Large-pitch special-shaped spiral drill rod

A technology of auger rod and large pitch, which is used in drill rods, drill pipes, and earth-moving drilling and mining, etc., can solve the problems of sticking, holding the drill, the friction between the helical blade and the body of the drill pipe, etc., so as to improve the drilling depth. , Improve the slag discharge efficiency and enhance the effect of the slag discharge function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

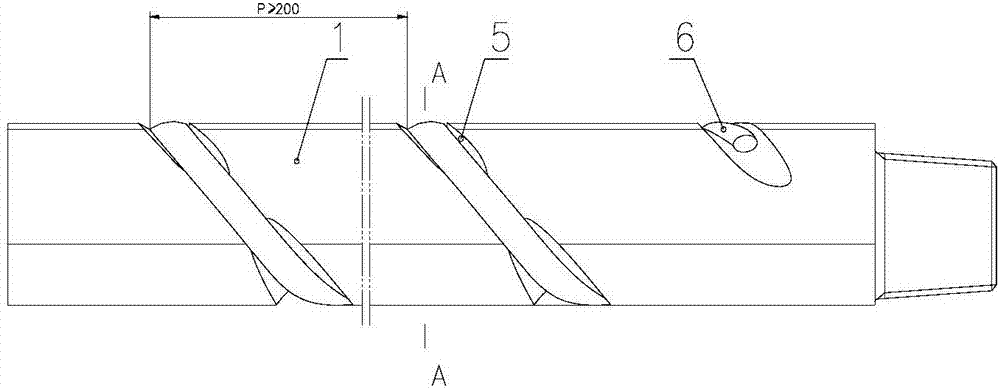

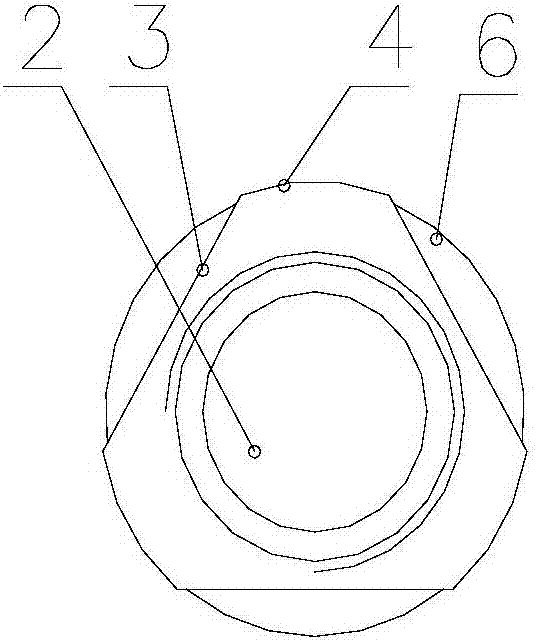

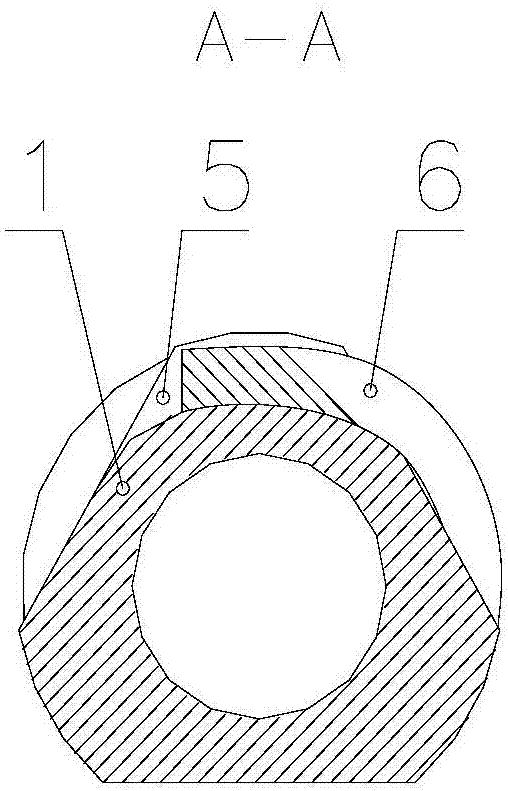

[0030] Embodiment one: if Figure 1-3 As shown, a large-pitch special-shaped helical drill pipe includes a drill pipe body 1 with a medium delivery channel 2 inside, and the two ends of the drill pipe body 1 are respectively provided with external threads and internal threads for mutual connection. The outline is composed of three straight line segments 3 of equal length and three arc line segments 4 of equal length arranged at intervals and connected from head to tail. The outer wall of the drill pipe body 1 is provided with a spiral groove 5, and the pitch of the spiral groove 5 is greater than or equal to 200 mm. A helical blade 6 is provided, and the helical groove 5 is intermittently arranged in the middle part of the straight section of the outer contour of the drill pipe body to form a discontinuous helical groove. The cross section of the helical groove 5 is arc-shaped, and the helical blade 6 is a continuous helical blade , the cross section of the spiral blade 6 is c...

Embodiment 2

[0031] Embodiment two: if Figure 4-6 As shown, the difference from Embodiment 1 is that the drill pipe body 1 includes a rod body 11, a male joint 12 and a female joint 13 fixedly connected by friction welding, the external thread is arranged on the male joint 12, and the internal thread is arranged on the female joint 13 superior. In the embodiment, the external thread on the male joint and the internal thread on the female joint are processed first, and the external thread and the internal thread are treated with nitriding, high-frequency quenching, phosphating or nickel-phosphorus plating; then the male joint and the female joint are It is fixedly connected with the drill pipe body by friction welding; then the spiral groove and three cutting surfaces are processed, and finally the spiral blade is fixed on the bottom of the spiral groove by welding. Nitriding, high-frequency quenching, phosphating or nickel-plated phosphorus treatments are used for the external thread and...

Embodiment 3

[0032] Embodiment three: as Figure 7 As shown, the difference from Embodiment 1 lies in the cross-sectional profile of the drill pipe body 1. The cross-sectional profile of this embodiment is composed of four equal-length straight line segments 3 and four equal-length arc line segments 4 end-to-end connected at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com