Inorganic chemical wastewater treatment tank capable of improving cleanness of wastewater

A technology for chemical wastewater and treatment tank, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of low clarity of wastewater, inconvenient operation, and installation at the bottom, etc. Achieve the effect of improving water treatment efficiency, slag discharge efficiency, and increasing wastewater flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

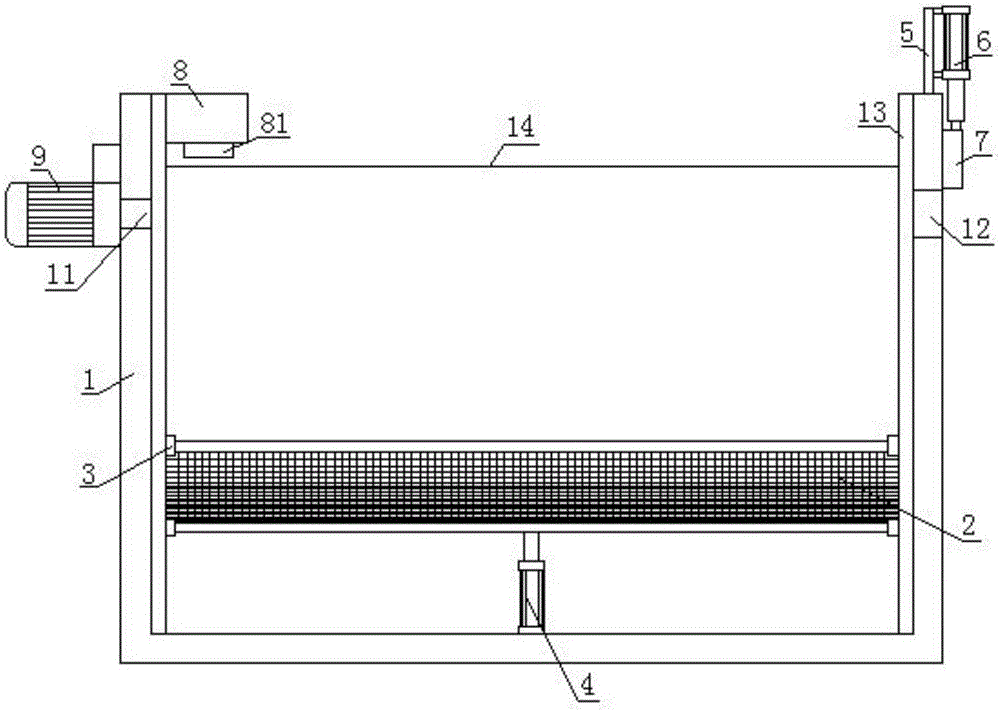

[0021] Such as figure 1 As shown, the present invention includes a settling tank 1, one end of the settling tank 1 is provided with a water inlet 11, the other end of the settling tank 1 is provided with a water outlet 12, and the side wall of the settling tank 1 is provided with a chute 13. A filter screen 2 is arranged obliquely, and the side of the sedimentation tank 1 close to the lower end of the filter screen 2 is provided with a slag outlet 14, and the edge of the filter screen 2 is connected with a slider 3, and the slider 3 is sleeved in the chute 13; the sedimentation tank 1 bottom is equipped with lifting cylinder 4, and the piston rod of lifting cylinder 4 is fixed on filter screen 2 bottoms.

[0022] The sedimentation tank 1 of the present invention is provided with a chute 13 , and the filter screen 2 can rise or fall in the chute 13 under the drive of the lifting cylinder 4 . Thereby, the inclined filter screen 2 can push the settled sludge out from the slaggin...

Embodiment 2

[0024] Such as figure 1 As shown, the present invention includes a settling tank 1, one end of the settling tank 1 is provided with a water inlet 11, the other end of the settling tank 1 is provided with a water outlet 12, and the side wall of the settling tank 1 is provided with a chute 13. A filter screen 2 is arranged obliquely, and the side of the sedimentation tank 1 close to the lower end of the filter screen 2 is provided with a slag outlet 14, and the edge of the filter screen 2 is connected with a slider 3, and the slider 3 is sleeved in the chute 13; the sedimentation tank 1 bottom is equipped with lifting cylinder 4, and the piston rod of lifting cylinder 4 is fixed on filter screen 2 bottoms. The sedimentation tank 1 of the present invention is provided with a chute 13 , and the filter screen 2 can rise or fall in the chute 13 under the drive of the lifting cylinder 4 . Thereby, the inclined filter screen 2 can push the settled sludge out from the slagging outlet ...

Embodiment 3

[0027] Such as figure 1 As shown, the present invention includes a settling tank 1, one end of the settling tank 1 is provided with a water inlet 11, the other end of the settling tank 1 is provided with a water outlet 12, and the side wall of the settling tank 1 is provided with a chute 13. A filter screen 2 is arranged obliquely, and the side of the sedimentation tank 1 close to the lower end of the filter screen 2 is provided with a slag outlet 14, and the edge of the filter screen 2 is connected with a slider 3, and the slider 3 is sleeved in the chute 13; the sedimentation tank 1 bottom is equipped with lifting cylinder 4, and the piston rod of lifting cylinder 4 is fixed on filter screen 2 bottoms. The sedimentation tank 1 of the present invention is provided with a chute 13 , and the filter screen 2 can rise or fall in the chute 13 under the drive of the lifting cylinder 4 . Thereby, the inclined filter screen 2 can push the settled sludge out from the slagging outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com