Patents

Literature

469results about How to "Fix fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight composite wall panel moulding apparatus and product line

ActiveCN101244581ASignificant progressFix fixMouldsCeramic shaping plantsProduction lineVehicle frame

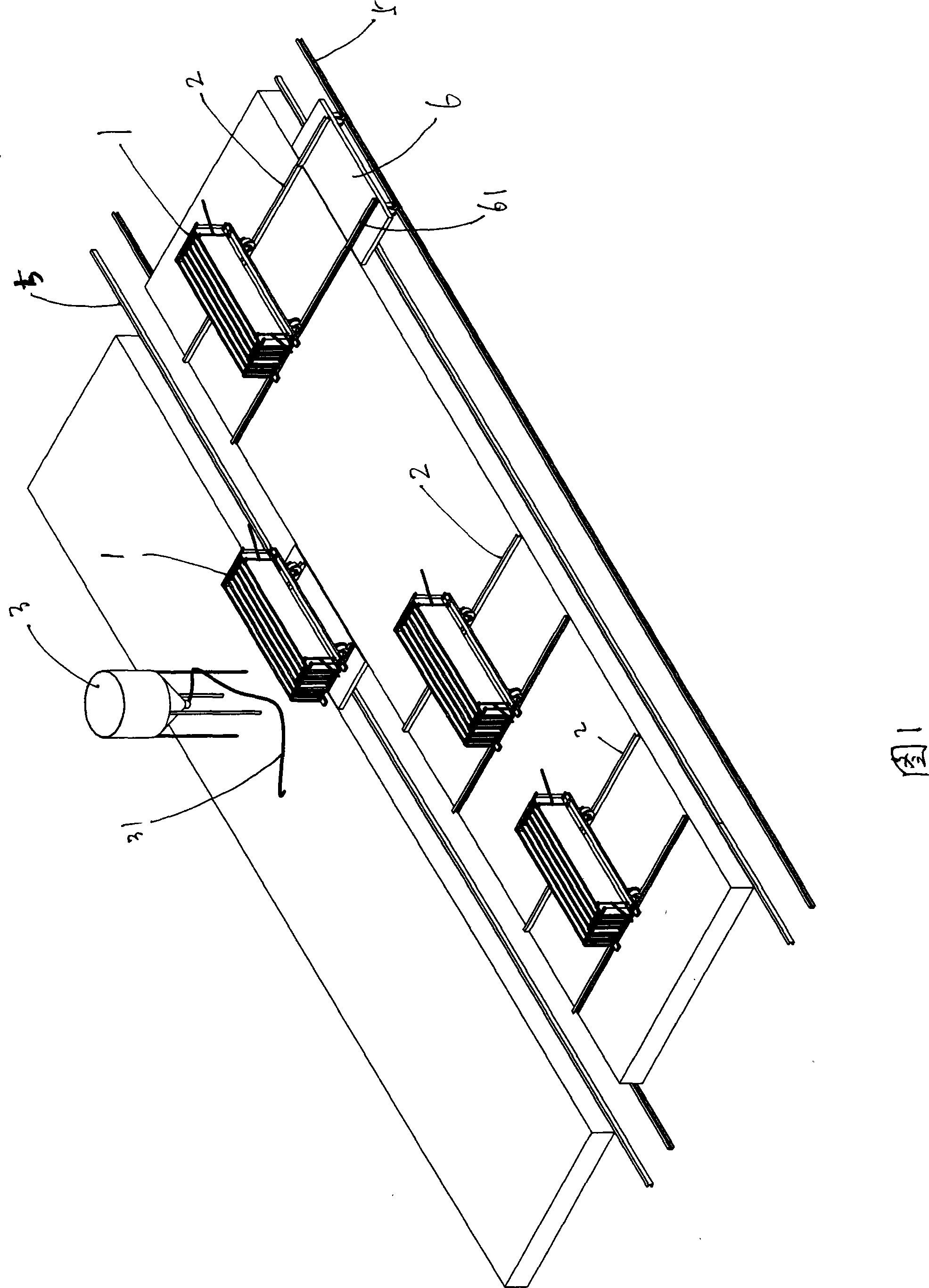

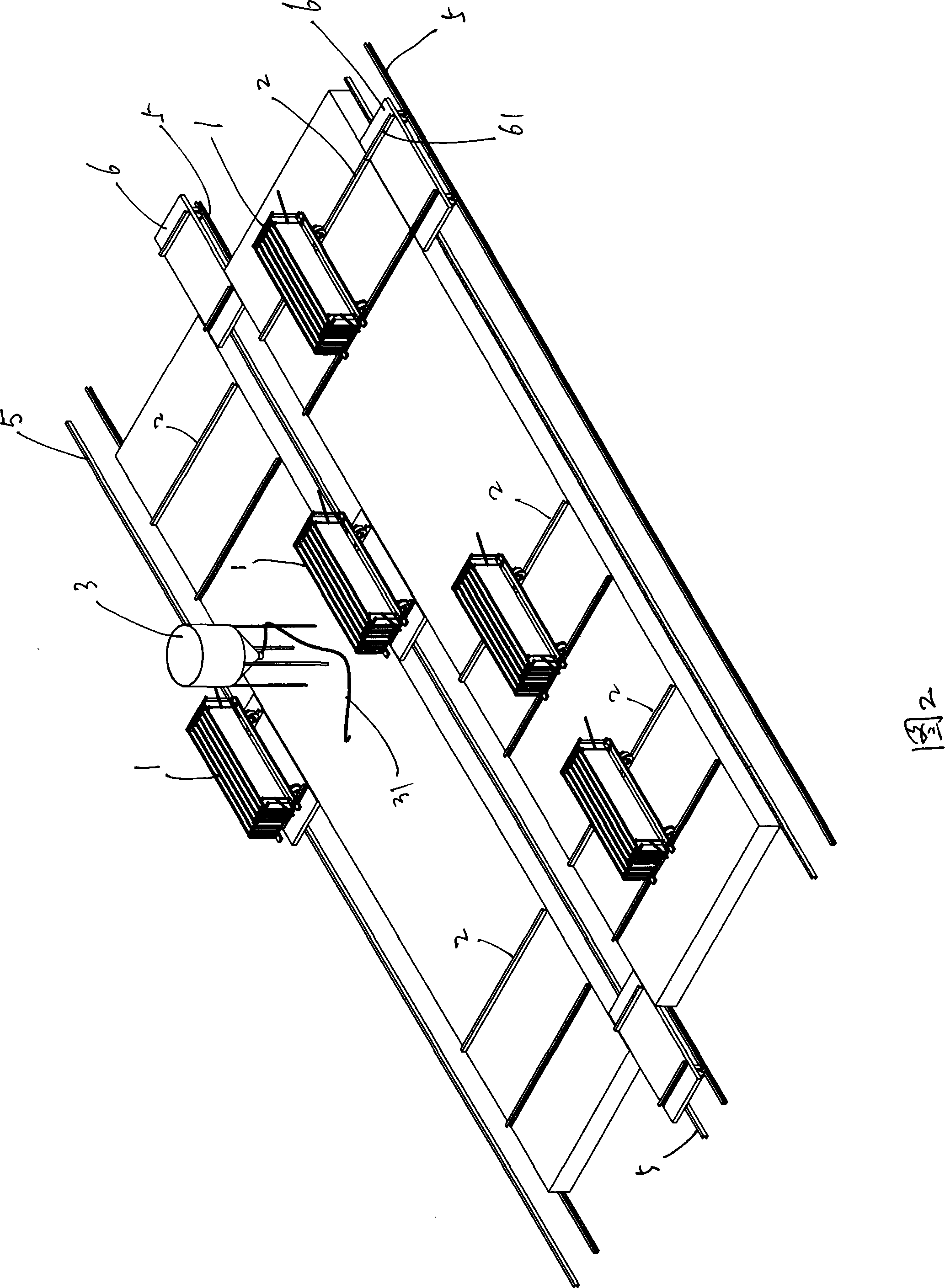

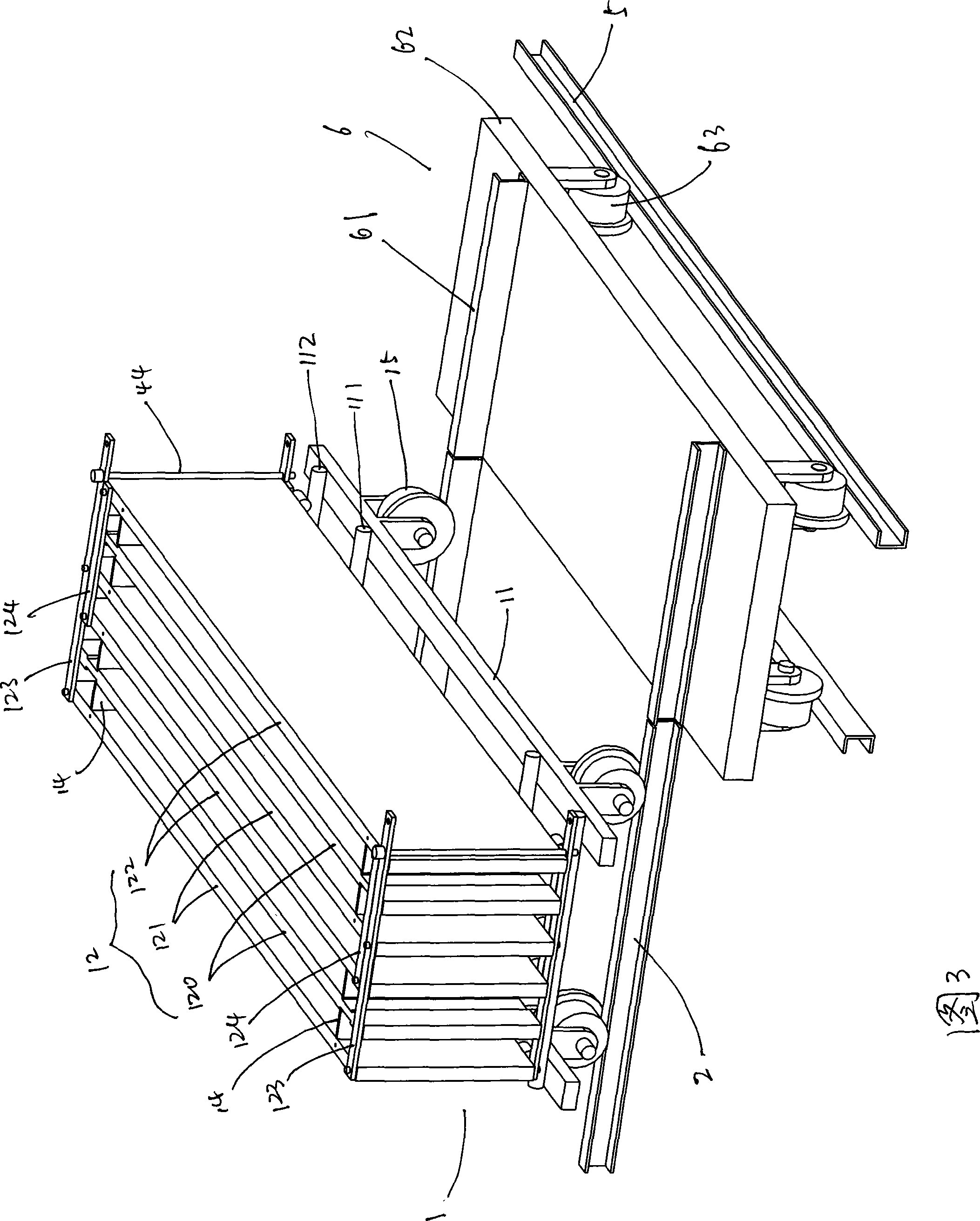

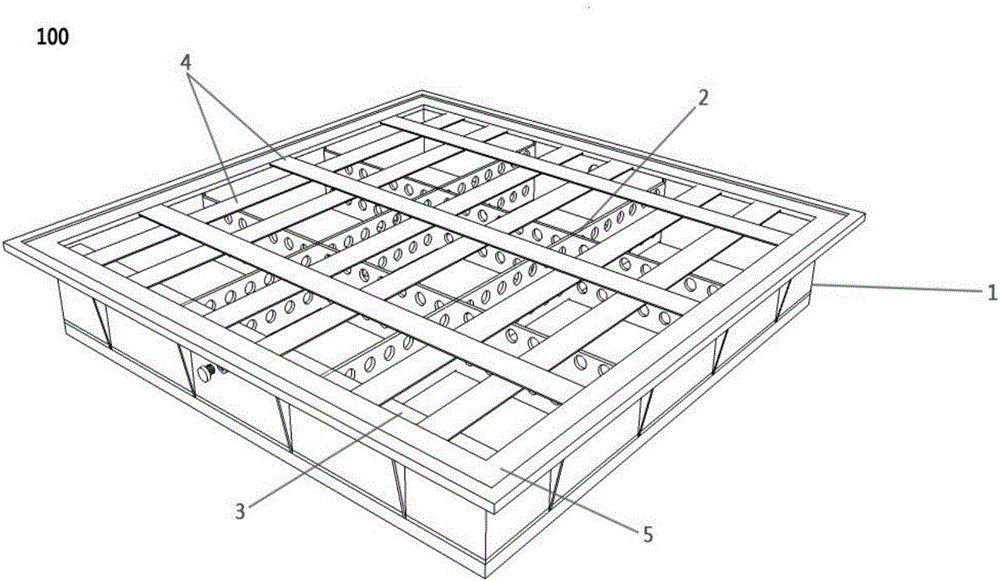

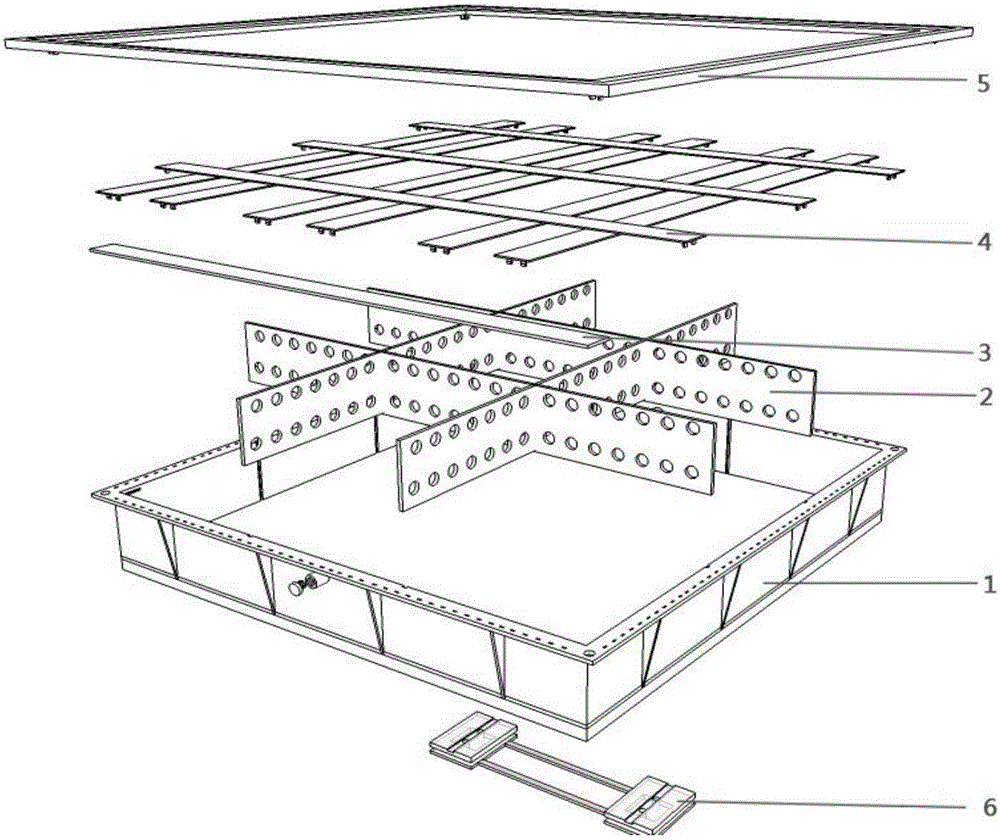

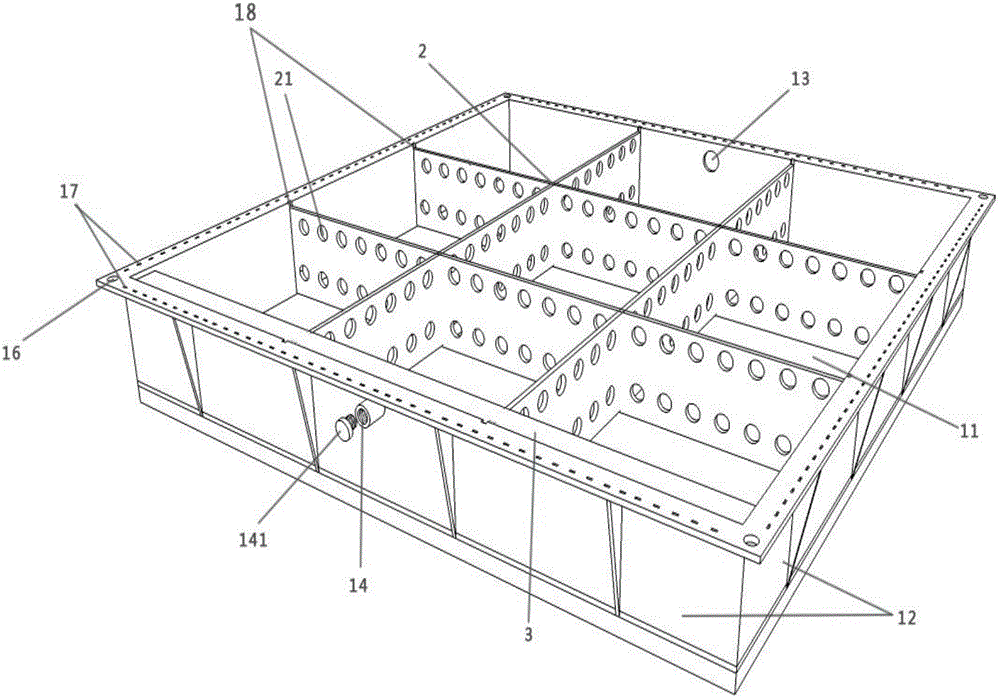

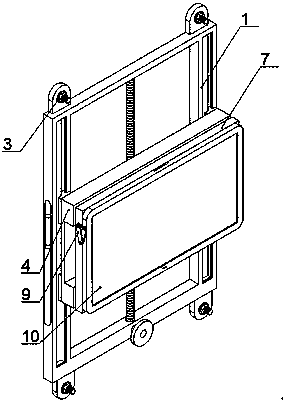

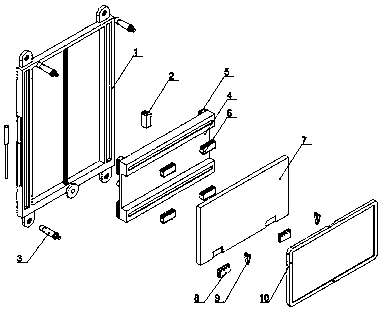

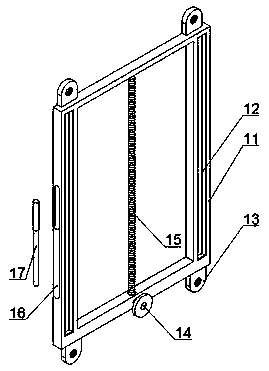

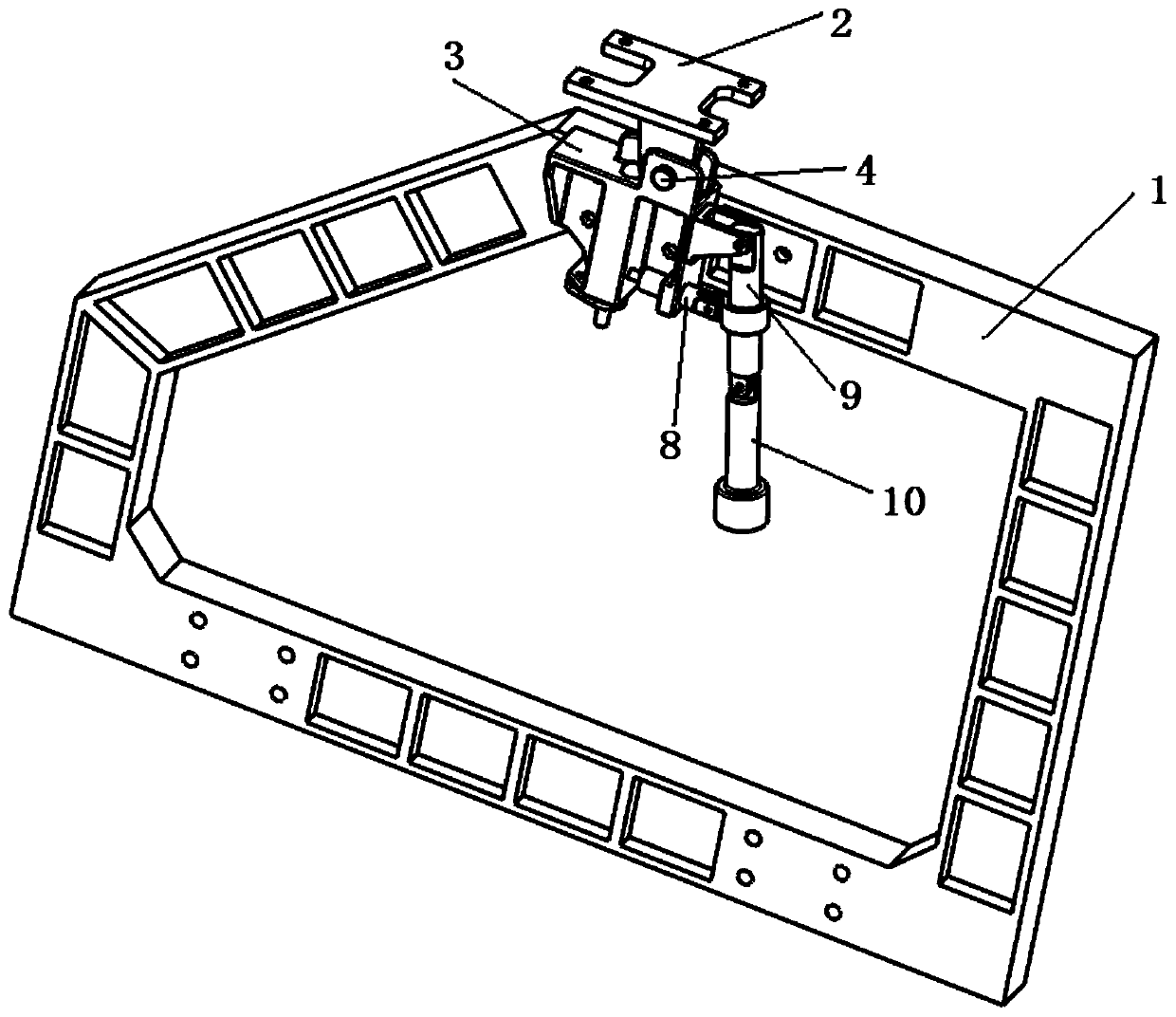

The invention provides a forming machine for a lightweight composite wallboard, which is characterized in that three side vertical templates are classified as a group; one template in the center of each group is the fixed template; two templates at two sides of each group are respectively the left moving template and right moving template; the fixed template is fixed at a frame; the left moving template, the right moving template, a left bed die band and a right bed die band are flexibly connected with the beams of the frame; each left moving template, right moving template, left bed die band and right die band are respectively connected with a plurality of link bars. The invention still provides a production line for lightweight composite wallboard. The production line is provided with a die car track and a sinking transfer orbit; a transfer wheelbarrow is arranged at the orbit; the forming machine can be arranged at the transfer wheelbarrow through a connection orbit or can enter into a die car orbit from the transfer wheelbarrow. The forming machine for a lightweight composite wallboard has the advantages of simple equipment and light weight, overcoming the defect that traditional wallboard forming machine is so big that the machine can not be moved; the side vertical template and bed die band adopt the grouping connection design, solving the problem of the heeling and opening of the side vertical template and the fixation of the bed die band; the open die facility is classified and the operation becomes very convenient; the wallboard production line uses flow shop and the forming machine is handled movably according to the working procedure, improving work efficiency.

