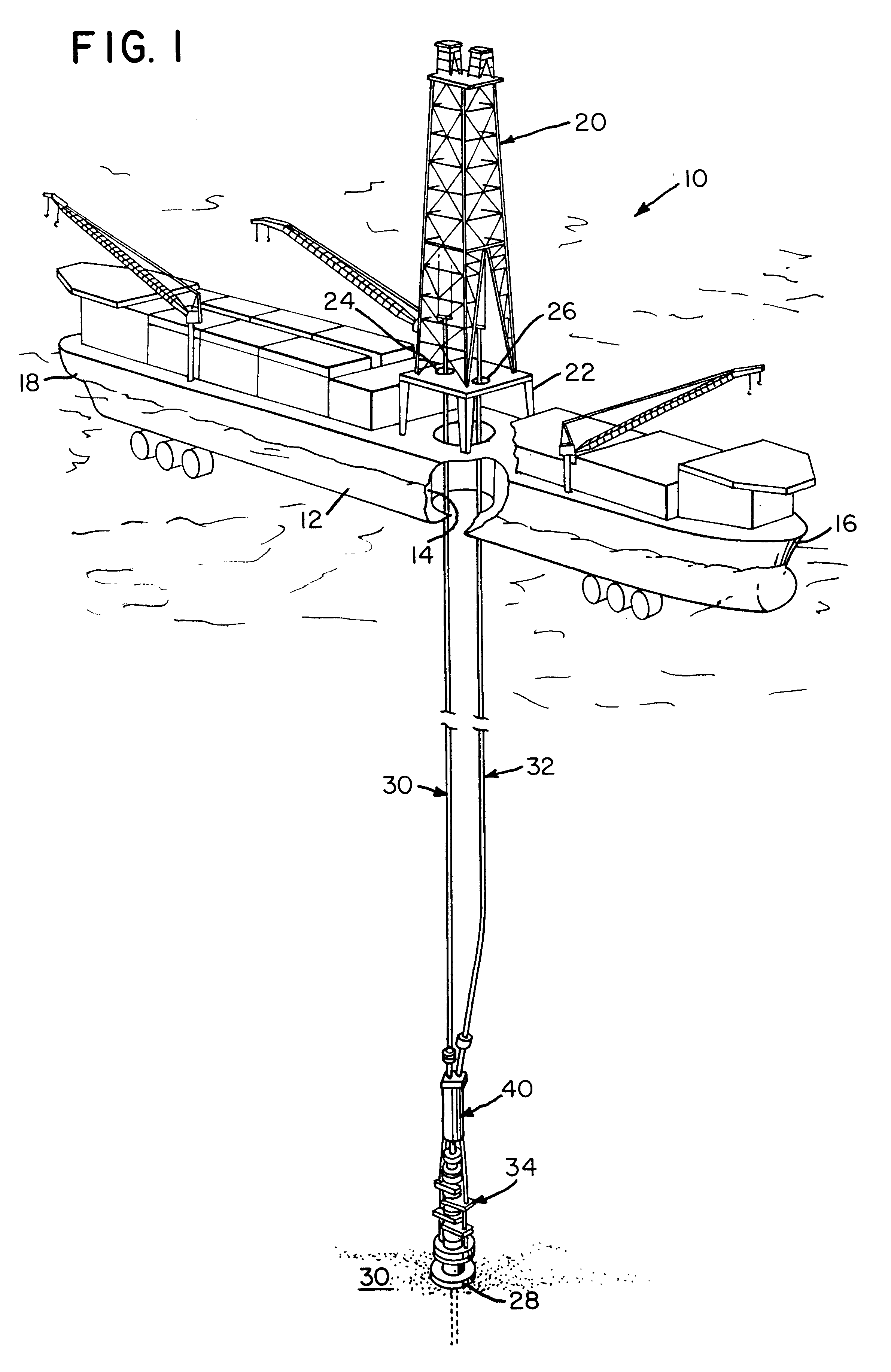

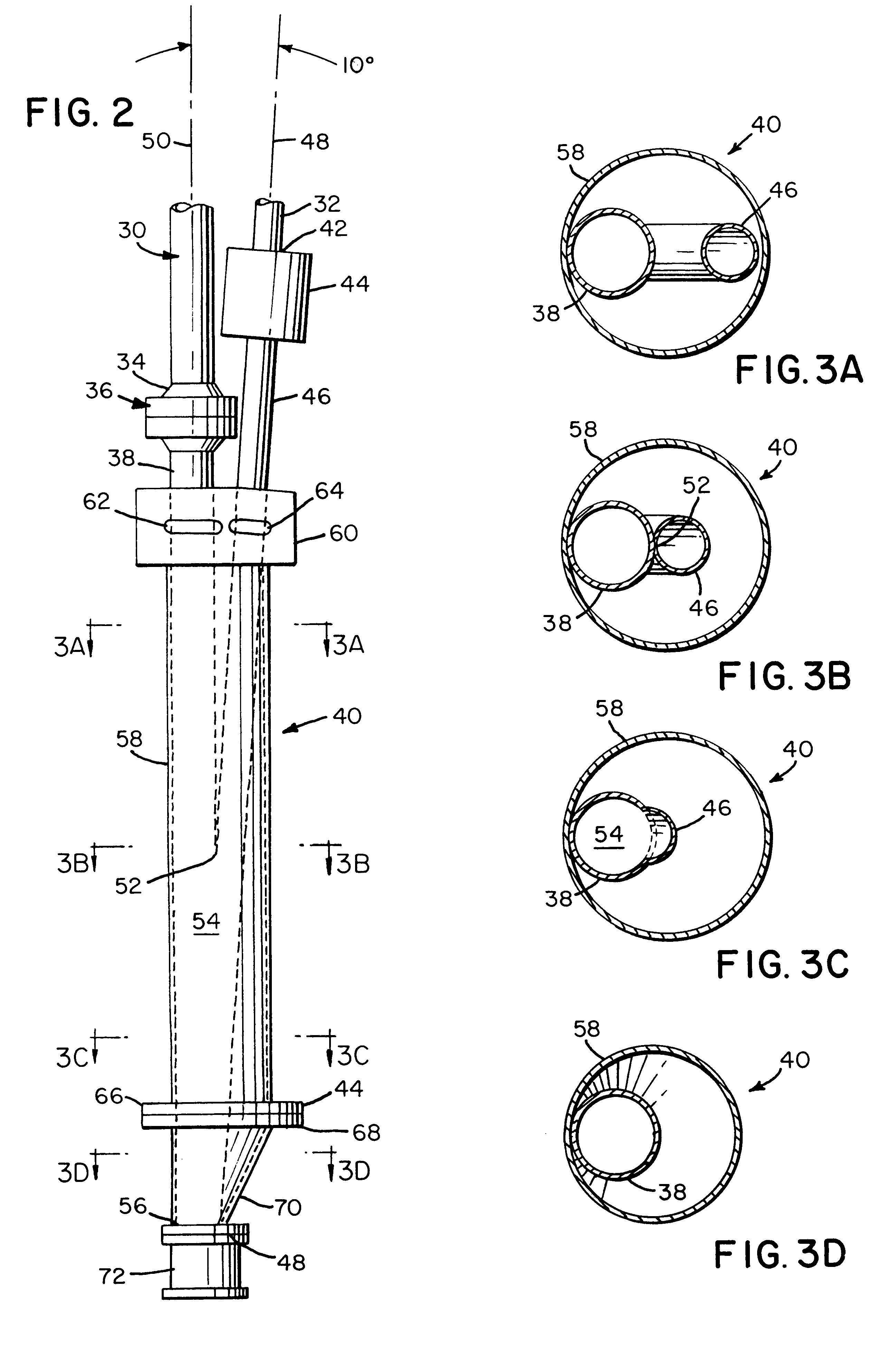

Dual riser assembly, deep water drilling method and apparatus

InactiveUS6443240B1Improve drilling efficiencyEasy to useDrilling rodsDerricks/mastsMarine engineeringWell drilling

A dual riser assembly for use with an offshore multi-activity drilling assembly to conduct drilling operations from a deck above the surface of a body of water into the bed of the body of water utilizing two risers, a first and a second, which extend from a location above the surface of a body of water to a common location adjacent to the bed of the body of water. Each riser terminates, at a distal end, into a dual riser assembly, allowing for selective open internal communication between each of the two risers and a single wellhole.

Owner:TRANSOCEAN OFFSHORE DEEPWATER DRILLING +1

Power system for downhole toolstring

InactiveUS20150107824A1Improve drilling efficiencyEasy to operateHybrid capacitor electrolytesCharge equalisation circuitSupercapacitorEnergy storage

A downhole power system is provided that includes an energy storage adapted to operate at high temperatures, and a modular signal interface device that serves to control the energy storage component as well as offer a means of data logging at high temperatures. The controller is fabricated from pre-assembled components that may be selected for various combinations to provide desired functionality. The energy storage may include at least one ultracapacitor.

Owner:FASTCAP SYST

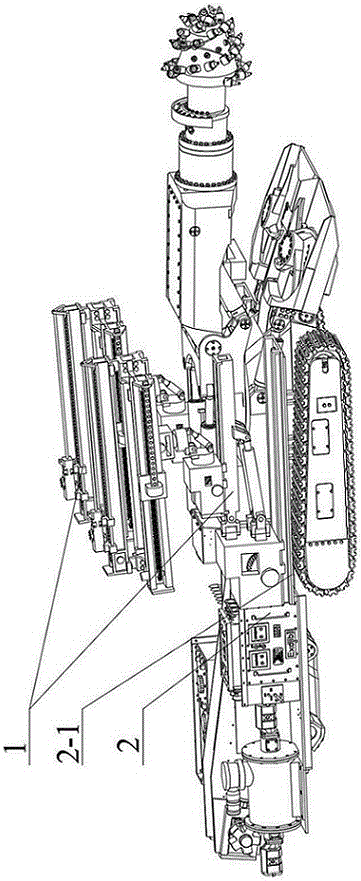

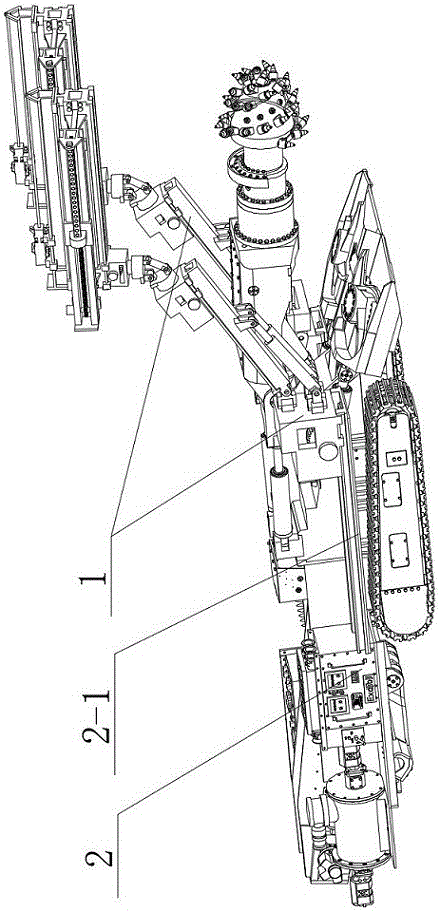

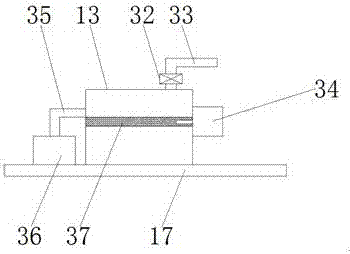

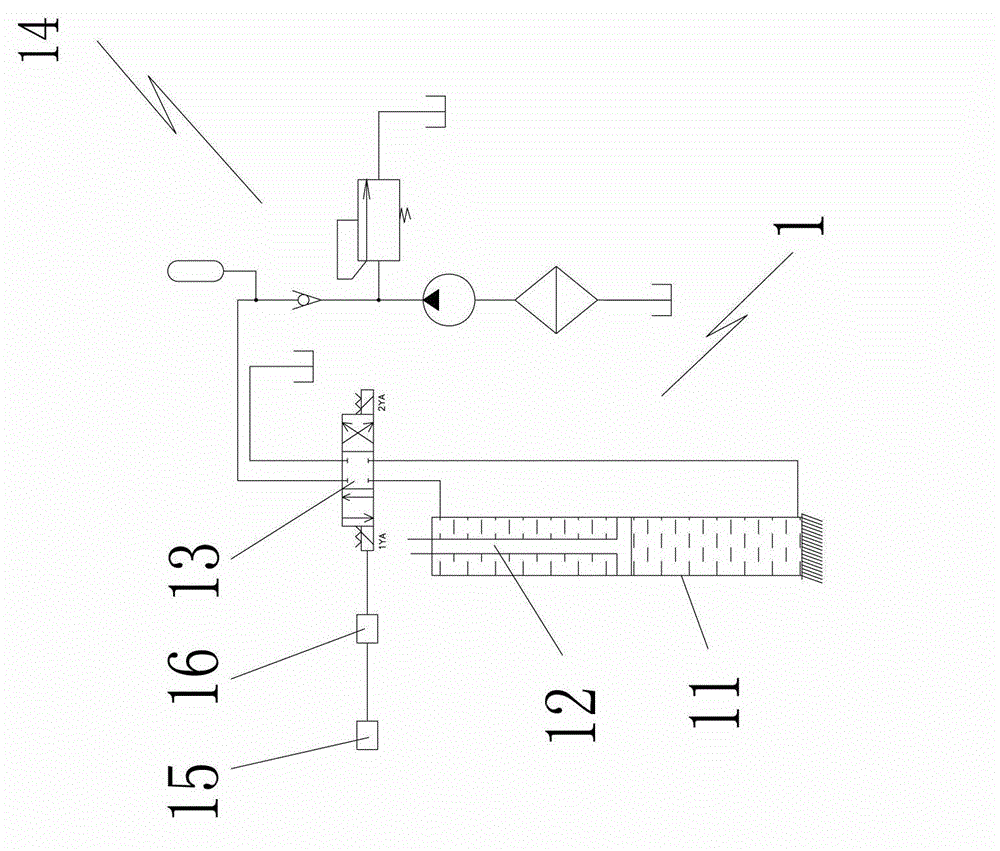

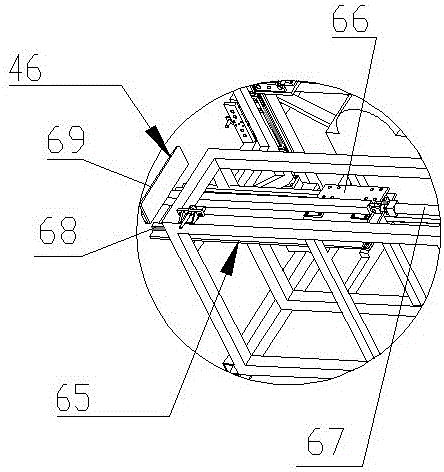

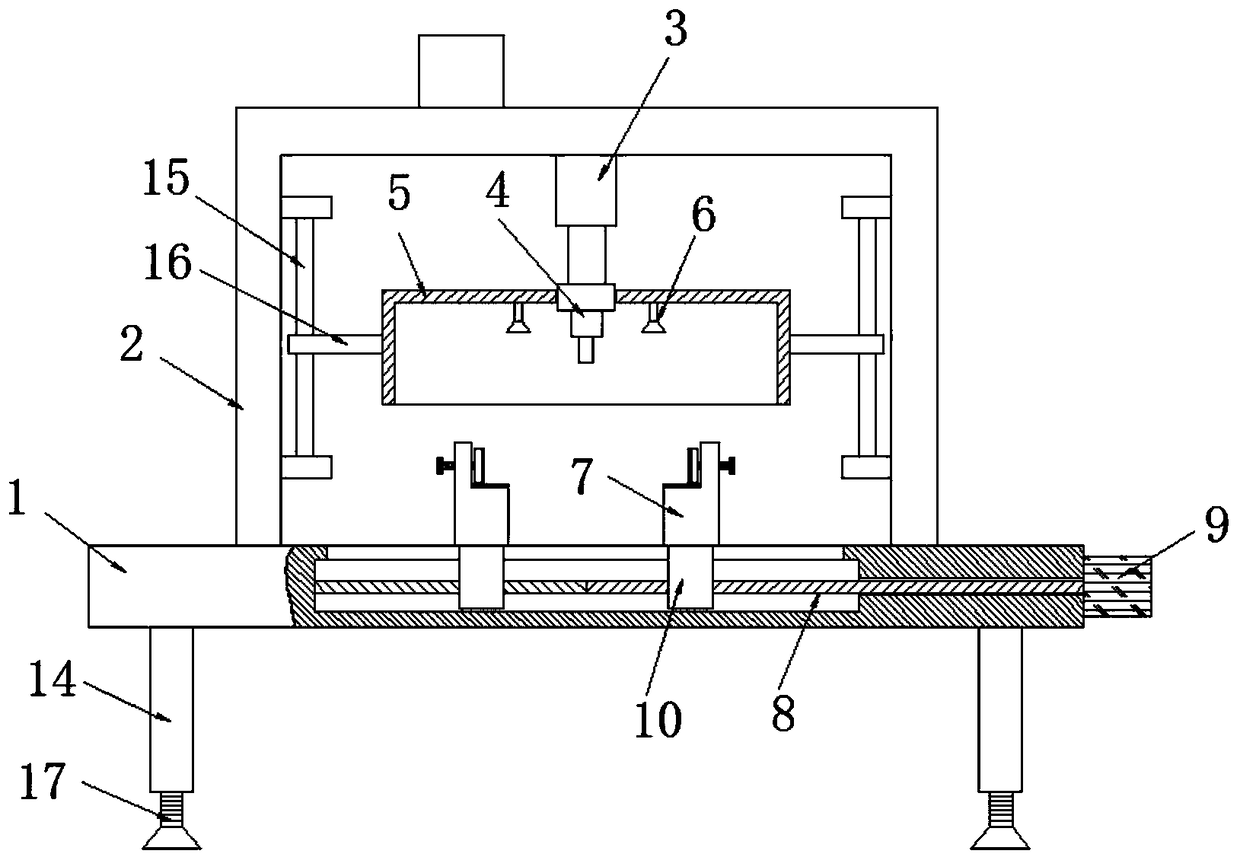

Drilling and bursting type heading machine

ActiveCN105804764AImprove drilling efficiencyLow drilling efficiencyDisloding machinesSlitting machinesHydraulic motorHydraulic cylinder

The invention discloses a drilling and bursting type heading machine which comprises a drilling and bursting device, an angle control device, a front-back telescopic device and a cantilever type heading machine body. The drilling and bursting device is installed on a front-back moving component of the front-back telescopic device. The front-back telescopic device is installed on the cantilever type heading machine body. The drilling and bursting device comprises a fixing frame, a rock drill component and a bursting device component, wherein the rock drill component and the bursting device component are fixed to and installed on the fixing frame. The angle control device comprises an installation base, an auxiliary rotary hydraulic motor, an adjusting hydraulic cylinder and a main rotary hydraulic motor. When the front-back moving component of the front-back telescopic device completely stretches out, the distance between the front end of the drilling and bursting device and a working surface is smaller than the distance between the front end of a cutting head of the cantilever type heading machine body and the working surface. The drilling and bursting type heading machine is compact in structure, a hard rock stratum with the rock stratum hardness being larger than 10 can be rapidly drilled and burst on the premise that the energy consumption is not increased, and accordingly the purposes of improving the heading efficiency and reducing potential safety hazards are achieved.

