Micro motor magnetic steel assembly device

A technology for micro-motors and assembly equipment, which is applied in electromechanical devices, manufacturing motor generators, circuits, etc., can solve problems such as increased labor intensity, enterprise losses, and impact on enterprise production, and achieves reduced labor intensity, reduced production costs, and stabilized The effect of the staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

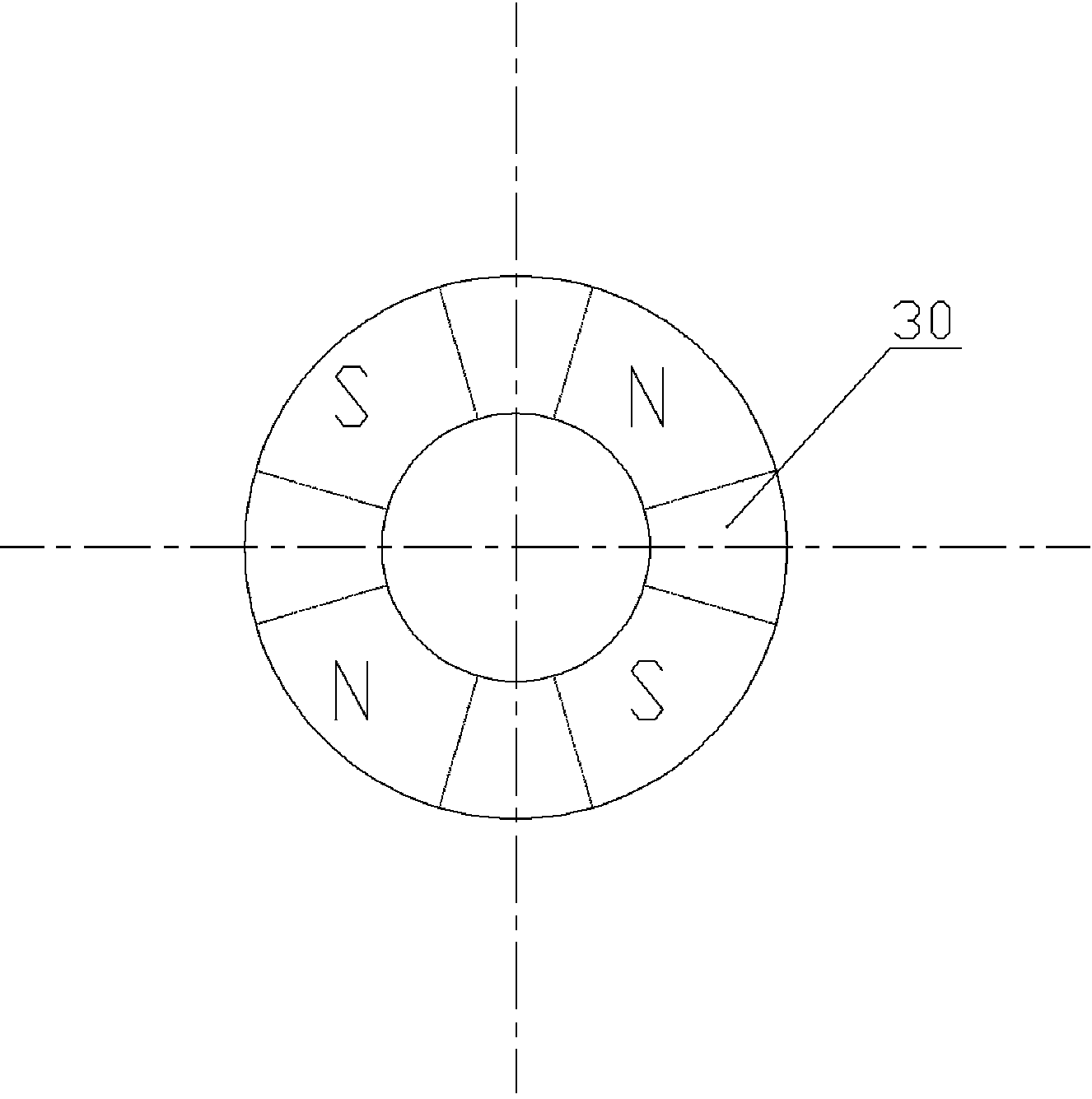

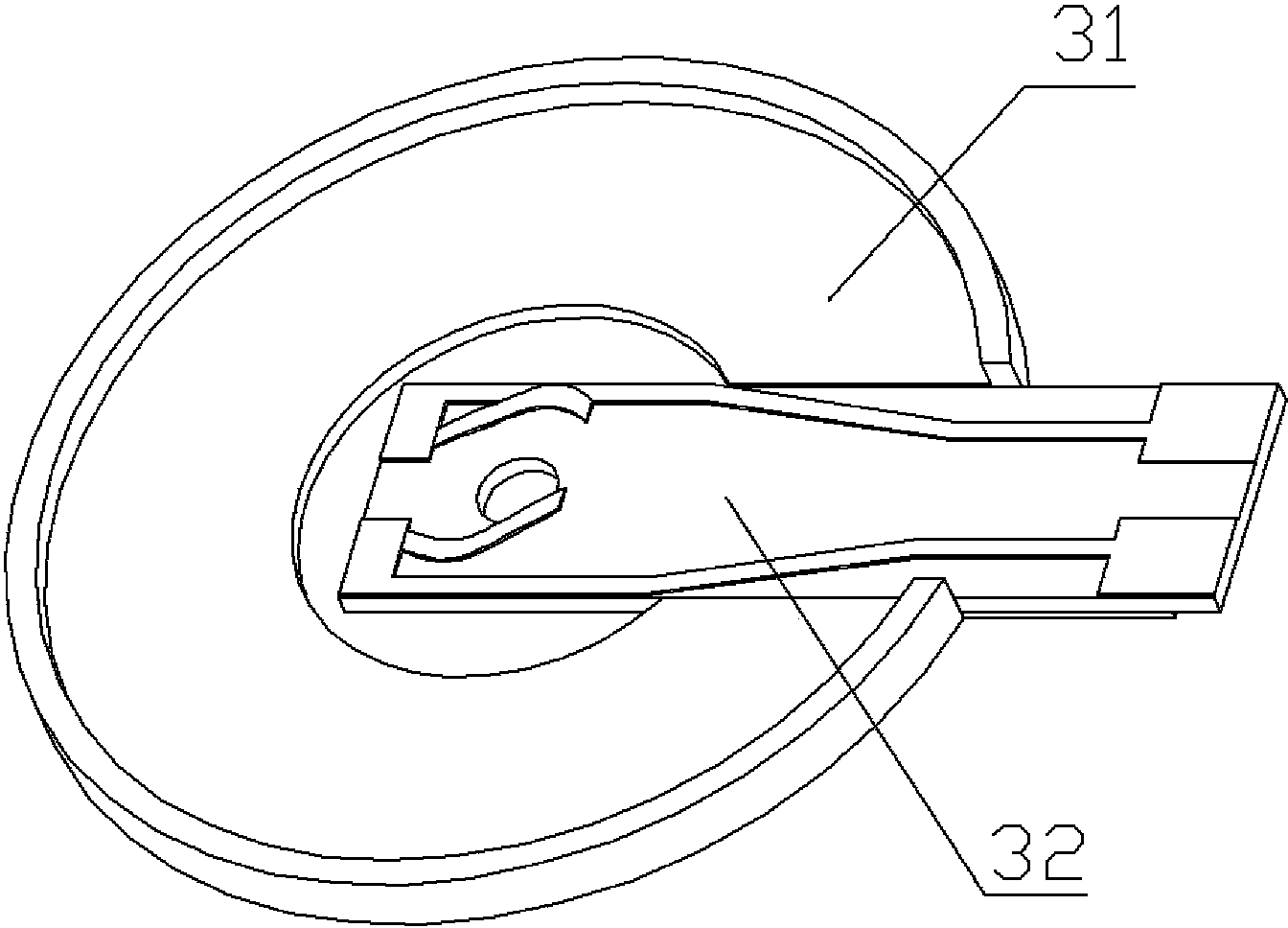

