Patents

Literature

212results about How to "Improve slag discharge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

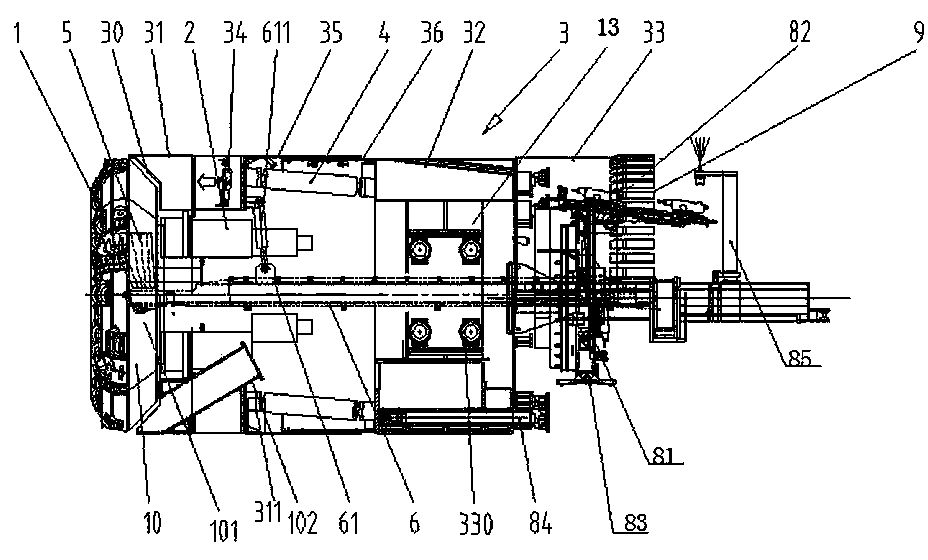

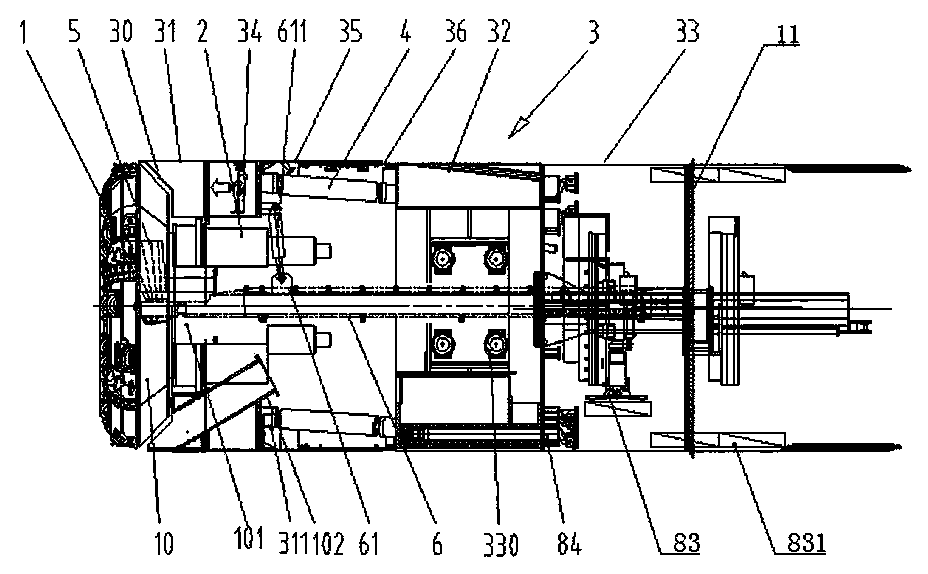

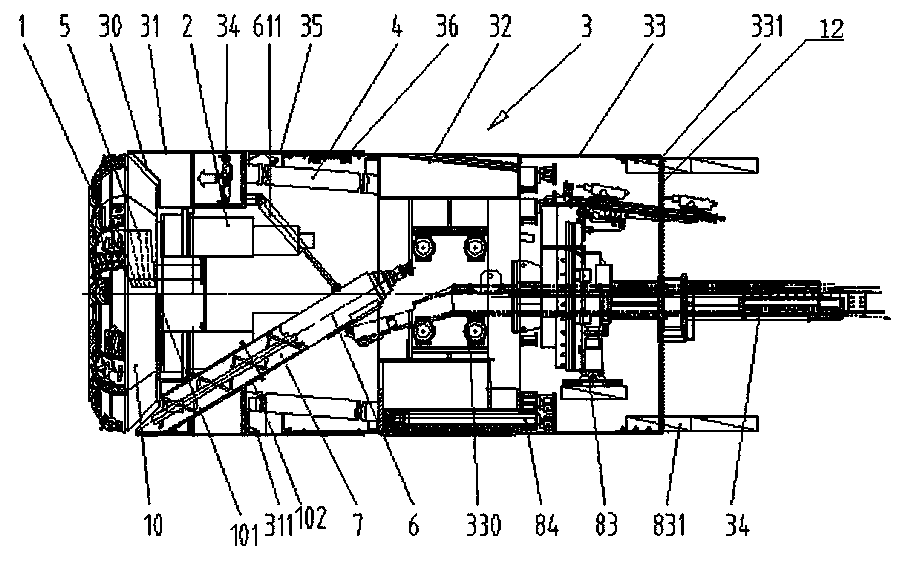

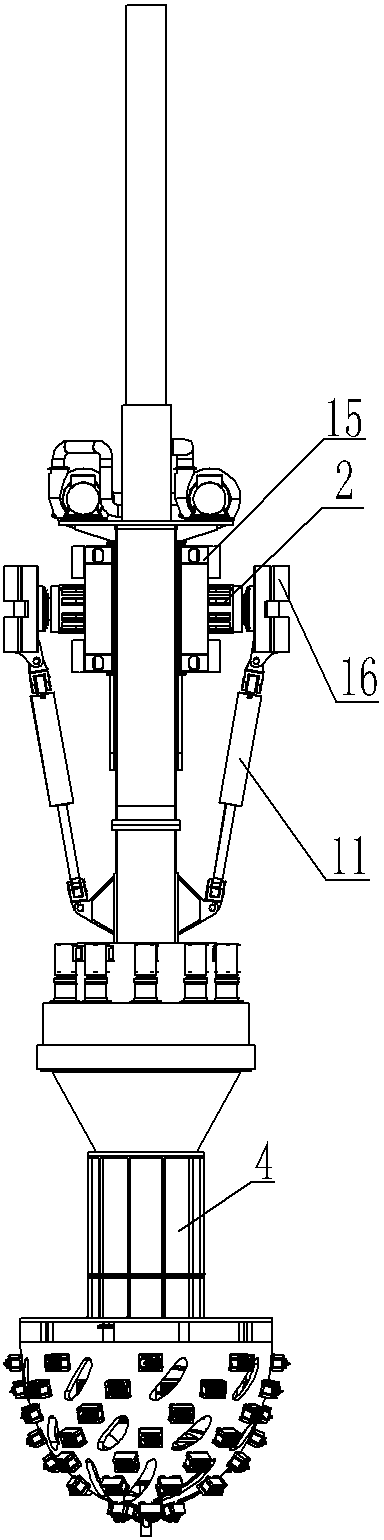

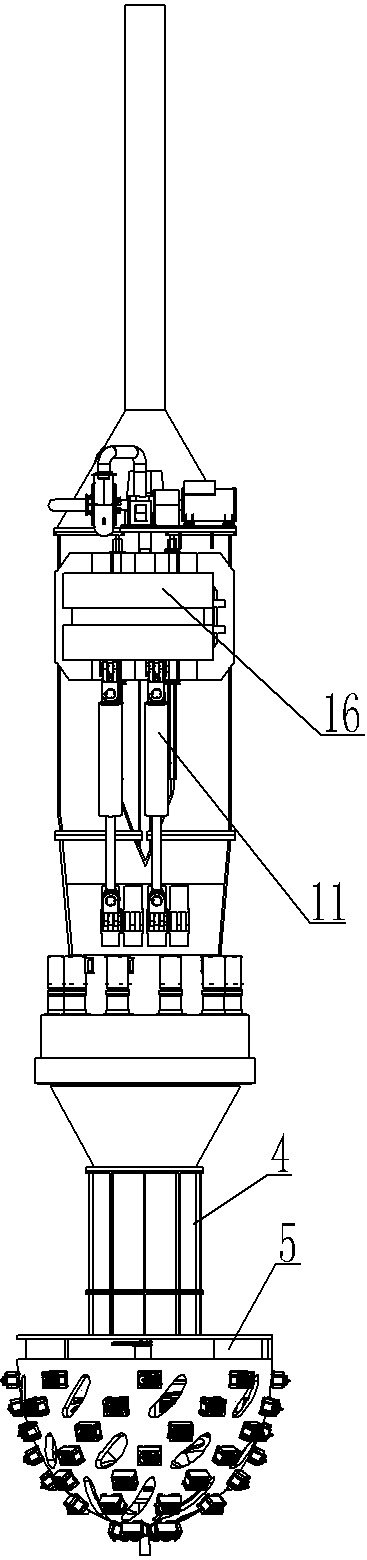

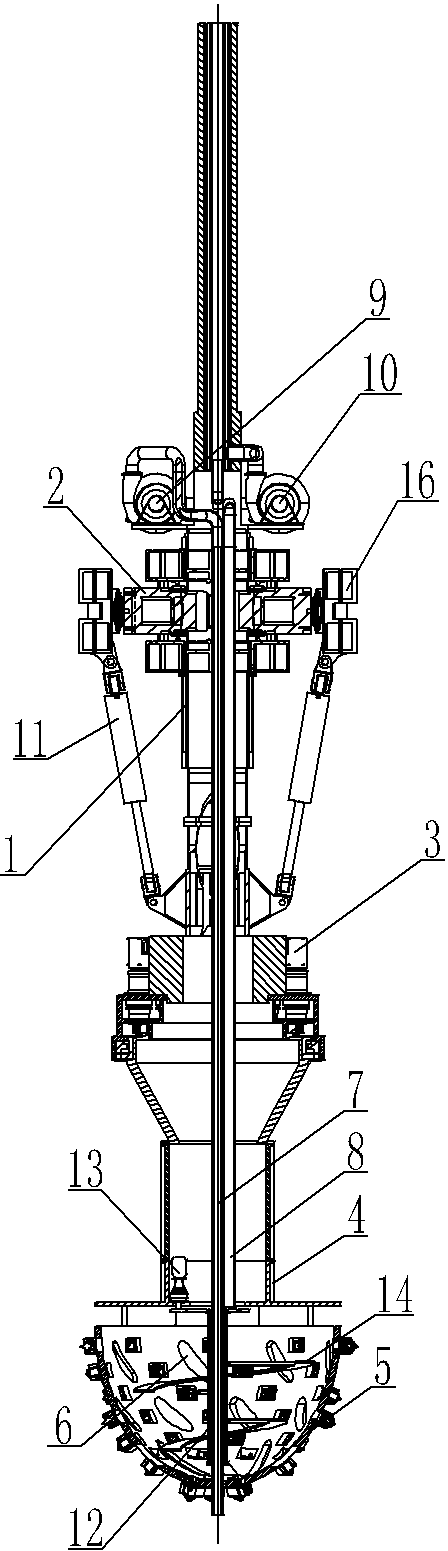

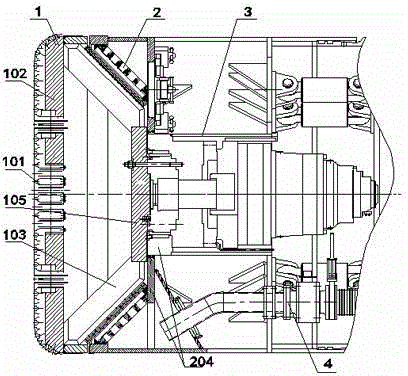

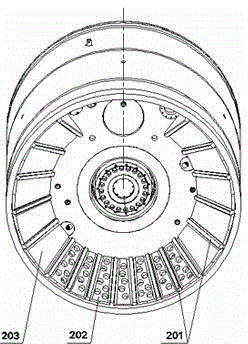

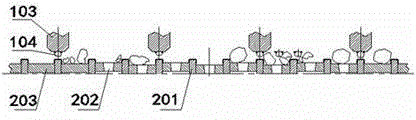

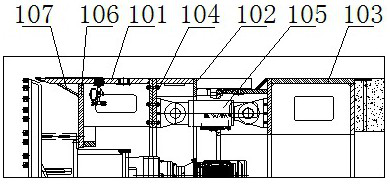

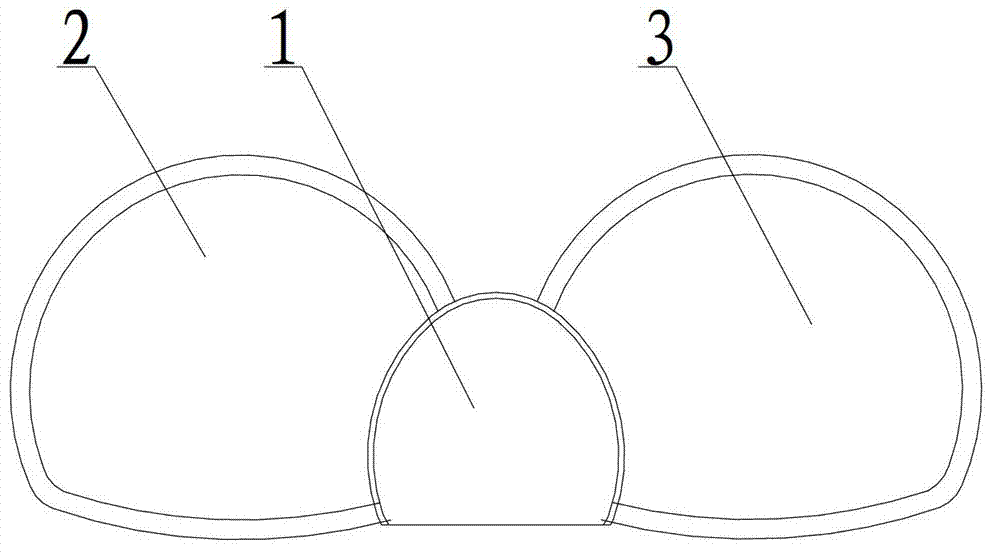

Combined type double-shield tunneling machine

ActiveCN104196538AIncrease the lengthShorten the lengthUnderground chambersTunnel liningSupporting systemDual mode

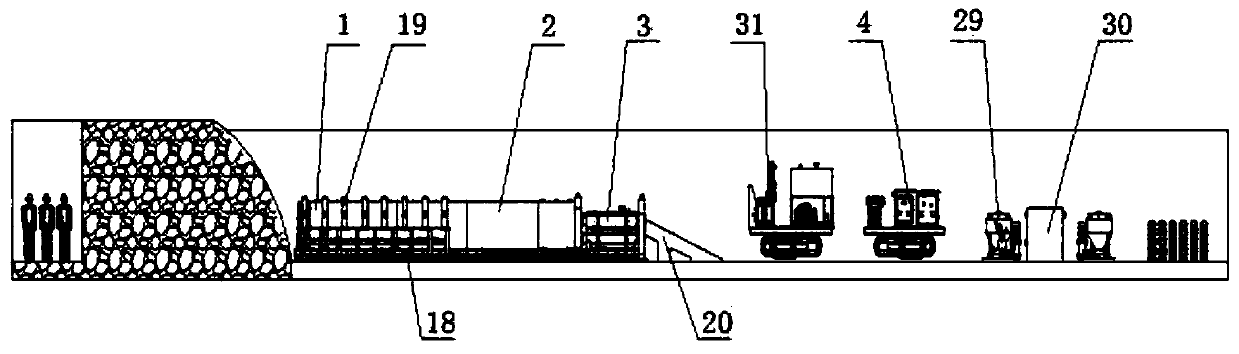

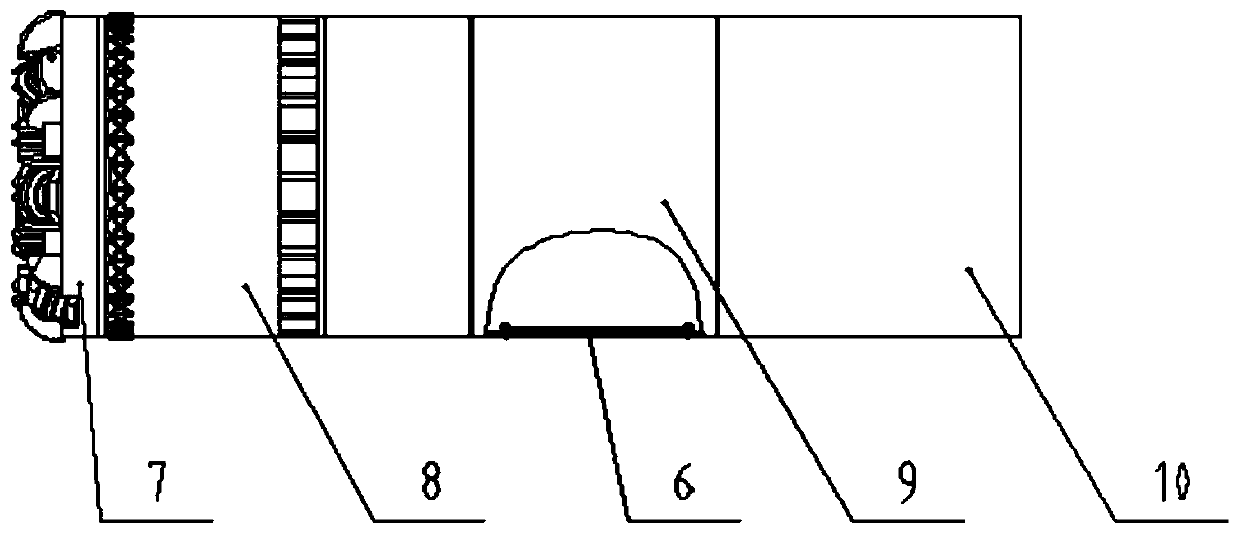

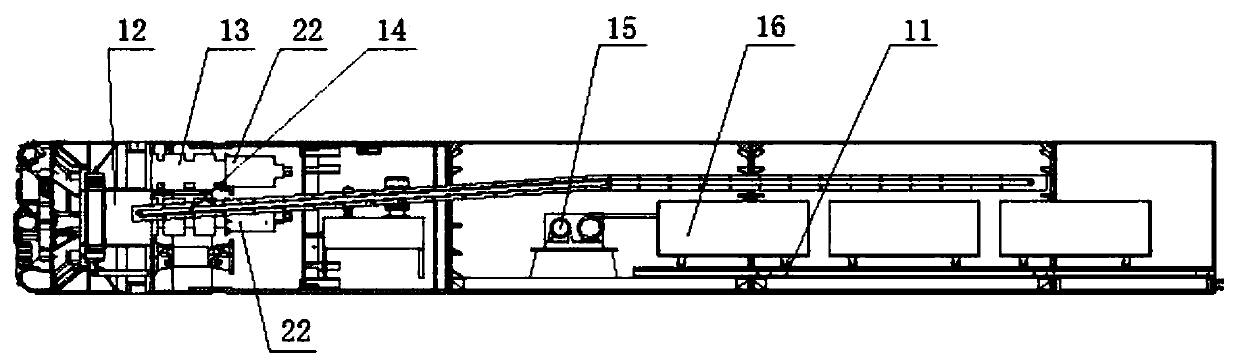

The invention discloses a combined type double-shield tunneling machine which comprises a cutter, an anterior shield, a cab, a main driving device, an inside-and-outside stretching shield, a V-shaped arrangement main propelling system, a hinge system, a supporting shield, a boot supporting system, a tail shield, an auxiliary propelling system, a dual-mode deslagging system, an integration supporting system and the like. Four working modes including of the double shielding modes including the support boot and segmental lining mode and the support boot and anchor-plate timbering mode, the single shielding mode and the ERB mode can be achieved, and efficient tunneling, efficient deslagging and efficient timbering are achieved under the hard rock, sandy soil and soft soil geological conditions. The combined type double-shield tunneling machine has the outstanding advantages that one device can meet various complex-geology tunneling construction requirements, the geology applicability of the tunneling machine is greatly improved, the frequency of tunneling machine replacement in tunnel construction is decreased, and production efficiency is greatly improved.