Owner:CHINA UNIV OF MINING & TECH

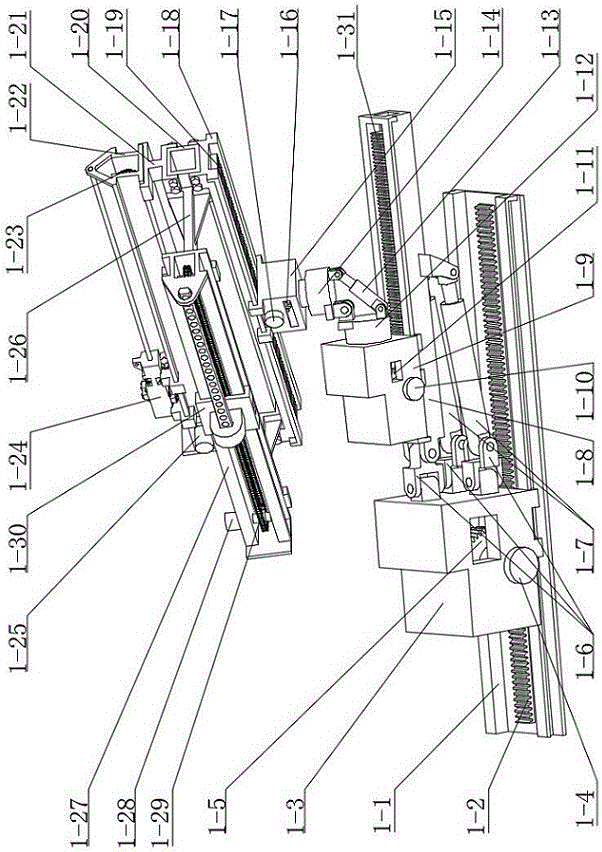

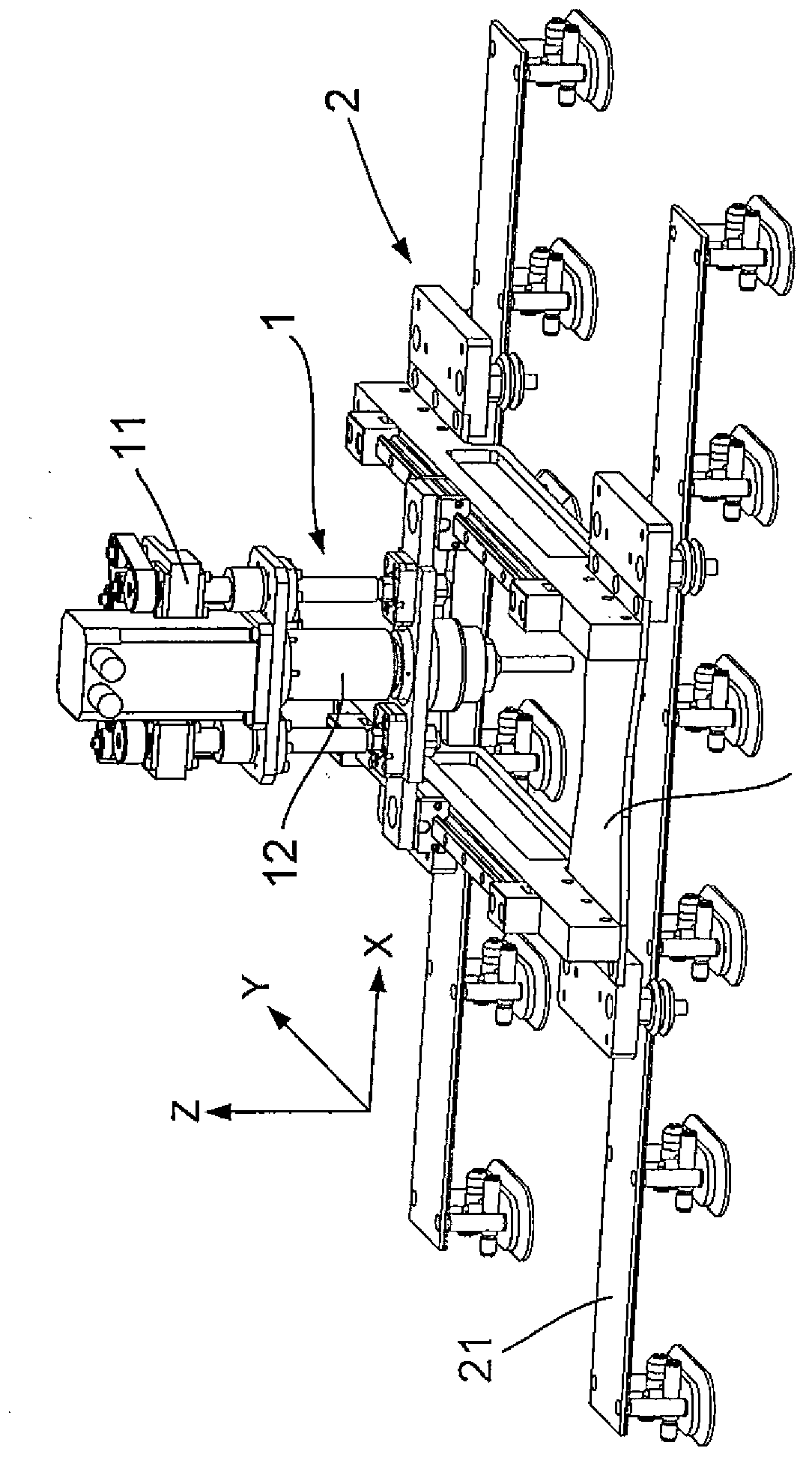

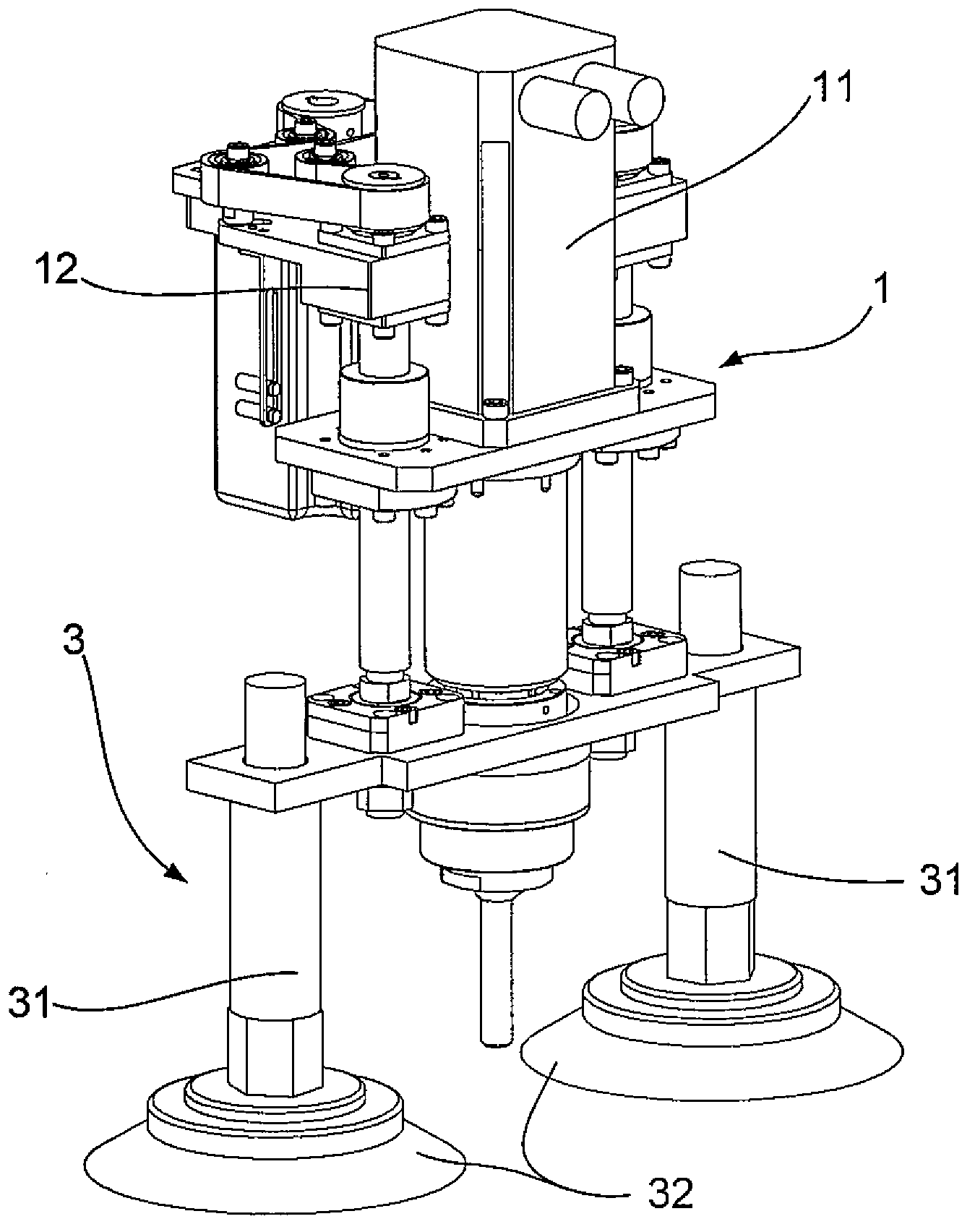

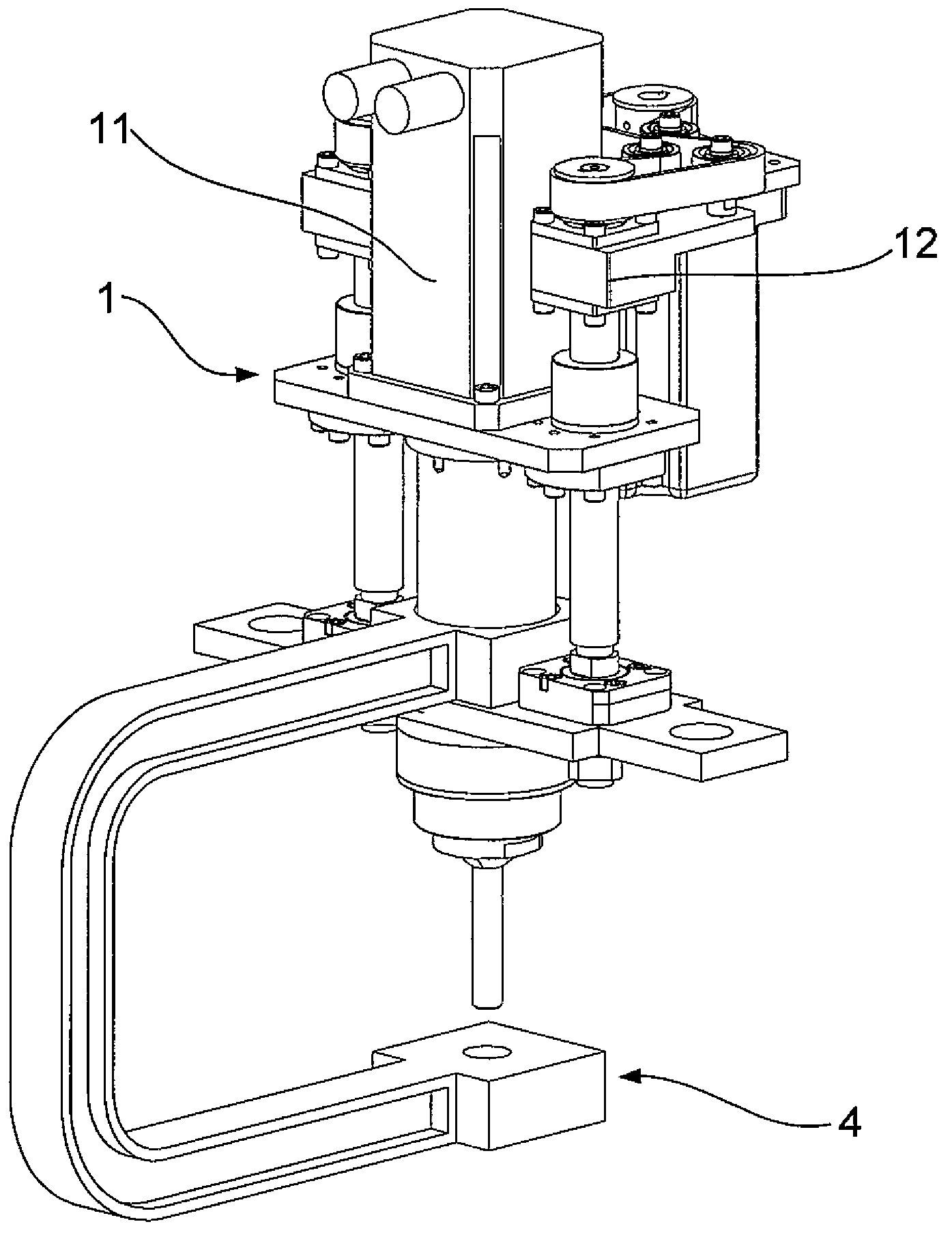

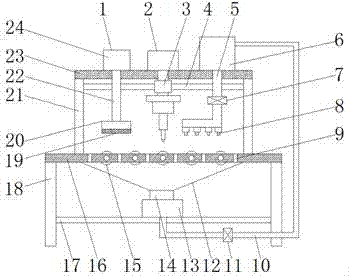

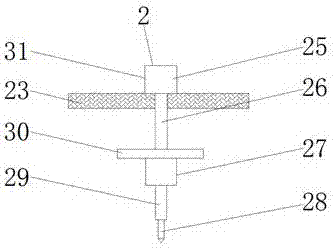

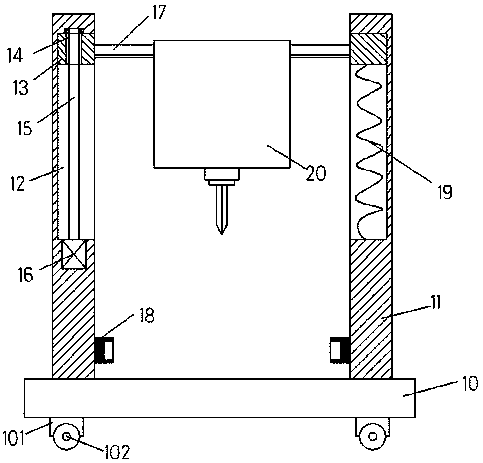

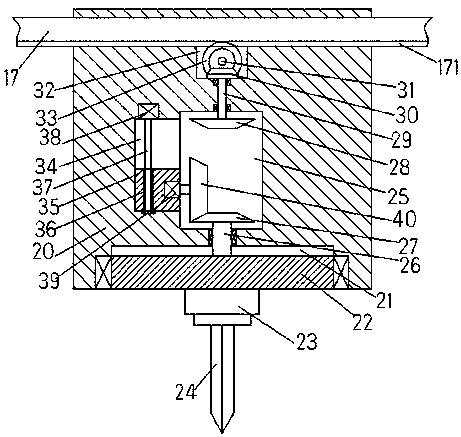

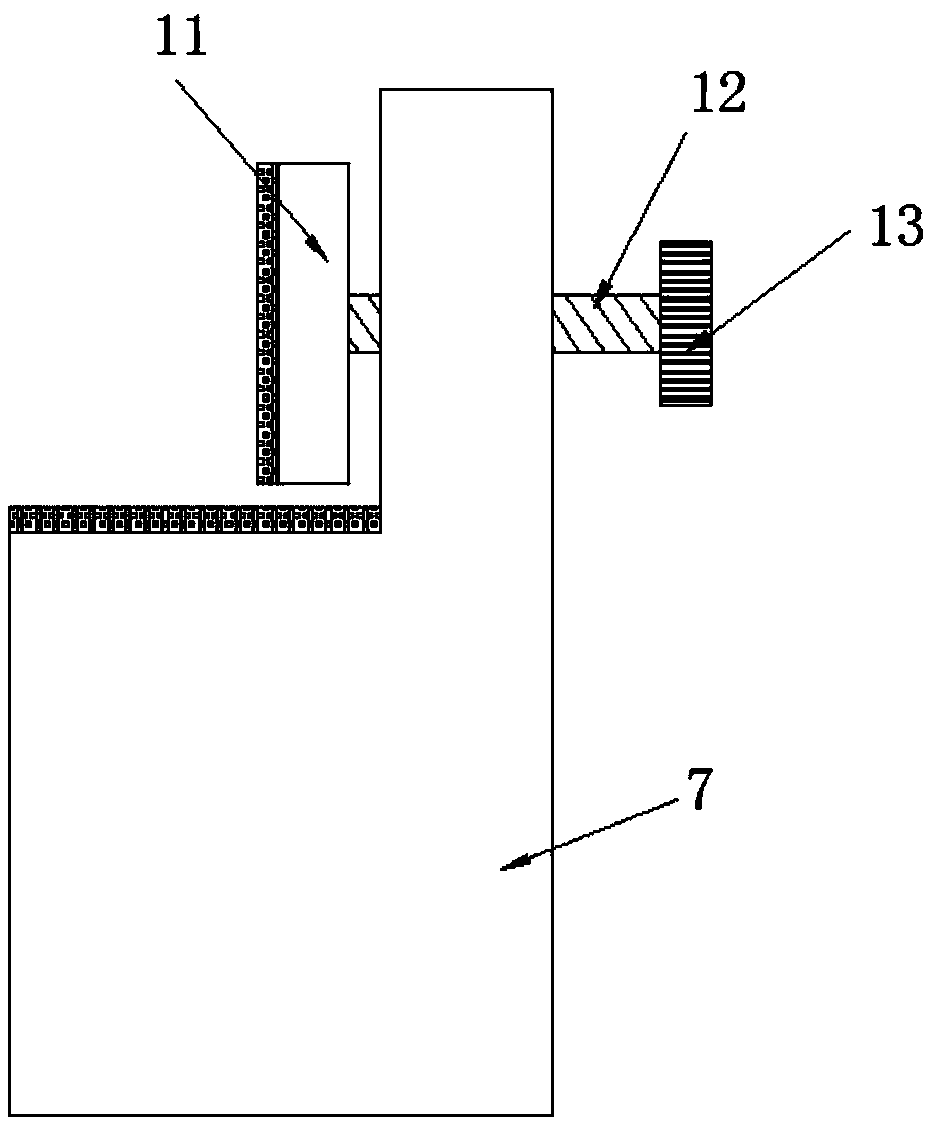

Replaceable precise automatic feeding drill

The invention discloses a replaceable precise automatic feeding drill, which consists of an automatic feeding drill main body and working platforms. Different working platforms can be selected according to different using environments or conditions, and operation of drilling, reaming, counter sinking and the like of machined workpieces are implemented. The working platforms comprise an X-Y flexible track platform (1), a bilateral sucking disc platform (2) and a C-shaped jaw platform (3), wherein the X-Y flexible track platform (1) can adapt to and attract surfaces with different curvatures; the bilateral sucking disc platform (2) can attract the fixed workpieces in a narrow space; and the C-shaped jaw platform (3) can be used for conventional drilling as a bench drill. The invention has the advantages that the automatic feeding drill is precise and portable, can be quickly replaced and can be used for accurately and quickly drilling various different workpieces.

Owner:SHANGHAI AIRCRAFT MFG +1

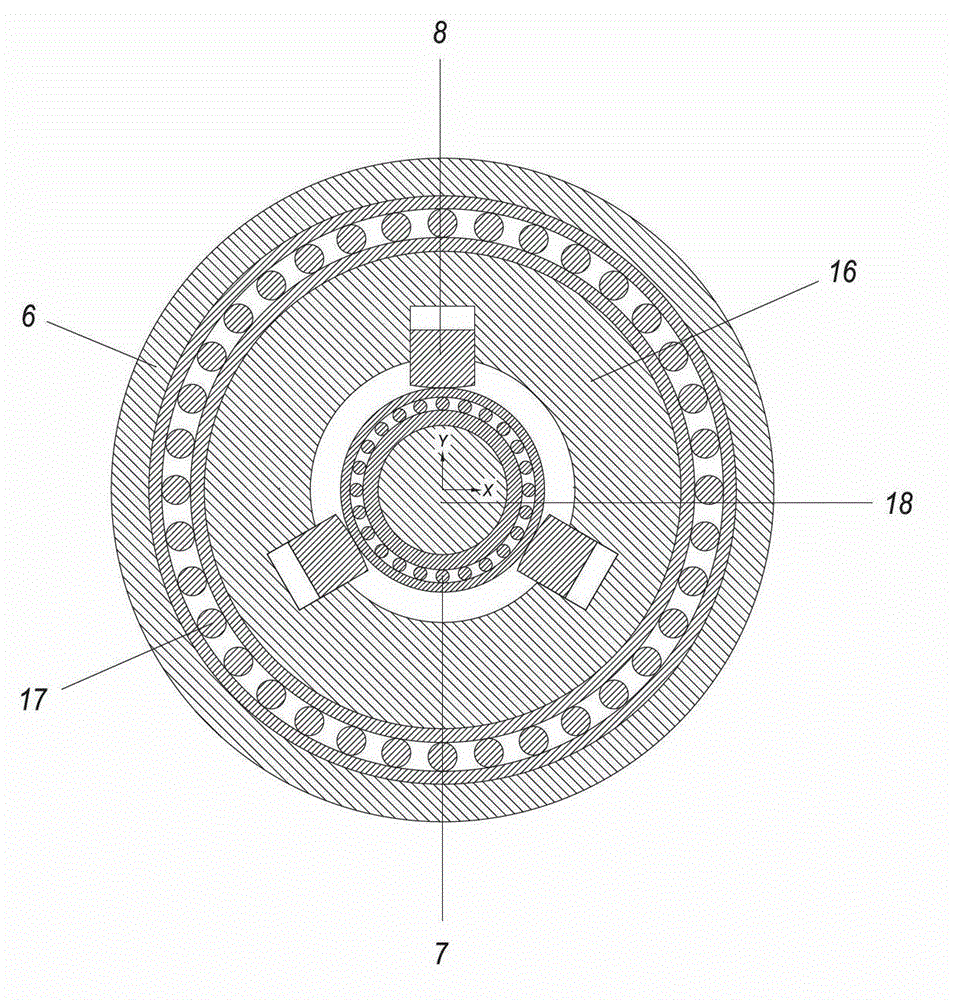

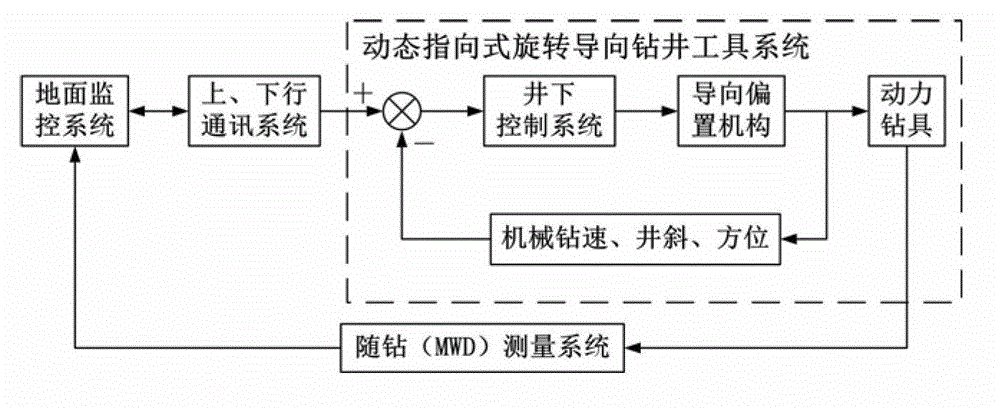

Dynamic point-the-bit rotary steering drilling tool

InactiveCN102913131AFulfill control requirementsEliminate the effects ofDirectional drillingBorehole drivesMonitoring systemTransfer mechanism

The invention relates to a dynamic point-the-bit rotary steering drilling tool. The dynamic point-the-bit rotary steering drilling tool comprises a rotary outer cylinder, a stable platform, a steering offset mechanism, a bit pressure transfer mechanism, a torque transfer mechanism, an upper support plate, a lower support plate, a drill shaft, a drill bit, a sealed corrugated pipe, a drill shaft connecting bearing and a conductive slip ring, and is characterized in that the rotary outer cylinder is used for directly applying bit pressure and torque on