Patents

Literature

160results about How to "Increased drilling depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

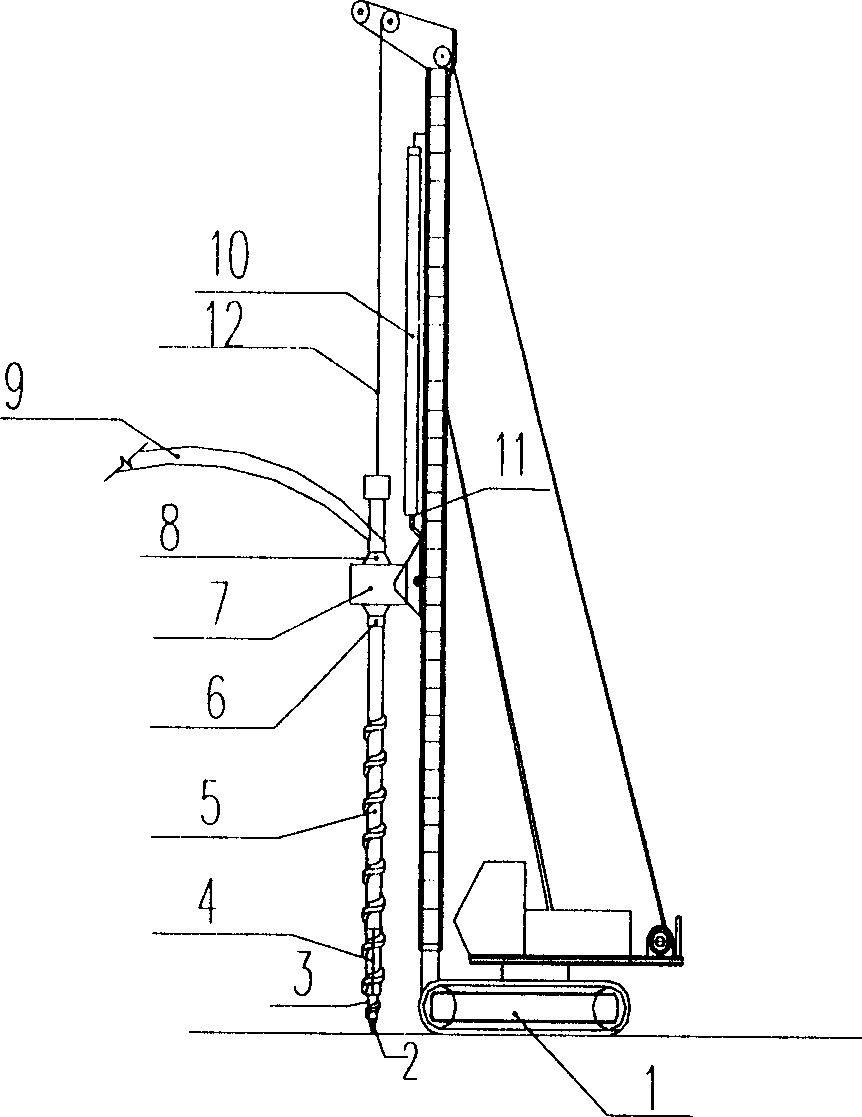

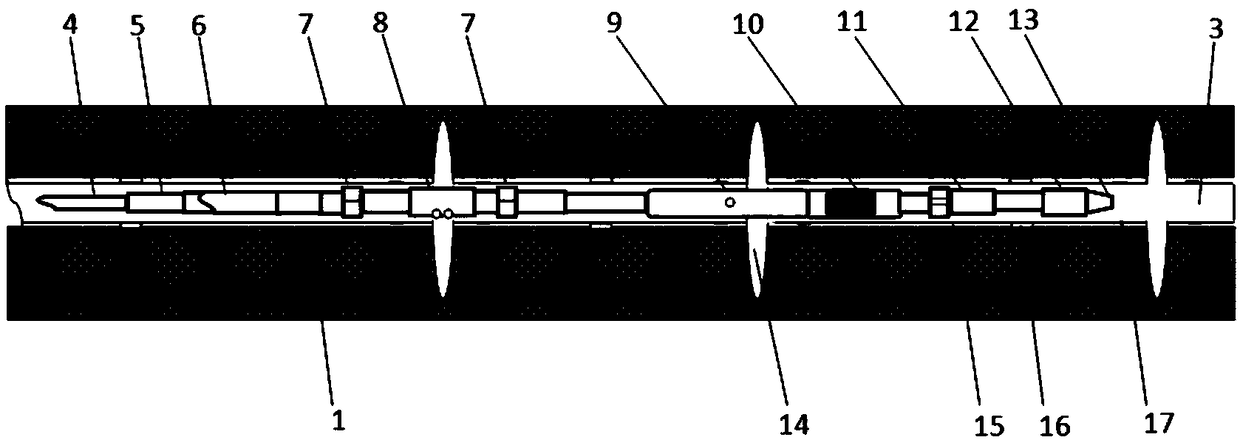

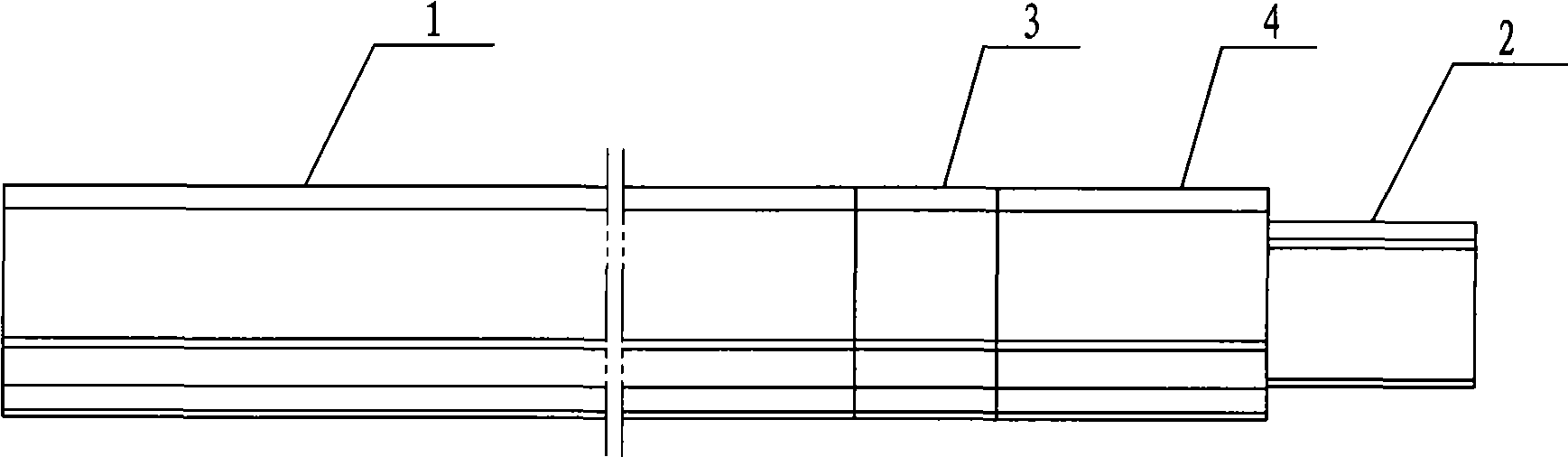

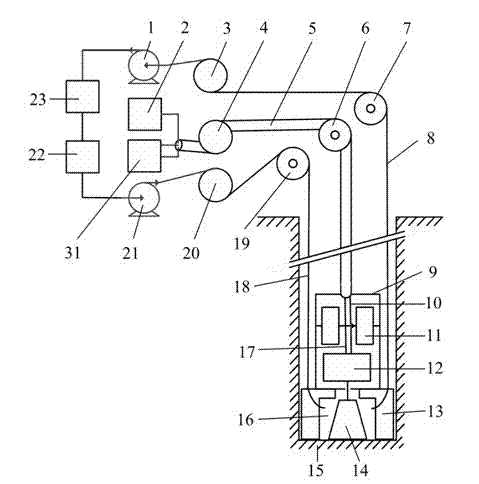

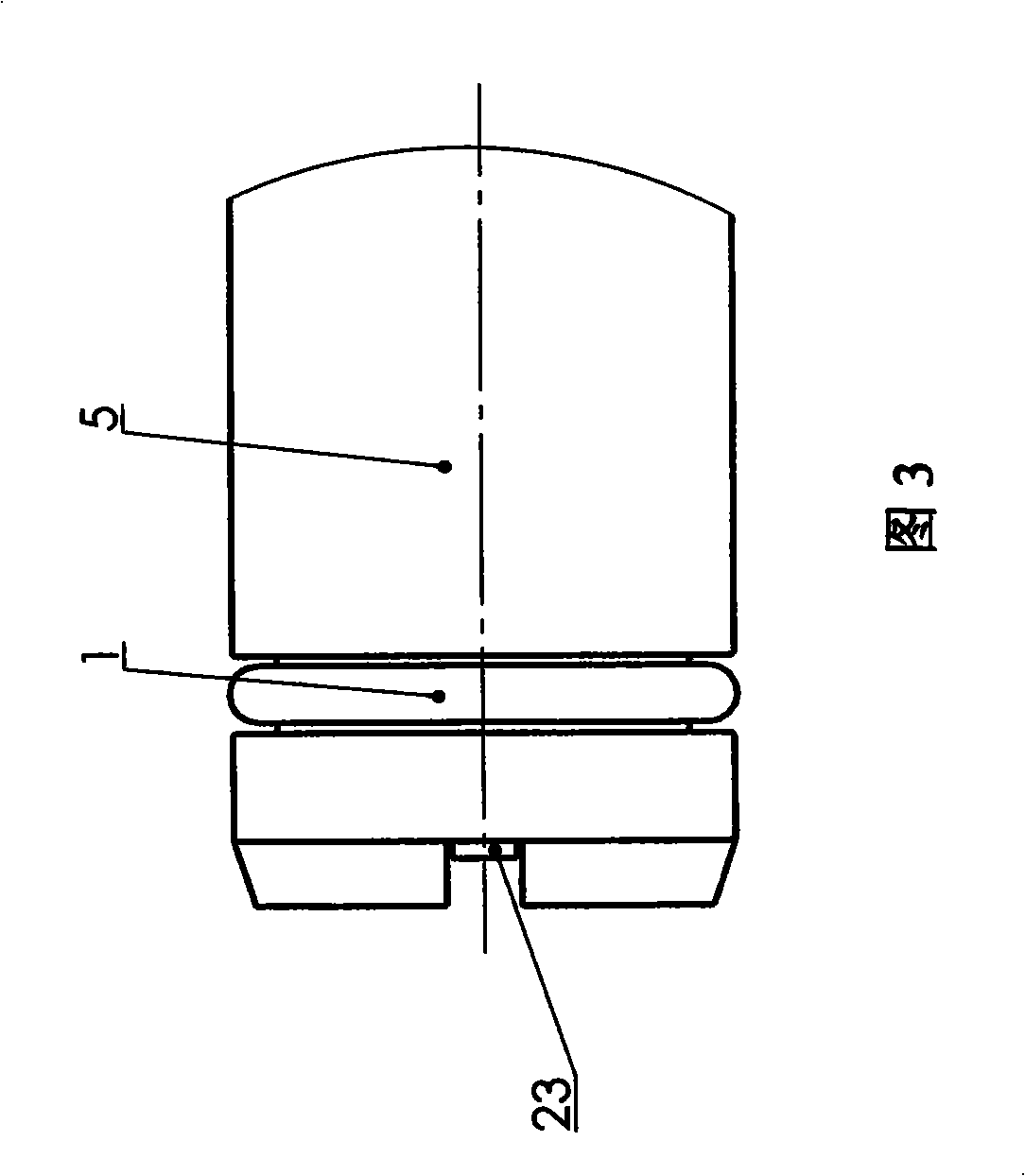

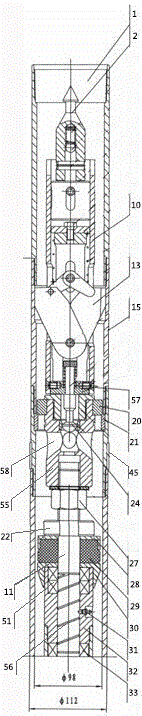

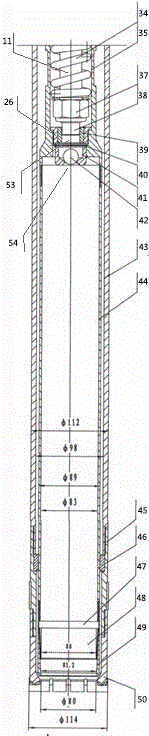

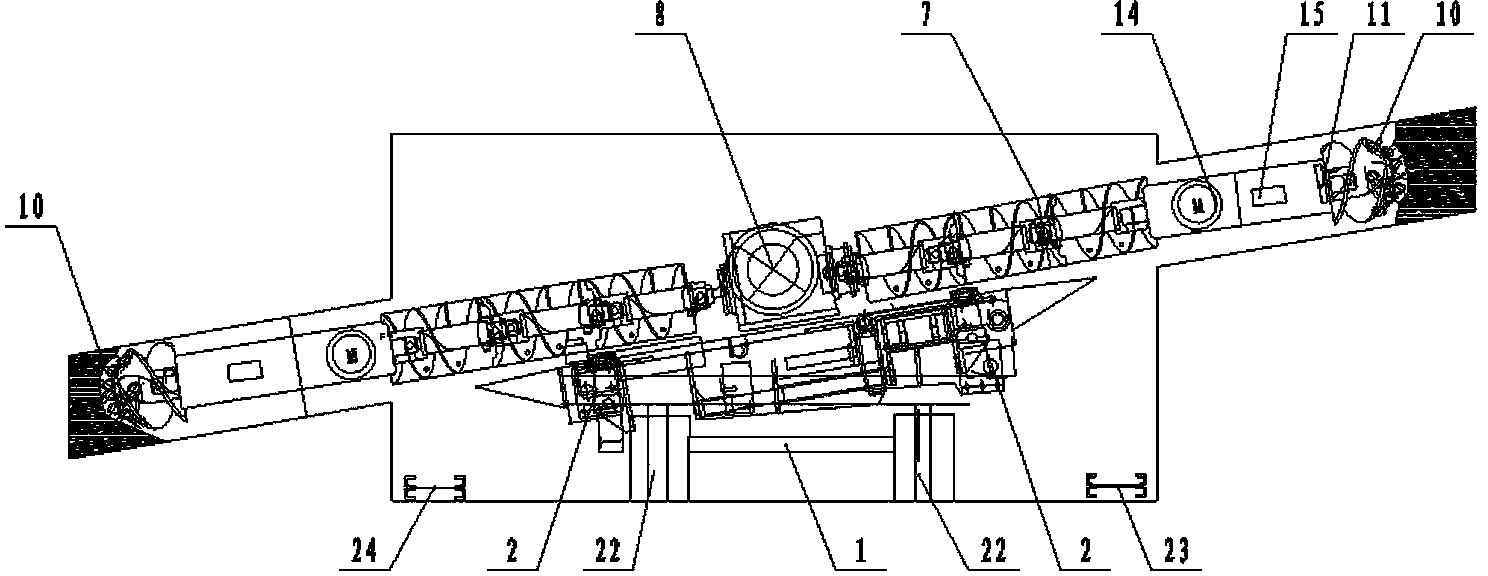

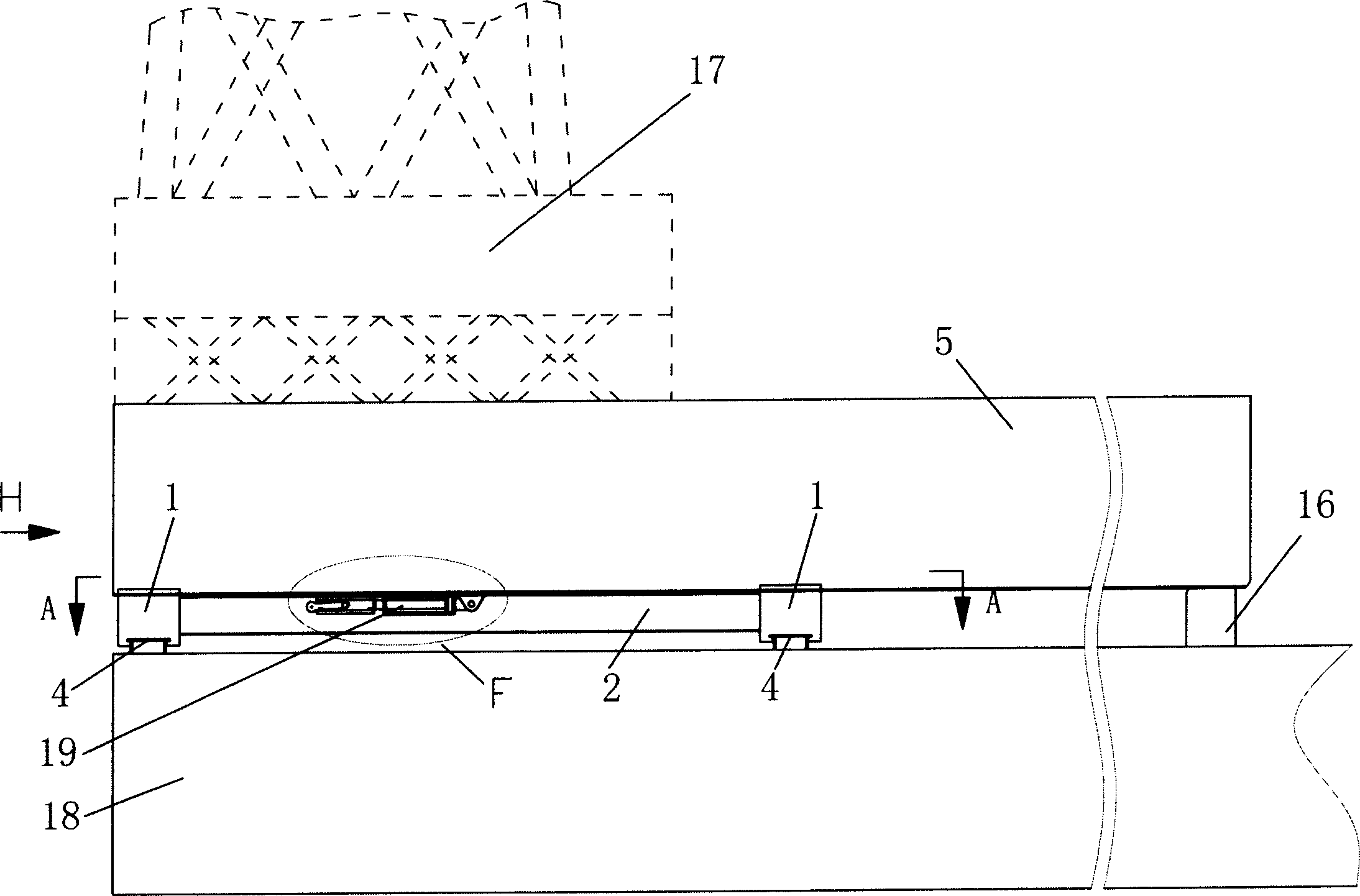

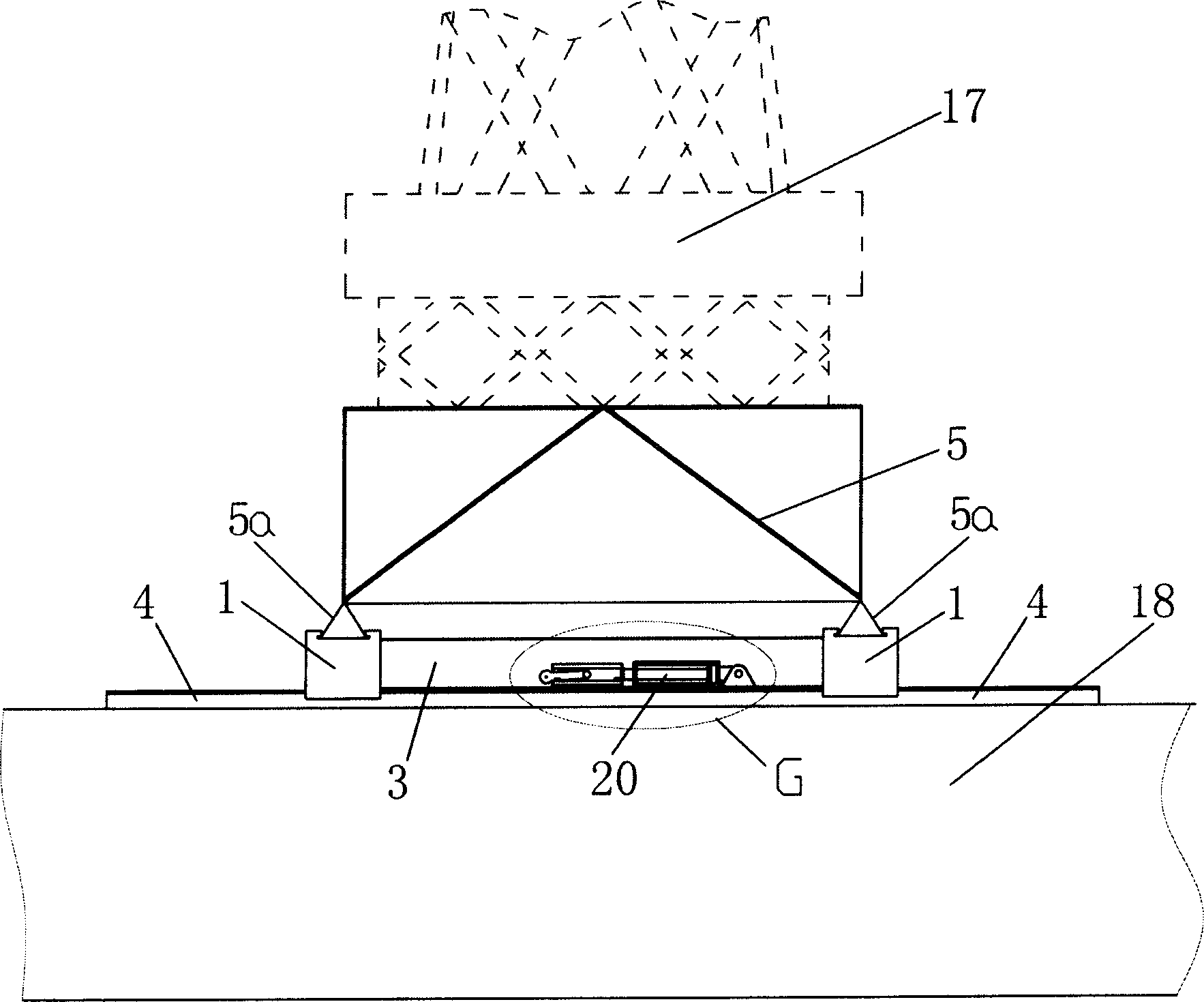

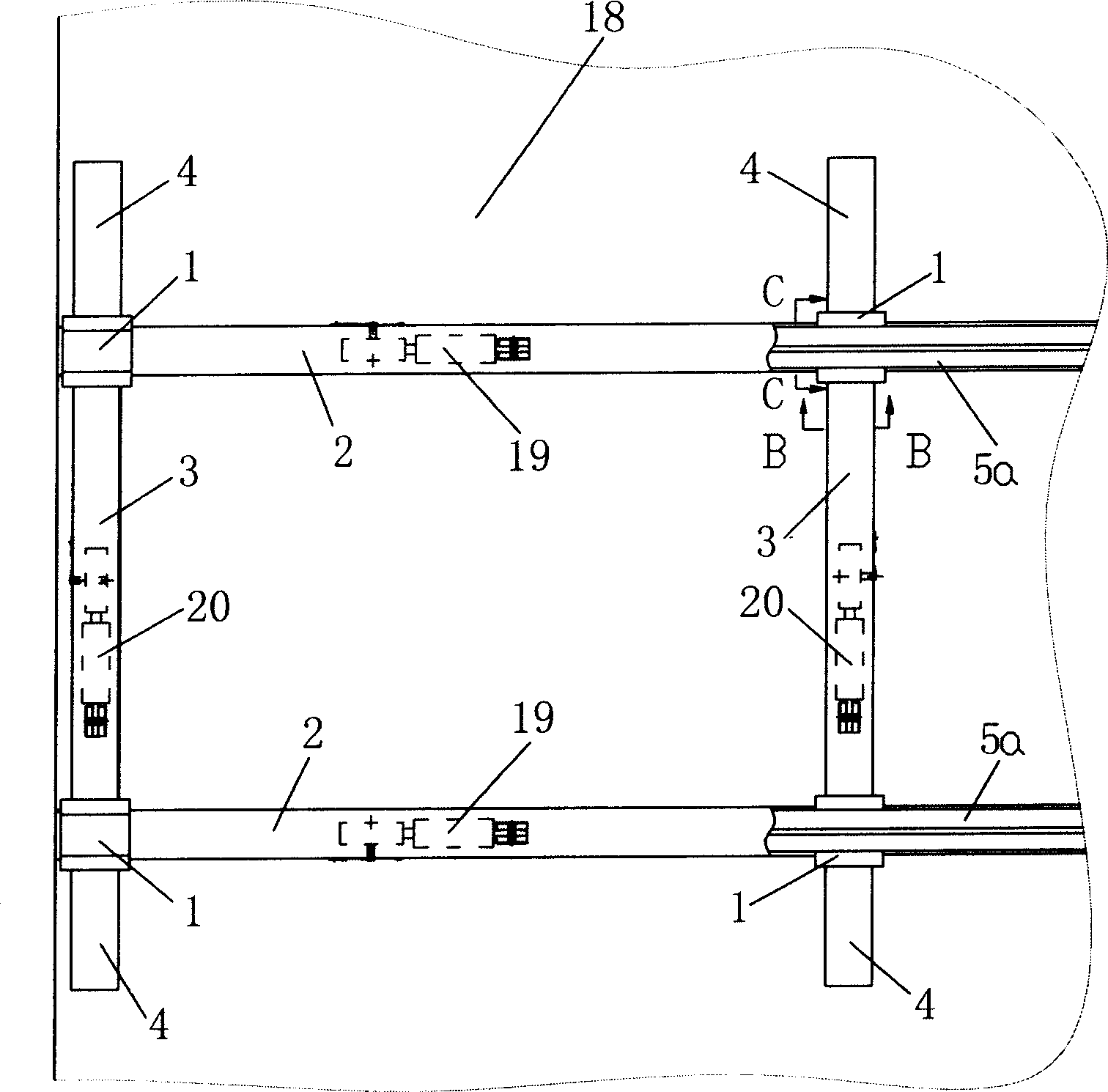

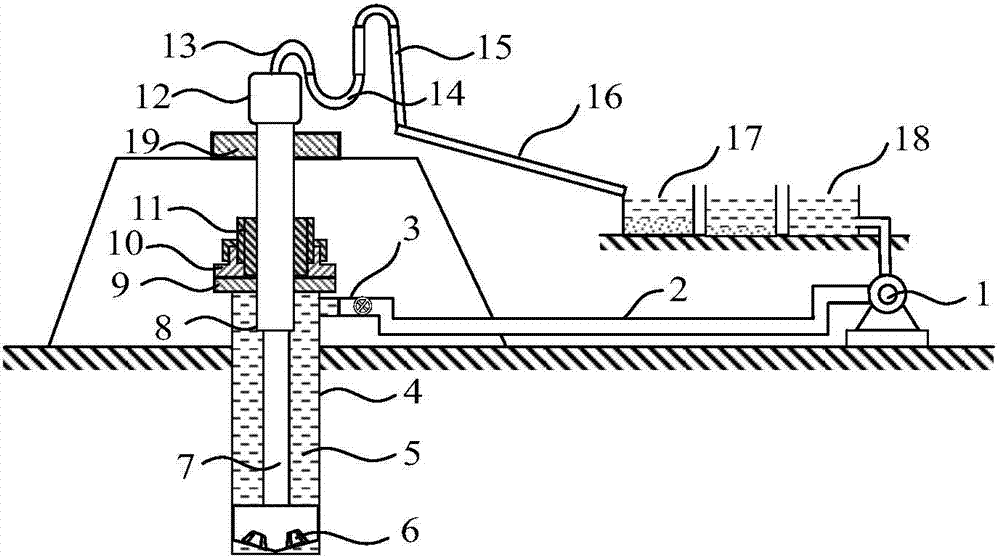

Screw pile, thread pile piling equipment and piling method

InactiveCN1904225AIncreased drilling depthImprove homogeneityBulkheads/pilesElectricityAutomatic control

This invention relates to screw stake, making screw stake equipment and the making method. The making screw stake equipment is mainly composed of the engine body, the oil cylinder, the hydraulic electric engine, the automation equipment and the transfer piping. The power head is installed on the engine body base's stand support. The hydraulic electric engine is installed on the engine body's base. The hydraulic electric engine connects with the power head through the power head. The drill pipe's clamp apparatus connects with the power's removable clamp apparatus. The transfer piping connects with the inner drill pipe. The automation equipment separately connects with the hydraulic electric engine and the oil cylinder. This invention has the following advantages: the power output saves electricity and time, it enlarges the equipment's application range and the construction speed excels other similar inventions evidently; the equipment adopts the extensible drill pipe, the drill's drilling depth largely improves; the three independent drill heads' structure has the unique ability of thrice enlarging aperture; it realizes the revolution and the raising to keep synchronous and non- synchronous; it adopts low gravity center pile frame, the equipment's weight is reduced evidently, the safety improves; it realizes the stake's stirring and evidently improves the stake's uniformity

Owner:卓典设计(海南)有限公司

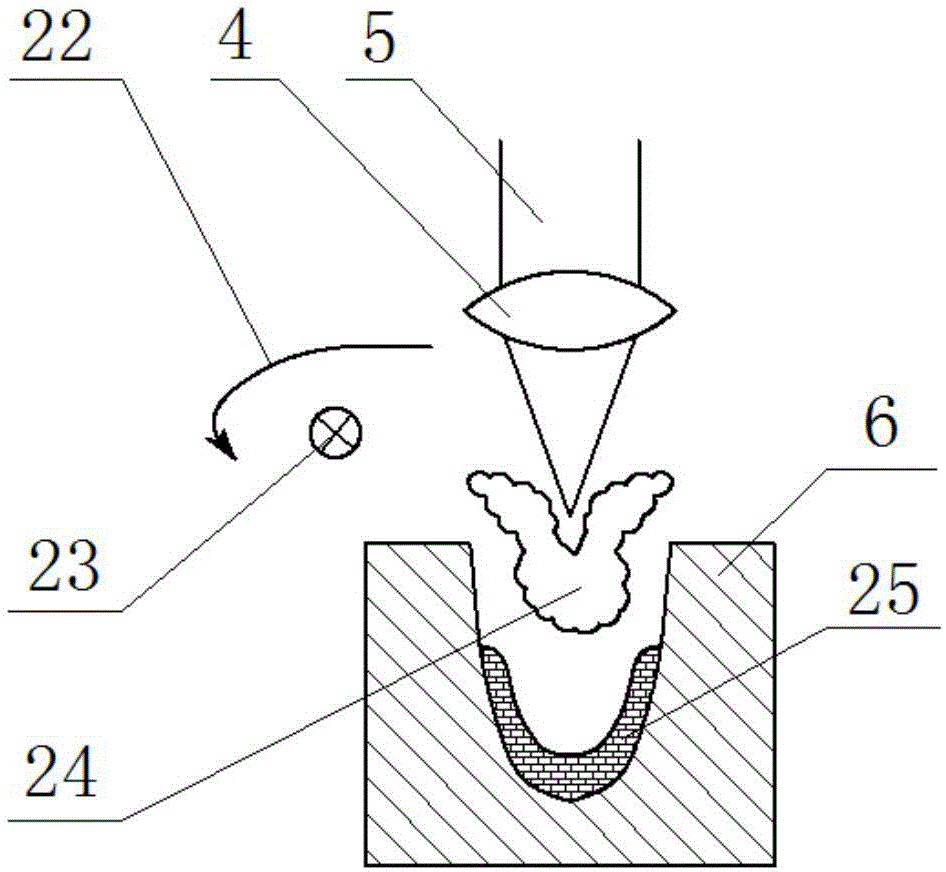

Electromagnetically-assisted laser drilling method and device

ActiveCN103817430ALow densityEnhanced magnetic fieldLaser beam welding apparatusMagnetic tension forceEngineering

The invention provides an electromagnetically-assisted laser drilling method. The method includes the steps of 1, clamping a workpiece to be processed onto an electromagnetically-assisted laser drilling device; 2, driving a fixture base to rotate by a motor so that a permanent magnet clamped on the fixture base rotates at high speed and forms a rotational magnetic field; meanwhile, allowing a mouse cage in the rotational magnetic field to produce electromagnetic force whereby the workpiece rotates in sync with the mouse cage; 3, after the speed of the motor stabilizes to a preset value, starting a laser, which generates a laser beam acting on the surface of the workpiece via a focusing lens so as to finish the electromagnetically-assisted laser drilling process. According to the method, the application of the operating method of rotating the workpiece enhances the assistance of the magnetic field in laser drilling; meanwhile, the rotational magnetic field can control motion of plasma and molten metal generated in the laser drilling process, so that laser drilling effect is optimized. The invention further provides the electromagnetically-assisted laser drilling device.

Owner:上海尚朴光电技术有限公司

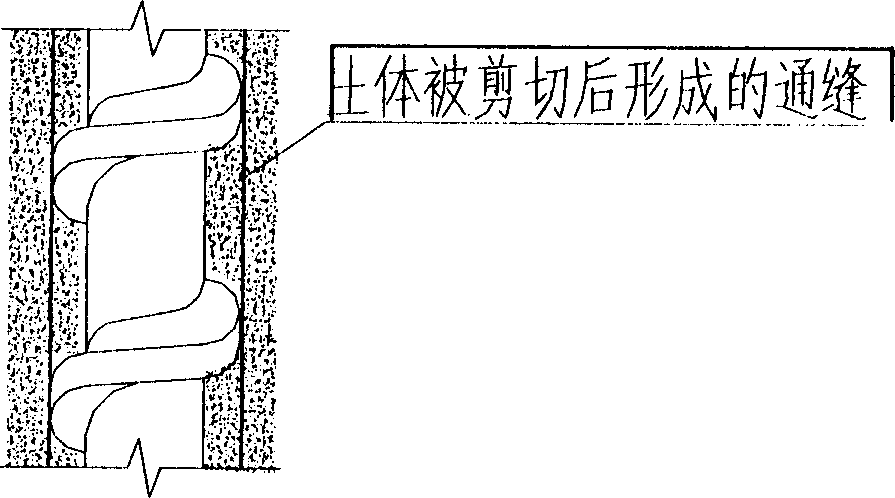

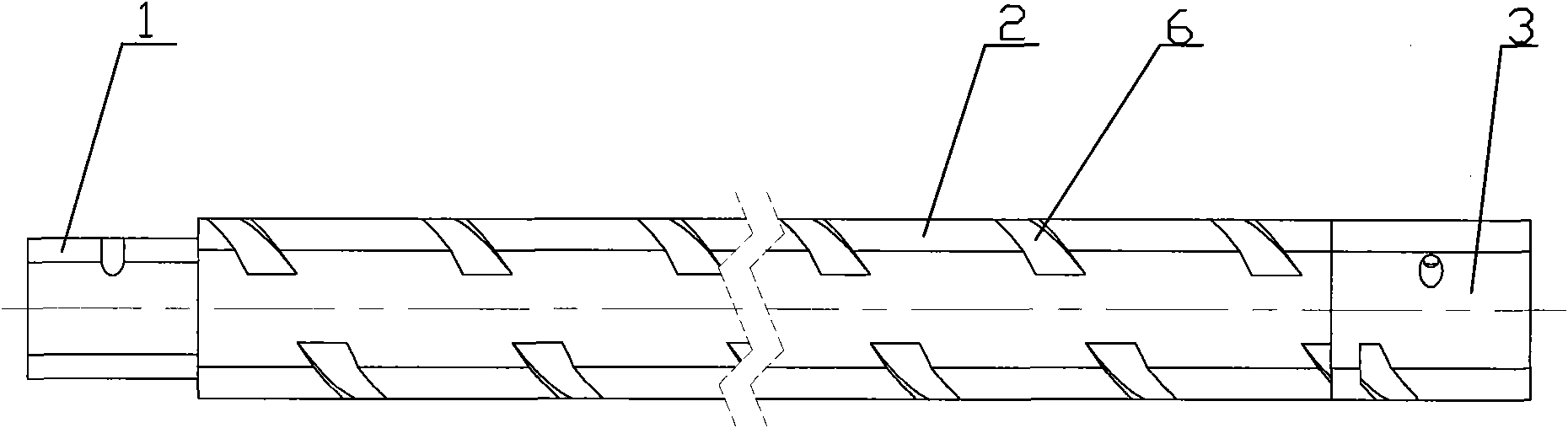

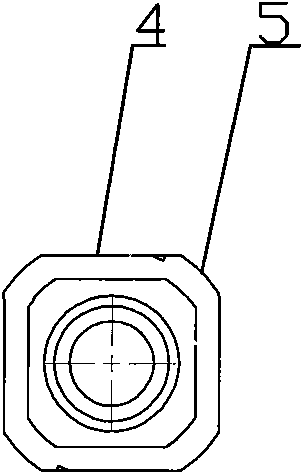

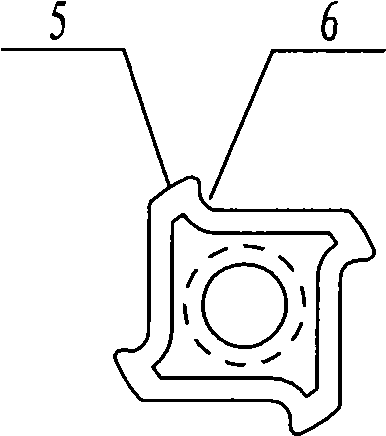

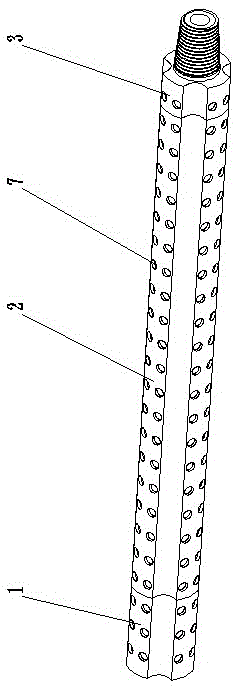

Irregularly shaped multi-land notch groove drill rod

ActiveCN101566049ALow rotational resistanceTake away in timeDrilling rodsDrilling casingsLine segmentHelix