Owner:中船(青岛)轨道交通装备有限公司

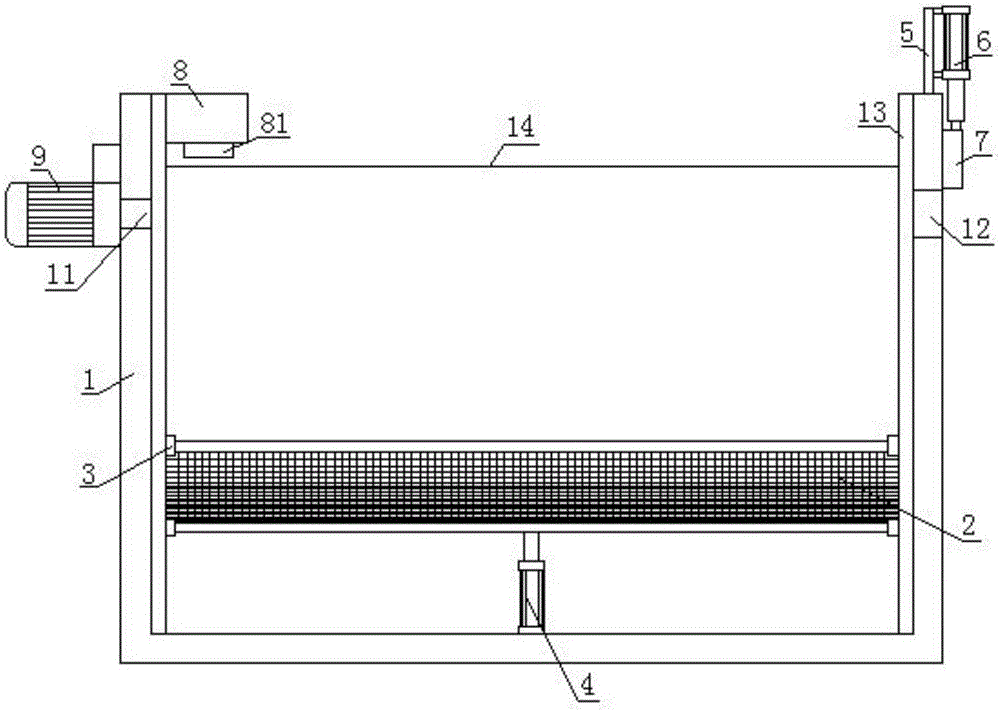

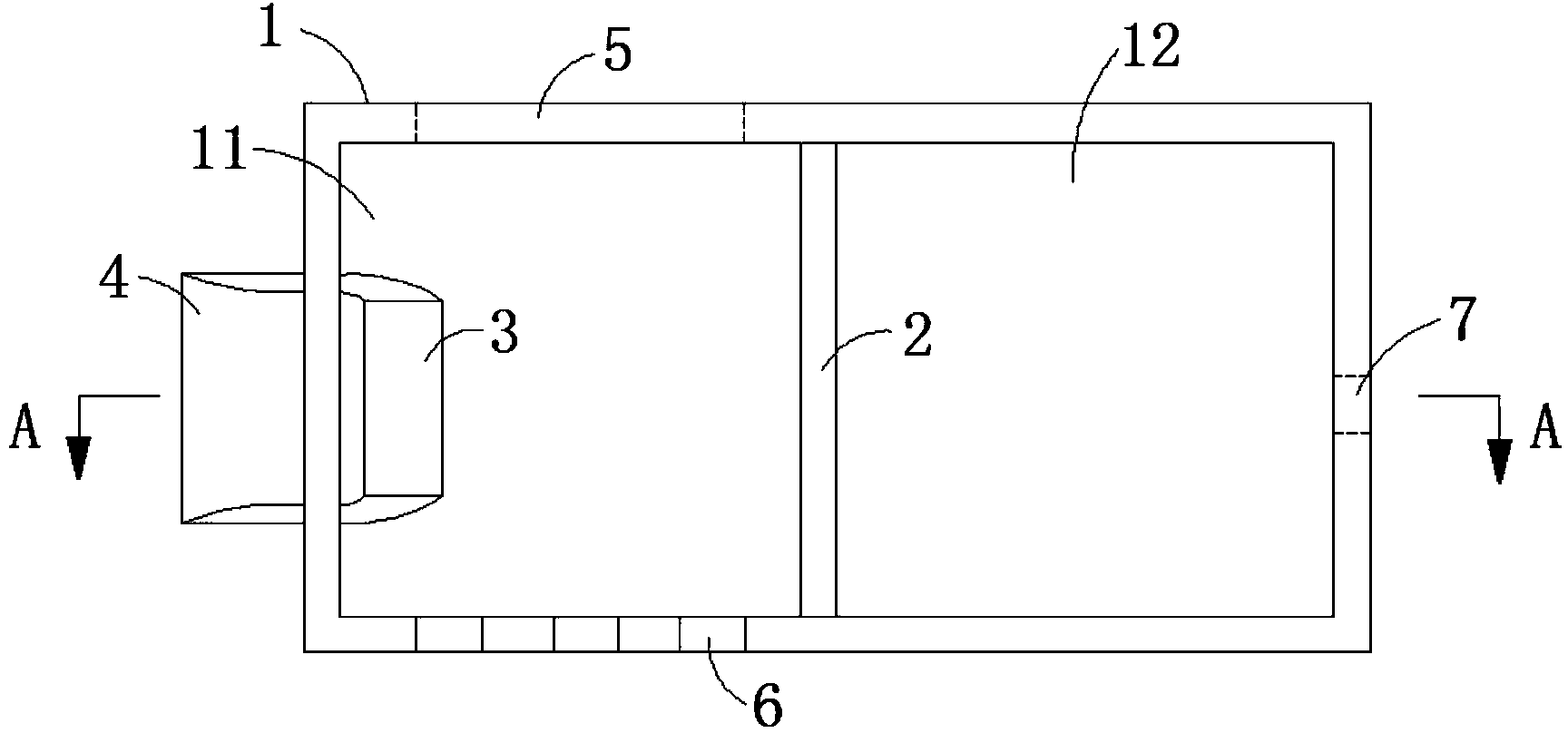

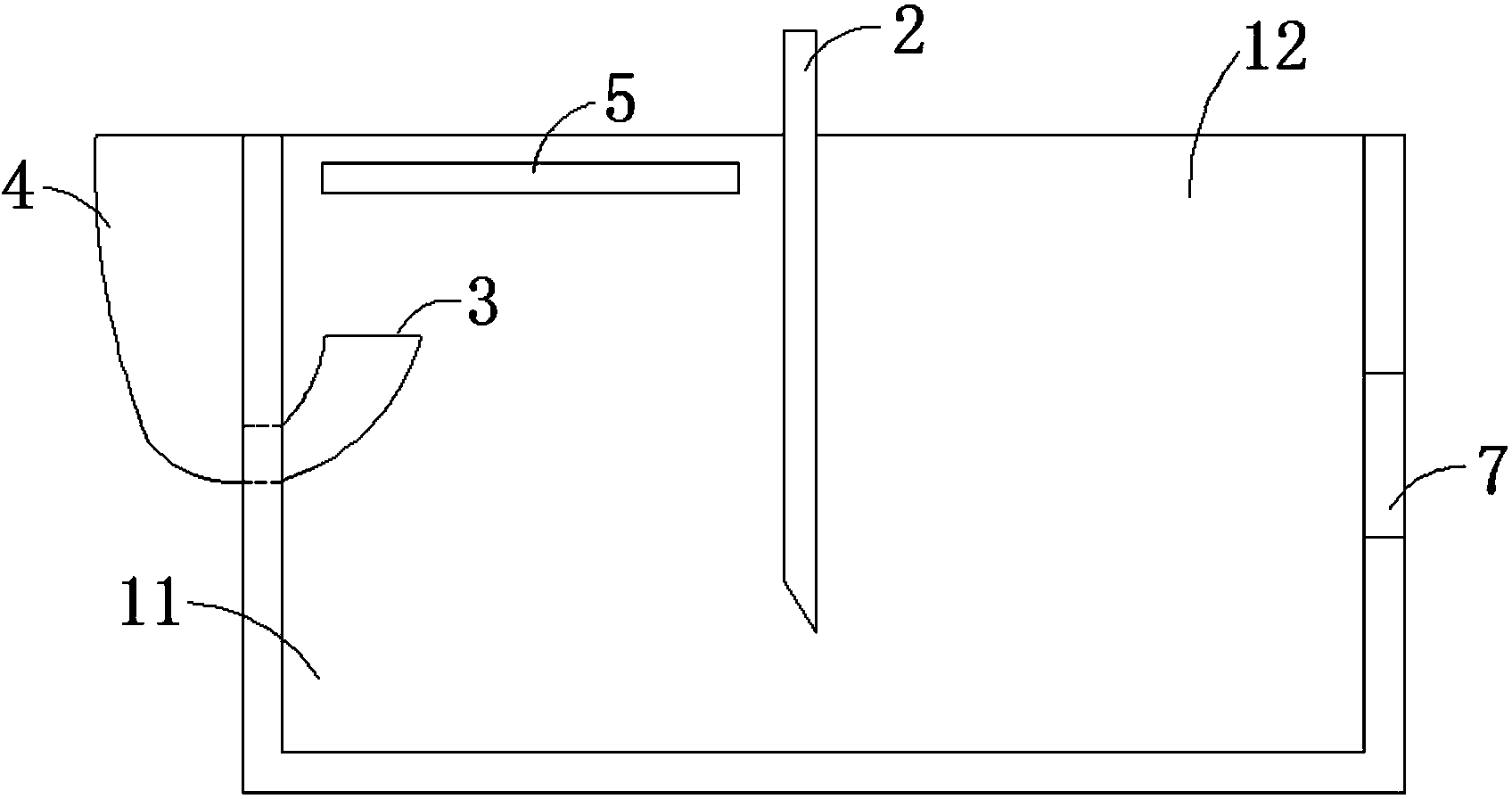

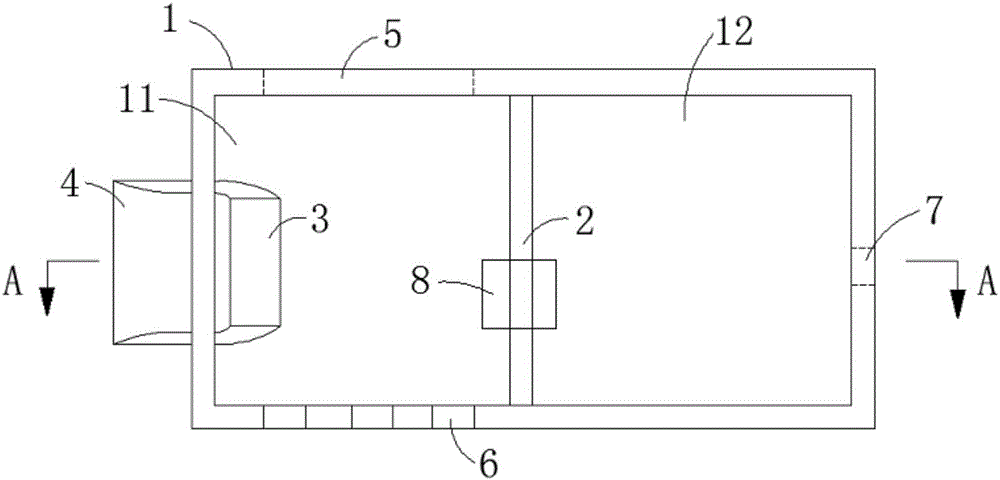

Inorganic chemical wastewater treatment tank capable of improving cleanness of wastewater

InactiveCN106746030AReal-time dischargePrevent cloudingTreatment involving filtrationMultistage water/sewage treatmentInorganic ChemicalSludge

The invention relates to the field of wastewater treatment and in particular relates to an inorganic chemical wastewater treatment tank capable of improving the cleanness of wastewater. The inorganic chemical wastewater treatment tank capable of improving the cleanness of the wastewater, provided by the invention, is characterized by comprising a sedimentation tank; a water inlet is arranged at one end of the sedimentation tank and a water outlet is arranged at the other end of the sedimentation tank; a sliding groove is formed in a side wall in the sedimentation tank; a filtering screen is obliquely arranged in the sedimentation tank; a dreg discharging hole is formed in one side, close to the lower end of the filtering screen, of the sedimentation tank; the edge of the filtering screen is connected with a sliding block; the sliding groove is arranged in the sliding block in a sleeving manner; a hoisting air cylinder is mounted at the bottom of the sedimentation tank; a piston rod of the hoisting air cylinder is fixed at the bottom of the filtering screen. According to the inorganic chemical wastewater treatment tank provided by the invention, the disadvantages in the prior art are overcome, and the inorganic chemical wastewater treatment tank capable of discharging sludge from the upper side and convenient for blow-off operation is provided; the problems that a blow-off hole of an existing wastewater treatment tank is arranged at the lower side and the clarification degree of the wastewater is low are solved.

Owner:CHENGDU YANXINGGUO TECH CO LTD

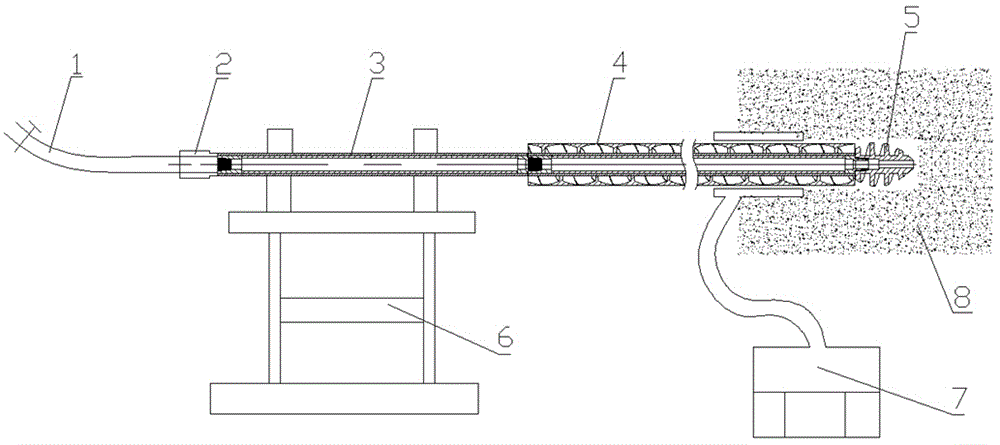

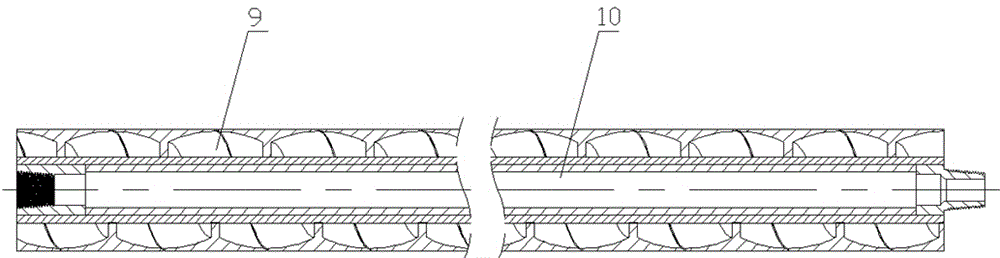

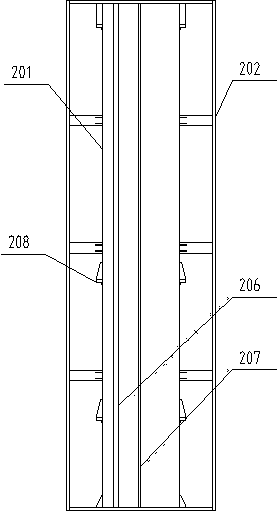

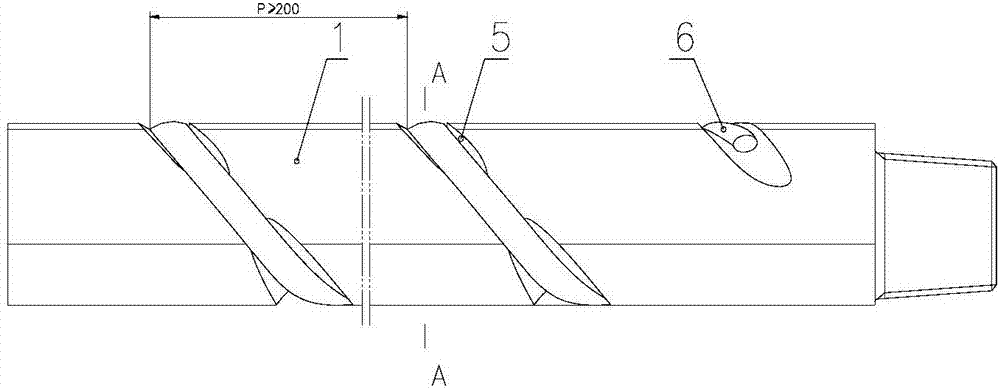

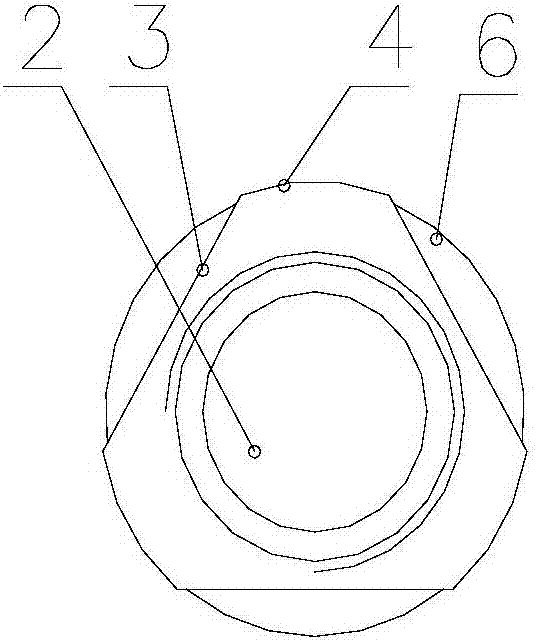

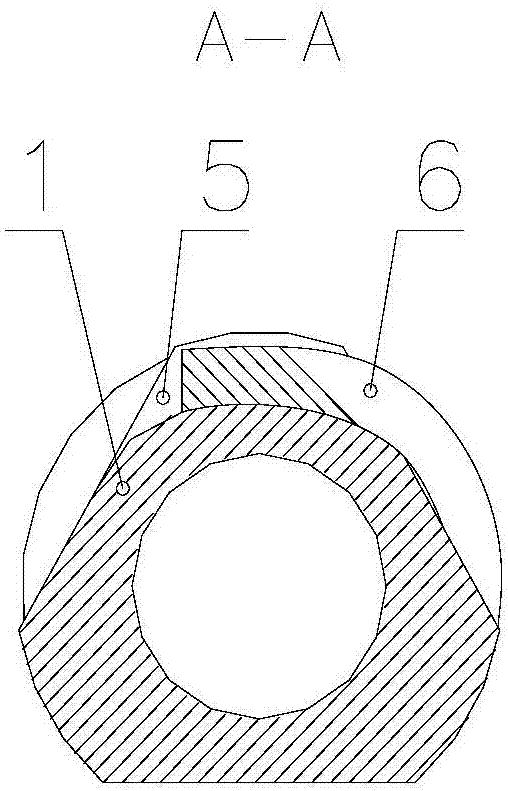

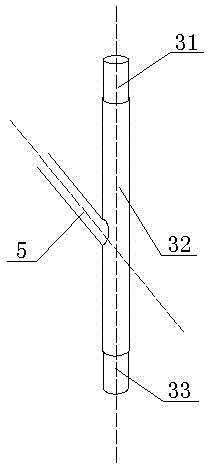

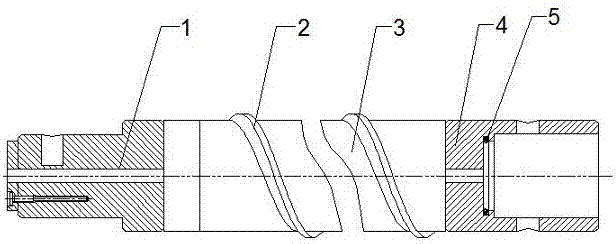

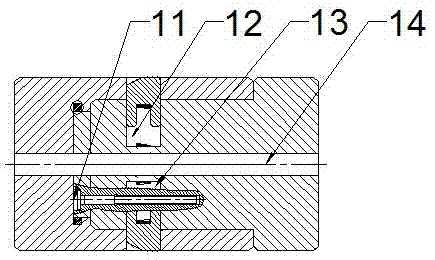

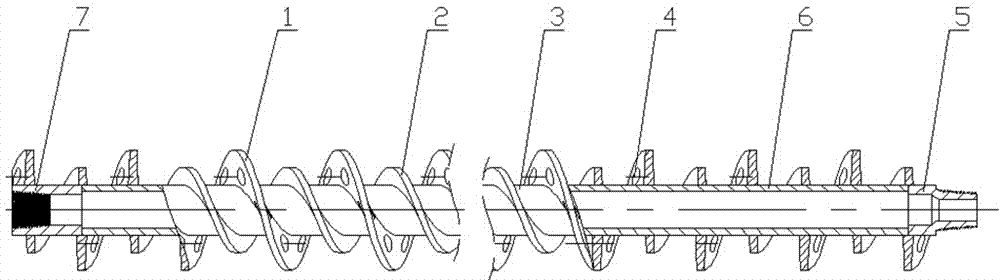

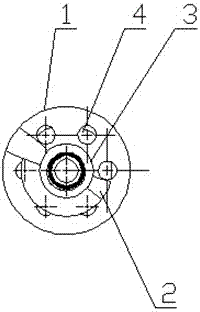

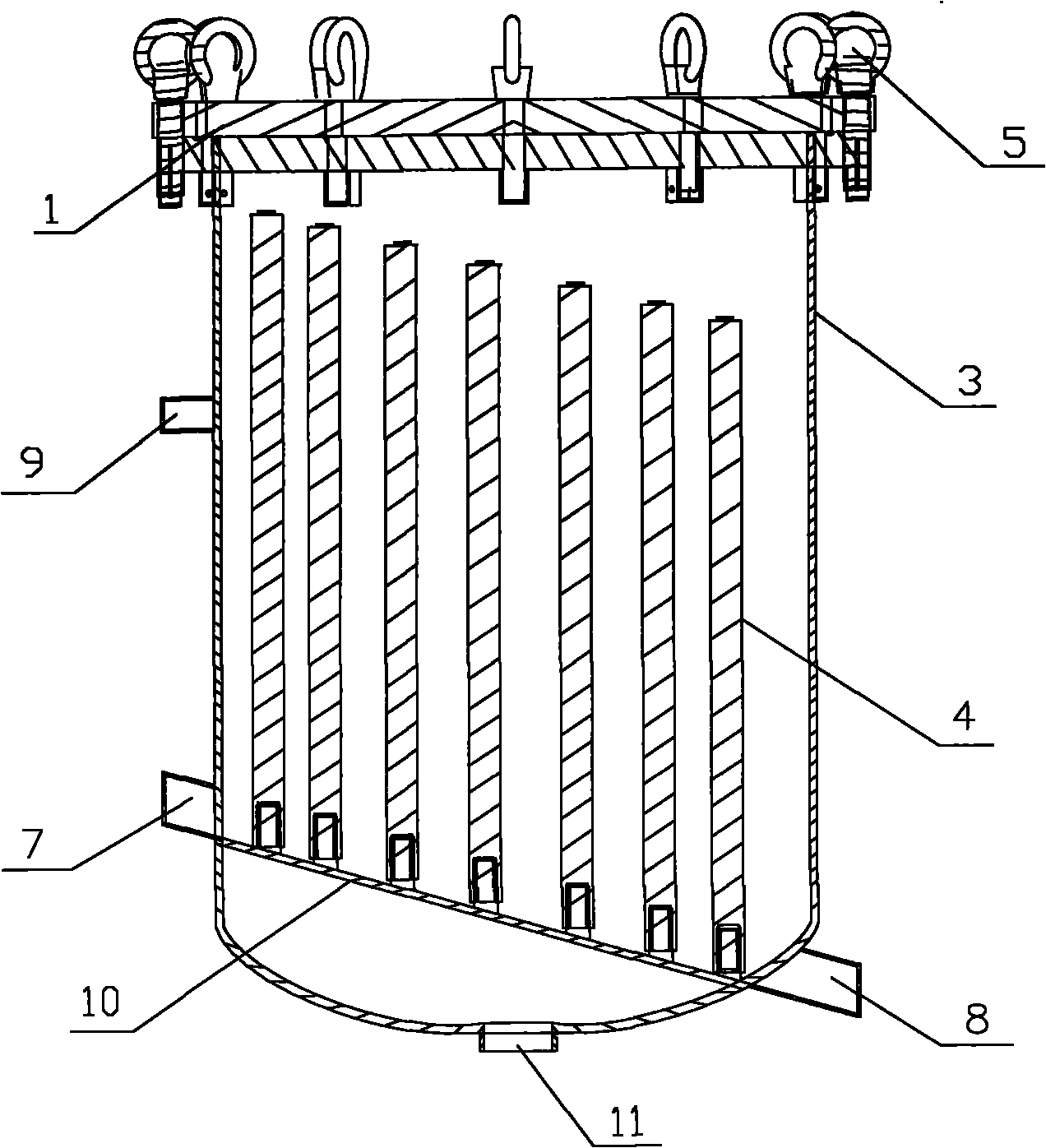

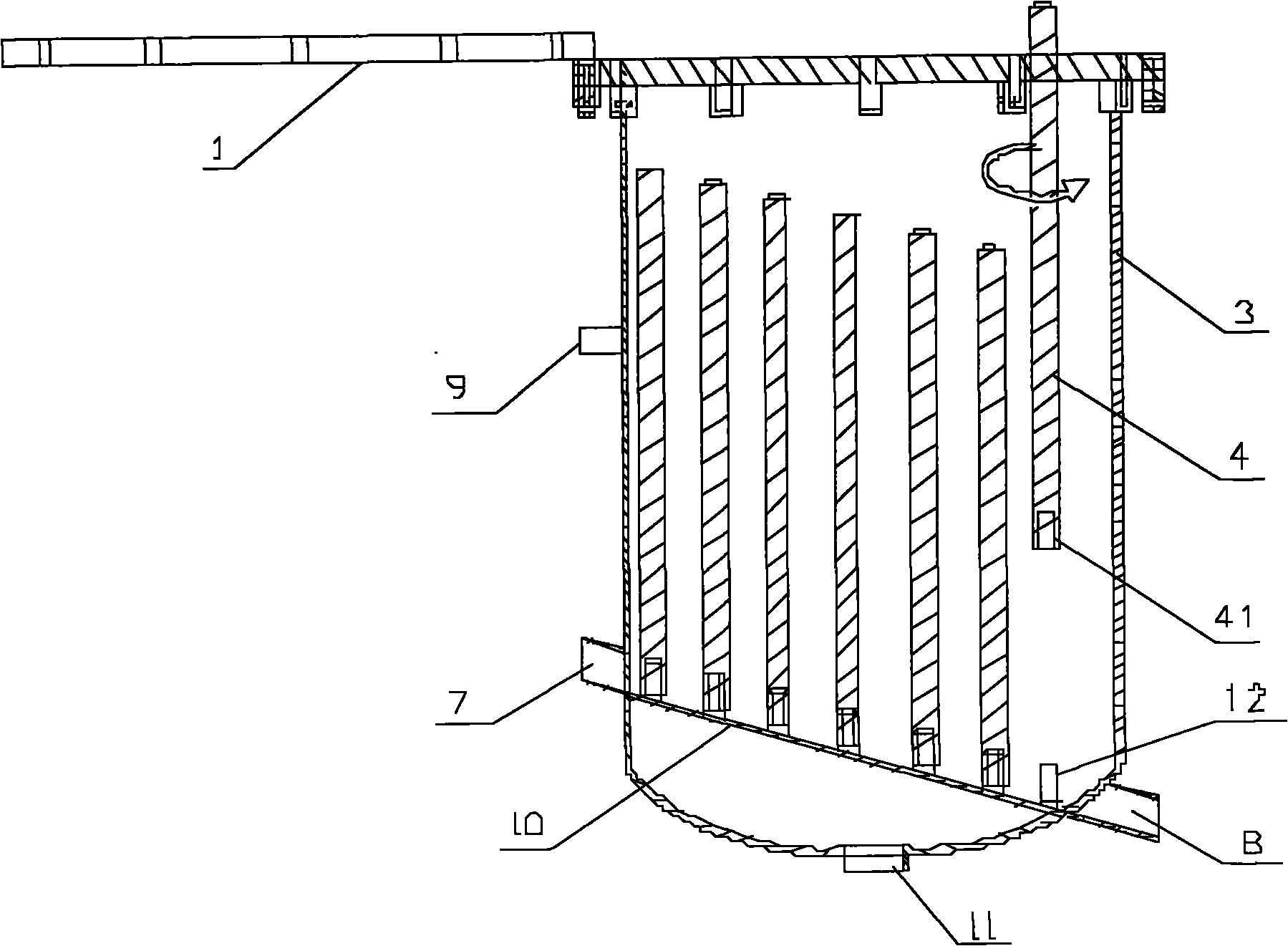

Closed type helical hole-protecting drill and using method thereof for drilling of soft coal bed

ActiveCN104314482ALow rotational resistanceIncreased drilling depthDrill bitsDrilling rodsDischarge efficiencySlag

The invention discloses a closed type helical hole-protecting drill and a using method thereof for drilling of a soft coal bed. The closed type helical hole-protecting drill comprises a closed type helical hole-protecting drill pipe and a helical slag-guiding drill bit, and the helical slag-guiding drill bit is mounted at the front end of the closed type helical hole-protecting drill pipe. The closed type helical hole-protecting drill is mainly applied to the drilling engineering of the soft and breaking coal rock layer. The using method includes mounting and connecting a drill, the closed type helical hole-protecting drill pipe, the helical slag-guiding drill bit and an orifice slag discharging device, starting the drill, breaking and drilling the coal bed by the helical slag-guiding drill bit, guiding drillings into the helical slag discharging space of the closed type helical hole-protecting drill pipe along slag-guiding helical grooves of the drill bit, and discharging the drillings out of the hole through friction of helical blades. The closed type helical hole-protecting drill is novel in design, and is provided with a hole protecting function via structural innovation of the helical blades, the drillings are discharged within in the protected space and prevented from being influenced by deformation and collapse of drilled holes, and the defect that a conventional casing drill is high in drilling resistance, low in slag discharging efficiency and the like is overcome.