the drill bit and driving the drill shaft and the drill bit to rotate jointly, information of hole deviation angle and azimuth angle to be controlled can be calculated by a calculating unit according to a preset borehole trajectory parameter or a remote control command of a ground monitoring system, and precision control of bend angle, in particular to the hole deviation angle and the azimuth angle of the offset mechanism can be realized by adopting a geostationary control method of the stable platform and combining with working principles of a hydraulic drive piston and the steering offset mechanism.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

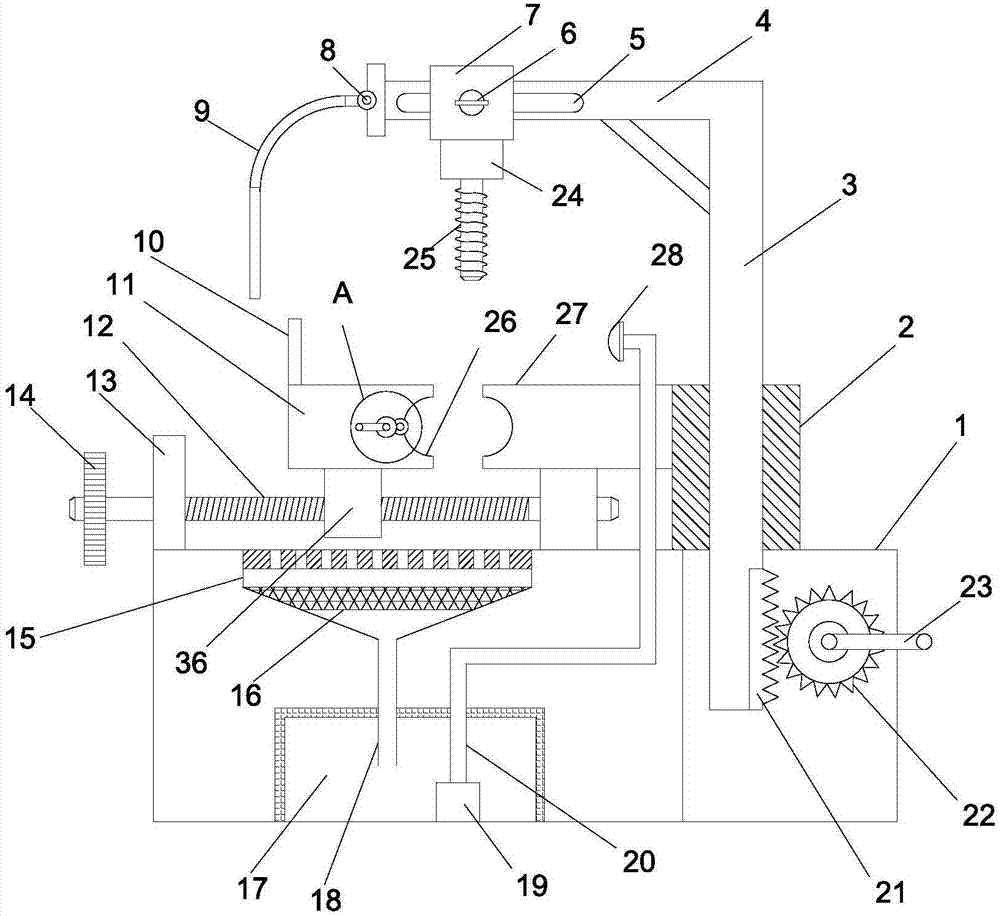

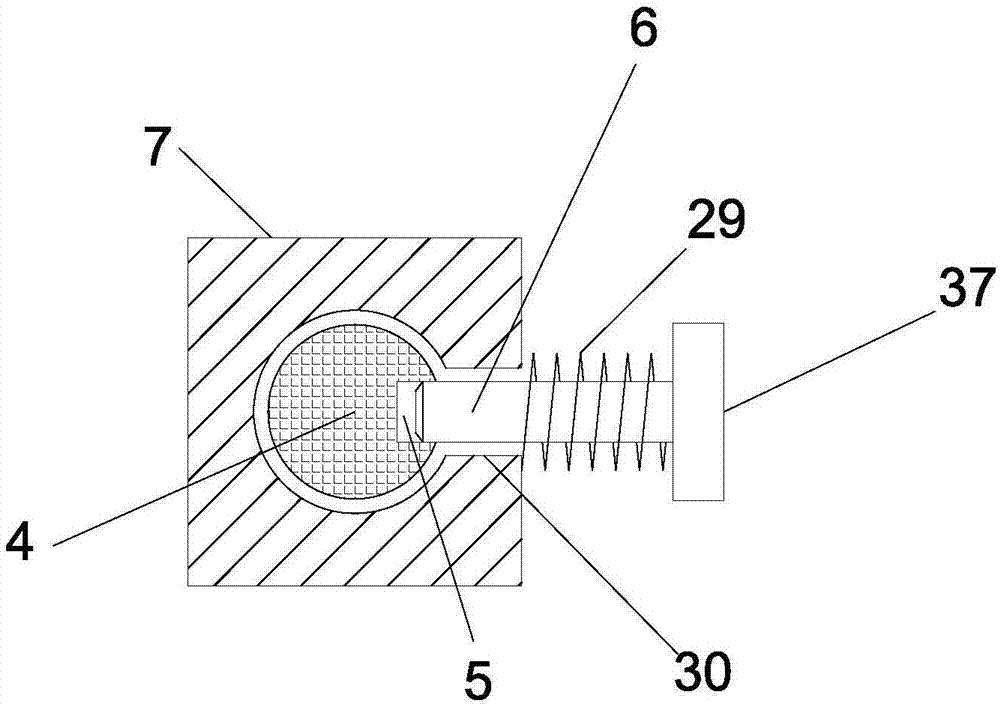

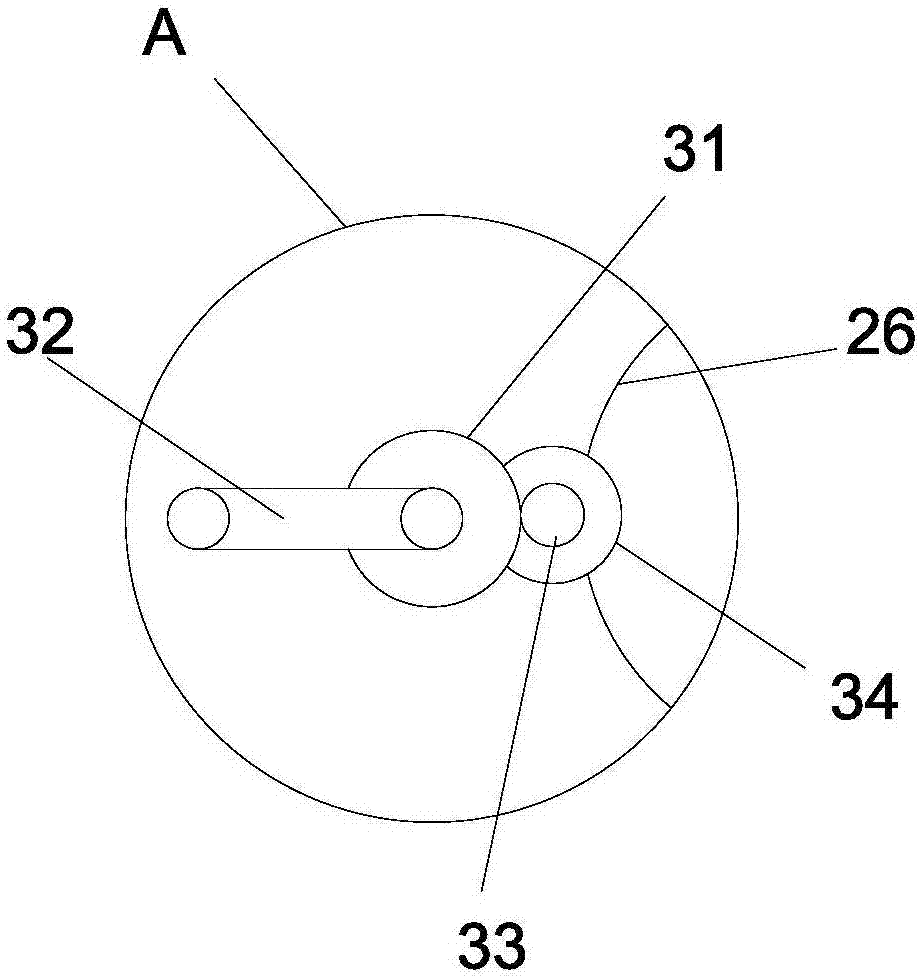

Steel plate drilling machine with scrap recycling and fixing functions

PendingCN107378024ARealize the purpose of drilling in different positionsImprove stabilityMaintainance and safety accessoriesBoring/drilling machinesFixed-functionHydraulic cylinder

The invention discloses a steel plate drilling machine with scrap recycling and fixing functions. According to the steel plate drilling machine, a first hydraulic cylinder drives a first hydraulic rod to drive a pressure plate to move downwards, so that a steel plate is extruded and fixed, the influence of movement of the steel plate in drilling on drilling effects and drilling accuracy is avoided, stability of a second hydraulic rod in the downward movement process is improved by the aid of a sliding sleeve, so that the drilling accuracy is further improved, water in a water storage tank enters a water outlet pipe by the aid of a first booster pump and is sprayed from a flushing sprayer, so that scraps generated by drilling the steel plate are flushed, cleanness of the surface of the steel plate is ensured, waste water generated by flushing the scraps falls into a water receiving funnel through a through hole, the waste water is collected by the water receiving funnel, environmental pollution caused by the waste water is avoided, the waste water entering a scrap recycling and drying box is filtered by the aid of a screen plate, the scraps are recycled, resources are saved, and practicability of the steel plate drilling machine is improved.