The invention discloses an irregularly shaped multi-arris notch groove drill rod, which consists of a hollow multi-arris rod body and a connecting piece, the section outline of the multi-arris rod body consists of tangential paths and circular arc sections, and incontinuous spiral grooves are distributed on the surface of the rod body simultaneously. The drill rod can cause vortex flow when whirling in loose cinder and raise coal dust deposited on the bottom of a drilling hole in virtue of the arris of the drill rod, and the coal dust in the drilling hole is at a moving status all the time, thus preventing the coal dust from accumulating in the drilling hole and resulting in blockage; simultaneously, the incontinuous spiral grooves distributed on the surface can assist in the outward transmission of the cinder, and when hole collapsing in the drilling hole, the outside of the collapsed hole is unchoked by the hole digging function of the spiral grooves, thus being not easy to have drill absorption and drill blockage. The drill rod has the advantages of reasonable design, simple structure, safety and reliability, thus greatly improving deslagging effect, being beneficial to increasing the depth of the drilling holes, shortening hole drilling time, improving work efficiency and having high hole forming rate. Therefore, the drill rod is worth popularizing and applying in mining enterprises.

Owner:山东益矿钻采科技有限公司

Multifunctional self-oscillation flow jet flow drill

InactiveCN101413380AImprove permeabilitySimple structureLiquid/gas jet drillingVibration drillingJet flowSelf-oscillation

The invention relates to a multifunctional self-oscillation jet drill bit. The prior similar product not only has shallow drilling depth and complex structure but also has large resistance loss and short service life of a drill bit, can not repeatedly switch drilling and groove cutting during the drilling process, and limits the application scope. A crushing blade and a valve body are arranged inside a cutting head body of the drill bit; a first offsetting spring in the valve body is matched with a valve core A in the form of sliding; a valve core B is matched with a second offsetting spring for operation under the action of a lined ring, a washer and the valve body together; and the valve core and a limber hole of the valve body are matched for use with a self-oscillation nozzle. The multifunctional self-oscillation jet drill bit adopts high-pressure water as power to realize repeated switching between drilling and groove cutting of coal seam and terrane, not only has a simple structure and is flexible to switch but also can promote development of coal seam fissure through oscillation jet generated by the nozzle, strengthens the permeability of the coal seam, improves the gas extraction rate, particularly has obvious effect on low-permeability coal seam, and widely promotes and applies the fluid technology of the high-pressure water in the fields of drilling and gas extraction of the low-permeability coal seam.

Owner:CHONGQING UNIV

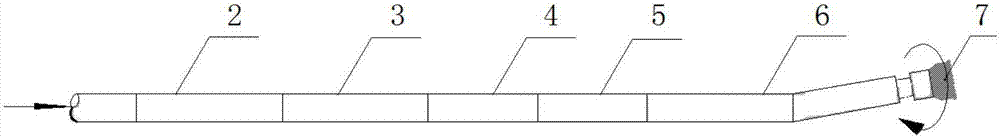

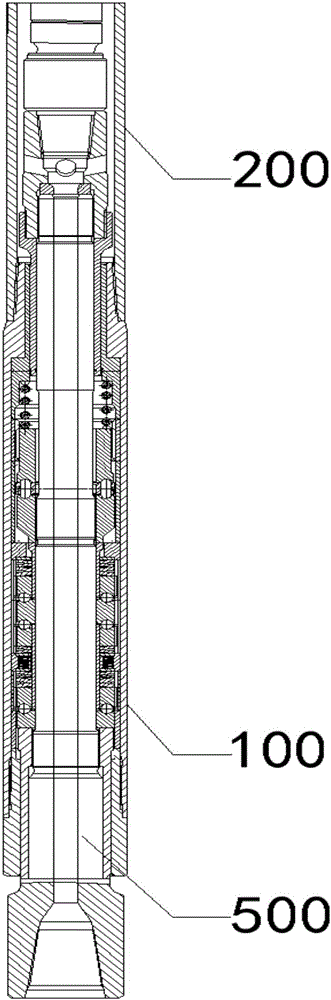

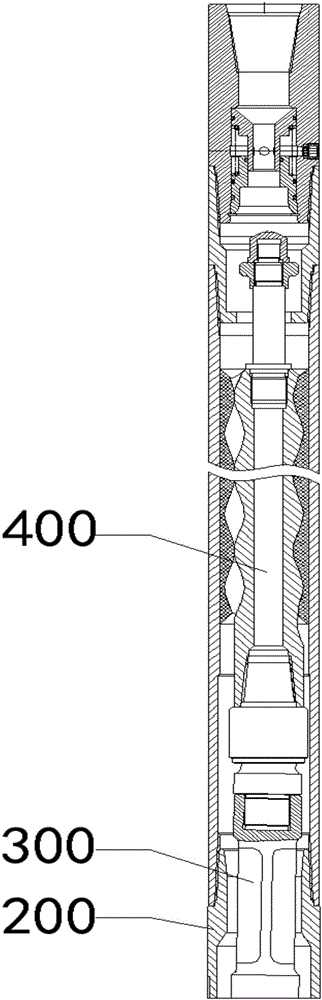

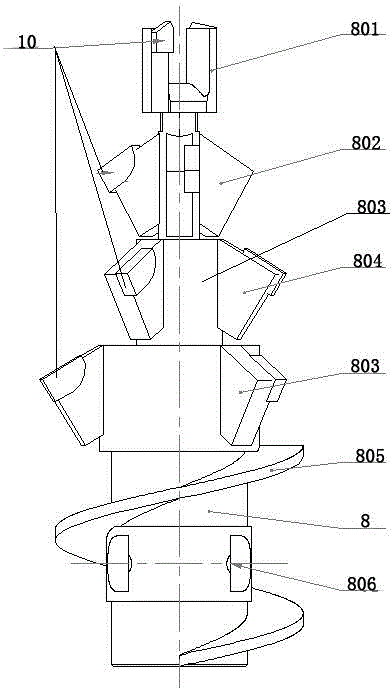

Drilling tool assembly used for directional hole-forming underground coal mine and provided with air screw motor and construction method

InactiveCN106869791AIncrease the encounter rateIncreased drilling depthDrilling rodsConstructionsMotor driveNon magnetic

Disclosed is a drilling tool assembly used for directional hole-forming underground a coal mine and provided with an air screw motor and construction method. The drilling tool assembly comprises a directional drill bit, the air screw motor, a lower non-magnetic drill rod, a wireless electromagnetic wave measurement while drilling short section, an upper non-magnetic drill rod, a middle drill rod and a blower which are connected in sequence. The drilling tool assembly can carry out composite drilling and sliding directional drilling for construction: when composite drilling is conducted, the air screw motor drives the directional drill bit to crush rocks in rotatably, meanwhile, the middle drill rod rotates to drive the air screw motor to rotate, boring mud at the bottom of a hole is discharged from the bottom of the hole by compressed air along an annular gap, and the middle drill rod can be used for auxiliary slagging; and when sliding directional drilling is conducted, the middle drill rod does not rotate, the directional drill bit is driven by the air screw motor driven by the compressed air to rotate to crush rocks, and the track of the hole is controlled by changing the elbow orientation of the air screw motor. Thus, according to the drilling tool assembly used for directional hole-forming underground the coal mine and provided with the air screw motor and construction method, the drilling depth of a soft coal seam and the coal seam drilling-encounter rate can be improved greatly, and the drilling gas extraction effect is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

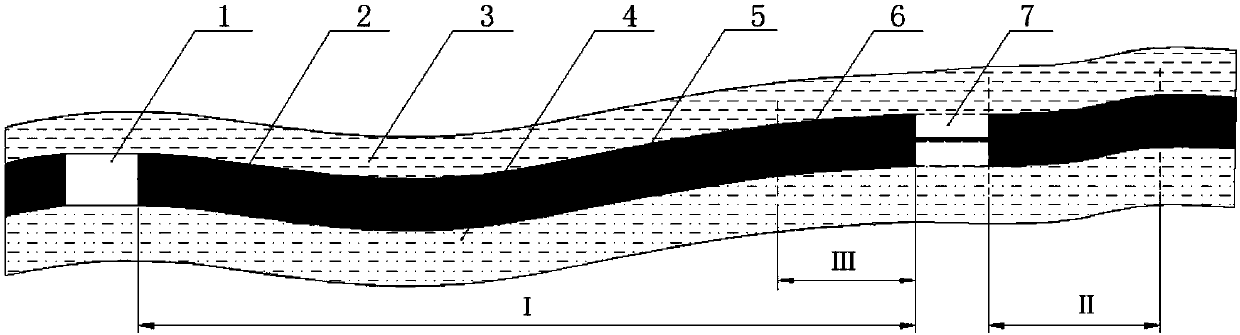

Coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method

ActiveCN109339855AAvoid prone to collapse holesAvoid problems such as drill stickingFluid removalGas removalSand blastingCoiled tubing