Owner:广州市建筑材料工业研究所有限公司

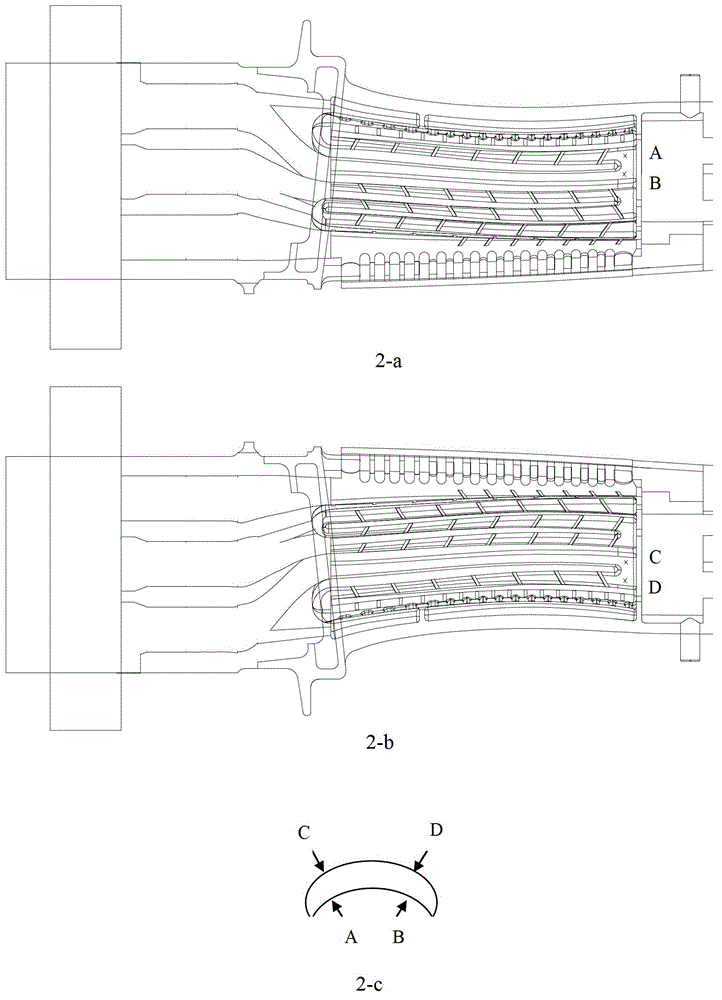

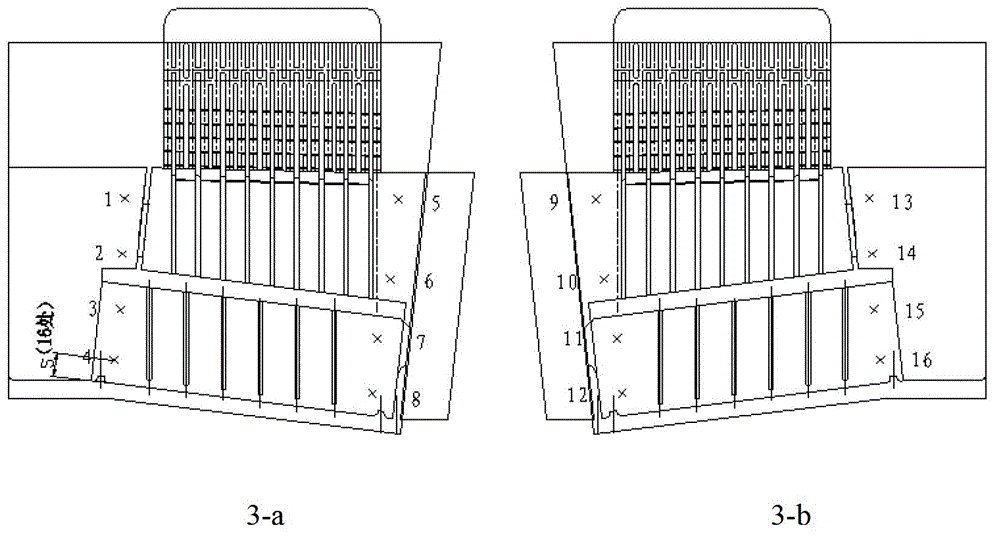

Fixing method of isometric crystal and columnar crystal ceramic mold core in mold shell

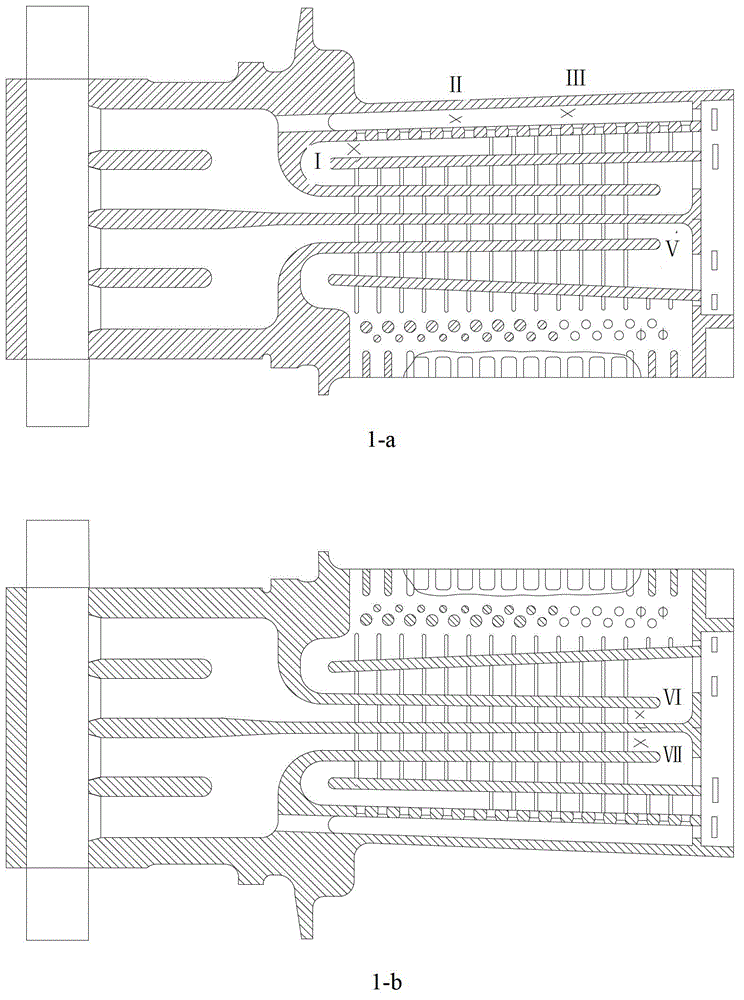

The invention relates to a precision casting production technology of a fired mold having a complex hollow blades, and particularly relates to a fixing method of an isometric crystal and columnar crystal ceramic mold core in a mold shell. The fixing method solves the fixing problem of the ceramic mold core in the mold shell when the complex inner cavity of the blades is formed by employing a preformed ceramic mold core technology, guarantees that the position of the ceramic mold core in the mold shell is relatively fixed during a metal liquid casting process, reduces or prevents the shift of the ceramic mold core, and for the ceramic mold core with relatively complex structure and relatively large core head space, effectively decreases the shift of the ceramic mold core caused by high-temperature creep of the ceramic mold core in a pouring process, thereby preventing the problems of core leakage or extremely poor wall thickness of the casting from generating. The method effectively improves the qualified rate of the investment casting of the complex hollow blades.

Owner:AECC AVIATION POWER CO LTD

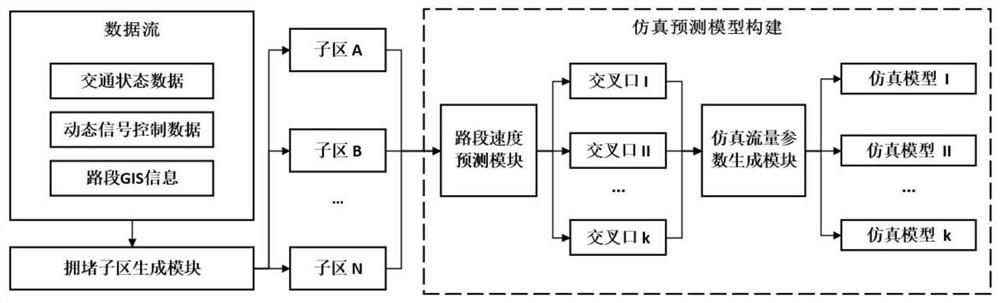

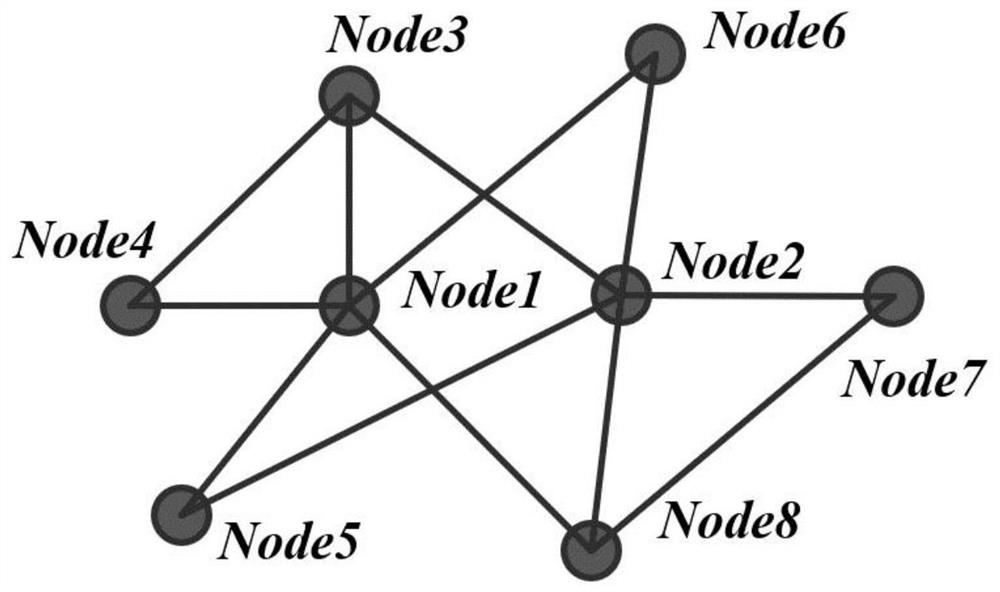

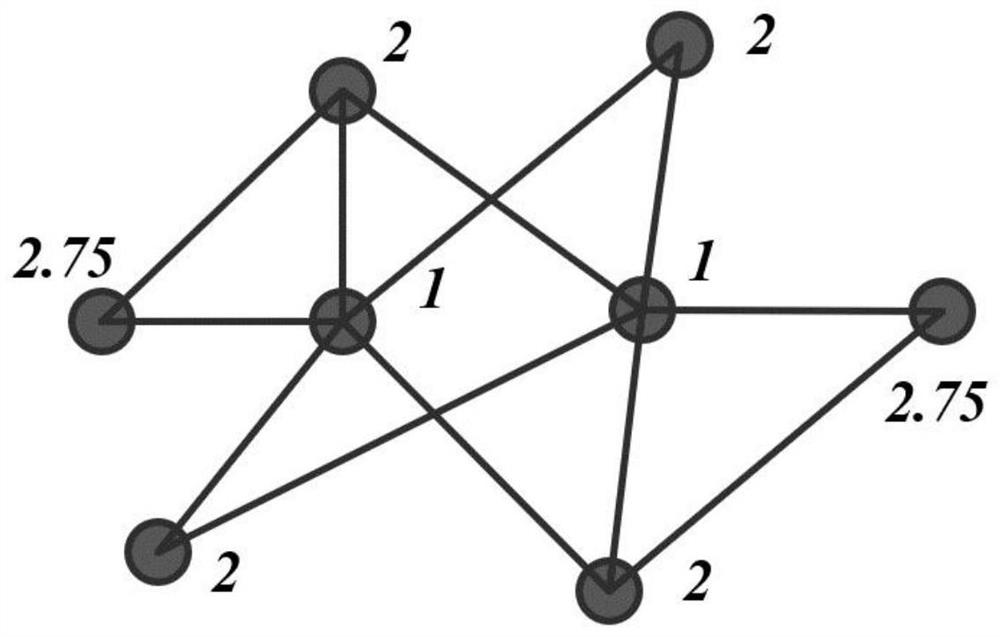

Traffic operation state prediction method and system for congested area

ActiveCN112382082AImprove generalizationFix fixDetection of traffic movementCharacter and pattern recognitionTraffic predictionState prediction

The invention relates to the technical field of traffic prediction, in particular to a traffic operation state prediction method and system for a congested area. The method comprises the following steps: S1, acquiring regional traffic data information; S2, generating a plurality of congestion subareas according to the regional traffic data information; S3, performing road section speed predictionon each road section in each congestion subarea according to the prediction time period to obtain a road section prediction speed of the corresponding prediction time period; S4, carrying out the OD prediction according to the obtained prediction speed of the road section to obtain OD prediction parameters; S5, simulating the regional traffic operation state according to the road section prediction speed and the OD prediction parameters of the congestion subarea so as to predict the regional traffic operation state. According to the method, the dynamic characteristics of the road section association relationship are reserved by constructing the congestion subareas, the problem that a previous traffic simulation area is fixed is solved, the problem of simulation flow parameter calibration under data loss is solved by utilizing the generalization performance of the meta-learning model, and the traffic operation state of the congestion area can be better predicted.

Owner:ENJOYOR COMPANY LIMITED

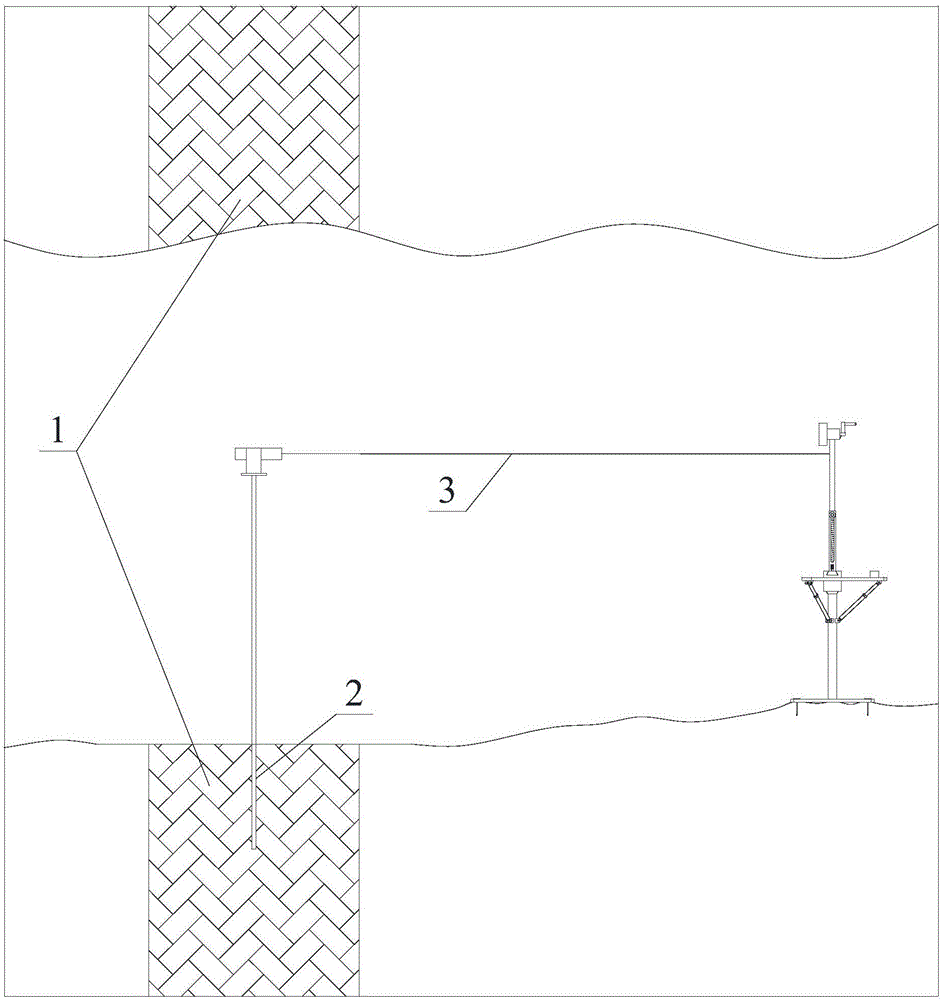

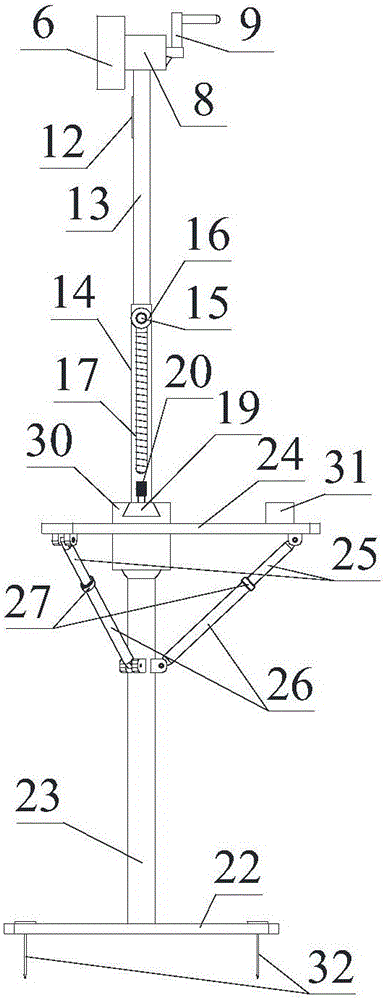

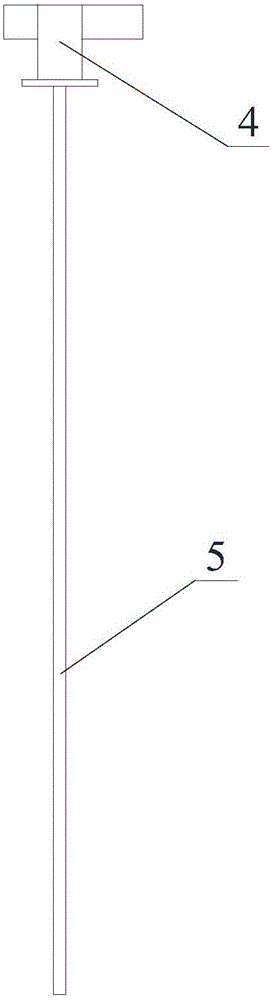

Tunnel surrounding rock deformation monitoring device and method

ActiveCN105783759AReduce labor intensityReduce volumeUsing optical meansSpatial OrientationsLaser ranging

The present invention discloses a tunnel surrounding rock deformation monitoring device and method. The device comprises a measurement support, a leveling pedestal and an assistant position device. The measurement support is vertically arranged on the leveling pedestal through a channel, is able to horizontally move along the channel and is provided with a laser range finder with adjustable height and an observation target, and the assistant position device includes a support bar vertically arranged and a laser locator fixed on the support bar. The tunnel surrounding rock deformation monitoring device and method are configured to employ a laser locator to perform spatial orientation and employ a laser range finder with an adjustable height and a channel adjusting the horizontal position of the measurement support so as to realize that the origins of each measurement are all located at the same straight line in a three-dimensional space and conveniently and rapidly determine the whole deformation characteristics of the tunnel surrounding rock.

