Cam compression clamp

A technology of cams and fixtures, used in clamping, manufacturing tools, supports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

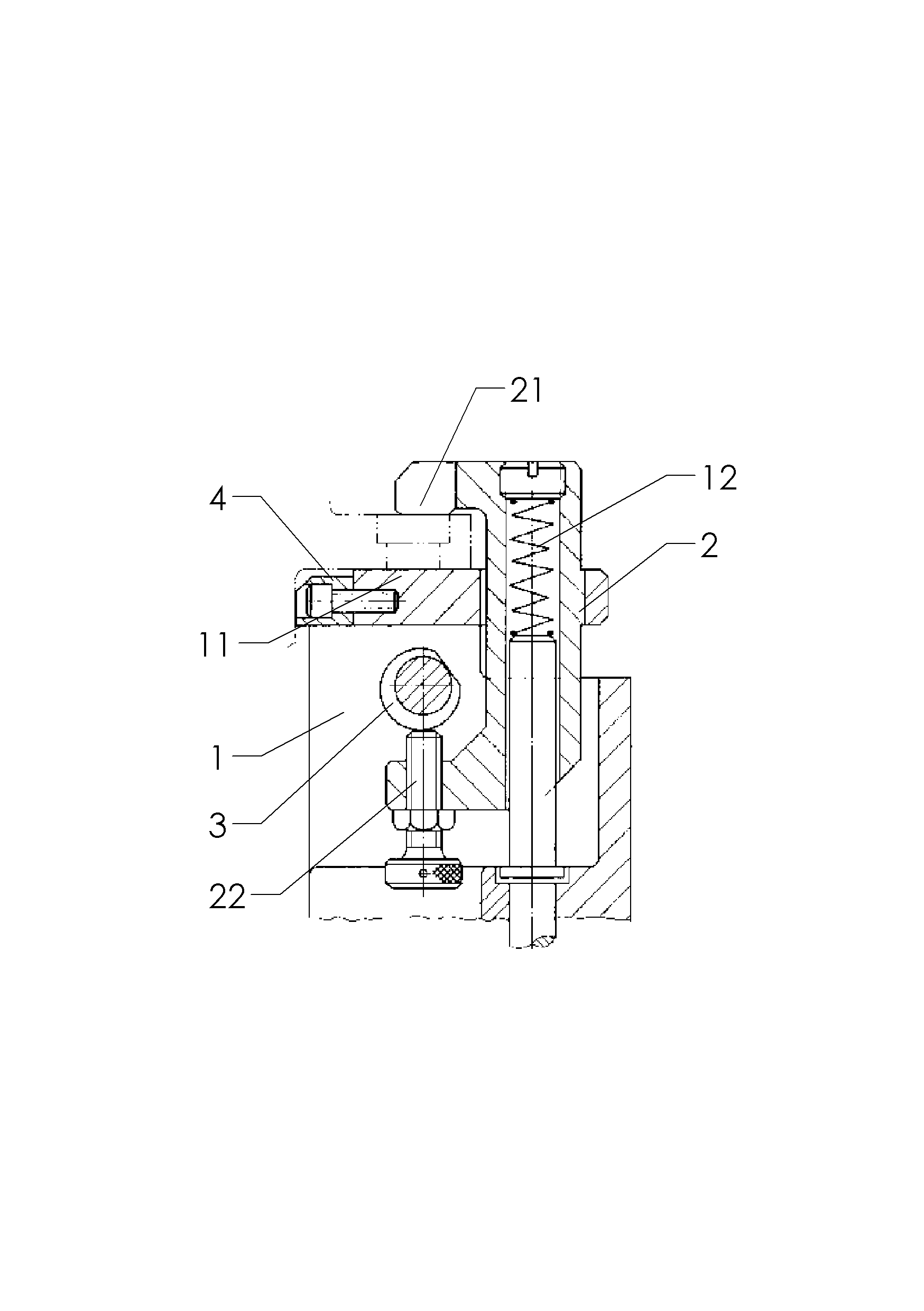

[0010] like figure 1 As shown: the cam pressing fixture in this implementation includes a fixed support part 1 and a movable pressing part 2, the supporting surface 11 of the fixed supporting part 1 cooperates with the lower surface of the boss on the workpiece, and the movable pressing part 2 is a hollow C Glyph, the fixed support part 1 is provided with a guide rod, the movable pressing part 2 is slidingly socketed with the guide rod, and the movable pressing part 2 is also provided with a compression spring 12 connected with the guide rod.

[0011] The C-shaped upper end 21 of the movable pressing part 2 cooperates with the upper surface of the workpiece boss, and a rotatable cam 3 is provided directly below the supporting surface 11 of the fixed supporting part 1, and the end of the C-shaped lower part of the movable pressing part 2 The head is a vertical adjustment bolt 22, and the vertical adjustment bolt 22 is connected with the movable pressing part 2 by threads.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com