Owner:湖州南浔永方机械有限公司

Self-sharpening polycrystalline diamond compact and preparation method thereof

InactiveCN103722174AEnhance "self-sharpening"Enhance the \"retouching\" effectUltra-high pressure processesPolycrystalline diamondAlloy

The invention discloses a self-sharpening polycrystalline diamond compact and a preparation method thereof. The self-sharpening polycrystalline diamond compact comprises a hard alloy base body and a polycrystalline diamond polycrystalline layer, wherein the polycrystalline diamond polycrystalline layer comprises 60-95% of diamond micro-powder and 5%-40% of binding agents, the binding agents are composite binding agents of metal and ceramics, the metal accounts for 1%-11% of the polycrystalline diamond polycrystalline layer, and the ceramics accounts for 1%-40% of the polycrystalline diamond polycrystalline layer, and the diamond micro-powder and the binding agents form the diamond compact respectively through chemical acid-base processing, physical vacuum processing, ball mill mixing, compression moulding and final high-temperature and high-pressure sintering. The diamond compact is good in self-sharpening, even in abrasive ratio and suitable for high-speed cutting machining and precise machining of non-black metal and geological prospecting.

Owner:ZHONGYUAN ENGINEERING COLLEGE

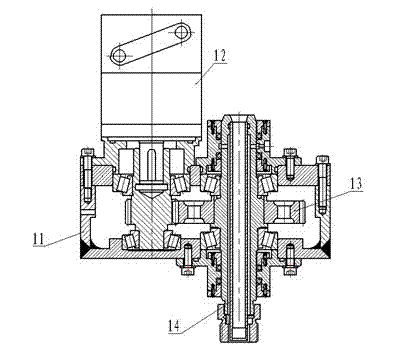

Hydraulic oscillator for well drilling

InactiveCN103696693AReduce frictionImprove drilling efficiencyVibration drillingUpper jointWell drilling

The invention relates to the technical field of well drilling tools and discloses a hydraulic oscillator for well drilling. The hydraulic oscillator comprises an axial oscillator mechanism and a power assembly, the axial oscillator mechanism comprises a joint, a disc spring, a shell and a piston, the joint is mounted on the rear portion of the shell in a sleeve manner, the disc spring is connected between the shell and the joint in a clamped manner, the piston is arranged at the front end of the shell, the power assembly comprises an upper joint, a stator, a rotor, an upper valve piece, a lower valve piece and a lower joint, the rotor is arranged inside the stator and can rotate in the stator, one end of the stator is connected with the axial oscillator mechanism through the upper joint while the other end of the same is connected with a drilling tool through the lower joint, the upper valve piece is connected with the rotor, the lower valve piece is fixedly connected inside the stator below the upper valve piece, an eccentric hole is arranged on the upper valve piece, and a central hole is arranged on the lower valve piece. In the process of horizontal well drilling, the hydraulic oscillator can generate certain oscillating frequency, so that effect of reducing friction resistance of the drilling tool in the process of horizontal well drilling and improving working efficiency in well drilling is realized.

Owner:SHANDONG LUHAI GASOLINEEUM EQUIP

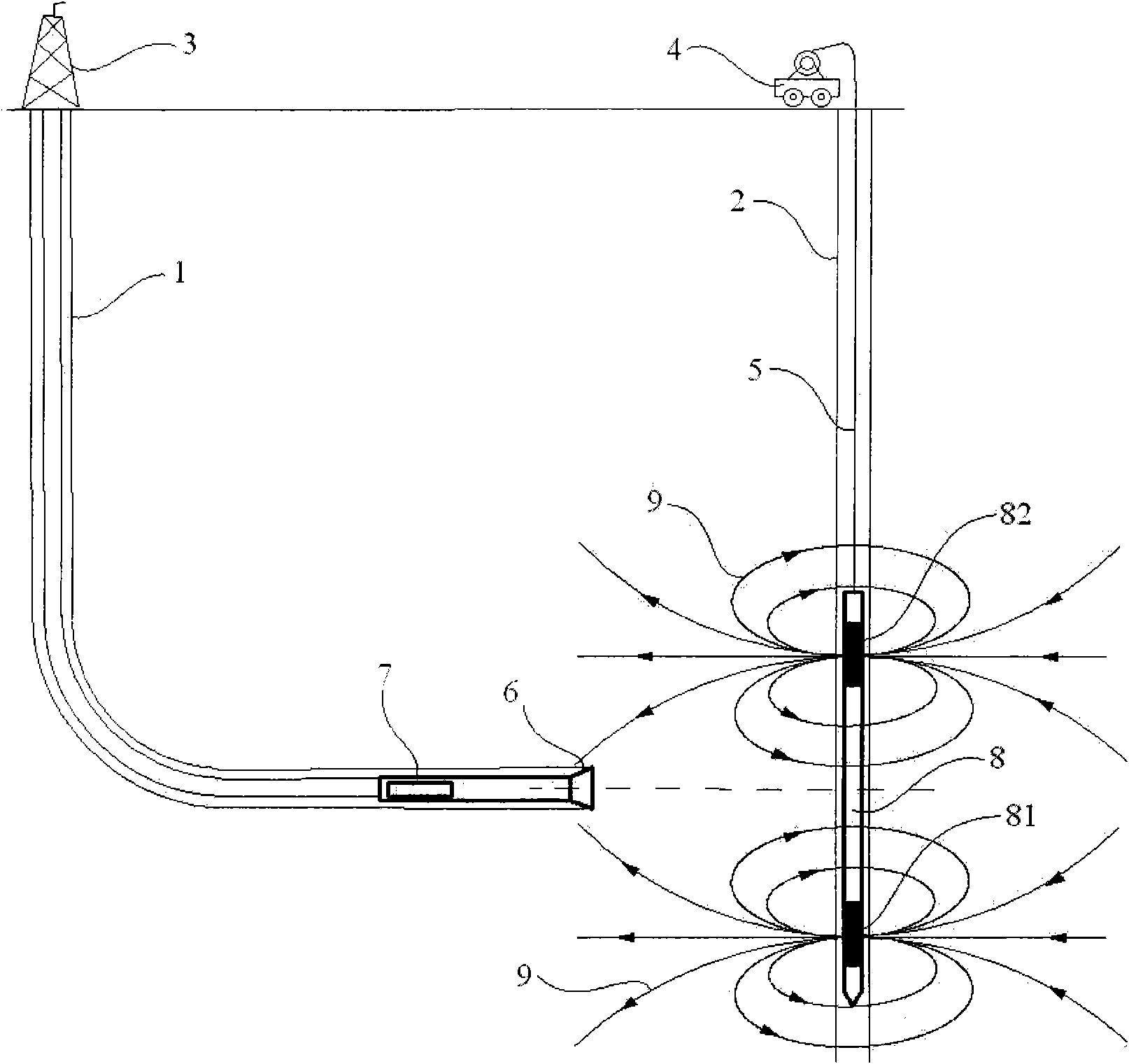

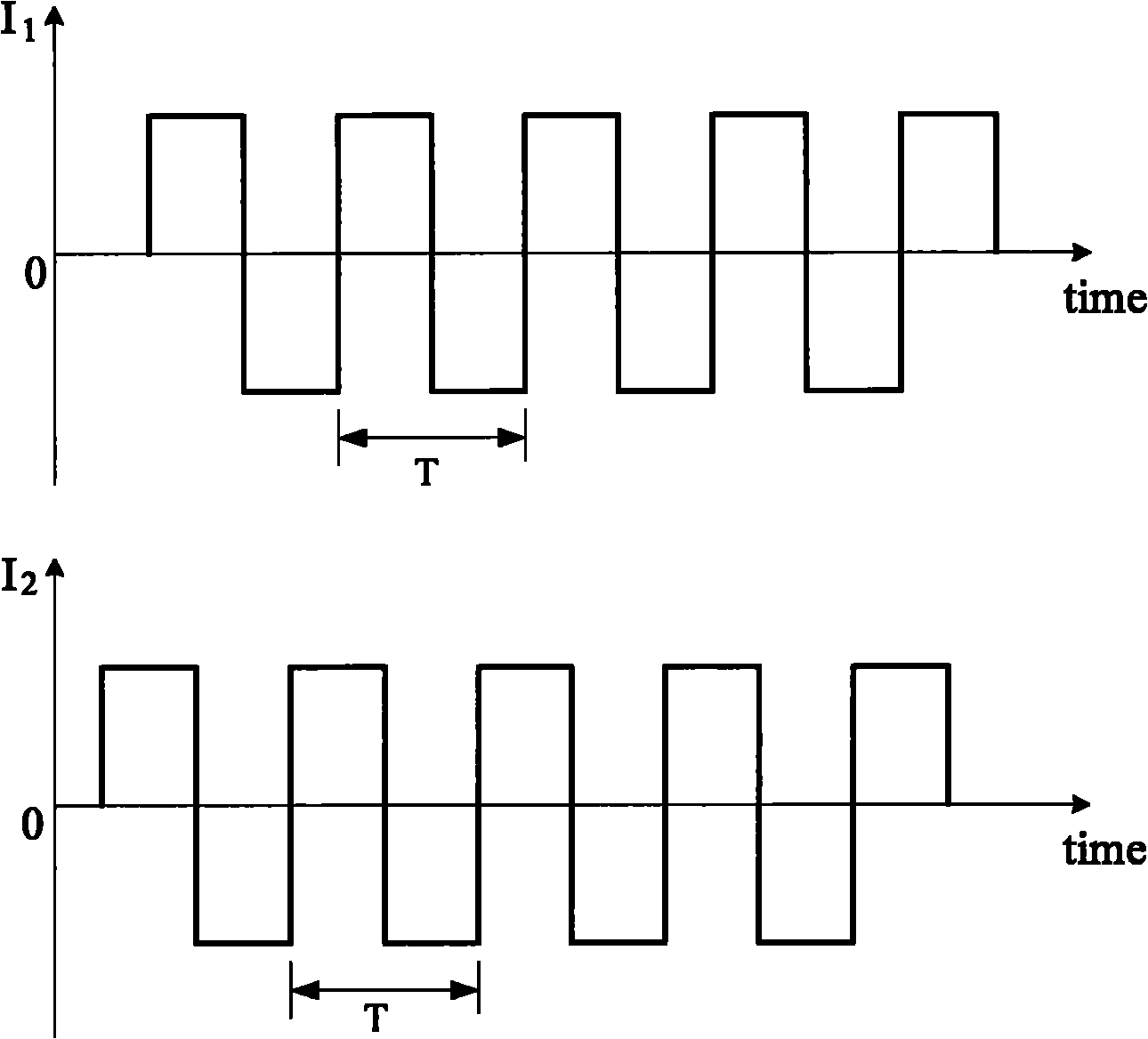

Electromagnetic distance measurement guide system for double solenoid set during drilling

InactiveCN101852078AEasy to change intensityHigh precisionSurveyConstructionsHorizontal wellsData transmission time

The invention discloses an electromagnetic distance measurement guide system for a double solenoid set during drilling. The system can provide accurate guide measurement and calculation for well track control of double horizontal wells, communicated wells, U-shaped wells, infill wells, and other complex-structure wells. The system mainly comprises a double solenoid set pup joint, a converted MWD,a ground display system, ground equipment, and the like. The double solenoid set pup joint serving as a magnetic signal emission source is put into a drilled well, two rotating magnetic fields with different frequencies are generated, and the system has the measurement accuracy equivalent to the RMRS. During measurement and calculation, the spacing between adjacent wells and relative azimuth can be accurately detected and calculated without dragging the double solenoid set pup joint. Therefore, the measurement can be finished in short time. The data analysis and adjacent well spacing calculation program of the system can be put underground, only a little of calculated necessary data is transmitted to the ground, and the data transmission time is saved. Meanwhile, by improving the current intensity of a solenoid coil, and the like, the intensity of the magnetic signal emission source is improved, and the distance measurement range of the system is easily increased. The system has the advantages of high guide accuracy, wide distance measurement range, short measurement time, and simple structure, and is an effective high-tech means for the detection and control of the distance between the adjacent wells during drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

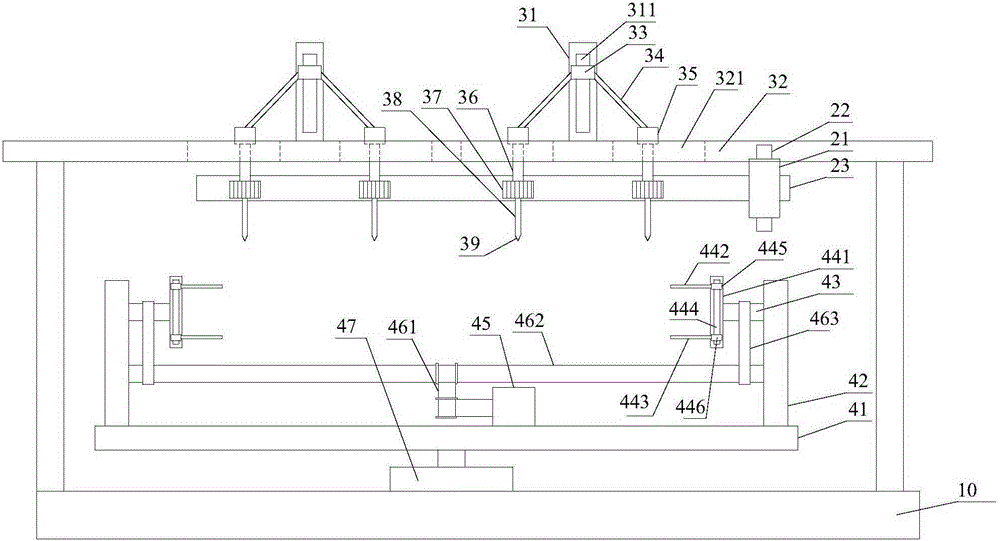

Steel tube drilling device provided with multiple drill heads

The invention provides a steel tube drilling device provided with multiple drill heads. The device comprises a workbench, a driving mechanism, a drilling mechanism and a clamping mechanism, wherein the driving mechanism comprises a first gear, a rack and a drive shaft; the drilling mechanism comprises multiple drilling apparatuses, and each drilling apparatus comprises a stand column mounted on the workbench, a cross bar mounted on the stand column, a connecting plate mounted on the stand column and at least two drilling units; each drilling unit comprises a slider, a first connecting rod, a second gear and a drill rod; the connecting plates are hinged with the sliders through second connecting rods with equal lengths; the clamping mechanism comprises a mounting plate, a first drive device and clamping devices symmetrically arranged at two ends of the mounting plate; each clamping device comprises a bracket, a first rotating shaft and a clamping unit, the first rotating shaft is horizontally and rotationally mounted on the bracket, and the clamping unit is mounted on the first rotating shaft; the first drive device is in transmission connection with the first rotating shafts through transmission mechanisms. The device can drill multiple holes in the same steel tube, and the product quality is high.

Owner:芜湖精钻机电技术有限公司

Winch heave compensation device for ocean floating drilling platform

InactiveCN102943636AReduce incidenceImprove safety and reliabilityDrilling rodsDrilling casingsCompensation effectEngineering

The invention relates to a winch heave compensation device for an ocean floating drilling platform. The device comprises an active compensator and a passive compensator which are arranged on one side of a winch in parallel. The active compensator comprises a first single-rod piston cylinder with a piston rod stretching upwards and a force transducer, wherein two chambers of the first single-rod piston cylinder are connected to a hydraulic system through a three-position four-way magnetic exchange valve, and the force transducer is used for detecting force on a steel wire rope and electrically connected with a force feedback controller which controls exchange actions of the three-position four-way magnetic exchange valve. The passive compensator comprises a second single-rod piston cylinder with a piston rod stretching upwards. Tops of the piston rods of the first piston cylinder and the second piston cylinder are connected onto a movable pulley, a fixed pulley is further arranged on the drilling platform, and the steel wire rope on the winch is connected with a crown block and a traveling block after bypassing the movable pulley and the fixed pulley sequentially. According to the device, the compensation effect that active compensation and passive compensation are mutually synchronous and promoted can be achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

