Patents

Literature

2421 results about "Mechanical field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical engineering is a broad field that involves the design and creation of a vast array of products, from regular household items such as kitchen appliances to airplanes or artificial organs.

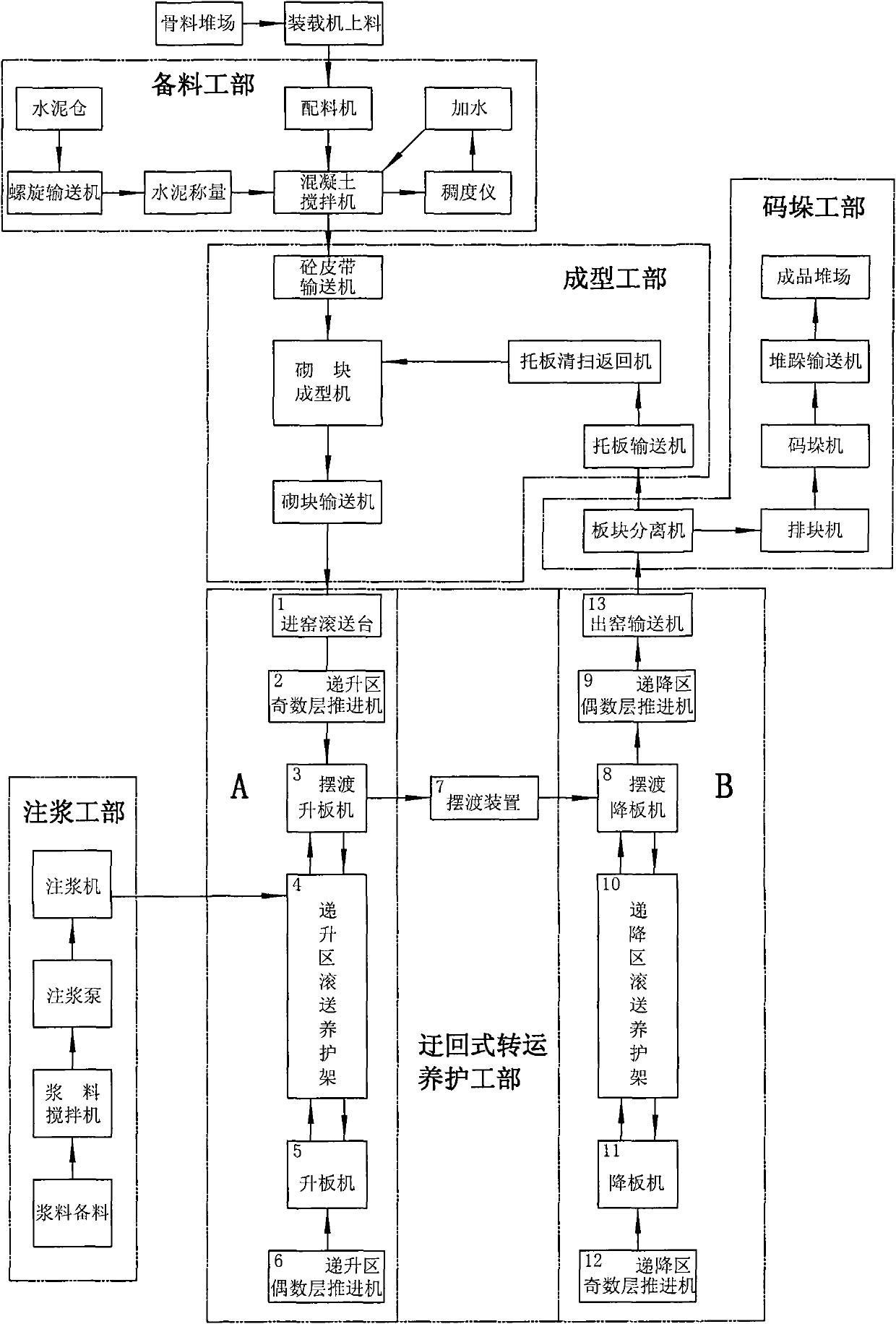

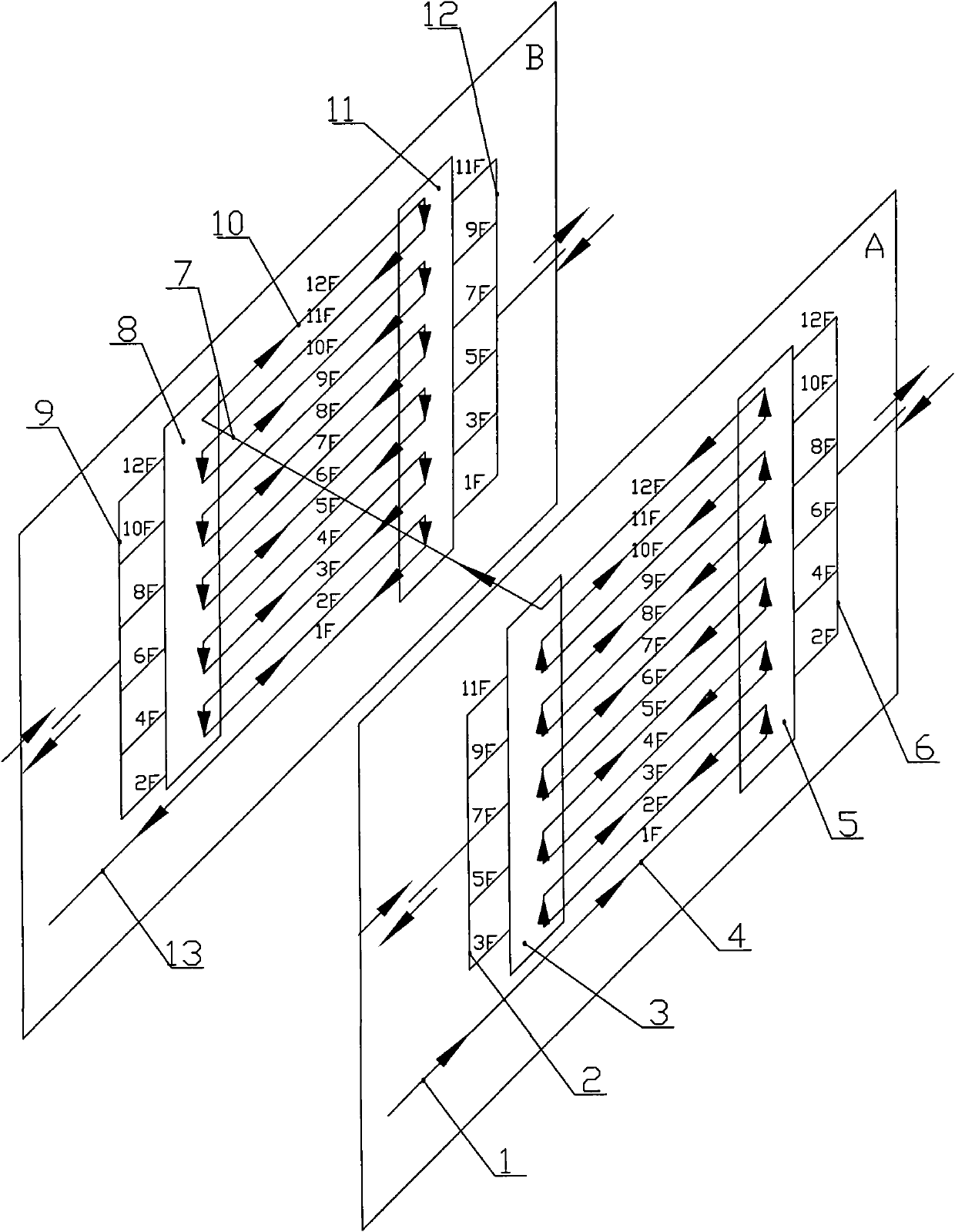

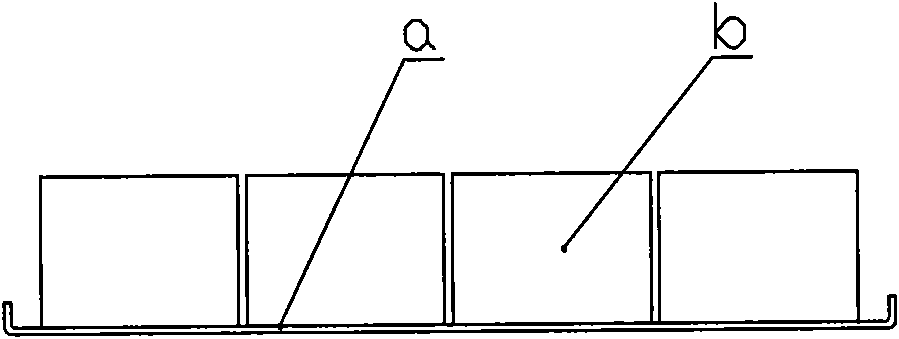

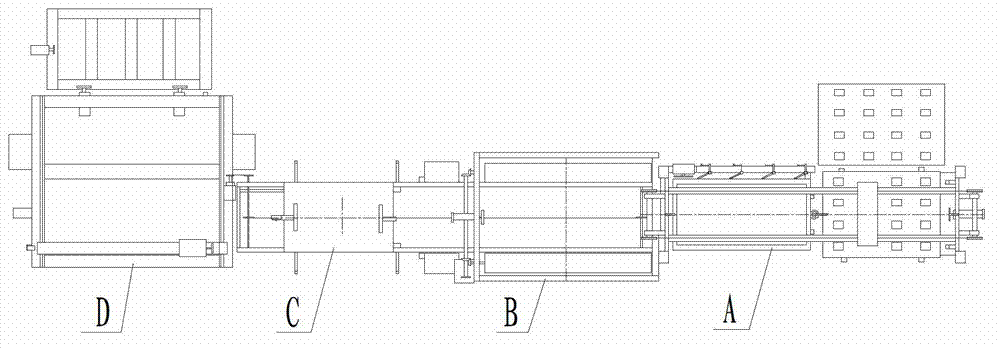

Production method of concrete grouting compound heat-insulating building block

InactiveCN101767365AAvoid manual operationIncrease productivityCeramic shaping plantsProduction lineMaterials preparation

The invention discloses a production method of a concrete grouting compound heat-insulating building block, which belongs to the field of building material machines and comprises a material preparation part, a forming part, a roundabout type transfer curing part, a grouting part and a stacking part, wherein the material preparation part is used for evenly stirring raw materials of building blocks and conveying the stirred raw materials to the forming part; the forming part is used for forming hollow building blocks by a building block forming machine and placing the hollow building blocks on a support plate; the hollow building blocks enter the roundabout type transfer curing part and are cured while being transferred; in the process of transferring and curing, the grouting part is used for grouting the hollow building blocks, so that the hollow building blocks become heat-insulating building blocks; and the cured compound heat-insulating building blocks are stacked into piles by the stacking part. By using the method, the transferring and the curing are combined into a whole, the curing is carried out in the process of the transferring, the transferring is carried out in the process of curing, any idle stroke does not exist and the production efficiency is greatly improved. In addition, in the curing process, the hollow building blocks can be grouted, so that the filling of a heat-insulating material can be finished in the production line and the manual operation can be avoided.

Owner:扬州威奥重工机械有限公司 +1

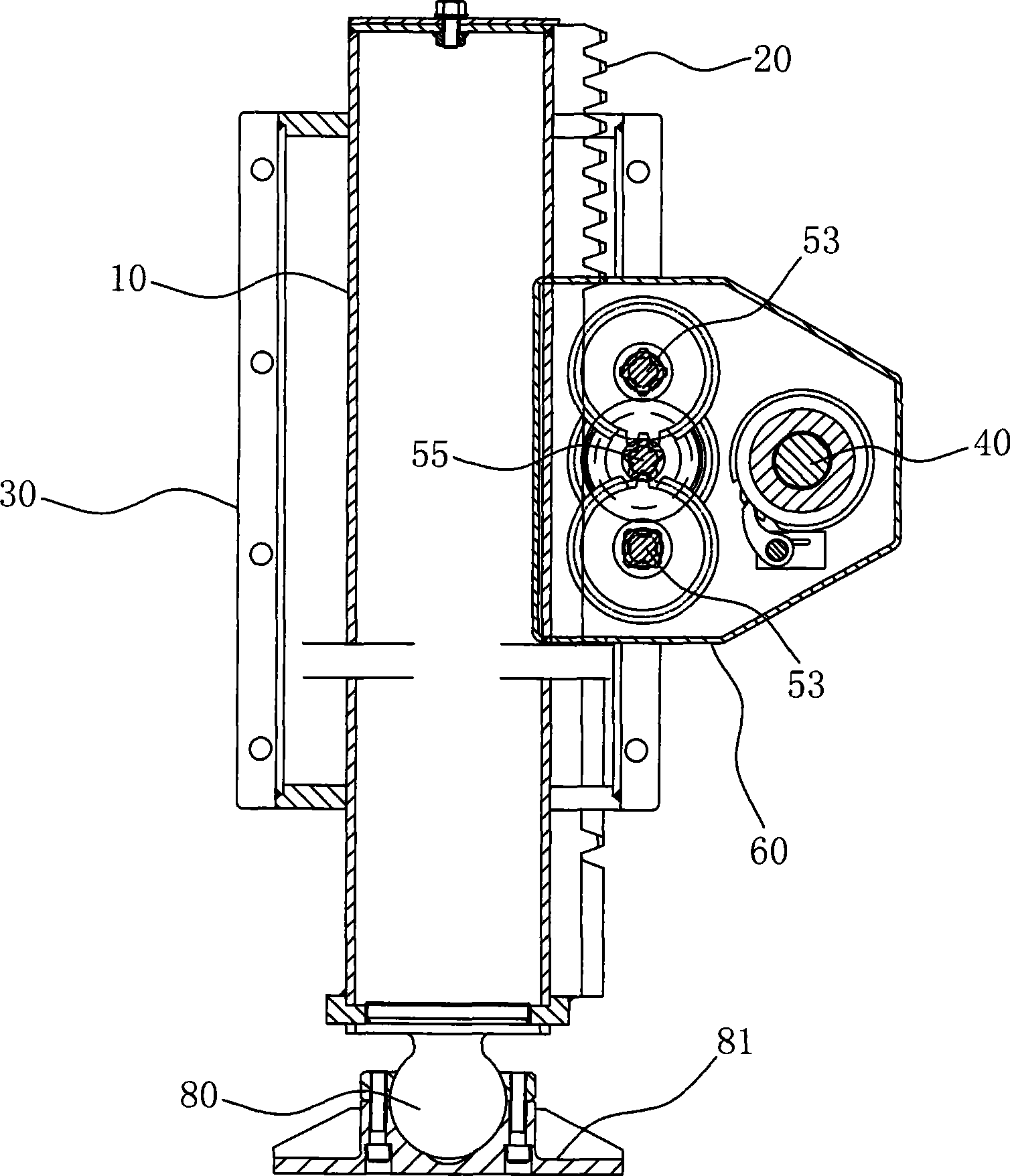

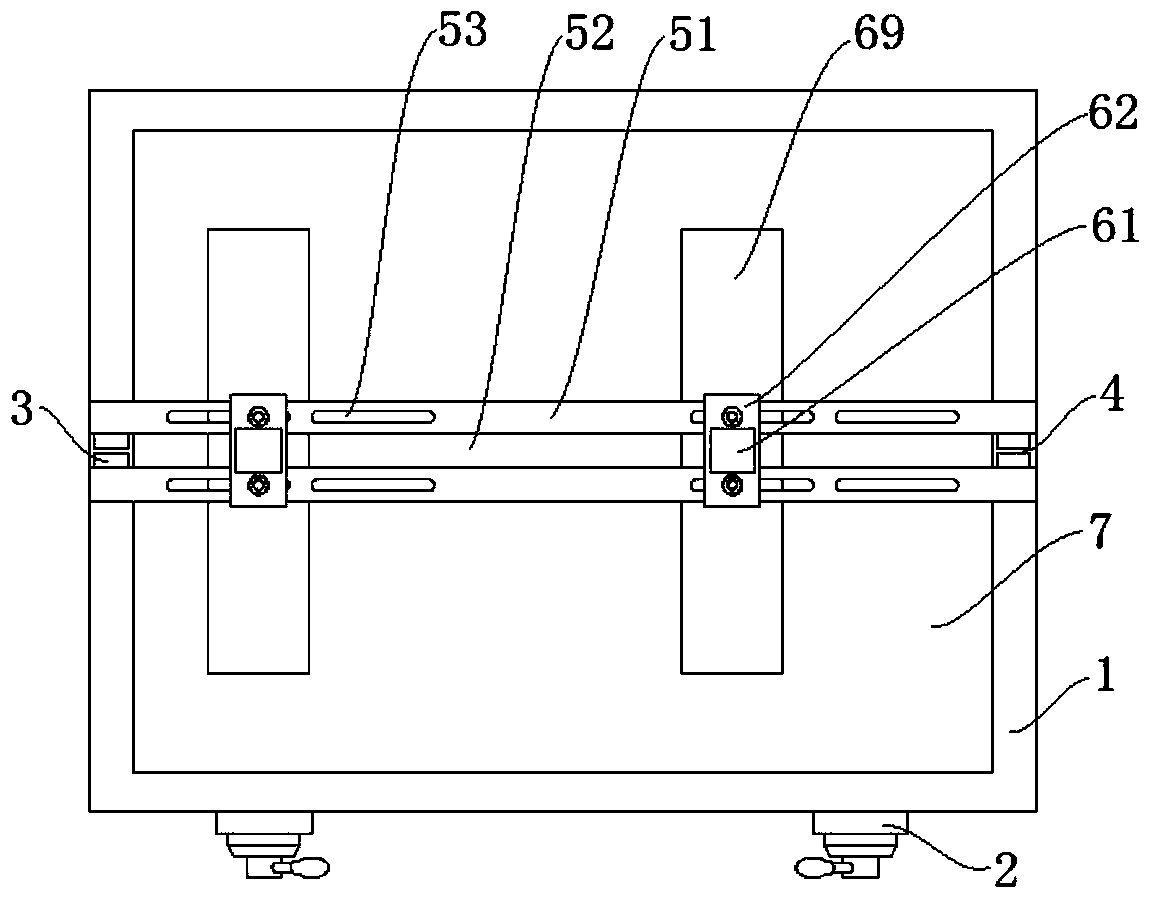

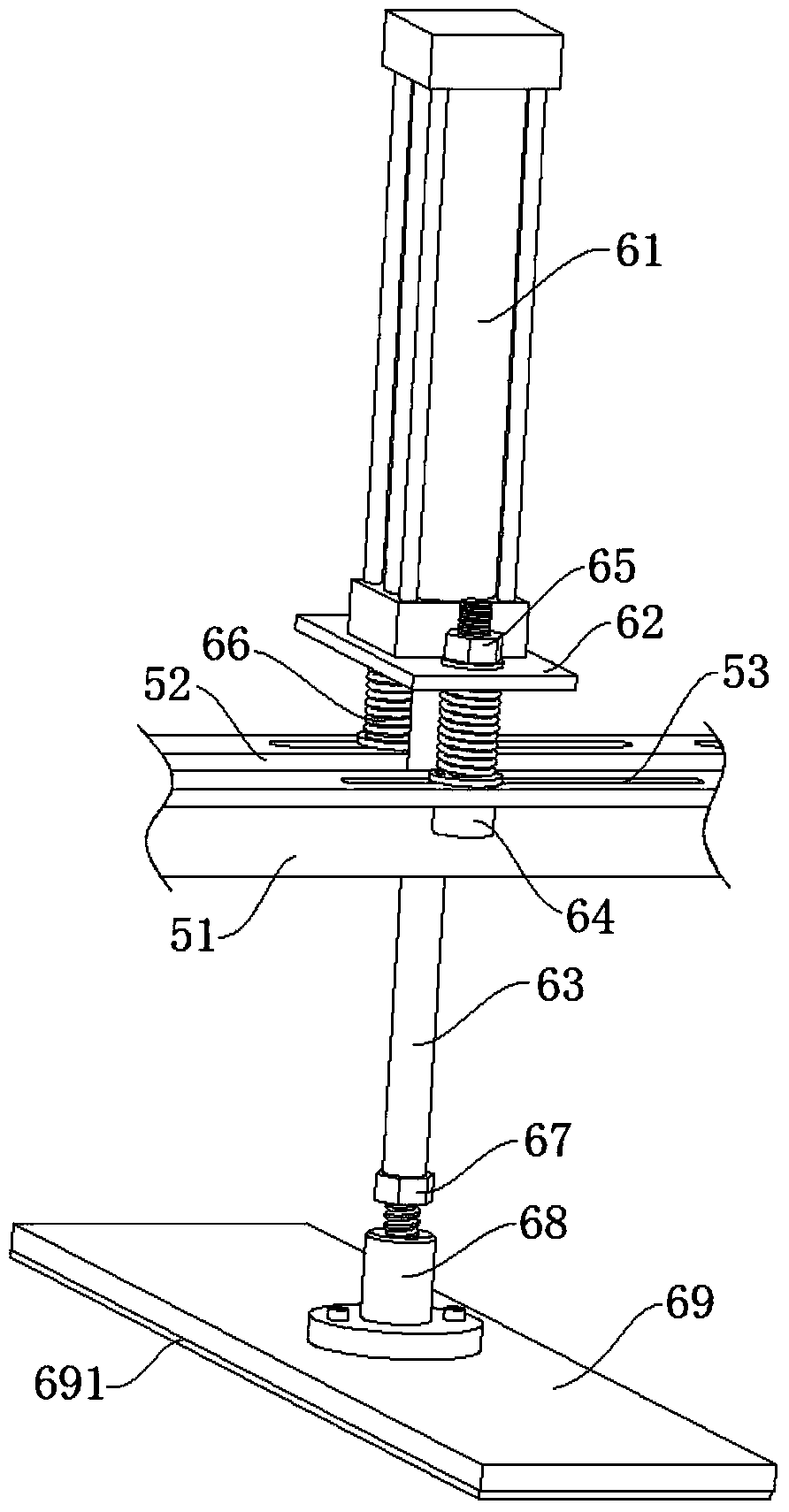

Lifting mechanism

InactiveCN101367486ASimple structureSimple and fast operationLifting framesIndustrial engineeringMechanical field

The invention belongs to the field of the crane machinery, in particular relates to a hoisting mechanism, which comprises an upright post, wherein, the outer side of the upright post is provided with a rack; the direction of the rack is paralleled to the axis direction of the upright post; the upright post is also provided with a transmission device; the transmission device can move along with the limited direction of the rack, and the transmission device is provided with a bracket. Through the technical proposal, the upright post with a rack is adopted as a supporting element and a guiding element; when in use, the upright post fixes the working platform that is required to be supported and leveled on the bracket, and then the transmission device drives the bracket to move along with the limited direction of the rack, thereby completing the hoisting of the working platform and adjusting and leveling the working platform; therefore, the hoisting mechanism has simple structure, simple and convenient operation, and occupies less land area, and is safe and reliable.

Owner:HEFEI HUALIN MOLD

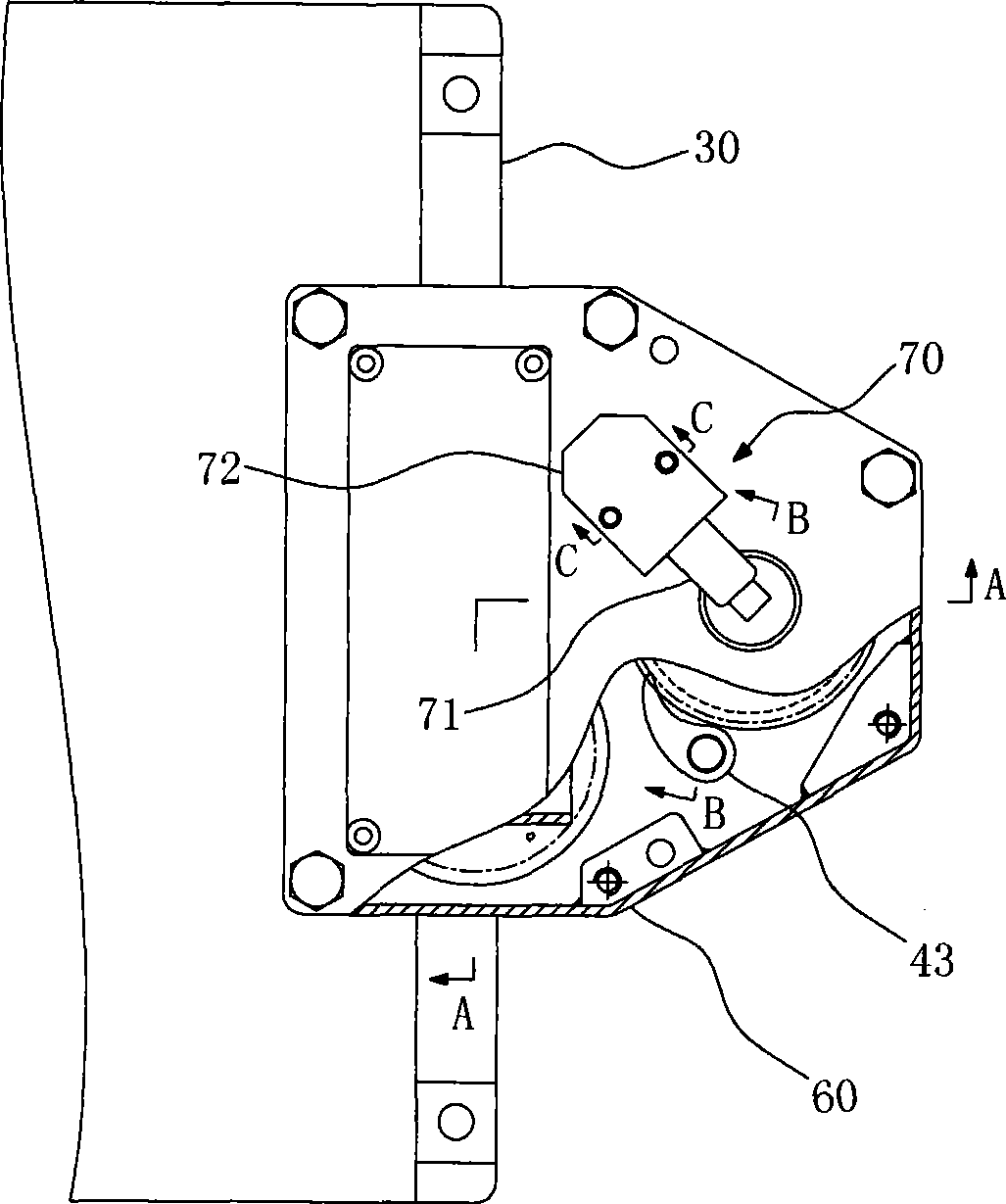

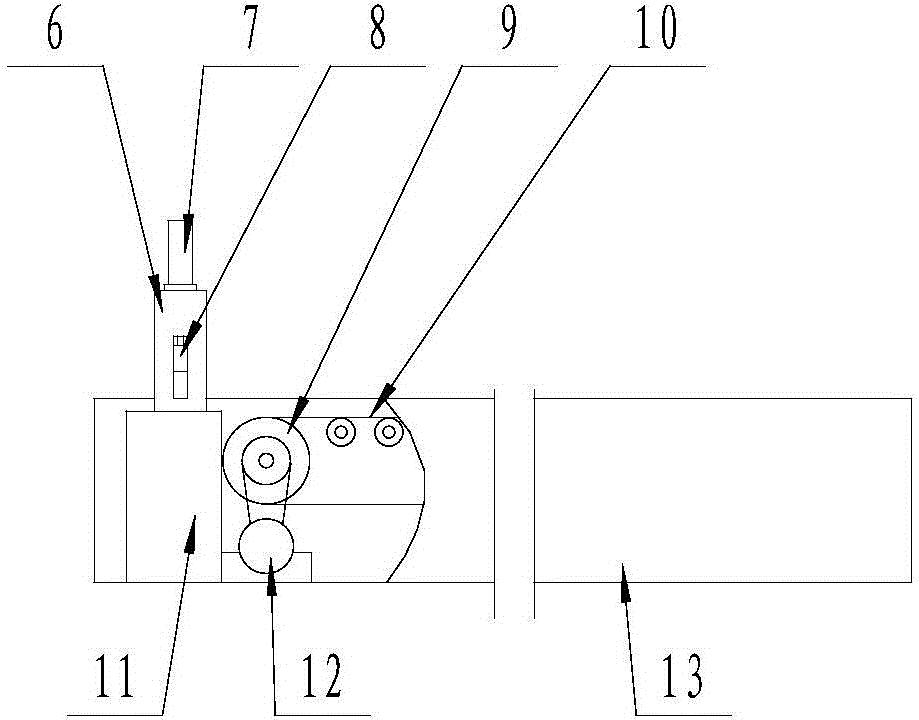

Automatic cutting device for ceramic tiles

ActiveCN107379285AAvoid scratchesQuality improvementWorking accessoriesStone-like material working toolsEngineeringMechanical field

The invention relates to the field of machines for building materials, in particular to an automatic cutting device for ceramic tiles. The automatic cutting device for the ceramic tiles comprises a unit body, a rotating module, a horizontal movement module, a clamping module, a cutting module, an adjustment module, a removing module, a measurement module, an input module and a controller, wherein the rotating module is mounted at the lower end of the unit body, the horizontal movement module is fixed to the upper end of the rotating module, the clamping module is fixed to the upper end of the horizontal movement module, the cutting module is located above the clamping module and fixedly connected with the unit body, the adjustment module is located on the left-front portion of the unit body, the removing module is located on the right-rear portion of the unit body, the measurement module is mounted on the unit body, and the input module is used for transmitting input parameters into the controller. By adoption of the automatic cutting device for the ceramic tiles, the ceramic tiles can be automatically cut at multiple angles, the cutting precision is high, and the cutting efficiency is high.

