Multi-roller overrun clutch

An overrunning clutch and multi-roller technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve problems such as limited torque capacity, easy failure of products, poor workmanship, etc., to achieve improved torque capacity, stable and reliable product performance, and easy assembly simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

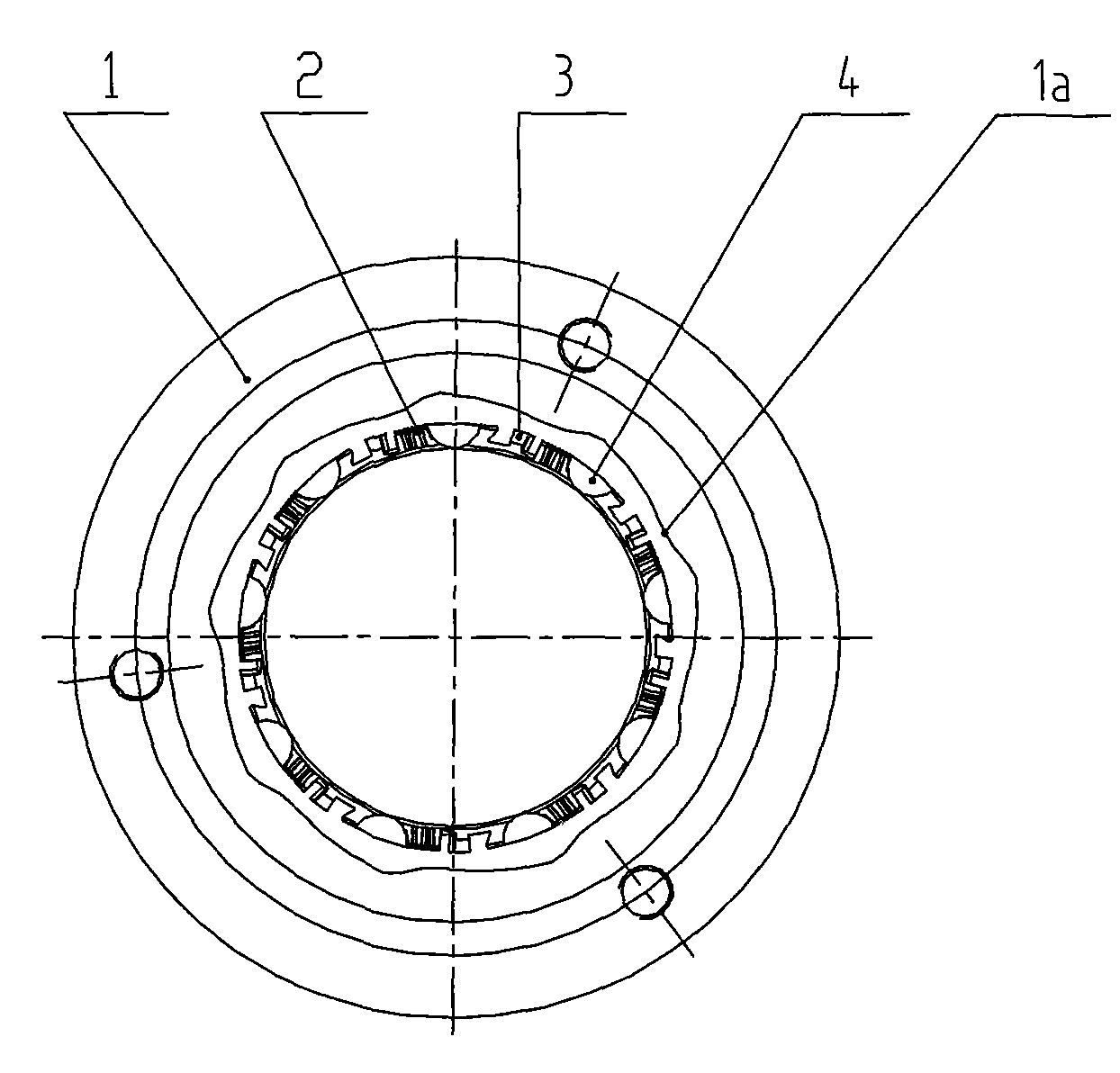

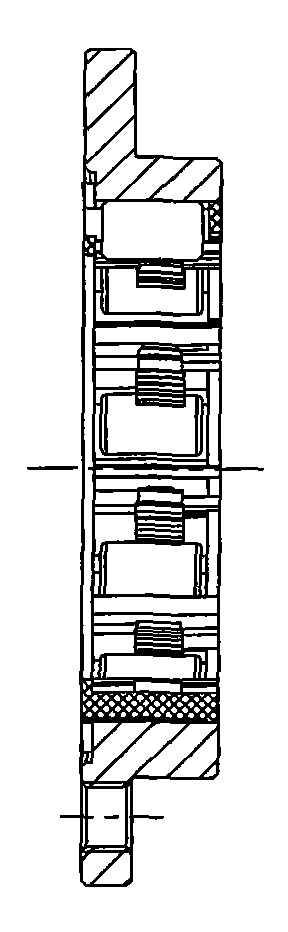

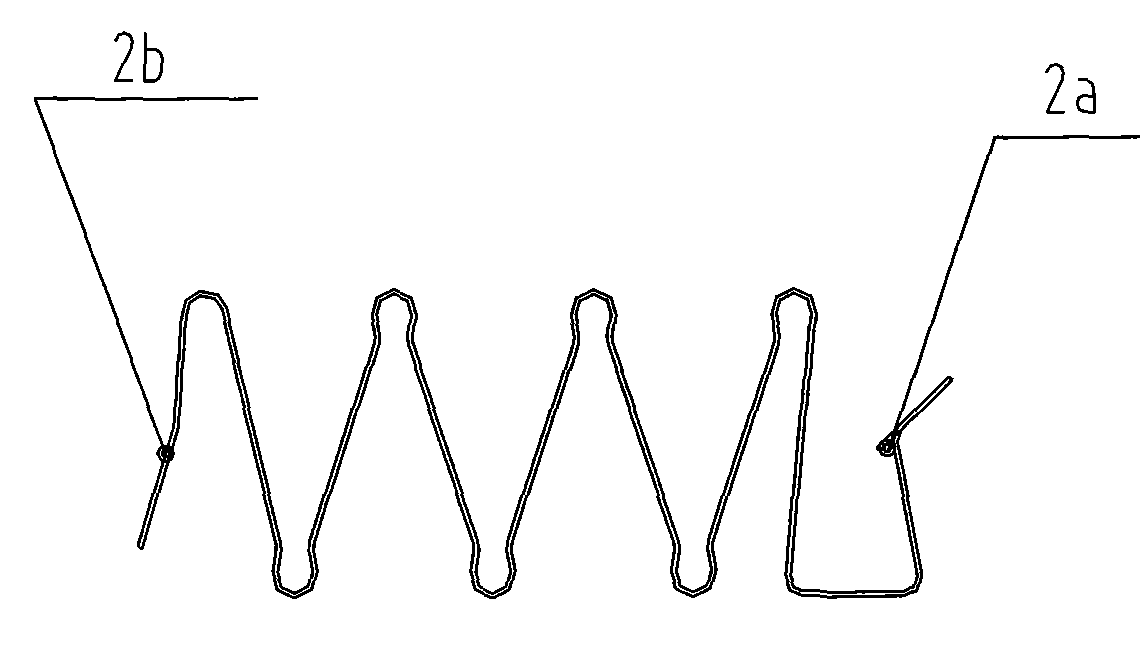

[0016] like Figure 1~4 The best embodiment of the multi-roller type overrunning clutch shown in the present invention has an inner star wheel type outer ring 1, a cage 3, nine spring plates 2 and nine rollers 4. The inner circular surface 1a of the inner star wheel type outer ring 1 has nine sections of concave arc-shaped wedge surfaces; the cage 3 is tightly fitted in the inner star wheel type outer ring 1, solving such as Figure 5 The conventional three-roller clutch shown needs to drill the oblique hole 60a on the inner star wheel outer ring 60 to press the spring seat 20 and the spring cap 40 as the carrier of the spring 30, so that the number of star wheels 60b cannot be too large, and the torque capacity of the clutch The problem of the limitations of lifting. The cage 3 is a plastic cage. The cage 3 includes two end rings and a beam 3a connecting the two end rings. The rollers 4 are respectively placed in the windows 3b formed by the end rings and the beam 3a, and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com