Owner:CHINA UNIV OF MINING & TECH

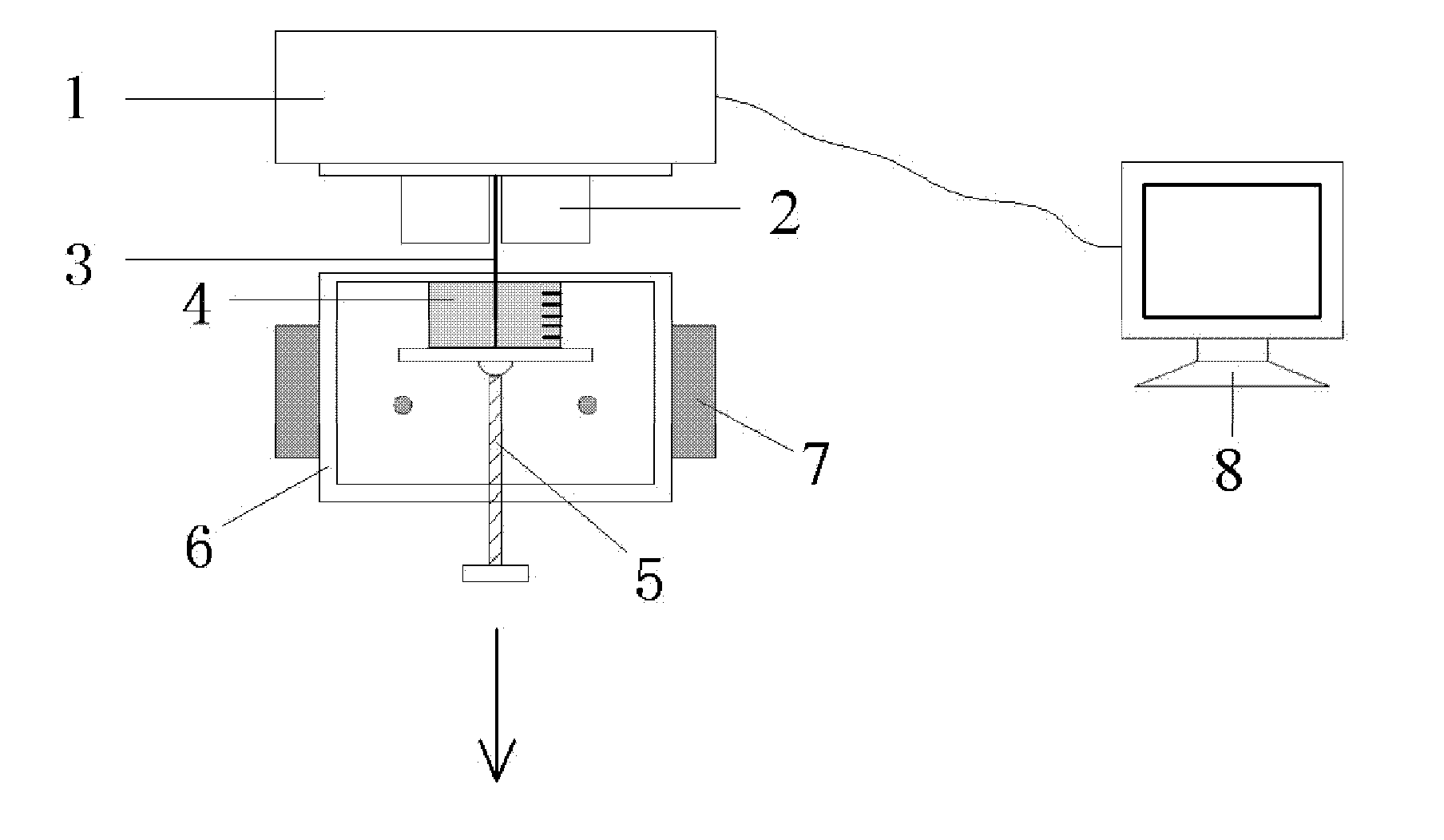

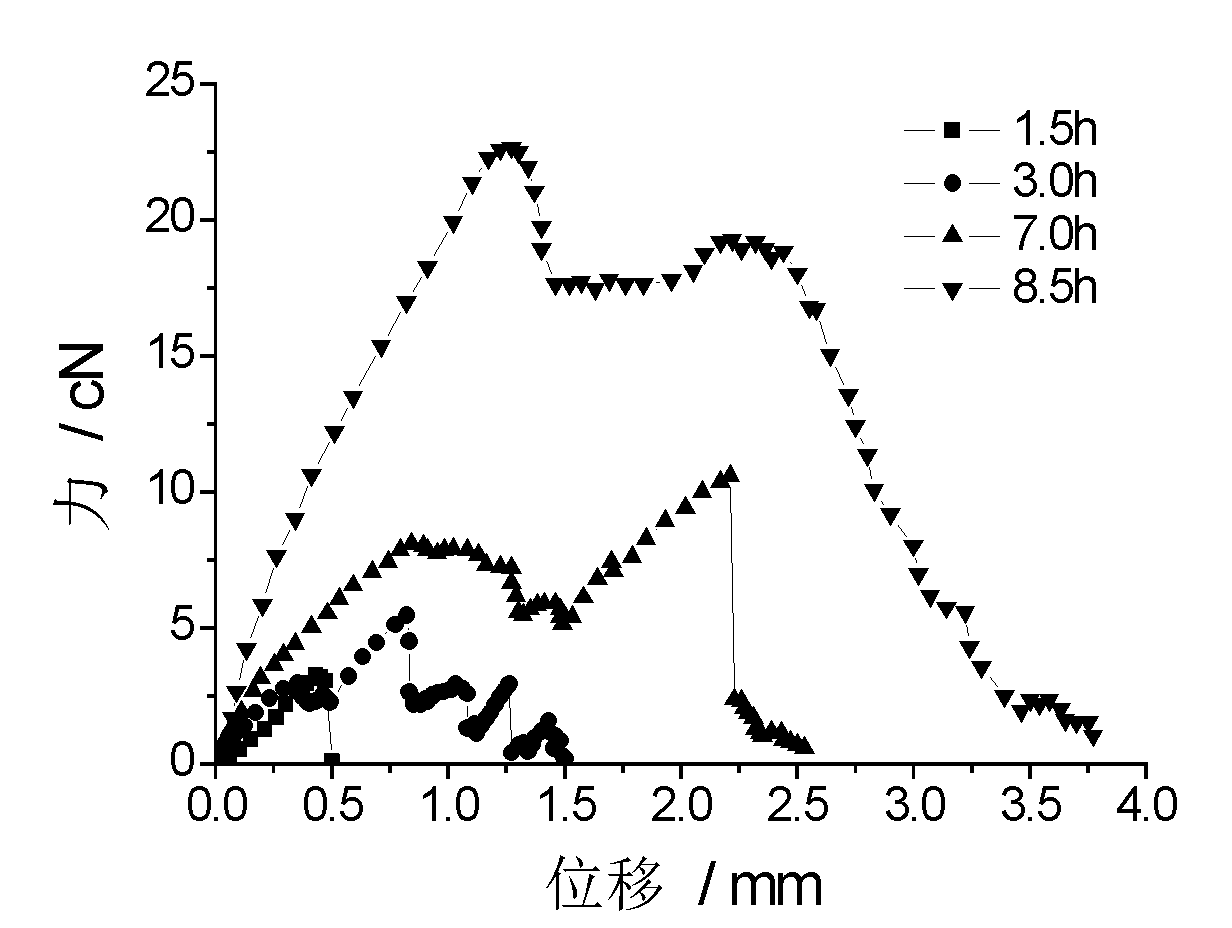

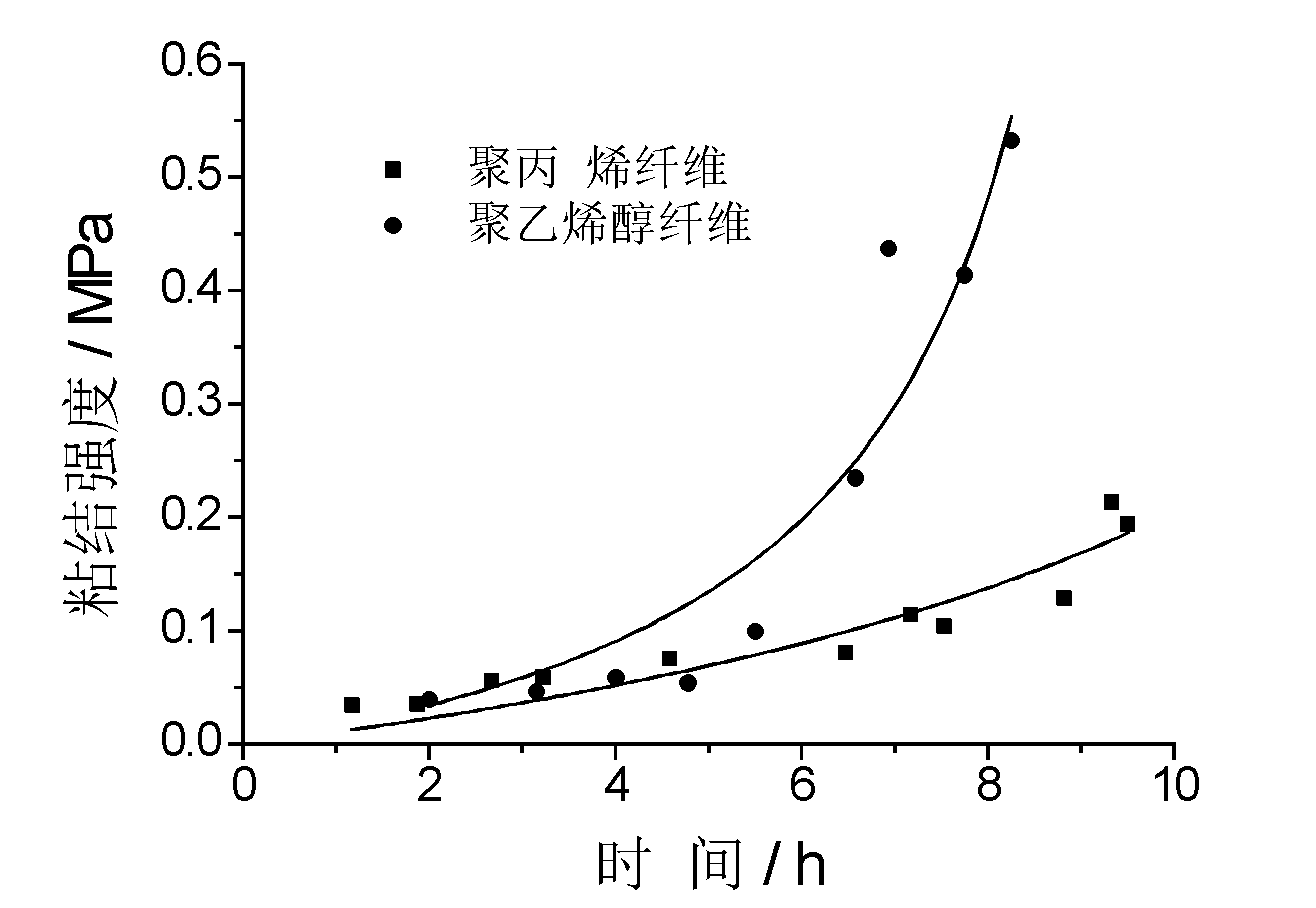

Device for testing bonding performance of synthetic fiber and cement based material during plastic stage

ActiveCN102519799AGuaranteed validityGuaranteed accuracyMaterial strength using tensile/compressive forcesControl parametersSynthetic fiber

A device for testing bonding performance of a synthetic fiber and cement based material during the plastic stage contains a force transducer, a holder, a drive system and a computer. The upper end of synthetic fiber is fixed by the holder and the lower end is embedded in a cement matrix. The holder is installed on the force transducer. The cement matrix is linked with the transmission system. The end of the synthetic fiber clamped by the holder is fixed. Under the control of the computer, the transmission system drives the cement matrix to move such that the synthetic fiber is pulled out from the cement matrix. The force transducer inputs force parameters measured during the pulling process into the computer for test and analysis. The invention solves problems of large measuring range and insufficient precision of present test equipment. According to the invention, the whole process is completed by the operation of the computer, and corresponding measurement and control parameters are arranged for the synthetic fiber, so as to guarantee validity and accuracy of the test result.

Owner:JIANGSU SOBUTE NEW MATERIALS

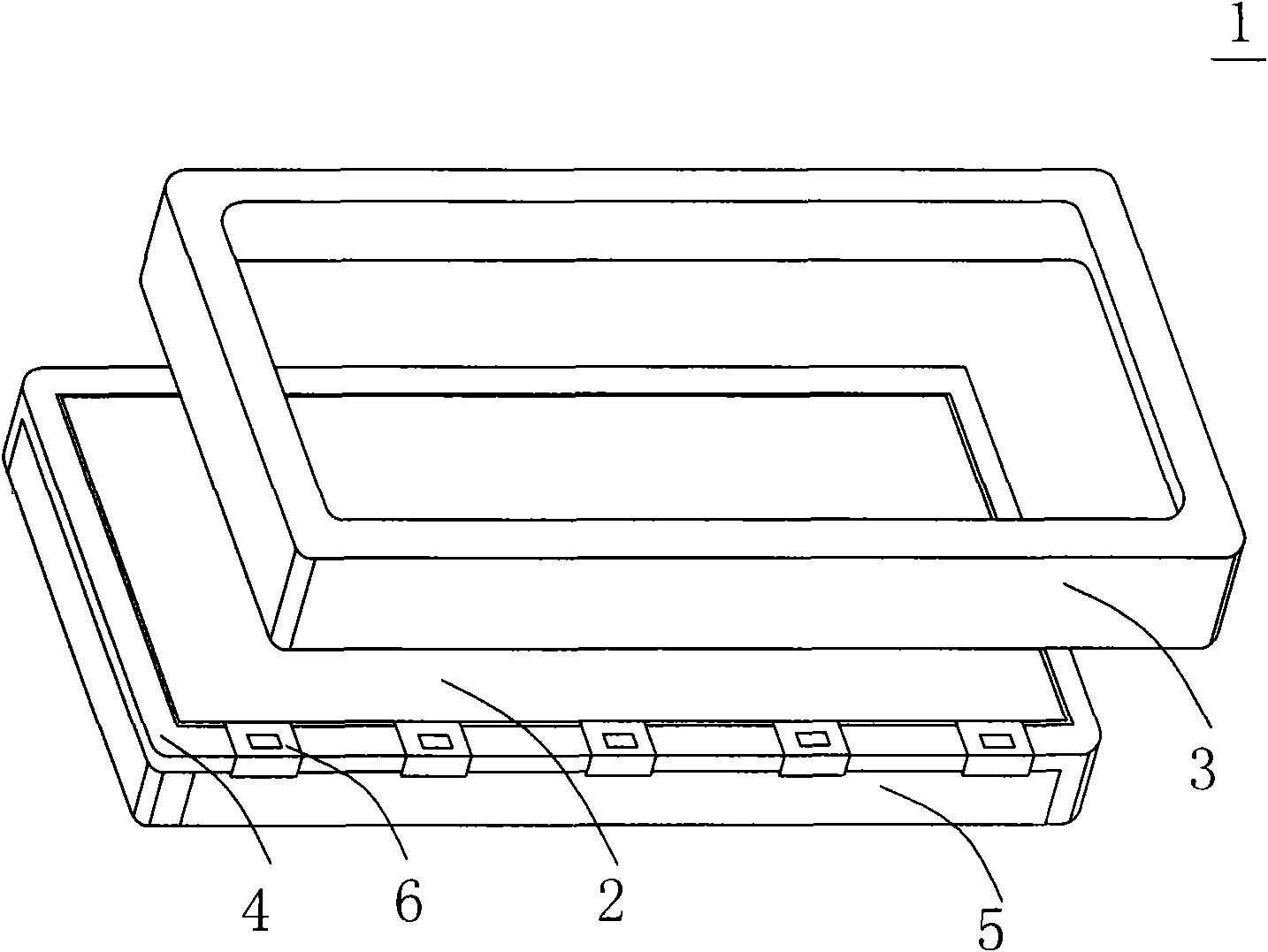

Display module assembly and method for fixing circuit wafer thereof

ActiveCN101576668AFix fixImprove EMI phenomenonPrinted circuit detailsNon-linear opticsEngineeringBackplane

The invention provides a display module assembly and a method for fixing a circuit wafer thereof; wherein, the display module assembly comprises a backboard, at least a fixed component and the circuit wafer; the fixed components are provided with a pair of connecting pieces arranged at the backboard and a pair of fasteners arranged at the connecting pieces; a first distance is kept between the connecting pieces of the fixed components; and the connecting pieces of the fixed components are suitable to deform in a flexible way by means of shortening the first distance. The circuit wafer is provided with at least a fixed hole, the connecting pieces of the fixed components penetrate through one of the fixed holes and the fixed holes are restricted between the fasteners and the backboard of the corresponding fixed components.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

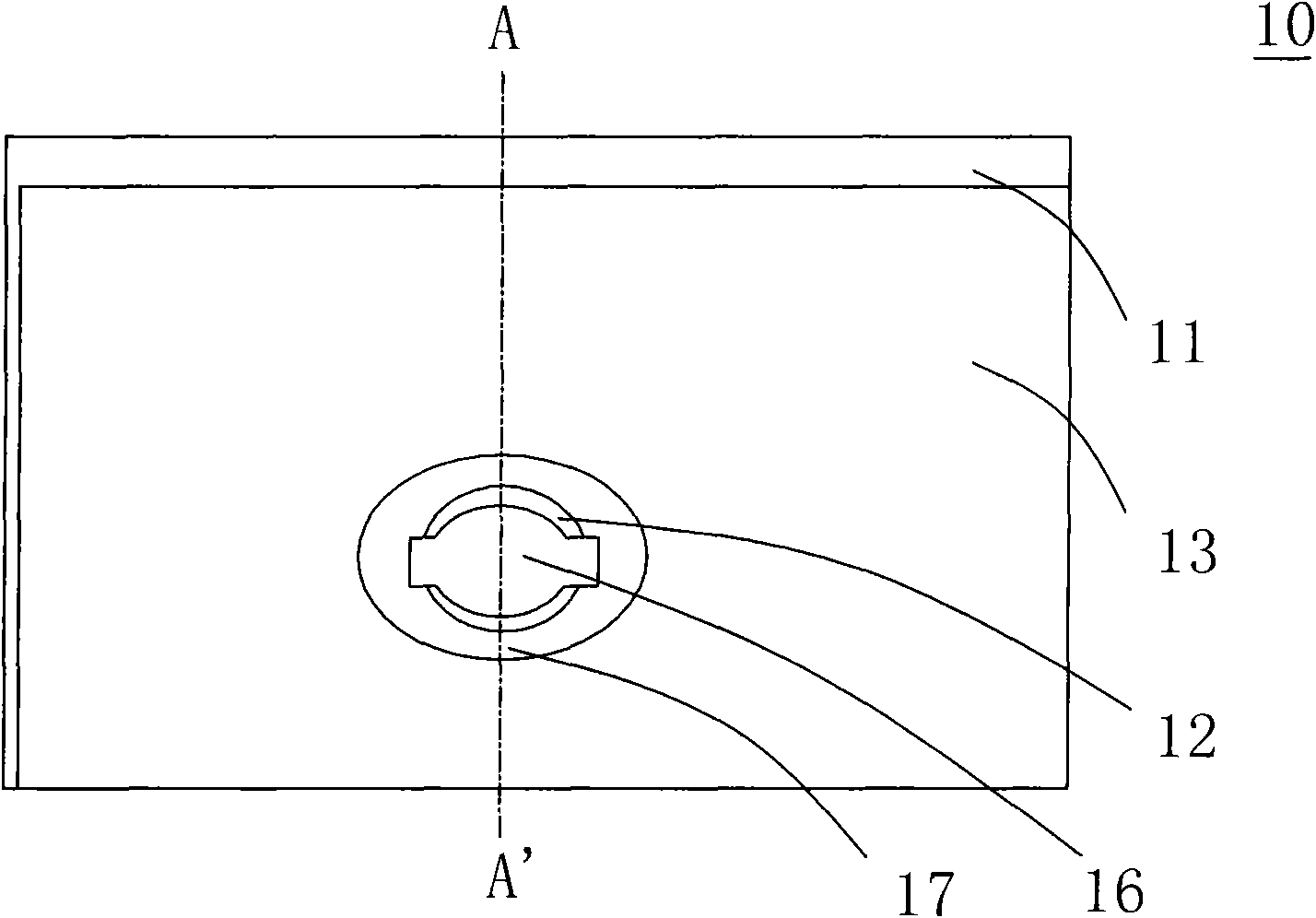

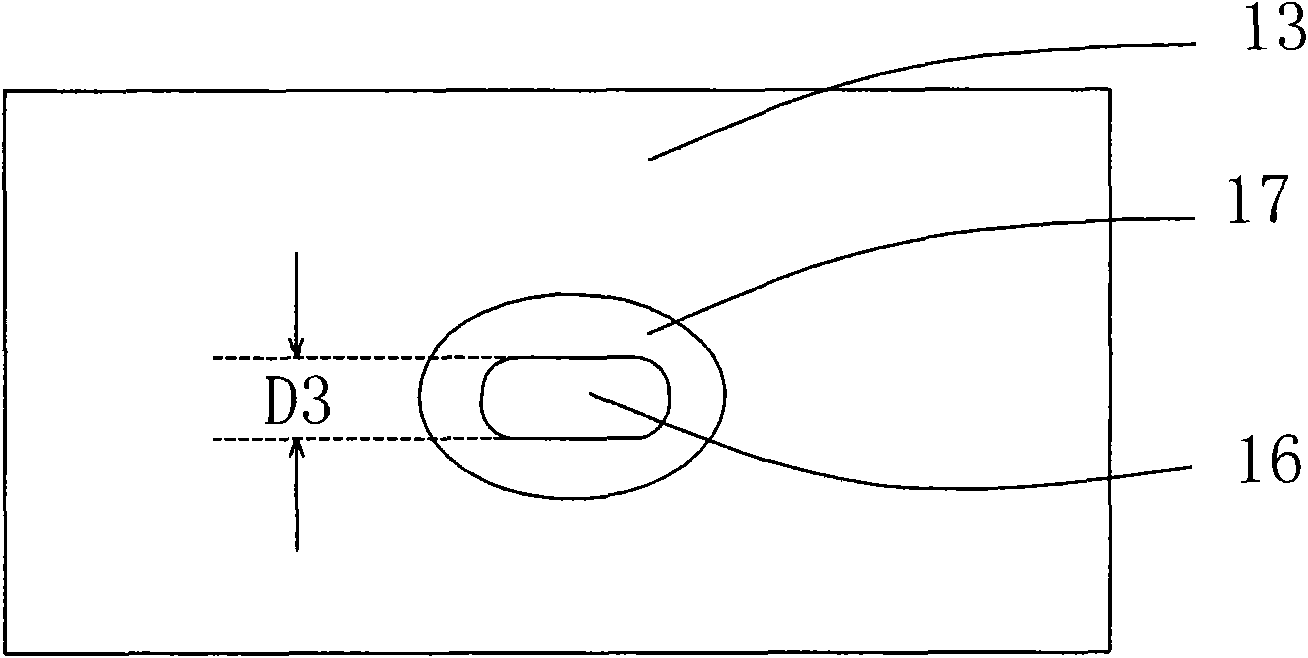

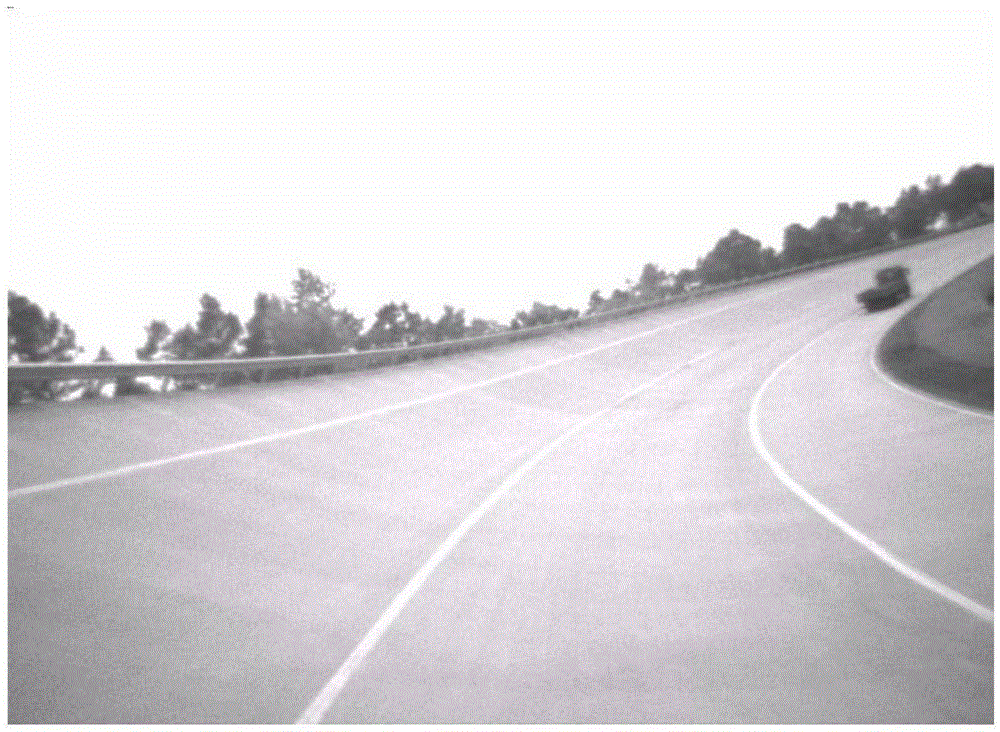

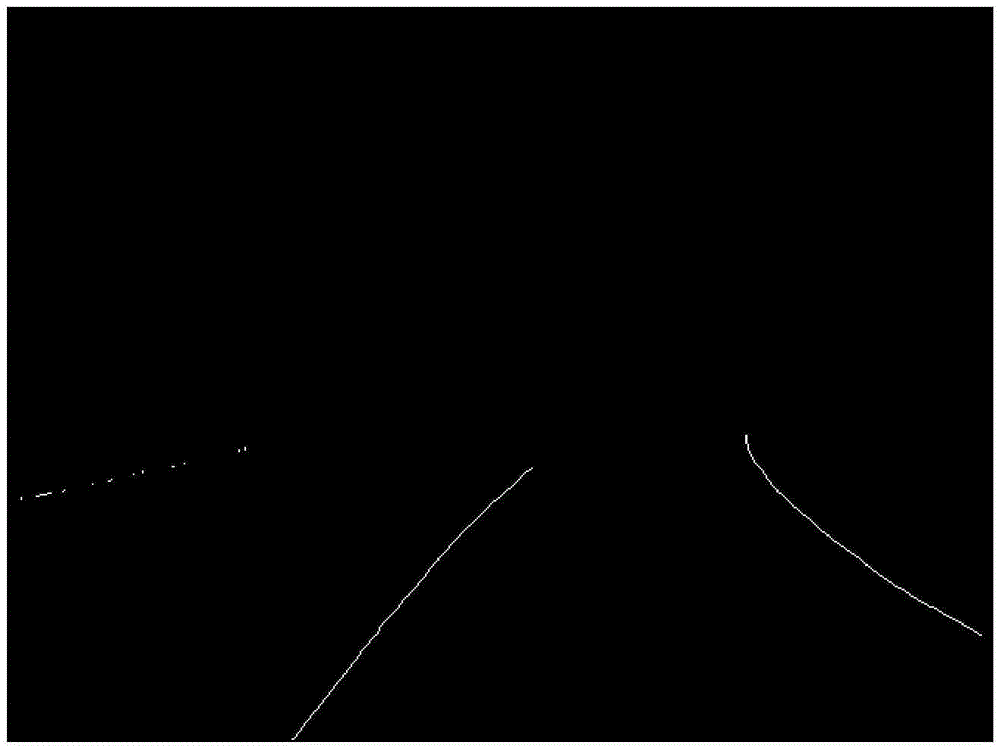

Lane detection method based on adaptive region of interest

ActiveCN105426868AAccurate detectionStable detectionCharacter and pattern recognitionBusiness forecastingLinear prediction

The invention relates to a lane detection method based on an adaptive region of interest. The method specifically comprises the following steps: (1) acquiring a road image; (2) pre-processing: detecting edges, binarizing the image, and eliminating isolated points to eliminate non-lane noise; (3) determining the initial position of a lane by single Hough transformation, retaining the upper end point of the initial position of the lane, linearly forecasting the lane in combination with least square fit to obtain an adaptive region of interest changed along with the direction of the lane, and detecting the lane within the obtained adaptive region of interest; and (4) judging that the lane detected in step (3) is straight or curved and outputting video marking the lane. According to the method, the initial position of the lane is determined by single Hough transformation, and a least square method with higher operation speed is adopted in the following linear forecasting process, so that the contradiction between accuracy and instantaneity of a single method is solved, and accuracy and instantaneity are ensured.

Owner:山东智瞰深鉴信息科技有限公司

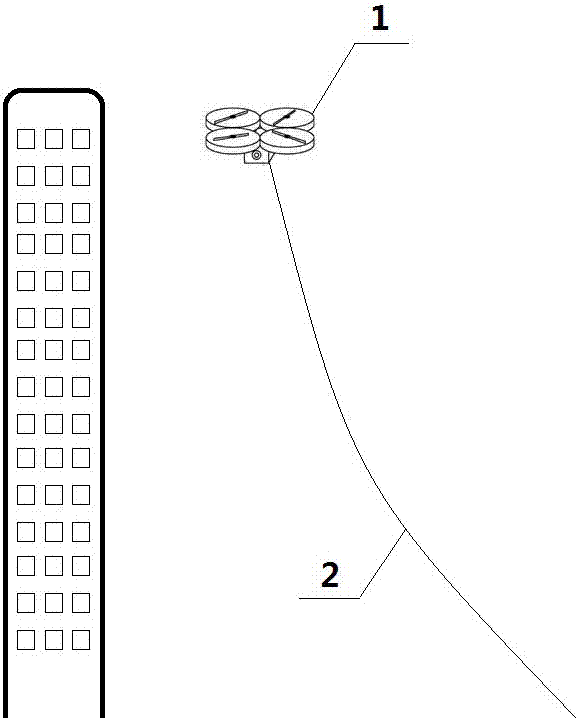

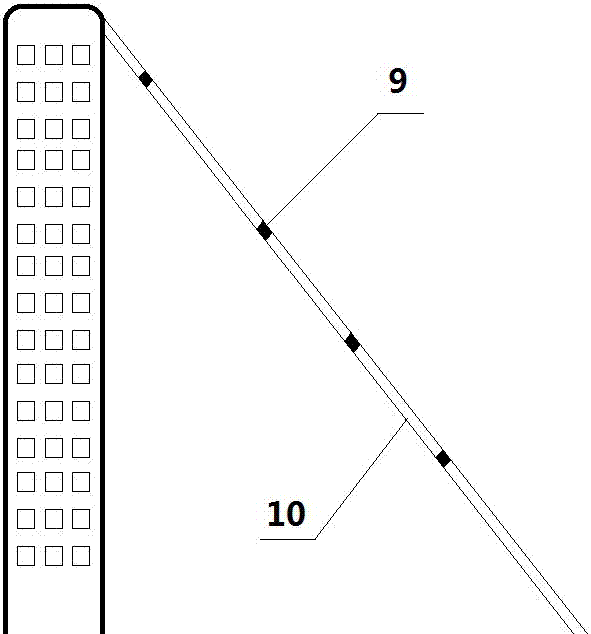

High-rise building life saving system developed based on unmanned aerial vehicle technology

The invention discloses a high-rise building life saving system developed based on the unmanned aerial vehicle technology and especially relates to a technology that a cable is delivered to the interior or the top of a high-rise building by means of an unmanned aerial vehicle system, an escaping cableway is built through the cable, an emergency life saving slide is fixed through the escaping cableway, and trapped personnel are evacuated by means of the emergency life saving slide.