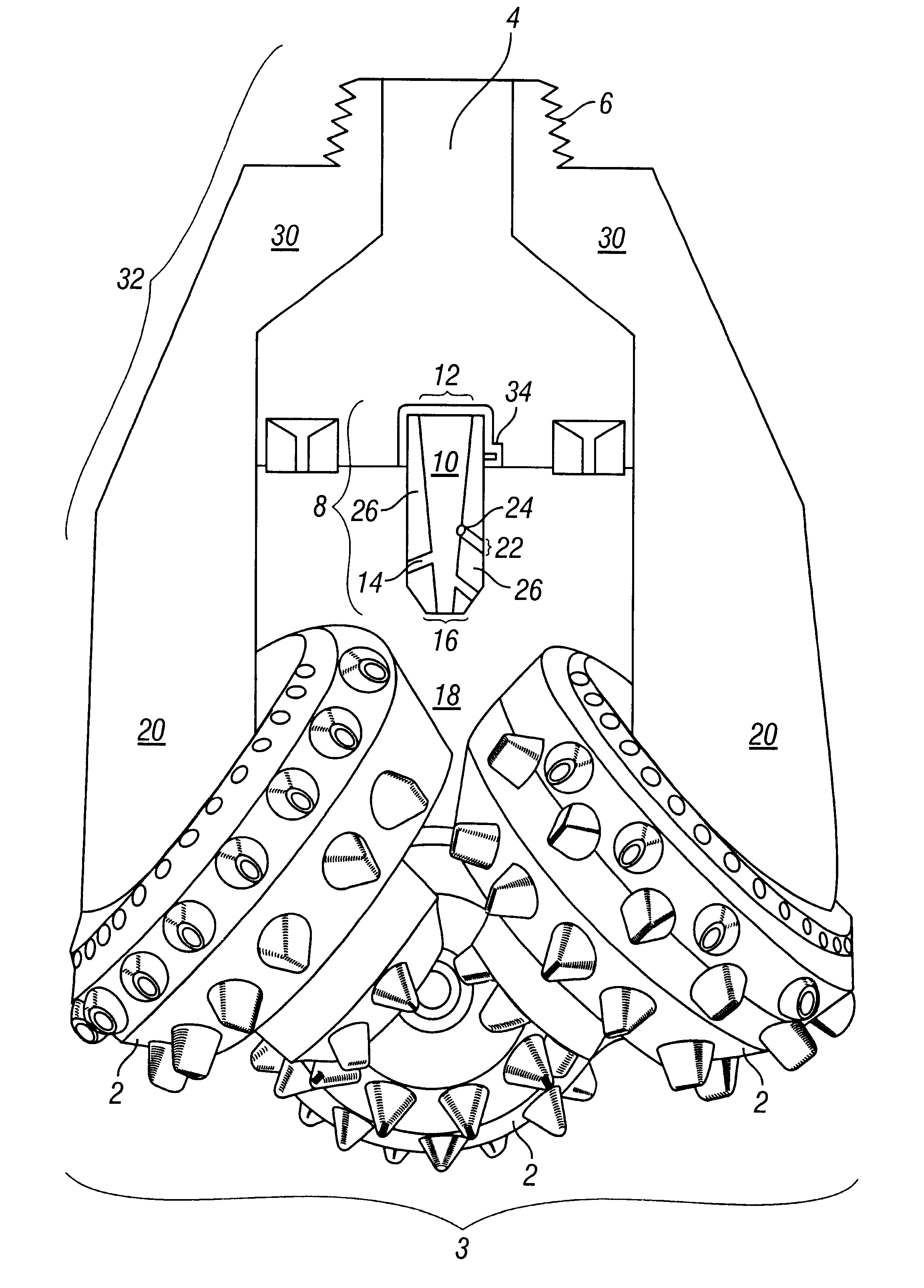

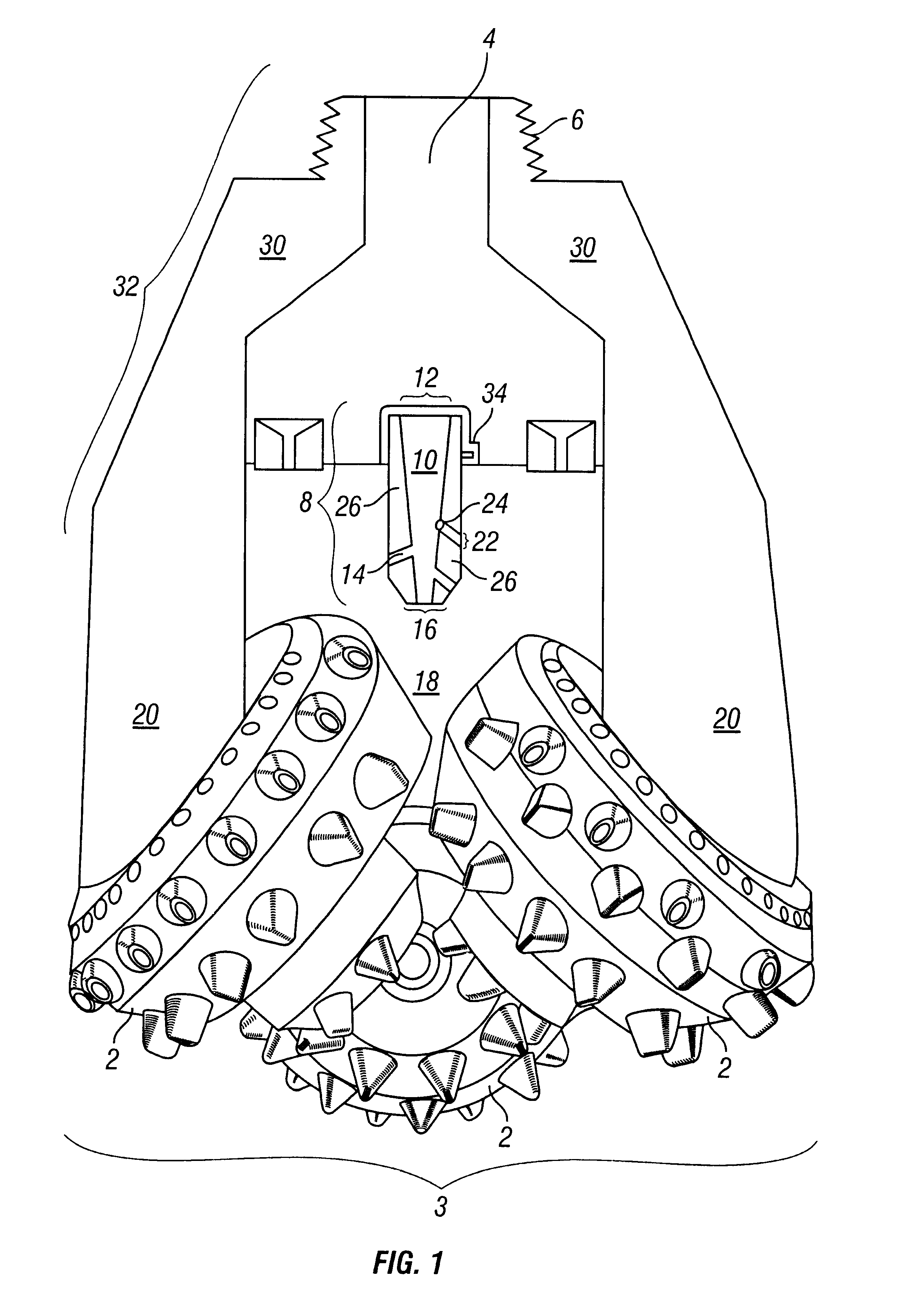

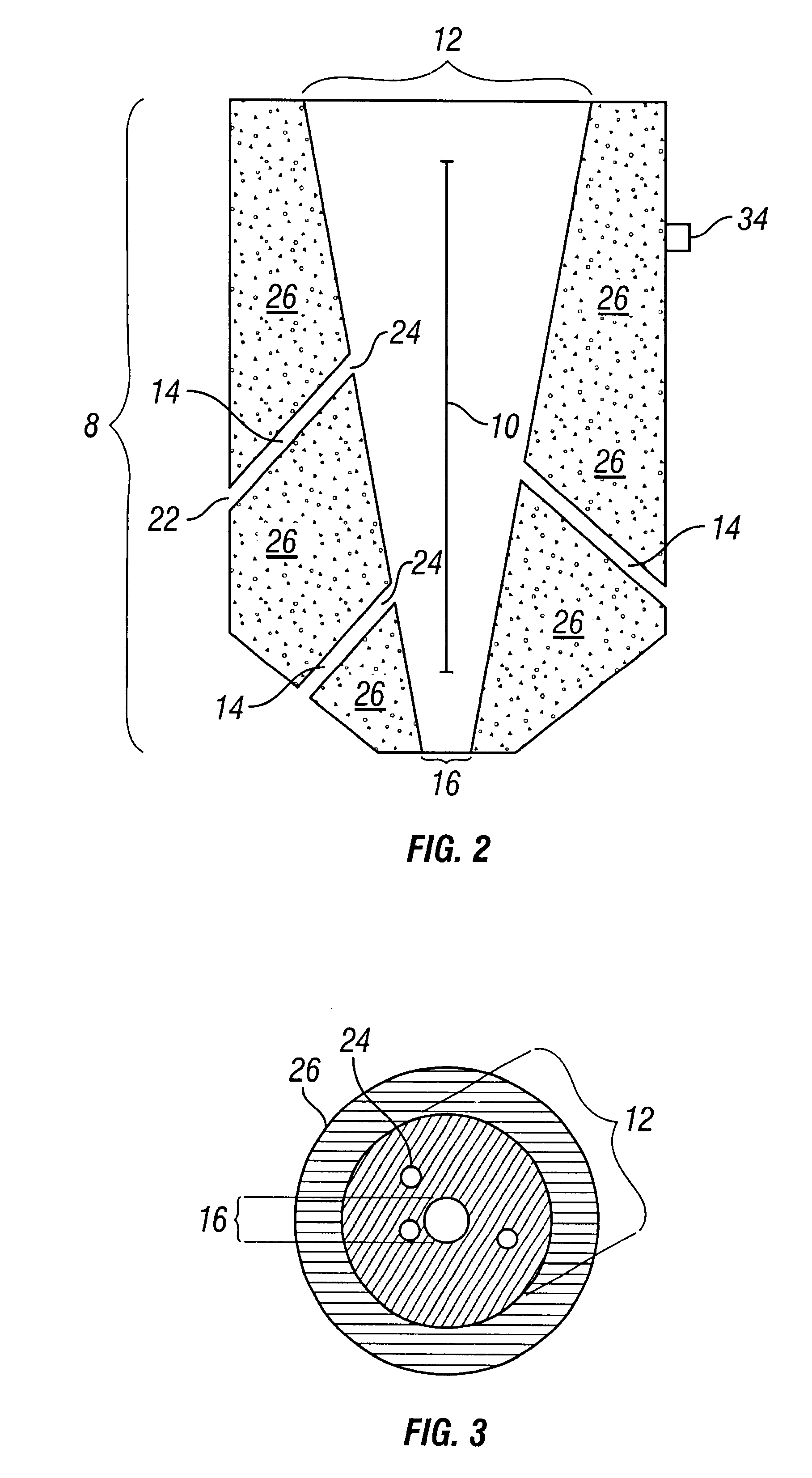

Three-cone rock bit with multi-ported non-plugging center jet nozzle and method

A three-cone rock bit employing a non-plugging center jet nozzle with a plurality of staggered inlet orifices leading to side passageways to reduce bit balling. The nozzle defines a tapered cavity through which drilling mud flows and exits in streams. Streams are directed from the nozzle through a main exit aperture of sufficient size to avoid plugging and from side passageways boring through a sidewall of the nozzle. Jetting streams promote washing of voids within the bit and of cutting surfaces. The nozzle uses staggered inlet orifices leading to side passageways, in conjunction with a tapering shape of a central passageway to facilitate maintenance of drilling mud velocity within the central passageway and thus of stream velocity to targeted regions of the drill bit.

Owner:DICKEY WINTON B

Self-propelled drilling robot

InactiveCN102518395AImprove drilling efficiencyWell drilledDrilling rodsBorehole drivesGyroscopeControl system

The invention discloses a self-propelled drilling robot which comprises a drilling system, a power system and a control system, wherein the drilling system is used for realizing cutting and conveying of soil; the power system is used for providing the motion capability; the control system is used for controlling the drilling system and the power system; the power system is connected with the drilling system through a transmission; and the control system is in communication connection with the power system and the drilling system. Under the drive of a motor, the robot can realize moving forwards and steering by being pushed by supporting feet. Moreover, the robot is provided with a detection device, a gyroscope and a control circuit board. The application of a combined cable to transmission of a power source and information is beneficial for implementing remote real-time monitoring on the robot by personnel above the ground. The robot has simple mechanism and compact structure, is provided with a drill bit and a dumping device, is beneficial for moving in a self-propelled mode, can successfully drill into the ground, can freely move and steer in the soil, and is suitable for exploration of underground mineral resources, geological exploration, earthquake and mining disaster rescue and the like.

Owner:TONGJI UNIV

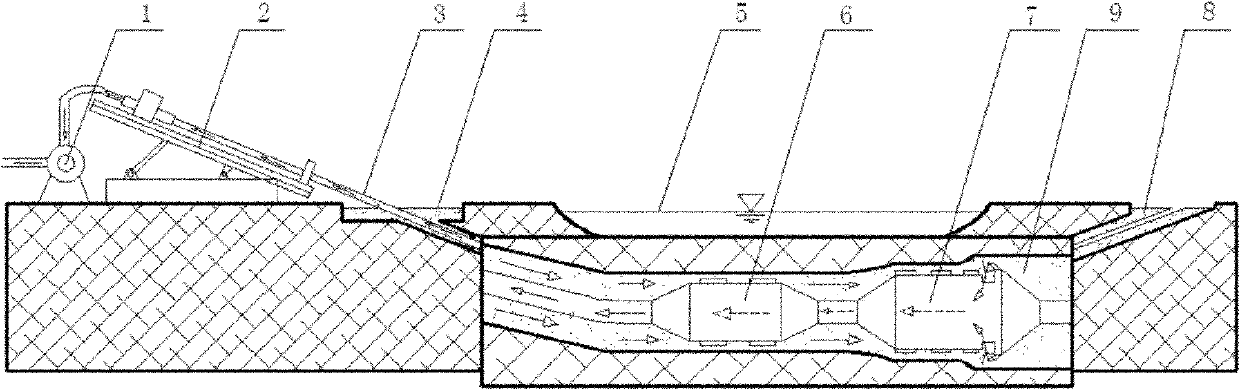

Traversing reverse circulating drilling method of horizontal directional drilling pipeline and special drilling bit

InactiveCN102003140AReduce consumptionImprove drilling efficiencyPipe laying and repairDrill bitsSlurryDirectional drilling

The invention provides a traversing reverse circulating drilling method of a horizontal directional drilling pipeline and a special drilling bit, which are suitable for laying oil-gas pipelines and municipal pipelines. The drilling method comprises the following steps of: mounting a gravel pump at the outer end of a drilling machine or a pit, wherein hollow cavities are formed in the drilling bit and the drilling stem in use; arranging a slag suction port communicated with a borehole circular space on a reaming drilling bit; sleeving a roller cone seat with a roller cone outside the body of the reaming drilling bit, wherein the position of the roller cone corresponds to that of the slag suction port; arranging a plug for blockage at one end of the reaming drilling bit; and circularly flowing slurry according to a flowing direction from a slurry pond to the borehole circular space, the reaming drilling bit, the drilling stem, the gravel pump and the slurry pond during drilling so as to reach the aim of deslagging. The method and the drilling bit of the invention can be adopted to effectively remove drilling slag and gravel in the horizontal borehole and solve various problems in the traversing construction of the large-diameter horizontal directional drilling pipeline.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Novel workshop equipment

InactiveCN108311724ASimple structureEasy to useBoring/drilling componentsBoring/drilling machinesEngineeringRotating disc

The invention discloses novel workshop equipment which comprises a machine base, brackets and a tank shell body, wherein the brackets are arranged at two ends of the top of the machine base in a left-right symmetric manner; the tank shell body is arranged between the left and right brackets through a pushing-lifting device; a first rotating cavity of which the end port faces down is arranged at the inner bottom of the tank shell body; a second rotating cavity is arranged in the tank shell body in an up-down extending manner and positioned above the first rotating cavity; a first sliding troughis arranged in the inner wall of the left side of the second rotating cavity in a communicating manner; a rotating disc is rotatably mounted in the first rotating cavity through a bearing; a first rotating shaft which extends into the second rotating cavity is fixedly arranged at the top of the rotating disc; a first conical wheel is fixedly mounted on the first rotating shaft in the second rotating cavity; and a first sliding block is arranged in the first sliding trough in an up-down slidable manner.