Owner:倡创(上海)咨询管理事务所

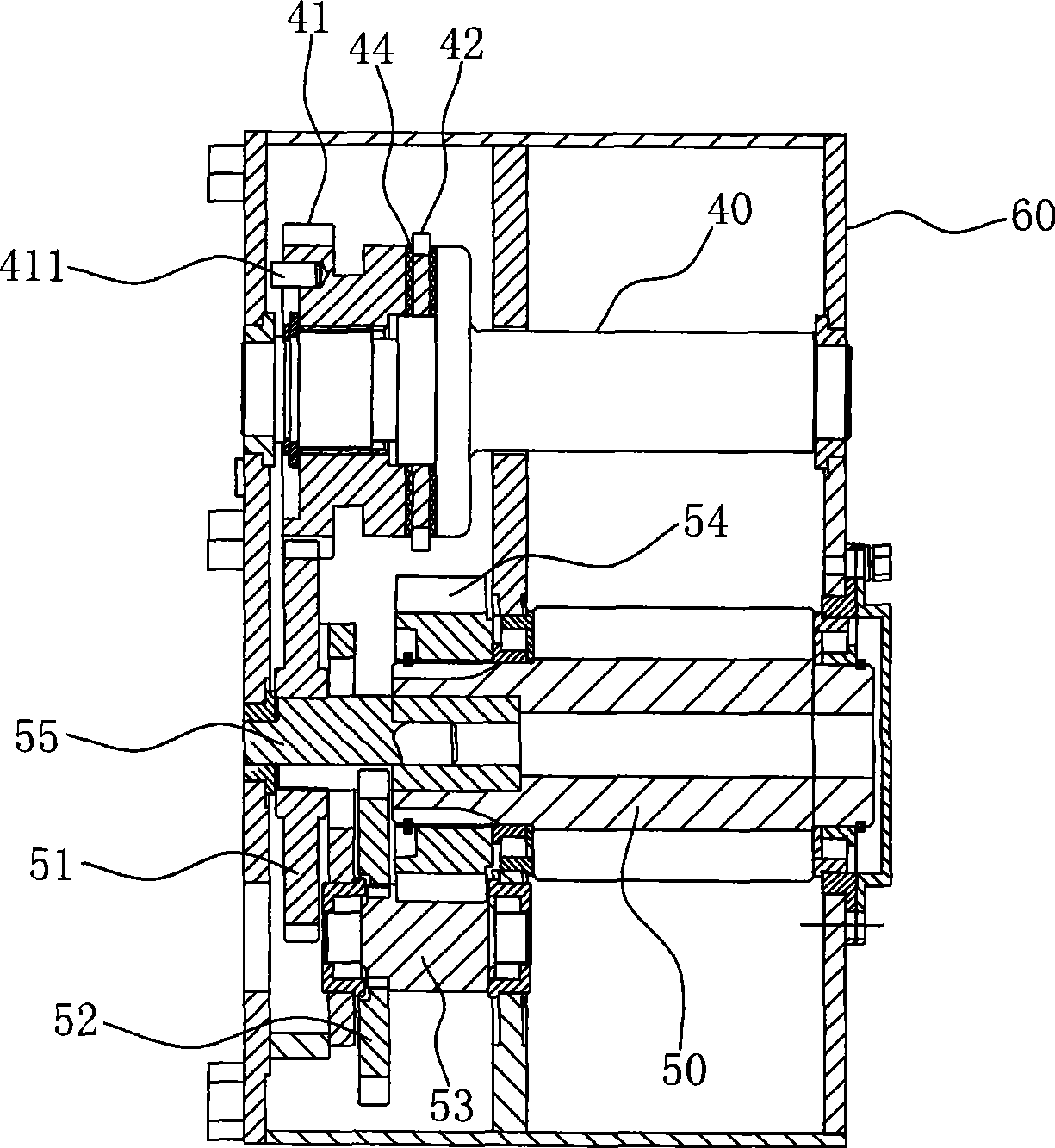

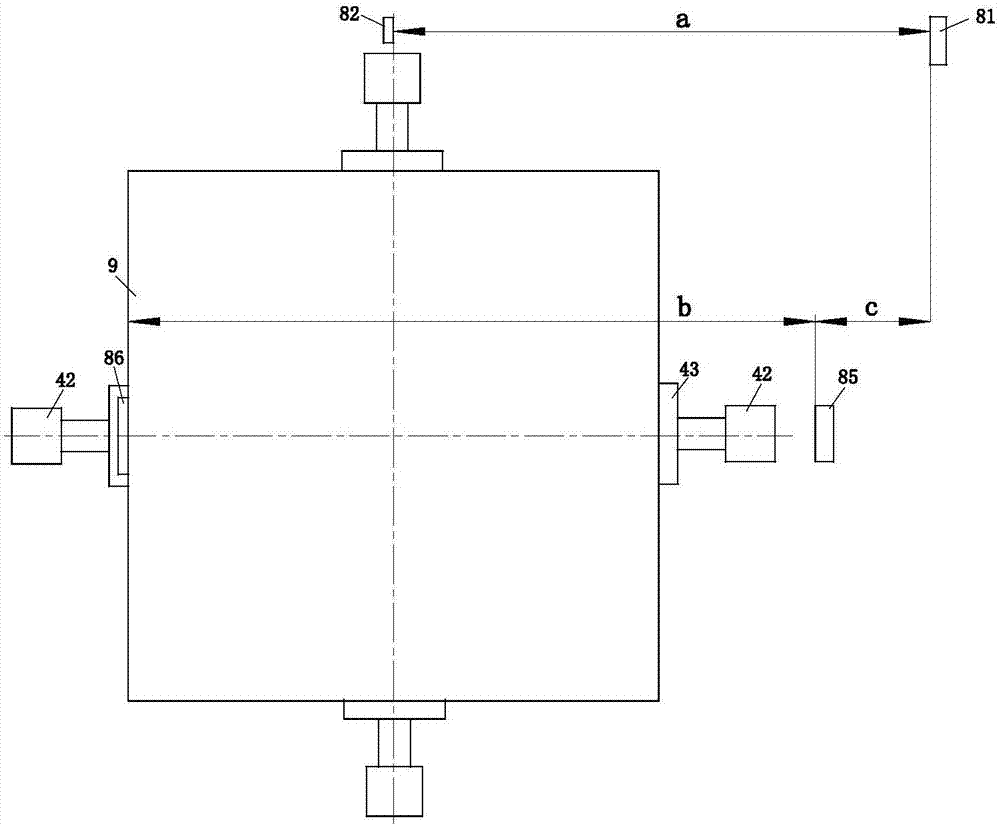

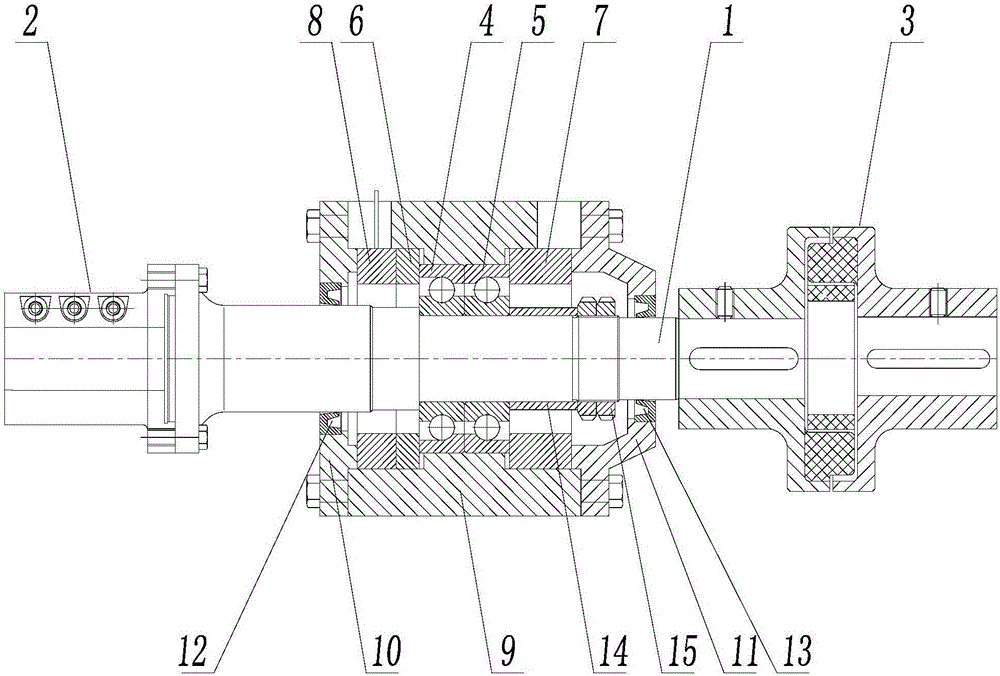

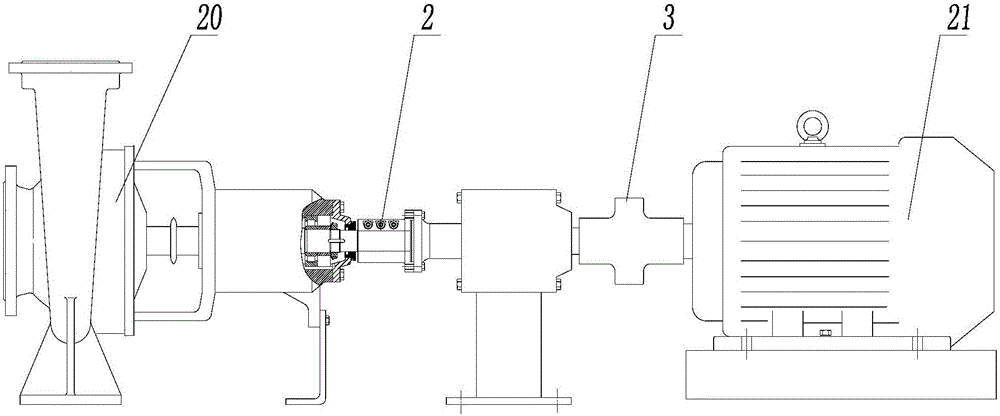

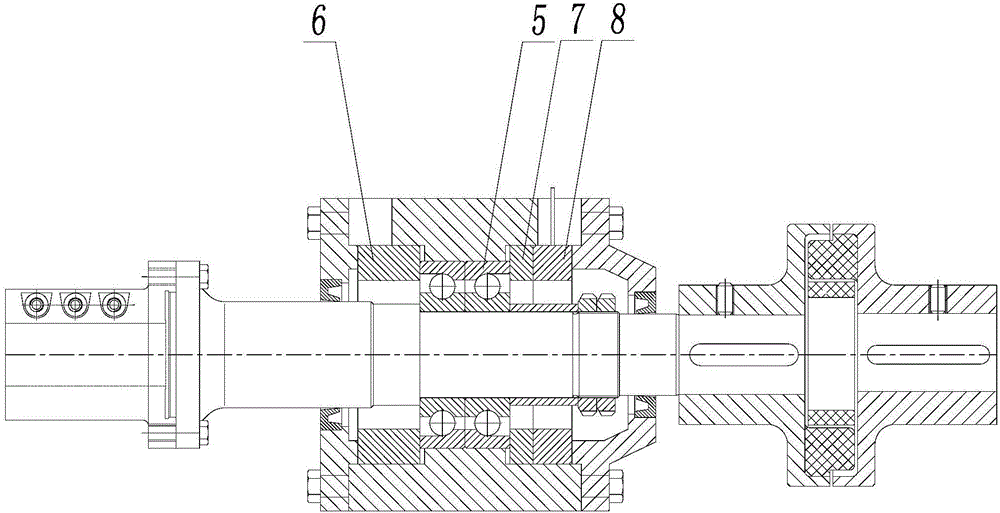

Rotation machine axial force testing apparatus and testing method thereof

ActiveCN105092129AAccurate measurementWide versatilityApparatus for force/torque/work measurementCouplingElectric machine

The invention relates to the technical field of a rotation machine, more particularly to a rotation machine axial force testing apparatus and a testing method thereof. The apparatus comprises a housing, a bearing, a rotation shaft and a sensor. The rotation shaft is fixedly connected to the inner ring of the bearing. The outer ring of the bearing is fixedly connected with the housing. The rotation shaft is sleeved by the sensor. Signals outputted from the sensor are electrically connected to a signal processing device; the rotation shaft and a rotation machine are connected through a keyless connection component and the rotation shaft is connected with a motor through a shaft coupler. The apparatus has great universality to test the axial force of a variety of rotation machines. The apparatus can also carry out / perform in one direction or two directions with a 1% range error tolerance. Simple in structure, the apparatus is an independent device and is convenient to install. When in use, a rotation machine needs not to be modified. Capable of providing an effective means to problems of axial force balance among various machines, the apparatus and method can be promoted for wider applications.

Owner:GUANGDONG KENFLO PUMP CO LTD +1

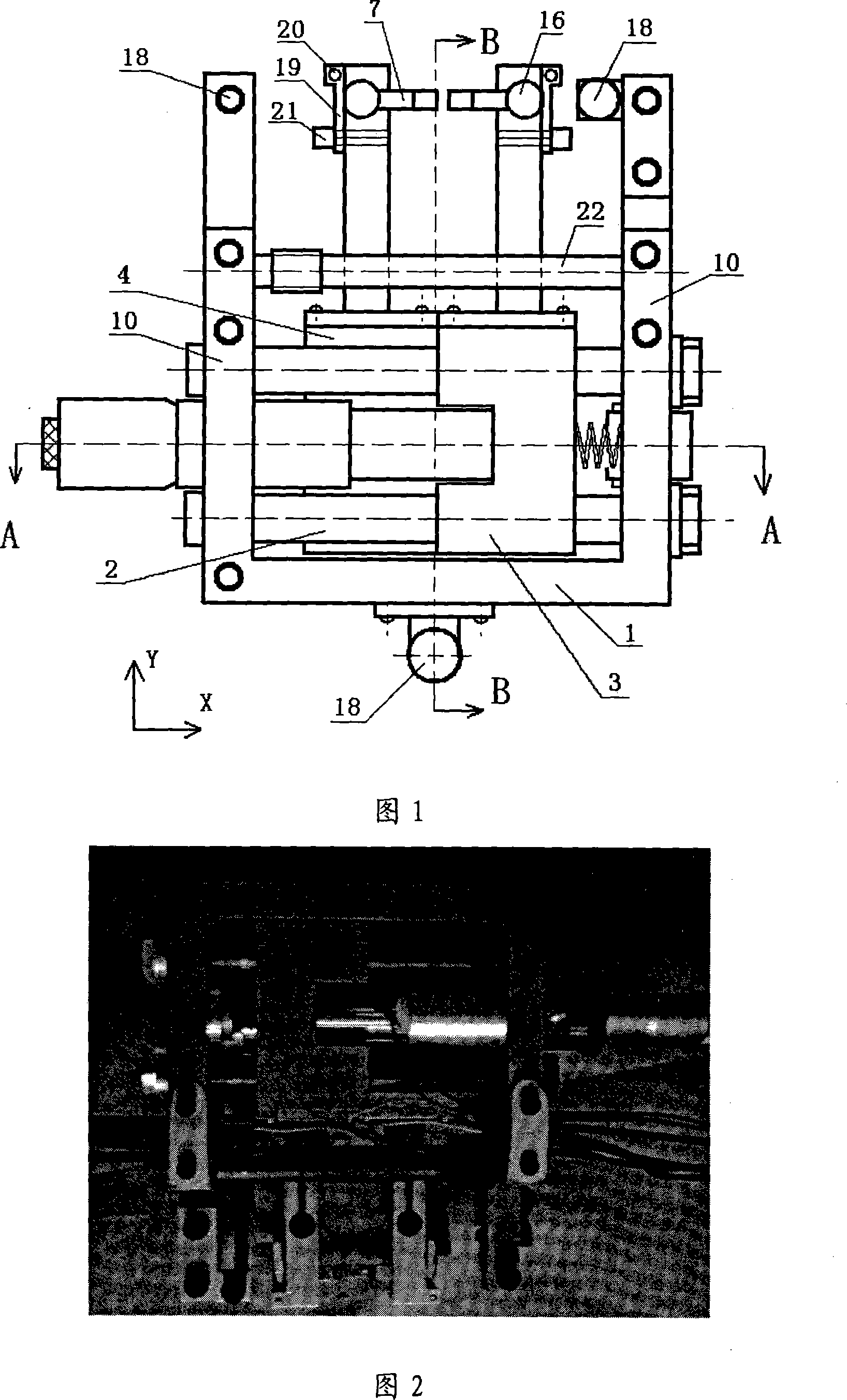

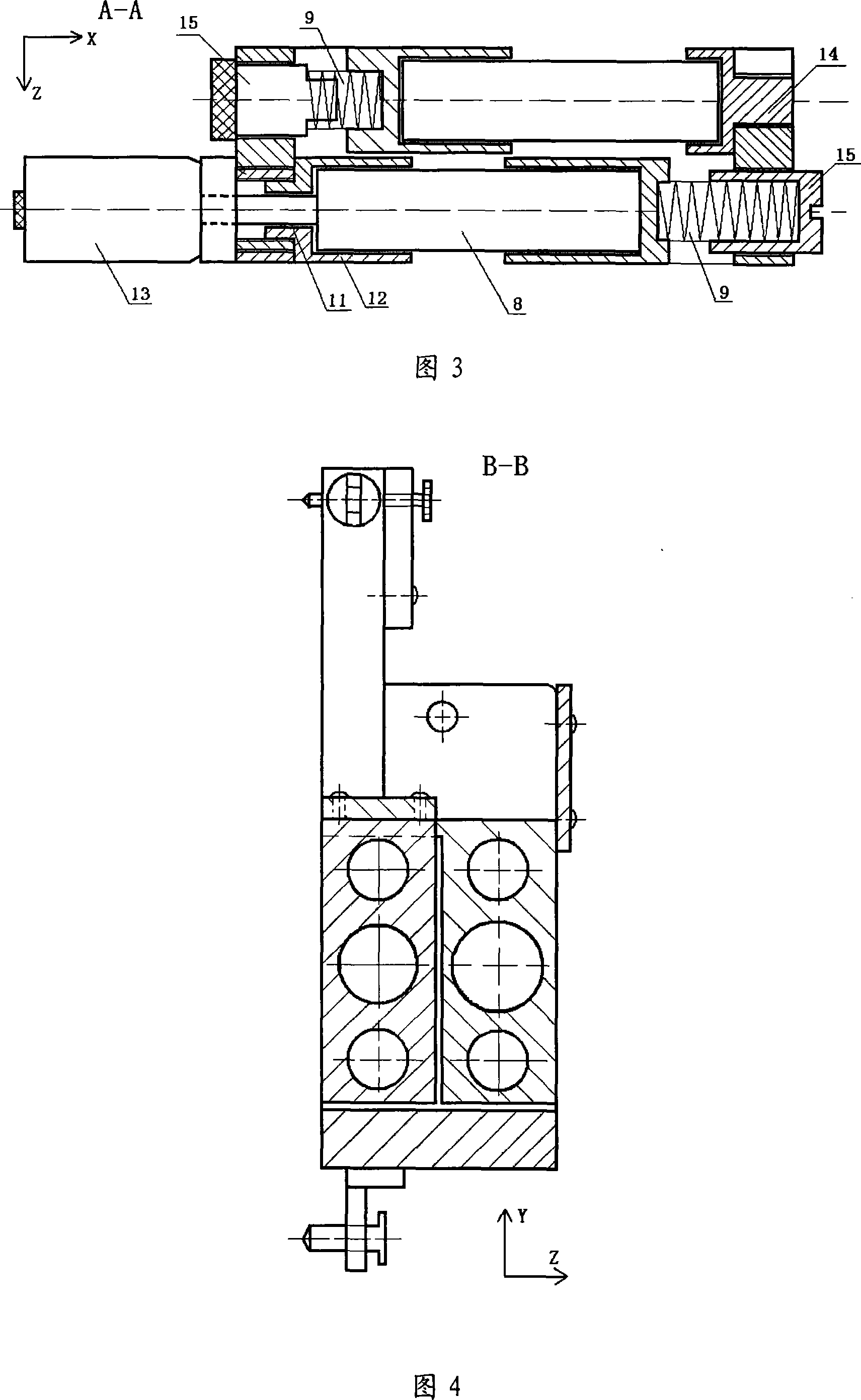

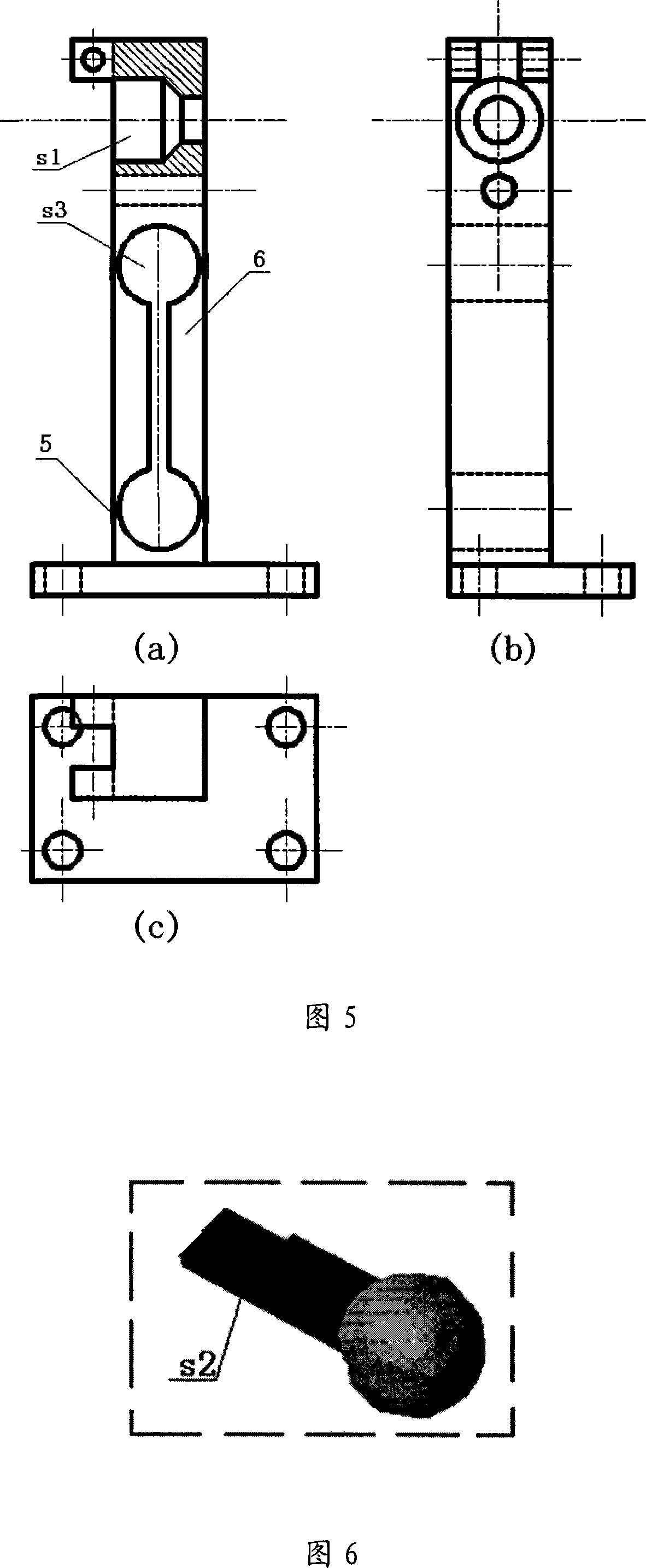

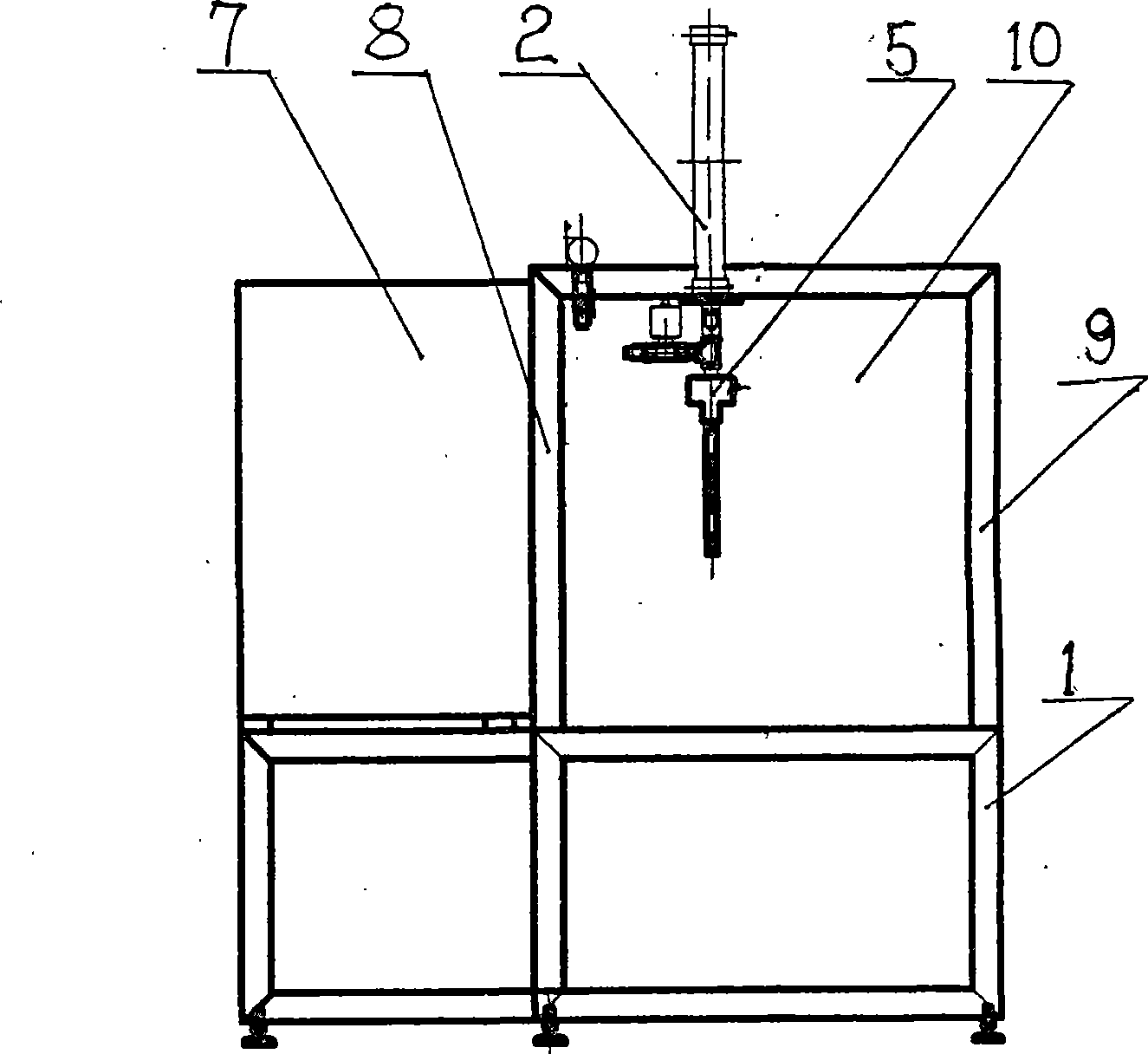

Film single-axis bidirectional decline micro-stretching device and method for measuring

InactiveCN101109680ASuitable for testingExpand the measurement rangeSurface/boundary effectUsing mechanical meansEngineeringCeramic

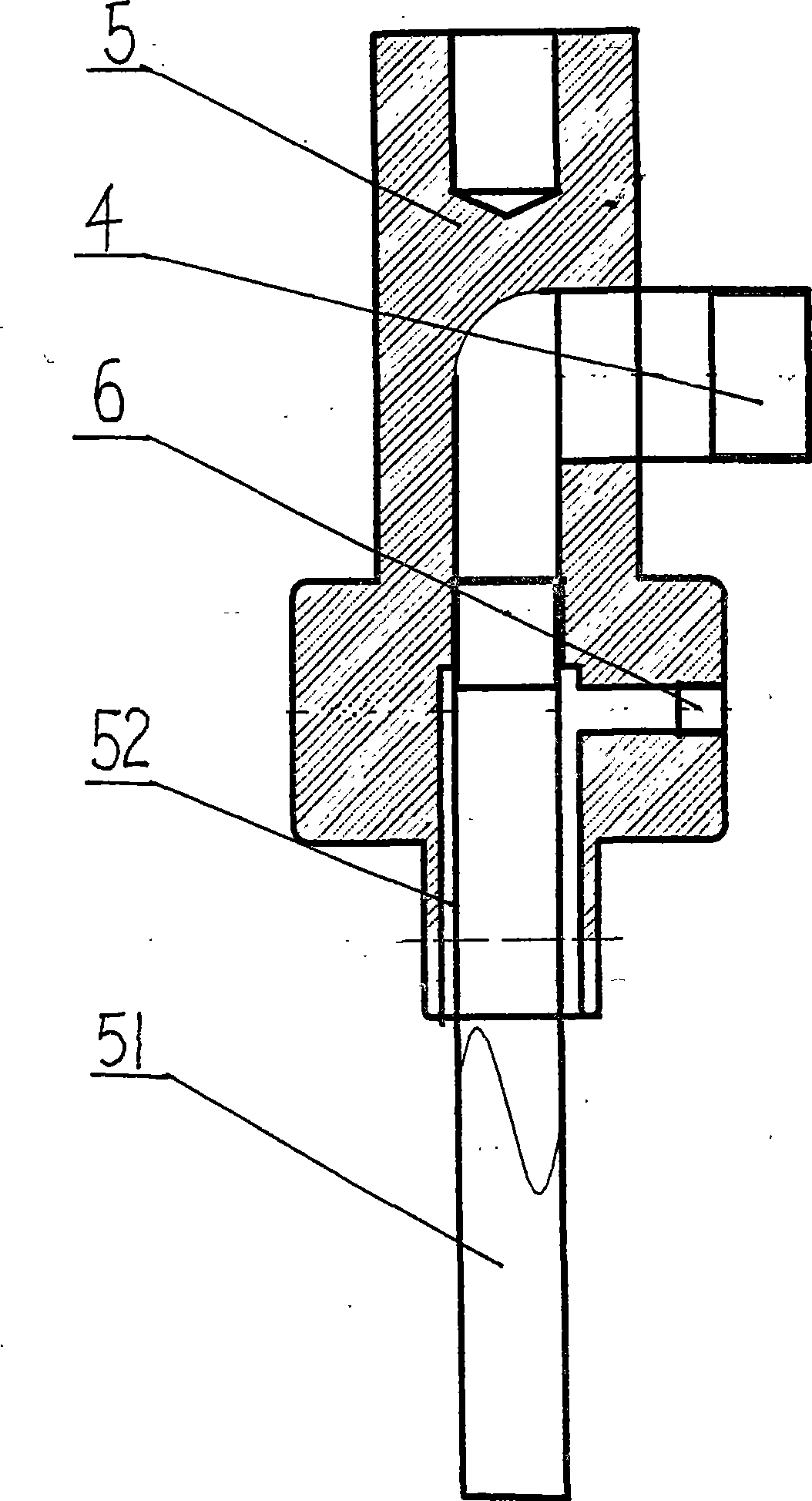

The invention provides a film single-shaft bidirectional tensing mechanism and a measuring method for the deformation in the film, and pertains to the field of precision machinery. The mechanism uses two piezoelectric ceramics 8 to push from two directions respectively a slider 4 and an adjustable slider 3 that can move along a slideway 2, between the slider 4 / the adjustable slider 3 and a support 1, limit springs 9 are used for limiting; on the slider 4 and the adjustable slider 3, a force sensing arm 6 is fixedly connected respectively; the top of the force sensing arm 6 is connected with a stage. At measuring, first a film specimen to be measured is clamped on the stage; then the piezoelectric ceramics 8 are applied with voltage continuously, so that the two force sensing arms 6 will have mini displacement opposite to each other; meanwhile, the images and mechanic parameters of the film deformation are recorded by a real-time acquisition system and stress pieces 5 attached on the force sensing arms 6. By the invention, the measuring area can be observed continuously, and measurement of wider range can be carried out by force sensing arms of different measuring ranges.