Owner:HENAN POLYTECHNIC UNIV

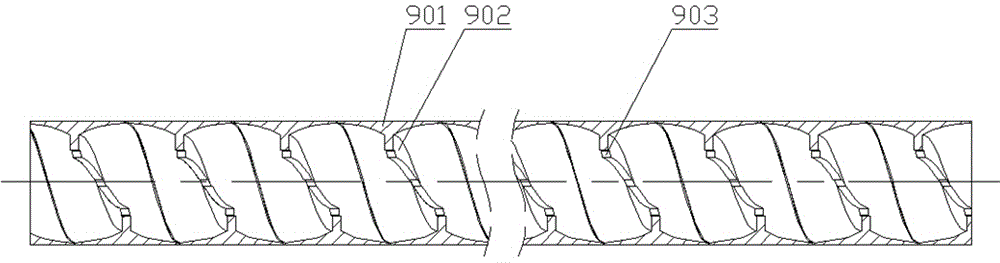

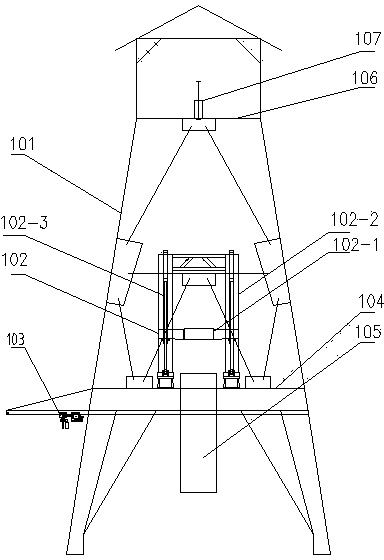

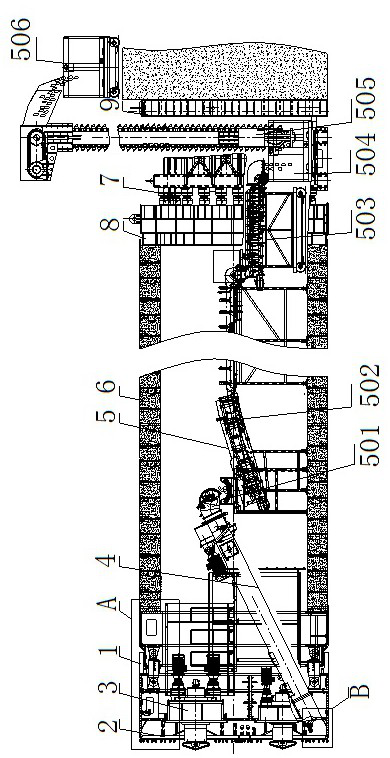

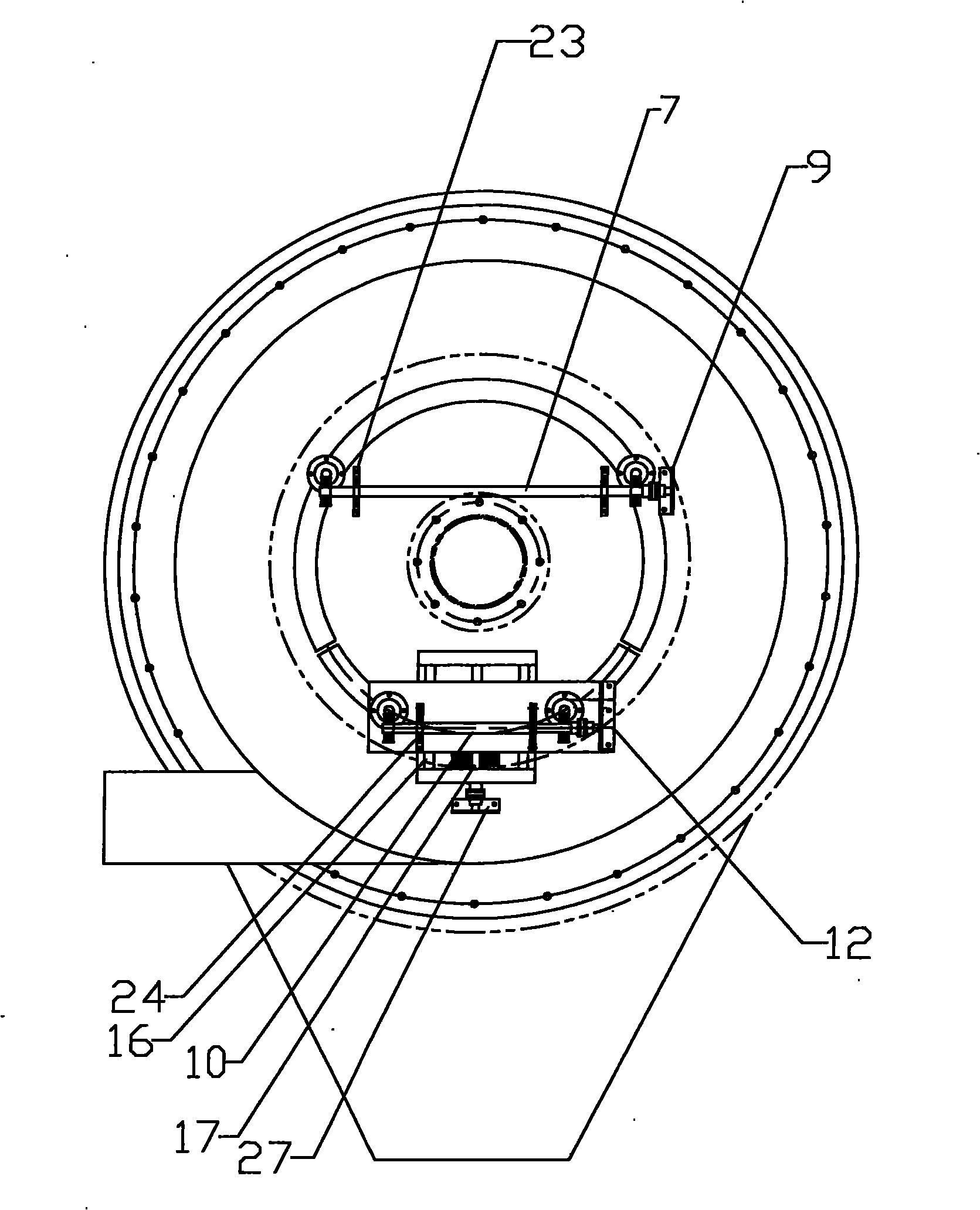

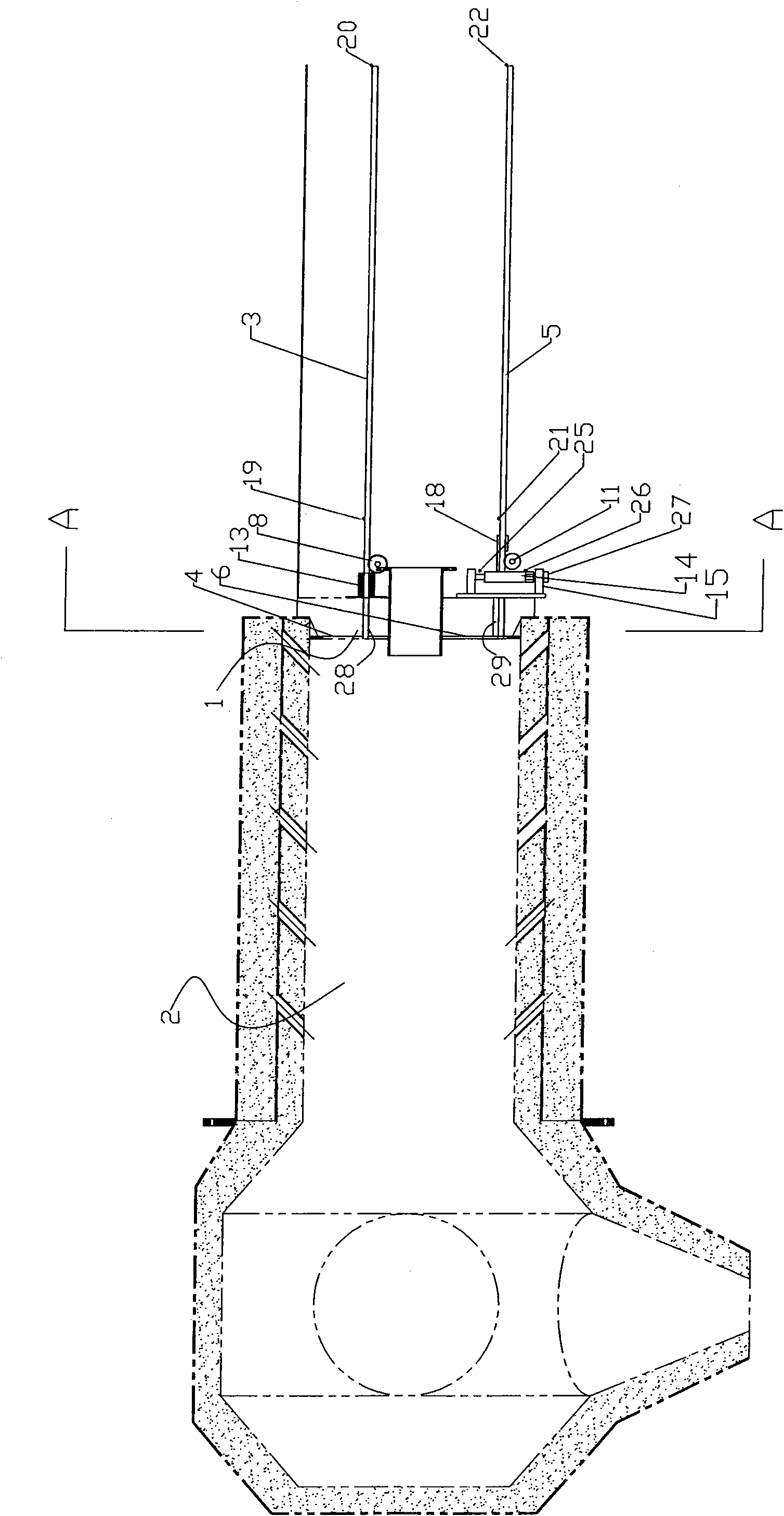

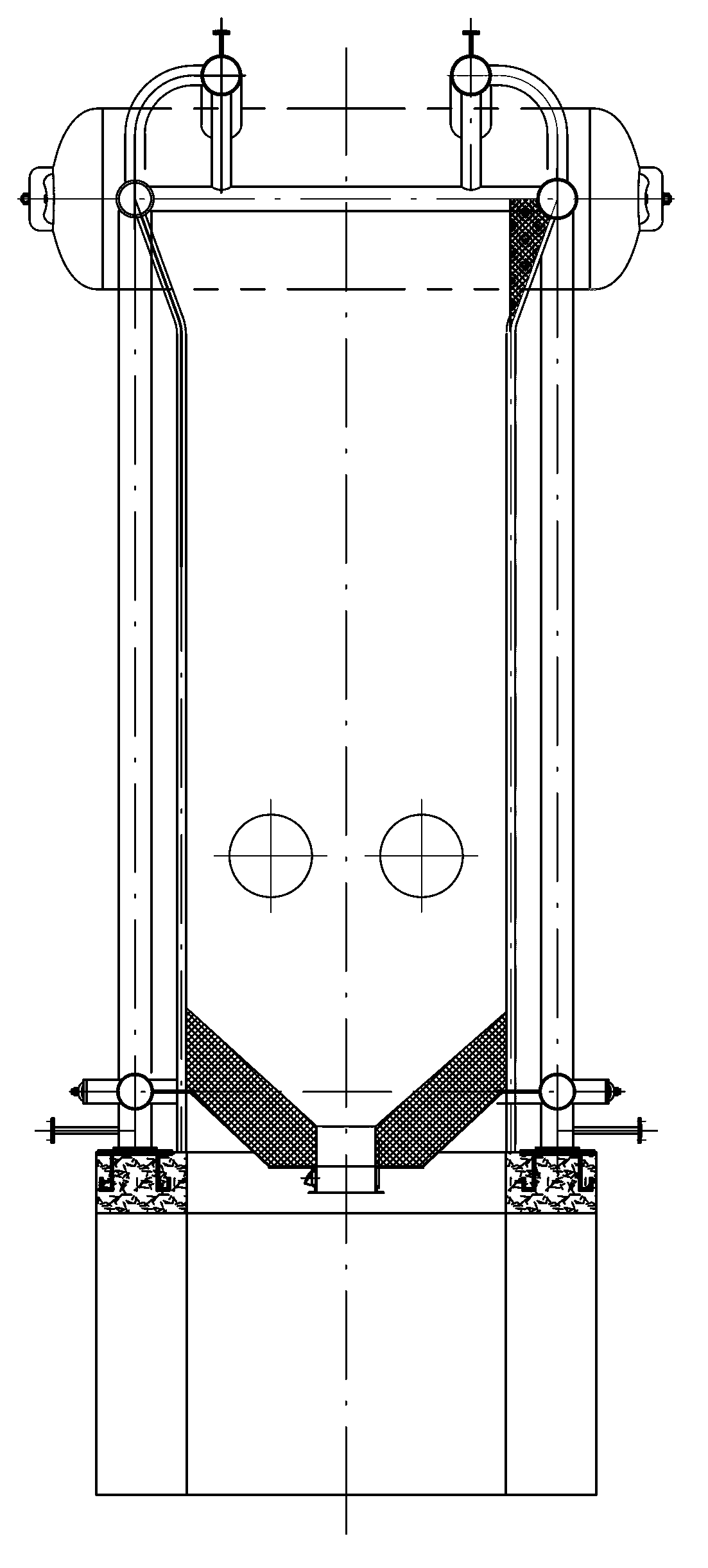

Novel drilling and blasting method vertical shaft drilling machine

The invention discloses a novel drilling and blasting method vertical shaft drilling machine. The machine mainly comprises a derrick, a numerical control umbrella drill, a loading machine, an equipment suspension system, a drainage system, a ventilation system, a slag discharge system, a shaft wall casting system, a shaft bottom hanging scaffold, a hydraulic station and a control room, wherein the equipment suspension system comprises a center vertical column, a vertical column lifting mechanism and a sealing flatcar; the center vertical column is connected with the vertical column lifting mechanism, and extends underground; the lower part of the center vertical column is connected with the shaft bottom hanging scaffold; the derrick and the sealing flatcar are mounted in a shaft mouth; the vertical column lifting mechanism is fixed and mounted on the derrick; the loading machine is mounted at the lower end of the center vertical column; the numerical control umbrella drill is mounted in the center vertical column; and the hydraulic station, the drainage system and the control room are mounted on the shaft bottom hanging scaffold. The machine adopts the reinforced derrick and the equipment suspension system, so that the equipment connection is reliable, and the construction is safer. The construction of the numerical control umbrella drill needs no shaft lifting, and is full-automatically controlled, so that the construction efficiency is improved; the slag loading efficiency of the loading machine is higher; the operation is more convenient; and the slag discharge efficiency is further improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

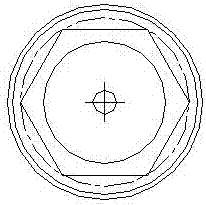

Rotary fire grate

The invention relates to a rotary fire grate which comprises a fixed shaft, a main shaft sleeve, a first forward driven fire grate, a second forward driven fire grate and a forward driving fire grate connected with a driving mechanism. The forward driving fire grate, the first forward driven fire grate and the second forward driven fire grate have slag removing holes. The forward driving fire grate, the first forward driven fire grate and the second forward driven fire grate are fixedly connected with the main shaft sleeve which is movably sleeved with the fixed shaft. The rotary fire grate further comprises a reverse driving fire grate. The forward driving fire grate, the reverse driving fire grate, the first forward driven fire grate and the second forward driven fire grate are arranged sequentially from bottom to top and distances are reserved between adjacent fire grates. The forward driving fire grate is connected with the driving mechanism, the reverse driving fire grate is movably sleeved with the main shaft sleeve, and the reverse driving fire grate has a slag removing hole. The rotary fire grate is good in slag breaking effect and smooth in slag discharge.

