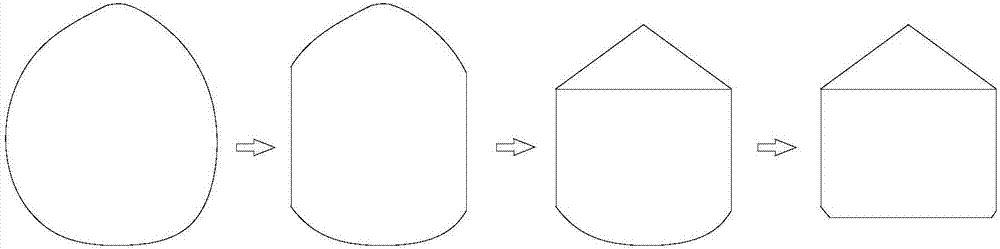

Online continuous tender coconut cutting and forming equipment and method

A molding equipment and green coconut technology, which is applied in metal processing and other fields, can solve the problems of low efficiency and inability to meet the demand for mass sales of coconut green market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

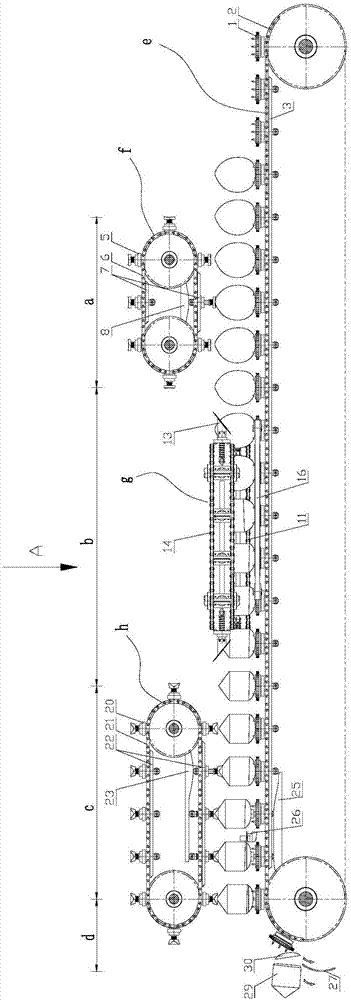

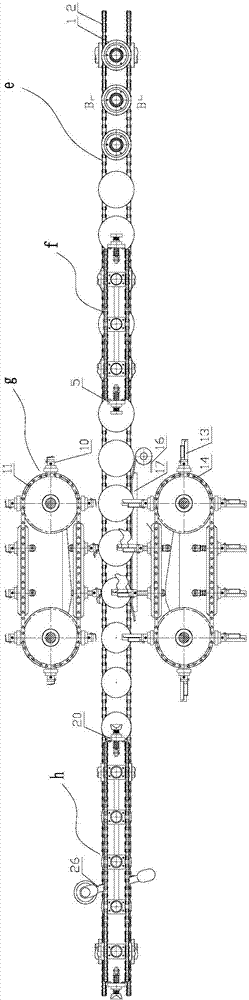

[0088] In this embodiment, an online continuous cutting and forming equipment for young coconut, such as figure 1 or figure 2 As shown, the illustration omits the equipment rack, sealing plate, power unit and its transmission system, and only retains the core mechanism. The core mechanism of the equipment mainly includes four parts, namely positioning and conveying device e, fruit body pressing device f, fruit body cutting device g and end cutting device h.

[0089] The positioning and conveying device includes a conveying chain 2 and a plurality of positioning disc mechanisms 1. Each positioning disc mechanism is equally spaced on the conveying chain, and each positioning disc mechanism corresponds to a green coconut; along the conveying direction of the coconut green, the fruit body is pressed together The device, the fruit cutting device and the end cutting device are sequentially arranged above the conveyor chain, wherein the fruit pressing device and the end cutting device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com