Owner:TSINGHUA UNIV

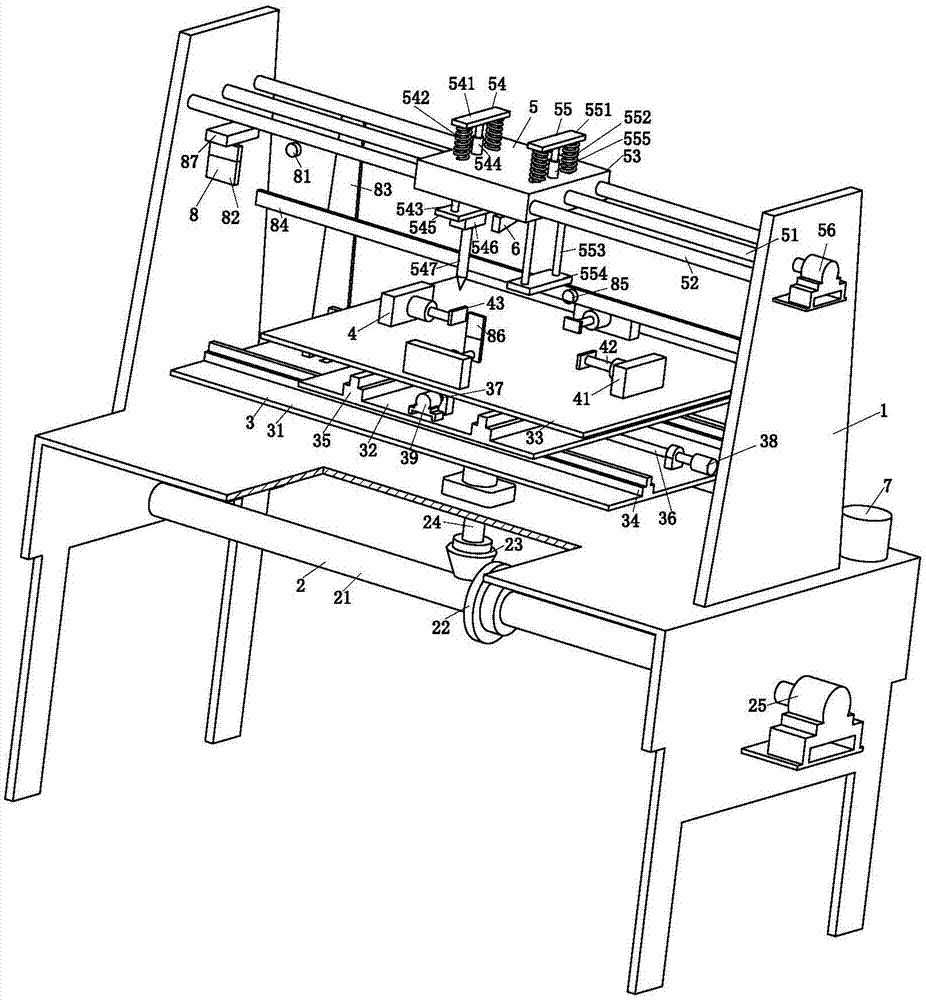

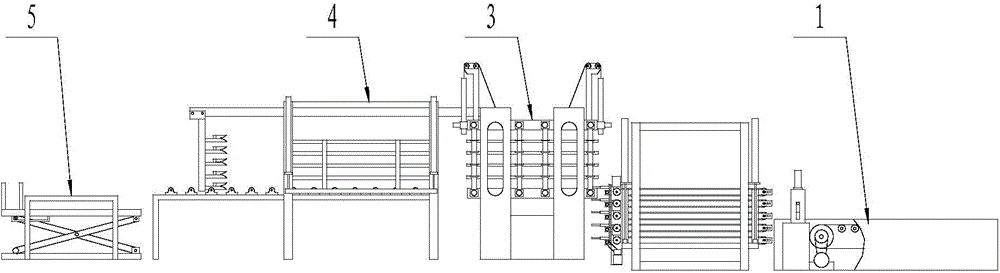

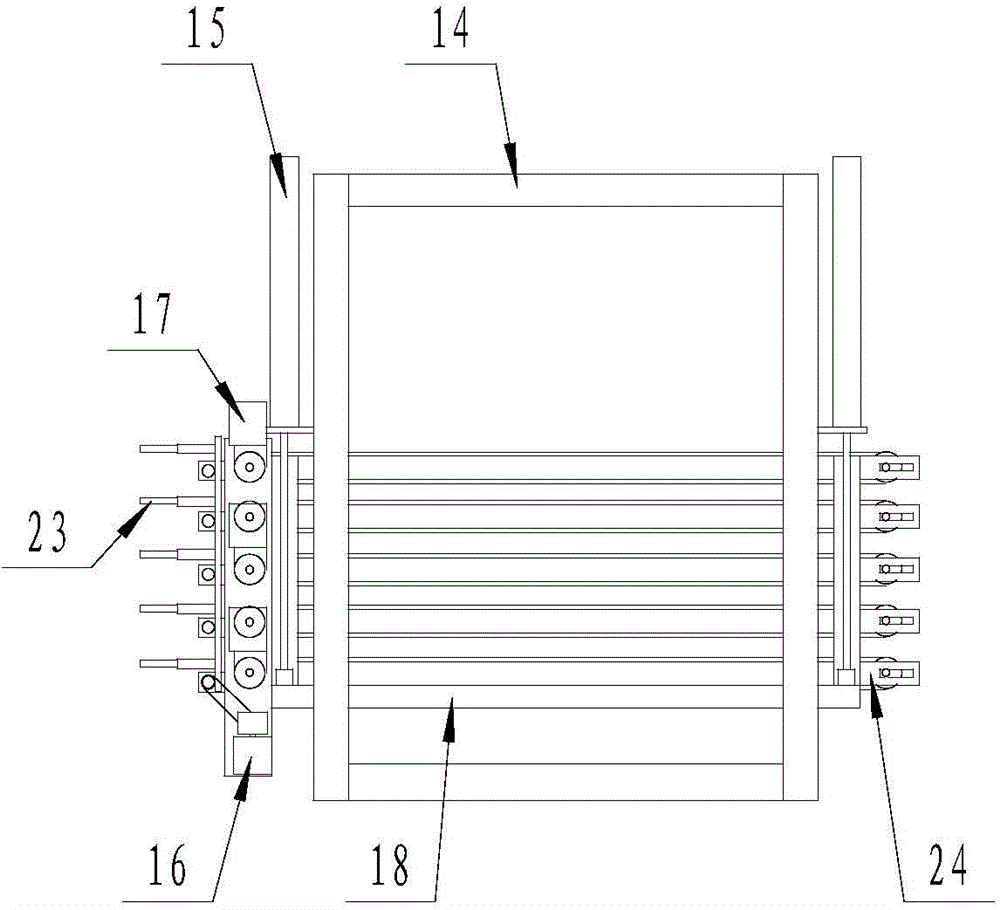

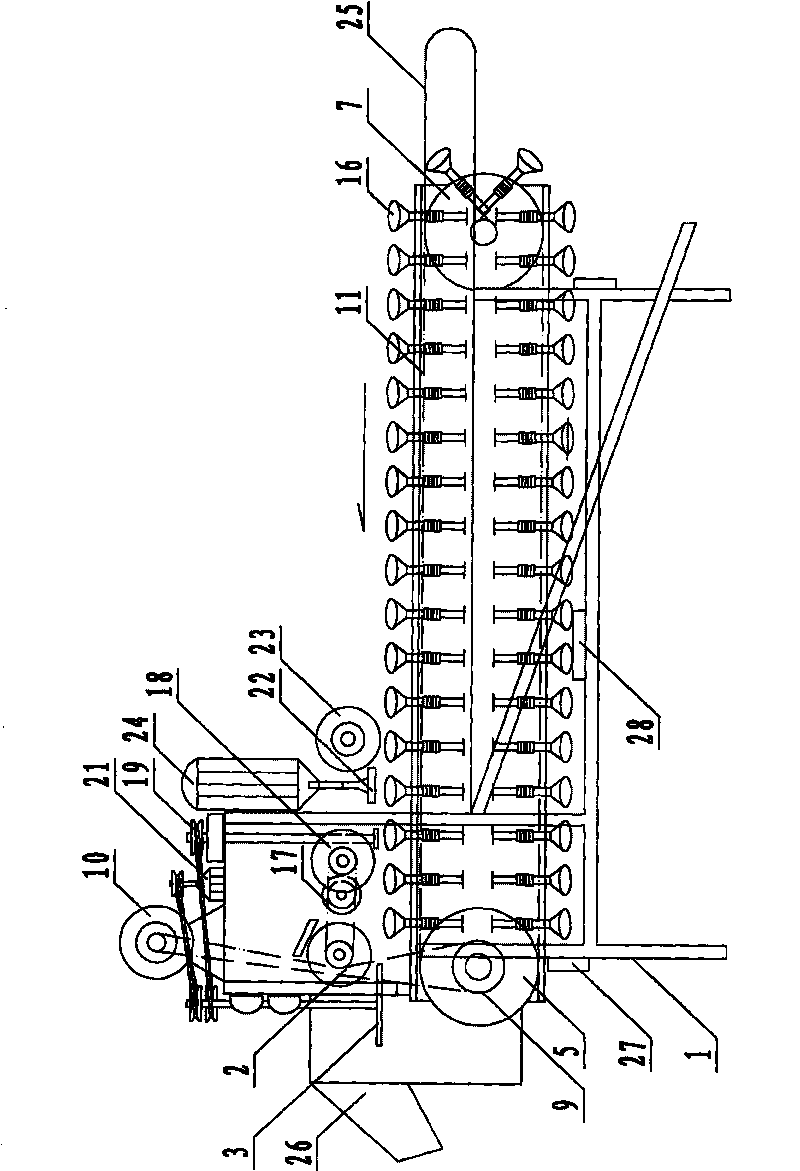

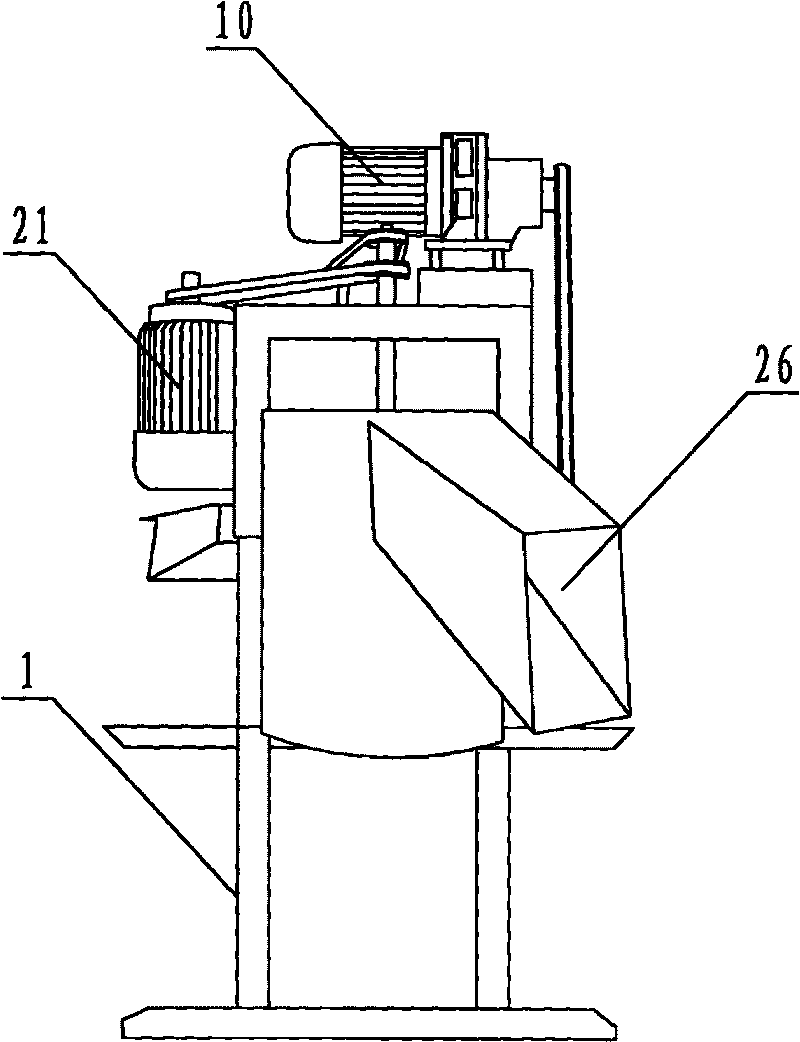

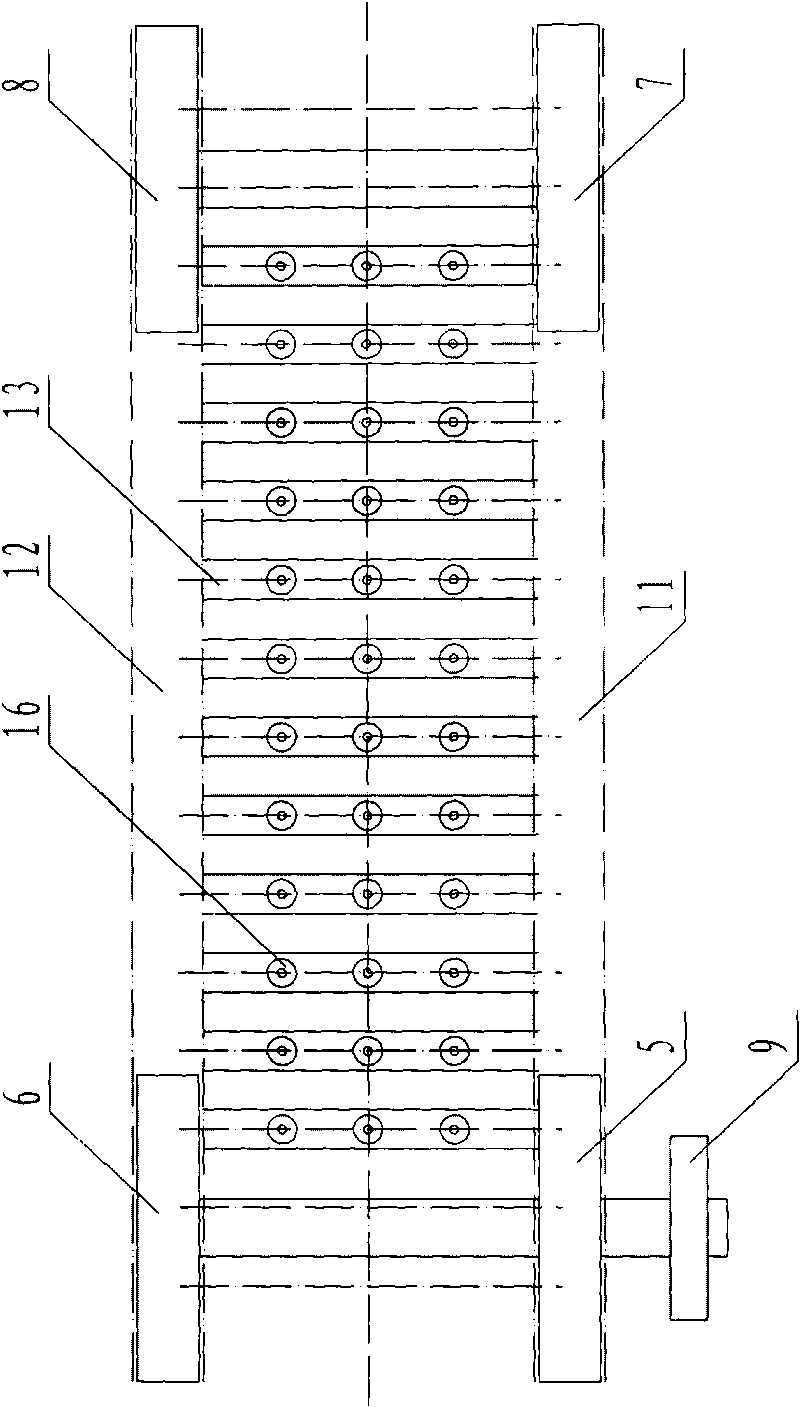

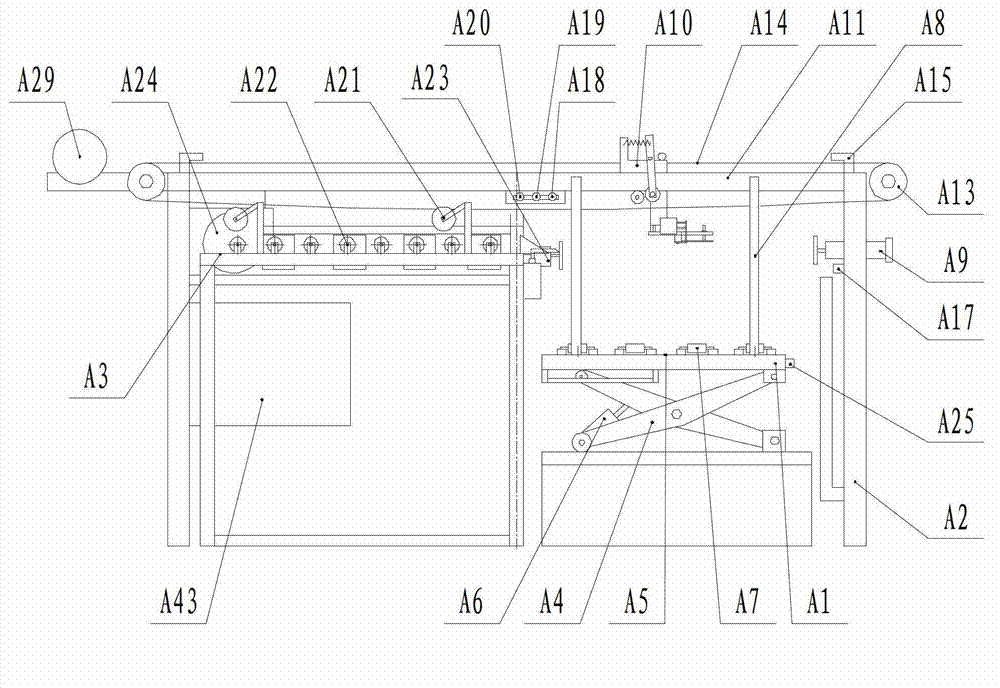

Woodworking plate paving-hot-pressing all-in-one machine

InactiveCN104526796AImprove processing qualityRise steadilyOther plywood/veneer working apparatusPlywood pressesControl systemSlide plate

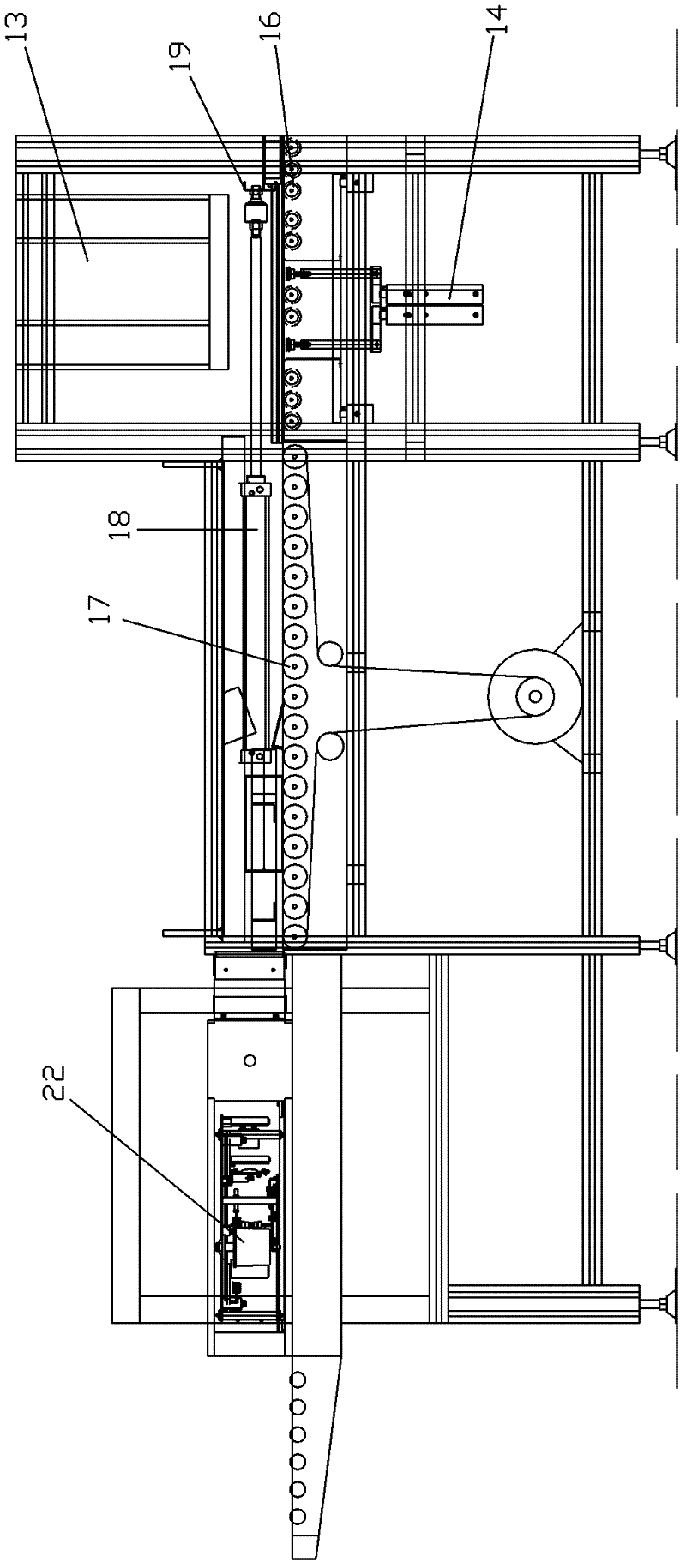

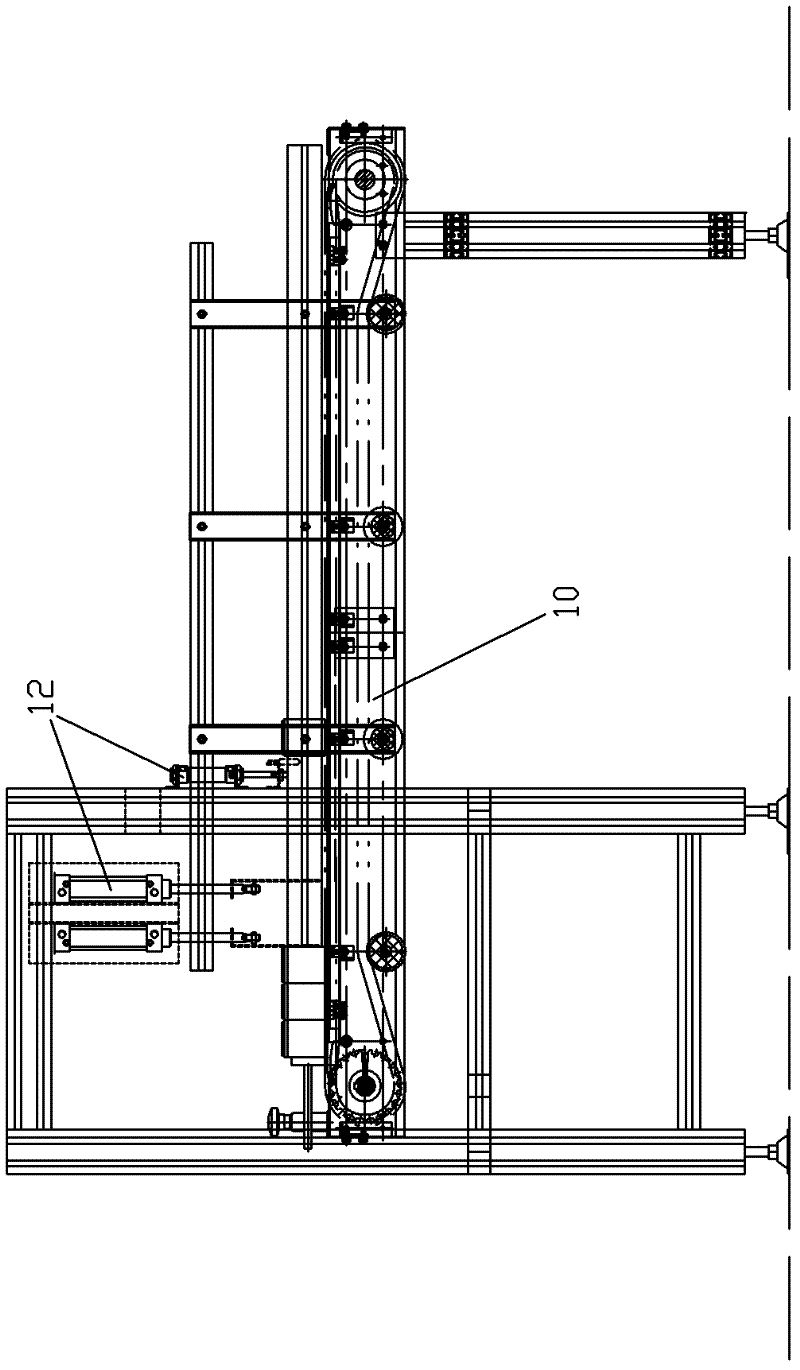

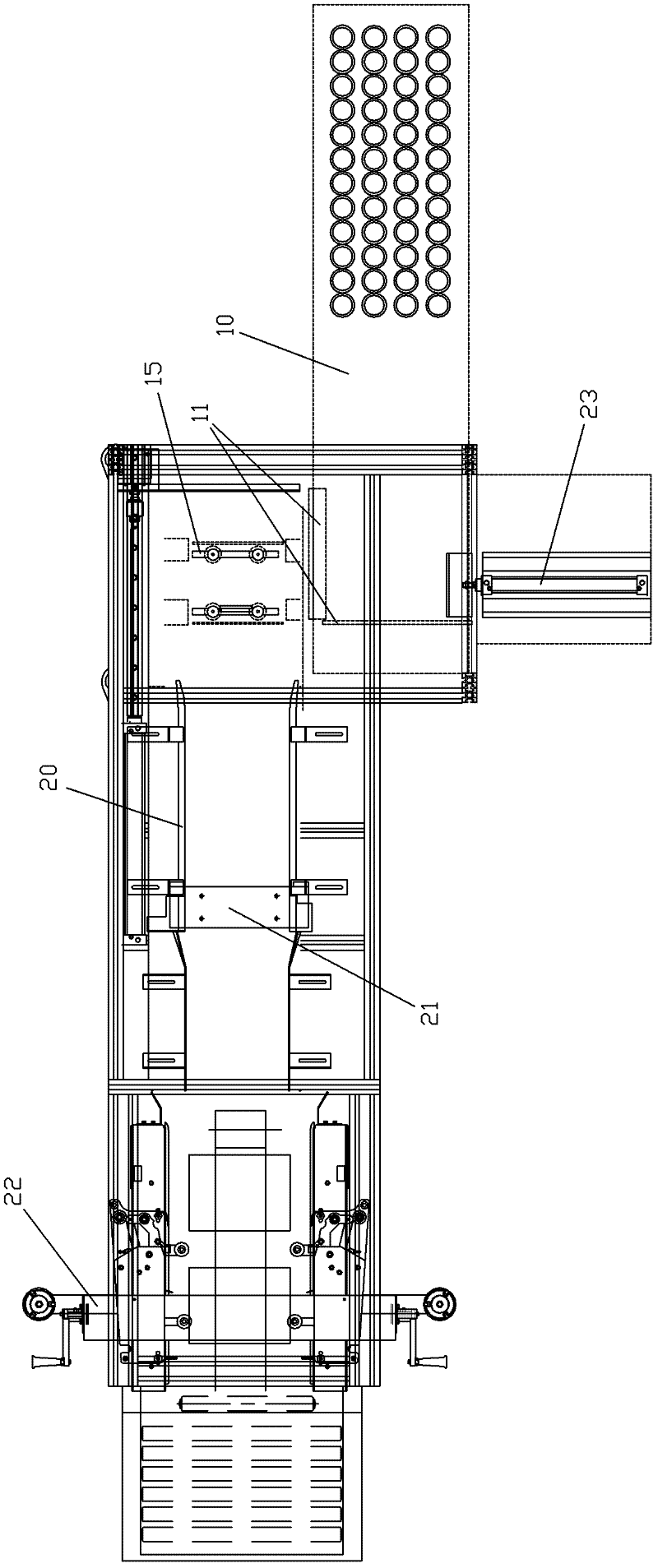

The invention discloses a woodworking plate paving-hot-pressing all-in-one machine and belongs to the field of plate machining machinery. The woodworking plate paving-hot-pressing all-in-one machine comprises a jointed plate conveying platform, an automatic feeder, a multilayer thermal press, an automatic plate taking device, a plate stacker and a programming control system. The automatic feeder comprises a feeder frame, a lifting table, a lifting oil cylinder I connected with the lifting table and at least two plate storing platform layers arranged on the lifting table. Transmission devices and conveying sliding plates connected with the transmission devices are arranged on the plate storing platforms. The machine is used for woodworking plate production and machining, automatic conveying, automatic sawing, automatic multilayer thermal press placing in, automatic plate taking and automatic stacking can be achieved, following plate joining operation is not affected, the automatic degree and the production efficiency are high, and plate machining quality is high.

Owner:姜皓月

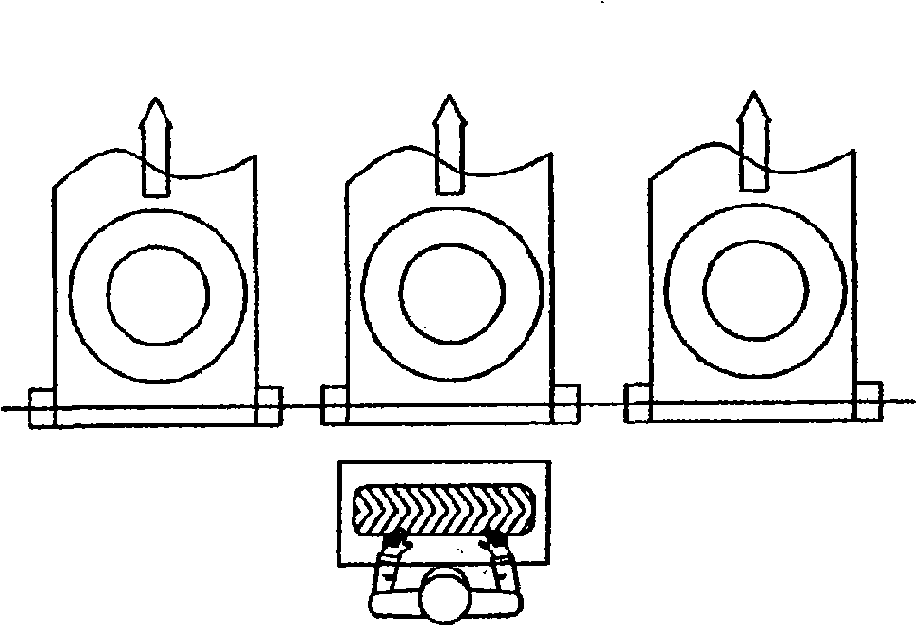

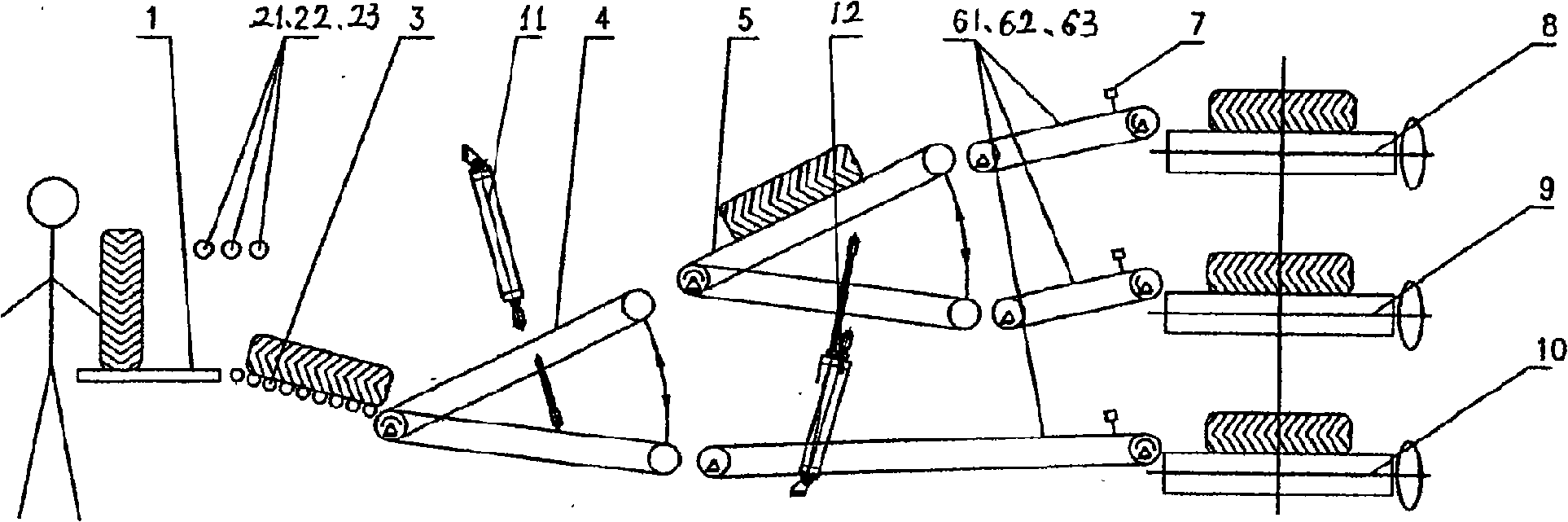

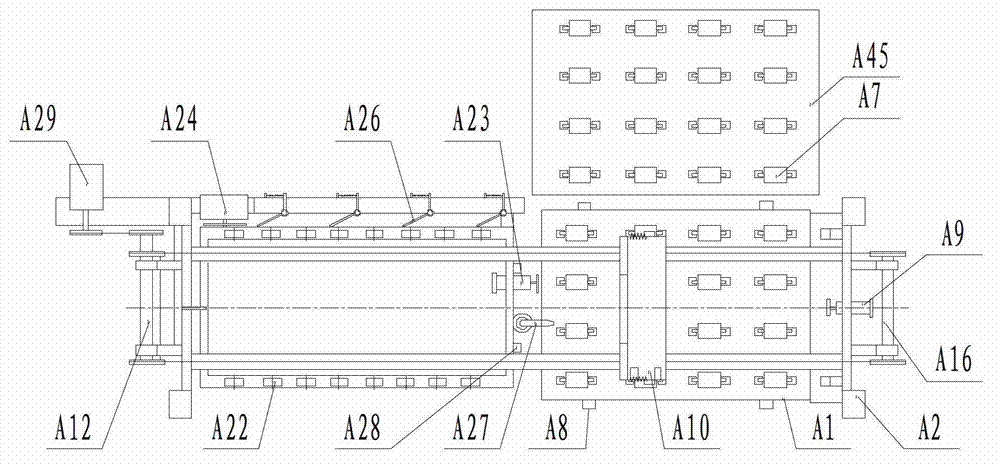

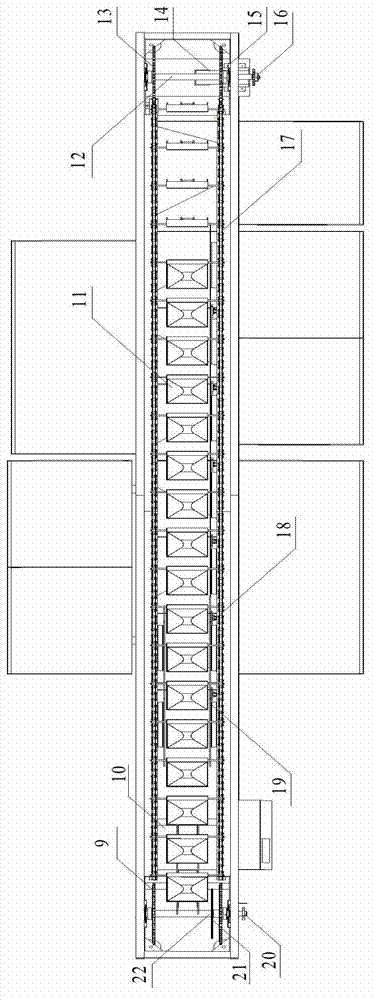

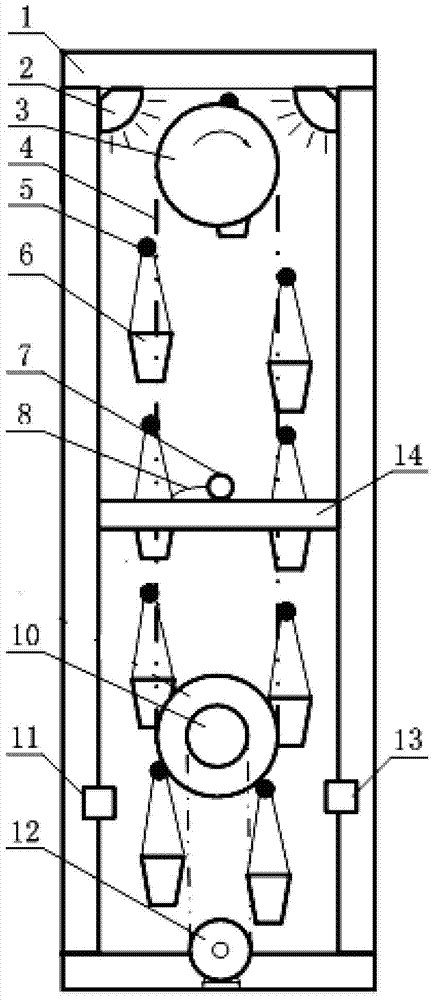

Shutter tire roller tire graded conveyer device

InactiveCN101337224AReduce labor intensityImprove work efficiencySortingConveyor partsLower gradeLow graded

The invention relates to a turnover plate series tire grading conveying device, which belongs to the mechanical field of tire conveying. The device is provided with an inspection bench, as well as an upper grading conveying belt, a middle grading conveying belt and a lower grading conveying belt which are arranged on an identical vertical surface; a take-off roller track tilting forwards and downwards is mounted at the front end of the inspection bench; a primary turnover plate belt conveyor is arranged in the front of the take-off roller track, connected with the end part of the telescoping rod of a primary hydraulic oil cylinder, and pushed by the primary hydraulic oil cylinder to swing around the rear end thereof; a lower transitional belt conveyor is arranged between the primary turnover plate belt conveyor and the lower grading conveying belt; a secondary turnover plate belt conveyor is mounted above the lower transitional belt conveyor, connected with the end part of a the telescoping rod of a secondary hydraulic oil cylinder, and pushed by the secondary hydraulic oil cylinder to swing around the rear end part thereof; a middle transitional belt conveyor is arranged between the secondary turnover plate belt conveyor and the middle grading conveying belt; an upper transitional belt conveyor is arranged between the secondary turnover plate belt conveyor and the upper grading conveying belt.