Owner:宁波泰来环保设备有限公司

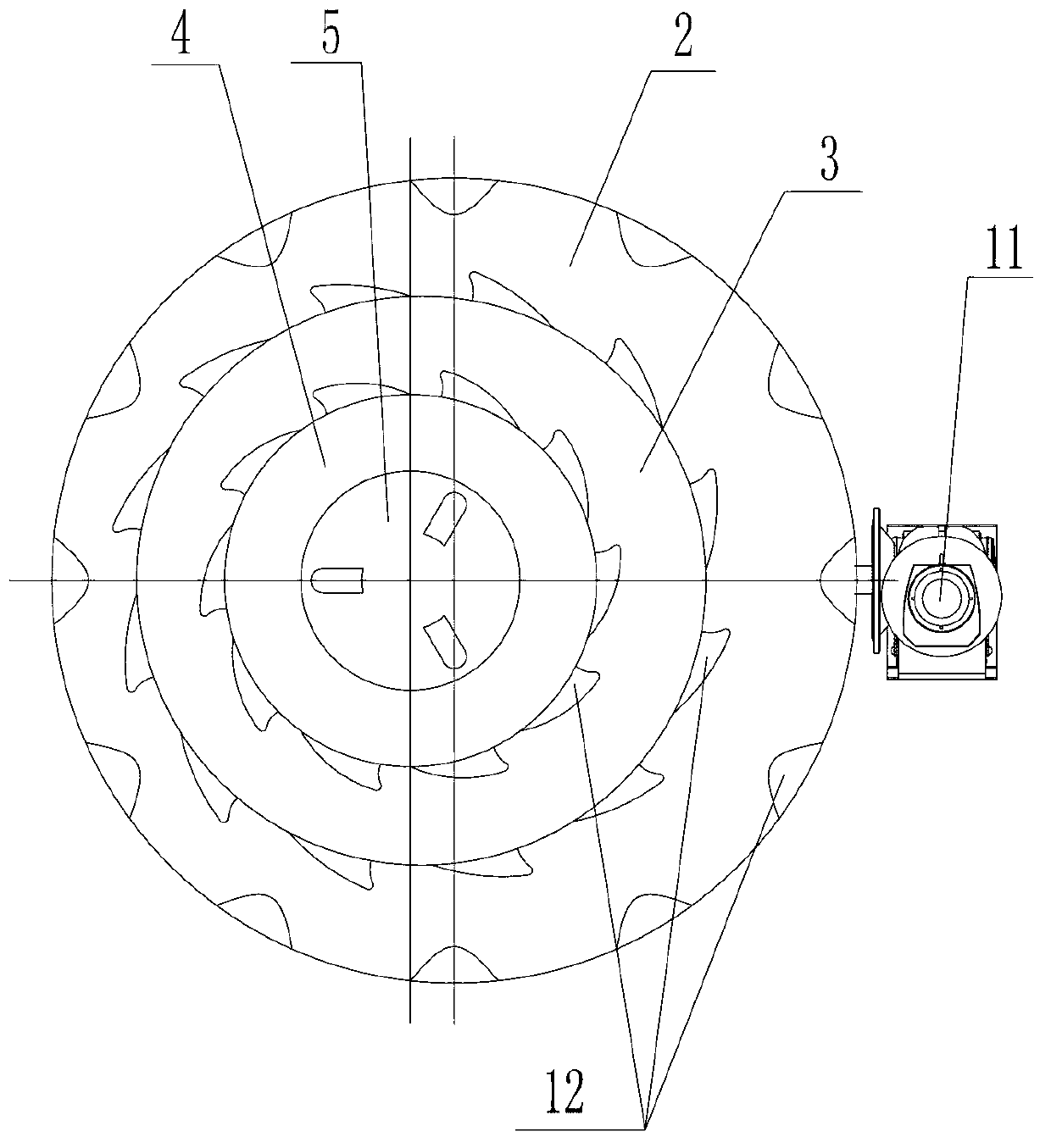

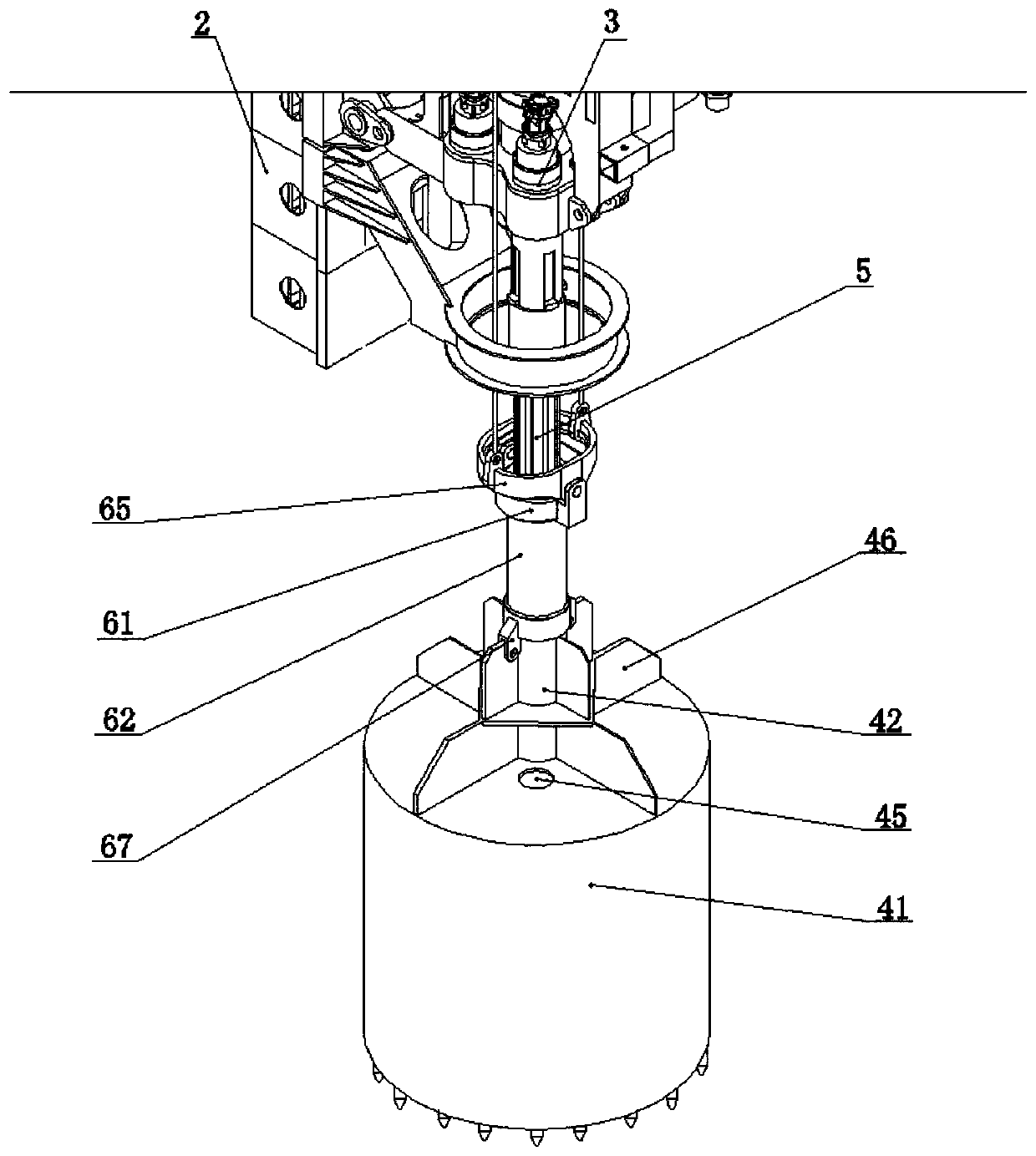

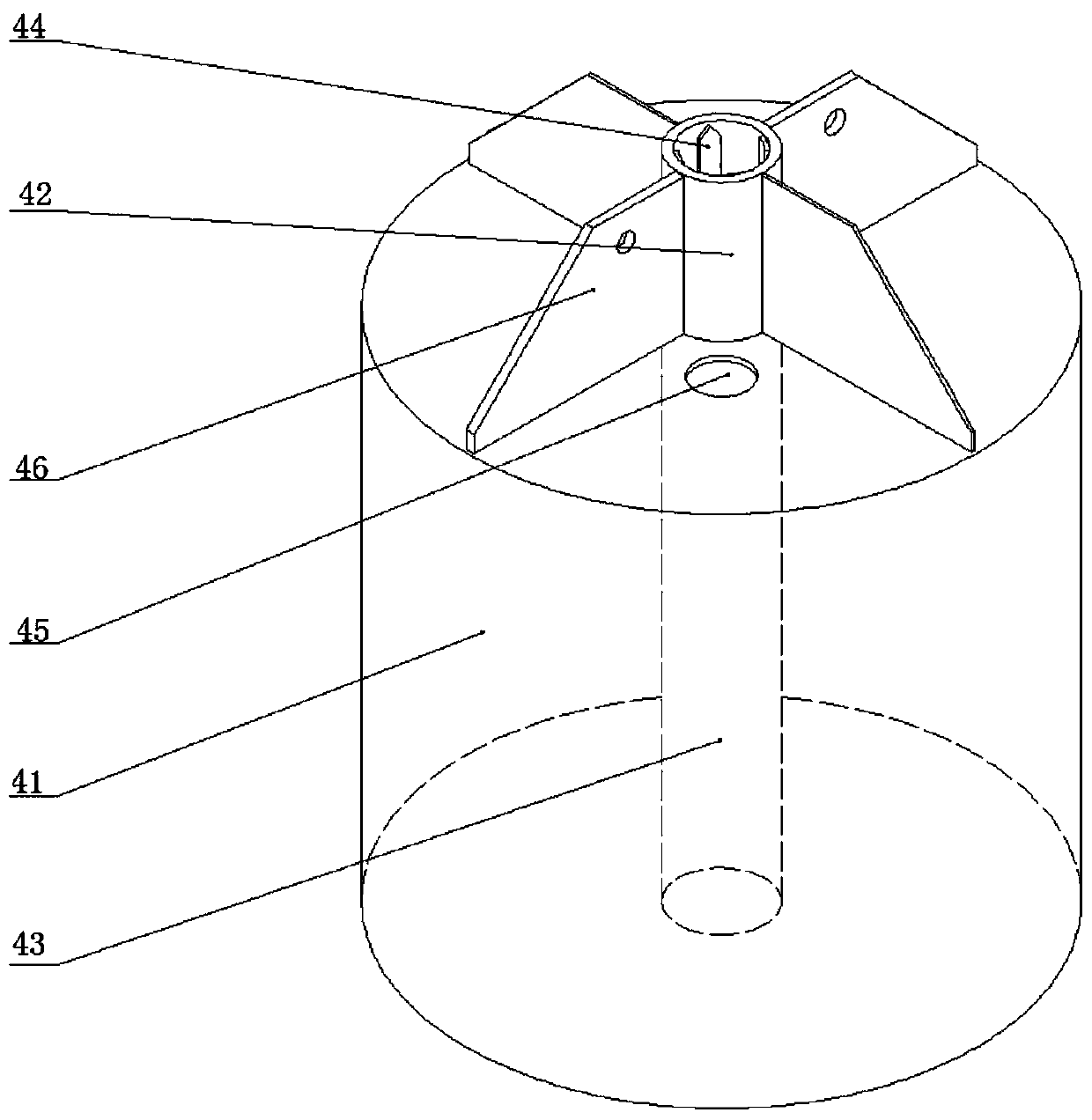

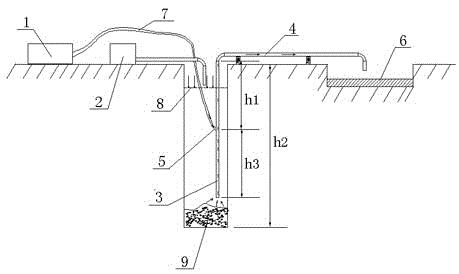

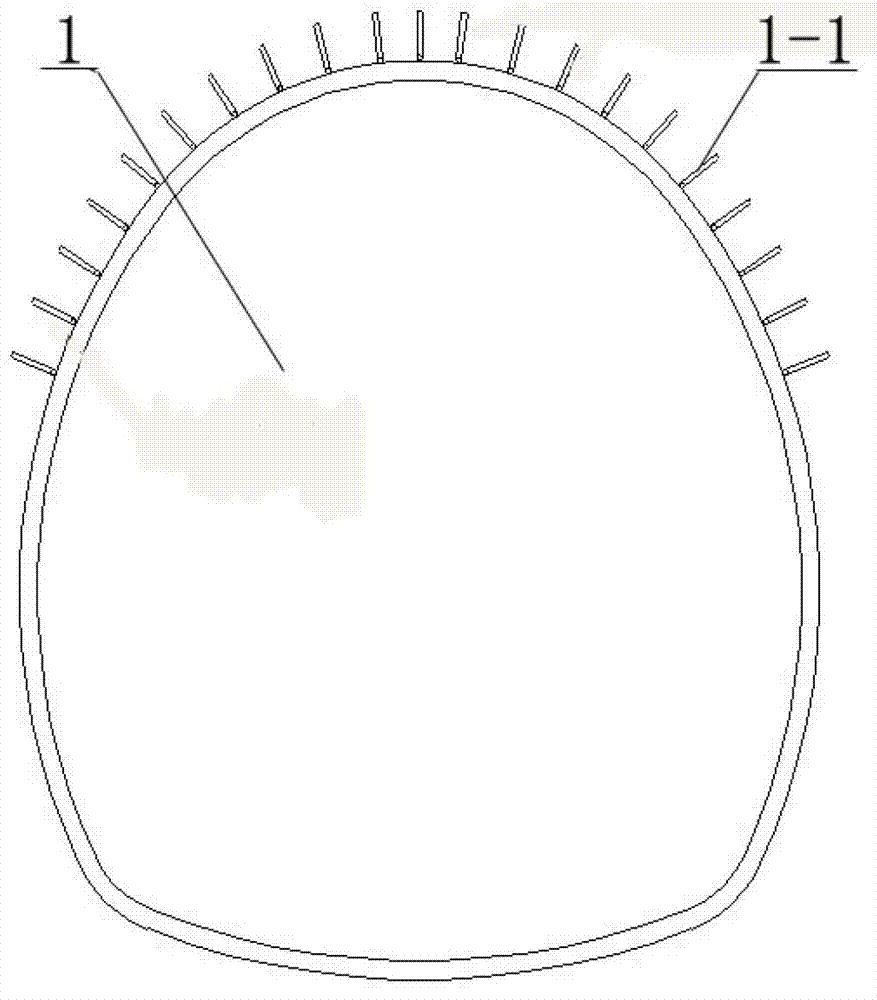

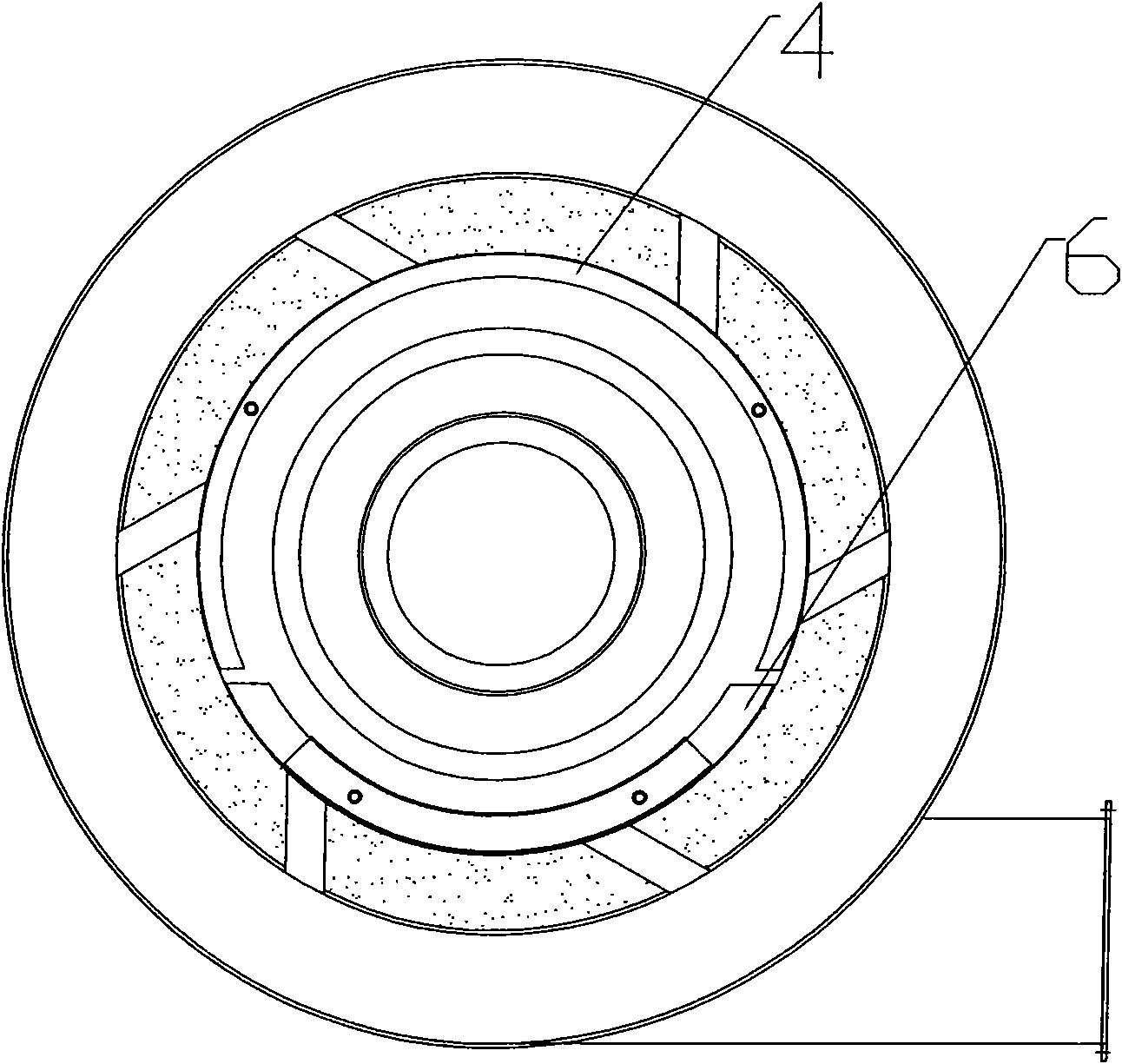

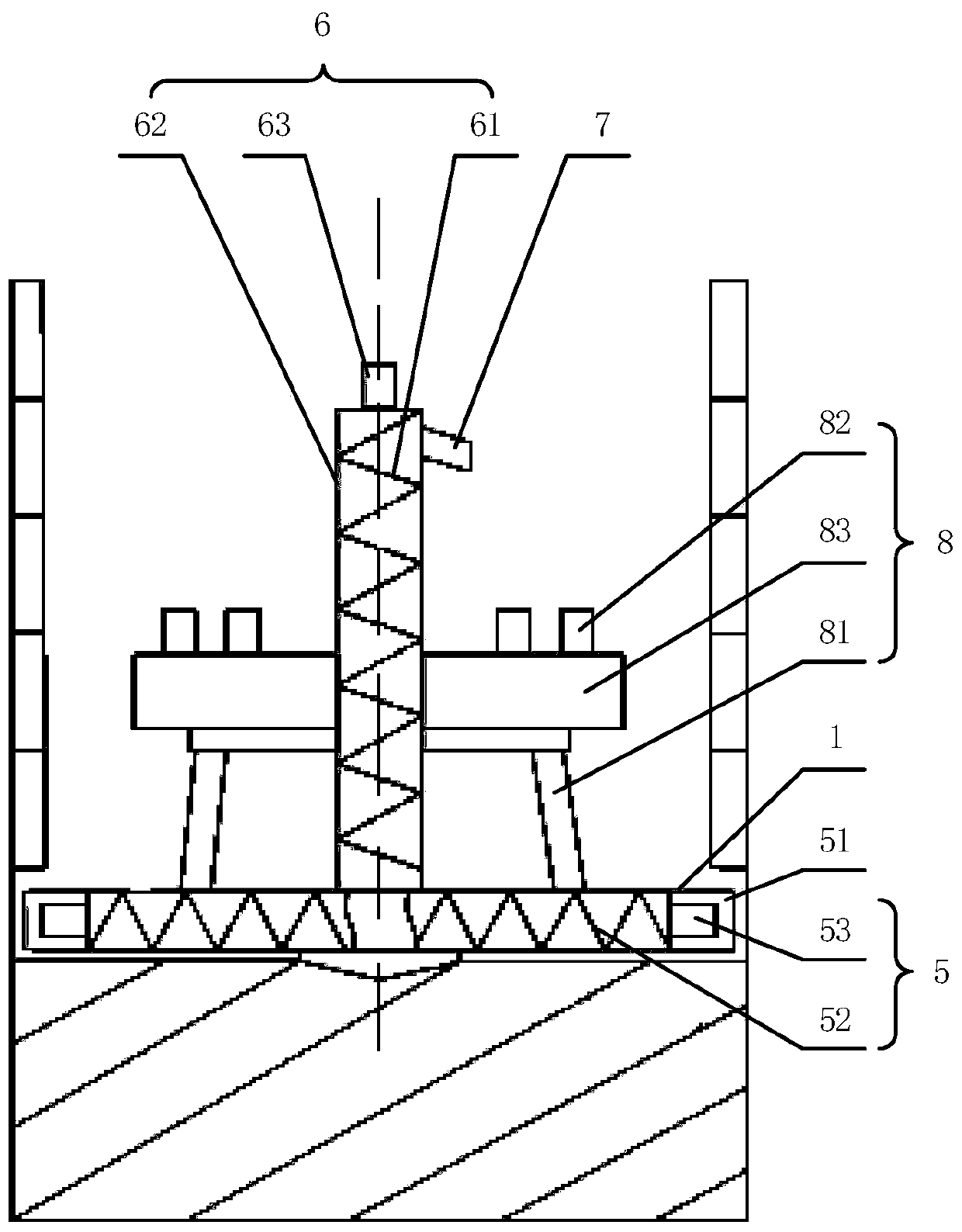

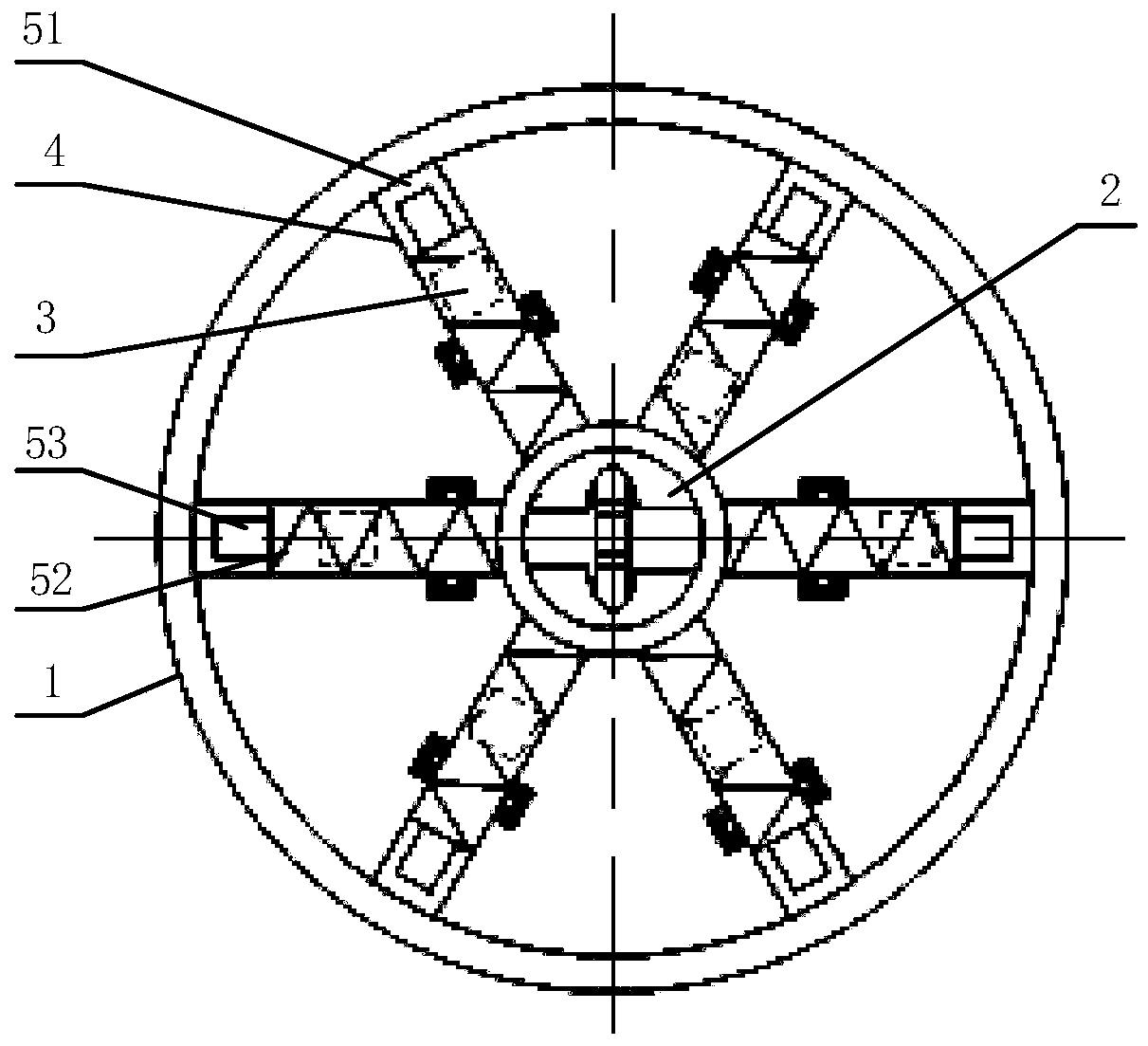

Vertical shaft TBM device

ActiveCN103452566AFast constructionImprove excavation efficiencyTunnelsEngineeringTunnel boring machine

The invention discloses a vertical shaft TBM (Tunnel Boring Machine) device. The front part of a girder of the vertical shaft TBM device is provided with a cutter head driving system; rotation of the cutter head driving system drives a cutter head to rotate; the cutter head adopts a cavity-type hemi-ellipsoidal structure; a stirring device is arranged in a cavity of the cutter head; a cutter is arranged on the outer surface of the cutter head; a feed inlet is reserved on the cutter head; a slurry input pipeline and a slagging pipeline are arranged in the girder; the front end of the slurry input pipeline extends to the front end face of the cutter head; the rear end part of the cutter head is provided with the slagging pipeline communicated with the cavity of the cutter head; the rear end of the slagging pipeline extends out of the girder; both sides of the girder are provided with propelling systems; each propelling system comprises a thrust oil cylinder; one end of each thrust oil cylinder is hinged to the girder and the other end of the thrust oil cylinder extends backwards and is hinged with a supporting shoe; a telescopic oil cylinder for pressing two supporting shoes on the wall of a vertical shaft is arranged between the two supporting shoes. According to the invention, full-face integral forming of the vertical shaft can be implemented and the tunneling speed of the vertical shaft is greatly improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