Owner:郭鹏

Nanometer Ag antimicrobial and preparation method thereof

InactiveCN102613243ABroad-spectrum antibacterialImprove permeabilityBiocideAntifouling/underwater paintsPlasticizerDistilled water

The invention discloses a nanometer Ag antimicrobial comprising nanometer Ag particle, a solubilizer, a water-soluble polymer, a plasticizer, a processing modifier, a solvent, a film-forming assistant, essence, pigment, distilled water or deionized water. The invention also disclosed a preparation method of the nanometer Ag antimicrobial. The preparation method comprises the steps of: adding the nanometer Ag particle into the distilled water or the deionized water, adding the solubilizer and the water-soluble polymer, and stirring to prepare a solution A; adding the plasticizer and the processing modifier (acrylate (ACR)) into the solvent, stirring, adding the film-forming assistant, and stirring to prepare a solution B; and adding the solution A into the solution B, adding the essence and the pigment, and stirring to obtain the nanometer Ag antimicrobial. The nanometer Ag antimicrobial disclosed by the invention has the advantages of strong adhesion on objects, good film forming property, good friction resistance and long-lasting antibacterial effect; and the preparation method has the advantages of simpleness and strong operability.

Owner:宋信宇

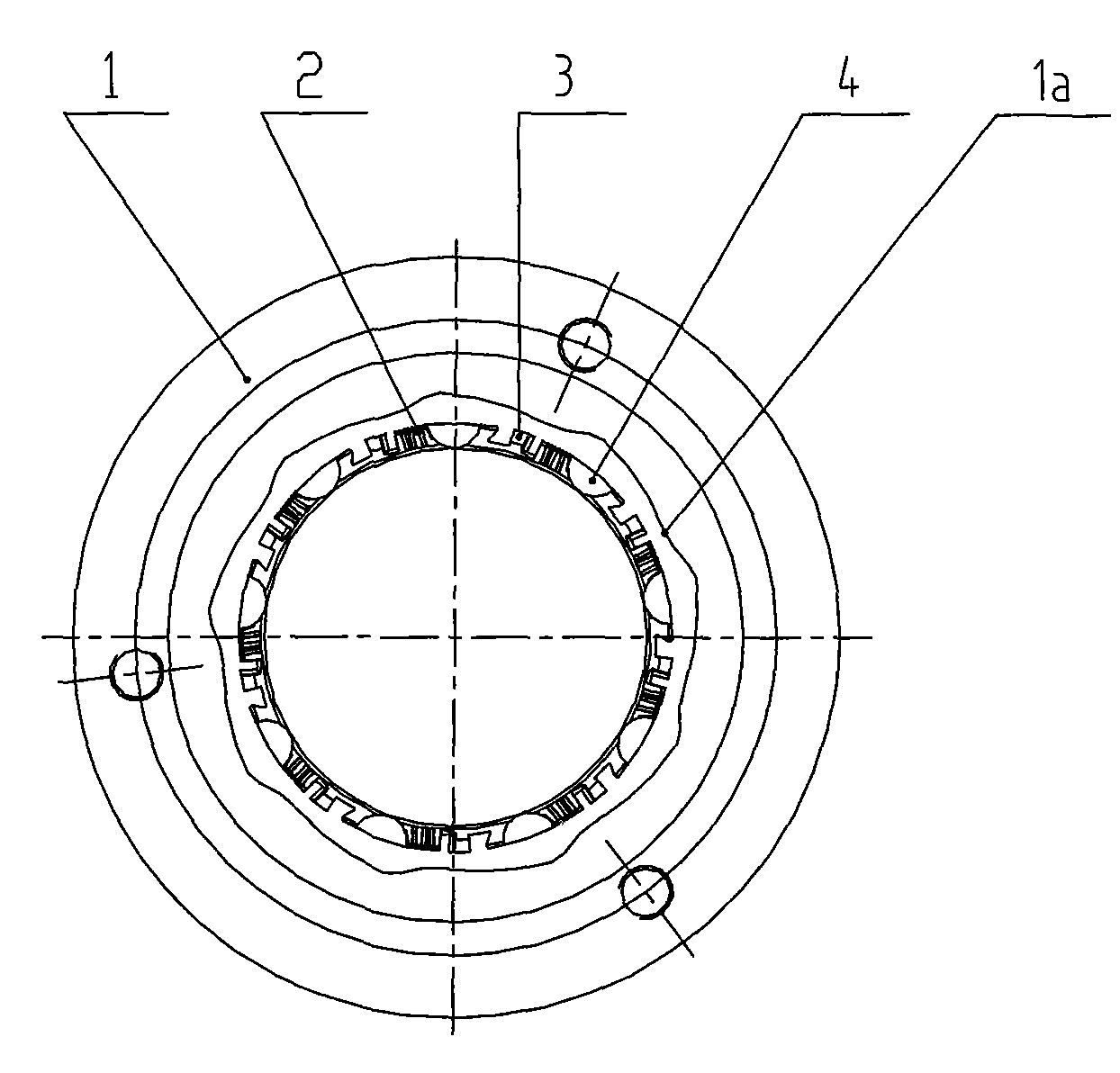

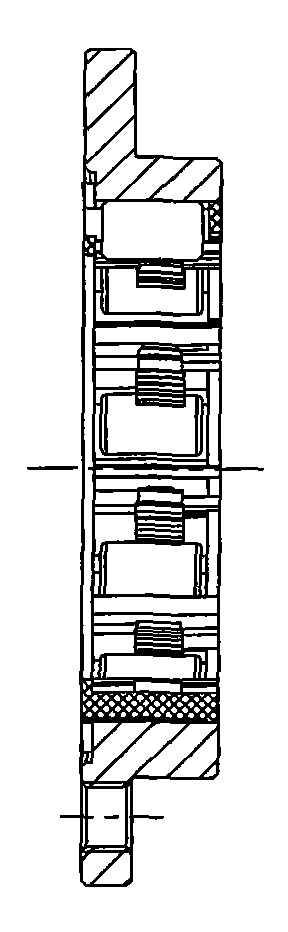

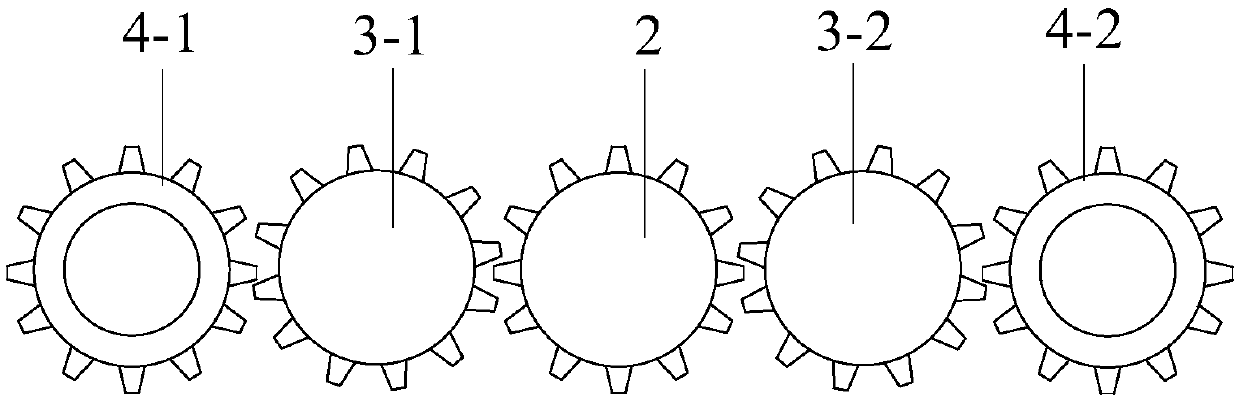

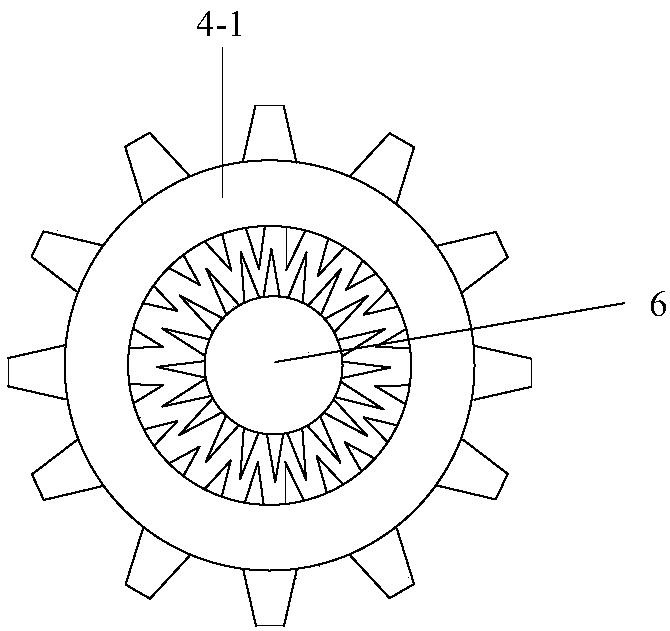

Multi-roller overrun clutch

The invention relates to a multi-roller overrun clutch, in particular to a multi-roller overrun clutch suitable for occasions with small design space and high torsional moment. The clutch comprises at least six rollers, a star wheel type outer ring, a retainer and six spring pieces, wherein the retainer is tightly arranged in the star wheel outer ring; the rollers are placed in each window formed by an end ring and a beam and each concave curved wedge surface in the star wheel type outer ring; one end of the spring piece is provided with an elastic bayonet, and the other end is an arc-shaped end matched with the outer circle surface of each roller; the elastic bayonet of the spring piece is buckled on the beam of the retainer; and the arc-shaped end is matched with the roller and pushes the roller. The invention solves the technical problems that the prior roller clutch has fewer rollers, small transmission torque, complex structure, poor stability and short service life.

Owner:JIANG SU NAN FANG BEARING CO LTD

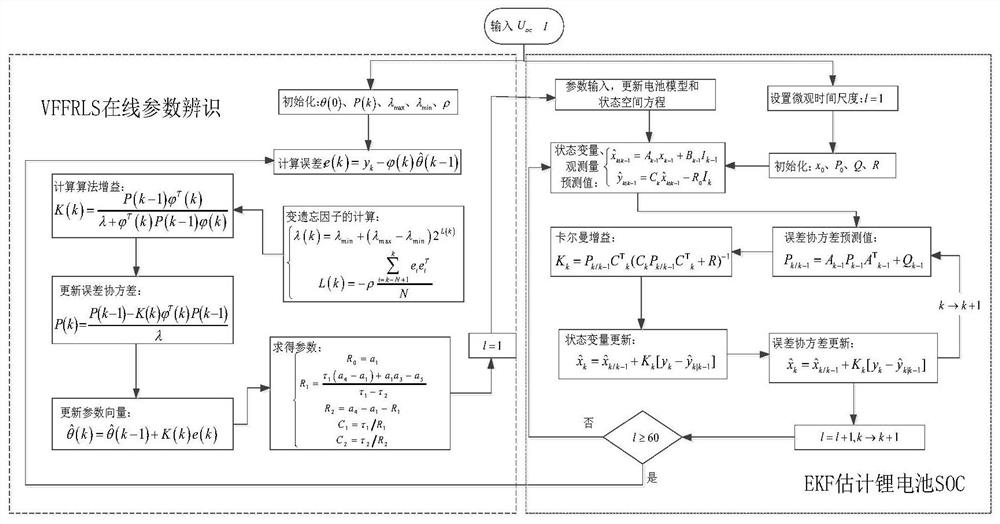

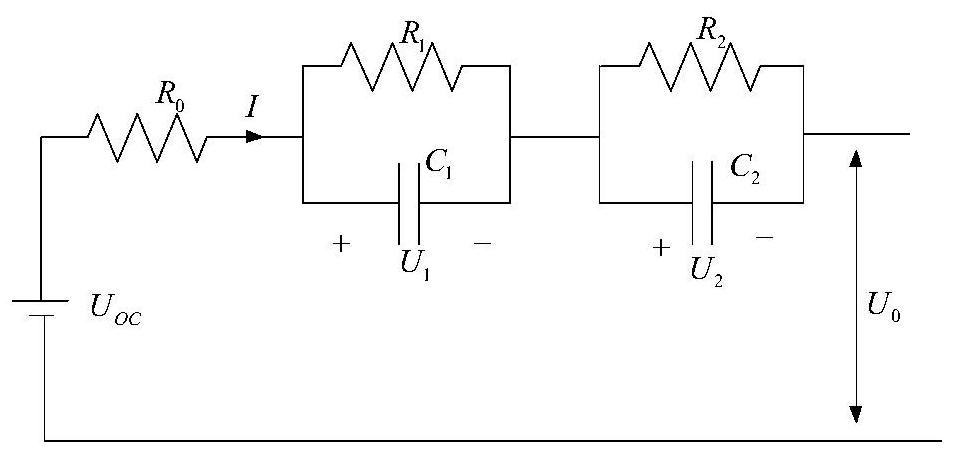

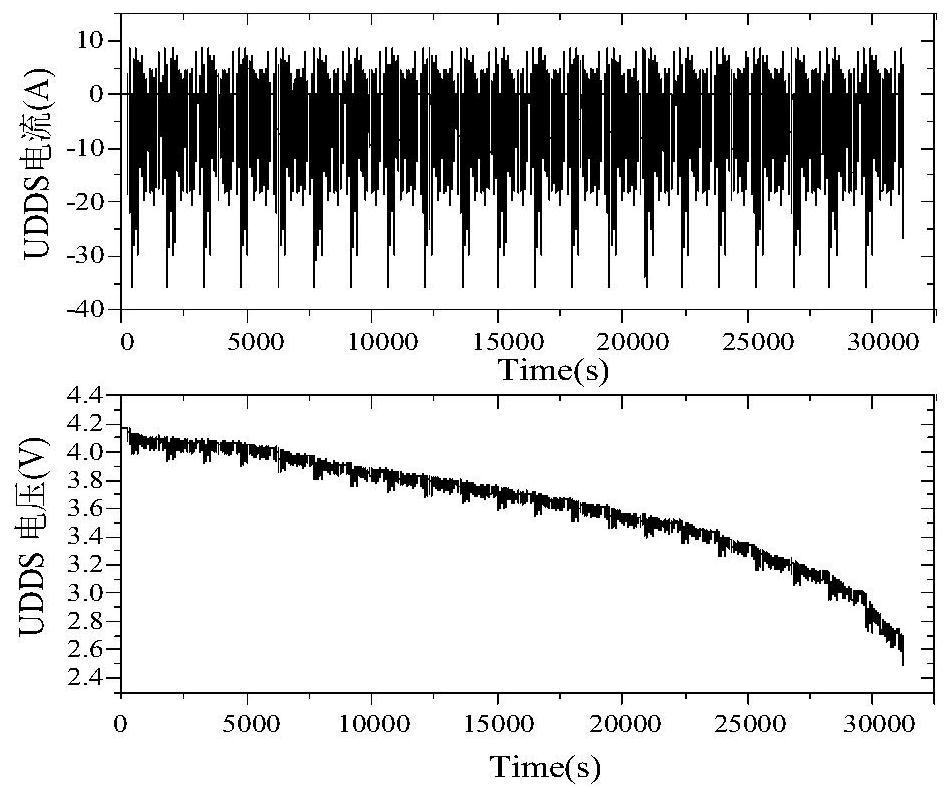

Online parameter identification and SOC joint estimation method based on variable forgetting factor

PendingCN113030752AAccuracy and SOC estimation accuracy improvedHigh precisionElectrical testingExtended kalman filter algorithmLithium battery

The invention discloses an online parameter identification and SOC joint estimation method based on a forgetting factor. The method comprises the following steps: establishing a lithium battery second-order equivalent circuit model; determining a function relationship between each parameter of the circuit and the SOC, and establishing a state-space equation of the lithium battery; initializing an SOC state variable and a parameter state variable, and estimating the SOC of the lithium battery by using an extended Kalman filtering algorithm under a microscopic time scale; when the SOC estimation of the lithium battery reaches a preset time, switching to a macroscopic time scale, identifying equivalent circuit parameters by using a variable forgetting factor recursive least square method, and finally updating the equivalent circuit parameters and the state-space equation of the lithium battery to carry out a next round of calculation. According to the method, online parameter identification is performed on the lithium battery model through the variable forgetting factor recursive least square method, and the SOC of the lithium battery is estimated in combination with the extended Kalman filtering algorithm, so that the problem that the forgetting factor is fixed in the forgetting factor recursive least square method is solved, online updating of the parameters of the lithium battery is realized, and the SOC estimation precision of the lithium battery is improved.

Owner:ANHUI UNIV OF SCI & TECH

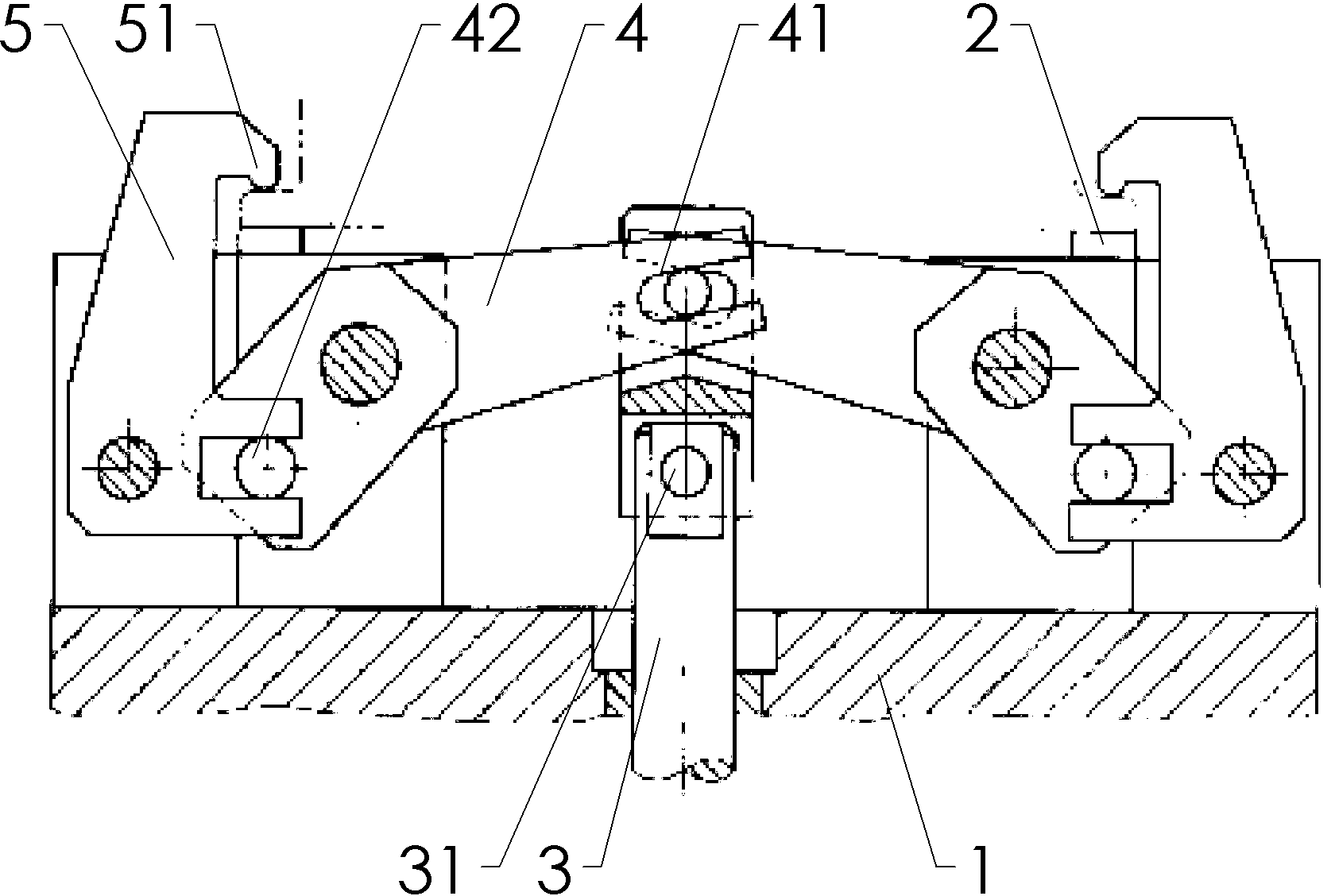

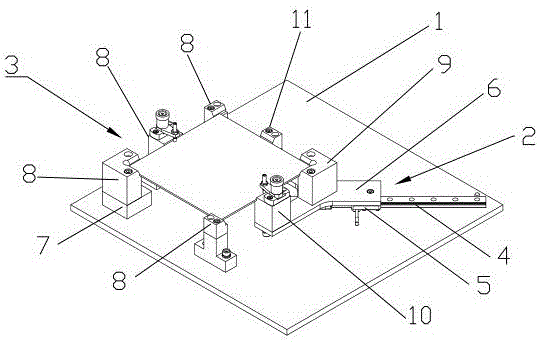

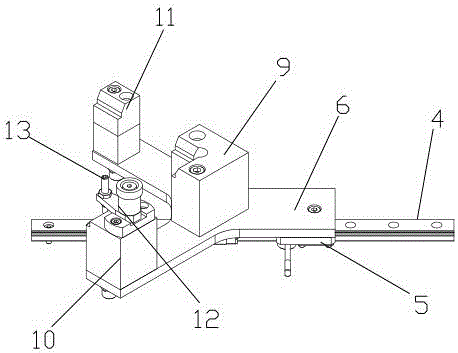

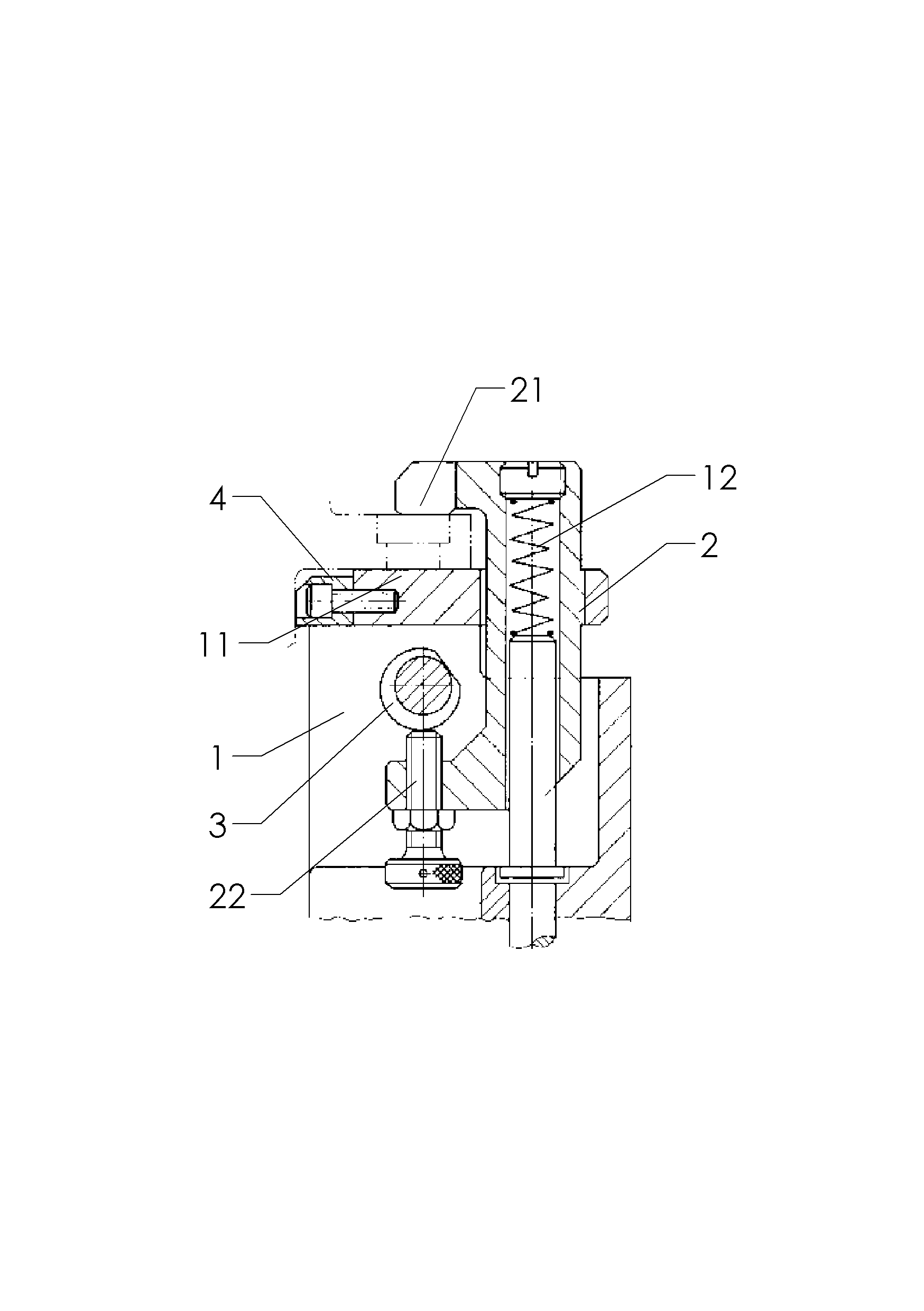

Floating compression device

InactiveCN103009090AFix fixPositioning apparatusMetal-working holdersHorizontal forceCompression device

The invention discloses a floating compression device, which is used for solving the problem of fixation of lower supporting legs of workpieces in the prior art. In the scheme, the floating compression device is characterized by comprising a base, fixed supporting seats, a force application rod, swing stems and compression rods, wherein the fixed supporting seats are fixed on the base; the force application rod can move vertically and axially; the swing stems are articulated on the base; the compression rods are articulated on the base; the force application rod is provided with a horizontal force application rod pin; one end of each swing stem is provided with a swing stem sliding chute which is in sliding fit with the force application rod pin; the other end of each swing stem is provided with a swing stem pin; the lower ends of the compression rods are provided with compression rod sliding chutes which are in sliding fit with the swing stem pins; the upper ends of the compression rods are provided with compression blocks, and are positioned above the fixed supporting seat; and the upper and lower ends of the compression rods are positioned on the same side of the articulation rotation center plumb line of the compression rods. The technical scheme is characterized in that lower supporting legs of workpieces can be well fixed.