Owner:楼碧云

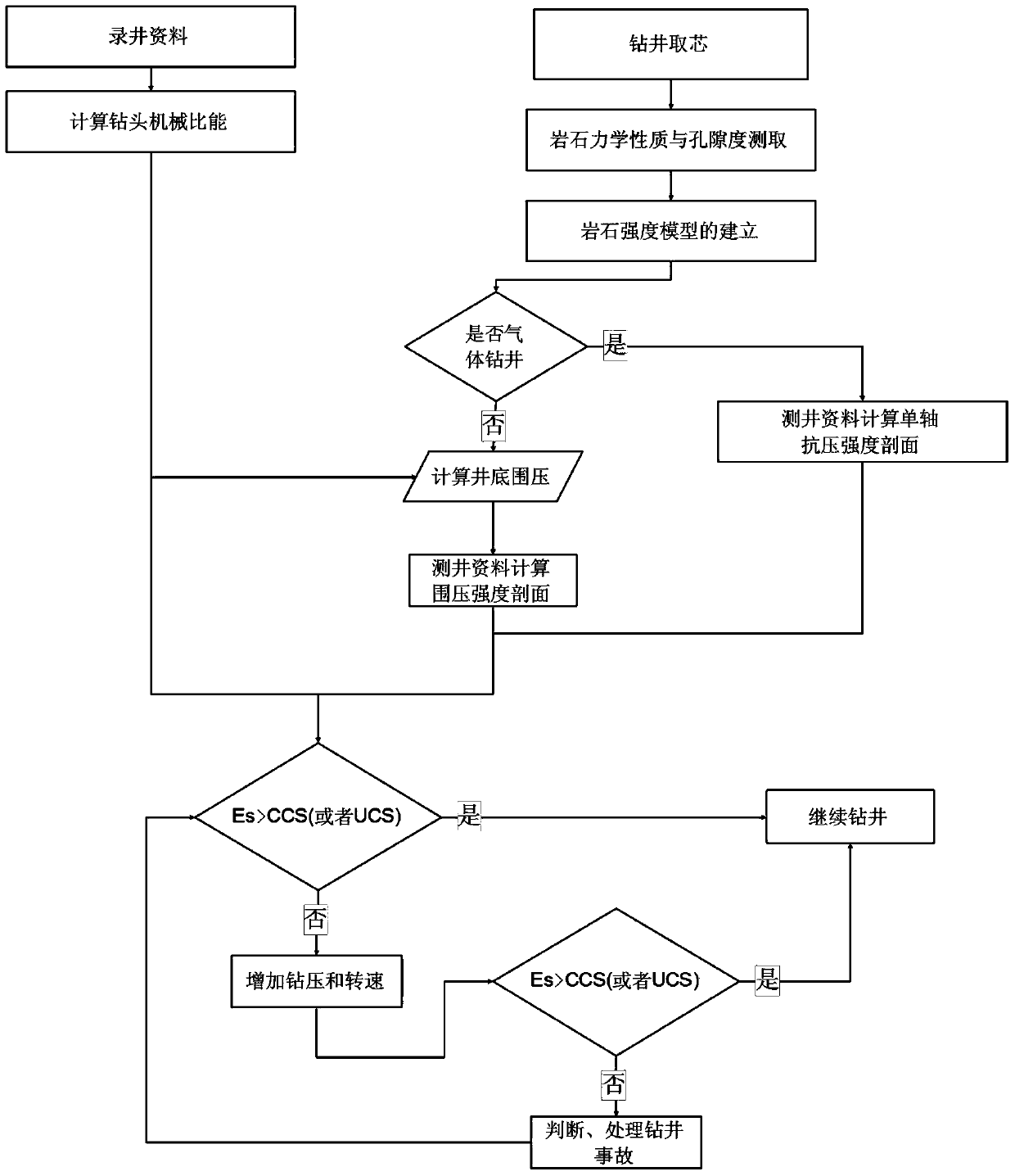

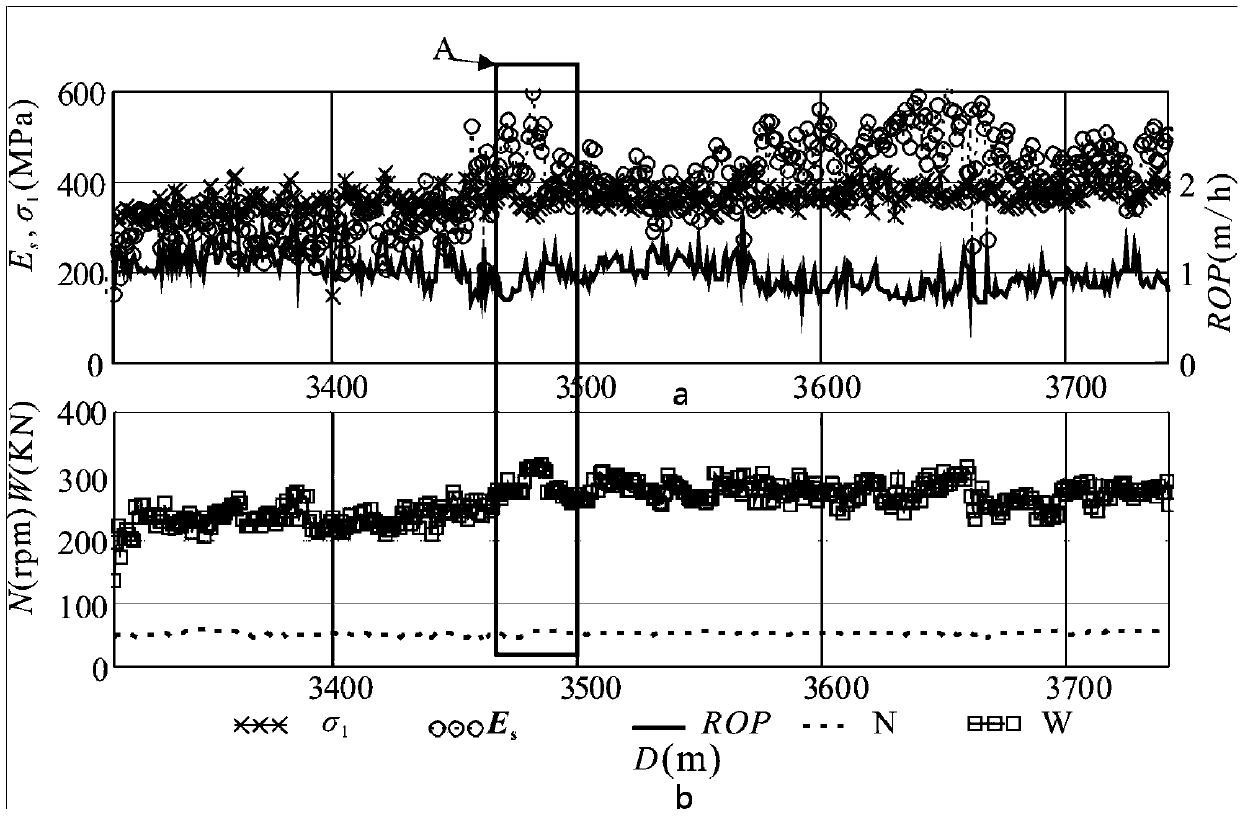

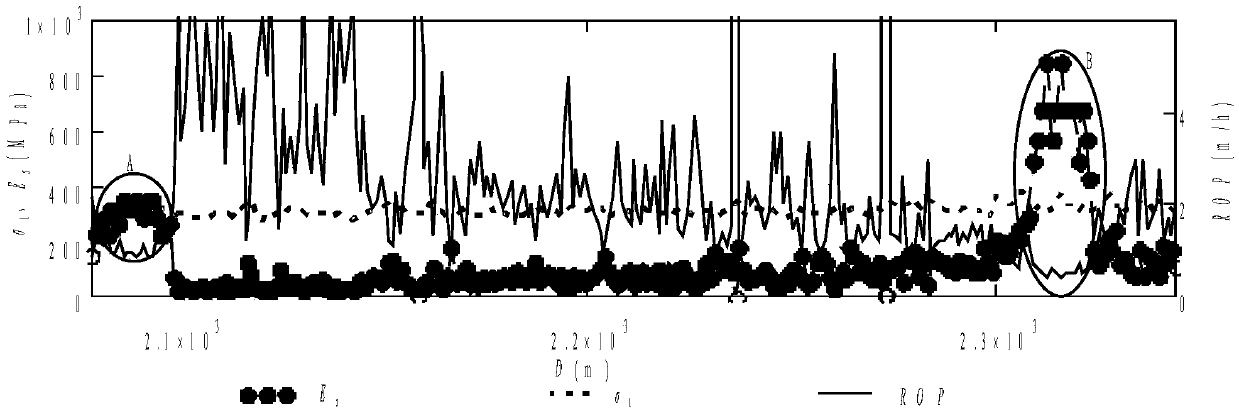

Real-time drilling parameter and efficiency optimization method

InactiveCN103790568AImprove drilling efficiencyAutomatic control for drillingCompressive strengthUltimate tensile strength

The invention discloses a real-time drilling parameter and efficiency optimization method. The method includes: drilling for coring; setting a rock strength model according to a method in a step A; judging which type the drilling mode belonging to according to drilling fluid density, property and formation pore pressure; if the drilling mode belongs to gas drilling, directly using uniaxial compressive strength, and otherwise, calculating the rock strength under the condition of bottom confining pressure; calculating mechanical specific energy of a drill according to logging data; comparing calculated mechanical specific energy of the drill with the rock strength under the bottom confining pressure. Critical fail points of drilling parameters such as drilling pressure, rotate speed and the like can be found out by the model, real-time optimization of the drilling parameters is realized, and drilling capacity can be effectively promoted on the existing basis of drilling.

Owner:SOUTHWEST PETROLEUM UNIV

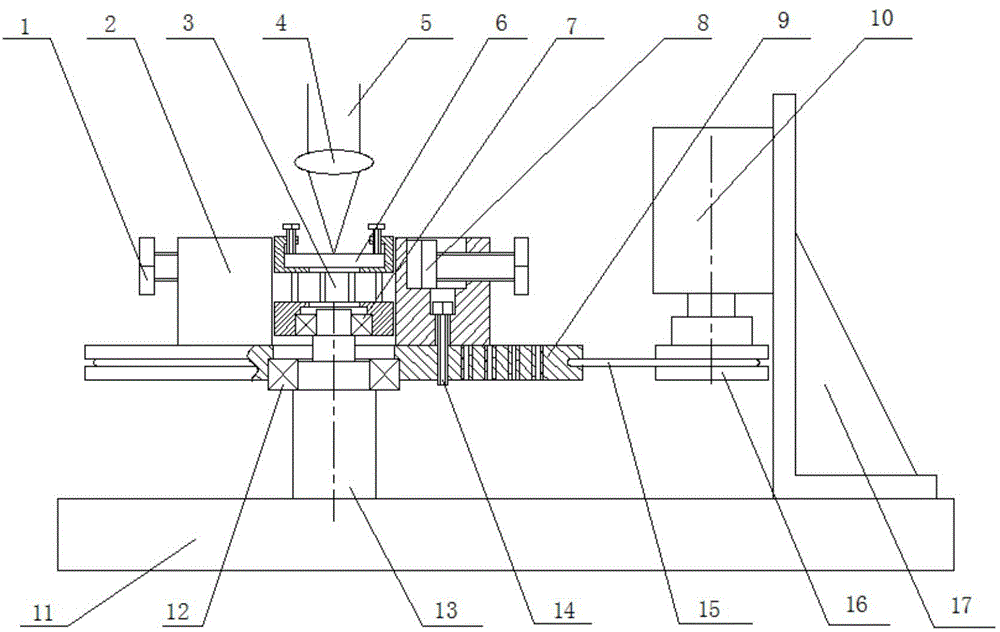

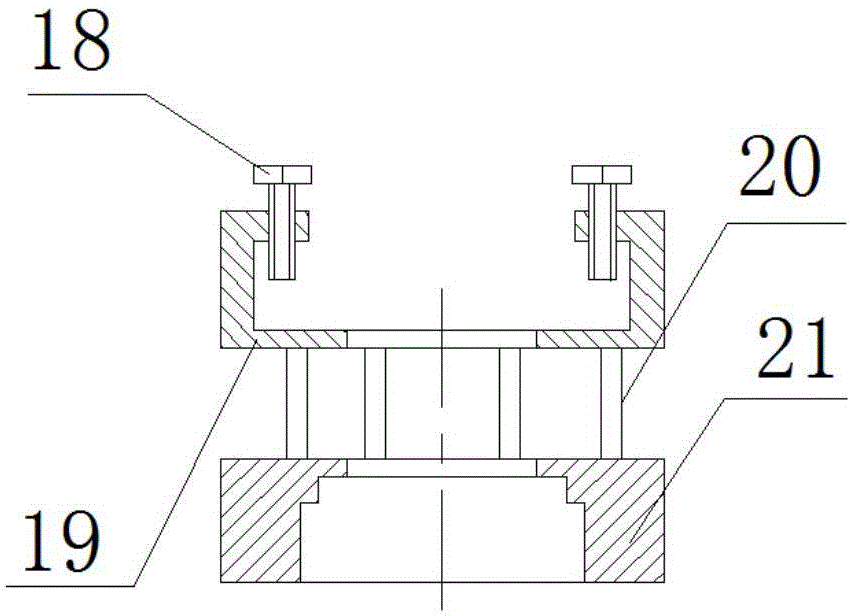

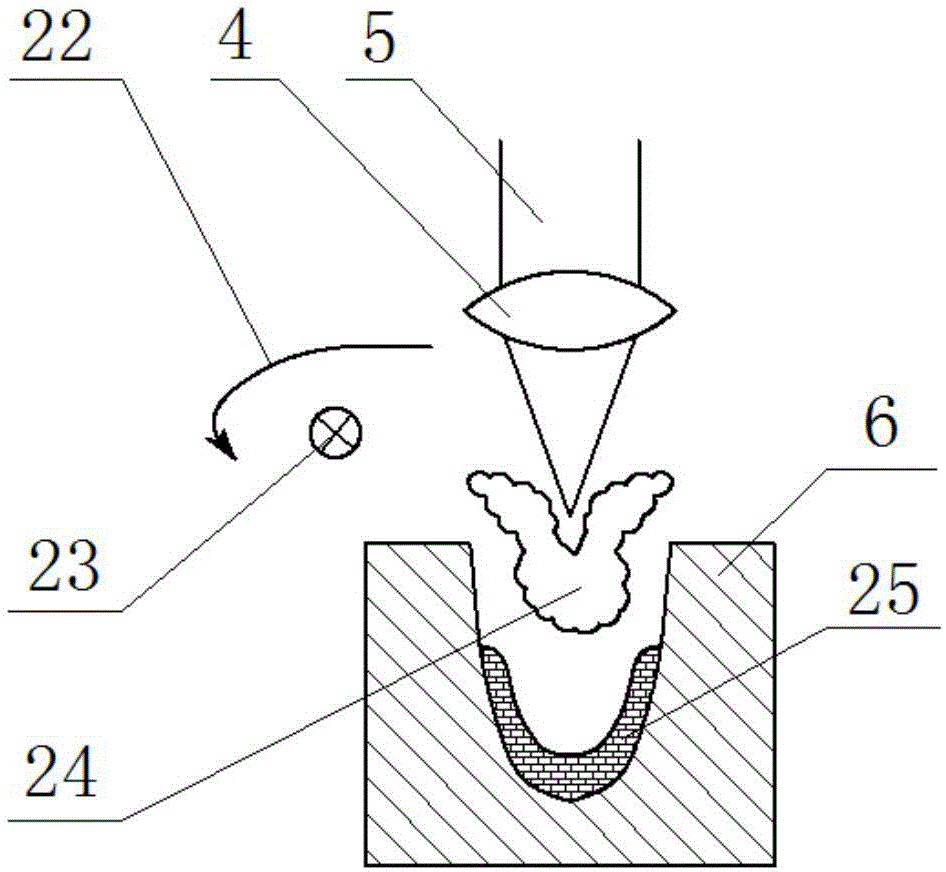

Electromagnetically-assisted laser drilling method and device

ActiveCN103817430ALow densityEnhanced magnetic fieldLaser beam welding apparatusMagnetic tension forceEngineering

The invention provides an electromagnetically-assisted laser drilling method. The method includes the steps of 1, clamping a workpiece to be processed onto an electromagnetically-assisted laser drilling device; 2, driving a fixture base to rotate by a motor so that a permanent magnet clamped on the fixture base rotates at high speed and forms a rotational magnetic field; meanwhile, allowing a mouse cage in the rotational magnetic field to produce electromagnetic force whereby the workpiece rotates in sync with the mouse cage; 3, after the speed of the motor stabilizes to a preset value, starting a laser, which generates a laser beam acting on the surface of the workpiece via a focusing lens so as to finish the electromagnetically-assisted laser drilling process. According to the method, the application of the operating method of rotating the workpiece enhances the assistance of the magnetic field in laser drilling; meanwhile, the rotational magnetic field can control motion of plasma and molten metal generated in the laser drilling process, so that laser drilling effect is optimized. The invention further provides the electromagnetically-assisted laser drilling device.

Owner:上海尚朴光电技术有限公司

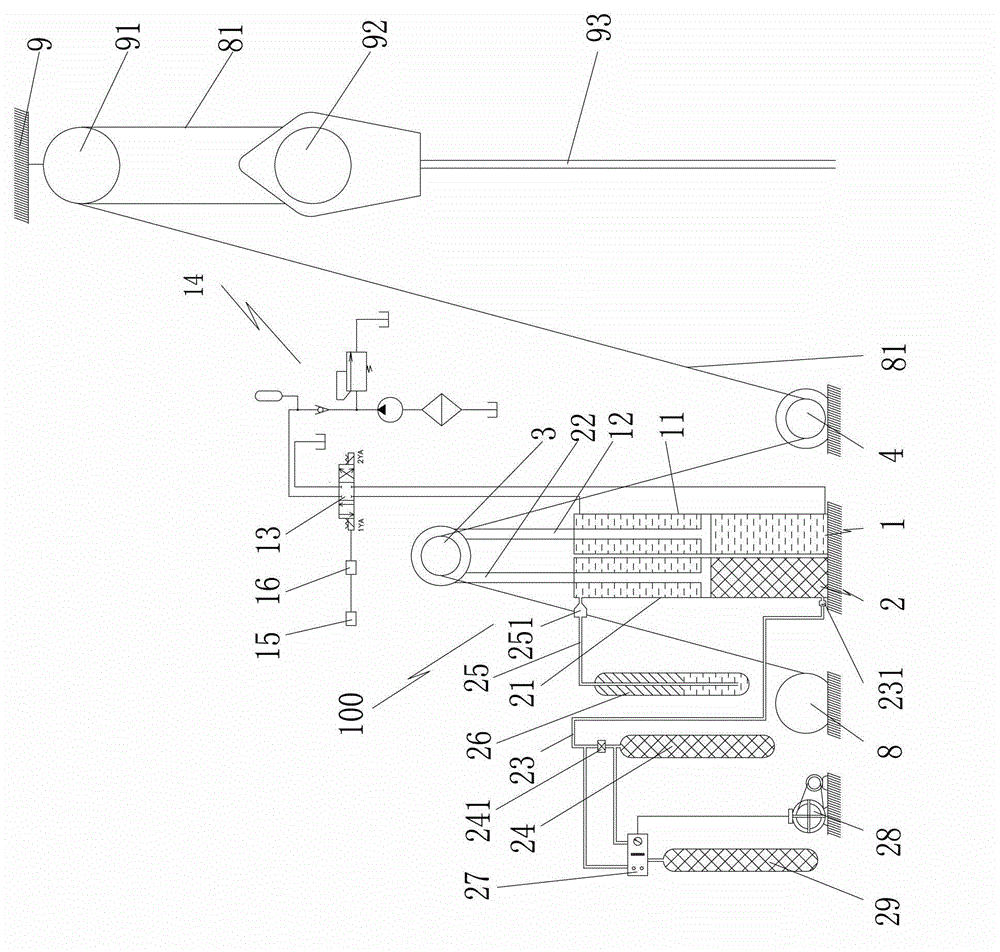

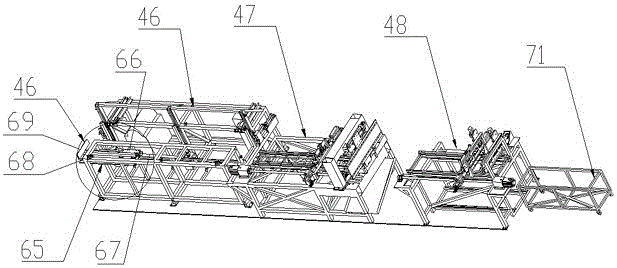

Automatic assembly line for feeding, cutting and punching pipe automatically

ActiveCN106271629AHigh degree of automationImprove cutting efficiencyMetal sawing devicesOther manufacturing equipments/toolsPunchingAssembly line

The invention discloses an automatic assembly line for feeding, cutting and punching a pipe automatically. The automatic assembly line comprises a front feeding mechanism, a middle feeding and cutting mechanism and an automatic punching and unloading mechanism which are arranged in sequence from left to right; the front feeding mechanism comprises a first supporting frame, a lifting mechanism, a pipe clamping mechanism, a transverse pushing mechanism and a longitudinal pushing mechanism; the middle feeding and cutting mechanism comprises a second supporting frame, a first clamping conveying mechanism, an automatic cutting mechanism and an automatic clamping mechanism; the automatic punching and unloading mechanism comprises a third supporting frame, a second clamping conveying mechanism, a drilling clamping mechanism and two sliding drilling mechanisms which are positioned on the right side of the second clamping conveying mechanism and are arranged at an interval. The automatic assembly line can realize automatic feeding, and is low in labour intensity and high in work efficiency; the pipe can be cut automatically; the cutting quality is good; high-efficiency cutting operation of one or more pipes can be realized synchronously; the punching operation can be performed on the two ends of the pipe simultaneously; the function of clamping a plurality of pipes at one time and punching the pipes in sequence can be realized.