The invention relates to a coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method. The method includes the steps that first, a gas extraction long drilled hole is constructed in a mudstone or sandstone roof with a certain distance to the top boundary of a broken soft coal seam or a hard layer of the broken soft coal seam or a hard coal seam with a good coal body structure; second, a guiding shoe and a rigid casing are lowered; third, cement paste blocking is carried out on annular space between the gas extraction long drilled hole and the rigid casing so as to solidify the hole; fourth, packing staging is carried out through a mode of dragging a packer by coiled tubing, an ejector carries out sand blasting perforation, and fracturing is carried out on the annulus between the coiled tubing and the casing; fifth, a fracturing tool is lifted out, and uniform blowout of fracturing fluid is carried out. The method can solve the problems that in existing gas extraction hole-drilling, hole forming is difficult, the crack initiation position of fracturing cracks is not determined, the fracturing cracks extend short, the fracturing modification effect is poor, the extraction affecting range is small and nonuniform, and extraction duration is short, and realizes gas extraction long drilled hole forming and multi-level precise staged fracturing.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

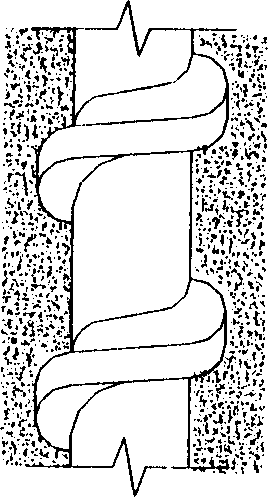

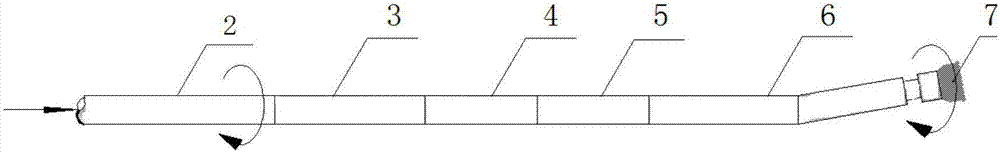

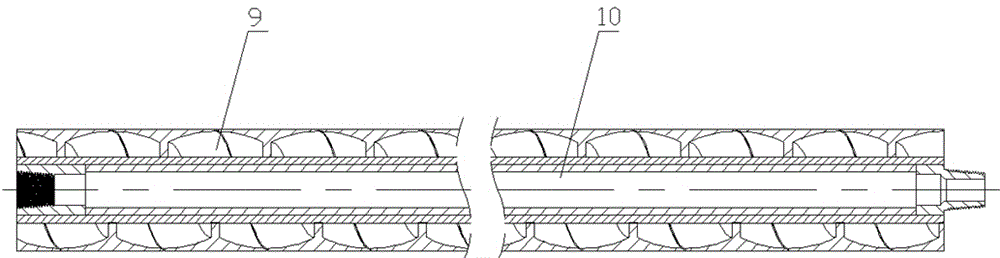

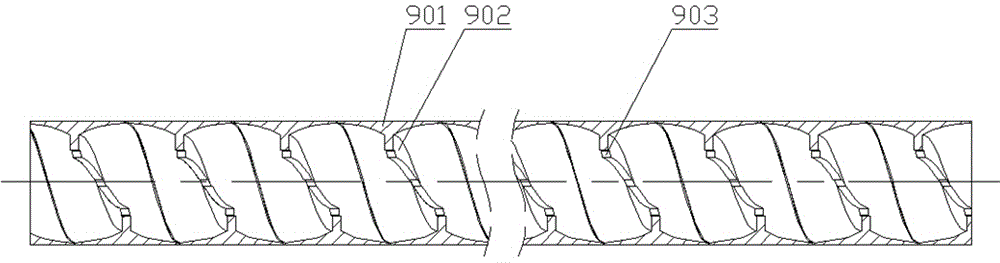

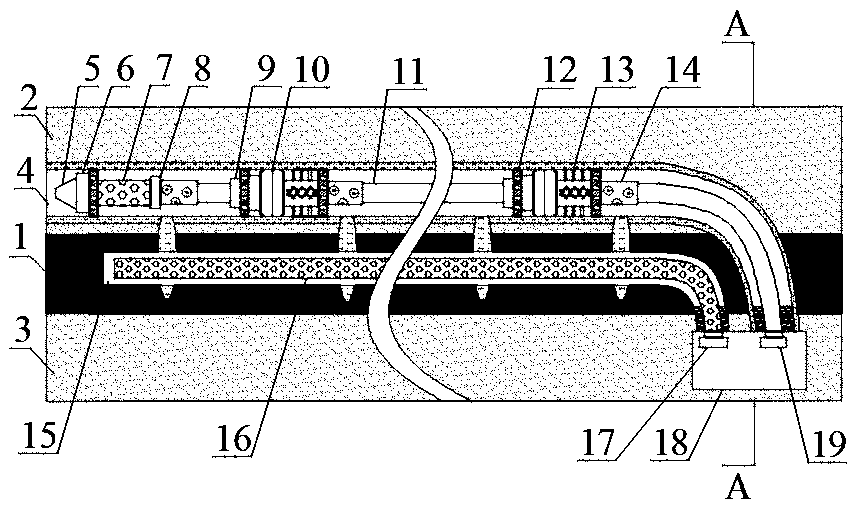

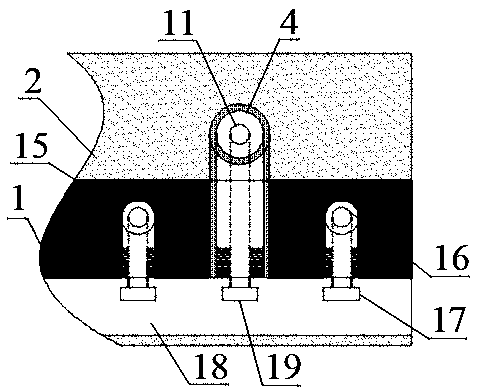

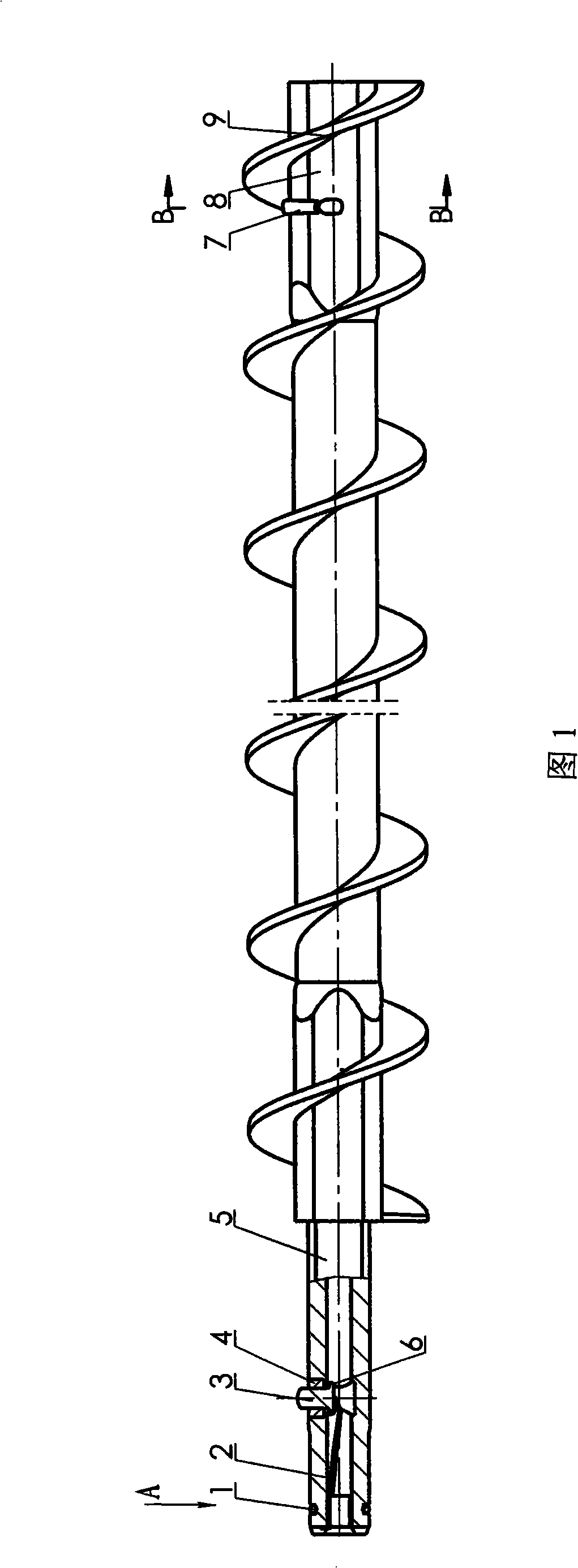

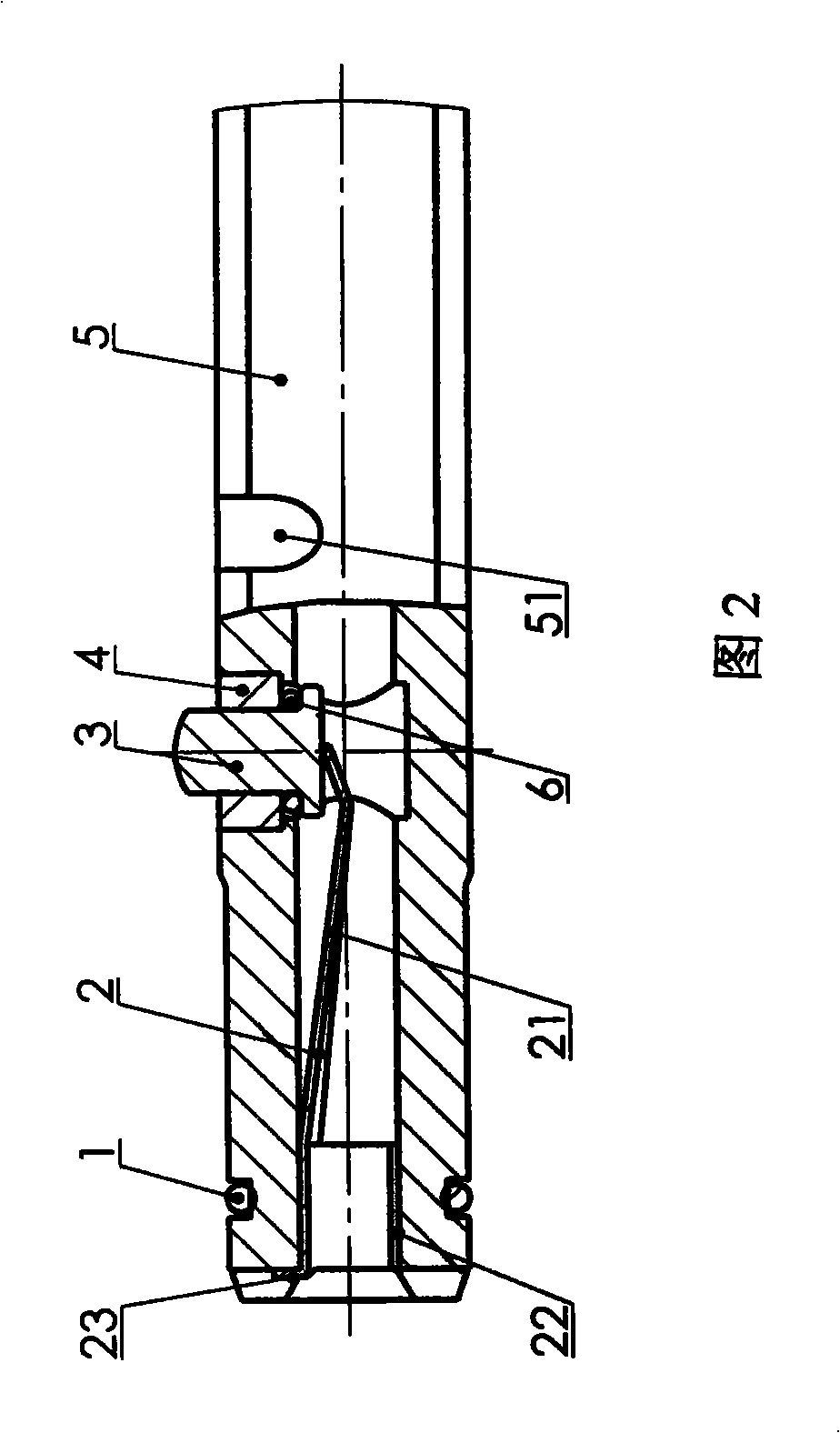

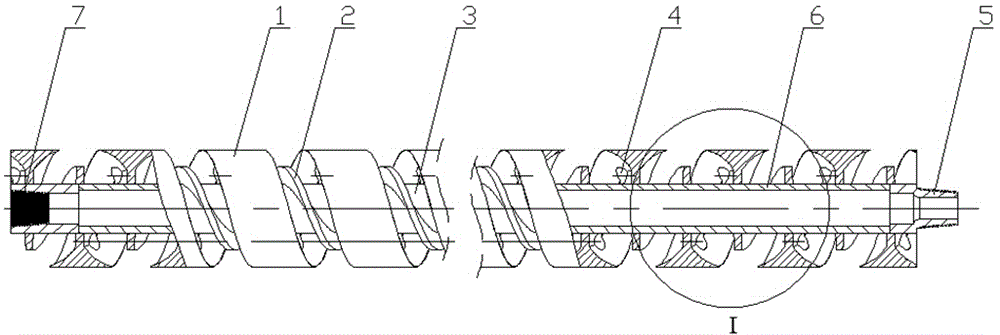

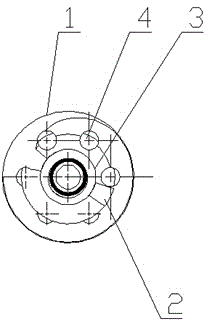

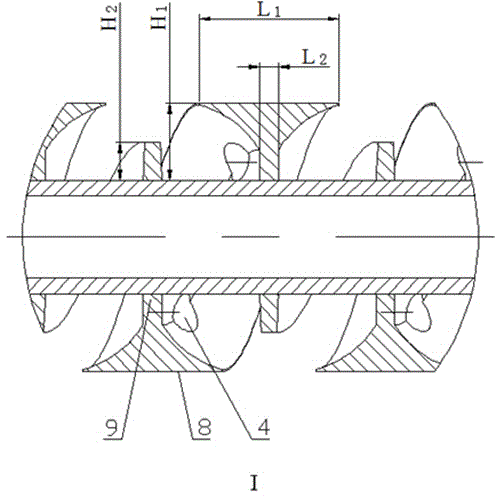

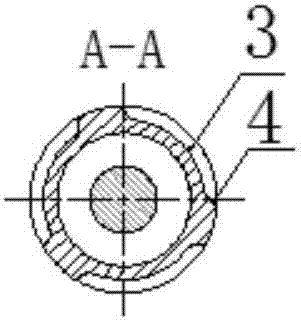

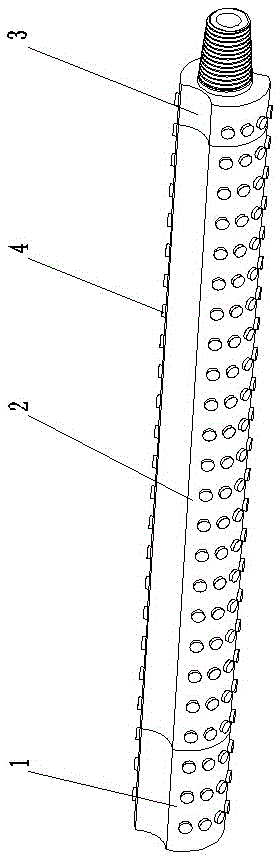

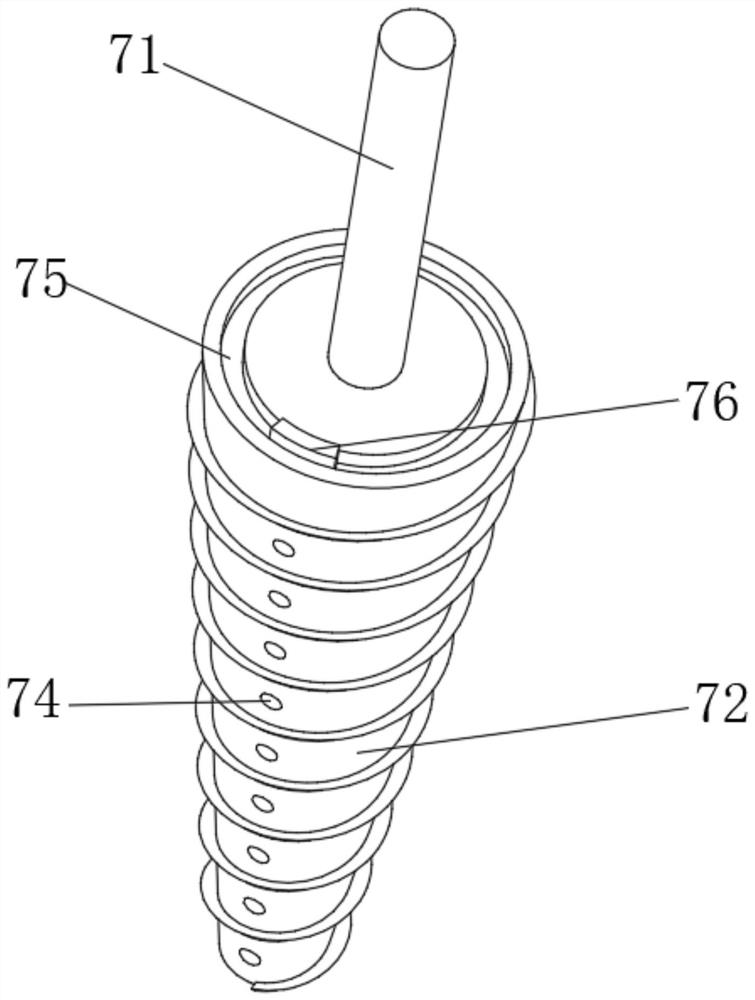

Closed type helical hole-protecting drill and using method thereof for drilling of soft coal bed

ActiveCN104314482ALow rotational resistanceIncreased drilling depthDrill bitsDrilling rodsDischarge efficiencySlag

The invention discloses a closed type helical hole-protecting drill and a using method thereof for drilling of a soft coal bed. The closed type helical hole-protecting drill comprises a closed type helical hole-protecting drill pipe and a helical slag-guiding drill bit, and the helical slag-guiding drill bit is mounted at the front end of the closed type helical hole-protecting drill pipe. The closed type helical hole-protecting drill is mainly applied to the drilling engineering of the soft and breaking coal rock layer. The using method includes mounting and connecting a drill, the closed type helical hole-protecting drill pipe, the helical slag-guiding drill bit and an orifice slag discharging device, starting the drill, breaking and drilling the coal bed by the helical slag-guiding drill bit, guiding drillings into the helical slag discharging space of the closed type helical hole-protecting drill pipe along slag-guiding helical grooves of the drill bit, and discharging the drillings out of the hole through friction of helical blades. The closed type helical hole-protecting drill is novel in design, and is provided with a hole protecting function via structural innovation of the helical blades, the drillings are discharged within in the protected space and prevented from being influenced by deformation and collapse of drilled holes, and the defect that a conventional casing drill is high in drilling resistance, low in slag discharging efficiency and the like is overcome.

Owner:HENAN POLYTECHNIC UNIV

Method for gas extraction through bedding directional long drill hole traversing working face in broken and soft coal seam

InactiveCN107740677AIncreased drilling depthImprove coal seam encounter rateFluid removalDirectional drillingDrill holeSoft Coals

The invention relates to a method for gas extraction through a bedding directional long drill hole traversing working face in a broken and soft coal seam. According to the method, through an air screwmotor directional drilling technology, the bedding gas extraction long drill hole is constructed in a tunneled roadway on one side of the working face of the coal seam, and the drill holes penetratesthrough a to-be-tunneled roadway on the other side of the working face to the position, within the control range of 15-20 m, of the outer side of the roadway; and after the drill hole is completed, adrill tool is lifted up, an open-close type guiding drill bit and a drill rod with a large through hole are put down, then a hole protection screen pipe is put down through the center of the drill rod, then the drill rod is lifted up, the screen pipe stays in the hole, and then a gas extraction pipeline is connected for gas pre-extraction. An air screw motor directional drilling method is adoptedin the gas treatment technology so that the drilling depth of bedding extraction of the broken and soft coal seam and the coal seam drilling-encounter rate can be greatly increased, invalid footagesare reduced in quantity, meanwhile the drill hole coverage range is ensured, the purpose of gas pre-extraction outburst elimination of the stope face and the to-be-tunneled roadway is achieved, and safe tunneling of the coal seam roadway and safe extraction of coal extraction work face are ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP +1

Drilling rod with asymmetric special-shaped cross section

ActiveCN101481999ALow rotational resistanceHigh porosityDrilling rodsDrilling casingsSlagDrilling riser

The invention discloses an asymmetric deformed-section drill pipe which is composed of a hollow pipe body and a connecting piece which are detachably connected; beads which are more than or equal to two and less than or equal to eight are arranged on pipe body along the pipe body, and the outer surface of the bead is an arc surface which takes an axle wire of the pipe body as a circle center, and one side of the bead and the pipe body form a long-strip groove. The drill pipe has reasonable design and simple structure; drill adsorption and drill blocking can not easily happen according to the principle of vortex flow caused by rotation of the deformed-section rigid body in loose coal slag, therefore, the drill pipe is safe and reliable, slag-off effect is greatly improved, thus being beneficial to improving drilling depth, shortening drilling time and improving working efficiency and pore-forming efficiency and being worth of being popularized and applied in coal mine enterprises.