Owner:重庆市南川区富民科技推广中心

X-ray tomography-based in-situ loading device

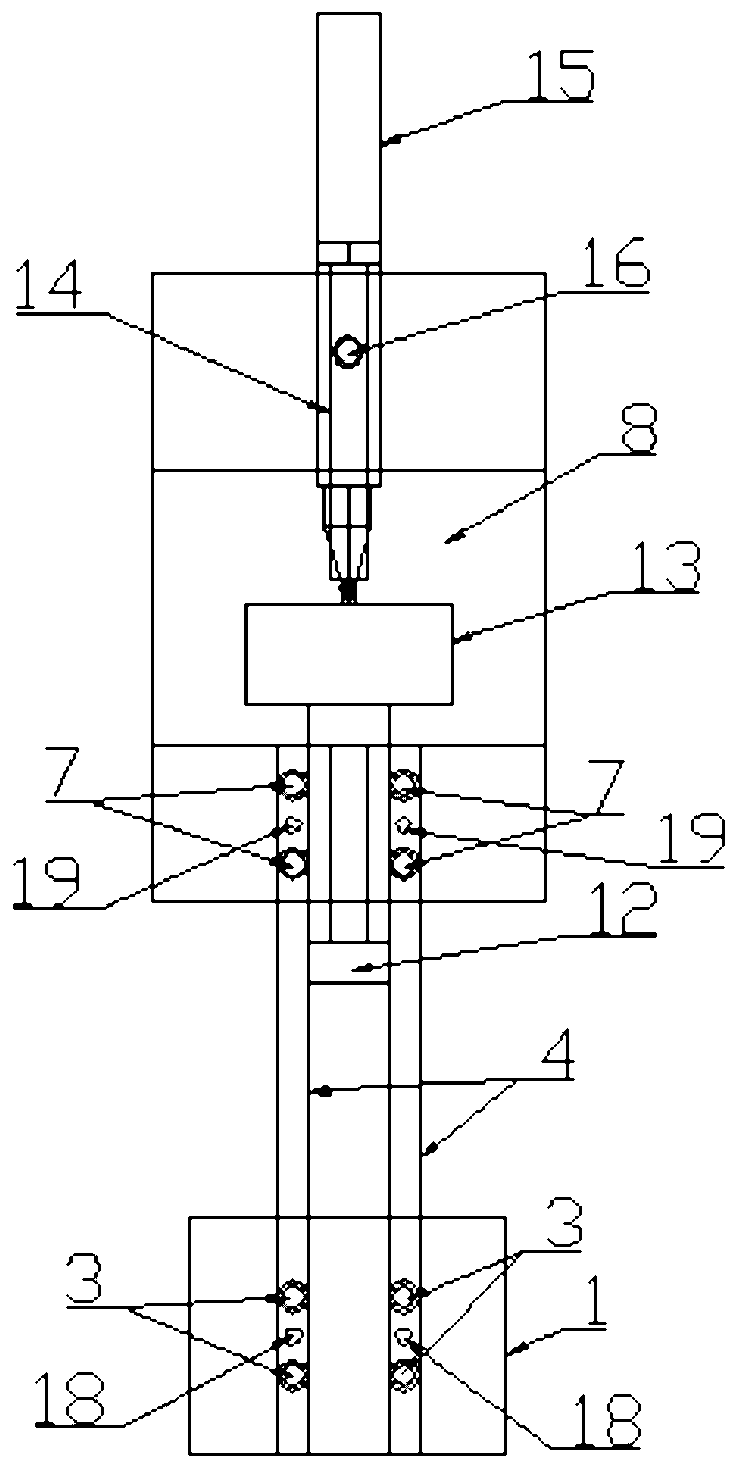

InactiveCN102323279AFix fixGuaranteed image qualityMaterial analysis by transmitting radiationFiberCarbon fibers

The invention relates to an X-ray tomography-based in-situ loading device, which comprises a lower clamping block, an upper clamping block, a displacement sensor and carbon-fiber reinforced plastic rods, wherein a cavity, a moving dowel bar and a loading screw are arranged on the upper clamping block; the moving dowel bar is glidingly connected with the upper clamping block, one end of the movingdowel bar is positioning outside the upper clamping block, and the other end of the moving dowel bar is positioned in the cavity; the loading screw is in threaded connection with the upper clamping block; a stress sensor is arranged in the cavity, and a displacement sensing head of the displacement sensor is propped against the stress sensor at the part where the stress sensor is positioned between the other end of the moving dowel bar and the loading screw; upper-end connection holes and lower-end connection holes are respectively arranged on the upper clamping block and the lower clamping block; the upper and the lower ends of the carbon-fiber reinforced plastic rods are arranged in the upper-end connection holes and the lower-end connection holes and are fastened through upper-end fastening blots and a lower-end fastening blots which are respectively arranged on the upper clamping block and the lower clamping block; and upper-end fixing pins and lower-end fixing pins are respectively arranged on the upper clamping block and the lower clamping block and radially penetrate through the carbon-fiber reinforced plastic rods.

Owner:SOUTHEAST UNIV

Succulent planting matrix, method for building greening wall and greening wall

InactiveCN106613451AMeet growth needsNot easy to hardenBioloigcal waste fertilisersGrowth substratesEngineeringOrganic matter

The invention belongs to the technical field of greening walls, provides a succulent planting matrix and further provides a method for building a greening wall and the greening wall. The planting matrix is prepared from, by weight, 40-60 parts of organic matter, 40-60 parts of particular matter, 0.5-1 part of plant protection agent and 3-5 parts of slow release fertilizer. The method for building the greening wall includes the following steps that S1, multiple greening wall planting modules not provided with fixing strips and decorative frames are provided; S2, succulents are transplanted into a planting chamber; S3, the greening wall planting modules are fixed to a wall through hanging grooves and hanging pieces, and the greening wall is obtained through combination. The succulent planting matrix is loose and breathable, water drainage and retention effects are good, no hardening is likely to happen, no settling is likely to occur on a vertical face, certain fertility can be kept for a long time, and root rot is avoided.

Owner:GUANGDONG DONGLEE ENVIRONMENT CO LTD

Fixing clamp for circuit board welding

InactiveCN106624536AFix fixSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a fixing clamp for circuit board welding. The fixing clamp for circuit board welding comprises a base and a clamp device; the clamp device is installed on the base; the clamp device comprises a movable assembly and a fixed assembly; the movable assembly comprises a guide rail, a sliding block and a fixed plate, the guide rail is fixedly installed on the base and provided with the sliding block which is connected with the fixed plate, and a movable clamping block is installed on the fixed plate; and the fixed assembly comprises a fixed seat and a fixed clamping block, the fixed seat is fixedly installed on the base and provided with the fixed clamping block. When a circuit board needs to be fixed, firstly the circuit board is placed on the fixed clamping block, then the sliding block is pushed to move on the guide rail, the movable clamping block works on the circuit board, thus the circuit board is fixed, and accordingly welding work of the circuit board by workers is facilitated; the fixing clamp is simple in structure, convenient and practical and can be applied to circuit boards with different sizes; and labor intensity of the workers is effectively reduced, and production efficiency is improved.

Owner:王丽春

Casting method of sand core oil tube of internal combustion engine

ActiveCN104070135ASolve sticky sandSolve shrinkageFoundry mouldsFoundry coresInternal combustion engineRejection rate

The invention relates to a casting method, and particularly relates to a casting method of a sand core oil tube of an internal combustion engine. The casting method comprises the steps of molding, core making, mold assembling and casting. The casting method is characterized in that in the core making process, an oil tube sand core is adopted to position, i.e. the oil tube sand core passes through all inner cavity cores, so as to determine the position of an oil tube by positioning outer mold core heads on both sides, a steel tube is selected as core iron, and chromite sand is used as raw materials of the oil tube core; in the mold assembling process, the oil tube sand core is prevented from being bent and deformed, i.e. ends are additionally arranged, a mold shrinkage joint disappears, forced cooling is performed by blowing compressed air, and a special leakproof chaplet is additionally arranged in the position of the oil tube in the mold assembling process. The casting method has the advantage of unique process, the casting quality can be increased, and the product rejection rate can be reduced.

Owner:KOCEL EQUIP

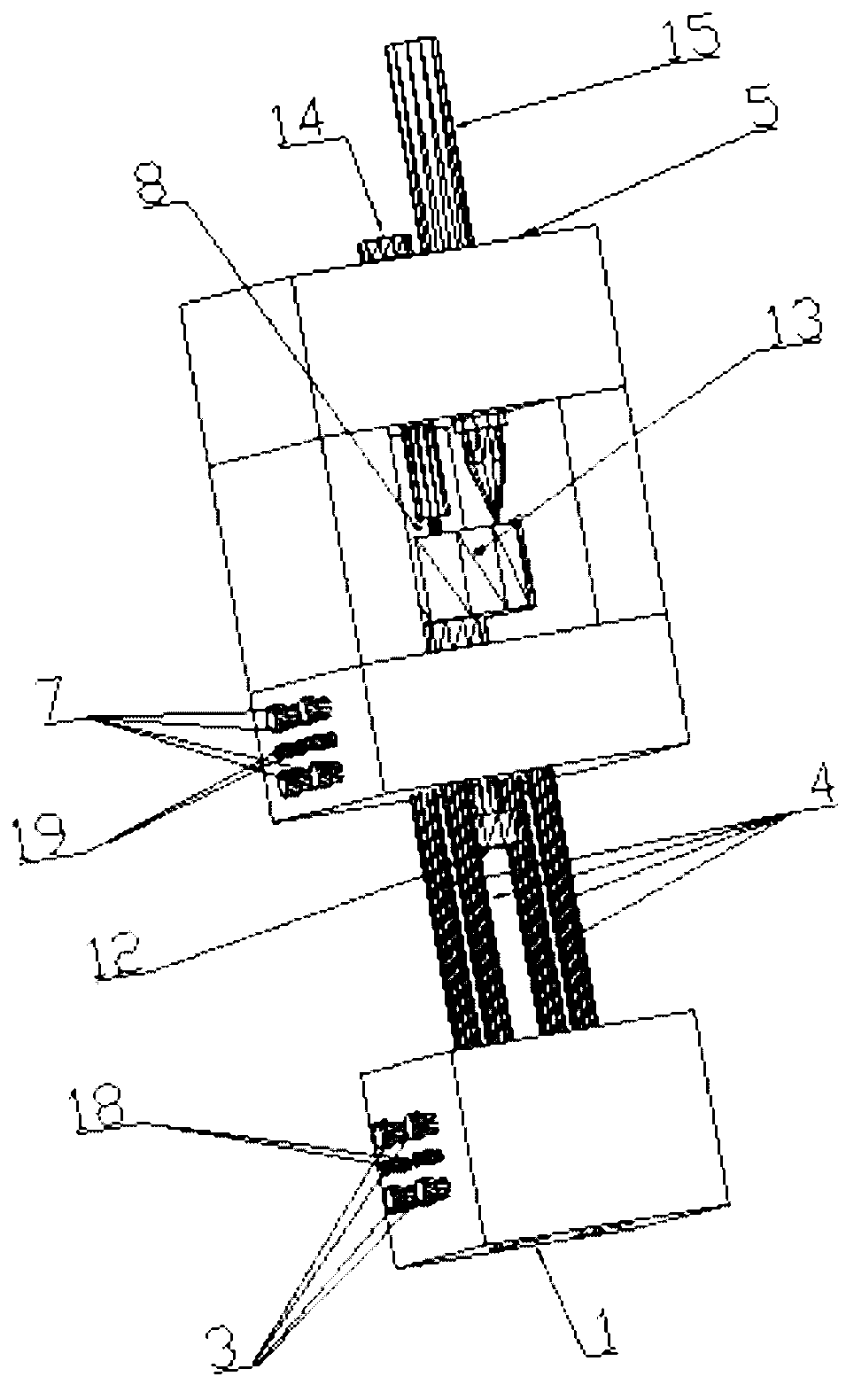

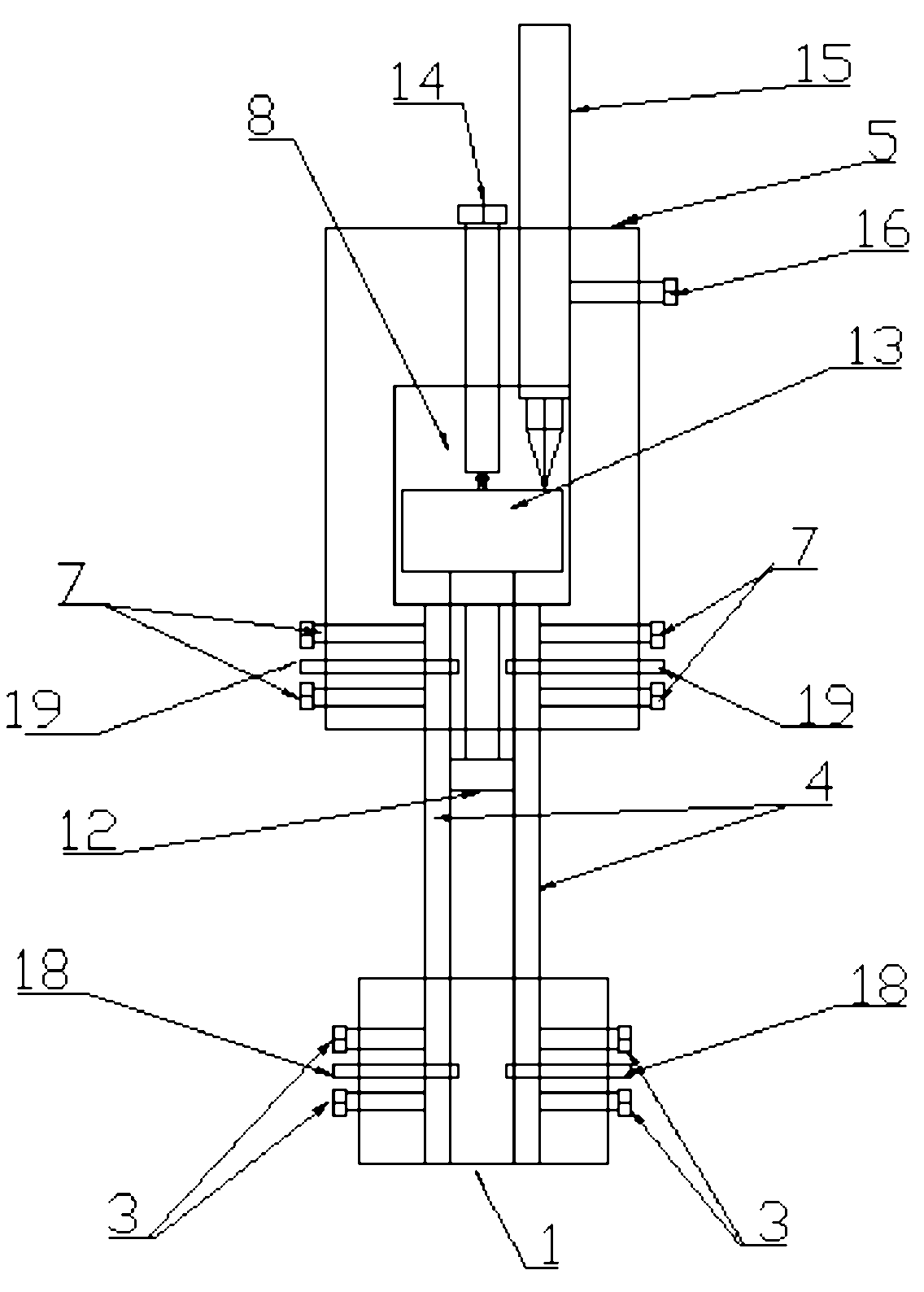

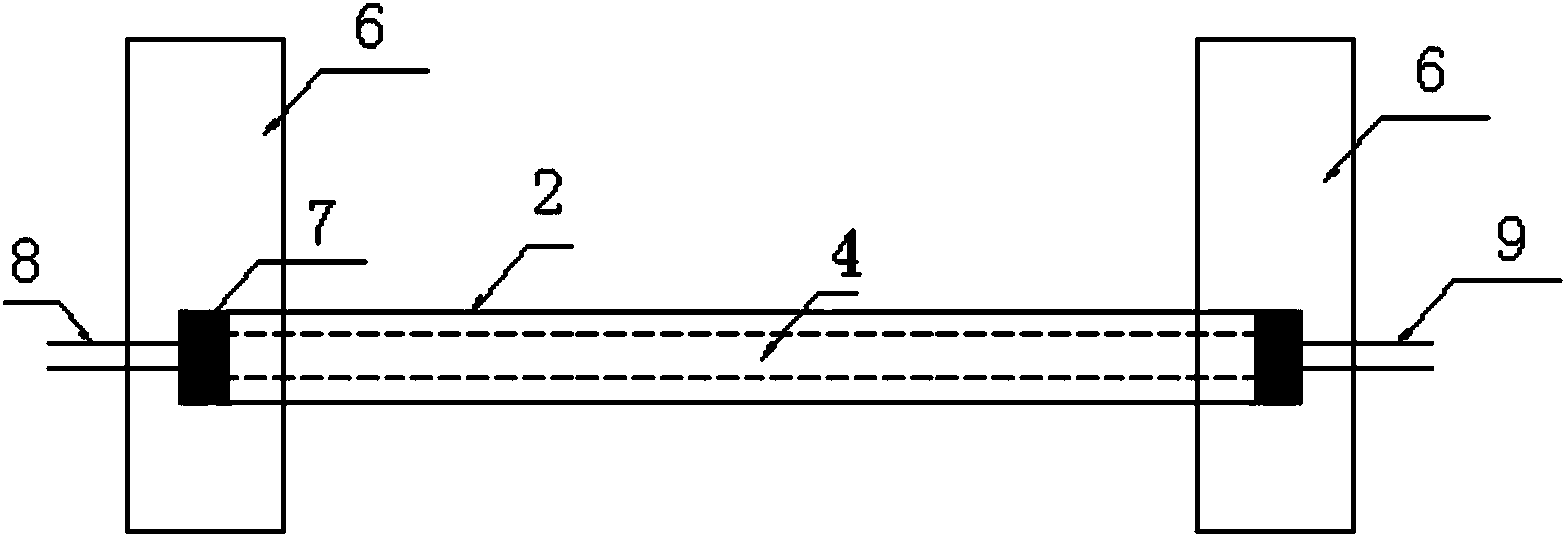

Column beam type grouting device and hole sealing and grouting technology thereof

InactiveCN104196489AAdvantages of sealing and grouting processGrouting pressure is easy to controlSealing/packingEconomic benefitsHigh pressure

The invention discloses a column beam type grouting device and a hole sealing and grouting technology of the grouting device. The grouting device comprises a grouting pipe connecting device and a high-pressure sluice valve. The grouting pipe connecting device comprises an upper ring flange, a lower ring flange and a middle short connecting pipe. A grouting pipe connector is arranged on the outer side of the middle short connecting pipe of the grouting pipe connecting device. A short casing is connected to the interior of the middle short connecting pipe of the grouting pipe connecting device. A fixing device is arranged below the grouting pipe connecting device and comprises an upper ring flange, a lower ring flange and a middle short connecting pipe. An I-steel column beam is welded to the outer side of the middle short connecting pipe of the fixing device. The two ends of the I-steel column beam are symmetrically provided with balance weights. A casing connector is connected to the lower ring flange of the fixing device. The lower end of the casing connector is connected with a long casing which downwards penetrates through an original hole. The lower ring flange of the grouting pipe connecting device is connected to the upper ring flange of the fixing device. The upper ring flange of the grouting pipe connecting device is connected with the high-pressure sluice valve. The grouting problem under the condition that an original water supply hole casing is damaged seriously is solved, and economic benefits are remarkable.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