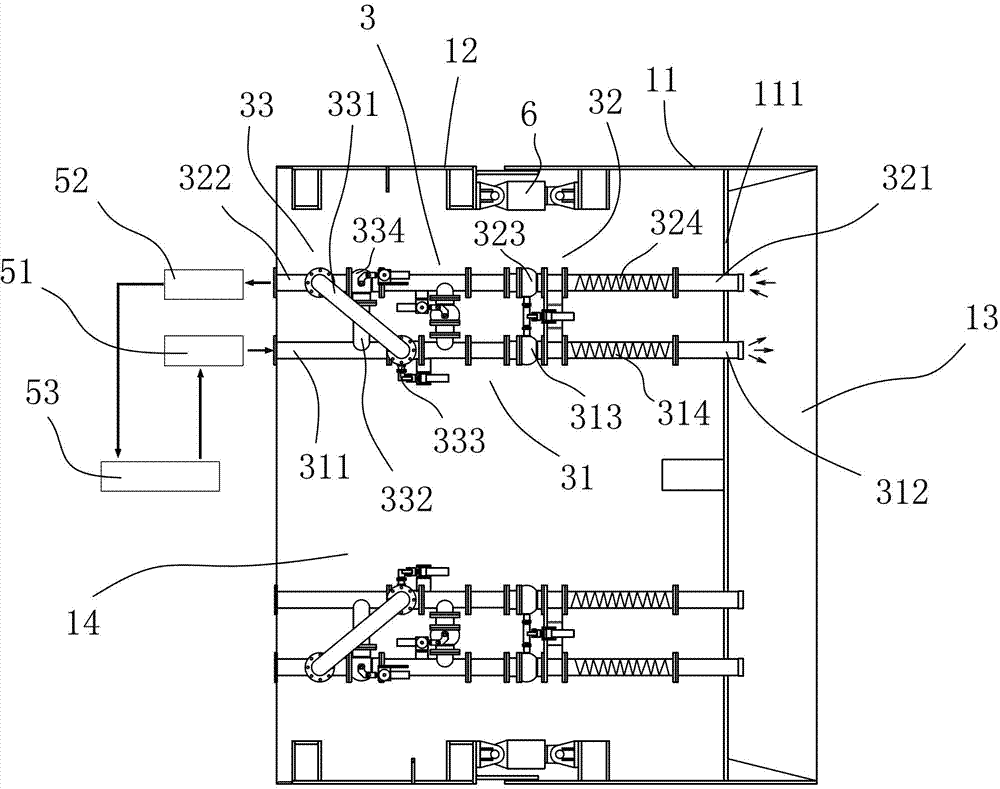

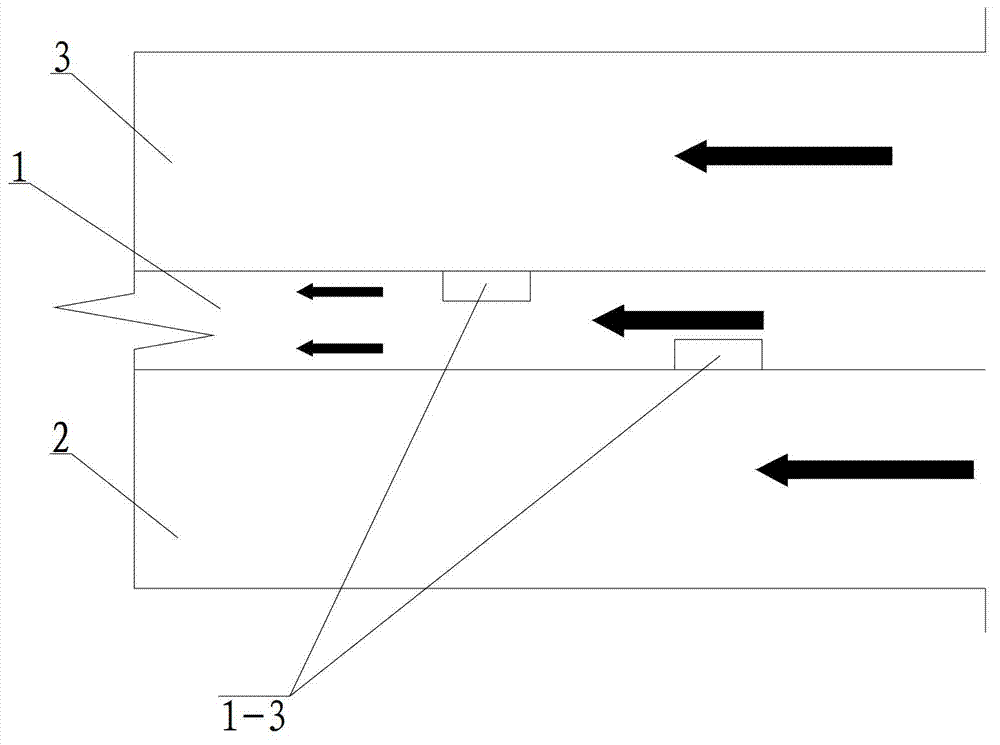

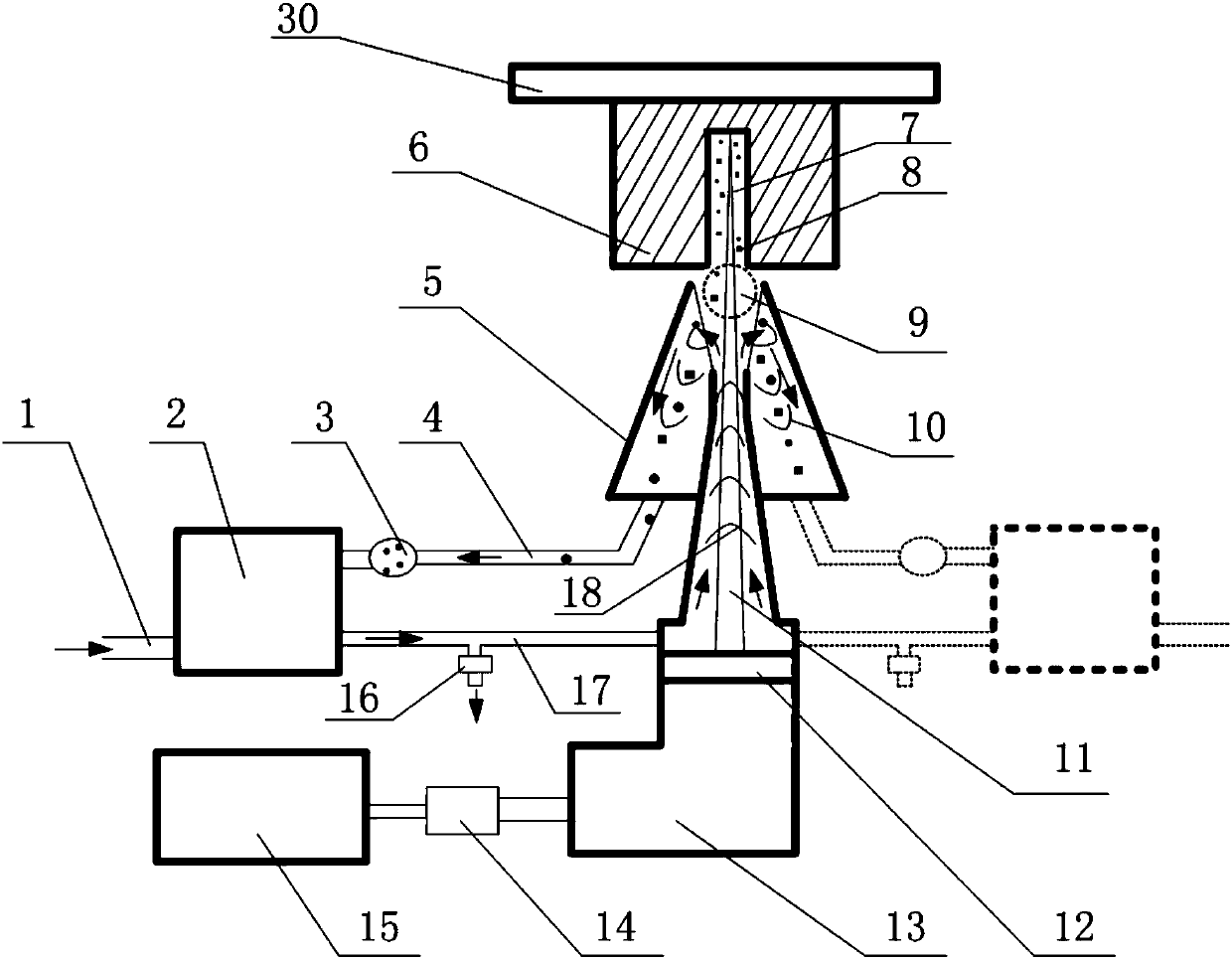

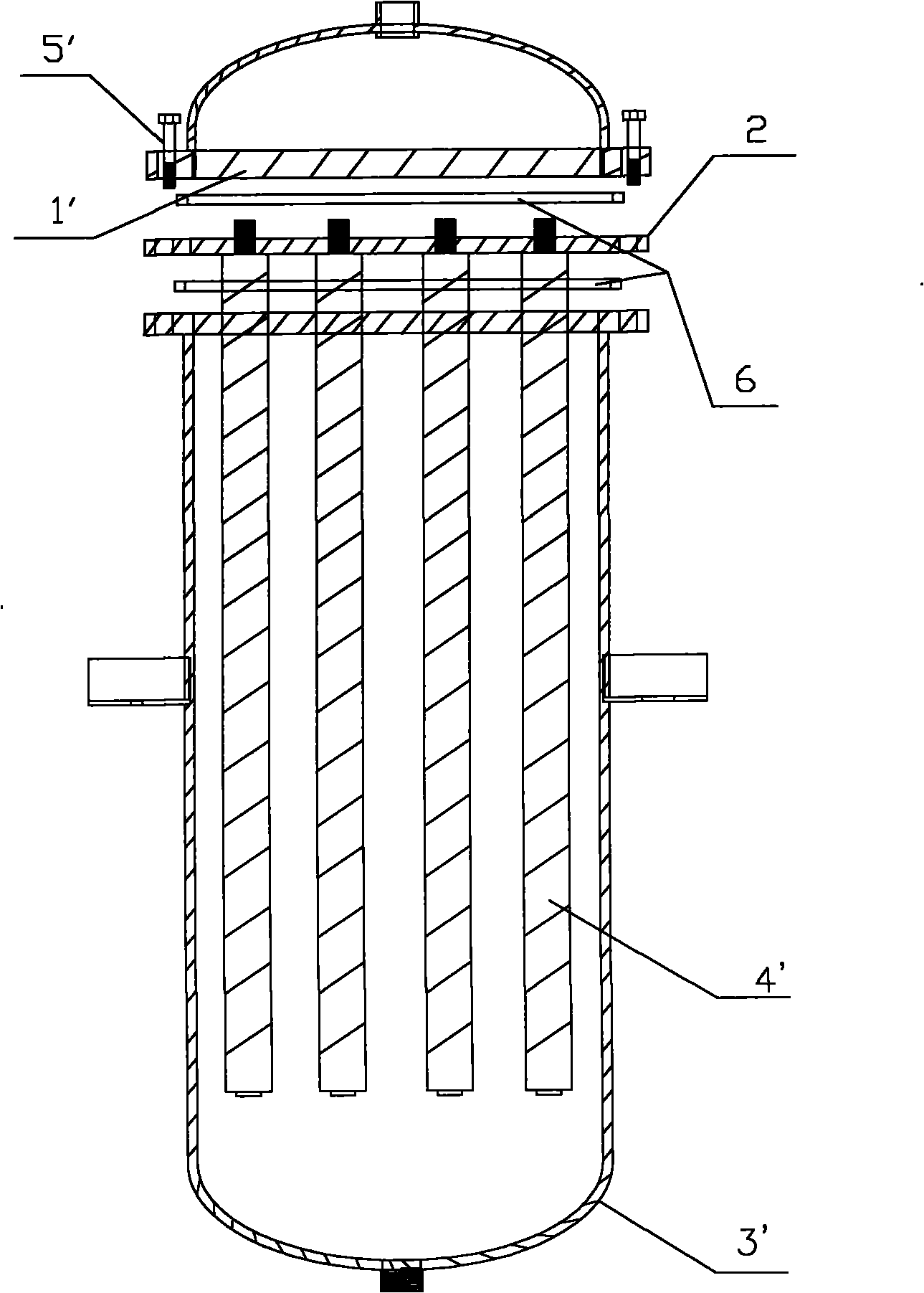

Slurry balance type tube push bench and circulative slurry deslagging method

InactiveCN102966793AImprove slag discharge efficiencySimple and safe operationPipe laying and repairSludgeSlurry

The invention discloses a slurry balance type tube push bench and a circulative slurry deslagging method utilizing the same. The internal cavity of the slurry balance type tube push bench is internally provided with at least one driving system and at least one circulative deslagging system used for discharging sludge in a slurry cavity, wherein the output end of the driving system is connected with a cutter head by penetrating though a partition plate; and in the process of performing circulative slurry deslagging by virtue of the slurry balance type tube push bench, the slurry is discharged into the slurry cavity by virtue of the at least one circulative deslagging system; the soil and slurry in the slurry cavity are fully mixed to form sludge, the sludge in the slurry cavity is discharged into a slurry pool by virtue of at least one circulative deslagging system, and the discharged sludge precipitates in the slurry pool so as to form slurry. The slurry balance type tube push bench and a circulative slurry deslagging method utilizing the slurry balance type tube push bench can be used for improving the deslagging efficiency, are simple, convenient and reliable in construction, are safe and convenient in operation, and are used in the field of non-excavation engineering construction.

Owner:GUANGDONG FOUND ENG GRP CO LTD

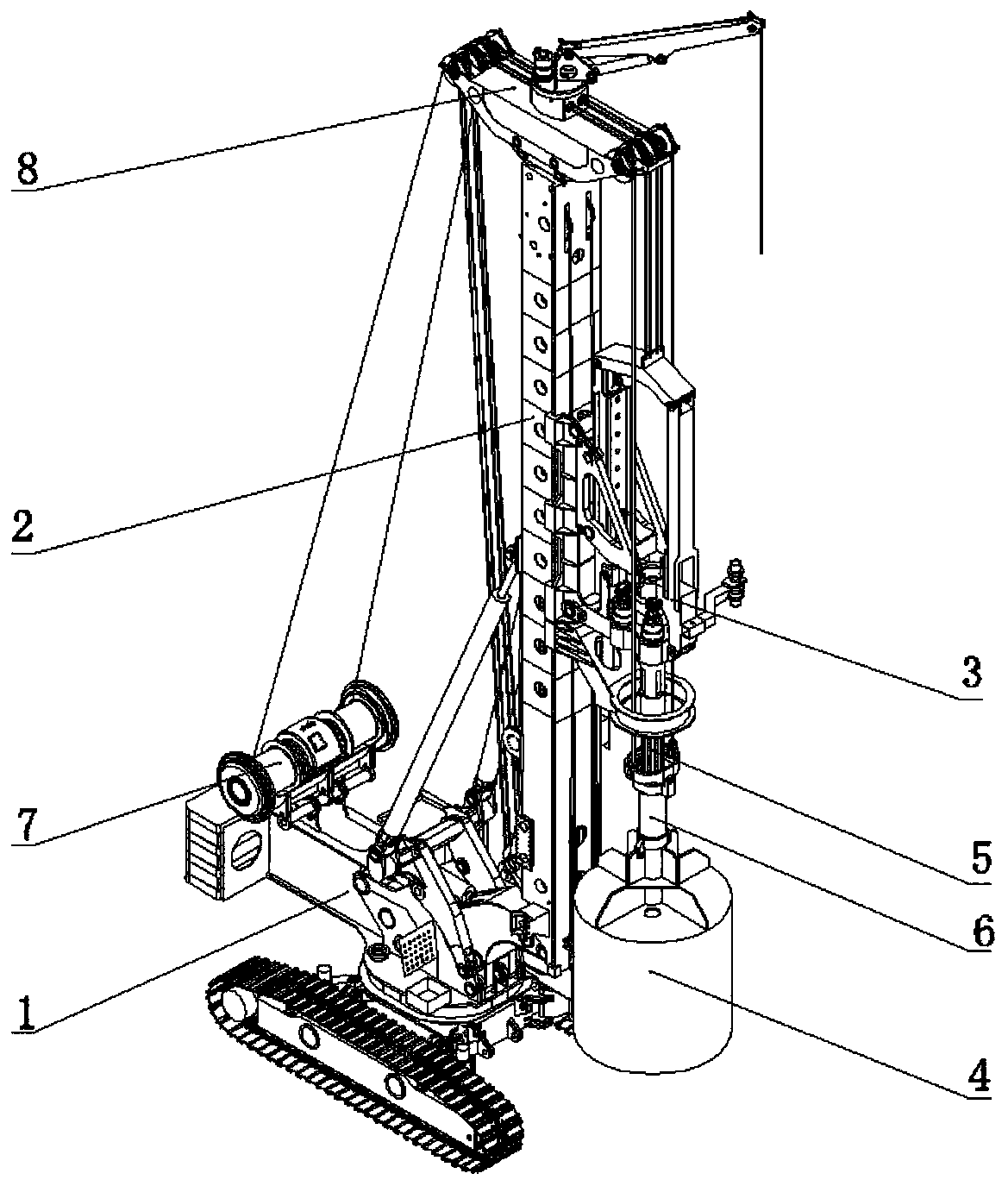

Engineering driller capable of efficiently discharging slag

PendingCN109989705AImprove slag discharge efficiencyAvoid entanglementDrill bitsDrilling rodsDischarge efficiencySlag

An engineering driller capable of efficiently discharging slag relates to the technical field of drilling equipment, and is mainly used for solving the problem of low deslagging efficiency of drillingslag. The engineering driller capable of efficiently discharging slag comprises a driller body, a drill tower is mounted at the front end of the driller body, a power head is mounted on the drill tower, a drilling tool assembly is mounted on the power head, and the drilling tool assembly comprises a rotary excavating drill bit, a drill rod assembly and a slip ring assembly; the rotary excavatingdrill bit comprises a barrel, an upper cover is arranged at the top of the barrel, a torque transmission sleeve is fixedly arranged in the center of the upper cover, and a torque transmission internalspline is fixedly arranged in the torque transmission sleeve; the drill rod assembly comprises a torque transmission drill rod and a plurality of upper drill rods, the slip ring assembly comprises astatic ring and a movable ring, a winch used for lifting the rotary excavating drill bit is fixedly installed on the driller body, and a pulley block is installed at the top of the drill tower. The rotary excavating drill bit can be pulled out of the drill rod to discharge drilling slag, the slag discharging efficiency of drilling is greatly improved, energy is saved, and the engineering driller has the advantages of being simple in structure, convenient to use, high in slag discharging efficiency, capable of saving energy and the like.

Owner:天明(南京)智能装备科技有限公司

Large-pitch special-shaped spiral drill rod

InactiveCN106894771AImprove slagging functionIncreased drilling depthDrilling rodsDrilling casingsSpiral bladeScrew thread

The invention relates to a large-pitch special-shaped helical drill rod, which includes a drill rod body provided with a medium conveying channel inside. The two ends of the drill rod body are respectively provided with external threads and internal threads. Composed of arc segments, the straight segment and the arc segment are arranged at intervals, the head and tail are connected with each other and the number is equal, the arc segment is not less than two, the outer wall of the drill rod is provided with a spiral groove, the A helical blade is arranged in the helical groove. The purpose of the present invention is to increase the slag discharge capacity by setting the spiral blade in the spiral groove on the outer wall of the drill pipe, and prevent the coal dust from being blocked in the gap between the drill pipe and the coal wall to cause gas accumulation, difficult drilling, and even drill sticking , Drill drop and other accidents in the hole, improve the hole formation rate and drilling efficiency; by nitriding, high-frequency quenching, phosphating or nickel-phosphorus treatment on the internal and external threads of the drill pipe body, avoid The internal and external threads are bonded together, which makes the removal of the drill pipe easier.

Owner:CHONGQING UNIV OF ARTS & SCI

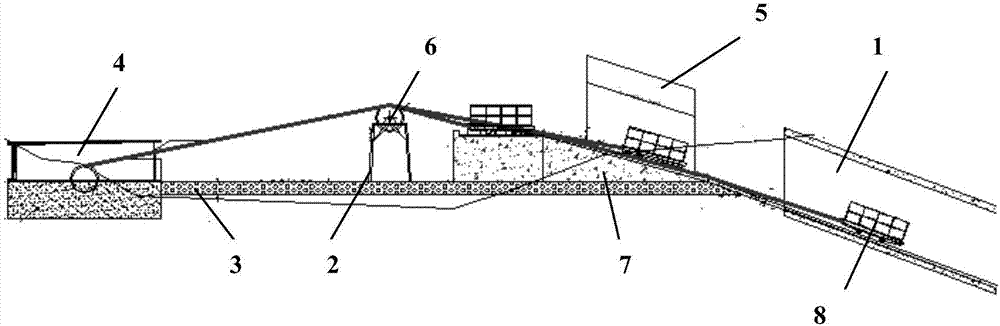

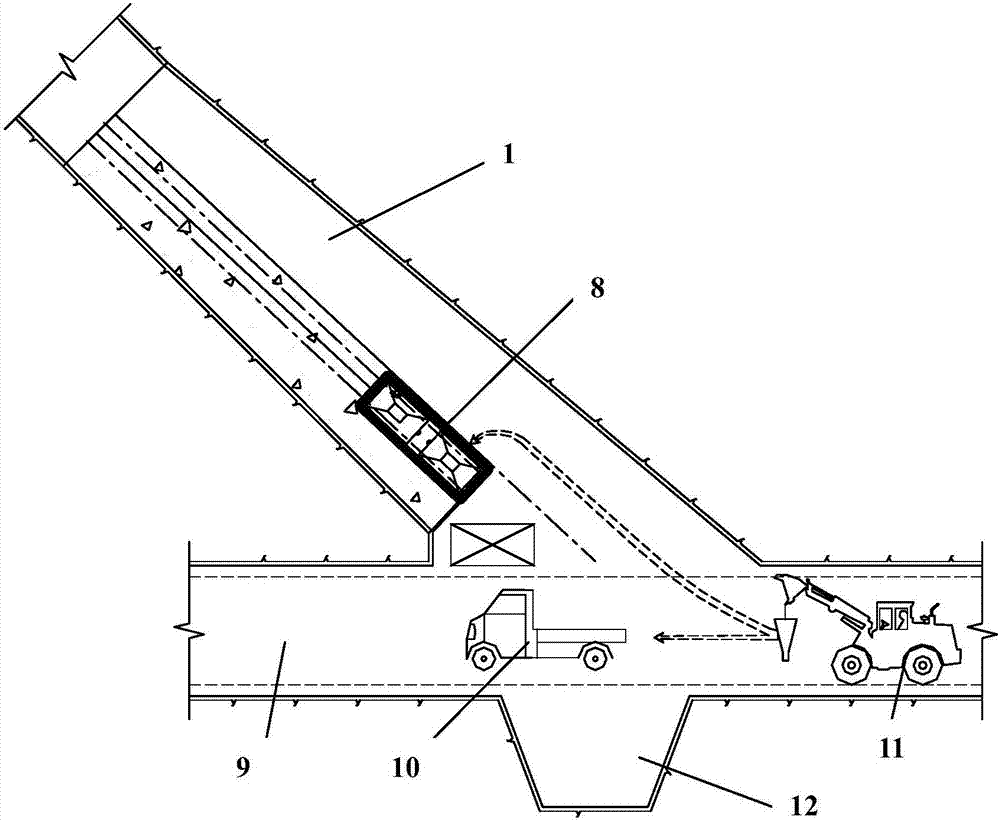

Large-gradient small-section underground cavity excavating construction method

InactiveCN107387094ALittle construction disturbanceReduce construction costsTunnelsDischarge efficiencySlag

The invention discloses a large-gradient small-section underground cavity excavating construction method. By combination of inclined shaft track transport and main tunnel trackless transport, people-oriented safety construction is realized, construction safety is guaranteed, construction interferences are reduced, construction cost is saved, and safety accidents in a construction process are avoided. In construction, the construction progress requirement is met, slag discharging efficiency is improved, and inclined shaft transport is no longer an engineering construction progress restriction factor. According to engineering construction practice, the construction method is effective and has advantages of technical reliability, high mechanization degree, convenience in operation, safety, reliability, high slag discharging efficiency, low operating cost and high economic benefits, thereby having a certain reference significance and popularization value in similar engineering construction.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

Smelting water receiving and residue filtering tank

ActiveCN104390467ASpeed up the outflowImprove outflow efficiencyCharge manipulationContinuous operationWaste management

The invention relates to a smelting water receiving and residue filtering tank. The smelting water receiving and residue filtering tank comprises a tank body, wherein the tank body is made of a refractory material and comprises a first branch tank and a second branch tank; a partition plate which can move in the vertical direction is arranged between the first branch tank and the second branch tank; a water inlet is formed in an inner side face of a side part of the first branch tank, and an opening of the water inlet faces upwards; a water receiving opening, corresponding to the water inlet, is formed in an outer side face of the side part of the first branch tank; the water receiving opening is communicated with the water inlet; a residue discharging opening is formed in one side part adjacent to the side part of the water receiving opening; at least one fan is arranged at the upper end of the other side part adjacent to the side part of the water receiving opening; a water drainage opening is formed in a side part of the second branch tank. Compared with the prior art, the smelting water receiving and residue filtering tank has the advantages that dross floats quickly, the residue removing efficiency is high and continuous operation can be realized.