Owner:山东益矿钻采科技有限公司

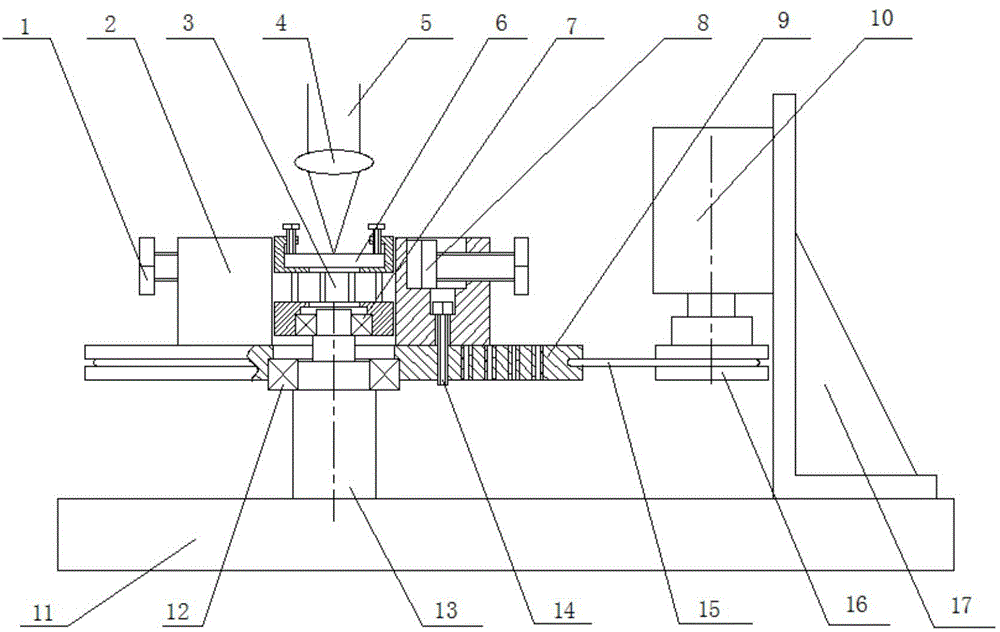

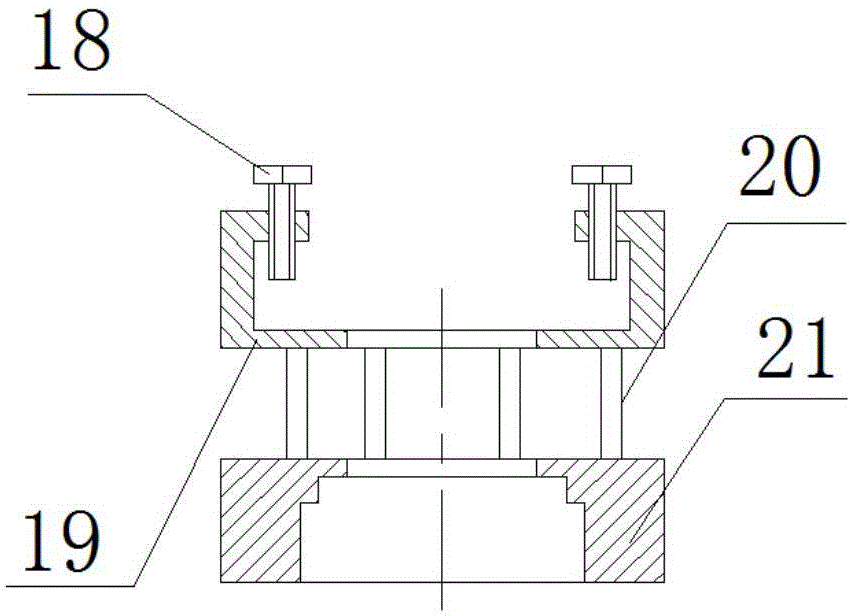

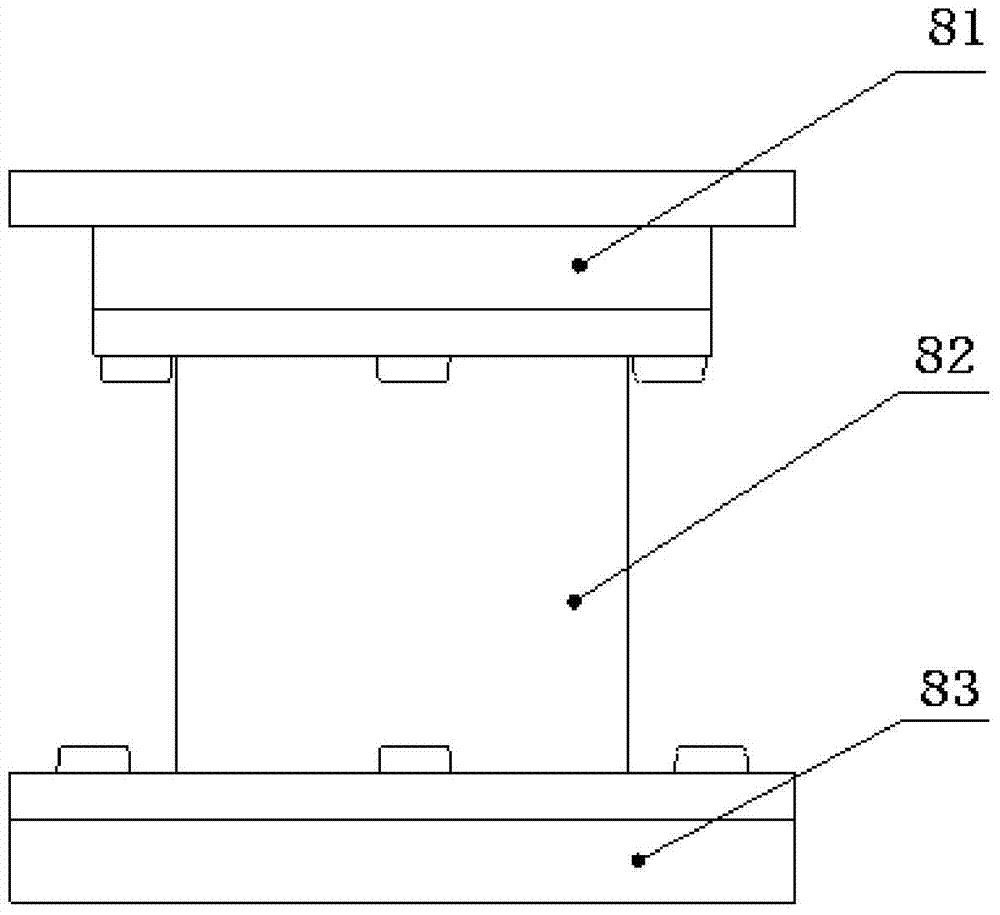

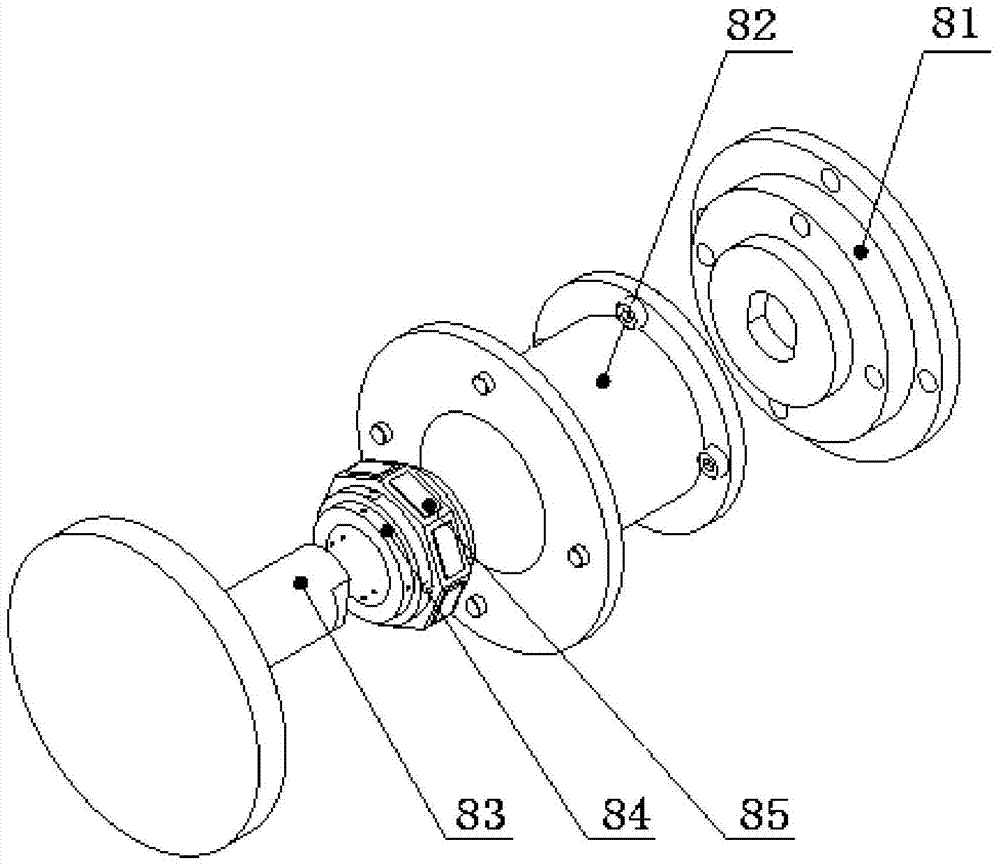

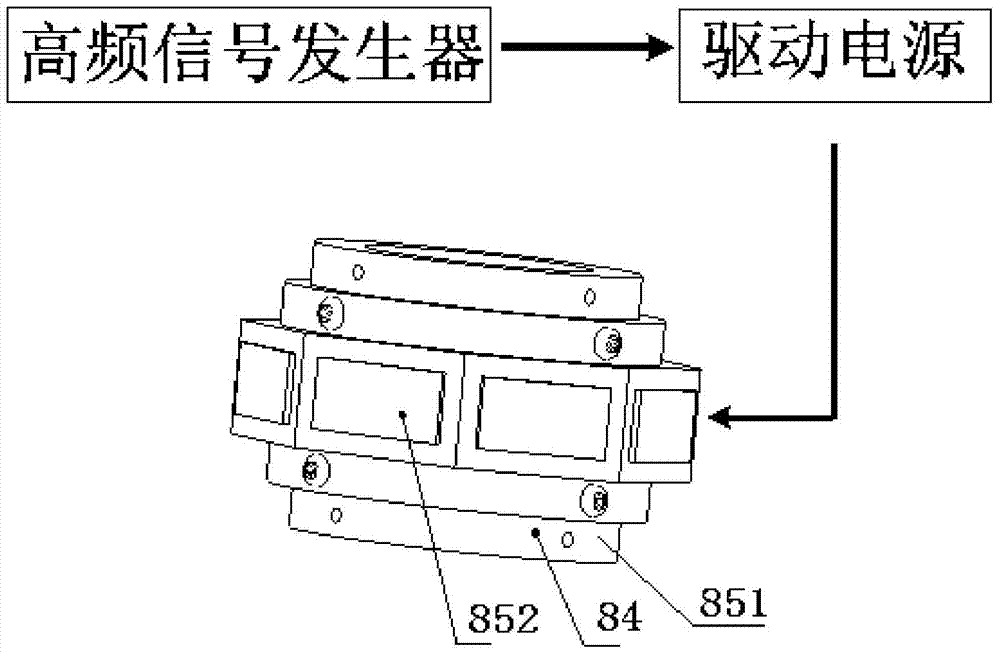

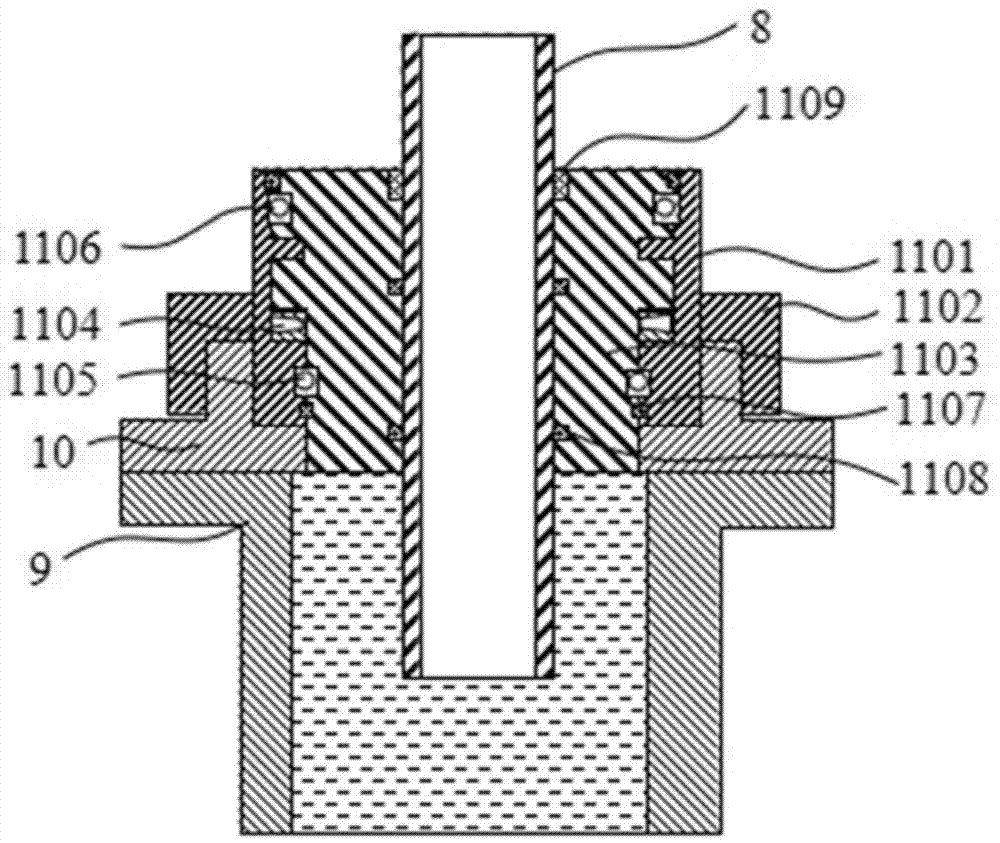

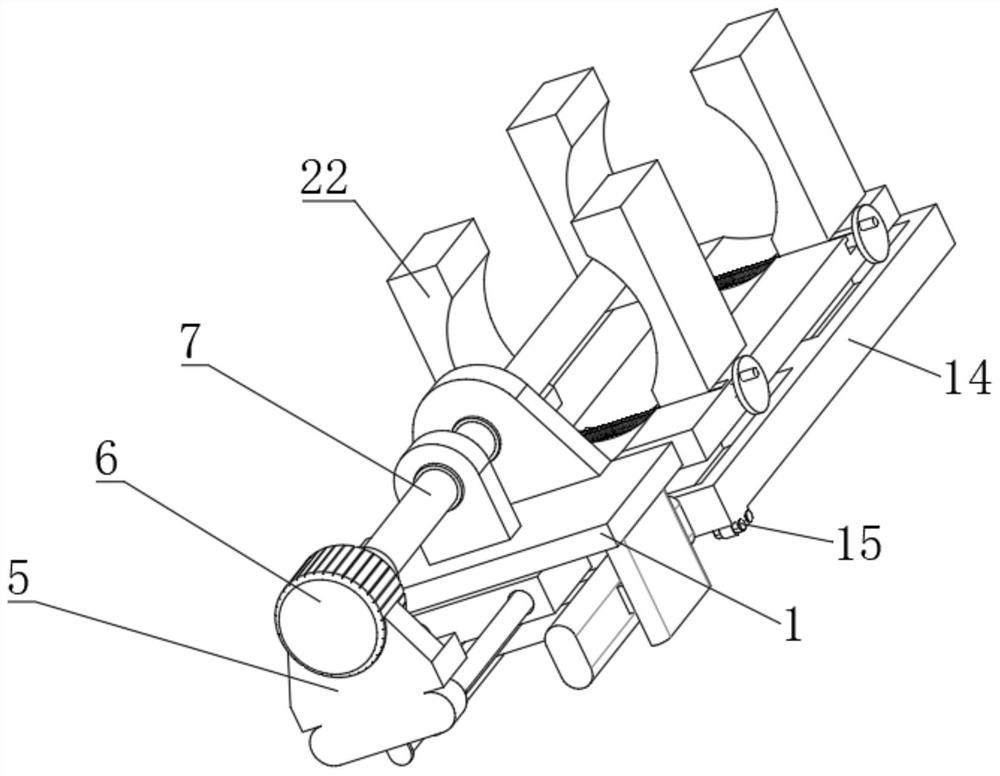

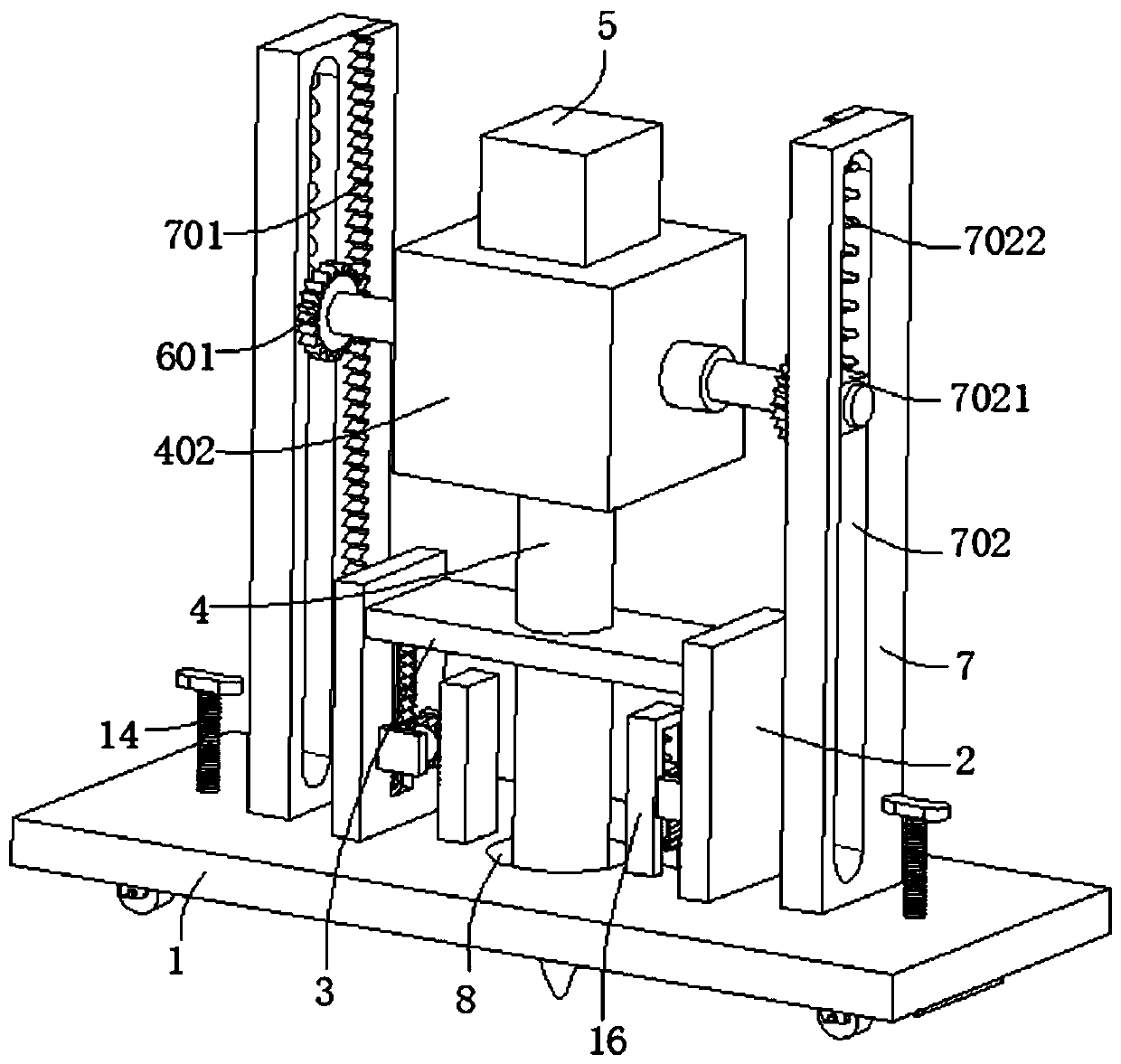

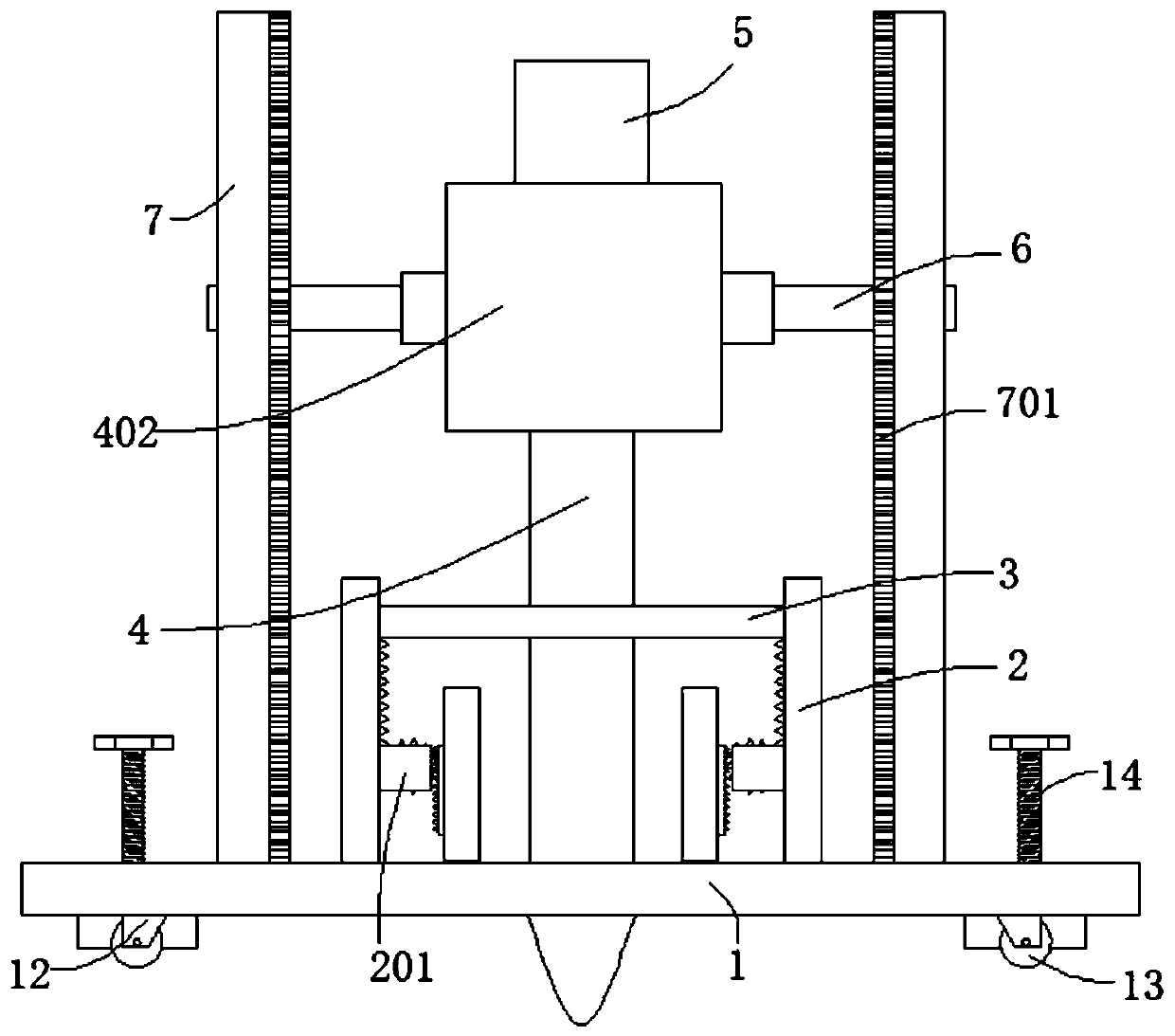

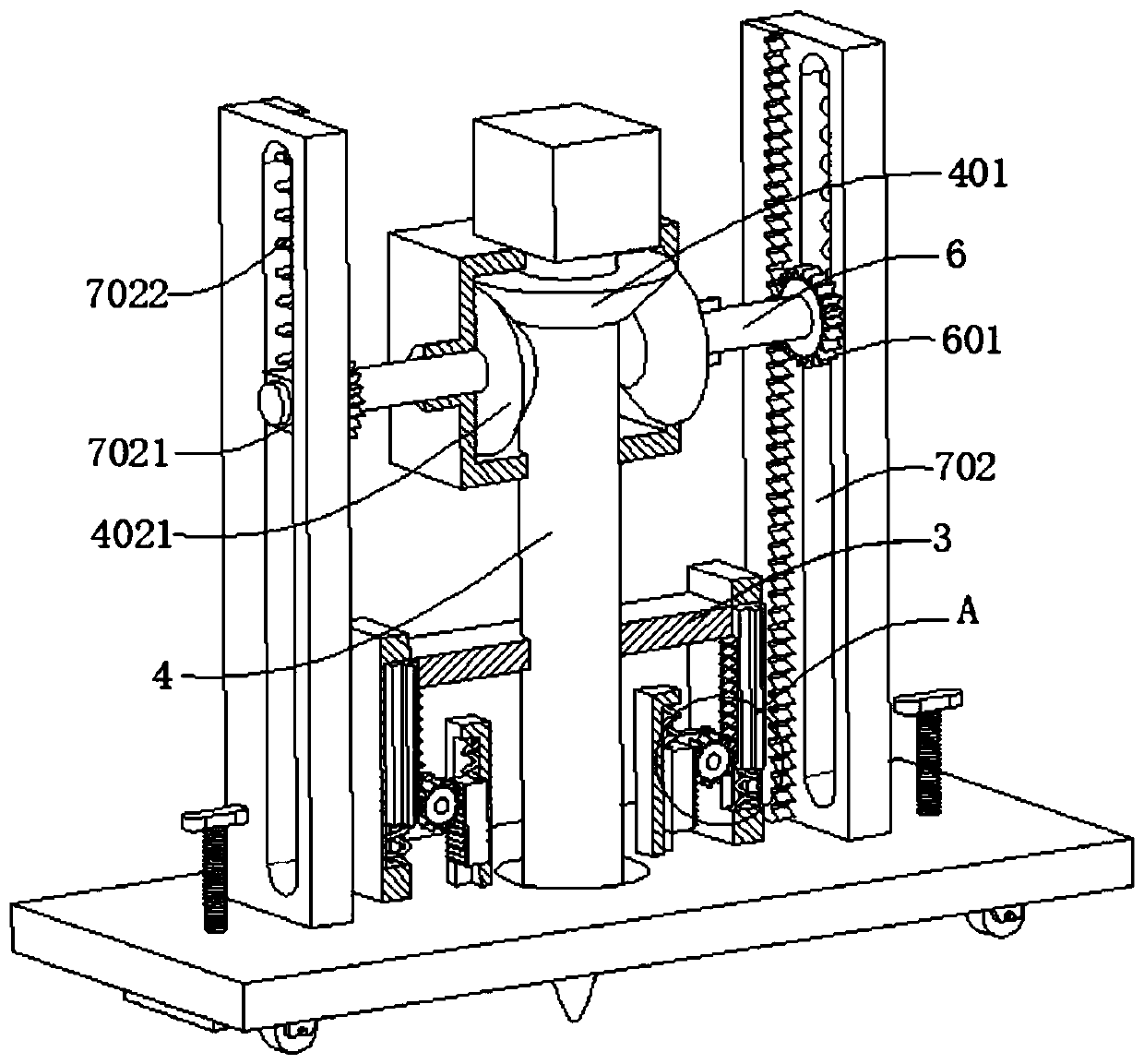

Workpiece loading device and machining device for machining tiny deep holes

InactiveCN103586504AControllable torsional vibrationReduce frictionBoring/drilling machinesEngineeringActuator