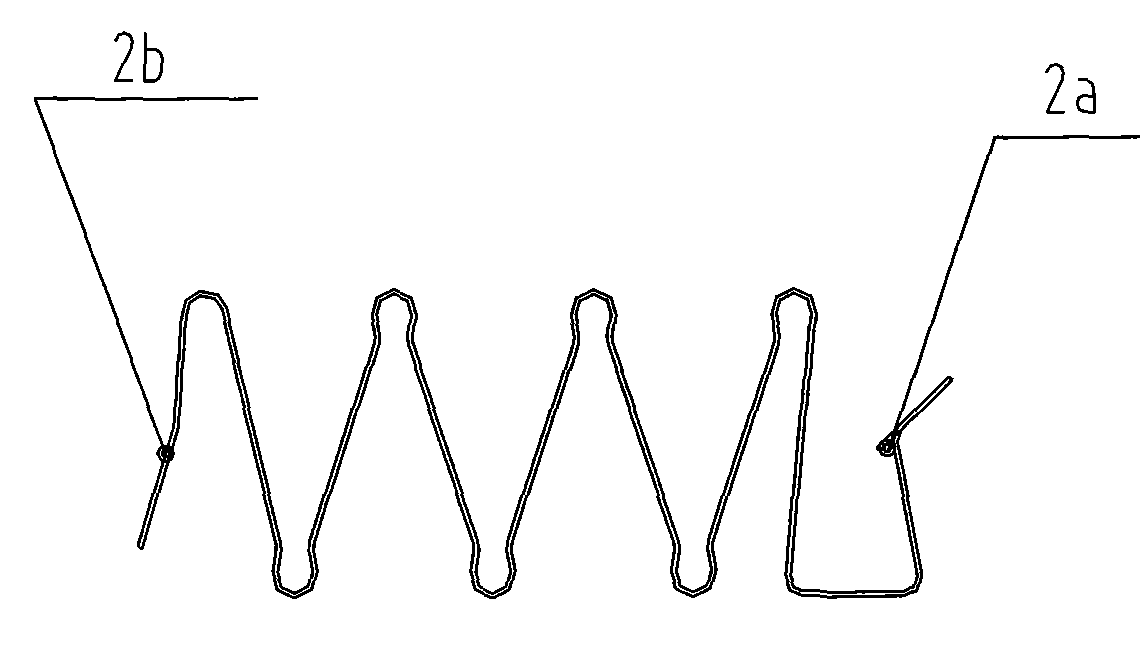

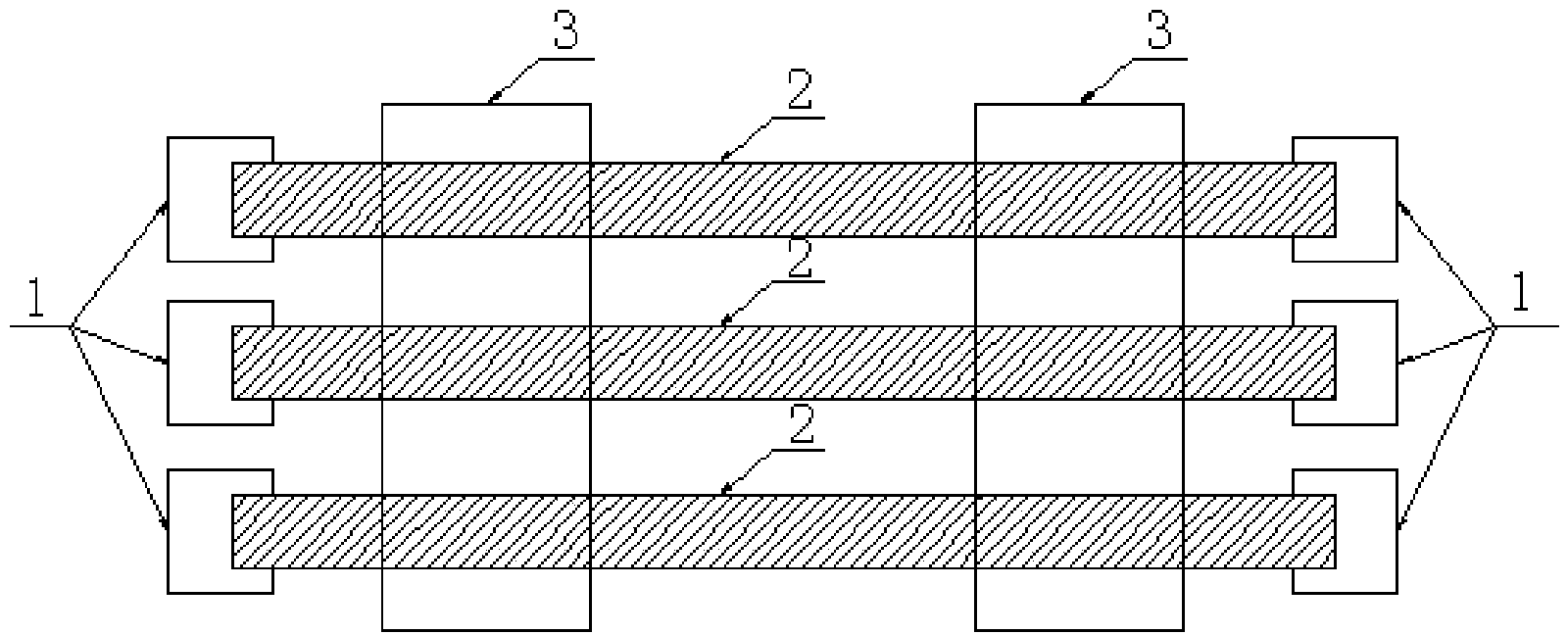

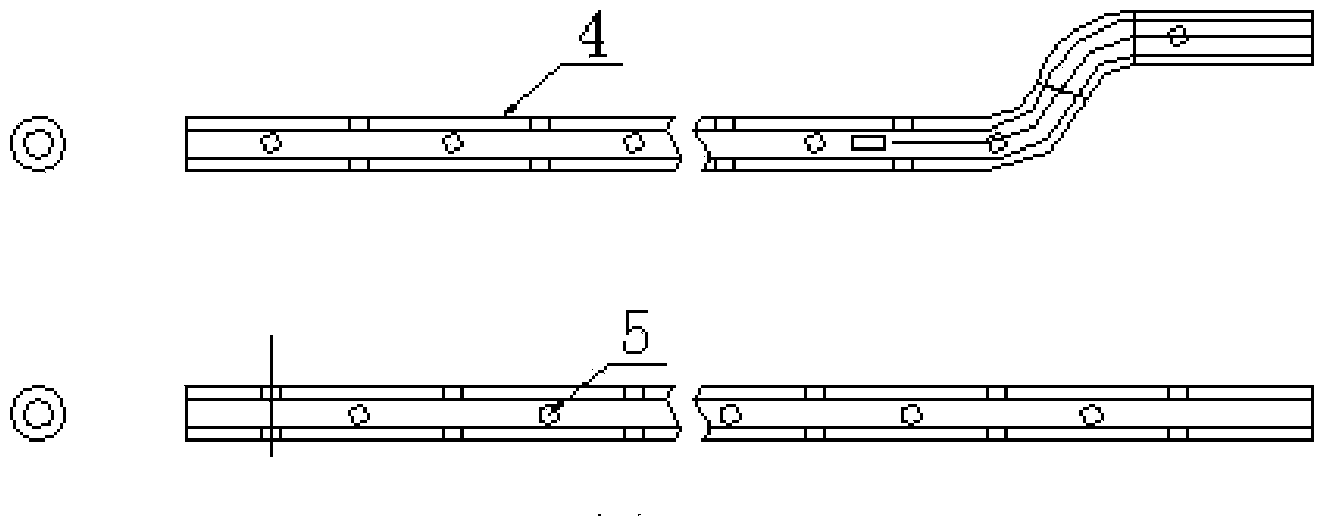

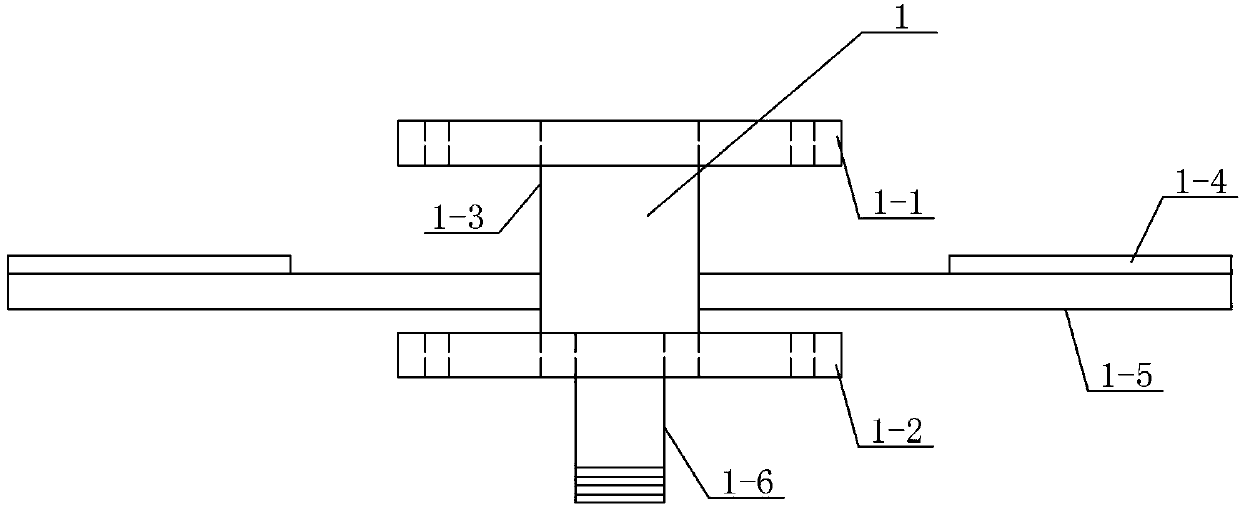

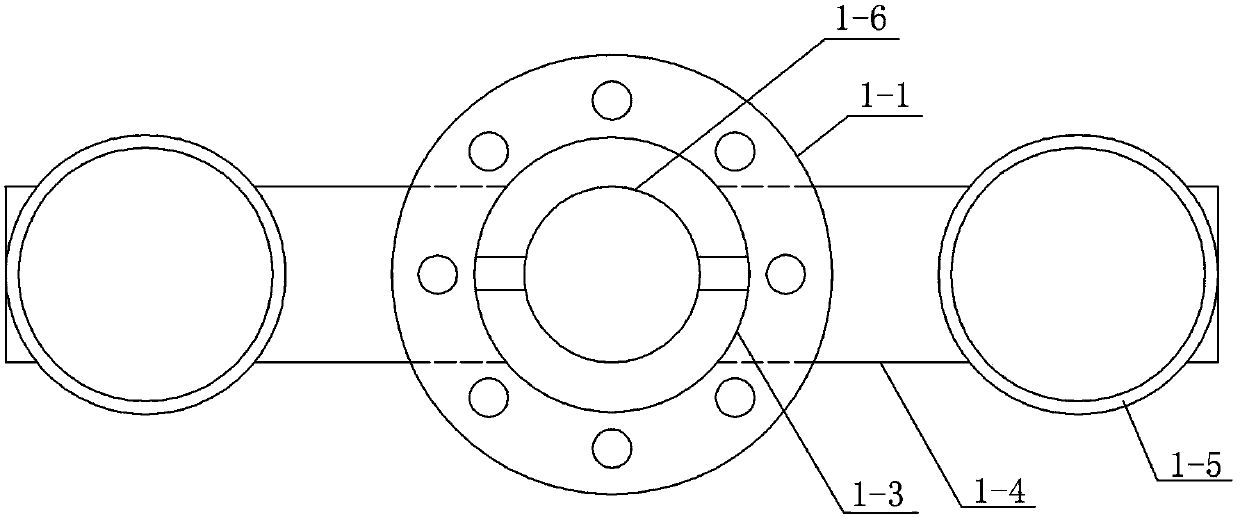

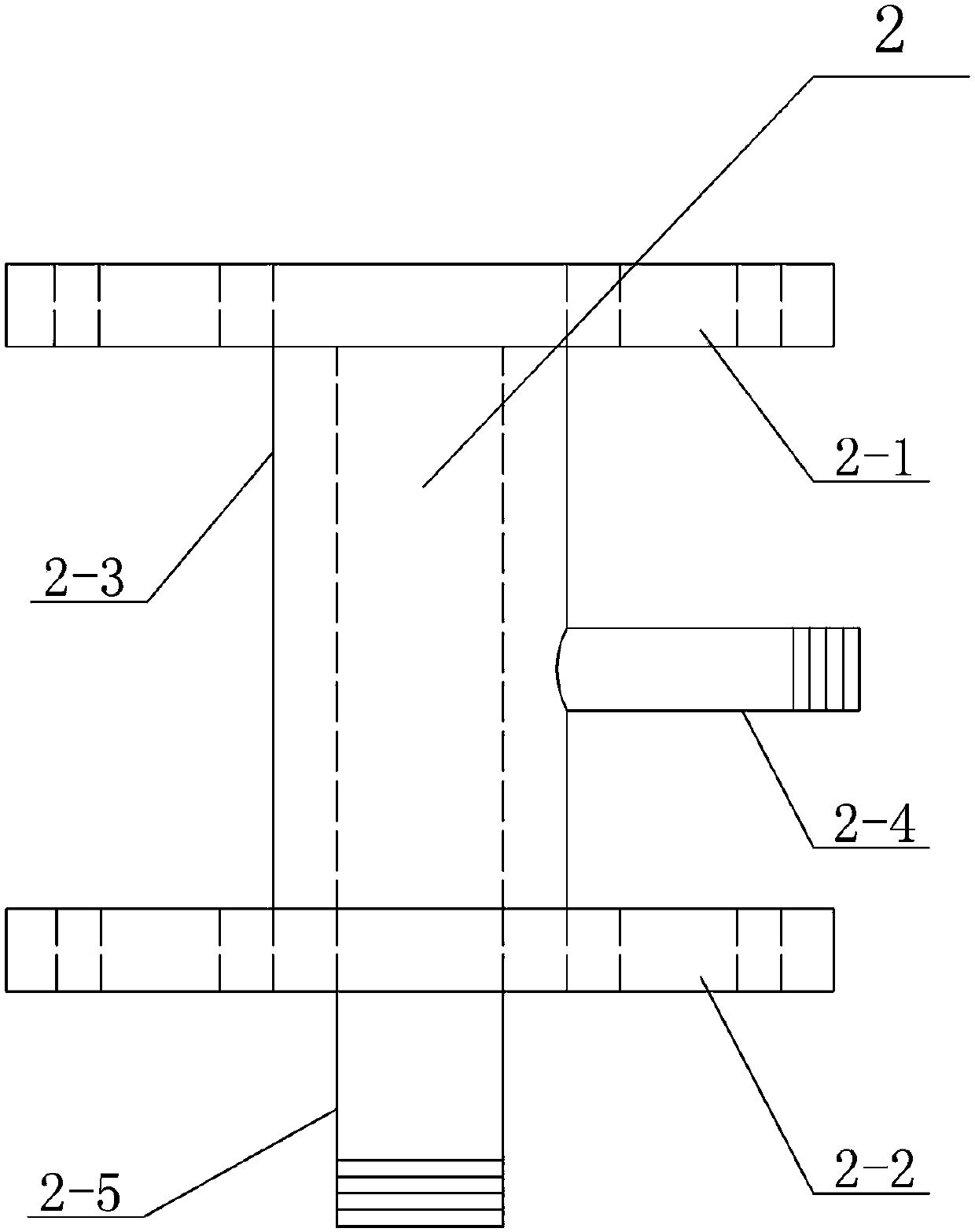

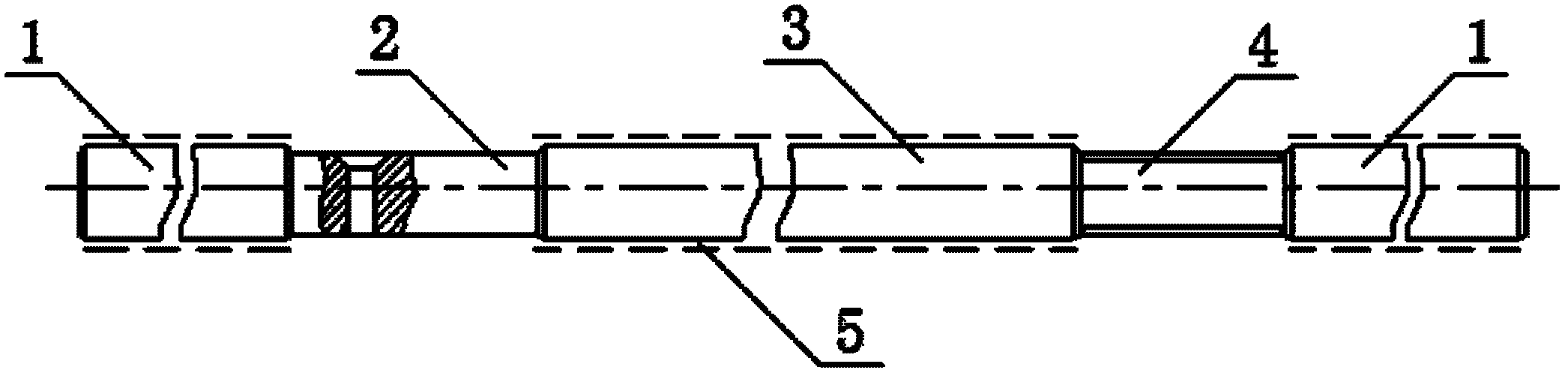

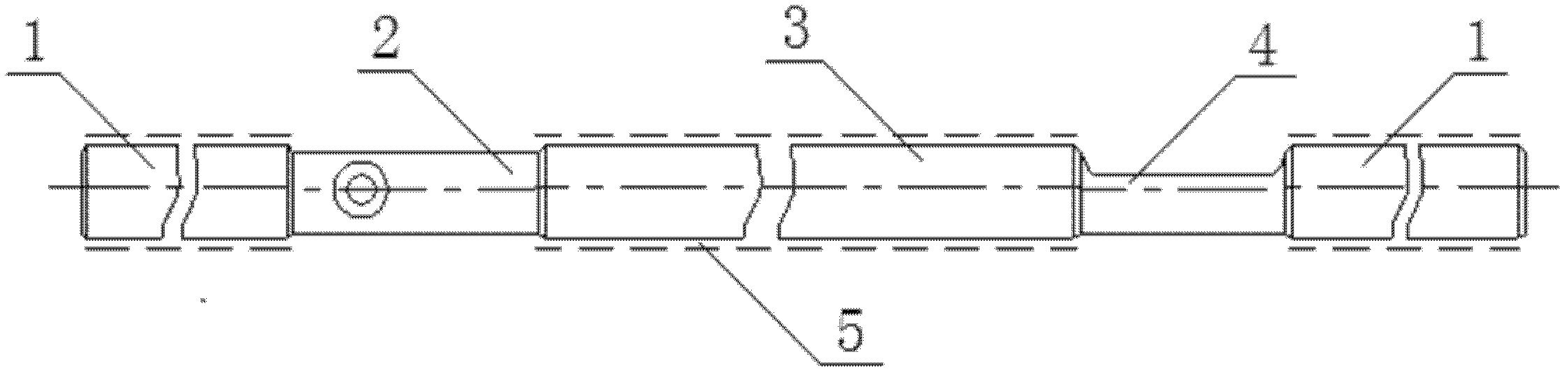

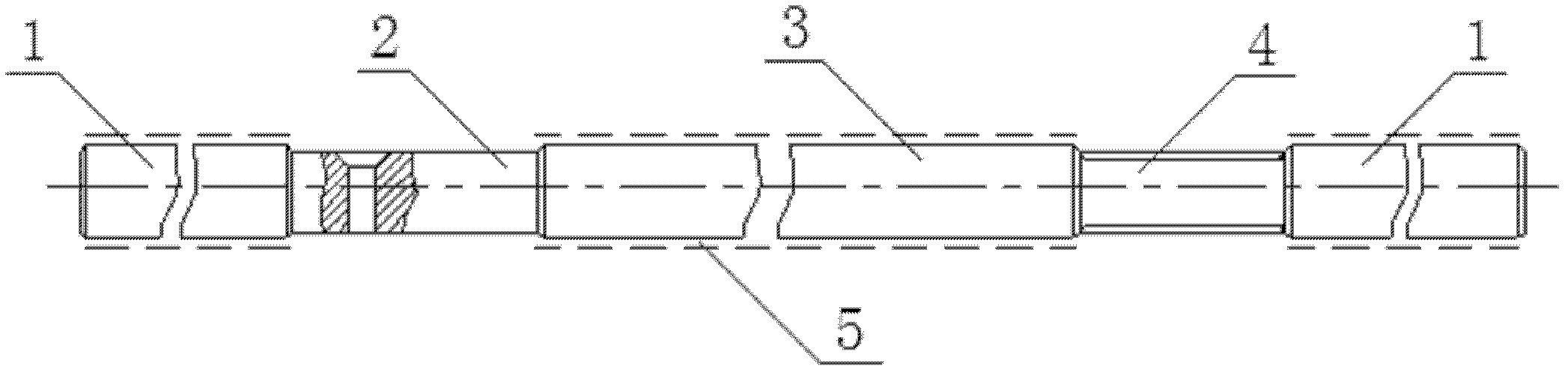

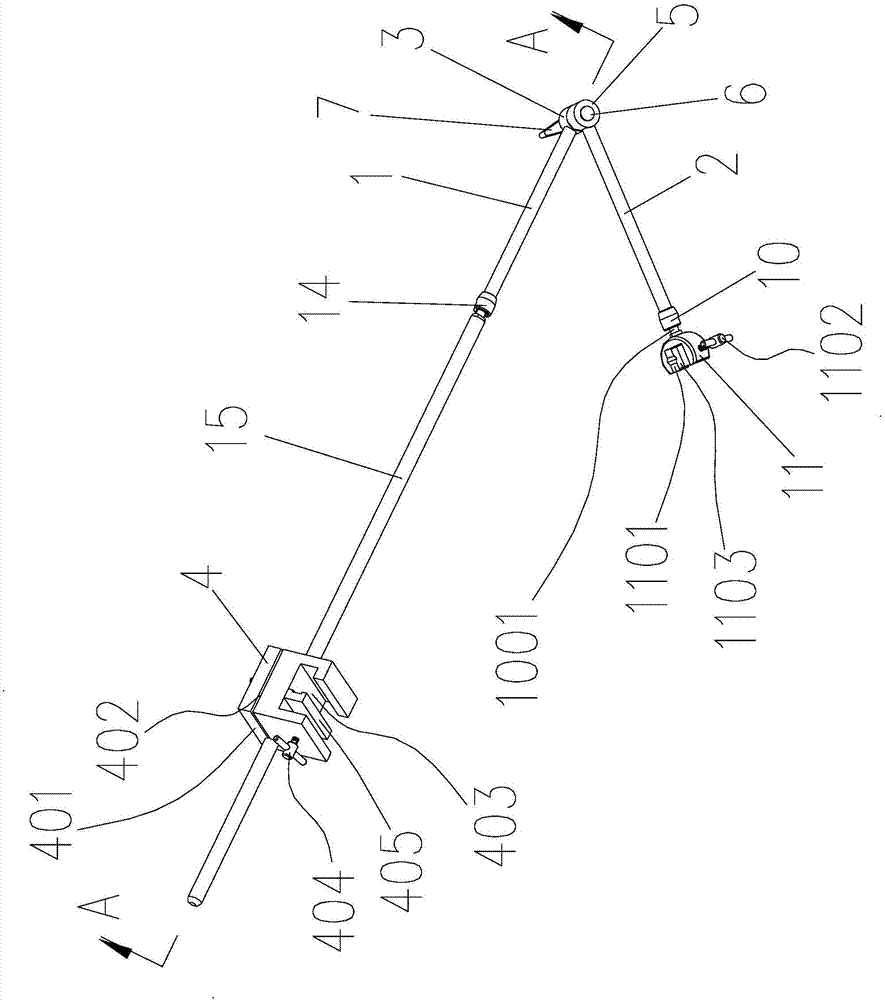

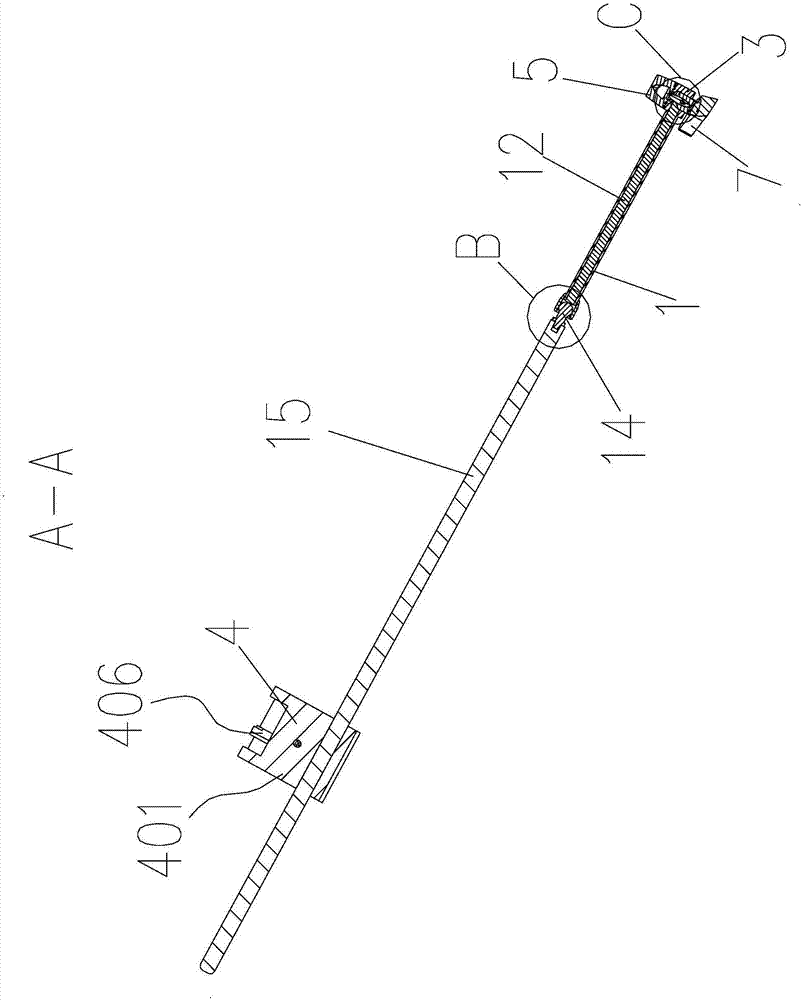

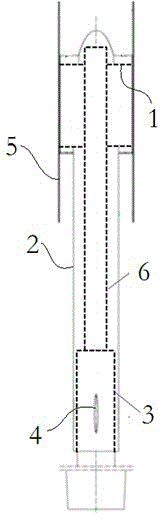

Core bar for high-pitch precision spiral line and manufacturing method of core bar

ActiveCN102592915AFix fixGuaranteed accuracyCoils manufactureCold cathode manufactureEngineeringMechanical engineering

The invention discloses a core bar for a high-pitch precision spiral line and a manufacturing method of the core bar. The core bar comprises a process section (1), a porous structure (2), a spiral line coiling section (3), a planar structure (4) and a process section (1), wherein the spiral line coiling section (3) is positioned in the middle position; one end of the spiral line coiling section (3) is of the porous structure (2), the other end of the spiral line coiling section (3) is of the planar structure (4), and the other end of the porous structure (2) and the other end of the planar structure (4) are the process sections (1); and the diameter of each process section (1) is same as that of the spiral line coiling section (3), and the outer circumference surfaces of each process section (1) and the spiral line coiling section (3) are provided with coatings (5). According to the core bar for the high-pitch precision spiral line, with the special structure, in the axial direction of the core bar, one end of the core bar is of the porous structure, and a strip material of the spiral line is inserted into a hole and begins to be coiled when the spiral line is coiled; and after coiling is finished, the spiral line can be fixed by a step of the planer structure at the other end, and thus the problem of fixing the spiral line during coiling is solved.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

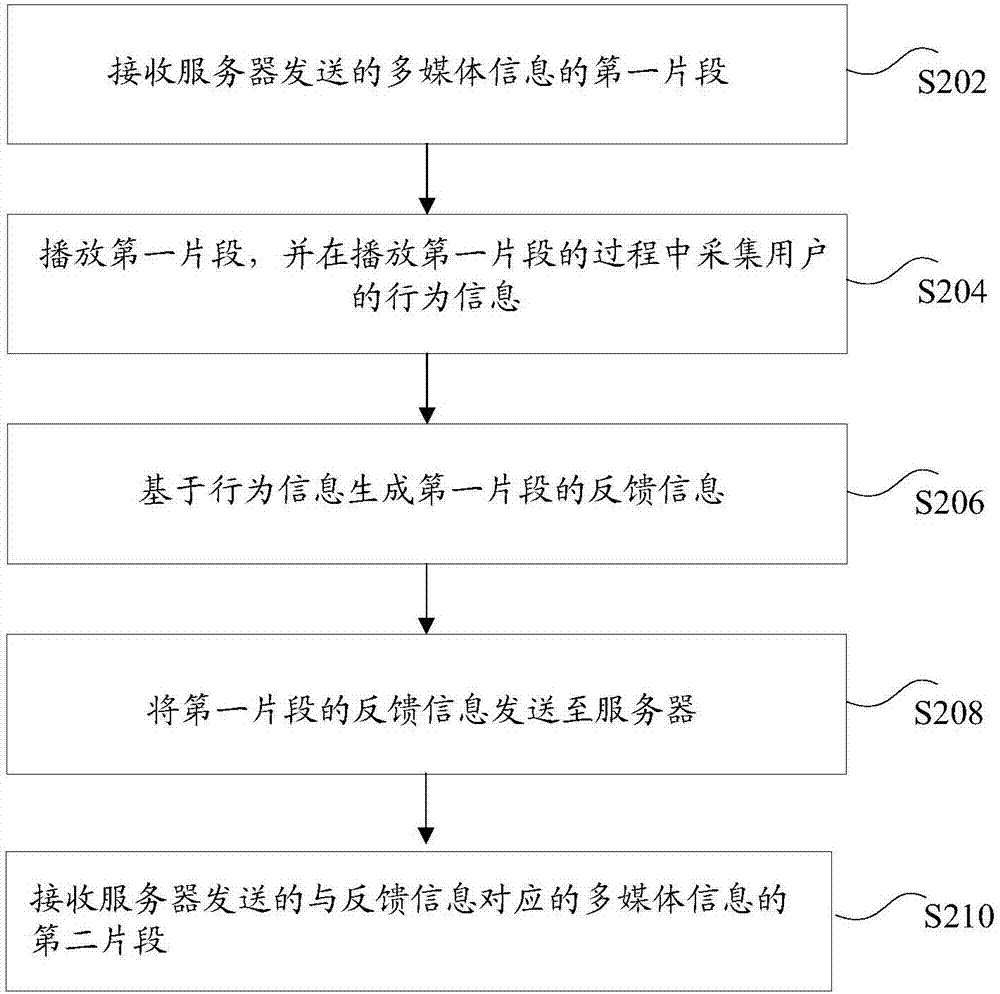

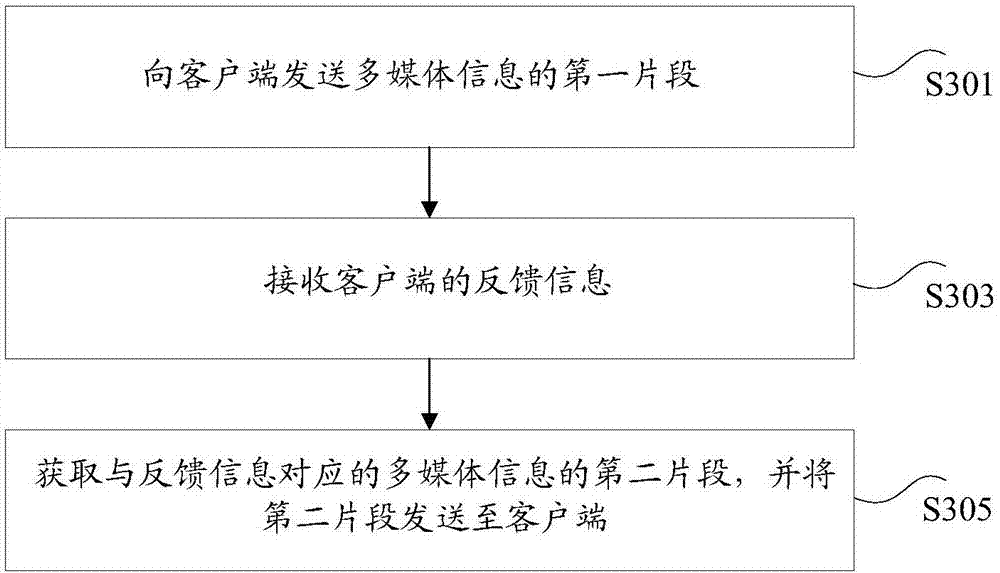

Information processing method, device and system

ActiveCN107547922AFix fixSolve the problem of no feedback entrySelective content distributionInformation processingWorld Wide Web