Owner:XINGHUA GUANGFU METAL PROD

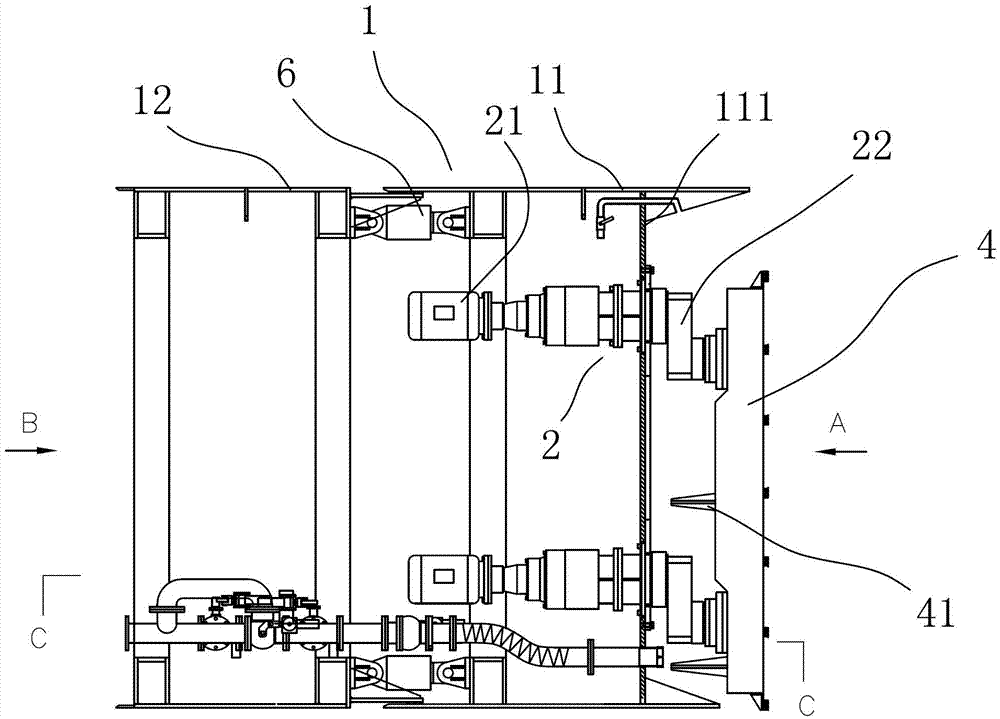

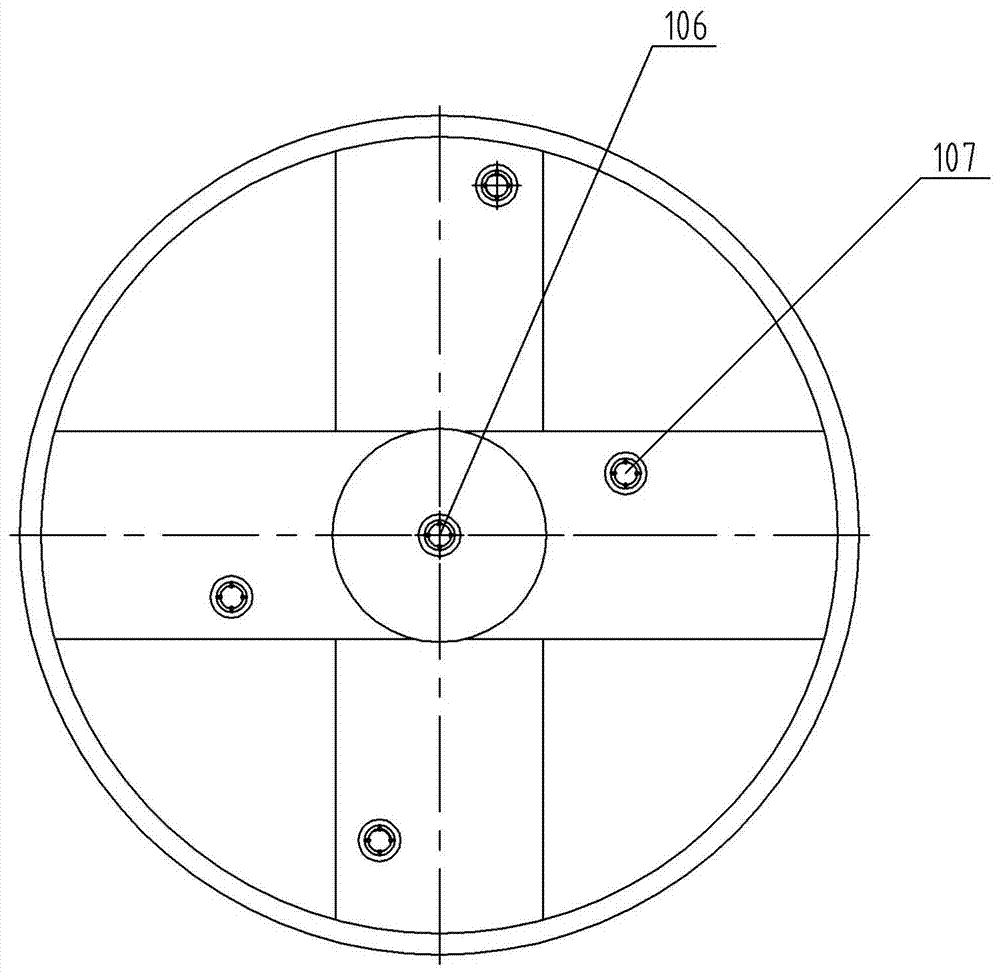

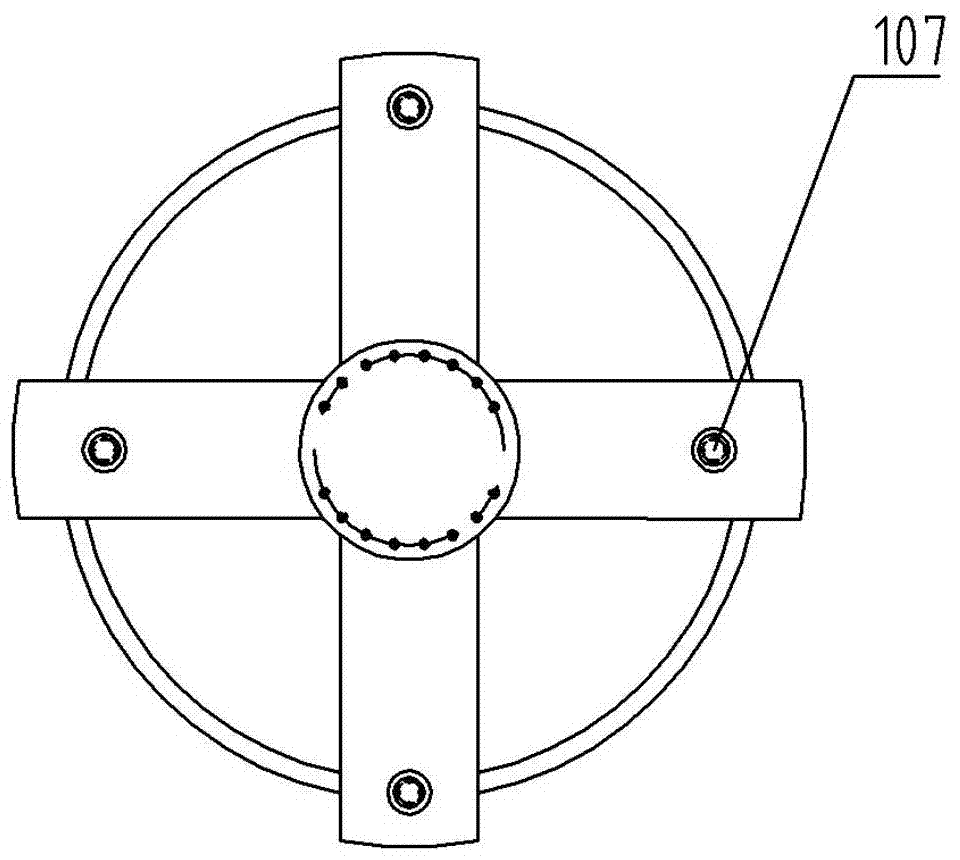

Variable-position shearing and breaking device of compound stratum pipe pushing machine

The invention discloses a variable-position shearing and breaking device of a compound stratum pipe pushing machine and relates to the technical field of tunneling. A tool disc is arranged at the front end of the pipe pushing machine, the output end of a main driving device is fixedly connected with a flange of the tool disc, and the main driving device is fixedly connected with a pressure cabin partition of an anterior shield cone ring. When the main driving device drives the tool disc to rotate along a rotary central shaft, an active breaking plate of the tool disc rotates along a bracket and generate alternative shear space relative to the anterior shield cone ring, large rock can be passively stopped by a baffle when rotating along with the active breaking plate and can be broken into many small rocks by shearing force as the principal and extrusion force as the auxiliary, and the small broken rocks can be discharged to a discharge device via slag holes in a trapezoidal slag discharge plate, and a bus of the conical surface formed spatially is parallel to the bus of the spatial conical surface formed by the anterior shield cone ring when the bracket rotates. Accordingly, large rocks can be broken by the variable-position shear space, and invalid rolling is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

Device and method for removing hole bottom sediment of pore-forming pouring pile

The invention discloses a device and a method for removing hole bottom sediment of a pore-forming pouring pile. The device comprises an air supply mechanism, a liquid supply mechanism, a hose, a sediment discharging pipe and an inclined pipe; the sediment discharging pipe comprises a vertical sediment discharging pipe part and a horizontal sediment discharging pipe part; the vertical sediment discharging pipe part is communicated with the air supply mechanism through the hose, and comprises an upper pipe, a middle pipe and a lower pipe; the middle pipe comprises an outer pipe and an inner pipe of which the central axes are overlapped; the upper pipe is connected with the outer pipe or the inner pipe through screw threads; the lower pipe is also connected with the outer pipe or the inner pipe through screw threads; the inclined pipe penetrates through the inner pipe and the outer pipe downwards; an air outlet of the air supply mechanism is communicated with the inner pipe through the hose and the inclined pipe in sequence. By adoption of the structure, the sediment removal efficiency is improved effectively, but energy consumption is not increased obviously.

Owner:CHINA MCC5 GROUP CORP

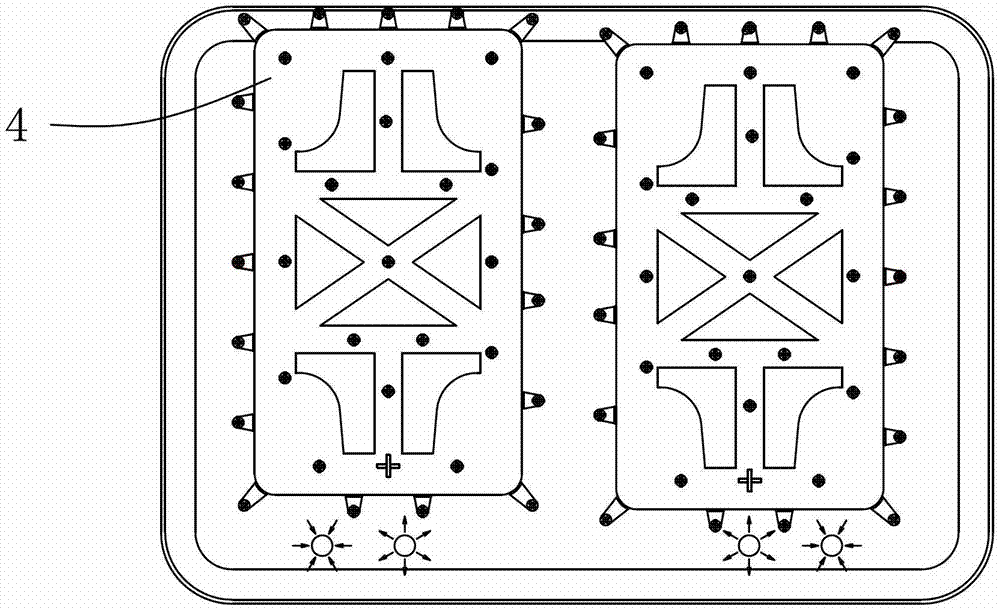

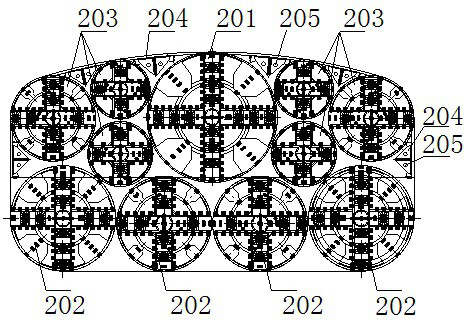

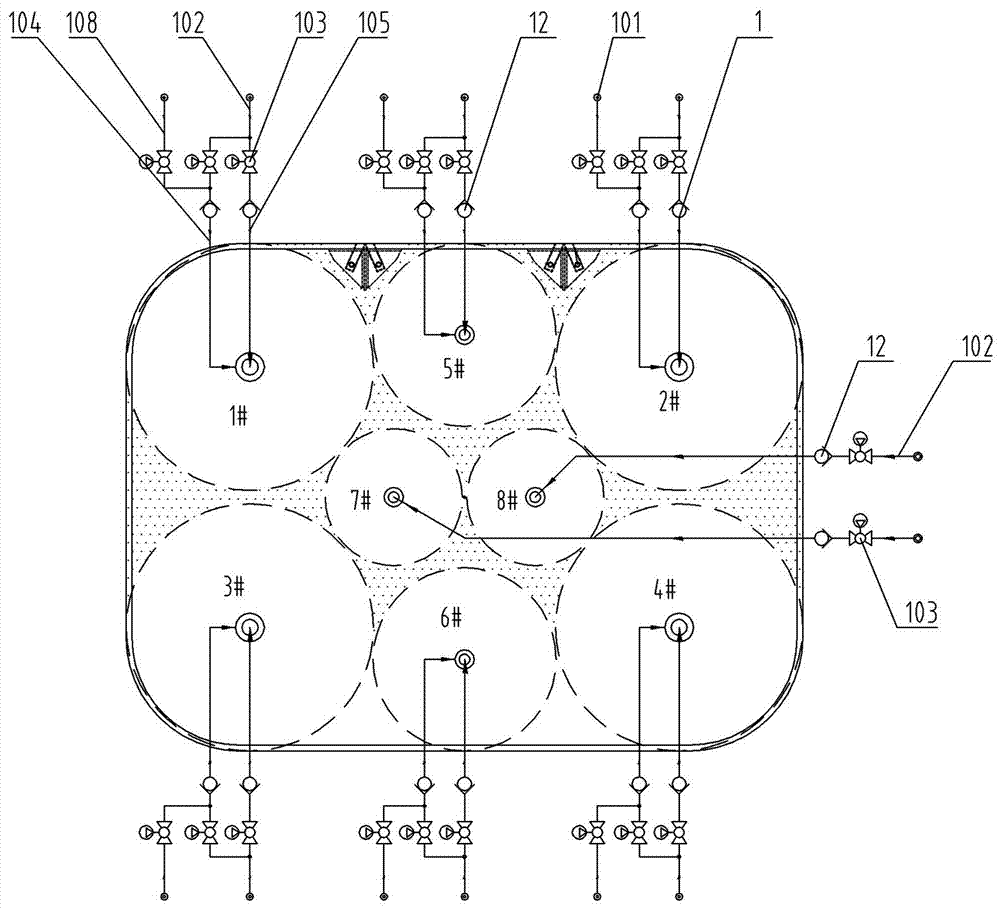

Multi-cutter-disk heading machine

ActiveCN111997645APlay a supporting roleIncrease the scope of geological applicationTunnelsRock breakingEnvironmental geology

The invention discloses a multi-cutter-disk heading machine which comprises an outer shell. A drive system is arranged at the front end of the outer shell and is connected with an excavation mechanism; the excavation mechanism is provided with a deslagging system and a muck conveying system; the excavation mechanism comprises a plurality of cutter disks; the multiple cutter disks are arranged at the front end of the outer shell in parallel; the orthographic projections of the cutter disks form a shape consistent to the cross section of the outer shell; a gap between each two adjacent cutter disks and a gap between each cutter disk and the outer shell are excavation blind areas; a blind area conical plate is arranged at the position, opposite to each excavation blind area, on the outer shell; the deslagging system comprises a blind area screw conveyer; a rock breaking structure opposite to each excavation blind area is arranged at the front end of the blind area screw conveyer; and theblind area screw conveyer is connected with the muck conveying system. The multi-cutter-disk heading machine provided by the invention not only can achieve the maximum effects of excavation and stirring, but also plays a role in supporting a palm surface to prevent collapse. Meanwhile, the geological application scope of the extra-large rectangular section heading equipment over 14 meters is expanded.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Large-span underground space structure and construction method thereof

InactiveCN106640155AFlexible layoutTo achieve the function needsUnderground chambersSpatial structureUnderground tunnel

The invention belongs to the technical field of underground tunneling engineering, particularly relates to a large-span underground space structure and a construction method thereof, and provides the underground tunneling space structure and the construction method thereof which have a small influence on social environments and effectively, so that the technical problem that construction difficulty of underground space structure engineering is large is effectively solved. The large-span underground space structure is mainly composed of an underground tunnel structure and underground pipe curtain structures, wherein the underground tunnel structure is mainly composed of a plurality of longitudinal going-ahead tunnels excavated by a shield tunneling machine or a tube push bench; the transverse underground pipe curtain structures which are each composed of a plurality of pipe bodies are arranged between the adjacent longitudinal going-ahead tunnels correspondingly, wherein the pipe bodies are arranged by adopting a linear or arched structure; and therefore, excavating and slag tapping efficiency of excavating equipment is greatly improved, the mechanized construction extent of underground engineering is greatly improved, construction efficiency is improved, and safety of underground engineering construction is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Jacking pipe rescue equipment for coal mine collapse roadway and jacking pipe rescue method for coal mine collapse roadway

PendingCN110735661ASolve complexityAddress usability issuesUnderground chambersTunnel liningSlagArchitectural engineering

The invention relates to the technical field of rescue of a mine collapse roadway, and provides jacking pipe rescue equipment for the coal mine collapse roadway. A machine body and jacking pipes are movably arranged on a main jacking mechanism rail; the machine body comprises a cutterhead arranged at the front end of the machine body and a cutterhead driving device driving the cutterhead to rotate; the jacking pipes are in end-to-end butt joint one by one to form a jacking pipe group; the head end of the jacking pipe group is abutted against the tail end of the machine body; a material conveying rail is arranged outside the machine body, the plurality of jacking pipes and a main jacking mechanism; and the material conveying rail is arranged in a way of extending from the positions of the jacking pipes to the outside of the roadway, so that carbide slag cut by the cutterhead can be conveyed to a slag conveying vehicle through a scraper conveyor, and is transported out of the roadway through a slag conveying vehicle rail and the material conveying rail. The equipment can solve the problems of low slag discharging efficiency and the like. The invention also provides a jacking pipe rescue method for the coal mine collapse roadway.

Owner:CCTEG SHENYANG RES INST

Method for quickening construction of multiple-arch tunnel

ActiveCN103244127ASave the construction period of entering the holeShorten the construction periodTunnelsDischarge efficiencyBuilding construction

The invention relates to a method for quickening construction of a multiple-arch tunnel. The method includes: firstly, pre-supporting a middle pilot tunnel; and secondly, excavating the middle pilot tunnel, constructing a left main tunnel, a right main tunnel, and a cover arch and a long pipe roof of the middle pilot tunnel, setting a widened segment allowing a loader to turn around in the middle of the middle pilot tunnel, and after the middle pilot tunnel is through, constructing a middle partition wall from an entrance of the middle pilot tunnel to an exit of the middle pilot tunnel. The method has the advantages that construction entering is assisted by advanced small pilot pipes so that entering construction period of the middle pilot tunnel is reduced; the section of the middle pilot tunnel is locally enlarged, the loader is used with a dumper for construction, and accordingly residue discharging efficiency is improved greatly; the construction method of the middle partition wall is modified, so that the main tunnels can be constructed in advance; and the middle partition wall and the main tunnels are constructed in parallel, time and space are more reasonable, and accordingly personnel idleness and machine idleness are avoided and construction speed is increased.

Owner:CHINA COMM NORTH ROAD & BRIDGE +1

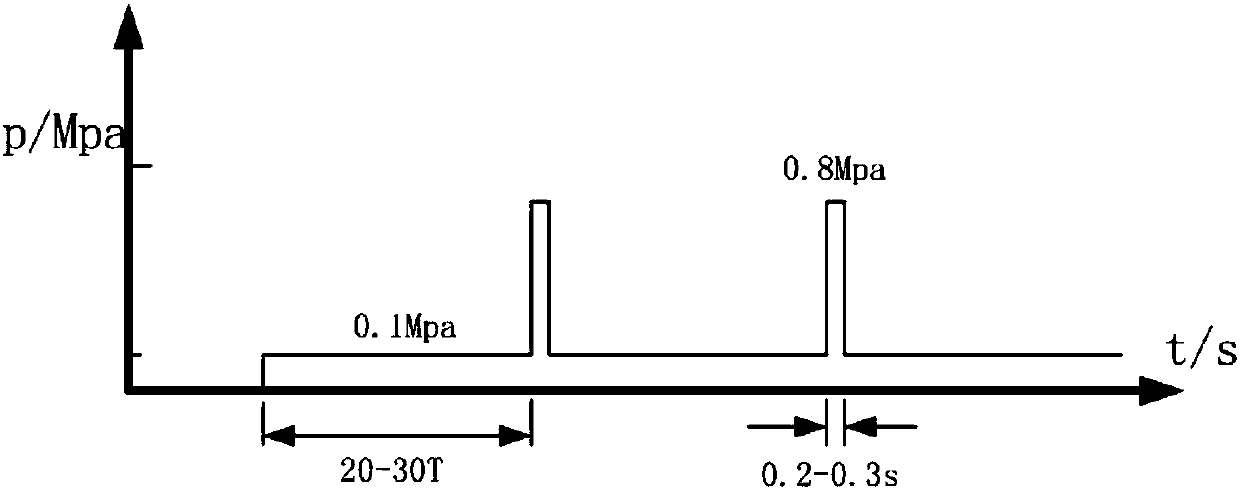

Muck improving system of multi-cutter tunnel boring machine

The invention belongs to the technical field of tunnel engineering construction equipment, and particularly relates to a muck improving system of a multi-cutter tunnel boring machine. The muck improving system comprises a cutter improving system, a clay injecting system, an excavation dead zone scouring system and a general control mechanism, collaborative or independent working of the cutter improving system, the clay injecting system and the excavation dead zone scouring system is controlled by the general control system, the cutter improving system can realize injection of muck improvers for multiple cutters, the cutters are independent from each other, and different improvers can be selectively injected to the cutters; the clay injection system can inject clay to the top of a clay bin, the upper portion of a residue discharging port and areas prone to residue accumulation on two sides of the bottom of an anterior shield partition to respectively realize functions of supporting an arch crown, reducing jacking friction force and wrapping large-particle muck; the excavation dead zone scouring system realizes muck cutting of excavation dead zones and assists in muck improving through high-pressure water.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Double-power quick connector screw drilling rod

InactiveCN106854981ANot easy to dropRealize dual power slag dischargeDrilling rodsDrilling casingsEngineeringHigh pressure

The invention discloses a helical drill pipe with dual power quick joint, which comprises a main body of the drill pipe. The main body of the drill pipe is provided with helical blades. Both ends of the main body of the drill pipe are respectively provided with a male joint and a female joint. The main body of the male joint is a hexagonal prism. , the inside of the female connector is a hexagonal hole corresponding to the male connector, the middle part of the male connector is provided with blind holes, the lock tongue is installed in the hole, and the bottom surface of the lock tongue is provided with a compression spring; the end surface of the male connector is processed with a small blind hole for installation limit Screws in order to limit the telescopic range of the lock tongue. A circular through hole is provided on the axial side of the female joint to cooperate with the lock tongue. A cylindrical groove is provided at the bottom of the female joint. The O-ring is radially sealed with the straight shaft end of the male joint; the end faces of the male joint and the female joint have a central through hole along the axial direction for the passage of high-pressure air. The drill pipe of the present invention adopts the dual power combination of wind slagging and mechanical slagging to improve the efficiency of slagging in soft coal seams, which is safe, reliable and has high working efficiency.

