Automatic assembly line for motor

An assembly line and robot technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high motor manufacturing cost, low installation efficiency, non-standard installation, etc., and achieve high installation efficiency, reasonable layout, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

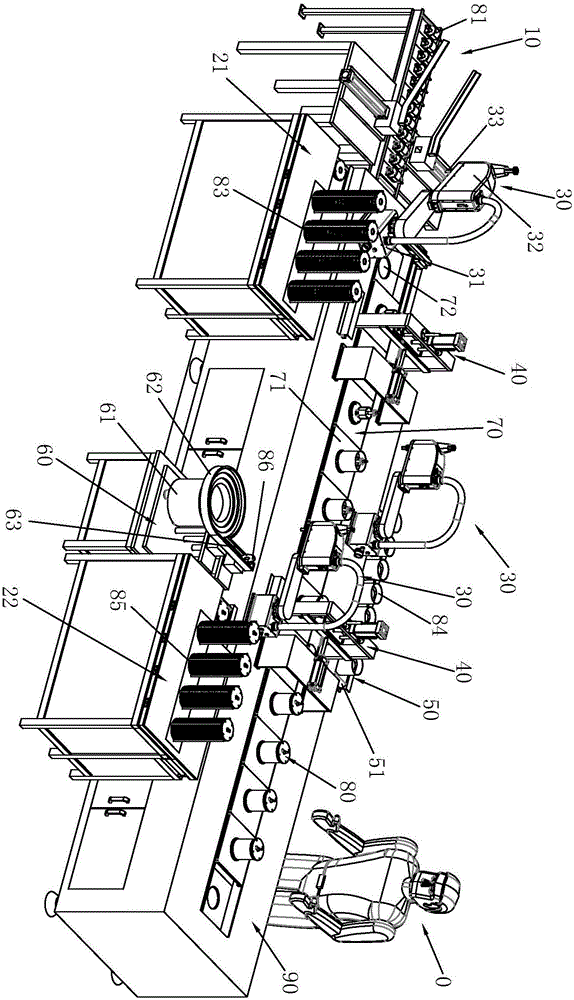

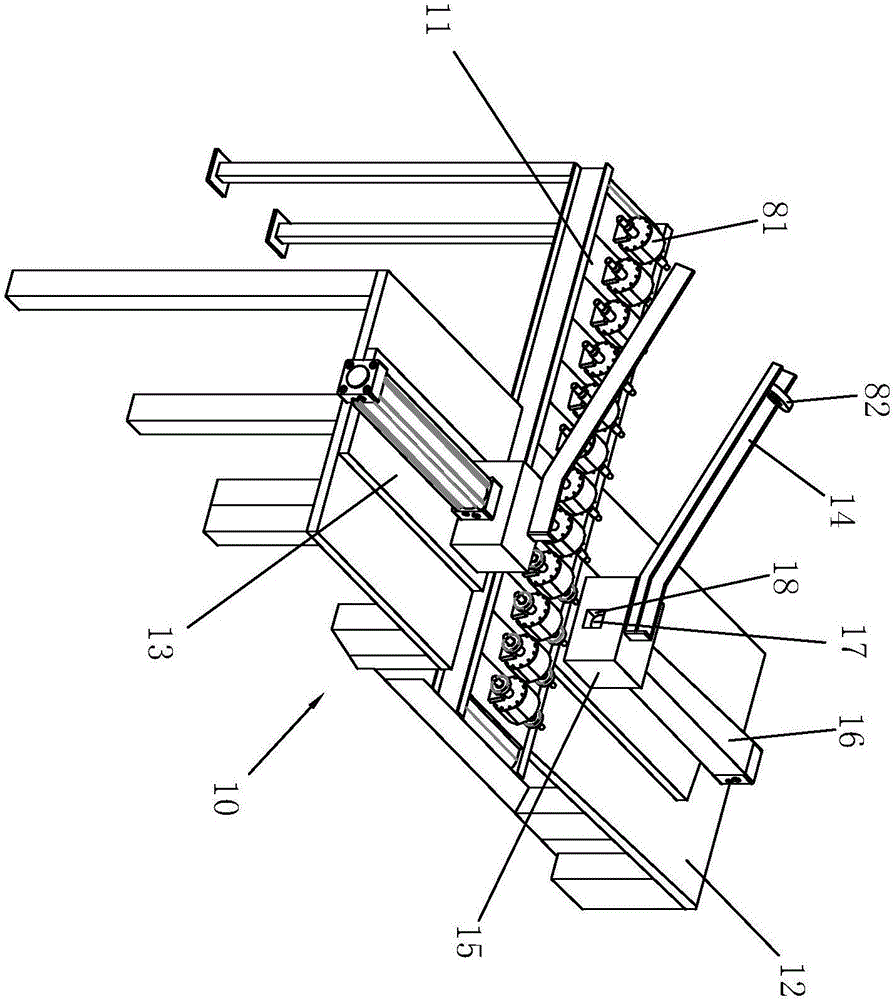

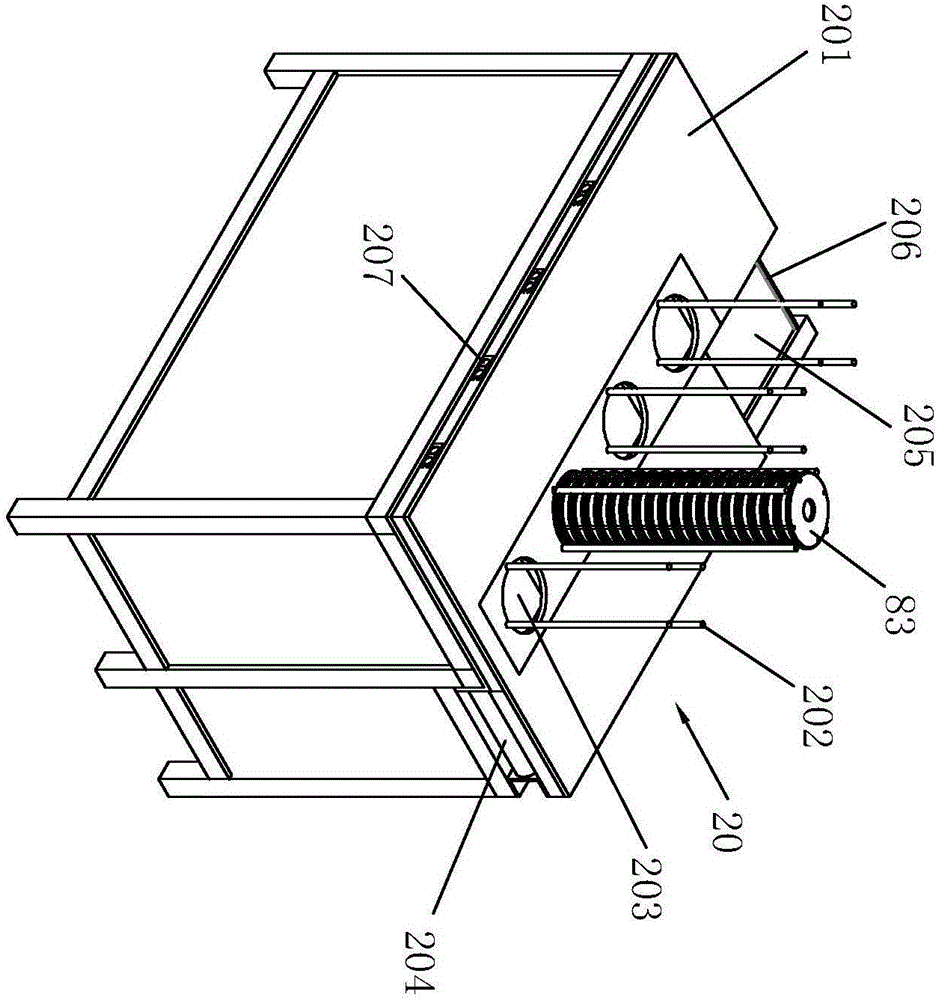

[0018] like Figure 1 to Figure 4 As shown, the motor automatic assembly line of the present invention includes a bearing pressing mechanism 10 , a pushing mechanism 20 , a robot 30 , a pressing mechanism 40 , a stator conveying mechanism 50 , a gasket feeding mechanism 60 and a conveying mechanism 70 . The components of the motor 80 to be installed by each mechanism include a rotor 81 , bearings 82 at both ends of the rotor 81 , a bottom cover 83 , a stator 84 , an upper cover 85 and a gasket 86 . At the end of the conveying mechanism 70 is a manual installation station 90 . The manual installation station 90 is used for feeding the stator 84 to the stator conveying mechanism 50 , and finally performing screw installation and unloading work for the motor 80 .

[0019] like Figure 1 to Figure 4 As shown, the conveying mechanism 70 includes a conveying plate 71 on which a mold 72 for placing the rotor 81 and the bottom cover 83 is arranged, and the conveying plate 72 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com