The invention discloses an information processing method, device and system. The method comprises the steps of receiving a first fragment of multimedia information sent by a server; playing the firstfragment and collecting behavior information of a user in a process of playing the first fragment; and generating feedback information of the first fragment based on the behavior information; sendingthe feedback information of the first fragment to the sever; and receiving a second fragment of the multimedia information which is sent by the server and corresponds to the feedback information. According to the method, the device and the system, the technical problem that only fixed video content can be sent to a client and the flexibility is low is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

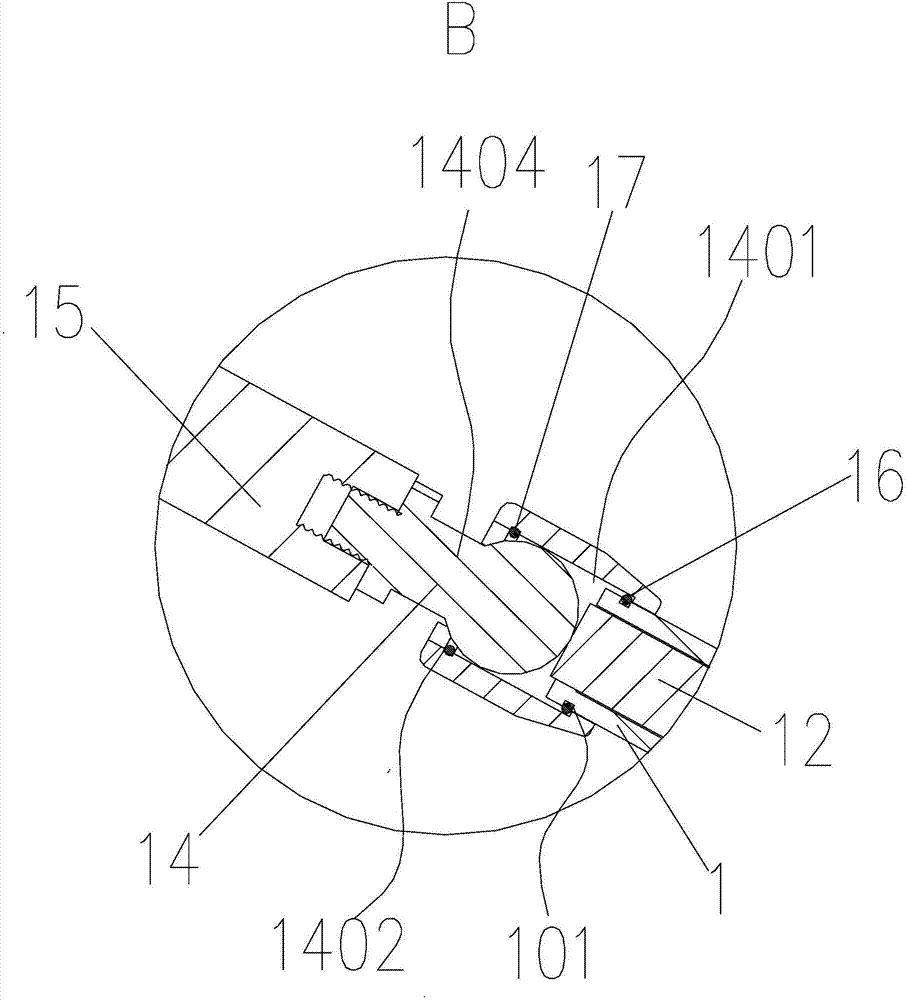

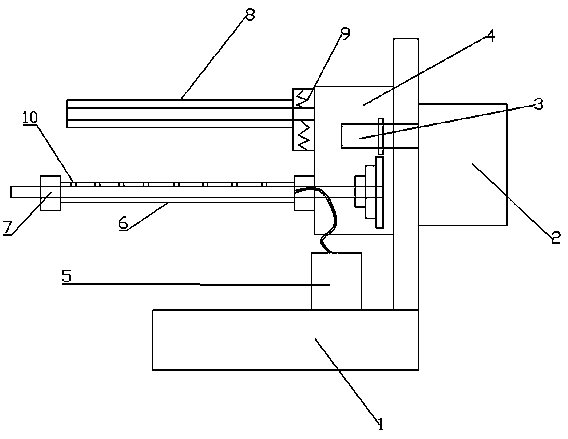

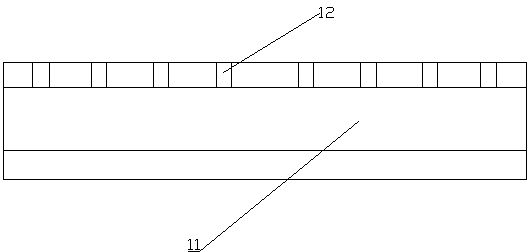

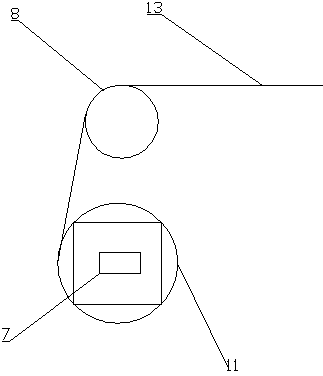

Universal mechanical instrument support with screwing and locking function

PendingCN107374744ASimple organizationLow costSurgical furnitureSurgical instrument supportPhysicsMedical practitioner

The invention belongs to the field of medical instruments, and particularly relates to a universal mechanical instrument support with a screwing and locking function. The support comprises a first cannula and a second cannula, and a first sleeve is fixed to the first cannula; a second sleeve is fixed to the second cannula; cylindrical head screws are arranged in the first sleeve and the second sleeve in a penetrating mode, and screwing handles are connected to the cylindrical head screws; second threaded holes are formed in the cylindrical head screws, and locating screws are connected to the second threaded holes; second shaft rods are arranged in the second cannula in a penetrating mode, first wedge-shaped surfaces are arranged on the second shaft rods, second wedge-shaped surfaces are arranged on the cylindrical head screws, and the second wedge-shaped surfaces are attached to the first wedge-shaped surfaces; a second ball head joint is arranged on the second cannula, and the second shaft rods abut against a ball head of the second ball head joint; an instrument chuck is fixedly arranged on the ball head. The universal mechanical instrument support with the screwing and locking function has the advantages that the workload of a doctor is reduced, the work efficiency of the doctor is improved, the shake caused when all instruments are manually supported is avoided, and the stability and precision of an operation are improved.

Owner:张磊

Plastic differential film rolling device for clothes

The invention discloses a plastic differential film rolling device for clothes and belongs to the field of clothes design devices. The plastic differential film rolling device comprises a rack, a motor, a gearbox and a film rolling rod. The motor is connected with the power input end on the gearbox through a main shaft, and the power output end of the gearbox is connected with the film rolling rod which is a hollow pipe. The port, away from the gearbox, of the film rolling rod is closed, and the port, close to the gearbox, of the film rolling rod is connected with an exhaust fan through a pipeline. A plurality of through holes are formed in the film rolling rod and communicated with the interior of the hollow pipe and the exterior of the hollow pipe. The film rolling rod further comprises a plurality of sleeves which are matched with the hollow pipe, and a plurality of through holes are formed in the sleeves which are fixed on the hollow pipe through a locking ring. According to the plastic differential film rolling machine, multiple levels of speeds are provided for rolling films, the problem of fixation of film rolling in the initial stage and the problem of breaking caused by high tension are solved, and the plastic differential film rolling device for clothes is particularly used in the field of clothes design.

Owner:DALIAN UNIV

Auxiliary pile sinking device for prefabricated hollow pile

ActiveCN112982407AFix fixAddressing Adaptive IssuesBulkheads/pilesStructural engineeringHigh pressure water

The invention discloses an auxiliary pile sinking device for a prefabricated hollow pile. The device is composed of a booster pump, a water pipe, a nozzle and a fixing frame. The fixing frame is installed on the inner wall, close to the pile bottom, of the prefabricated hollow pile. The nozzle is installed on the fixing frame. The nozzle and the booster pump are connected through the water pipe. During implementation, after water is pressurized through the booster pump, the water is connected with the nozzle fixed to the fixing frame through the water pipe and sprayed out through the nozzle to be sprayed to pile bottom soil, pile sinking resistance is reduced after the pile bottom soil is softened and liquefied by high-pressure water, and sinking of the prefabricated hollow pile can be accelerated. The problems that the prefabricated hollow pile is difficult to sink in sandy soil and hard clay soil layers, and the construction efficiency is low can be effectively solved.

Owner:江苏诚晖工程技术有限公司

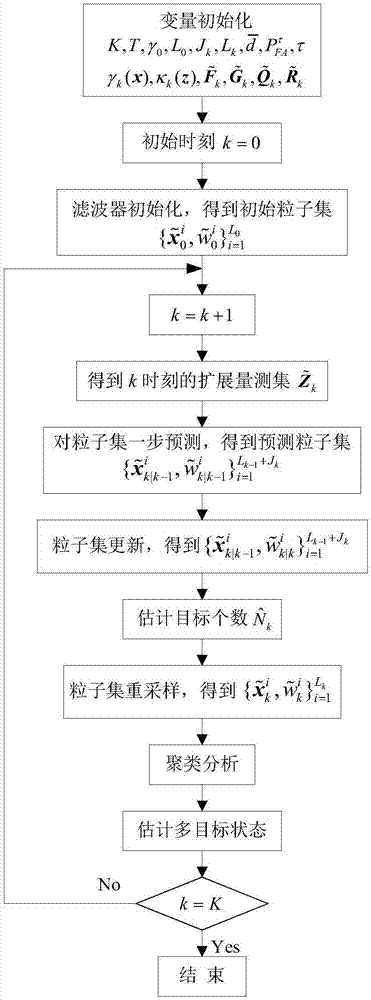

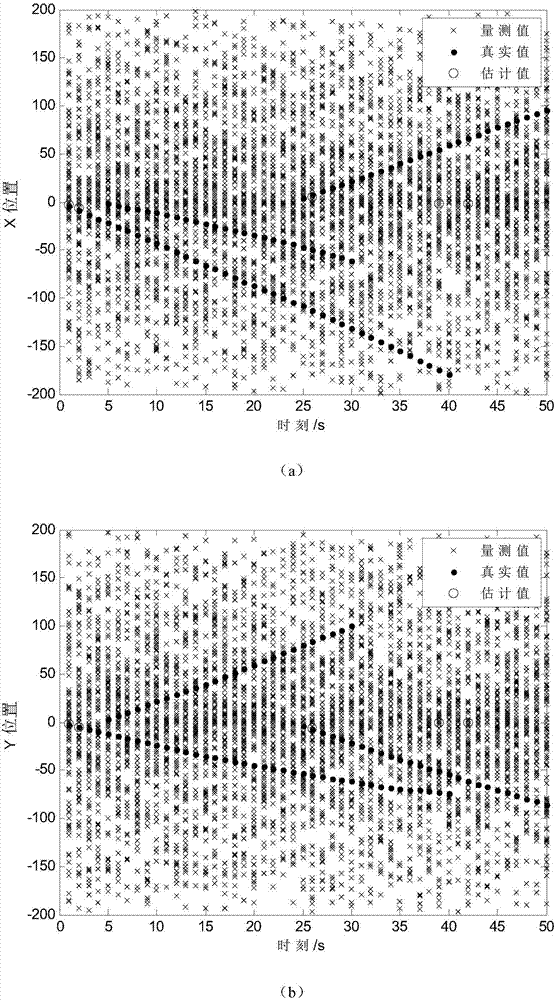

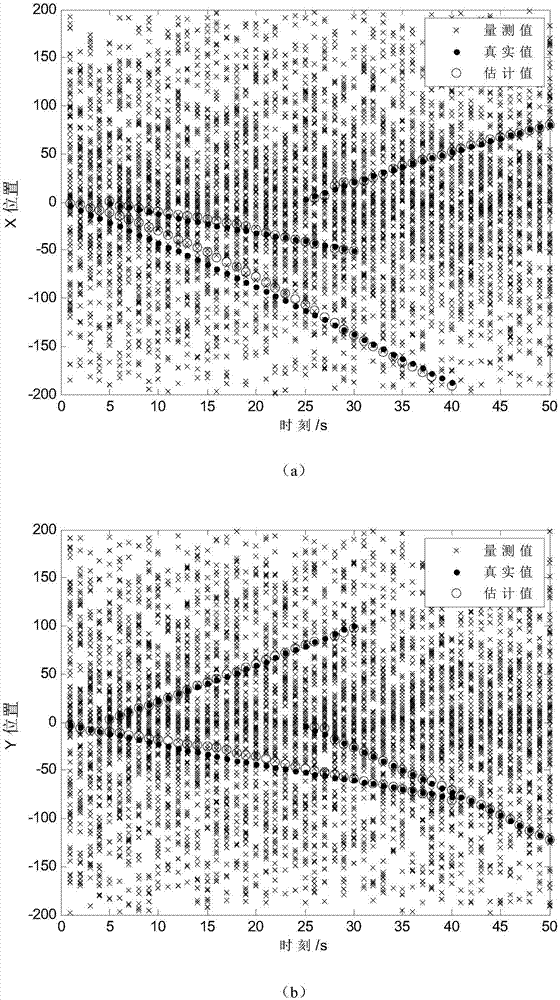

PHD filtering multi-target tracking method in combination with amplitude information

InactiveCN107037423ASolve the problem of underutilization of measurement informationFix fixCharacter and pattern recognitionRadio wave reradiation/reflectionRadar data processingUtilization factor

The invention discloses a PHD filtering multi-target tracking method in combination with amplitude information, which belongs to the radar data processing field. The method is based on the JPDA multi-target tracking method which fails to fully utilize the target measurement information, requires that the number of the targets is fixed because the computation amount increases explosively along with the increase in the number, and does not fit an environment with intense clutters. The PDH filtering multi-target tracking method proposed by the invention is combined with amplitude information and aims to solve the above problems. On the basis of PHD filtering and in combination with the amplitude information of the targets, the utilization efficiency of the measurement information can be increased effectively, and at the same time, estimation can be made to the number of the targets and the target states so that it is possible to adapt to the unknown condition led by the change in the number of the target. In the method, the computation amount increases in a linear manner along with the increase in the number of the measurement targets, making the method especially fit for the multi-target tracking in an environment with intense clutters and overcoming the limitations of the JPDA method. Therefore, the method boasts strong engineering application value and has a wider range of promotions.

Owner:谭顺成

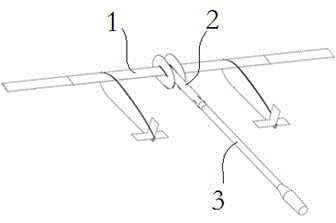

Double-body super-high aspect ratio aircraft wind tunnel force measurement test supporting device

The invention discloses a double-body super-high aspect ratio aircraft wind tunnel force measurement test supporting device, which comprises an aerofoil ladle cover, a balance ladle cover and a lever balance, wherein the balance ladle cover is of a cylindrical structure with both ends, one end of the balance ladle cover is connected with the aerofoil ladle cover, and the balance ladle cover and the aerofoil ladle cover are integrally arranged; the balance ladle cover and the aerofoil ladle cover are each of a hollow structure, and the hollow structure in the balance ladle cover is vertically communicated with the hollow structure in the aerofoil ladle cover; and the other end of the balance ladle cover is provided with a joint to be connected with a supporting rod. The double-body super-high aspect ratio aircraft wind tunnel force measurement test supporting device firstly solves the fixing problem of a high aspect ratio aircraft model during the test in a wind tunnel, and can ensure that the test on the model can be effectively finished during the wind tunnel wind blowing test because of the unique nature of the device structure; and the double-body super-high aspect ratio aircraft wind tunnel force measurement test supporting device avoids the problem that test results cannot be obtained finally because the test environment is destroyed by adopting the existing test method.

Owner:AERODYNAMICS NAT KEY LAB

English teaching equipment fixing device

The invention discloses an English teaching equipment fixing device. The English teaching equipment fixing device comprises a teaching equipment vertical moving base, a threaded shaft connecting block, expansion screws, a teaching equipment horizontal moving base, vertical moving modules, horizontal moving modules, an English teaching equipment fixing seat, a hinge, a pull rod and English teaching equipment, wherein the teaching equipment vertical moving base is fixed on the wall surface through the expansion screws, the back side of the teaching equipment horizontal moving base is welded and connected with the threaded shaft connecting block, the back of the teaching equipment horizontal moving base is fixedly connected with the four vertical moving modules through screws, and the teaching equipment horizontal moving base is connected with the teaching equipment vertical moving base through the threaded shaft connecting block and the vertical moving modules at the same time. According to the English teaching equipment fixing device, the problem of fixation of English teaching equipment is solved, the flexible use of English teaching equipment is improved, and the multi-azimuth tridimensional character adjustment can be conducted.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

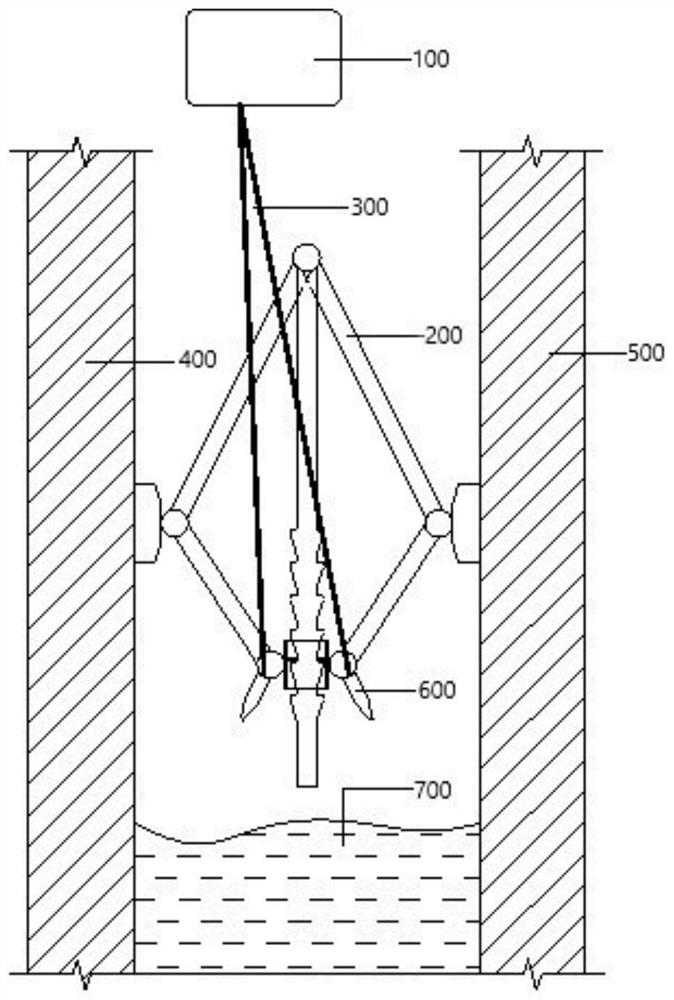

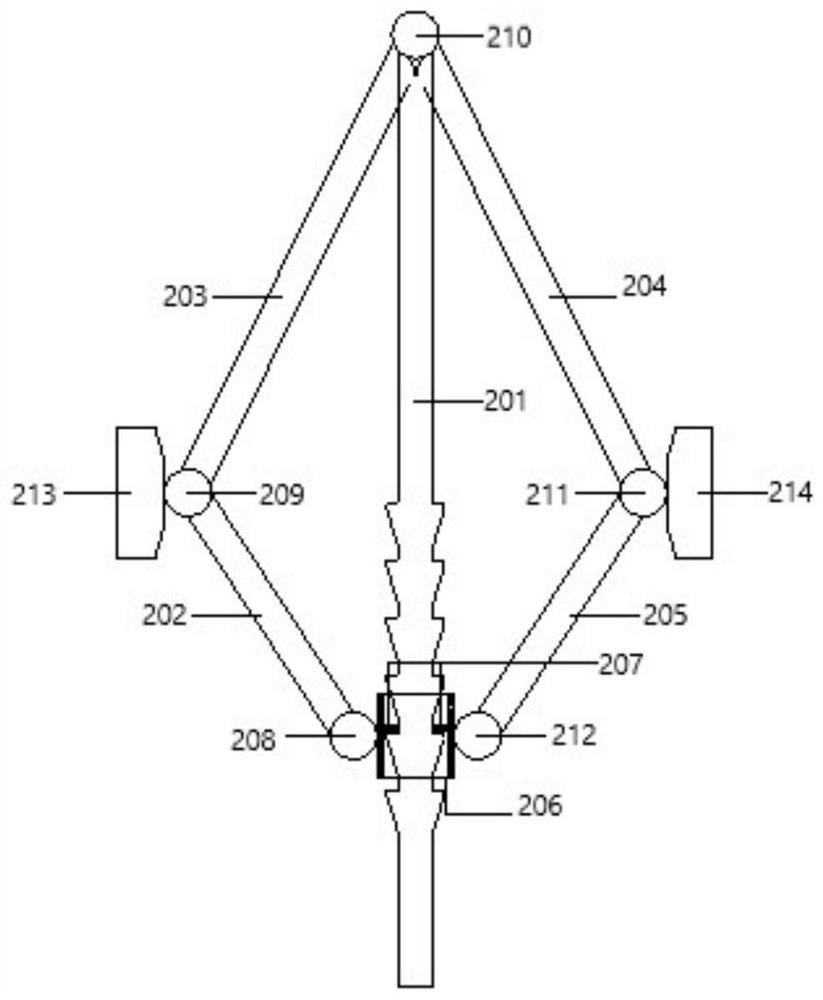

Unmanned aerial vehicle launch shutting and releasing device and method

The invention provides an unmanned aerial vehicle launch shutting and releasing device and method, and relates to the technical field of unmanned aerial vehicle launch recovery. The unmanned aerial vehicle launch shutting and releasing device can realize the locking of the unmanned aerial vehicle on a launch pulley before launch and automatic unlocking in the acceleration segment after launch, theunmanned aerial vehicle launch shutting and releasing device has an avoidance function of a supporting frame to the launch path, the structure is reliable, and the use is simple; the unmanned aerialvehicle launch shutting and releasing device comprises the supporting frame, a launch hook and a shutting and releasing mechanism and a supporting frame toppling device, the supporting frame is used for fixing the shutting and releasing mechanism and is connected with the supporting frame toppling device to realize the toppling action after the unmanned aerial vehicle is launched, the launch hookis arranged on the abdomen of the unmanned aerial vehicle and is used for connecting the unmanned aerial vehicle with the shutting and releasing mechanism, the shutting and releasing mechanism is usedfor locking and unlocking the unmanned aerial vehicle through locking and unlocking the launch hook, and the supporting frame toppling device is used for installing the supporting frame to enable thesupporting frame to realize the toppling action after the unmanned aerial vehicle is launched. According to the technical scheme, the unmanned aerial vehicle launch shutting and releasing device andmethod are applicable to the launch process of the unmanned aerial vehicle.