Owner:TRIANGLE TIRE

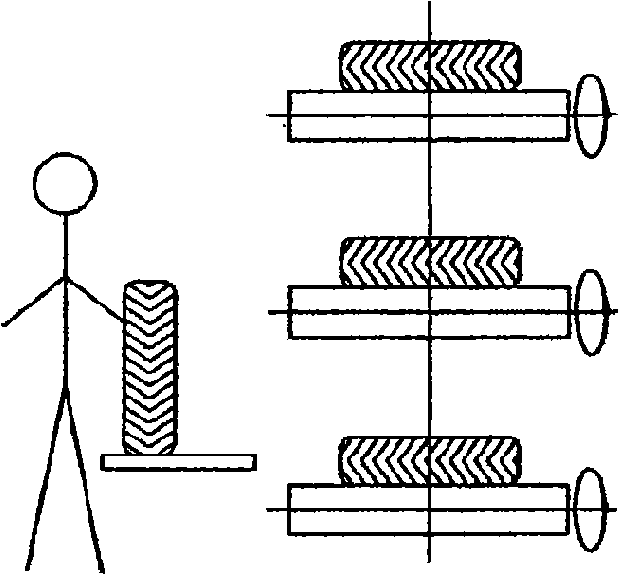

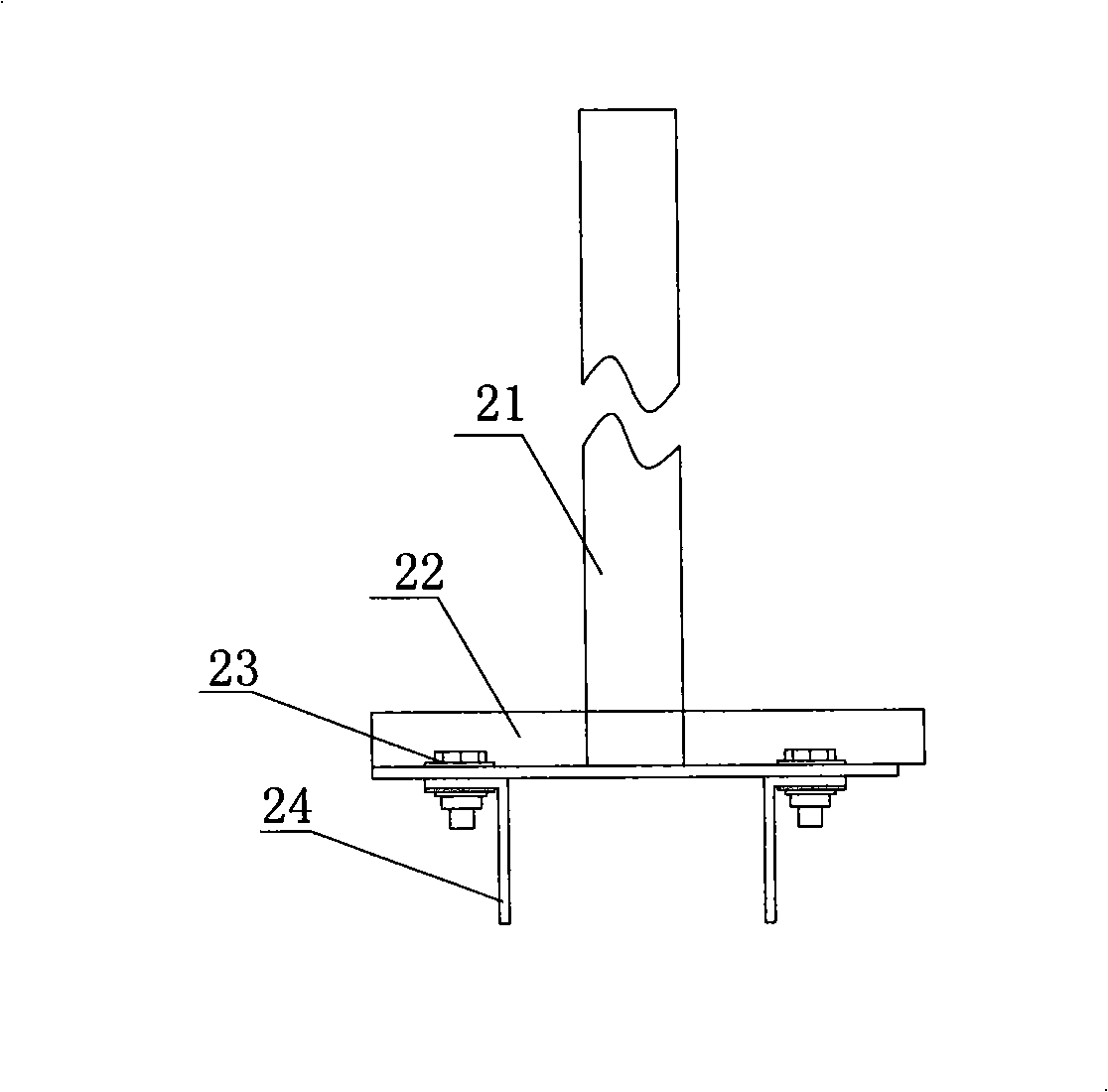

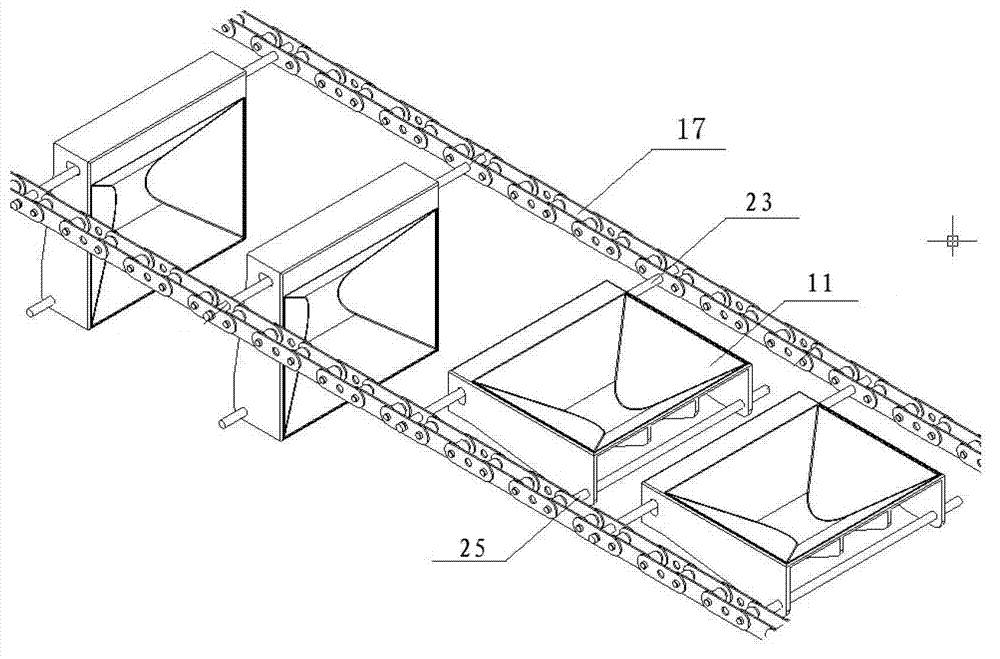

Garlic root cutter

The invention provides a garlic root cutter which belongs to the field of deep processing machines of garlic. The garlic root cutter comprises a stand and a chain wheel and chain transmission mechanism, wherein the chain wheel and chain transmission mechanism is installed on the stand; a material cup assembly is arranged on the chain wheel and chain transmission mechanism; the chain wheel and chain transmission mechanism is connected with a power mechanism and drives the material cup assembly to do rotating movement from back to front around a chain wheel; the front end of the stand is provided with a root cutting press wheel and a sawtooth blade which are connected with the power mechanism; one side of the root cutting press wheel is provided with a wheel cleaning device, and the rotating plane of the sawtooth blade is parallel to the upside of the running plane of the material cup assembly. The garlic of which the garlic root is upward is placed into a material cup of the material cup assembly when in use; and when the material cup is run from back to front, the root cutting press wheel presses the garlic, and the garlic root is cut by the sawtooth blade. Because the producing areas of the garlic are different, and the lengths of hair roots on the garlic are different, a hair root cleaning mechanism and a hair shearing mechanism are selectively arranged at the back of the root cutting press wheel. Compared with the prior art, the garlic root cutter has the advantages of great saving of manpower, high root cutting efficiency, low garlic loss rate, time saving, and the like and has unique design, skillful structure and environmental protection, water saving and labor intensity reduction.

Owner:JINAN HUAQING AGRI MACHINERY TECH CO LTD

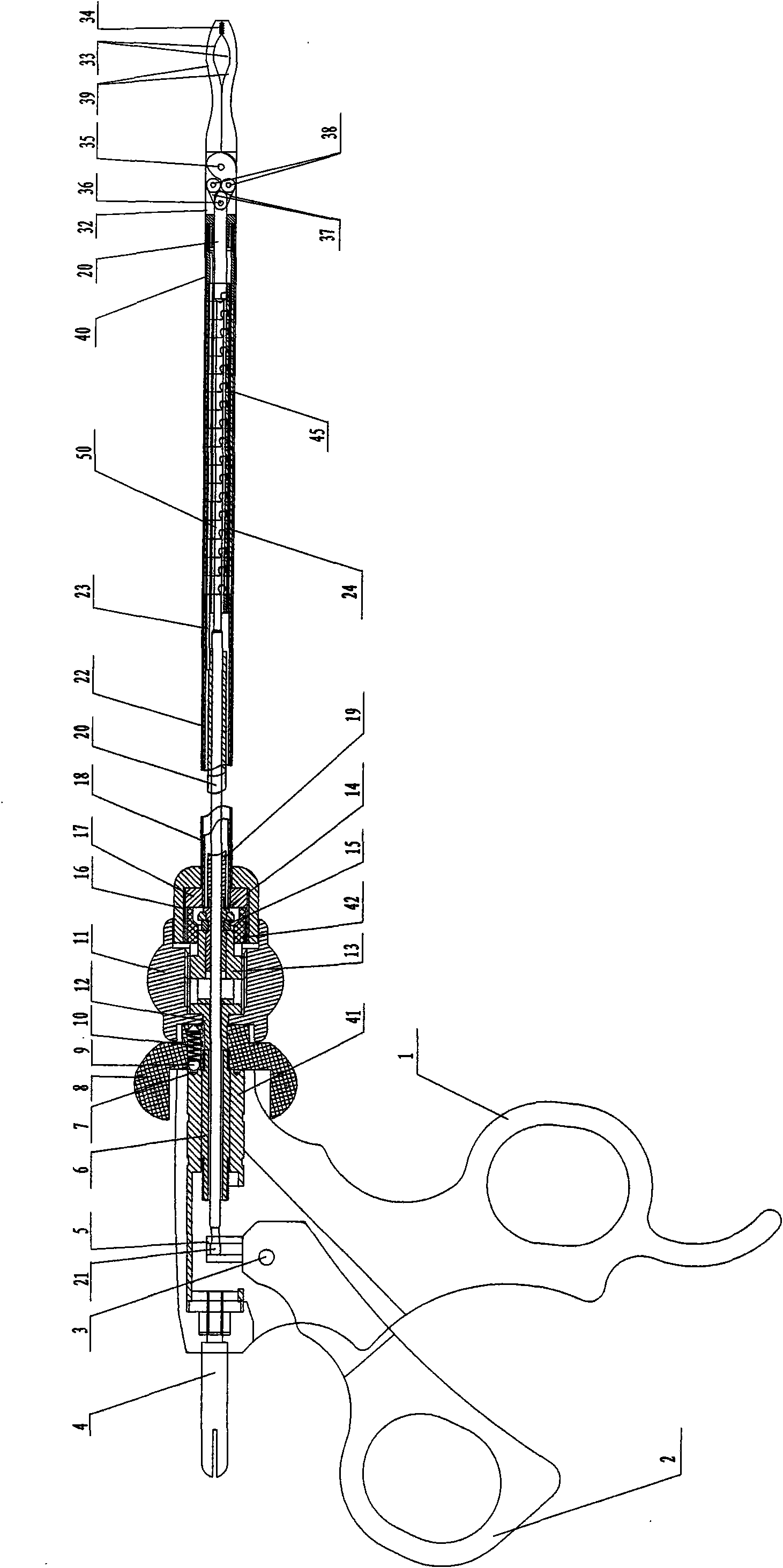

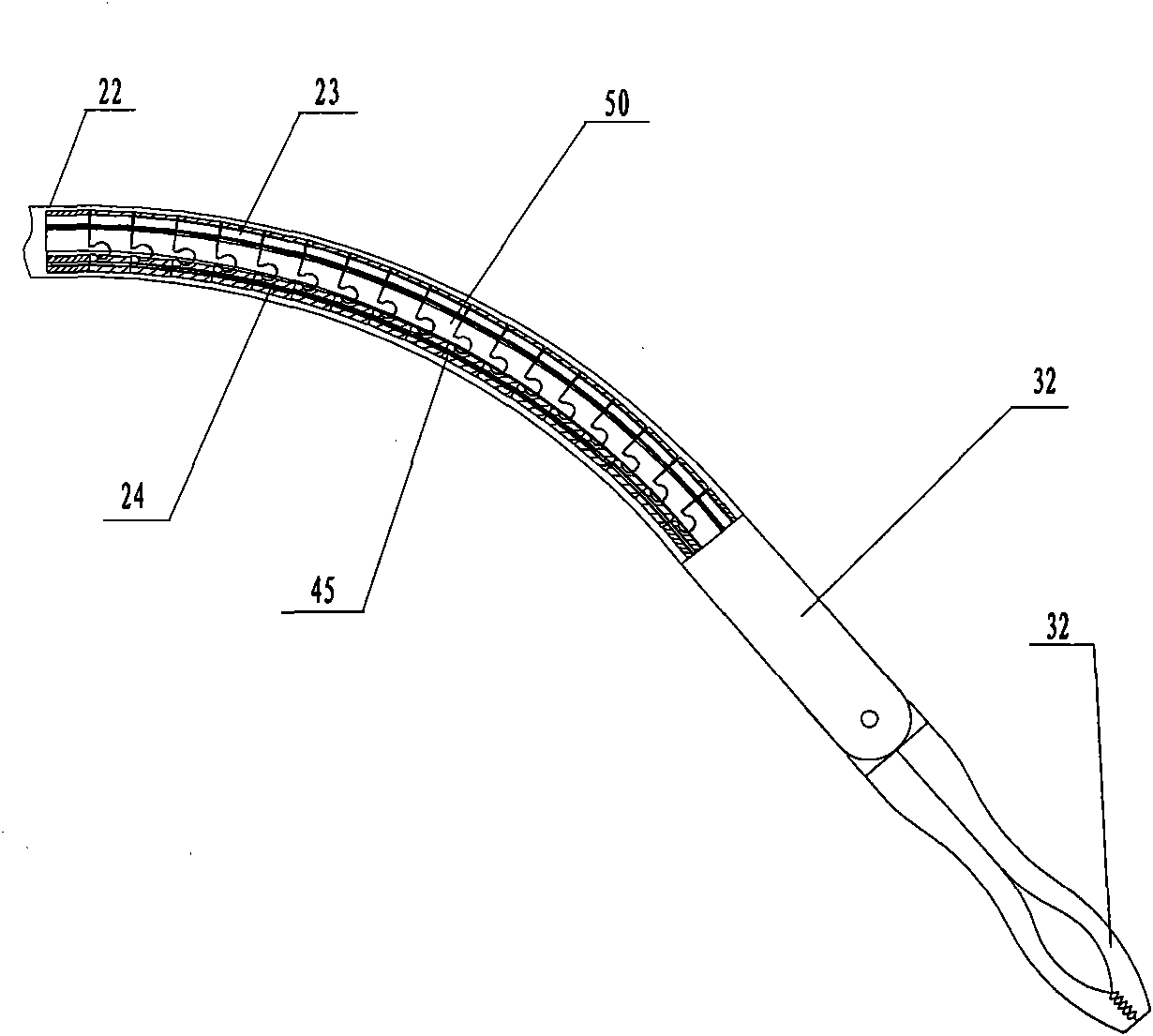

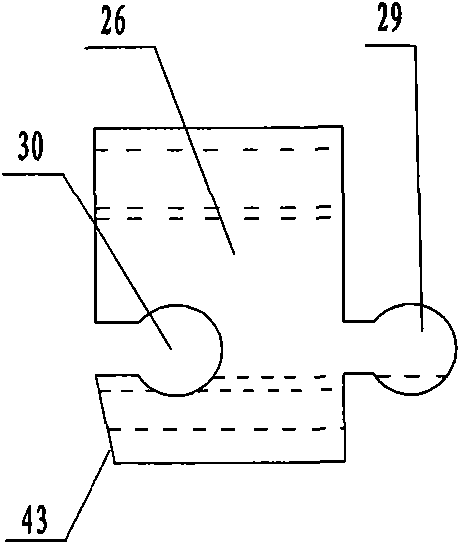

Multifunctional bendable forceps for laparoscopic surgeries

ActiveCN101912290AResolve trivial bugs with replacementSimple structureSurgical instruments for heatingSurgical forcepsForcepsPositioning system

The invention relates to a pair of multifunctional bendable forceps for laparoscopic surgeries, which is mainly applied to human internal organ surgeries and belongs to the mechanical field of medical apparatus and instrument technology; and forceps heads are provided with bent joint components, a forceps holder is provided with nondestructive holder teeth and an arc-shaped groove which are matched with each other up and down, a forceps body has an electric coagulation hemostasis function, and forceps levers can rotate 360 degrees and have 16 positioning system points. The forceps have simple and reasonable structure and good application effects and can be used for finding, grasping, linking by pulling, separating and imaging tissues of organs in a human peritoneal cavity and for electric coagulation hemostasis, and the forceps are convenient and safe to use in surgeries; and the defects of the prior art are solved that the surgical equipment forceps have a single application function, which causes many operation channels required in the surgeries, many surgical procedures and frequent renewal of the surgical equipment.

Owner:HANGZHOU SHIKONGHOU MEDICAL INSTR

Board edge cutting machine

InactiveCN102814839AAvoid the trouble of manual frequent board deliveryPrecise positioningCircular sawsControl systemEngineering

The invention discloses a board edge cutting machine, belonging to the field of board processing machinery and overcoming the defect that in the prior art, machinery which can replace manpower to cut edges of boards is lacked. The board edge cutting machine is characterized by comprising a board feeding machine, a board dropping machine, a longitudinal edge cutting machine, a transverse edge cutting machine and a control system, wherein the board feeding machine comprises a board feeding rack, a positioning platform and an elevator I; the tail of the board feeding machine is connected with the head of the board dropping machine; a part of the longitudinal edge cutting machine stretches into the inside of the board dropping machine; the longitudinal edge cutting machine is vertically connected with the transverse edge cutting machine; and the control system comprises an electrical cabinet and a control circuit. The board edge cutting machine can realize the full-automatic cutting of the deckle edges of the boards, saves the manpower cost and improves the production efficiency.

Owner:LINYI SHENGHUA MACHINERY MFG

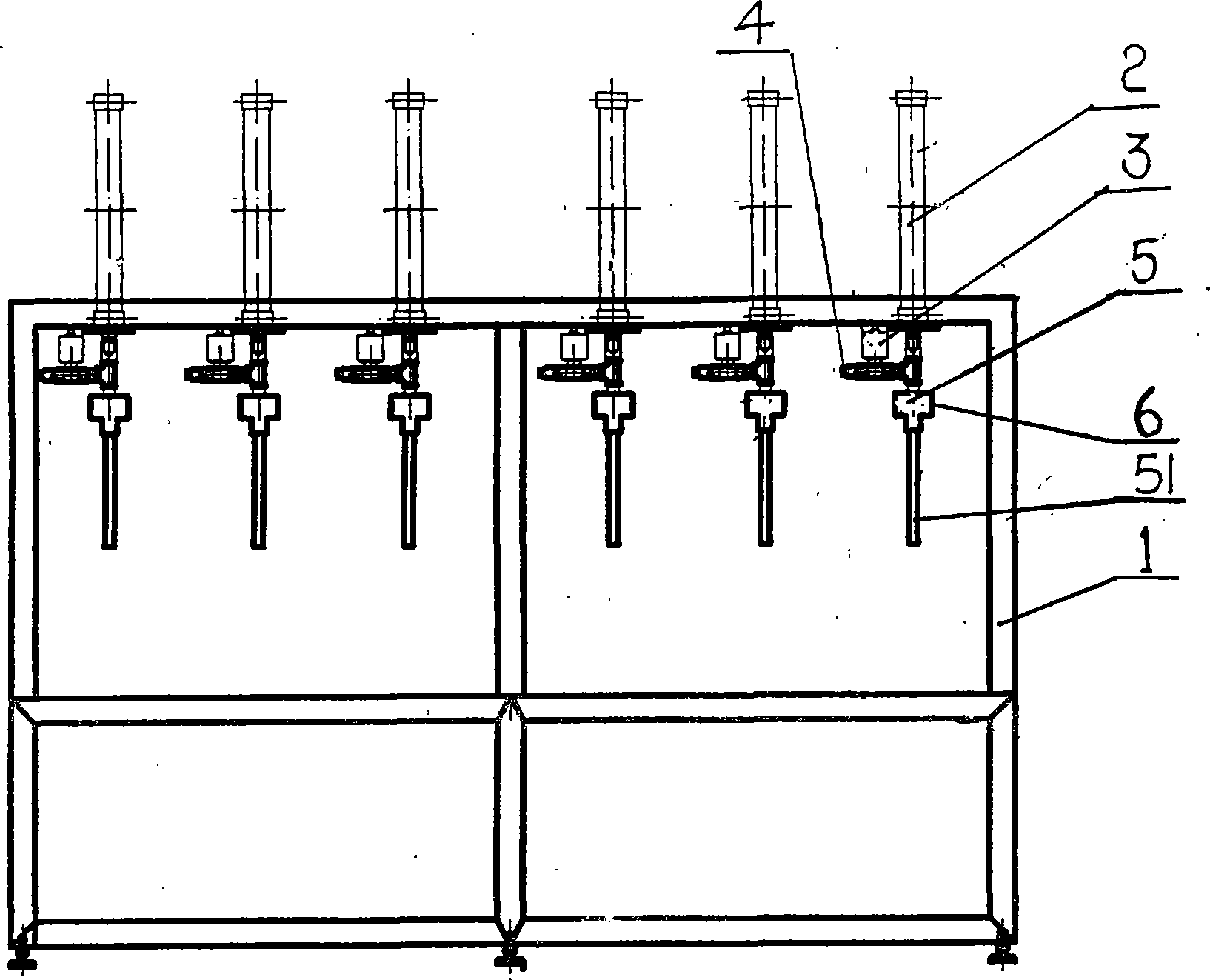

Beer sterilized bottle filler

InactiveCN101391735AReduce usageReduce oxygenationLiquid fillingBottle-handling machinesPositive pressureSolenoid valve

The invention discloses a beer aseptic filling machine which belongs to the light industrial machinery field and aims to solve the defects of the existing equipments that the universality is poor and the cost is high. The beer aseptic filling machine comprises a frame and a filling mechanism arranged on the frame and is characterized in that: the filling mechanism comprises lifting-controllable filling heads; the filling heads are connected with beer inlets controlled by solenoid valves; the beer inlets are communicated with long tubes provided with bottom ends adjacent to bottoms of filling containers; clearances are arranged at the lower ends of the jointing parts between the filling heads and the long tubes and the clearances are communicated with vents arranged on the filling heads; both the filling heads and the long tubes are arranged in the aseptic positive-pressure environment formed by an air outlet of a film filtration fan. The filling machine can realize the automatic aseptic filling and the cleaning is convenient and thorough without dead angles, the universality is better, the cost is low, therefore the beer aseptic filling machine can be applicable to various small and medium size containers for realizing the aseptic filling of beer or beverage.

Owner:济南百脉泉啤酒饮品有限公司

Automatic incasing machine for bottles

InactiveCN102381494AWrapper folding/bending apparatusWrapper twisting/gatheringHuman–machine interfaceControl system

The invention relates to the field of packaging machinery and particularly relates to an automatic incasing machine for bottles, which comprises a bottle-conveying mechanism, an arraying and settling mechanism, a bottle-pushing mechanism, a carton-opening mechanism, a carton-pushing mechanism, a power roller, a cover-closing mechanism, a carton-sealing mechanism, a control system and a human-computer interface, wherein the bottle-conveying mechanism is used for conveying the bottles; the bottle-pushing mechanism is used for pushing the bottles into a carton; the carton-opening mechanism is used for opening the carton; the carton-pushing mechanism is used for pushing the incased carton onto the power roller; the power roller is used for conveying the incased carton; the cover-closing mechanism is used for covering a carton cover; and the carton-sealing mechanism is used for sealing the carton cover. Compared with the prior art, the automatic incasing machine for bottles has the advantages that the carton used in the automatic incasing machine is a box type carton and materials are charged in the manner of side horizontal straightly pushing; an upright type carton mainly adopted by a present manufacturing enterprise and an incasing work with high labor cost caused by manually charging and manually sealing the carton are replaced; the automatic incasing machine for bottles is finally recognized by customers; and a blank of a small-size incasing machine is filled up.

