Equipment for full-automatic assembling of car seat sliding rail lock

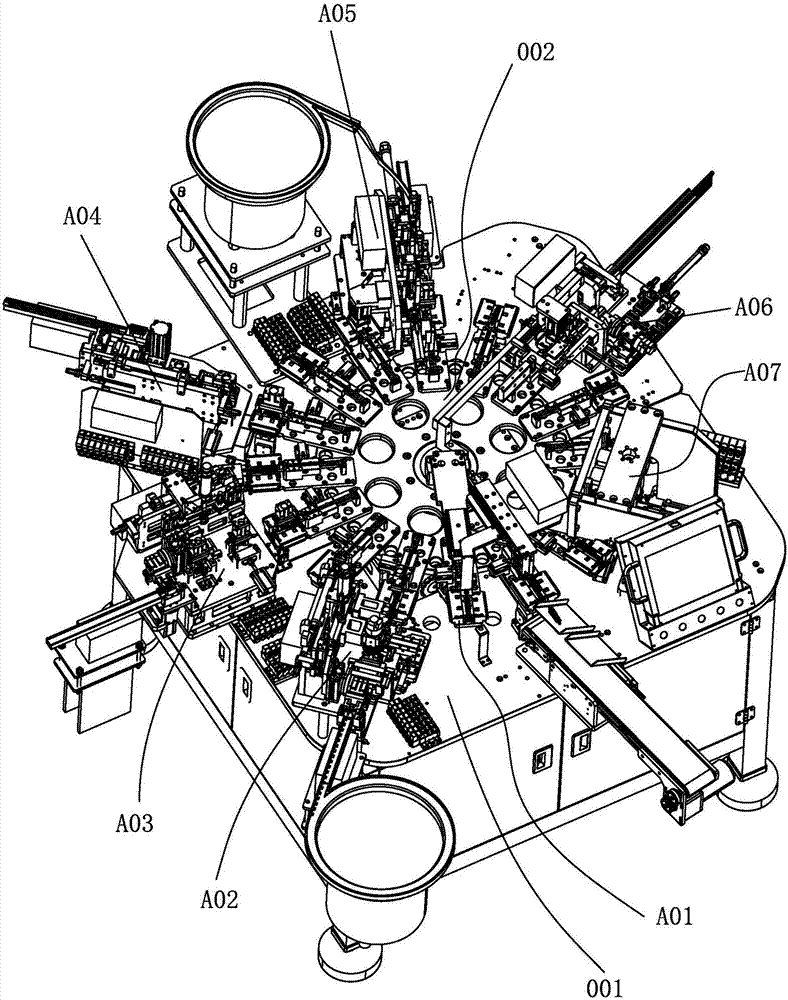

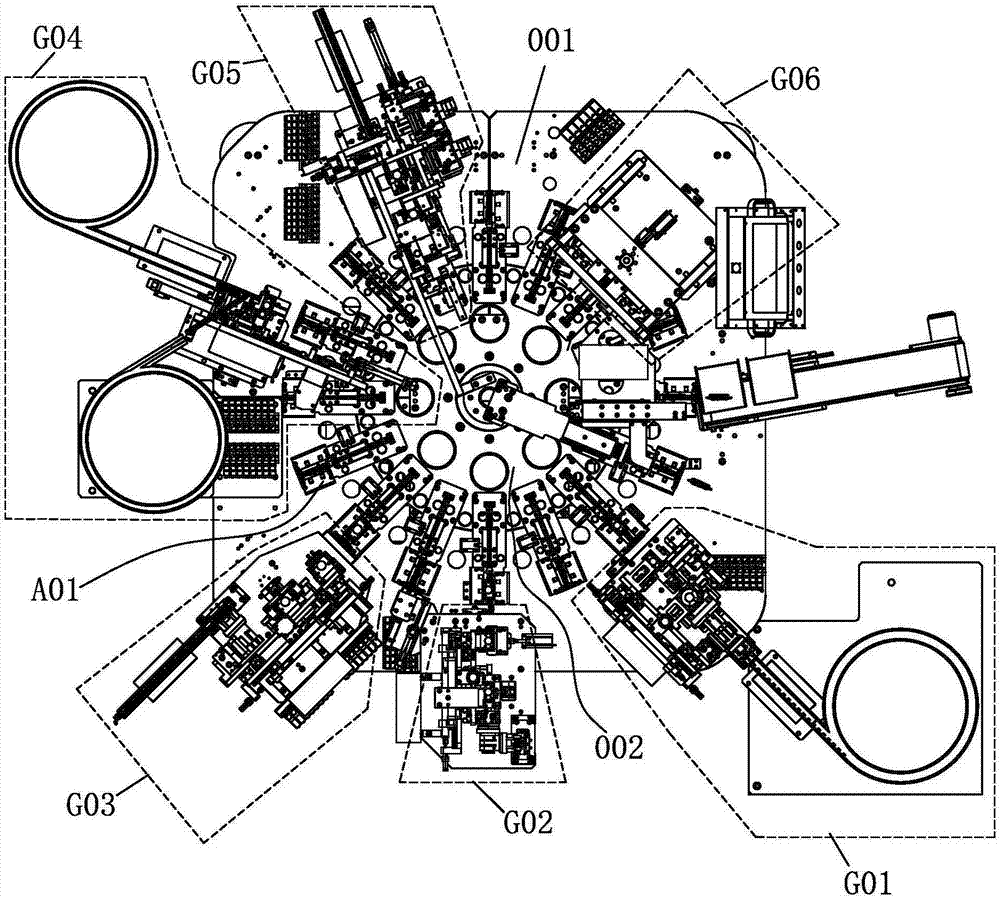

A car seat slide, fully automatic technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of high cost and low efficiency, and achieve the effect of high work efficiency, reasonable layout and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

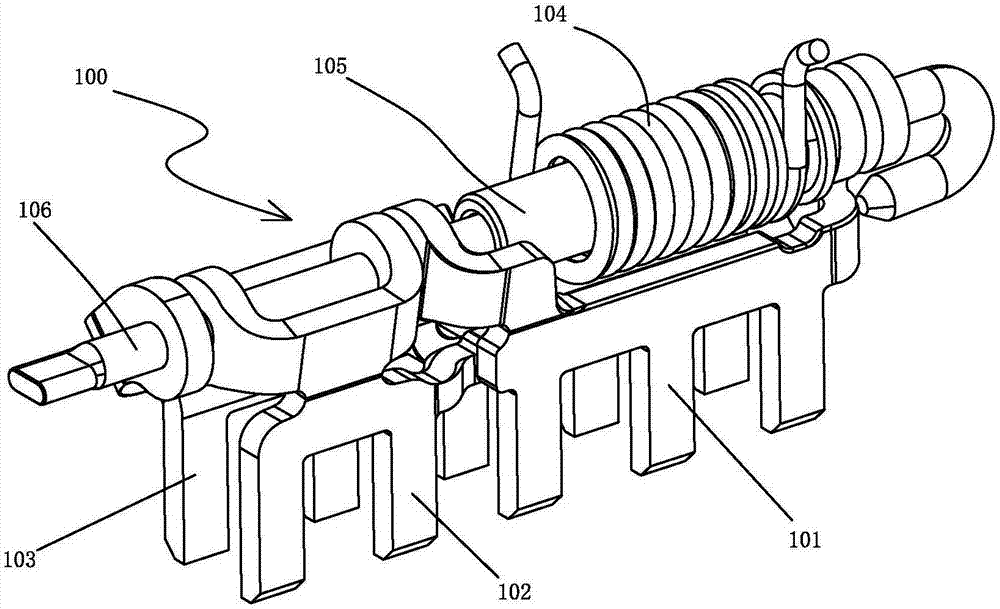

[0045] For ease of understanding, first briefly describe the automatic assembly steps of the car seat slide rail lock 100, a: install the first locking claw 101, the second locking claw 102, and the third locking claw 103 on the car seat slide rail lock in sequence On the fixture A01, for this purpose, the fixture has a pressing and positioning mechanism for positioning and clamping the first locking claw 101, the second locking claw 102, and the third locking claw 103 respectively; b: Insert the torsion spring 104 into the torsion spring bushing 105 , and then the torsion spring 104 and the torsion spring bushing 105 are placed between the first locking pawl 101, by inserting the guide pin 162 on the fixture into the first locking pawl 101, the second locking pawl 102, and the third locking pawl 103 both sides Realize the positioning of the torsion sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com