Electromagnetically-assisted laser drilling method and device

A technology for assisting laser and punching devices, which is used in laser welding equipment, welding equipment, metal processing equipment, etc. It can solve the problem that laser welding units cannot be used for laser drilling, impact hole repetition accuracy is low, and plasma shielding effect is serious, etc. It can fully absorb the energy of laser action, improve the punching efficiency, and reduce the loss of laser energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The details and working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

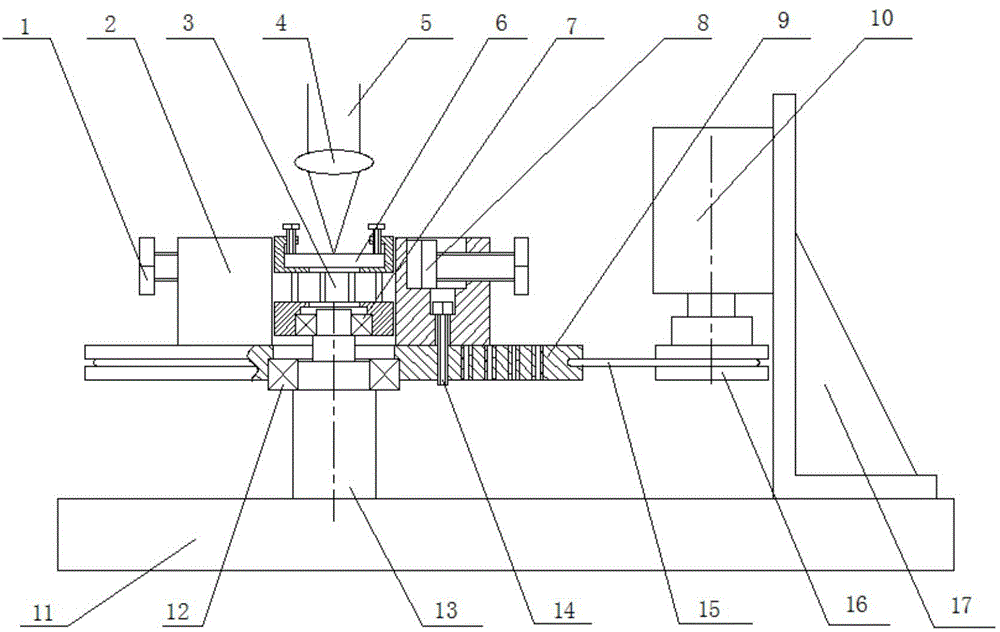

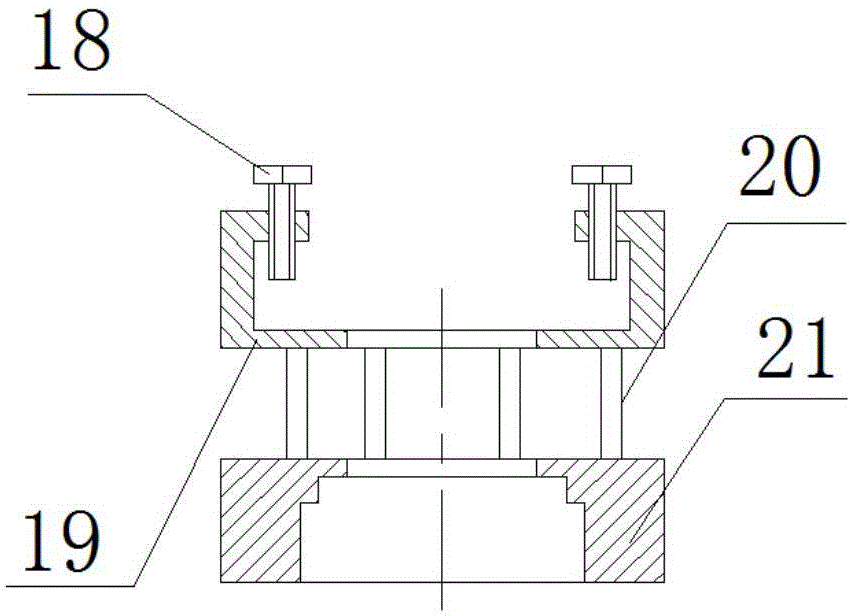

[0038] The invention provides an electromagnetic-assisted laser drilling device (such as figure 1 with figure 2 As shown), it includes four parts, which are laser generating unit, workpiece clamping unit, rotating magnetic field generating unit and driving unit.

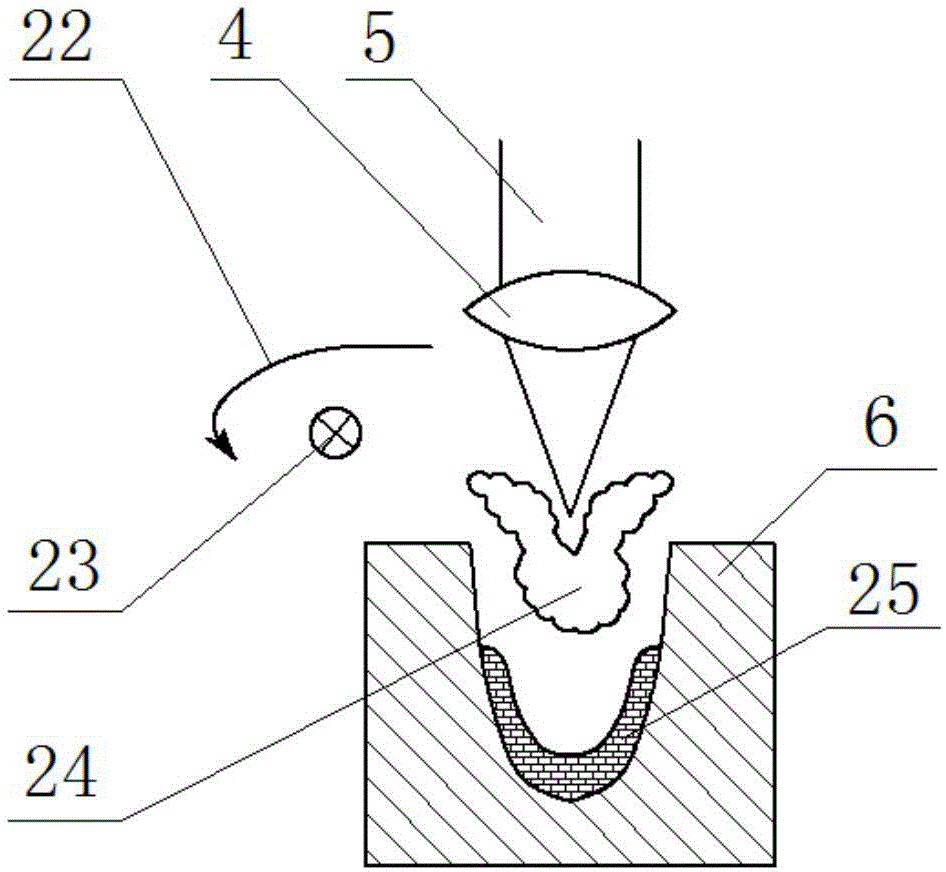

[0039] The laser generating unit includes a laser and a focusing lens 4, and the laser beam output by the laser is focused by the focusing lens 4 and acts on the surface of the workpiece 6 to be processed;

[0040] The workpiece clamping unit includes a main shaft 13, a base plate 11, a first bearing 7 and a squirrel cage 3, wherein the main shaft 13 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com