Owner:QUANZHOU NANFANG FOOD MACHINERY

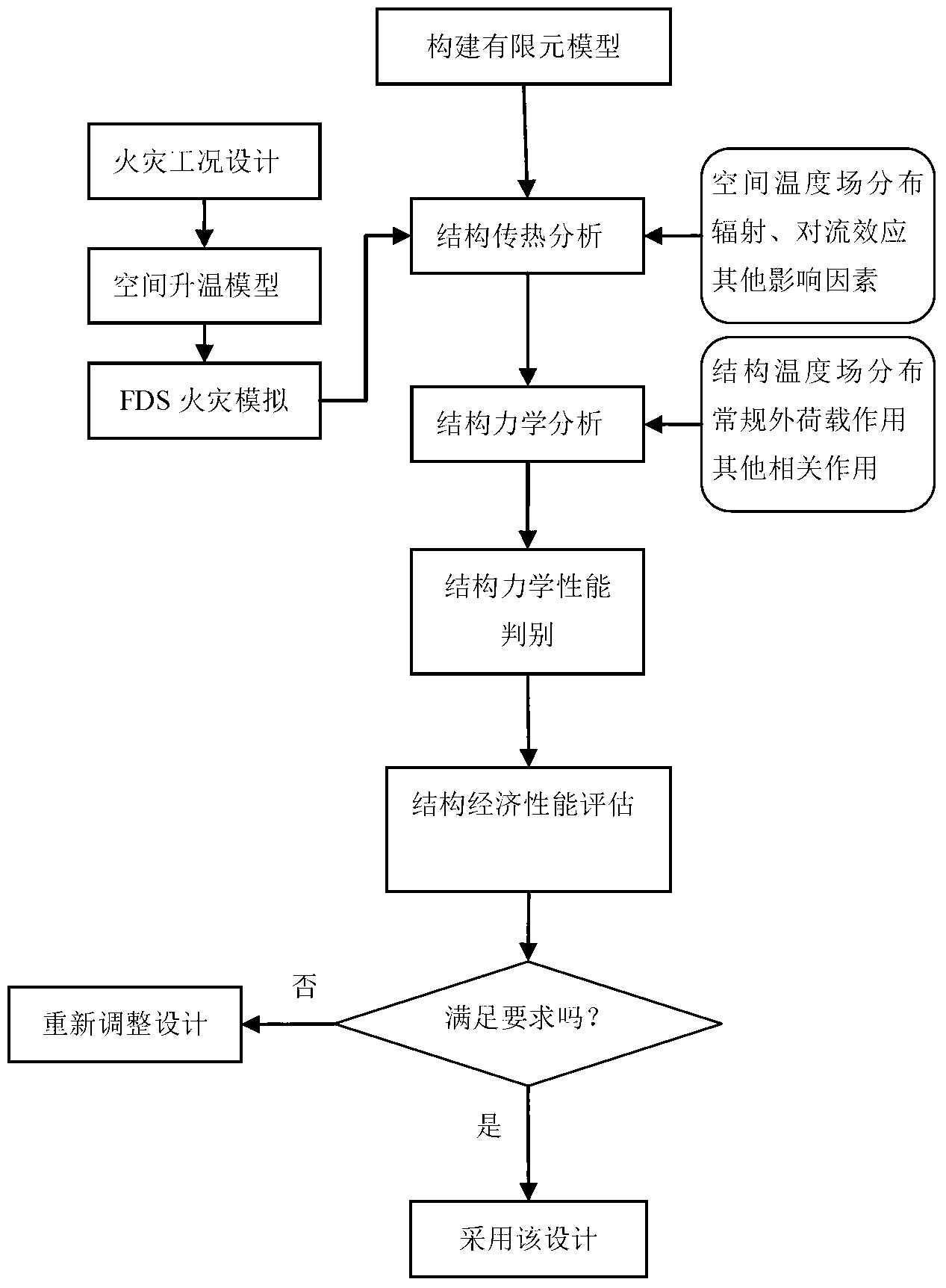

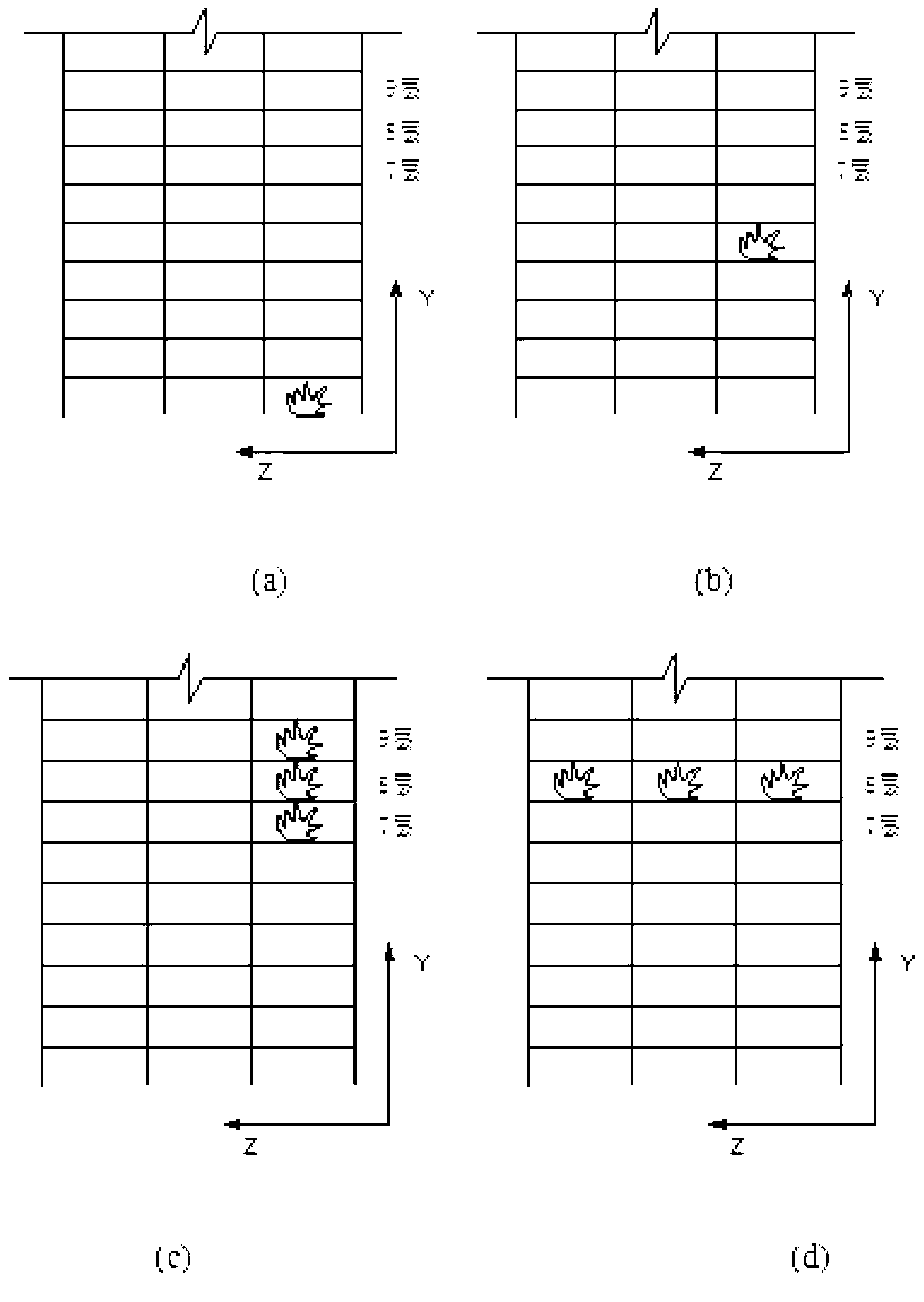

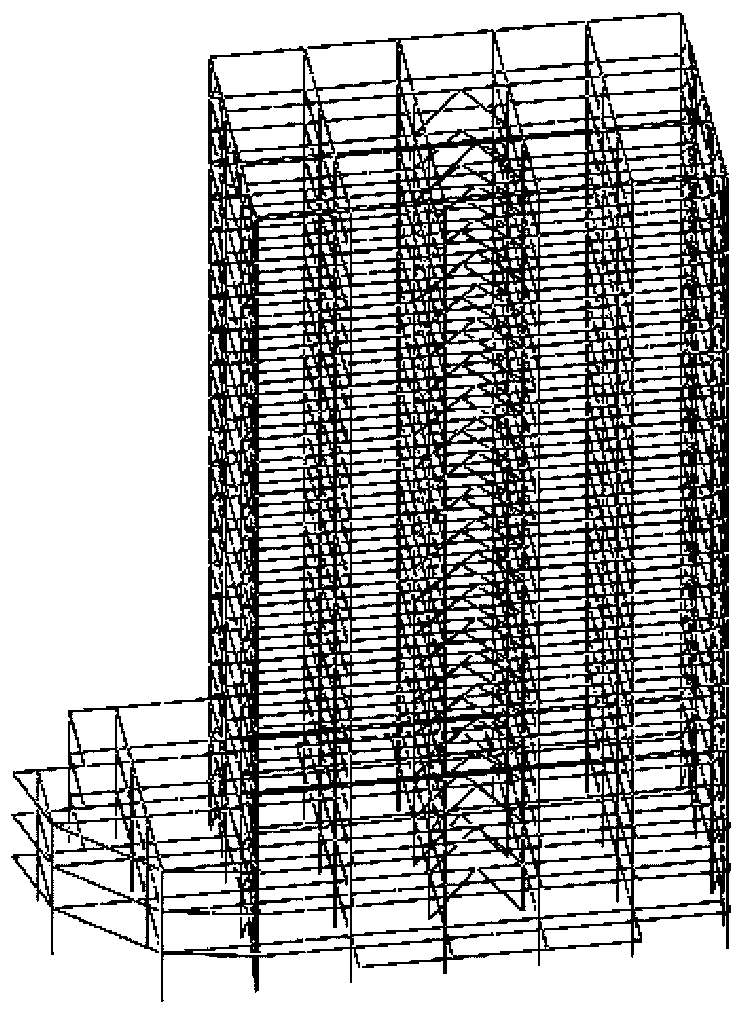

Test and analysis method for overall fire resistance of high-rise steel frame structure

InactiveCN103324797ASimple calculationImprove efficiencySpecial data processing applicationsFire proofingElement modelDynamic models

The invention provides a test and analysis method for overall fire resistance of a high-rise steel frame structure. The method includes: establishing a temperature field finite element model and a mechanical field finite element model for a high-rise steel frame structure system; designing corresponding fire condition parameters according to standard fire conditions, establishing a fire dynamics model by a spatial air temperature rise model or by a fluid dynamics calculation procedure FDS to calculate spatial temperature fields under various fire conditions, and using an obtained time-varying spatial temperature field as a thermal boundary condition for the temperature field finite element model of the whole structure; calculating the finite element model by finite element software; calculating the temperature field finite element model by software, substituting the obtained finite element temperature field to the mechanical field finite element model, and calculating to obtain a mechanical field; estimating whether the structure system collapses or not or exceeds the design limits or not according to calculation results; performing quantitative analysis on fire loss economy, and judging the economy of a fire protection design scheme.

Owner:SHANGHAI JIAO TONG UNIV

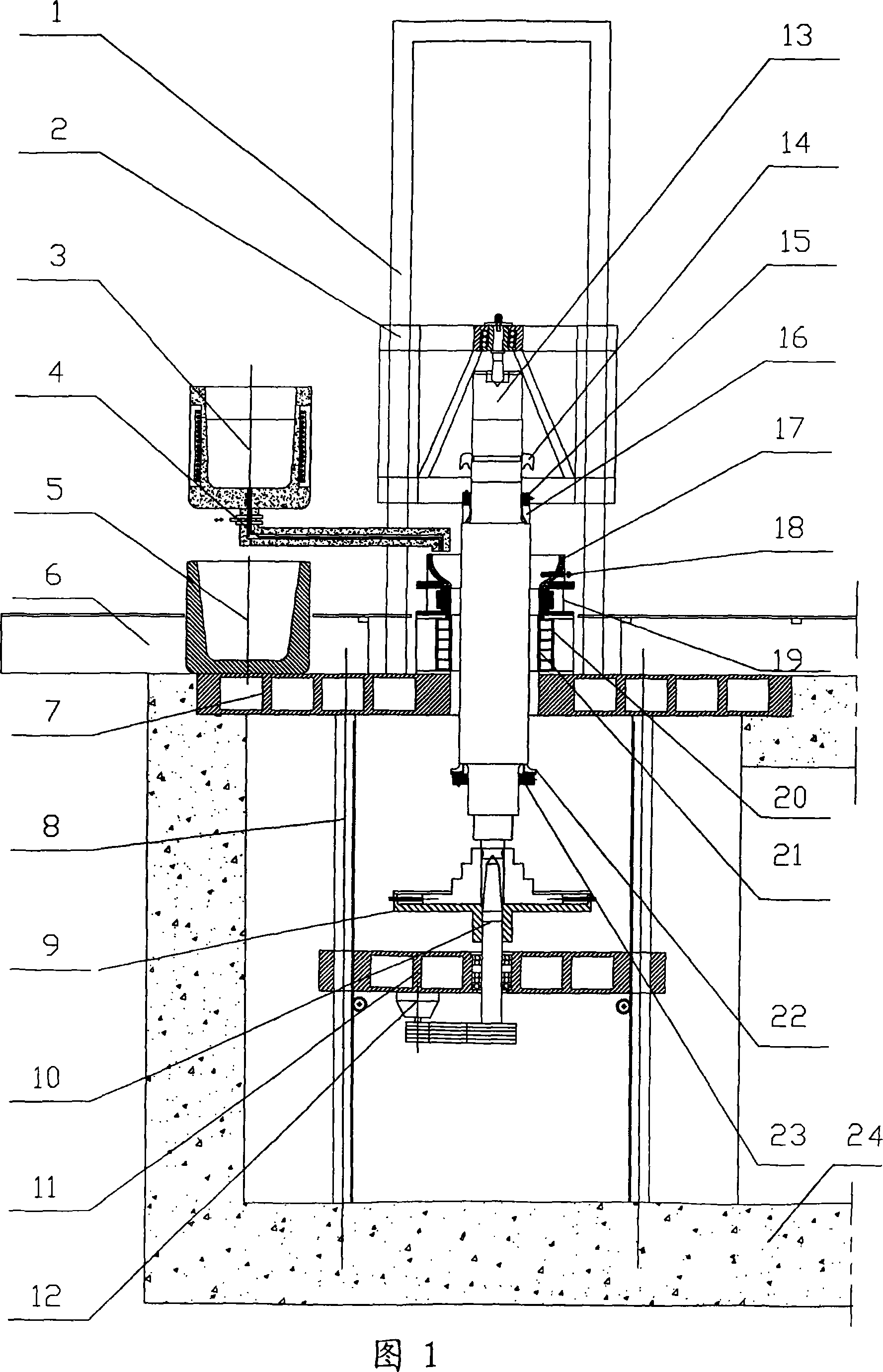

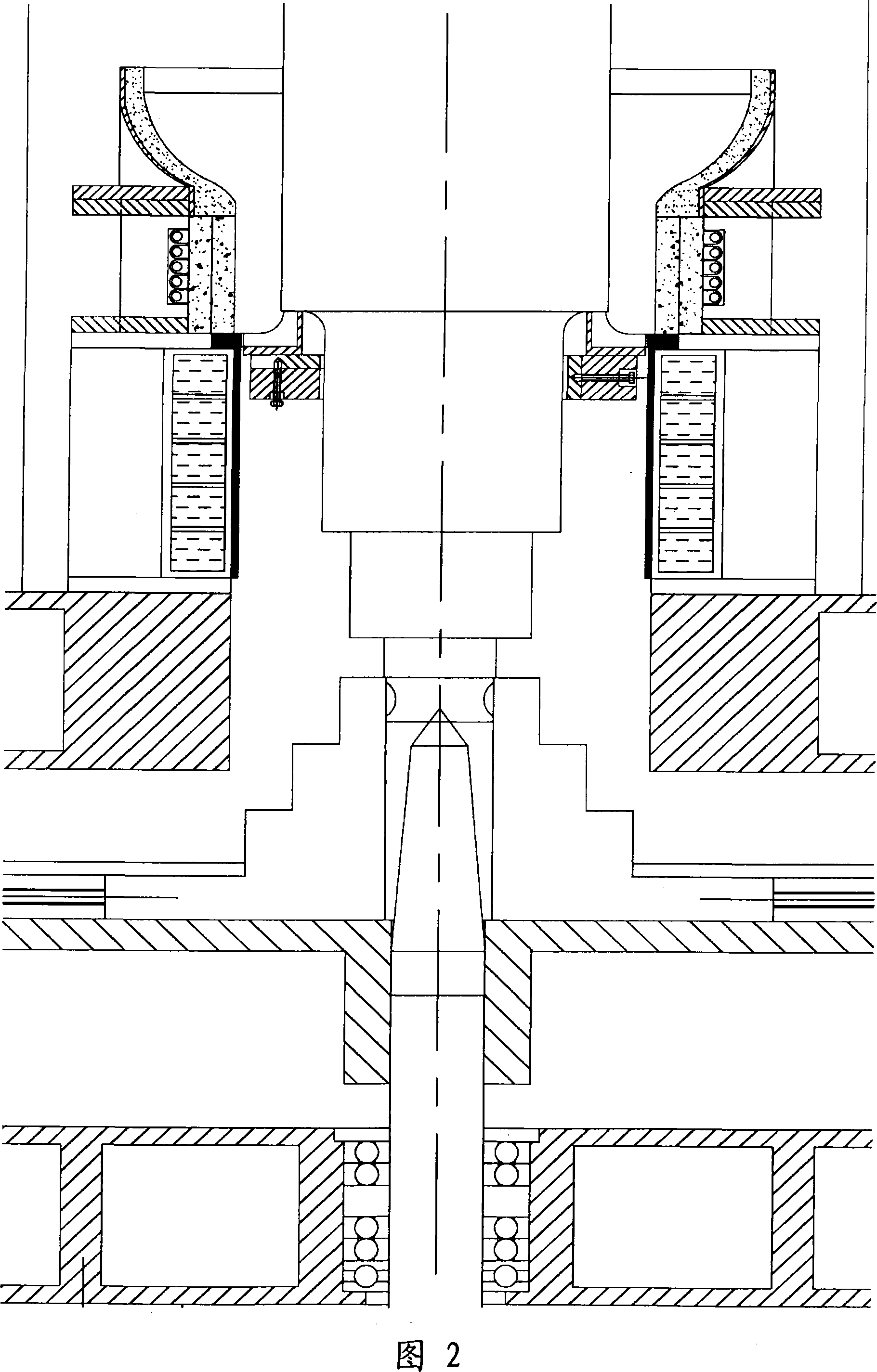

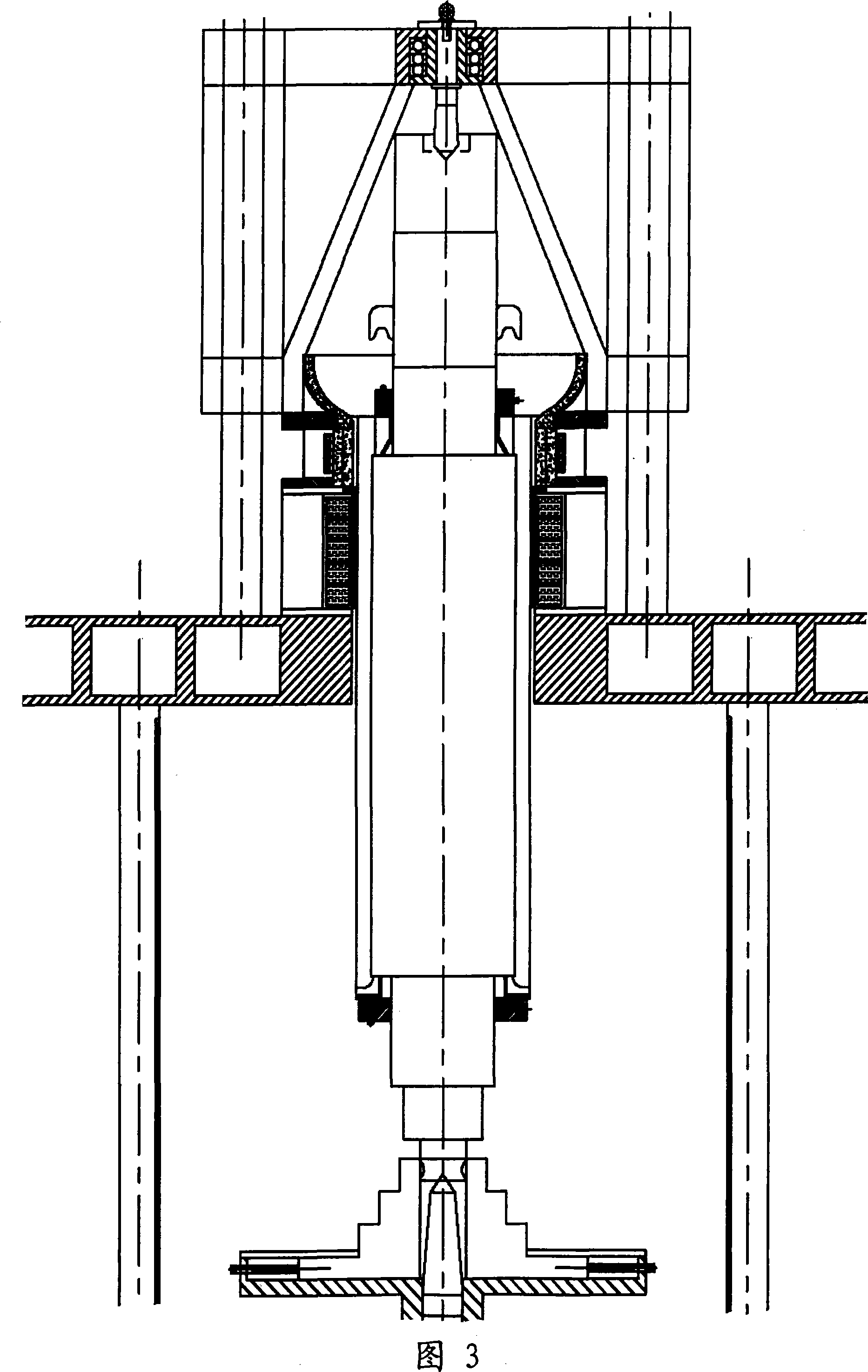

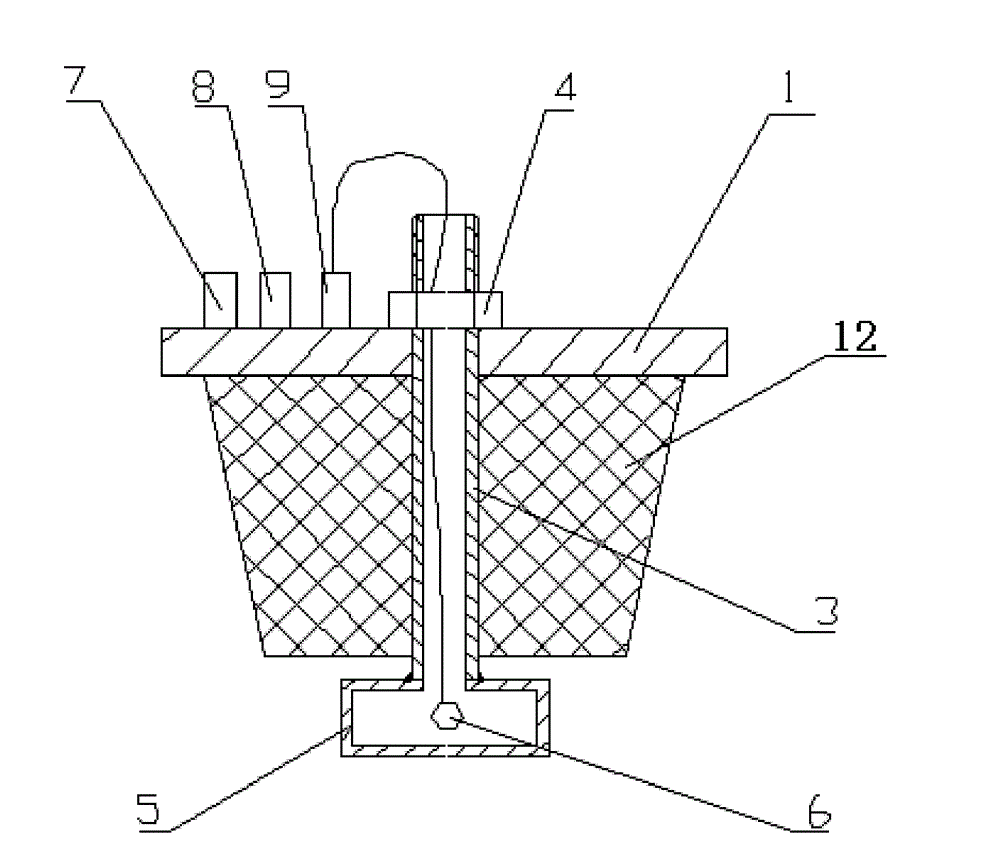

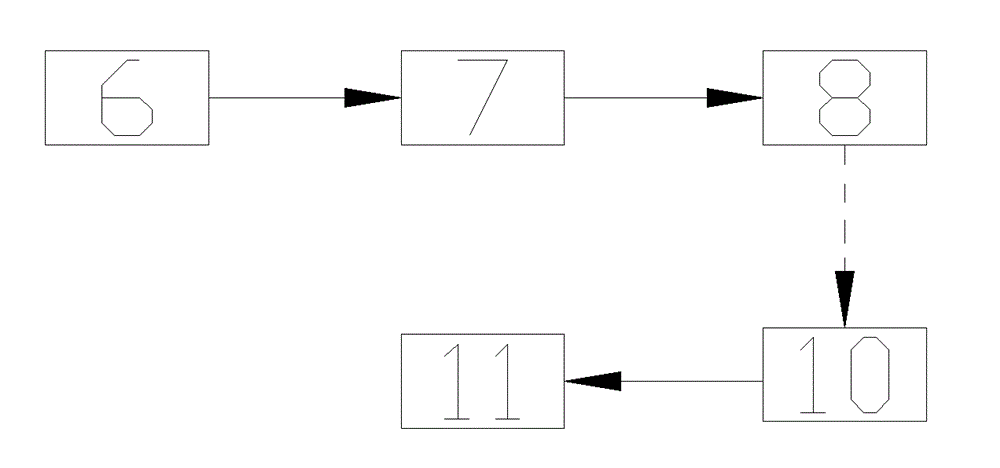

Large-scale shaft products vertical casting and repairing device and using method

The invention relates to a large scale axle kind product vertical casting and restoration apparatus and a use method thereof, belonging to mechanical fields. A frame is fastened with an operation table and a frame station and is movably connected with a mobile arm, a temperature holding pot is fastened with the operation table and a base and is screwed connected with a guide tube, a leak protection pot is fastened with the operation table and the frame station and the base, and the operation table is fastened with the frame station and the base, a column is fasened with the operation table and the base and is movably connected with a lifting table which is connected with a center shaft by bearing and is fastened with an electric machine. The center shaft is connected with a gear box of the electric machine and is connected with a chuck by key. The center shaft, basic parts and a location tip of the mobile arm are provided for supporting. The chuck is buckled with the basic parts. The frame station, a crystallizer, an inductor, and a pouring cup are connected with each other by flanges. The crystallizer is covered by a liner, and the basic parts are covered by a seal ring and a leak protection groove. The pouring cup is inlayed with a thermocouple, the basic parts are fastened with a fixture, an upper lock loop and a lower lock loop. A product / a restoration product can be obtained by treating, assembling, processing, stopping process and post-treating the basic parts, which is applicable for casting or repairing the axle kind product, with high quality.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

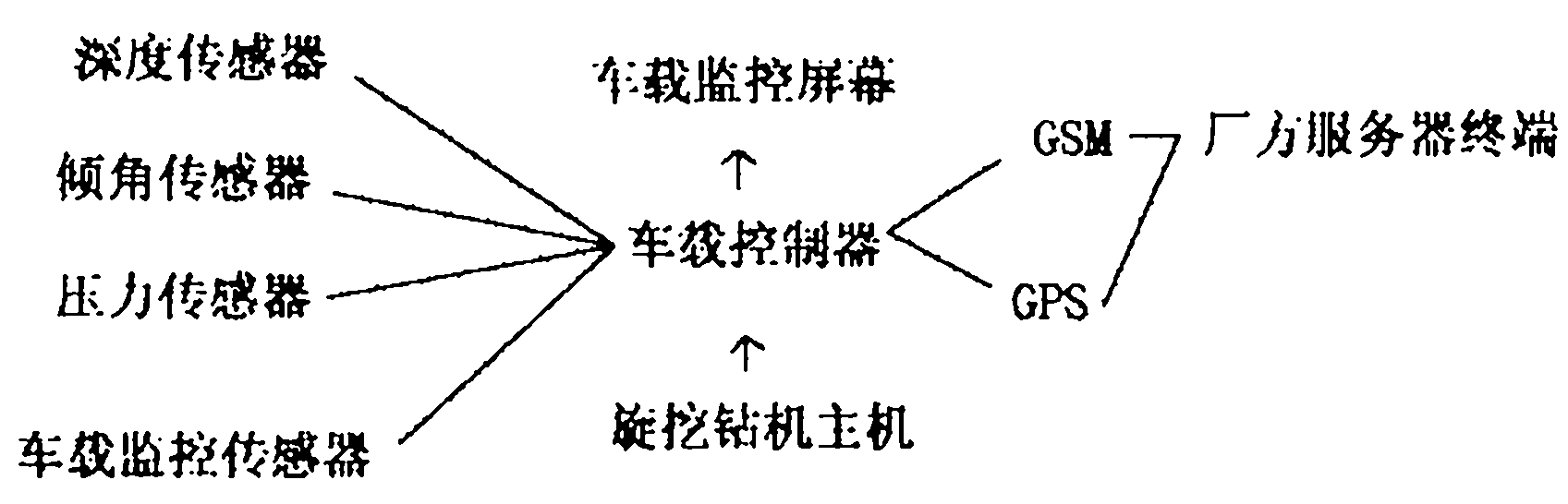

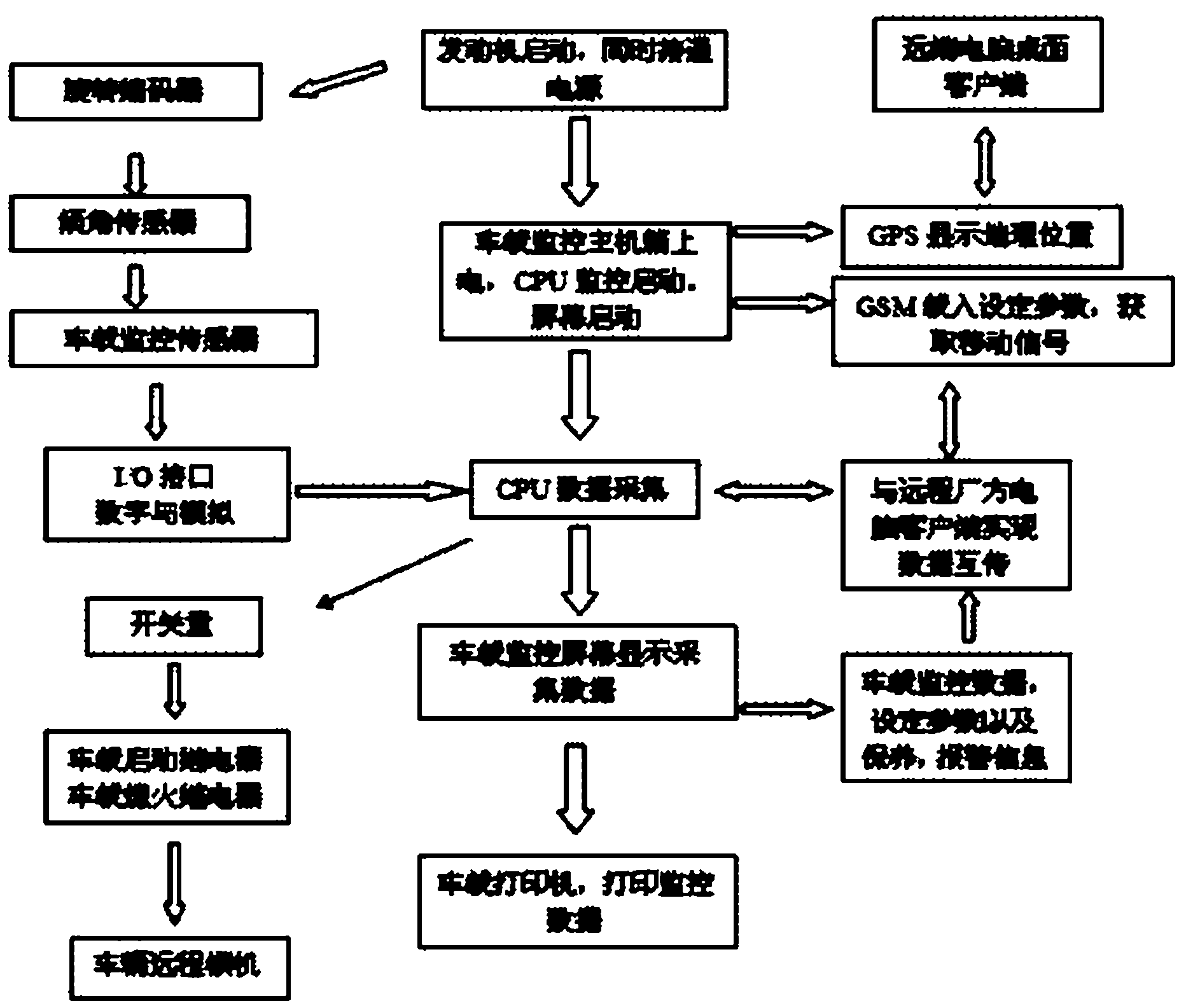

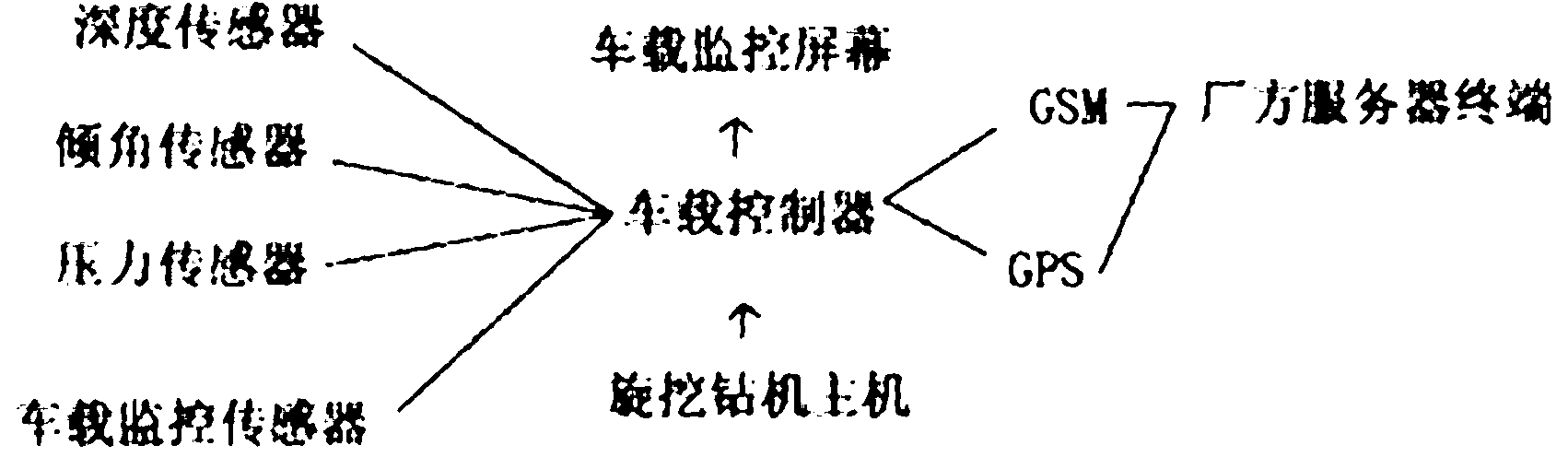

System and method for monitoring rotary drilling machine

InactiveCN102359367AShorten the development cycleShorten the stable periodAutomatic control for drillingCommand and controlData acquisition

The invention relates to the field of remotely-monitored industrial machines, in particular to a system and a method for monitoring a rotary drilling machine. The system comprises a vehicle-mounted rotary drilling machine monitor, and is characterized in that: a central processing unit (CPU) of a vehicle-mounted controller is arranged on the rotary drilling machine; and the vehicle-mounted controller is used for acquiring sensing information, position information and commands of a server terminal of a remote monitoring management center manufacturer, setting operation parameters, monitoring operation states, transmitting inquiry commands and controlling cathode ray tube (CRT) display of a screen in a vehicle-mounted mode. The monitoring method comprises the following steps of: starting an engine; switching on a power supply; starting the monitoring of the CPU; operating a rotary encoder, a depth sensor, an inclination sensor, a pressure sensor or a monitoring sensor input information device; and transmitting a digital analog signal to a CPU data acquisition device through an input / output (I / O) interface. By the system and the method, the development period and the stable period of a product are shortened; and the current advanced communication technology is deeply developed through a master control system which is completely autonomously researched and developed, so that the system and the method have favorable practical application.