Owner:JIANGSU JINPENG VEHICLE CO LTD

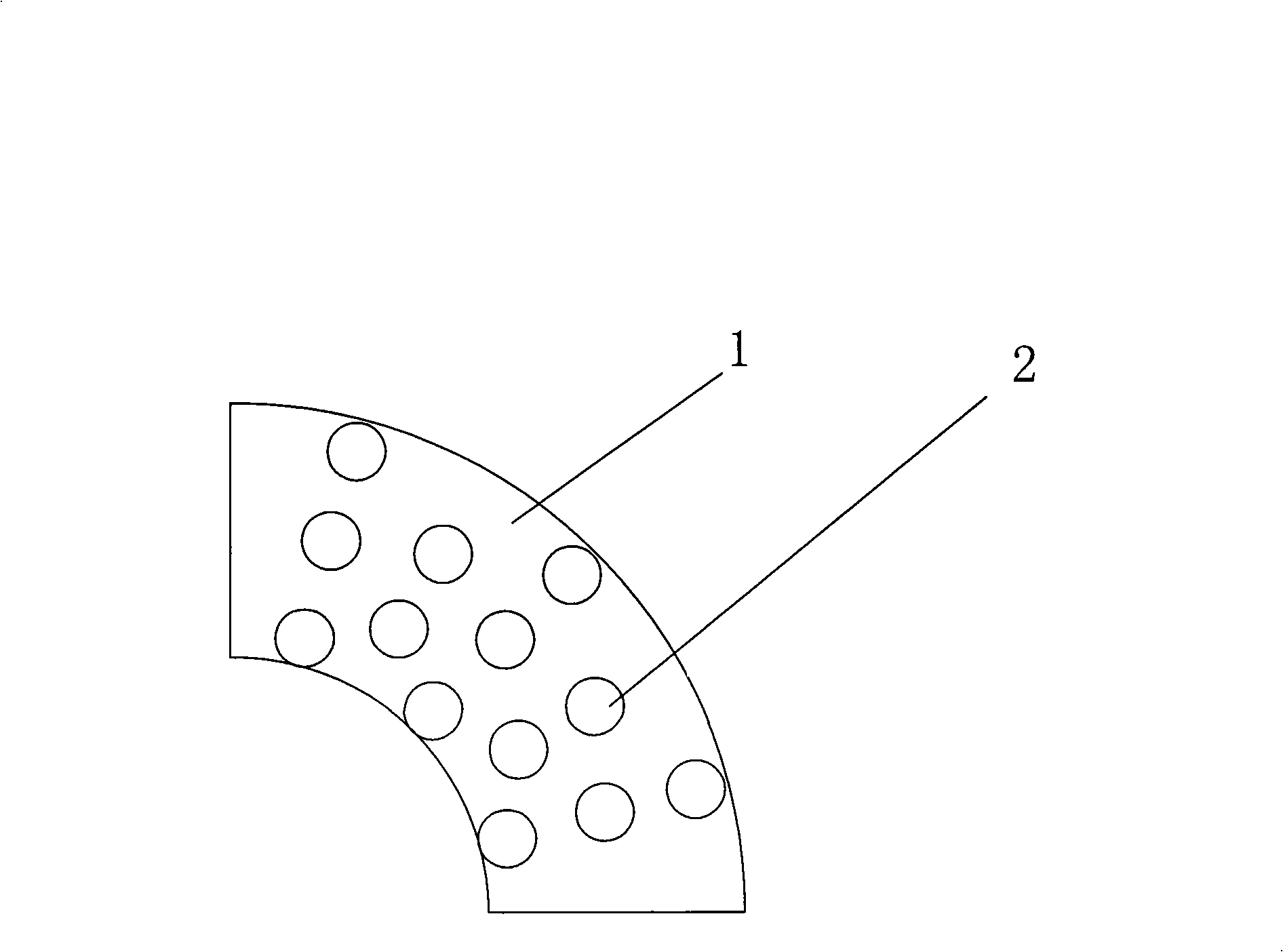

Diamond positioning and arrangement impregnated rock bit and fabrication technology thereof

The invention discloses a diamond positioning-arranging impregnated geological drill bit, comprising a diamond matrix (1) and diamonds (2), wherein the diamonds (2) are orderly arranged in the diamond matrix (1) according to designed specified positions. A method for making the diamond positioning-arranging impregnated geological drill bit comprises the following steps of mixing diamond matrix powder, pressing the matrix powder into thin stocks, laying and arranging the diamonds on the thin stocks, cold-pressing a plurality of layers of thin stocks compositely, reducing a cold-pressing matrix cutter head, loading a steel body to be sintered, cooling, demoulding, dressing and packaging. The diamond positioning-arranging impregnated geological drill bit is long in life span, high in working efficiency, and can keep the stability of the life span and efficiency of a diamond drill bit at the same time, so as to ensure that product performance can be controlled better. The manufacturing process of the diamond positioning-arranging impregnated geological drill bit is simple, reliable and convenient to operate.

Owner:CENT SOUTH UNIV

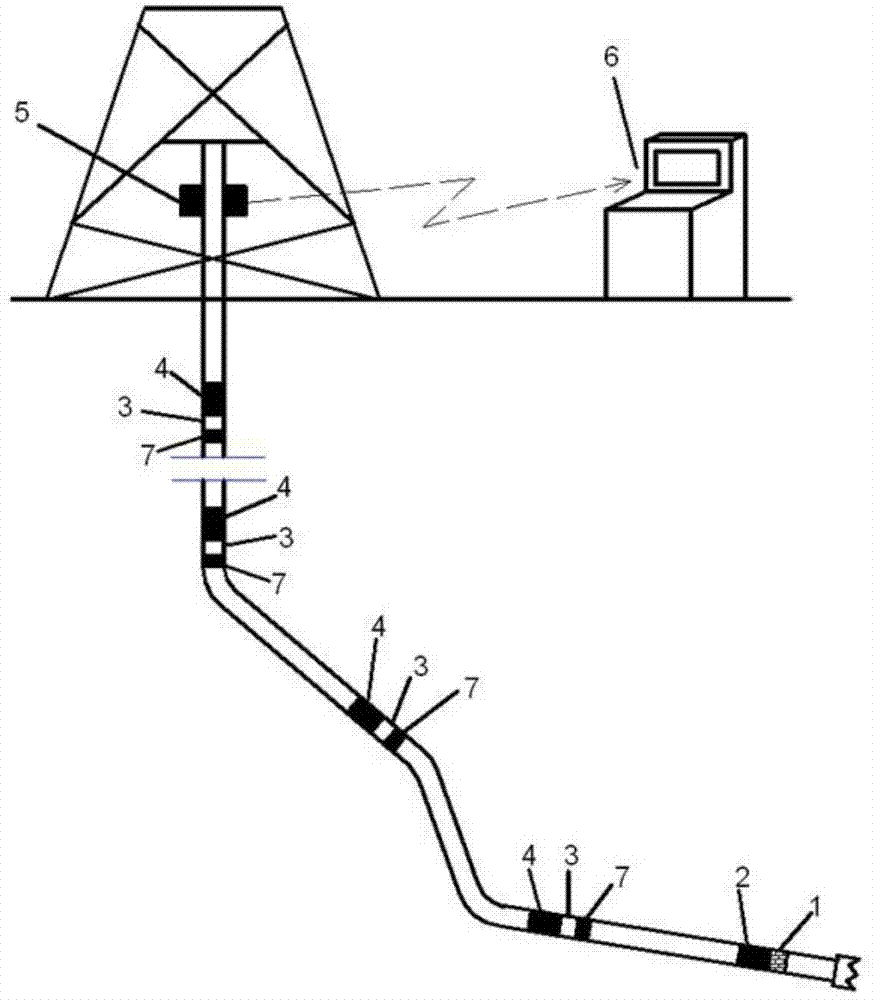

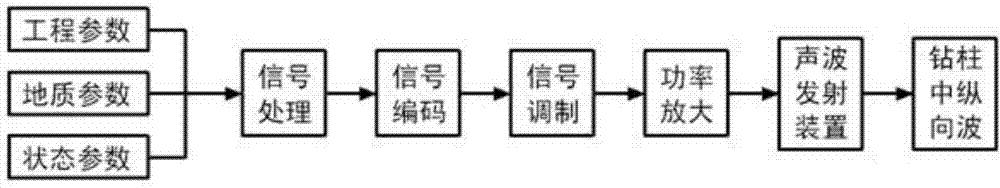

Method and system for real-time multi-parameter measurement and transmission while drilling in all well sections

The invention discloses a method and a system for implementing parameter measurement while drilling and real-time transmission to the ground at a plurality of points in a mineshaft along a drill column based on sound wave information transmission. An underground while-drilling parameter measurement system is used for acquiring underground information, the information is regulated and then transmitted to an underground signal transmitting system and transmitted upwards in a sound wave manner along the drill column; sound wave signal relay systems are used for receiving a signal upwards-transmitted from the underground, decoding the signal, combining the measurement information, and then transmitting the information upwards; afterwards, the signal is upwards-transmitted to the ground, received by a ground receiving system, decoded and then wirelessly transmitted to a ground information display and decision making system, wherein a plurality of relay systems are arranged along the drill column according to the well drilling construction requirements so as to realize real-time acquisition of the parameters of all well sections along a well body. The method and the system provided by the invention can be used for acquiring real-time underground parameters of all well sections so as to effectively reduce the risk of accidents such as underground jamming of a drill and hole-wall collapse, improve the well drilling efficiency and provide support for best well drilling decisions. The method and the system can be used for greatly improving the precise pressure control capability especially during a managed pressure drilling process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

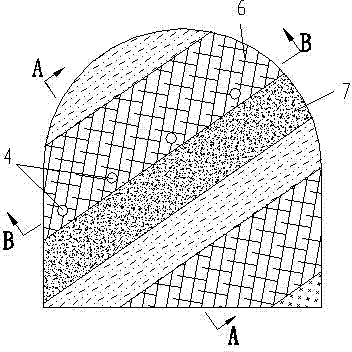

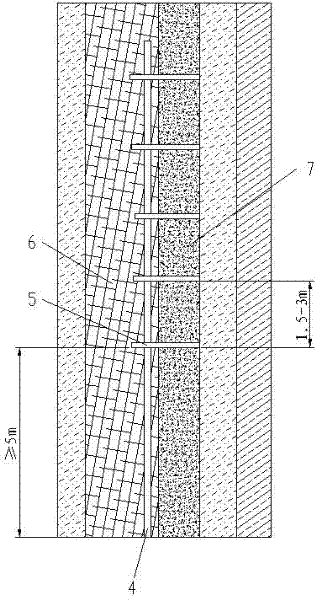

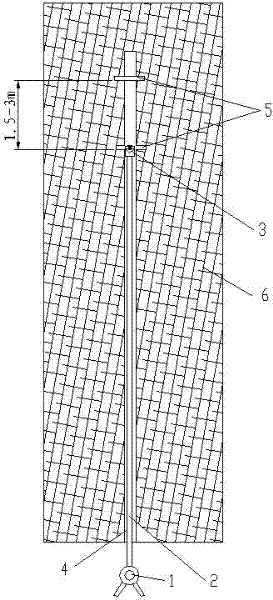

Depressurized extraction method for cutting through roof or floor of coal seam by abrasive water jet

InactiveCN102493833AGood sealing effectReduce gas extraction costsFluid removalGas removalAbrasive water jetCoal

The invention discloses a depressurized extraction method for cutting through a roof or a floor of a coal seam by an abrasive water jet, which comprises the following steps: a. drilling a bedding drill hole to set depth on the roof or the floor of a coal-rock mass or a hard layer by using a drilling machine through a drill stem and a slotting drill bit; b. delivering a high-pressure abrasive water jet of which the pressure is 25-30MPa to the slotting drill bit through the drill stem, wherein the drill stem rotates in situ; forming a radial slit on the hole wall of the bedding drill hole, wherein the slit penetrates the roof or the floor of the coal-rock mass or the hard layer and a soft layer; c. enabling the drill stem to rapidly retreat for 1.5-3m so as to form a new slit; d. repeating the step c until a plurality of radial slits are formed on the bedding drill hole, and moreover, reserving a safety rock pillar of at least 5m at the slit located at the position of the orifice of the bedding drill hole at a certain distance from the orifice; e. retreating the drill stem and the slotting drill bit and sealing the hole; and f. extracting gas by a gas extraction system. The depressurized extraction method for cutting through the roof or the floor of the coal seam by the abrasive water jet has the beneficial effects that the drill hole does not have potential safety hazards and is easy to form; a hole sealing effect is good; the time of reaching the standards of extraction is short; the production efficiency is high; and the extraction is safe.