A workpiece loading device for machining tiny deep holes comprises a base, an upper cover and a protection shell, wherein the upper cover is used for bearing a workpiece to be drilled, and the protection shell is connected with the base and the upper cover. The base, the upper cover and the protection shell are coaxially arranged. A torsional vibration generating mechanism is arranged inside the protection shell and comprises a torsional actuator for generating torsional vibration and an exciting device for providing an exciting signal for the torsional vibration actuator. The torsional actuator generates the torsional vibration through intelligent materials. The machining device for machining the tiny holes comprises a drilling machine, a main shaft, a drill bit clamp, a drill bit, an intelligent material for driving the drill bit to be torsionally vibrated and a workpiece loading device, wherein the drill bit clamp is fixedly connected with the main shaft, and the drill bit and the workpiece loading device are reversely and torsionally vibrated. The workpiece loading device and the machining device have the advantages that the tiny hole machining efficiency and the machining precision can be improved.

Owner:ZHEJIANG UNIV

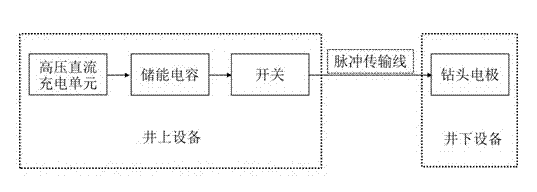

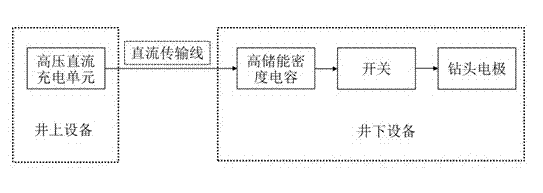

Pulse plasma drilling machine system

InactiveCN102733754AThere is no problem of characteristic impedance mismatchImprove utilization efficiencyDrilling machines and methodsHigh-voltage direct currentWater circulation

The invention discloses a pulse plasma drilling machine system. The pulse plasma drilling machine system comprises a trigger signal generating device, a high-voltage direct-current charging unit, a photoelectric composite transmission cable, a first winch, a first fixed pulley, a high-voltage pulse forming unit, a deionized water circulation unit and a drill electrode. An aboveground device and an underground device in a circuit part are connected together through a direct-current transmission line, high-voltage pulse generated by the high-voltage pulse forming unit can be directly loaded on the drill electrode, the using of a long-distance pulse transmission line is avoided, the problem of mismatching between the impedance of the pulse transmission line and the characteristic impedance of a passageway after a rock is punctured does not exist, and thus the energy utilization efficiency and the drilling depth are greatly increased.

Owner:ZHEJIANG UNIV

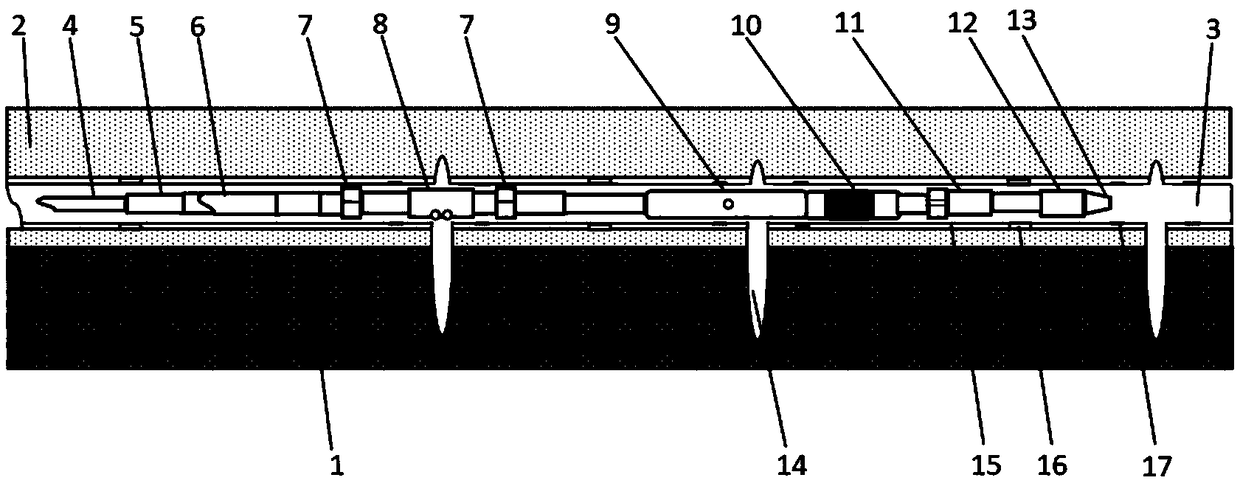

High efficient gas extraction method of long drill hole directional segmental fracturing in soft and low permeability coal seam

ActiveCN110953015AIncreased drilling depthReduce the amount of constructionLiquid/gas jet drillingFluid removalMining engineeringFracturing fluid

The invention discloses a high efficient gas extraction method of long drill hole directional segmental fracturing in a soft and low permeability coal seam. The method comprises the following steps that firstly, a kilometer drilling rig passes through the coal seam from a coal seam floor rock tunnel to a roof rock seam to drill a horizontal fracturing hole, the horizontal fracturing hole is controlled to be in a rock stratum with a distance of 0.5 to 1 meter from the top boundary of the coal seam; then, the sectional downward directional perforating is carried out in the horizontal fracturinghole section to communicate with the lower target coal seam, and the target coal seam is subjected to step-by-step fracturing by adopting a hydraulic jet sectional fracturing technology; after fracturing of the horizontal fracturing hole is completed, a drainage gas production hole is drilled in the target coal seam again in the liquid discharging process, a full-sleeve pipe protection hole technology is adopted, and a sleeve pipe is arranged to protect the holes while drilling ; and finally, hole sealing and drainage are conducted on the horizontal fracturing hole and the drainage gas production hole, and after the liquid level is reduced, the drainage gas production hole is used as a extraction hole to draw gas. The method can effectively overcome the problems of gas extraction in the soft and low-permeability coal seam, such as the difficulty of hole formation, the poor effect of fracturing and permeability increasing and the fracture blocking by fracturing fluid, and realize the high efficient gas extraction in the soft and low permeability coal seam.

Owner:TAIYUAN UNIV OF TECH

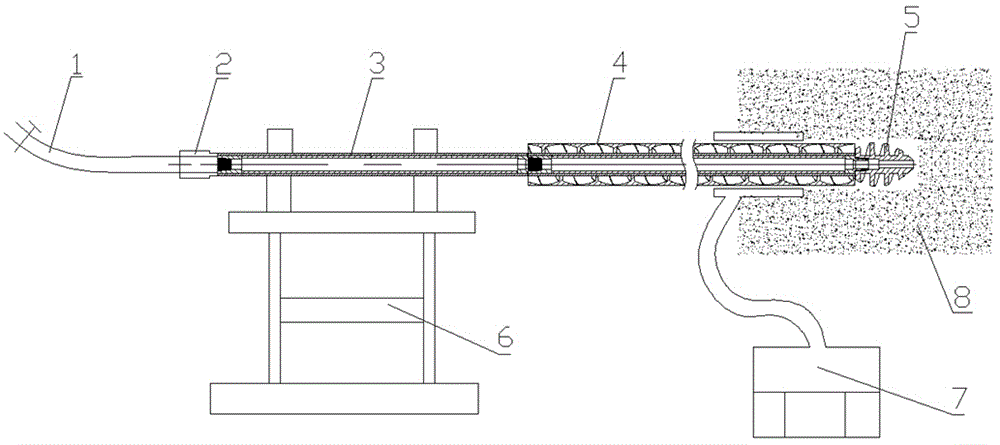

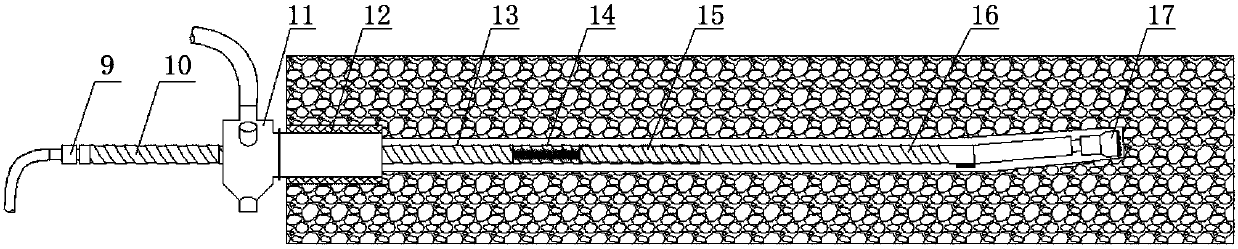

Injection type suction drilling tool for cutting removal of drilling center of weak formation and using method of drilling tool

InactiveCN105781419AImprove slag feeding efficiencyImprove drilling efficiencyDrilling rodsConstructionsEngineeringDrill cuttings

The invention discloses an injection type suction drilling tool for residual removal of a drilling center of a weak formation. The drilling tool comprises an air inlet pipe, a cutting removal pipe, a power head and a drill rod, wherein a cutting removal passage and an air inlet passage are formed in the drill rod; an injection type suction drill bit is arranged at the front end of the drill rod; cutting heads are arranged on the end part of the injection type suction drill bit; cutting inlets are formed in the top sidewall of the injection type suction drill bit; injection holes are formed in the inner sidewalls of the cutting heads; high-pressure injection passages are formed in the injection type suction drill bit. According to the drilling tool, a negative pressure area is formed in the cutting removal passage by jetting of the high-pressure injection passages in the cutting removal passage of the center, a suction effect on drilling cuttings is achieved by the cutting inlets, a stirring effect on the bottom of a borehole is achieved by air jets injected by the injection holes, and the drilling cuttings at the bottom of the borehole are driven to be transferred into the cutting holes, and are promoted to enter the cutting removal passage of the center through the cutting inlets, so that the problems of jamming of the drilling tool, burying of the drilling tool, difficulty in removal of the cuttings in the borehole and the like in an existing coal bed gas exhaust drilling process are solved, the drilling efficiency is greatly improved, and the drilling depth is greatly increased.

Owner:CHONGQING UNIV

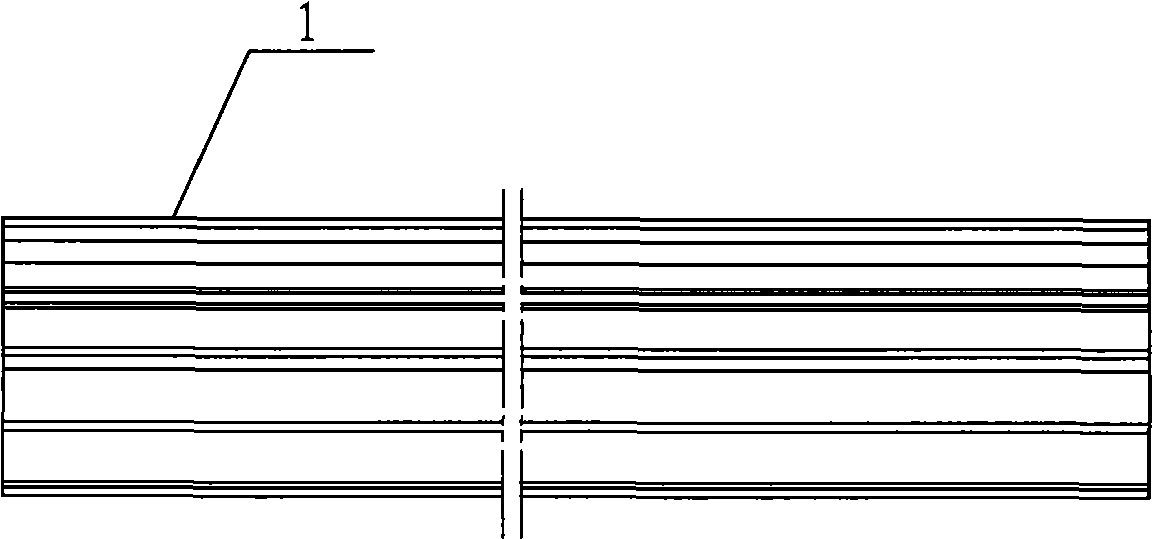

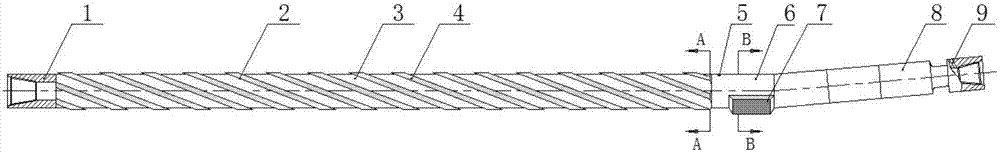

High-efficiency helical water-through jackrod

InactiveCN101294481AImprove water flow capacityImprove ventilationDrilling rodsDrilling casingsWorking environmentGas passing

The invention discloses an efficient water spiral drill pipe which comprises a plurality of drill pipe units. Each drill pipe unit comprises a drill pipe core, a spiral body, a tetragonal rod, a retaining ring, a lateral pin and a spring body which supports the lateral pin for splicing-positioning and connecting two adjacent drill pipe units into one body. The spring body of each drill pipe unit is provide with a cylindrical connector which is nested and clamped in a water and gas vent at the end of the tetragonal rod of the drill pipe unit, a bending knob which is connected with the connector into one body and is clamped in the end groove of the tetragonal rod, and a flat spring which is connected with the connector into one body and is inclined in the water and gas vent of the tetragonal rod; and the tail of the flat spring bends upwards for supporting the bottom end of the lateral pin on the tetragonal rod. The drill pipe has little possibility of blockage, solves the problem that drill pipe is difficult for water and gas passing through, and effectively reduces the occurrence of hole collapse, drill pipe sticking and drill pipe losing, and improves the working environment by reducing coal dust. The drill pipe has the advantages of wide application, high drilling efficiency and reduced drilling cost.

Owner:HEBEI JIKAI IND GRP +1

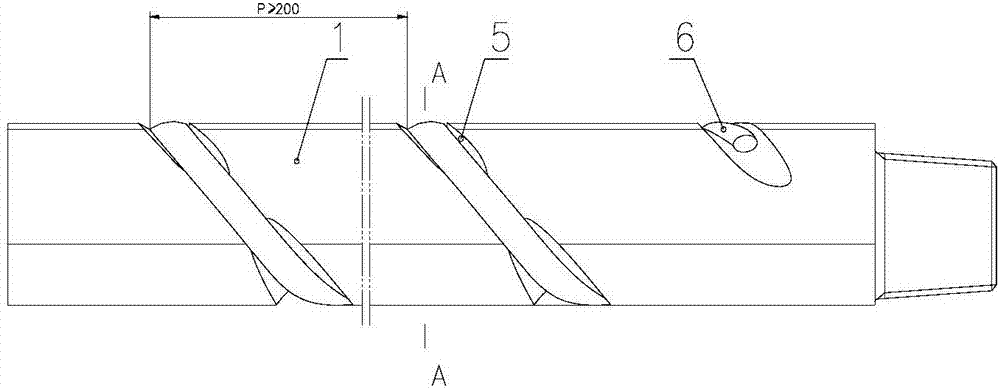

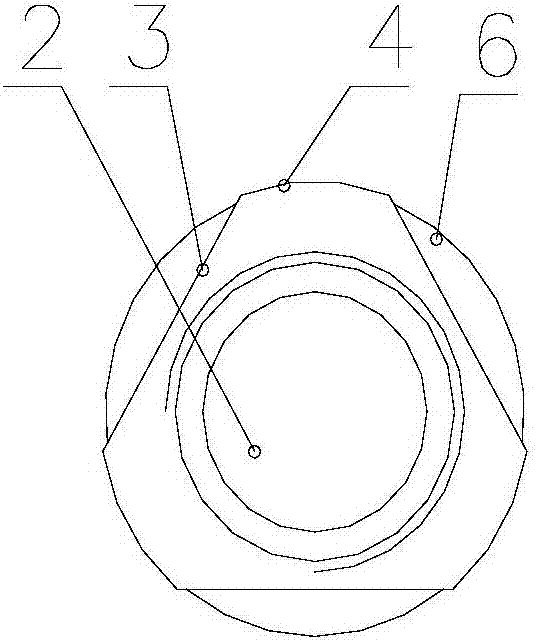

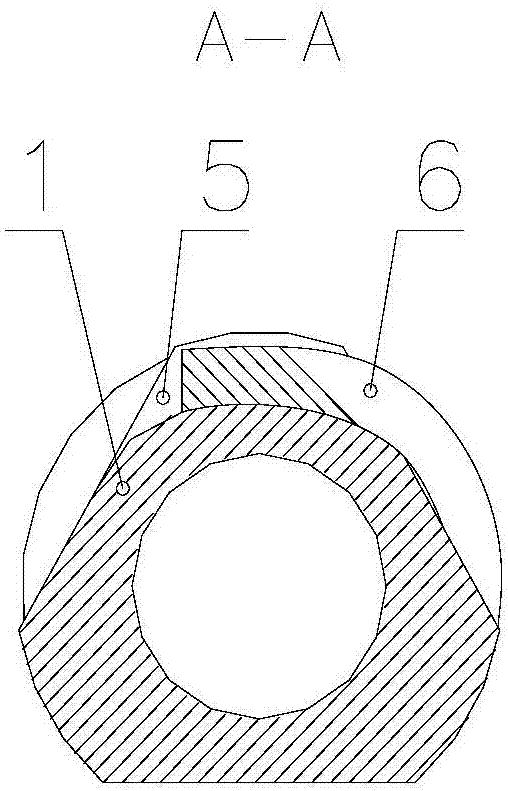

Large-pitch special-shaped spiral drill rod

InactiveCN106894771AImprove slagging functionIncreased drilling depthDrilling rodsDrilling casingsSpiral bladeScrew thread

The invention relates to a large-pitch special-shaped helical drill rod, which includes a drill rod body provided with a medium conveying channel inside. The two ends of the drill rod body are respectively provided with external threads and internal threads. Composed of arc segments, the straight segment and the arc segment are arranged at intervals, the head and tail are connected with each other and the number is equal, the arc segment is not less than two, the outer wall of the drill rod is provided with a spiral groove, the A helical blade is arranged in the helical groove. The purpose of the present invention is to increase the slag discharge capacity by setting the spiral blade in the spiral groove on the outer wall of the drill pipe, and prevent the coal dust from being blocked in the gap between the drill pipe and the coal wall to cause gas accumulation, difficult drilling, and even drill sticking , Drill drop and other accidents in the hole, improve the hole formation rate and drilling efficiency; by nitriding, high-frequency quenching, phosphating or nickel-phosphorus treatment on the internal and external threads of the drill pipe body, avoid The internal and external threads are bonded together, which makes the removal of the drill pipe easier.