Owner:上海思萌特电子科技有限公司

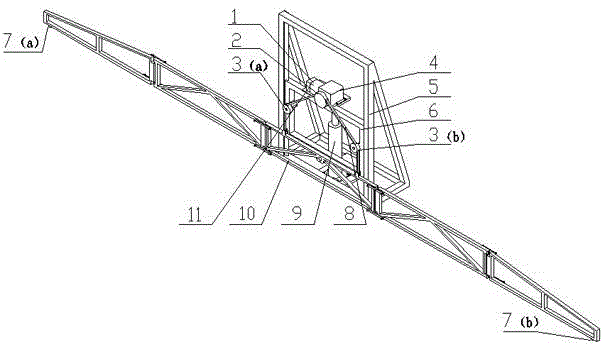

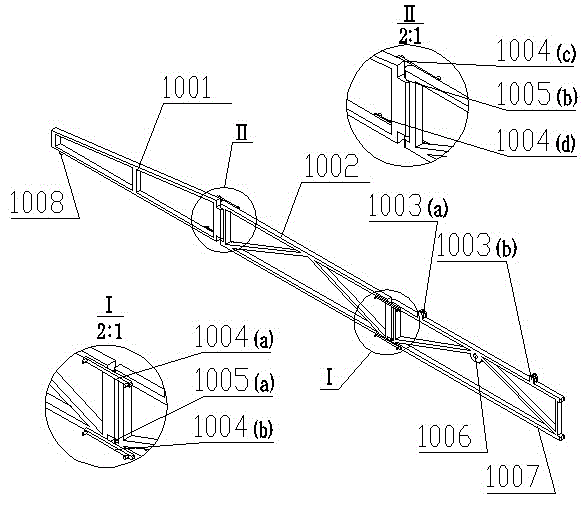

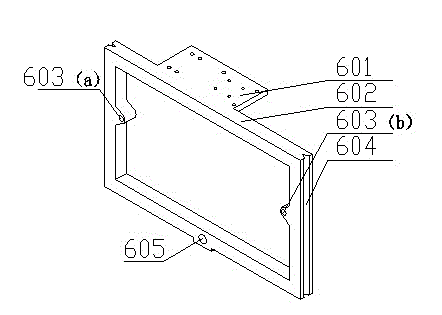

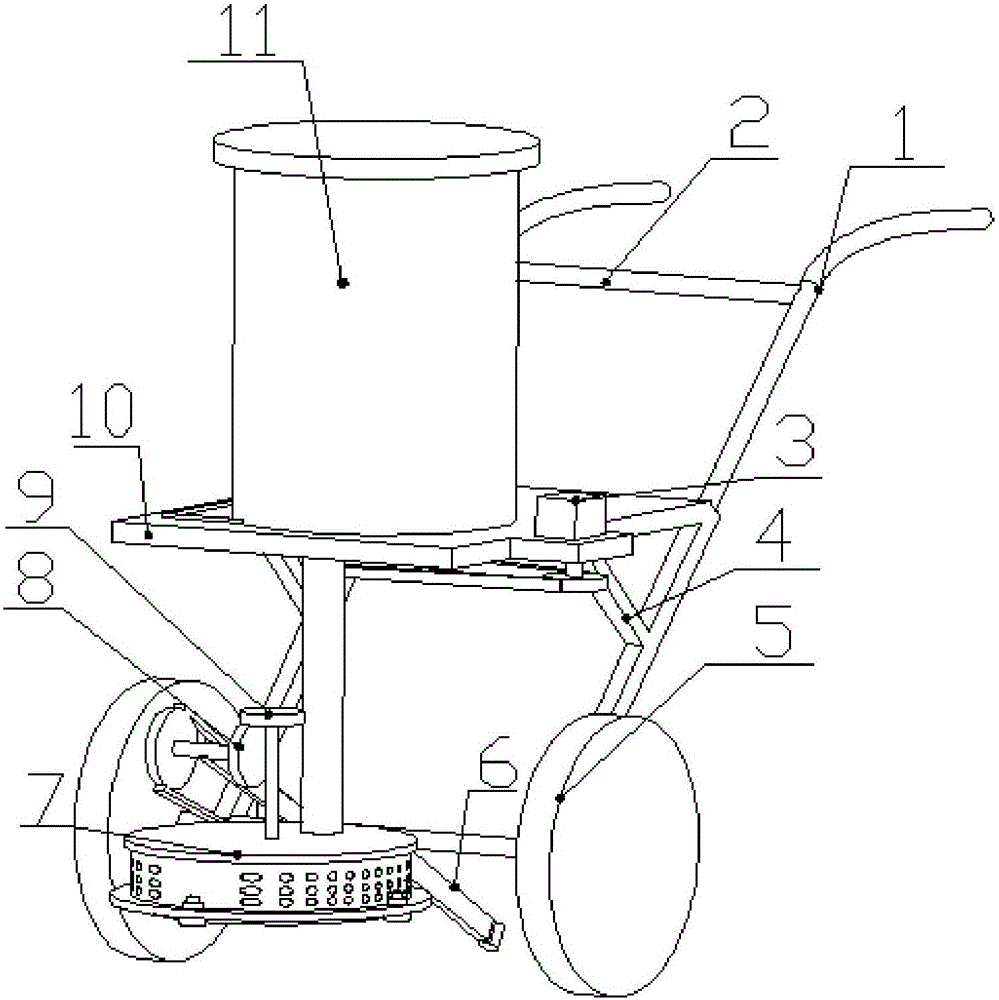

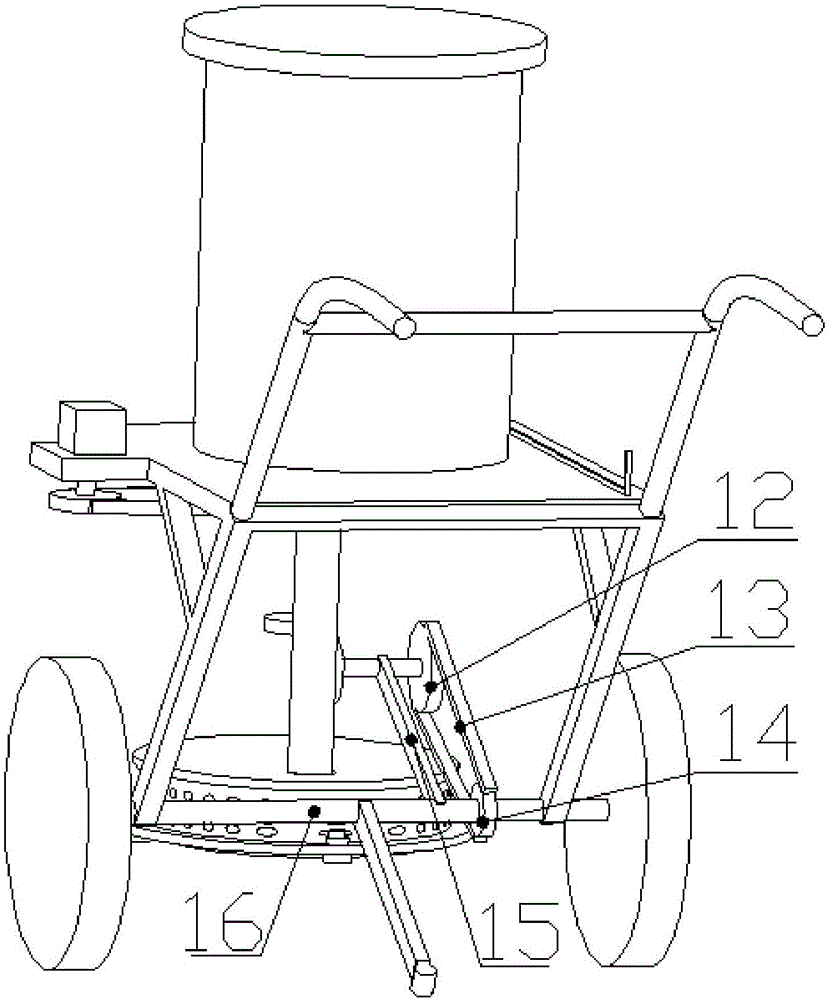

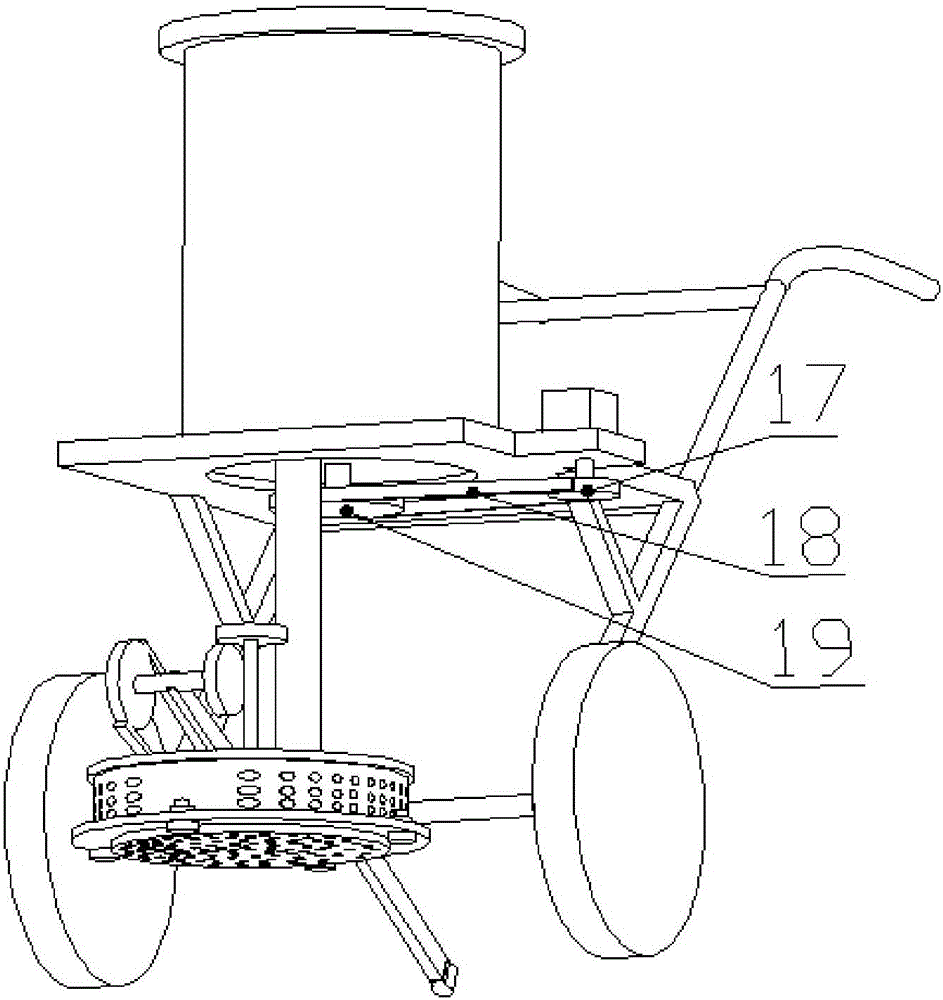

Lance boom capable of actively adjusting pose

ActiveCN103141461ASuppresses irregular movement in the vertical directionOvercome the effects of deposition uniformityInsect catchers and killersHydraulic cylinderWorking environment

The invention discloses a lance boom capable of actively adjusting the pose, which relates to the field of plant protection machinery. The lance boom consists of a mechanical part and a control part. The mechanical part comprises a direct-current servomotor, a driving pulley, two auxiliary pulleys, a worm-gear reducer, a frame, a hydraulic lifting frame, a rope, a lifting hydraulic cylinder and a lance boom assembly. The control part comprises distance sensors and a controller. When a spraying machine operates, the direct-current servomotor is controlled by the control part to drive the lance boom, so that the pose of the lance boom is adjusted. The spraying machine structured with the lance boom can inhibit the vertical irregular motion of the lance boom, and can ensure that the lance boom can be adapted to the working environment of the slope, and the uniformity of spray deposition is increased.

Owner:JIANGSU UNIV

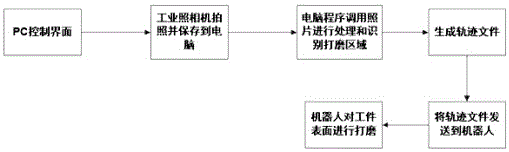

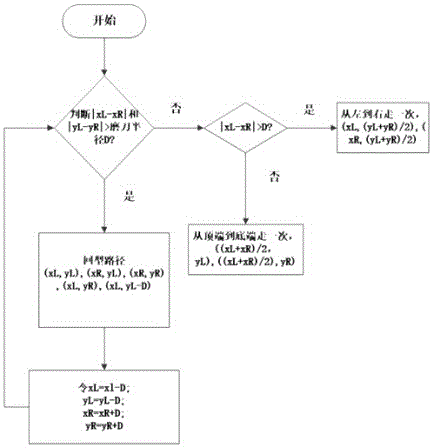

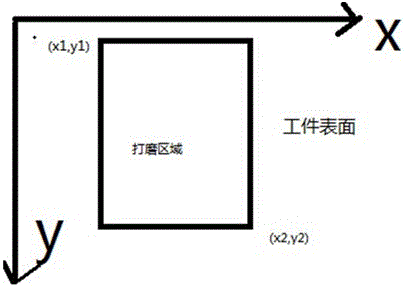

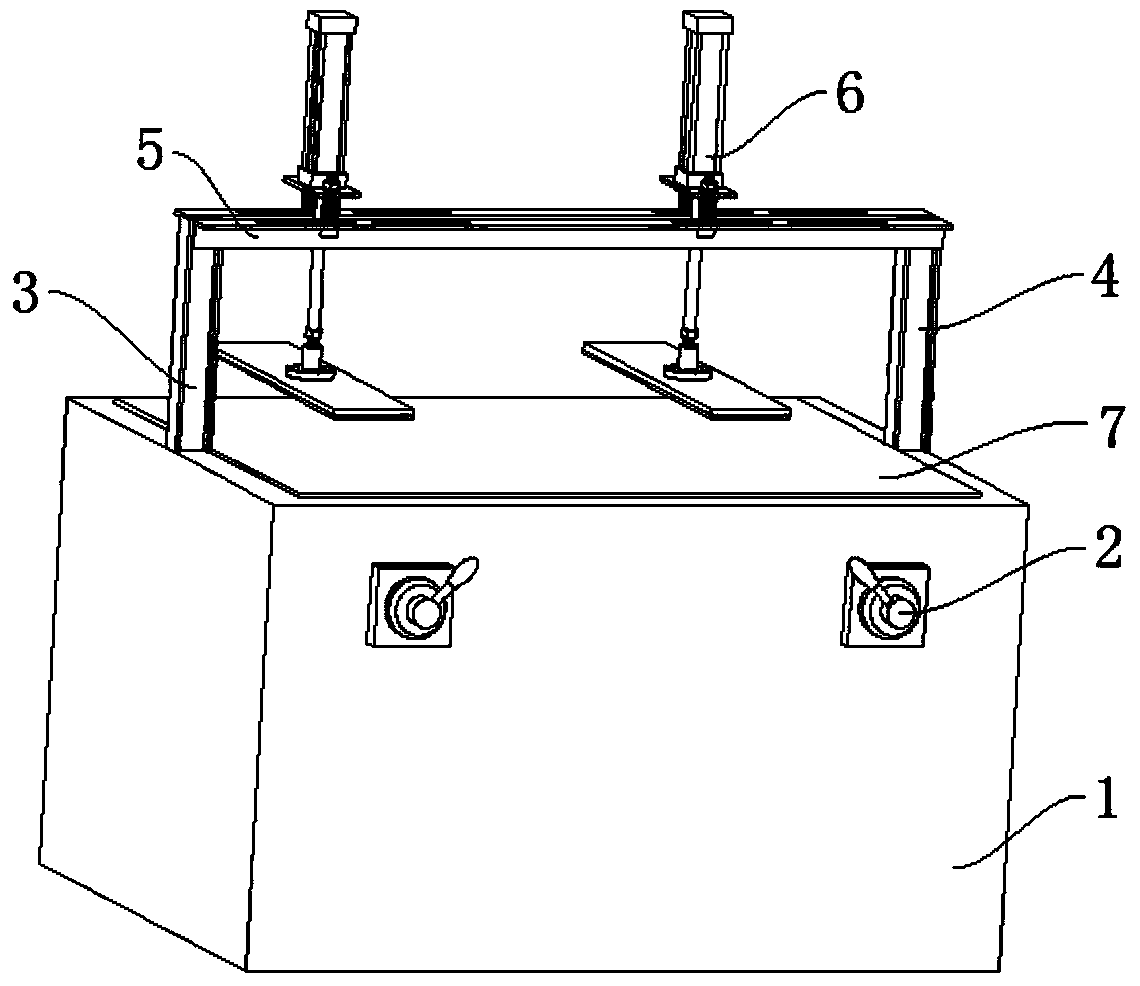

Image-processing-based robot polishing production method and production system applying same

InactiveCN106041946AReduce work intensitySolve the inconvenience caused by manual operationProgramme-controlled manipulatorImaging processingComputer science

The invention relates to the field of polishing machinery, in particular to an image-processing-based robot polishing production method and a production system applying the same. The production method comprises the following steps that (1) a workpiece image is obtained; (2) the workpiece image is processed and recognized; (3) a trail file is generated; and (4) automatic polishing is achieved through the trail file. According to the production system, a software trigger method is used for controlling an industrial camera to take a picture for the surface of a workpiece needing polishing, the camera saves the shot picture into a computer, a computer program reads and processes the image and recognizes a polishing area, according to the recognized polishing area, three-dimensional trail path coordinates and the trail file are planned, and a robot automatically polishes the surface of the workpiece. According to the production method, the computer is used for recognizing the polishing area and calculating the polishing trail coordinates, thus the polishing efficiency and polishing precision can be greatly improved, manpower resources are saved effectively, constraint of production time is broken, and production speed is increased effectively.

Owner:GUANGDONG UNIV OF TECH

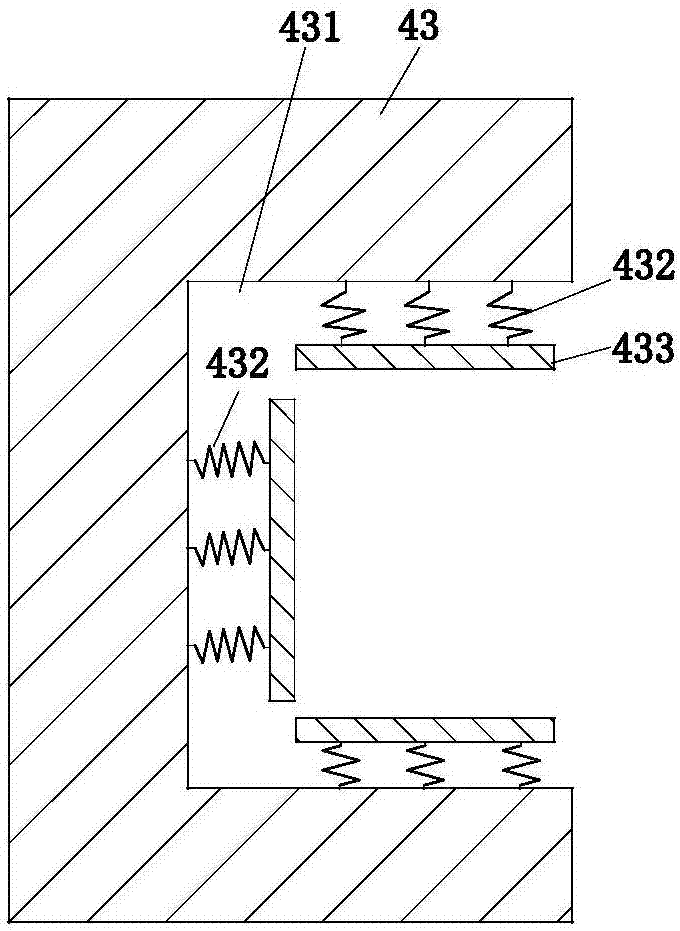

Pneumatic flat pressing machine for sticking carton box

ActiveCN103847132AImprove adhesionImprove uneven pressurePaper-makingBox making operationsCartonEngineering

The invention discloses a pneumatic flat pressing machine for sticking a carton box and belongs to the field of carton box formation machines. The pneumatic flat pressing machine comprises a pneumatic pressing bed, a first support, a second support, a cross beam and a flat pressing mechanism, wherein the first support and the second support are arranged vertical to the working plane of the pneumatic pressing bed, the cross beam is fixedly connected between the first support and the second support, and the flat pressing mechanism is arranged on the cross beam; the flat pressing mechanism comprises an air cylinder, a mounting plate, a self-adaption inclining device, a press plate and a pneumatic system; the air cylinder is fixedly arranged on the mounting plate and is connected with the cross beam through the self-adaption inclining device; a piston rod of the air cylinder is connected with the press plate through the cross beam; the air cylinder is connected with the pneumatic system and controls the lifting of the air cylinder through a control valve arranged on the outer wall of the pneumatic pressing bed. According to the pneumatic flat pressing machine disclosed by the invention, the problem that the pressure of a sticking part of the carton box is uneven is modified; the flatly pressed carton box is firm in sticking and is flat; the position of the flat pressing mechanism is adjustable, and the press plate is rotatable, so that the use of the flat pressing machine is convenient, the applicability of the flat pressing machine is improved, the structure is simple, the operation is convenient, the cost is low, and the use effect is remarkable.

Owner:江苏东方印务有限公司

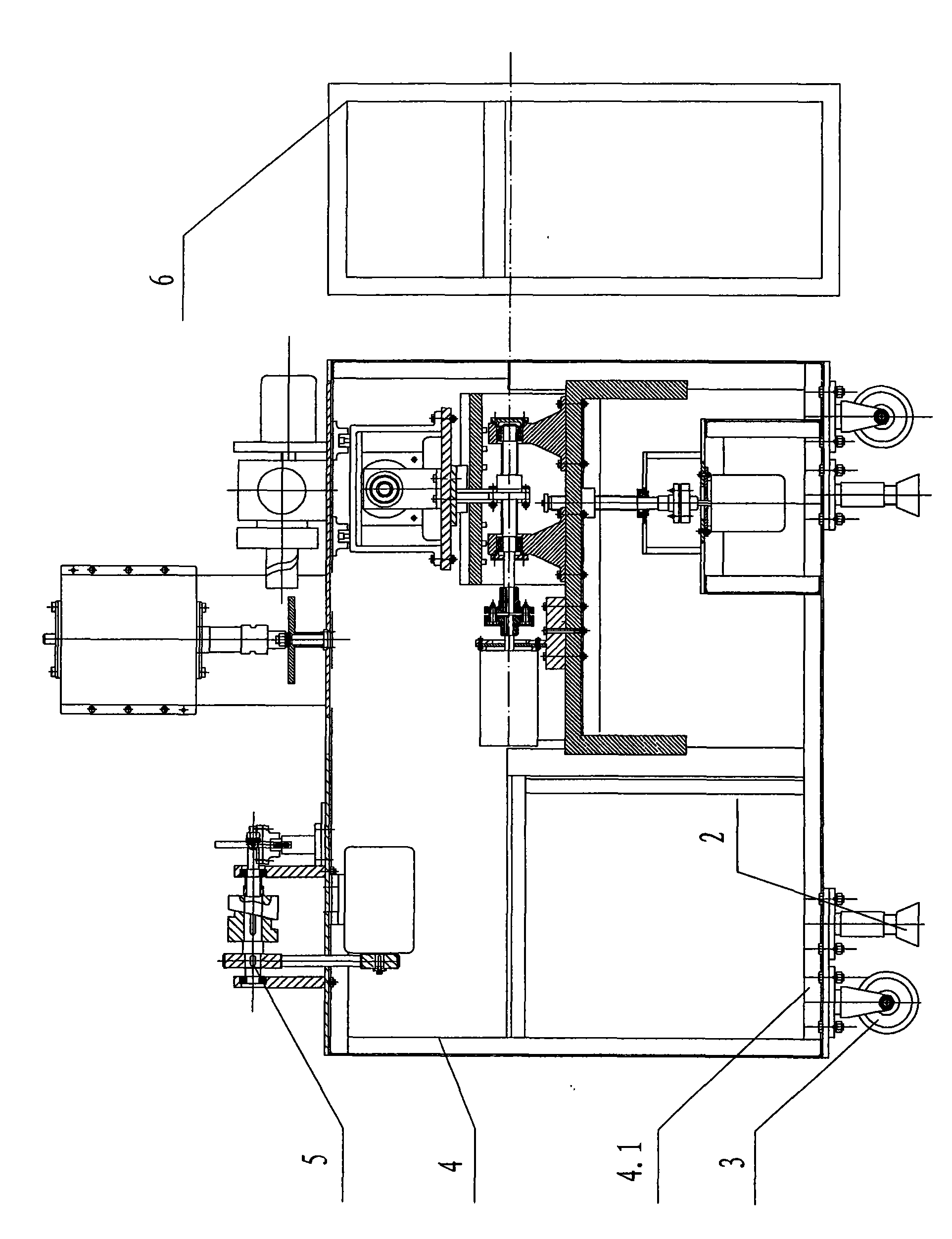

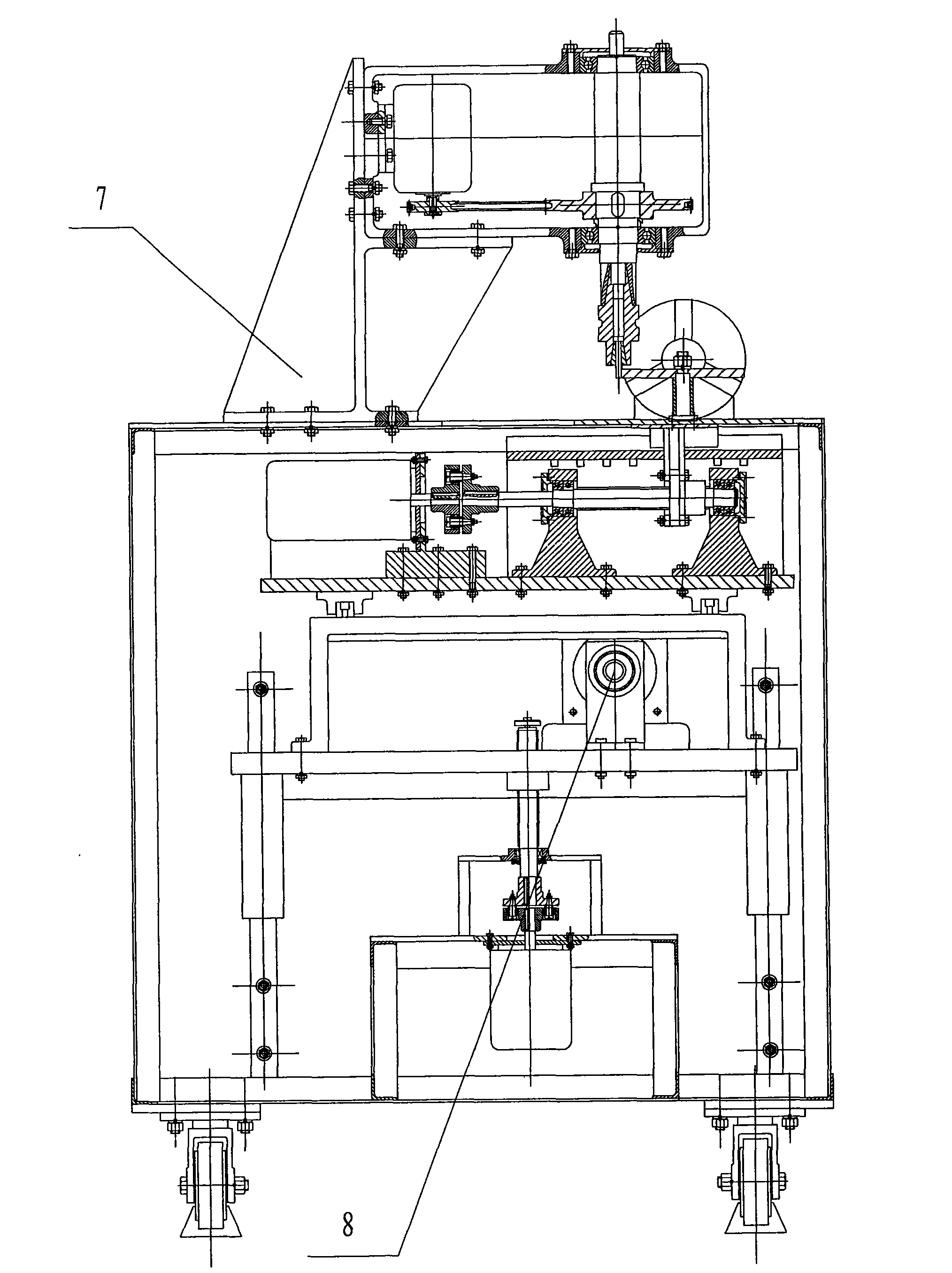

Cam profile detection and simulation processing experimental device

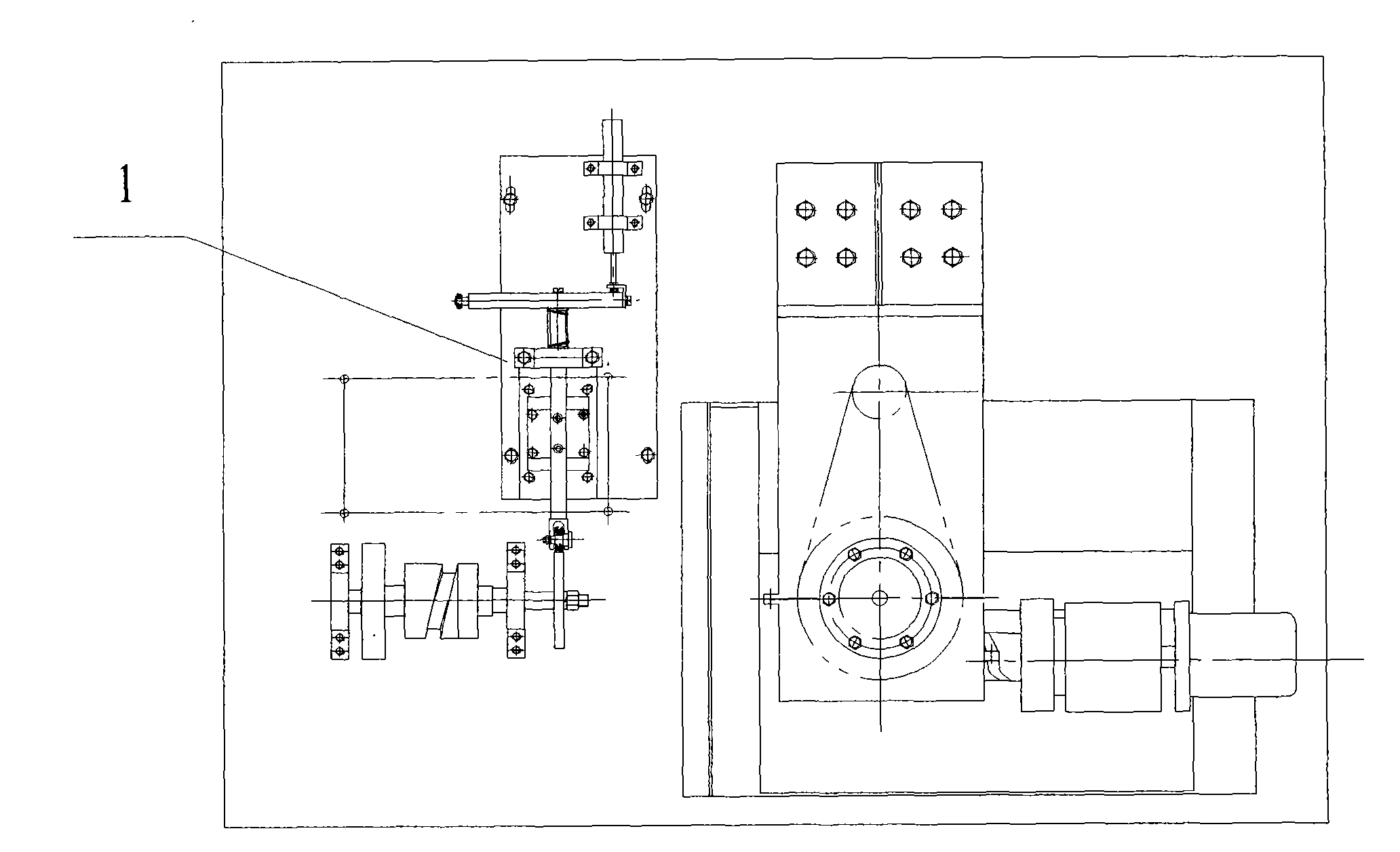

InactiveCN101673485AImprove machining accuracyVersatileMachine gearing/transmission testingEducational modelsMilling cutterEngineering

The invention belongs to experimental devices in the field of machines, in particular to a cam profile detection and simulation processing experimental device which can detect the motion profile of acam and simultaneously realize the simulation processing of the cam. The cam profile detection and simulation processing experimental device comprises a cabinet, a cam profile measuring mechanism, a mounting mechanism of the measured cam and a simulation processing experimental mechanism, wherein the cam profile measuring mechanism comprises a linear displacement sensor, a cylindrical cam profilemeasuring rod and a disc-shaped cam profile measuring rod, and the mounting mechanism of the measured cam comprises a cam shaft which is mounted on the cabinet, connected with the rotation power and used for mounting the measured cam; and the simulation processing mechanism comprises a milling cutter part with the vertical milling form and a workbench part, and the workbench part comprises a driving mechanism which can produce the three-axis movement and the one-axis movement, and a workbench mounted on the driving mechanism. The cam profile detection and simulation processing experimental device has the beneficial effects of integrating the cam profile simulation design processing and the detection into a whole, having complete functions, and compact structure, and realizing multiple purposes on an experimental platform.