Owner:重庆市能源投资集团科技有限责任公司

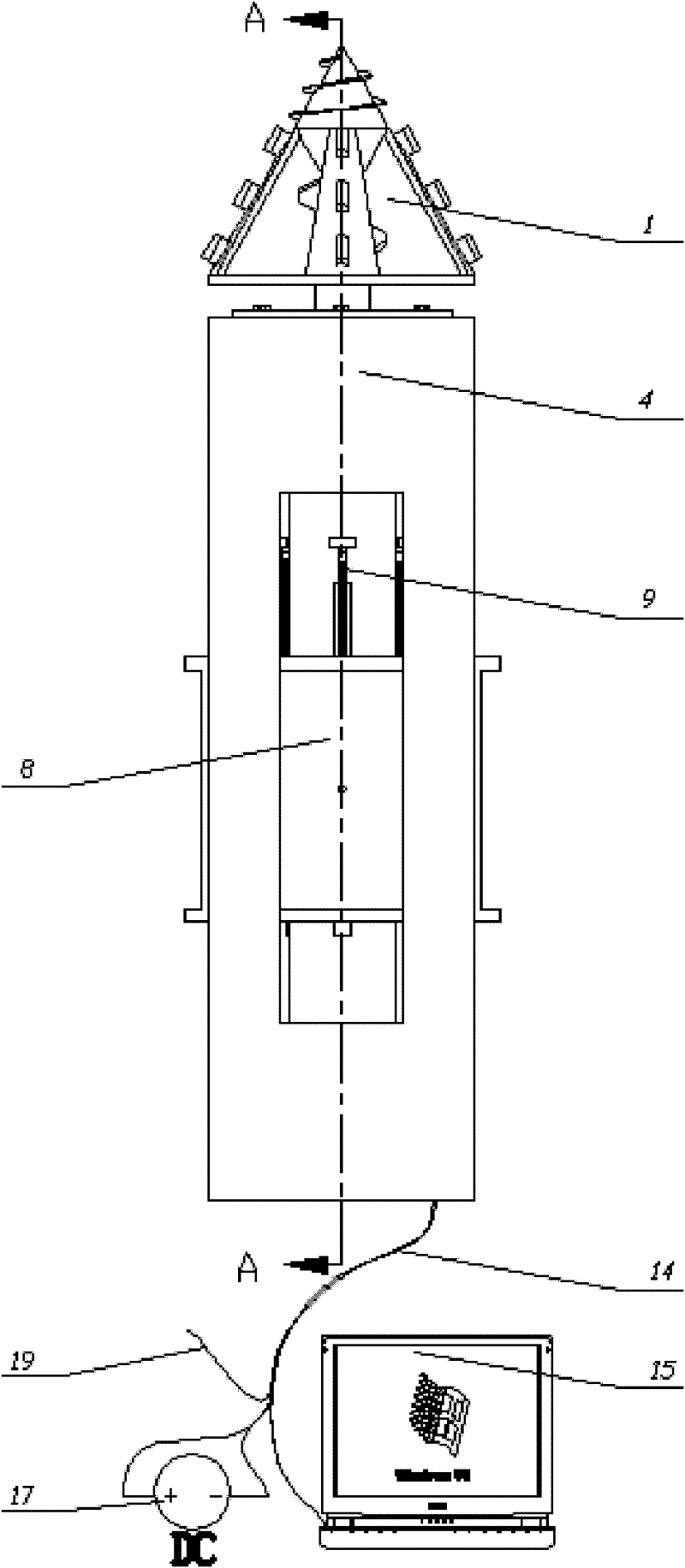

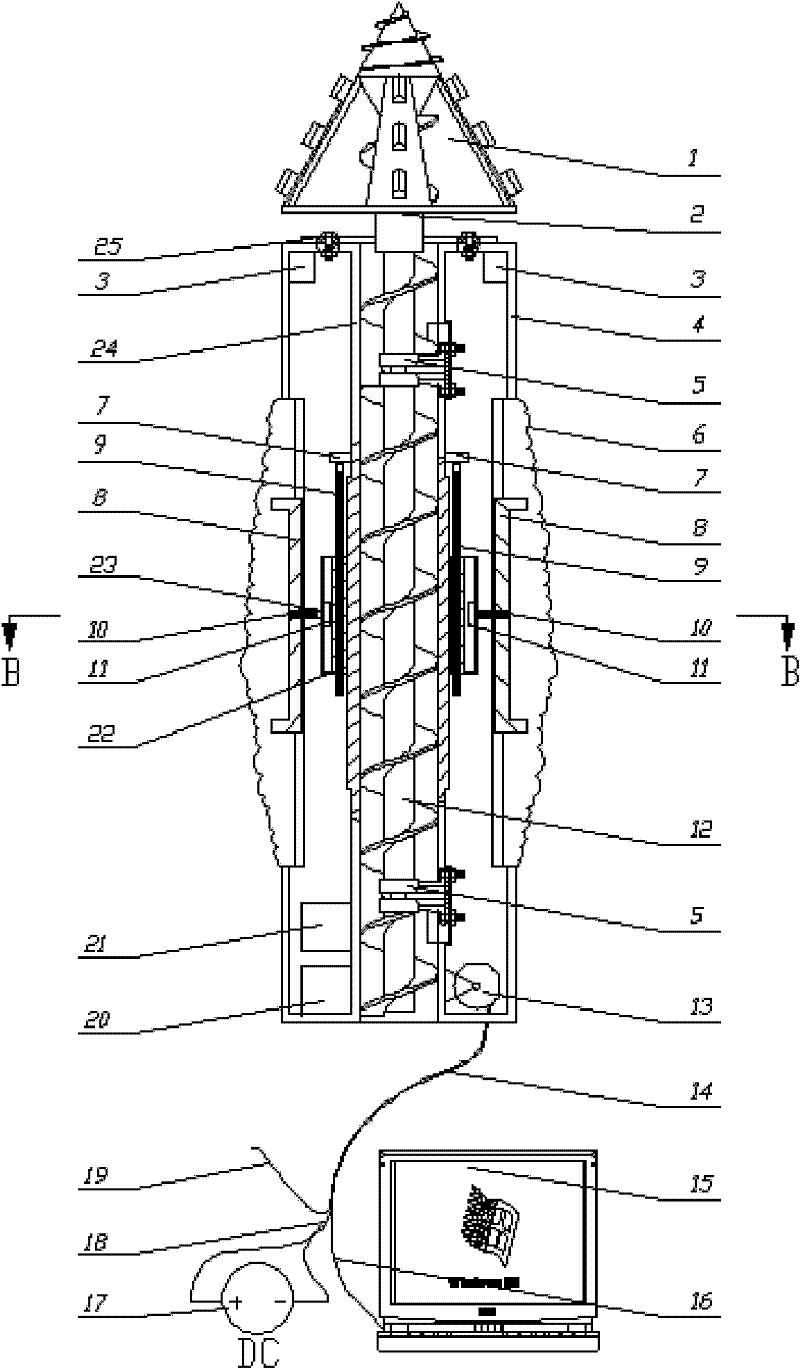

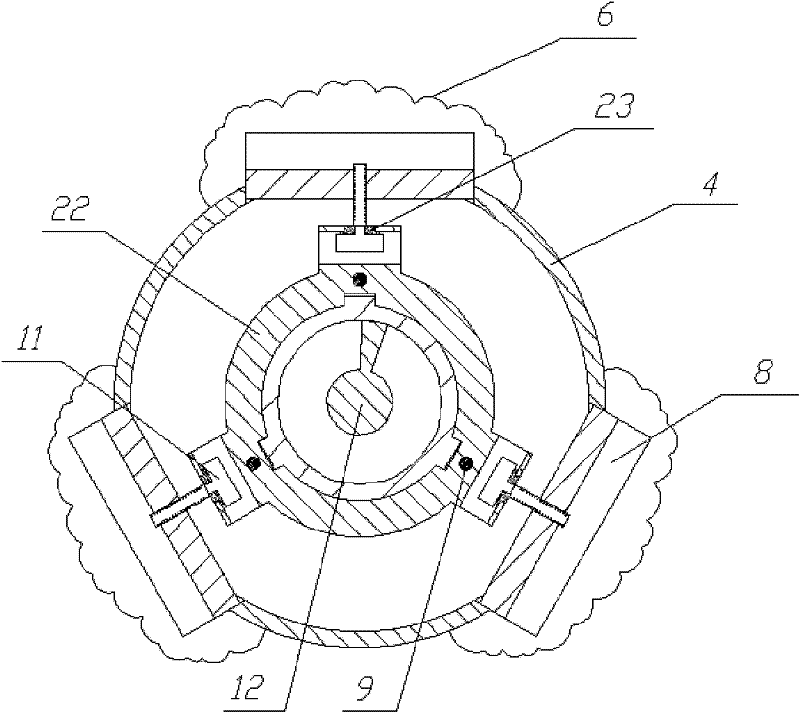

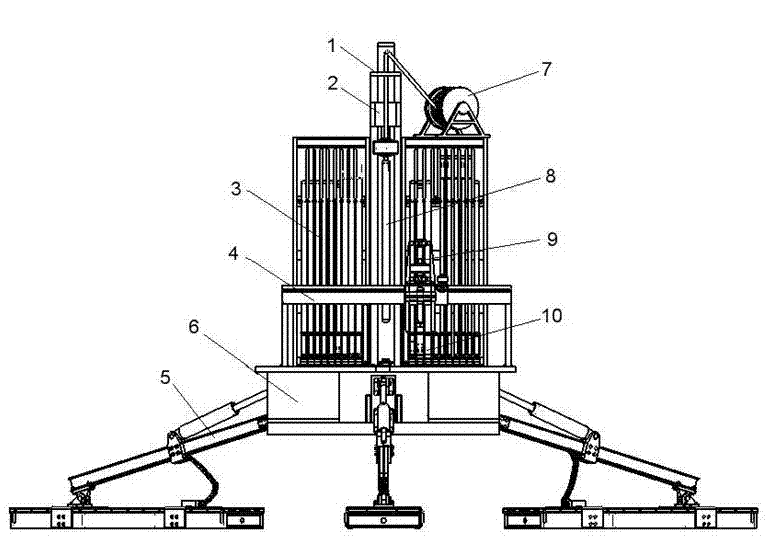

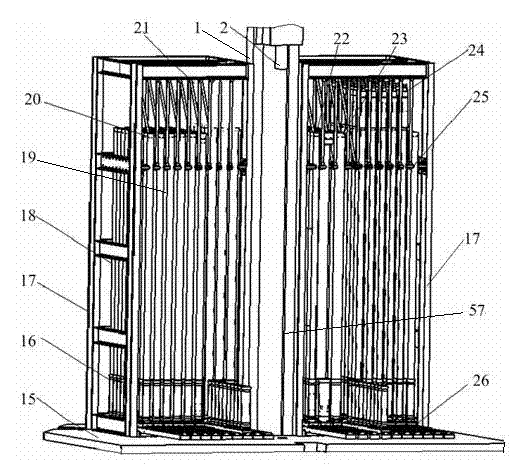

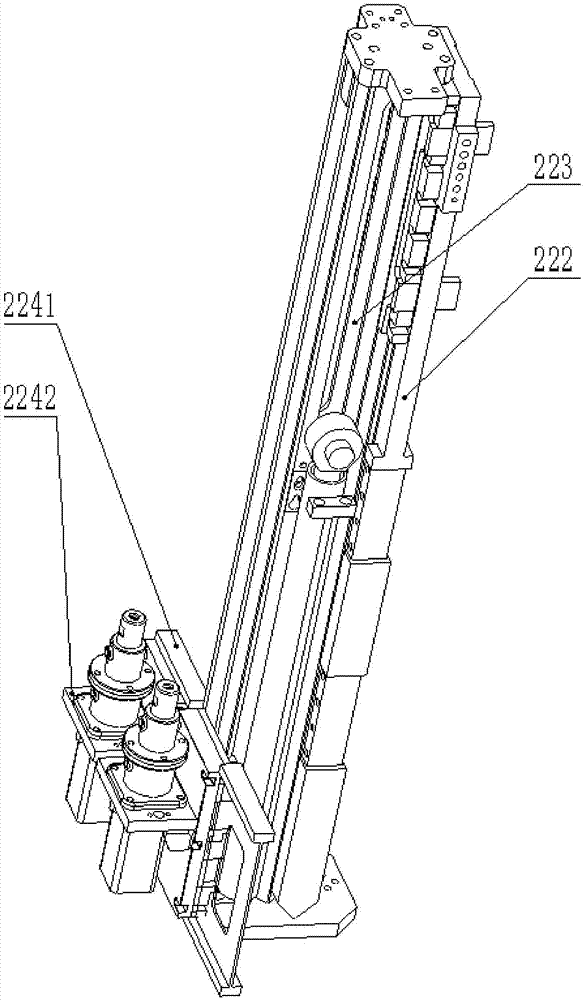

Seabed type conical investigating and drilling integrated machine

InactiveCN102383723AIncrease coefficient of frictionImprove securityDrilling rodsConstructionsManipulatorEngineering

The invention relates to a seabed type conical investigating and drilling integrated machine which comprises a tower, a power head, a drilling tool storeroom, a manipulator mechanism, a leveling mechanism, an instrument box, a winch, a drilling tool, a clamp holder and a hydraulic pump. According to the drilling process of a seabed drilling machine, the power head provides the rotation power and realizes the feeding and recycling of the drilling tool through a tower guide rail on the tower; the drilling tool storeroom is arranged on the two sides of the power head and used for storing variousdrilling tools; the drilling tools are automatically stored and fetched through the manipulator mechanism, and the leveling mechanism keeps the drilling tool vertical to the seafloor when the integrated machine works; a core barrel for wire line coring is released and recycled by the winch; and the drilling tool is clamped and removed by the clamp holder. The integrated machine provided by the invention has a scientific and reasonable structure, is simple and convenient to control and safe and reliable to use and is suitable for the large-depth deep hole core sampling on seabed and also for operation on land.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Drilling machine for metal pipe tapping

InactiveCN107159922AEasy to fixAvoid compromising drilling qualityPositioning apparatusMaintainance and safety accessoriesGear wheelEngineering

The invention discloses a drilling machine for metal pipe tapping. The drilling machine comprises a main body; a sleeve is arranged on the main body; a stand column is slidingly mounted on the sleeve; a straight rack is arranged at the lower part of the stand column; a driving gear is arranged on the right side of the stand column; a right pressing block is fixedly mounted on the left side of the sleeve; a bracket is fixedly mounted on the main body; a lead screw is horizontally arranged on the bracket; a hand wheel is fixedly mounted at the left end of the lead screw; a sleeve block sleeves the lead screw; arc grooves are respectively formed in the right side surface of the left pressing block and the left side surface of the right pressing block; a leakage pipe is arranged at the bottom of a liquid collecting tank, and extends into a liquid storage box; a conveying pimp is arranged at the bottom of the liquid storage box; a conveying pipe is arranged at an outlet end of the conveying pump; and a nozzle is arranged at one end, far from the conveying pump, of the conveying pipe. A metal pipe is driven to rotate through rotation of a rotating roller, so that multiple places of the side surface of the pipe are conveniently drilled, and the drilling efficiency is improved; cooling liquid sprayed by the nozzle can cool a drill bit to prevent damage of the drill bit due to overheating; and meanwhile, the cooling liquid can be recycled, so that the waste of the cooling liquid is prevented.

Owner:惠安县长信机电科技有限公司

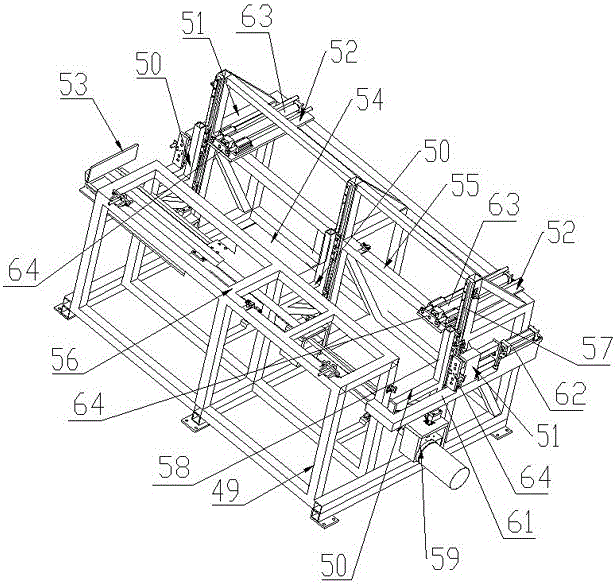

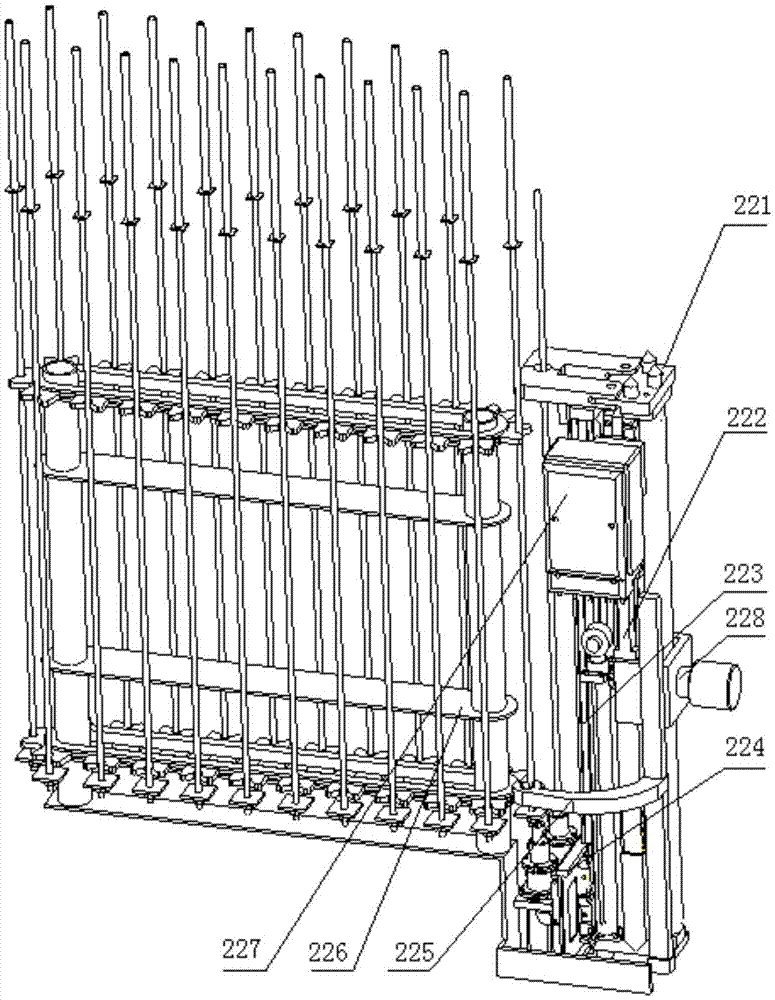

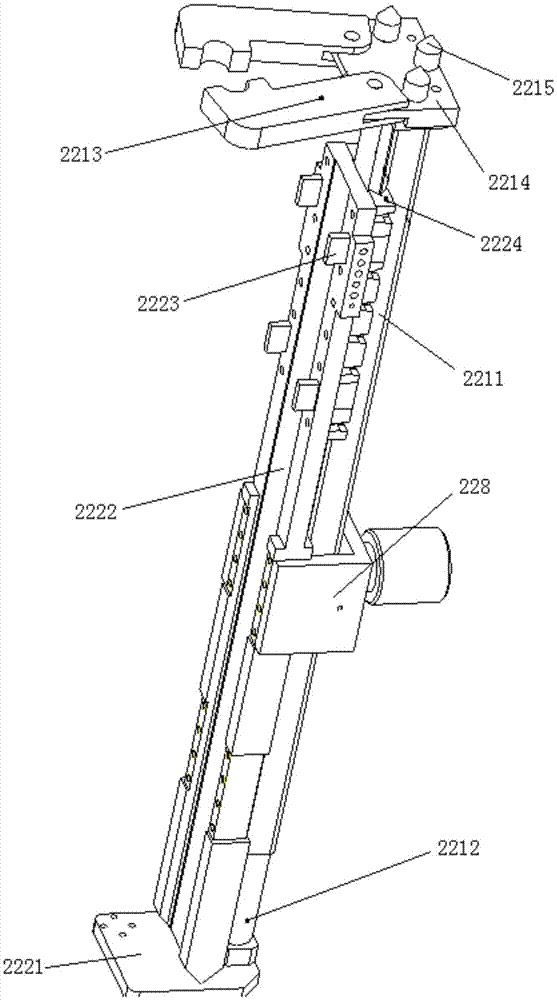

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

Numerical control equipment for plate drilling

InactiveCN108817461AImprove drilling efficiencyCause some damagesFeeding apparatusPositioning apparatusNumerical controlEngineering

The invention discloses numerical control equipment for plate drilling. The numerical control equipment comprises a worktable and a gantry arranged on the worktable, the lower end of a beam of the gantry is fixedly provided with a hydraulic rod, the lower end of a piston rod of the hydraulic rod is fixedly provided with a drilling machine, the side wall of the drilling machine is fixedly providedwith a protective cover, the inner wall of the upper end of the protective cover is fixedly provided with two dust collecting covers, and the two dust collecting covers are in central symmetry about the drilling machine; the upper end of the worktable is symmetrically and fixedly provided with two L-shaped fixing bases, and a clamping mechanism is arranged at a vertical part of each L-shaped fixing base; the worktable is internally provided with a cavity, a first screw is transversely arranged in the cavity, and one end of the first screw is rotatably connected with the left side wall of the cavity. The numerical control equipment is convenient to operate, the damage to the human body in the drilling process can be avoided, and the plate drilling efficiency is improved.

Owner:佛山元聚数控设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com