M-shaped packaging bag opening mechanism

A technology of packaging bags and rotating shafts, applied in packaging and other directions, can solve the problems of inability to guarantee the opening of M-shaped packaging bags, occupying a large space, and running unevenly, achieving the effects of small inertial impact, stable operation and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

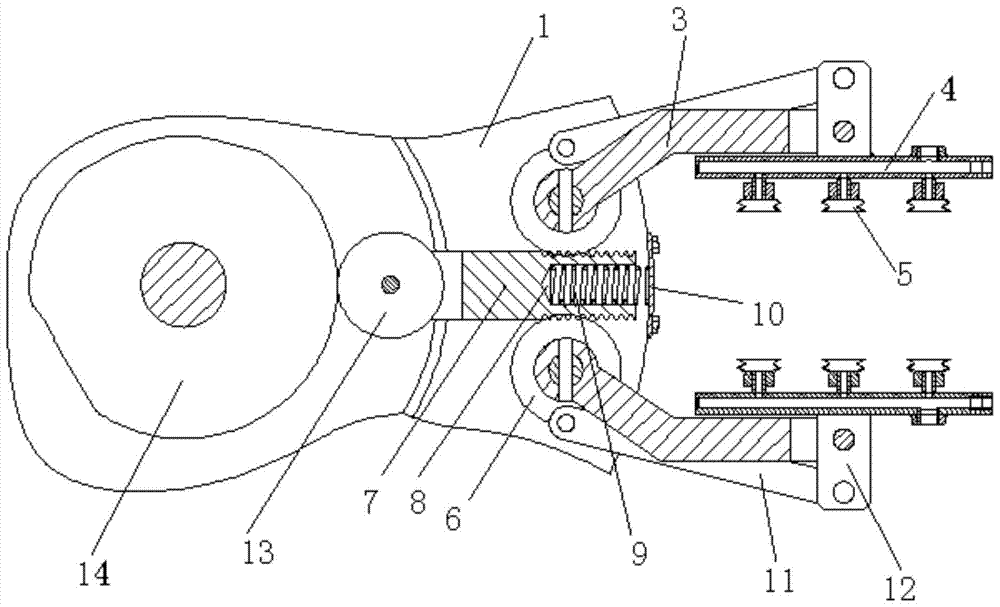

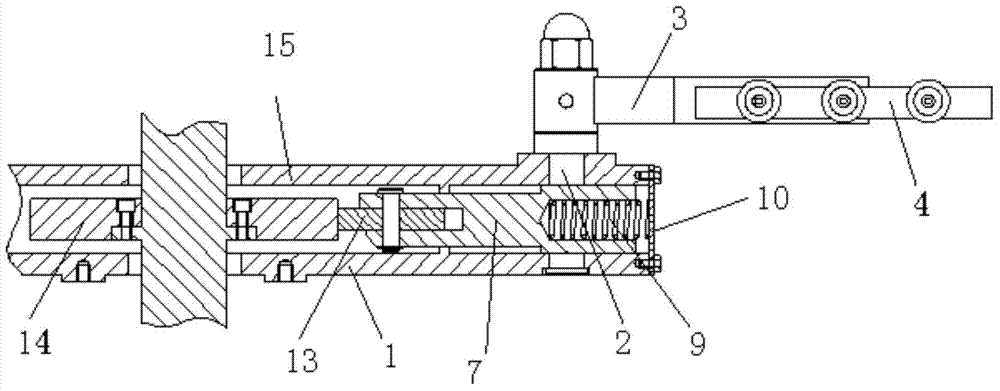

[0012] Referring to the accompanying drawings, a bag opening mechanism for an M-shaped packaging bag includes a rotating main disk 1, and two corresponding swing arm shafts 2 are mounted on the front end of the rotating main disk 1, and swing arms are respectively installed on the upper ends of the swing arm shafts 2. 3. The front end of the swing arm 3 is respectively equipped with a suction cup seat 4, and the corresponding end surfaces of the suction cup seat 4 are respectively installed with corresponding suction cups 5, and the lower end of the swing arm shaft 2 is respectively equipped with a gear 6, and the two gears 6 are provided with There are tooth racks 7 meshing with it respectively, and a guide hole 8 is provided in the front end of the tooth rack 7, a spring 9 is installed in the guide hole 8, and a limiter that cooperates with the end of the spring 9 is provided on the rotating main disk at the protruding end of the spring 9. A connecting plate 11 is also arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com