Owner:ZHONGBEI UNIV

Movable industrial manipulator

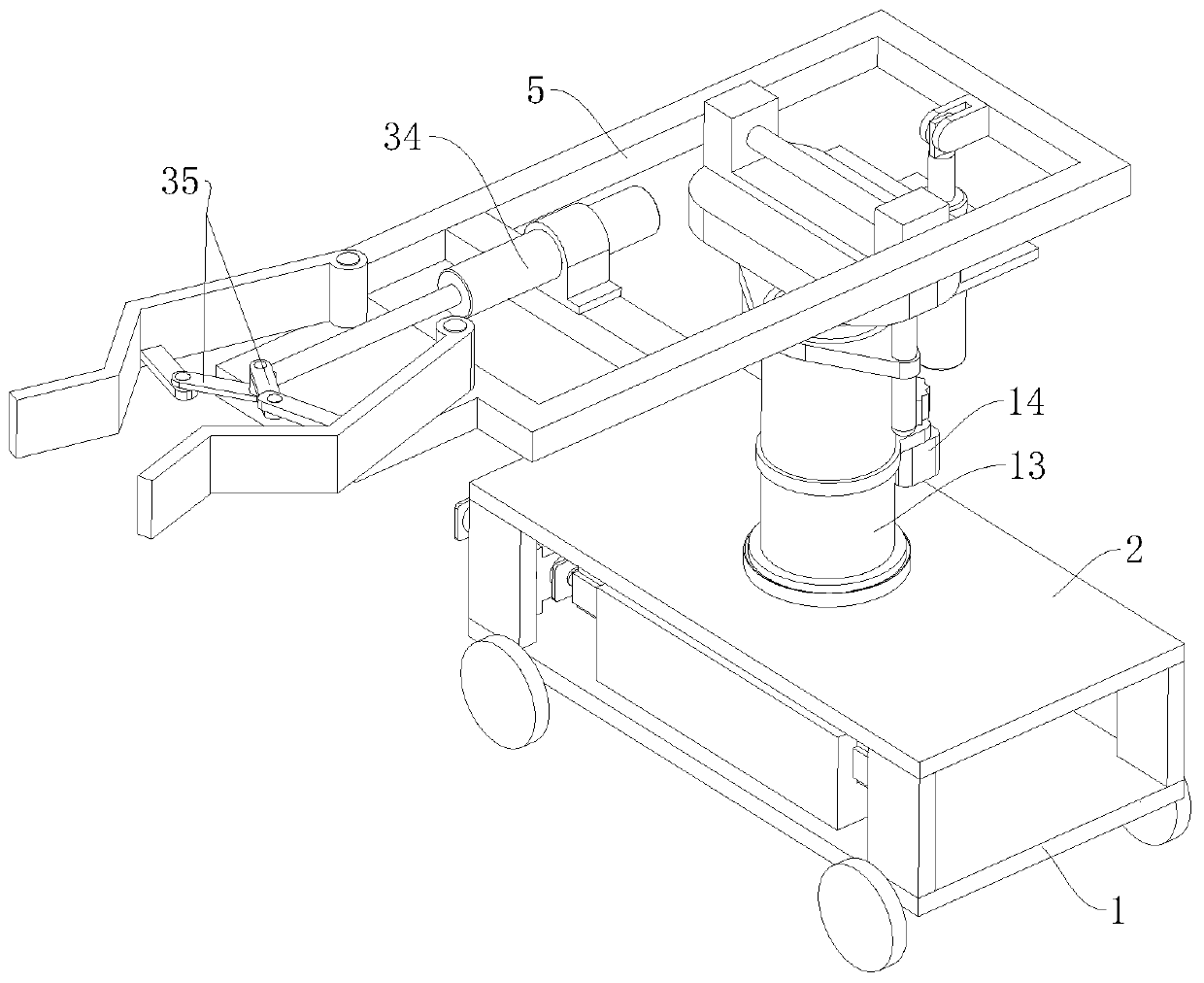

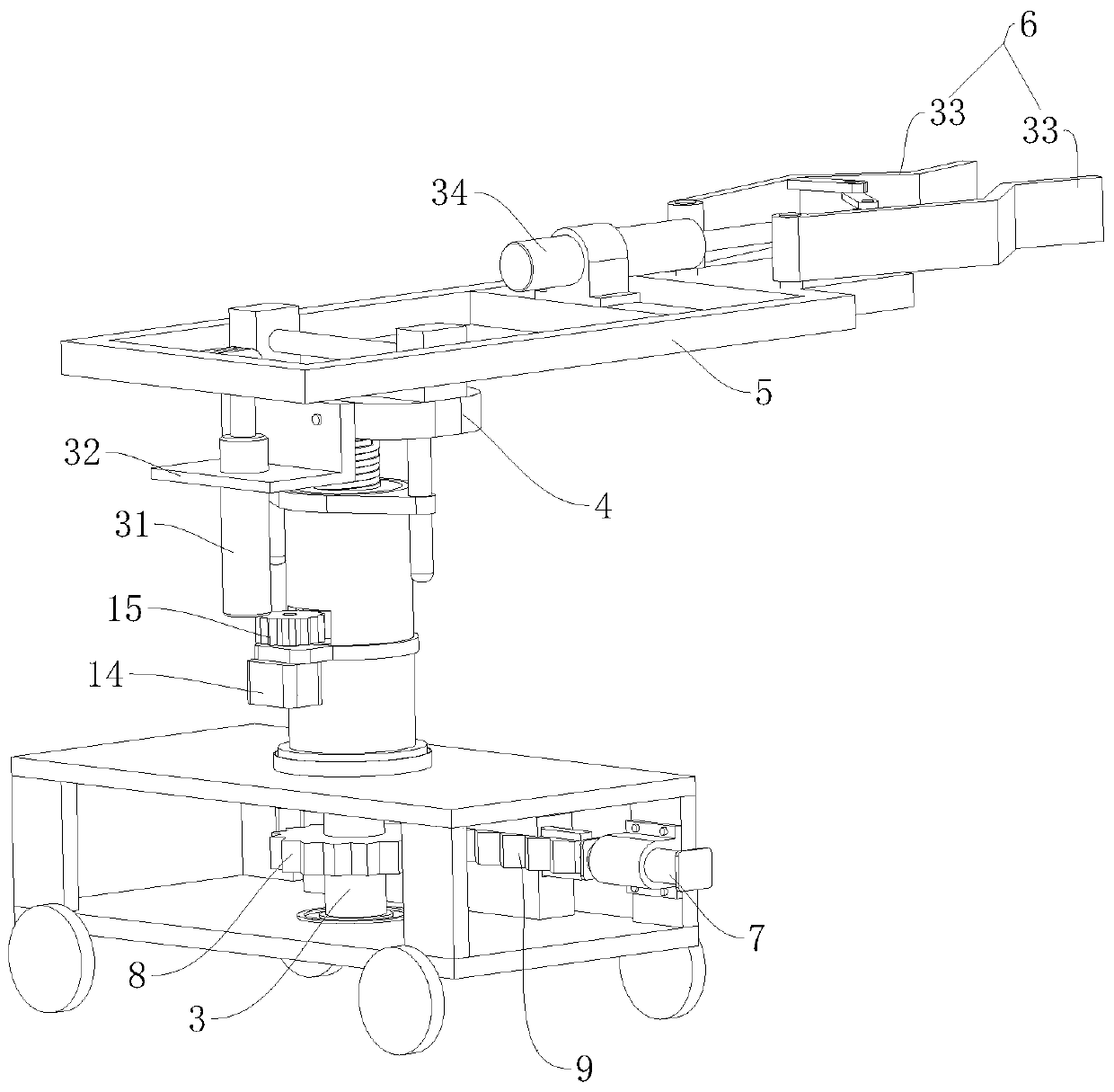

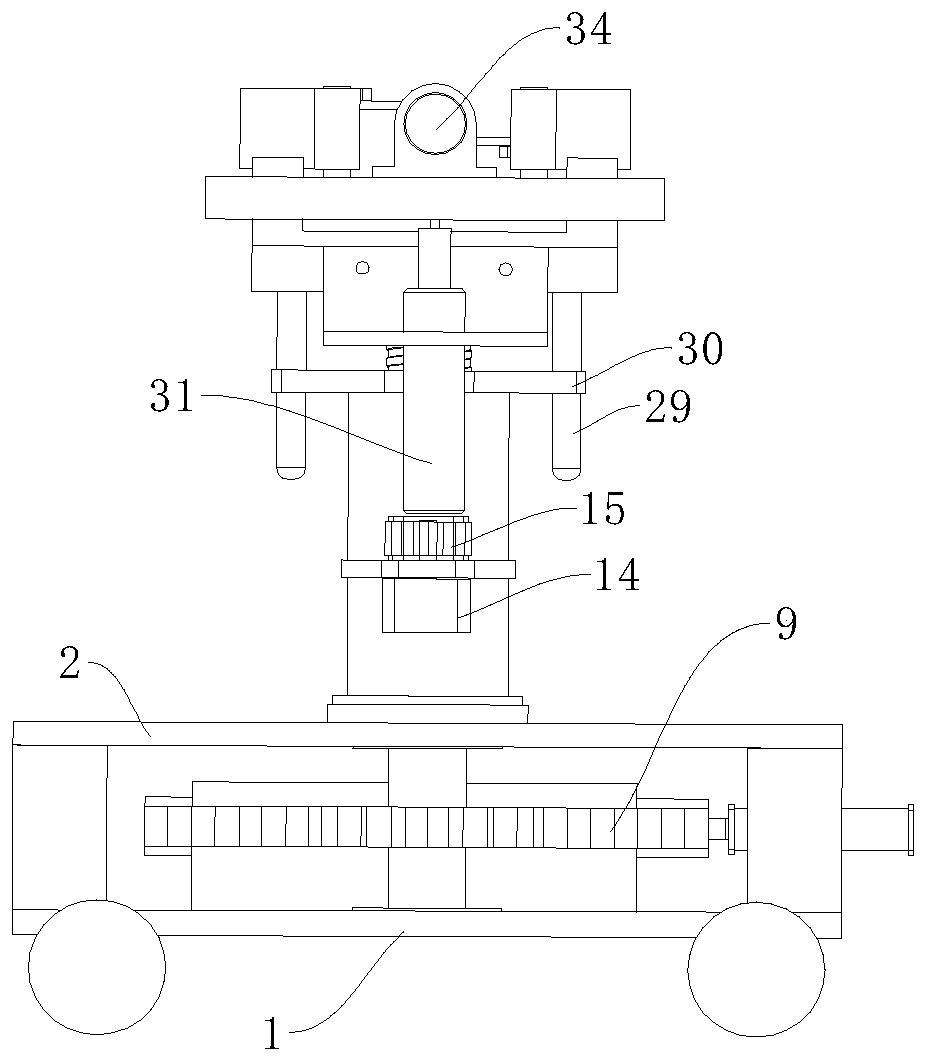

InactiveCN109986532APlay a guiding roleLow costProgramme-controlled manipulatorIndustrial manipulatorIndustrial engineering

The invention relates to the field of industrial machinery, in particular to a movable industrial manipulator. The movable industrial manipulator comprises a flat car, and further comprises a rotatingcomponent, a lifting component, a swing component and a clamping component mounted on the flat car. The upper part of the flat car is provided with a supporting plate; the supporting plate is fixedlyconnected to the top of the flat car through a fixed bracket; the rotating component comprises a guiding shaft capable of rotating and a rotating driving component for driving the rotating shaft to rotate; the lifting component comprises a lifting plate capable of lifting and a lifting driving component for driving the lifting plate to lift; the swing component comprises a swing frame capable ofswinging and a swing driving component for driving the swing frame to swing; the clamping component comprises a clamping plate capable of clamping a workpiece; and the clamping plate is arranged at one end, away from the swing driving component, of the swing frame. By means of the movable industrial manipulator, the clamping can be carried out according to the height of different goods, so that the cost is reduced, and the efficiency is improved.

Owner:丽水奇异果信息技术有限公司

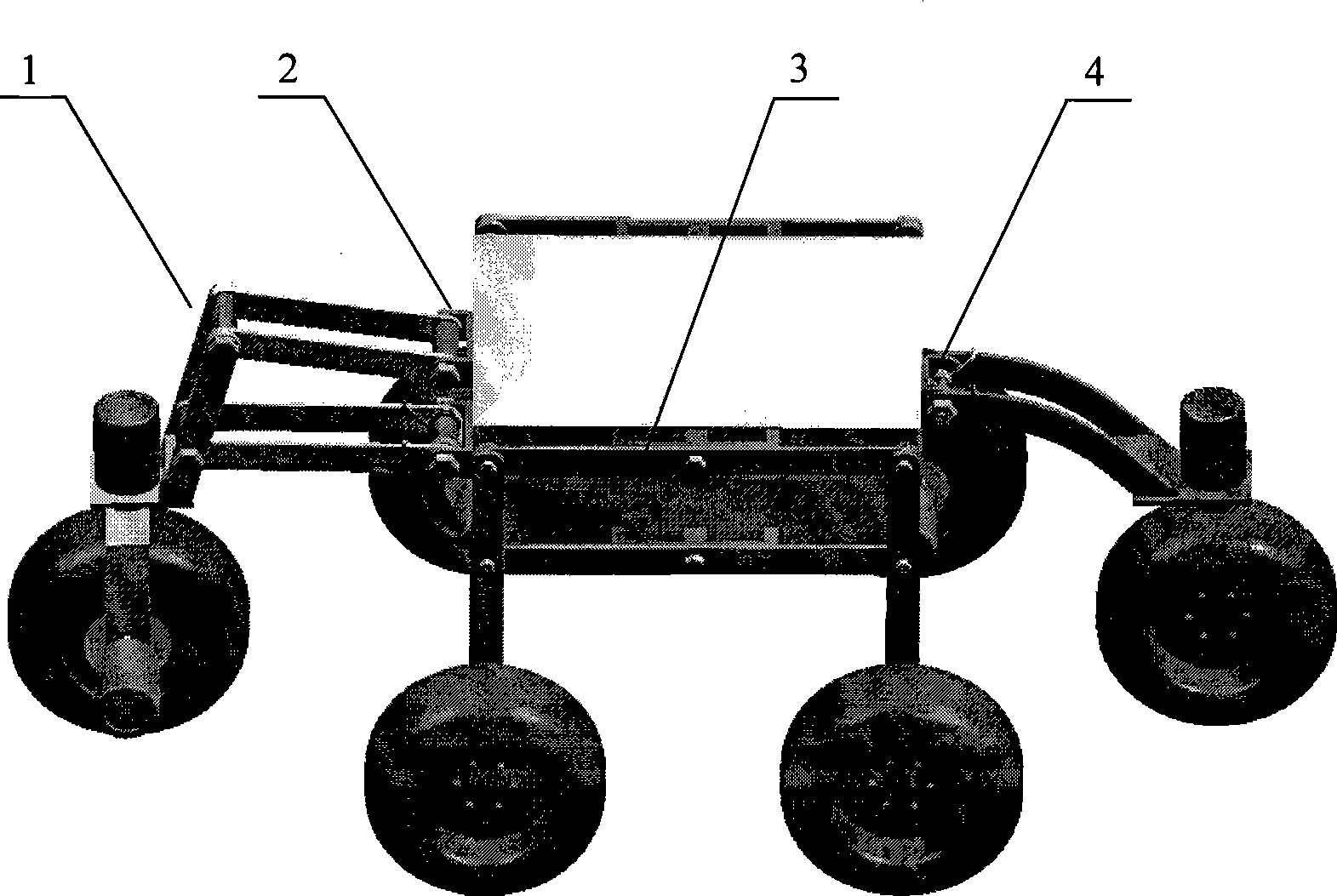

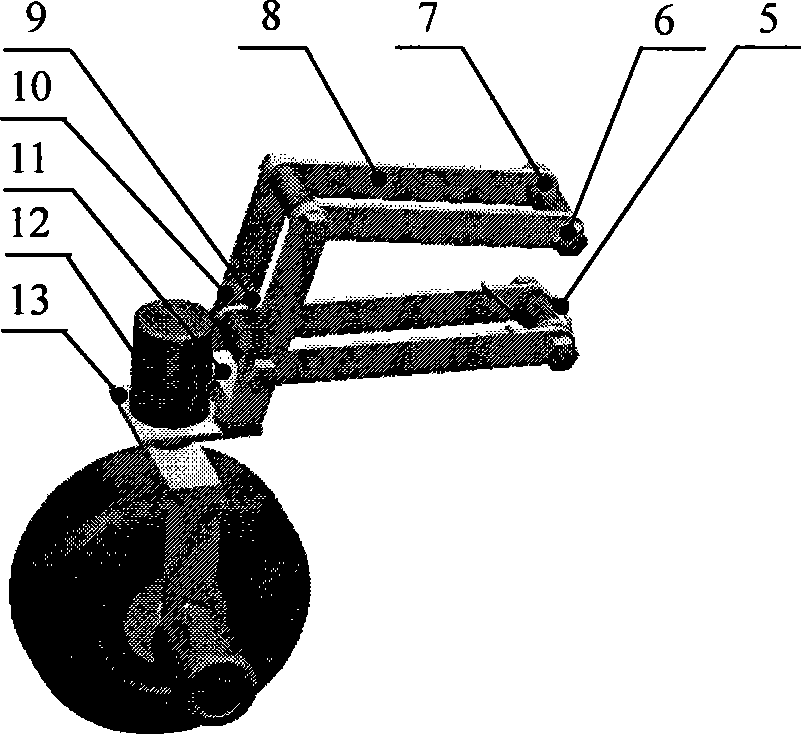

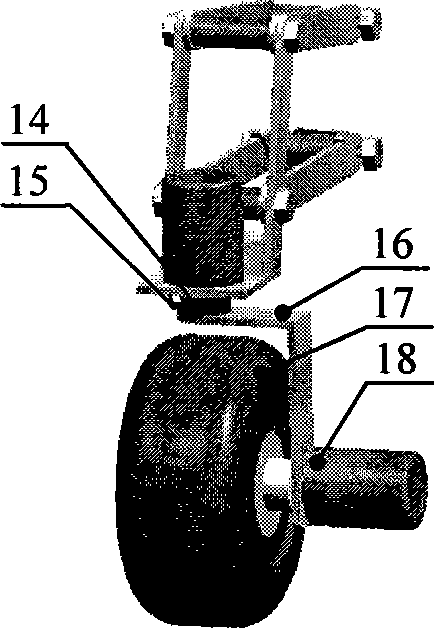

Shrimp-shaped six-wheel mobile robot

InactiveCN101380978AAutomatically overcome obstaclesRealize the use of turningVehiclesShrimpGyration

The invention relates to a shrimp-shaped six-wheeled moving robot which can fit for complex road conditions automatically, has stronger capacity for crossing obstacle and belongs to the mechanical field. The shrimp-shaped six-wheeled moving robot consists of a head part, an abdomen part, lateral wings and a tail part, and the shape likes a shrimp; the head part is articulated with the front wall of the abdomen part; the left lateral wing and the right lateral wing are respectively articulated with the left side and the right side of the abdomen part; the tail part is articulated with the back wall of the abdomen part; the head part is a four bar mechanism; the end of a connecting rod is equipped with a wheel which is driven by a drive motor and realizes the turning by a turning motor; each lateral wing is a parallelogram mechanism, and each parallelogram mechanism is provided with two legs; two wheels are respectively installed at the ends of the legs and are respectively driven by a drive motor; and the end of the abdomen part is equipped with a wheel which is driven by a drive motor and realizes the turning by a turning motor. The shrimp-shaped six-wheeled moving robot can cross the vertical stage 1.5 and 2 times higher than the diameter of the wheel, has stronger bearing capacity and higher mechanism efficiency and can make the turning movement with the gyration radius which is zero approximately.

Owner:SHANDONG UNIV OF SCI & TECH

Analogue driving examination system

InactiveCN106023714AAchieve experienceImprove experienceCosmonautic condition simulationsSimulatorsCar drivingDisplay device

The invention relates to the mechanical field, and provides an analogue driving examination system. The system comprises an automobile driving simulator. The automobile driving simulator is in connection with a virtual reality helmet, and comprises a computer host which is in connection with a wireless communication module, wherein the virtual reality helmet comprises a signal processing module and a display device which are in connection; the signal processing module is in connection with a wireless transmit-receive module matching the wireless communication module. The system combines the virtual reality helmet and the automobile driving simulator, and provides lifelike feeling for students.

Owner:上海悉德信息科技有限公司

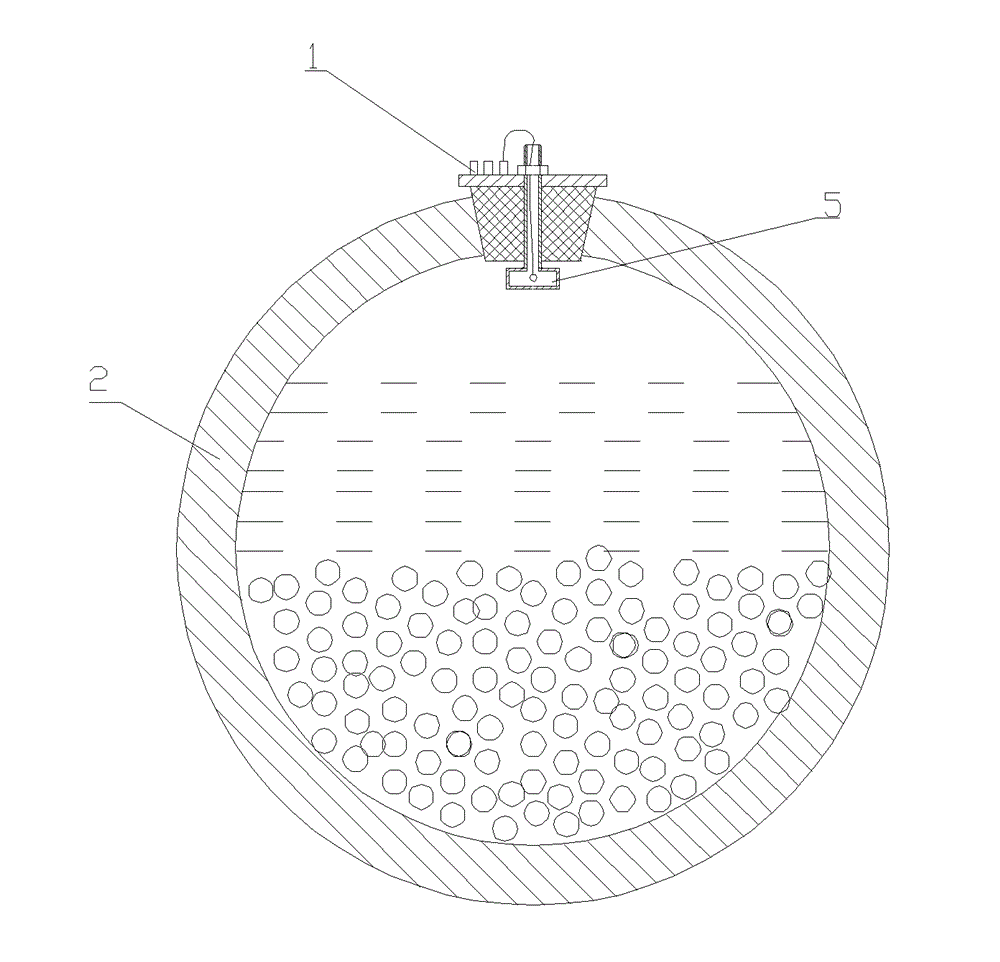

System and method for detecting motion state of ball mill

InactiveCN102744141ARealize online measurementSimple structureVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesSound detectionInformation processing

The invention relates to the mechanical field of the milling engineering, and especially relates to a ball mill. A system for detecting the motion state of the ball mill comprises: a ball mill support, wherein the ball mill support is provided with a ball mill body, the ball mill body is provided with a ball mill cover, the inner side of the ball mill cover is provided with a rubber pad, the rubber pad is provided with a through hole, a hollow screw traverses through the through hole, one end of the hollow screw is fixedly connected with a resonance case, and the other end of the hollow screw is in threaded connection with a nut after traversing through the ball mill cover; a sound detection device arranged in the resonance case, wherein the sound detection device is connected with a signal processing device, and the signal processing device is connected with a wireless emission device; and a wireless receiving device which is connected with a display information processing circuit. Through adopting above technical scheme, the system allows the motion state of the ball mill body to be determined through detecting various noises in the ball mill body, has the advantages of simple structure and low cost, and is difficultly influenced by the onsite working environment.

Owner:SHANDONG UNIV OF TECH

Mounting method of crane sliding contact line in workshop

ActiveCN101348213AReduce cage construction workHigh precisionLoad-engaging elementsObservational errorSliding contact

The invention relates to the field of industrial machinery, in particular to a method for installing travelling crane trolley lines in workshops. The method comprises the following steps of utilizing a Z-shaped trolley line bracket mounting mold to mount a trolley line bracket and utilizing a trolley line straightening detector to straighten a trolley line. With the technical proposal, the suspension cage construction operation of constructors is remarkably reduced, the construction safety is improved, installation quality problems caused by artificial measurement errors are reduced, the precision of trolley line installation is improved, construction efficiency is remarkably improved, and construction cost is reduced.

Owner:CHINA MCC20 GRP CORP

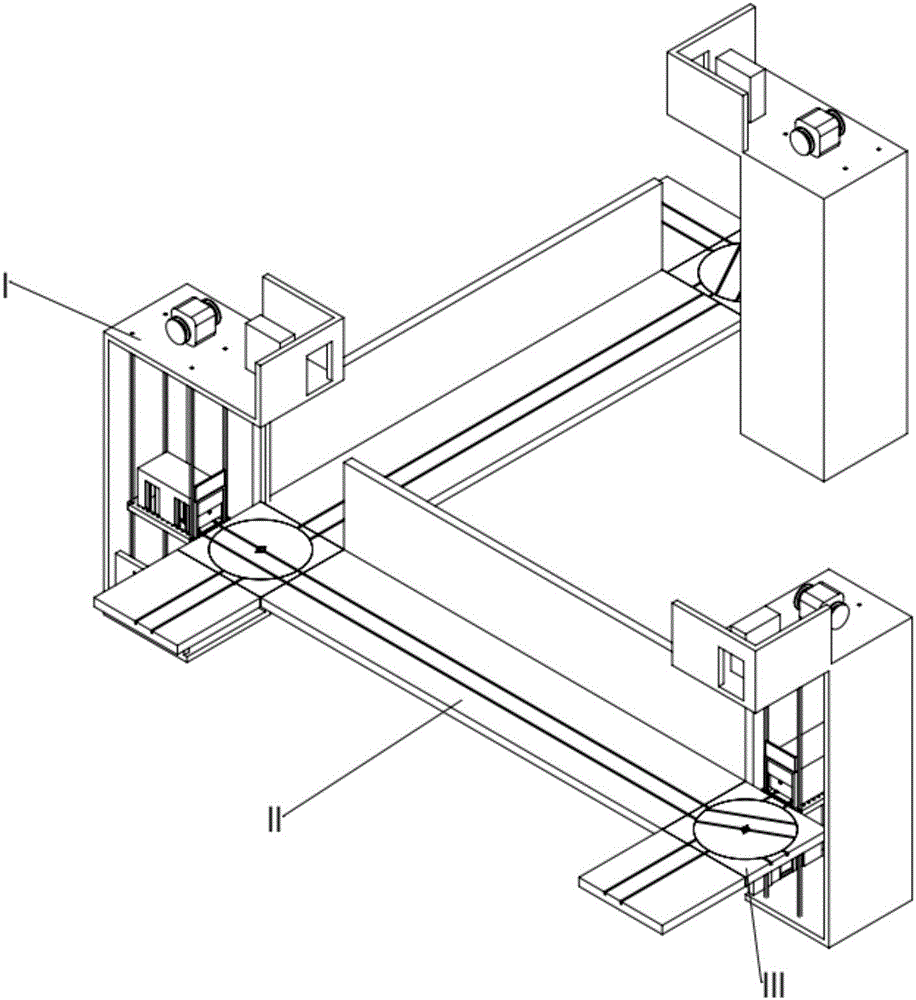

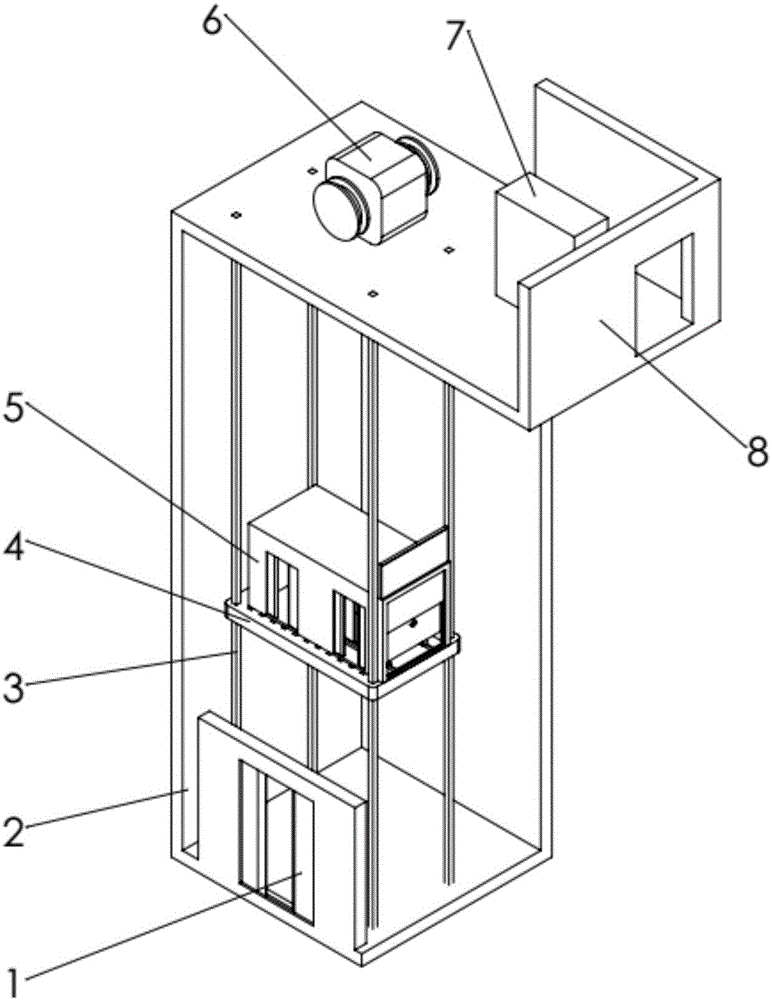

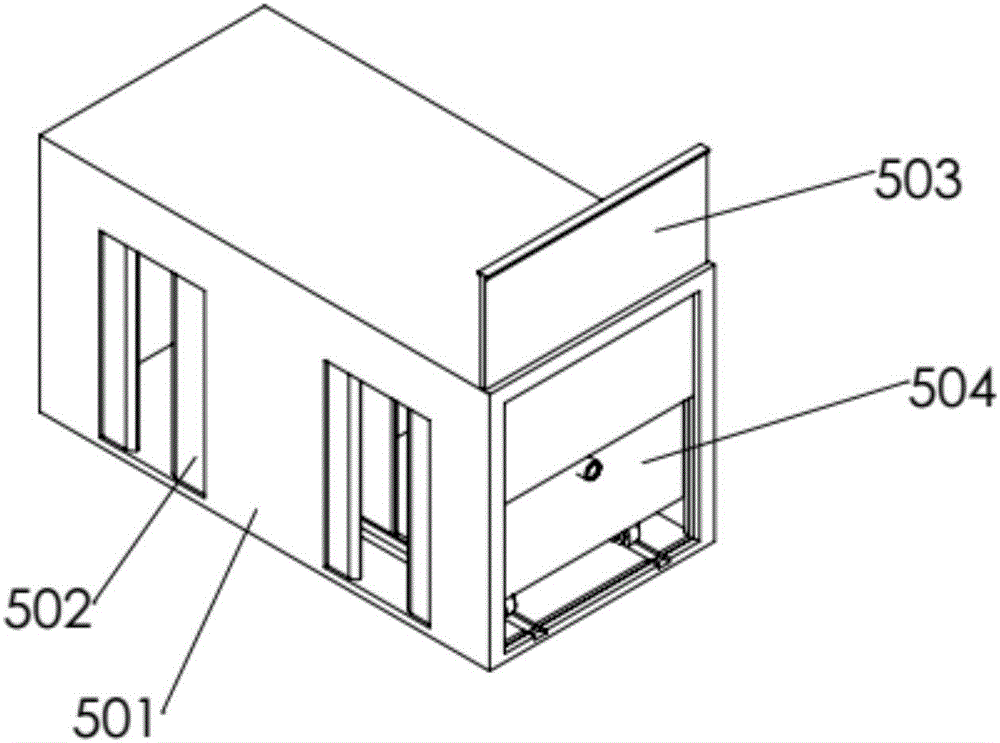

Three-opening-door nested type building through elevator

A three-opening-door nested type building through elevator is composed of an elevator system, an aisle system and a turning table system. The elevator system is composed of a landing door, a shaftway, guide rails, a bracket, a dual-car system, a traction machine, a control cabinet and a machine room. The turning table system is composed of a turning table, turning devices and a stay table. Specifically, the elevator is an elevator adopting a nested inner car and the turning table capable of carrying out transposition by 90 degrees, 180 degrees, 270 degrees and 360 degrees, and the elevator belongs to the field of industrial machines. The three-opening-door nested type building through elevator has the beneficial effects that dual cars are adopted as elevator cars for car nesting, the inner car can be separated from the outer car, and the transfer work of passengers between buildings is completed. The work space and time relation between the cars is considered, the stay table is additionally mounted outside the turning table, switching between the cars is not influenced, and the waiting time is short. An infrared sensor is utilized for achieving locating and sensing control on the inner car, so that it is ensured that the cars are safe, accurate and stable during work.