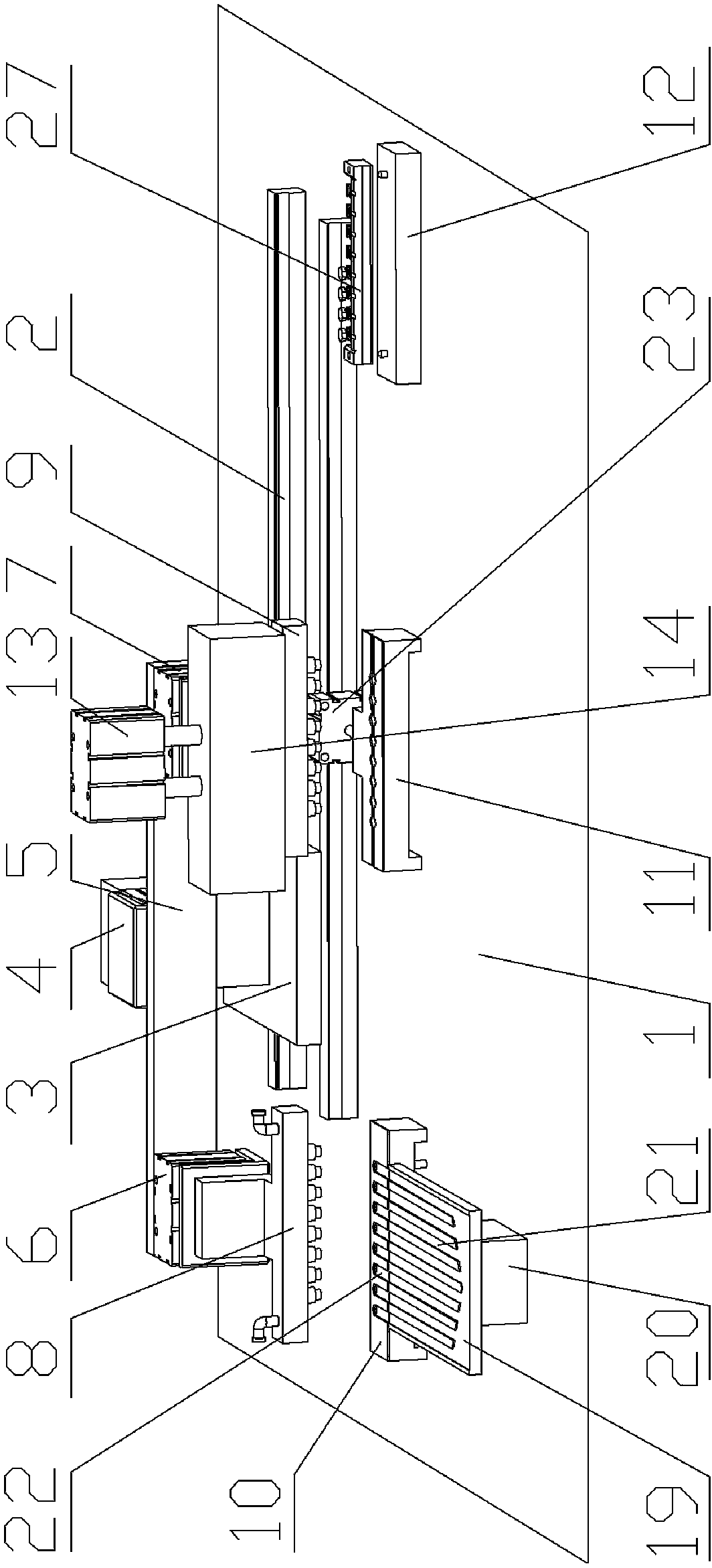

[0035] see Figure 1 to Figure 7 , is an embodiment of the assembly equipment of micro-motor magnetic steel, including a working platform 1, the working platform is fixed on a frame, and the working platform 1 is provided with two guide rails 2 parallel to each other, and the two guide rails are fixed on the working platform by bolts. On the platform 1, a mobile supporting seat 3 is provided on the two guide rails 2, and a driving device is connected with the mobile supporting seat 3 to drive the mobile supporting seat to translate along the two guide rails. Further, the lower part of the mobile supporting seat 3 extends to the guide rails 2, the extension part of the mobile supporting base 3 is screwed with a screw rod, the screw rod is parallel to the two guide rails 2, and one end of the screw rod is connected with the driving motor to form a drive for driving the moving supporting base 3 to translate along the two guide rails 2. device.

[0036] Described mobile supportin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com