Owner:CHONGQING UNIV OF ARTS & SCI

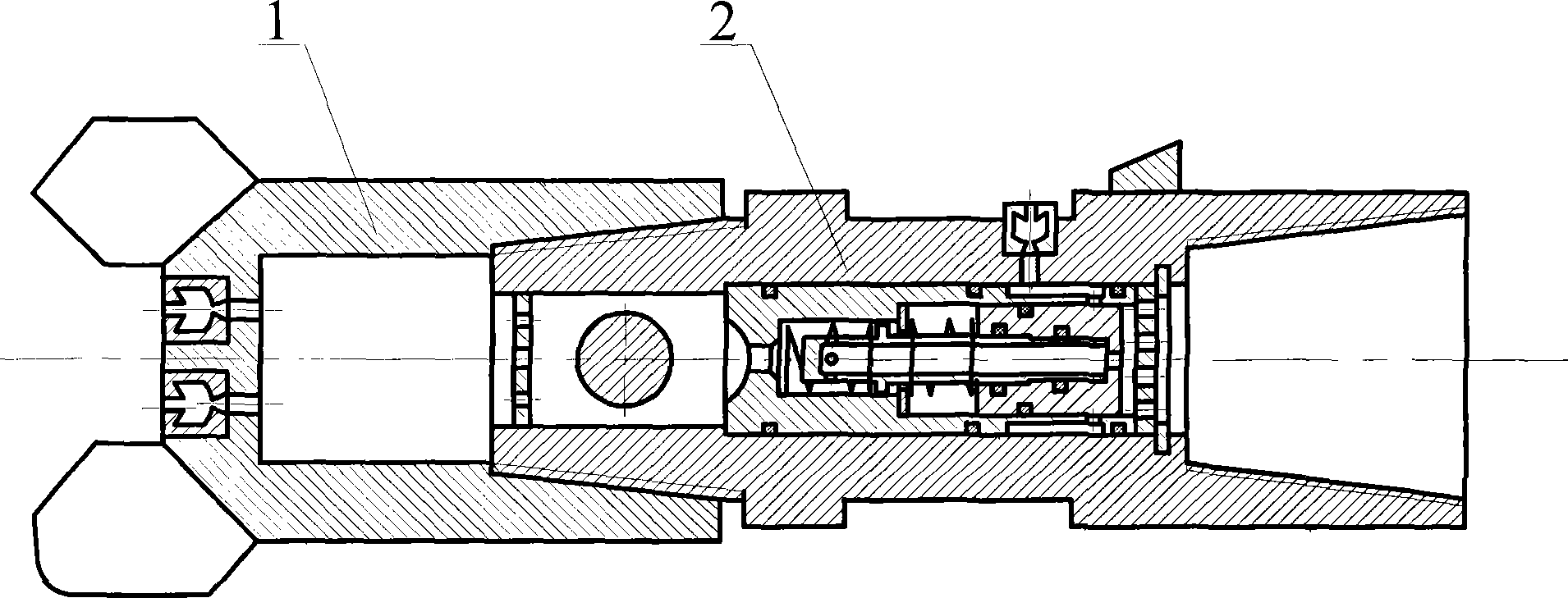

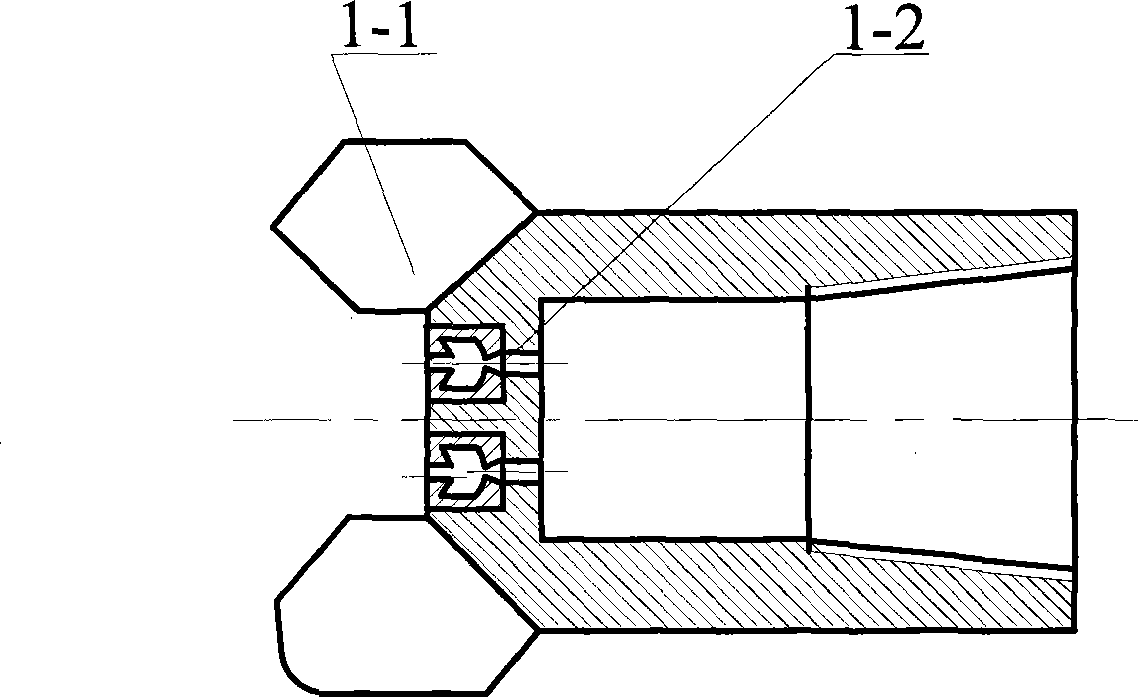

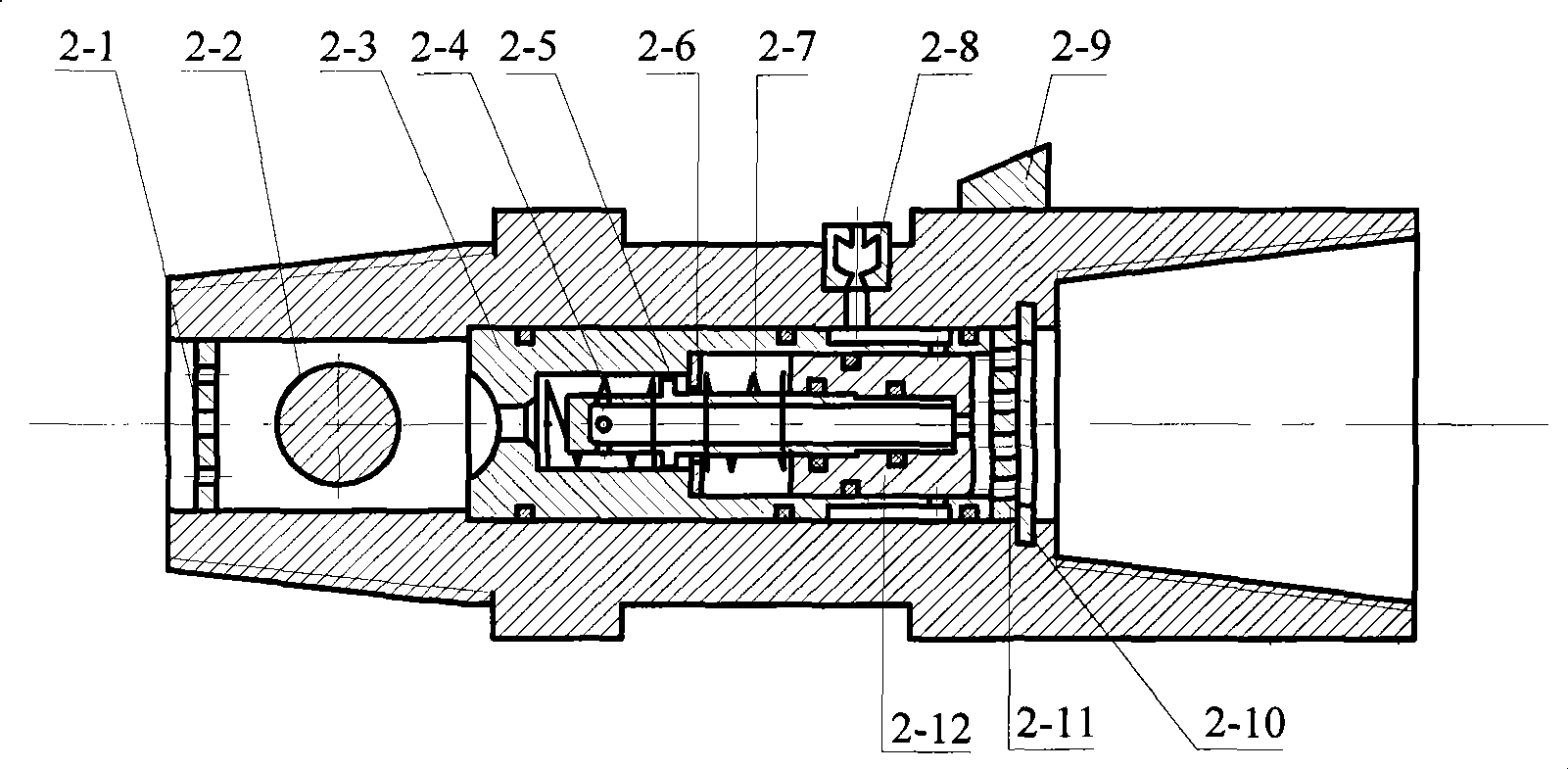

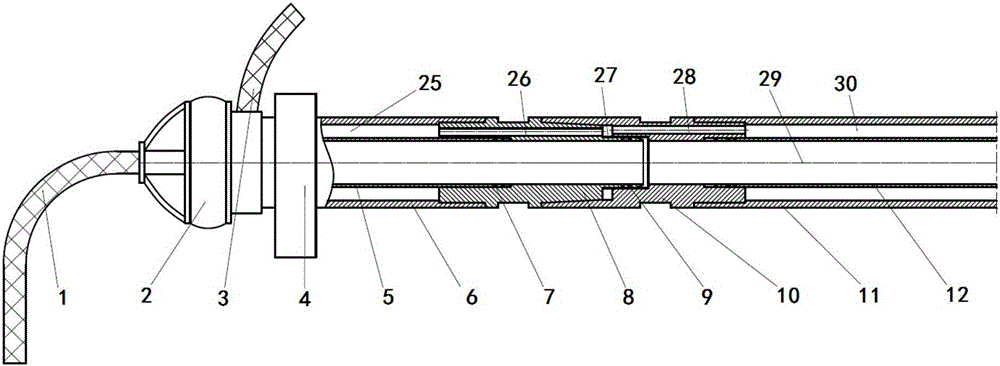

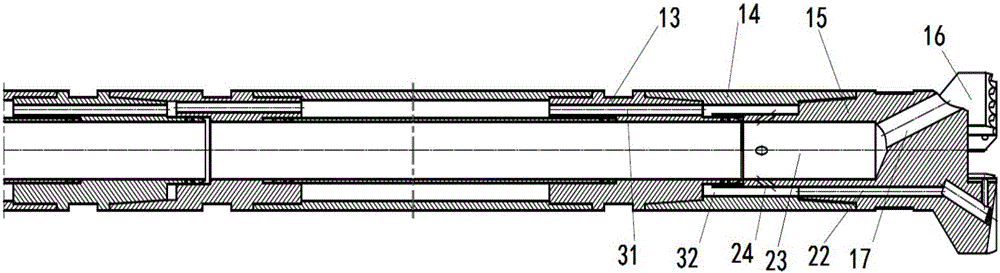

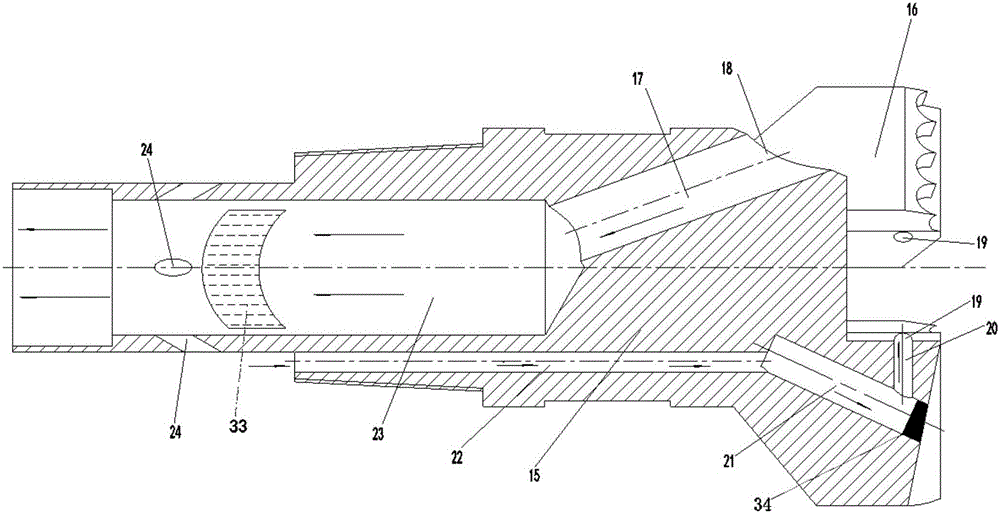

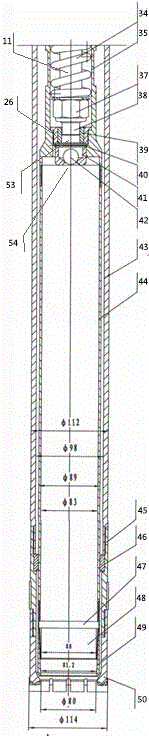

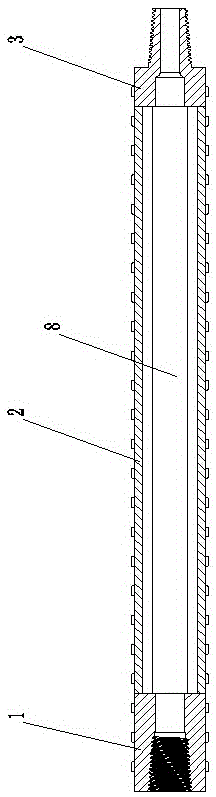

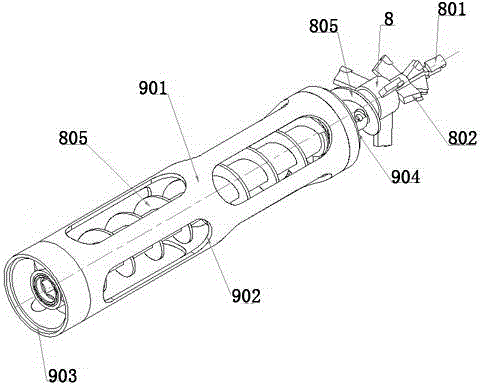

A wireline core drilling tool

ActiveCN104481439BImprove connection strengthIncreased drilling depthCore removalRubber ringMechanical engineering

The invention discloses a wire core drilling tool which comprises an inner pipe assembly and an outer pipe assembly. A blockage notifying mechanism comprises a pull rod and an alarming rubber ring fixed on the pull rod, a conical pad and a sliding sleeve connected on the pull rod in a sleeved manner are arranged at the lower end of the alarming rubber ring, the conical pad comprises an annular extrusion portion and a conical portion, the upper end of the annular extrusion portion is matched with the alarming rubber ring for extrusion, the conical portion is arranged at the lower end to protect the sliding sleeve, the upper end of the sliding sleeve and the conical pad are rotatably connected through a bearing, a clamping block is arranged on the lower portion of the pull rod, a buffering spring is connected between the clamping block and the sliding sleeve in a clamped manner and connected on the pull rod in a sleeved manner, a buffering spring sleeve is arranged outside the buffering spring, and the lower end of the buffering spring sleeve is connected with an inner pipe. The blockage notifying mechanism of the drilling tool is simplified, so that structure of the drilling tool is simplified greatly, and the drilling tool is enabled to be convenient to maintain, reliable to use and high in practicability.