Owner:AEROSPACE TIMES FEIHONG TECH CO LTD +1

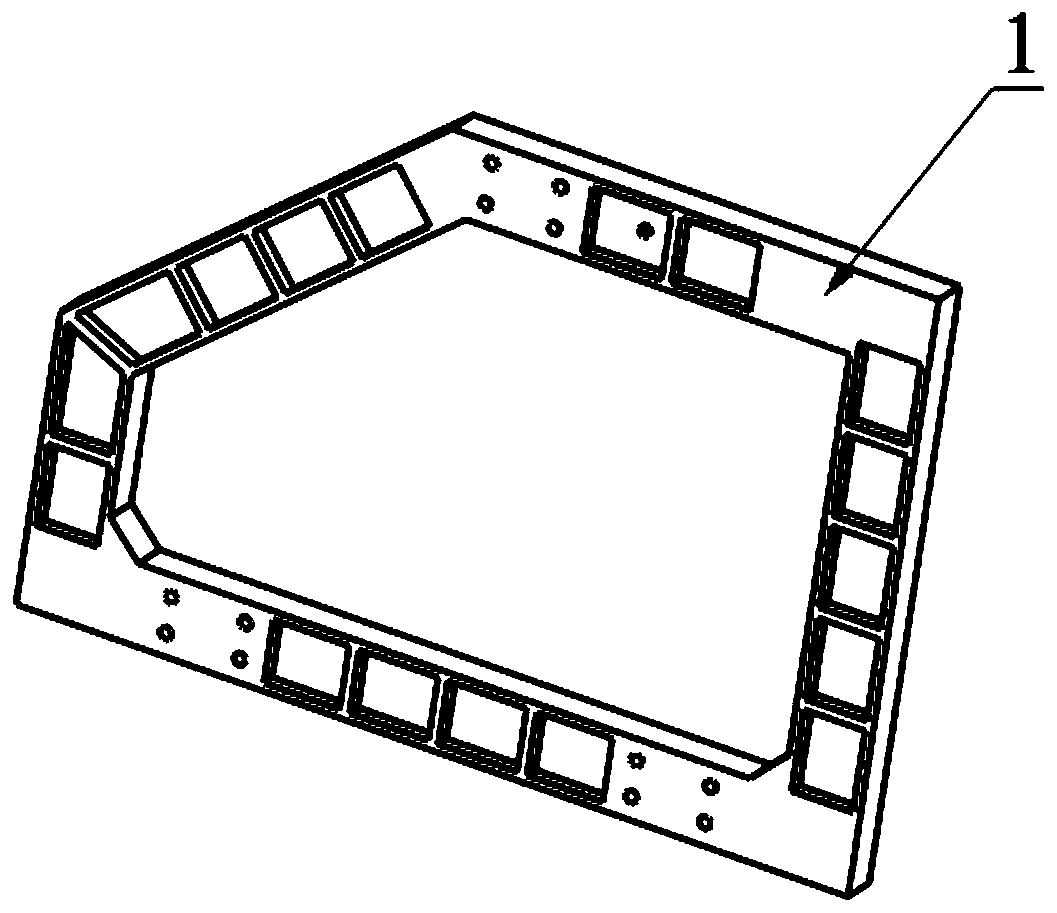

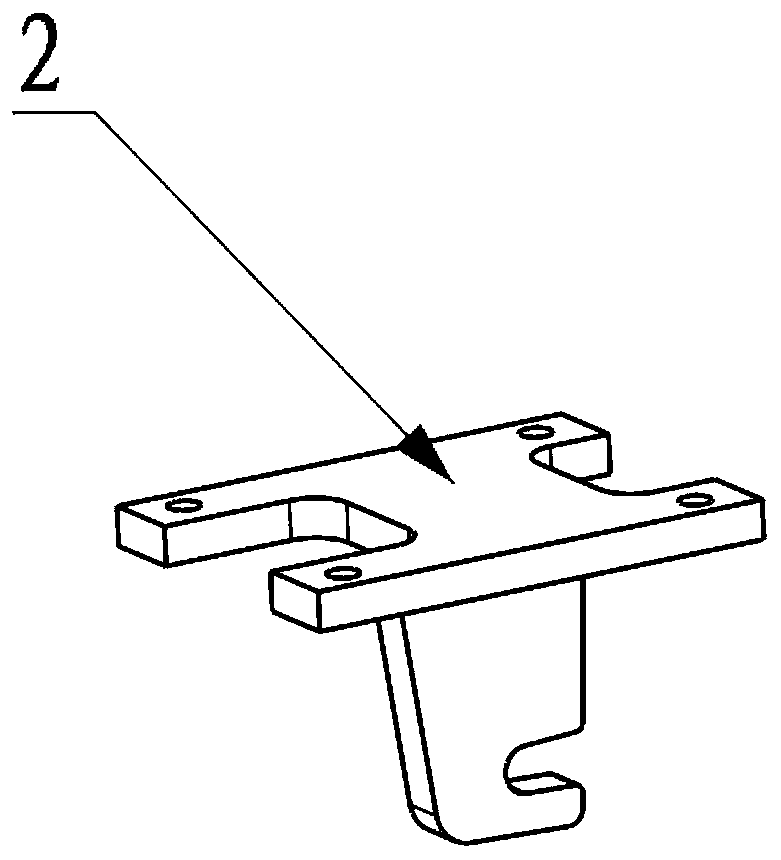

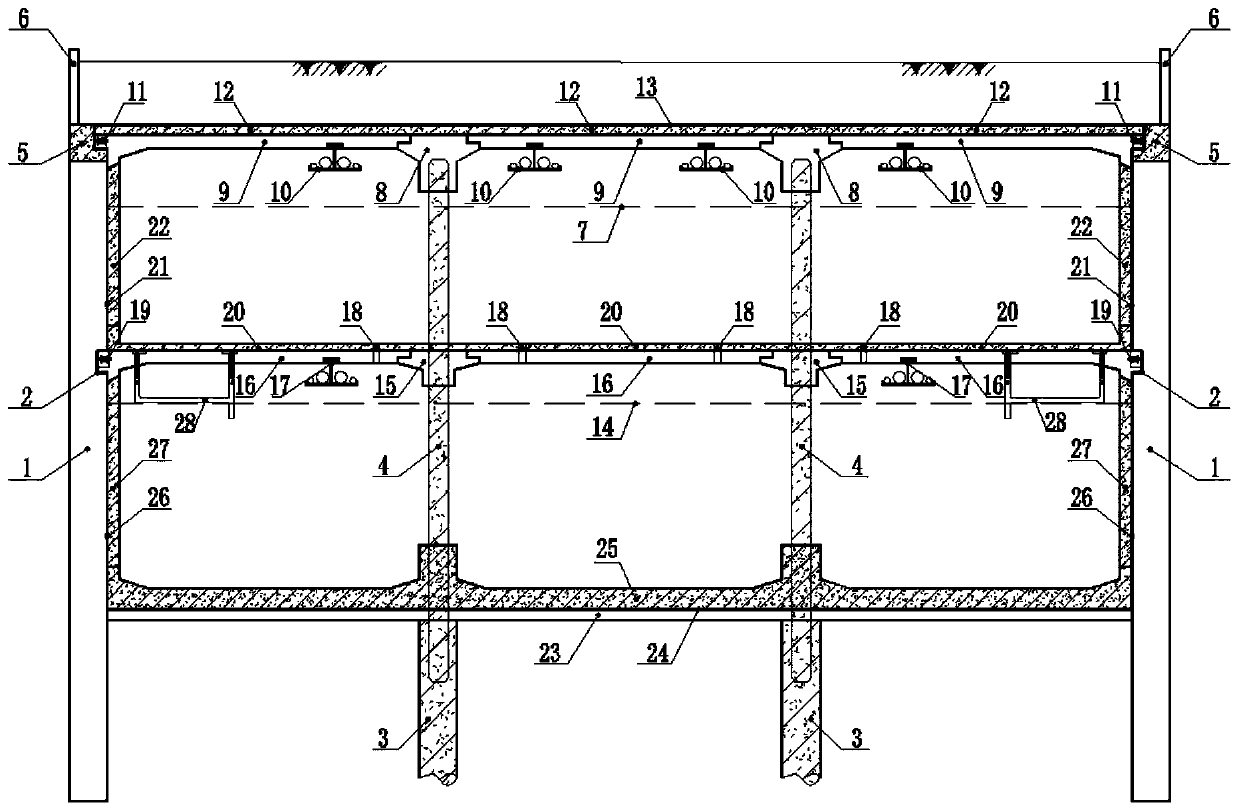

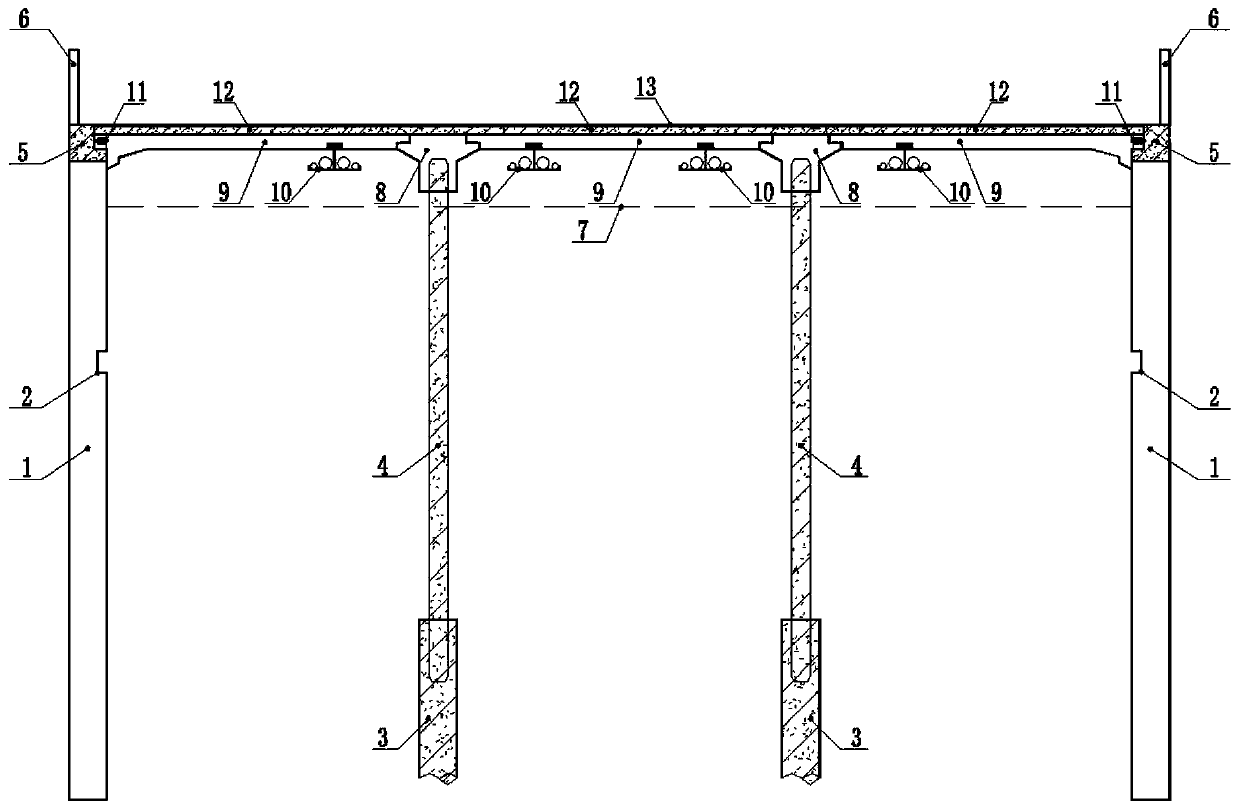

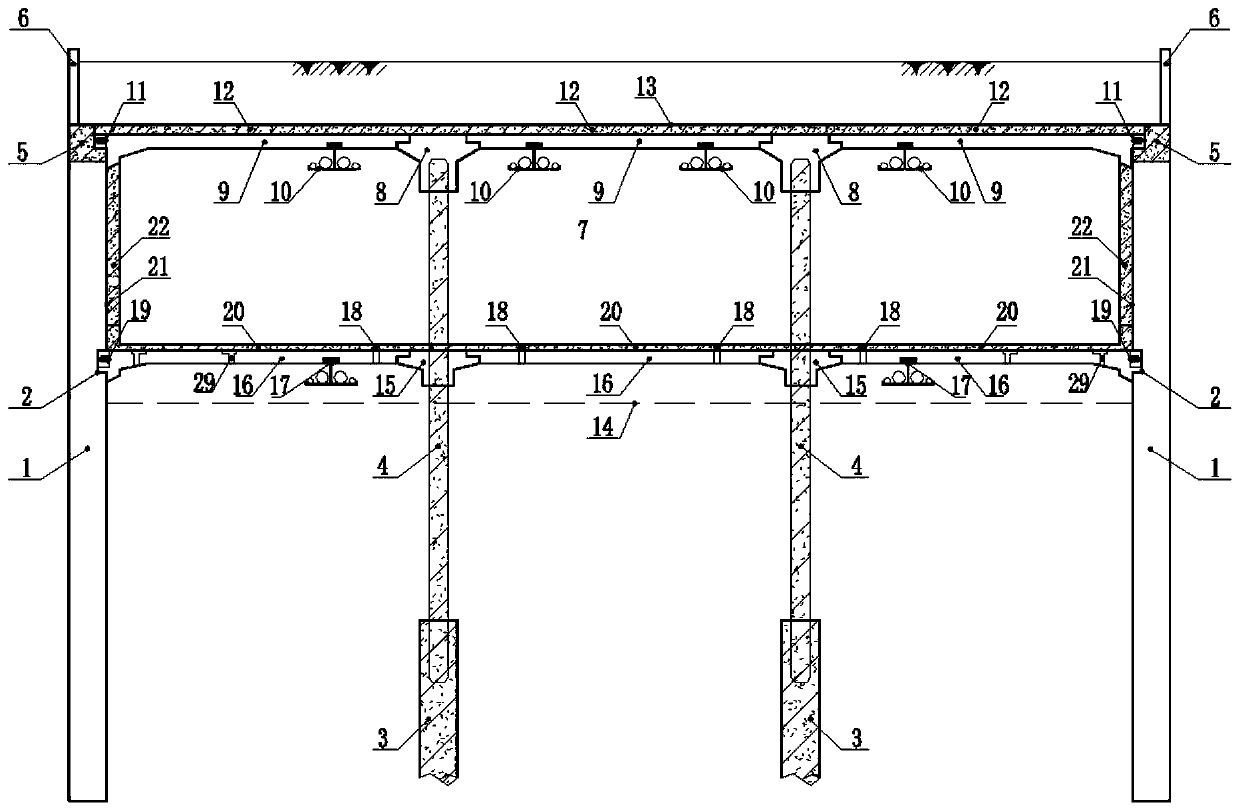

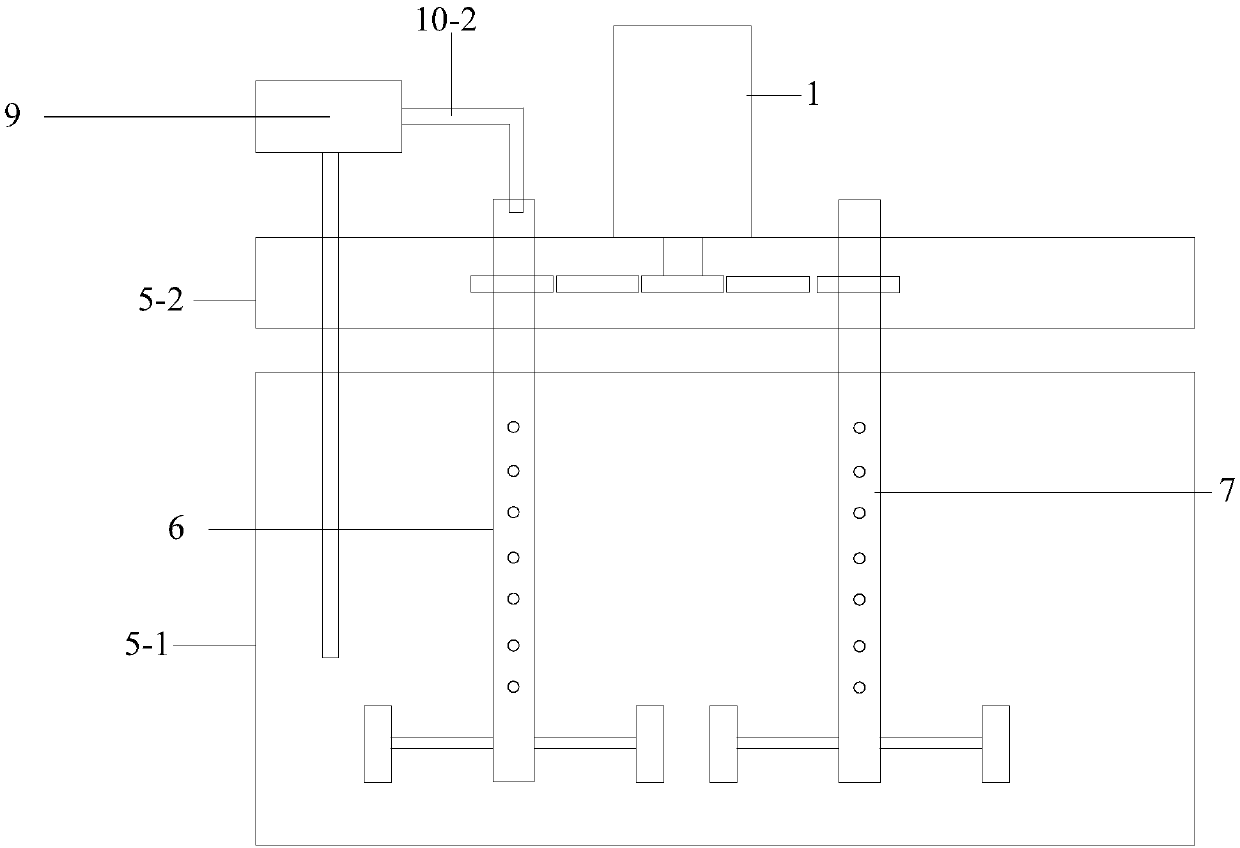

Composite fabricated underground structure and reverse construction method thereof

PendingCN110004981AQuality improvementImprove qualityArtificial islandsProtective foundationWater leakagePre stress

The invention discloses a composite fabricated underground structure. The composite fabricated underground structure comprises underground walls, steel structure clamping grooves, prestressed jacks, and main structure standing columns; prefabricated top longitudinal beams, prefabricated top plates, top plate cast-in-place layers, and top plate waterproof layers jointly form composite waterproof prestressed top plates; prefabricated middle longitudinal beams, prefabricated middle plates, and middle plate cast-in-place layers jointly form composite middle plates; prefabricated cushion layers, bottom plate waterproof layers and cast-in-place bottom plates jointly form composite waterproof bottom plates; the underground walls, side wall waterproof layers, and side wall cast-in-place layers jointly form composite waterproof walls; the composite waterproof prestressed top plates, the composite prestressed middle plates, the composite waterproof bottom plates and the composite waterproof walls are all effectively connected, and the full-package waterproof full-composite fabricated underground structure is formed; thus the problem of water leakage of the fully fabricated underground structure is solved, the limitation of the application range of the fabricated underground structure is broken, the composite fabricated underground structure can be applied to the areas with water-rich stratums, complicated surrounding environment and high deformation control, and the extensive application of the prefabricated structure in underground engineering can be effectively promoted.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Electrolyte solution charging device

ActiveCN108166022ASolve the problem of deposits on the lower part of the stirring shaftUniform reflowPhotography auxillary processesElectrolysis componentsElectrolysisPhysical chemistry

The invention discloses an electrolyte solution charging device which is used for producing copper foils. The electrolyte solution charging device comprises an electrolyte solution stirring barrel, abuffer storage barrel, an electrolysis slot and a controller, wherein a first pump is used for extracting an electrolyte solution in the electrolyte solution stirring barrel through a pipeline, and feeding the electrolyte solution into the buffer storage barrel through a solution transfer pipeline; the electrolyte solution in the buffer storage barrel is fed into the electrolysis slot through a flow pump; an electrolyte solution sensor is arranged in the electrolysis slot; and the electrolyte solution sensor is mainly used for measuring concentration of copper sulfate in the electrolysis slotin real time. The invention aims to provide the electrolyte solution charging device which can solve the problem about how to automatically charge the electrolyte solution.

Owner:陈治政

Online continuous tender coconut cutting and forming equipment and method

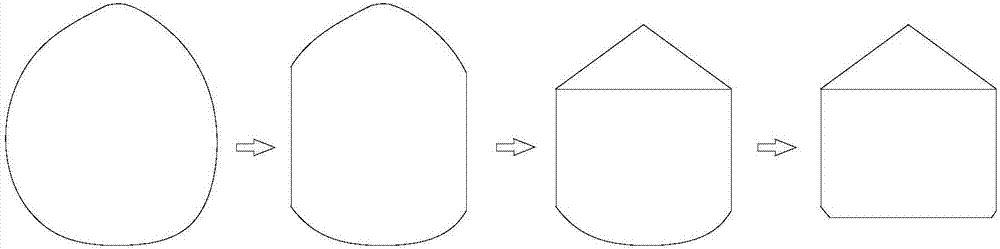

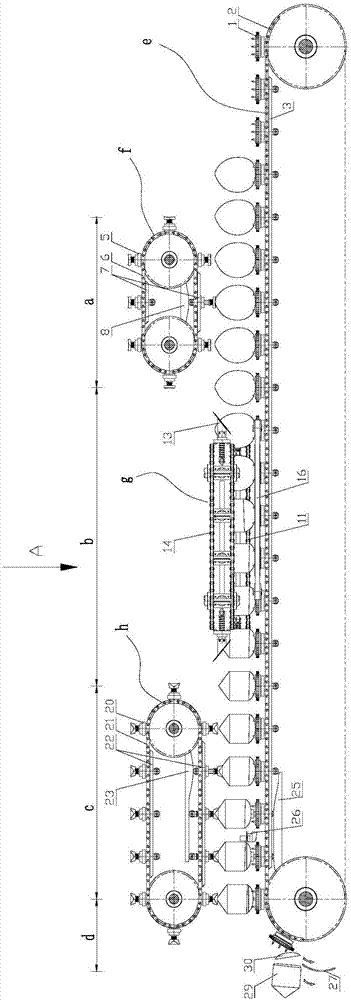

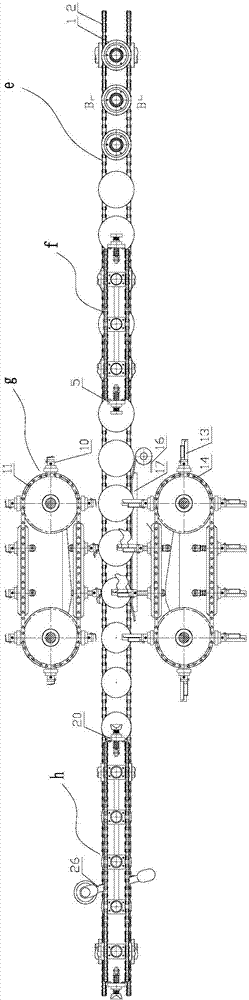

InactiveCN107097284ARealization of continuous cuttingAdapt to mass productionMetal working apparatusHigh volume manufacturingEngineering

The invention discloses online continuous tender coconut cutting and forming equipment and a method. The equipment comprises a positioning and conveying device, a coconut body pressing device, a coconut body cutting device and an end cutting device. The positioning and conveying device comprises conveying chains and a plurality of positioning disc mechanisms, all the positioning disc mechanisms are distributed on the conveying chains at an equal interval, and each positioning disc mechanism is correspondingly provided with a tender coconut; and the coconut body pressing device, the coconut body cutting device and the end cutting device are sequentially arranged above the conveying chains, the coconut body pressing device and the end cutting device are arranged on the tender coconuts, and the coconut body cutting device is arranged on the two sides of the tender coconuts. The method comprises the steps that the tender coconuts are conveyed continuously through the positioning and conveying mechanism and pressed and locked through the coconut body pressing device; then, the outer-side cylindrical faces and top conical faces of the tender coconuts are cut and formed through the coconut cutting device; and finally, the bottom ends of the tender coconuts are cut through the end cutting device to form tender coconut products. By means of the online continuous tender coconut cutting and forming equipment and the method, manual operation can be replaced, continuous cutting and forming of the tender coconut products are achieved, and the equipment and the method are suitable for mass production of the tender coconut products.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

Cam compression clamp

The invention discloses a cam compression clamp and aims to solve the problem that a boss horizontally extending out on a workpiece cannot be well fixed in the prior art. According to the scheme disclosed by the invention, the cam compression clamp comprises an engine bed, a fixed supporting part, a clamping jaw, a cam and a guide rod, wherein the fixed supporting part is used for lifting up the workpiece; the clamping jaw is used for compressing the upper surface of the workpiece; the cam is located below the clamping jaw and serves as a force application device; the guide rod is connected onto the clamp body; the clamping jaw has a freedom of vertical motion under the restraint of the guide rod; a reset spring is also arranged between the clamping jaw and the guide rod; the clamping jaw comprises an upper driven end and a lower driving end, wherein the upper driven end plays a clamping role, and the lower driving end plays a force application role. The cam compression clamp is characterized in that the cam is abutted with the lower driving end, and the geometric center of a clamping part of the upper driven end and the geometric center of the part, contacted with the cam, of the lower driving end are located on the same plumb line. The technical scheme disclosed by the invention has the characteristic that the boss horizontally extending out on the workpiece can be well fixed.

Owner:重庆市南川区富民科技推广中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com