Storage switching mechanism for multi-vehicle-type vehicle body mixed line forming station clamps

A switching mechanism and station clamp technology, applied in manufacturing tools, vehicle parts, metal processing, etc., can solve the problems of only a certain storage warehouse, time-consuming and labor-intensive switching of fixtures, and rigid operation methods, and achieve economical savings. Fixture transit time, great promotion value, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

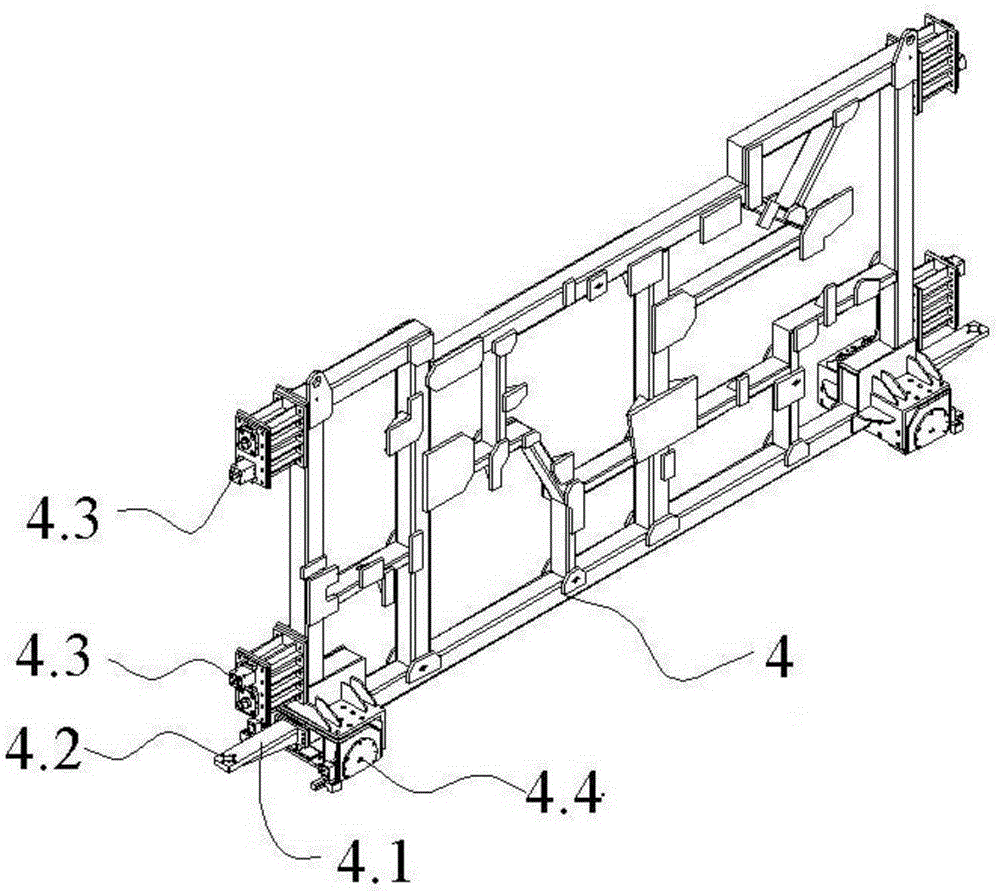

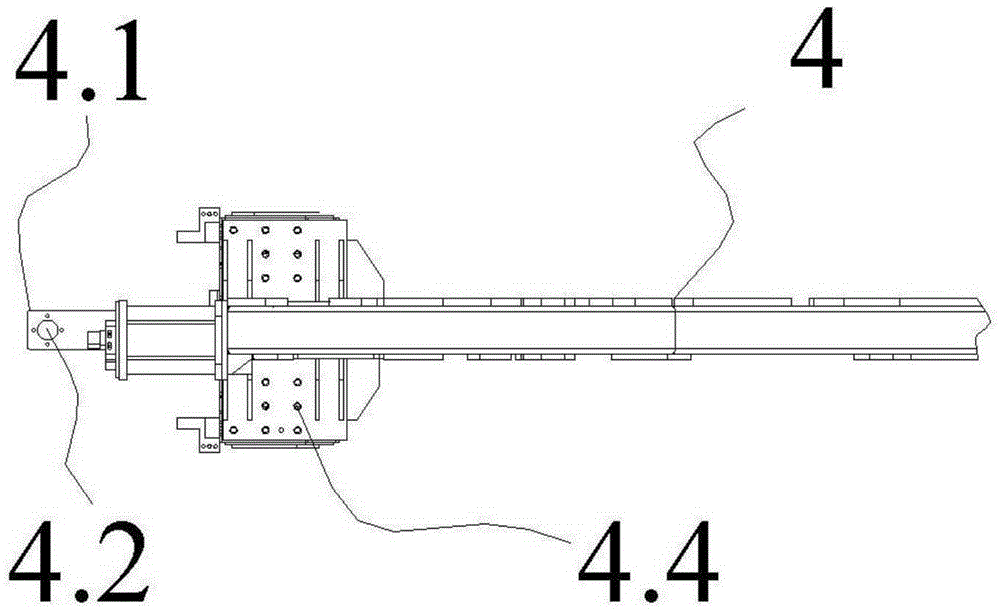

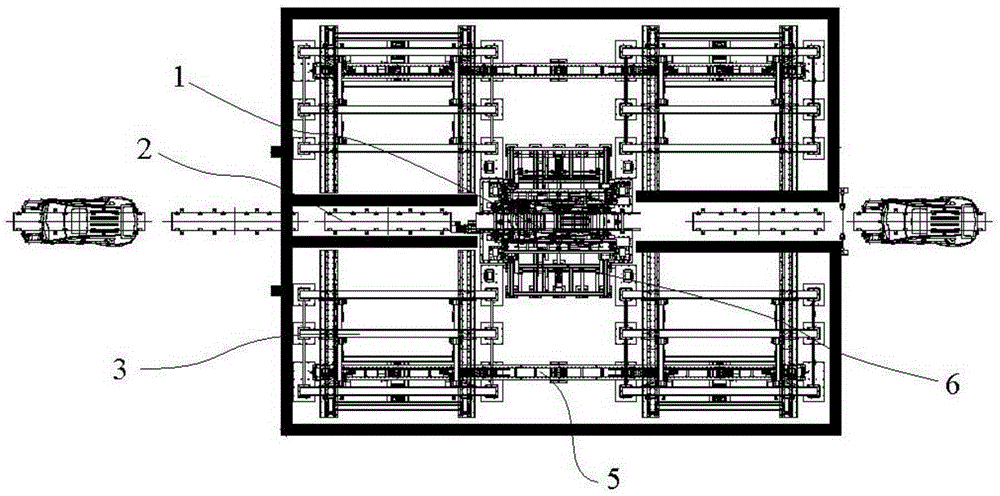

[0052] Such as Figure 3-14 , is a schematic structural diagram of this embodiment, image 3 For the overall structural arrangement of this embodiment, such as image 3 As shown, in this embodiment, the welding production line 2 is taken as the center line, and four sets of fixture storages 3 are placed on both sides of the welding production line 2, and the welding station 1 is symmetrically arranged around it. This embodiment is not limited to four sets of fixture storages 3 , as long as it can meet the needs of the welding production line 2 . Such as image 3 As shown, a fixture transfer device 5 and a fixture positioning device 6 are arranged between two sets of fixture storage warehouses 3 located on the same side of the welding assembly line 2. The fixture 4 falls from the fixture storage warehouse 3 and enters the fixture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com