Owner:无锡锡钻地质装备有限公司

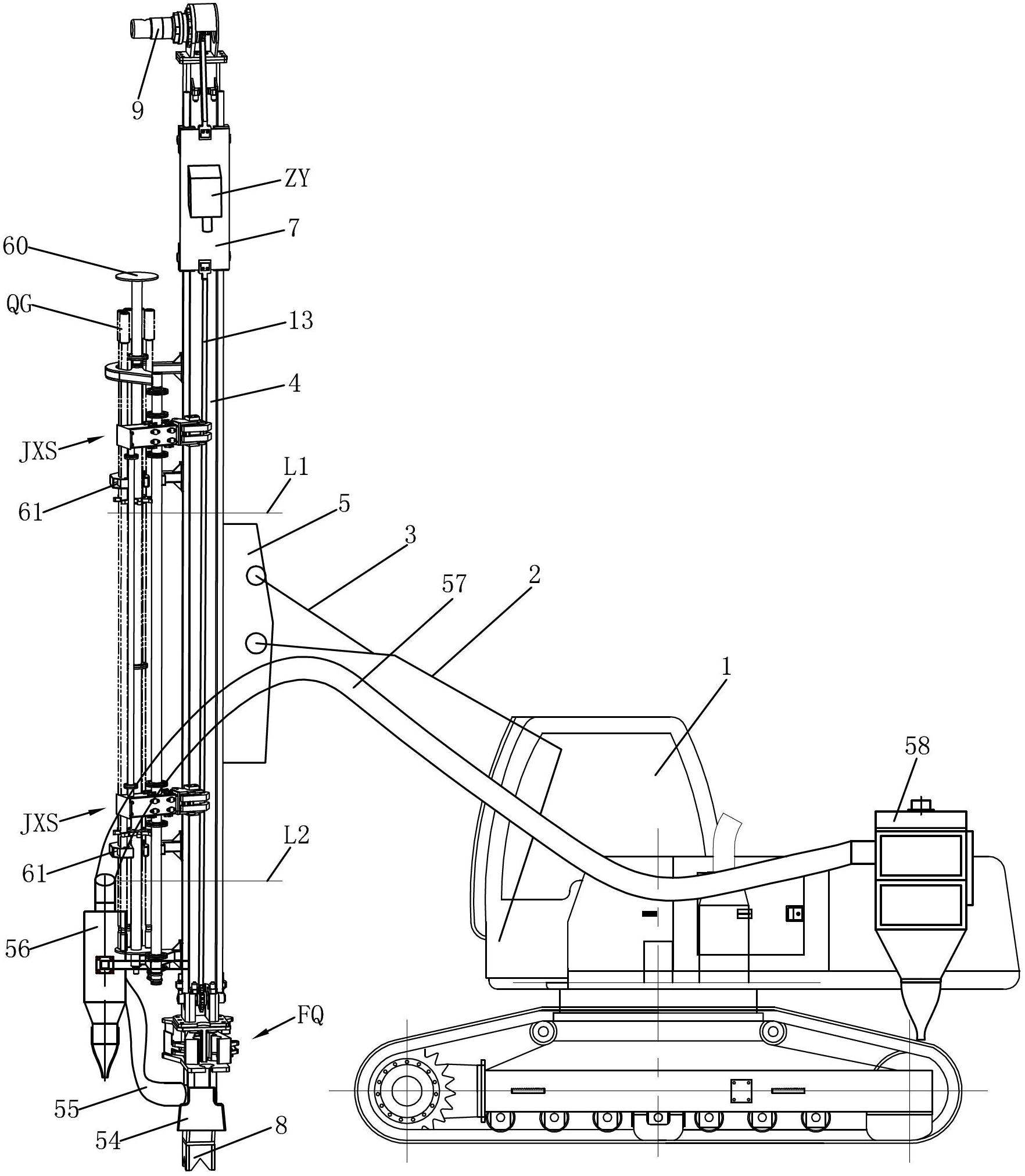

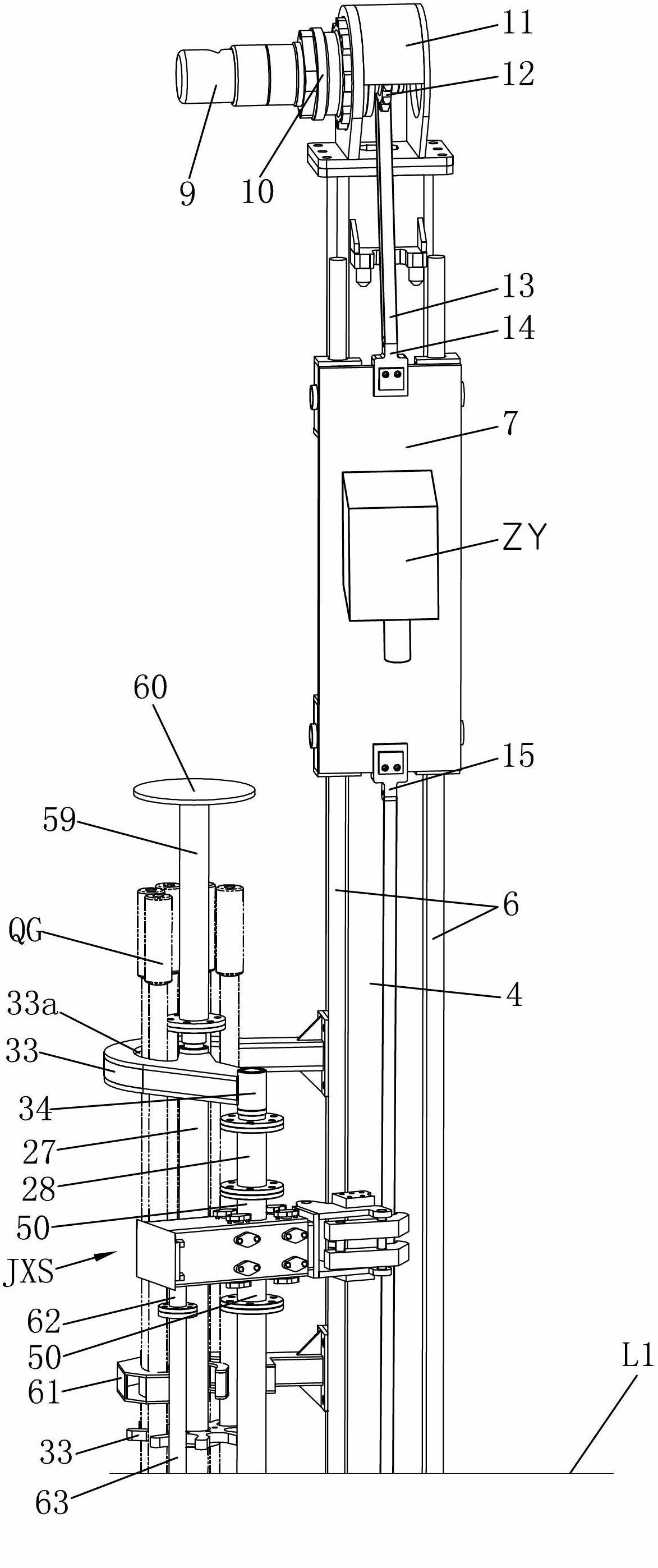

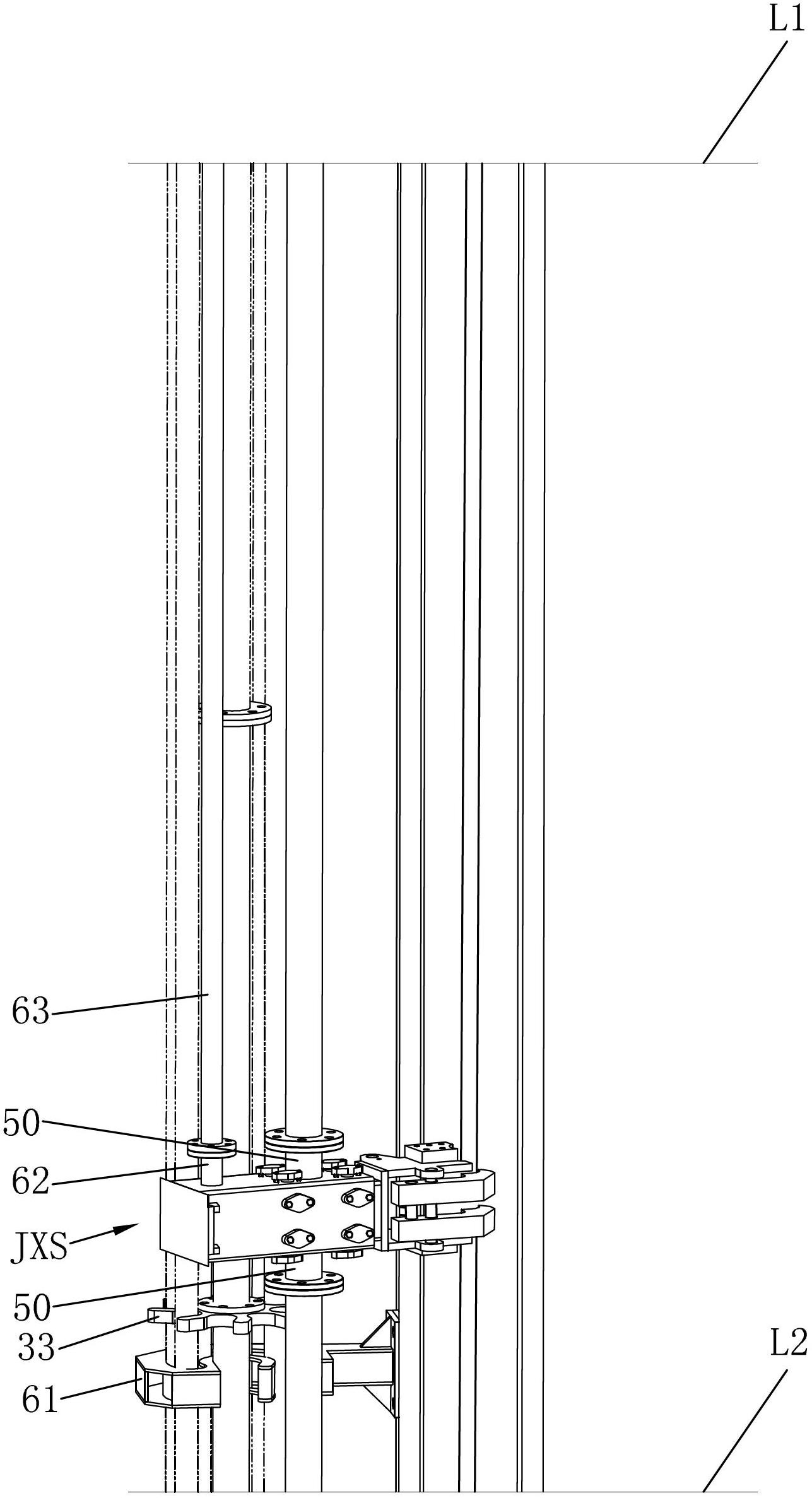

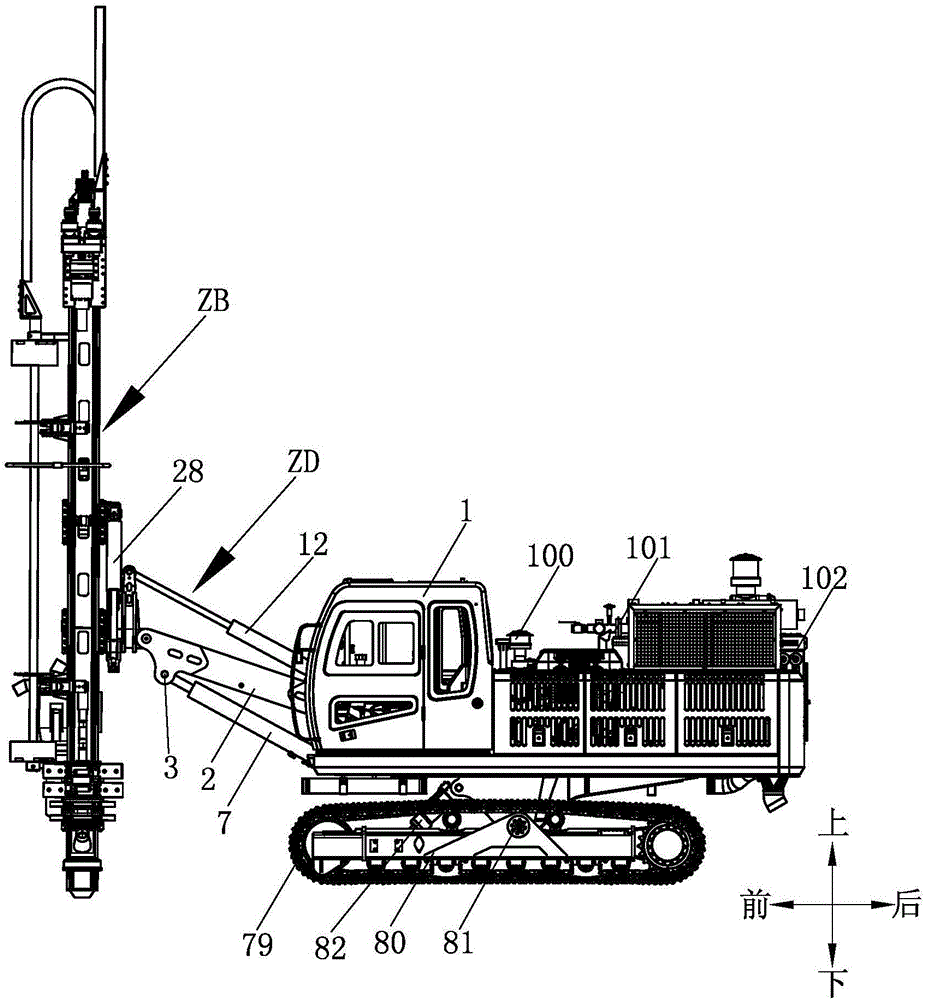

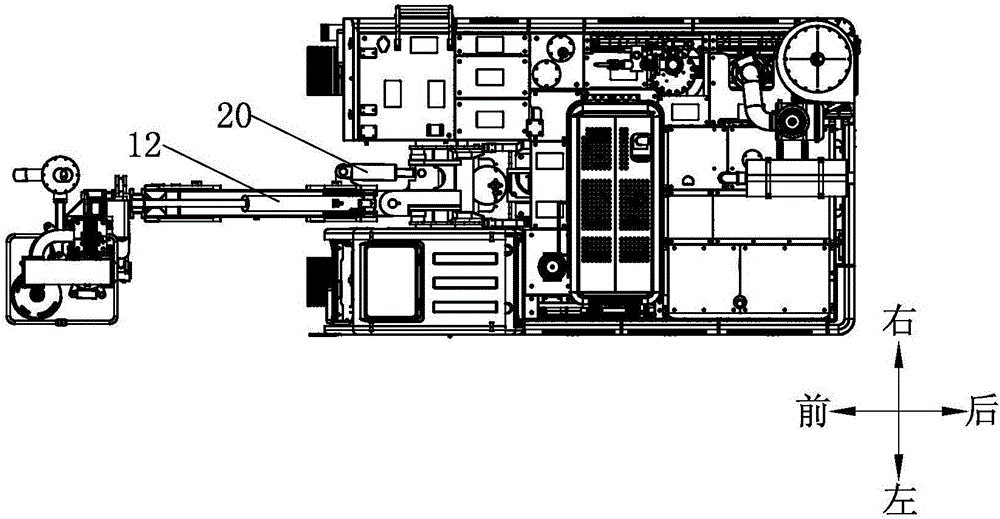

Multifunctional engineering machinery based on excavator platform

ActiveCN102691323AIncrease the lengthAvoid blocking the line of sightMechanical machines/dredgersDrilling machines and methodsControl engineeringSlide plate

The invention discloses multifunctional engineering machinery based on an excavator platform. The front part of an operation arm of an excavator is hinged with an execution oil cylinder; a boring frame is vertically arranged in front of the operation arm; the middle of the rear surface of the boring frame is provided with a connection plate; the middle of the connection plate is hinged with the front end of the operation arm, while the upper part of the connection plate is hinged with the piston rod stretching end of the execution oil cylinder; the left surface of the boring frame is provided with two guide rails which are arranged vertically side by side; and a sliding plate is connected with the two guide rails and also can slide up and down along the guide rails under traction of a traction device. The multifunctional engineering machinery integrates excavation, stone crushing, boring and sand rock blasting, the cost for purchasing the engineering machinery can be reduced for users, construction is facilitated, and multiple drill rods can be connected together as required to increase boring depth, so that the problem of insufficient boring depth in the prior art is solved well; in addition, the multifunctional engineering machinery can prevent dust from flying in front of the excavator and consequently prevents the sight of an operator from being influenced.

Owner:CHONGQING DIMA IND

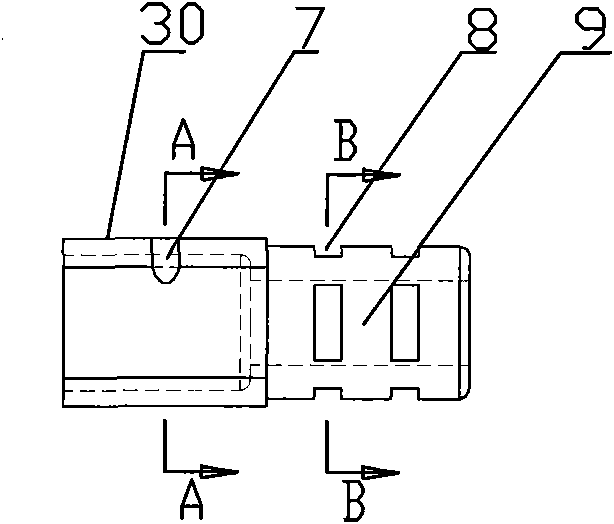

Wire core drilling tool

The invention discloses a wire core drilling tool which comprises an inner pipe assembly and an outer pipe assembly. A blockage notifying mechanism comprises a pull rod and an alarming rubber ring fixed on the pull rod, a conical pad and a sliding sleeve connected on the pull rod in a sleeved manner are arranged at the lower end of the alarming rubber ring, the conical pad comprises an annular extrusion portion and a conical portion, the upper end of the annular extrusion portion is matched with the alarming rubber ring for extrusion, the conical portion is arranged at the lower end to protect the sliding sleeve, the upper end of the sliding sleeve and the conical pad are rotatably connected through a bearing, a clamping block is arranged on the lower portion of the pull rod, a buffering spring is connected between the clamping block and the sliding sleeve in a clamped manner and connected on the pull rod in a sleeved manner, a buffering spring sleeve is arranged outside the buffering spring, and the lower end of the buffering spring sleeve is connected with an inner pipe. The blockage notifying mechanism of the drilling tool is simplified, so that structure of the drilling tool is simplified greatly, and the drilling tool is enabled to be convenient to maintain, reliable to use and high in practicability.

Owner:无锡锡钻地质装备有限公司

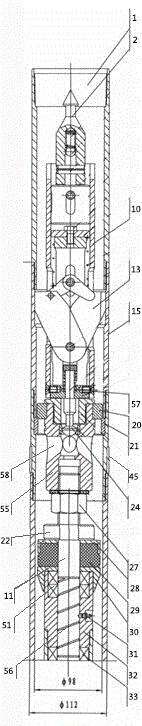

Screw drill

ActiveCN105156023AExtension of timeImprove drilling efficiencyBorehole drivesDrive shaftScrew thread

The invention provides a screw drill belonging to the field of drilling tools. The screw drill comprises a motor assembly, an upper shell and a lower shell, wherein the upper shell and the lower shell form a transmission chamber; the transmission chamber is internally provided with a transmission shaft and a strainer; through holes allowing drilling fluid to flow are formed in the transmission shaft; the bottom of the strainer is fixedly connected with an upper dynamic sliding bearing; the top of the inner wall of the lower shell is provided with an upper static sliding bearing; the bottom of the outer wall of the transmission shaft is sleeved by a lower dynamic sliding bearing; the bottom of the inner wall of the lower shell is in threaded connection with a lower static sliding bearing; a buffering disc spring group composed of a plurality of disc springs is arranged between the lower dynamic sliding bearing and the upper dynamic sliding bearing; and the transmission shaft is sleeved by the buffering disc spring group. By using the screw drill, the effective working time of a bit can be effectively prolonged, the drilling efficiency of the bit can be effectively increased, the bit pressure acting distance can be effectively increased, and the effective drilling depth of the bit at the one-time bit feeding pressure is can be increased.

Owner:四川泰和石油科技有限公司

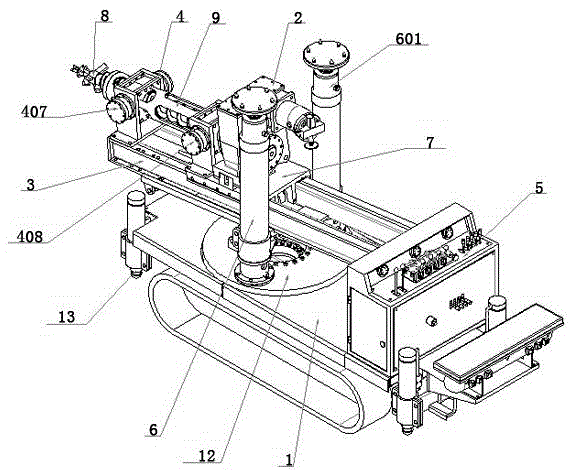

Self-traveling drilling type coal mining machine with two-way drilling

ActiveCN103643952AImprove securityReduce labor intensityPropulsionCutting machinesCircular discVehicle frame

The invention discloses a self-traveling drilling type coal mining machine capable of two-way drilling, belonging to the technical field of design application of the coal mining machine. In the coal mining machine provided by the invention, a drilling rod is easily butted, a drilling power of a drilling bit is large and two-way drilling can be carried out on a roadway. The self-traveling drilling type coal mining machine comprises a frame assembly, a traveling device, an electric control assembly, a hydraulic assembly, drilling tool assemblies, a ventilating device, a propelling arm device, a propelling-arm propelling device and a propelling-arm butting pushing device; the traveling device comprises a hydraulic motor and a crawler belt; the frame assembly is connected with a frame supporting frame on the traveling device by a coupling and fixing device; the electric control assembly, the hydraulic assembly and an armored disc are respectively connected with the frame assembly by pin shafts; each drilling tool assembly comprises drilling bits, a transmission box, a left screw, a right screw, a water cooling motor and a speed reducer; the drilling bits are connected with the left screw and the right screw which are connected with the propelling arm device. The self-traveling drilling type coal mining machine disclosed by the invention is mainly applied in the aspect of coal mine.

Owner:江阴市康盛机械有限公司

Movable bracket of cantilever beam on platform of drilling for oil

InactiveCN1687533AImprove stress conditionImprove carrying capacityArtificial islandsUnderwater structuresCantilevered beamTower

This is a kind of cantilever moving bracket of petroleum artesian well platform belonging to petroleum artesian well platform equipment field. This kind of ancon moving bracket of petroleum artesian well platform adopts the square framework structure comprising of four bracket pedestals, two bracket longerons and two crossbeams. The lower part of the four corners of the bracket of the square framework equips sliding trough making the moving bracket have transverse movement on the slideway under bracket, and the upper of which equips the sliding trough making ancon and bracket have lengthways movement together on the slideway. The boring tower is fixed at the rump of ancon. Inside the moving bracket there equips driving device having transverse and lengthways movement, making that moving bracket can conveniently make boring tower exactly locate in the position need artesian. Besides its structure is simple, and its work is dependable. Especially it improves the carrying situation of ancon, enhances the hole-making capability of artesian platform, increases artesian depth, and makes the hole-making efficiency and economy performance ulteriorly improved.

Owner:DALIAN UNIV OF TECH

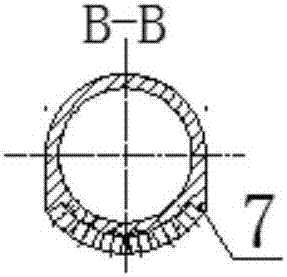

Pressure-relief and hole-protection drill pipe for soft coal and rock drilling

The invention discloses a pressure-relief and hole-protection drill pipe for soft coal and rock drilling. The pressure-relief and hole-protection drill pipe comprises hole-protection spiral blades, discharge aiding spiral blades and a hollow drill pipe body, wherein the height of the discharge aiding spiral blades is smaller than the height of the hole-protection spiral blades; and the cross section of the hole-protection spiral blades is designed into a structure with the wider outer side and the narrow inner side. The hole-protection effect is achieved on the soft and weak coal and rock layer drill hole wall by a wide blade structure arranged at the outer side of the hole-protection spiral blades; the slag discharge passage blockage due to drill hole deformation is effectively avoided, and drilling chips are discharged under the protection of the hole-protection spiral blades; and the slag discharge capability of the drill pipe can be improved by the discharge aiding spiral blades, and the drill chip accumulation blockage is prevented from being formed under the hole-protection spiral blades. The pressure-relief and hole-protection drill pipe has the advantages that the design is novel; the hole-protection spiral blades have the hole-protection and slag-discharge duplex effects; meanwhile, a separated hole-protection space is formed between the hole-protection spiral blades; the pressure-relief effect is achieved; the contact area between the hole-protection pipe wall and the drill hole wall is reduced; the rotating resistance of the drill pipe is reduced; the drill clamping occurrence probability can be reduced; and the drilling depth and the drilling efficiency are improved.

Owner:王永龙

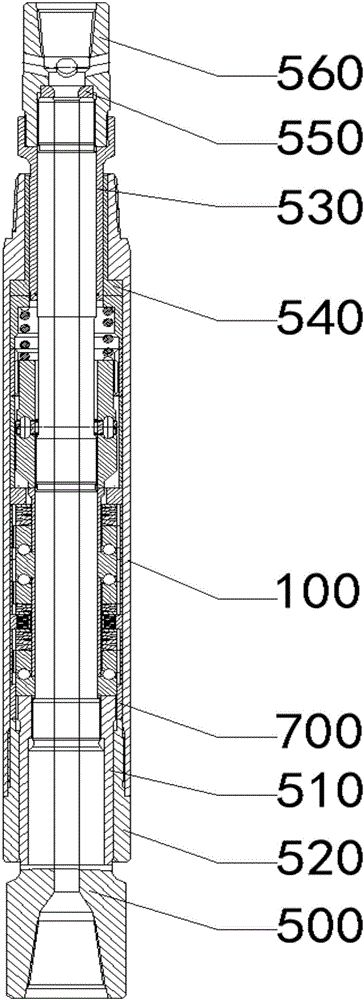

Multistage cuttings discharge air-screw motor for underground coal mine drilling

ActiveCN107217982AImprove slagging abilityEnables directional drillingConstructionsDirectional drillingTransmitted powerDrive shaft

A multistage cuttings discharge air-screw motor for underground coal mine drilling comprises a connector, a motor assembly, a universal shaft assembly, and a transmission shaft assembly; the motor assembly inputs compressed air for rotation driving, the universal shaft assembly and the transmission shaft assembly transmit power, a single-bend outer pipe of the universal shaft assembly can provide directional drilling, and the motor assembly is provided with a continuous right-handed spiral groove; when rotating, the screw motor stirs depositing cuttings, assisting air in discharging the cuttings out of a borehole; multistage cuttings discharge is achieved by adding two sets of reverse bypass holes, and it is ensured that the motor can still normally rotate to discharge powder when a bit blocks at the bottom of the borehole or cuttings accumulate at the bottom; by providing a one-way valve, high-pressure gas is avoided carrying the cuttings reversely into the motor, causing damage to the motor. The multistage cuttings discharge air-screw motor is used with an underground while-drilling measuring system in the construction of long boreholes along an underground coal mine broken-soft coalbed, cuttings discharge effect can be improved, intra-borehole resistance is decreased, construction safety is ensured, and construction depth of boreholes along underground coal mine broken-soft coalbeds and coalbed drilling catching ratio are increased.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling and drilling method

ActiveCN105545218AReduce drilling resistanceIncreased drilling depthDrilling rodsDrilling casingsPetroleum engineeringSoft Coals

Provided is a multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling. The drill rod comprises a multi-blade inwards-concave open-type concave connecting part, a multi-blade inwards-concave open-type hollow rod body and a multi-blade inwards-concave open-type convex connecting part; at least two long grooves are formed in the surfaces of the multi-blade inwards-concave open-type concave connecting part, the multi-blade inwards-concave open-type hollow rod body and the multi-blade inwards-concave open-type convex connecting part in the axial direction, all the long grooves are evenly arranged in the peripheral direction, and the cross section of each long groove is of an arc-shaped structure; the peripheral surfaces of the multi-blade inwards-concave open-type concave connecting part, the multi-blade inwards-concave open-type hollow rod body and the multi-blade inwards-concave open-type convex connecting part are separated by the long grooves to form arc-shaped wings for high-speed rotating drilling, bionic structures are evenly arranged on the outer peripheral surfaces of the multi-blade inwards-concave open-type concave connecting part, the multi-blade inwards-concave open-type hollow rod body and the multi-blade inwards-concave open-type convex connecting part, and the bionic structures are grooves and / or protrusions. By means of the multi-blade inwards-concave open-type bionic drag-reduction hole-protection drill rod for soft coal seam drilling, the drilling resistance of the drill rod is effectively reduced, and improvement of the drilling depth and drilling efficiency of soft coal rock is facilitated.

