Vacuum material suction conveying pump system and working method thereof

A technology of vacuum suction and conveying pumps, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc. It can solve the problem that material suction and discharge cannot be carried out at the same time, achieve continuous and uninterrupted slag suction and slag discharge, and improve Efficiency of slag discharge, effect of solving the problem of sewage transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

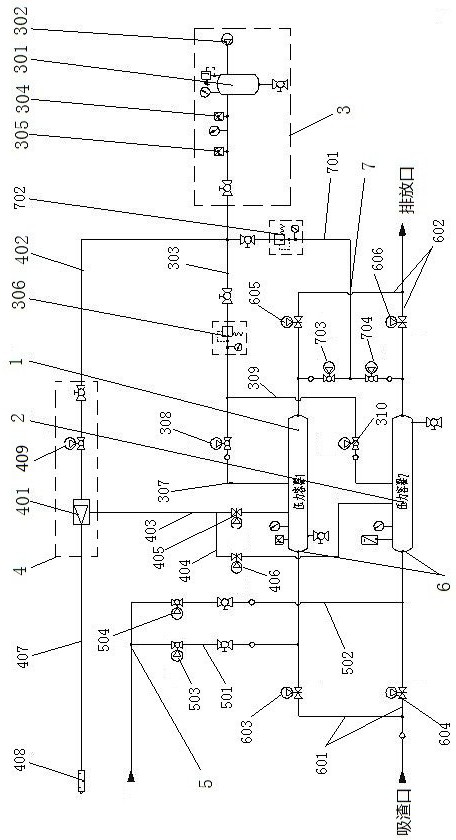

[0034] Embodiment 2, a vacuum suction and delivery pump system, the vacuum generating unit 4 includes a vacuum generator 401, the vacuum generator 401 uses a Laval nozzle vacuum generator, the Laval nozzle vacuum generator is used to provide a vacuum environment for the pressure vessel In turn, the material is pressed into the pressure vessel by atmospheric pressure. The vacuum generator 401 is connected to the positive pressure main line 303 through the positive pressure input pipeline 402. The positive pressure input pipeline 402 is provided with a 13th valve 409, which is used between the positive pressure pipeline and the vacuum generator. On-off of high-pressure gas. The vacuum generator 401 is connected to the first pressure vessel 1 through a first negative pressure sub-line 403, and the vacuum generator 401 is connected to the second pressure vessel 2 through a second negative pressure sub-line 404. The first negative pressure sub-line No. 10 valve 405 is provided on 4...

Embodiment 3

[0037] Embodiment 3 is a vacuum suction and delivery pump system. The suction and discharge unit 6 includes a suction pipe 601 and a discharge pipe 602. The suction pipe 601 is connected to the suction ports of the first pressure vessel 1 and the second pressure vessel 2, respectively, The discharge pipe 602 is respectively connected with the slag discharge ports of the first pressure vessel 1 and the second pressure vessel 2; the suction pipe 601 and the first pressure vessel 1 are provided with a No. 1 valve 603, which is used to control the first The on-off of the slag suction channel of the pressure vessel, a No. 2 valve 604 is provided between the suction pipe 601 and the second pressure vessel 2, and the No. 2 valve 604 is used to control the on-off of the slag suction channel of the second pressure vessel. A No. 3 valve 605 is provided between the discharge pipe 602 and the first pressure vessel 1. The No. 3 valve 605 is used to control the slag discharge of the first pre...

Embodiment 4

[0040] Embodiment 4: A pumping method of a vacuum suction and delivery pump system, including slag suction and slag discharge modes, suction pipe and discharge pipe backwash mode, pressurized pneumatic conveying mode, and improved mode.

[0041] The slag suction and discharge mode includes the following steps:

[0042] A1: When the air compressor is in working condition, firstly open the No. 13 valve, No. 10 valve and No. 1 valve to make the first pressure vessel vacuum so that the slag is sucked into the first pressure vessel;

[0043] A2: When the first pressure vessel is full of slag or the set time is reached, the No. 10 valve and the No. 1 valve are closed; the No. 7 valve, the No. 3 valve, the No. 9 valve, and the No. 2 valve are opened to allow the positive pressure air to enter The first pressure vessel thus realizes the slag discharge of the first pressure vessel, while the second pressure vessel forms a vacuum so that the slag is sucked into the second pressure vessel;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com