Owner:TAIYUAN UNIV OF TECH

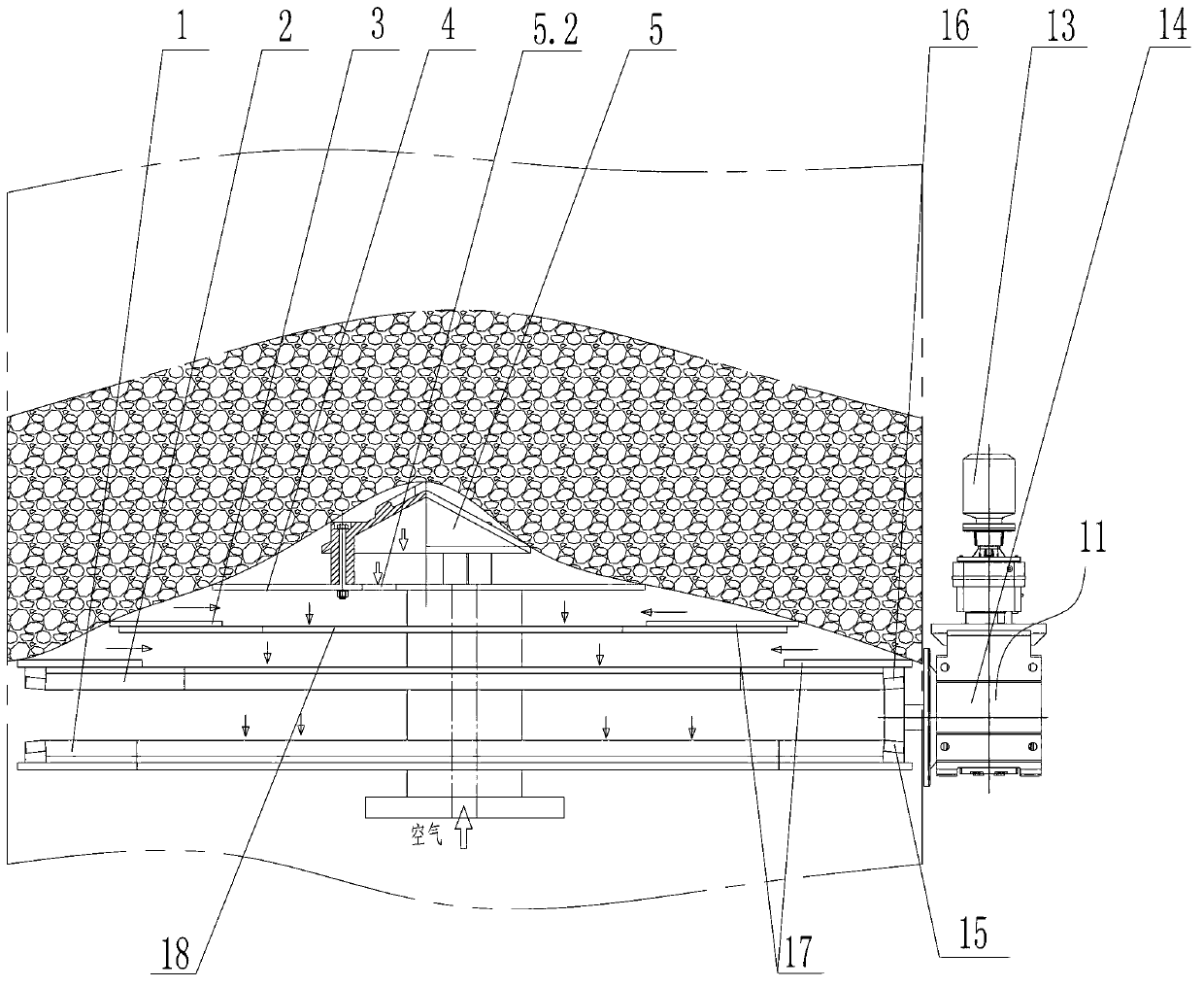

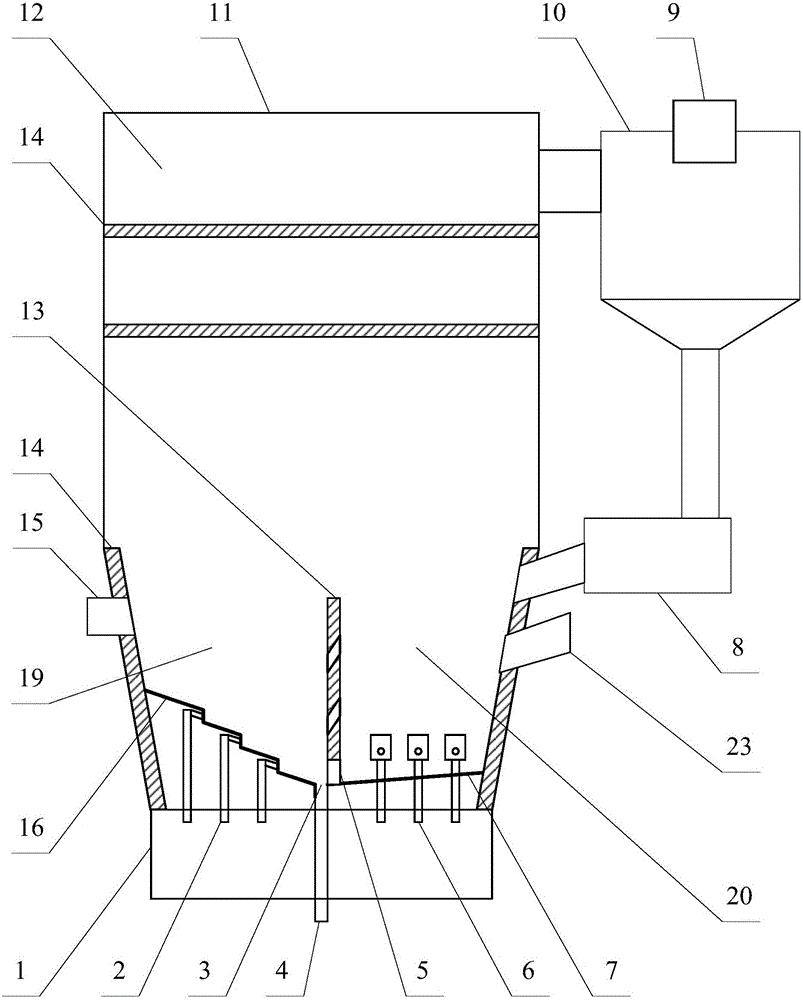

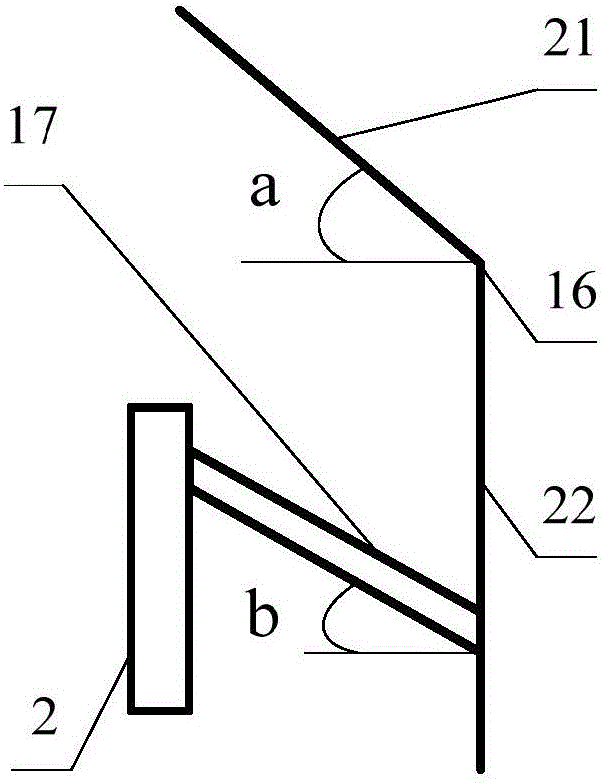

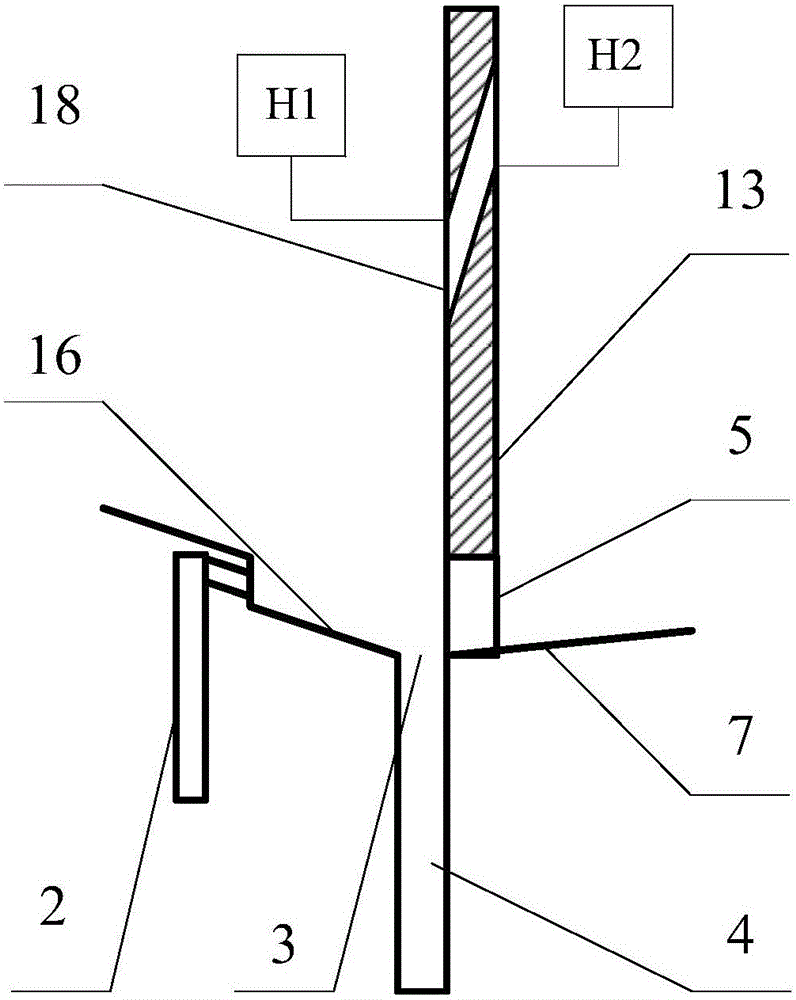

Fluidized bed garbage incinerator

ActiveCN104990086ASolve poor slag dischargeSolve the problem of frequent shutdown of the furnace for slag dischargeFluidized bed combustionIncinerator apparatusFailure rateFluidized bed

The invention provides a fluidized bed garbage incinerator which comprises a hearth, and the hearth is surrounded by a water wall to be of a sealed structure. A partition wall is arranged on the lower portion of the hearth and divides the lower space of the hearth into a residue discharging zone and a fluidizing zone. A garbage inlet is formed in the residue discharging zone, and an inclined stepping type air distributor is obliquely arranged at the bottom of the residue discharging zone; a residue discharging opening is formed in the lowest position of the inclined stepping type air distributor, and directional caps are arranged on the inclined stepping type air distributor, wherein the air outlets of the directional caps are towards the residue discharging opening. Objects with large grain sizes and density in the residue discharging zone move towards the residue discharging opening along the inclined stepping type air distributor through the gravity effect and the blowing effect of the directional caps and then are discharged through a residue discharging pipe. The problems that a traditional fluidized bed garbage incinerator is difficult in residue discharging and high in failure rate and needs to discharge residues frequently after being stopped are effectively solved, the availability, safety, stability and economical efficiency of the fluidized bed garbage incinerator are improved, and operation and maintenance cost is greatly lowered.

Owner:JIMEI UNIV +1

Slag discharging device and pulverized coal burner using same

InactiveCN101865474AClear in timeImprove combustion efficiencyPulverulent fuel combustion burnersCombustion chamberSlag

The invention discloses a slag discharging device which is installed on a pulverized coal burner to realize the purpose of discharging slag in real time. The slag discharging device comprises an upper slag discharging structure and a lower slag discharging structure, wherein the upper slag discharging structure comprises an upper push rod, an upper slag pushing plate and a driving power device I, wherein the upper push rod is driven by the driving power device I to push and scrape the slag accumulated on the surface on the upper part of the inner cavity wall of a burning chamber by front-and-back reciprocating slide; and the lower slag discharging structure comprises a lower push rod, a lower slag pushing plate and a driving power device II, wherein the lower push rod is driven by the driving power device II to push the slag accumulated on the surface of the lower part of the inner cavity wall of the burning chamber to a slag outlet at the back part of the burning chamber. The slag pushing device of the invention is designed according to colloidal materials in the burning process and agglutination mode of coal slag in the cavity and fully considers different structures and characteristics of the upper cavity part and the lower cavity part; and the slag discharging device has the advantages of high slag discharging efficiency, compact integral structure and convenient operation and can ensure that coal slag in the cavity can be cleared in time, thereby effectively improving the burning efficiency of pulverized coal.

Owner:重庆市牛人科技有限公司

Ultrafast laser film hole efficient processing method and device

PendingCN108031991ASolve problems that cannot be ruled outEasy to operateLaser beam welding apparatusLaser processingPositive pressure

The invention belongs to the technical field of laser processing, and particularly relates to an ultrafast laser film hole efficient processing method and device. Laser beams emitted by a laser deviceare transmitted vertically upwards after going through a scanning device and being focused, a preprocessing part is fixed on a workbench vertically downwards, the laser beams are enabled to align ata to-be-processed part, and laser scans to generate micropores; the method further includes: generating a negative pressure domain around micropore orifices, and generating a positive pressure domainalong the middle way of a laser path. The problem that hole making efficiency is lowered due to the fact that residue and plasma gather and cannot be discharged during processing of high-depth-diameter-ratio micropores.

Owner:XIAN MICROMACH TECH CO LTD

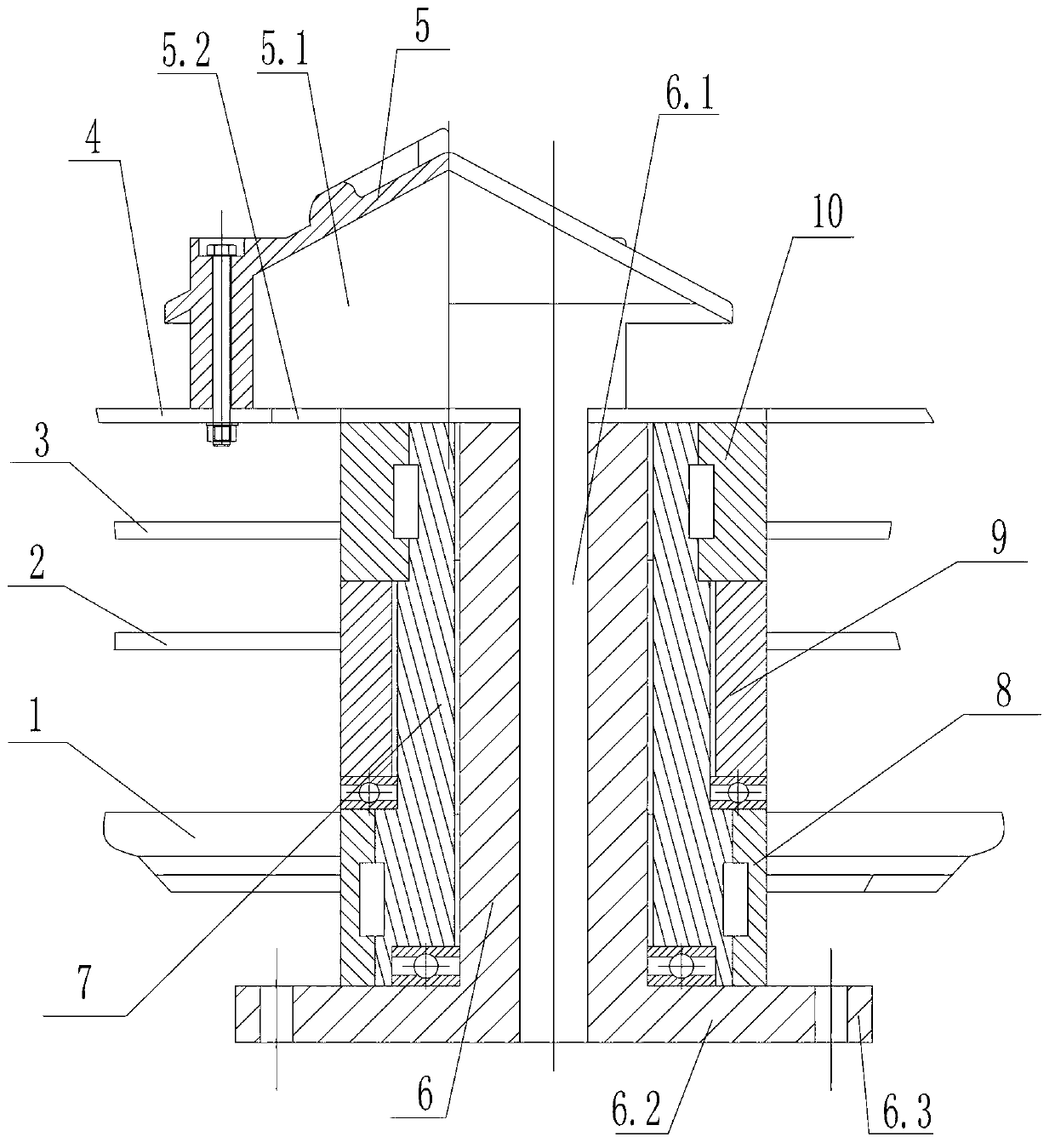

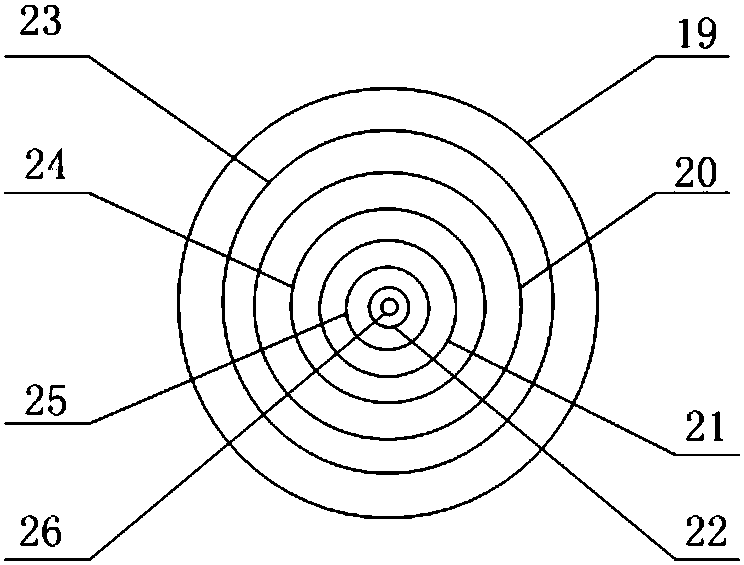

Muck discharging device of full-face tunnel boring machine for vertical shaft

The invention discloses a muck discharging device of a full-face tunnel boring machine for a vertical shaft. The device comprises an axial muck outlet formed in the center of a cutter head, a plurality of muck feeding spokes extending in the radial direction of the cutter head, radial spiral conveying assemblies arranged on the muck feeding spokes and an axial spiral conveying assembly extending in the axial direction of the cutter head and communicating with the axial muck outlet, wherein the muck feeding spokes are provided with muck inlets. Muck cut by a cutter on the cutter head flows intothe radial spiral conveying assemblies from the muck inlets, and flows into the axial muck outlet under conveying of the radial spiral conveying assemblies; the muck flowing into the axial muck outlet is discharged to the surface by the axial spiral conveying assembly. In the tunnel boring process of the shaft, the muck is continuously conveyed by the radial spiral conveying assemblies and the axial spiral conveying assembly, the influence of height difference on the muck discharging speed is avoided, and continuous and stable muck discharging can be achieved. Therefore, the muck dischargingdevice has high muck discharging efficiency, rich functions, simple and compact structure and good adaptability. The invention also discloses the full-face tunnel boring machine, comprising the muck discharging device, for the vertical shaft.

Owner:CHINA RAILWAY CONSTR HEAVY IND

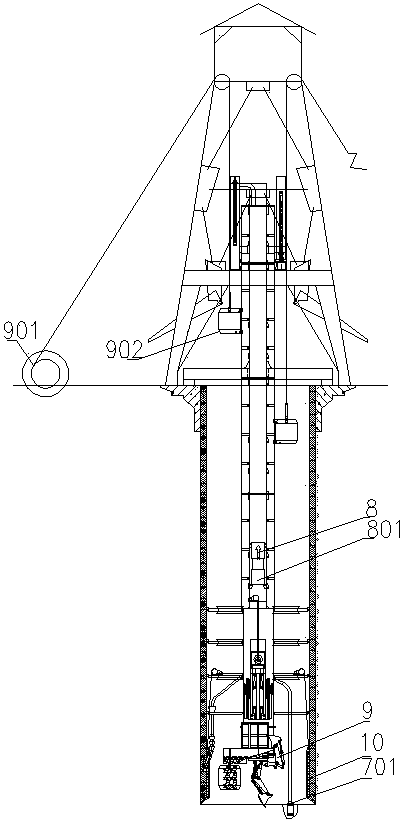

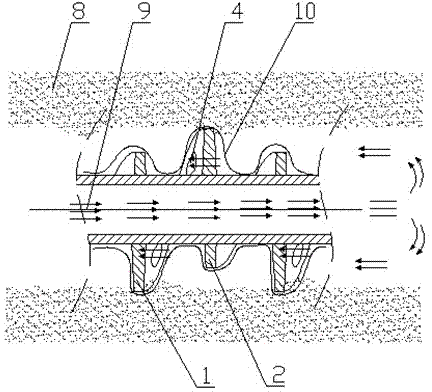

Drilling interval variable-diameter spiral drill pipe for soft-hard composite coal seam

InactiveCN104213853AFunction increaseReduce build-up cloggingDrilling rodsDrilling casingsSpiral bladeCoal

The invention discloses a drilling interval variable-diameter spiral drill pipe for a soft-hard composite coal seam. The drilling interval variable-diameter spiral drill pipe comprises a high spiral blade, a low spiral blade and a drill pipe body, wherein the high spiral blade is higher than the low spiral blade, and due to the different heights of the blades, the maximum outer diameter tangent line of the drill pipe axially forms a periodic high-low fluctuation state. According to the drilling interval variable-diameter spiral drill pipe disclosed by the invention, the migration of drilling cuttings is in a continuous fluctuation state and accumulation is not liable to cause by virtue of an interval high-low fluctuation-type deslagging space formed by the height different of the spiral blades, thus reducing the occurrence probability of accumulation blockage between conventional spiral drill pipe blades; meanwhile, air vents are formed in the high spiral blade to realize compressed air drilling, thus expanding the functions of the drill pipe. The drilling interval variable-diameter spiral drill pipe disclosed by the invention is novel in design; the characteristics of the deslagging space in a drill hole are changed, the deslagging efficiency is increased, and the problems of low drilling depth, low drilling efficiency, frequent drill hole accidents and the like of the conventional spiral drill pipe are overcome due to innovation for the section shape of the drill pipe; the drilling interval variable-diameter spiral drill pipe is especially suitable for the soft-hard composite coal seam with a firmness coefficient f of greater than 0.5 and not greater than 1.