Owner:HENAN POLYTECHNIC UNIV +1

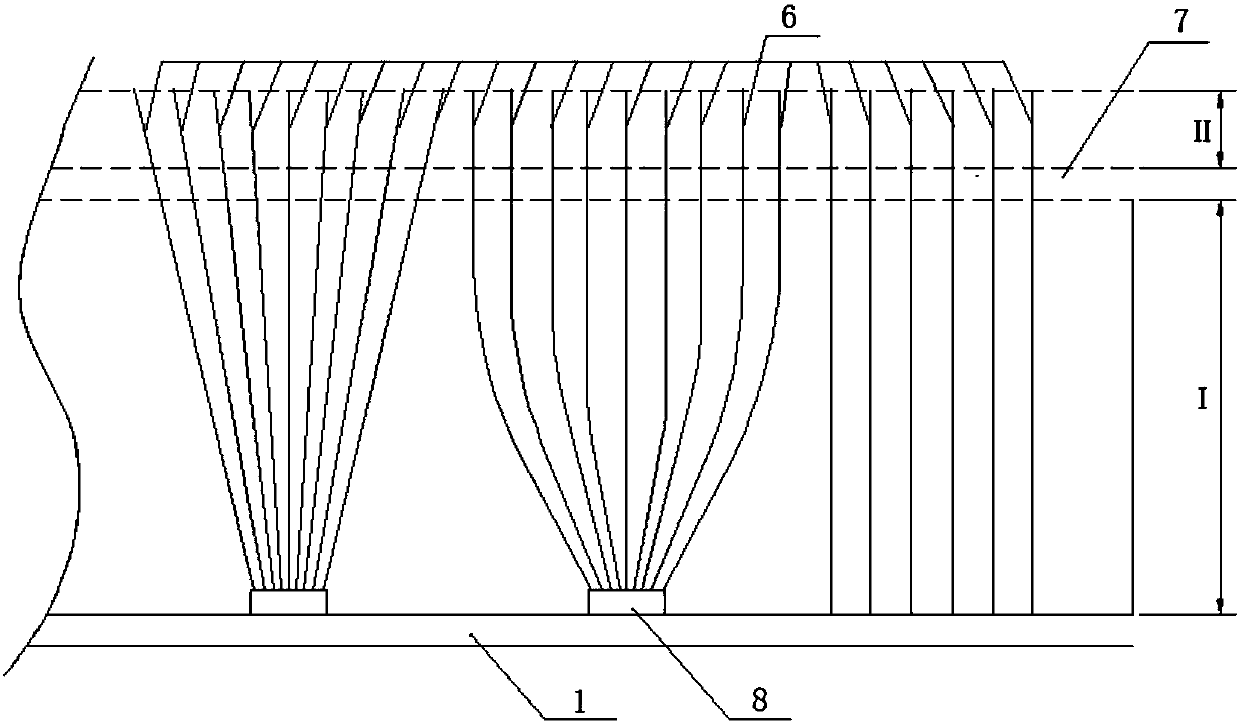

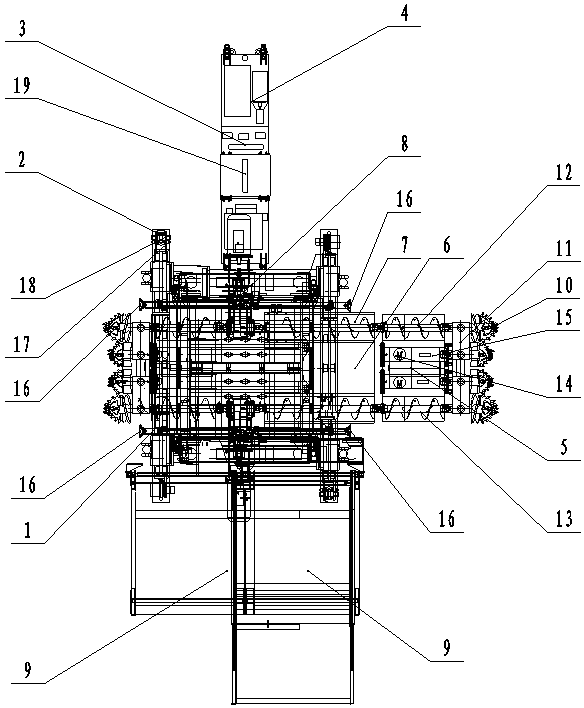

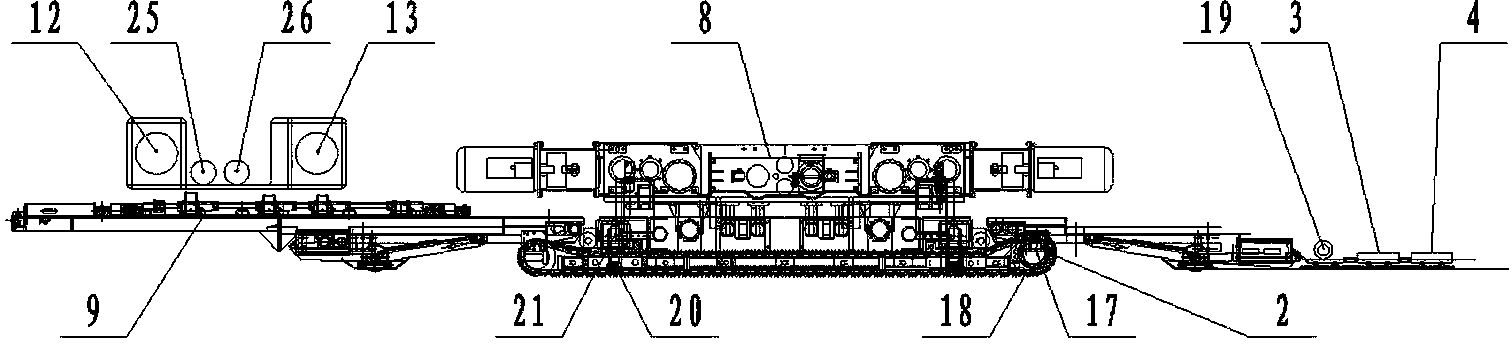

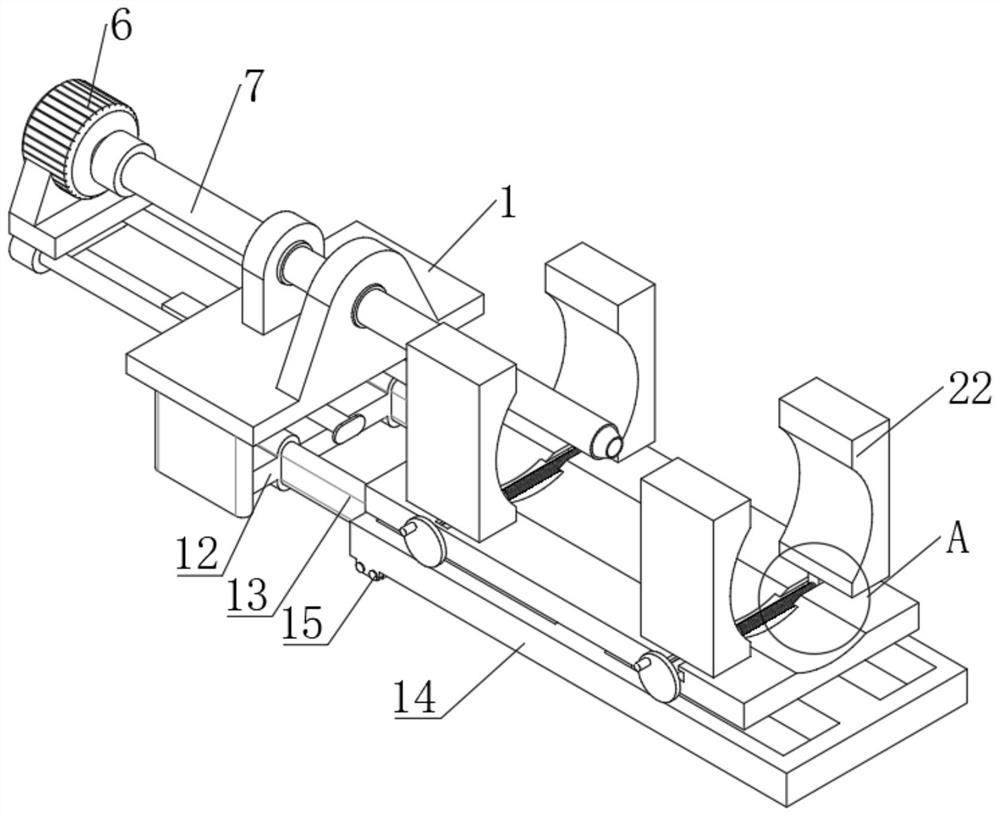

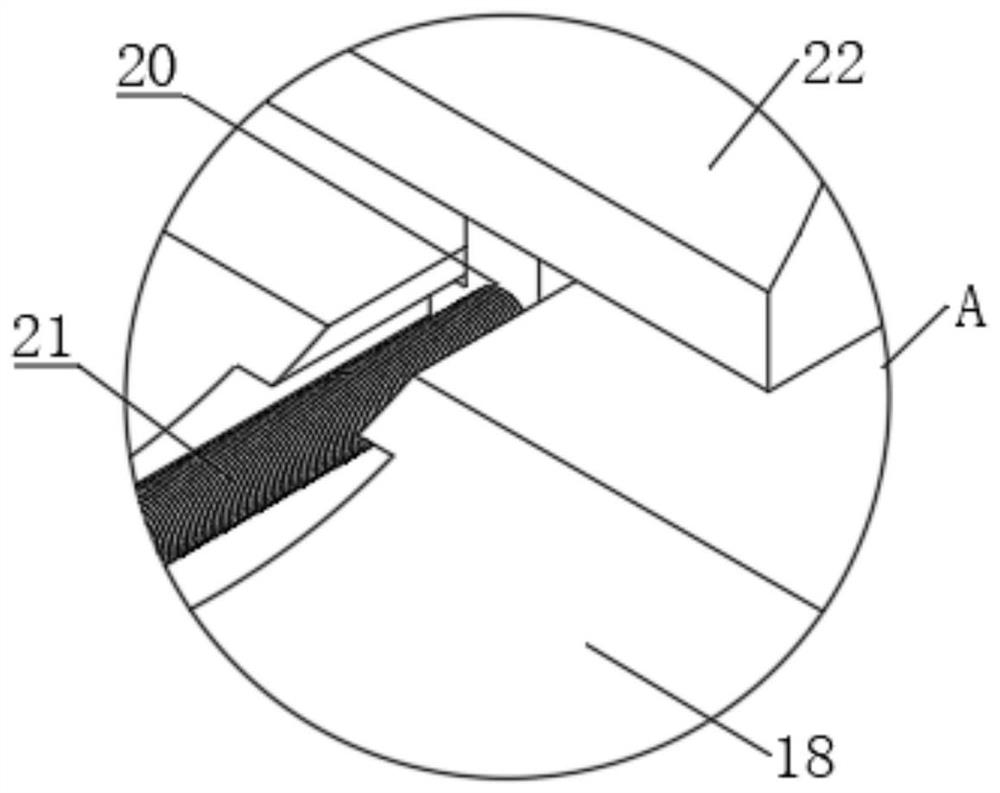

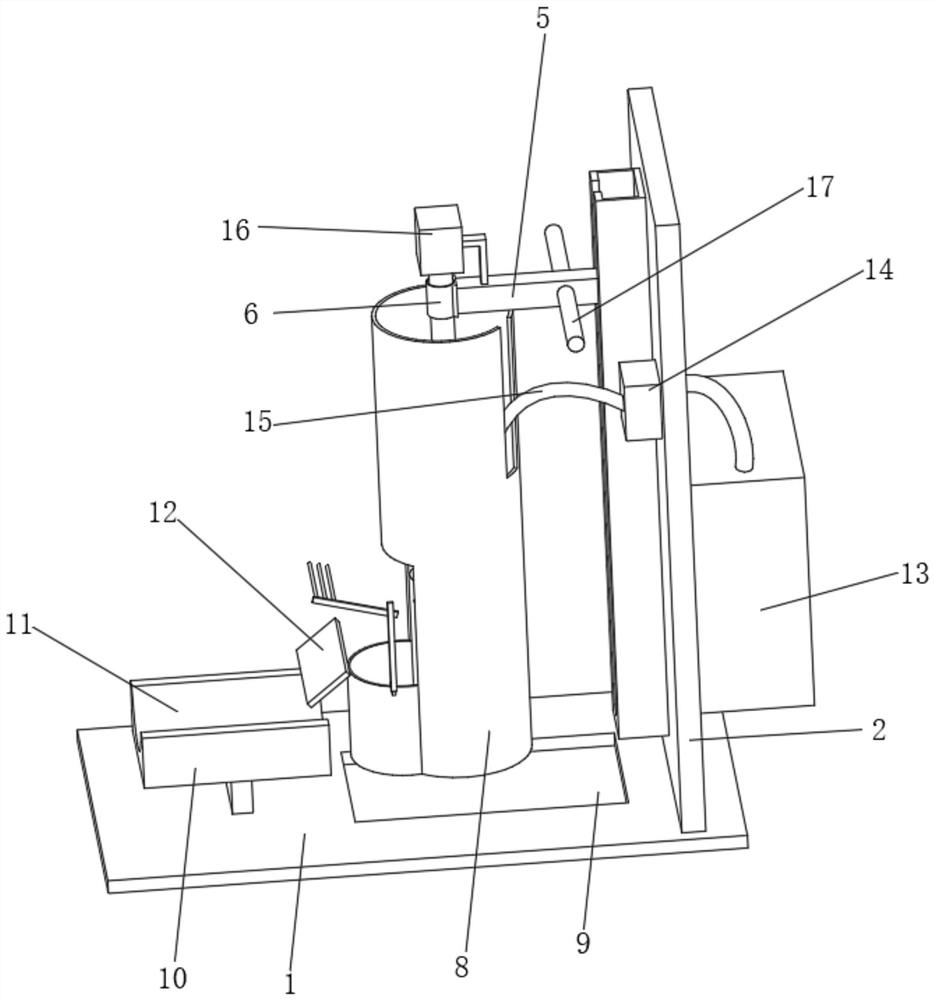

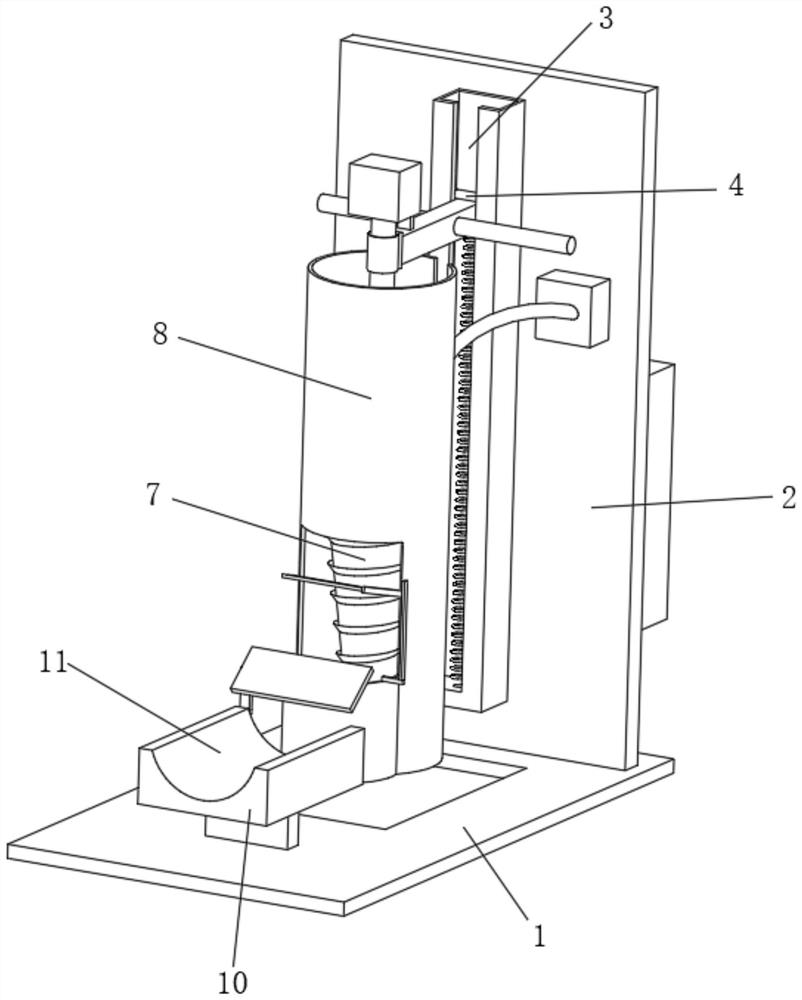

Drilling equipment for coal seam large-diameter boring construction

ActiveCN104453710AEffective chip removalResistance to influenceDrill bitsDrilling rodsEngineeringDrilling machines

Drilling equipment for coal seam large-diameter boring construction comprises a drilling tool and a drilling machine. The drilling machine comprises a walking mechanism, a power output device, a feeding mechanism, a clamping mechanism and an operation console, wherein the power output device controls the drilling tool to rotate. The walking mechanism is provided with the feeding mechanism driving the drilling tool to horizontally move, the power output device and the clamping mechanism are arranged on the feeding mechanism, and the drilling tool is connected with the power output device through the clamping mechanism so as to be driven to drill. By means of the drilling equipment, large holes with the diameter lager than 150 mm and with the length larger than 50 m can be drilled in the same coal seam, gas drainage efficiency is improved, a bottom suction roadway does not need to be tunneled, and coal mining cost is lowered.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

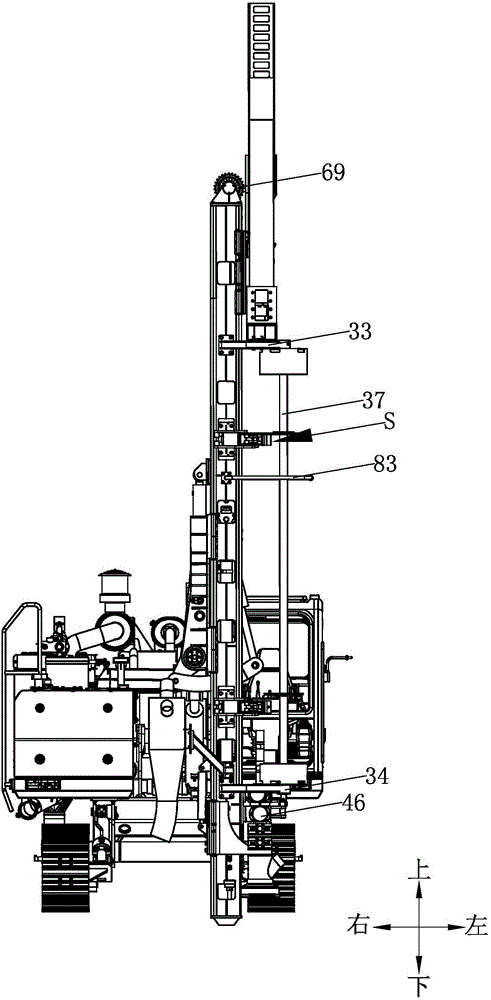

High-speed hydraulic drill with two engines

ActiveCN106014203AIncreased drilling depthReduce weightDrilling rodsConstructionsManipulatorEnergy consumption

The invention discloses a high-speed hydraulic drill with two engines. The high-speed hydraulic drill comprises a vehicle body and a drill arm assembly, wherein two engines are installed on the vehicle body, the vehicle body is installed on a chassis, and a left crawler unit and a right crawler unit are arranged on the chassis side by side; and a direct-acting arm assembly is arranged at the front part of the vehicle body, is connected with the drill arm assembly, and can drive the drill arm assembly to swing left and right, swing back and forth or move up and down. According to the drill arm assembly, a plurality of drill rods can be effectively connected through coordination of a drill pipe storage mechanism, a drill rod gripping manipulator and a disconnection rod device, thereby prolonging the total length of the drill rod; and a drill arm assembly feeding mechanism adopts a wire rope structure, and the wire rope is strong in impact resistance, convenient to replace and maintain and low in cost. A drill stand adopts an integral structure and is made of aluminum alloy, so that the weight of the high-speed hydraulic drill can be greatly reduced, the energy consumption of the entire vehicle can be effectively reduced, and the center of gravity of the entire vehicle can be prevented from facing forwards.

Owner:重庆勤牛工程机械有限责任公司

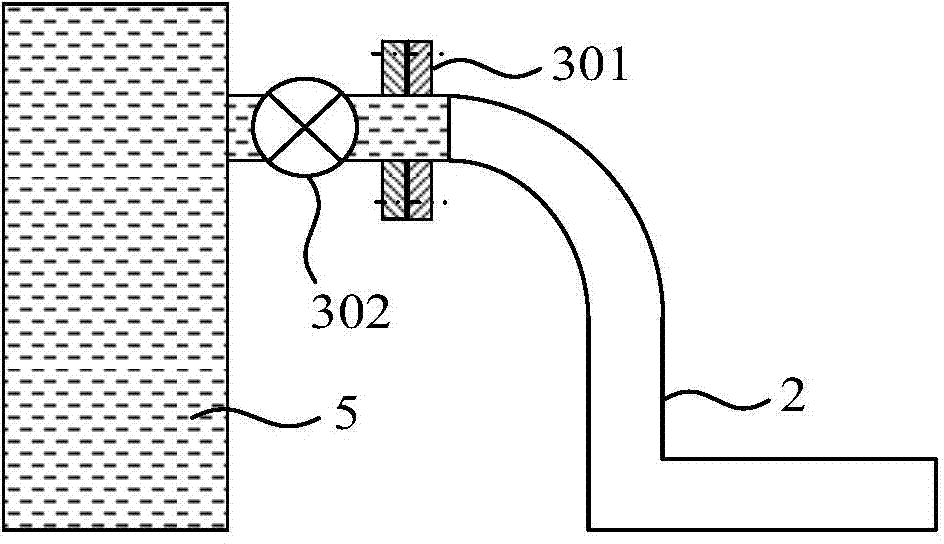

Pumping-pressure reverse-circulation well drilling method and system

InactiveCN103615191AAvoid pressure lossIncreased drilling depthConstructionsFlushingWellheadDrill bit

The invention relates to the field of machinery, in particular to a pumping-pressure reverse-circulation well drilling method and a system. The pumping-pressure reverse-circulation well drilling method comprises the steps of filling well drilling liquid into an annulus of a shaft; enabling the well drilling liquid to flow into a drill bit through a water hole of the drill bit; enabling the well drilling liquid to flow into a drill column from the drill bit and flow out of the drill column. By adopting the pumping-pressure reverse-circulation well drilling method and the system, the theoretical drilling depth can be infinitely great when the pressure resisting capacity of a well opening sealing device and a fracture pressure value of a stratum are enough.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Deep hole boring and drilling machine for roller production

InactiveCN112453495AEasy to useIncreased drilling depthPositioning apparatusBoring/drilling componentsThermodynamicsElectric machinery

The invention provides a deep hole boring and drilling machine for roller production, and relates to the technical field of roller deep hole boring and drilling. The deep hole boring and drilling machine for roller production comprises a main workbench and an auxiliary workbench, the main workbench is composed of two supporting frames and a supporting platform, the supporting platform is fixedly connected to the tops of the two supporting frames, and a bottom sliding seat is fixedly connected to the bottom face of the supporting platform; and a sliding rod is slidably connected to the side face of the bottom sliding seat, a connecting supporting plate is fixedly connected to the left end of the sliding rod, a motor mounting seat is fixedly connected to the top of the connecting supportingplate, and a driving motor is fixedly connected to the top of the motor mounting seat. The deep hole boring and drilling machine for roller production has the beneficial effects that by arranging themain workbench and the auxiliary workbench capable of adjusting the position, the position between the main workbench and the auxiliary workbench can be transversely adjusted, connection and installation are conducted on the top of the auxiliary workbench through a supporting rotary disc, axial and radial hole machining can be conducted, and use is very convenient.

Owner:HUNAN LIFANG ROLLER

Arid desert soil haloxylon ammodendron planting auxiliary apparatus based on water pressure slotting

InactiveCN111990204AAvoid breakingIncreased drilling depthWatering devicesCultivating equipmentsAridSoil science

The invention discloses arid desert soil haloxylon ammodendron planting auxiliary apparatus based on water pressure slotting. The apparatus comprises a supporting carrier plate, wherein the right sideof the top of the supporting carrier plate is fixedly connected with a driving side frame, a limiting rail is fixedly connected with the middle of the front face of the driving side frame, a limitingsliding block is connected with a vertical position inside the limiting rail in a slide manner, a transmission connecting rod is fixedly connected with the outer side of the front face of the limiting sliding block, one end, away from the limiting sliding block, of the transmission connecting rod is fixedly connected with a supporting bearing, an auxiliary tunneling mechanism is rotationally connected with the inside of the supporting bearing in a penetration manner, a limiting pipe insertion mechanism is fixedly connected with the bottom of the transmission connecting rod, a storage arc groove is formed in the top of a supporting frame, and a force storage inclined plate is fixedly connected with the right side of the top of the supporting frame. The invention relates to the technical field of planting. According to the arid desert soil haloxylon ammodendron planting auxiliary apparatus based on water pressure slotting, the operation of workers is facilitated, dry sandy soil adheresand condenses together through water, and thereby the high-strength wrapping performance of soil and plant roots is guaranteed.

Owner:李亨寿

Drilling device for road construction and using method thereof

InactiveCN111520072AQuality improvementReduce workloadConstructionsDerricks/mastsPunchingArchitectural engineering

The invention discloses a drilling device for road construction and a using method thereof, and belongs to the technical field of road construction equipment. The drilling device for road constructioncomprises a base, first vertical plates are connected with the two sides of the top of the base, a damping plate is connected between the two first vertical plates, a rotating shaft is slidably connected into the damping plate, a box body is rotatably connected with the outer wall of the rotating shaft through a bearing, a first bevel gear is connected with the outer wall of the rotating shaft, the inner wall of the box body is rotationally connected with a second bevel gear engaged with the first bevel gear, the top of the box body is connected with a motor, and the output end of the motor is connected with the rotating shaft. According to the drilling device for road construction, a drill bit can continuously deepen the punching depth in the punching process by only driving one motor tooperate, energy consumption is reduced, the punching cost is reduced, the workload of workers is relieved, vibration in the punching process is damped through the damping plate, and the punching precision is improved.

Owner:萧县众科电磁检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com