Owner:SHANDONG JIANZHU UNIV

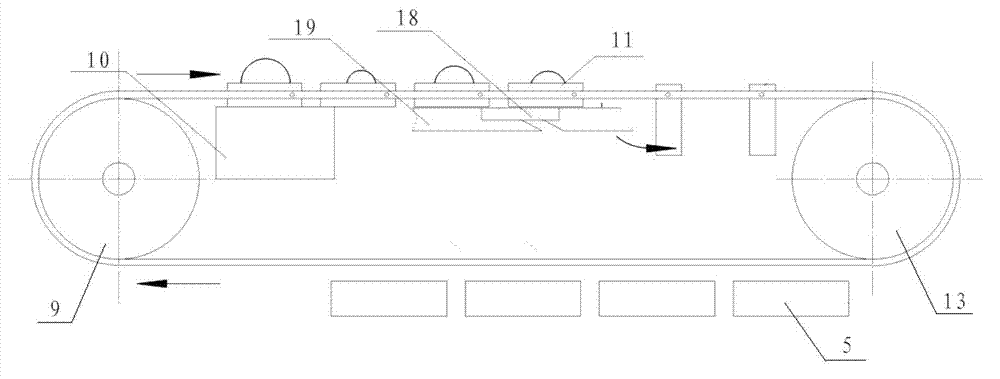

Fruit weighing and sorting system

InactiveCN103157606ARealize automatic controlHigh precisionSortingAutomatic controlAgricultural engineering

The invention relates to the field of agricultural machines and especially relates to a fruit weighing and sorting system. The fruit weighing and sorting system comprises a chain-type conveyer, fruit cups, operation guide rails, a weighing mechanism, a discharging mechanism and a controller. Hinged ends of the fruit cups are connected to two parallel chains of the chain-type conveyer by articulated shafts. Gaps allowing upward / downward movement are formed between the fruit cups and the articulated shafts. The discharging mechanism is arranged at a gap of the operation guide rails. The weighing mechanism is connected to the controller. The controller is connected to the discharging mechanism. The fruit weighing and sorting system realizes automatic control of fruit weighing and sorting, has a high weighing and sorting precision and a high automation degree, and saves a manpower cost.

Owner:CHINA AGRI UNIV

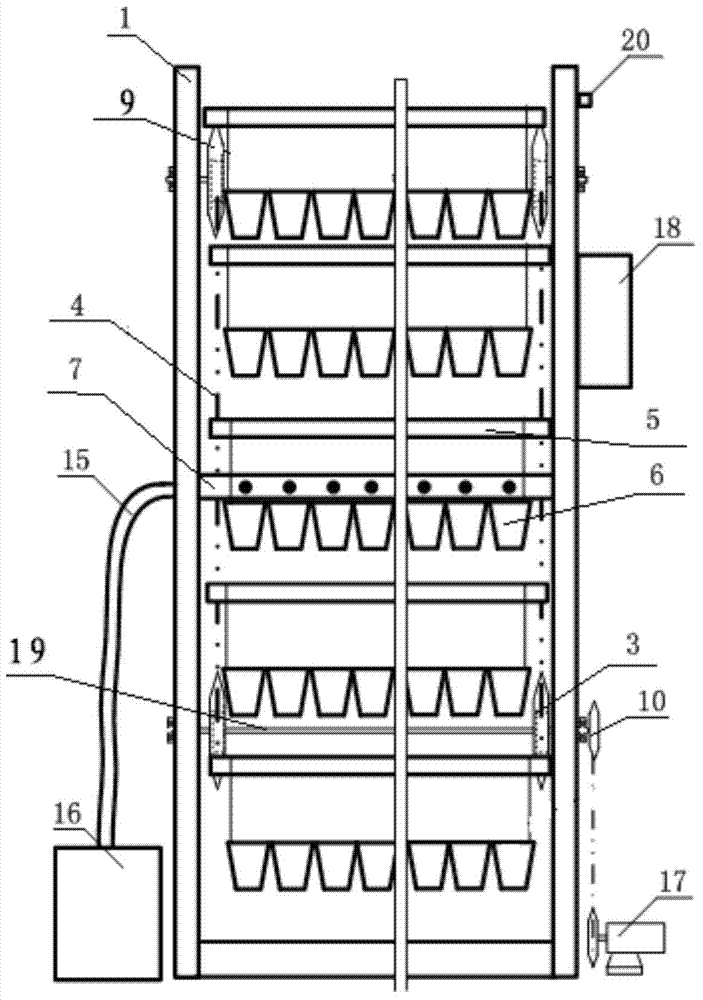

Three-dimensional rotating cultivation device

ActiveCN103477894AAchieve uniformityMeet uniformityGreenhouse cultivationReceptacle cultivationEngineeringChain conveyor

The invention relates to the field of agricultural machinery, in particular to a three-dimensional rotating cultivation device which comprises a support and a chain-type conveying mechanism arranged on the support. Multiple horizontal hanging rods are arranged on the chain-type conveying mechanism, and multiple cultivation containers are hung on each hanging rod. In this way, multiple rows of the cultivation containers are hung on the hanging rods to rotate up and down along with the chain-type conveying mechanism, and plants in the cultivation containers of each row can be rotated to an outer-layer illumination plane to contact with sunlight, so that illumination uniformity of the plants in the cultivation containers can be realized; light supplementing lamps are arranged at positions corresponding to the cultivation containers on the support, so that light supplementing can be performed on the cultivation plants at night, and requirements on illumination uniformity of the plants at night can be met.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

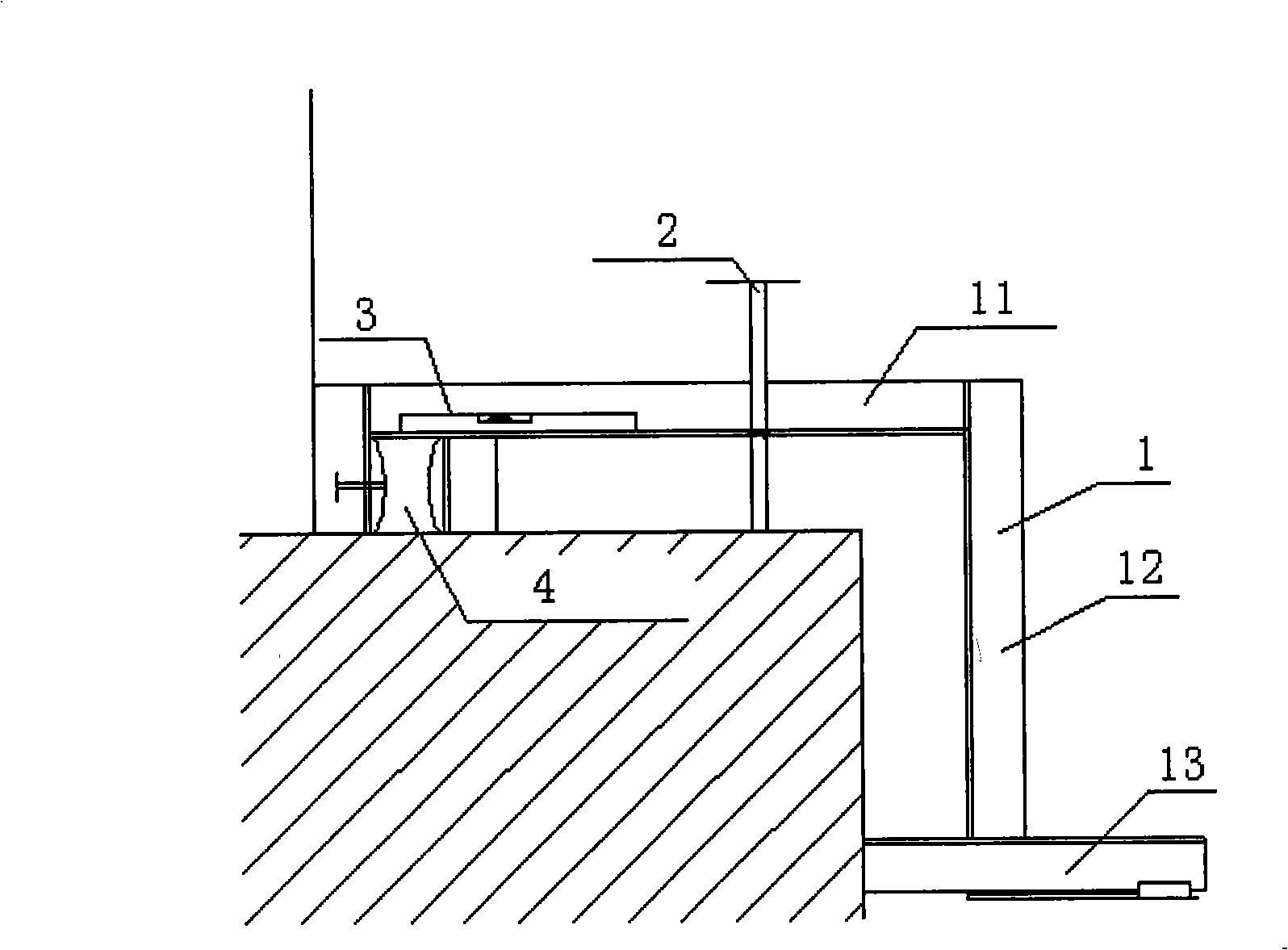

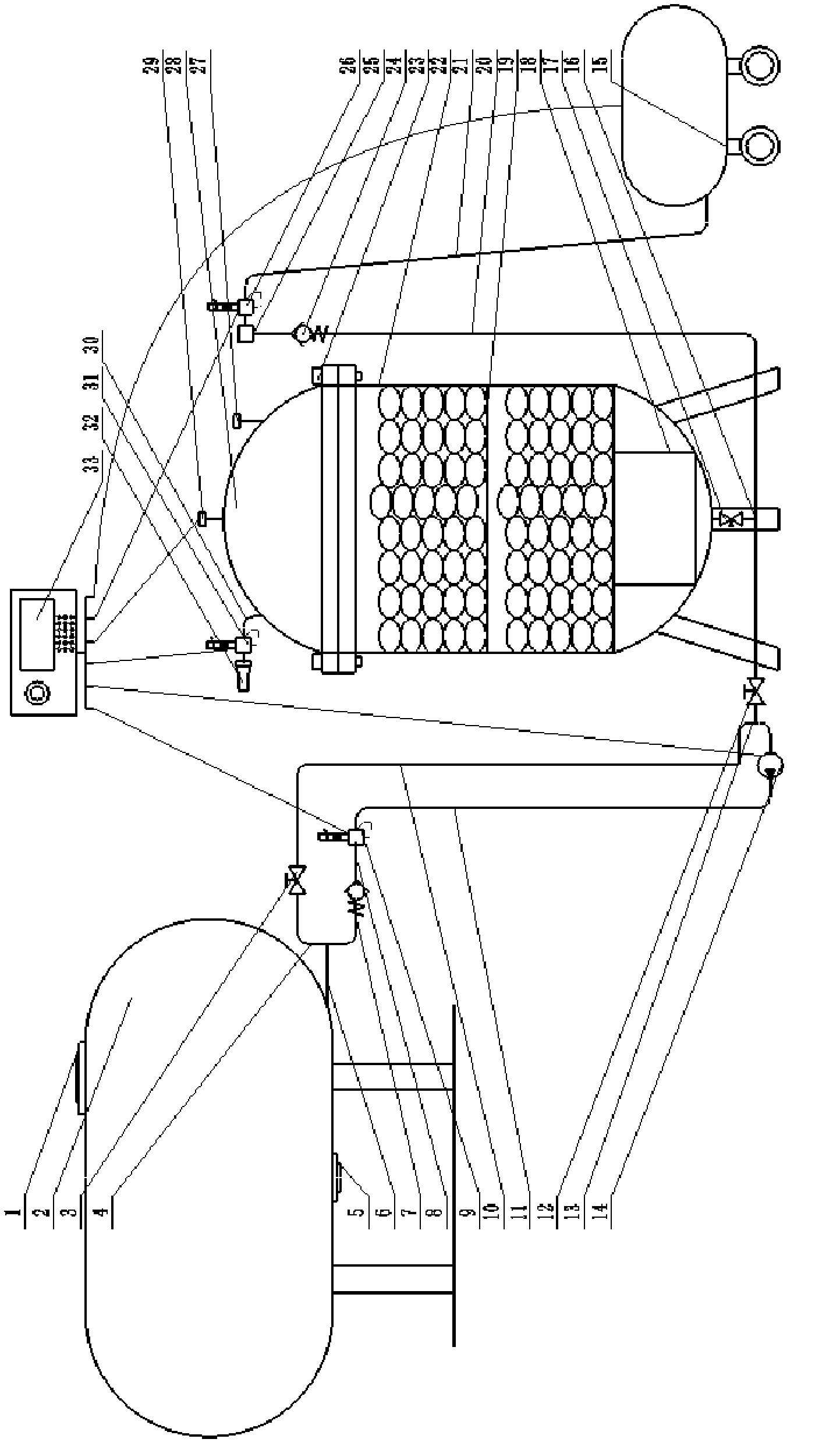

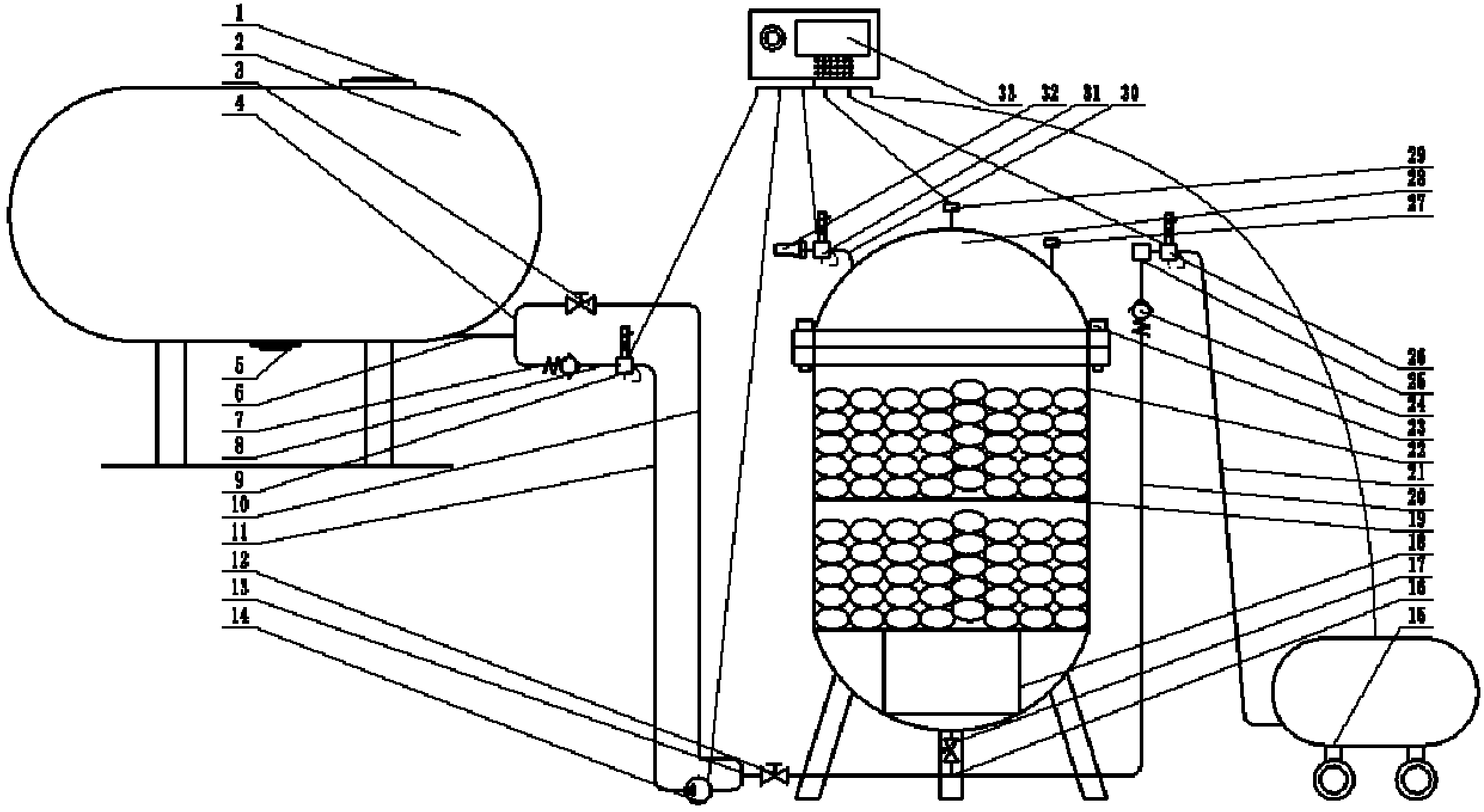

Device for pickling eggs

The invention belongs to the field of livestock and poultry processing machinery and relates to a device for pickling eggs. The device comprises a pickling liquid circulation system, a pickling tank, a pressurization system and a control system (33), wherein the pickling liquid circulation system can be used for recycling pickling liquid, so that solution waste and environmental pollution can be avoided, and the production cost can be reduced; an exhaust electromagnetic valve (31), a muffler (32), a pressure sensor (29) and a safety valve (27) of the pickling tank are all arranged at the upper part of a pressure vessel cover (28), so that the direct corrosion damage caused by the pickling liquid can be reduced; a bubble breaking plate (18) of the pickling tank can be used for breaking bigbubbles, so that the eggs are prevented from being directly impacted by the bubbles, and the rate of finished products can be guaranteed; and the pressurization system is respectively used for supplying air for a liquid storage tank (2) and a tank body (22) of the pickling tank from the bottom to stir the pickling liquid so that the pickling liquid in the device for pickling the eggs is uniform, and the processing quality of the eggs can be guaranteed. The device for pickling the eggs solves the problem of mechanical and industrialized egg pickling production, and is suitable for pickling salted eggs and preserved duck eggs industrially in a large scale.

Owner:CHINA AGRI UNIV

Agricultural centrifugal fertilizer-spreading device

ActiveCN106358544AAvoid manual crushingSpread evenlyFertiliser distributersCentrifugal wheel fertilisersMotor driveSpiral blade

The invention discloses an agricultural centrifugal fertilizer-spreading device, and belongs to the technical field of the agricultural machinery. The agricultural centrifugal fertilizer-spreading device uses a two-stage storing mode, and is composed of a spiral-type beating mechanism and a rotation centrifugal fertilizer-spreading mechanism. The agricultural centrifugal fertilizer-spreading device is characterized in that a motor drives spiral blades on an inner rotating disk to be rotated through a transmission mechanism, a large piece of the chemical fertilizer is smashed, a main rotation shaft connected on a wheel drives a rotation shaft to be rotated through the transmission mechanism, the rotation shaft passes through a connecting plate and is connected with a two-stage storing tank, a lot of small holes are opened around the two-stage storing tank so as to spread the fertilizer smoothly, five connecting holes are uniformly opened in the connecting plate, and the range of spreading the fertilizer can be controlled by connecting the different holes. The agricultural centrifugal fertilizer-spreading device is capable of automatically beating a large piece of the chemical fertilizer, uniformly spreading the fertilizer by the centrifugal rotation tank, and changing the spreading range, and is suitable for the particle-shaped and powder-shaped fertilizer.

Owner:黑龙江省樱田农机制造有限公司

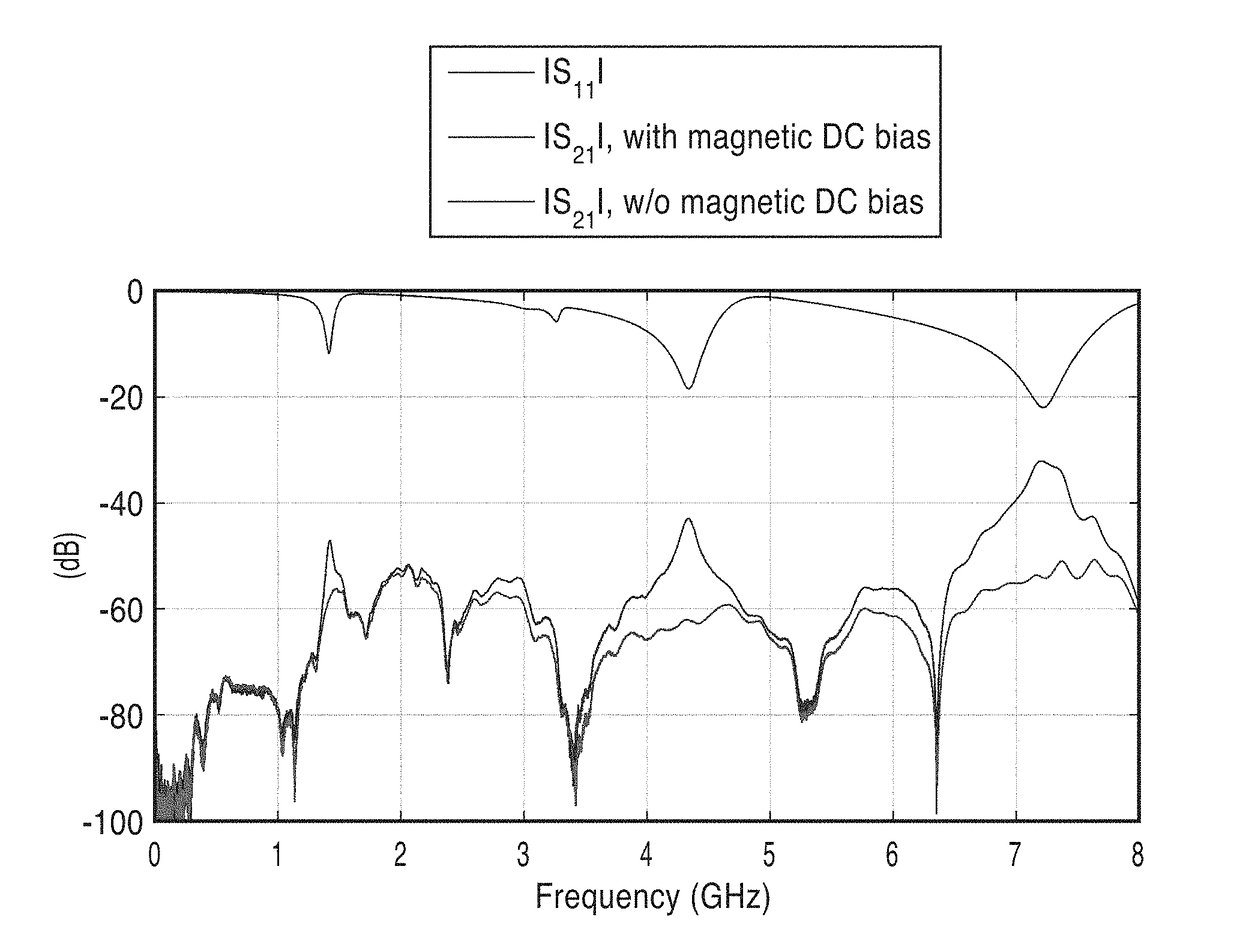

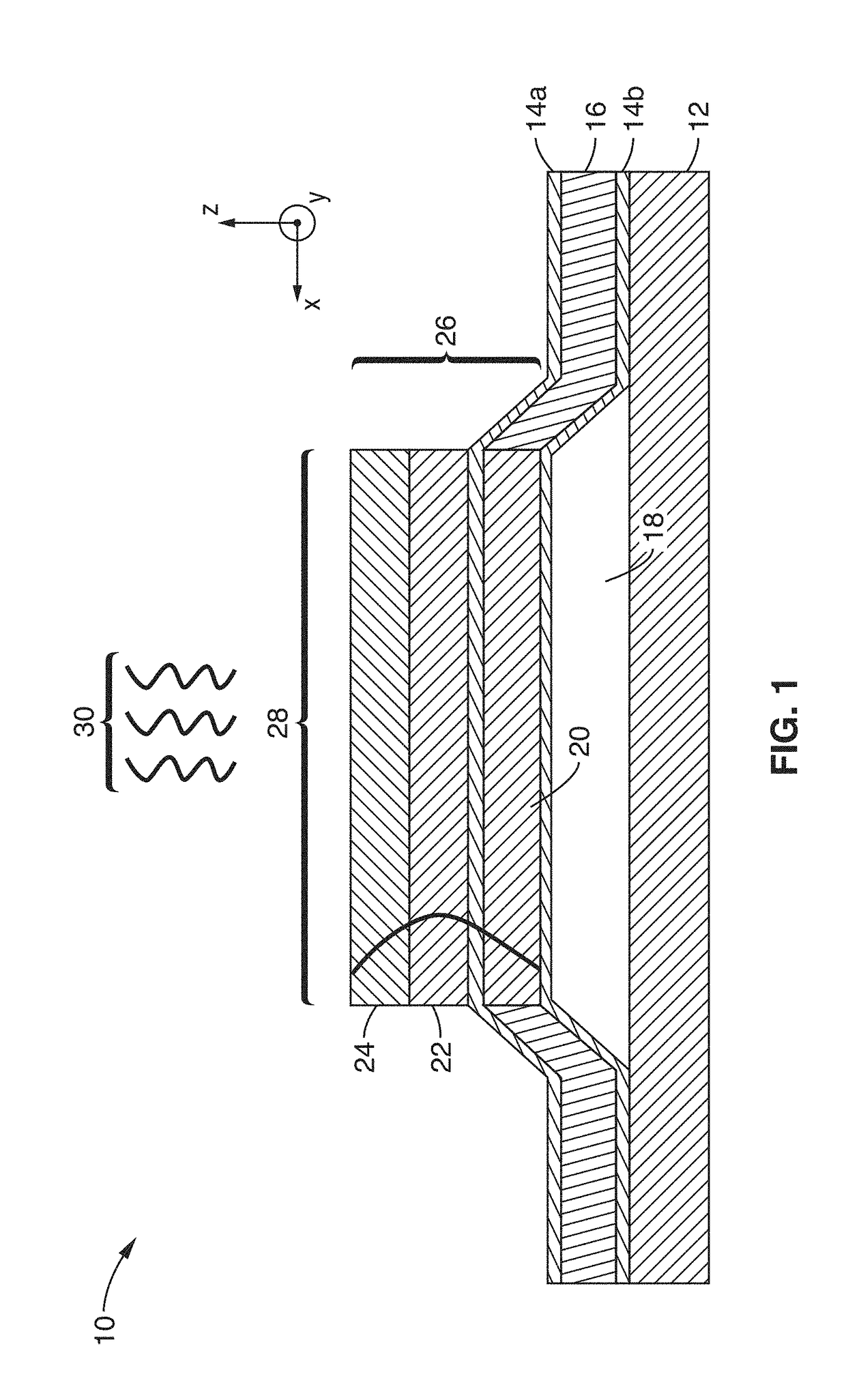

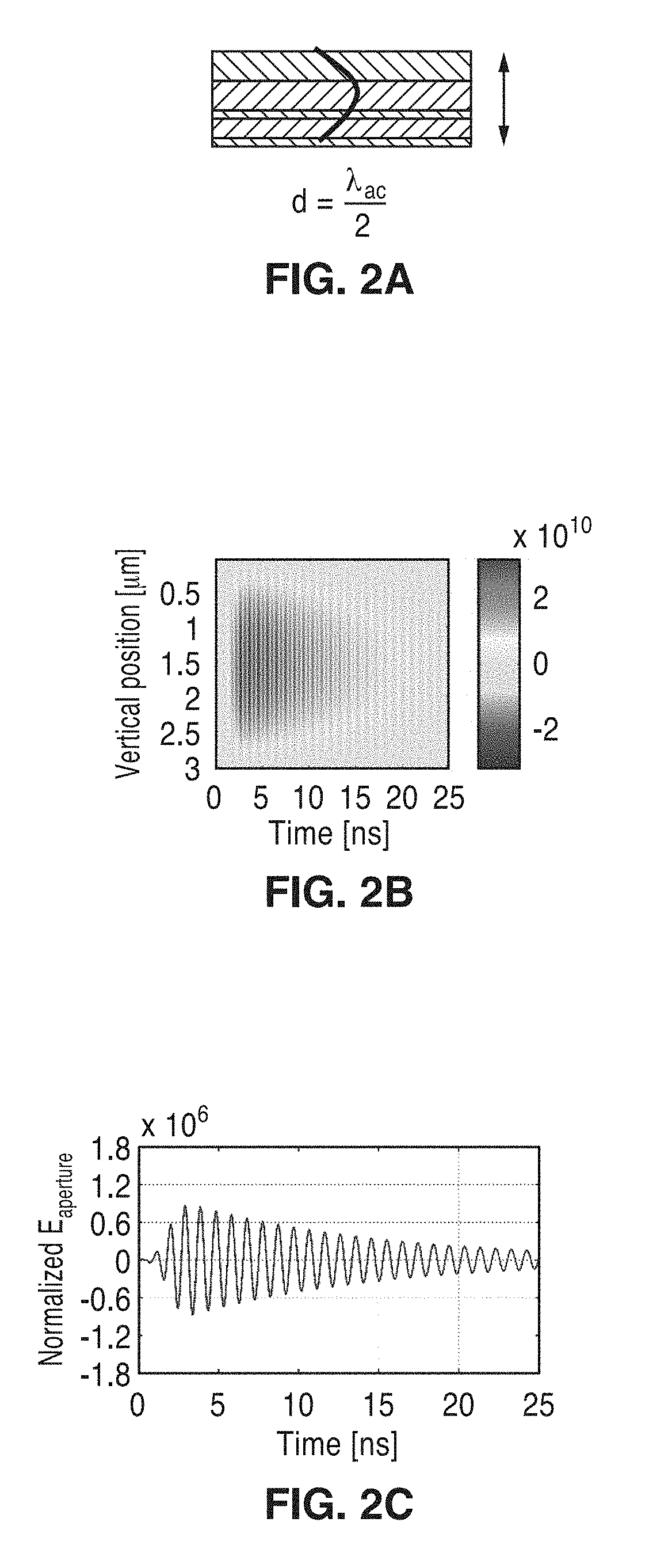

Bulk acoustic wave mediated multiferroic antennas

ActiveUS20180115070A1Lower quality factorImprove permeabilityLoop antennas with ferromagnetic coreImpedence networksCouplingAcoustic wave

An antenna apparatus utilizing bulk acoustic wave (BAW) resonances to transfer dynamic strain across multiple layers, which include piezoelectric layers coupled to magnetostrictive material layers. In at least one embodiment, a piezoelectric layer is coupled to a magnetostrictive layer to which another layer having similar acoustic properties as the piezoelectric layer is coupled as an inertial buffer. These multiple layers comprise a strain media to provide a vertical multiferroic coupling which couples electric field, magnetic field, and mechanical fields. Electrodes are coupled to excite one of the piezoelectric layers for injecting acoustic waves into the structure from which electromagnetic radiation is generated out of the plane.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com