Owner:王永龙

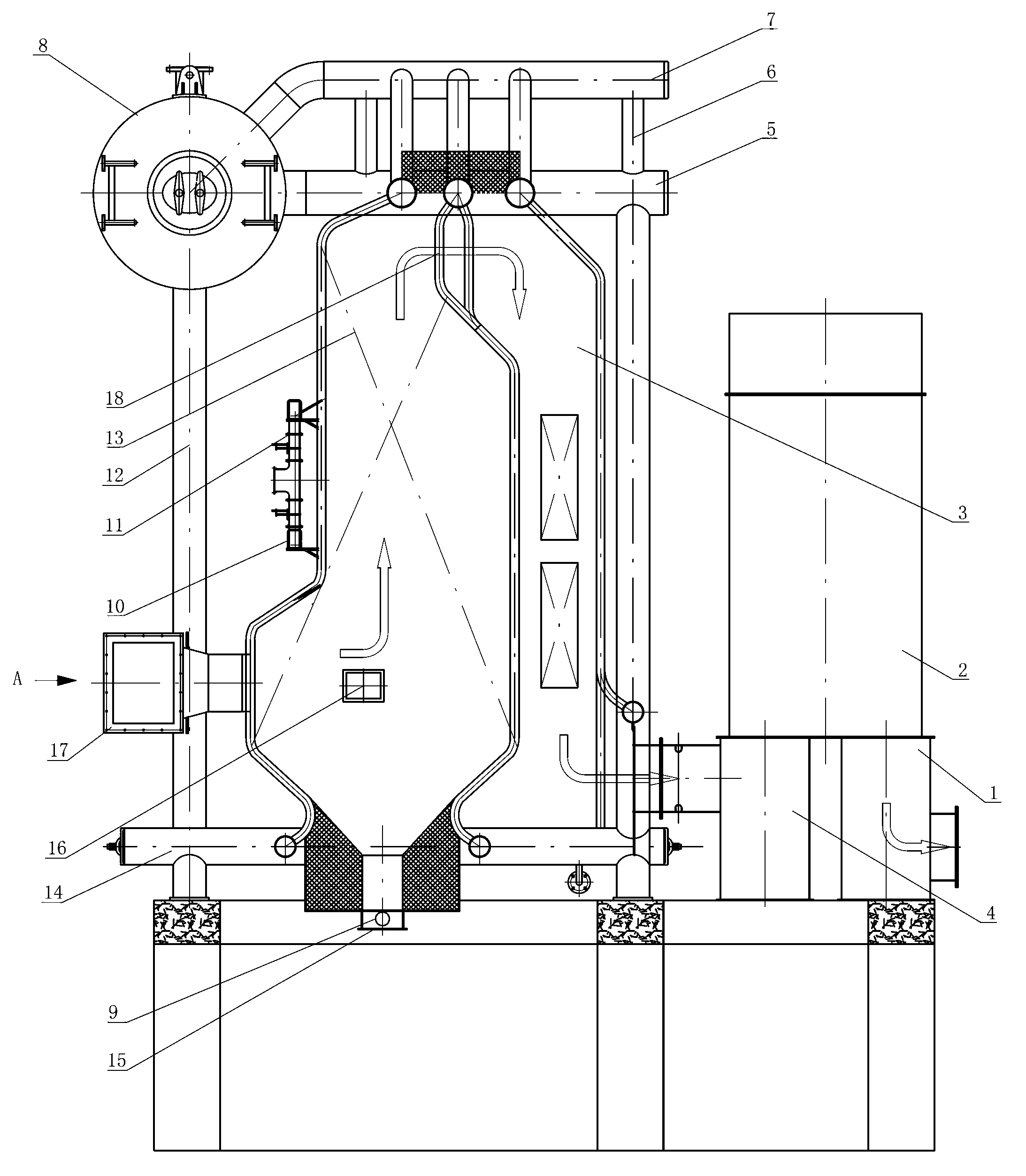

Vertical type coal dust corner tube boiler

InactiveCN103062747AFull reaction combustionImprove sealingSteam boilersAir preheaterDifferential pressure

The invention discloses a vertical type coal dust corner tube boiler which comprises a burner, a boiler furnace, a high temperature air preheater, a coal economizer, a low temperature air preheater convection tube bundle, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of a boiler body, and the upper collecting box and the top collecting box are arranged at the top of the boiler body and are communicated through a vapor communicating pipe. The vertical type coal dust corner tube boiler is characterized in that the burner is arranged in the front of the boiler body, the boiler body is of a vertical type tubular membrane type water-cooled wall structure, four down pipes are arranged at four corners, and the down pipes and two ends of the membrane type water-cooled wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged on the outer side of the membrane type water-cooled wall, the top of the convection tube bundle is communicated with a hearth smoke outlet, and the bottom of the convection tube bundle is communicated with the high temperature air preheater. The vertical type coal dust corner tube boiler has the advantages that an integral structure is compact, the appearance is arranged simply, an occupied area is small, steel consumption is small, water circulating differential pressure of the boiler is large, and water circulation is safe and reliable, and the like.

Owner:HANGZHOU JUNENG BOILER

Automatic smelting, water-containing and residue-filtering slot

InactiveCN106338207ASpeed up the outflowImprove outflow efficiencyCharge manipulationWater dischargeEngineering

The invention relates to an automatic smelting, water-containing and residue-filtering slot which comprises a slot body; the slot body is made of a refractory material; the slot body comprises a first sub slot and a second sub slot; a partition plate capable of moving in the vertical direction is arranged between the first sub slot and the second sub slot; a water inlet is formed in the inner side surface of the first sub slot; the opening of the water inlet faces upwards; a water containing hole is formed in the outer side surface, which corresponds to the side wall, of the water inlet; the water containing hole communicates with the water inlet; a residue discharge hole is formed in one side wall, which is adjacent to the side wall where the water containing hole is located; at least one fan is arranged at the upper end of the other side wall, which is adjacent to the side wall where the water containing hole is located; a water discharge hole is formed in the side wall of the second sub slot; the upper end of the partitioning plate is equipped with an air cylinder; the output shaft of the air cylinder is fixedly connected with the partition plate; and the output shaft of the air cylinder drives the partition plate to vertically move in a telescopic manner. Compared with the prior art, floating residues float quickly, residue removal efficiency is high, continuous operation can be realized, and degree of automation is high.

Owner:桂林百坚汽车附件有限公司

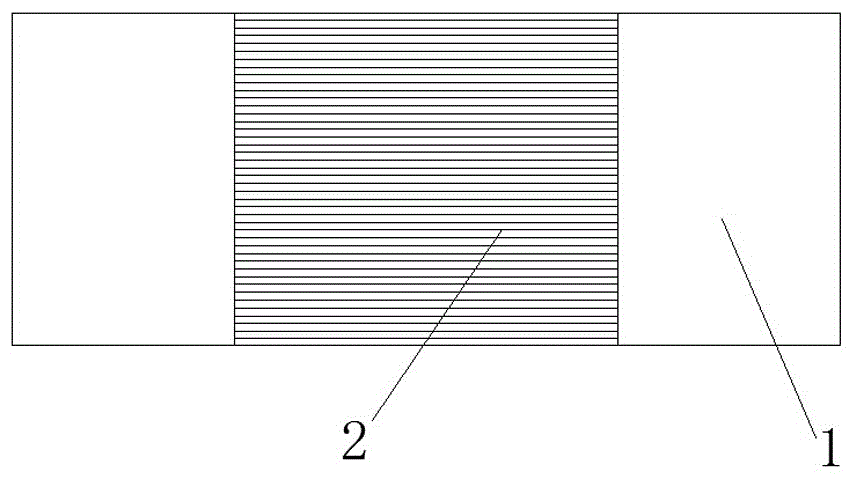

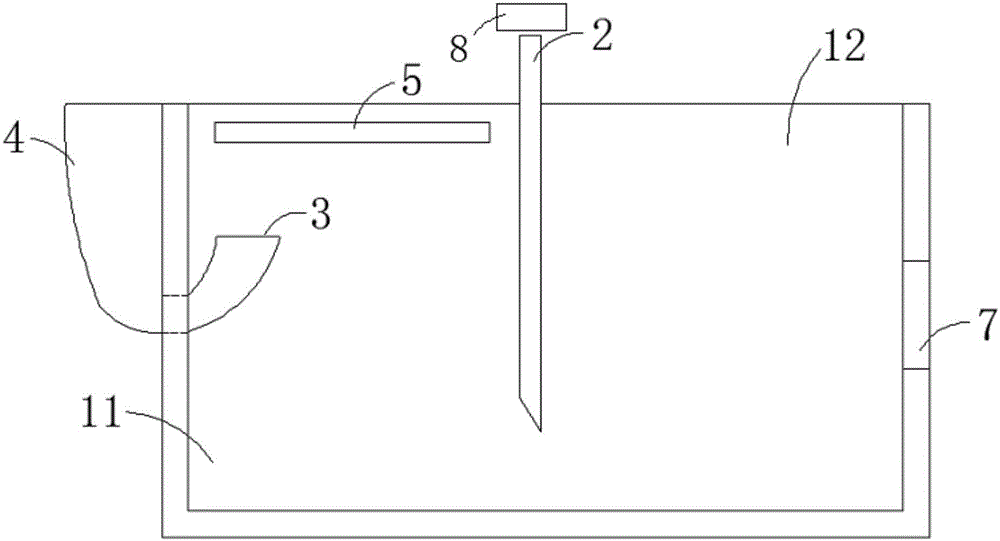

Improved structure of filter vat

ActiveCN102179090ASimple and fast operationWill not polluteStationary filtering element filtersPulp and paper industryFilter element

The invention relates to an improved structure of a filter vat. The filter vat comprises a vat body, a vat cover and a filter element; an inner cavity of the vat body is separated into an upper cavity and a lower cavity by a clapboard arranged on the lower part of the inner cavity of the vat body; the lower cavity is communicated with a clean oil outlet formed on the lower part of the vat body; the upper cavity is respectively communicated with a dirty oil inlet and a dirt outlet which are formed on the vat body; the lower end of the filter element is connected with the clapboard through a thread fastening mechanism; and the lower end face of the filter element is provided with an opening part communicated with the lower cavity. The filter vat is simple in structure, is assembled and maintained without matching of hoisting equipment and a plurality of operators, is time-saving, labor-saving, high-efficiency, quick, and low in assembly and maintenance cost, and cannot make the dirty oil and dirt scatter outside the filter vat so as to avoid polluting the ambient environment.

Owner:江苏福斯利特环保科技有限公司

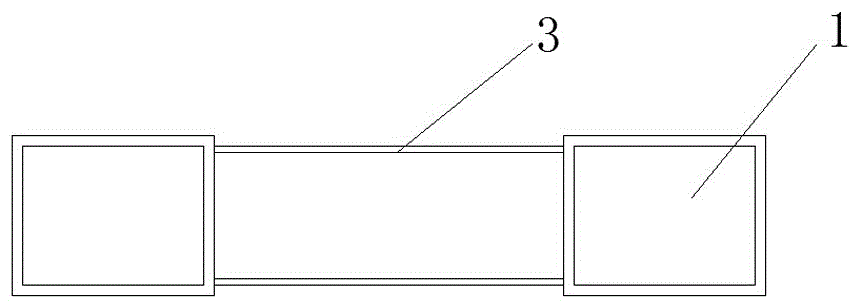

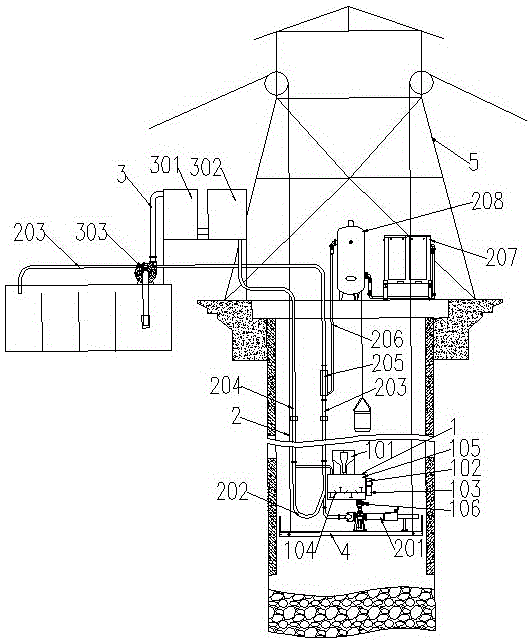

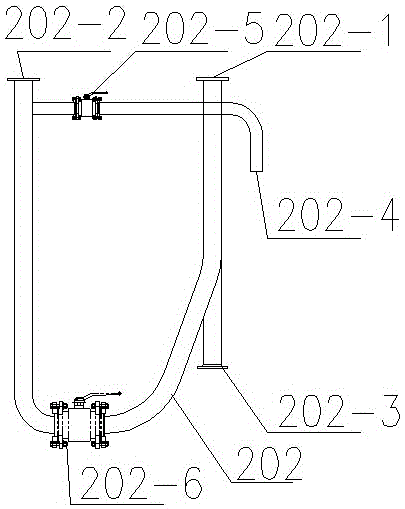

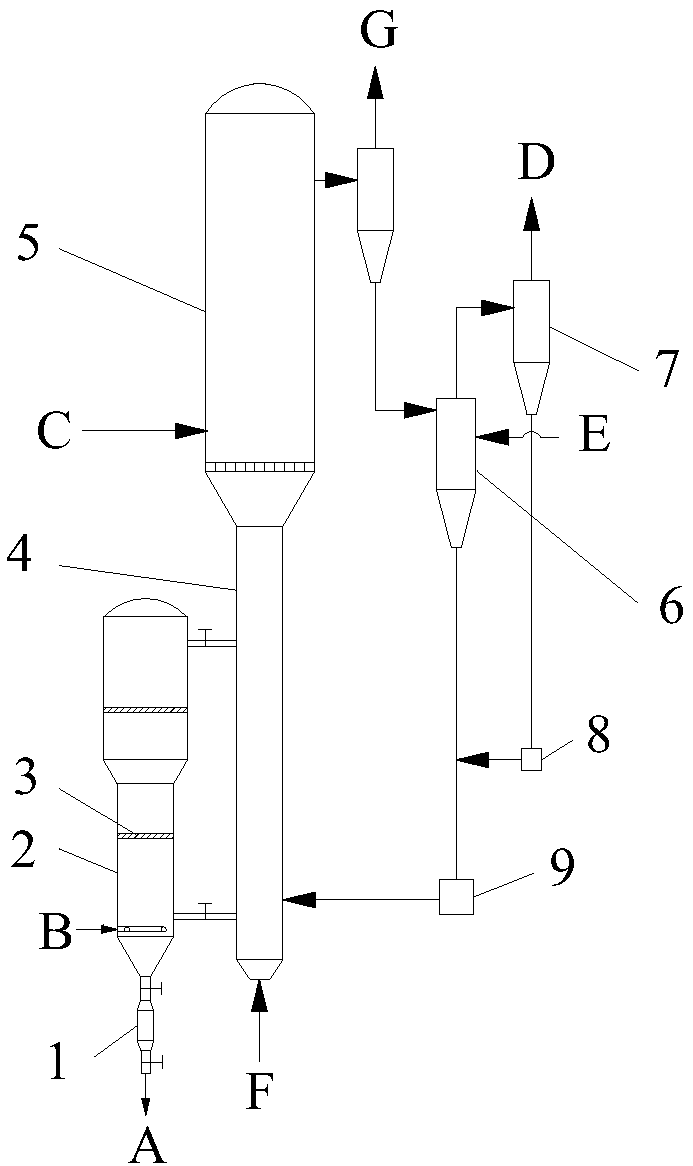

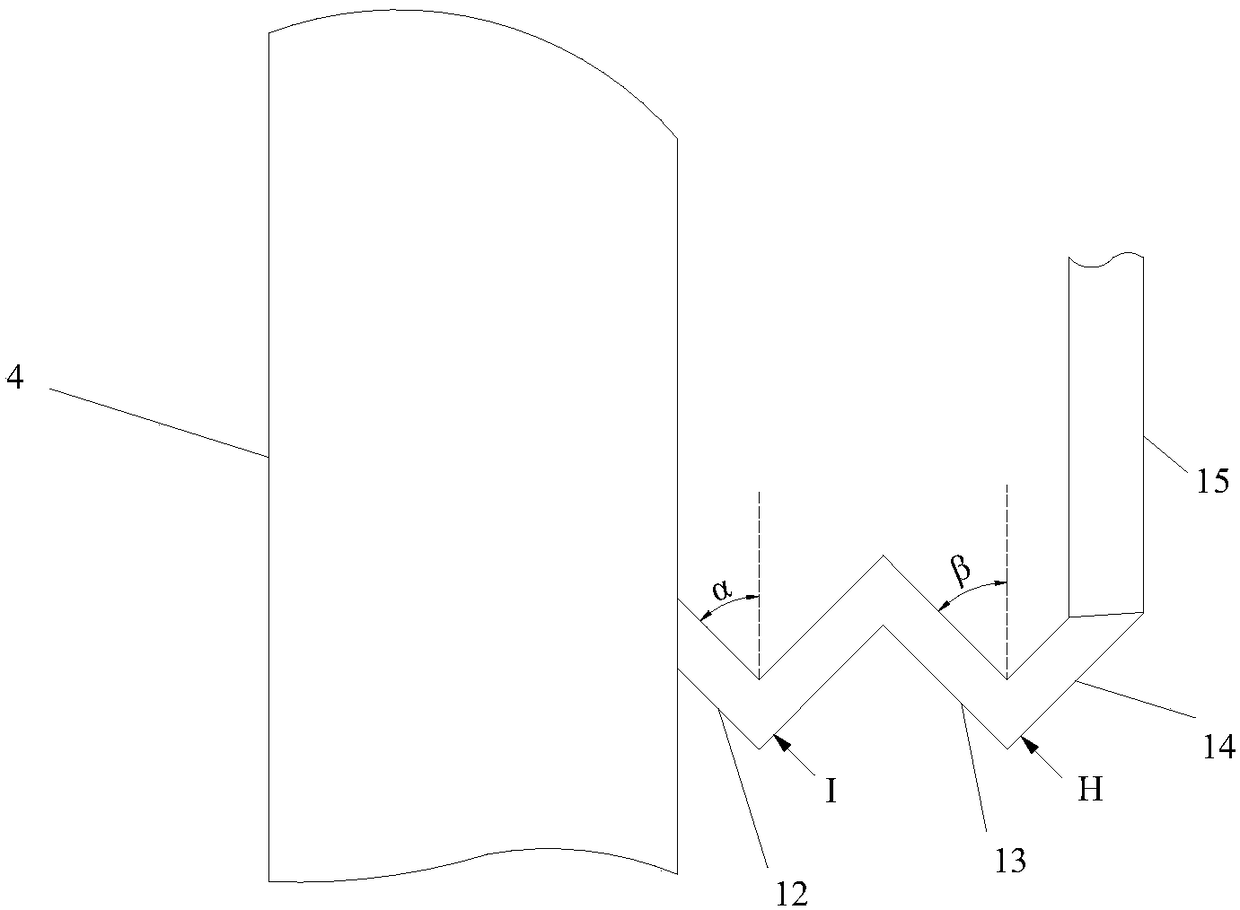

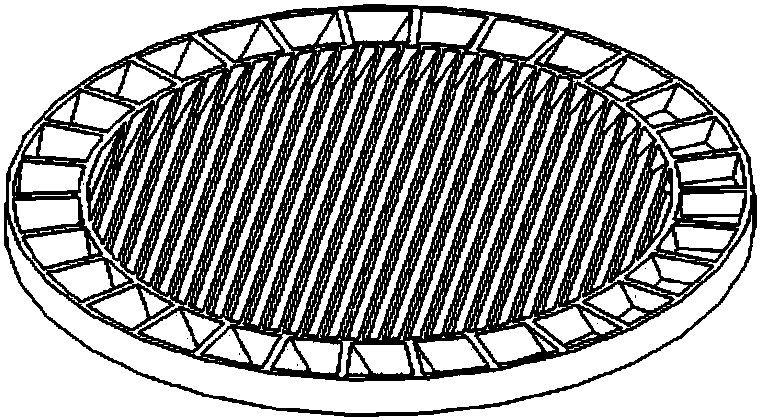

U-shaped continuous deslagging equipment for vertical shaft

The invention discloses U-shaped continuous deslagging equipment for a vertical shaft. The U-shaped continuous deslagging equipment comprises a residual soil slurrying system, a residual soil transportation system, a slurry separation system, a shaft bottom hanging scaffold and a headframe, wherein the shaft bottom hanging scaffold is hung on the headframe; the slurry separation system is arranged outside the vertical shaft; the residual soil slurrying system is arranged on the shaft bottom hanging scaffold; a slurry discharging hole of the residual soil slurrying system is connected with a slurry feeding hole of the residual soil transportation system; a slurry discharging hole of the residual soil transportation system is connected with a slurry feeding hole of the slurry separation system; a slurry discharging hole of the residual soil transportation system is connected with the residual soil slurrying system; and a slurry discharging hole of the slurry separation system is connected with the slurry feeding hole of the residual soil transportation system. According to the U-shaped continuous deslagging equipment, an underground slurry circulating channel is constructed by using a U-shaped pipe and other equipment through a gas lifting method, residual soil is injected to the U-shaped pipe through a grouting pump, is transported to the ground through the high-speed flowing slurry and is cleared after being separated by the slurry separation system, and the slurry is recycled. The U-shaped continuous deslagging equipment is simple in structure, automatic and continuous deslagging is realized, and the deslagging efficiency is increased.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

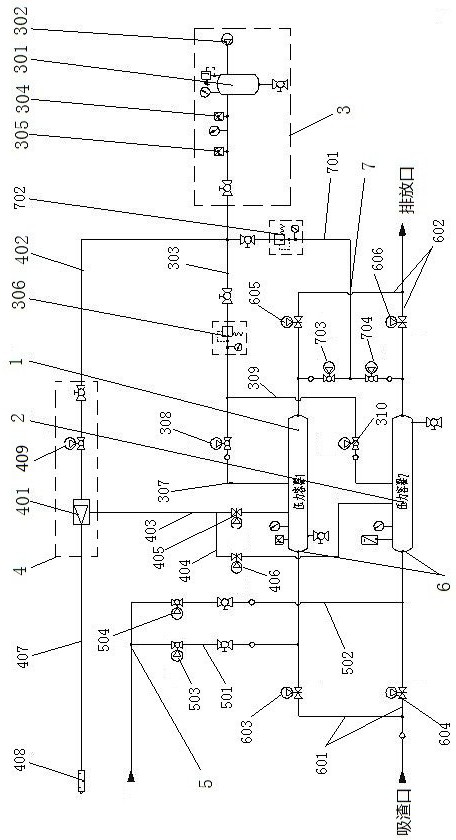

Reaction device and reaction method for grading conversion combined fluidized bed

ActiveCN109401794AIncrease cycle rateIncrease profitCombustible gas chemical modificationHydrocarbon from carbon oxidesSyngasCombustion

The invention relates to a reaction device and a reaction method for a grading conversion combined fluidized bed, and mainly solves the problems of low carbon conversion rate and gasification intensity, low methane yield, low treatment capacity, slagging difficulty and relatively low powdered coal utilization rate in the prior art. Through the technical scheme, according to the reaction device anda reaction method for the grading conversion combined fluidized bed, pyrolysis is carried out on a carbon-containing raw material of a supported catalyst in a pyrolysis furnace, tar gas is collectedafter being separated, partial combustion and a gasification reaction are carried out on semi-coke particles of the supported catalyst after pyrolysis as well as a gasifying agent and an oxidizing agent in a fine reactor, a further gasification reaction is carried out on subsequently generated synthesis gas and the carbon-containing particles without reacting completely in a coarse reactor, the carbon-containing particles after reaction and a part of the catalyst are returned into the pyrolysis furnace, and slagging is carried out on ash at the bottom in an intermittent grading slagging manner; and the above technical problems are solved preferably, so that the reaction device and the reaction method can be applied to industrial production of coal grading conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum material suction conveying pump system and working method thereof

The invention discloses a vacuum material suction conveying pump system and a working method thereof. The vacuum material suction conveying pump system solves the problem that in the prior art, a vacuum material suction conveying pump system cannot suck materials and discharge the materials at the same time. The vacuum material suction conveying pump system involves a first pressure container anda second pressure container arranged in parallel, wherein a positive pressure generation unit, a vacuum generation unit, an improvement unit and a slag suction and discharge unit are connected to thefirst pressure container and the second pressure container, the vacuum generation unit is connected with the positive pressure generation unit, and the improvement unit is connected with the slag suction and discharge unit. The vacuum material suction conveying pump system is ingenious in design, fluids carrying a large amount of particulate matter or the particulate matter and solid powder can beconveyed, and continuous and uninterrupted slag suction and slag discharge can be achieved so that the waste water conveying problem in tunnel construction can be better solved, and the vacuum material suction conveying pump system has high practicability and popularization value.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com